Permanent magnet drive support equipment for gear machining

A technology of rotating support and permanent magnet, which is applied in the field of gear processing, can solve problems such as motor shaft bending, achieve the effects of reducing radial force, accelerating detachment speed, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

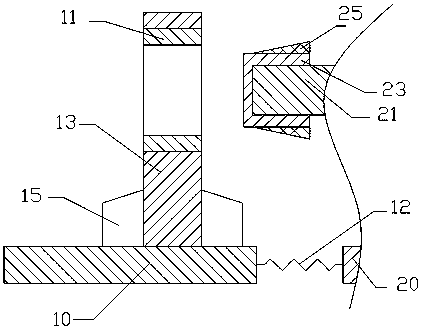

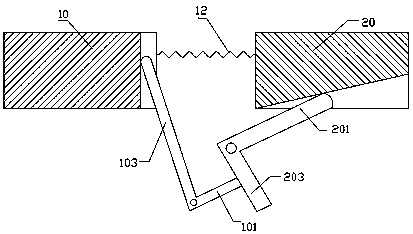

[0020] The reference signs in the accompanying drawings of the specification include: base 10, support bearing 11, extension spring 12, pole 13, support block 15, second swing end 101, second drive end 103, mounting seat 20, motor shaft 21, conductor Disk 23 , jacket 25 , first swing end 201 , first drive end 203 .

[0021] Explanation: In the manual, the first swing end refers to the swing end of the first V-shaped swing link, the first driving end refers to the drive end of the first V-shaped swing link, and the second swing end refers to the swing of the second V-shaped swing link end and the second driving end refer to the driving end of the second V-shaped swing link.

[0022] Such as figure 1 The shown permanent magnet rotating support device for gear processing includes a support base and a mounting base 20 that can move in reverse or opposite directions at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com