Automatic blade plate stacking device

An automatic, stacking technology, applied in the field of mechanical processing, can solve the problem that there is no way to detect whether the position of the fixed hole of the blade plate is accurate, and achieve the effect of reducing the possibility of collision and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is attached Figure 1-4 The application is described in further detail.

[0033] The embodiment of the present application discloses an automatic blade stacking device.

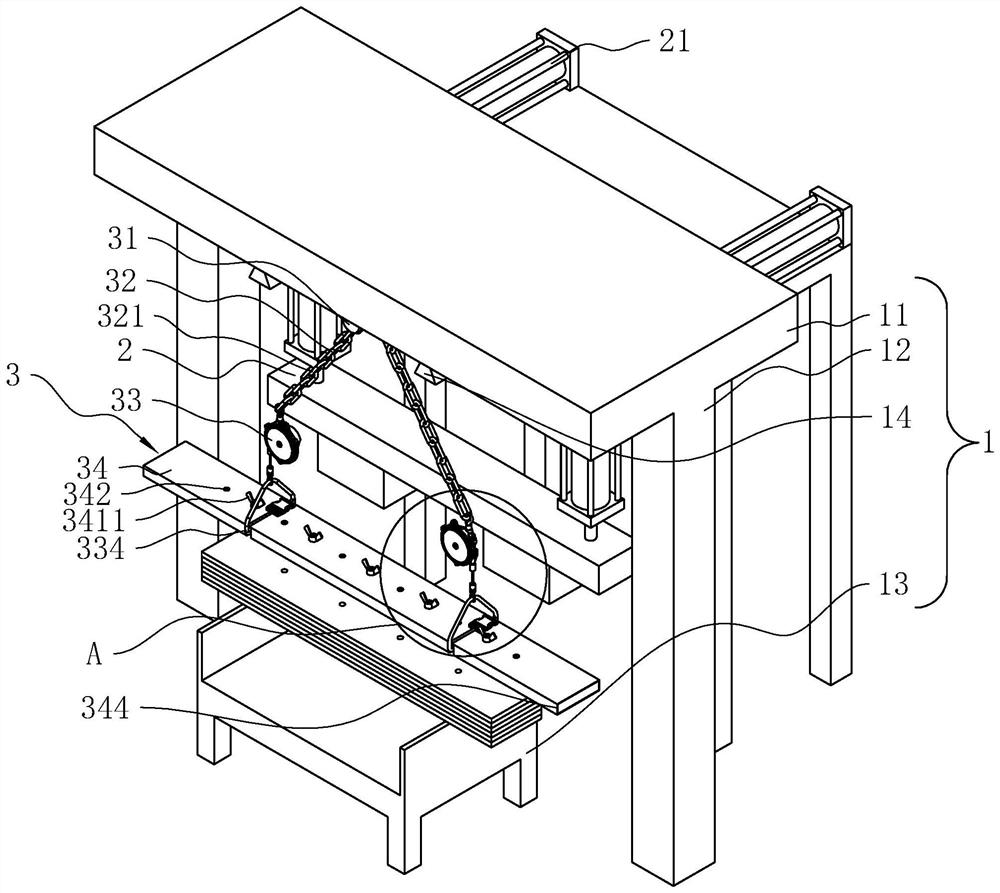

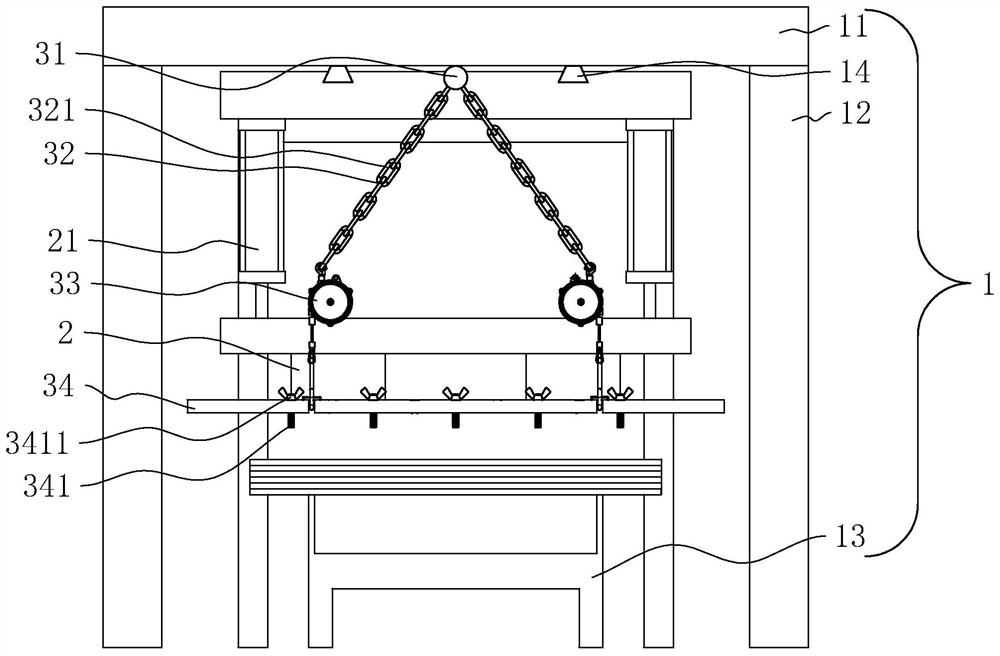

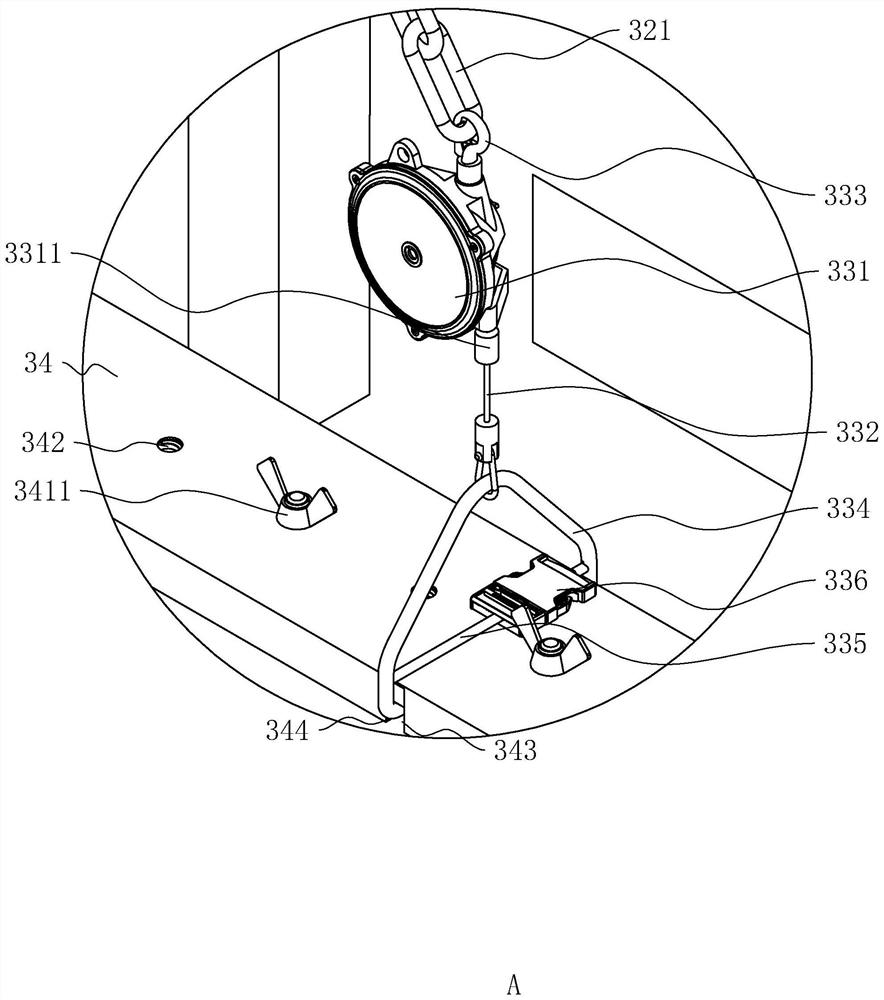

[0034] refer to figure 1 , an automatic blade stacking device includes a frame 1 and a transport assembly 2 arranged on the frame 1, the frame 1 includes a beam 11, a column 12 and a placement frame 13, and a slide rail is provided on the end surface of the beam 11 close to the ground 14. The transport assembly 2 is slidably arranged on the beam 11 through the slide rail 14 , and the transport assembly 2 is provided with a drive cylinder 21 , which controls the transport assembly 2 to reciprocate in the slide rail 14 .

[0035] refer to figure 1 and figure 2 , in the process of processing, the transportation component 2 transports and places the blade plates that have completed the previous process on the placement frame 13, so that the blade plates are stacked in a stack for later p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com