Double-face integrated machining clamp of pumping connector and machining method of double-face integrated machining clamp

A pump-integrated technology, which is applied to the double-sided integrated processing fixture of the pump joint and its processing field, can solve the problems of inability to guarantee the accuracy, cumbersome operation, complicated operation, etc., to avoid difficulties in finishing and size adjustment, and hole size The adjustment is convenient and the effect of ensuring the opening position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

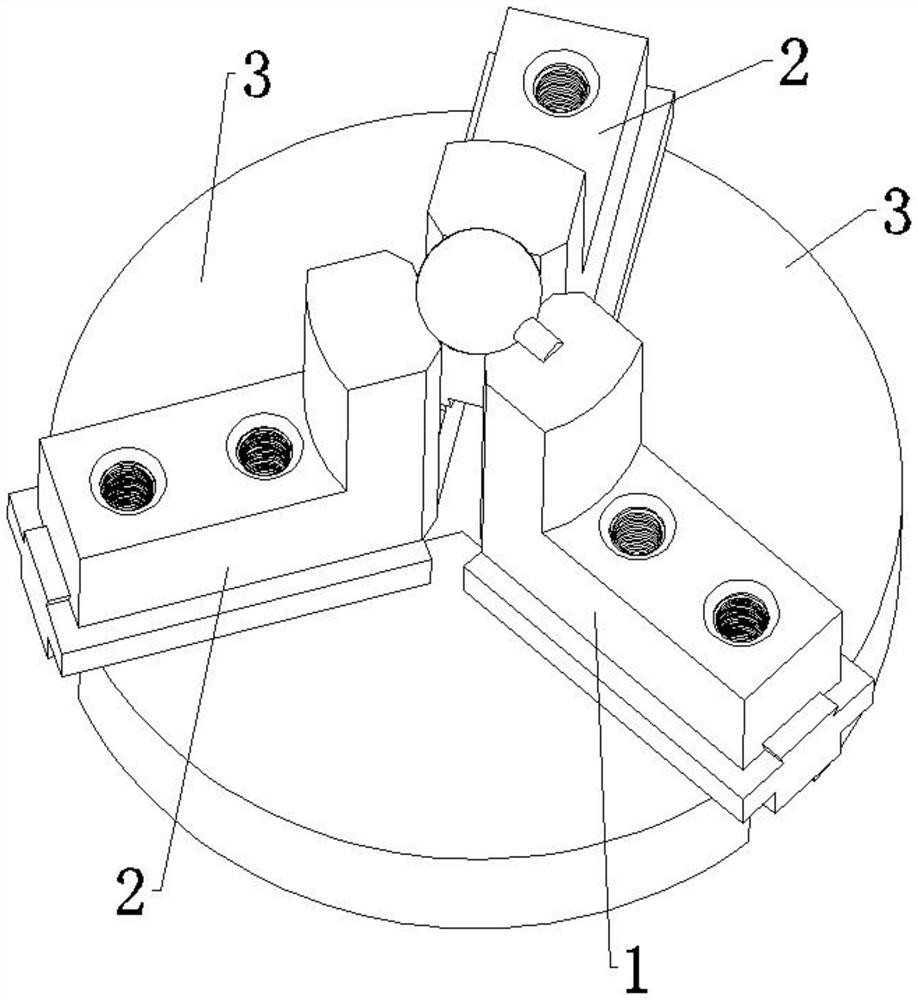

[0039] see Figures 1 to 8 As shown, the present invention provides a technical solution: a double-sided integrated processing fixture for pump joints, including:

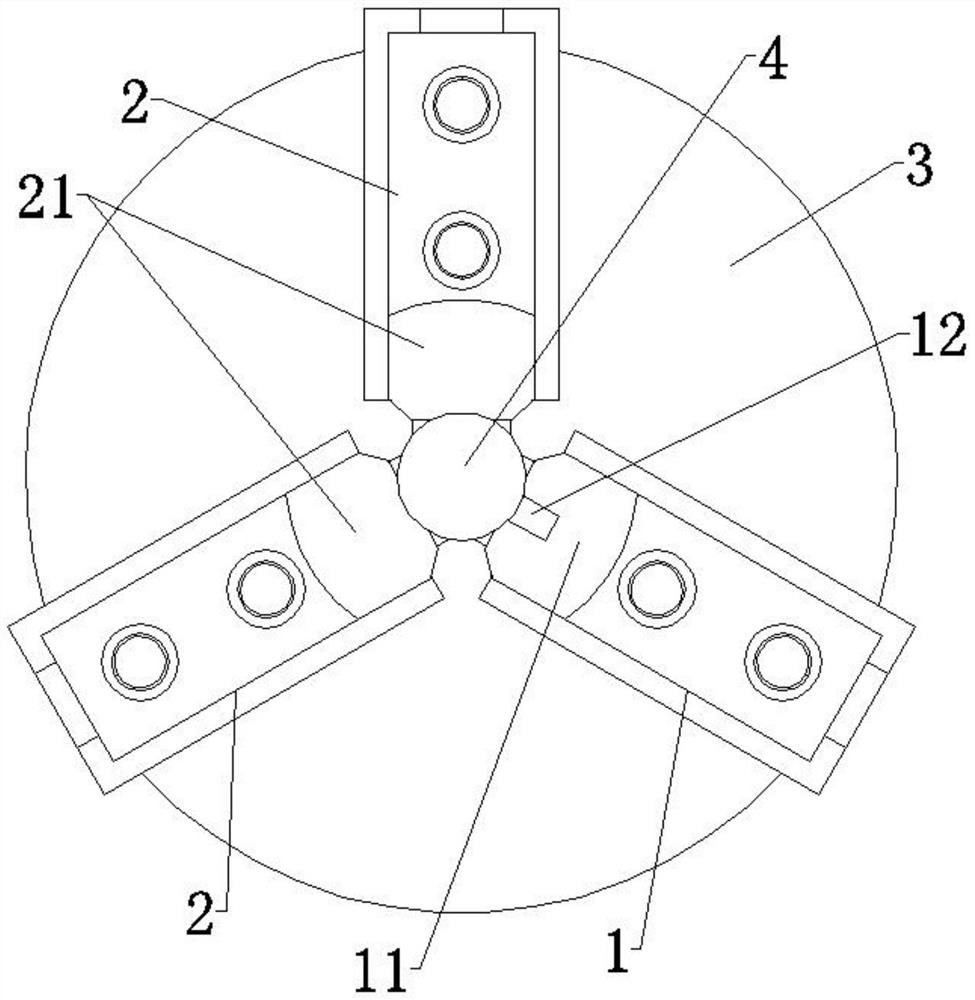

[0040] Work piece comprises sphere 4 and connecting rod 43, and described sphere 4 is fixed on an end of connecting rod 43; Fixture comprises: connecting rod jaw 1, ball jaw 2 and chuck 3, described connecting rod jaw 1, two A ball jaw 2 and a chuck 3 form a three-jaw chuck;

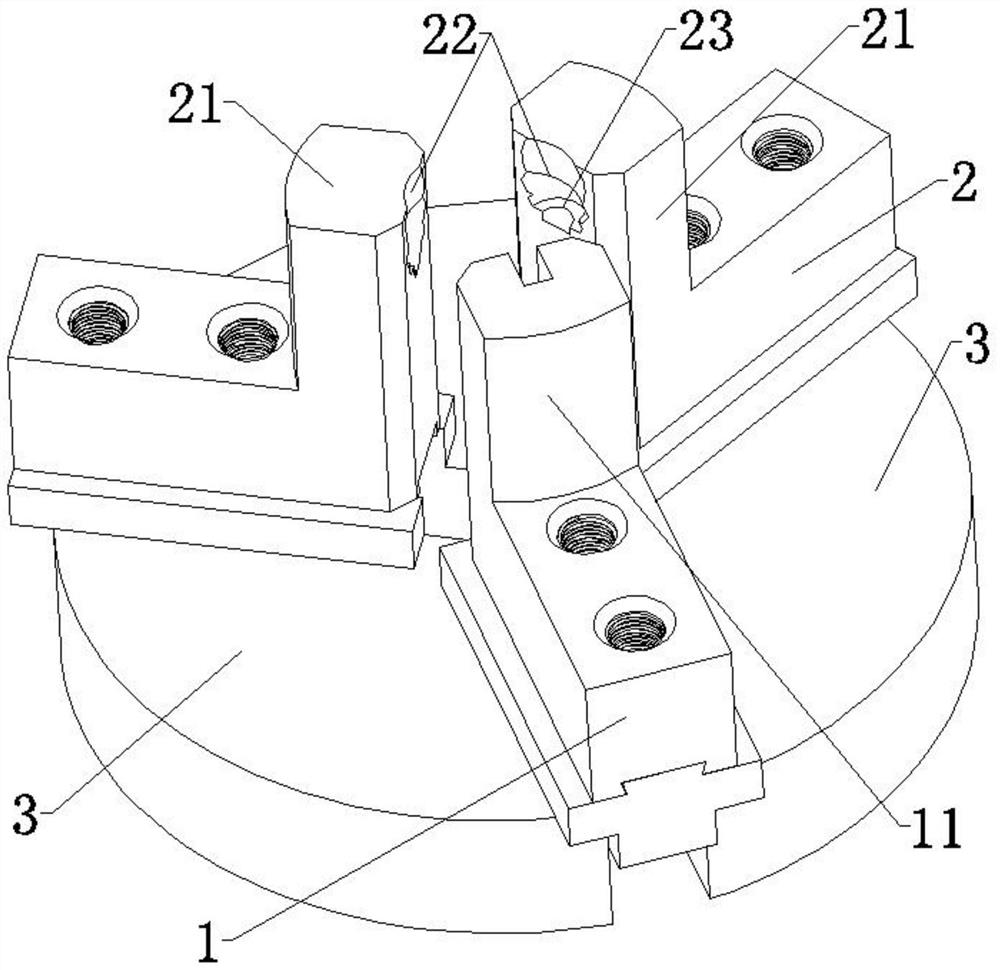

[0041] The inner side of the connecting rod jaw 1 is provided with a clamping platform 21, and the inner side of the clamping platform 21 is provided with a concave spherical surface clamping groove 22, and the clamping groove 22 is opened on the top end of the clamping platform 21, so An escape groove 23 is provided directly below the clamping groove 22

[0042] The inner side of the ball jaw 2 is provided with an erection platform 11, the top of the erection platform 11 is provided with a limiting groove 12, and a separate avoidance groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com