A mold for cable manufacturing and molding

A cable manufacturing and mold technology, which is applied in the field of cable manufacturing and molding molds, can solve the problems of not involving the cable cooling function, wasting working time, and reducing work efficiency, so as to improve the quality of injection molding, increase production efficiency, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

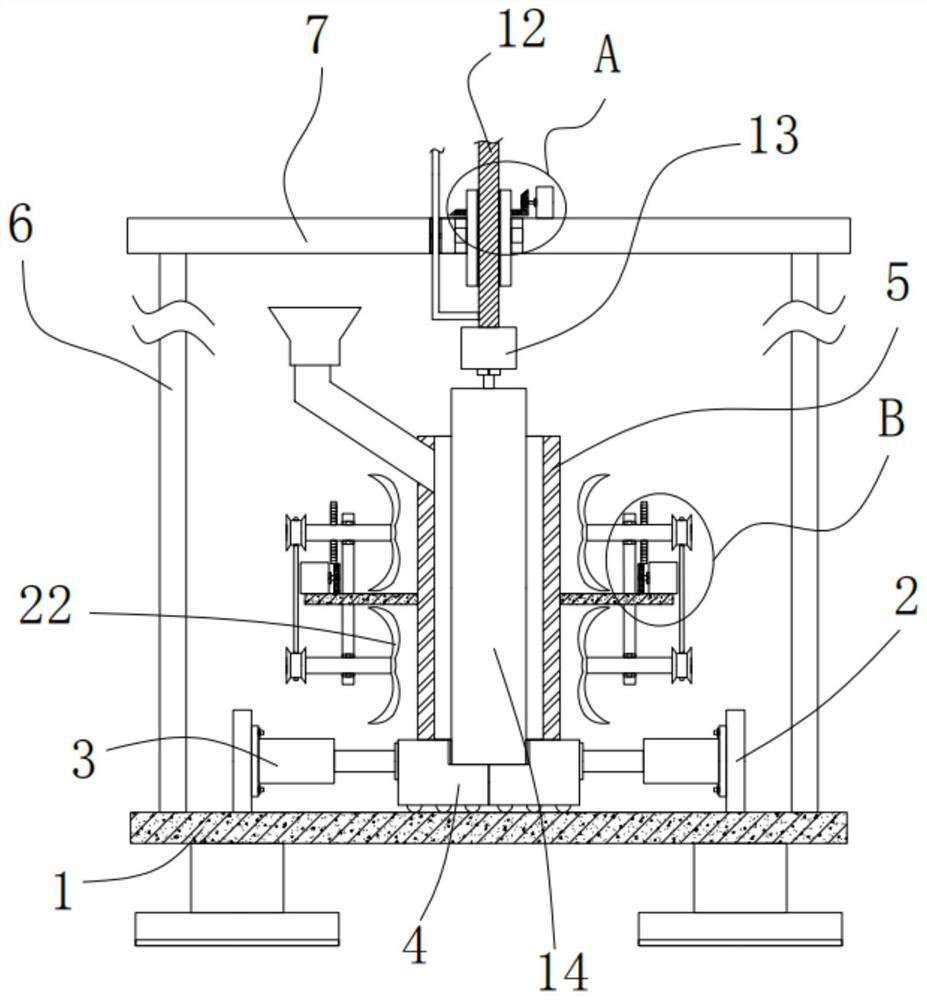

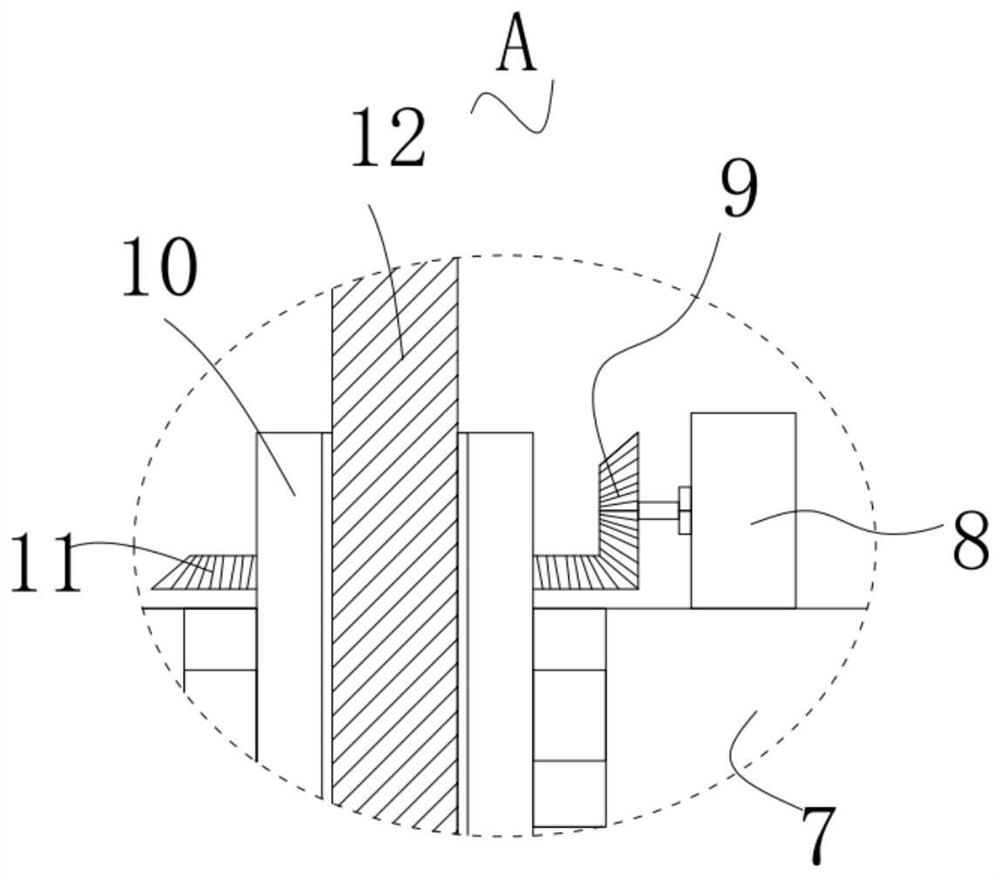

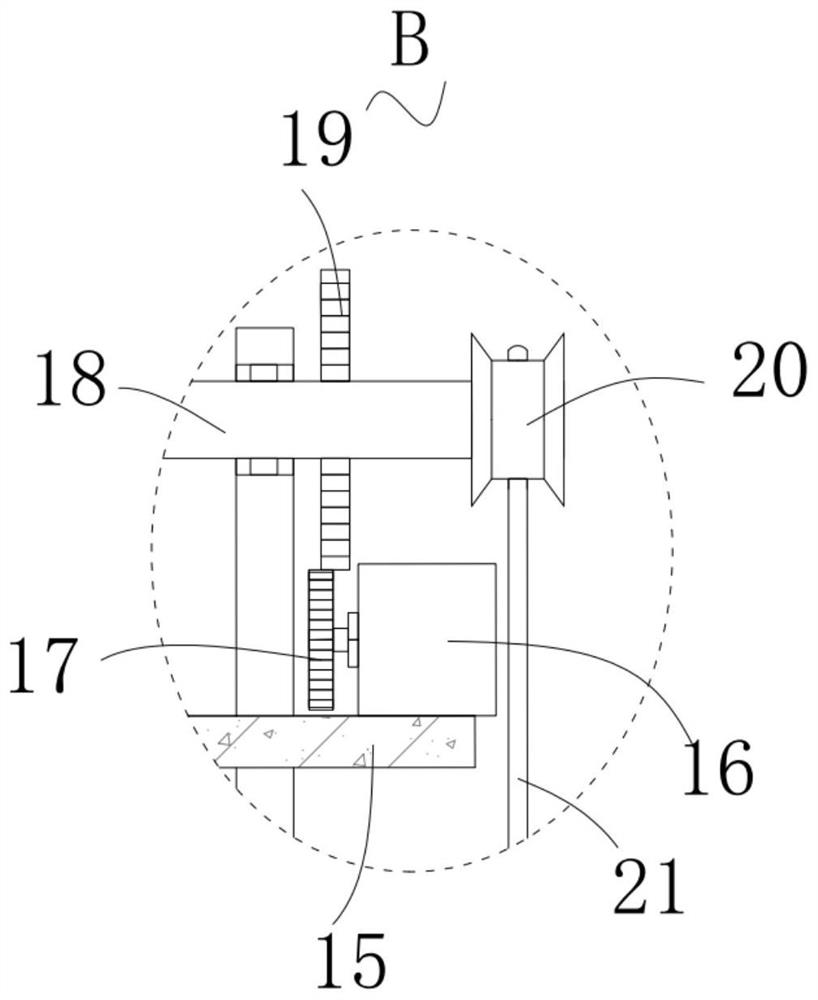

[0046] Please refer to Figure 1 to Figure 4 , in the first embodiment of the present invention, the mold used for cable manufacturing and molding includes: a base plate 1; The top of the top; two hydraulic cylinders 3, two hydraulic cylinders 3 are respectively fixedly installed on the side of two bar-shaped fixed blocks-2 close to each other; two semicircular support blocks 4, two semicircular support blocks 4 respectively Fixedly installed on the output shafts of two hydraulic cylinders 3; two semi-arc movable molds 5, two semi-arc movable molds 5 are respectively fixedly installed on the tops of two semicircular support blocks 4; Put plate 6, two vertical type put plate 6 all be fixedly installed on the top of base plate 1; Square top plate 7, square top plate 7 are fixedly installed on the top of two vertical type put plate 6; The motor one 8 is fixedly installed on the top of the square top plate 7; the first bevel gear 9, the first bevel gear 9 is fixedly installed on ...

no. 2 example

[0058] Based on the mold for cable manufacturing and molding provided in the first embodiment of the present application, the second embodiment of the application proposes another mold for cable manufacturing and molding, and the second embodiment is only an example of the first embodiment. In a further solution of the invention, the implementation of the second embodiment will not affect the independent implementation of the first embodiment. The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0059] Please refer to Figure 5-Figure 6 , in the second embodiment of the present invention, the mold used for cable manufacturing and molding also includes: two first placement plates 23, and the two first placement plates 23 are respectively fixedly installed on the two vertical placement plates 6 On the side close to each other, the top of the first placement plate 23 is placed with a cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com