Strip bar flat cable clamp perforating tool for generator stator

A technology for generator stators and cable clips, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc. It can solve the problems of waviness and cross-sectional size tolerance, complicated wire manufacturing process, time-consuming and laborious, etc., and achieve concentricity Good, easy-to-manufacture, well-placed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

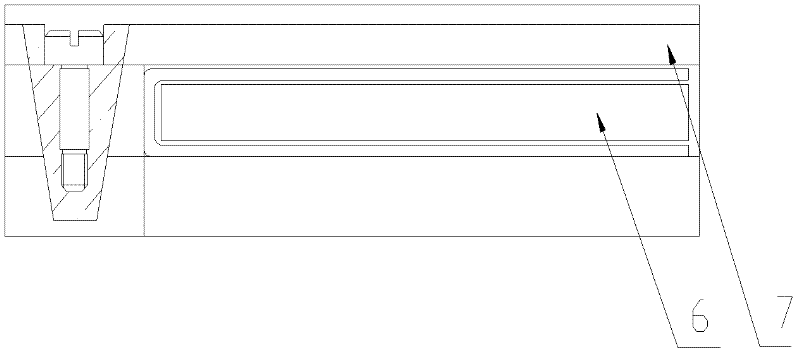

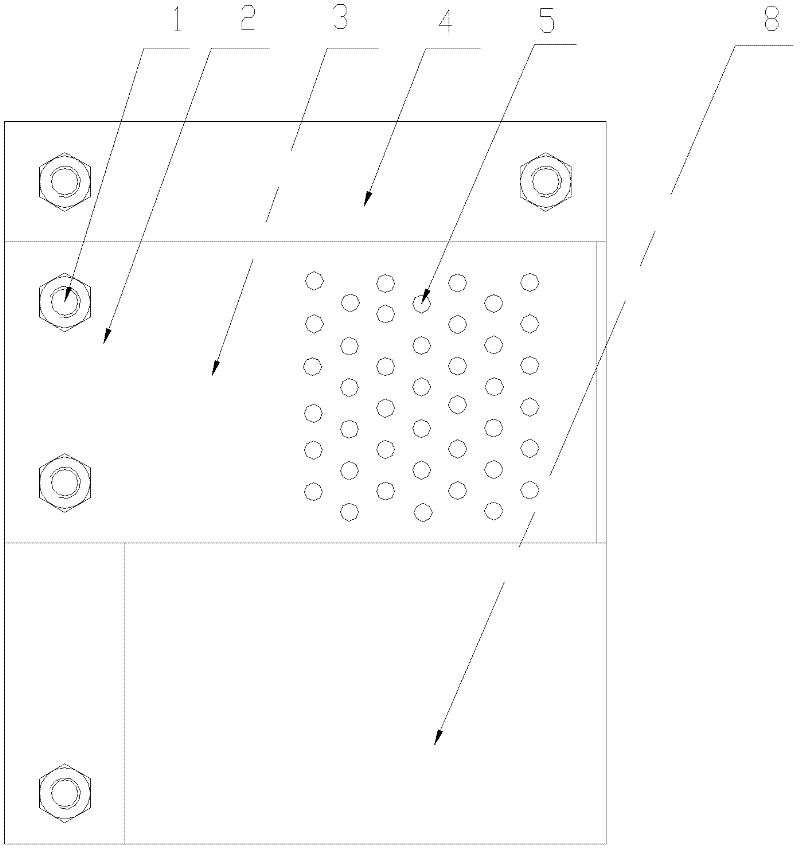

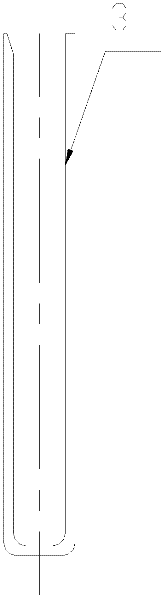

[0021] A tool for punching holes in generator stator bar-shaped cable-arrangement clips, including a positioning plate 4, a backing plate 6, an aperture plate 7 and a bottom plate 8, the aperture plate 7 is fixed on the bottom plate 8 by bolts 1, and the cable-arrangement clip 3 is punched The positioning plate is fixed on the base plate 8 for positioning, and the backing plate 6 is arranged in the cable clamp 3 .

[0022] The aperture plate 7 is provided with a preset aperture for processing the holes on both sides of the cable clip 3, and the hole distances on both sides of the cable clip 3 are consistent. There is a notch in the cable clip 3, and the backing plate 6 is contained in the notch. Backing plate 6 is a glass cloth plate.

[0023] Concrete structure and process of the present embodiment:

[0024] refer to Figure 1 to Figure 4 . A kind of tooling for positioning and punching holes for bar-shaped cable clips; the punching tool includes a bottom plate and a posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com