Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "Sufficient cooling capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

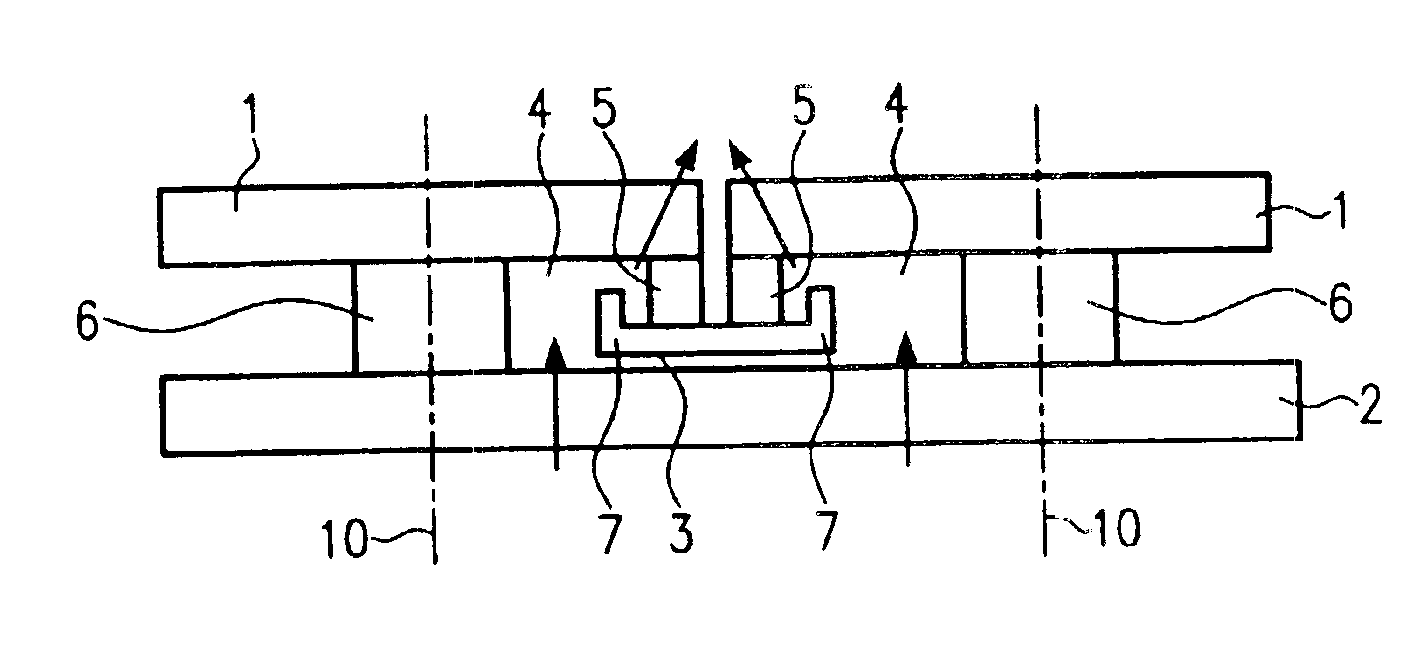

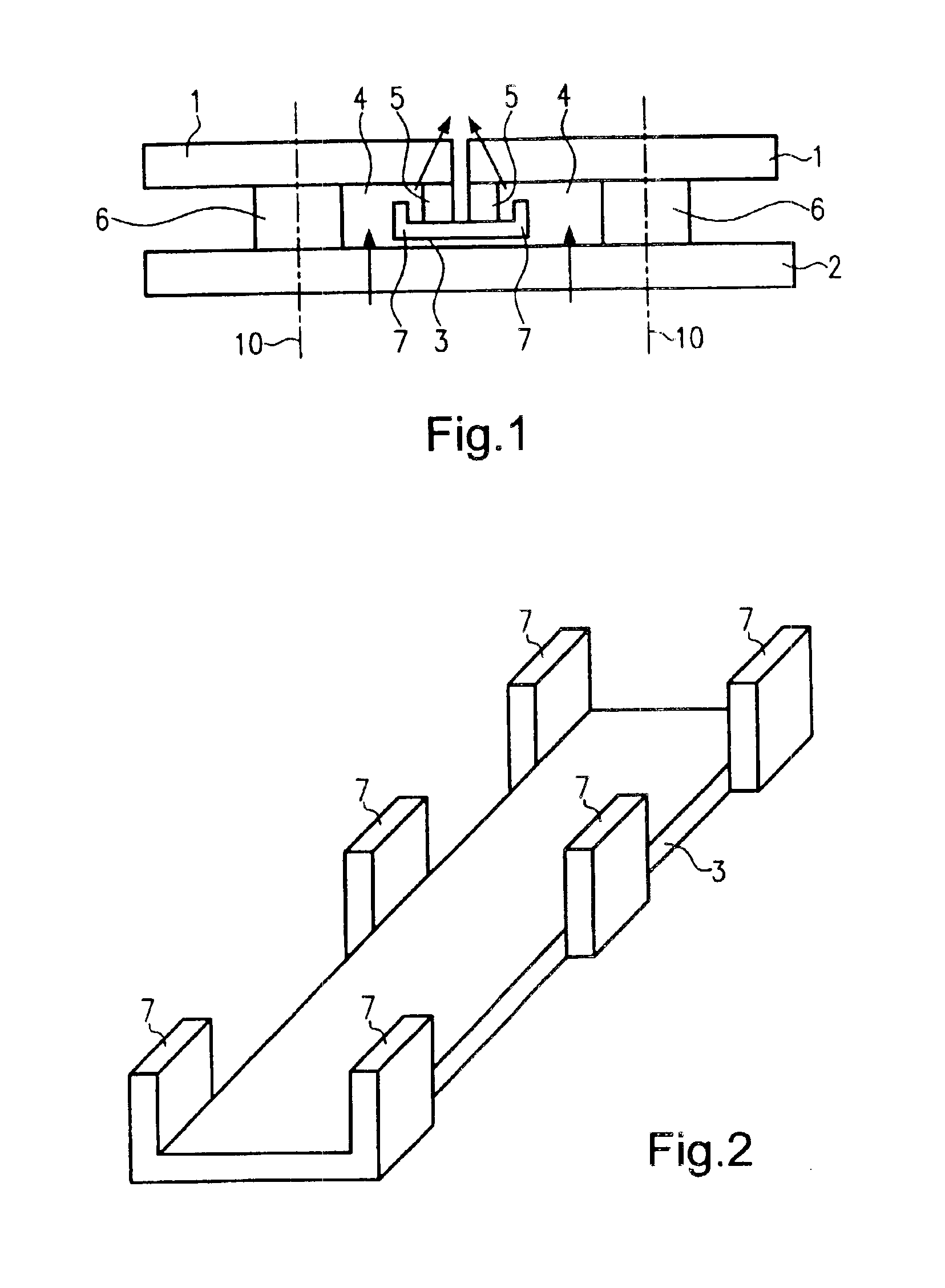

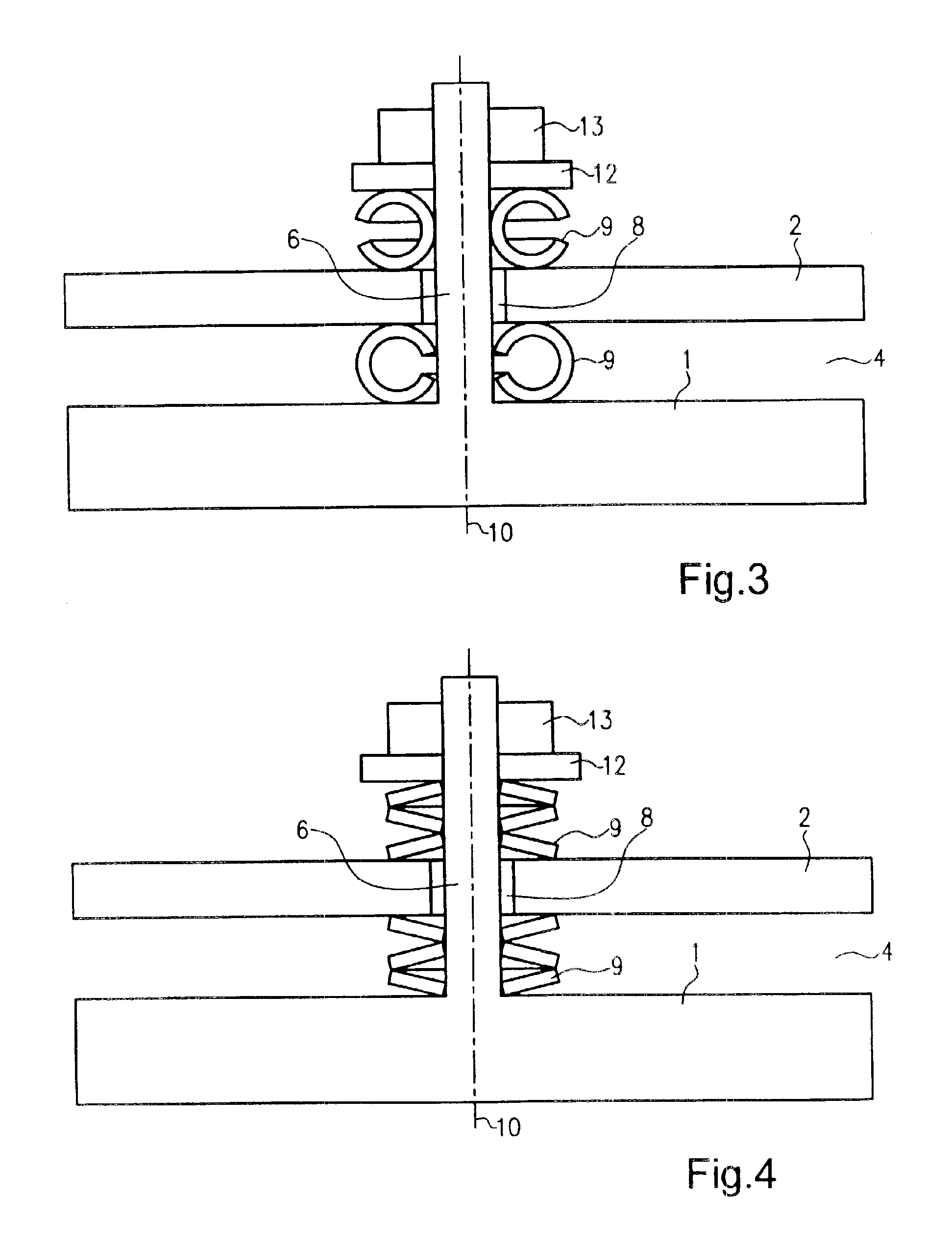

Heat shield arrangement with sealing element

InactiveUS6901757B2Reduce loadProlong lifeContinuous combustion chamberGas turbine plantsHeat shieldFastener

A heat shield arrangement includes several tiles 1 and several fasteners 6 for attaching the tiles at a spaced distance to a wall 2 to form an interspace 4 between the wall and the tiles which can be supplied with cooling air. At least one sealing element 3 is positioned between adjacent tiles 1 to provide a seal between rims 5 of the adjacent tiles 1. The rims 5 of the tiles 1 which are to be sealed are maintained at a spaced distance from the wall 2 by the fasteners 6 and the sealing element 3 is positioned remotely from the wall 2 and in abutment with the rims 5 of the tiles 1, with the sealing element 3 being allowed to float over the rims 5.

Owner:ROLLS ROYCE DEUT LTD & CO KG

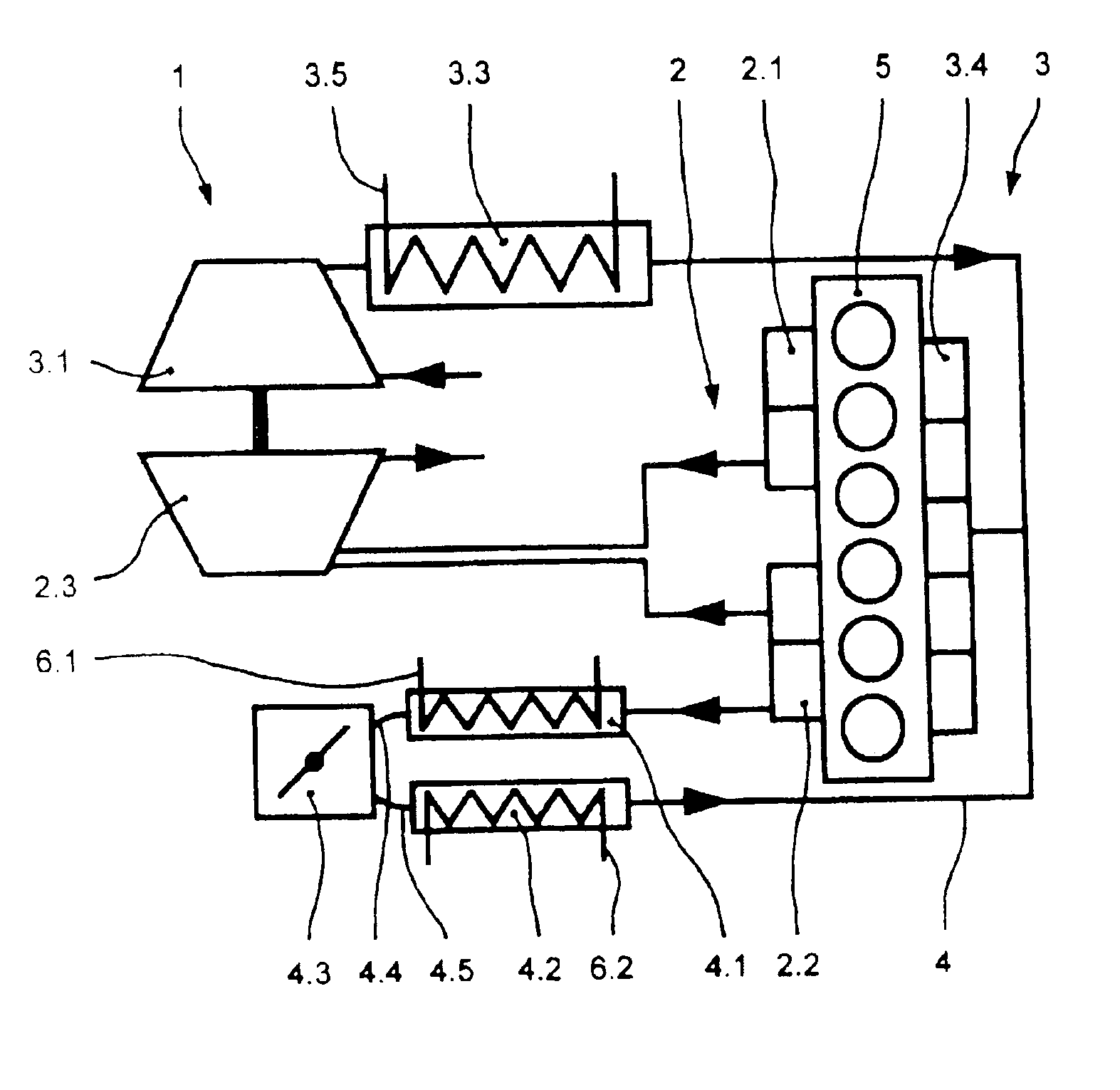

Exhaust-gas recirculation system of an internal combustion engine

InactiveUS6935319B2Convenient ArrangementReduce cooling capacityNon-fuel substance addition to fuelInternal combustion piston enginesExhaust fumesEngineering

In an exhaust-gas recirculation system of an internal combustion engine with an exhaust-gas recirculation line extending between an exhaust duct and an inlet duct, wherein the exhaust-gas recirculation line includes an exhaust-gas recirculation valve and also at least one first exhaust-gas cooler, at least one second exhaust-gas cooler is provided in the exhaust gas recirculation line and the exhaust-gas recirculation valve is arranged between the first exhaust-gas cooler and the second exhaust-gas cooler so that only the first exhaust gas cooler is subjected to the high exhaust gas pressure effective during engine braking when the exhaust gas recirculation valve is closed.

Owner:DAIMLER AG

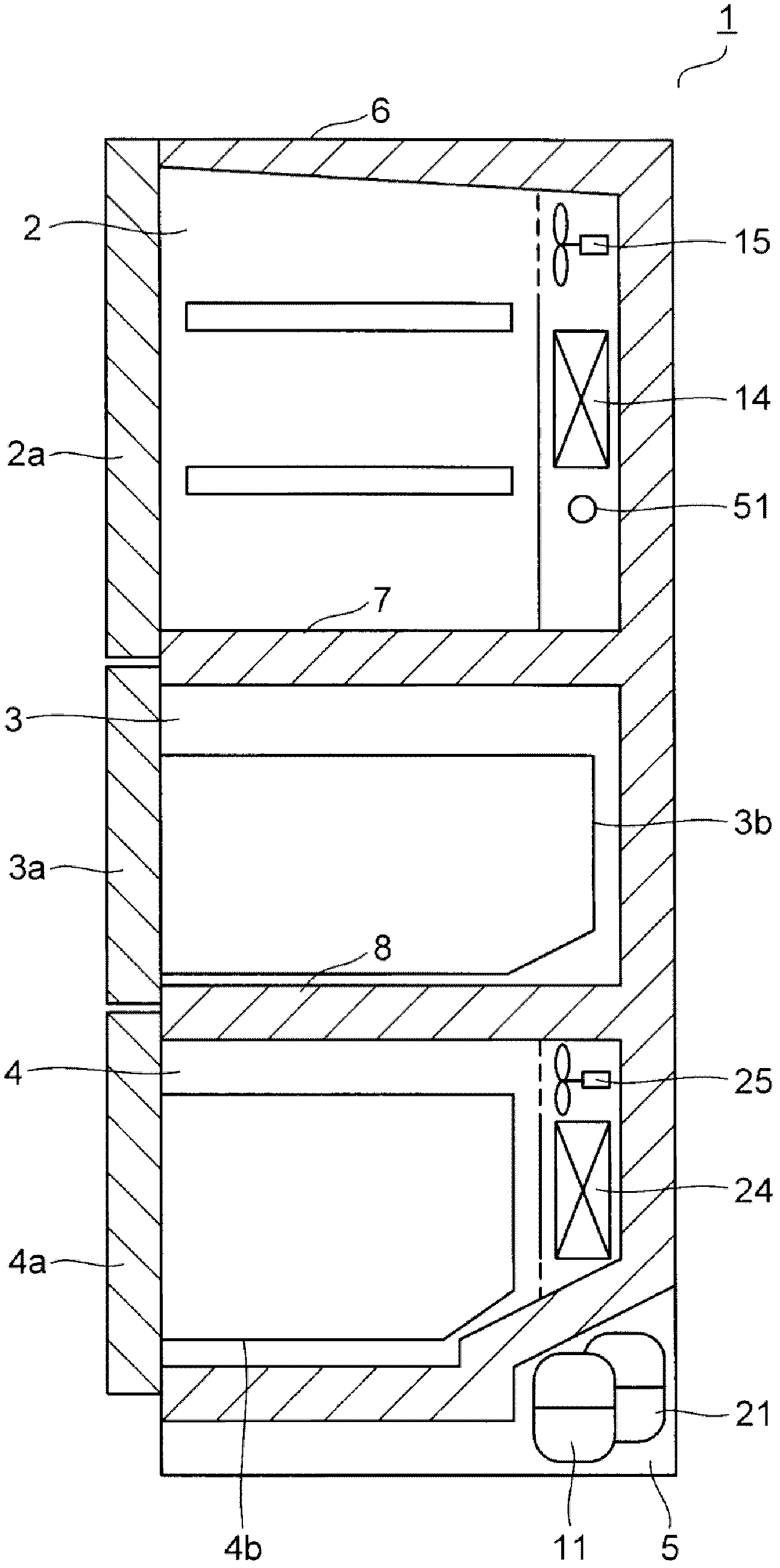

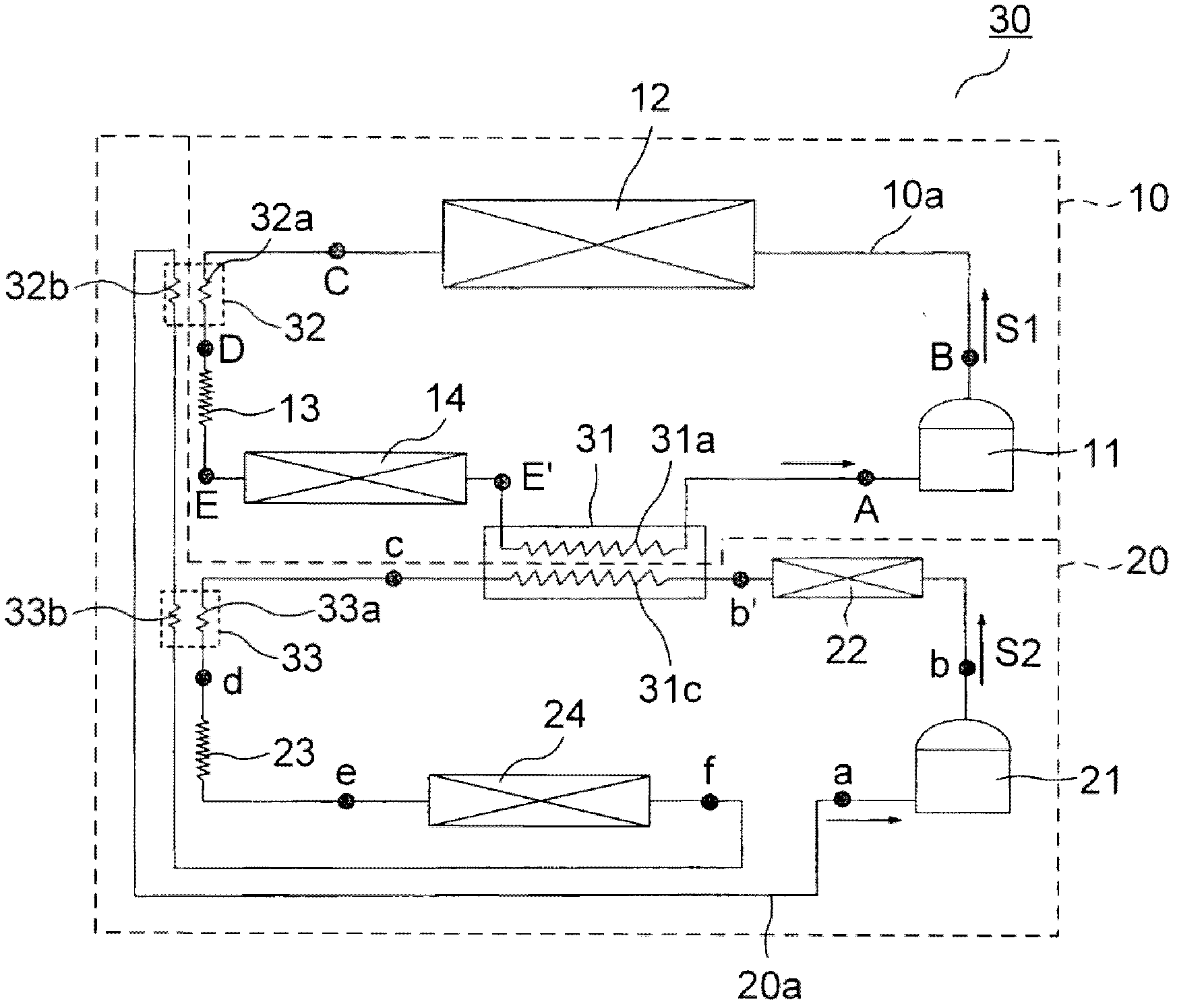

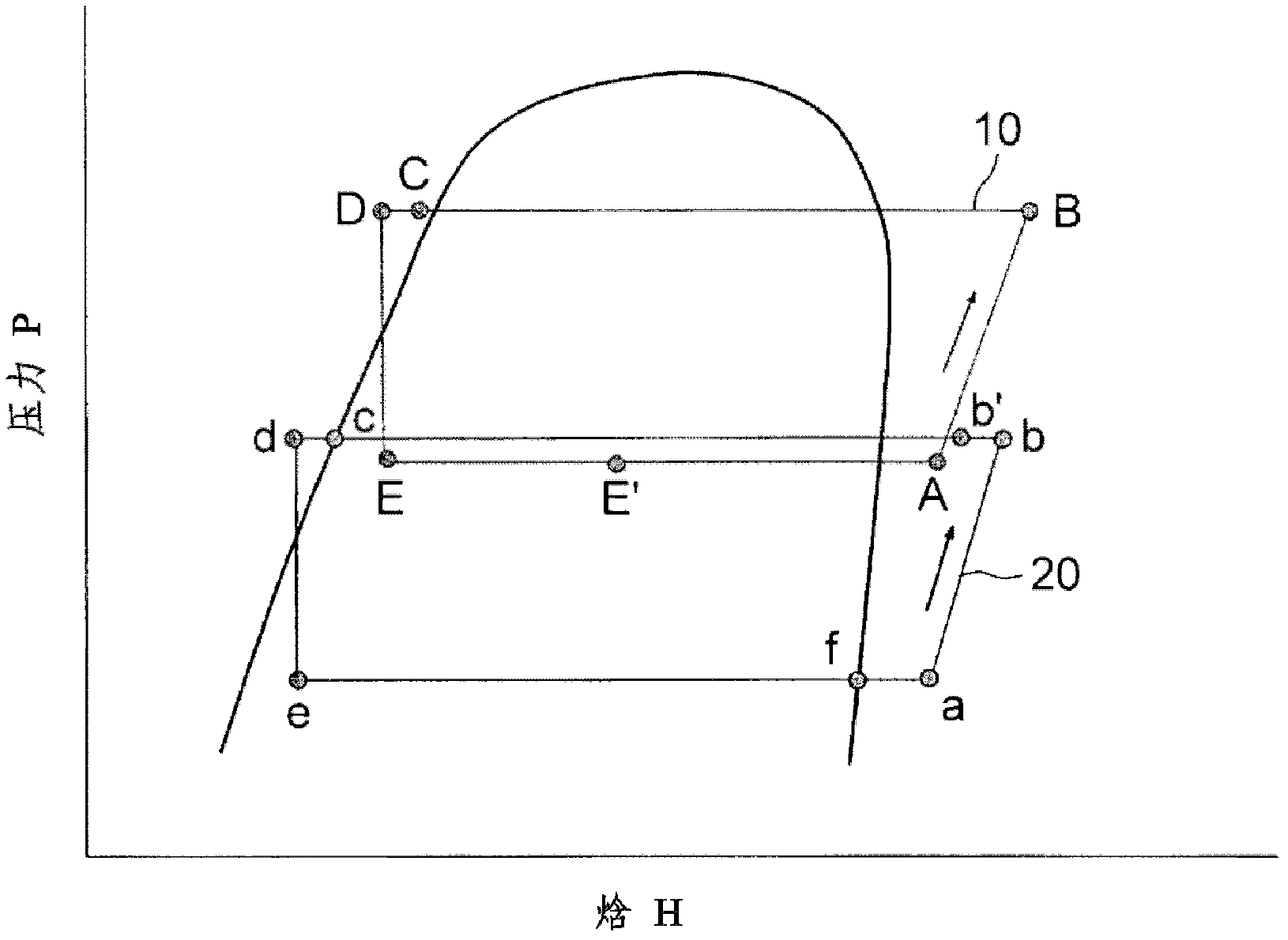

Freezer-refrigerator and cooling storage unit

InactiveCN102395840AImprove COPLess power consumptionCompression machines with non-reversible cycleDomestic refrigeratorsIntermediate heat exchangerEngineering

A freezer-refrigerator comprising: a refrigeration compartment (2) for refrigerating and storing an object to be stored; a freezing compartment (4) for freezing and storing an object to be stored; a first compressor (11) for operating a first refrigeration cycle (10) in which a first refrigerant flows; a first heat dissipater (12) provided to a high-temperature section of the first refrigeration cycle (10); a first evaporator (14) provided to a low-temperature section of the first refrigeration cycle (10); a second compressor (21) for operating a second refrigeration cycle (20) in which a second refrigerant flows; a second evaporator (24) provided to a low-temperature section of the second refrigeration cycle (20); and an intermediate heat exchanger (31) for performing heat exchange between the low-temperature section of the first refrigeration cycle (10) and a high-temperature section of the second refrigeration cycle (20). The first evaporator (14) cools the refrigeration compartment (2), and the second evaporator (24) cools the freezing compartment (4).

Owner:SHARP KK

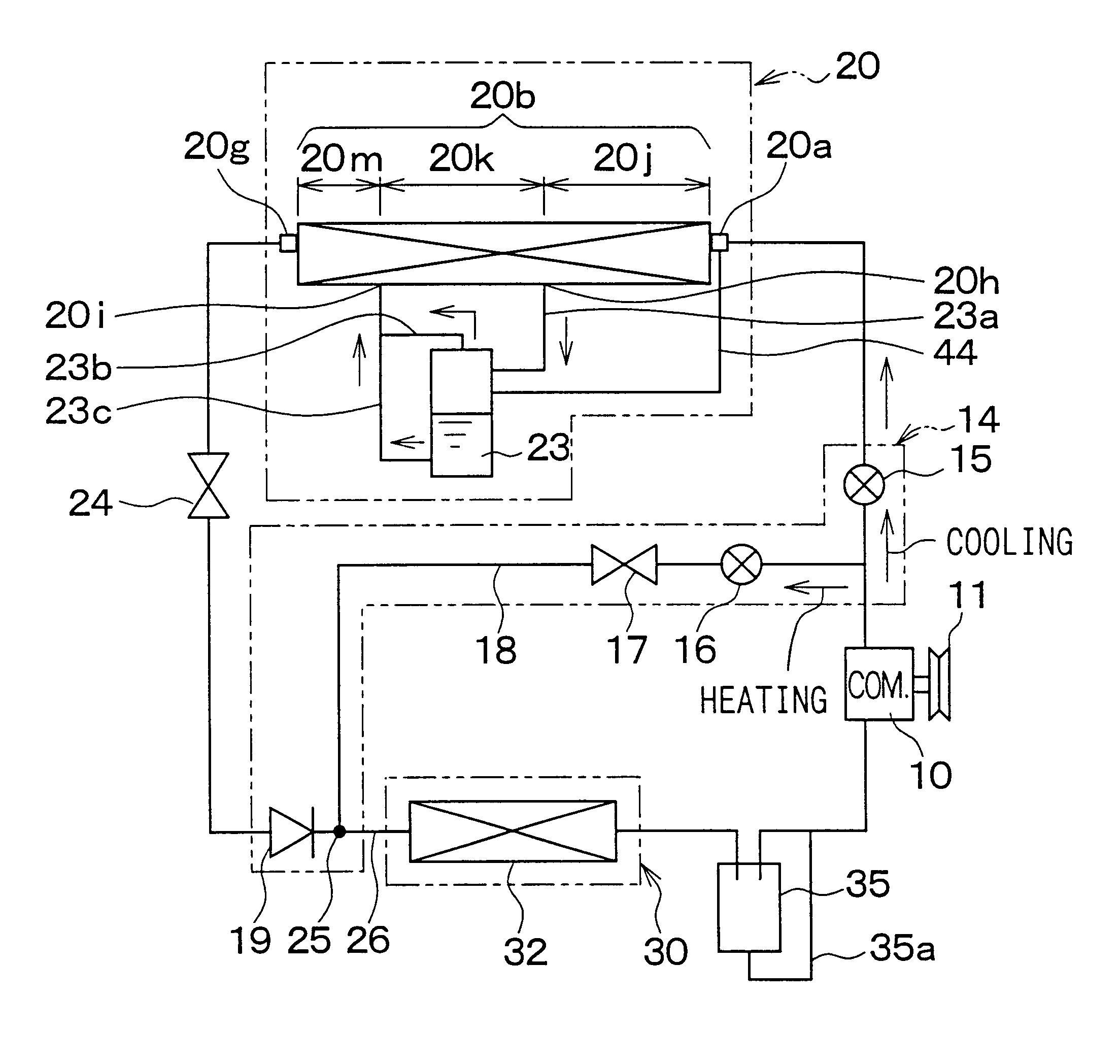

Ejector cycle

InactiveUS20040007014A1Improve efficiencySufficient cooling capacityMechanical apparatusCompression machines with non-reversible cycleThrottle controlPhase state

In an ejector cycle with an ejector including a nozzle for decompressing refrigerant, a variable throttle is disposed upstream from the nozzle of the ejector to decompress and expand high-pressure refrigerant flowing from a radiator. For example, the variable throttle decompresses and expands the high-pressure refrigerant in a gas-liquid two-phase state at an upstream position from the nozzle of the ejector. The variable throttle controls a throttle opening degree so that a refrigerant super-heating degree at a refrigerant outlet side of an evaporator or at a refrigerant suction side of a compressor becomes in a predetermined range. Accordingly, the ejector cycle has an improved nozzle efficiency and an improved ejector efficiency in a wide load variation range of the ejector cycle.

Owner:DENSO CORP

Ejector cycle

ActiveUS20040255611A1Easy to operateAvoid damageCompression machines with non-reversible cycleVehicle heating/cooling devicesInternal pressurePhase state

In an ejector cycle with an ejector including a nozzle for decompressing refrigerant, a variable throttle device is disposed upstream from the nozzle to decompress and expand high-pressure refrigerant flowing from a condenser. For example, the variable throttle device decompresses the high-pressure refrigerant in a gas-liquid two-phase state at an upstream position from the nozzle of the ejector. In addition, the variable throttle device includes a back pressure chamber having an inner pressure that changes by sensing a refrigerant temperature at a refrigerant outlet side of an evaporator, and a pressure introducing means for introducing a refrigerant pressure of a refrigerant outlet side of the evaporator to a side opposite to the back pressure chamber with respect to a diaphragm. Therefore, a pressure difference between the back pressure chamber and the side opposite to the back pressure chamber can be made smaller.

Owner:DENSO CORP

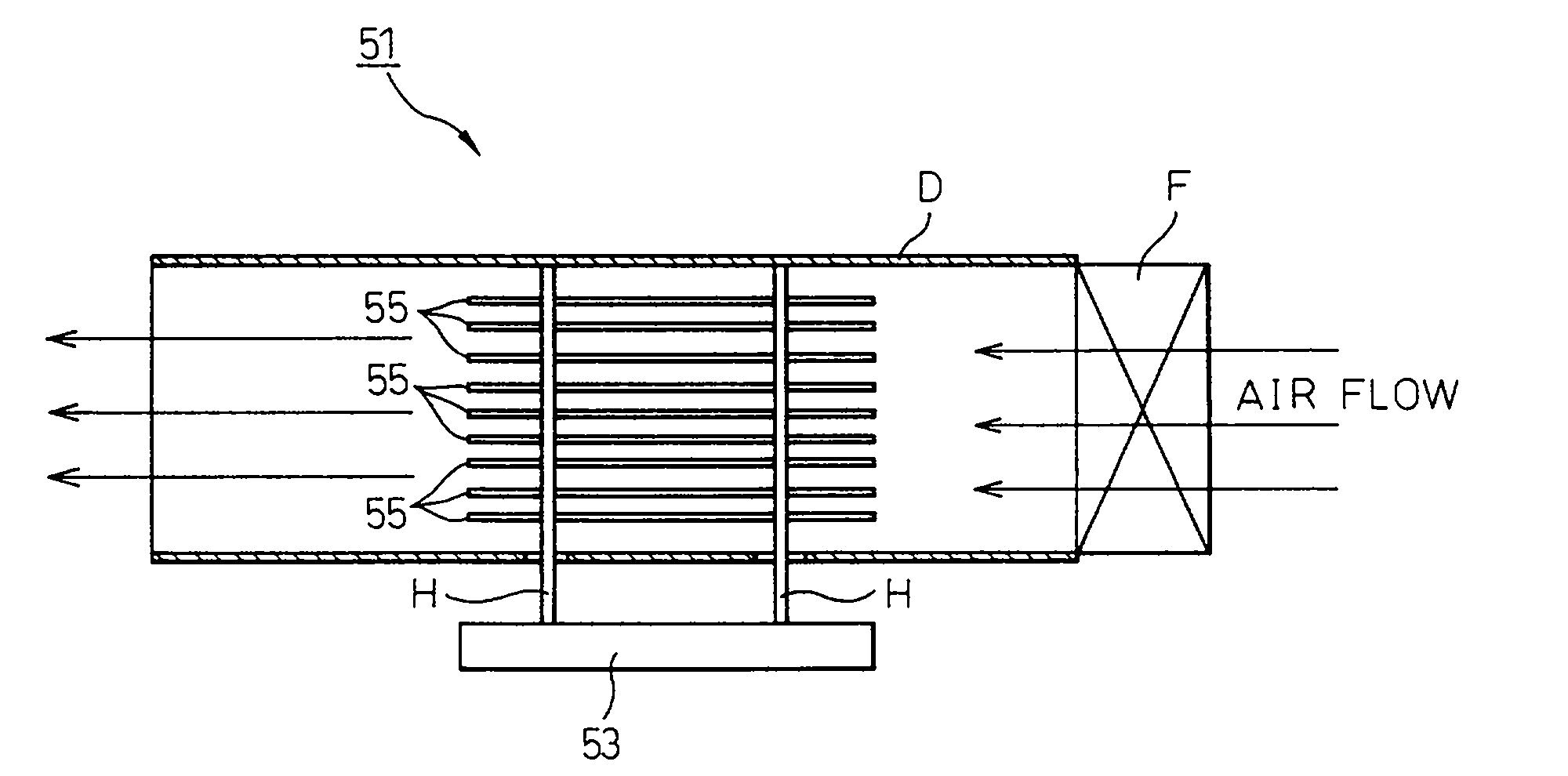

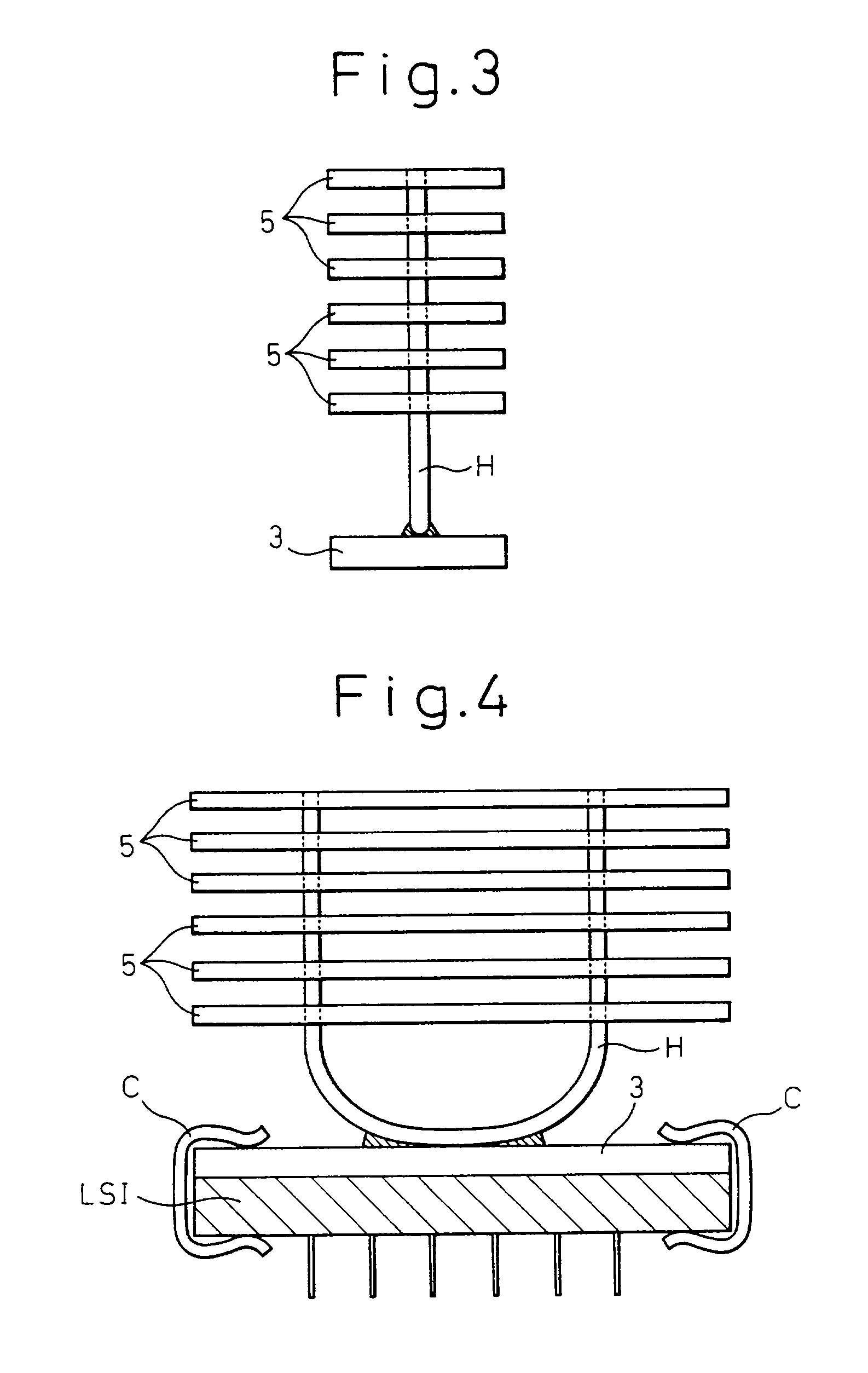

Heat pipe type cooler

InactiveUS7156158B2Sufficient cooling capacityReduce the overall heightSemiconductor/solid-state device detailsSolid-state devicesChillerEngineering

To realize a integrally constructed cooler of the heat pipe type which ensures the achievement of sufficient cooling capacity and the realization of a simple, compact and inexpensive cooler, that is especially low in height, employing and incorporating ingeniously a heat pipe, there is provided a heat pipe type cooler comprising: a heat receiving plate 3; a heat radiator having a configuration of a plurality of horizontally oriented heat radiation plates 5 extending vertically; and a heat pipe H having a generally U or V shaped profile, the middle portion of which is secured to the heat receiving plate 3: and wherein each end of the heat pipe H passes through the heat radiation plates 5.

Owner:FUJITSU LTD

Refrigerant cycle system with hot-gas bypass structure

InactiveUS6516628B2Small sizeShort timeAir-treating devicesMechanical apparatusVapor–liquid separatorProduct gas

In a refrigerant cycle system, a low-pressure side gas-liquid separator is disposed between a refrigerant outlet side of an evaporator and a refrigerant suction side of a compressor so that gas refrigerant is sucked into the compressor, and a throttle passage through which liquid refrigerant is introduced into the compressor is disposed in the low-pressure side gas-liquid separator. Further, in a condenser for condensing gas refrigerant discharged from the compressor in a cooling mode, both first and second heat-exchanging units are provided in this order in a refrigerant flow direction, and a high-pressure side gas-liquid separator is disposed between the first and second heat-exchanging units.

Owner:DENSO CORP

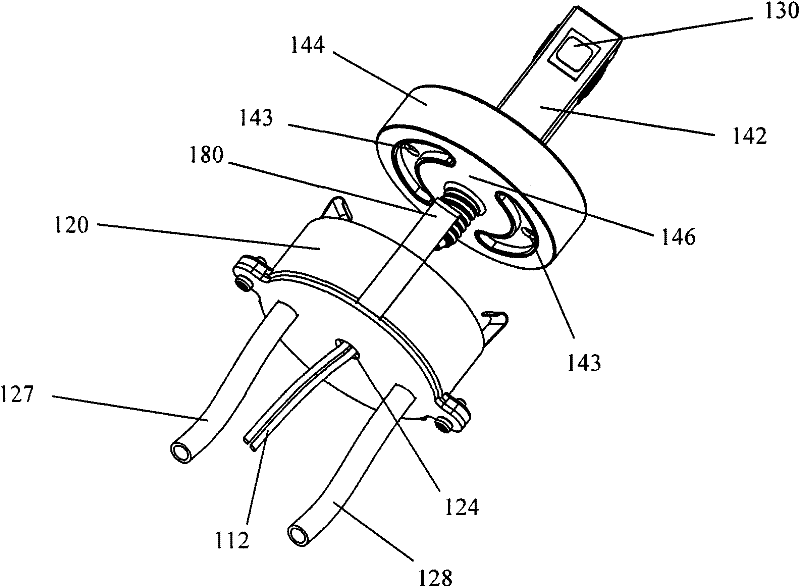

Method and System for Operating Winches and Use Thereof

InactiveUS20150083985A1Improve dynamic performanceRisk of breakageAnchor handling/lashingWinding mechanismsHydraulic motorLine tubing

This publication discloses a method and a winch system for powering a winch handling loads at an end of a line associated with a winch drum, the winch being powered by means of one or more electric motors and one or more hydraulic motors via a gear, in that said one or more hydraulic motors are operated when the load in the line exceeds a predetermined load level for taking care of quick hauling in or paying out the line to compensate for vertical motion of the winch, for example vessel due to waves, and the output shaft(s) of said one or more hydraulic motors are connected to the drum shaft through combination of a sun wheel, planet wheels and parallel wheels. Both a system and use of the invention are disclosed.

Owner:I P HUSE

Thermal flow density measuring device under adverse environment experiment

InactiveCN1818627ATemperature does not affect each otherSufficient cooling capacityMaterial thermal conductivityMaterial heat developmentAsynchronous serial communicationHeat flow

A measuring device for testing thermal flow density under adverse circumstances consists of heating element, probe core, water pipe, industrial thermocouple set at thermal flow incoming end, water in and water out head connected through to cavity formed by water pipe and probe, cooling water channel in heating element, water incoming element and water outgoing element connected separately to internal channel and external channel of heating element, thermocouple signal collection unit being used to transmit its signal to computer through signal line according to RS-485 asynchronous serial communication rule .

Owner:HARBIN INST OF TECH

Winter jujube planting method

InactiveCN105993783AGood qualityScientific and reasonable settingSuperphosphatesExcrement fertilisersTerrainBud

The invention provides a winter jujube planting method. The winter jujube planting method comprises the steps that land preparation is performed: land flat in terrain, convenient to irrigate, good in drainage, fertile in soil and loose in nature is selected for deep ploughing, and field planting furrows are dug according to line spacing; fertilizing is performed: organic fertilizer and loess are evenly mixed and backfilled to the field planting furrows, and leveling is performed; nursery stocks are selected: grafted seedlings with the stem thickness of more than 1 cm and the height of more than 0.7 m are selected as the nursery stocks; field planting is performed: field planting is performed from leaf falling in autumn to germination in a next year; seedling management is performed: young seedlings undergo watering in good time, fertilizer application, intertillage and disease and pest prevention and control within two years after the field planting is completed; reshaping and pruning are performed: resting-stage pruning is performed from leaf falling to sap flowing, wherein cuts are formed in the positions 0.5 cm higher than buds; fruit tree growing environment management is performed: artificial low-temperature dark-light dormancy promotion, mulching film coverage, temperature rise, ventilation and temperature and humidity control are adopted in the fruit tree growth process to manage a fruit tree growth environment. The winter jujube planting method is reasonable in design and achieves abundant winter jujube production in regions where are not suitable for cultivation by controlling temperature and cold needs.

Owner:泾阳佳沃农业有限公司

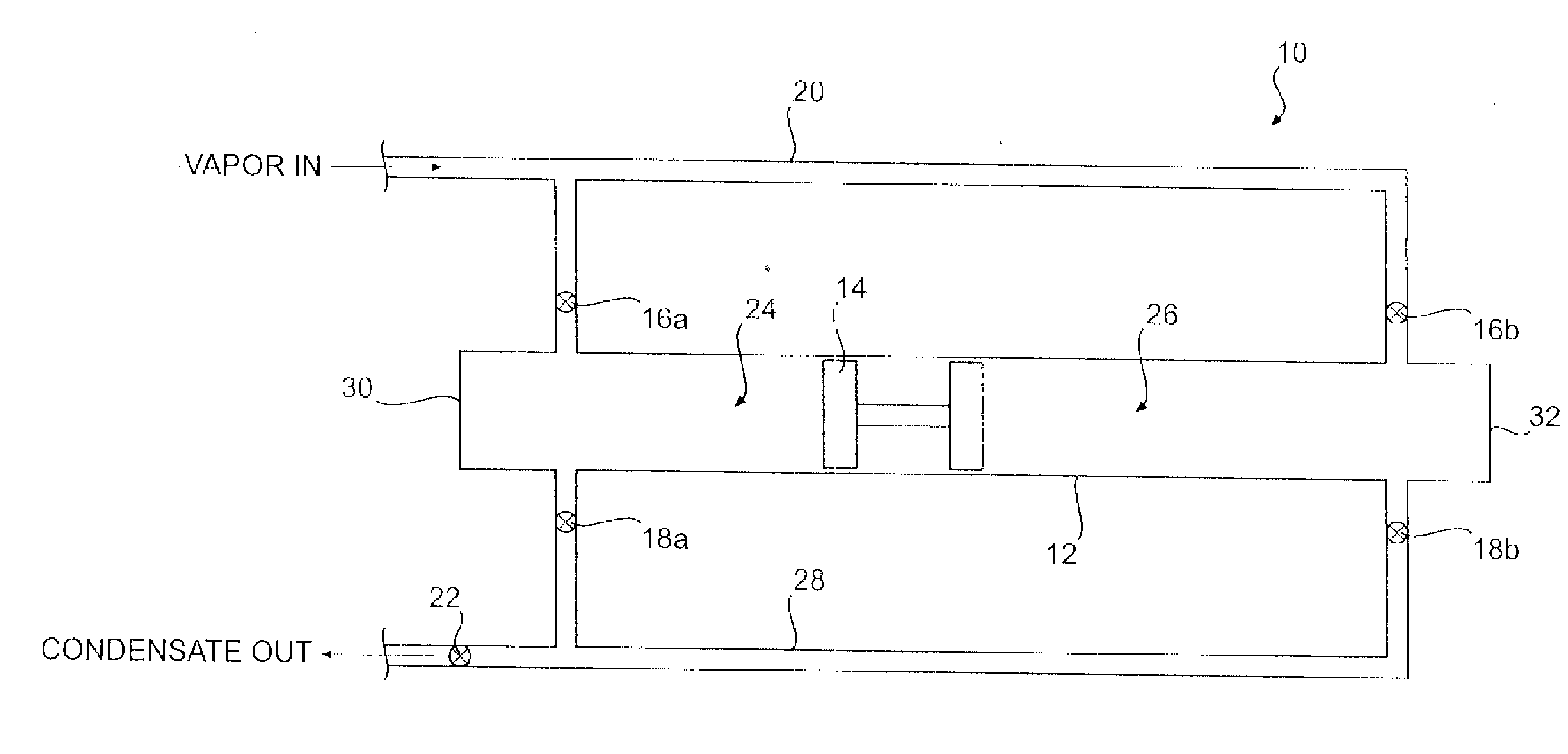

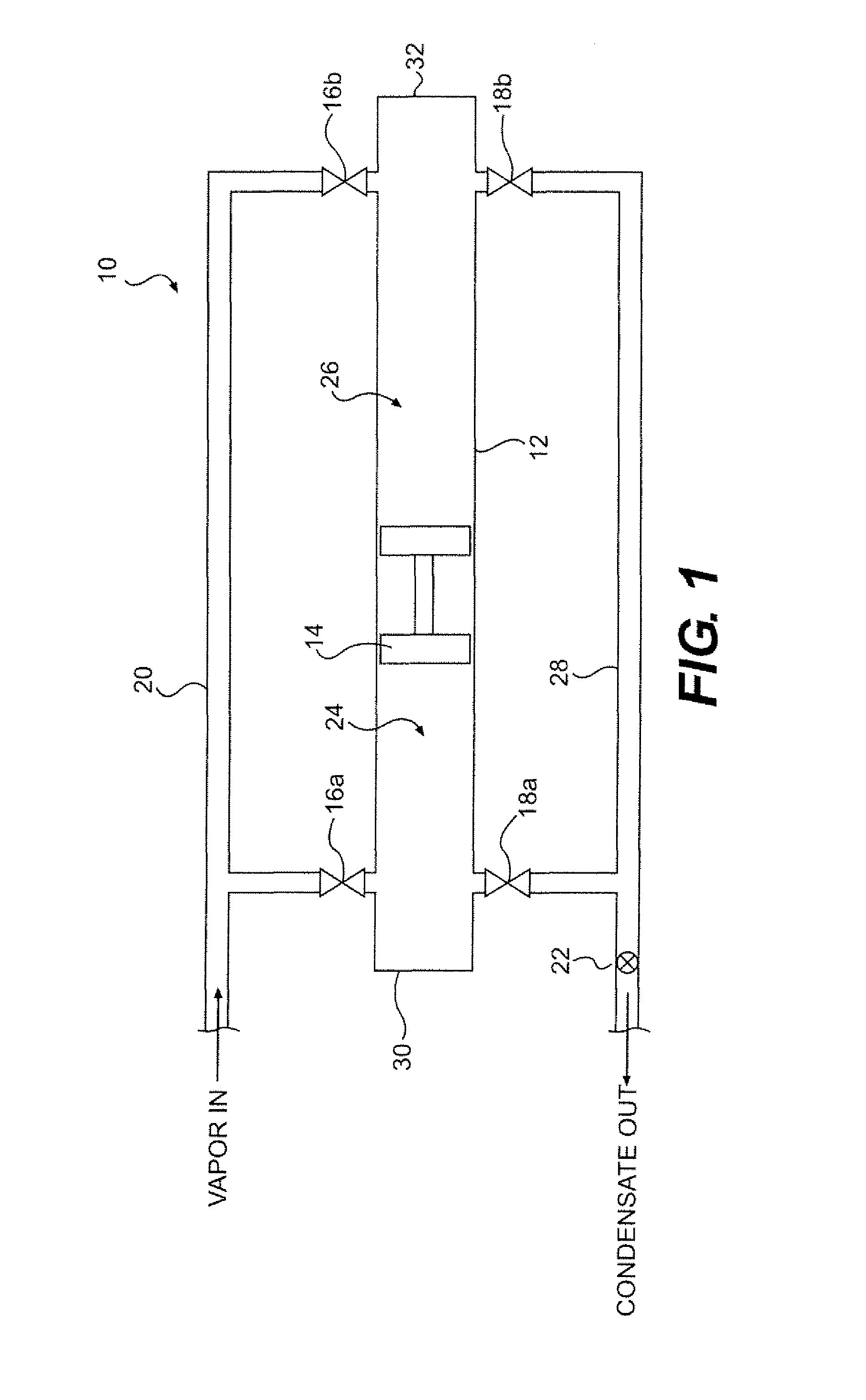

Open Loop Heat Pipe Radiator Having A Free-Piston For Wiping Condensed Working Fluid

An open loop heat pipe radiator comprises a radiator tube and a free-piston. The radiator tube has a first end, a second end, and a tube wall, and the tube wall has an inner surface and an outer surface. The free-piston is enclosed within the radiator tube and is capable of movement within the radiator tube between the first and second ends. The free-piston defines a first space between the free-piston, the first end, and the tube wall, and further defines a second space between the free-piston, the second end, and the tube wall. A gaseous-state working fluid, which was evaporated to remove waste heat, alternately enters the first and second spaces, and the free-piston wipes condensed working fluid from the inner surface of the tube wall as the free-piston alternately moves between the first and second ends. The condensed working fluid is then pumped back to the heat source.

Owner:NASA

Ejector cycle

InactiveUS6871506B2Improve efficiencyWide range of fieldsMechanical apparatusCompression machines with non-reversible cycleThrottle controlPhase state

In an ejector cycle with an ejector including a nozzle for decompressing refrigerant, a variable throttle is disposed upstream from the nozzle of the ejector to decompress and expand high-pressure refrigerant flowing from a radiator. For example, the variable throttle decompresses and expands the high-pressure refrigerant in a gas-liquid two-phase state at an upstream position from the nozzle of the ejector. The variable throttle controls a throttle opening degree so that a refrigerant super-heating degree at a refrigerant outlet side of an evaporator or at a refrigerant suction side of a compressor becomes in a predetermined range. Accordingly, the ejector cycle has an improved nozzle efficiency and an improved ejector efficiency in a wide load variation range of the ejector cycle.

Owner:DENSO CORP

Charging system having an integrated coolant reservoir

ActiveUS20190255961A1Sufficient cooling capacityPrevent excessively coldCharging stationsElectric vehicle charging technologyEngineeringCharging station

A charging system for charging an electric vehicle is provided. The charging system includes a charging station, at least one charging connector, which is able to be coupled to the electric vehicle in order to charge same, a buffer storage device for storing energy, power electronics that are configured to provide the energy from the buffer storage device and / or from a mains connection to the charging station at the at least one charging connector, and a coolant reservoir in which a coolant for cooling the power electronics is stored.

Owner:DR ING H C F PORSCHE AG

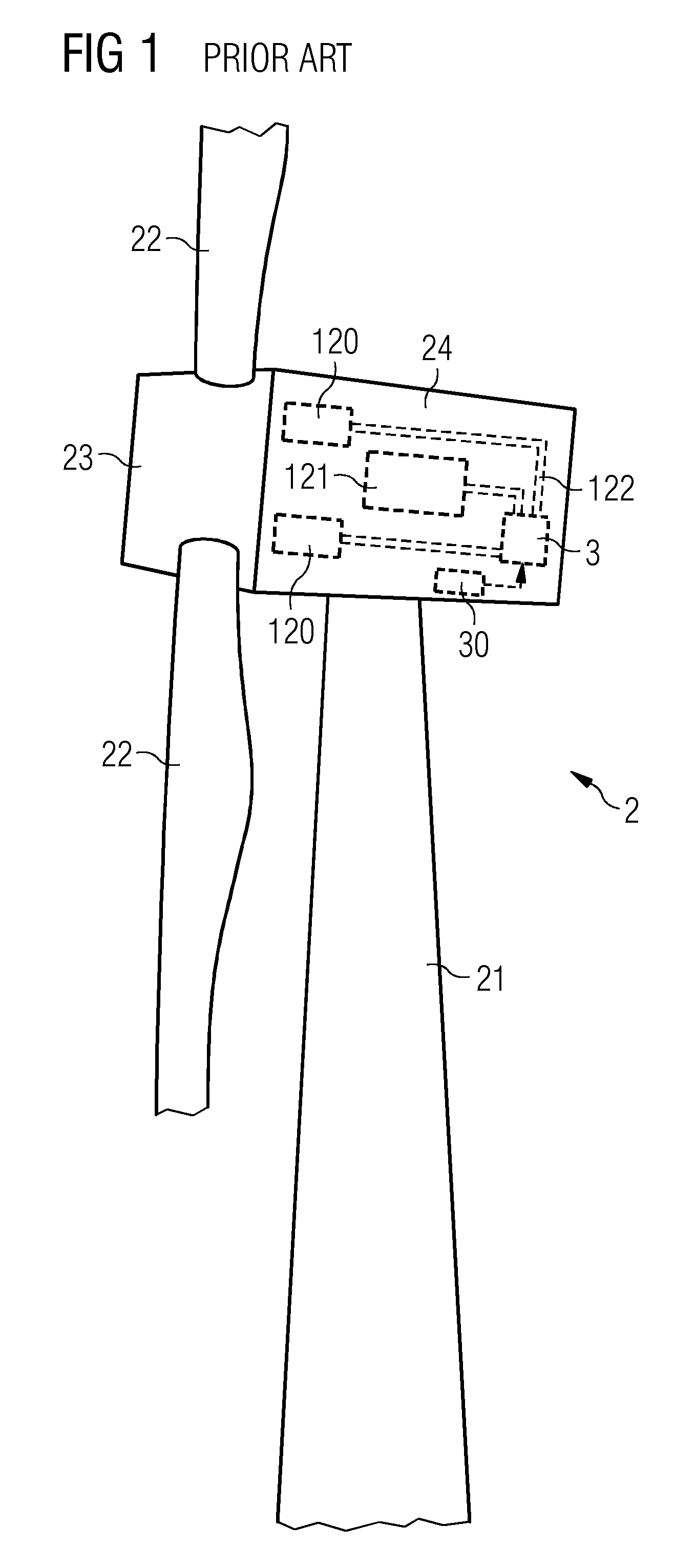

Wind turbine cooling arrangement

InactiveUS20130015665A1Improved cooling arrangementImprove cooling effectEngine fuctionsEfficient propulsion technologiesTurbineWind force

The disclosure describes a wind turbine cooling arrangement including a passive heat exchanger arranged to absorb heat from a cooling circuit of a wind turbine, the passive heat exchanger is arranged on the exterior of the canopy to extend above a canopy of the wind turbine. The wind turbine cooling arrangement includes a ventilation arrangement which includes at least one air channel for channelling air onto a surface of the passive heat exchanger. Further described is a wind turbine including such a wind turbine cooling arrangement.

Owner:SIEMENS AG

Ejector cycle

ActiveUS6877339B2Improve efficiencyWide range of fieldsCompression machines with non-reversible cycleVehicle heating/cooling devicesInternal pressureEngineering

Owner:DENSO CORP

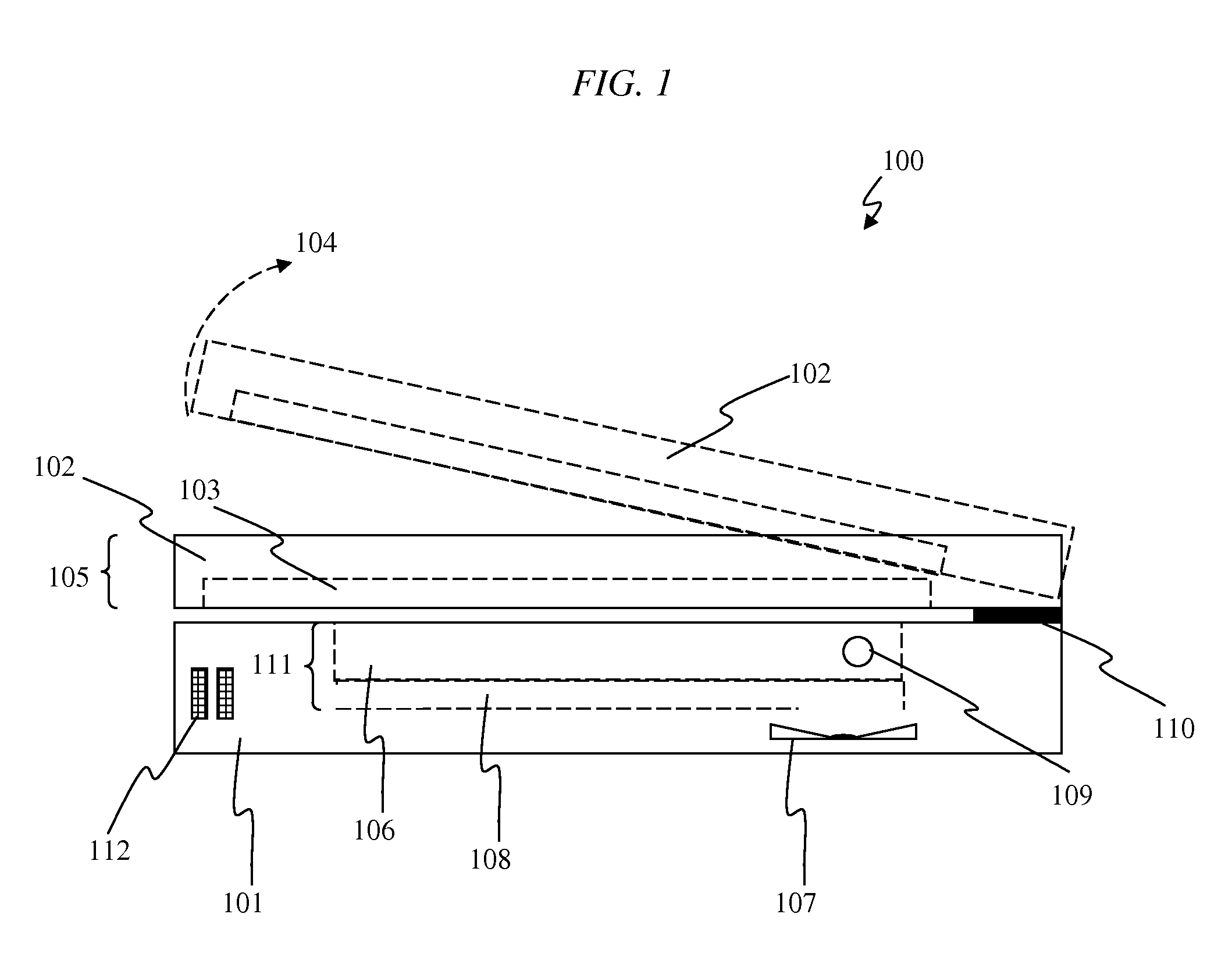

Notebook computer with tilting keyboard vent

InactiveUS7733644B2Reducing of ingestionReduce the possibilityDetails for portable computersCooling/ventilation/heating modificationsRepetitive motion injuryWrist strain

Owner:WILSON ROBYN L +1

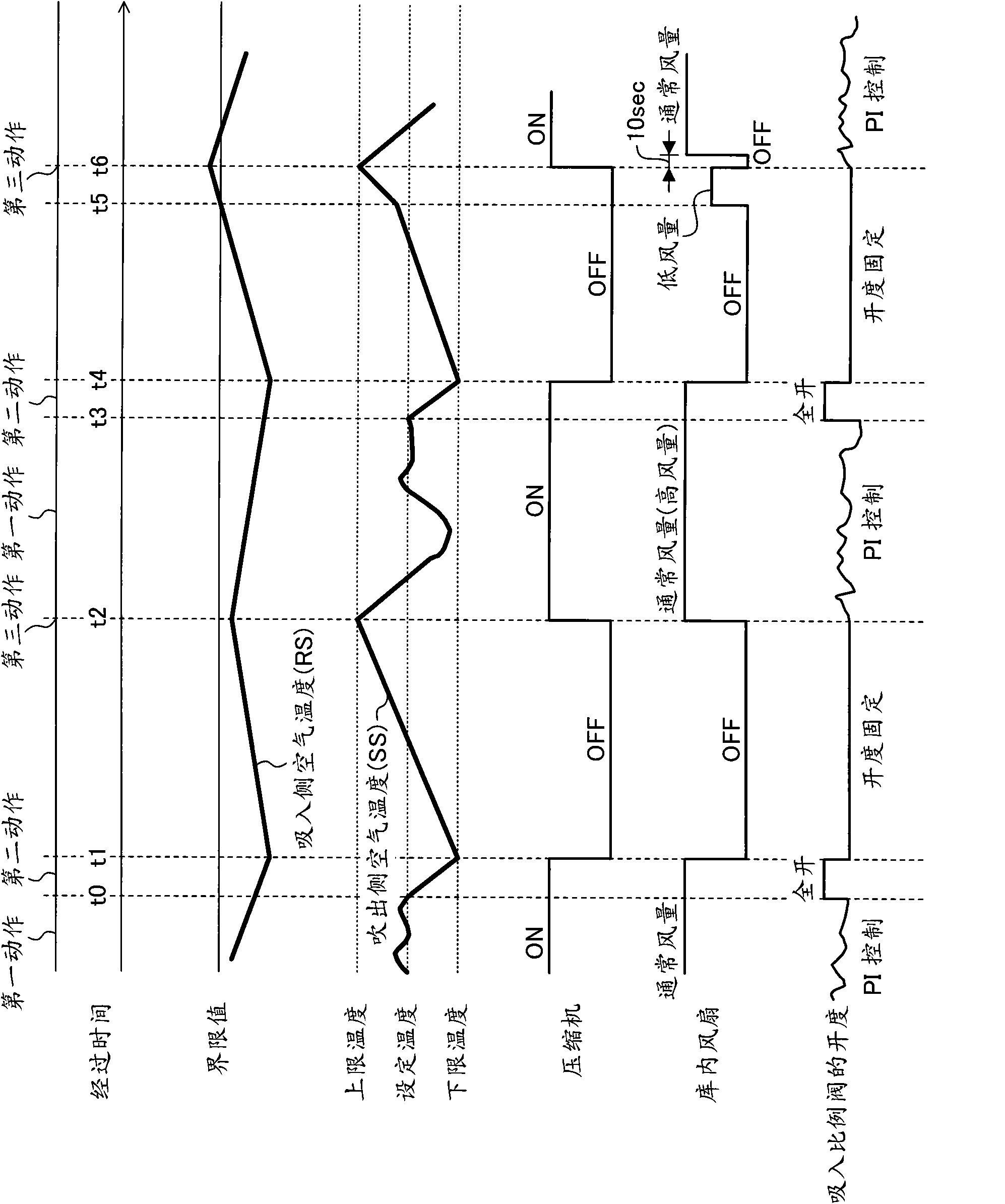

Refrigeration device

ActiveCN101568779AExtended stop timeReduce operating powerCompression machines with non-reversible cycleDomestic refrigeratorsLower limitAir volume

The invention discloses a refrigeration device. The refrigeration system has an energy saving operation mode performing: a first action in which a compressor (11) and an internal fan (16) are driven while the cooling capacity of an evaporator (14) is regulated; a second action in which, when the blow-off-side air temperature in a cold storage is kept at a set value in the first action, the cooling capacity of the evaporator (14) is increased to lower the blow-off-side air temperature to a lower limit temperature of a desired temperature range containing the set value and the compressor (11) and the internal fan (16) are then stopped; and a third action in which, when the blow-off-side air temperature after the second action rises to an upper limit temperature of the desired temperature range, the first action is restarted. Furthermore, the energy saving operation mode is configured so that when the suction-side air temperature in the cold storage after the second action rises to a limit value, the internal fan (16) is activated at a lower air flow rate than in the first action.

Owner:DAIKIN IND LTD

Notebook computer with tilting keyboard vent

InactiveUS20090273893A1Reducing of ingestionReduce the possibilityDetails for portable computersCooling/ventilation/heating modificationsRepetitive motion injurySecurity check

A notebook computer with a tilting keyboard, which opens a vent when tilted, solves multiple problems and may further materially contribute to countering terrorism. A tilted position of the keyboard allows the vent to open when the notebook lid is open, thereby providing extra cooling capacity during periods of computer use when there is a lessened need for compactness. The vent is it least partially closed when the keyboard is in the stowed position and the lid is closed, thereby reducing the possibility of debris ingestion when air flow needs are reduced and the need for compactness is increased. A security inspection position of the keyboard enables inspection of the inside of the computer, for example as part of a security checkpoint procedure. A negative tilt can reduce wrist strain and repetitive motion injuries for some users. Some embodiments tilt the keyboard automatically in response to the lid opening, and stow the keyboard automatically in response to the lid being closed.

Owner:WILSON ROBYN L +1

Air conditioner, control method thereof, operation control device and storage medium

ActiveCN110319547ARealize automatic controlEasy to controlMechanical apparatusLighting and heating apparatusElectricityAutomatic control

The embodiment of the invention provides an air conditioner, a control method thereof, an operation control device and a storage medium. The air conditioner comprises the operation control device anda temperature detection device, wherein the temperature detection device is electrically connected with the operation control device and is configured to be used for detecting a working condition temperature parameter, feeding back the detected working condition temperature parameter to the operation control device, and triggering the operation control device to determine to switch into a breezeless mode from a current cooling or heating mode according to the acquired working condition temperature parameter or maintain the current cooling or heating mode. According to the air conditioner provided by the scheme, the temperature detection device is arranged for detecting the working condition temperature parameter, an operating mode of the air conditioner is timely adjusted according to thechange of the working condition temperature parameter, and meanwhile, the mode switching of the air conditioner is realized by control through the operation control device according to the detected working condition temperature parameter, so that compared with manual control of a user, automatic control is realized, the convenience in control is realized, and the accuracy in mode switching controlis high.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Process for heating system

InactiveUS6840199B2Cycle time be maximizeAvoid problemSuperheating controlSteam/vapor condensersLiquid waterHeating system

A process for heating steam, in which steam is obtained by indirect heat exchange between liquid water and a hot gas; (b) the steam obtained in step (a) is heated by indirect heat exchange with the partly cooled hot gas obtained in step (a); and (c) additional water is added to the steam obtained in step (a) prior to or during heating the steam in step (b).

Owner:AIR PROD & CHEM INC

Apparatus and method for cooling a space in a data center by means of recirculation air

ActiveCN101530016AReduce the impactSave energyAir treatment detailsRegenerative heat exchangersData centerAir humidity

The present invention provides an apparatus for cooling an air humidity- and temperature-conditioned space in a data center in which ICT and / or telecom equipment is arranged. The space is cooled using air flow that recirculates in the space. The apparatus is characterized in that the air stream heated by the equipment is supplied as a first air stream to an air-to-air heat exchanger designed as a heat wheel, in which the first air stream is cooled by means of a separate second air stream.

Owner:KYOTOCOOLING INT

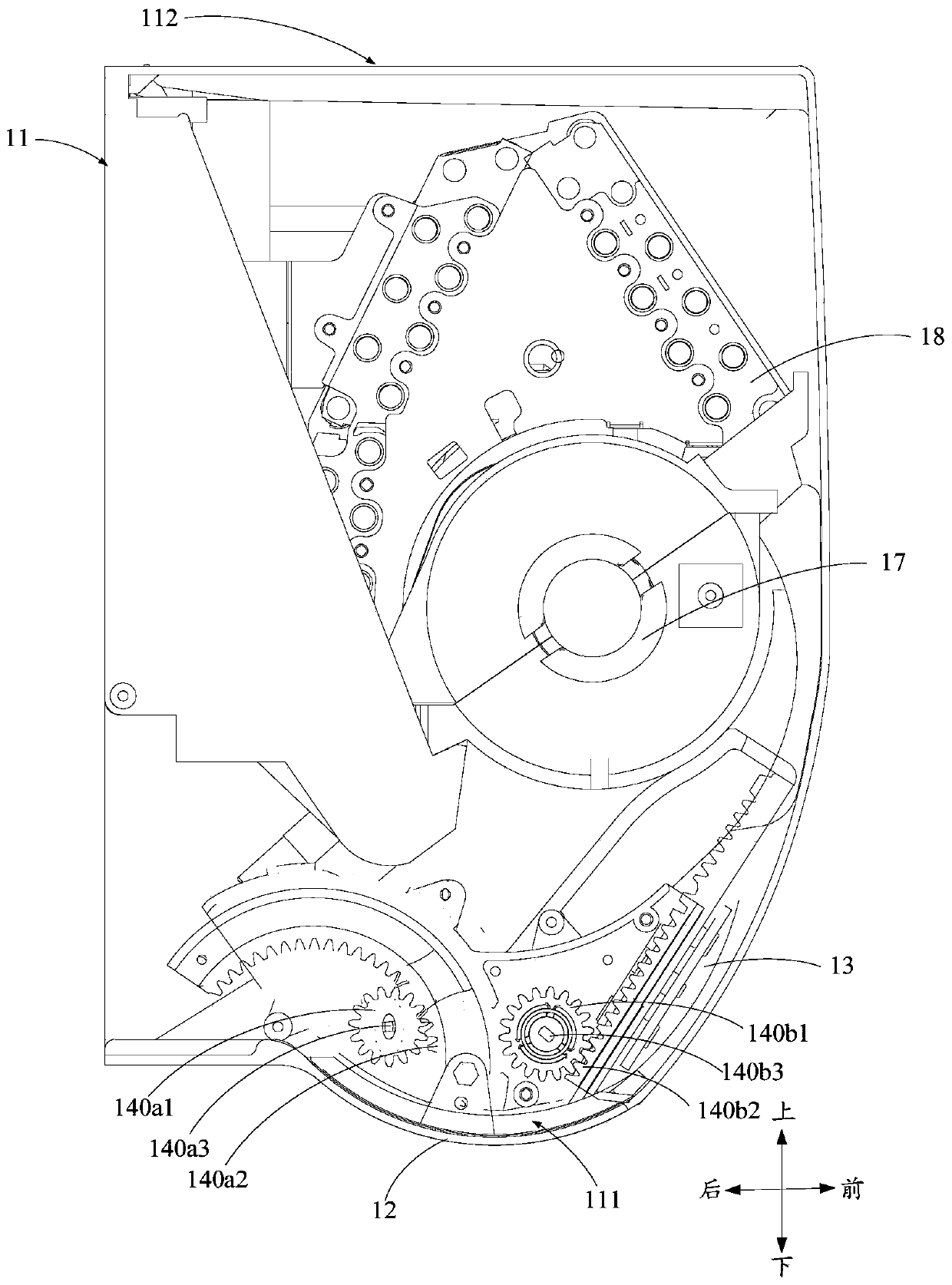

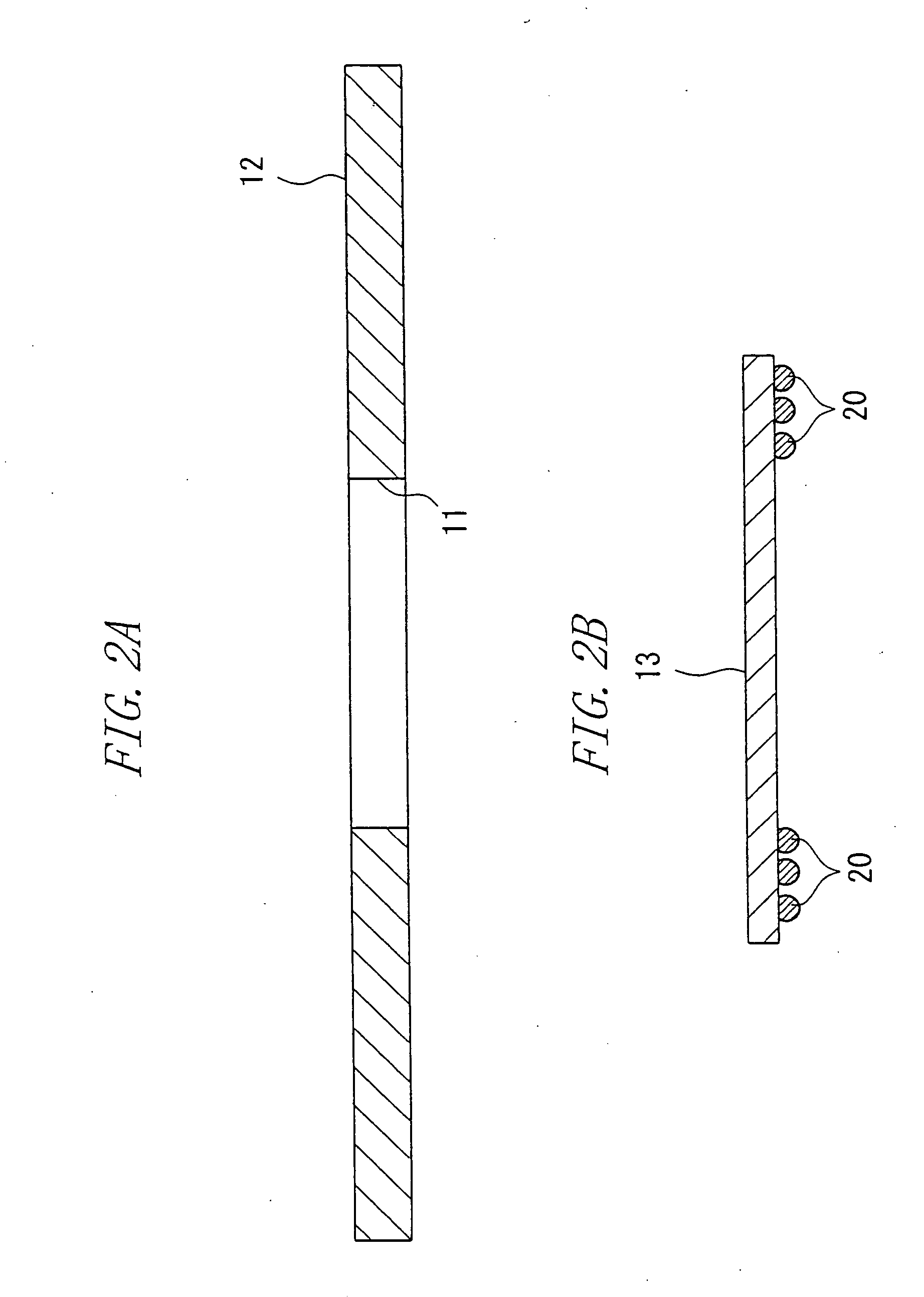

Packaging method, packaging structure and package substrate for electronic parts

InactiveUS20060063303A1Large cooling capacityLarge weightPrinted circuit assemblingSemiconductor/solid-state device testing/measurementEngineeringCooling capacity

A packaging method, a packaging structure and a package is substrate capable of restraining a warp of a thin film substrate, increasing a product yield, and building up a sufficient cooling capacity in the case of mounting an LSI having a high exothermic quantity. A package substrate 1 of the invention is such that an opening 11 is formed in a first substrate 12, a thin film substrate (a second substrate) 13 is laminated on the first substrate 12, the opening 11 is covered with the thin film substrate 13. Next, a capacitor (a first electronic part) 14 is inserted into the opening 11 and bonded to the thin film substrate, a resin 15 fills an interior of the opening 11 to a fixed or larger thickness and is hardened, the thin film substrate 13 and the capacitor 14 are thereby sustained by the resin 15, an LSI 16 (a second electronic part) that should be connected to the capacitor 14 is bonded to a surface, on an exposed side, of the thin film substrate 13, and the capacitor 14 is connected to the LSI 16.

Owner:FUJITSU LTD

Open loop heat pipe radiator having a free-piston for wiping condensed working fluid

InactiveUS9091490B2Low mass-to-power ratioReduce lifting costsIndirect heat exchangersWorking fluidEngineering

An open loop heat pipe radiator comprises a radiator tube and a free-piston. The radiator tube has a first end, a second end, and a tube wall, and the tube wall has an inner surface and an outer surface. The free-piston is enclosed within the radiator tube and is capable of movement within the radiator tube between the first and second ends. The free-piston defines a first space between the free-piston, the first end, and the tube wall, and further defines a second space between the free-piston, the second end, and the tube wall. A gaseous-state working fluid, which was evaporated to remove waste heat, alternately enters the first and second spaces, and the free-piston wipes condensed working fluid from the inner surface of the tube wall as the free-piston alternately moves between the first and second ends. The condensed working fluid is then pumped back to the heat source.

Owner:NASA

Heat conduction lamp holder and light-emitting diode (LED) lamp comprising same

InactiveCN102478225AFacilitate conductionExtend your lifeLighting support devicesPoint-like light sourceElectricityEngineering

The invention provides a heat conduction lamp holder, which comprises a power socket electrically connected with a light-emitting diode (LED) lamp. The heat conduction lamp holder also comprises a heat conduction part; the heat conduction part is provided with at least one surface which can be contacted with a heat conduction member in the manner of heat conduction, wherein the heat conduction member can be fixedly connected with an LED light source, and the heat conduction part is made of a material capable of conducting heat; and the heat conduction part is combined with at least one part of the power socket and is connected with a heat sink, so that heat generated by the LED light source is transferred out through the heat sink. The invention also relates to an LED illuminating lamp comprising the heat conduction lamp holder. According to the heat conduction lamp holder provided by the invention, the problem that a high-power LED emits heat is effectively solved, and simultaneously, the appearance dimension of the lamp can be made to be smaller.

Owner:MASS TECH (HK) LTD

Heat processing unit case heat treating method and its device

ActiveCN1699608AImprove productivityImprove qualityIncreasing energy efficiencyFurnace typesQuenchingEngineering

This invention provides a method for partially heat-treating a member to be heat-treated, which improves the quality of a heat-treated member, and to provide an apparatus therefor. The method for partially heat-treating only the particular part 1a of the member 1 to be heat-treated comprises an induction heating step 20P of induction-heating only the particular part, and a subsequent cooling step 30. The induction heating step 20P comprises charging n pieces (n is a natural number of 3 or more) of the members 1 to be heat-treated in one coil, and transporting each member to be heat-treated sequentially from the first heating position to an n-th heating position, to heat it over n times while beginning from the first heating 22(1) carried out at the first heating position and ending in the n-th heating 22(n) carried out at the n-th heating position. The partial heat treatment may be applied to partial quenching, to partial tempering, or to both of the partial quenching and the partial tempering.

Owner:TOPY INDUSTRIES

Battery thermal management system and method

PendingCN109103519AAchieve coolingSufficient cooling capacitySecondary cells servicing/maintenanceRefrigeration compressorNew energy

A battery thermal management system and method are provided. The system includes a battery module, a heat pipe unit, a heating unit, a main cooling system and a sub cooling system; the heat pipe unitcomprises a plurality of heat pipes, wherein each heat pipe comprises a heat end of the heat pipe and a cold end of the heat pipe; an end face of the battery module is thermally coupled with a surfaceof the hot end of the heat pipe; the heating unit is thermally coupled with the surface of the heat pipe hot end facing away from the battery module; a cold end of the heat pipe is thermally coupledto the surfaces of the primary cooling system and the secondary cooling system, respectively. The invention can flexibly start one of the cooling systems according to the ambient temperature to realize cooling of the battery module, so as to save as much power as possible for cooling the battery, avoid the use of antifreeze in the whole thermal management system, minimize the power consumption ofthe circulating water pump or the refrigeration compressor, and minimize the power consumption of the new energy vehicle for cooling the battery module.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

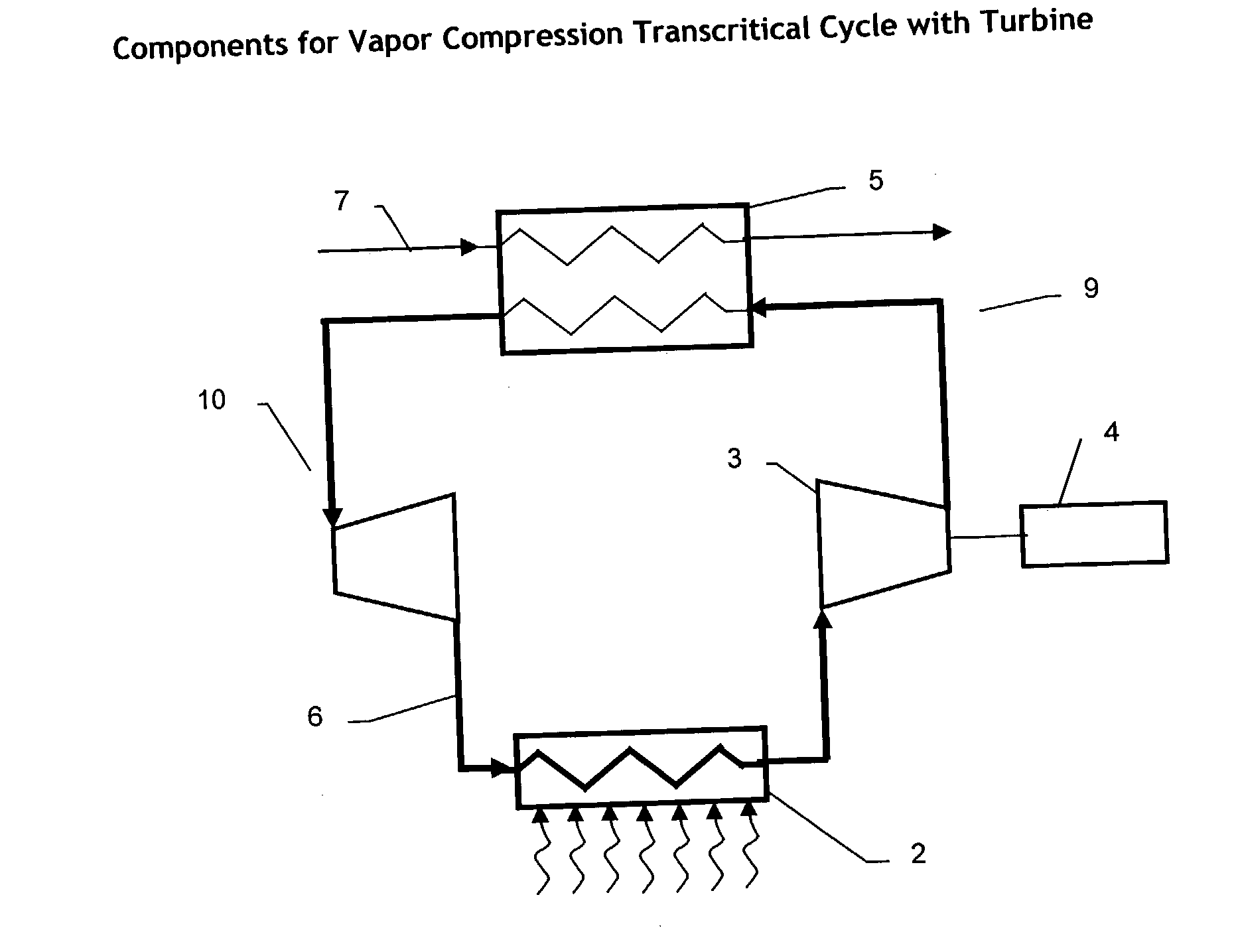

Means and apparatus for microrefrigeration

InactiveUS20030221446A1Guaranteed to workSufficient cooling capacityDomestic cooling apparatusCompression machines with non-reversible cycleWorking fluidClosed loop

An integrated, self-contained microrefrigeration apparatus, in a dimension small enough to fit inside small appliances, such as electronic cases and portable equipment is described. The microrefrigerator employs a working fluid that circulates between evaporator, compressor, condenser and turbine-expander components in a closed loop. Two configurations are claimed: one with the compressor and turbine operating on independent shafts, and the other with the turbine and compressor both operating on the motor shaft.

Owner:THAR PROCESS

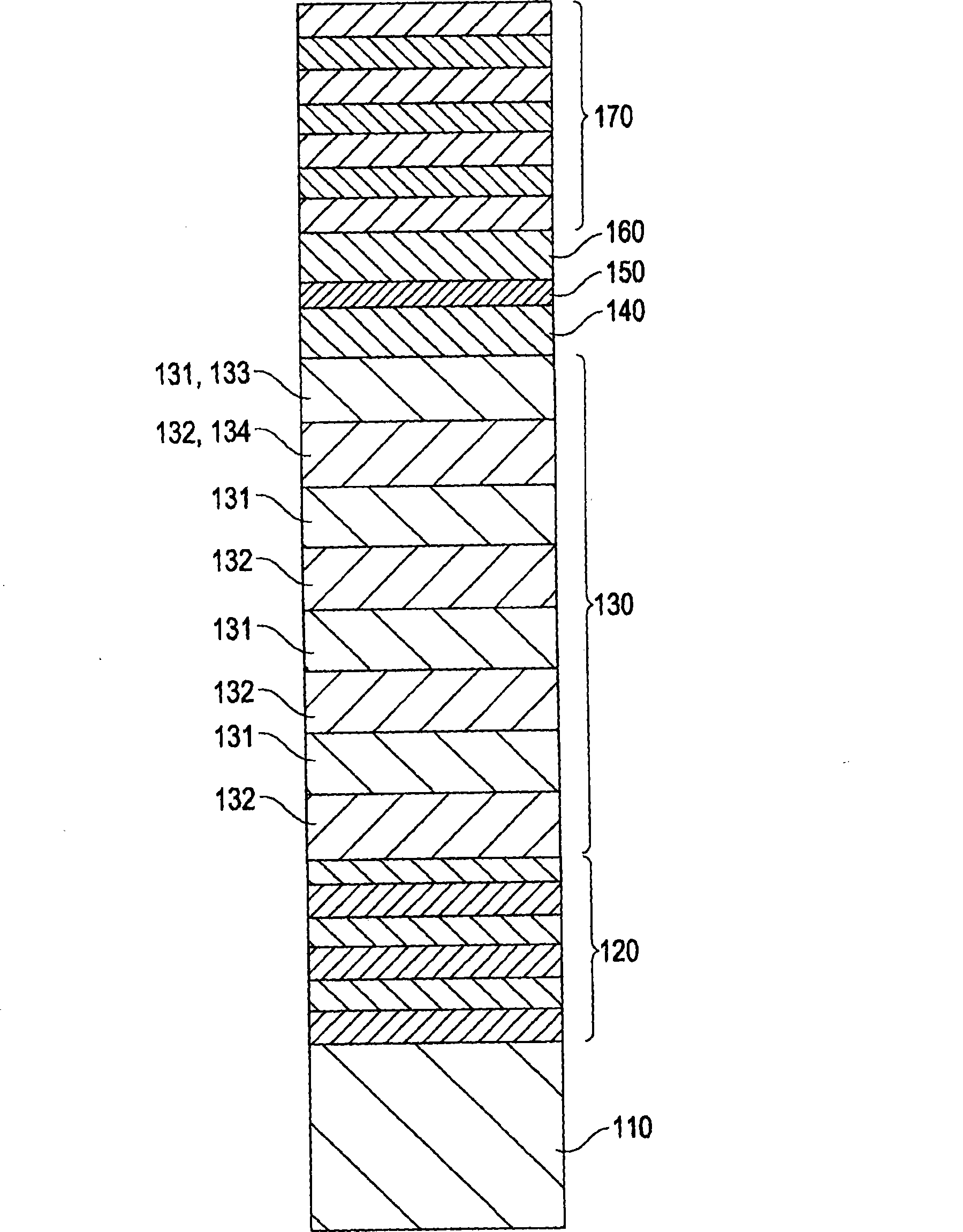

Surface emitting laser, surface emitting laser array, and image forming apparatus including surface emitting laser

ActiveCN101442182ASufficient cooling capacityHigh laser outputSemiconductor laser arrangementsLaser arrangementsLaser arrayImage formation

The invention discloses a surface emitting laser and an image forming device. The surface emitting laser oscillating at a wavelength Lambda comprises an upper reflector, a lower reflector, an active layer and a spacer layer. The spacer layer has a laminated structure comprising a first semiconductor sublayer with a composition of Al<x>Ga<1-x>As (x is more than 0 and equal to or less than 1) and a second semiconductor sublayer with a composition of Al<y>Ga<1-y>As (y is more than 0 and less than 1, and x is more than y).

Owner:CANON KK

Combined type evaporative cooling unit

InactiveCN105387543AImprove the situation of geographical constraintsImprove efficiencyLighting and heating apparatusSpace heating and ventilation detailsEngineeringPre cooling

The invention provides a combined type evaporative cooling unit. The unit comprises a shell, a direct evaporative cooling module and pre-cooling modules; the direct evaporative cooling module comprises a coiler heat exchanger and a first filler and is arranged inside the shell, the first filler is arranged below the coiler heat exchanger, and the coiler heat exchanger is sequentially provided with a first water distribution device and a first draught fan from bottom to top; the pre-cooling modules are arranged on two opposite sides of the shell and located below the first filler, one side of each pre-cooling module is provided with a communication opening communicated with the direct evaporative cooling module, and therefore air pre-cooled by the pre-cooling modules can flow into the direct evaporative cooling module; each pre-cooling module is formed by a vertical heat exchanger and a second filler; each pre-cooling module is sequentially provided with a second water distribution device and a second draught fan from bottom to top, and sliding devices capable of enabling the pre-cooling modules to slide are installed below the pre-cooling modules; and a ventilation opening is further formed in the lateral wall of the shell. By means of the sliding devices, the using manner of the unit is varied, the adaptability is good, and the practical performance is higher.

Owner:农继荣

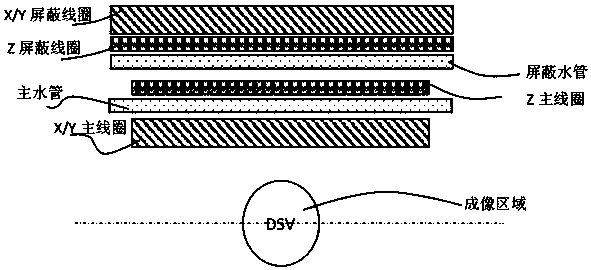

Gradient coil using composite cooling water pipe

PendingCN108241134AGuaranteed thermal conductivitySufficient cooling capacityMeasurements using magnetic resonanceUniform fieldEngineering

The invention discloses a gradient coil using a composite cooling water pipe. The gradient coil using the composite cooling water pipe comprises a gradient coil main body, wherein the coil main body is sequentially composed of a radio frequency shielding layer, a main coil part, a main water pipe, a uniform field space, a shielding water pipe and a shielding coil part from inside to outside; the main coil part is composed of an X coil, a Y coil and a Z coil in a stacking manner from inside to outside, the shielding coil part is composed of a Z shielding coil, an X shielding coil and a Y shielding coil in the stacking manner from inside to outside, the structure gives consideration to balance in performances of the X, Y and Z coils, the composite cooling water pipe is used, thermal conductivity of a cooling system is improved, and the uniform field space is located in a water cooling system, so that temperature stability of a uniform field material is guaranteed, and uniformity of a magnetic field is guaranteed.

Owner:HUNAN MAGTECH MEDICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com