Insulating layer production method, insulating layer, conductive backboard production method and conductive backboard

A production method and conductive backplane technology, applied in the field of solar photovoltaics, can solve the problems of complex manufacturing process, high cost, and unreliable connection of the insulating layer, and achieve the goal of avoiding pollution of the film layer, avoiding pollution, and improving precision and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

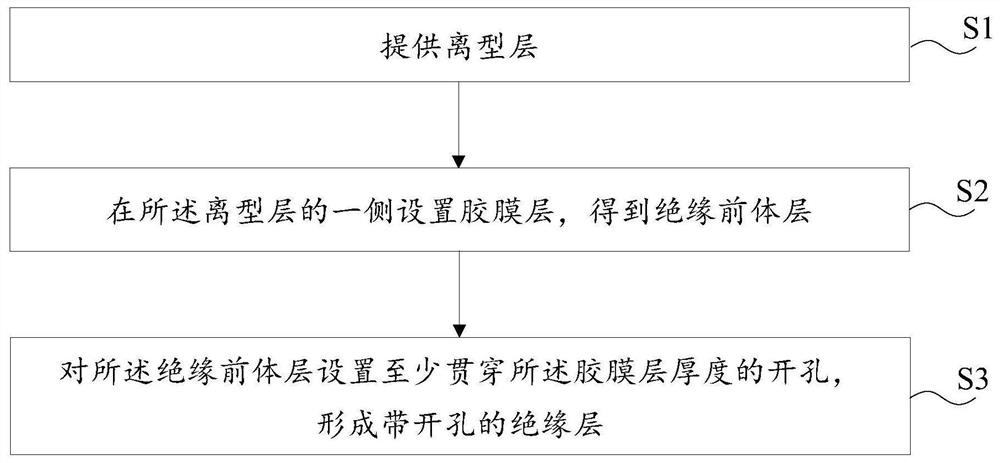

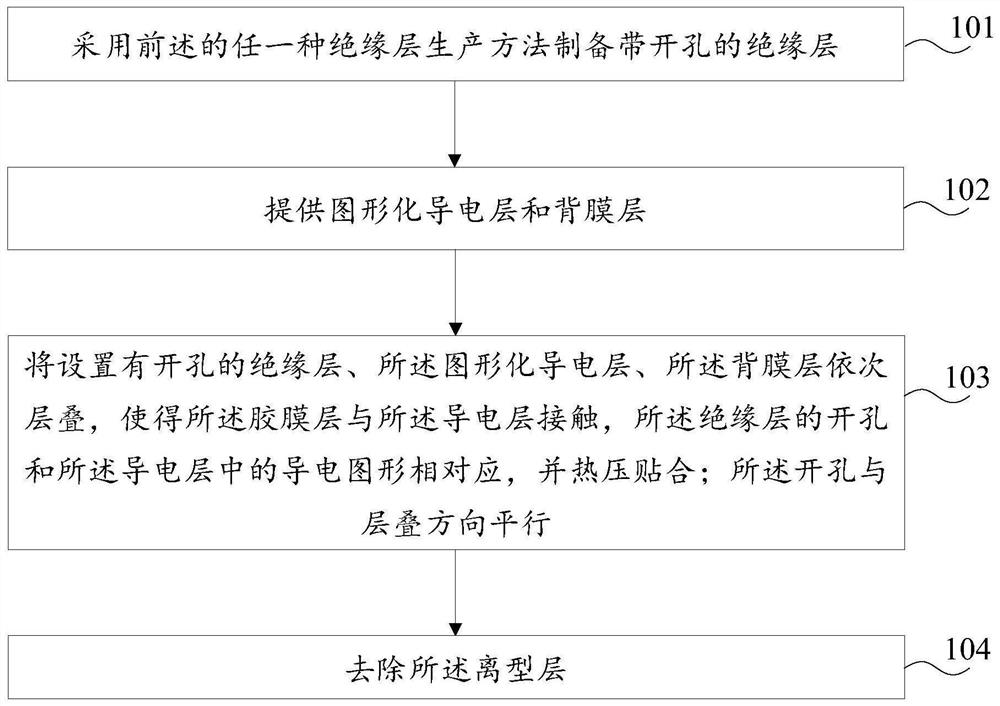

Method used

Image

Examples

Embodiment Construction

[0026] The inventors have found that currently in the manufacturing process of EPE, it is necessary to carry out surface treatment to PET, such as coating a primer coating, etc., to realize the bonding between PET and EVA, and then compound EVA on both sides of PET through the coating process, and manufacture The process is complex, which is not conducive to reducing costs. At the same time, EPE is prone to creep and deformation problems, which makes the accuracy of opening and alignment low, resulting in unreliable connections. In the prior art, a separate EVA is used as the insulating layer. Since EVA is an elastic body, the dimensional stability is poor, and it is easy to be deformed under the action of external force and heat during the process of opening holes and laying materials, so that it cannot be guaranteed. The accuracy of opening and alignment makes the connection unreliable.

[0027] Begin to introduce the embodiment of the present invention below:

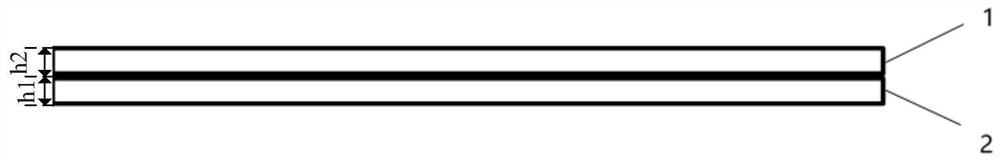

[0028] ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com