Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Speed up the breakaway" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

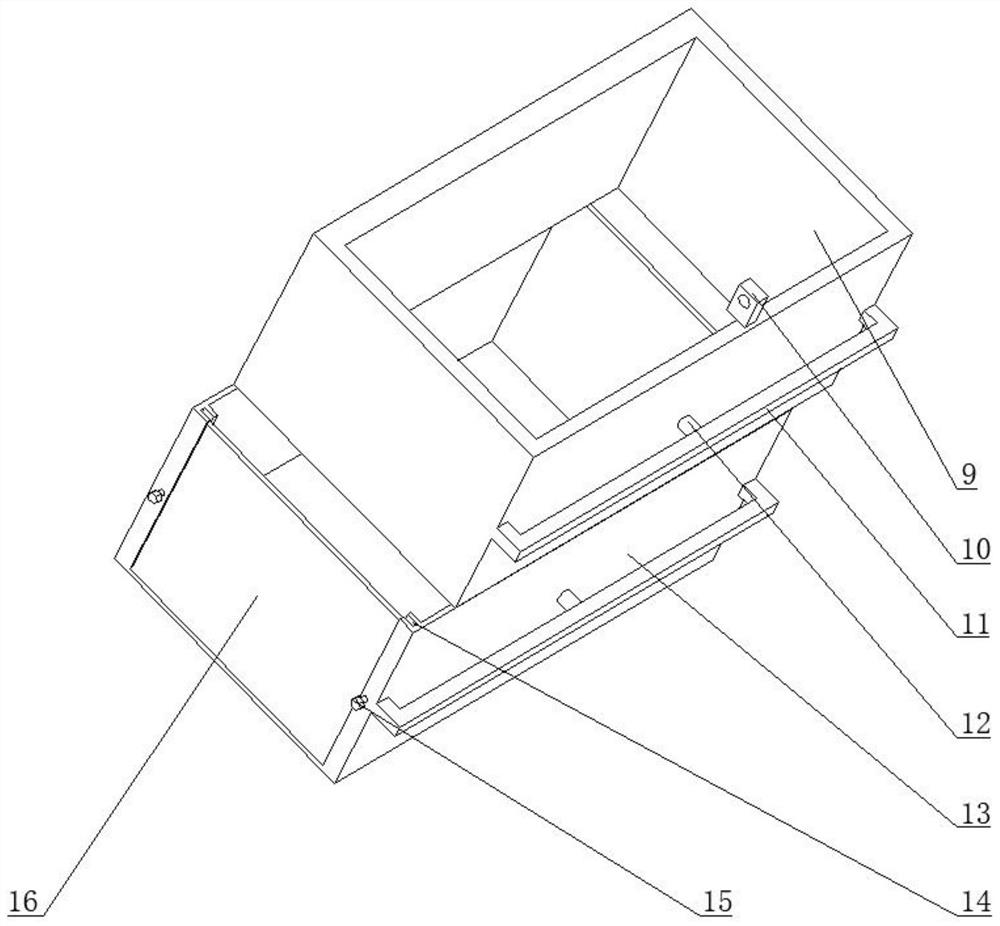

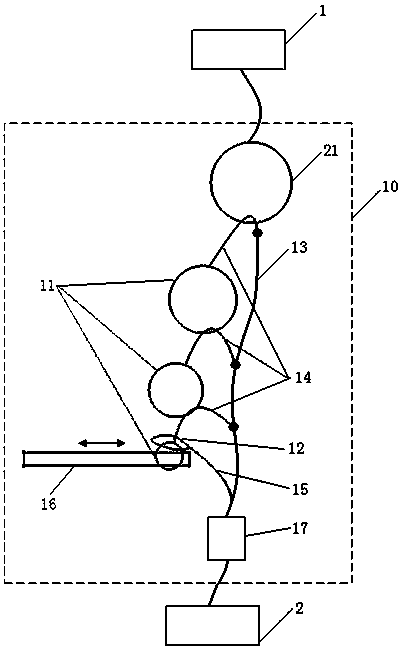

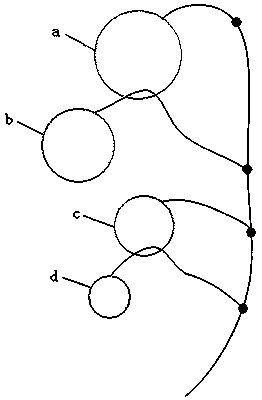

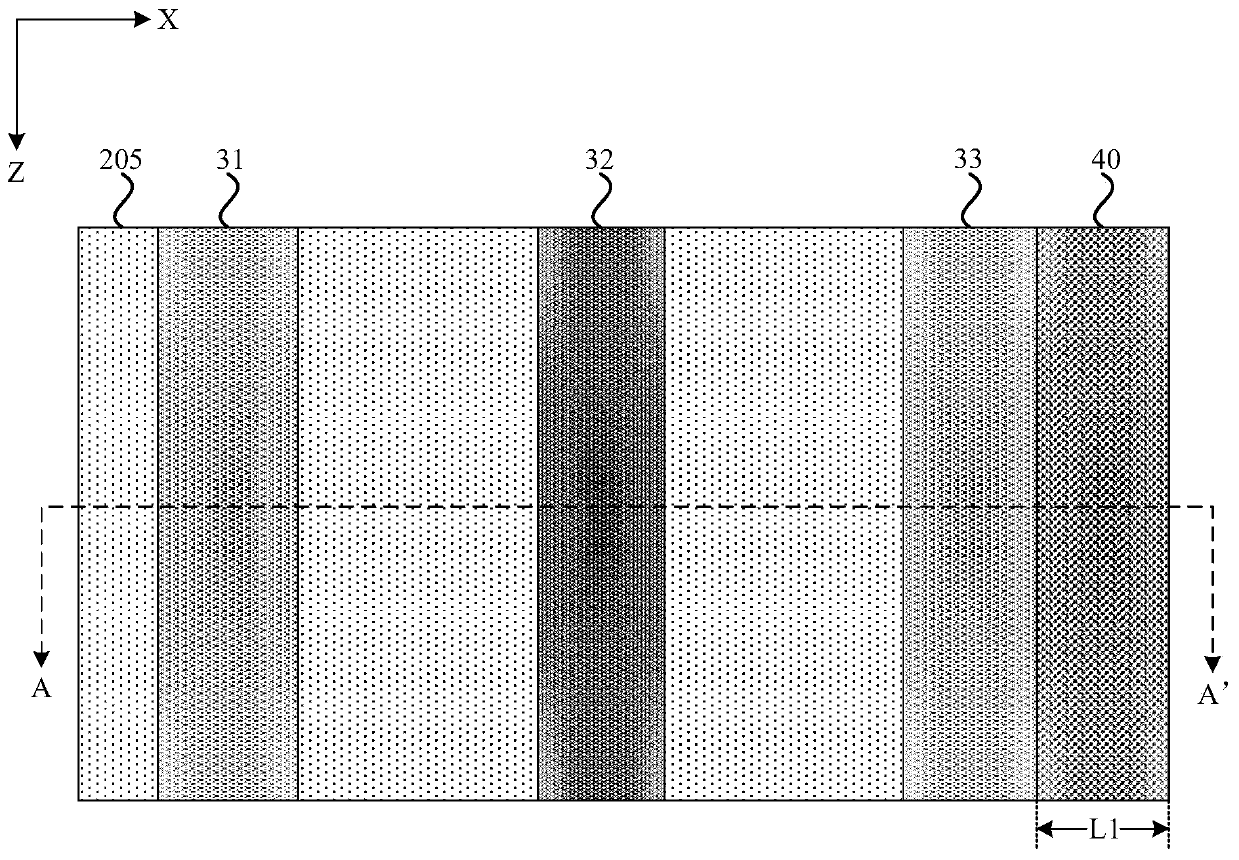

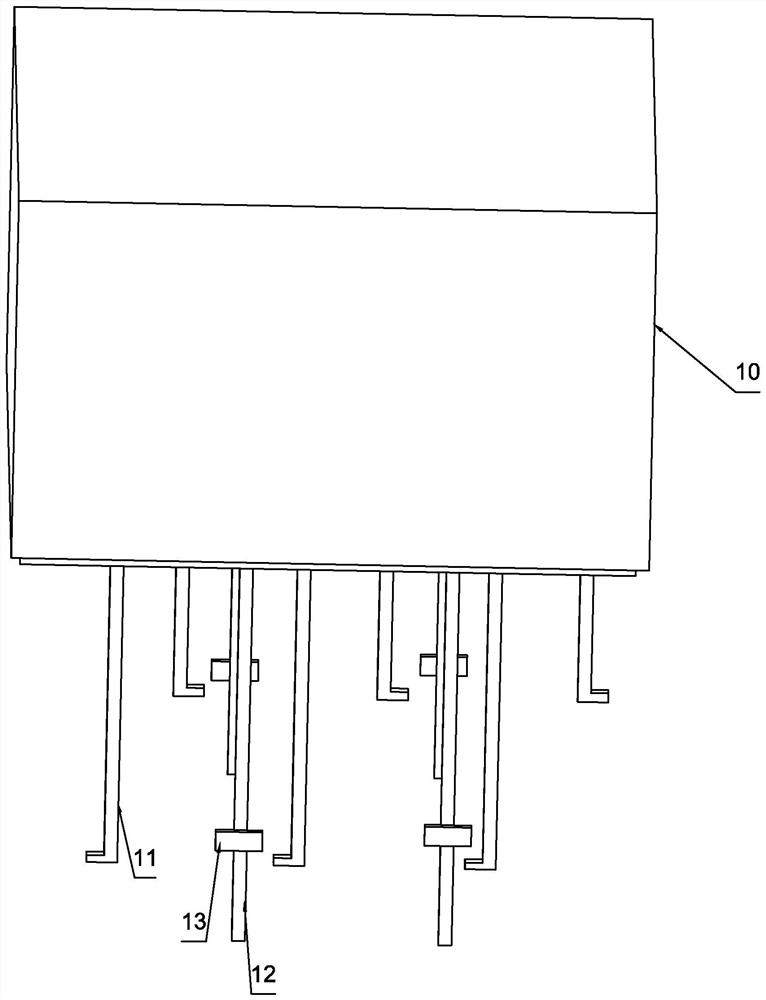

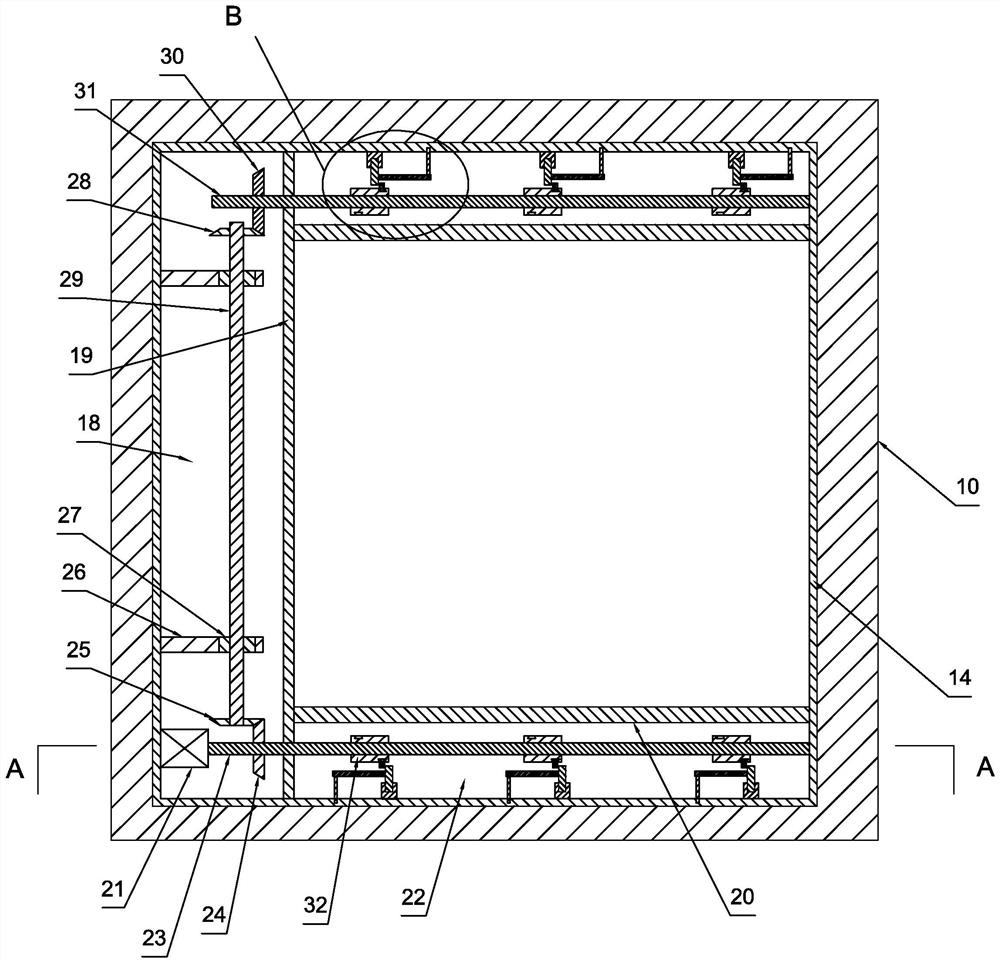

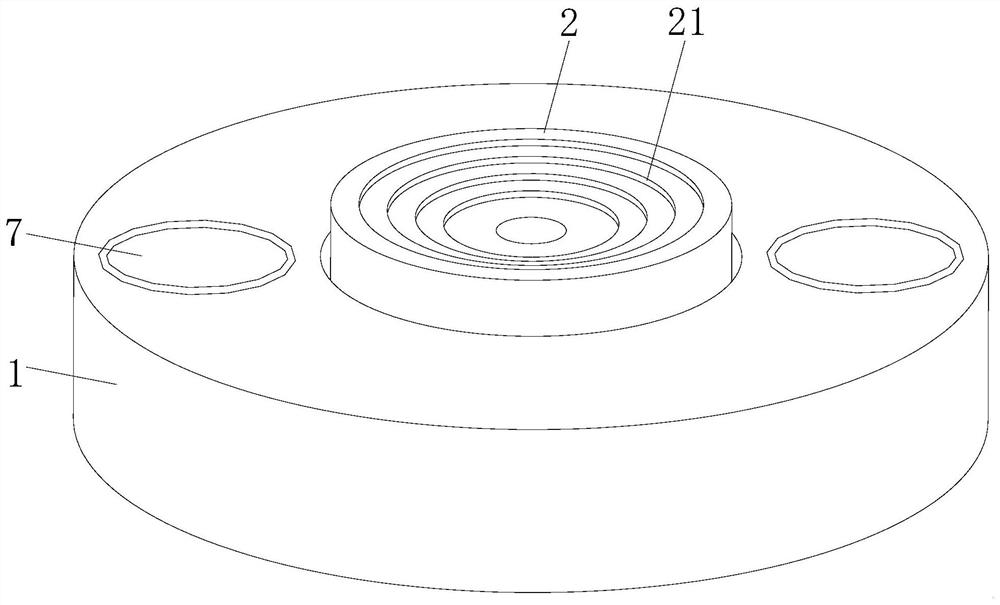

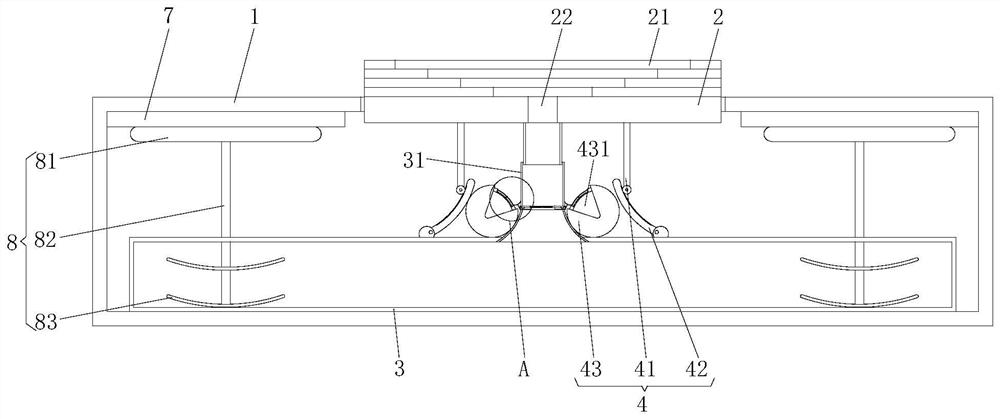

Photocuring 3D printing device and printing method thereof

ActiveCN110524874AGuaranteed accuracyAvoid deformationAdditive manufacturing apparatus3D object support structuresLight beamElectrical and Electronics engineering

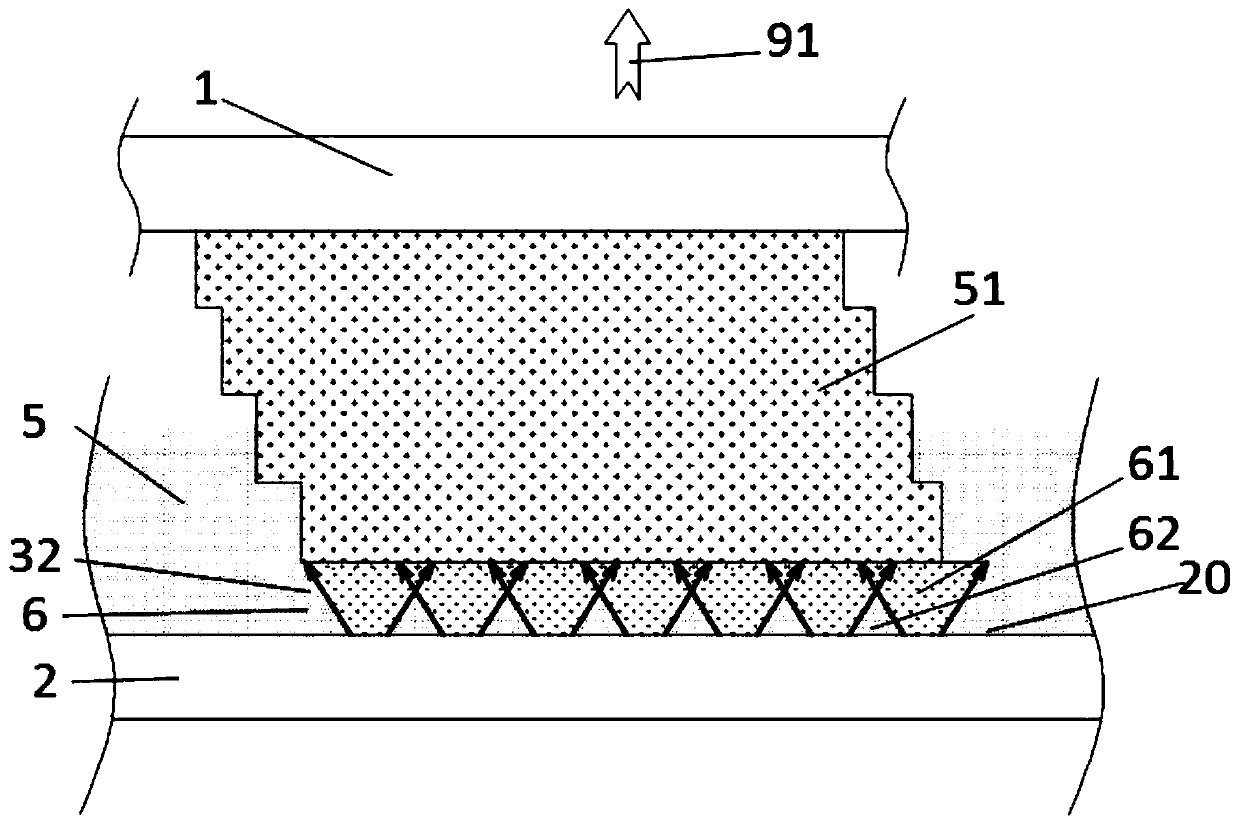

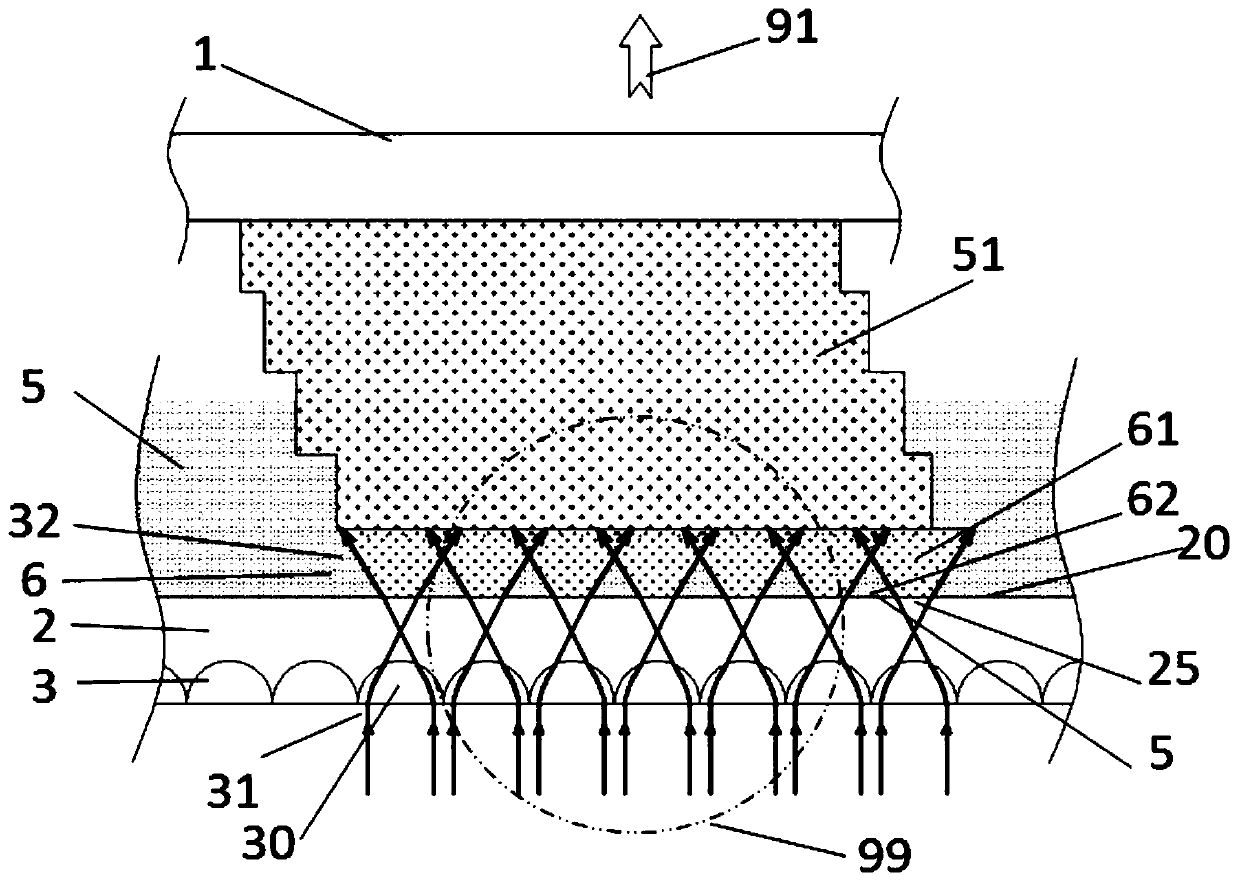

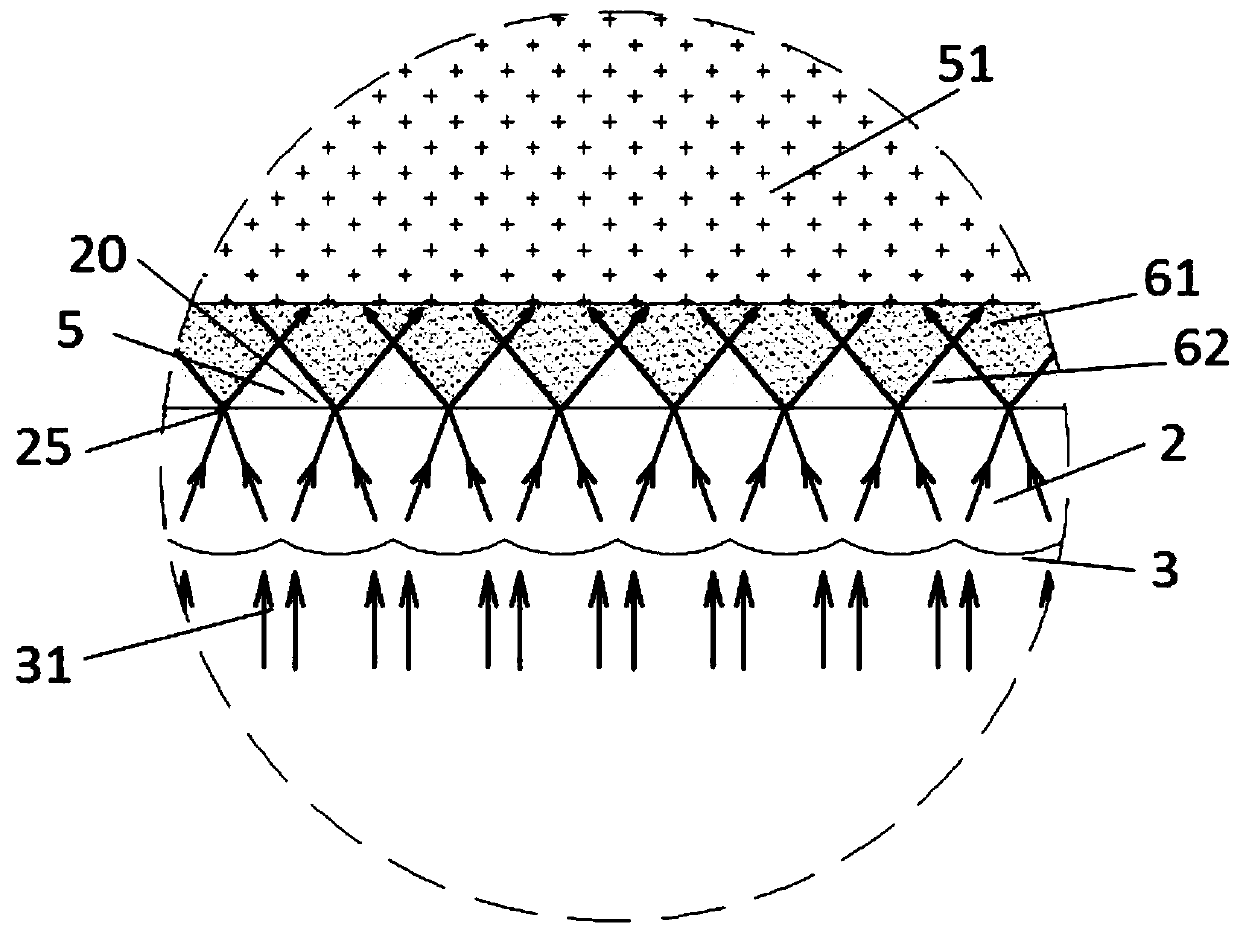

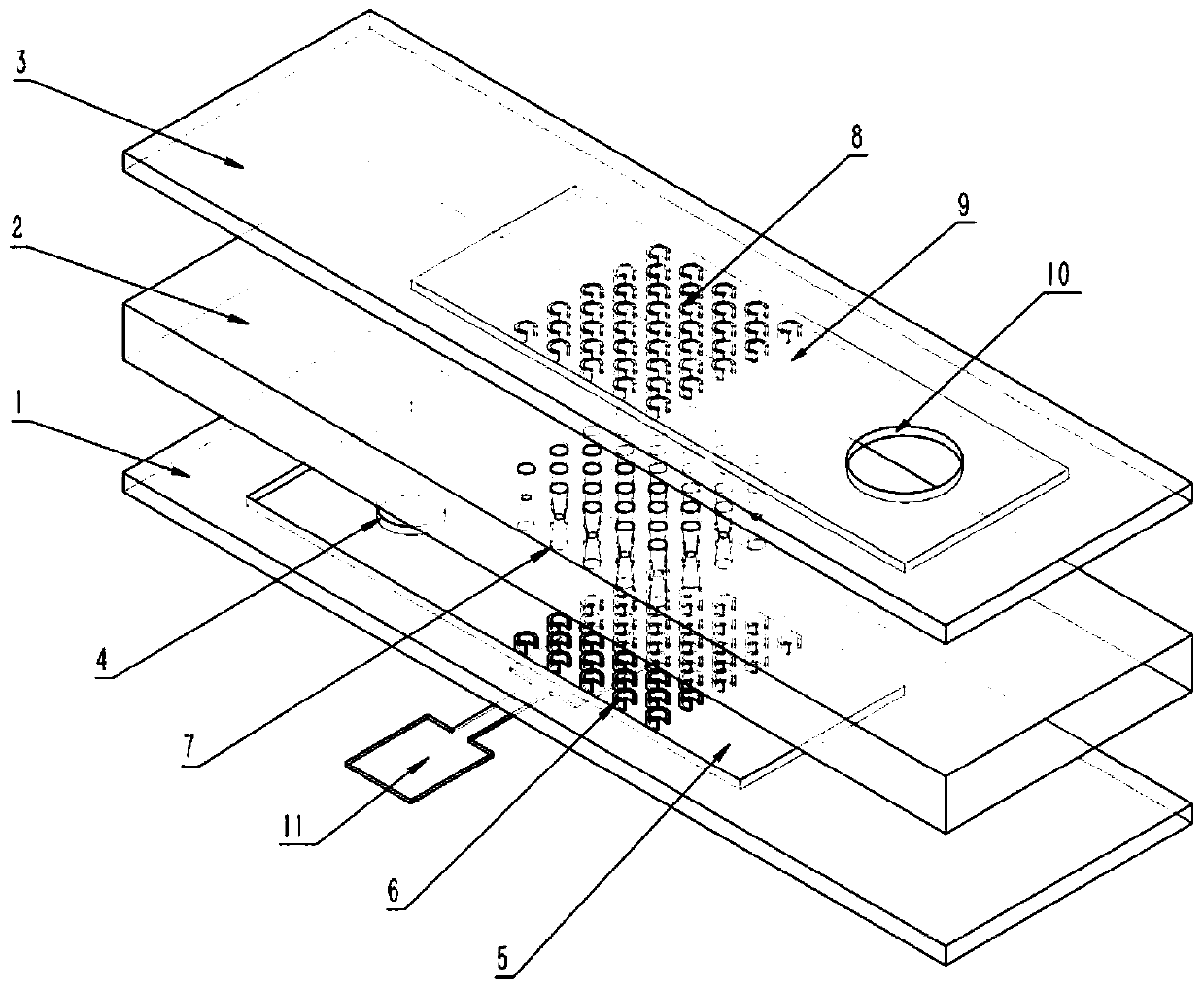

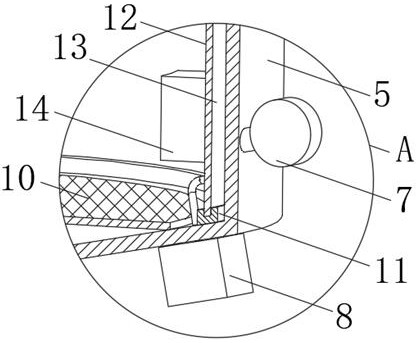

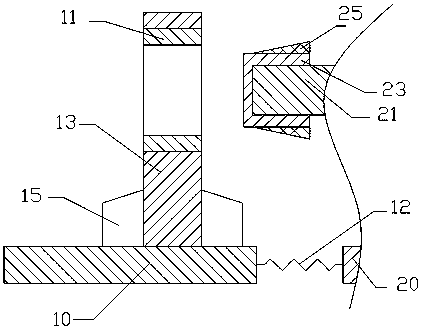

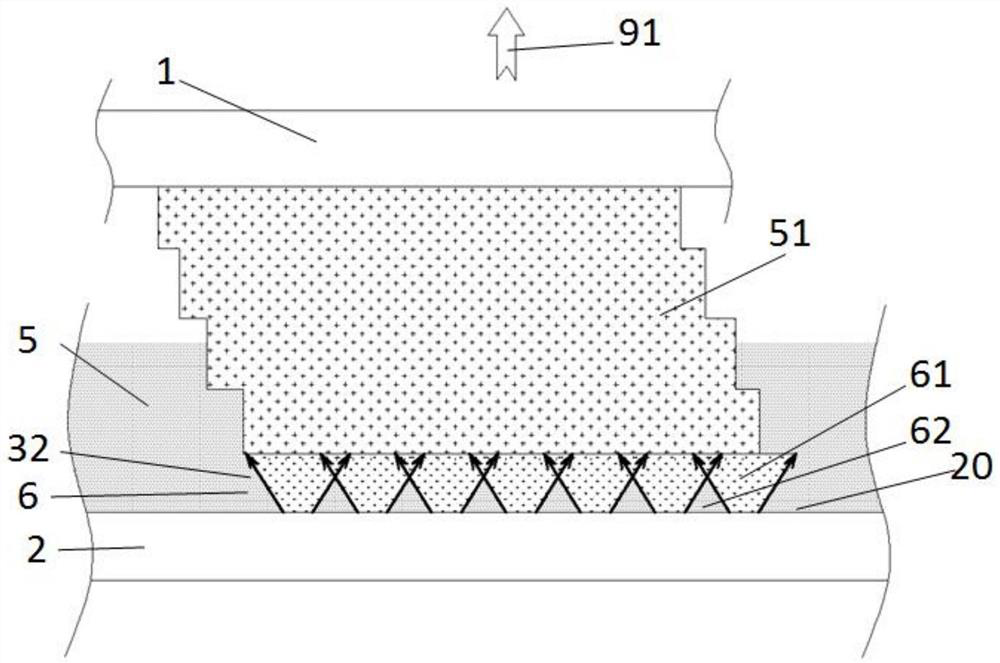

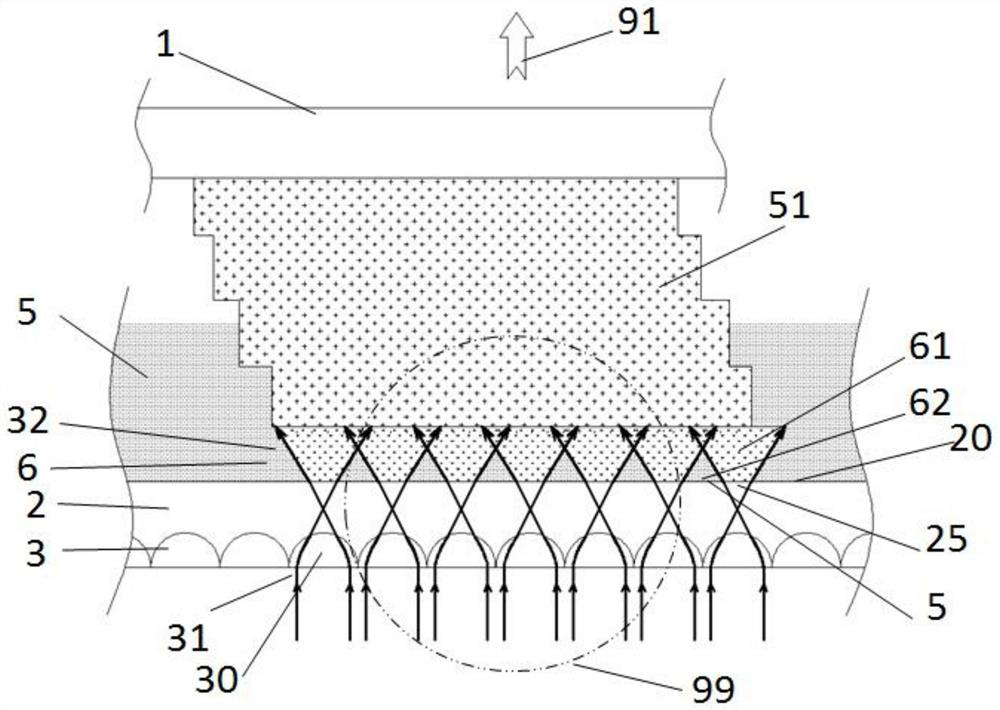

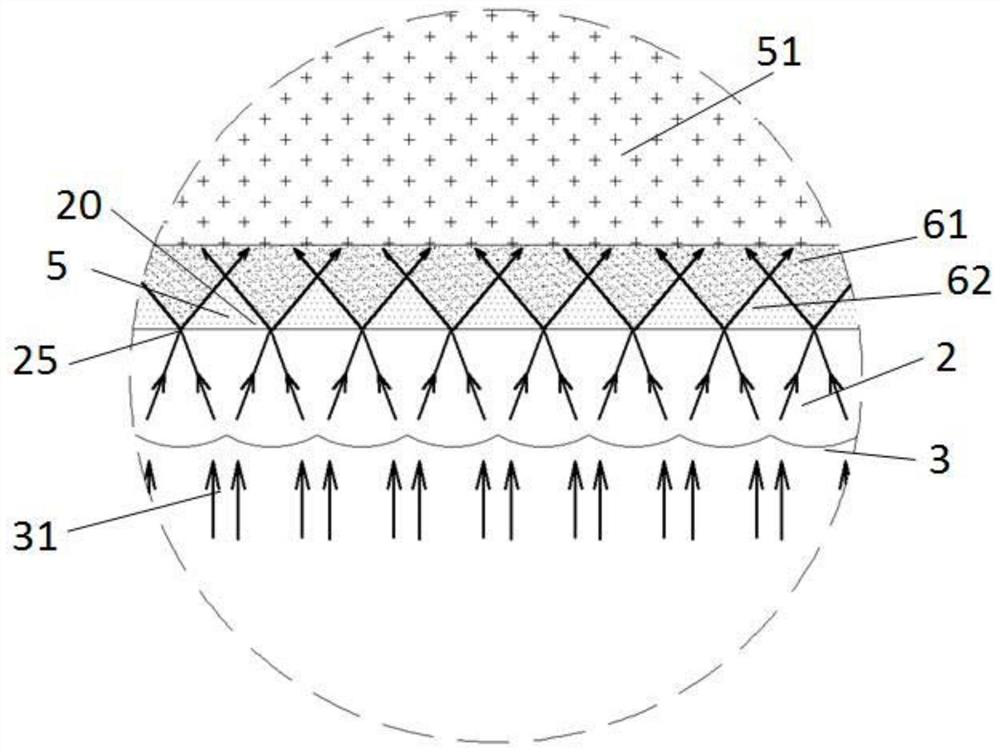

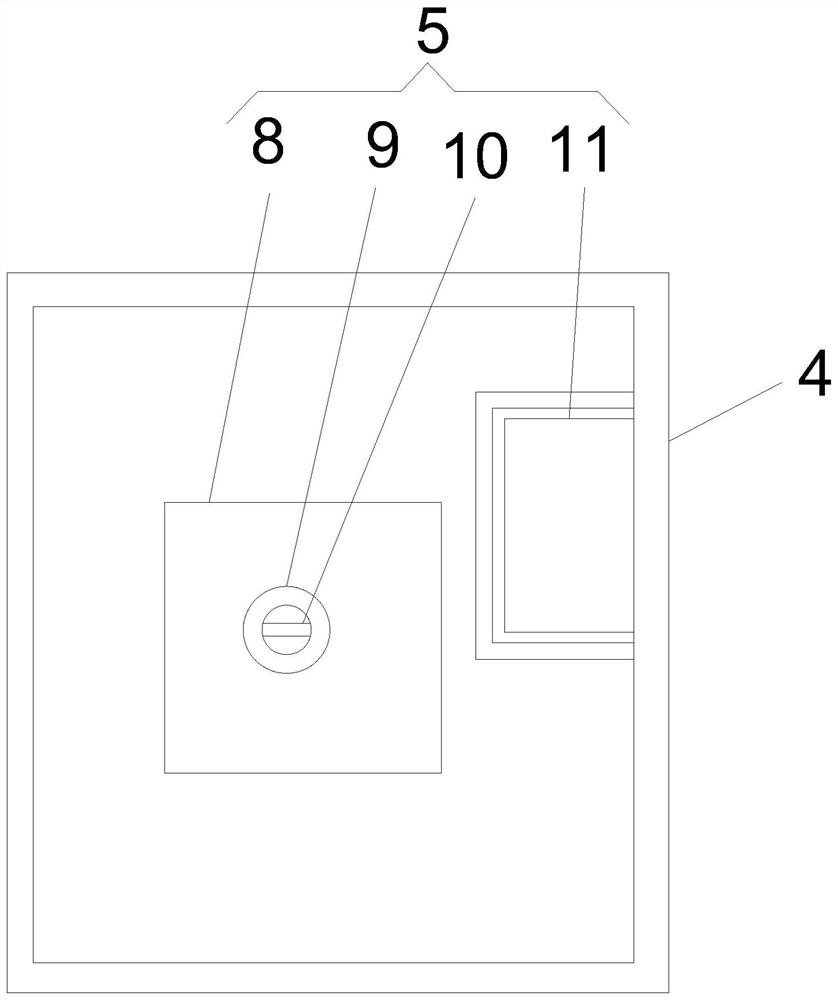

The invention relates to a photocuring 3D printing device and a printing method thereof. The printing device comprises a model plate and a light-transmitting plate, the model plate and the light-transmitting plate can move relatively, and a curing model is combined on the model plate. The light beams are emitted from the forming surface of the light-transmitting plate at intervals and in a diffusion mode, a plurality of light beam groups are formed between the forming surface of the light-transmitting plate and the curing model or the model plate, and the adjacent light beam groups are partially overlapped. The printing method comprises the following steps of carrying out data analysis on a to-be-printed model; adjusting the relative positions of the model plate and the light-transmittingplate for layer printing; emitting the light beams selectively from the forming surface of the light-transmitting plate at intervals in the diffusion mode to form a plurality of spaced light beam groups, and curing the printing materials in the light beam group areas; printing layer by layer until the whole model is printed. According to the present invention, the speed of printing materials flowing into the space between the curing model and the light-transmitting plate during the printing process can be increased, the separation acting force between the curing model and the light-transmitting plate is reduced, the printing efficiency is improved, and the printing precision is guaranteed.

Owner:YUANZHI TECH SHANGHAI CO LTD

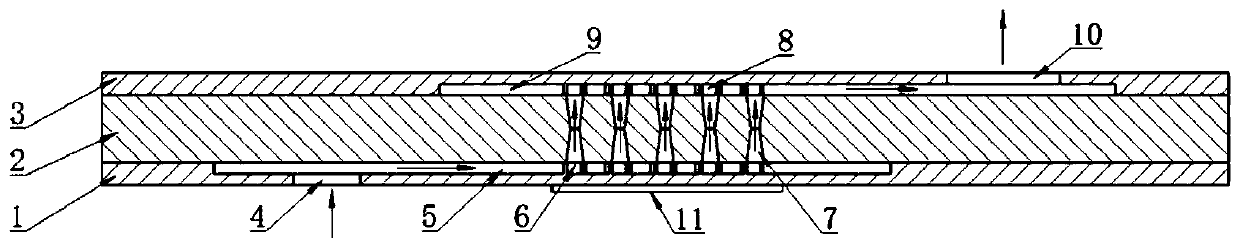

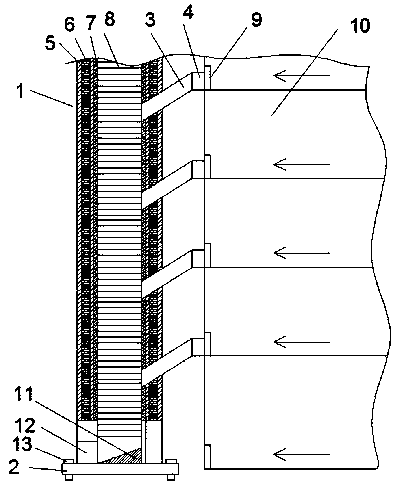

Microchannel heat exchanger structure with spray pipe and work method

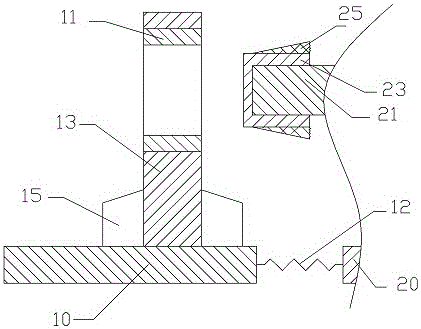

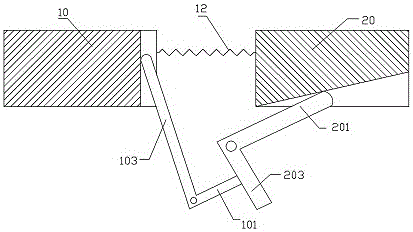

PendingCN109764706AImprove heat transfer effectIncrease critical heat fluxSemiconductor/solid-state device detailsStationary conduit assembliesHeat fluxEngineering

The invention relates to a microchannel heat exchanger structure with a spray pipe and a work method. The microchannel heat exchanger structure comprises a first heat exchange portion, a second heat exchange portion and at least one spray pipe portion located between the first heat exchange portion and the second heat exchange portion. A high pressure heat exchange flow channel is arranged in thefirst heat exchange portion, a first micro rib array is arranged in the high pressure heat exchange flow channel, a low pressure heat exchange flow channel is arranged in the second heat exchange portion, and the high pressure heat exchange flow channel communicates with the low pressure heat exchange flow channel through at least one spray pipe arranged in the spray pipe portion. The heat exchanger structure is good in heat exchange effect, and can achieve the better heat exchange heat flux.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

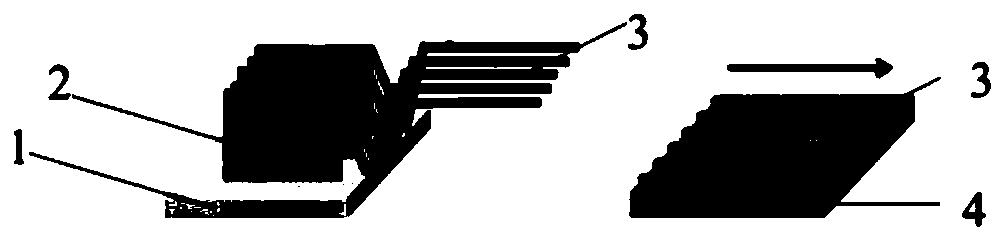

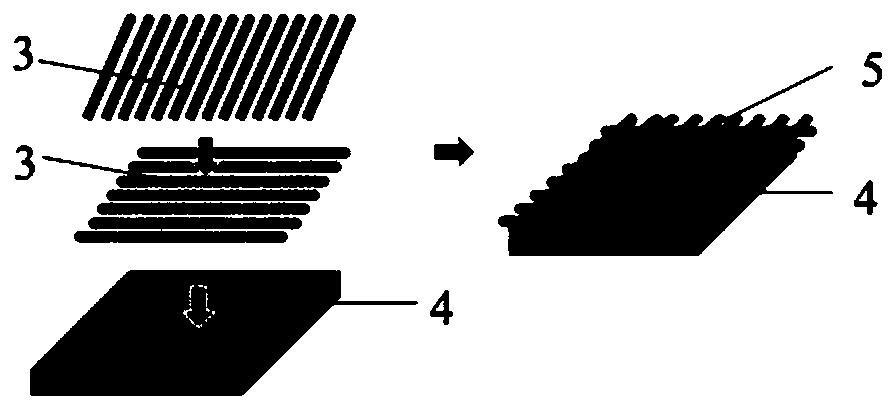

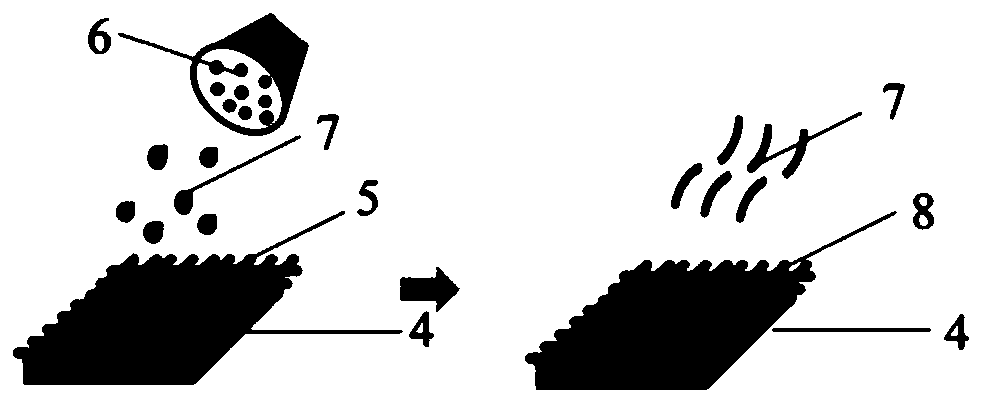

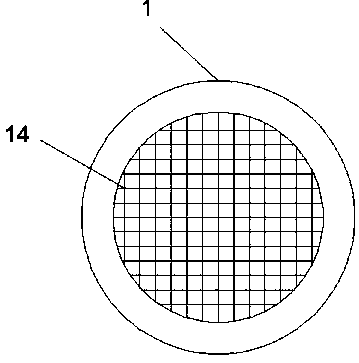

Method for preparing carbon nanotube film reticular structure for reinforcing water vapor condensation

InactiveCN110849167AChemically stableSmall additional thermal resistanceSteam/vapor condensersMultiwalled carbonThin membrane

The invention discloses a method for preparing a carbon nanotube film reticular structure for reinforcing water vapor condensation, and belongs to the technical field of water vapor condensation heattransfer reinforcement. The method comprises the following steps that S1, a carbon nanotube vertical array 2 is prepared on a silicon substrate 1; S2, the carbon nanotube vertical array 2 is pulled, so that single-layer carbon nanotube films 3 are formed; S3, the single-layer carbon nanotube films 3 are spread on the substrate 4 in a crossing manner, and the carbon nanotube film reticular structure 5 is manufactured; and S4, multiple carbon nanotube film reticular structures 5 are subjected to water atomization shrinkage reinforcing lamination. The surface of the carbon nanotube film reticularstructure prepared through the method has the advantages of being stable in chemical property, small in additional thermal resistance and the like.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

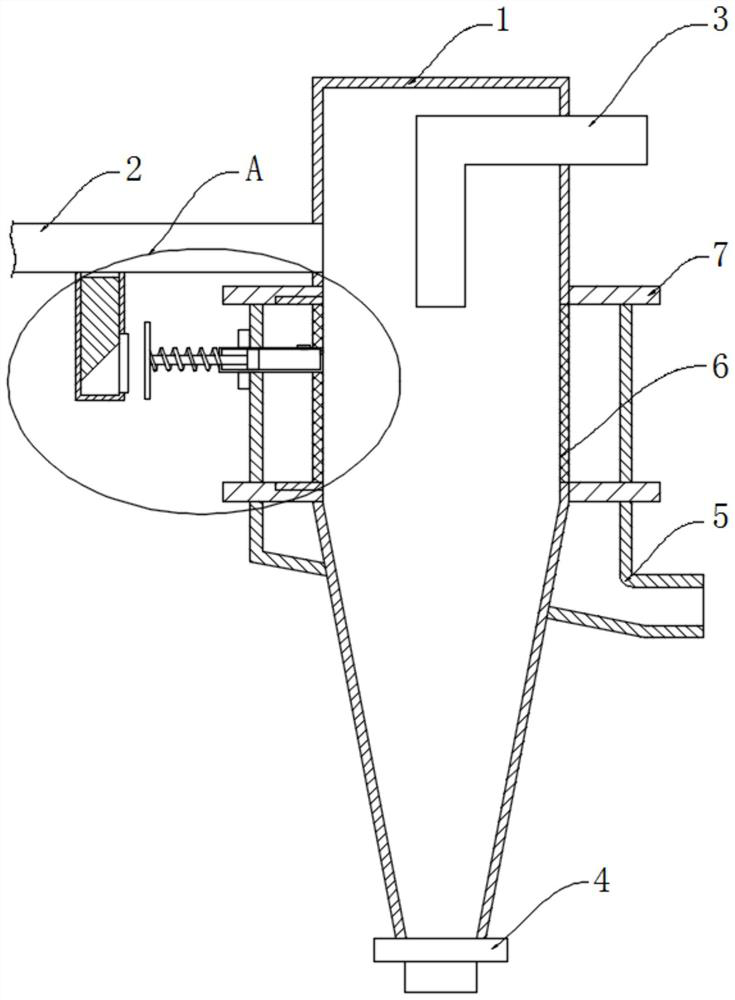

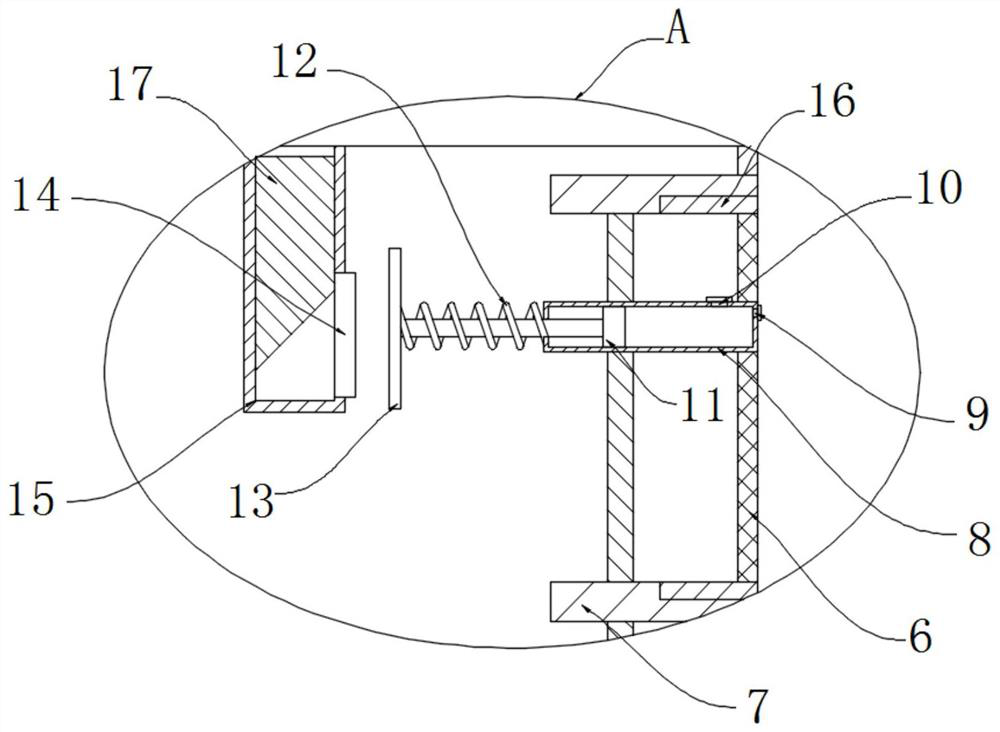

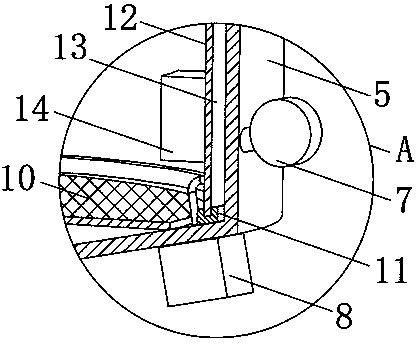

Flow-stabilizing anti-blocking screen hydraulic swirler

InactiveCN111715389AReduce the cross-sectional areaControl flow rateReversed direction vortexWet separationEngineeringMachine

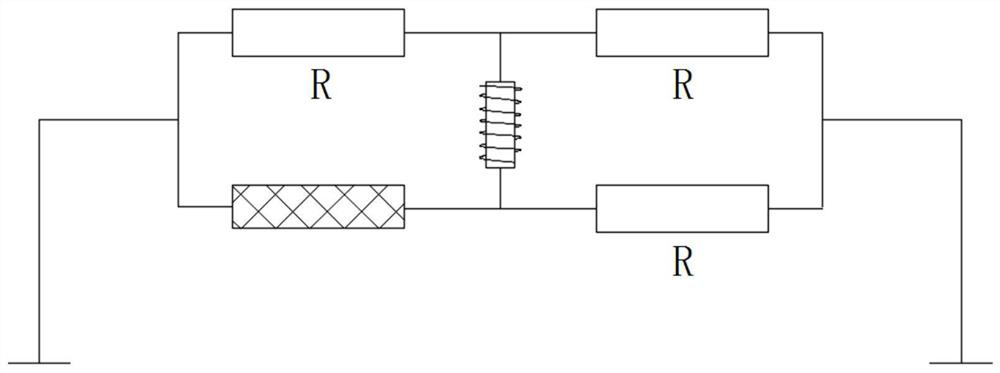

The invention discloses a flow-stabilizing anti-blocking screen hydraulic swirler. The flow-stabilizing anti-blocking screen hydraulic swirler comprises a machine body, a feeding pipe and an overflowpipe, wherein the bottom of the machine body adopts a conical structure; a discharging opening is formed in the bottom of the machine body; a screening box is in sleeving connection and fixation to outside of the middle part of the machine body; an annular screen is arranged between the screening box and the machine body in a communicating manner; a cylinder is fixedly connected to the inner partof the screening box; a piston is in sliding connection to the inner part of the cylinder in a sealing manner; one end of the cylinder penetrates through the screen in a sealing manner, and the otherend of the cylinder penetrates through the screening box; a pressing rod adopting a cross structure is arranged on one side of the screening box, of the cylinder, in a penetrating manner, and is fixedly connected with the piston; and a spring is in sleeving connection to the part outside the cylinder, of the pressing rod. The flow-stabilizing anti-blocking screen hydraulic swirler disclosed by theinvention has the advantages that the dust adhering state of the screen is detected through a bridge circuit; reciprocating action force on the pressing rod is produced through an electromagnet and the spring, so that inflating the inner side of the screen and pumping air on the outer side of the screen are realized to increase the pressure difference of two sides, so that a great deal of generated bubbles are impacted and broken, adhered coal ash is shattered down, and blocking is avoided.

Owner:张婉丽

Cloth processing and deodorizing device and deodorizing method

ActiveCN108035088AFacilitated DiffusionSpeed up the flowTextile treatment containersTextile treatment machine arrangementsActivated carbonEngineering

The invention discloses a cloth processing and deodorizing device in the technical field of cloth processing and deodorizing. The device comprises rollers, piston rods are arranged at the tops of therollers, the tops of the piston rods are sleeved with inner cavities of fixing rods, the fixing rods are located in inner cavities of supporting legs, a box is arranged at the tops of the supporting legs, fans are disposed at the bottom of an inner cavity of the box, electric heating screens are disposed at the tops of the fans, the bottom of a motor is provided with one suspended rotating shaft through a motor shaft, the outer wall of each suspended rotating shaft is sleeved with a driving gear, the bottoms of the suspended rotating shaft is provided with a rotating plate, ten groups of upright columns are disposed at the bottoms of the rotating plates, spice storage boxes are disposed at the bottoms of the upright columns, an activated carbon adsorption screen is arranged at the bottom of an inner cavity of a purification box, a draught fan is arranged on the top of the inner cavity of the purification box, and a sealing door is disposed at the front end surface of the box. The device is simple in principle, good in deodorization effect and high in deodorization speed, and peculiar smell gas can be purified, adsorbed and then discharged.

Owner:浙江好派服饰有限公司

A green synthesis device for 4-chloroacetoacetates

ActiveCN111203170BIncrease contact areaReduce generationPreparation from ketenes/polyketenesChemical/physical/physico-chemical stationary reactorsAcetoacetatesThermal insulation

The invention discloses a green synthesis device for 4-chloroacetoacetate, which comprises a sealed heat-insulating shell, a conductive cylinder is arranged inside the heat-insulating shell, and the upper and lower ends of the conductive cylinder are connected with the inner cavity of the heat-insulating shell. The upper and lower sides are sealed and fixedly connected. An electrostatic generator is installed outside the insulation shell. The output end of the electrostatic generator is connected to the side of the conductive cylinder through a cable, and the cable runs through the insulation shell. The upper part of the inner cavity of the conductive cylinder is equipped with an electrostatic Sprayer, a precooler is installed on the outside of the conductive cylinder; this green synthesis device of 4-chloroacetoacetates electrostatically atomizes the diketene solution to increase the contact area between the diketene solution droplets and chlorine gas, and double The downward movement distance of the diketene solution droplet determines the reaction time of the diketene solution droplet and chlorine gas, the reaction time of diketene solution and chlorine gas is easy to control, reduces the generation of by-products, and avoids the loss of raw materials.

Owner:山东昌邑灶户盐化有限公司

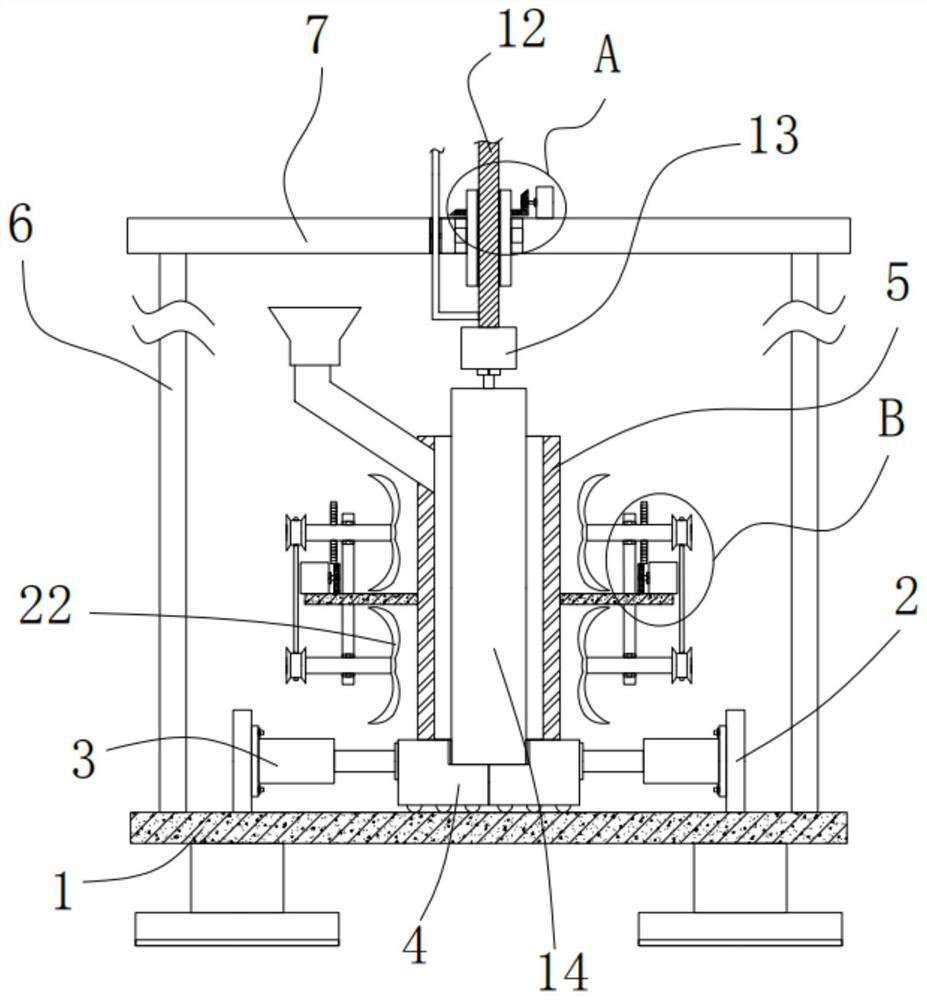

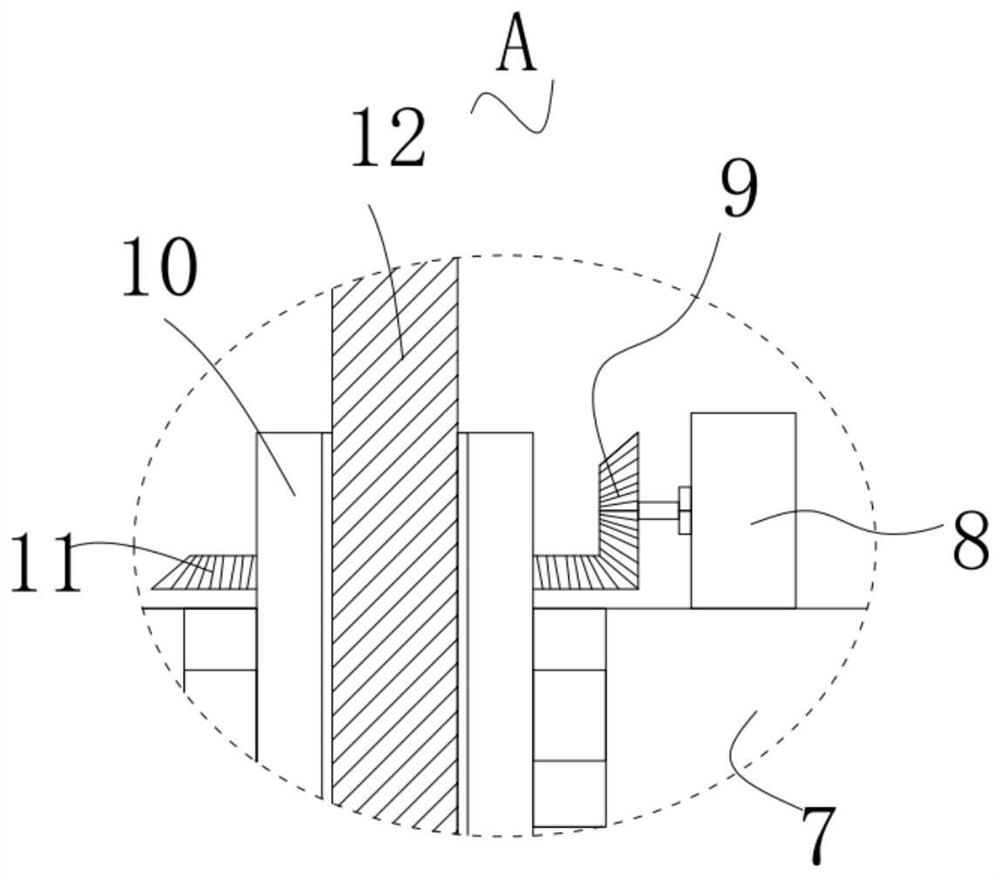

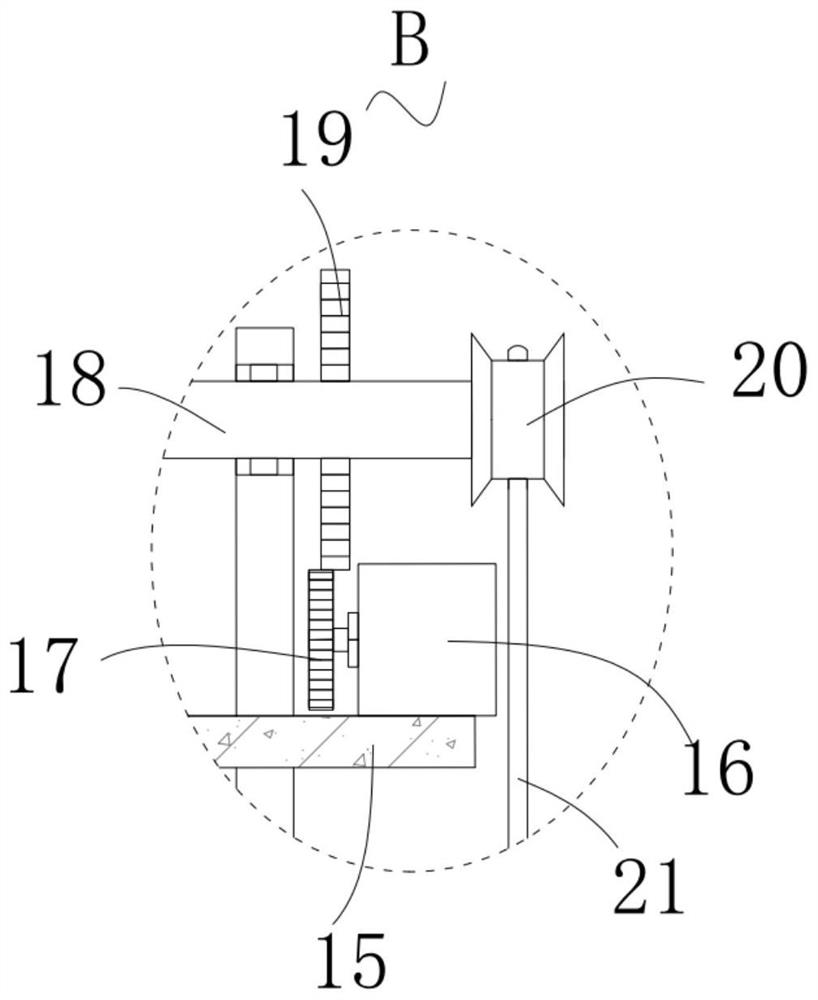

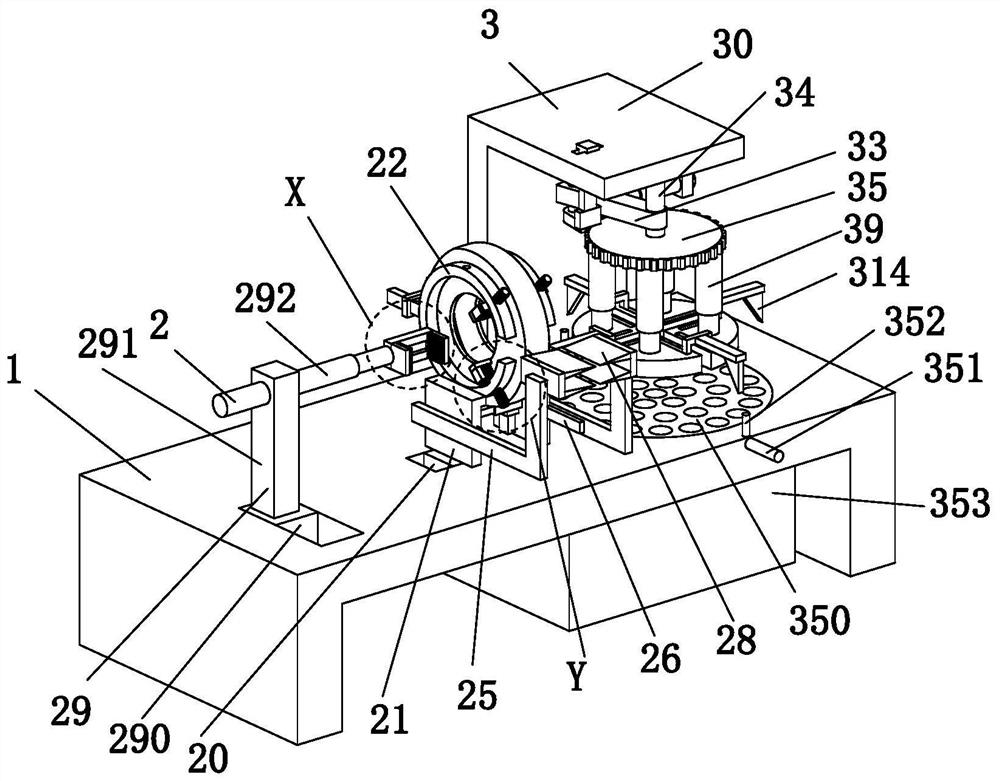

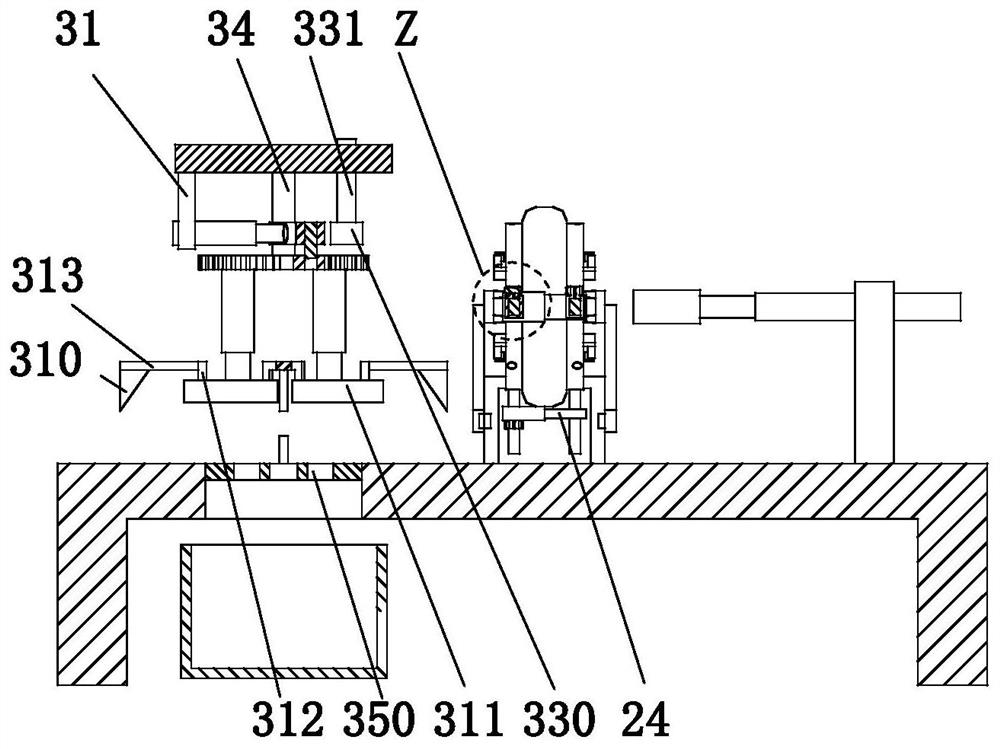

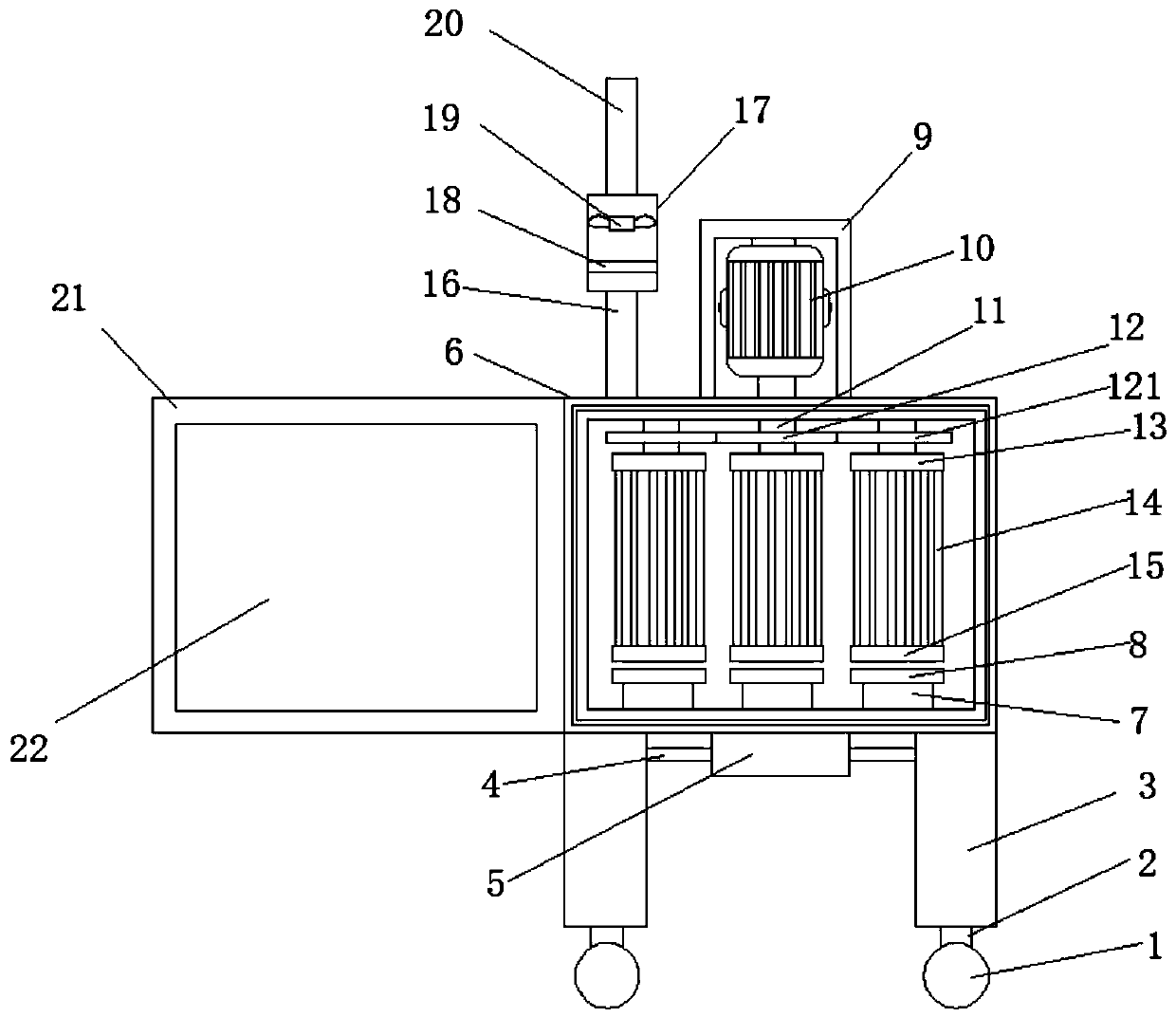

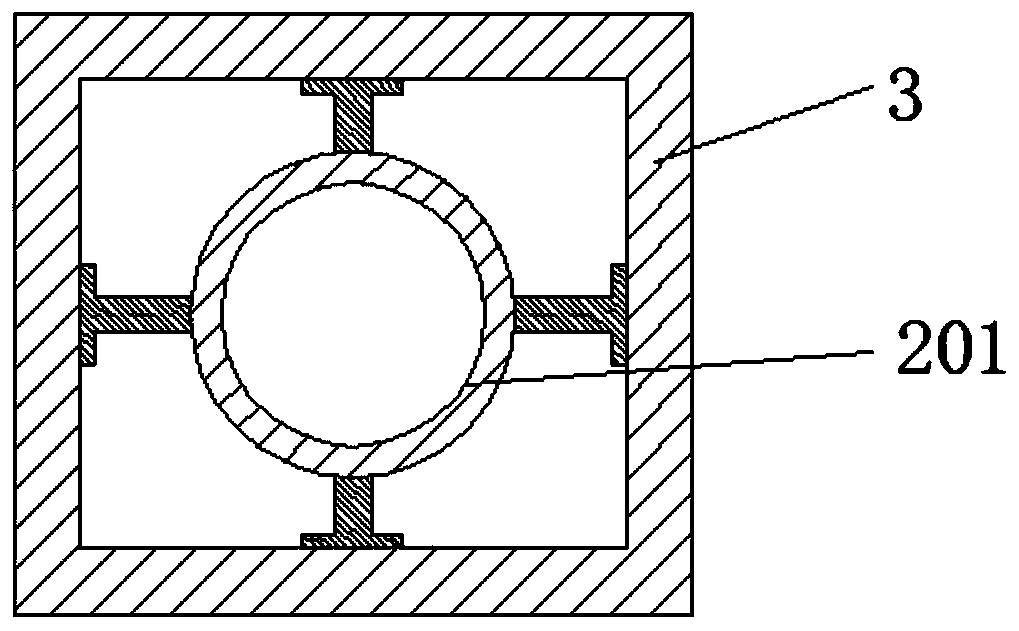

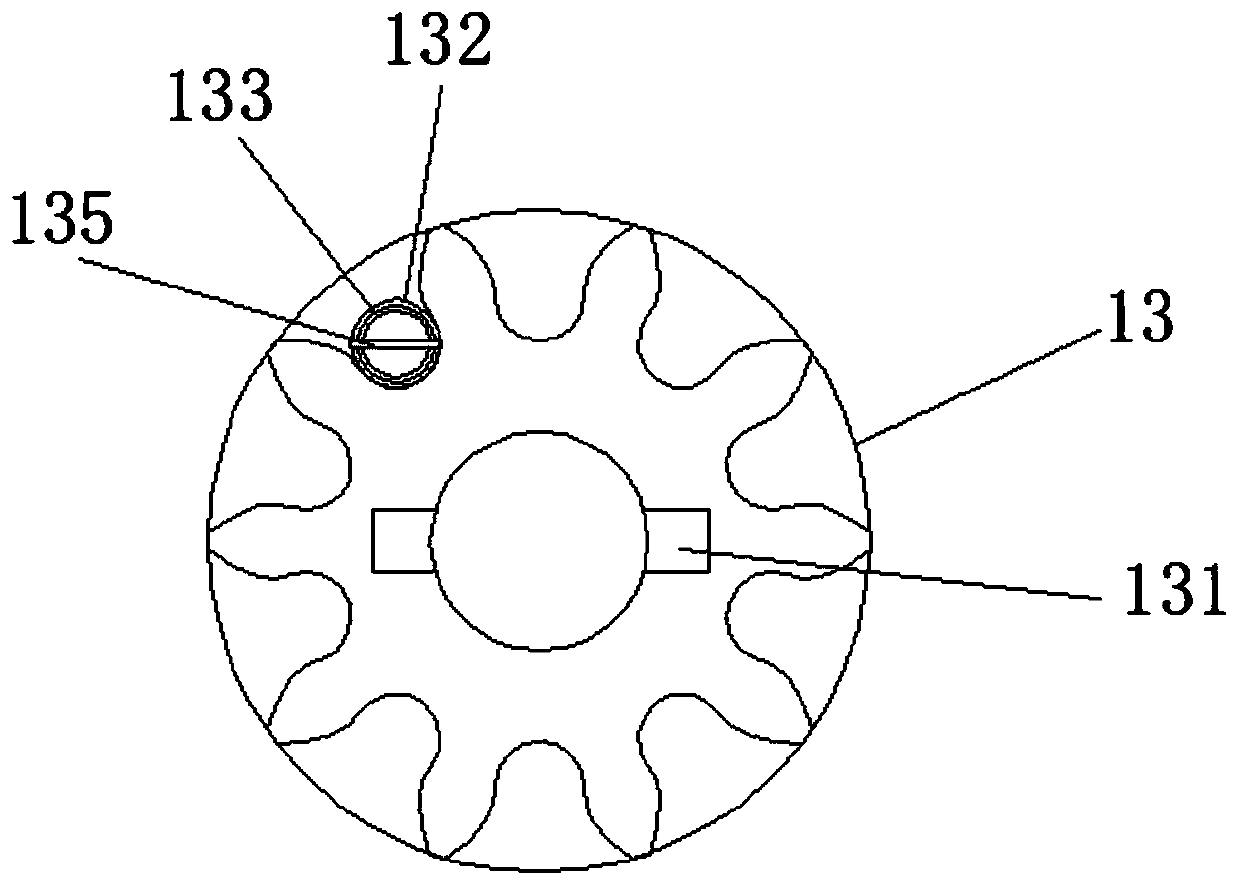

Permanent magnet drive support equipment for gear machining

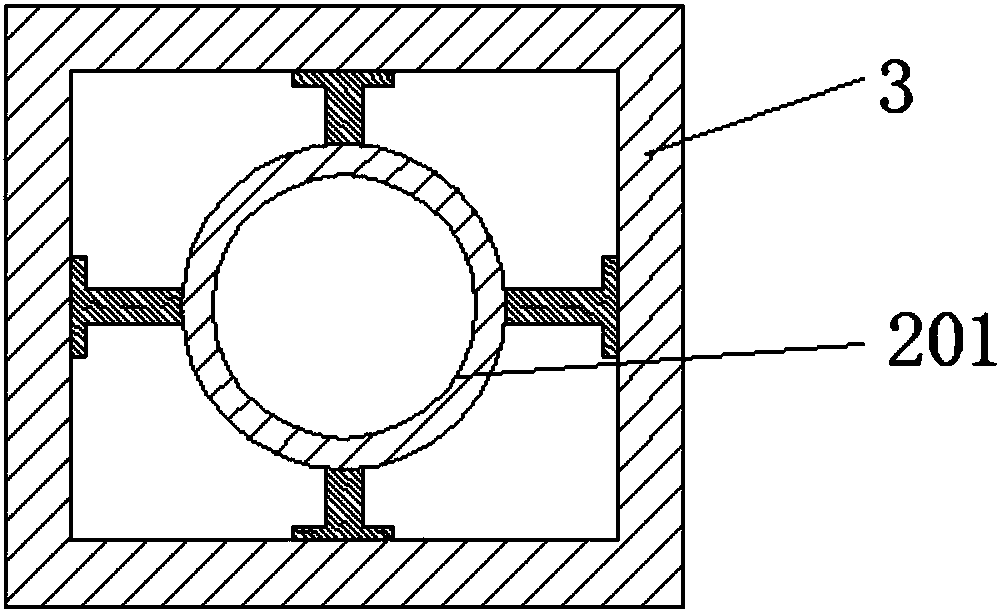

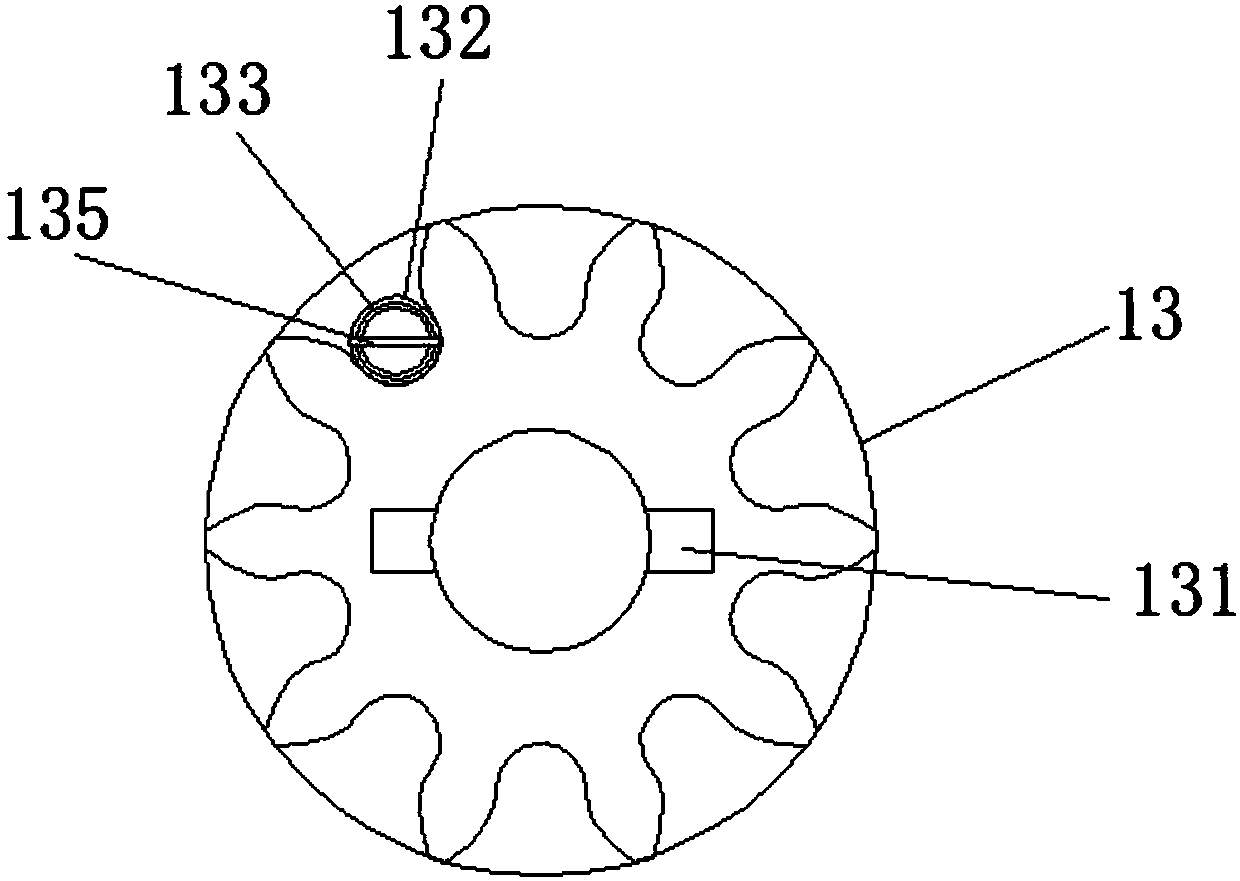

ActiveCN106787602BReduce radial forceExtended service lifeDynamo-electric brakes/clutchesElectrical conductorGear wheel

The invention relates to the technical field of gear machining, and particularly relates to permanent magnet transmission support equipment for gear machining. The permanent magnet transmission support equipment comprises a support seat and an installation seat which can be mutually driven to reversely move at the same time, wherein the support seat comprises a base and a support rod; the support rod is fixed on the base; a connection hole is formed in the upper part of the support rod; a support bearing is arranged in the connection hole; a motor is arranged on the installation seat; a motor shaft of the motor is connected with a conductor plate; the conductor plate is sleeved with an outer sleeve capable of shrinking under the action force of the support bearing; the outer sleeve can slide into the support bearing and is provided with an inner cavity containing lubricating oil; and the outer sleeve is provided with a seal cover capable of being opened outwards. The invention aims at providing equipment capable of supporting a permanent magnet in a transmission mechanism.

Owner:CHONGQING SUTENG MACHINERY MFG

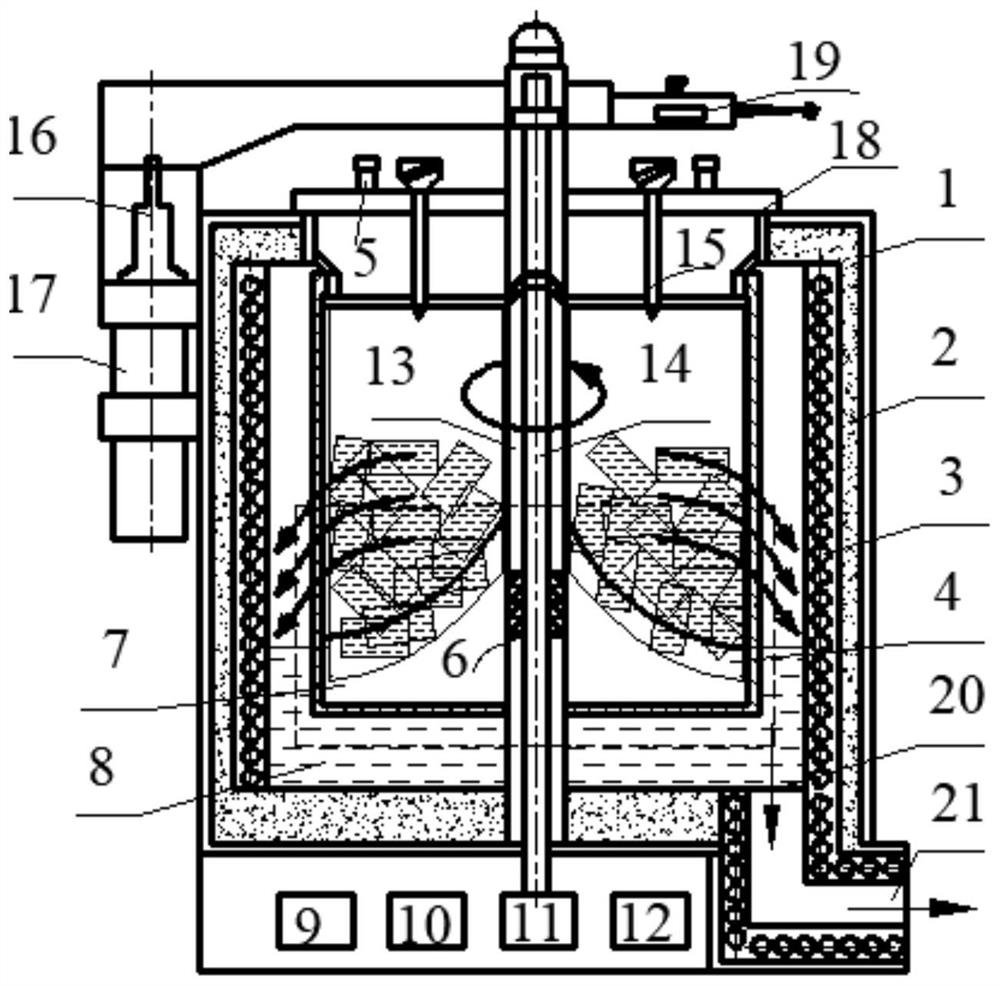

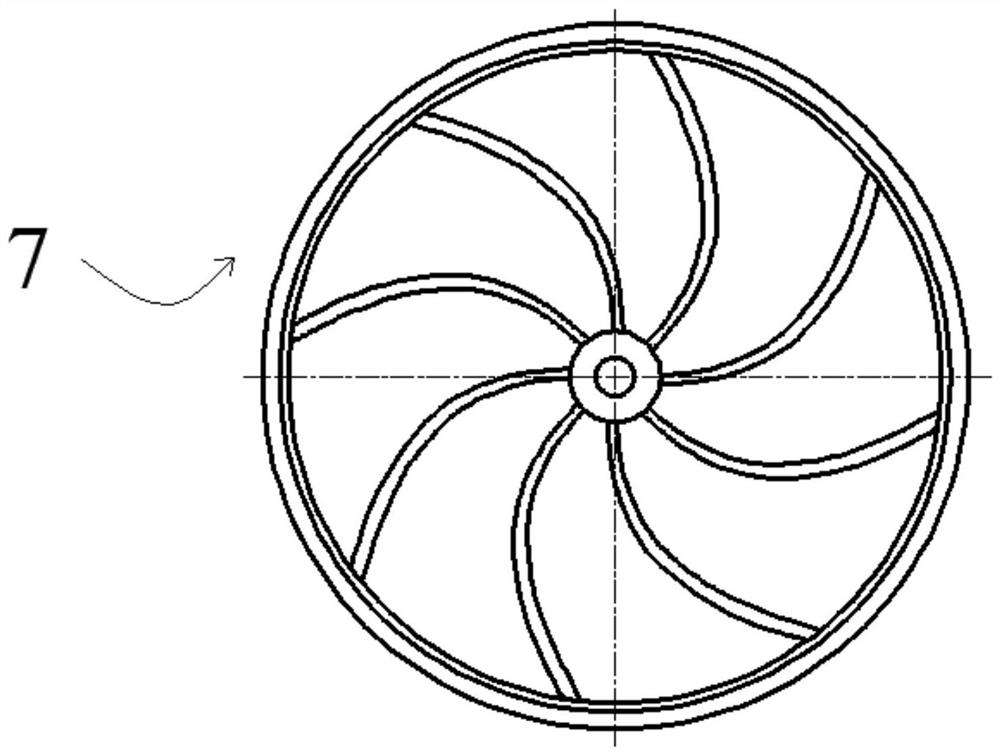

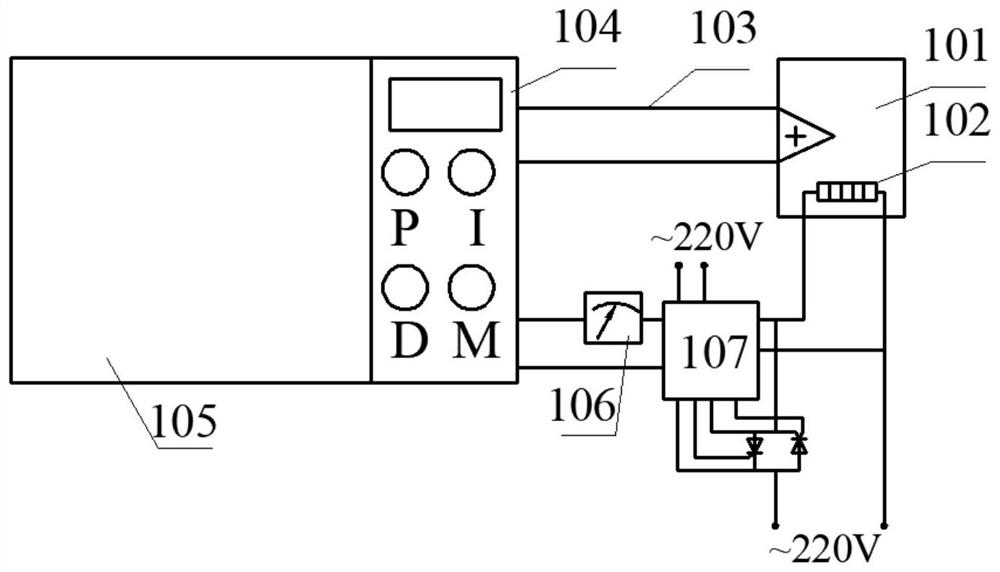

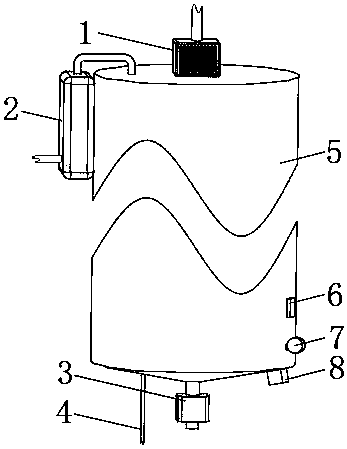

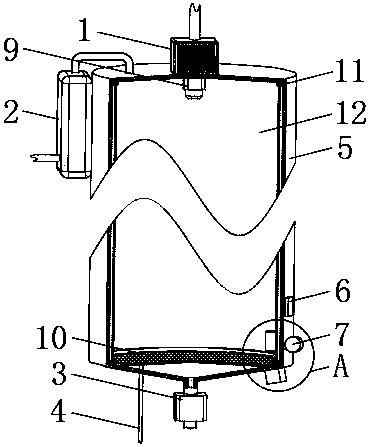

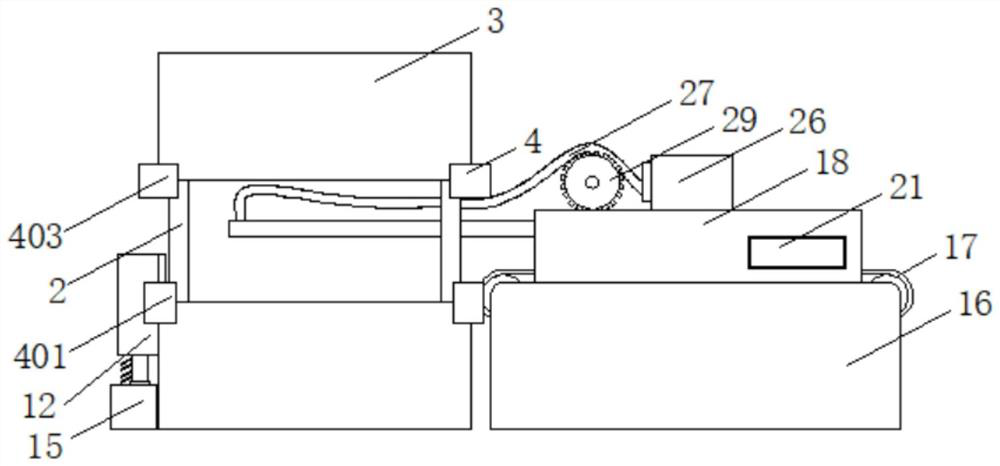

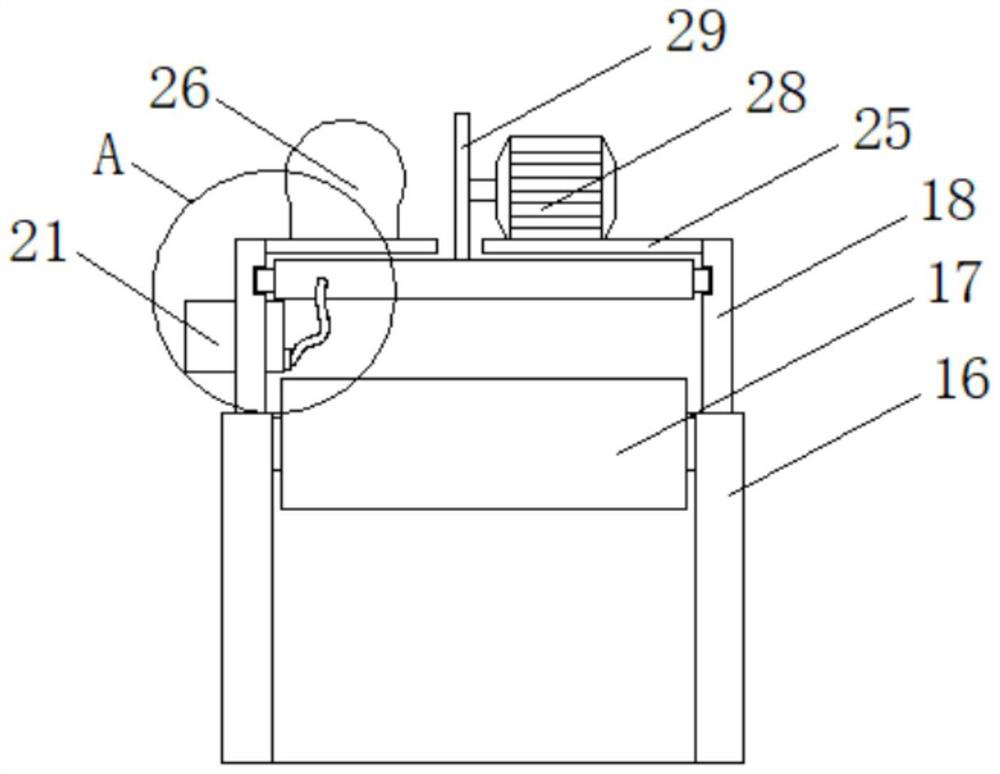

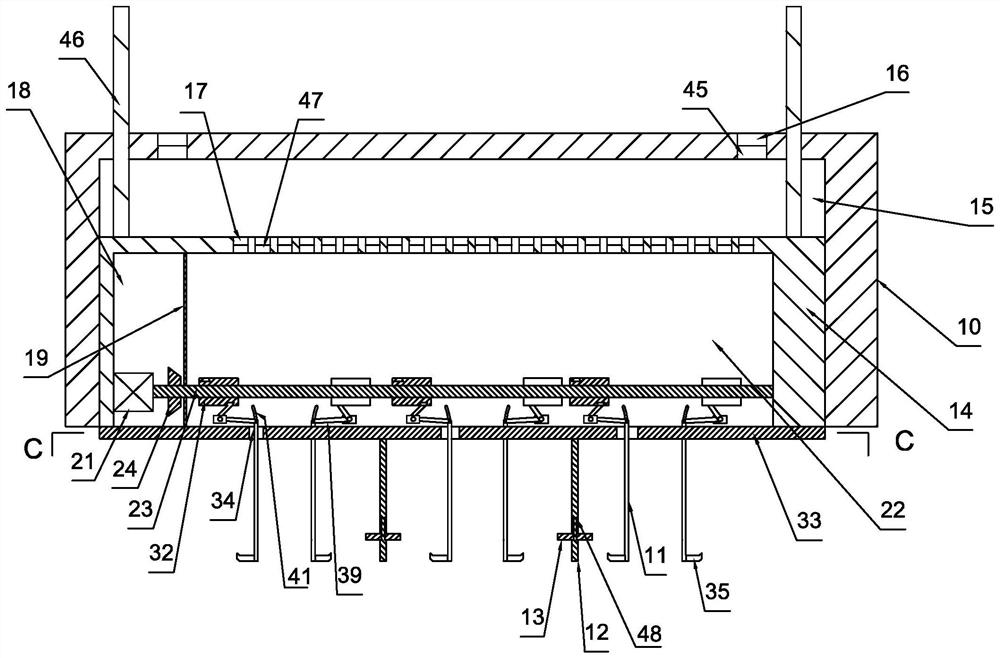

Method and device for separating 434 aluminum alloy composite plates

PendingCN114653486ALess impurity elementsQuality improvementRotary centrifugesFurnace temperatureNonferrous metal

The invention discloses a method and device for separating 434 aluminum alloy composite plates, belongs to the field of nonferrous metallurgy, and mainly solves the problem of recycling of the 434 aluminum alloy composite plates. The preparation method comprises the following steps: firstly, melting a coating alloy of the 434 aluminum alloy at 574-643 DEG C in a high-temperature centrifugal machine; then centrifugally separating the molten alloy, discharging the molten alloy through a liquid phase outlet pipe, closing a centrifugal mechanism, and taking out the unfused alloy; and finally, the molten alloy and the incomplete alloy are smelted in a smelting furnace and poured into cast ingots. The device comprises a shell, a heat preservation layer, a PID furnace temperature self-adjusting system, a centrifugal mechanism, a liquid outlet mechanism, a melt deposition tank, a liquid phase outlet pipe, a furnace cover lifting mechanism, a feeding and discharging mechanism and a tool. According to the method, a temperature field and a centrifugal force field are used for achieving same-grade recovery after a coating layer and a core layer of the 434 aluminum alloy composite plate are effectively separated, and 3003 aluminum alloy and 4004 aluminum alloy with the same-grade quality are obtained through separation.

Owner:HARBIN UNIV OF SCI & TECH

Green synthesis device of 4-chloroacetoacetate

ActiveCN111203170AIncrease contact areaEasy to controlPreparation from ketenes/polyketenesChemical/physical/physico-chemical stationary reactorsThermal insulationChemistry

The invention discloses a green synthesis device of 4-chloroacetoacetate. The synthesis device comprises a sealed thermal insulation shell; an electro-conductive barrel is arranged in the thermal insulation shell; the upper end and lower end of the electro-conductive barrel are hermetically and fixedly connected with the upper side and lower side of the inner cavity of the thermal insulation shellrespectively; an electrostatic generator is arranged outside the thermal insulation shell, the output end of the electrostatic generator is connected with the side face of the electro-conductive barrel through a cable, the cable penetrates through the thermal insulation shell, an electrostatic sprayer is arranged in the upper portion of the inner cavity of the electro-conductive barrel, and a pre-cooler is installed outside the electro-conductive barrel. The green synthesis device atomizes a diketene solution through static electricity, the contact area between liquid drops of the diketene solution and chlorine is increased, the time of reactions between the liquid drops of the diketene solution and chlorine is determined by the downward moving distance of the liquid drops of the diketenesolution, the time of reactions between the diketene solution and chlorine is convenient to control, byproducts are reduced, and raw material loss is avoided.

Owner:山东昌邑灶户盐化有限公司

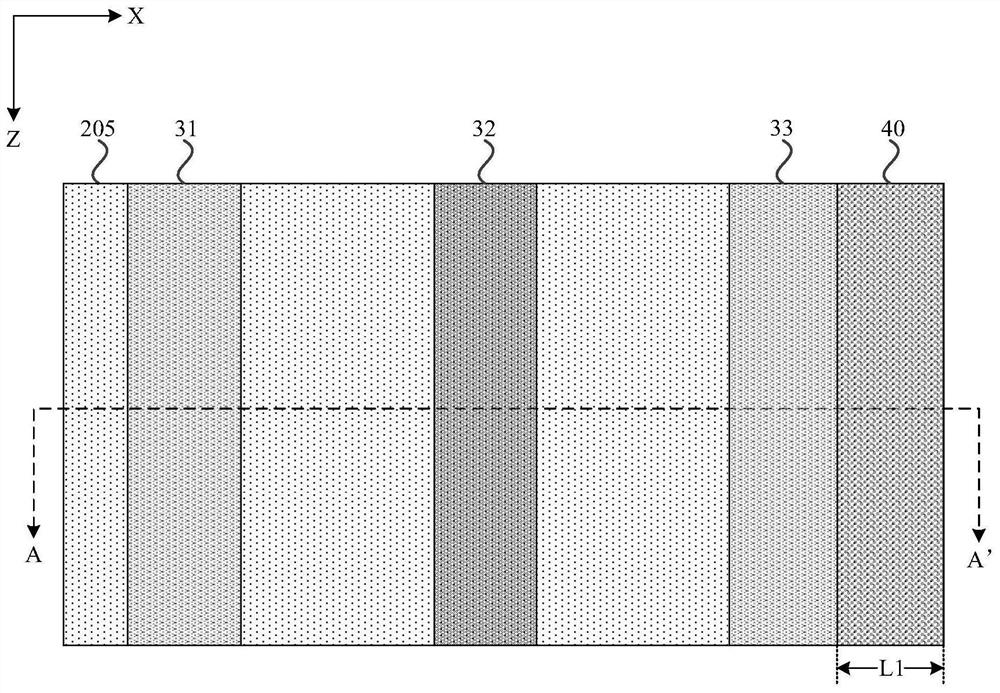

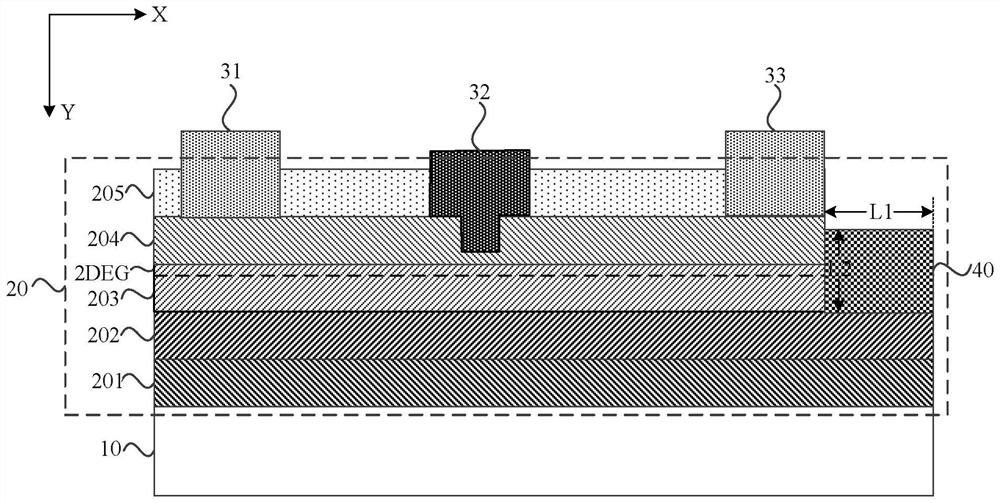

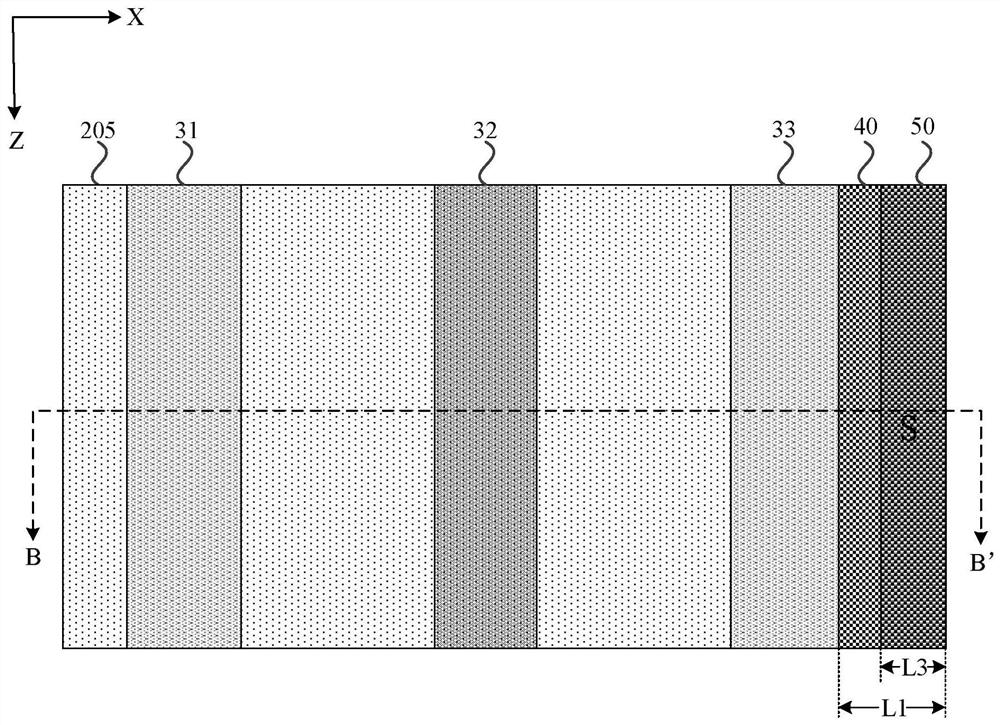

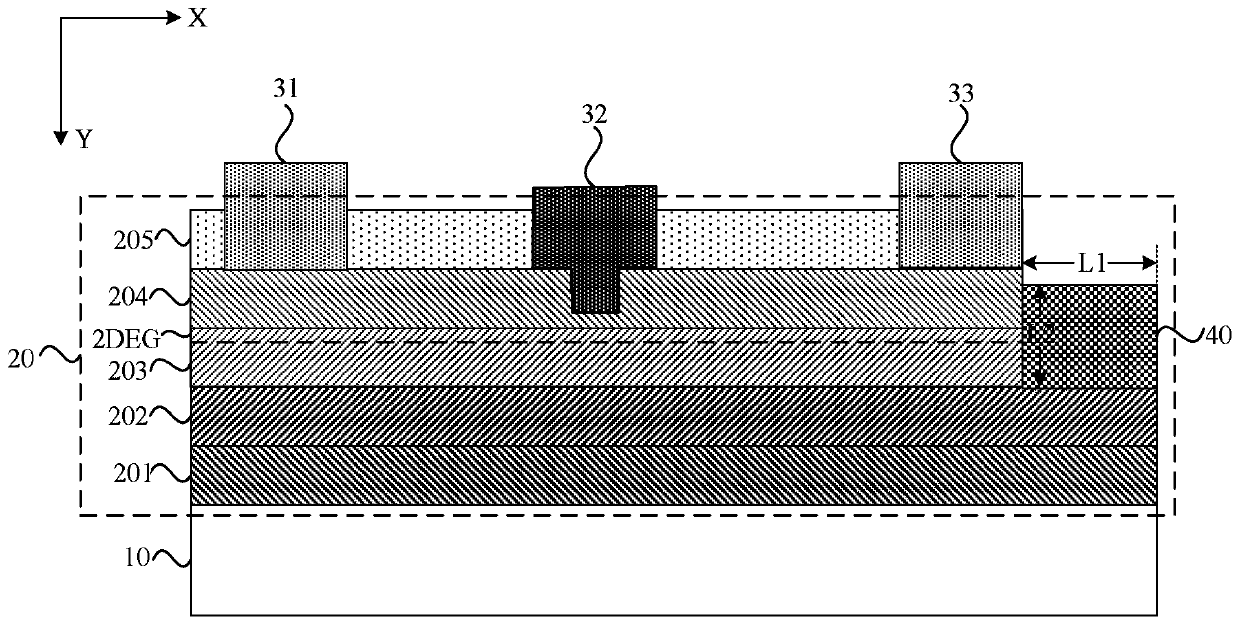

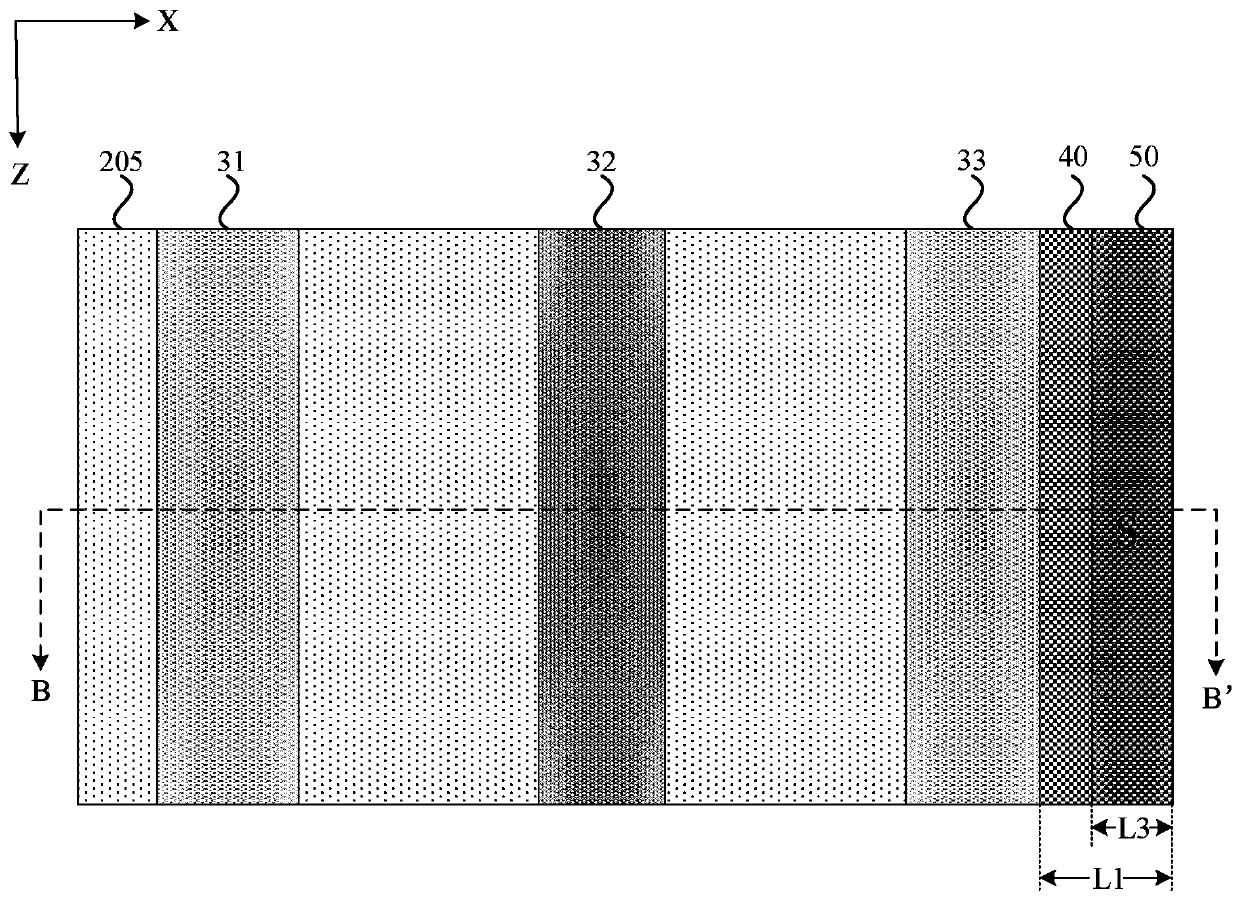

A kind of semiconductor device and its preparation method

ActiveCN111384164BIncrease saturation currentLower dynamic on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialElectrical connection

The embodiment of the present invention discloses a semiconductor device and a manufacturing method thereof. The semiconductor device includes a substrate; a multilayer semiconductor layer located on one side of the substrate, and the multilayer semiconductor layer includes a buffer layer and a channel layer located on one side of the substrate in sequence. and a potential barrier layer; the source, gate and drain located on the side of the multilayer semiconductor layer away from the substrate, the gate located between the source and the drain; located in the multilayer semiconductor layer and located at the drain far away from the gate The lower surface of the P-type material layer extends to the surface of the buffer layer close to the channel layer or extends to the inside of the buffer layer, and the P-type material layer is electrically connected to the drain. By setting the P-type material layer to be electrically connected to the drain, the P-type material layer injects holes into the buffer layer under forward bias, neutralizes the trapped electrons in the buffer layer due to lattice defects or doping, and improves the electron density. The speed of detachment from the buffer layer increases the saturation current of the semiconductor device, reduces the dynamic on-resistance of the semiconductor device, and improves the performance of the semiconductor device.

Owner:DYNAX SEMICON

Photocuring 3D printing device and printing method thereof

ActiveCN110524874BGuaranteed accuracyAvoid deformationAdditive manufacturing apparatus3D object support structuresLight beamEngineering

Owner:YUANZHI TECH SHANGHAI CO LTD

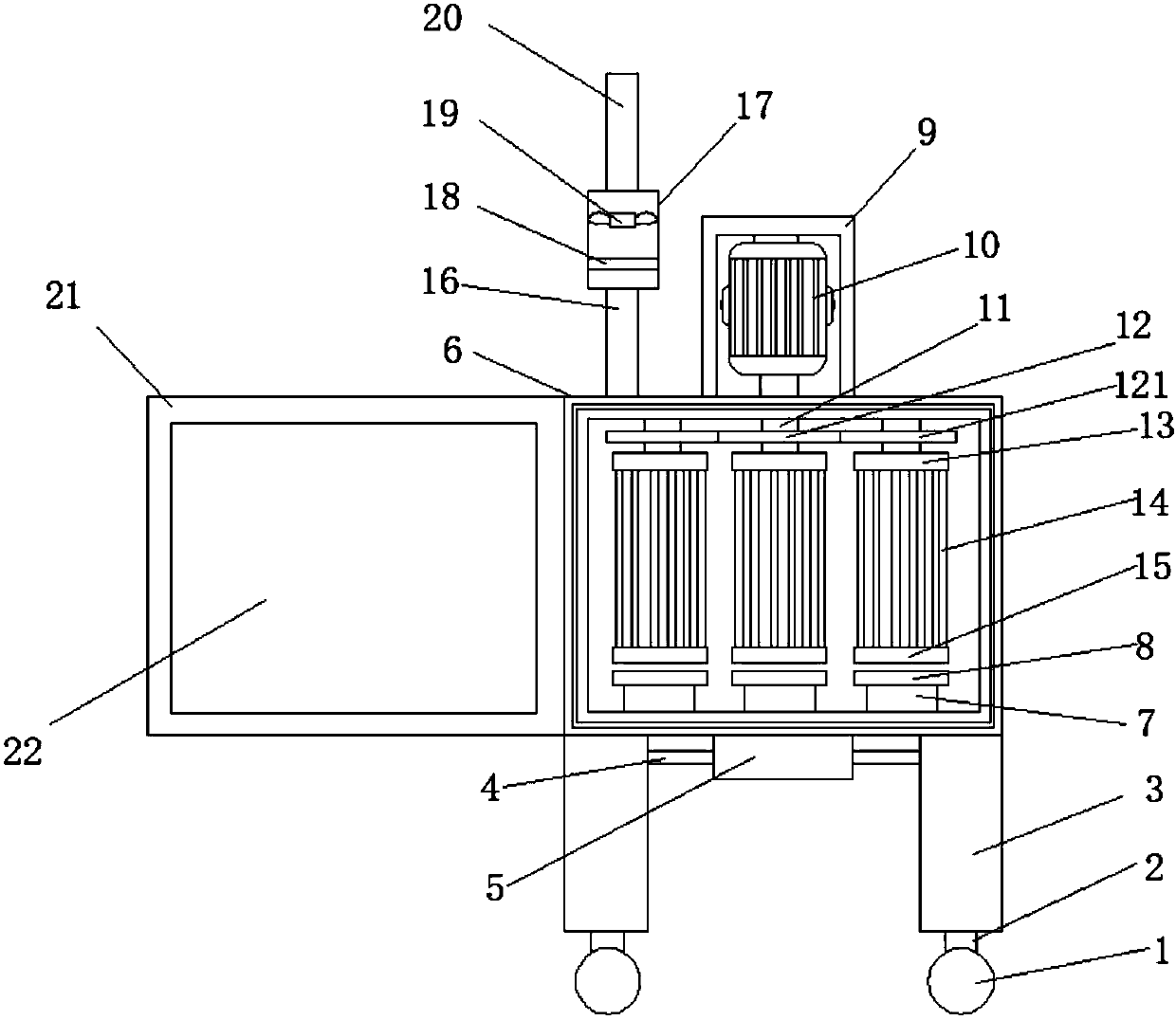

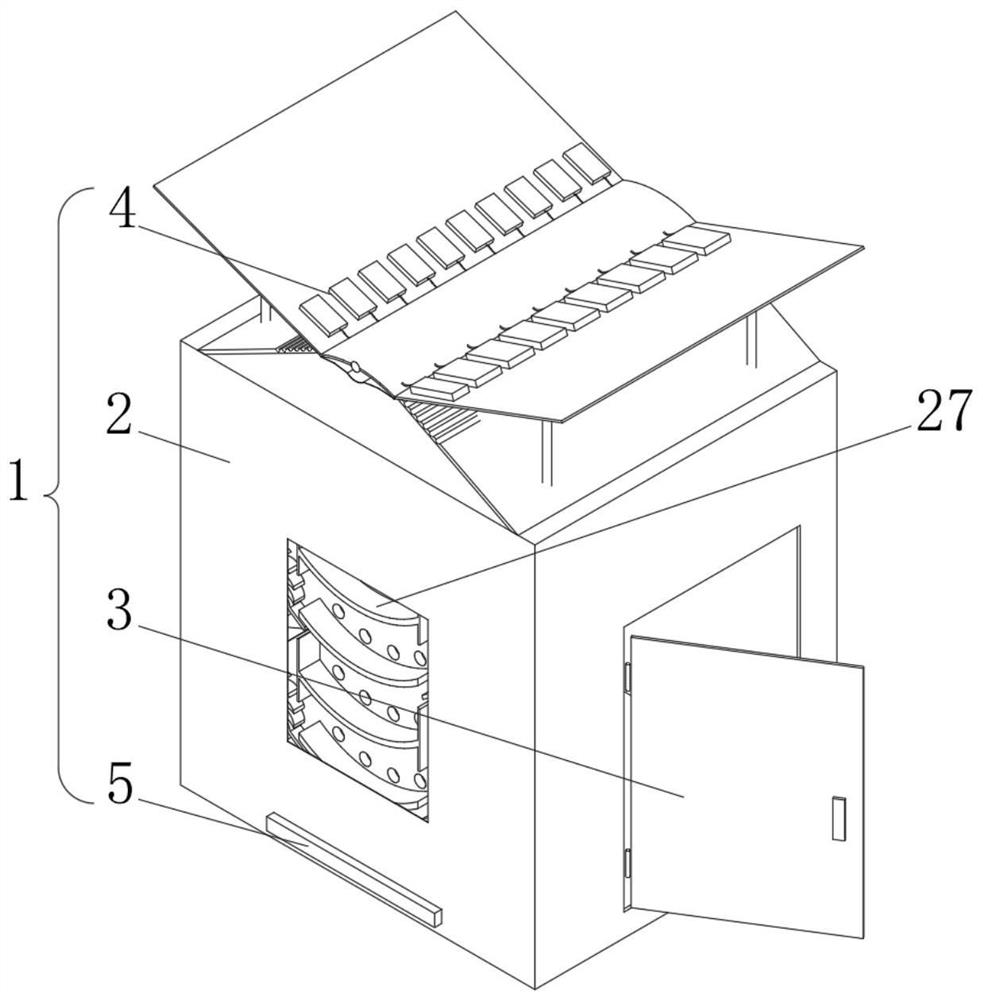

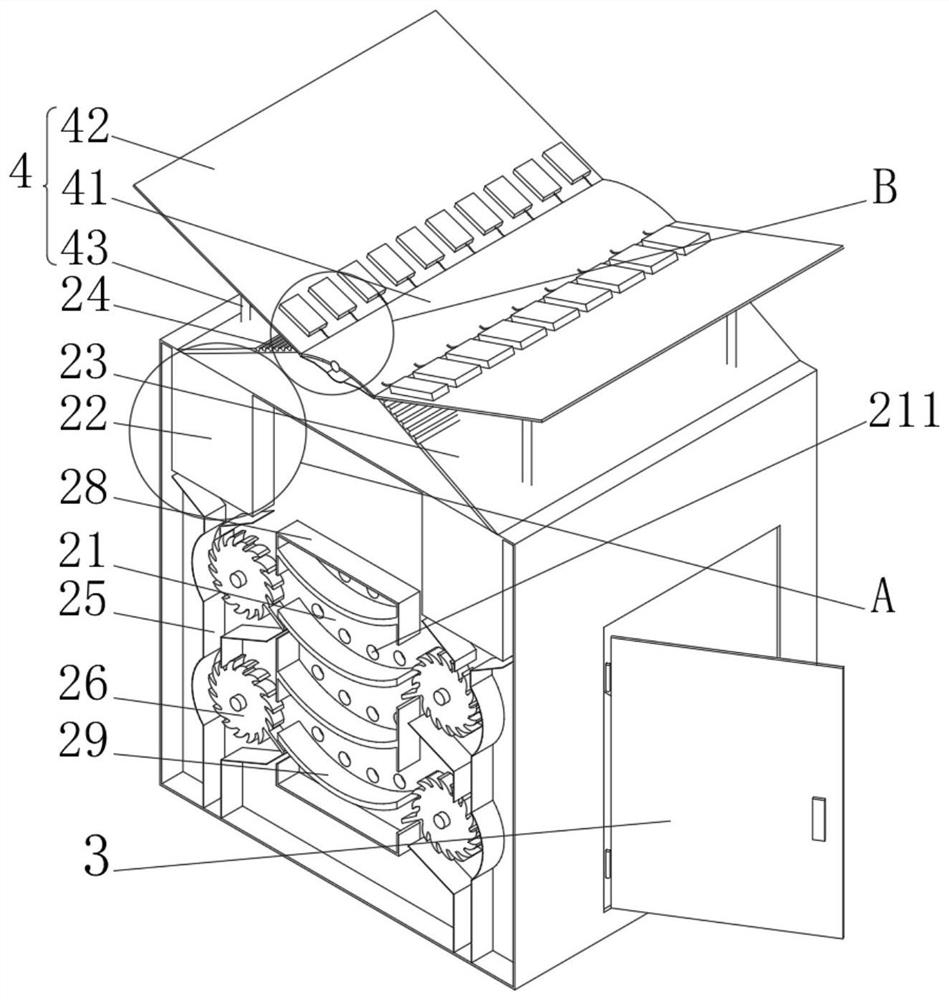

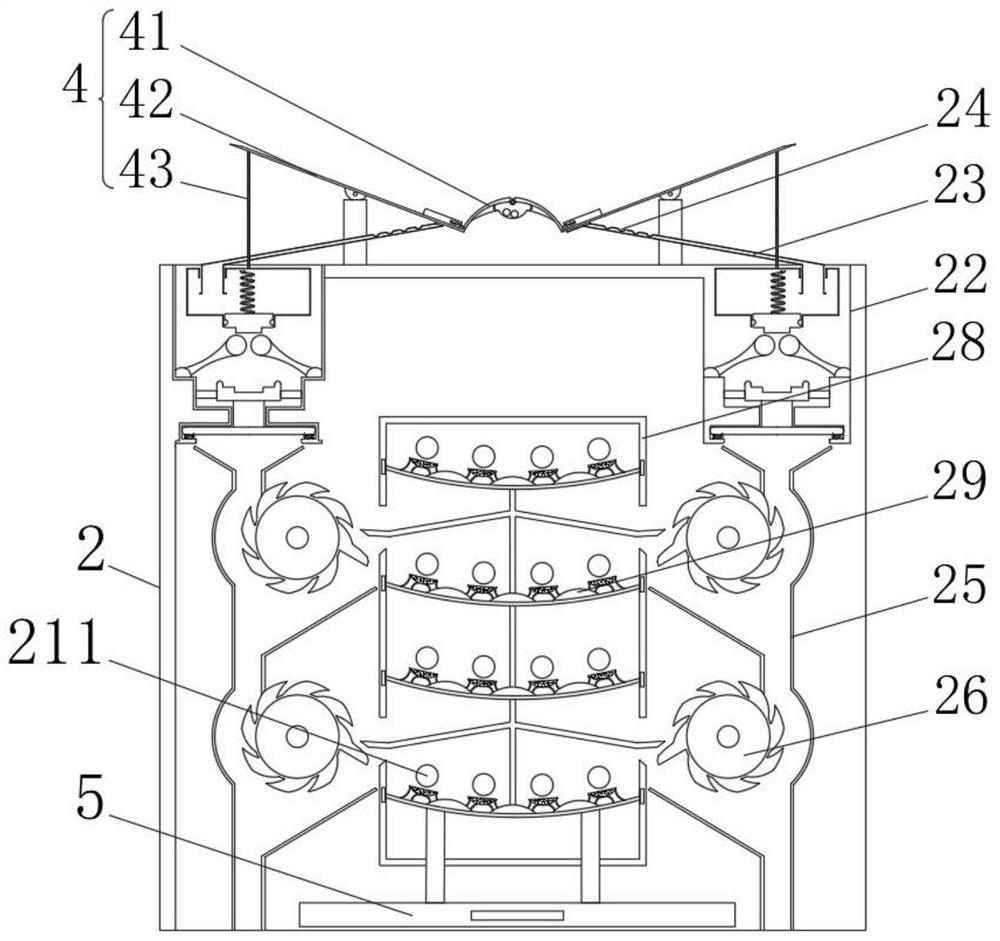

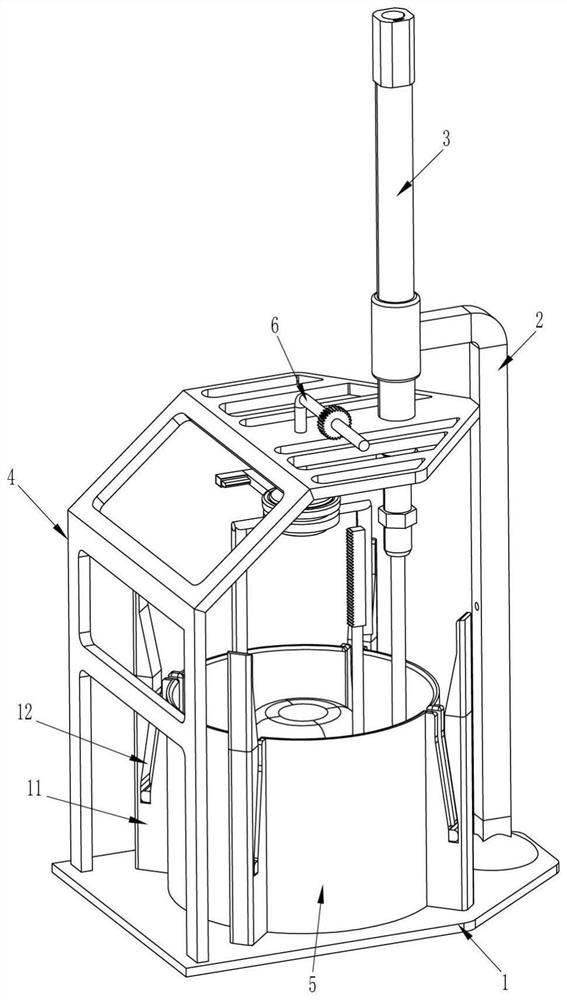

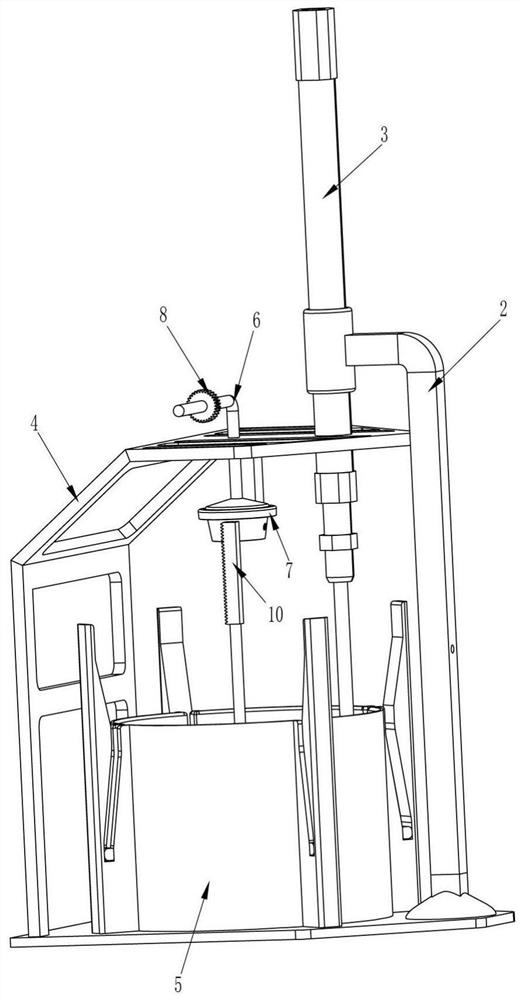

Syringe recovery treatment equipment for anesthesia department of hospital

ActiveCN112547764AImprove reprocessingFast Classification ProcessingSolid waste disposalSurgeryBiomedical engineering

The invention discloses syringe recovery treatment equipment for the anesthesia department of a hospital. The syringe recovery treatment equipment for the anesthesia department of the hospital comprises a box body, wherein a through hole is formed in the outer wall of the box body, a clamping part is installed in the box body, a buckle cover is buckled at the upper end of the box body, a needle tube separation device is installed on the buckle cover, and a partition plate is installed in the box body. By arranging the box body, a motor, a fixing rod and a clamping block, a needle cap insertedinto the through hole is limited through the needle tube limiting device, a needle tube is partially inserted into a strip-shaped opening in the fixing rod, the needle tube is wound through rotation of the motor, the curled shape of the needle tube is limited through the clamping block, the needle tube is wound and pulled out of the needle cap through rotation of the motor, and then separation forthe needle cap and the needle tube is realized; however, the motor is arranged on the buckle cover, the fixing rod is vertically arranged, the needle tube separated from the needle cap is spiral, theneedle tube falls off due to gravity and is separated from the fixing rod along with the rotation stop of the motor, and then automatic separation is realized.

Owner:JILIN UNIV

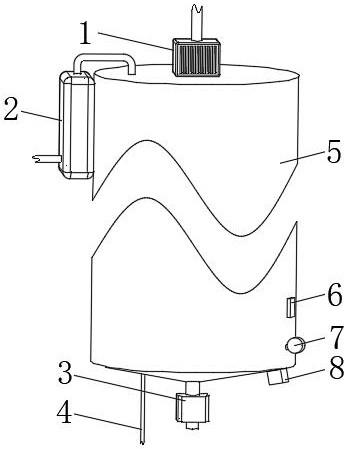

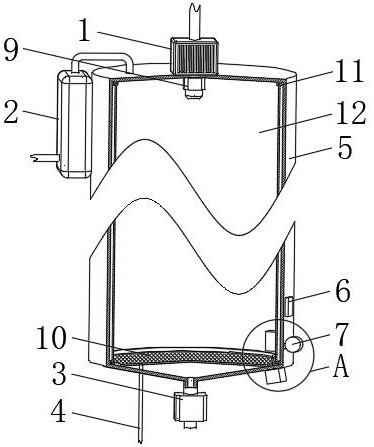

Novel security and protection fireproof firefighting channel system

InactiveCN109603021ASpeed up the breakawayReduce the difficulty of escapeBuilding rescueEngineeringReduced mobility

The invention provides a novel security and protection fireproof firefighting channel system which comprises a channel main body and an installing base. The installing base is arranged on the bottom of the channel main body. The installing base is fixedly connected to the ground through fixing bolts. The channel main body comprises a shell and a falling well. The falling well and the shell are arranged concentrically. The channel main body is arranged on one side of a high building. When a firefighting channel is used, multiple layers of buffering nets are arranged in the falling well, escaping personnel enter the falling well through a firefighting slideway and fall to the ground, by means of the design, the escaping speed of the escaping personnel can be increased, the escaping difficultis reduced greatly for personnel who have difficulty in moving, and life and property safety of people is ensured.

Owner:SHAANXI HUABANG TECH DEV CO LTD

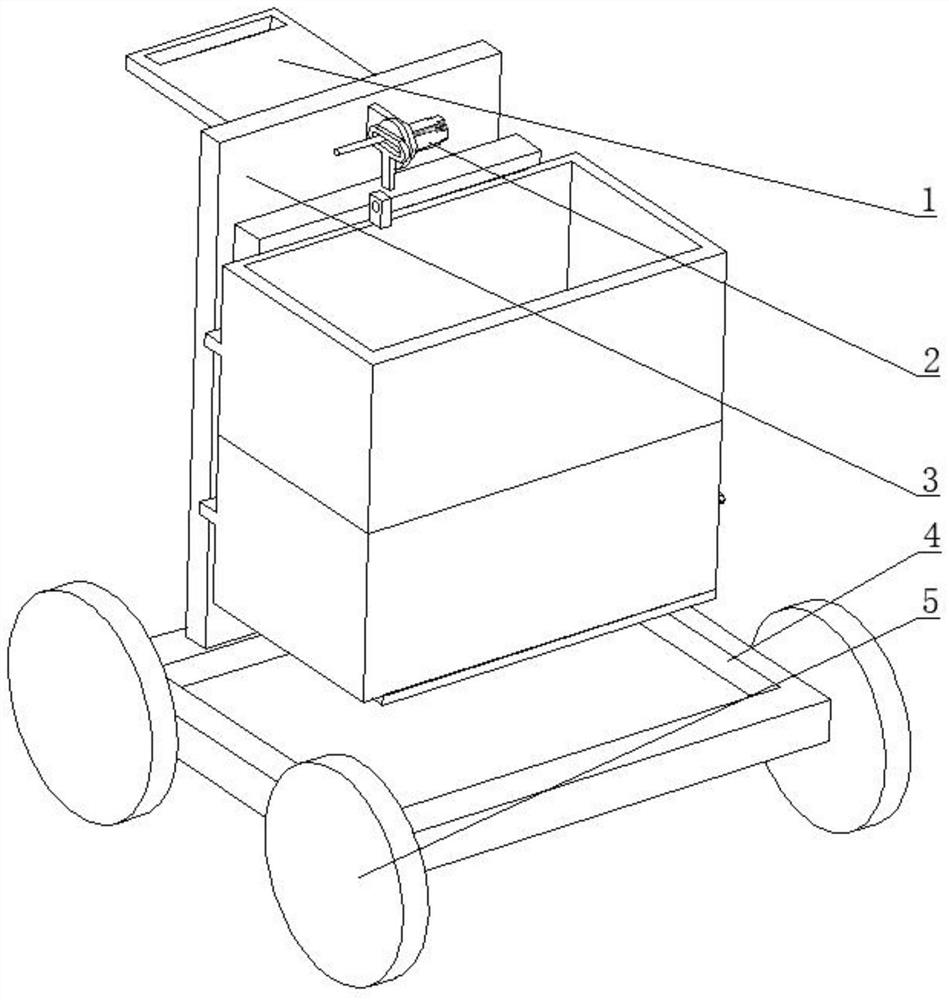

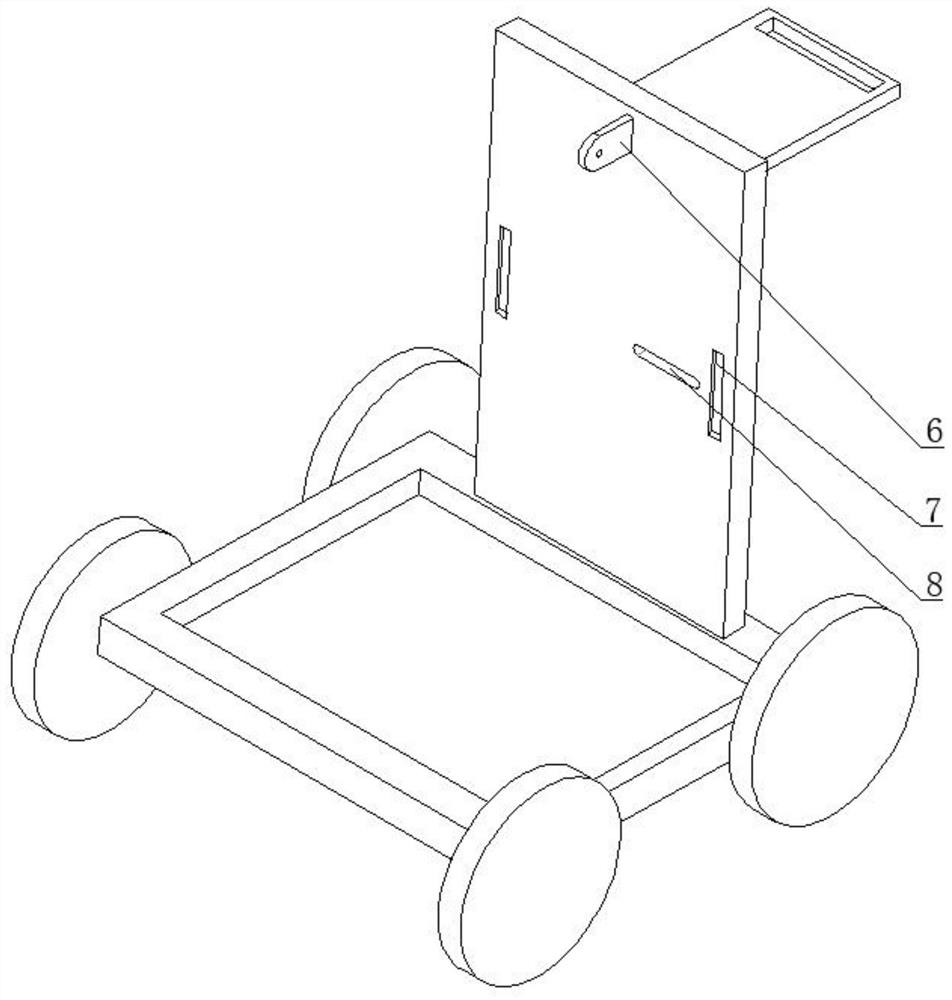

Environment-friendly cleaning vehicle convenient to move and clean

InactiveCN113458104AImprove work efficiencyLow costHollow article cleaningRefuse vehiclesElectric machineryProcess engineering

The invention discloses an environment-friendly cleaning vehicle convenient to move and clean. The environment-friendly cleaning vehicle convenient to move and clean comprises a chassis and is characterized in that the chassis is fixedly connected with a vertical plate, the vertical plate is provided with a straight groove, the vertical plate is provided with symmetrical trapezoidal sliding grooves, the vertical plate is fixedly connected with a motor bracket, the motor bracket is fixedly connected with a cleaning mechanism, and the cleaning mechanism is matched with a washing mechanism. The invention relates to the field of environment-friendly equipment, in particular to the environment-friendly cleaning vehicle convenient to move and clean. The technical problem to be solved by the invention is to provide the environment-friendly cleaning vehicle which is convenient to move and clean, and the cleaning of the environment-friendly cleaning vehicle is convenient.

Owner:HEBEI CHEM & PHARMA COLLEGE

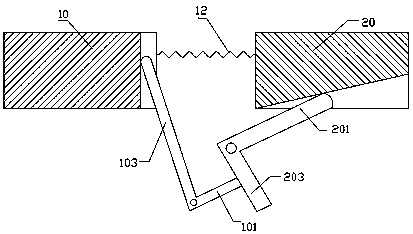

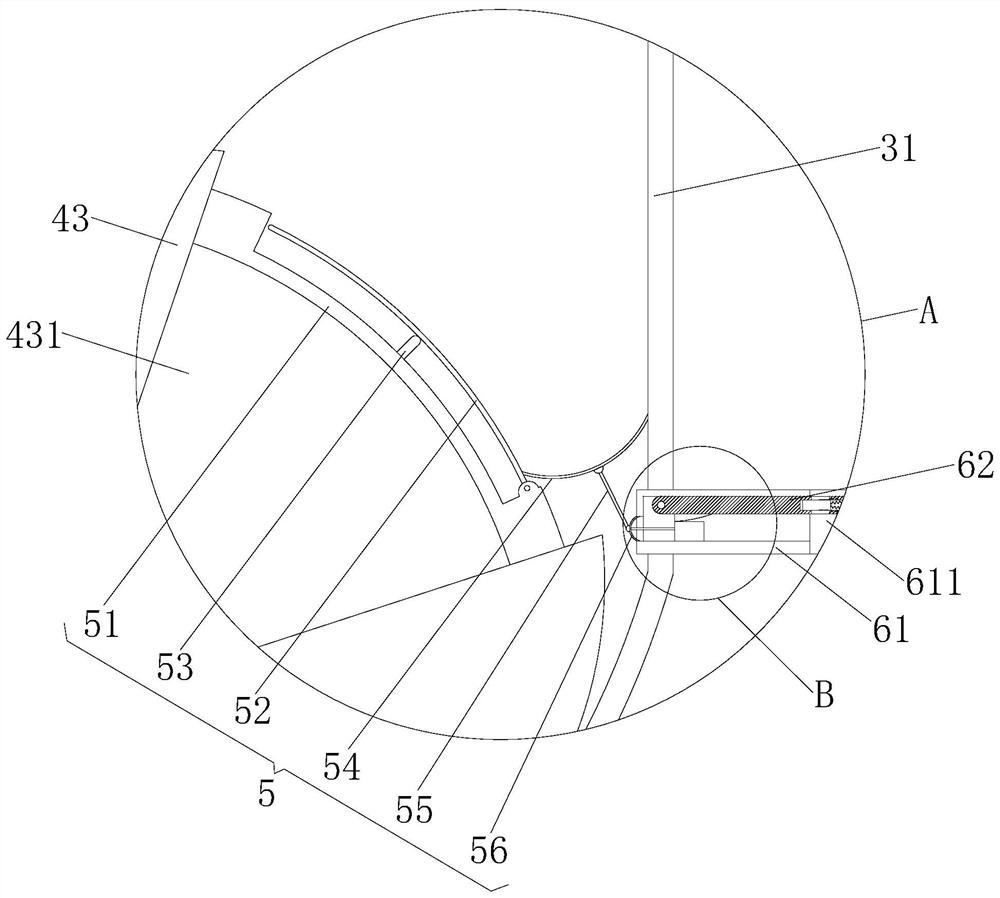

Quick disconnect attachment system, parachute system, attachment and disconnection method

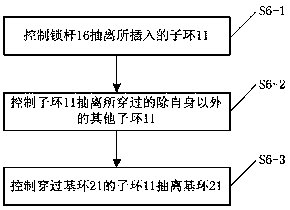

The present invention discloses a connection system, parachute system, connection, and detachment method that can be quickly detached. It is a connection device technology field. Among them, the connection system that can be quickly separated includes: the base ring, which is used to connect with the first connection parts; at least at leastTwo sub -rings, the sub -ring is connected to the first connection band through the second connection belt. The first connection belt is connected to the second to be connected.The holes in the middle of the ring; the lock rod is used to insert the hole in the middle of the rings during the connection.The present invention has the advantages of simple structure, low cost, high safety, high versatility, and reusable use.

Owner:北京耐威智能科技有限公司

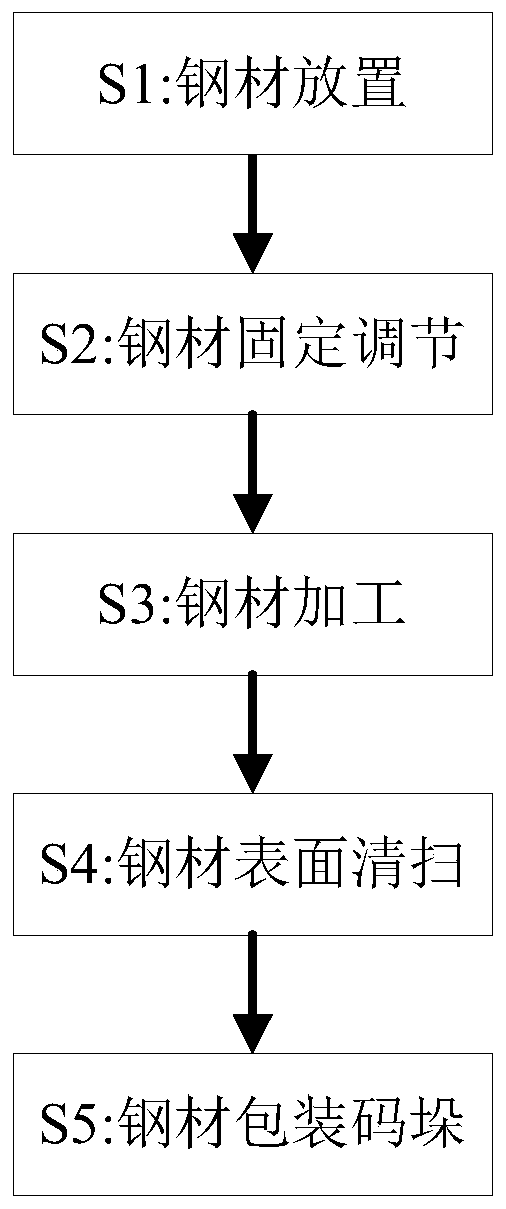

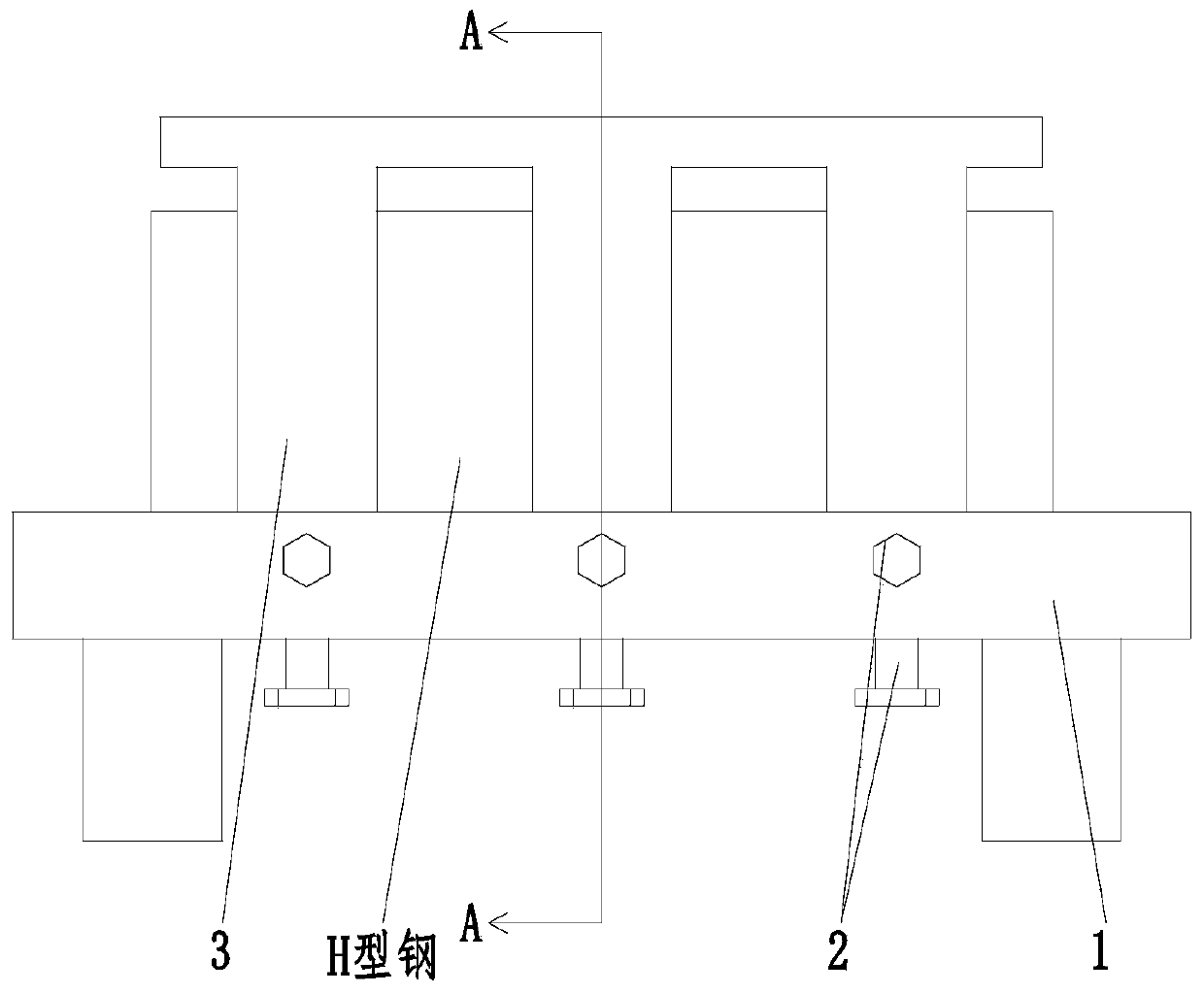

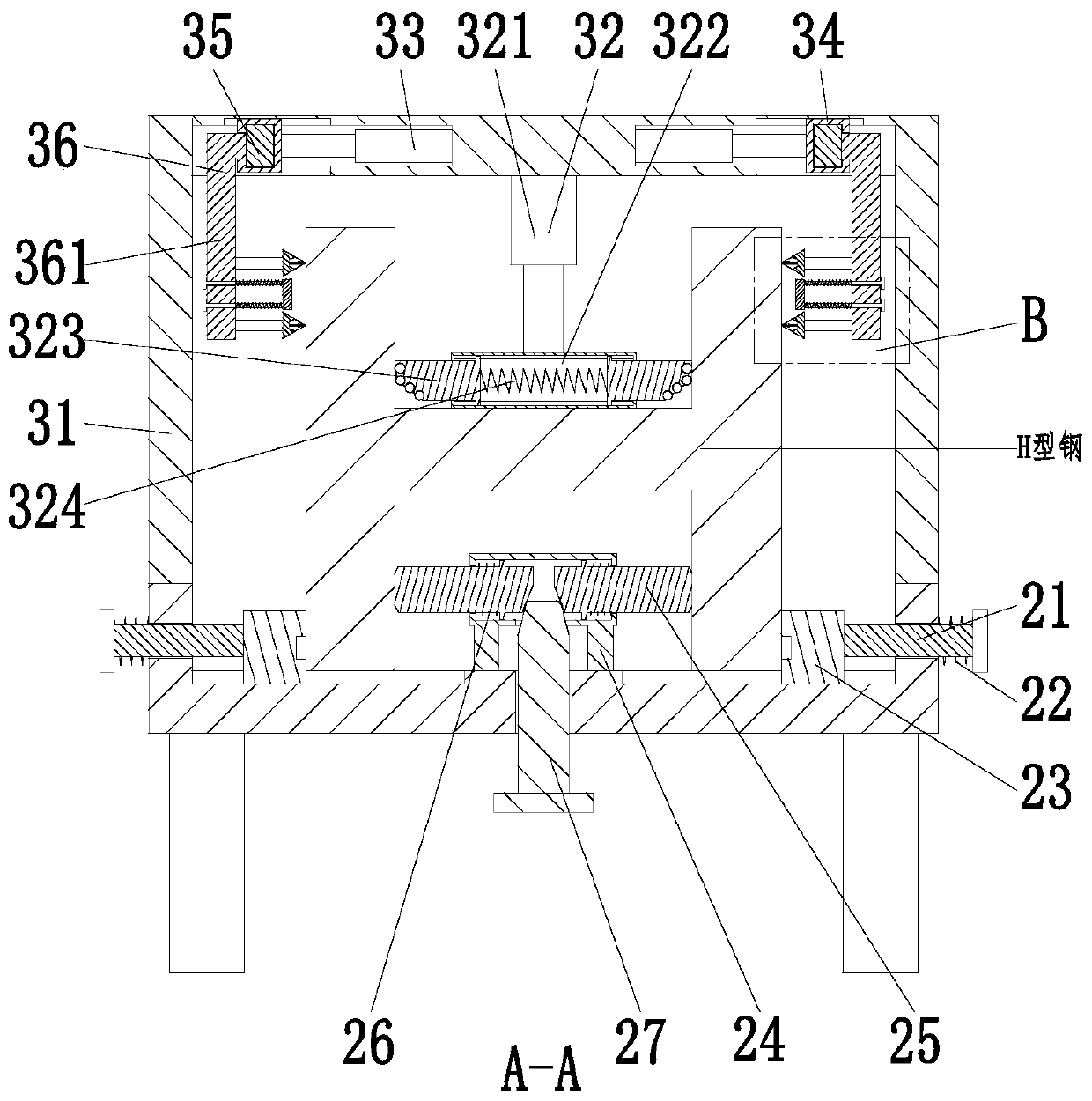

H-shaped steel manufacturing method

ActiveCN110976612AAvoid shakingSpeed up the breakawayMetal-working feeding devicesPositioning devicesUltimate tensile strengthIndustrial engineering

The invention provides an H-shaped steel manufacturing method. A bottom plate, a supporting frame, a flow guide hood, a shredding device, a pulverizing device, a spreading device and a screening device cooperate to complete environmental restoration of contaminated soil. The method solves the main problems existing in the process of forming a slotted hole through cutting in H-shaped steel by usinga cutting machine that on the one hand, in the cutting process, the H-shaped steel is easily shaken to cause an uneven notch surface and affect the later installation effect; on the other hand, the H-shaped steel is high in strength and hardness, the efficiency of cutting and slotting the H-shaped steel by using an existing cutting machine is low, a steel block obtained after cutting is difficultto take from the inside of the H-shaped steel, the steel block needs to be manually hammered by using a hammer, the surface of the H-shaped steel is easily damaged by manual hammering, and the rigidstructure of the H-shaped steel is affected.

Owner:诸暨泰泽机械有限公司

Multi-partition-based classifiable simple swing-cover-type garbage can

InactiveCN113666018ARealize automatic resetAchieve clearingRefuse receptaclesWater flowStructural engineering

The invention provides a multi-partition-based classifiable simple swing-cover-type garbage can, and relates to the technical field of garbage collection devices. The problems that vibration-type rapid separation of a solid-liquid mixture in a collection frame cannot be achieved through linkage while a swing cover is opened and closed through structural modification, and residues on a filter screen at the head end of a drainage pipeline cannot be cleaned away in a backflow mode while vibration separation is conducted are solved. The multi-partition-based classifiable simple swing-cover-type garbage can comprises a can body; and a screening structure is installed in the can body, a can cover is installed on the can body, and a base is installed at the bottom of the can body. The tail end of an extrusion rod is welded to the bottom end face of a screening frame, and the head end of the extrusion rod makes contact with a drainage pipe so that continuous extrusion of the drainage pipe can be achieved in a vertical movement process of the screening frame, and then residues attached to a filter screen can be removed through extrusion and backflow of water flows.

Owner:郑红

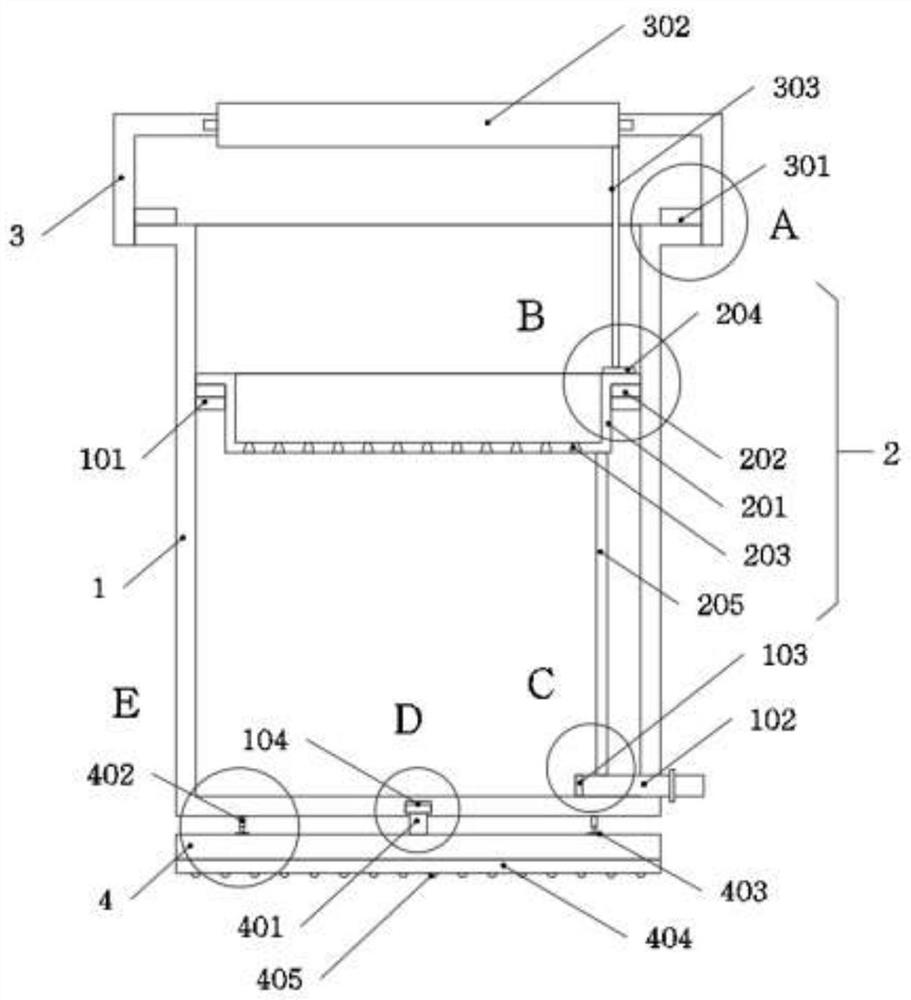

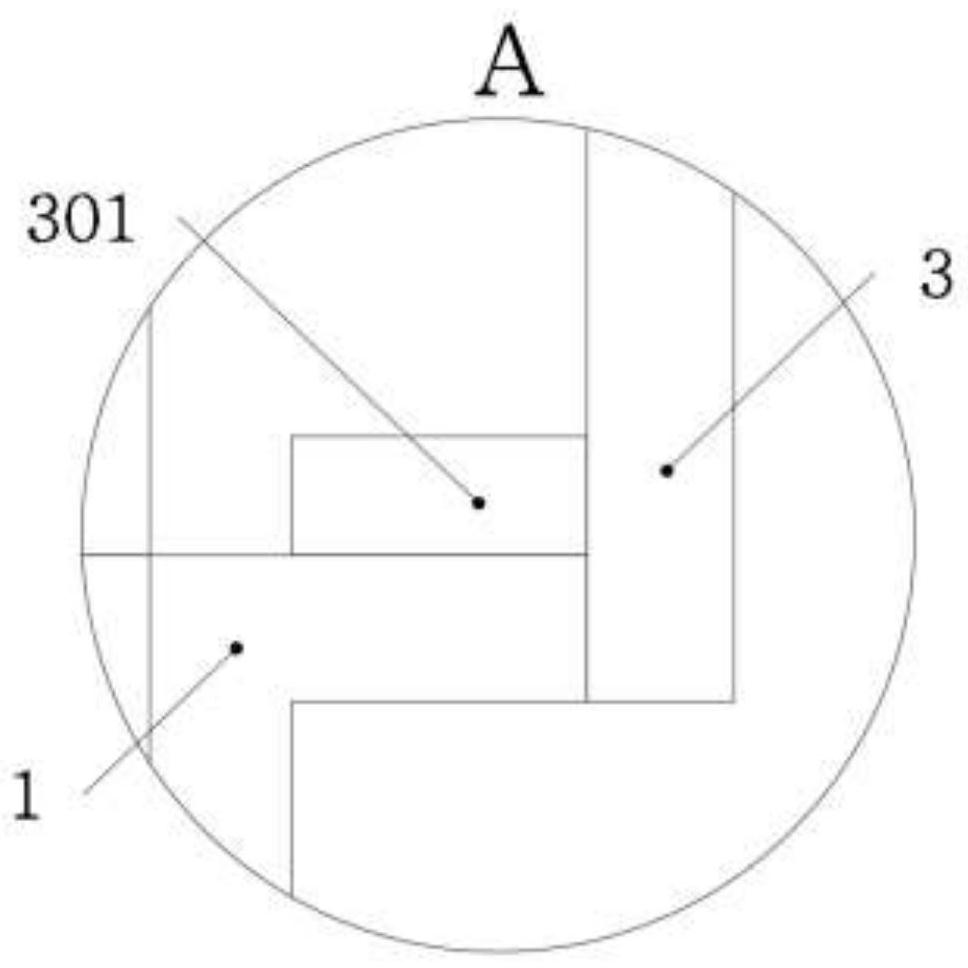

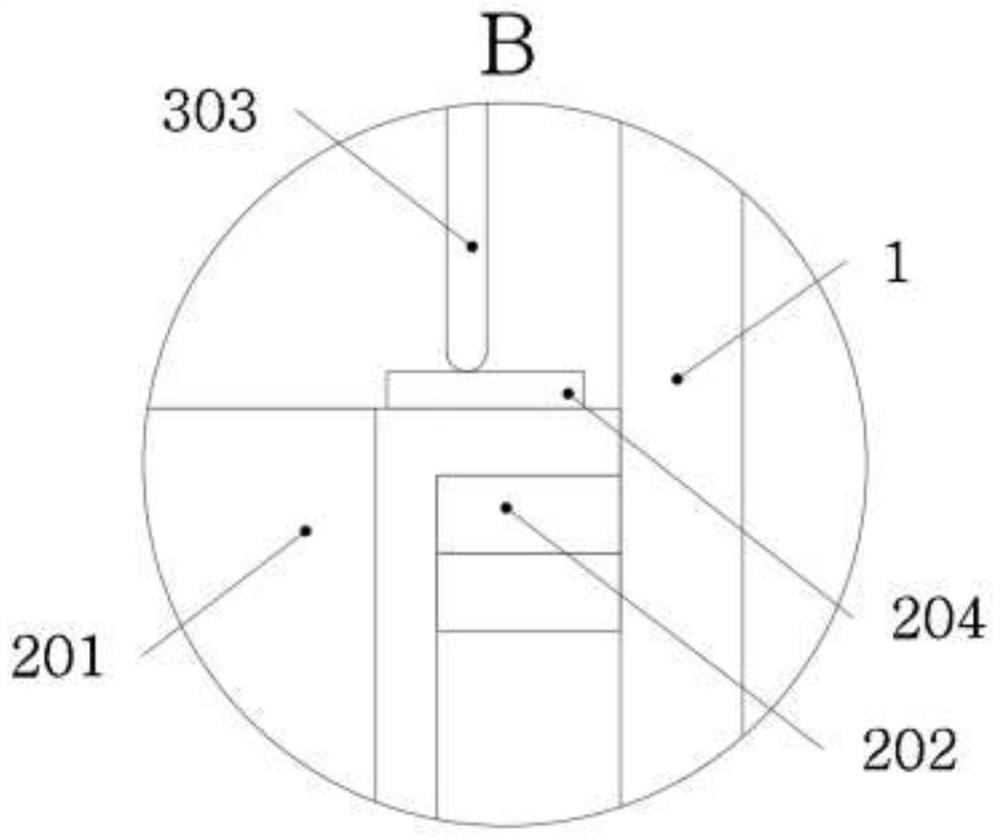

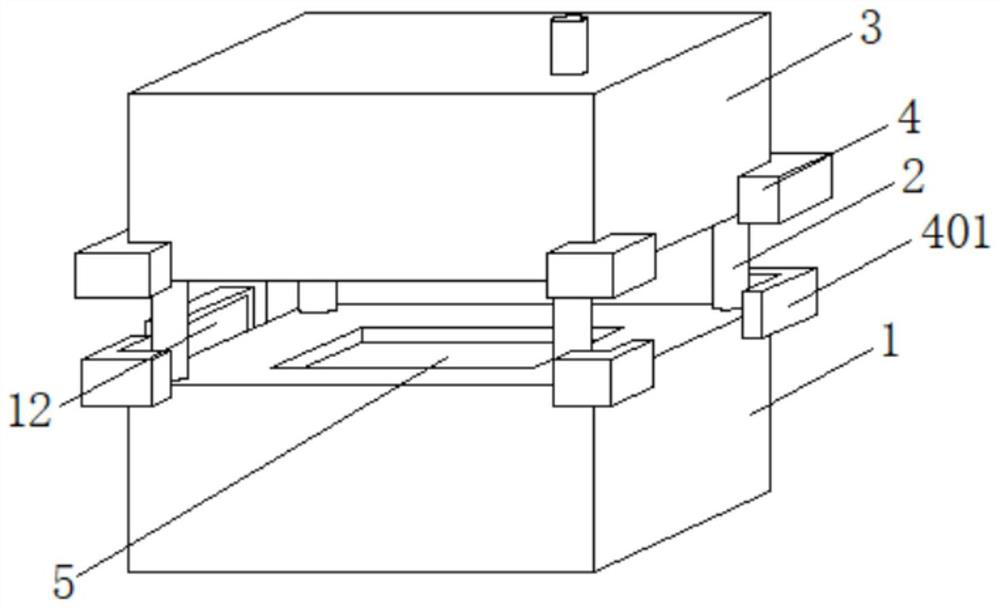

Forming die for keyboard production

PendingCN114368120ASolve the problem of being easily injured by moldEasy to demouldSuction forceGear wheel

The invention discloses a forming mold for keyboard production. The forming mold comprises a lower mold body, a limiting rod is arranged at the top end of the lower mold body, a mold groove is formed in the inner side of the lower mold body, a ventilation groove is formed in the lower mold body, an exhaust fan is installed on the left side of the lower mold body, and a mounting plate is arranged on the right side of the lower mold body. By arranging the gear, the movable plate, the conveying belt and the motor, when the movable plate moves to the position above the lower die, water in a water tank enters the movable plate through a water inlet pipe and is sprayed out through a plurality of water spraying holes, a keyboard is rapidly cooled, a second air pump collects air flow in the movable plate through a corrugated conveying pipe, the keyboard is sucked by suction force, and therefore the keyboard can be rapidly cooled. The motor is fixed to the bottom end of the movable plate in an attached mode, the motor drives the gear to rotate reversely, then the movable plate is driven to retract, the movable plate conveys the keyboard to the position above the conveying belt, the keyboard is separated from the movable plate and falls on the conveying belt to be conveyed, and the problem that workers are prone to being accidentally injured by the mold when taking the keyboard is effectively solved.

Owner:苏州凌瑞电子有限公司

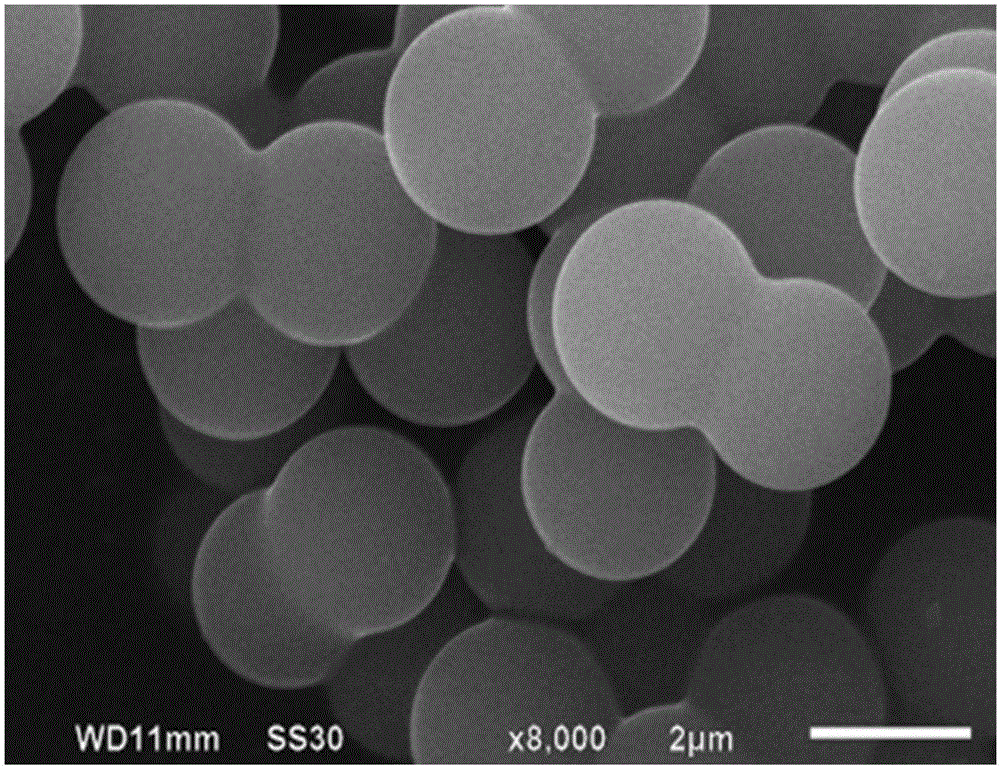

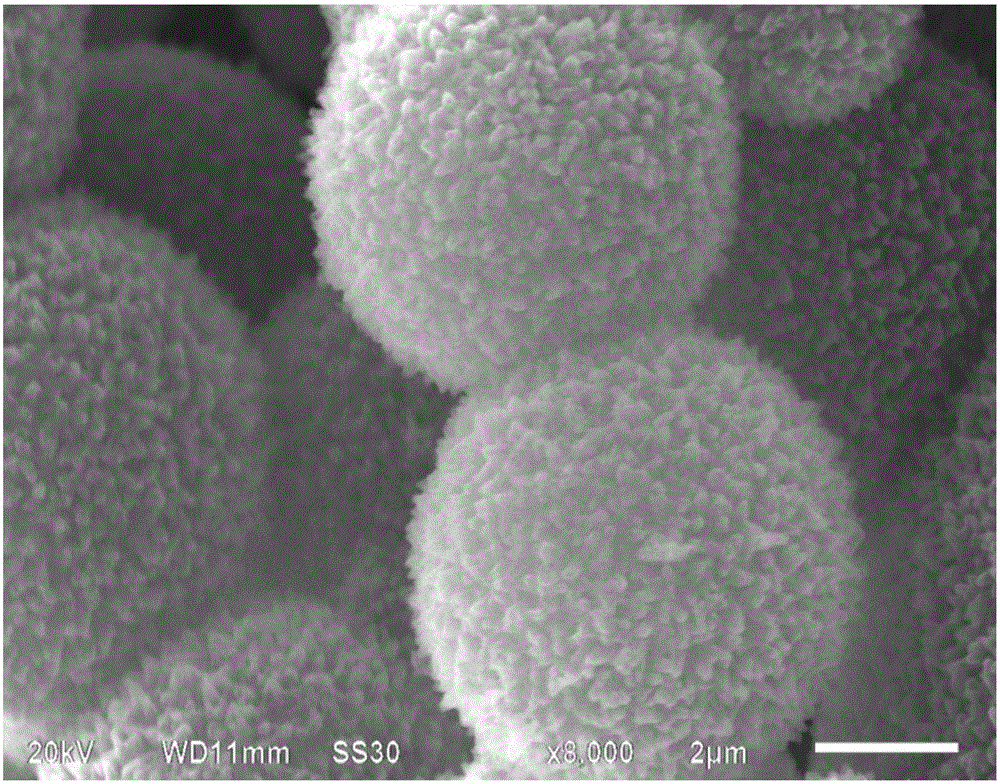

A kind of porous carbon microsphere tio2 composite material and its preparation method and application

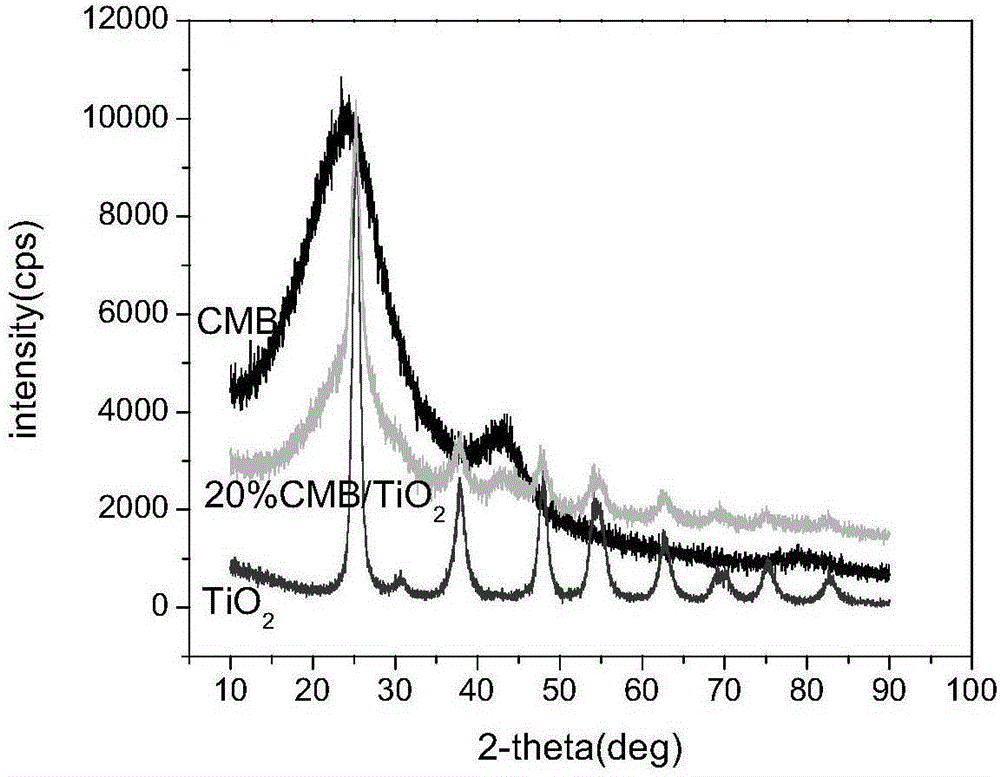

InactiveCN103785371BMaintain microsphere shapeImprove adsorption capacityPhysical/chemical process catalystsWater/sewage treatment by irradiationMicrospherePorous carbon

The invention discloses a porous carbon microsphere @TiO2 composite material and a preparation method and application thereof. Porous carbon microsphere @TiO2 is formed by evenly wrapping nano TiO2 on the surface of a porous carbon microsphere. The preparation method of the porous carbon microsphere @TiO2 composite material includes the steps that hydrothermal reaction, high-temperature carbonization and concentrated nitric acid activation are sequentially performed on glucose to obtain the porous carbon microsphere, TiO2 is prepared through a steam heat method, the surface of the porous carbon microsphere is wrapped by TiO2 in situ, and then the composite material is obtained. The preparation method is simple to operate and low in raw material price, and the prepared porous carbon microsphere @TiO2 composite material is stable in structure, meanwhile has high adsorption performance and catalytic activity, is applied to photocatalytic degradation of organic matter in waste water, and is high photocatalytic degradation, high in catalyst recovery rate and good in reuse effect.

Owner:XIANGTAN UNIV

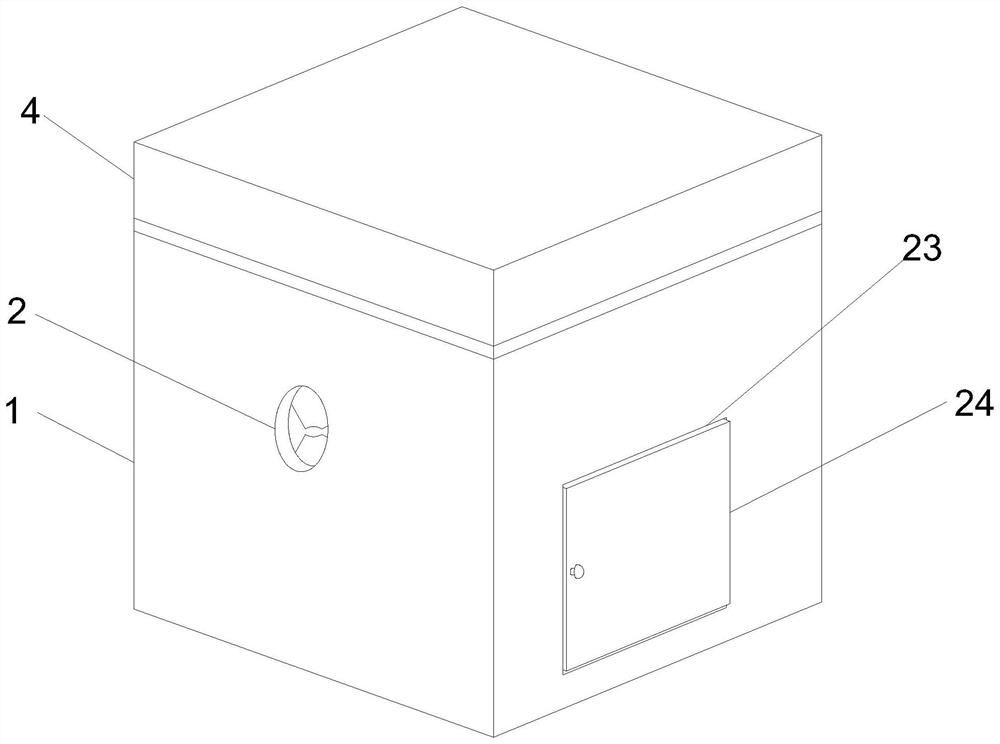

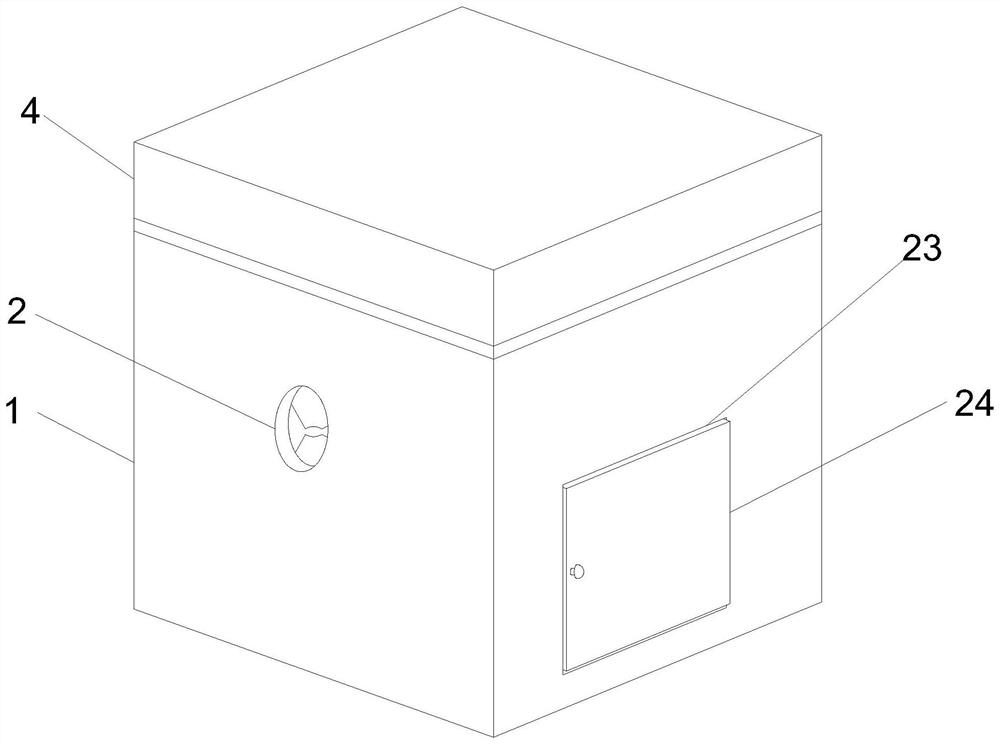

Outdoor dustproof control cabinet

PendingCN113488861AReduced service lifeWith self-cleaning functionSubstation/switching arrangement casingsCleaning using toolsMagnetic tension forceElectric power equipment

The invention discloses an outdoor dustproof control cabinet which comprises an outdoor dustproof control cabinet body composed of a box body, an opening and closing door, a water accumulation mechanism and a dust accumulation plate, wherein the front side of the box body is rotationally connected with the outer side of the opening and closing door through a hinge, and the top part of the water accumulation mechanism is fixedly connected with the top part of the box body through a connecting base. The outdoor dustproof control cabinet relates to the techncial field of control cabinets. The outdoor dustproof control cabinet solves the problems that when a traditional control cabinet is generally used outdoors, due to the fact that external air continuously flows, the dust content is large, and meanwhile a large amount of current flows through power equipment through lead wires, a magnetic field exists in the control cabinet, dust in the air is attracted by the magnetic force of the magnetic field and enters the control cabinet through heat dissipation holes, the dust is adsorbed on the inner walls of the heat dissipation holes by magnetic force, so that the heat dissipation holes are blocked, the heat dissipation effect in the control cabinet becomes poor, the temperature in the control cabinet rises, power equipment runs unstably and potential safety hazards exist.

Owner:方如意

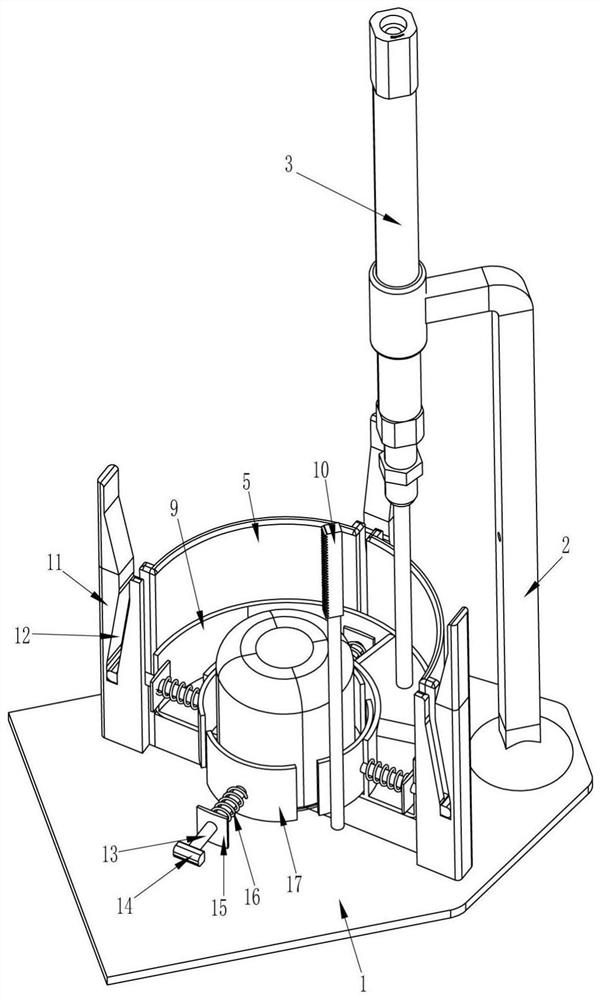

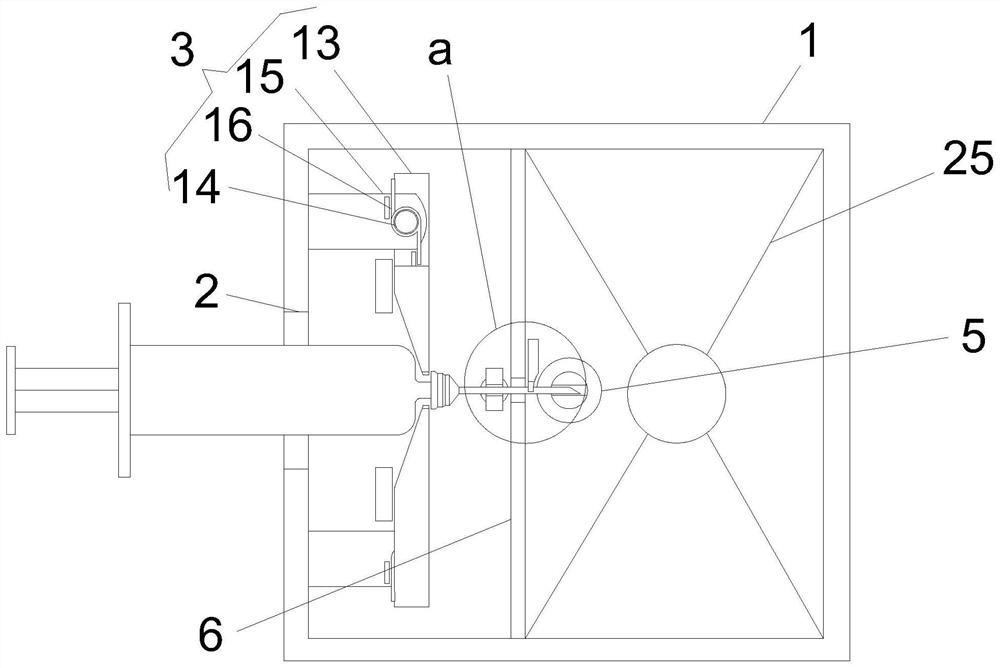

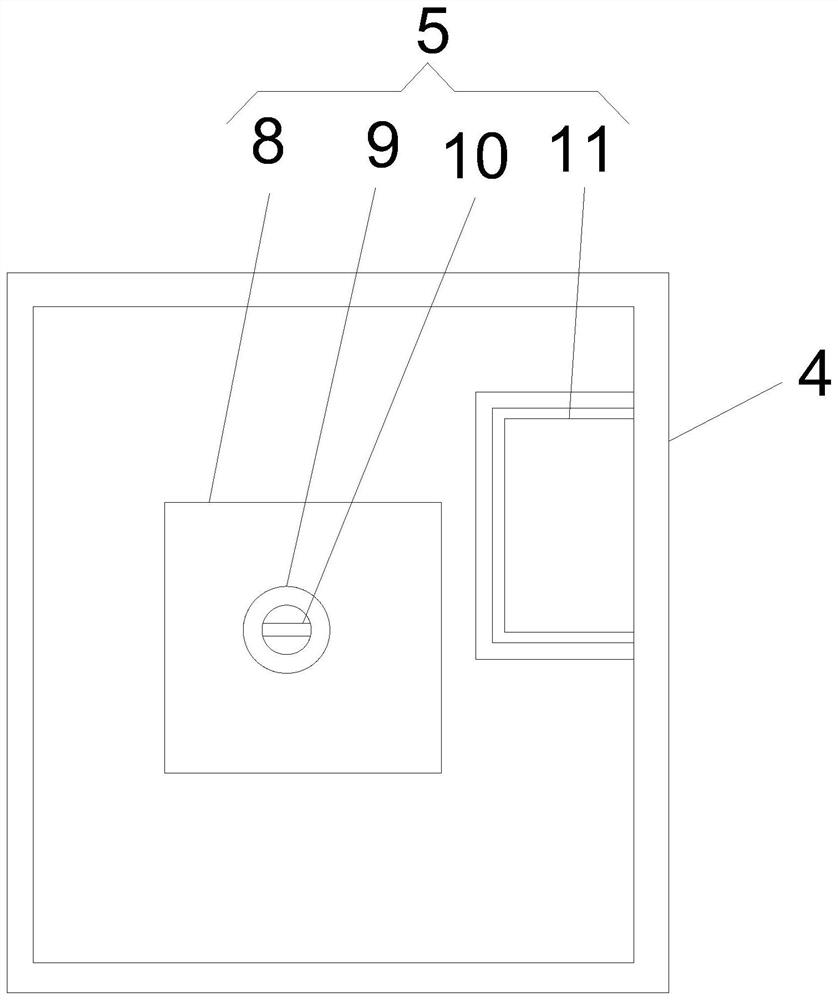

A mold for cable manufacturing and molding

ActiveCN112466556BEasy and effective installationImprove work efficiencyCable/conductor manufactureHydraulic cylinderElectric cables

The invention provides a mold for manufacturing and molding cables. The mold used for cable manufacturing and molding includes: a base plate; two strip-shaped fixed blocks one, and the two strip-shaped fixed blocks one are fixedly installed on the top of the base plate; two hydraulic cylinders, the two hydraulic cylinders respectively Fixedly installed on one side of two strip-shaped fixed blocks close to each other; two semicircular support blocks, the two semicircular support blocks are respectively fixedly installed on the output shafts of the two hydraulic cylinders; two semi-arc moving The mould, the two semi-arc movable molds are respectively fixedly installed on the top of the two semicircular support blocks; the two vertical placement plates are fixedly installed on the top of the base plate. The mold for cable manufacturing and molding provided by the invention can improve the uniformity of cable thickness and ensure product quality; it can effectively cool the cable after it is made and shaped, improve work efficiency, and is simple and convenient to operate.

Owner:天津市飞亚凤达线缆科技有限公司

Semiconductor device and preparation method thereof

ActiveCN111384164AIncrease saturation currentLower dynamic on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialElectrical connection

The embodiment of the invention discloses a semiconductor device and a preparation method thereof. The semiconductor device comprises: a substrate, multiple semiconductor layers which are positioned on one side of the substrate and comprise a buffer layer, a channel layer and a barrier layer which are sequentially positioned on one side of the substrate; a source electrode, a grid electrode and adrain electrode which are located on the side, away from the substrate, of the multiple semiconductor layers, wherein the grid electrode is located between the source electrode and the drain electrode; and P-type material layer located in the multiple semiconductor layers and located on the side, away from the grid electrode, of the drain electrode, the lower surface of the P-type material layer extends to the surface of the side, close to the channel layer, of the buffer layer or extends into the buffer layer, and the P-type material layer is electrically connected with the drain electrode. AP-type material layer is arranged to be electrically connected with a drain electrode; under forward bias, the P-type material layer injects holes into the buffer layer to neutralize electrons boundby traps caused by lattice defects or doping in the buffer layer, so that the speed of separating the electrons from the buffer layer is increased, the saturation current of the semiconductor device is improved, the dynamic on-resistance of the semiconductor device is reduced, and the performance of the semiconductor device is improved.

Owner:DYNAX SEMICON

A kind of air-blown ceramic original tire stripper

ActiveCN111136594BImprove work efficiencyEasy to operateDischarging arrangementGrinding devicesAir pumpEngineering

The invention relates to a demoulding device, in particular to an air-blowing ceramic original tire demoulding device. The technical problem is how to design a kind of air-blown ceramic original tire stripper that can replace manual airflow blowing into the gap between the original tire and the mould, is easy to operate, and is not easy to be tired and affect work efficiency. An air-blown ceramic original tire stripper, including a base, a frame is fixedly connected to the edge of one side of the base, a storage box is installed on the side of the base close to the frame, and a support rod is installed on the side of the base away from the frame . The invention puts the original tire and the mold into the middle of the placement frame, and then connects the high-pressure air pipe to the air pump, shortens the telescopic rod of the starting cylinder, so that the rack drives the switch to open, and the high-pressure air pipe sprays the airflow into the gap between the original tire and the mould. There is no need to hold the air gun to move the original tire from the mold continuously. It is easy to operate, not easy to be tired, and has high work efficiency.

Owner:DEHUA COUNTY LIDE HOUSEHOLD ARTICLE CO LTD

A kind of syringe recycling and processing equipment for hospital anesthesiology department

ActiveCN112547764BImprove reprocessingFast Classification ProcessingSolid waste disposalAnesthetic departmentEngineering

The invention discloses a syringe recycling and processing device for the anesthesiology department of a hospital. A needle tube separation device is installed on the top of the box, and a partition is installed inside the box. By setting the box, motor, fixing rod and block, the needle cap inserted into the through hole is limited by the needle tube limit device. , the needle tube is partially inserted into the strip-shaped opening on the fixed rod, the rotation of the motor winds up the needle tube, and the clamping block limits the curled shape of the needle tube, and the needle tube is wound up and pulled out from the needle cap through the rotation of the motor. Then realize the disengagement of the needle cap and the needle tube. However, the motor is arranged on the buckle cover, and the fixed rod is vertically arranged. Realize automatic disengagement.

Owner:JILIN UNIV

Quenching equipment for chain hinge pin with high static load bending strength

ActiveCN113897479AReduce internal stressReduced tendency to deform and crackFurnace typesHeat treatment process controlOil canWater storage tank

The invention provides quenching equipment for a chain hinge pin with high static load bending strength, and belongs to the technical field of hinge pin thermal treatment equipment. The quenching equipment for the chain hinge pin with the high static load bending strength comprises a treatment box body, a connecting pipeline, an oil storage tank, a water storage tank and a servo motor, a fixed disc is arranged in the interior of the treatment box body, a communicating opening is formed in the interior of the fixed disc, and the communicating opening is in a vertical linear shape. The equipment can accurately control the time point of double-liquid conversion, then the internal stress of martensite conversion of the hinge pin can be effectively reduced, the tendency of deformation and cracking of a workpiece is reduced, the structural performance of the workpiece is optimized, used water and oil can be well classified and collected, and meanwhile, the production efficiency is also improved.

Owner:绩溪徽腾机械有限公司

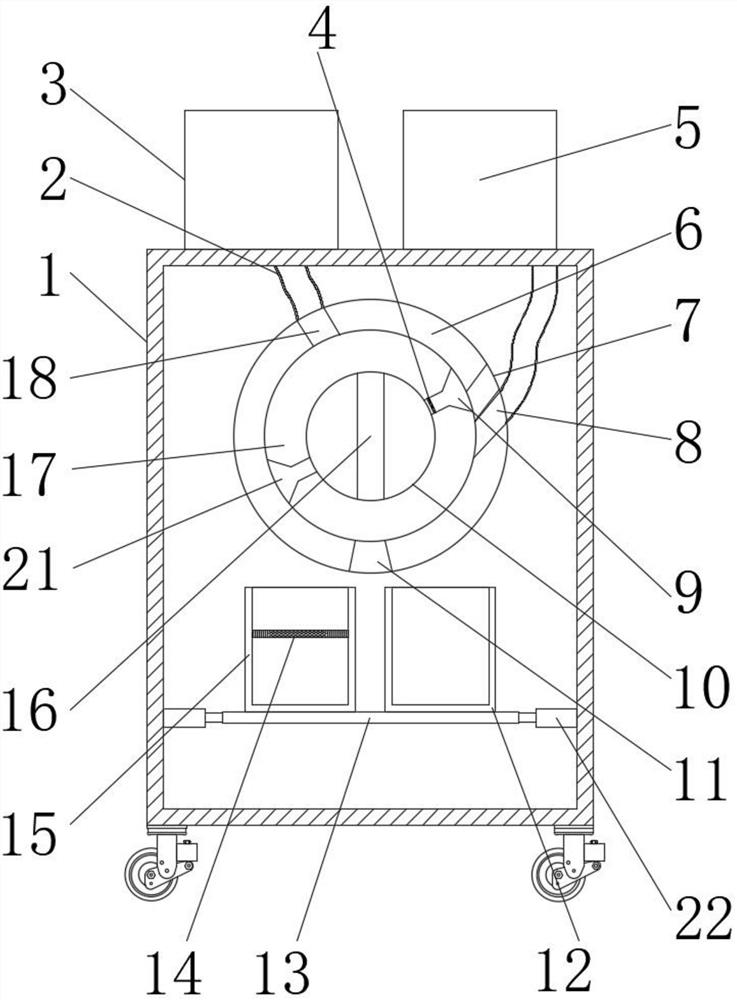

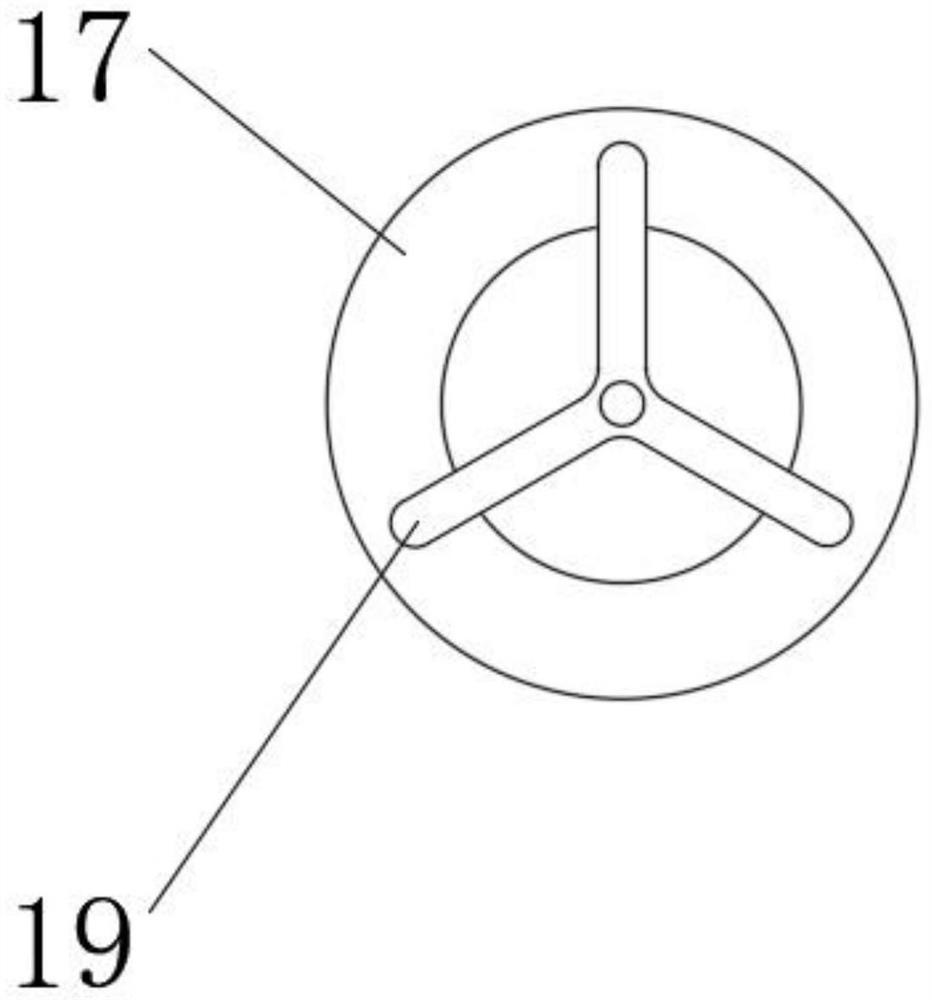

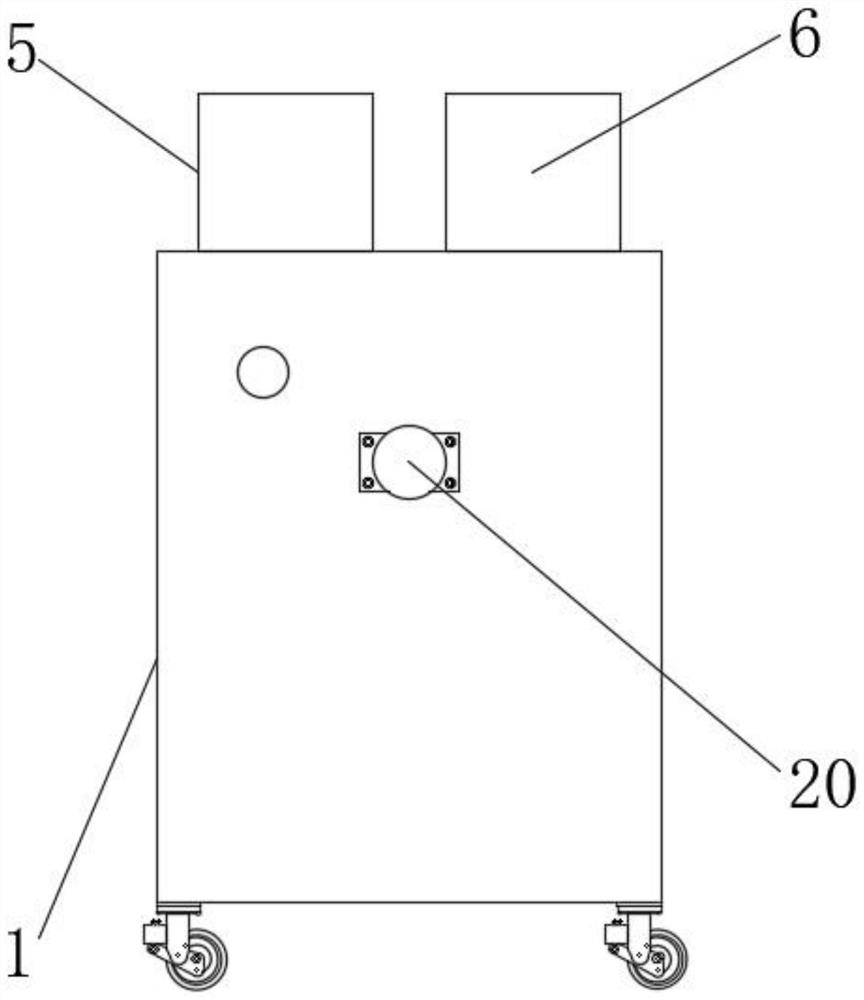

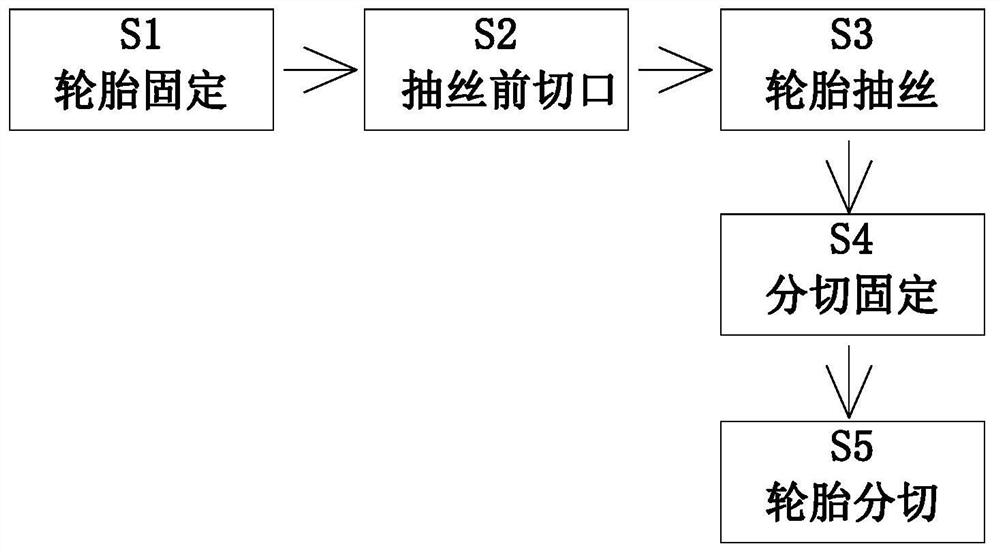

Environment-friendly recycling treatment method for rubber parts

InactiveCN112549366AImprove the stabilitySpeed up the breakawayPlastic recyclingWorkbenchIndustrial engineering

The invention relates to an environment-friendly recycling treatment method for rubber parts, which uses a rubber part recycling environment-friendly treatment device, the rubber part recycling environment-friendly treatment device comprises a workbench, a wire drawing mechanism and a slitting mechanism; the lower end of the workbench is installed on the existing working ground; the wire drawing mechanism is arranged at the left end of the upper end of the workbench; and the slitting mechanism is arranged at the right end of the upper end of the workbench. According to the environment-friendlyrecycling treatment method for the rubber parts provided by the invention, the design concept of a structure combining wire drawing and slitting is adopted for rubber part recycling and environment-friendly treatment, the arranged wire drawing mechanism adopts a structure with multiple clamping and fixing effects so as to improve the stability degree in the tire wire drawing process, and then theseparation speed between a steel wire and a tire is increased; and the arranged slitting mechanism can slit the tire into strips, a structure for quickly and intensively picking up the slit tire strips is arranged, and the structure can separate chippings generated by slitting the tire.

Owner:南京入海流科技有限公司

Hot galvanizing bridge rack

PendingCN114231873AReduce lossAvoid collision with each otherHot-dipping/immersion processesDirt cleaningStructural engineeringManufacturing engineering

The invention relates to the field of hot-dip galvanizing bridges, in particular to a hot-dip galvanizing bridge hanger which comprises a movable frame, a gas collection cavity provided with an anti-corrosion coating is formed in the movable frame, a sliding frame is slidably connected into the gas collection cavity, an exhaust port is formed in the position, above the gas collection cavity, of the movable frame, and a first one-way valve is arranged in the exhaust port. A plurality of exhaust holes communicated with the gas collection cavity are formed in the upper portion of the sliding frame body, second one-way valves are arranged in the exhaust holes, a first partition plate fixedly connected is arranged in the sliding frame body, and two second partition plates which are perpendicular to the first partition plate and are symmetrically arranged are arranged in the sliding frame body; one end of the second partition plate is fixedly connected with the first partition plate, the other end of the second partition plate is fixedly connected with the inner wall of the sliding frame body, four fixedly-connected hydraulic rods are arranged above the sliding frame body, and a smoke prevention plate is fixedly connected below the sliding frame body. And the phenomenon that the hot galvanizing quality is reduced due to mutual collision between the bridges can be avoided.

Owner:周继伟

Cloth processing deodorization equipment and deodorization method

ActiveCN108035088BFacilitated DiffusionSpeed up the flowTextile treatment containersTextile treatment machine arrangementsActivated carbonElectric machine

Owner:浙江好派服饰有限公司

Permanent magnet transmission support equipment for gear machining

ActiveCN106787602AReduce radial forceExtended service lifeDynamo-electric brakes/clutchesElectrical conductorGear wheel

The invention relates to the technical field of gear machining, and particularly relates to permanent magnet transmission support equipment for gear machining. The permanent magnet transmission support equipment comprises a support seat and an installation seat which can be mutually driven to reversely move at the same time, wherein the support seat comprises a base and a support rod; the support rod is fixed on the base; a connection hole is formed in the upper part of the support rod; a support bearing is arranged in the connection hole; a motor is arranged on the installation seat; a motor shaft of the motor is connected with a conductor plate; the conductor plate is sleeved with an outer sleeve capable of shrinking under the action force of the support bearing; the outer sleeve can slide into the support bearing and is provided with an inner cavity containing lubricating oil; and the outer sleeve is provided with a seal cover capable of being opened outwards. The invention aims at providing equipment capable of supporting a permanent magnet in a transmission mechanism.

Owner:CHONGQING SUTENG MACHINERY MFG

In-vehicle light-emitting cup mat

The invention discloses an in-vehicle light-emitting cup mat, and relates to the technical field of in-vehicle decorative lighting. The in-vehicle light-emitting cup mat comprises a cup mat body, a driving block penetrates through the center of the top of the cup mat body and is movably connected with the driving block, a plurality of placing layers are arranged at the top of the driving block, the diameter of the placing layer closer to the cup mat body is smaller, and a water conveying channel is formed in the center between the top and the bottom of the driving block in a penetrating mode. According to the in-vehicle light-emitting cup mat, when a water cup is placed at the top of the cup mat body, a driving block descends under the gravity action of the water cup, a driving mechanism opens a sealing mechanism through a connecting mechanism, water sliding down along the outer wall of the water cup enters a water storage device through a water conveying channel to be stored, and the water sliding down along the outer wall of the water cup is prevented from damaging a light-emitting piece; when the water cup is taken away, the sealing mechanism can be automatically closed again, and therefore the situation that water in the water storage device spills out due to the fact that the vehicle body shakes in the driving process is prevented.

Owner:王森林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com