A kind of air-blown ceramic original tire stripper

A stripper and ceramic technology, applied in the field of strippers, can solve the problems of easy fatigue, affecting work efficiency, and troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

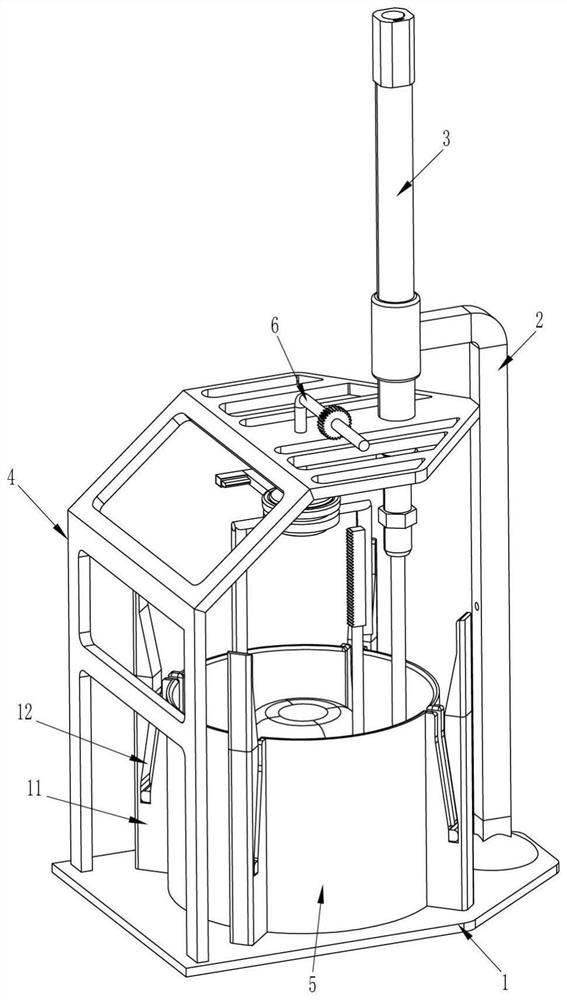

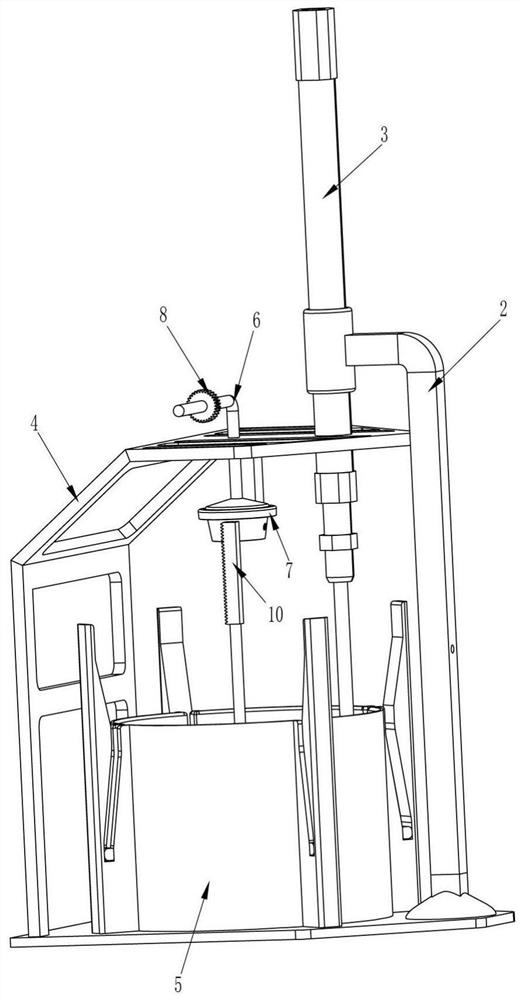

[0023] see Figure 1-Figure 3 , a kind of air-blown ceramic tire stripper, including a base 1, a support rod 2, a driving mechanism, a frame 4, a placement box 5, an air blowing mechanism and a placement frame 9, and the left side of the top of the base 1 is fixedly connected with an organic Frame 4, an air blowing mechanism is provided in the middle of the top of the frame 4, a storage box 5 is fixed in the middle of the top of the base 1, a sliding frame 9 is provided in the storage box 5, and a support rod 2 is fixed in the middle of the top right side of the base 1 , A drive mechanism is provided between the left end of the support rod 2 and the placement frame 9.

[0024] The driving mechanism includes a cylinder 3 and a rack 10. The left end of the support rod 2 is fixedly connected with the cylinder 3. The cylinder 3 is vertically arranged. The bottom of the cylinder 3 runs through the right side of the top of the frame 4. The right side is fixedly connected, and the b...

Embodiment 2

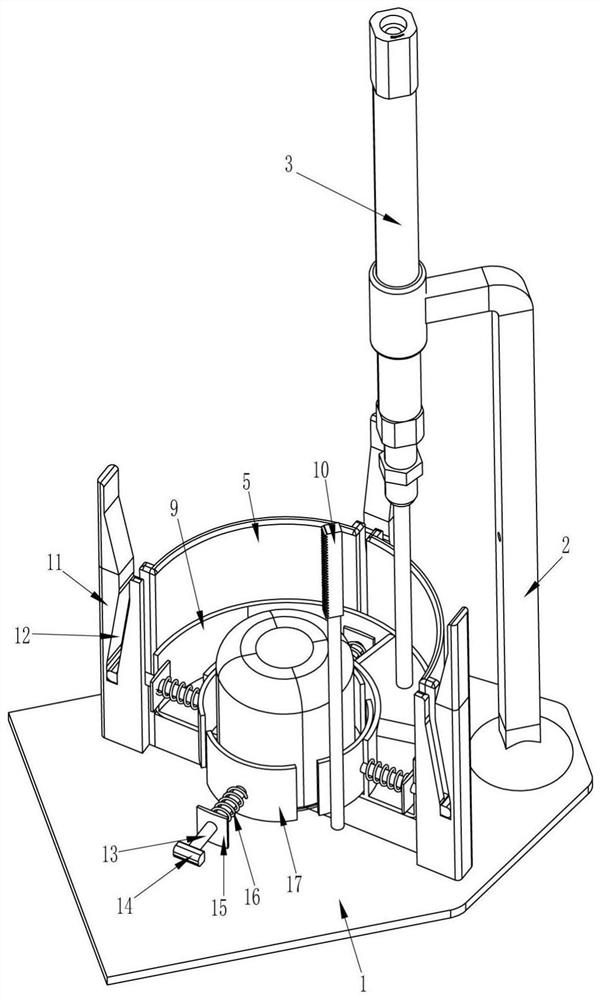

[0030] see Figure 1-Figure 3 , the present embodiment is with respect to embodiment 1, and main difference is that in the present embodiment, also comprise limiting block 11, slide bar 13, first slide block 14, baffle plate 15, first spring 16 and splint 17, place box 5 The outer surface is circumferentially evenly spaced and fixedly connected to the limit block 11, the bottom of the limit block 11 is fixedly connected with the top of the base 1, the upper part of the limit block 11 is provided with a chute 12, and the chute 12 communicates with the inside of the placement box 5, and the placement frame 9 The sliding type evenly spaced in the inner circumferential direction is provided with a slide bar 13, the slide bar 13 corresponds to the limit block 11, the inner end of the slide bar 13 is fixedly connected with a splint 17 which can limit the mold, and the outer end of the slide bar 13 runs through the placement frame 9 1. The placement box 5 and the limit block 11 are l...

Embodiment 3

[0033] see figure 1 , Figure 4 and Figure 5 , the main difference between this embodiment and embodiment 1 and embodiment 2 is that in this embodiment, it also includes a connecting ring 18, an L-shaped hollow push rod 19, a push block 20, a second spring 21, a clamping rod 22, a second Three springs 23, backguy 24, jet pipe 25, windshield block 26, pulley 27, the second slide block 28 and the 4th spring 29, high-pressure air pipe 6 outer lower parts are connected with connection ring 18 in rotation type, connection ring 18 left and right sides All are connected with air jet pipe 25, and the lower part of high-pressure air pipe 6 is evenly spaced circumferentially with air outlet 271, and air outlet 271 cooperates with connecting ring 18. The windshield block 26 cooperates with the air outlet 271 and the jet pipe 25. The top of the windshield block 26 is connected with a fourth spring 29, and the tail end of the fourth spring 29 is fixedly connected with a second slide blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com