Forming device for drilling multiple holes in glassware bottom through one-time fire

A glassware, disposable technology, applied in burners, combustion types, gas fuel burners, etc., can solve the problems of easy cracking, long time, cracking, etc., to improve product quality, improve efficiency, and facilitate drilling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

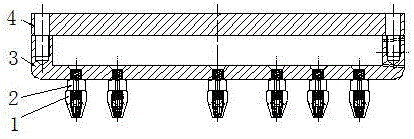

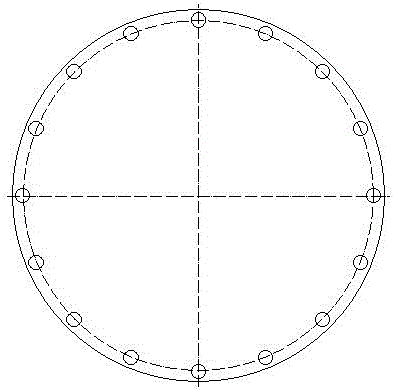

[0021] refer to figure 1 and figure 2 , a kind of one-time fire-beating porous molding device at the bottom of glassware, comprising a gun body and more than one gun head, the gun body includes a gun body body 3 and a gun body cover plate 4 detachably connected with the gun body body 3, and the inside of the gun body body 3 It is a cavity, and the gun heads are evenly distributed along the circumferential direction of the outer edge of the gun body 3. The gun heads include a gun tip inner core 2 and a gun tip shell 1, and one end of the gun tip inner core 2 is connected to the gun body. Figure 5 The gun tip inner core 2 is threadedly connected with the gun tip shell 1 .

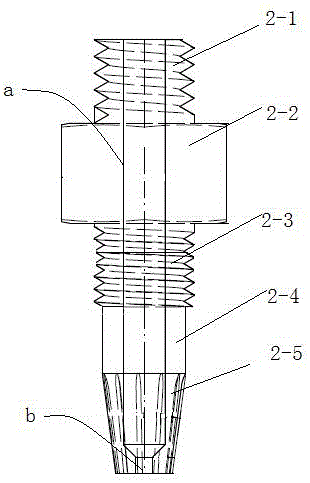

[0022] refer to image 3 , the inner core 2 of the upper gun head includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com