A large flange type workpiece drilling positioning device

A large-scale flange and hole positioning technology, which is applied in positioning devices, drilling dies for workpieces, metal processing machinery parts, etc. Precisely positioned and evenly distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

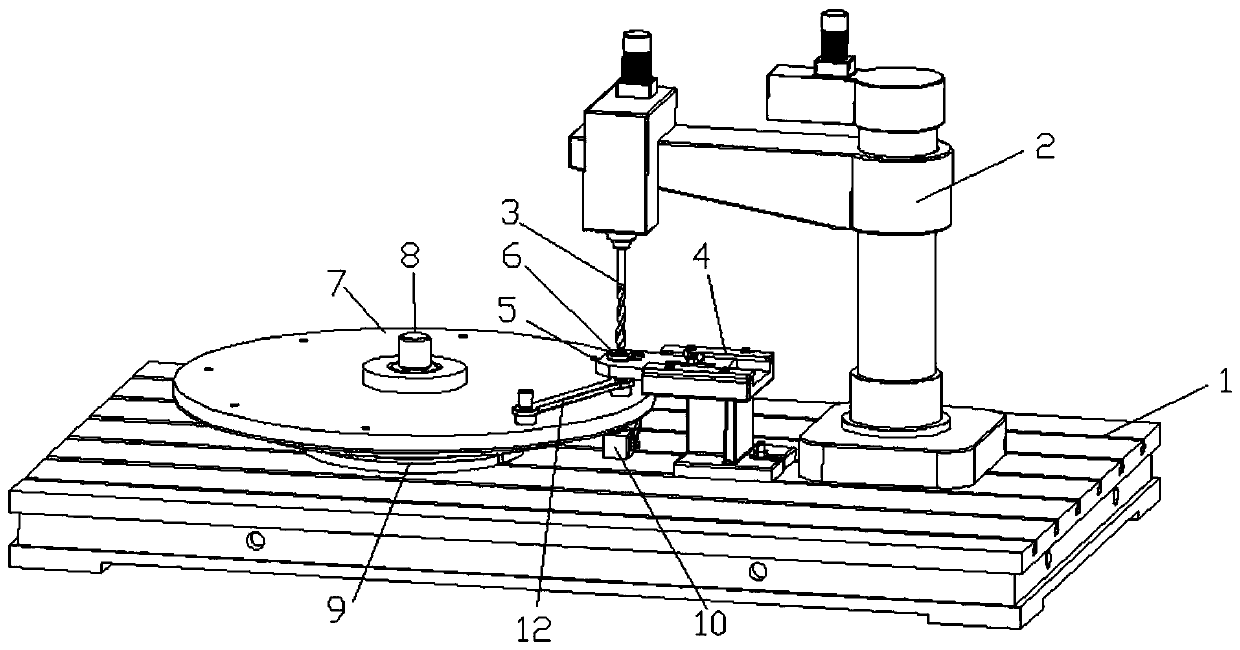

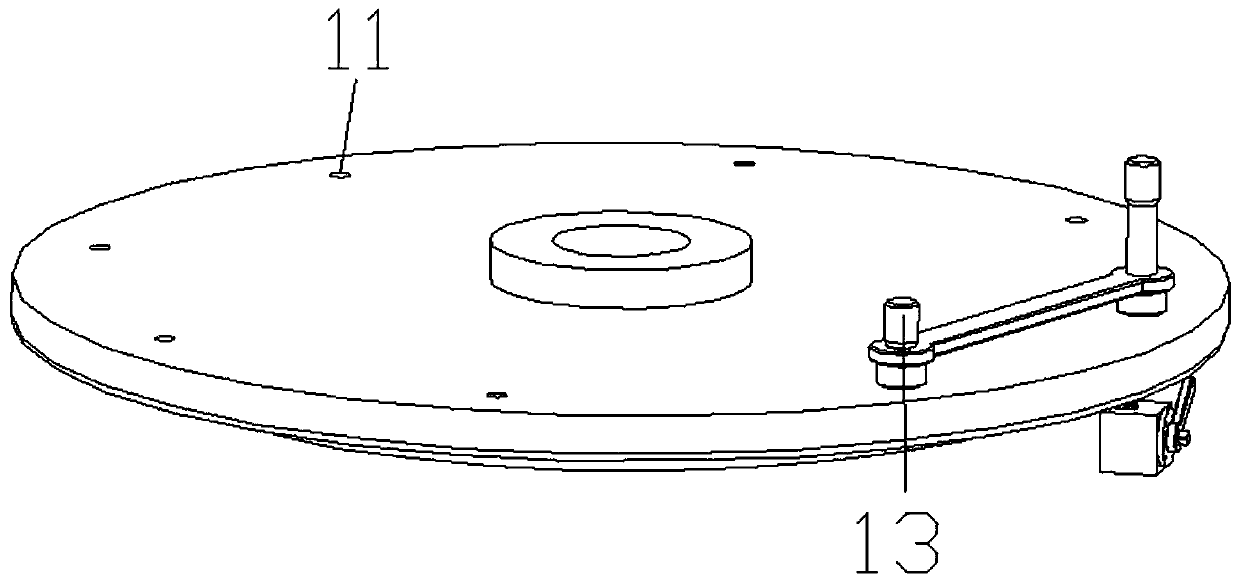

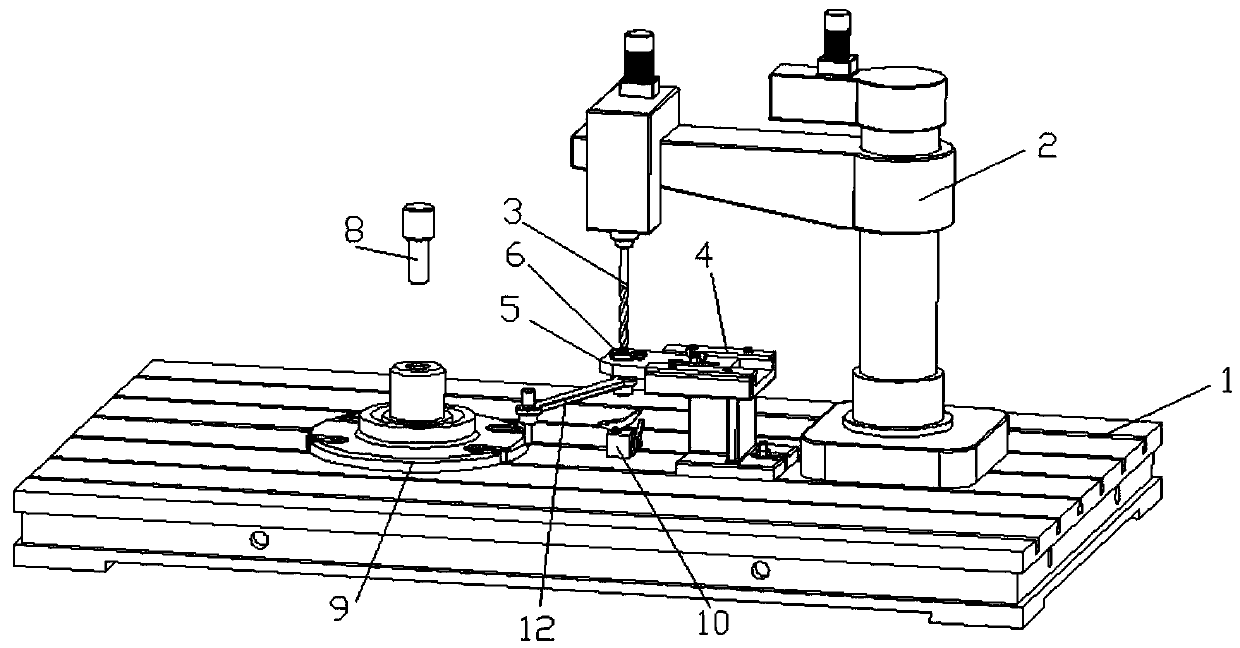

[0020] Example: such as figure 1 , figure 2 , image 3 As shown, it includes a horizontally arranged workbench 1, and a vertically arranged drill press 2 is provided on the right side of the top surface of the workbench 1. The rocker arm of the drill press 2 faces to the left, and the drill press 2 rocker arm is equipped with a downward drill bit 3, and the drill bit 3 passes through the drill press. 2 rotations, the drilling machine 2 left side is provided with a vertical positioning plate bearing 4, and the positioning plate bearing 4 top surface is provided with a transverse groove, and a horizontal positioning plate 5 is provided in the groove, and the positioning plate 5 has the same shape and size as The groove is matched, and the positioning plate 5 moves left and right through the groove. The right end of the positioning plate 5 is provided with a long hole, and the screw for locking the positioning plate 5 is worn in the hole, and the left part of the positioning pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com