Large-scale hydro-generator rotor connecting sheet punching tool

A hydro-generator and connecting piece technology, which is applied in the manufacture of stator/rotor body, etc., can solve the problems of difficult positioning of the drill bit, easy slippage of the drill bit, scrapped connecting piece, etc., and achieves the effects of good concentricity, cost saving and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

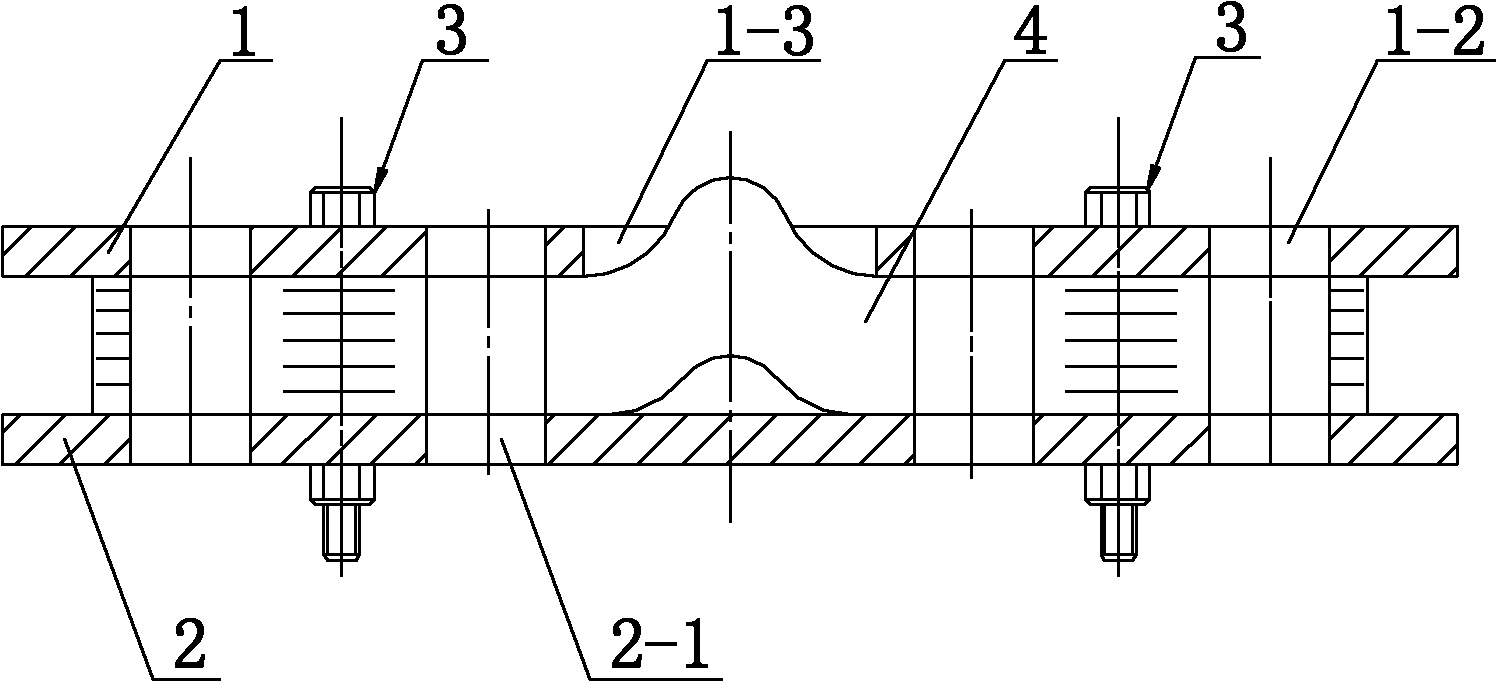

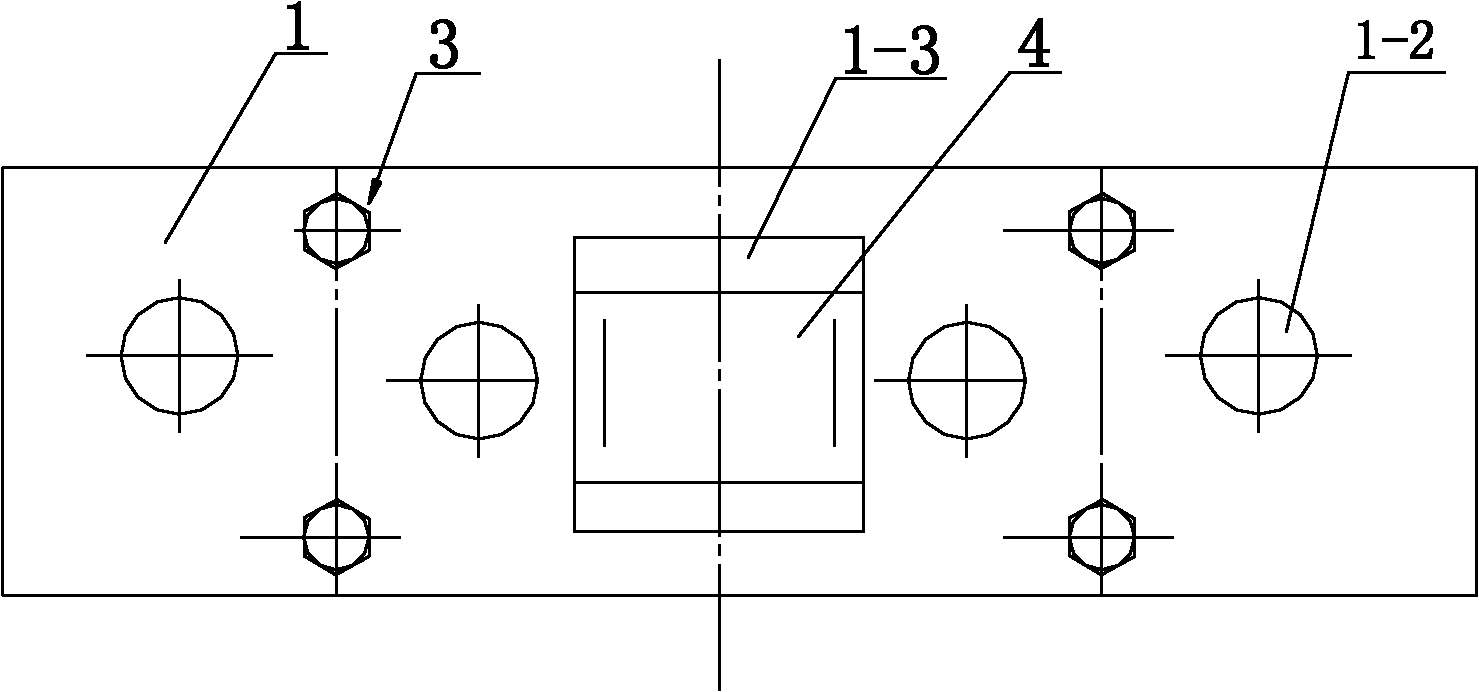

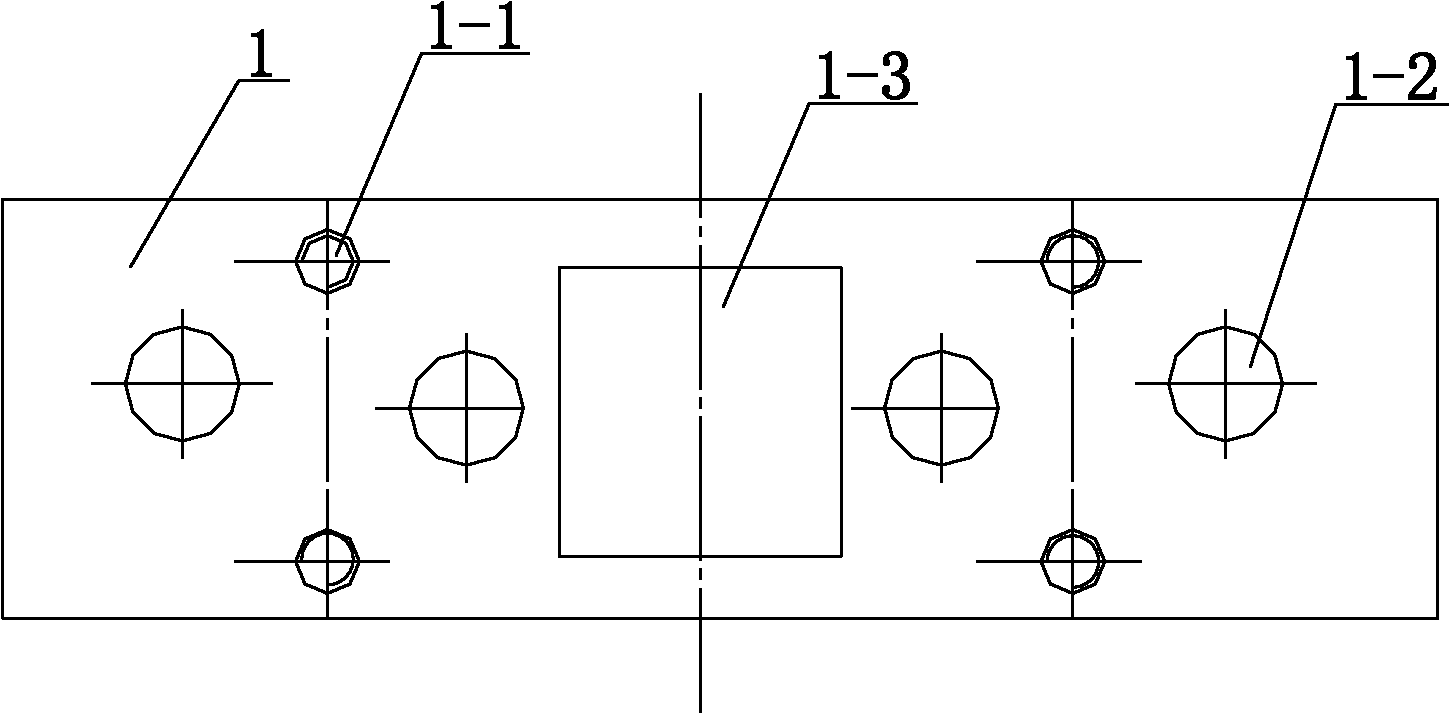

[0018] see Figure 1 to Figure 6 , a large-scale hydraulic generator rotor connecting piece punching tool, the punching tool includes an upper pressure plate 1 and a lower pressure plate 2, and a fastening assembly 3 connecting the upper pressure plate 1 and the lower pressure plate 2; the upper pressure plate 1 is provided with There are threaded holes 1-1 for wearing fasteners and preset holes 1-2 for processing. The hollow distance between the preset holes 1-2 is consistent with the hole distance requirements of the punched connecting piece. The upper platen 1 A preset opening 1-3 for accommodating the convex circle 4-1 of the connecting piece is also provided at the central position of the center. The preset opening is rectangular or circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com