Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Steady and straight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blast furnace iron-making raw material and blast furnace iron-making method

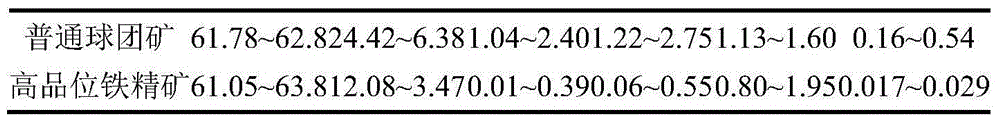

InactiveCN104531923ASteady and straightLow cost of industrializationBlast furnace detailsLow magnesiumBlast furnace

The invention provides a high-aluminum low-magnesium blast furnace iron-making raw material and a method for high-aluminum low-magnesium blast furnace iron-making by using the high-aluminum low-magnesium blast furnace iron-making raw material. The high-aluminum low-magnesium blast furnace iron-making raw material consists of high-aluminum low-magnesium sintered ore, pellet ore and raw ore; the blast furnace material is free of magnesium-containing ore; the high-aluminum low-magnesium sintered ore is prepared from a mixture of high-aluminum low-magnesium iron ore powder and auxiliary sintering materials in a sintering way; the pellet ore is ordinary pellet ore; the raw ore is high-grade iron ore concentrate. In the blast furnace iron-making process, the high-aluminum low-magnesium sintered ore and the ordinary pellet ore together with reasonably added raw ore are adopted, and appropriate blast furnace operation mechanisms are selected, so that the coal gas flow can be reasonably distributed in the blast furnace iron-making process, the blast furnace slag is good in property, the slag iron can be smoothly discharged, stable and smooth operation of a blast furnace is maintained, and the pig iron making cost is lowered.

Owner:SHANDONG IRON & STEEL CO LTD

Method for controlling abnormal furnace temperature of blast furnace according to temperature changes of cooling wall

ActiveCN103439999ASteady and straightImprove accuracyBlast furnace componentsAuxillary controllers with auxillary heating devicesFurnace temperatureSlag

The invention relates to a method for controlling the abnormal furnace temperature of a blast furnace according to temperature changes of a cooling wall. According to the method, the fall-off positions and the fall-off amount of blast furnace slag crusts are timely identified through the data mining technology according to the temperature conditions of the cooling wall of the blase furnace, cooling water inlet-outlet water temperature change conditions and blast furnace heat load change conditions, then the measures that additional coke is added inside the blast furnace through a furnace top PLC system and the air temperature, the coal powder injection amount and the oxygen enrichment amount of an air blower on the lower portion of the blast furnace are adjusted are further taken to enable the furnace temperature to be controlled to be in a stable level, the stable and smooth operation of the blast furnace is ensured, and the blast furnace can run at the optimum interval. The control accuracy of the abnormal furnace temperature of the blast furnace is improved, and the service life of the blast furnace is prolonged.

Owner:武汉钢铁有限公司

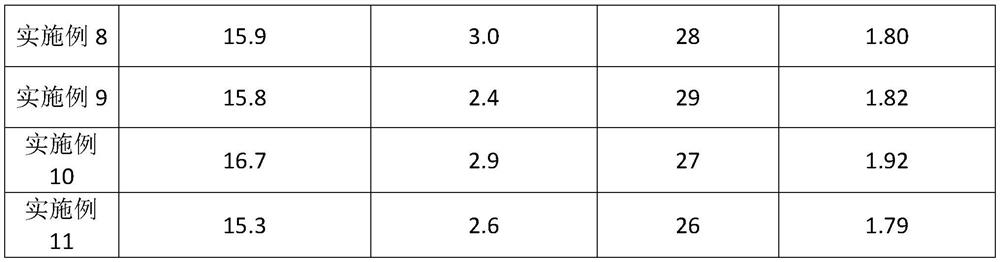

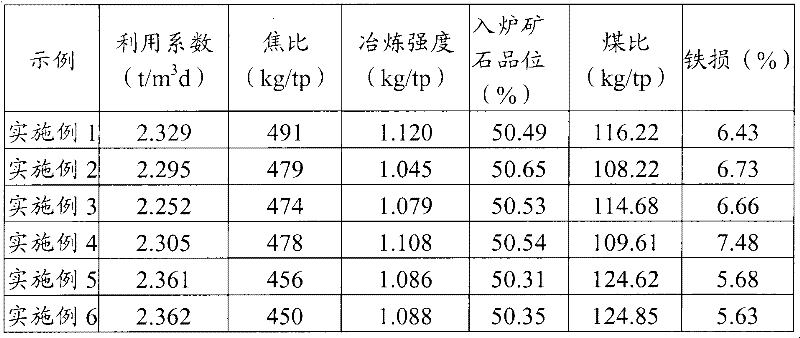

Method for smelting vanadium-titanium magnetite in blast furnace

ActiveCN102041331AImprove technical and economic indicatorsReduced stabilityBlast furnace detailsFurnace temperatureSlag

The invention provides a method for smelting vanadium-titanium magnetite in a blast furnace, which comprises the following steps of: controlling blast kinetic energy, air quantity and air speed of the blast furnace with different furnace volume in different ranges respectively, and forming an air inlet with the length of 450 to 480mm on the two sides of an iron notch of the blast furnace respectively; controlling the blast oxygen enrichment rate in the range of 2.6 to 3.0 percent; controlling the blast temperature in the range of 1,150 to 1,200 DEGC; and controlling the furnace temperature of the blast furnace in the range of 1,450 to 1,500 DEG C. By methods of adjusting the blast kinetic energy, blast volume and the blast temperature, controlling feeding rate, the reaction temperature of the blast furnace and slag basicity, and the like, the strengthened smelting of the vanadium-titanium magnetite in the blast furnace is realized, the utilization factor of the blast furnace is improved, and iron loss is reduced.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Preparation method of iron ore powder pelletized magnesian binding agent

A preparation method of an iron ore powder pelletized magnesian binding agent comprises the following processing steps that firstly, mixed adding is carried out, wherein, according to raw material ratio, 90%-95% of sepiolite and 5%-10% of magnesia are included, and according to the mass percent of the prepared chemical components, SiO2 is smaller than 60%, MgO is larger than 18%, Al2O3 ranges from 3% to 6%, the blue absorption power ranges from 18m.mol / 100g to 20m.mol / 100g, the two-hour water absorption rate ranges from 100% to 105%, the expansion capacity ranges from 2ml / g to 3ml / g, and after raw materials are prepared, a spiral stirrer or cylindrical mixer is used for full mixing; secondly, rough breaking is carried out, wherein a hammer type breaker or jaw type breaker is used for breaking a mixture of the sepiolite and the magnesia to be particles with the granularity smaller than 3 mm; and thirdly, grinding is carried out, wherein a raymond mill or medium-speed mill is used for continuously grinding the mixture broken to the particles with the granularity smaller than 3 mm in a fine manner to -200 meshes, and the occupation is above 95%. The magnesian binding agent is used for replacing bentonite and other efficient binding agents for producing, the pelletizing performance is greatly improved, the pressure of MgO is improved while the sintered ore is reduced, stability and the improvement of the quality of the sintered ore are facilitated, and the production process is simple.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Online switching process for blast furnace blowers

InactiveCN109234480ASteady and straightLow running costBlast furnace componentsBlast furnace detailsMetallurgyCheck valve

The invention discloses an online switching process for blast furnace blowers. The online switching process comprises the following steps that (1) when molten iron is output from a blast furnace, a standby blower is started, and the wind outlet pressure of the standby blower is regulated to F+(4-6) kPa, wherein F is equal to 70-75% of the wind outlet pressure of a main blower before the molten iron is output from the blast furnace; (2) after the molten iron is output from the blast furnace, the wind outlet pressure of the main blower is regulated to the value of F selected in the first step, and a wind supply valve and a communication valve in a standby wind supply pipe network are opened; and (3) under the condition that wind outlet pressure fluctuation of the main and standby blowers iscontrolled at + / -5 kPa, a valve on a diffusion pipeline in the standby wind supply pipe network is gradually closed, a valve on a diffusion pipeline in a main wind supply pipe network is gradually opened at the same time until a check valve on a wind supply pipeline in the main wind supply pipe network is automatically closed due to the decreased wind volume, and then a wind supply valve and a communication valve in the main wind supply pipe network are closed. By means of the online switching process, the main and standby blowers can be switched online in stable, rapid and safe modes.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

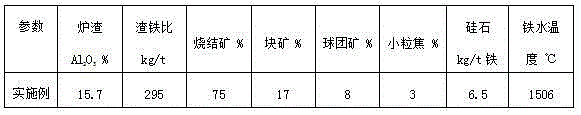

Blast furnace high-aluminum slag smelting method

InactiveCN106555019AImprove breathabilitySteady and straightBlast furnace detailsBlast furnace smeltingMaterials science

The invention discloses a blast furnace high-aluminum slag smelting method to mainly solve the technical problems of unstable production and high blast furnace molten iron smelting cost of blast furnace high-aluminum slag smelting blast furnaces in the prior art. The blast furnace high-aluminum slag smelting method comprises the following steps: 1, preparing a raw material: preparing the raw material according to the following control requirements: the slag-iron ratio is not more than 300 kg / t and the mass percentage content of Al2O3 in the slag is not more than 17%, adding small-size coke to the raw material, uniformly mixing the raw material and the small-size coke to form ore layers, wherein the raw material comprises, by mass, 70-80% of sintered ores, 15-17% of lump ores and 3-15% of pellet ores, and the small-size coke accounts for 2-5% of the mass of the raw material; 2, distributing: alternately distributing the coke and the ore layers in a blast furnace to form layer and coke layer alternating structure; 3, carrying out blast furnace smelting; and 4, normally discharging iron. The method realizes low-cost high-aluminum slag smelting of the blast furnace.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Method for controlling abnormal furnace temperature of blast furnace according to temperature changes of cooling wall

ActiveCN103439999BSteady and straightImprove accuracyBlast furnace componentsAuxillary controllers with auxillary heating devicesFurnace temperatureSlag

The invention relates to a method for controlling the abnormal furnace temperature of a blast furnace according to temperature changes of a cooling wall. According to the method, the fall-off positions and the fall-off amount of blast furnace slag crusts are timely identified through the data mining technology according to the temperature conditions of the cooling wall of the blase furnace, cooling water inlet-outlet water temperature change conditions and blast furnace heat load change conditions, then the measures that additional coke is added inside the blast furnace through a furnace top PLC system and the air temperature, the coal powder injection amount and the oxygen enrichment amount of an air blower on the lower portion of the blast furnace are adjusted are further taken to enable the furnace temperature to be controlled to be in a stable level, the stable and smooth operation of the blast furnace is ensured, and the blast furnace can run at the optimum interval. The control accuracy of the abnormal furnace temperature of the blast furnace is improved, and the service life of the blast furnace is prolonged.

Owner:武汉钢铁有限公司

Determining method of reasonable oxygen enrichment rate of blast furnace

InactiveCN109112240ASteady and straightReduce consumptionBlast furnace detailsDesign optimisation/simulationCoalMaterials science

The invention relates to a determining method of the reasonable oxygen enrichment rate of a blast furnace. The determining method is characterized in that aiming at the blast furnace with the effective furnace volume of 450-6,000 m<3> applying an oxygen enrichment process, in the daily production process, the blast volume, the spray-blow coal ratio, the volatile matter content of spray-blow mixedcoal powder, the grain size of the spray-blow mixed coal powder, the iron content of raw materials in the furnace, and the hot reactivity of coke in the furnace are taken as reference data to determine the reasonable oxygen enrichment rate of blasted hot air in the blast furnace. According to the operation indexes of the blast furnace in different stages, the mathematic correlation between the operation indexes and the oxygen enrichment rate of the blast furnace is built to determine the reasonable oxygen enrichment rate of the blasted hot air in the blast furnace, thus, stable operation of the blast furnace is achieved while production of the blast furnace is enhanced, and meanwhile, the effects of reducing fuel consumption and the production cost of iron making can be further achieved.

Owner:ANGANG STEEL CO LTD

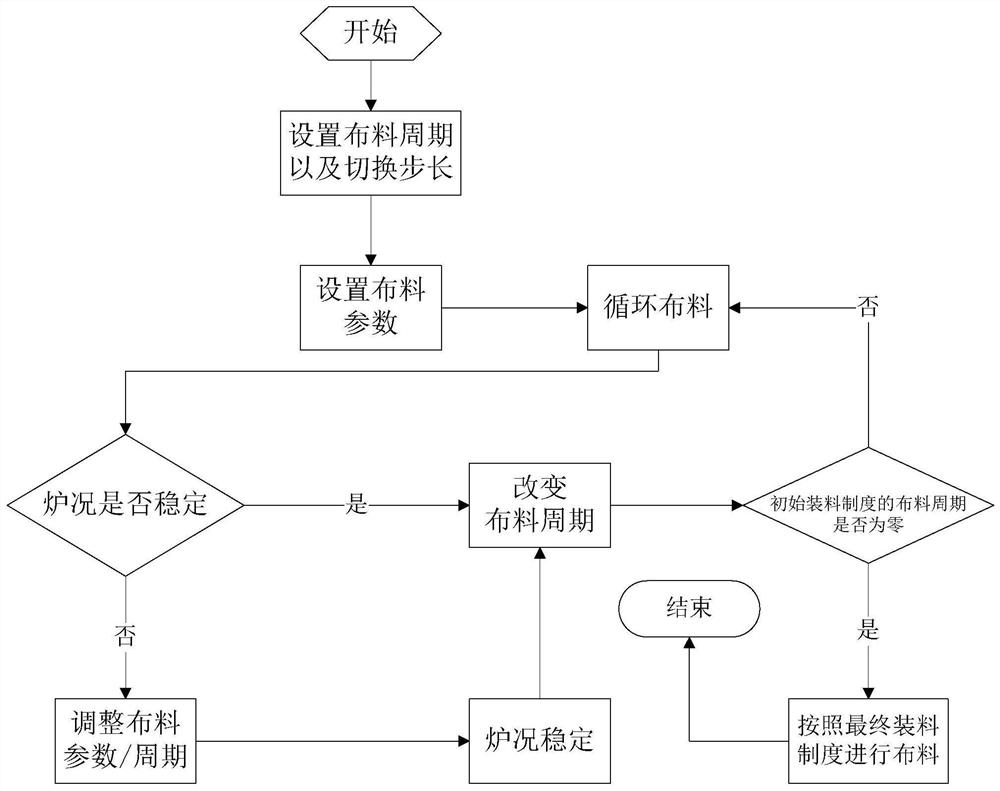

Control method for blast furnace top material distribution

ActiveCN114015826ASteady and straightAchieve fine-tuningBlast furnace detailsTotal factory controlProcess engineeringMaterial distribution

A control method for blast furnace top material distribution comprises the following steps that 1) the material distribution period of an initial charging system and the material distribution period of a final charging system are set, and the switching step length of the material distribution periods is set; 2) material distribution parameters of an initial charging system and a final charging system are set; 3) the blast furnace conducts circulating material distribution according to the initial charging system and the final charging system in sequence, and the furnace condition of the blast furnace is judged, specifically, if the furnace condition is not stable, material distribution parameters or material distribution periods of all the charging systems are adjusted; and if the furnace condition is stable, the material distribution period of the initial charging system is reduced once according to the switching step length of the material distribution period, and the material distribution period of the final charging system is increased once according to the switching step length of the material distribution period; and 4) the step 3) is repeated until the material distribution period of the initial charging system is zero.

Owner:CHONGQING IRON & STEEL GRP ELECTRONIC CO LTD

Tundish cover castable and method for preparing tundish cover by using same

ActiveCN113200753AImprove microstructureImprove heat transfer characteristicsMelt-holding vesselsProcess efficiency improvementAluminateMetallic aluminum

The invention relates to a tundish cover castable and a method for preparing a tundish cover by using the same, aiming at preventing the tundish cover from cracking, peeling, chipping and the like. The formula of the tundish cover castable comprises 55 to 65 wt% of alumina particles, 10 to 20 wt% of alumina fine powder, 2 to 4 wt% of silicon micro powder, 3 to 5 wt% of prefabricated powder, 5 to 10 wt% of prefabricated particles, 3 to 6 wt% of alumina micro powder, 0.1 wt% of metal aluminum powder, 3 to 6 wt% of aluminate cement, 1 to 3 wt% of stainless steel fiber, 0.1 wt% of sodium tripolyphosphate, 0.02 to 0.1 wt% of propylene glycol alginate and 4 to 6 wt% of water. The method for preparing the tundish cover by using the castable comprises the following steps: putting the mixed castable in a mold for vibration molding, conducting standing at room temperature for 24 hours, and then carrying out heat treatment at 110 DEG C for 24 hours.

Owner:山西昊业新材料开发有限公司

Raw material for blast furnace smelting and blast furnace smelting method

InactiveCN104531923BSteady and straightLow cost of industrializationBlast furnace detailsSmelting processBlast furnace smelting

The invention provides a high-aluminum and low-magnesium blast furnace smelting raw material and a method for using the charge for high-aluminum and low-magnesium blast furnace smelting, wherein the charge is composed of high-aluminum and low-magnesium sintered ore, pellets and raw ore, and the blast furnace No magnesium-containing ore is added to the burden. The high-alumina and low-magnesium sintered ore is sintered from a mixture of high-aluminum and low-magnesium iron ore powder and sintering auxiliary materials. The pellets are ordinary pellets. The raw ore It is a high-grade iron ore concentrate. The present invention selects high-alumina and low-magnesium sintered ore and ordinary pellets in the blast furnace smelting process, and rationally mixes raw ore. By selecting a suitable blast furnace operation system, the gas flow distribution in the blast furnace smelting process is reasonable, and the performance of the blast furnace slag is good. The smooth discharge of iron keeps the blast furnace running smoothly and reduces the cost of pig iron smelting.

Owner:SHANDONG IRON & STEEL CO LTD

A Rotary Kiln Air Guide Cover Structure

ActiveCN110360839BGuaranteed uptimeImprove cooling effectRotary drum furnacesEngineeringBolt connection

The invention discloses a rotary kiln air-guiding cover structure which comprises an air guiding cover, a rib plate and a barrel. The rib plate is located between the air guiding cover and the barrel;the air guiding cover and the rib plate are welded; the rib plate and the barrel are welded; and the barrel is arranged on a rotary kiln. The rotary kiln air-guiding cover structure is characterizedin that two groups of U-shaped connecting plates are further arranged on two sides of the rib plate and are arranged between the air guiding cover and the rib plate; the other two groups of connectingplates are arranged between the rib plate and the barrel; U-shaped ports of the connecting plates are connected onto the rib plate; threaded holes are correspondingly formed in the connecting plates,the air guiding cover and the rib plate; the connecting plates, the air guiding cover and the rib plate are connected through two-ended bolts in the threaded holes; threaded holes are correspondinglyformed in the connecting plates, the barrel and the rib plate; and the connecting plates, the barrel and the rib plate are connected through countersunk bolts in the threaded holes. The rotary kiln air-guiding cover structure provided by the invention runs stably and reliably under a high-temperature environment, the equipment failure rate is reduced, and the service life is prolonged.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

Conveyor chain automatic start-stop control method based on section steel conveyor chain control system

ActiveCN107600895BRealize automatic start-stop controlSteady and straightConveyorsControl devices for conveyorsProduction lineControl system

The invention provides an automatic conveyor chain start / stop control method based on a profile steel conveyor chain control system. The automatic conveyor chain start / stop control method is applicable to the technical field of electrical drive control. According to the method, the automatic start / stop control over the advancing step pitch of a conveyor chain is achieved through a circulatory-pulse generator under different duty ratios, automatic start / stop control over the advancing step pitch of the conveyor chain is achieved under the condition of not using a conveyor chain moving positiondetection encoder, the problem that the conveyor chain moving position detection encoder frequently fails due to the poor working environment is solved, and the stable operation of a large H-shaped steel production line is guaranteed.

Owner:MAANSHAN IRON & STEEL CO LTD

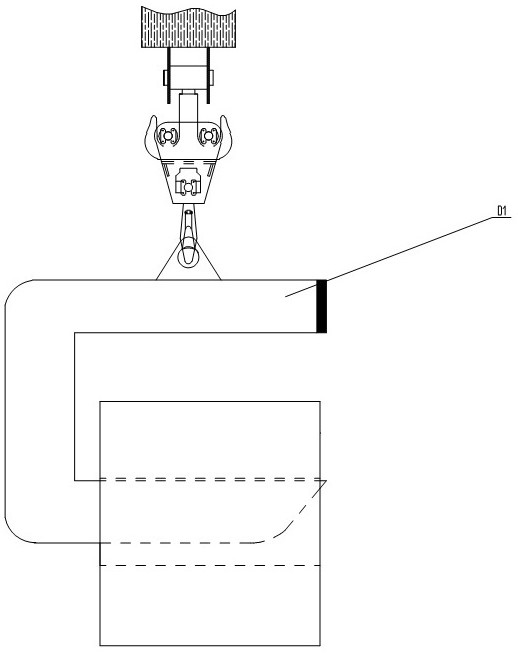

Single-hook and double-hook conversion type hook head of hoisting equipment

PendingCN113860148AQuick conversionIncrease profitLoad-engaging elementsIndustrial engineeringLifting equipment

The invention discloses a single-hook and double-hook conversion type hook head of hoisting equipment. The single-hook and double-hook conversion type hook head comprises a double-hook hook head connected to the hoisting equipment, wherein the lower end of the double-hook hook head is detachably connected with a single-hook hook head; two connecting pieces are arranged on the upper portion of the single-hook hook head, and when the single-hook hook head is connected to the double-hook hook head, the two connecting pieces are clamped in grooves of the double-hook hook head correspondingly; and each connecting piece is a convex hanging rod, a hook or a hanging ring. According to the single-hook and double-hook conversion type hook head of the hoisting equipment, the utilization rate of the 80T crown block in the production process can be improved; and particularly, after finished steel coil transportation equipment breaks down, an anchor-head-hook hook head can be quickly converted into the single-hook hook head, and the single-hook hook head can be matched with a C-shaped lifting appliance to participate in the operation activity of lifting finished steel coils from a coiling machine, so that the production rhythm is stabilized, the production guarantee is improved, the accident potential of production interruption is completely eradicated, and stable and smooth production is ensured.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Sintered iron-containing material, sintered composition, sintered ore and preparation method thereof

The invention provides a sintered iron-containing material, a sintered composition, sintered ore and a preparation method of the sintered ore, and belongs to the technical field of blast furnace smelting. The sintered iron-containing material comprises, by mass, 5%-11% of Brazil SFLA fines, 14%-20% of yandi fines, 19.5%-25.5% of Australia PB fines, 20%-25.5% of Brazil BRBF fines, 4%-10% of iron concentrate fines, 8%-12% of iron-containing sundries and 10%-14% of sintered return fines. The sintered composition comprises, by mass, 80%-84% of the sintered iron-containing material, 4%-5% of fuel and the balance solvent. The preparation method of the sintered ore includes the steps that sintering processing is conducted on the sintered composition, and the sintered ore is obtained by sinteringthe sintered composition. The sintered ore good in molten drop performance is obtained by replacing part of fine powder with the Brazil SFLA fines, and cost of sintered ore blending is reduced by effectively using the Brazil SFLA fines.

Owner:SGIS SONGSHAN CO LTD

Method for smelting vanadium-titanium magnetite in blast furnace

ActiveCN102041331BImprove technical and economic indicatorsReduced stabilityBlast furnace detailsFurnace temperatureSlag

The invention provides a method for smelting vanadium-titanium magnetite in a blast furnace, which comprises the following steps of: controlling blast kinetic energy, air quantity and air speed of the blast furnace with different furnace volume in different ranges respectively, and forming an air inlet with the length of 450 to 480mm on the two sides of an iron notch of the blast furnace respectively; controlling the blast oxygen enrichment rate in the range of 2.6 to 3.0 percent; controlling the blast temperature in the range of 1,150 to 1,200 DEGC; and controlling the furnace temperature ofthe blast furnace in the range of 1,450 to 1,500 DEG C. By methods of adjusting the blast kinetic energy, blast volume and the blast temperature, controlling feeding rate, the reaction temperature ofthe blast furnace and slag basicity, and the like, the strengthened smelting of the vanadium-titanium magnetite in the blast furnace is realized, the utilization factor of the blast furnace is improved, and iron loss is reduced.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

A kind of ore ball mixing method

ActiveCN111763790BReduce scrollingPrevent moving upBlast furnace detailsProcess efficiency improvementSlagProcess engineering

Owner:XINXING DUCTILE IRON PIPES CO LTD

Method of matching coke into furnace during blast furnace smelting

ActiveCN106399607BMeet smelting requirementsSolve the technical problems of simultaneously entering the furnaceBlast furnace detailsSmelting processBlast furnace smelting

The invention discloses a method for matching coke and adding the coke into a furnace in the blast furnace smelting process. The technology of the method comprises the steps that according to the smelting need, the coke is matched according to the high-low sequence of indexes and added into the blast furnace; according to the indexes from high to low, CSR>M10>the average grain size>M40>the ash content>CRI>the sulfur content; the coke is firstly matched according to the indexes of the highest sequence and added into the blast furnace; if the operation state of the blast furnace is good, coke index modification is stopped; if the operation state of the blast furnace is still poor, the coke is matched according to the indexes of the next sequence and added into the blast furnace; and whether the coke is matched according to the indexes of the next sequence or not is judged according to the operation state of the blast furnace till the operation state of the blast furnace is good. According to the method, the technical aim of adding multiple kinds of coke into the furnace at the same time can be achieved, the situation of excessive coke indexes is avoided, and high-quality coking coal resources are saved; and it is guaranteed that the blast furnace stably and smoothly operates, and meanwhile the ironmaking cost is reduced. The method has the beneficial effects of being simple in technology, high in operability and easy to implement.

Owner:TANGSHAN IRON & STEEL GROUP

Method for calculating blast furnace burden distribution drop point based on laser measurement data

InactiveCN113699291AImprove accuracyIncrease profitBell-and-hopper arrangementBlast furnace detailsThermodynamicsCoke

The invention relates to a method for calculating a blast furnace burden distribution drop point based on laser measurement data. The method comprises the following steps of 1, calibrating basic data; 2, dividing a calculation range; 3, calculation of any angle under a basic stock line; and 4, calculating the inclination angle of any chute under any stock line. According to the technical solution, on the basis of material flow data measured by laser when a blast furnace is opened, a series of derivation calculation methods are used for calculating the material distribution drop points of ore and coke at different chute inclination angles and different material lines, and accurate basic data are provided for fine adjustment of an upper system of the blast furnace.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A red coke quenching method and coke quenching device

ActiveCN113088298BShorten the soaking timeReduce moisture contentCoke quenchingAqueous dropletPhysical chemistry

The invention provides a red coke quenching method and a coke quenching device, which belong to the technical field of coking. The method includes: water-drawing and quenching the red coke to obtain the first coke; atomizing and quenching the first coke coke to obtain wet quenched coke; in the atomized coke quenching, the relationship between the fog droplets and the first coke temperature conforms to the following relationship: when the temperature of the first coke is ≥400°C, the fog droplets are composed of 30-50% of the volume fraction Composed of air and water droplets with a volume fraction of 50-70%; when the temperature of the first coke is ≥150°C and <400°C, the fog droplets are composed of air with a volume fraction of 60-80% and water droplets with a volume fraction of 20-40% . The coke quenching method provided by the present invention can control the moisture content in the coke to 3.25-3.45%, the moisture content is low, the quality of the coke is improved, and the maximum moisture content is 4.5-4.9%, and the minimum moisture content is 2.1-2.5%. , the fluctuation range is reduced, the moisture is more uniform, and the coke ratio and fuel ratio are reduced due to the guarantee of the smooth running of the blast furnace.

Owner:武汉钢铁有限公司

A Method of Controlling Blast Furnace Gas Flow Distribution by Measuring Blast Furnace Ratio of Ratio of Raw Materials with Phased Array Radar

The invention discloses a method for controlling the blast furnace gas flow distribution by using a phased array radar to measure the ore coke ratio of a blast furnace material surface. According to the method, the target O / C ratio distribution curves under different furnace conditions are firstly determined and gas flow adjusting case databases are established, the gas flow adjusting case database is selected and the adjusting principle is determined, the O / C ratio distribution condition of the furnace top material distribution is directly calculated under the premise of consideration of the furnace material descending, the influence of the bottom layer material surface shape, and the influence of the furnace material collapsing, and by comparing the corresponding relationship between the material distribution and the gas flow distribution and by controlling the furnace top gas flow distribution through the targeted material distribution, the precise gas flow adjusting is achieved, and the empirical blast furnace top gas flow control is improved to the quantification level so as to achieve the stable and smooth operating of the blast furnace.

Owner:武汉钢铁有限公司

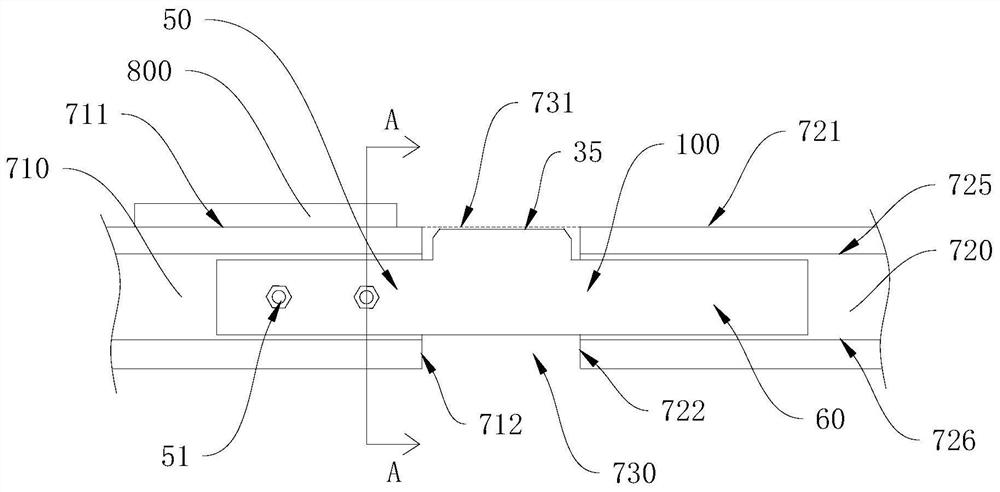

Fracture correction device and track power slide line system

ActiveCN111817094BEliminate fracture failureSteady and straightCoupling device connectionsCoke burnerControl theory

The application relates to a fracture correction device and a track power slide wire system, which belong to the technical field of coke oven electrics. The present application proposes a fracture correction device, including: an installation part, which is used to install on the slide line of the first track; a positioning part, which is located at the end of the fracture correction device away from the installation part, and is used for positioning the second track Slide the line to limit the longitudinal deviation range and lateral deviation range at the fracture. The present application also proposes a track power slide wire system, which includes a plurality of track slide wires connected in series in sequence, a fracture is set between two adjacent track slide wires among the plurality of track slide wires, and each fracture is arranged with one of the above-mentioned Fracture correction device. The use of the fracture correction device at the fracture can effectively prevent the occurrence of fracture faults in the rail power slide line system and ensure the stable and smooth operation of the coke oven vehicle power supply system.

Owner:SGIS SONGSHAN CO LTD

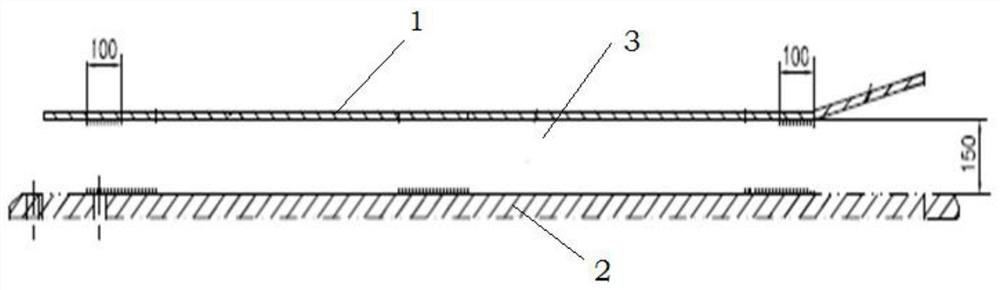

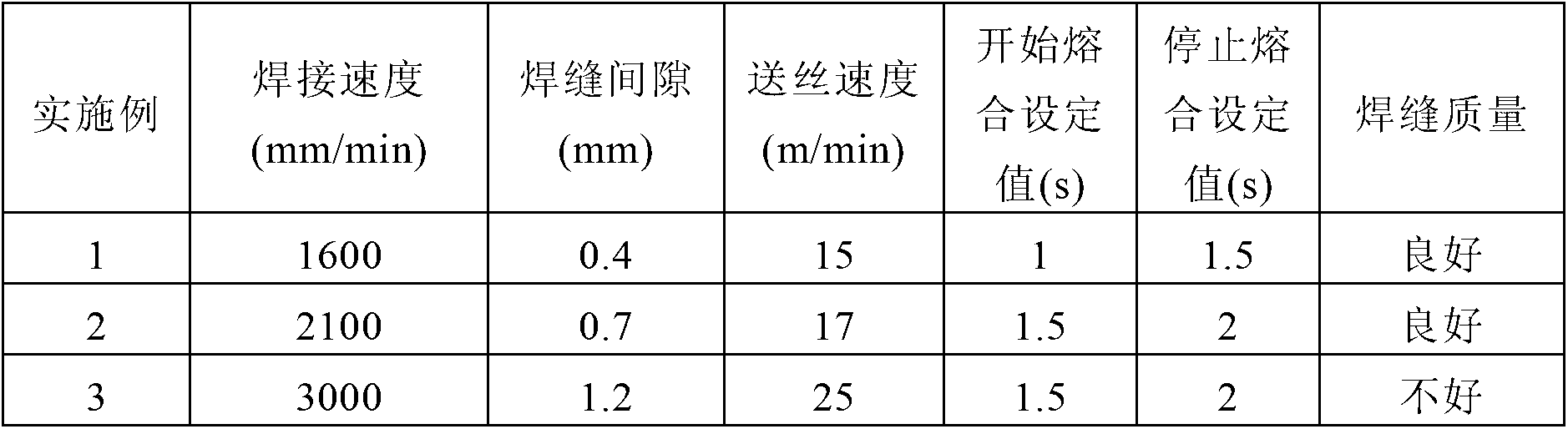

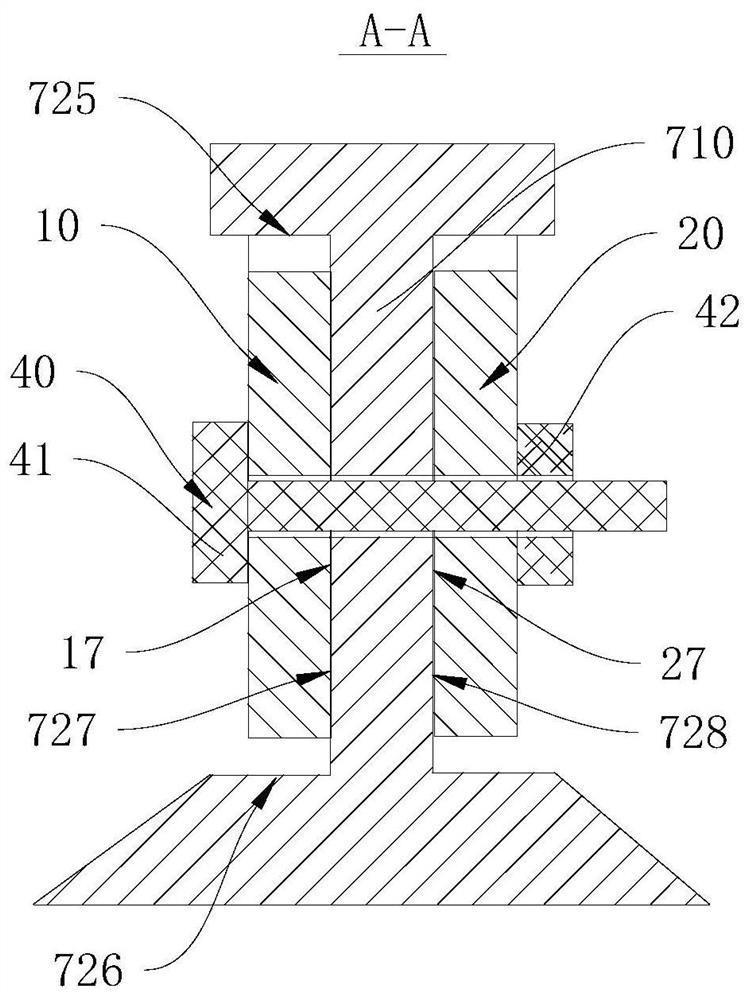

Stable welding method for argon arc welding of high-silicon-content silicon steel

ActiveCN102451946BImprove surface qualityDiffusion fastWelding/cutting media/materialsWelding electrode featuresAbnormal growthsStopping set

The invention relates to a stable welding method for the argon arc welding of high-silicon-content silicon steel which containing more than 2%of Si, which comprises the following steps: carrying out structural design on a welding inverse electrode for supporting the formation of weld seams, designing an electrode groove in the length direction on the upper surface of the welding inverse electrode, and designing the cross section of the electrode groove into a circular arc, wherein the width of the electrode groove is 4-10mm, the radius of the circular arc is 5.5-15.5mm, and the depth of the arc-shaped electrode groove is 0.6-3.6mm; and welding, and arranging a steel plate to be welded on the welding inverse electrode, wherein the welding seam clearance is 0.4-2.0mm, the welding speed is 1500-2900mm / min, the wire feed speed is 10-35m / min, and the fusion start set value and the fusion stop set value are respectively set to 0.1-1.5s and 0.2-2.0s. The stable welding method for the argon arc welding greatly improves the quality of lower surfaces of welding seams, the infused energy can be diffused more quickly, the abnormal growth of crystal grains can not be found in the thermal reaction region, and the mechanical property of the welding seams is greatly enhanced.

Owner:BAOSHAN IRON & STEEL CO LTD

Pore channel cooling method of damaged cooling wall of blast furnace and device thereof

Owner:NANJING IRON & STEEL CO LTD

A method for controlling the cold rolling of high-silicon thin strip non-oriented silicon steel

ActiveCN110369497BEasy to wearSteady and straightTemperature control deviceMetal rolling arrangementsEngineeringStrip steel

The invention relates to a method for controlling the cold rolling of high-silicon thin strip non-oriented silicon steel. In the cold-rolled non-oriented silicon steel, by weight percentage: Si≥3.0%, Al≥0.8%, finished product thickness≤0.35mm; During the pass rolling, thickness transition rolling is adopted within 30-50m from the tail of the strip, and at least 2 pairs of friction rollers are installed in front of the rolling mill on the strip-threading side of the second pass of cold rolling to frictionally heat the edge of the strip. . In the present invention, a friction roller is added after the cold rolling uncoiling equipment of the single-stand reversible rolling mill, and it is put into use when the strip is threaded and started in the second pass of cold rolling, and it is stopped when the thickness of the strip steel transitions to the normal control range, and at the same time, it is controlled by the cold rolling process , so that the edge of the strip is heated more evenly, reducing the difficulty of production and reducing the rate of brittle fracture.

Owner:ANGANG STEEL CO LTD

A timing gear protection device for a molding machine

The invention provides a timing gear protecting device of a forming machine. The timing gear protecting device comprises a limiting switch and a motor control device. The limiting switch is installedon a backward track of a movable roller of the forming machine and composed of a limiting touch plate and a switch body, wherein the switch body is an electric contact switch, and the original state of a pair of electric contacts is a connection state; the motor control device is connected in a power circuit of the forming machine, and the motor control device is an electric connection device which is formed by a forward compression roller instruction relay in the power circuit of the forming machine, contacts of the forward compression roller instruction relay, a backward compression roller instruction relay in the power circuit of the forming machine, contacts of the backward compression roller instruction relay, a detection limiting relay, contacts of the detection limiting relay, a forward maintenance relay, contacts of the forward maintenance relay, a backward maintenance relay, contacts of the backward maintenance relay, a forward maintenance button, a backward maintenance button, a limiting switch, an alarm light, an forward solenoid valve of the forming machine, a backward solenoid valve and a main motor frequency converter of the forming machine. By means of the timing gear protecting device, the gap expanding situation of compression rollers can be reflected in real time, and the situation is avoided that the gap between a fixed roller and a moving roller is excessively expanded, so that equipment failures are caused.

Owner:BAOSHAN IRON & STEEL CO LTD

Blast Furnace Real-time Material Line Calculation Method and Device

ActiveCN104451011BLong-term stabilitySteady and straightBlast furnace detailsChecking devicesAir volumeDisplay device

The invention relates to a method for computing real-time stockline of a blast furnace. The method comprises the following steps: computing the oxygen amount o of a tuyere zone; computing the weight V of required dried cokes for burning in the tuyere zone; computing the falling head C of material batches in the furnace; computing the height P of a material batch newly added into the furnace; and computing the latest stockline X. The invention also relates to a device for computing the real-time stockline of the blast furnace by using the method, and the device comprises a sensor for acquiring different data, a PLC controller, a data analysis server and a display. By adopting the method and the device provided by the invention, the charge level height position in the blast furnace is computed according to carbon balance of blast furnace smelting and combining information including operation air volume of the blast furnace, crude fuel structures and the like, so that the problem of damping down caused by stock rod faults at the top of the furnace during blast furnace production is solved, and a guarantee for long-term stable running of the blast furnace and cost conservation is provided.

Owner:恒创数字科技(江苏)有限公司

Fracture deviation rectifying device and rail power supply slide wire system

ActiveCN111817094AEliminate fracture failureSteady and straightCoupling device connectionsCoke burnerEngineering

The invention relates to a fracture deviation rectifying device and a rail power supply slide wire system, and belongs to the technical field of coke oven electricity. The fracture deviation rectifying device comprises a mounting part used for mounting a first rail slide wire, and a positioning part located at the end, away from the mounting part, of the fracture deviation rectifying device and used for positioning a second rail slide wire so as to limit the longitudinal deviation range and the transverse deviation range of the fracture. The invention further provides a rail power supply slidewire system, the rail power supply slide wire system comprises a plurality of rail slide wires which are sequentially connected in series, a fracture is formed between every two adjacent rail slide wires, and each fracture is provided with one fracture deviation rectifying device. When the fracture deviation rectifying device is used at the fracture, the fracture fault of the rail power supply slide wire system can be effectively avoided, and stable and smooth operation of a coke oven vehicle power supply system is ensured.

Owner:SGIS SONGSHAN CO LTD

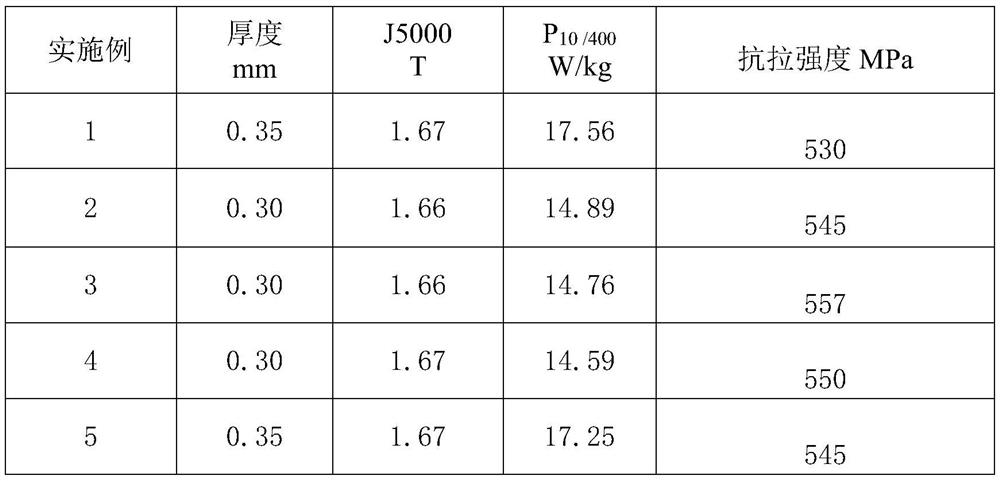

A kind of non-oriented silicon steel for driving motor and its production method

ActiveCN110241362BSteady and straightReduce broken beltProcess efficiency improvementChemical compositionElectric machine

The invention relates to the field of manufacturing non-oriented silicon steel, in particular to a production method of a cold-rolled non-oriented silicon steel product for driving motors of new energy vehicles. Its chemical composition is wt%: C≤0.0030, Si: 3.0~3.3, Mn: 0.5~1.0, P: 0.005~0.010, S: 0.0016~0.0025, N≤0.0035, Als: 1.0~1.5, Cu: 0.30~0.50 , Nb: 0.0020 ~ 0.0040, the rest are Fe and unavoidable residual elements. Among them, control [Si]+[Al]+[Mn]: 4.5~5.5, [Cu] / [S]: 120~320. The present invention adopts reasonable chemical composition design and adopts the above-mentioned control process to obtain a non-orientation drive motor with excellent electromagnetic properties, good mechanical properties, simple preparation process, short production cycle, and low production cost. Silicon steel.

Owner:ANGANG STEEL CO LTD

Red coke quenching method and quenching device

ActiveCN113088298AShorten the soaking timeReduce moisture contentCoke quenchingAqueous dropletPhysical chemistry

The invention provides a red coke quenching method and a quenching device, and belongs to the technical field of coking. The method comprises the following steps: carrying out water quenching on red coke to obtain first coke; carrying out atomization quenching on the first coke to obtain wet quenched coke. In the atomization coke quenching, fog drops and a first coke temperature meet the following relation: when the first coke temperature is greater than or equal to 400 DEG C, the fog drops consist of air with the volume fraction of 30-50% and water drops with the volume fraction of 50-70%; when the first coke temperature is greater than or equal to 150 DEG C and less than 400 DEG C, the fog drops consist of air with the volume fraction of 60-80% and water drops with the volume fraction of 20-40%. By adopting the coke quenching method provided by the invention, the moisture content in the coke can be controlled to be 3.25-3.45%, the moisture content is low, the quality of the coke is improved, the maximum moisture value is 4.5-4.9%, the minimum moisture value is 2.1-2.5%, the fluctuation range is reduced, the moisture is more uniform, and the coke ratio and the fuel ratio are reduced because the stable and smooth operation of the blast furnace is ensured.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com