Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Strict process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

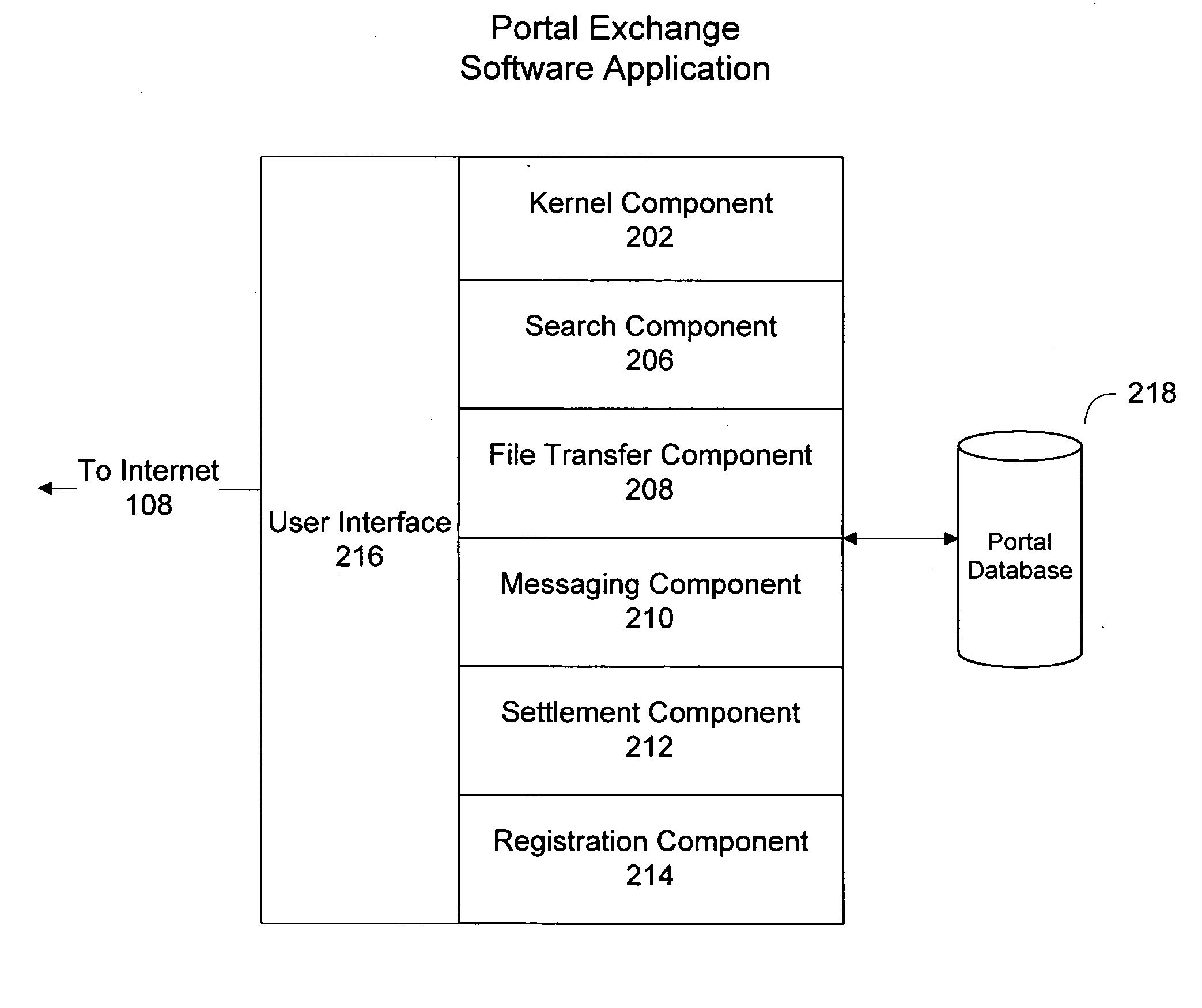

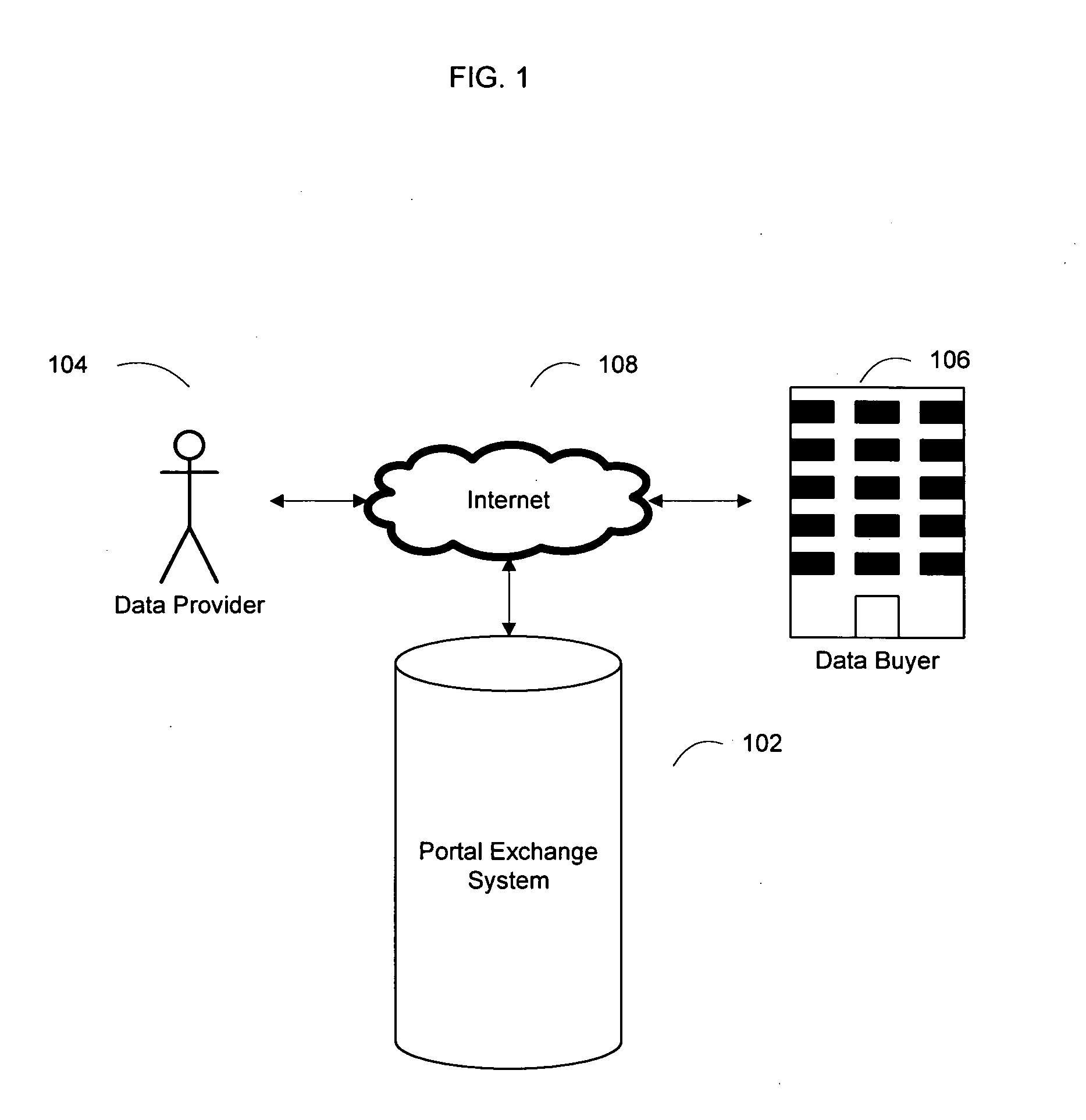

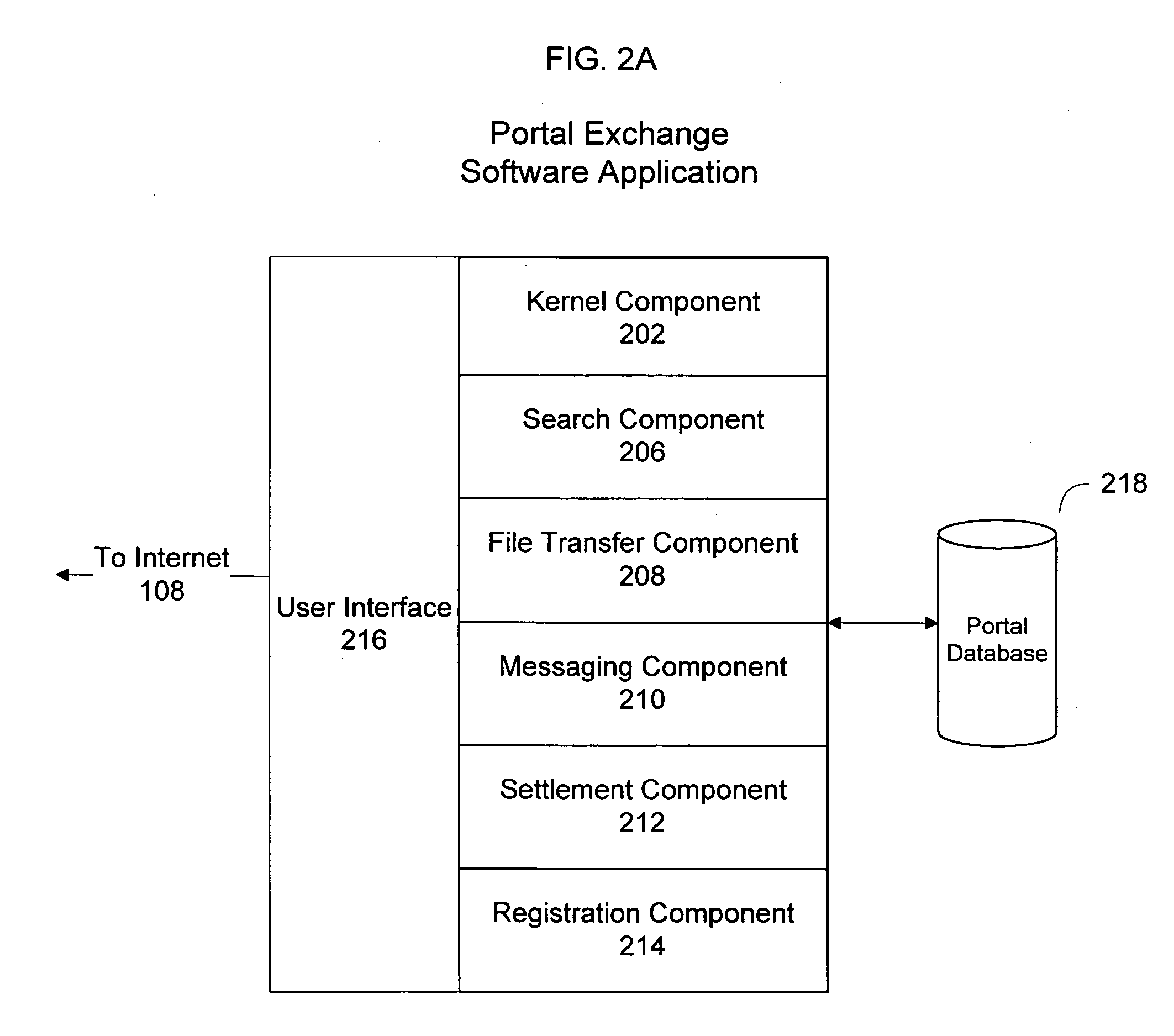

System and method for an online exchange of private data

Based on the small world theory of networking, the present invention provides access to a previously unavailable source of private data, necessary for commerce, by facilitating the sale of private data from members of the general public. For example, the seeker of private data, such as consumer information, submits a data request to an online portal system. The request submission includes legal representations stating the legally permissible purpose for seeking the information. The portal system may display the data request to registered data providers, based on their demographic data. The system facilitates the exchange between the data buyer and the data provider. A payment invoice can be generated and electronically presented by the portal system. The payment may be electronically debited from the designated account of a data. In addition, a portion of such funds may be retained by the portal entity.

Owner:CREDIGY TECH

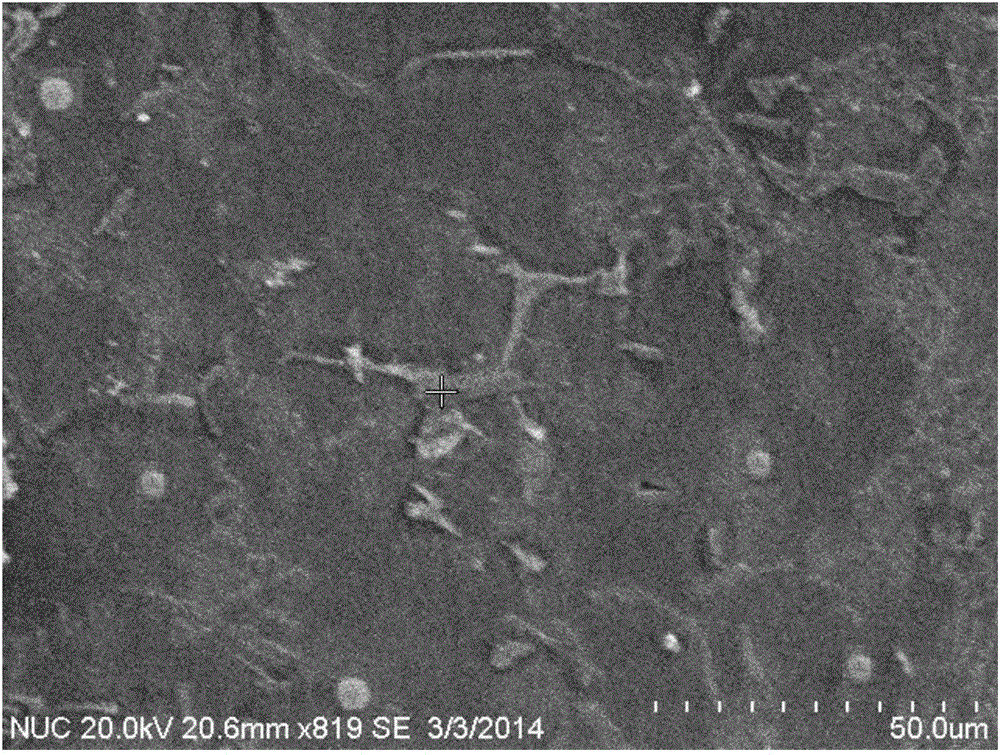

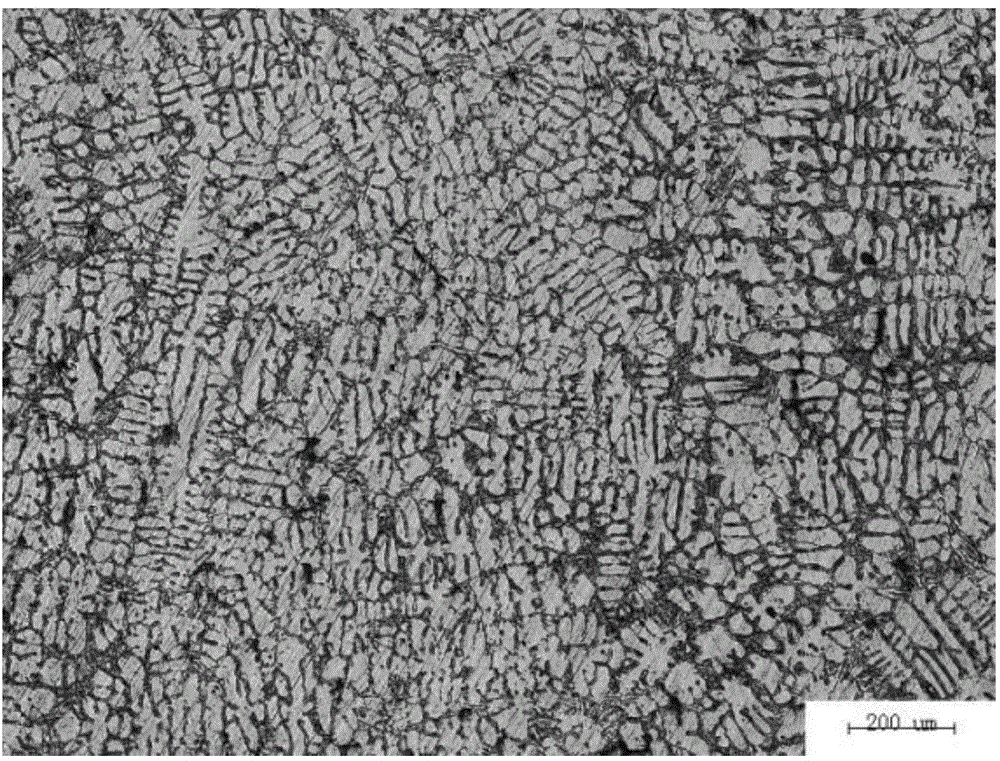

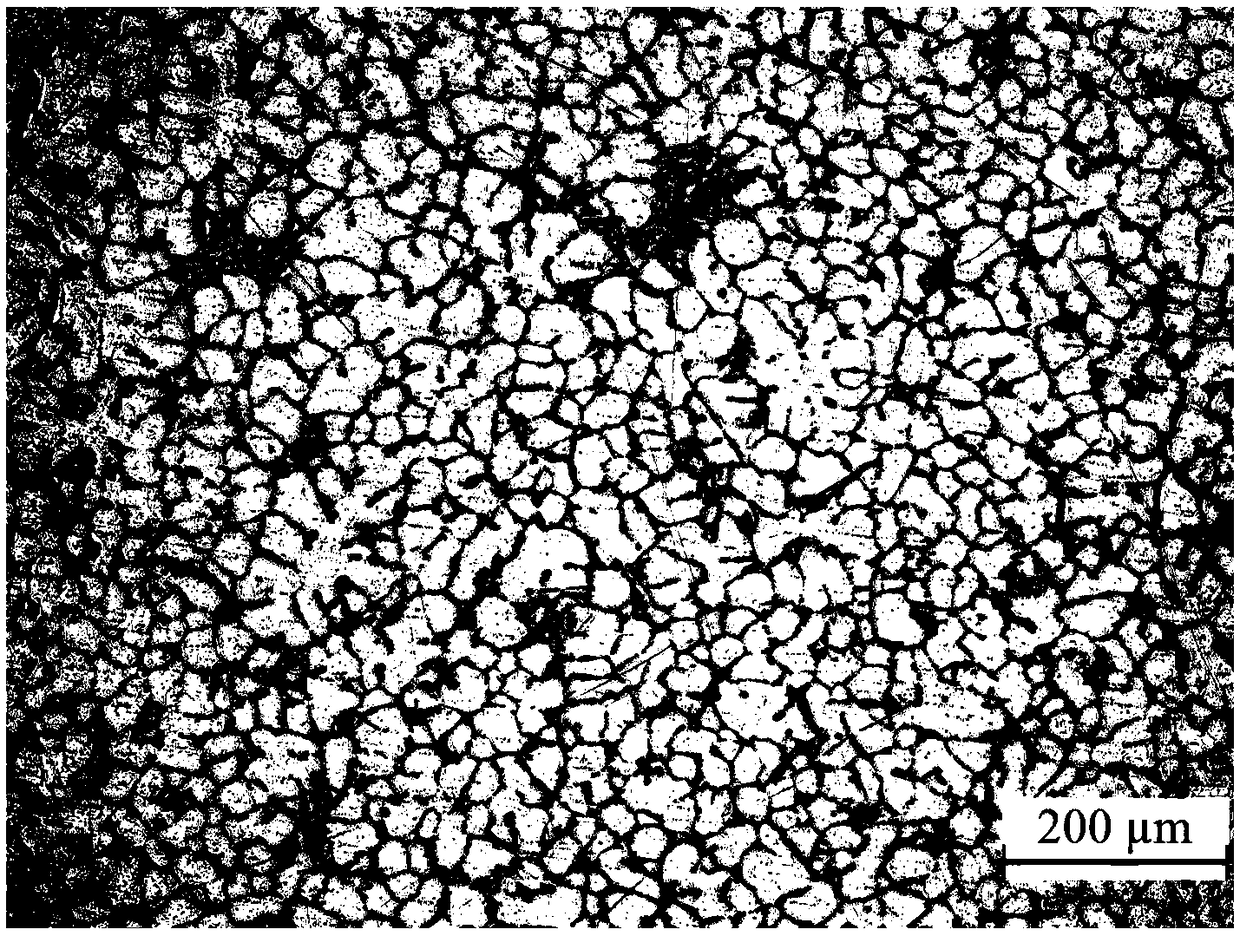

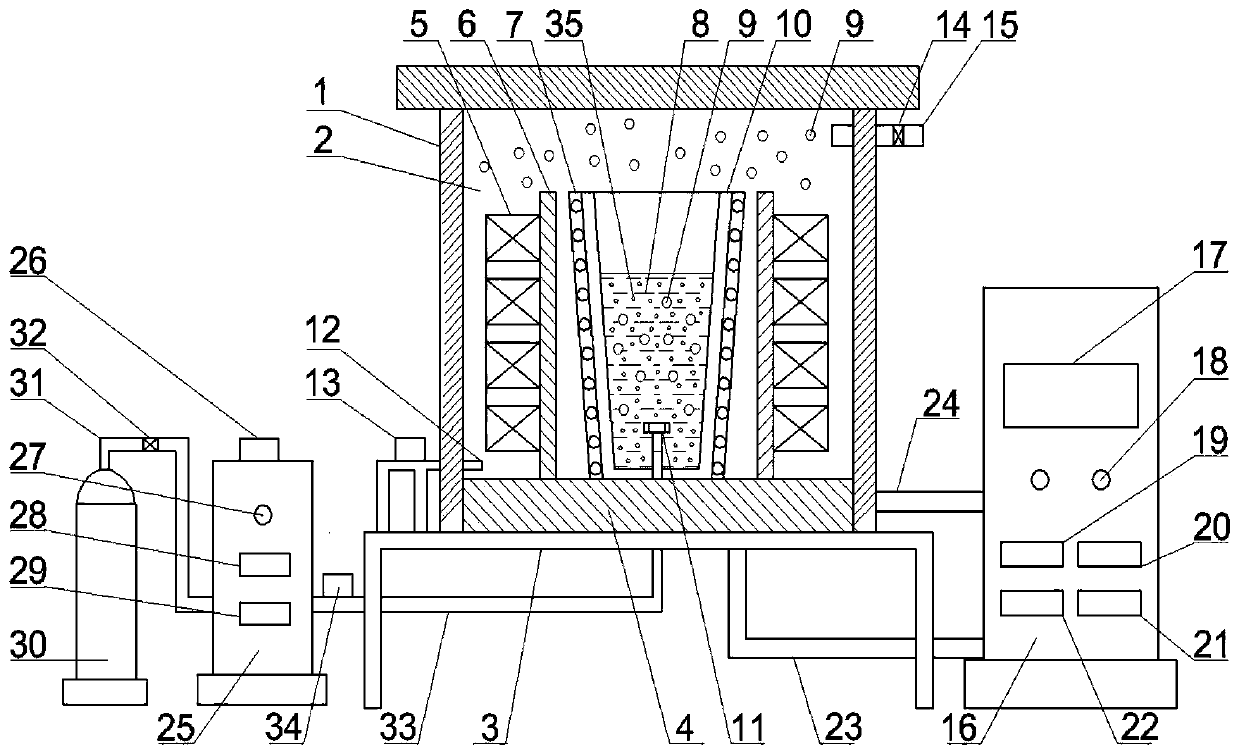

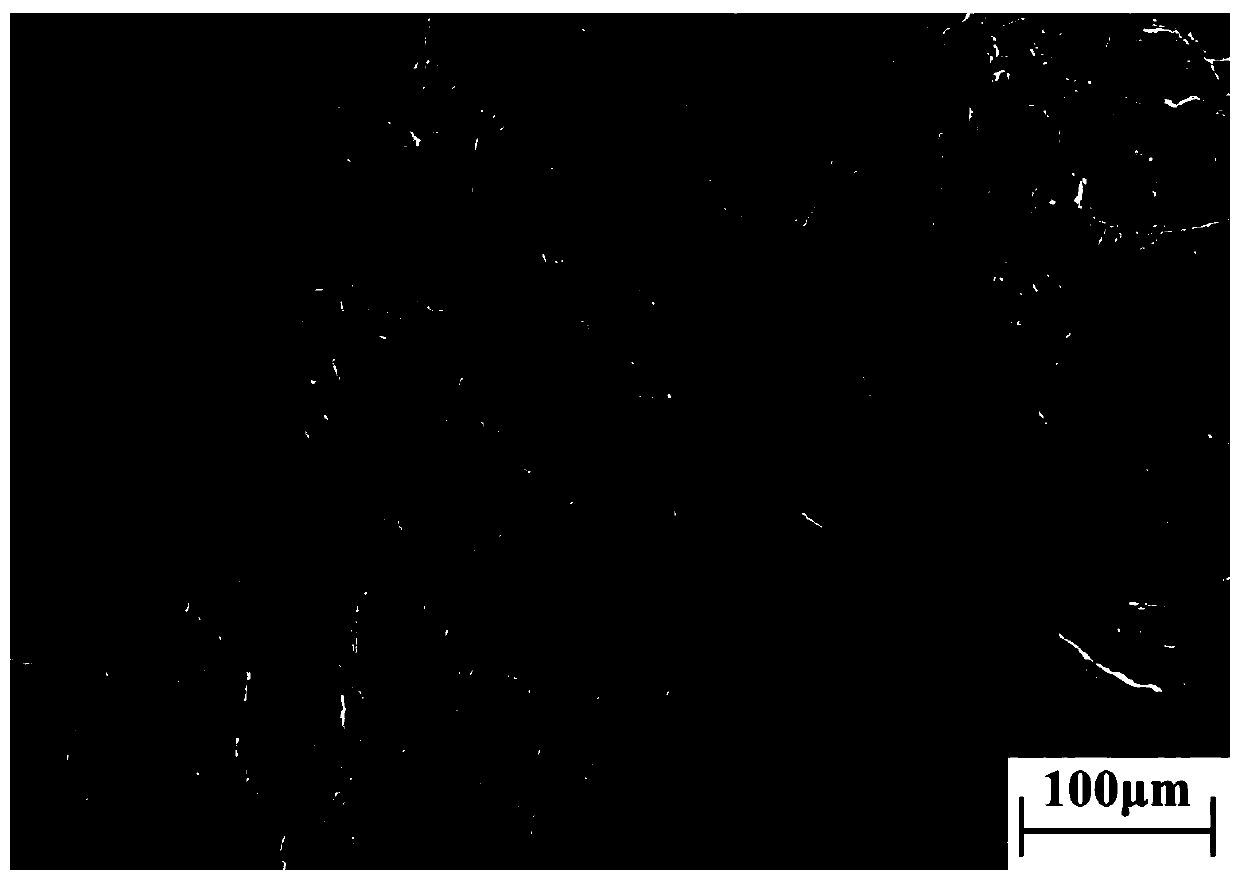

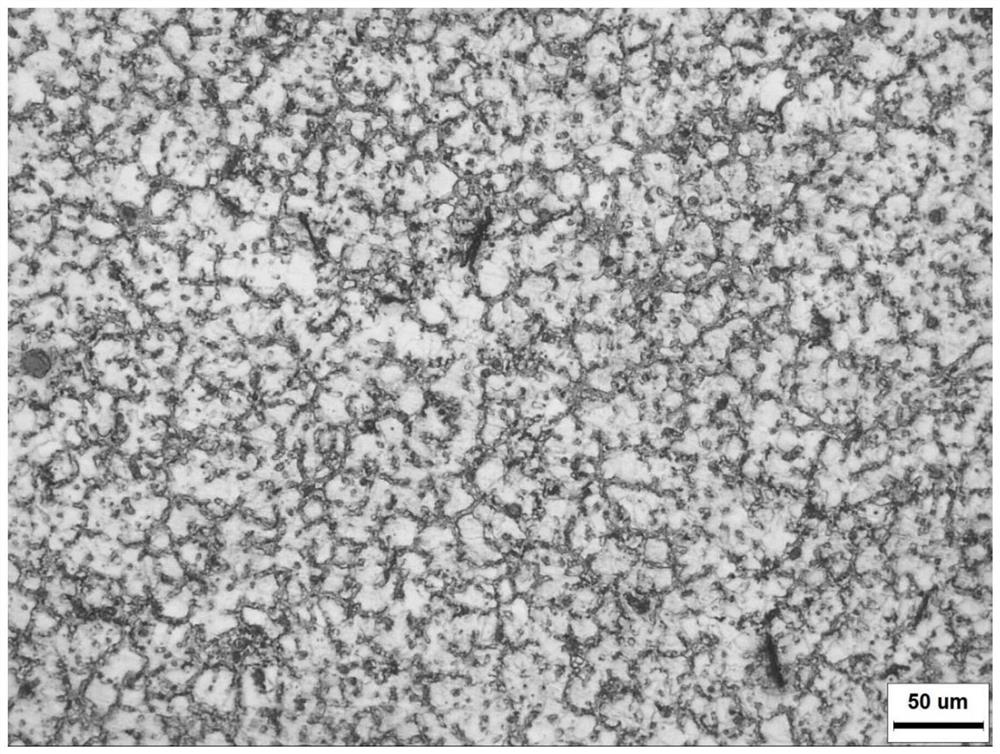

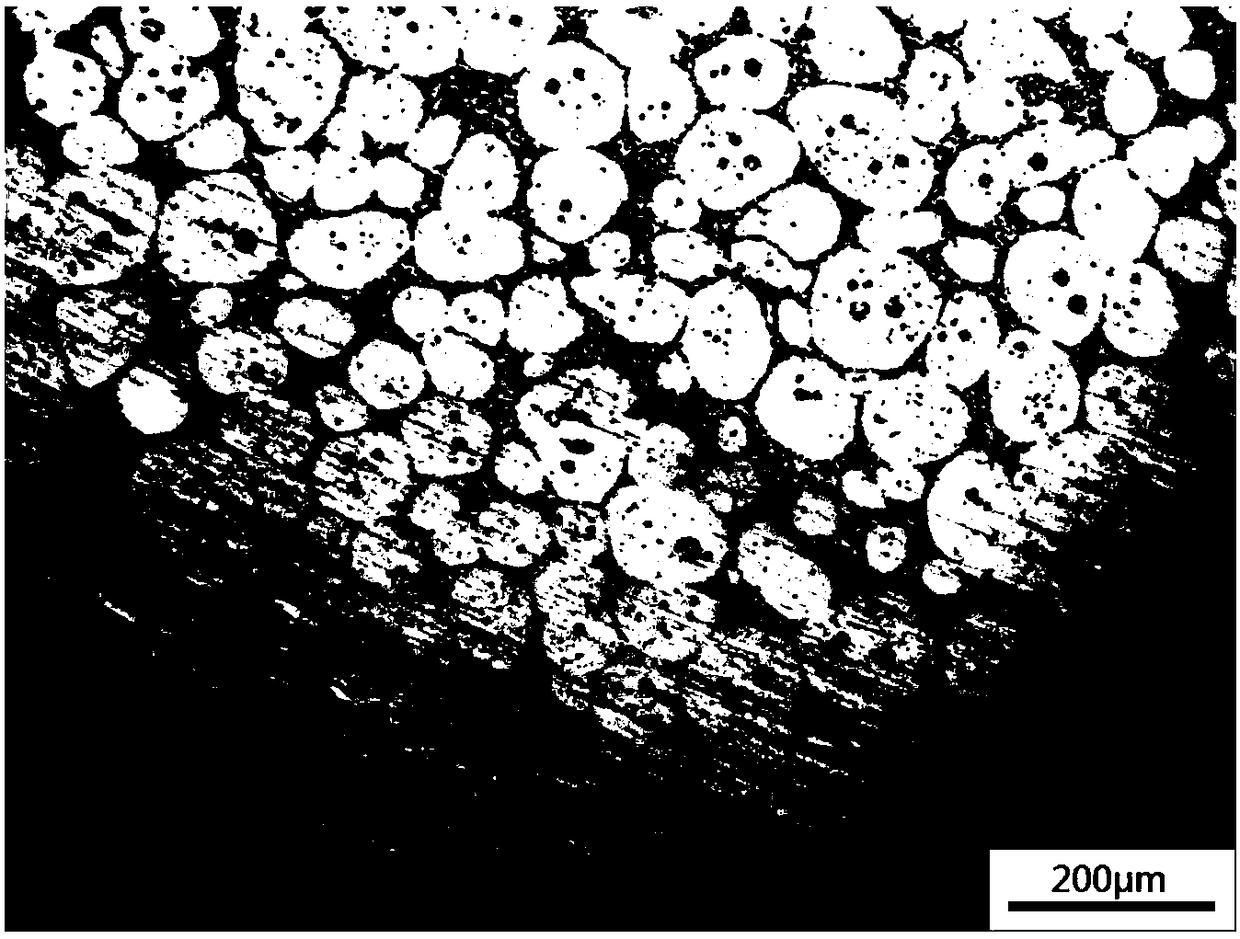

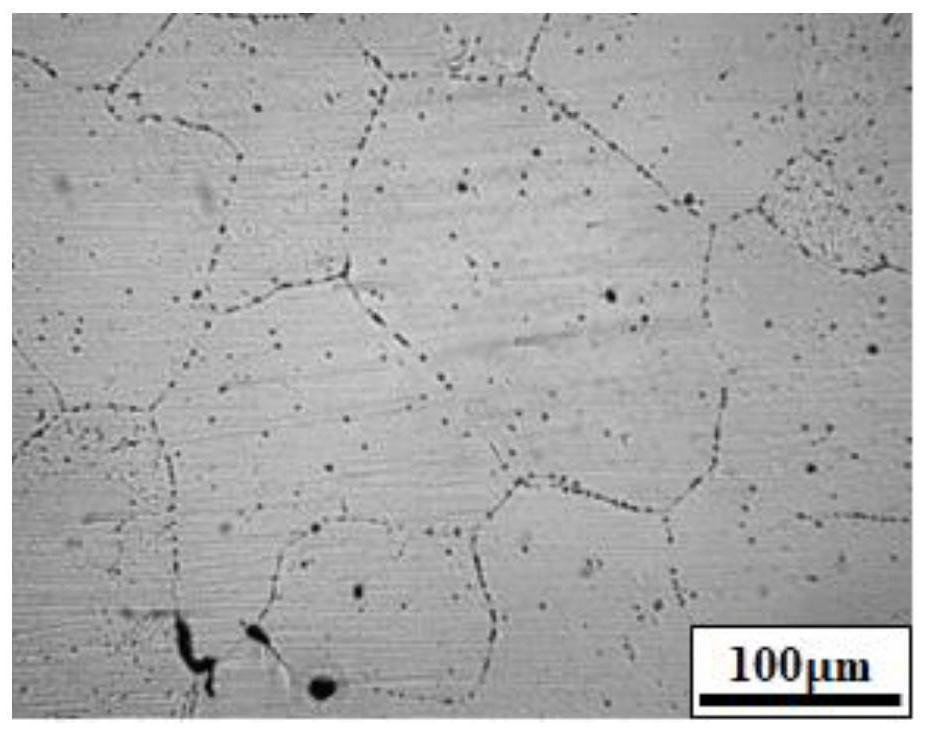

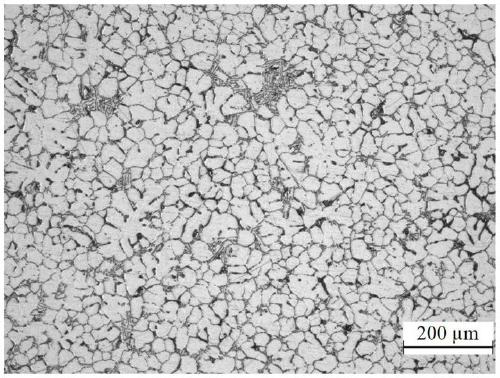

Preparation method of graphene-reinforced aluminum matrix composite

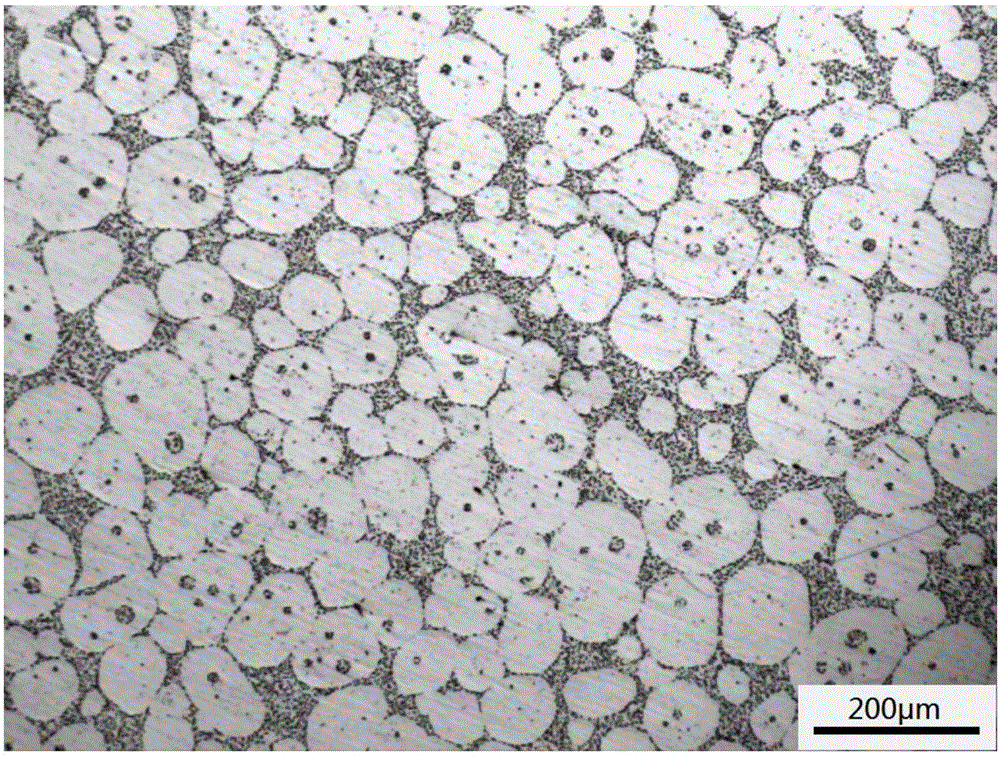

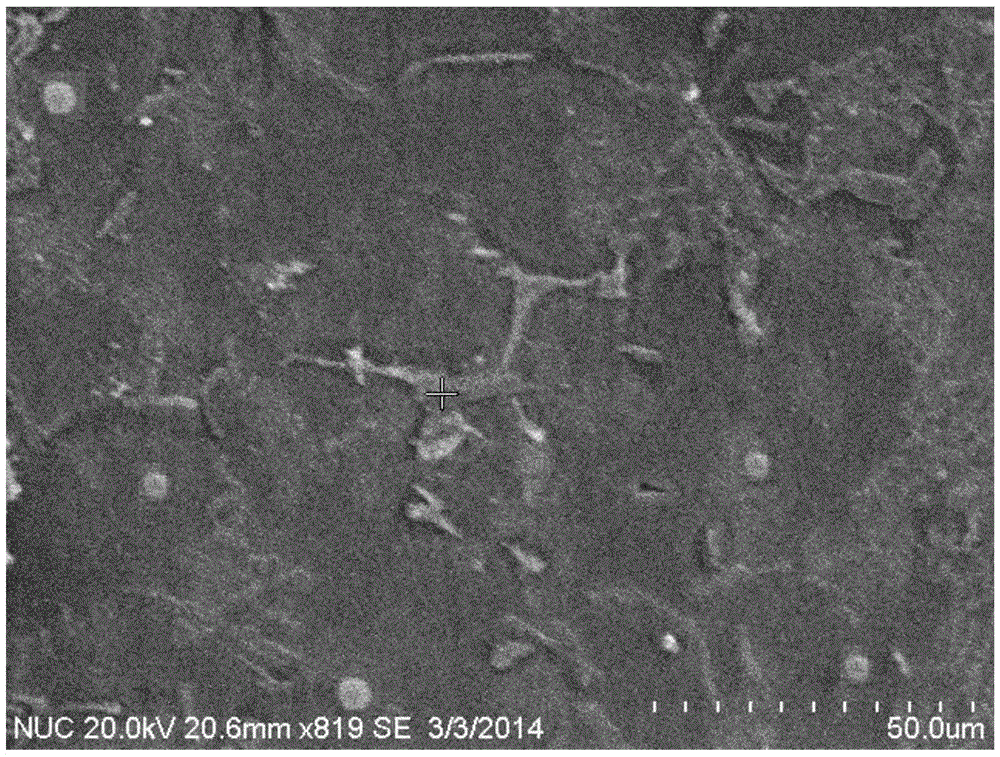

The invention relates to a preparation method of a graphene-reinforced aluminum matrix composite. Aiming at the conditions that graphene is nonuniformly dispersed in an aluminum alloy matrix and is difficult to combine with the matrix, the preparation method adopts a semi-solid squeeze casting method, and comprises the steps of smelting in a smelting and stirring atmosphere oven, electromagnetically stirring, pouring, and conducting squeeze casting to obtain the graphene-reinforced aluminum matrix composite. The preparation method is advanced in process, accurate and detailed in data, and precise in process; a slurry is pure; a metallographic structure is good in compactness without the phenomenon of shrinkage porosity; the prepared graphene-reinforced aluminum matrix composite has the hardness reaching to 87 HB, the tensile strength reaching to 255 MPa, the elongation reaching to 8%, and the compactness reaching to 99.6%; and the preparation method is the advanced preparation method of the graphene-reinforced aluminum matrix composite.

Owner:ZHONGBEI UNIV

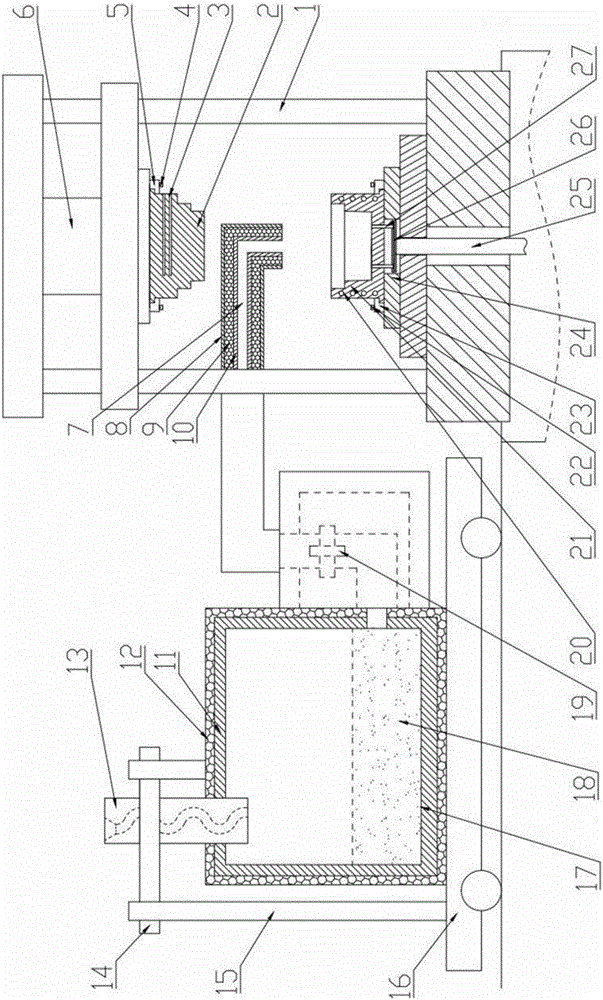

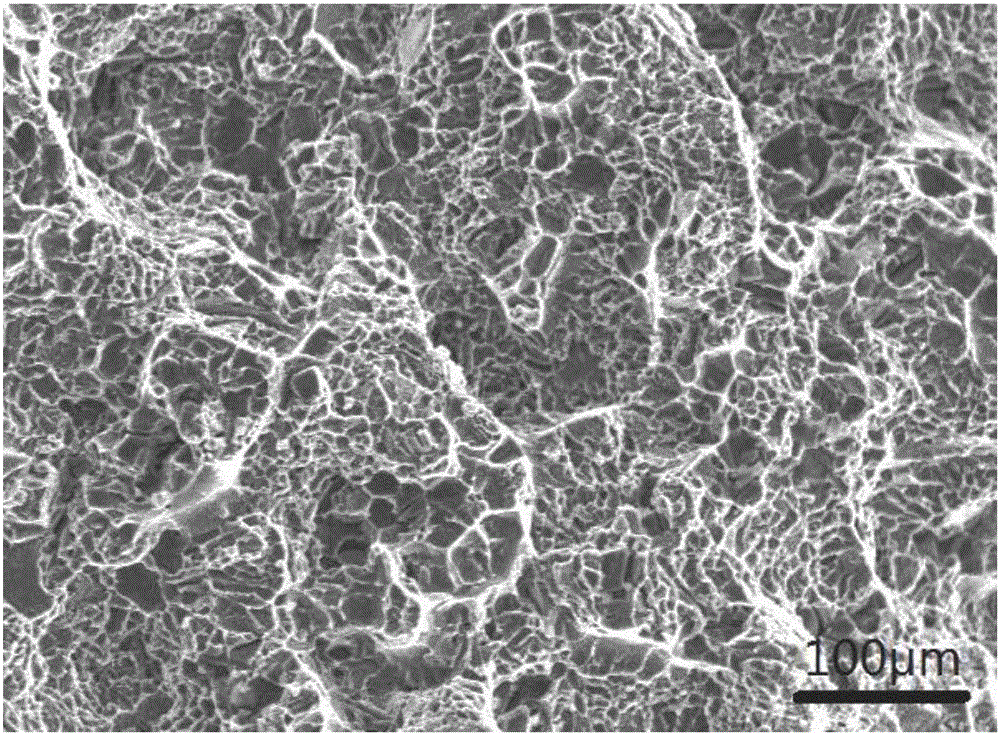

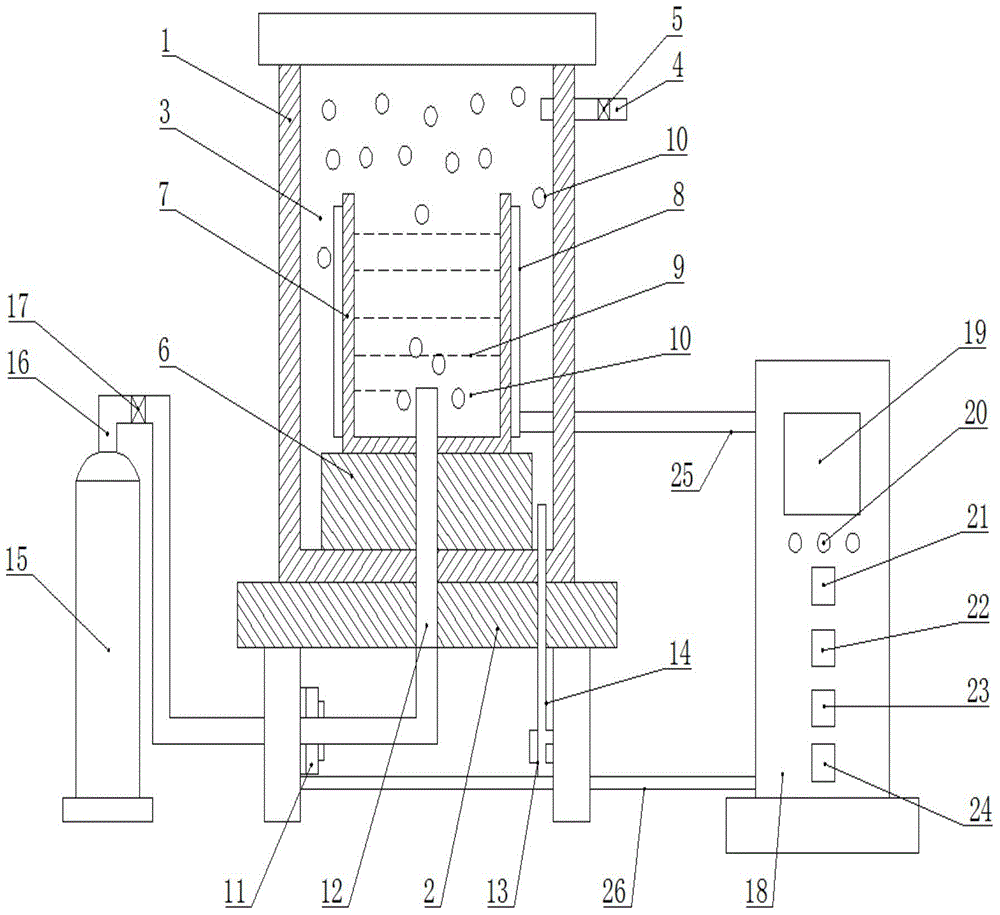

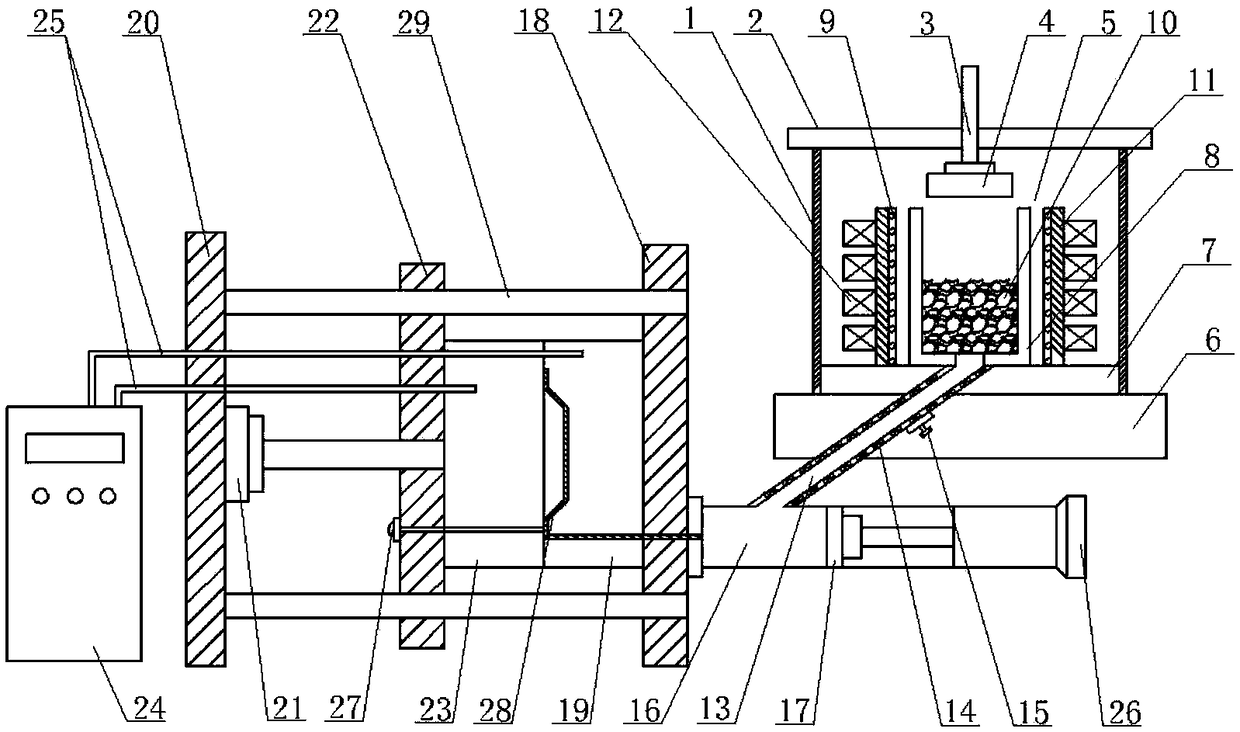

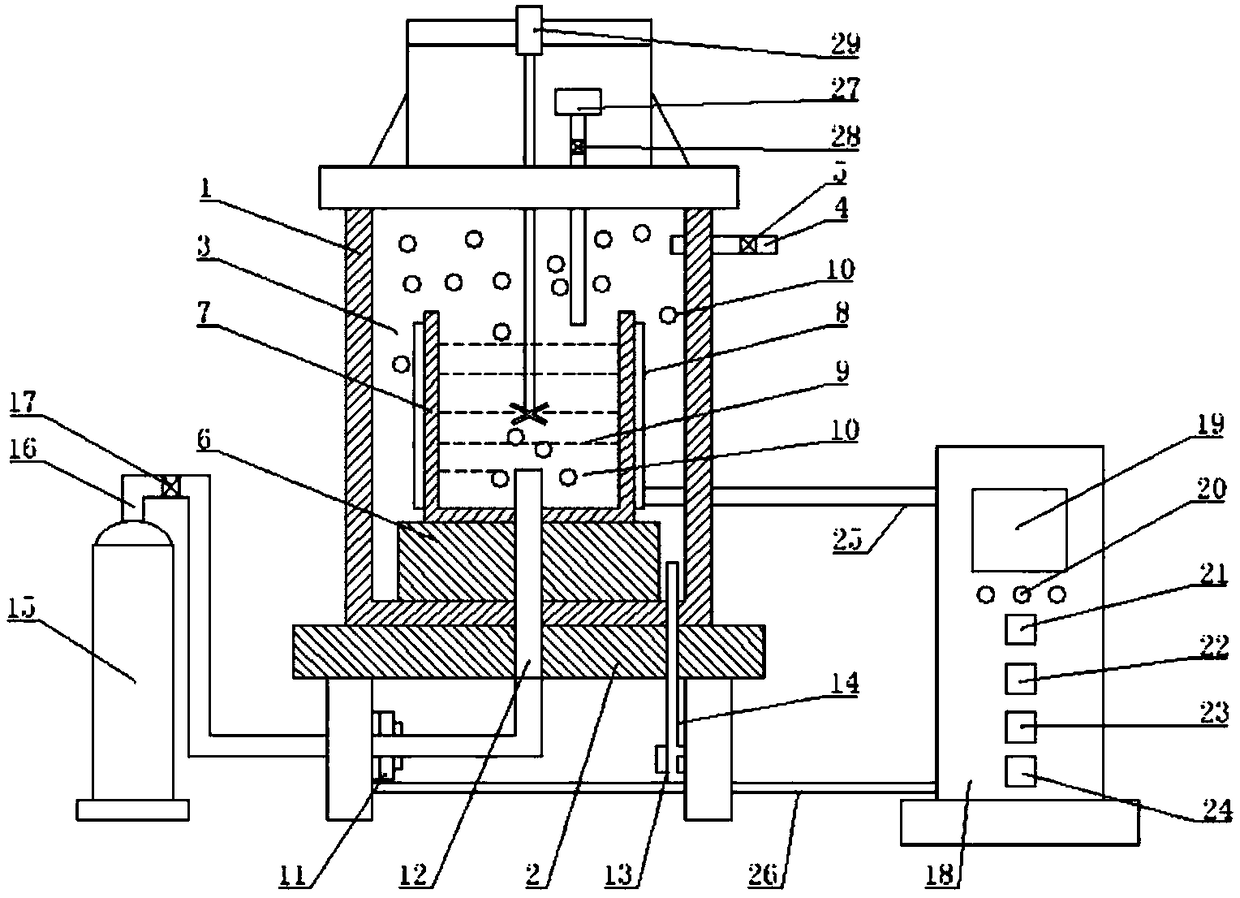

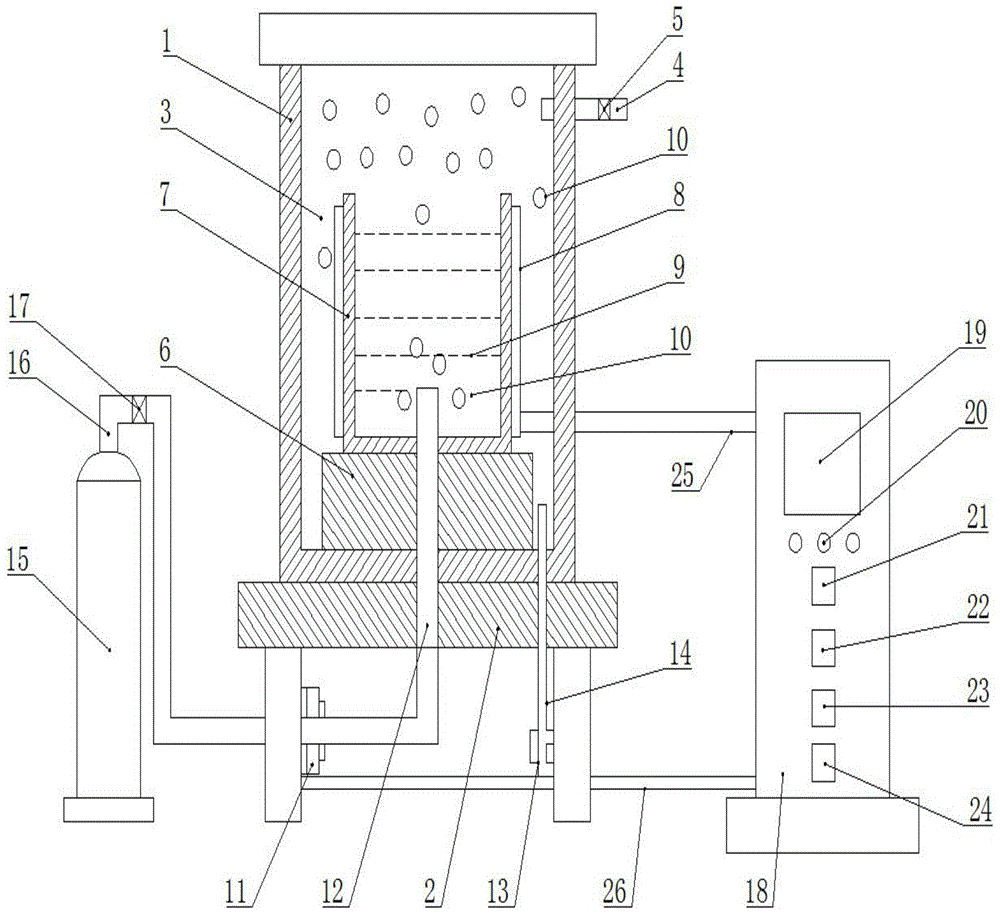

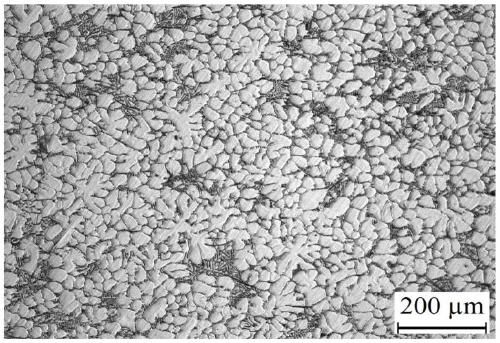

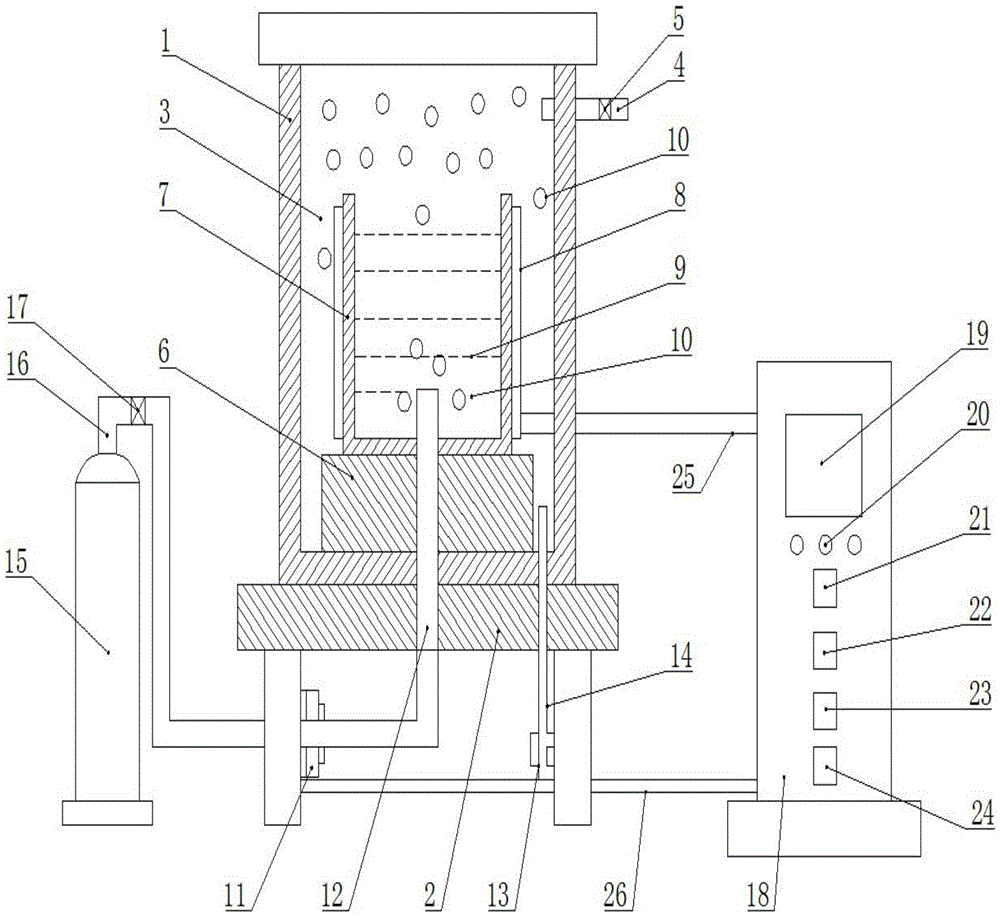

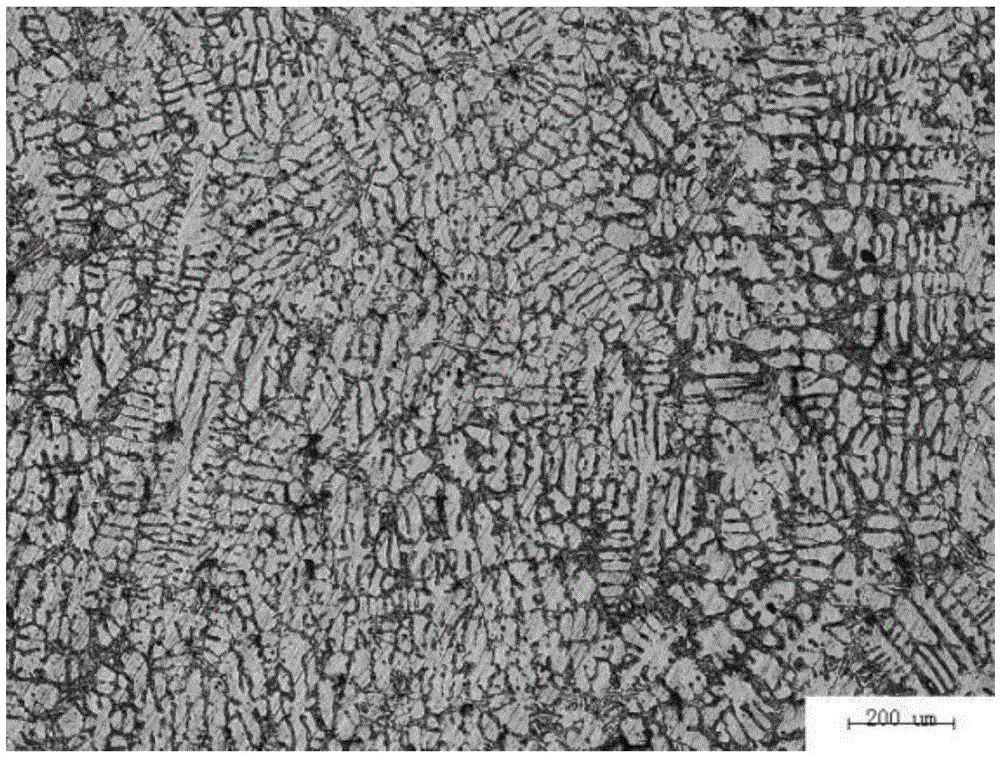

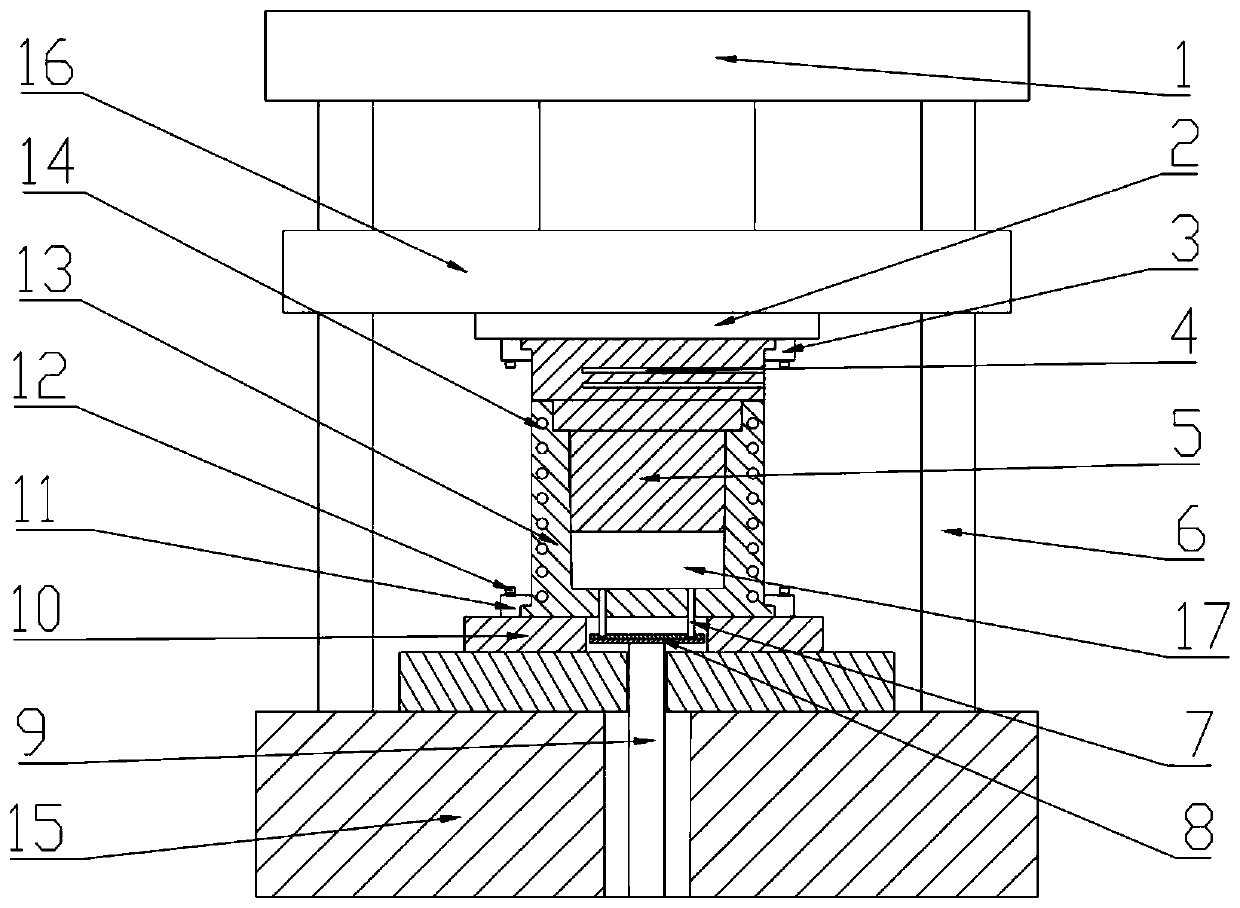

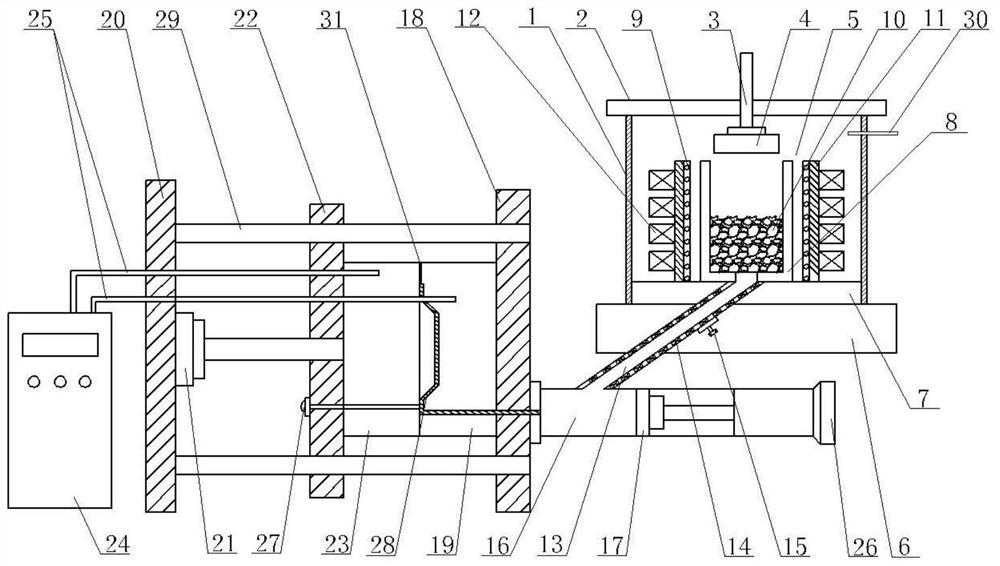

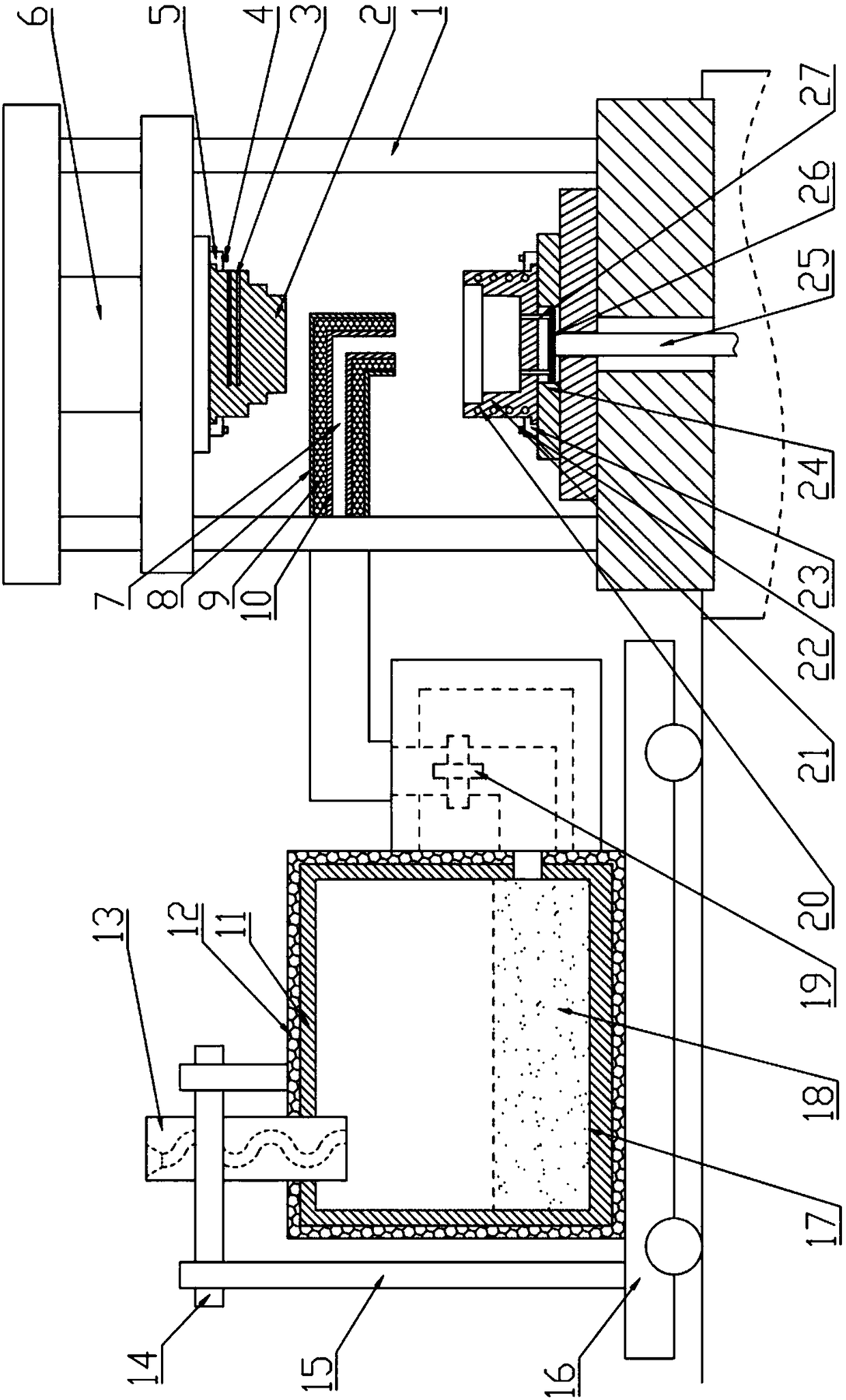

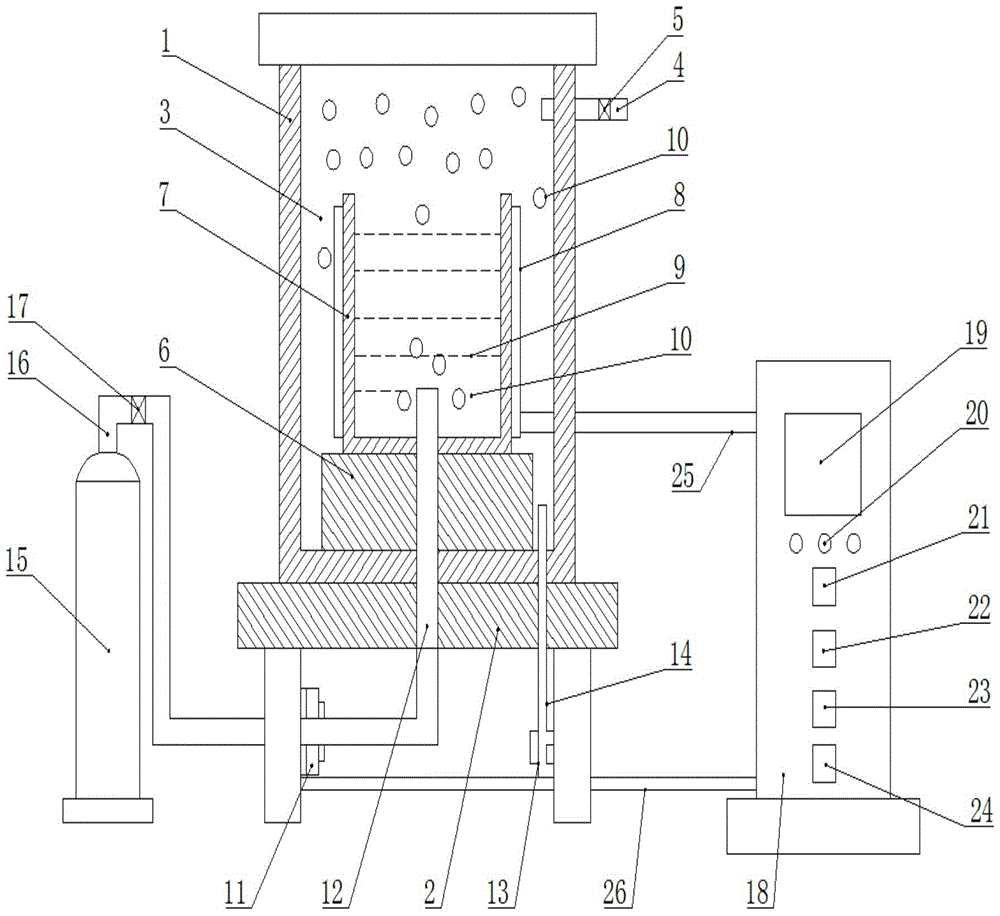

Semi-solid squeezing casting method and system for aluminum alloy

The invention relates to a semi-solid squeezing casting method and system for aluminum alloy and belongs to the technical field of preparation and application of nonferrous materials. The method comprises the following steps that firstly, an aluminum alloy block is cut into aluminum alloy pieces, the aluminum alloy pieces are wrapped with aluminum foil correspondingly, and then the wrapped aluminum alloy pieces are preheated; the preheated aluminum alloy pieces are smelted, so that molten aluminum alloy is obtained; the molten aluminum alloy is poured into a heat preservation device for heat preservation via a sprue with a bent channel or an inverted conical channel, and semi-solid aluminum alloy slurry is obtained; the semi-solid aluminum alloy slurry is poured into a heat preservation squeezing mold to be subjected to squeezing molding treatment; and finally, pressure application continues after the squeezing molding treatment is completed, then a casting is jacked out and subjected to air cooling, and an semi-solid aluminum alloy squeezed casting is obtained. According to the preparation method, the advanced process is achieved, procedures are precise, data are accurate and full, and after heat treatment of the prepared semi-solid aluminum alloy squeezed casting, the hardness of the casting can be up to 82.9 HB and the tensile strength of the casting can be up to 279 Mpa.

Owner:ZHONGBEI UNIV

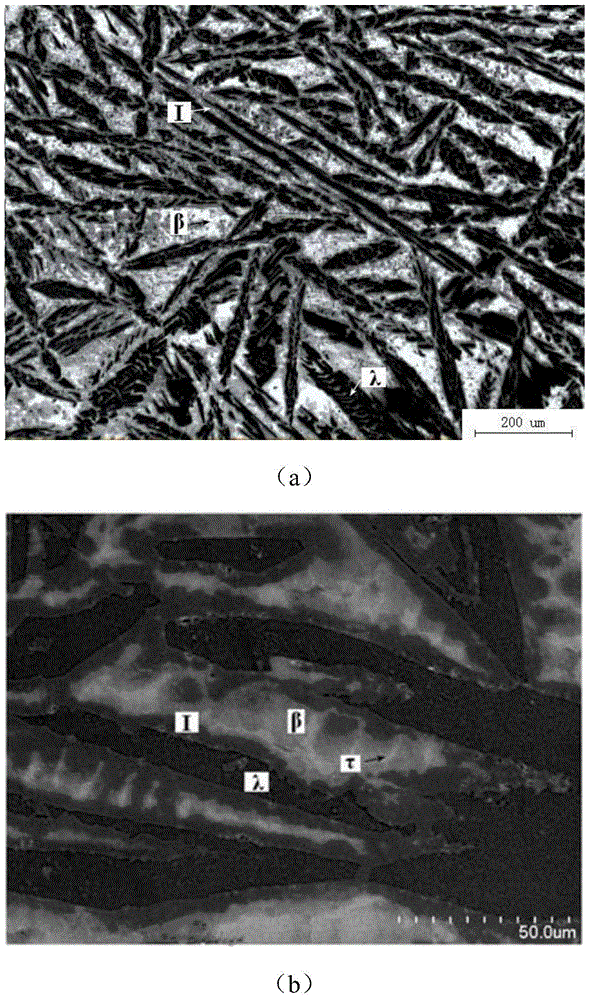

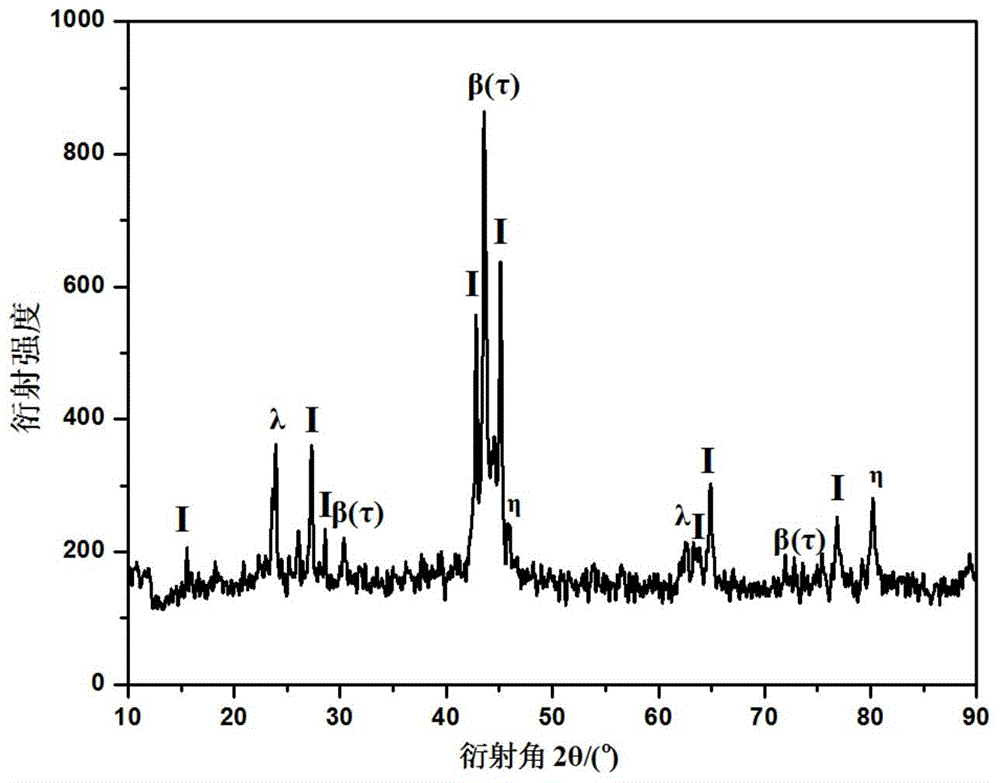

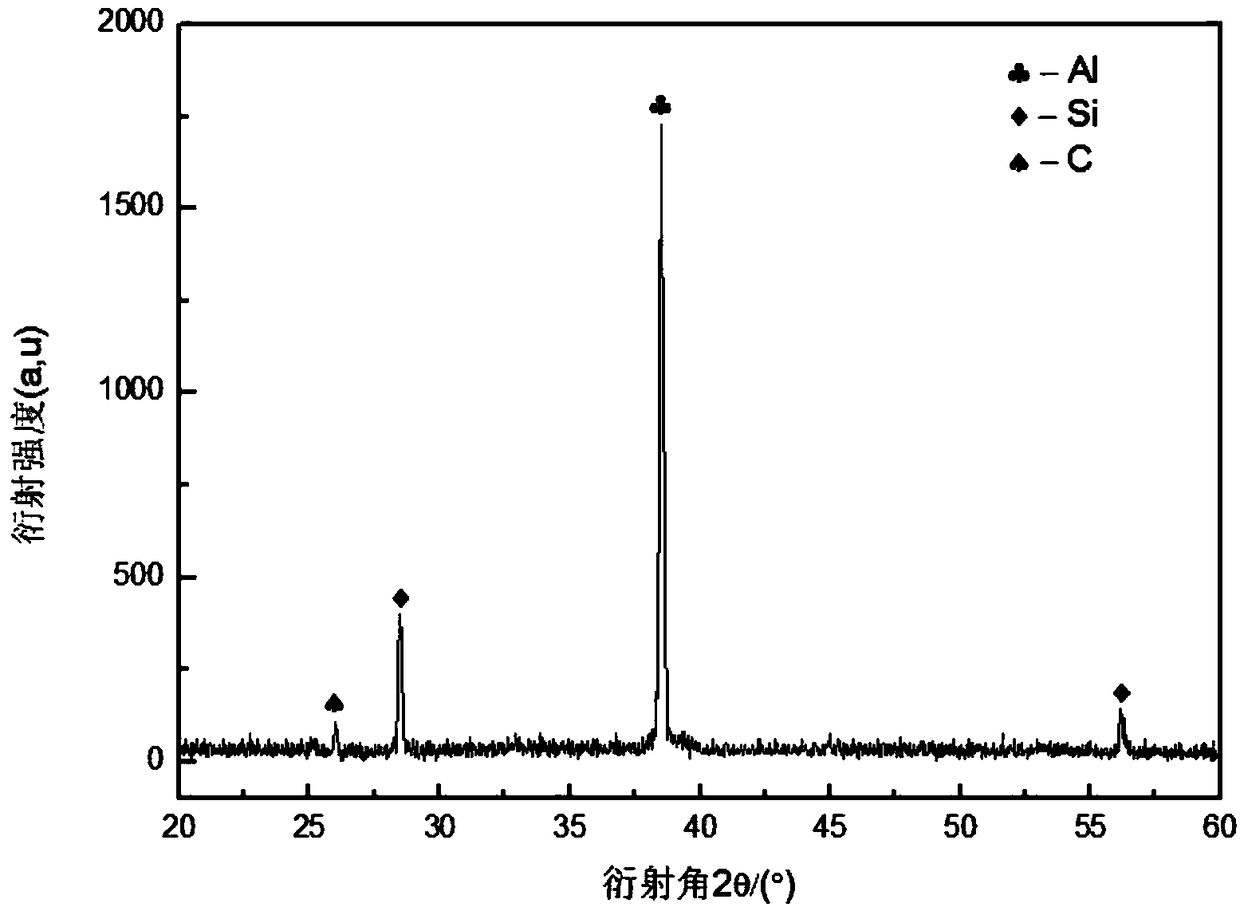

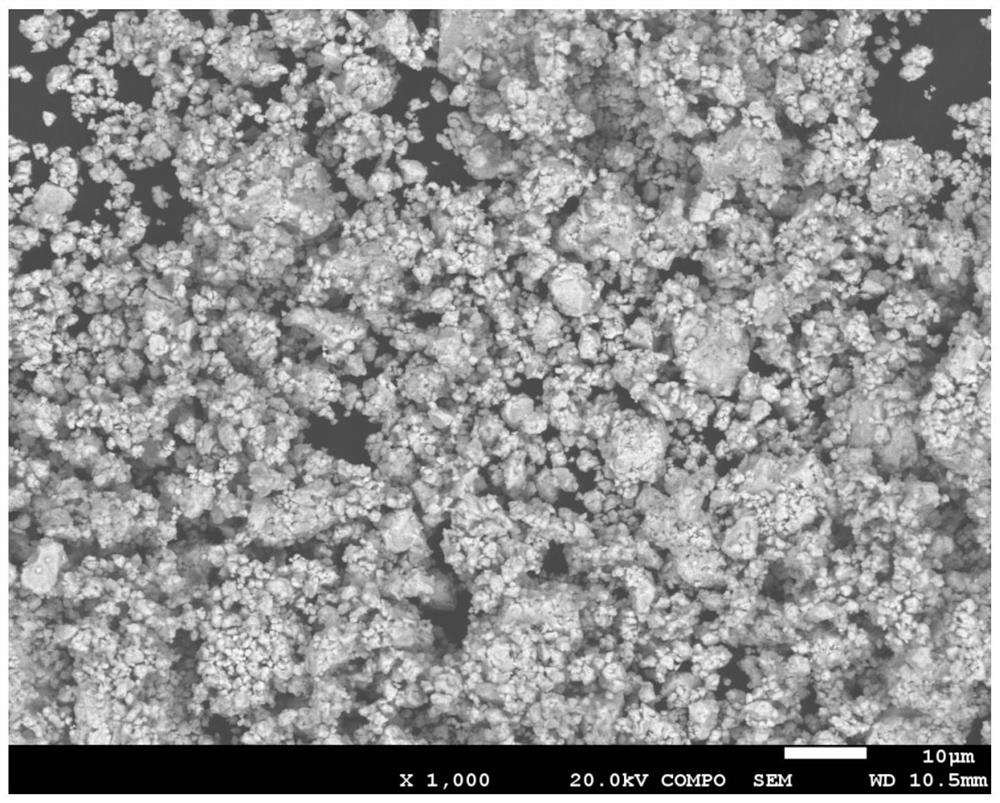

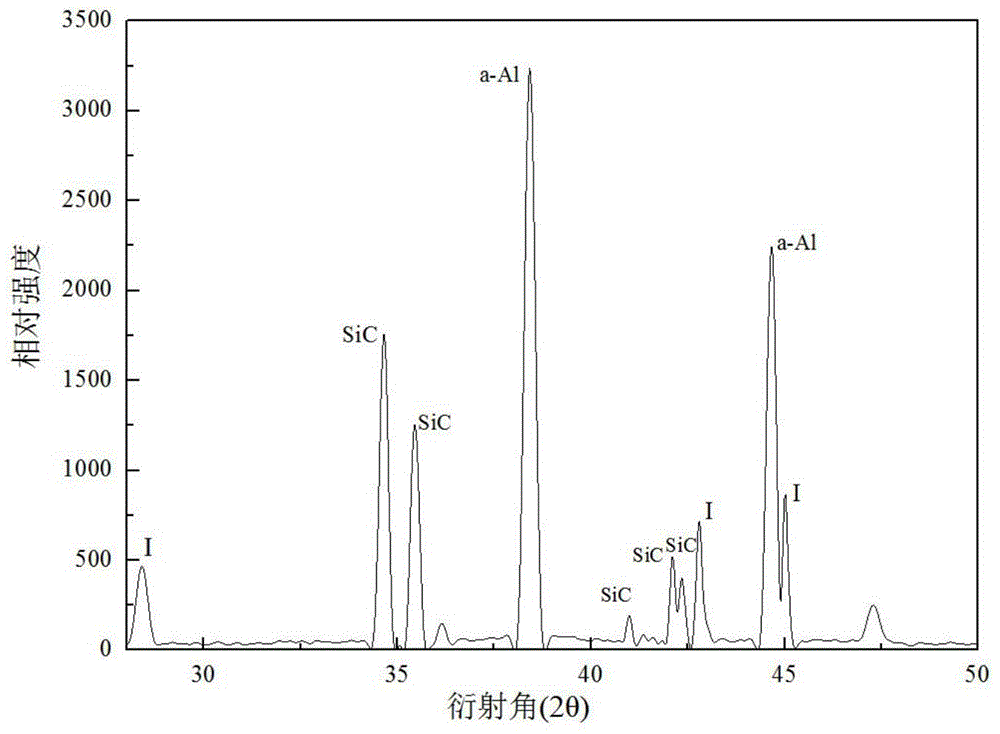

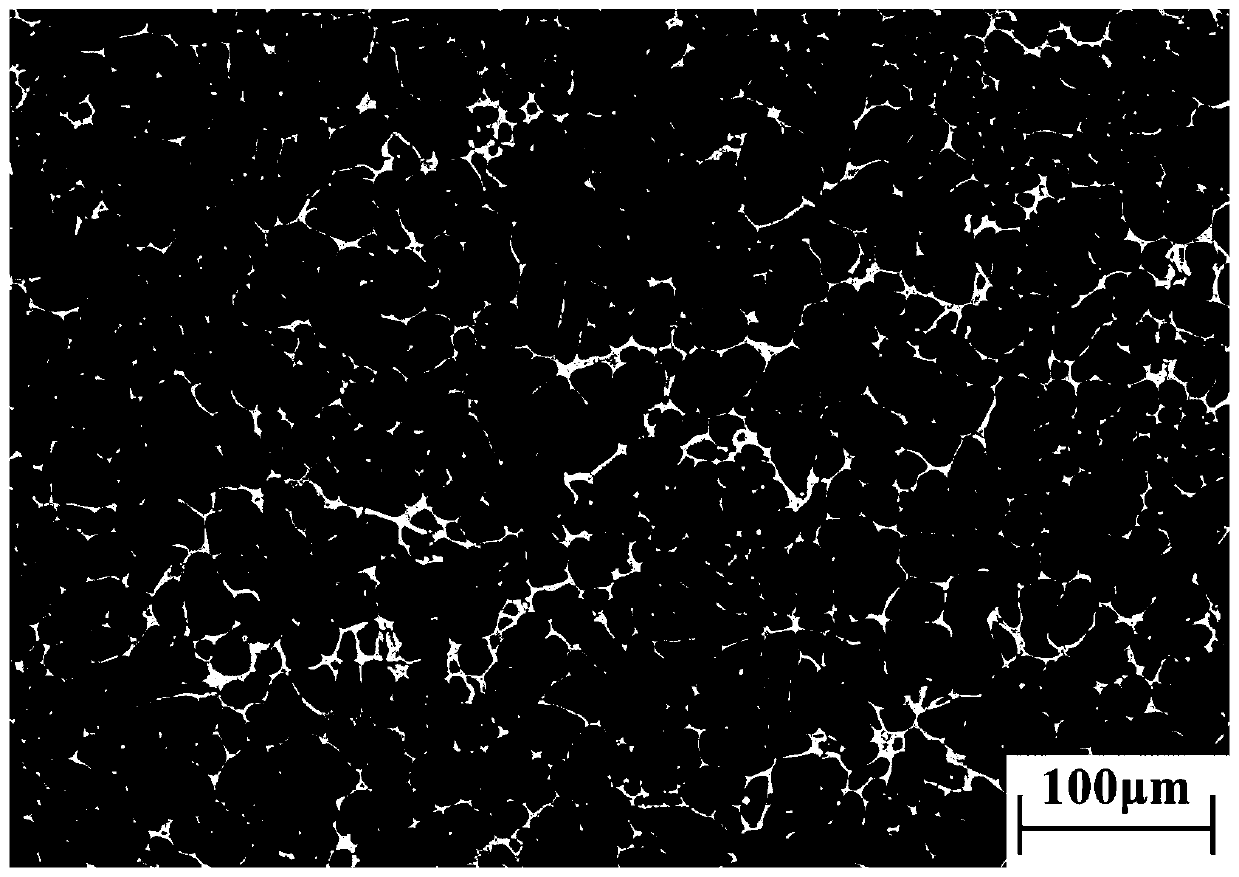

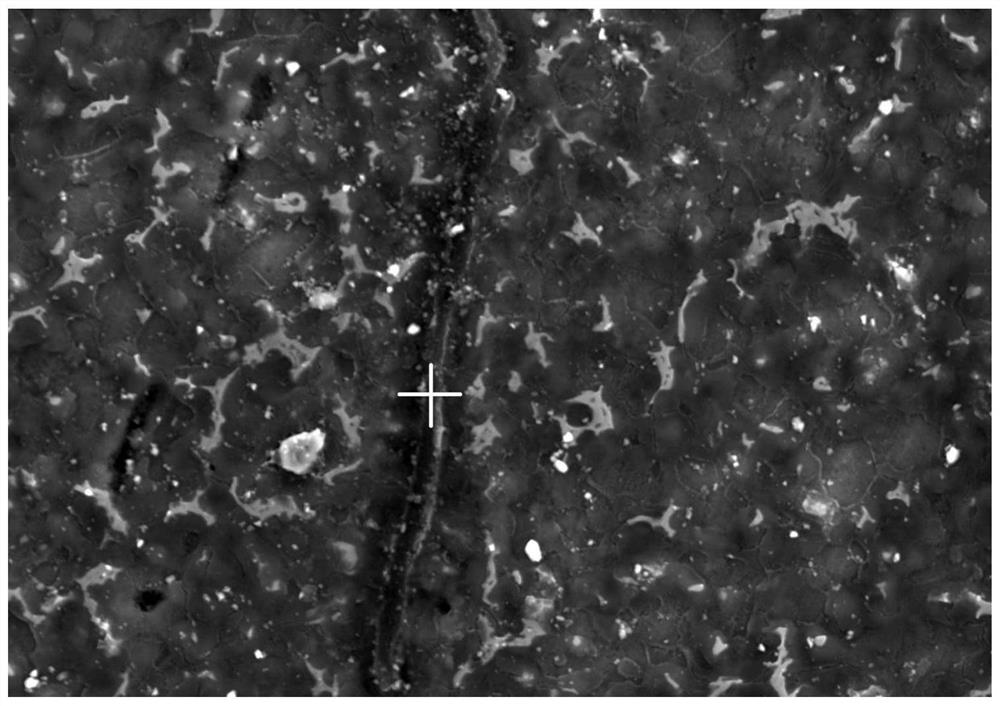

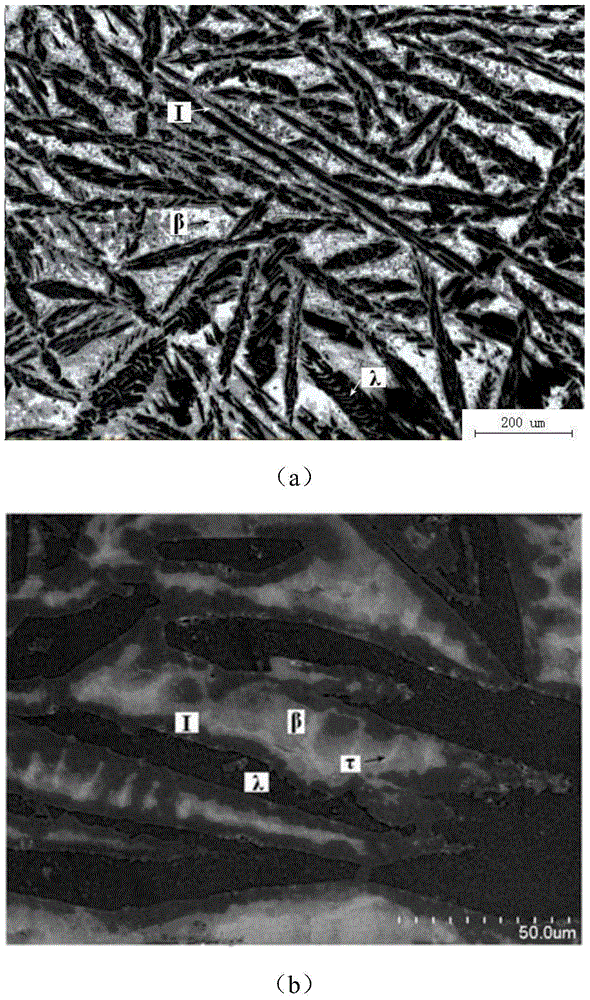

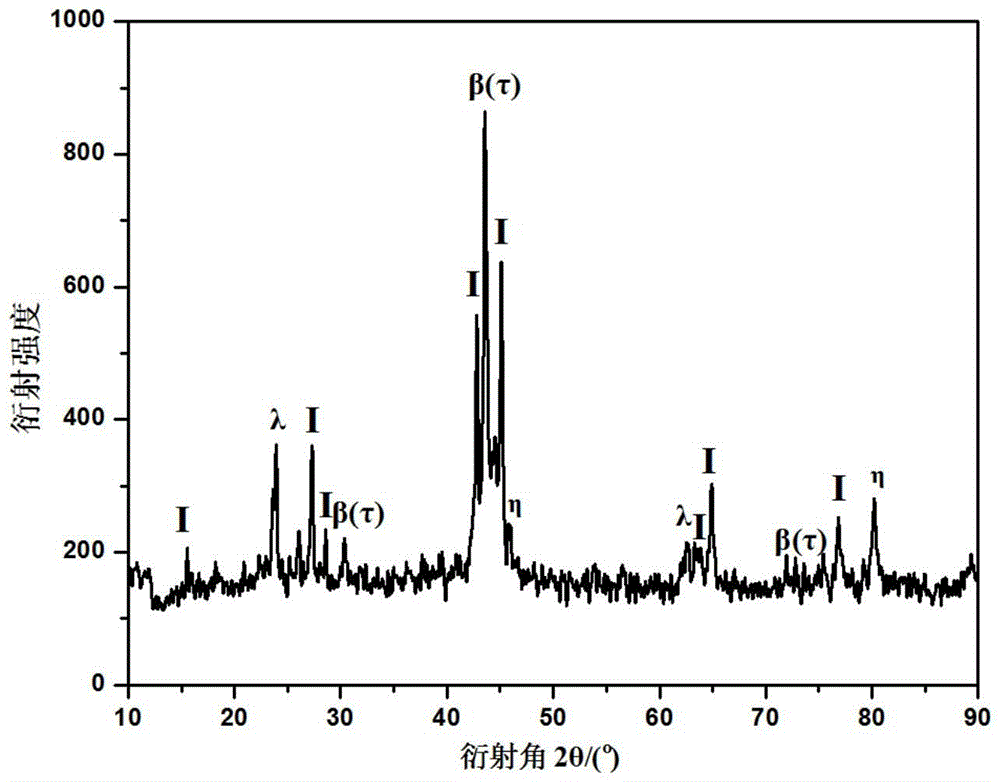

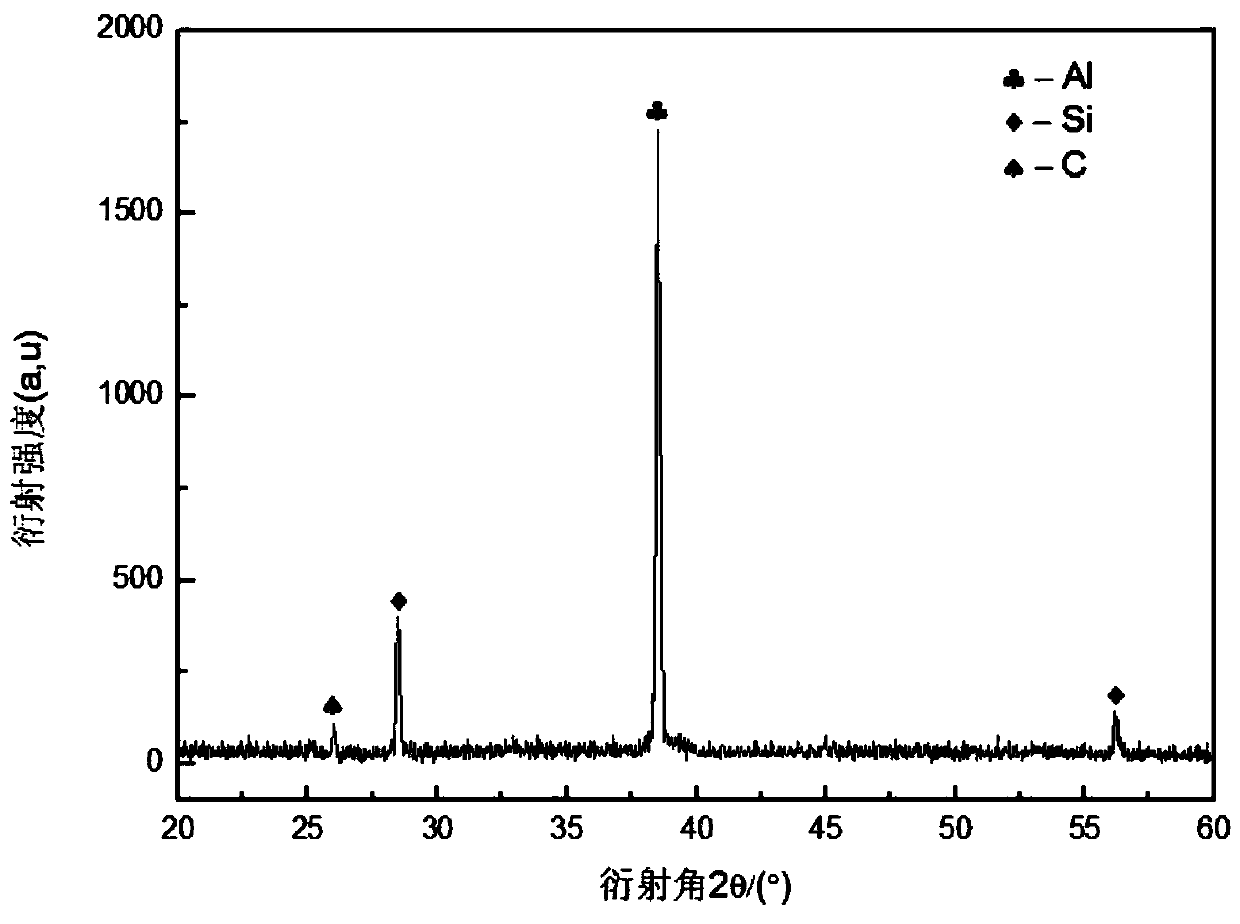

Preparation method of aluminum, copper and iron quasicrystal

The invention relates to a preparation method of an aluminum, copper and iron quasicrystal. In order to solve the problem that process defects exist as the preparation method of the aluminum, copper and iron quasicrystal is difficult, the preparation method comprises the following steps: smelting and casting, quickly cooling, thermally treating and annealing and quenching to prepare an aluminum, copper and iron quasicrystal block material by adopting a medium-frequency induction smelting furnace casting method. The preparation method of the aluminum, copper and iron quasicrystal disclosed by the invention is advanced in process, accurate and full in data; the I phase of the quasicrystal is Al61.92Cu26.21Fe11.87, the product purity is high, the I phase content of the quasicrystal is 98%, the mechanical performances are stable, the hardness is 796HV, and therefore, the preparation method can be applied to various industrial fields and is a very ideal preparation method of the aluminum, copper and iron quasicrystal.

Owner:ZHONGBEI UNIV

Die-casting method of graphene enhanced aluminum based composite material

The invention relates to a die-casting method of a graphene enhanced aluminum based composite material, and aims at solving the problems of nonuniform dispersion and difficult combining with a substrate of graphene in an aluminum alloy substrate. A semi-solid die-casting method is adopted, the graphene enhanced aluminum based composite material is prepared through melting, heat preserving, electromagnetic stirring, tamping and die-casting. The method has the advantages that the technology is advanced, data is accurate and real, procedures are strict, slurry is purified, metallographical structure compactness is good, hole shrinkage and loosening are prevented, the hardness of the prepared graphene enhanced aluminum based composite material reaches up to 85 HB, the hardness is improved by 66% compared with the substrate, the tensile strength reaches up to 8%m the tensile strength is improved by 5% compared with the substrate, the compact degree reaches up to 99.6%, and the preparation method of the graphene enhanced aluminum based composite material is advanced.

Owner:ZHONGBEI UNIV

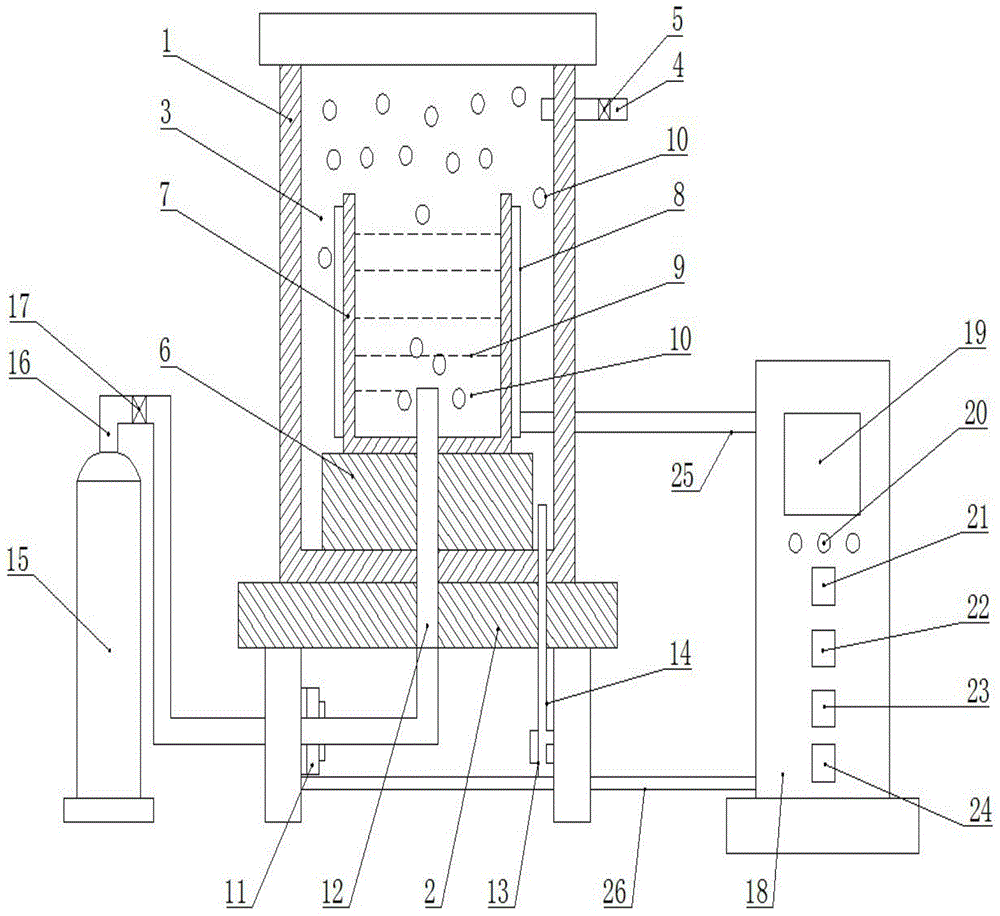

Preparation method of quasi-crystal reinforced type aluminum-based composite material

The invention relates to a preparation method of a quasi-crystal reinforced type aluminum-based composite material. Aiming at a condition that the aluminum-base material has low hardness, low tensile strength and bad corrosion resistance, the preparation method comprises the following steps: smelting in a vacuum smelting furnace, performing argon gas bottom-blowing protection, casting and extruding by using the aluminum alloy as a matrix and taking aluminum copper iron quasi-crystal as an enhancer. The preparation method is advanced in process, strict in procedure and precise and accurate in data. The prepared quasi-crystal enhanced aluminum matrix composite material has hardness up to 82.6 HB which is increased by 61.33%, tensile strength up to 283Mpa which is increased by 74.75%, and corrosion resistance is increased by 30%. The preparation method is an ideal preparation method of the quasi-crystal reinforced type aluminum-based composite material.

Owner:ZHONGBEI UNIV

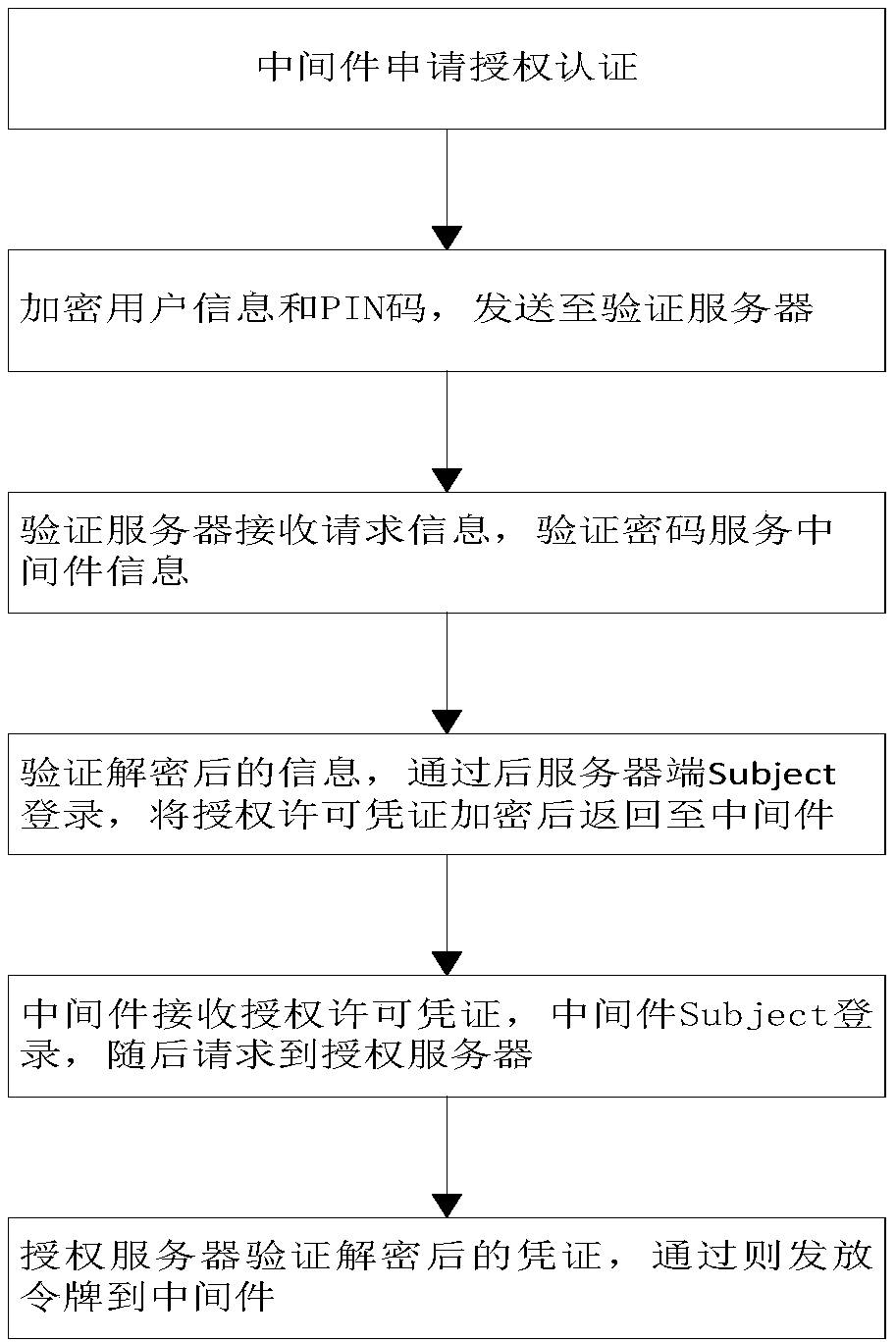

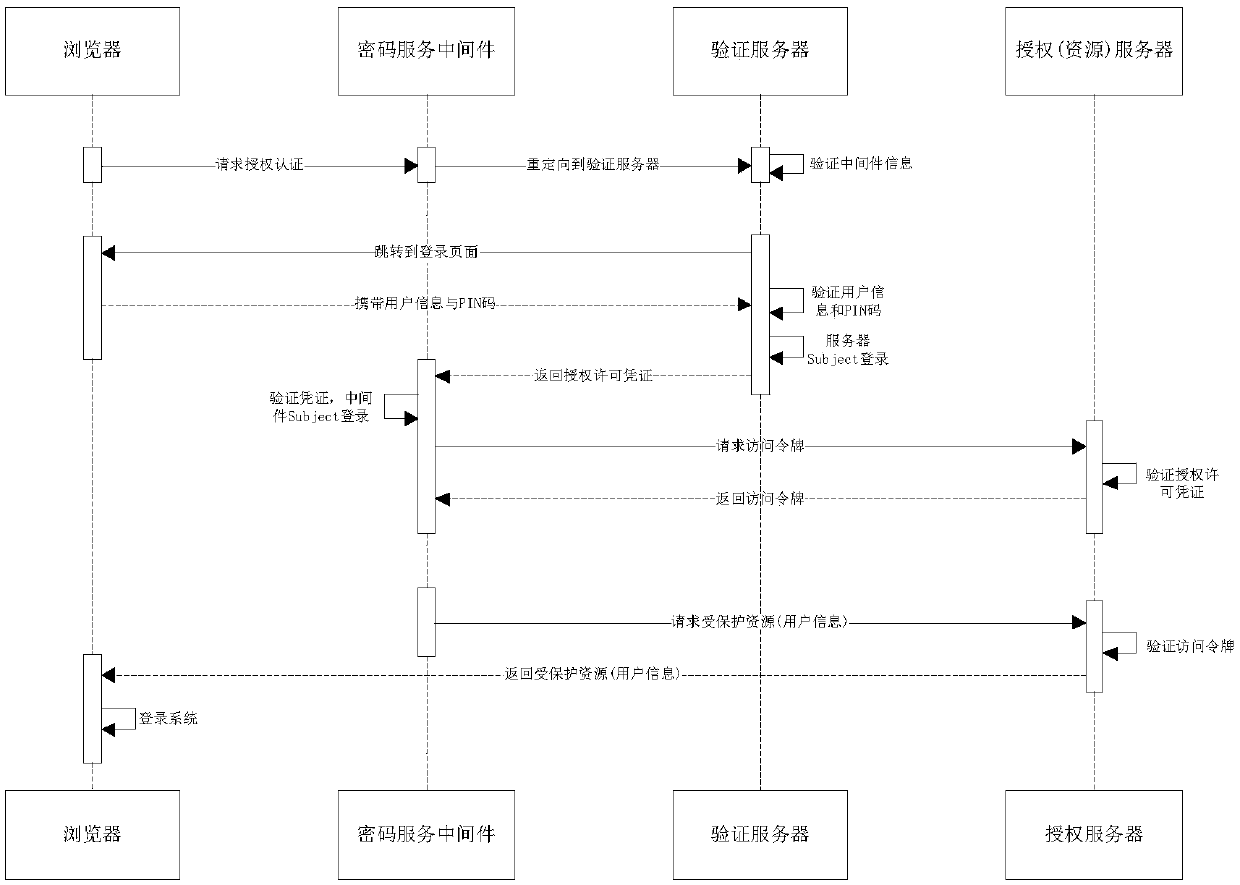

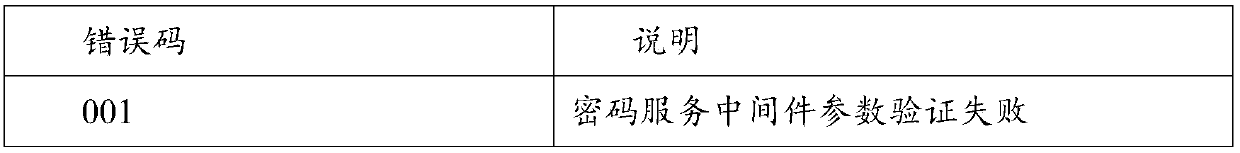

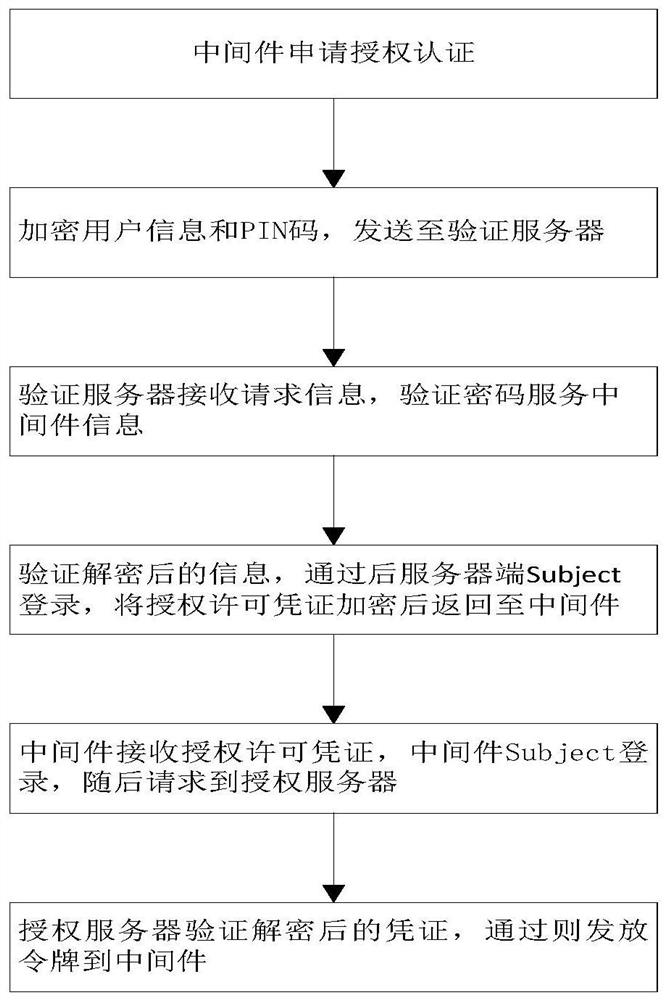

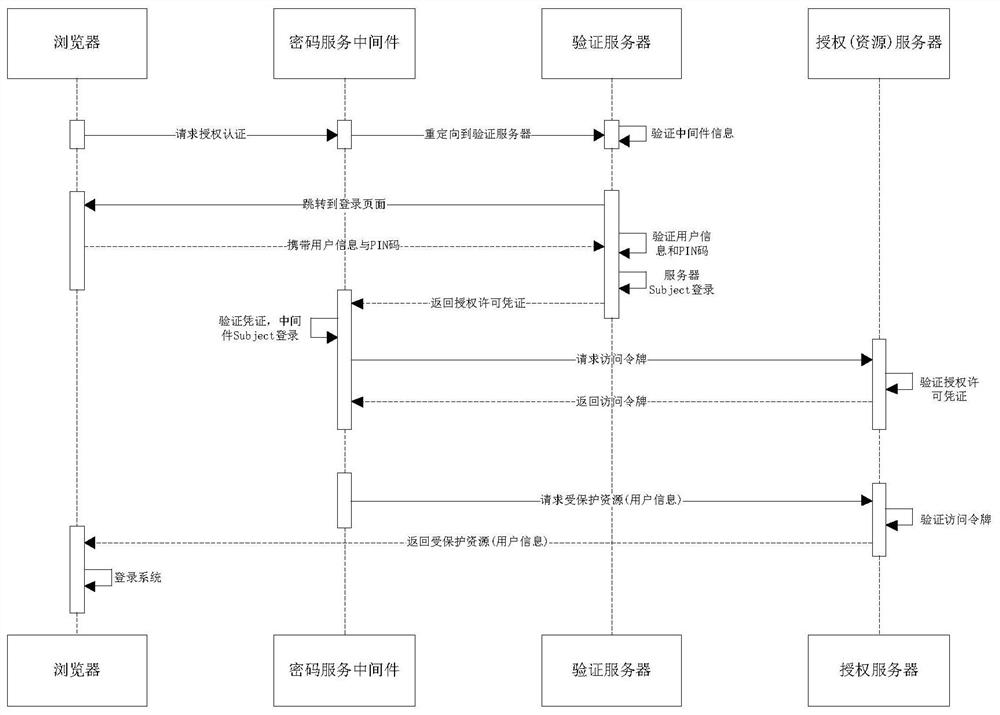

OAuth2.0-based WEB authentication method of password service middleware

ActiveCN109672675ASolve the security problem of single password authenticationStrict processUser identity/authority verificationAuthorization certificateWeb authentication

The invention provides an OAuth2.0-based WEB authentication method of password service middleware. The method comprises the following steps: firstly, the password service middleware applies for authorization authentication to a verification server; the password service middleware performs DES encryption on user information submitted by a browser and a smart password key PIN code, and then sends the same to the verification server; after receiving a request, the verification server verifies the information of the password service middleware; the verification server verifies the decrypted user information and the PIN code, performs Subject login through a background server, encrypts an authorization permission certificate, and returns the authorization permission certificate to the middleware; after the middleware receives the authorization permission certificate, the middleware performs Subject login, and then sends a request to an authorization server; and the authorization server verifies the decrypted authorization permission certificate, and then issues an access token to the password service middleware. According to the OAuth2.0-based WEB authentication method provided by the invention, the user password is combined with the smart password key to further solve the problem that the OAuth2.0 protocol single password verification security is weak, the process is more rigorous,and the security guarantee of the authorization authentication process is enhanced.

Owner:成都三零瑞通移动通信有限公司

Air-conditioning load prediction method and system based on big data

ActiveCN107220514APrediction is accurateStrict processInformaticsSpecial data processing applicationsOpen waterOutdoor temperature

The invention discloses an air-conditioning load prediction method based on big data. The method includes the steps: 1) acquiring outdoor temperature t in DEG C of a site with an air conditioner at a simulated prediction moment; 2) acquiring a temperature interval [t-s and t+s] based on a predetermined prediction step size s in DEG C and the outdoor temperature t; 3) screening data in the temperature interval from historically accumulated big data of cold or heat load measured values, total power of lighting and devices, the number of indoor people, open water surface area, indoor and outdoor air enthalpy differences and indoor and outdoor temperature differences of the air conditioner running under stable conditions; 4) calculating final load value of the prediction moment based on screened date. Based on a lot of gradually accumulated historical data of practical cooling capacity and heating capacity of the air conditioner running under the stable conditions, models for calculating cold or heat loads at the simulated prediction moment are continually optimized, and the built models are more accurate with the passage of time. The invention further discloses an air-conditioning load prediction system based on the big data.

Owner:SICHUAN INSITITUTE OF BUILDING RES

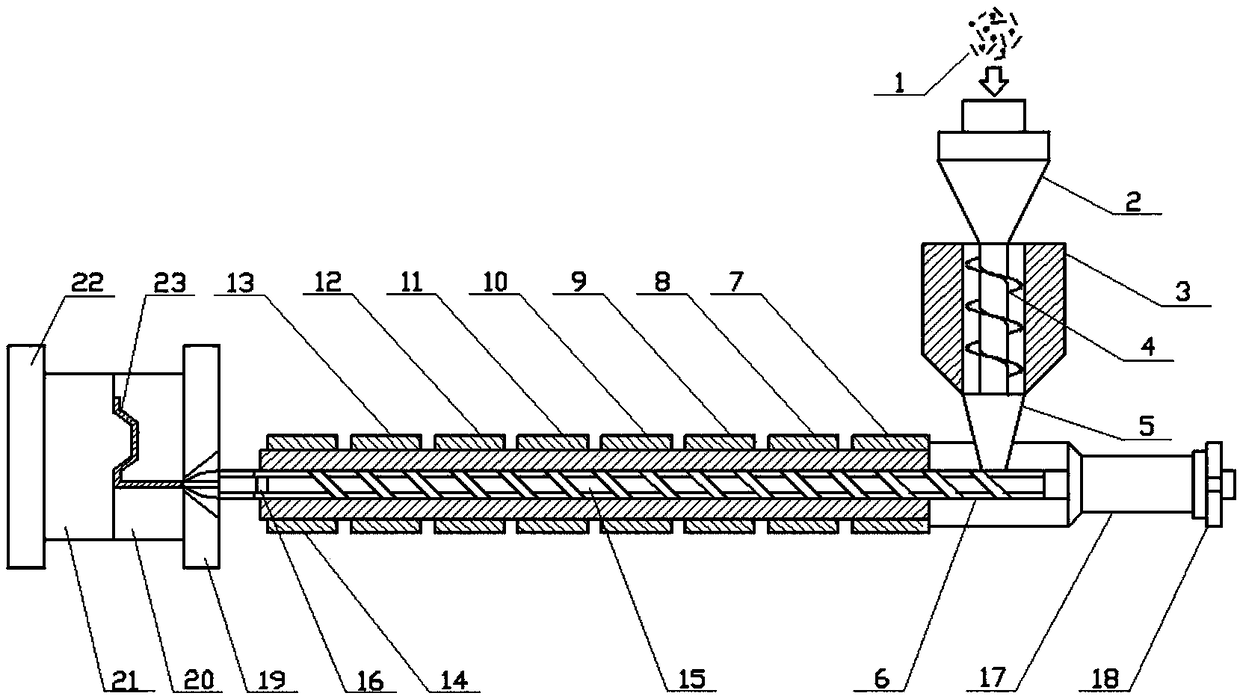

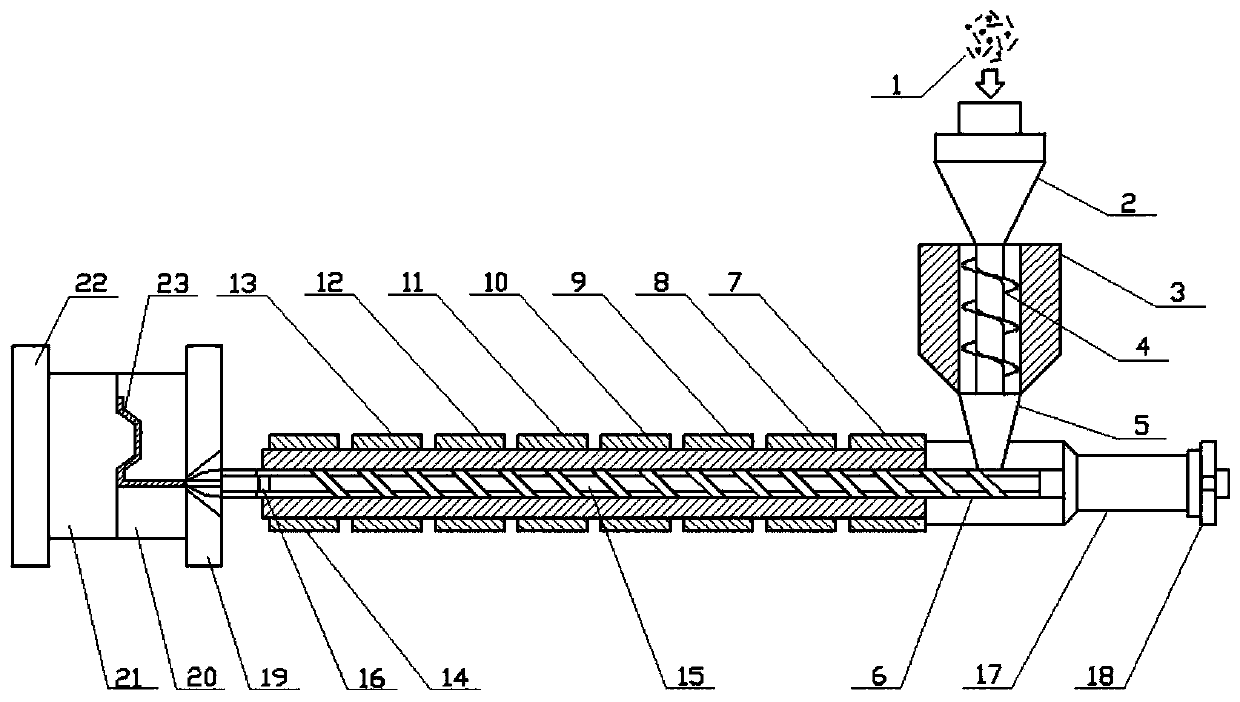

Method for preparing graphene-reinforced aluminum matrix composite material by injection molding

The invention relates to a method for preparing a graphene-reinforced aluminum matrix composite material by injection molding, and aims at the situation that graphene is unevenly dispersed in an aluminum alloy matrix and is difficult to form firm interface combination with the matrix, semi-solid injection molding method is adopted, aluminum alloy is used as a matrix body, graphene is used as a reinforcing body, and the graphene-reinforced aluminum matrix composite material is prepared through mixing powder, feeding, quantitative conveying, heating, screw shearing, preparing semi-solid slurry,high-speed injection molding. The method is advanced in technology, accurate and detailed in data, and strict in procedures, the hardness of the prepared graphene-reinforced aluminum matrix compositematerial is 82.2HV, the tensile strength of the prepared graphene-reinforced aluminum matrix composite material is 235MPa, an elongation of the prepared graphene-reinforced aluminum matrix composite material is 7.22%, and the method is an advanced preparation method for the prepared graphene-reinforced aluminum matrix composite material.

Owner:ZHONGBEI UNIV

Making method for quick-frozen sliced horse mackerel food

ActiveCN103549498AColor adjustableImprove freshnessFood freezingFood ingredient as taste affecting agentBiotechnologyAnimal science

The invention relates to a making method for quick-frozen sliced horse mackerel food. The method includes: selecting a fresh or frozen fresh horse mackerel soaked and thawed by saline as the raw material, subjecting the raw material fish to dorsal spine removal, decapitating, vertebra removal, evisceration, belly bone removal and fishbone removal treatment, then cutting the fish body into fish slices, washing the fish slices, then soaking them into a seasoning solution made of melanin, red yeast, soybean protein, lemon juice and water to undergo impregnation to be tasty, then placing the slices into a dish, scattering sesame seeds, and performing quick-freezing treatment, then performing packaging and inspection, thus obtaining qualified quick-frozen sliced horse mackerel food. The making method for the quick-frozen sliced horse mackerel food provided by the invention has the advantages of advanced technology, reasonable processes, strong operability and high making efficiency. The sliced fish product produced by the method has the characteristics of safety and sanitation, stable quality, nutrition and health, can be eaten raw or heated to eat after opening the package and thawing. And the sliced fish product has tender and soft meat, fresh and mellow taste, unique flavor, and no peculiar or fishy smell.

Owner:威海蓝谷海洋生物科技有限公司

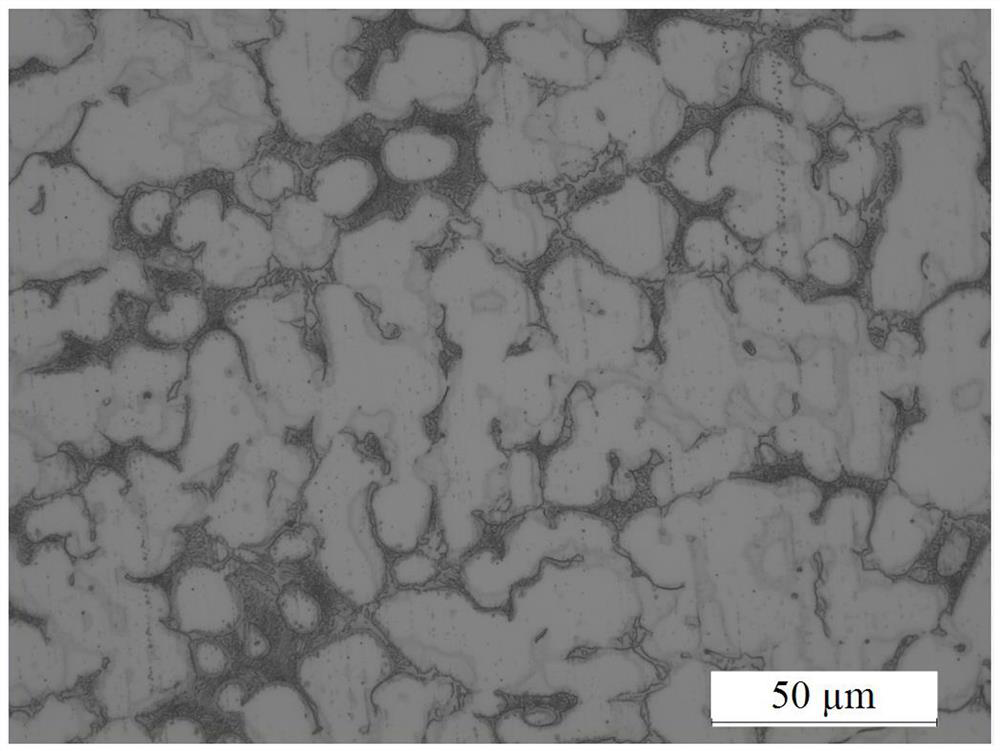

Preparation method of magnesium-zinc-yttrium quasi-crystal and boron carbide mixing enhanced magnesium-based composite material

ActiveCN108467962AAdvancedStrict processFoundry mouldsFoundry coresMagnesium matrix compositeIntermediate frequency

The invention relates to a preparation method of a magnesium-zinc-yttrium quasi-crystal and boron carbide mixing enhanced magnesium-based composite material. The magnesium-zinc-yttrium quasi-crystal and boron carbide mixing enhanced magnesium-based composite material is prepared by taking a magnesium alloy as a substrate and taking endogenous quasi-crystal magnesium-zinc-yttrium and boron carbideas a strengthening phase through the steps of smelting in a vacuum intermediate-frequency induction smelting furnace, argon bottom blowing, mechanical stirring, squeeze casting and heat treating for the condition that a magnesium-based composite material is poor in mechanical property. According to the preparation method, the technology is advanced, the processes are strict, data are precise and full and accurate, the tensile strength of the prepared magnesium-based composite material reaches 315 MPa, the elongation of the prepared magnesium-based composite material reaches 7%, the hardness ofthe prepared magnesium-based composite material reaches 108 Hv, and the preparation method is an advanced preparation method for the magnesium-zinc-yttrium quasi-crystal and boron carbide mixing enhanced magnesium-based composite material.

Owner:ZHONGBEI UNIV

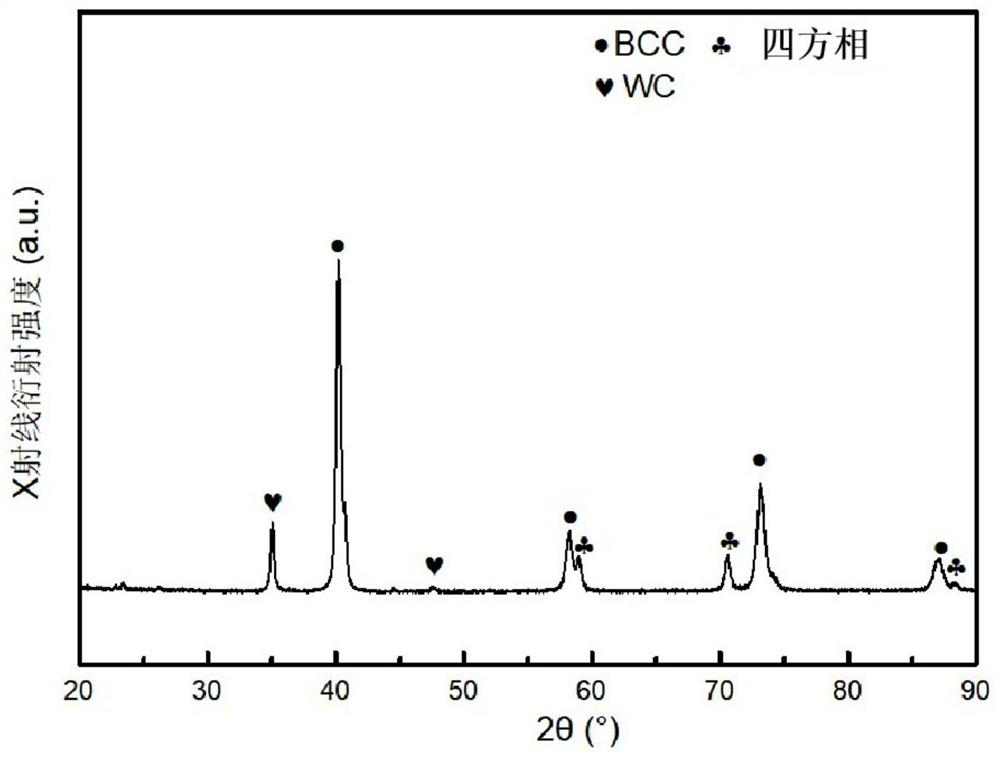

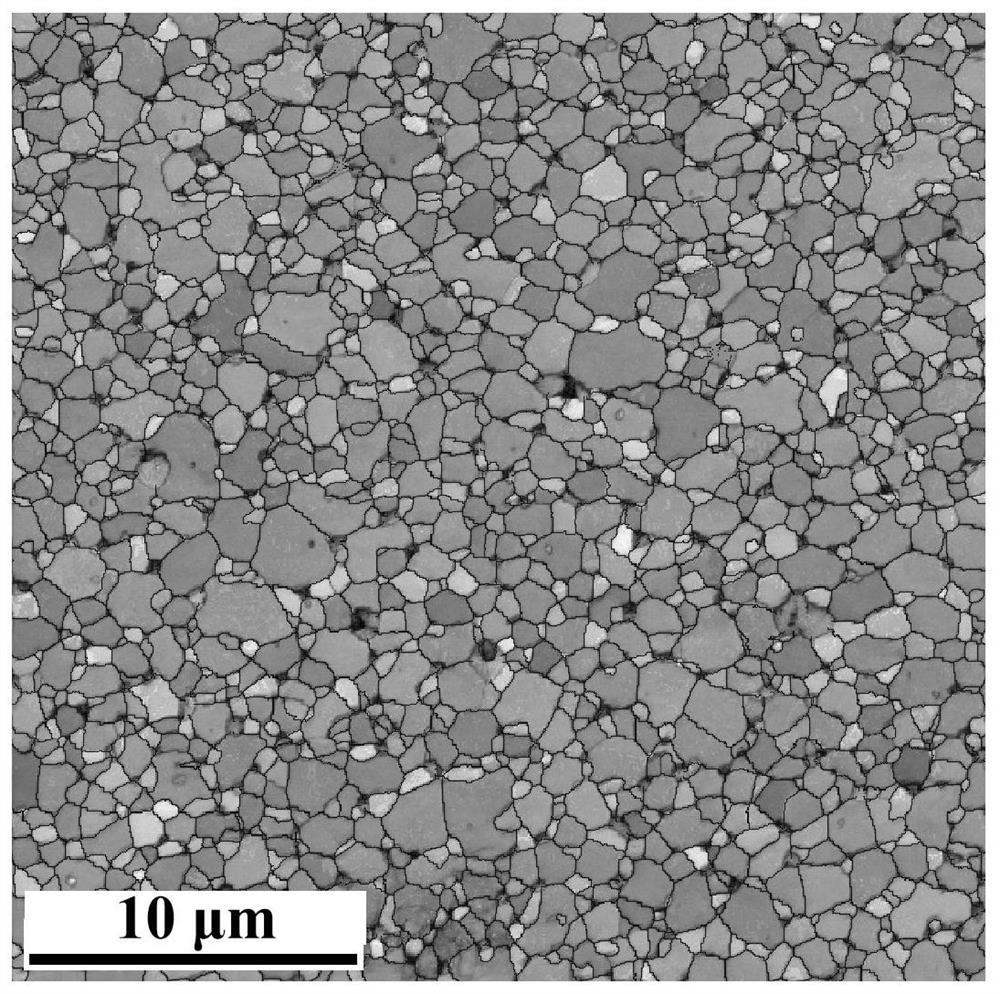

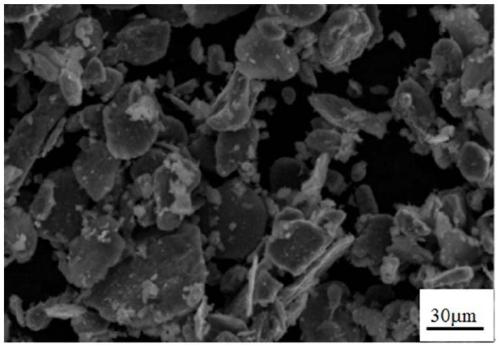

Particle-reinforced refractory high-entropy composite material and preparation method thereof

InactiveCN113373364AThe preparation method is simple and easyStrict processAlloyCompressive strength

The invention provides a particle-reinforced refractory high-entropy composite material and a preparation method thereof. The particle-reinforced refractory high-entropy composite material comprises a matrix phase and WC particles distributed in the matrix phase, wherein a Nb-Mo-Ta-W-Re alloy composed of Nb, Mo, Ta, W and Re elements serves as the matrix phase; and the mass of the WC particles accounts for 1-10% of the mass of the matrix phase. The Nb-Mo-Ta-W-Re alloy is adopted as the matrix phase and the WC particles are adopted as a reinforcing phase, so that the particle-reinforced refractory high-entropy composite material has high hardness, high compressive strength and stable structure performance; and meanwhile, the particle-reinforced refractory high-entropy composite material is prepared through ball-milling alloying and spark plasma hot-pressing sintering methods, the preparation is easy, and the application prospects are good.

Owner:有研纳微新材料(北京)有限公司

Preparation method for cold-air-dried and seasoned mackerel fillets

The invention relates to a preparation method for cold-air-dried and seasoned mackerel fillets. The method comprises the following steps: preferably selecting mackerel as a raw material, removing the back bones and head of the mackerel, separating a mackerel body from the vertebra, and cutting the mackerel body into mackerel fillets; cleaning the mackerel fillets and soaking in seasoning liquid prepared by mixing boiled potherb mustard liquid, boiled hawthorn liquid, salt, melanin, red yeasts, soybean protein, lemon juice, raw ginger, Chinese prickly ash, anise, cassia bark and water in proportion; controlling the liquid content, arranging the seasoned mackerel fillets in a plate, supporting the plate on a drying net of a drying machine, pushing the plate into a cold air drying workshop for drying, quickly freezing, packaging, and checking to obtain the finished cold-air-dried and seasoned mackerel fillets. The method is reasonable in technology, strict in process, strong in operability, high in preparation efficiency and suitable for industrialized production; a mackerel fillet food prepared by the method is comprehensive in nutrition, unique in flavor, tender and soft in meat, free of peculiar fishy smell, convenient to eat and long in shelf life.

Owner:HENGMAO IND GRP

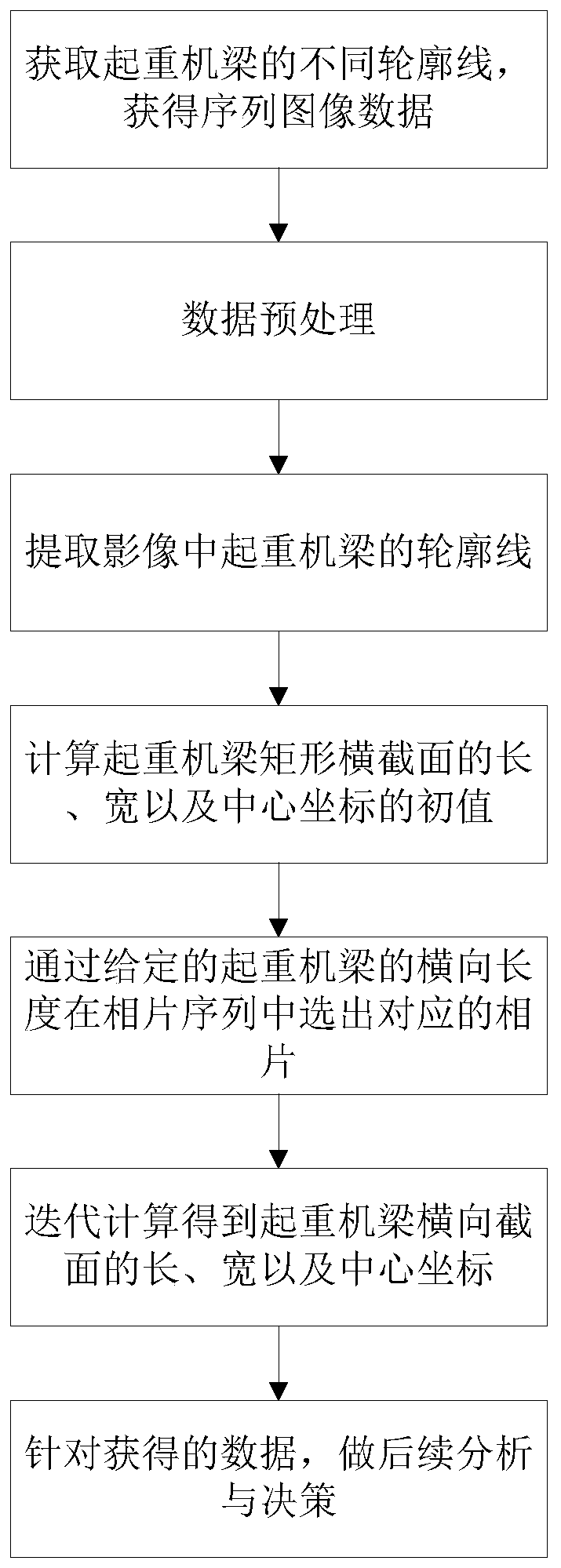

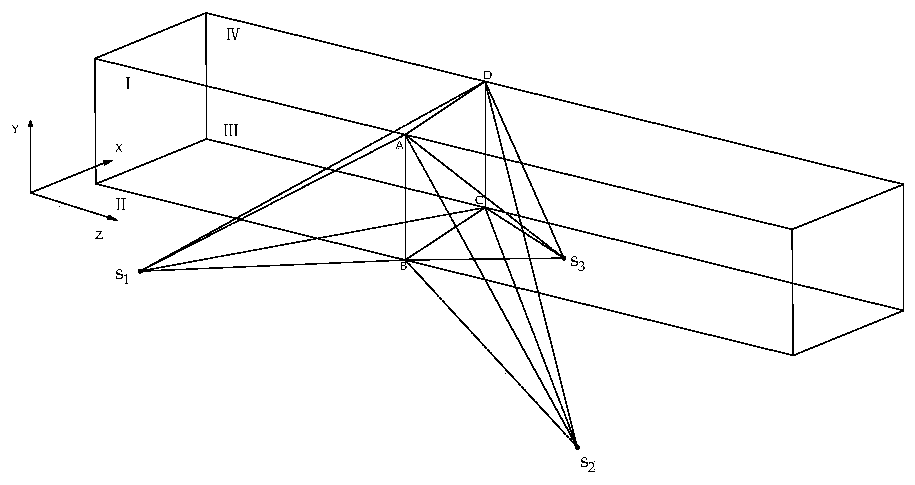

Large portal crane beam deformation measuring method based on image and geometric contour

InactiveCN109764822ADoes not affect production operationsHigh measurement accuracyUsing optical meansMeasurement precisionData pre-processing

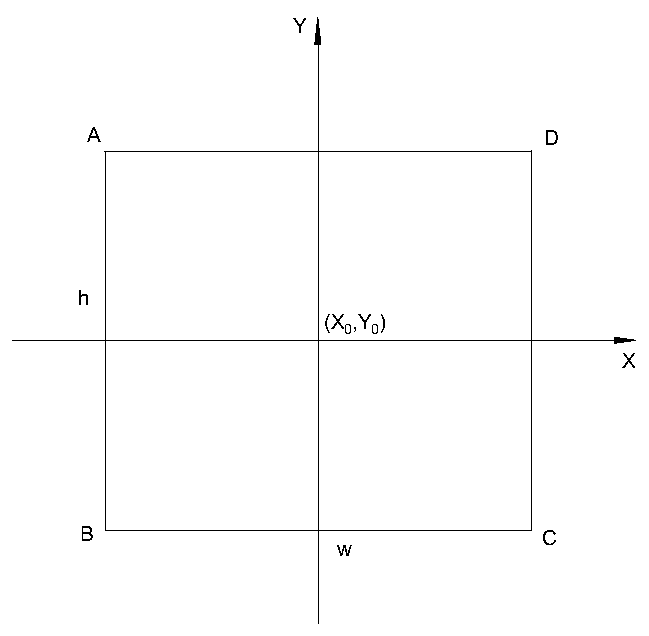

The invention discloses a large portal crane beam deformation measuring method based on an image and a geometric contour. The method comprises the following steps of firstly, acquiring different contour lines of a crane beam to obtain sequence image data; carrying out data preprocessing, and extracting the contour lines of the crane beam in the image; computing initial values of the length, the width and the center coordinates of a rectangular cross section of the crane beam; selecting a corresponding photo from a photo sequence through the transverse length of the given crane beam; carrying out iterative computation to obtain the length, the width and the center coordinates of a transverse section of the crane beam; and finally, carrying out subsequent analysis and decision-making on theobtained data. The method is low in requirement for personnel for field measurement, and does not need to have a relatively high skill requirement for field measurement like a traditional measuring method, and a relatively high measurement precision is kept for a long time; and the method is obtained by strict mathematical calculation, so that the whole process is stricter.

Owner:WUHAN UNIV OF TECH

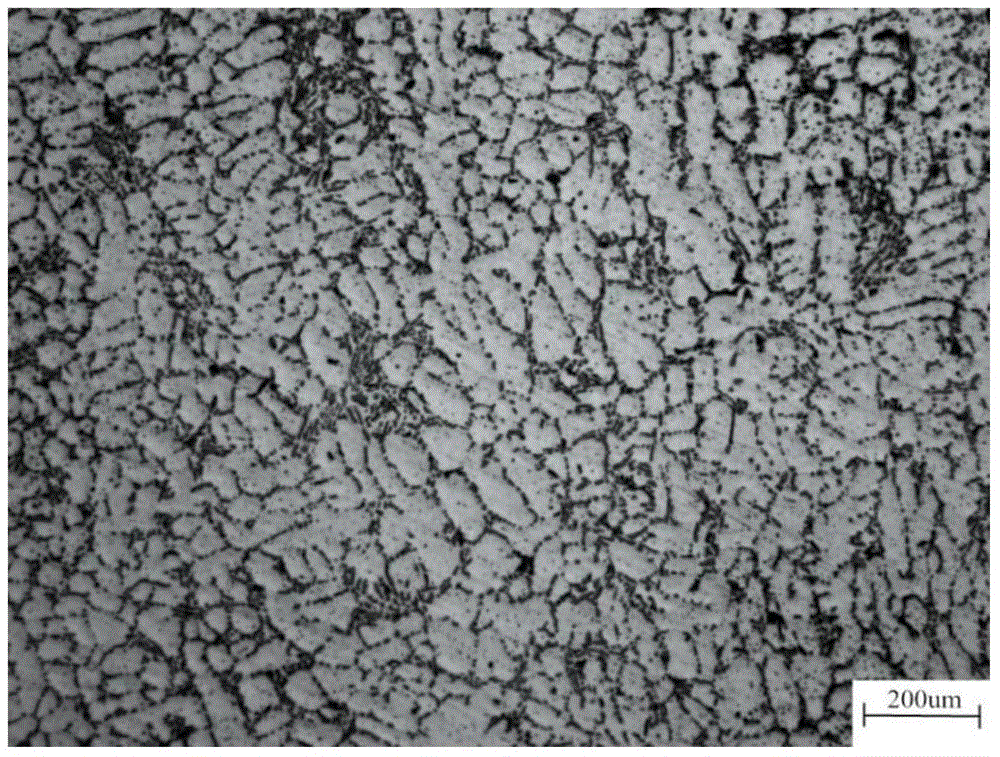

Aluminum-copper-iron quasi-crystal and silicon carbide mixed enhanced aluminum-based composite preparation method

The invention relates to an aluminum-copper-iron quasi-crystal and silicon carbide mixed enhanced aluminum-based composite preparation method. In order to overcome the defects of low tensile strength and low hardness of aluminum-based materials, aluminum alloy serves as a matrix and aluminum-copper-iron quasi-crystal and silicon carbide serve as reinforcing agents to prepare an aluminum-copper-iron quasi-crystal and silicon carbide mixed enhanced aluminum-based composite by means of smelting in a medium-frequency induction melting furnace, argon bottom blowing protection, casting and vacuum heat treatment. The preparation method is technically advanced, precise in procedure and accurate and detailed in data, the aluminum-copper-iron quasi-crystal and silicon carbide mixed enhanced aluminum-based composite prepared according to the method is 80.3HB in hardness which is improved by 50.64%, 285Mpa in tensile strength which is improved by 60.42%, and corrosion resistance is improved by 40%, and the aluminum-copper-iron quasi-crystal and silicon carbide mixed enhanced aluminum-based composite preparation method is pretty optimal.

Owner:ZHONGBEI UNIV

A kind of preparation method of graphene reinforced aluminum matrix composite material

The invention relates to a preparation method of a graphene-reinforced aluminum-based composite material. Aiming at the situation that graphene is not uniformly dispersed in an aluminum alloy matrix and difficult to combine with the matrix, a semi-solid squeeze casting method is adopted. Furnace smelting, electromagnetic stirring, pouring, and extrusion casting to make graphene-reinforced aluminum matrix composites. This preparation method has advanced technology, accurate and detailed data, strict procedures, pure slurry, good metallographic structure and no shrinkage cavity. The hardness of the prepared graphene-reinforced aluminum-matrix composite material reaches 87HB, the tensile strength reaches 255Mpa, the elongation rate reaches 8%, and the density reaches 99.6%. It is an advanced preparation method of graphene-reinforced aluminum-matrix composite materials.

Owner:ZHONGBEI UNIV

A kind of preparation method of quasicrystal reinforced aluminum matrix composite material

The invention relates to a preparation method of a quasi-crystal reinforced type aluminum-based composite material. Aiming at a condition that the aluminum-base material has low hardness, low tensile strength and bad corrosion resistance, the preparation method comprises the following steps: smelting in a vacuum smelting furnace, performing argon gas bottom-blowing protection, casting and extruding by using the aluminum alloy as a matrix and taking aluminum copper iron quasi-crystal as an enhancer. The preparation method is advanced in process, strict in procedure and precise and accurate in data. The prepared quasi-crystal enhanced aluminum matrix composite material has hardness up to 82.6 HB which is increased by 61.33%, tensile strength up to 283Mpa which is increased by 74.75%, and corrosion resistance is increased by 30%. The preparation method is an ideal preparation method of the quasi-crystal reinforced type aluminum-based composite material.

Owner:ZHONGBEI UNIV

A kind of preparation method of quasicrystal reinforced magnesium matrix composite material

ActiveCN108467957BAdvancedAdvanced technologyFoundry mouldsFoundry coresMagnesium matrix compositeHardness

The invention relates to a preparation method of a quasi crystal enhanced type magnesium-based composite material and directs at the conditions that a magnesium-based material is low in hardness and tensile strength. A magnesium alloy serves as a base body, magnesium-zinc-yttrium quasi crystals serve as an enhancing agent, and the quasi crystal enhanced type magnesium-based composite material is prepared through smelting in a vacuum smelting furnace, semi-solid casting and extrusion forming. The preparation method is advanced in process and strict in procedure, data are accurate and detailed,the hardness of the prepared quasi crystal enhanced type magnesium-based composite material reaches 88.9 HV, the tensile strength reaches 235 MPa, the elongation percentage is 10.5%, and the preparation method is an advanced preparation method of the quasi crystal enhanced type magnesium-based composite material.

Owner:KANG MEI TECH DEV

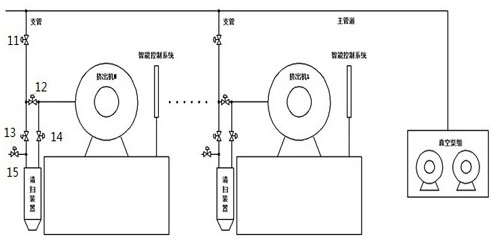

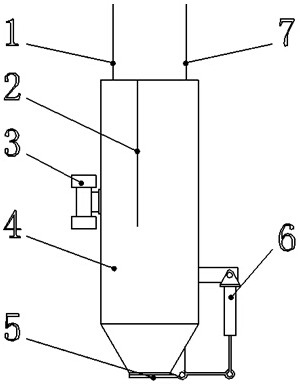

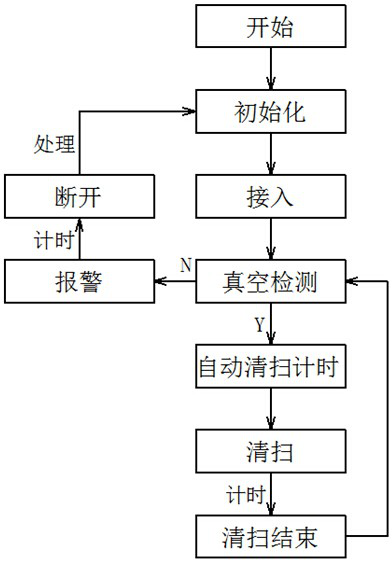

A pvc double-wall corrugated pipe production material dehumidification system cleaning device, dehumidification system and dehumidification method

The invention relates to the technical field of dehumidification of PVC production materials and more particularly relates to a cleaning device for dehumidification of a PVC double-wall corrugated pipe production material and a dehumidification system and method. The cleaning device is connected to an exhaust port and a branch pipe of an extruder, and comprises: a box body and an input tube and anoutput tube at the top of the box body. The input tube is connected to the exhaust port of the extruder. The input tube is connected to the branch pipe. The cleaning device also comprises a cleaningport at the bottom of the box body, a cleaning port baffle located at the cleaning port and used for controlling opening and closing of the cleaning port, and a partition plate located in the box body, extending downwardly from the top in the box body and arranged between the input tube and the output tube.

Owner:HESHAN LESSO IND DEV

A kind of die-casting preparation method of graphene-reinforced magnesium-based composite material

The invention relates to a die-casting preparation method of a graphene-reinforced magnesium-based composite material. Aiming at the uneven dispersion of graphene in the magnesium alloy matrix and the difficulty in combining with the matrix, a semi-solid die-casting method is adopted. After melting, heat preservation, and electromagnetic Stirring, compacting, and die-casting to make graphene-reinforced magnesium-based composite materials. The graphene-reinforced magnesium-based composite material has a hardness of 82.5HB, a tensile strength of 235Mpa, and an elongation of 7.3%. It is an advanced preparation method of graphene-reinforced magnesium-based composite materials.

Owner:ZHONGBEI UNIV

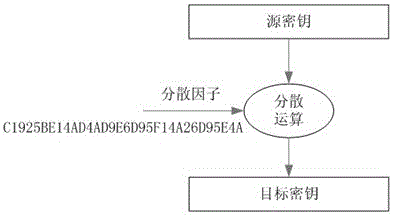

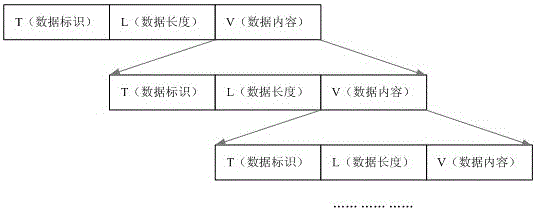

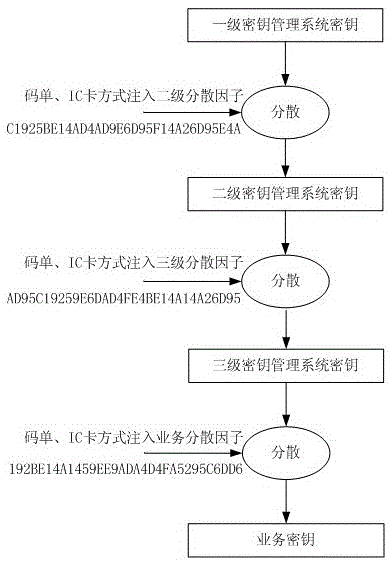

A data preparation management method based on task mechanism

ActiveCN103580850BSatisfy the release operation requirementsImprove securityRecord carriers used with machinesSecuring communicationComputer hardwareStart time

The invention discloses a data preparation and management method based on a task mechanism. The original card making data and key data are combined, and the dispersion factor is involved in the key data preparation process, which avoids the single key data being directly used as an IC card or The potential safety hazard of the chip key has high practicability; by specifying the key, using different and multiple distribution factors, the key is distributed and calculated layer by layer, and several pieces of dispersed key data and key data are obtained. The preparation process is interlocking and rigorous, with high security; the introduction of the task mechanism, the establishment of the card production task, the determination of the task start time, the system can start or suspend the card production task, the background service according to the card production Tasks perform corresponding operations to meet the different needs of different application systems for key data preparation, and have wide adaptability. Improve the security of the key data preparation process and meet the user's large-scale and centralized issuance operation requirements for IC cards or chips.

Owner:中电科网络安全科技股份有限公司

Method and system for semi-solid extrusion casting of aluminum alloy

Owner:ZHONGBEI UNIV

A kind of preparation method of aluminum-copper-iron quasicrystal

The invention relates to a preparation method of an aluminum, copper and iron quasicrystal. In order to solve the problem that process defects exist as the preparation method of the aluminum, copper and iron quasicrystal is difficult, the preparation method comprises the following steps: smelting and casting, quickly cooling, thermally treating and annealing and quenching to prepare an aluminum, copper and iron quasicrystal block material by adopting a medium-frequency induction smelting furnace casting method. The preparation method of the aluminum, copper and iron quasicrystal disclosed by the invention is advanced in process, accurate and full in data; the I phase of the quasicrystal is Al61.92Cu26.21Fe11.87, the product purity is high, the I phase content of the quasicrystal is 98%, the mechanical performances are stable, the hardness is 796HV, and therefore, the preparation method can be applied to various industrial fields and is a very ideal preparation method of the aluminum, copper and iron quasicrystal.

Owner:ZHONGBEI UNIV

A method for preparing multi-component synergistically strengthened aluminum matrix composites

The invention relates to a method for preparing a multi-component synergistically strengthened aluminum-based composite material. Aiming at the poor mechanical properties of cast aluminum-lithium alloys, different alloy elements and endogenous titanium carbide phases are added to the aluminum-lithium alloys, and the aluminum-lithium alloys are smelted. , argon bottom blowing, electromagnetic stirring, extrusion casting and heat treatment to make a multi-component synergistically strengthened aluminum matrix composite; Up to 485MPa, hardness up to 189Hv, is an advanced multi-component synergistically strengthened aluminum matrix composite material preparation method.

Owner:滨州北海瑞格金属新材料有限公司

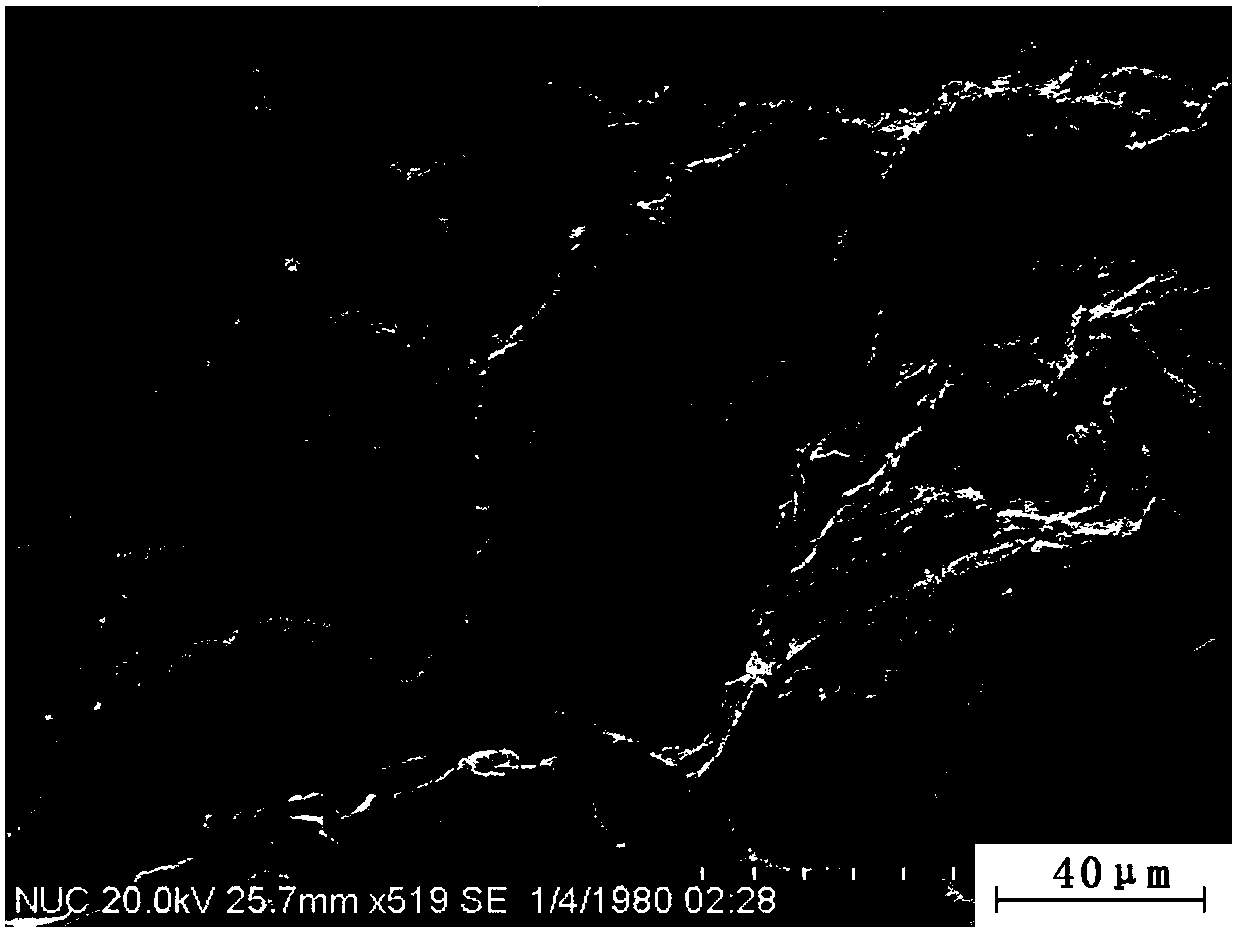

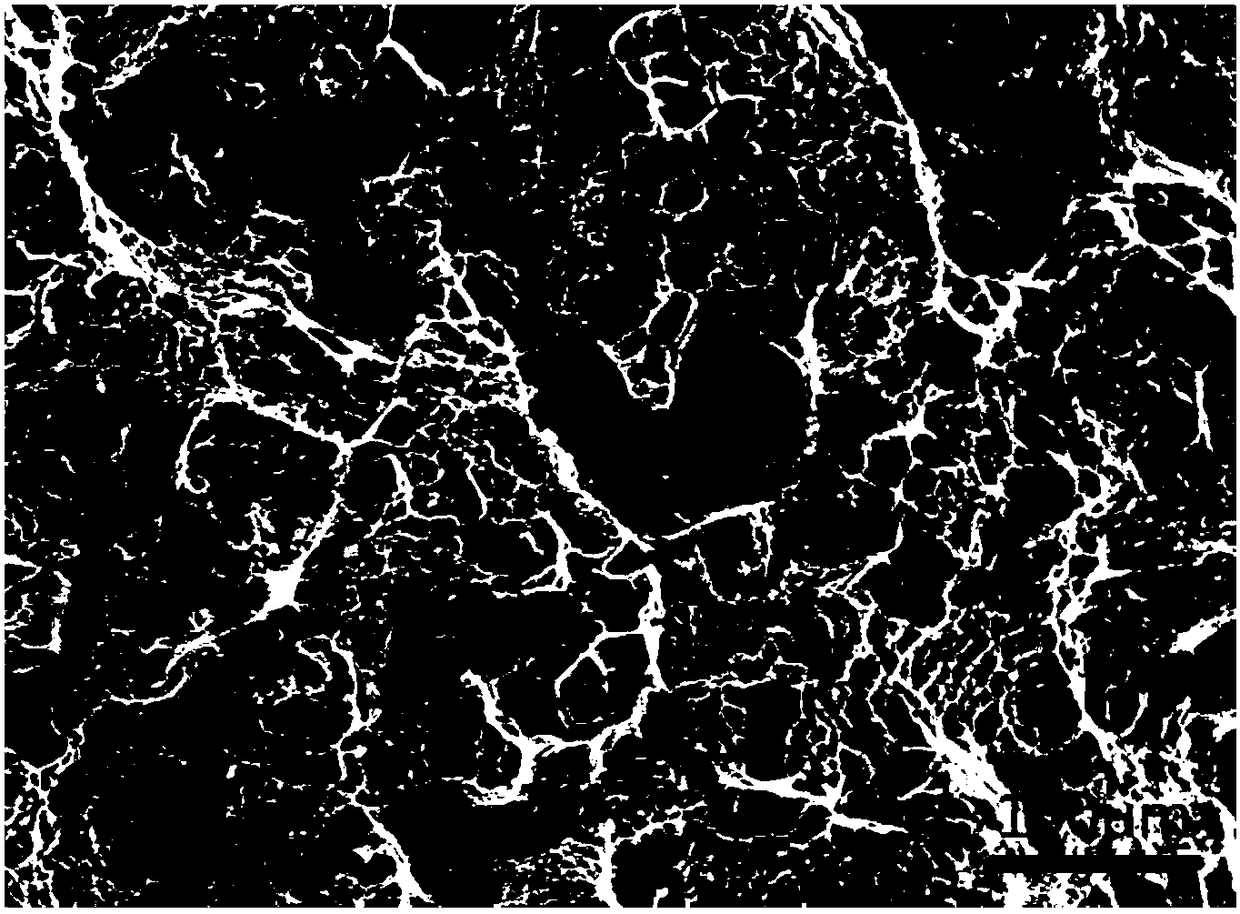

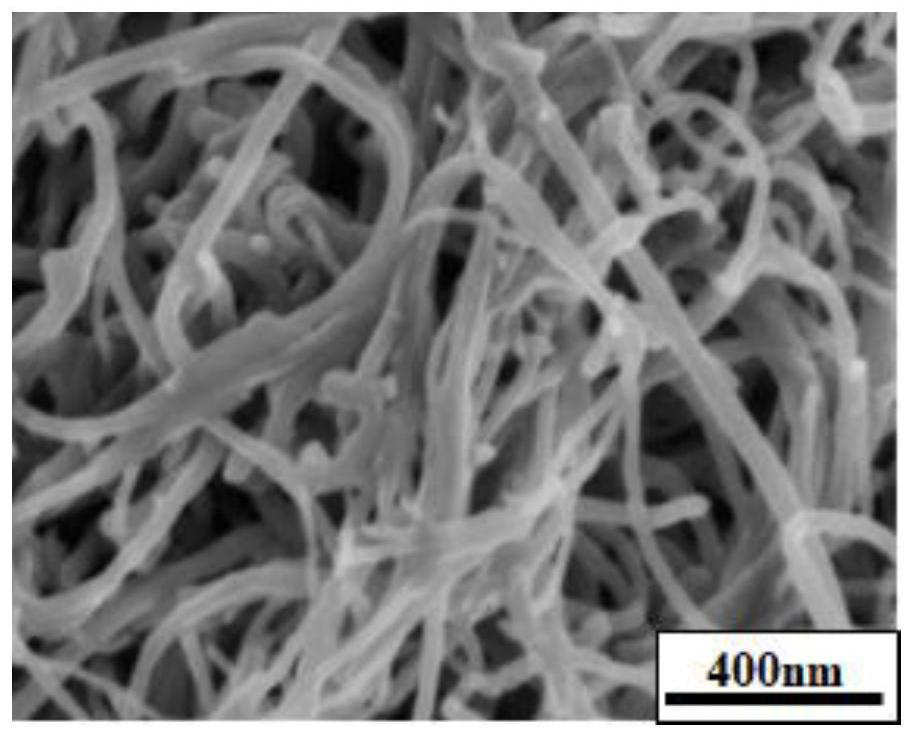

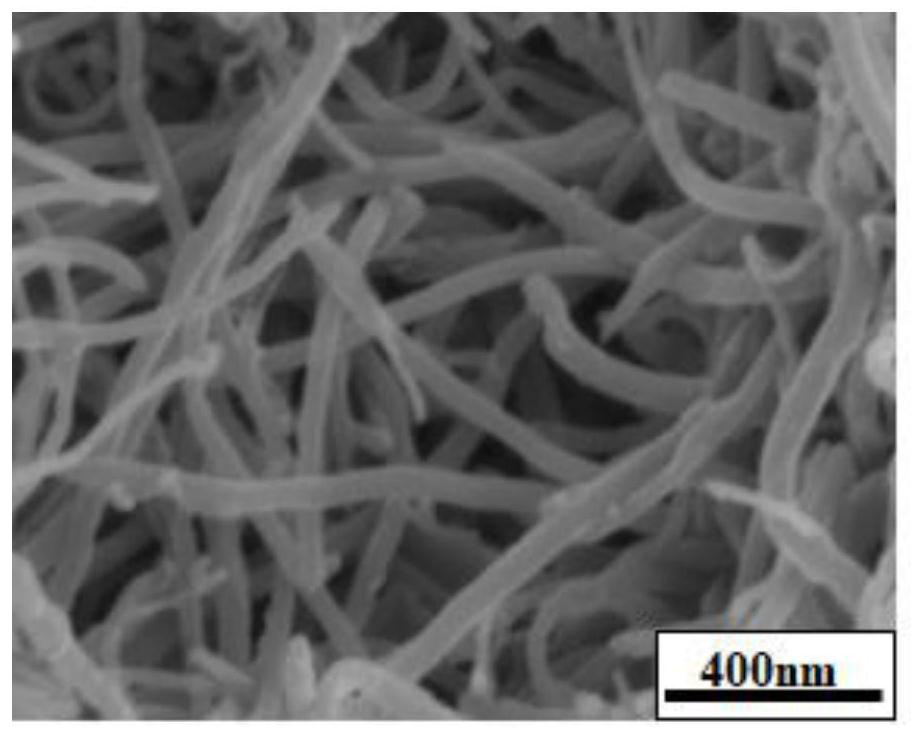

A kind of cnts reinforced magnesium-based composite material and preparation method thereof

The invention discloses a CNTs-reinforced magnesium-based composite material and a preparation method thereof. The CNTs are pre-dispersed by a chemical pretreatment method, and the CNTs-reinforced magnesium-based composite material is prepared by a stirring casting method. The results show that the chemical pretreatment composite stirring The casting method has a positive effect on the uniform dispersion of CNTs; the present invention aims at the poor wettability of CNTs on the metal interface, and the phenomenon that agglomeration easily occurs in the metal melt, and the magnesium alloy is used as the matrix and the CNTs are used as reinforcements. The CNTs / Mg-6Zn composite material is made after semi-solid stirring smelting, ultrasonic-assisted stirring, casting, solid solution and aging treatment under the action of the atmosphere. This preparation method has advanced technology and strict procedures. The prepared CNTs / Mg6ZnCNTs / Mg ‑6Zn composite material, after adding CNTs, the structure of CNTs / Mg‑6Zn composite material is more refined, and the grain size is obviously finer, which realizes fine grain strengthening; near the grain boundary of CNTs / Mg‑6Zn composite material, it can be found that With multiple second phases, CNTs hinder the movement of dislocations, resulting in the accumulation of dislocations, which plays a role in strengthening the second phase.

Owner:SHAANXI UNIV OF SCI & TECH

A method for preparing magnesium-zinc-yttrium quasicrystals and titanium carbide synergistically strengthened magnesium-based composites

ActiveCN113106277BAdvanced technologyAdvancedFoundry mouldsFoundry coresMagnesium matrix compositeTitanium carbide

The invention relates to a preparation method of a magnesium-zinc-yttrium quasicrystal and titanium carbide synergistically strengthened magnesium-based composite materials. Aiming at the poor mechanical properties of magnesium-based composite materials, the magnesium-zinc-yttrium quasicrystal and inner Synergistically strengthened magnesium-zinc-yttrium-zirconium alloys with raw titanium carbide, and made magnesium-zinc-yttrium quasicrystals and titanium carbide synergistically strengthened magnesium matrix composites through smelting, argon bottom blowing, mechanical stirring, electromagnetic stirring and extrusion casting; this preparation The method has advanced technology, strict procedures, and accurate and detailed data. The tensile strength of the prepared magnesium-based composite material reaches 268MPa, the hardness reaches 93.5Hv, and the elongation rate reaches 8.1%. It is an advanced synergistic strengthening of magnesium-zinc-yttrium quasicrystal and titanium carbide. Preparation method of magnesium-based composite material.

Owner:ZHONGBEI UNIV

Making method for quick-frozen sliced horse mackerel food

ActiveCN103549498BColor adjustableImprove freshnessFood freezingFood ingredient as taste affecting agentBiotechnologyAnimal science

The invention relates to a method for making quick-frozen horse mackerel fillet food, which uses fresh horse mackerel as raw material or fresh horse mackerel that has been frozen and soaked and thawed in salt water. Remove the abdominal bones and fish bones, then cut into fish fillets, wash the fish fillets and immerse them in the seasoning liquid prepared by melanin, red koji, soybean protein, lemon juice and water for dipping to taste, then place on a plate and sprinkle sesame seeds Afterwards, quick-freezing treatment is carried out, and quick-frozen horse mackerel fillet food is obtained after packaging and testing are qualified. The preparation method of the quick-frozen horse mackerel fish fillet food of the present invention has advanced technology, reasonable process, strong operability and high production efficiency; the fish fillet food produced by the method is safe and hygienic, stable in quality, nutritious and healthy, and can be produced after opening the package and thawing. Eating or heating, the meat is tender and soft, the taste is fresh and mellow, the flavor is unique, and there is no fishy smell.

Owner:威海蓝谷海洋生物科技有限公司

A Key Dispersion Method for Enhancing the Security of Symmetric Key System

ActiveCN102946311BImprove securityStrong reliabilityKey distribution for secure communicationPasswordNational standard

The invention discloses a key dispersion method for enhancing the security of a symmetric key system, and relates to the technical field of information security encryption, comprising the following steps: step (1), respectively injecting a secondary dispersion factor into a primary key management system; In step (2), the first-level key management system uses the national standard algorithm to perform distributed operations on the second-level dispersion factor with the designated key, and obtains the key data of the second-level key management system. The beneficial effect of the present invention is that: adopting the present invention, different dispersive factors can be distributed and calculated by specifying a key to obtain several pieces of different key data. This method avoids the single derivation and transformation method in which the random number is directly used as a key, provides multiple key derivation transformation methods, and enhances the security of the key derivation transformation process.

Owner:中电科网络安全科技股份有限公司

A web authentication method based on oauth2.0 password service middleware

ActiveCN109672675BSolve the security problem of single password authenticationStrict processUser identity/authority verificationWeb authenticationSecret code

The present invention provides a WEB authentication method based on OAuth2.0 cryptographic service middleware. First, the cryptographic service middleware applies to the authentication server for authorization authentication; the cryptographic service middleware performs DES on the user information and the smart cryptographic key PIN code submitted by the browser. Encrypted, and then sent to the authentication server; after receiving the request, the authentication server verifies the password service middleware information; the authentication server verifies the decrypted user information and PIN code, and after passing through, the server performs Subject login, encrypts the authorization certificate and returns it to the middleware ; After the middleware receives the authorization certificate, the middleware Subject logs in, and then requests to the authorization server; the authorization server verifies the decrypted authorization certificate, and issues an access token to the password service middleware after passing the verification. The invention combines the user password with the intelligent password key to further solve the problem of weak verification security of the single password of the OAuth2.0 protocol, the process is more rigorous, and the security guarantee of the authorization authentication process is strengthened.

Owner:成都三零瑞通移动通信有限公司

A method for preparing graphene-reinforced aluminum matrix composites by injection molding

The invention relates to a method for preparing a graphene-reinforced aluminum-based composite material by injection molding. Aiming at the situation that graphene is not uniformly dispersed in an aluminum alloy matrix and it is difficult to form a firm interface with the matrix, a semi-solid injection molding method is adopted. The alloy is the matrix and the graphene is the reinforcement. After powder mixing, feeding, quantitative transportation, heating, screw shearing, preparation of semi-solid slurry, and high-speed injection molding, the graphene-reinforced aluminum matrix composite material is made. This equipment method is advanced and The data is accurate and detailed, the process is rigorous, and the prepared graphene-reinforced aluminum-based composite material has a hardness of 82.2HV, a tensile strength of 235MPa, and an elongation of 7.22%. It is an advanced preparation method of graphene-reinforced aluminum-based composite materials.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com