Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Small stroke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

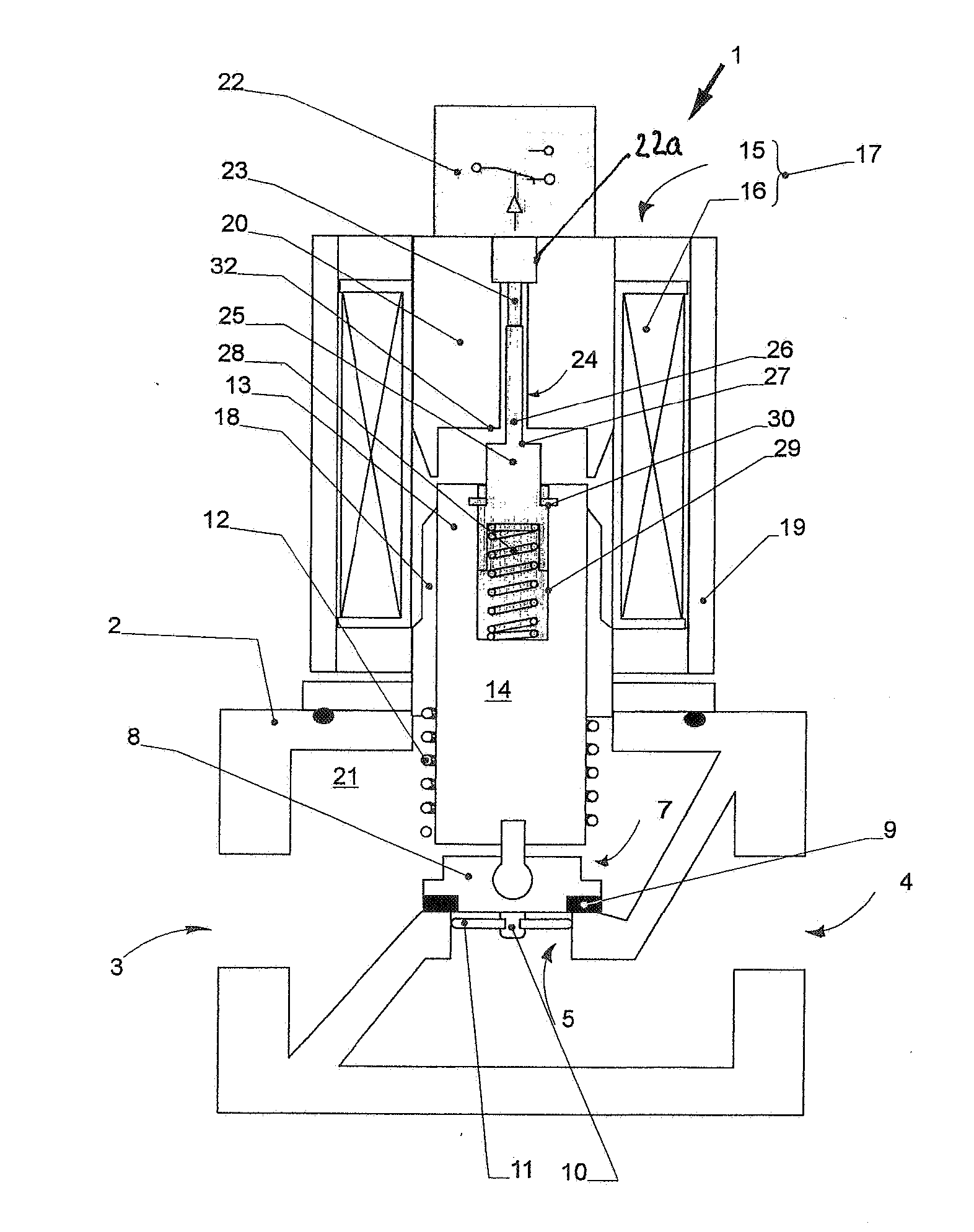

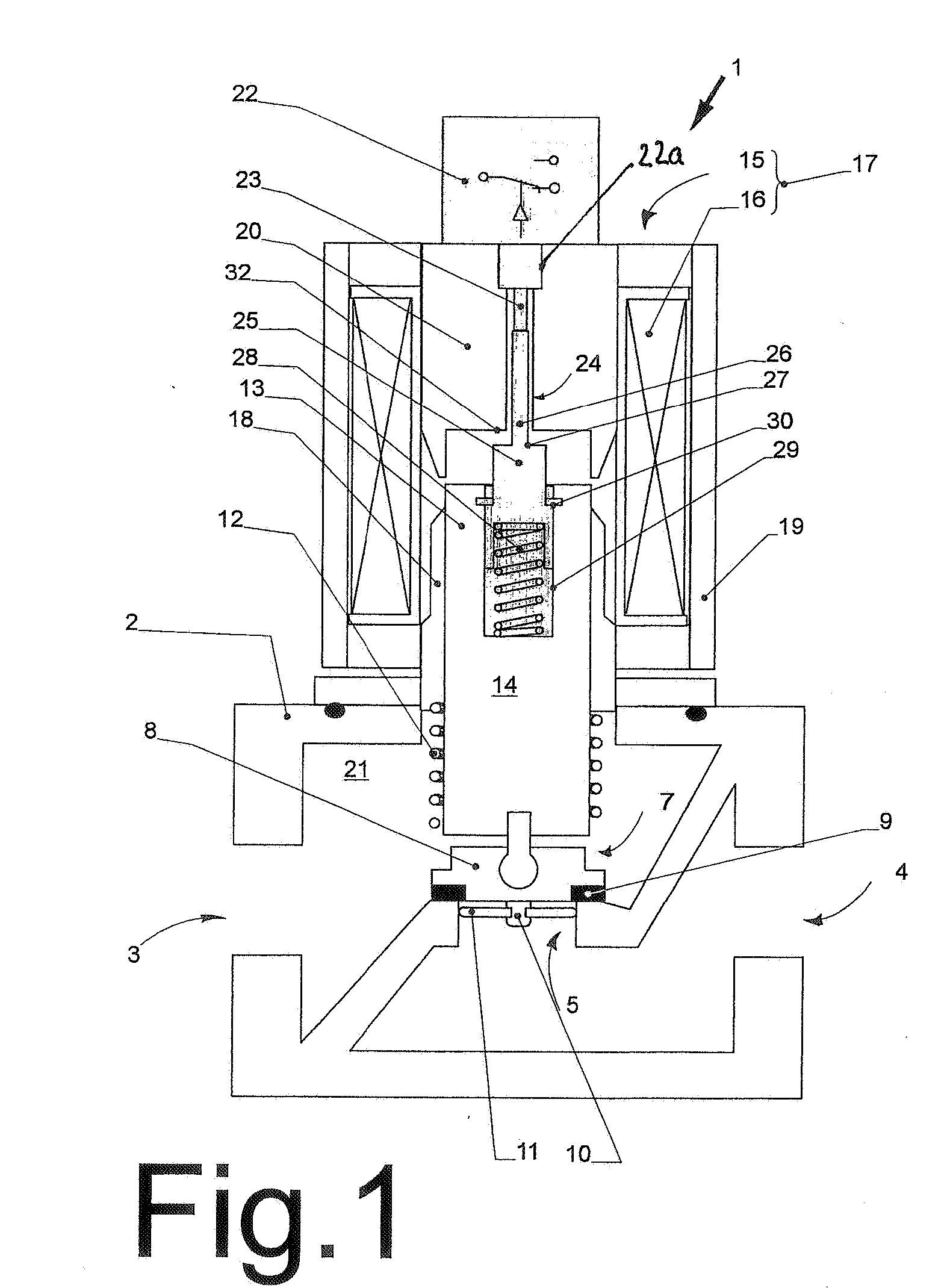

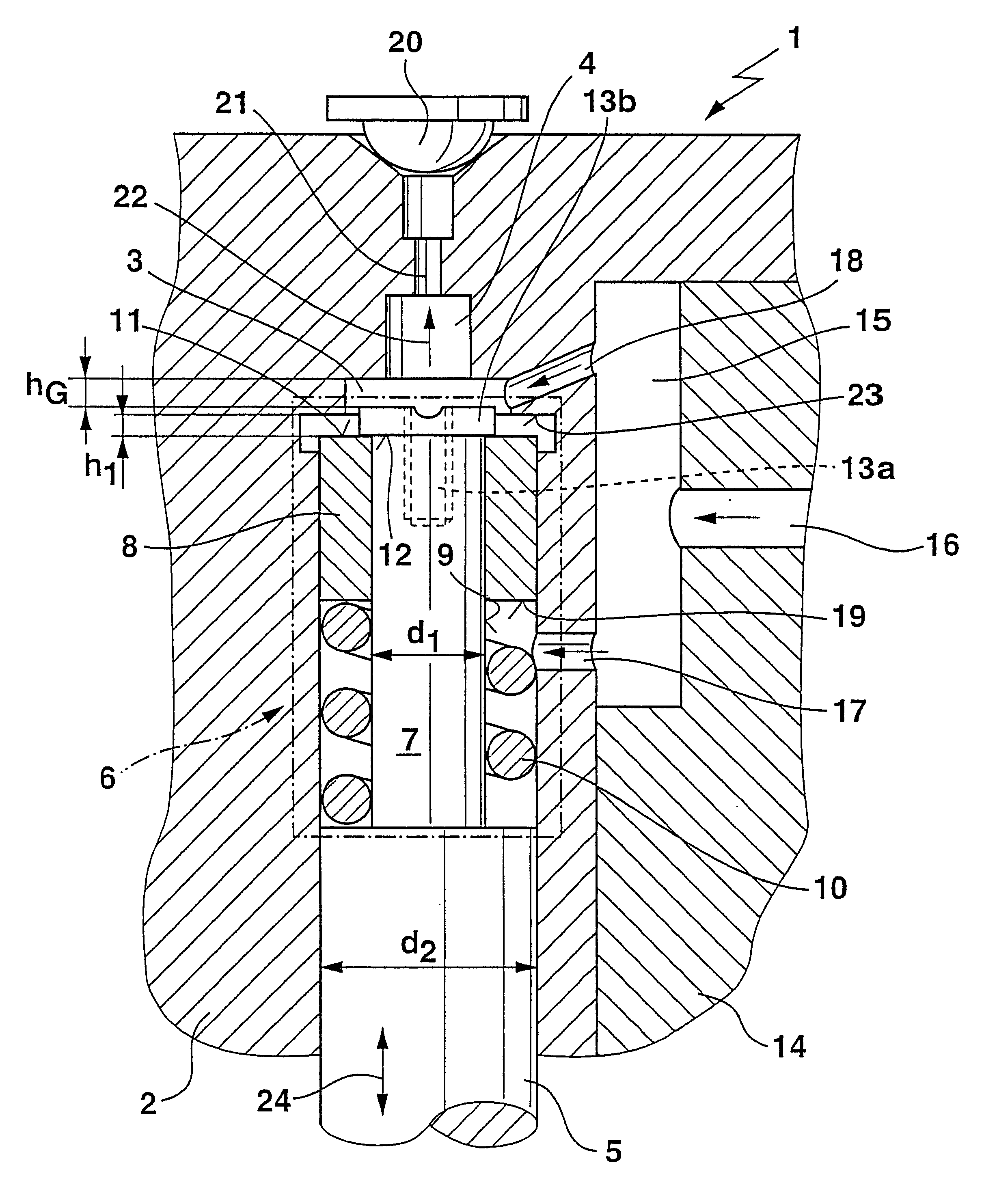

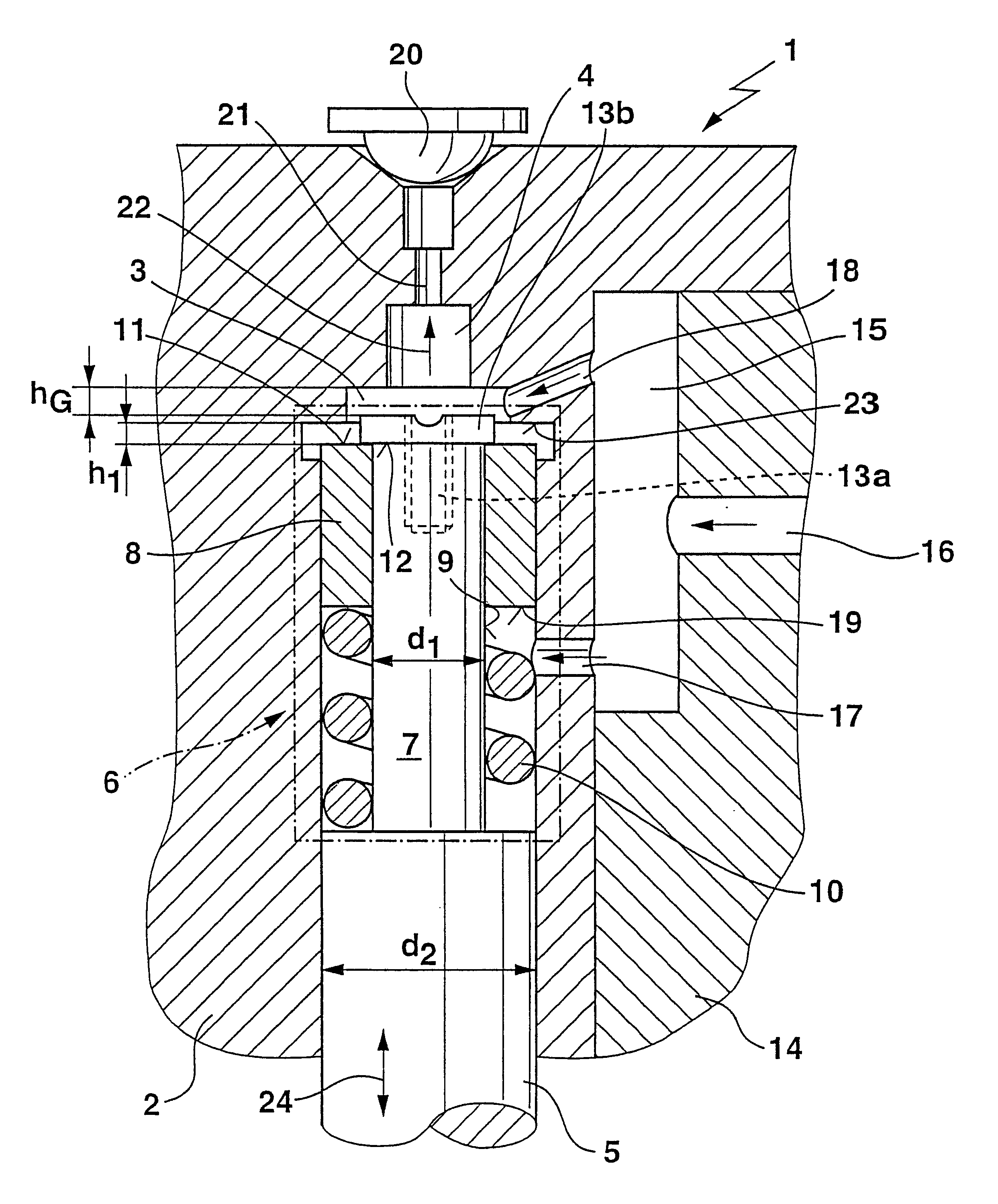

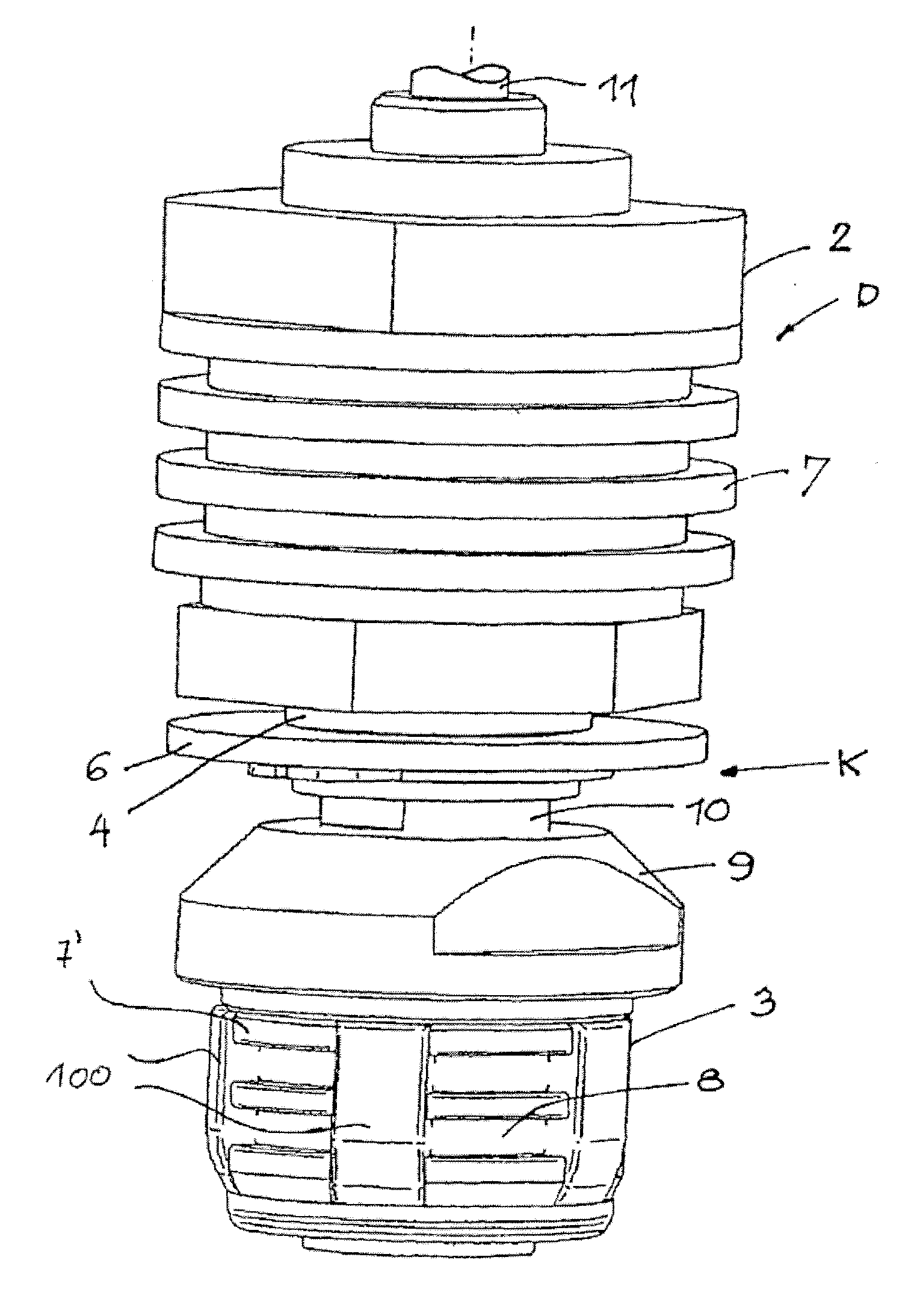

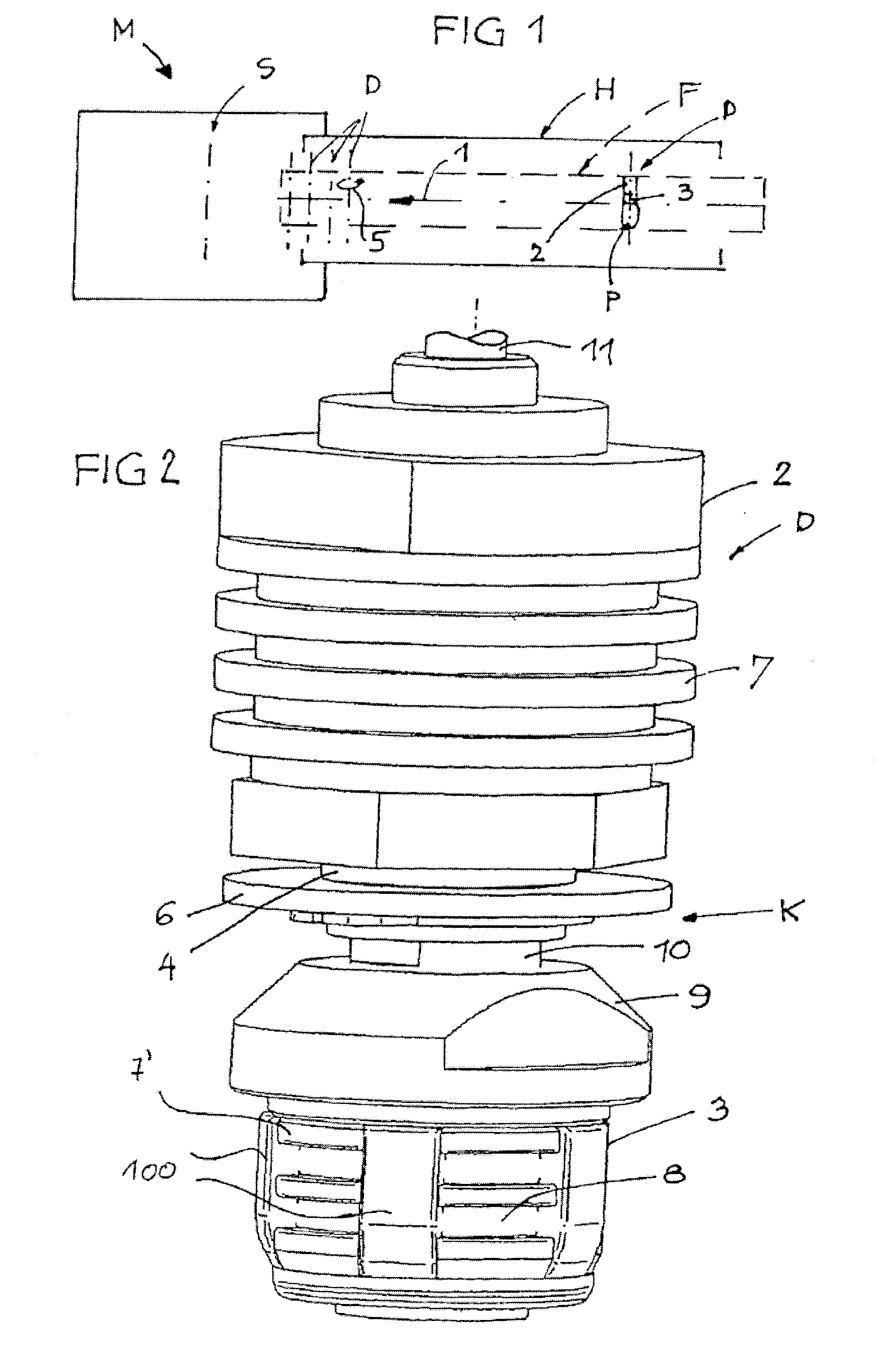

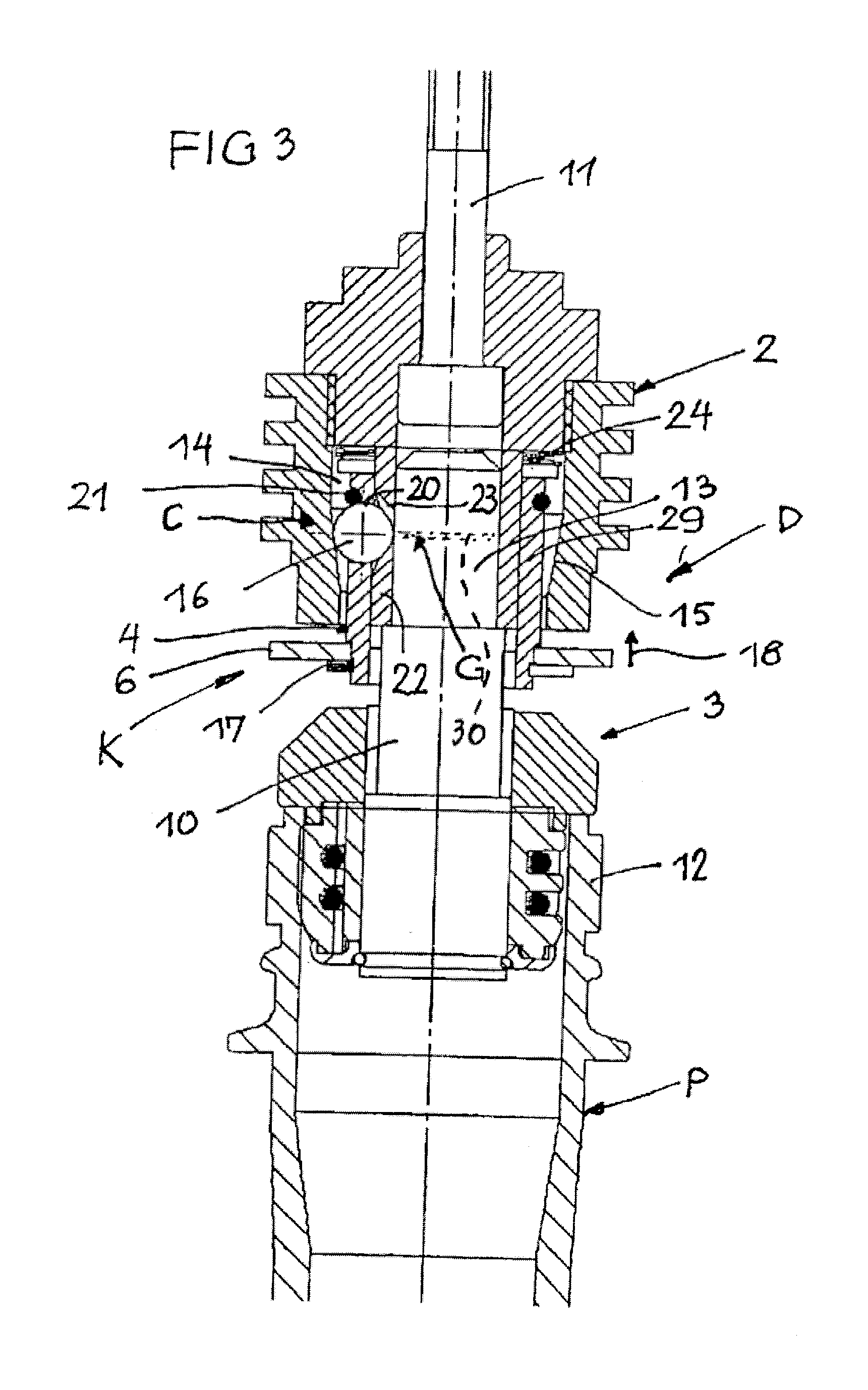

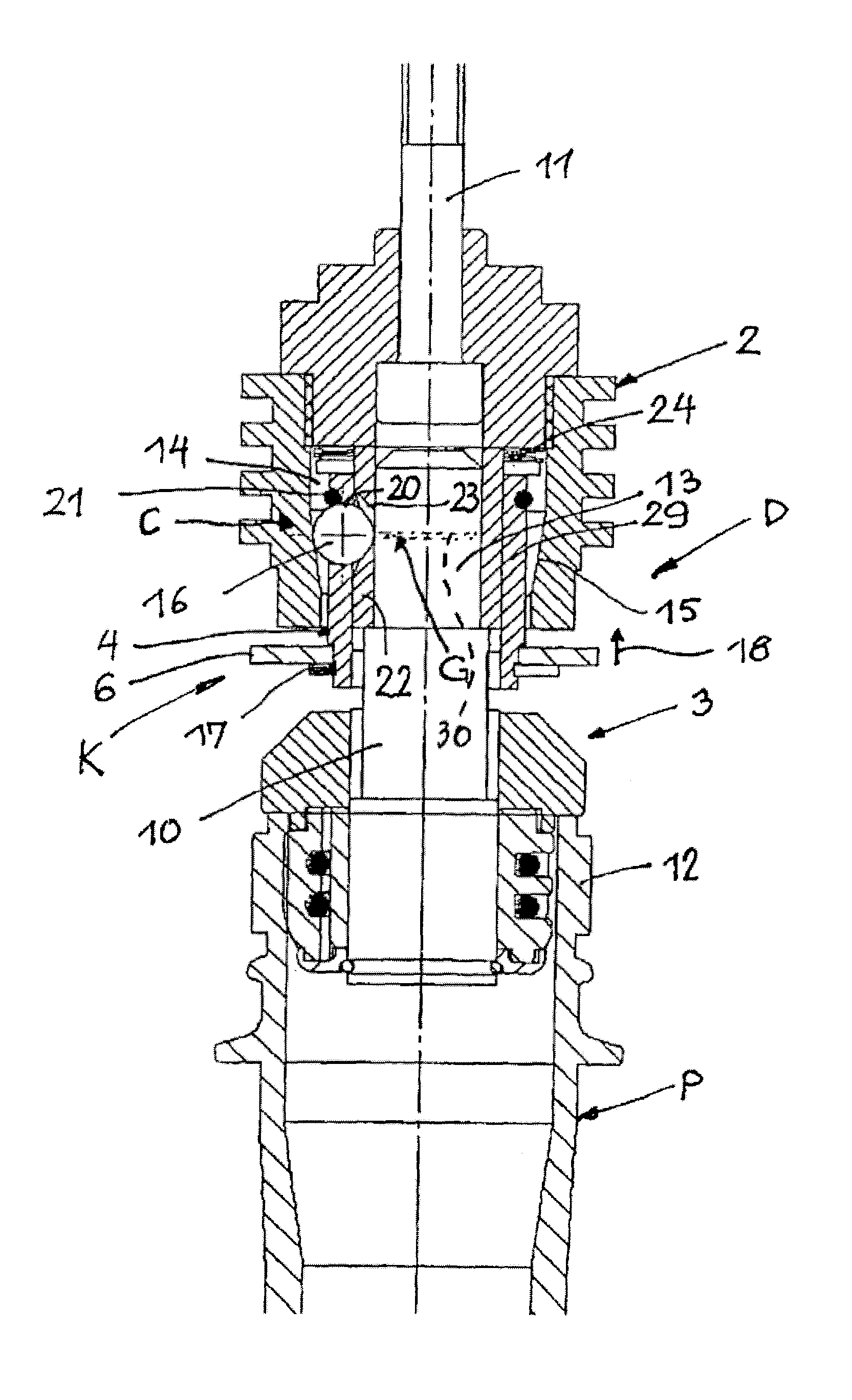

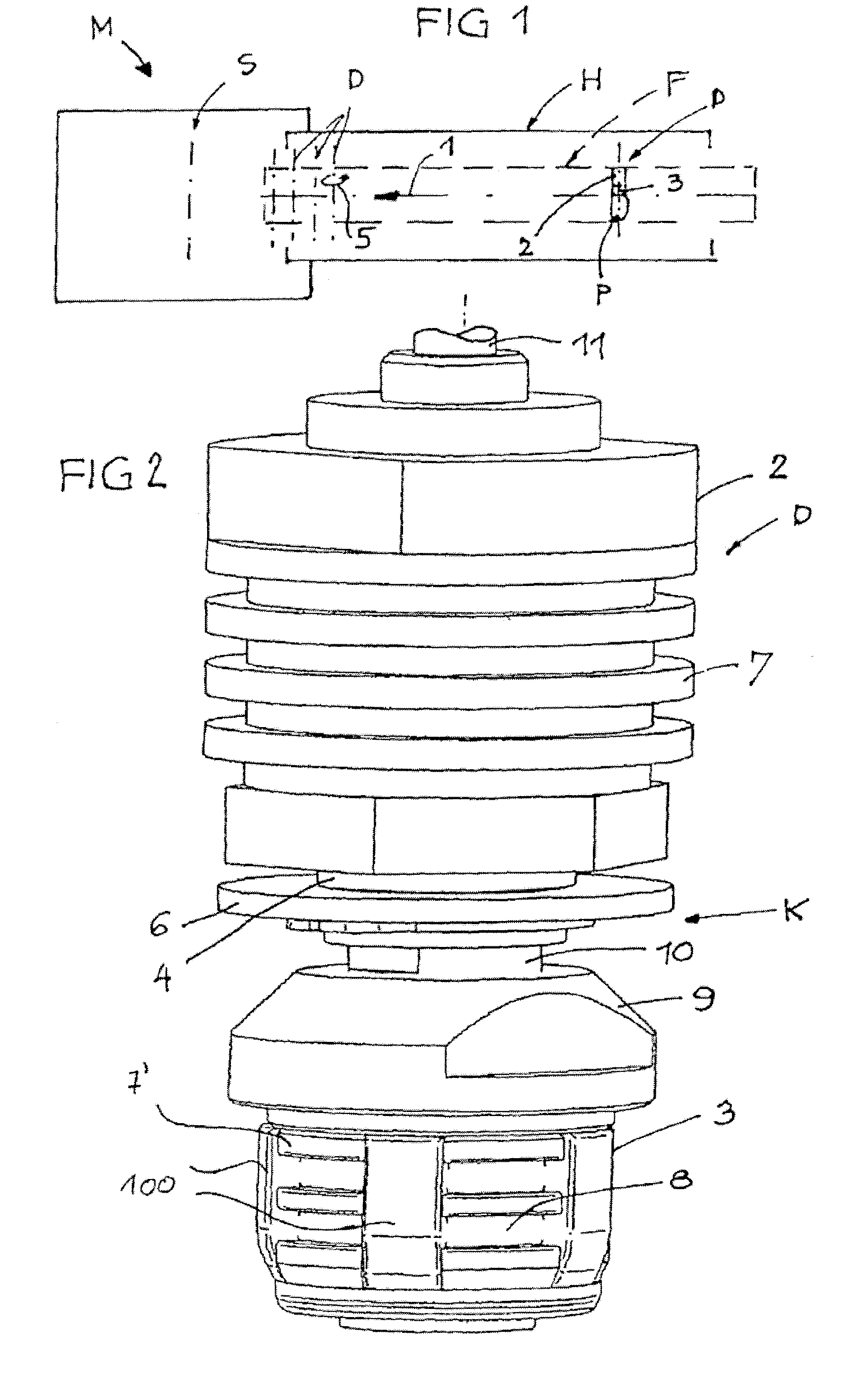

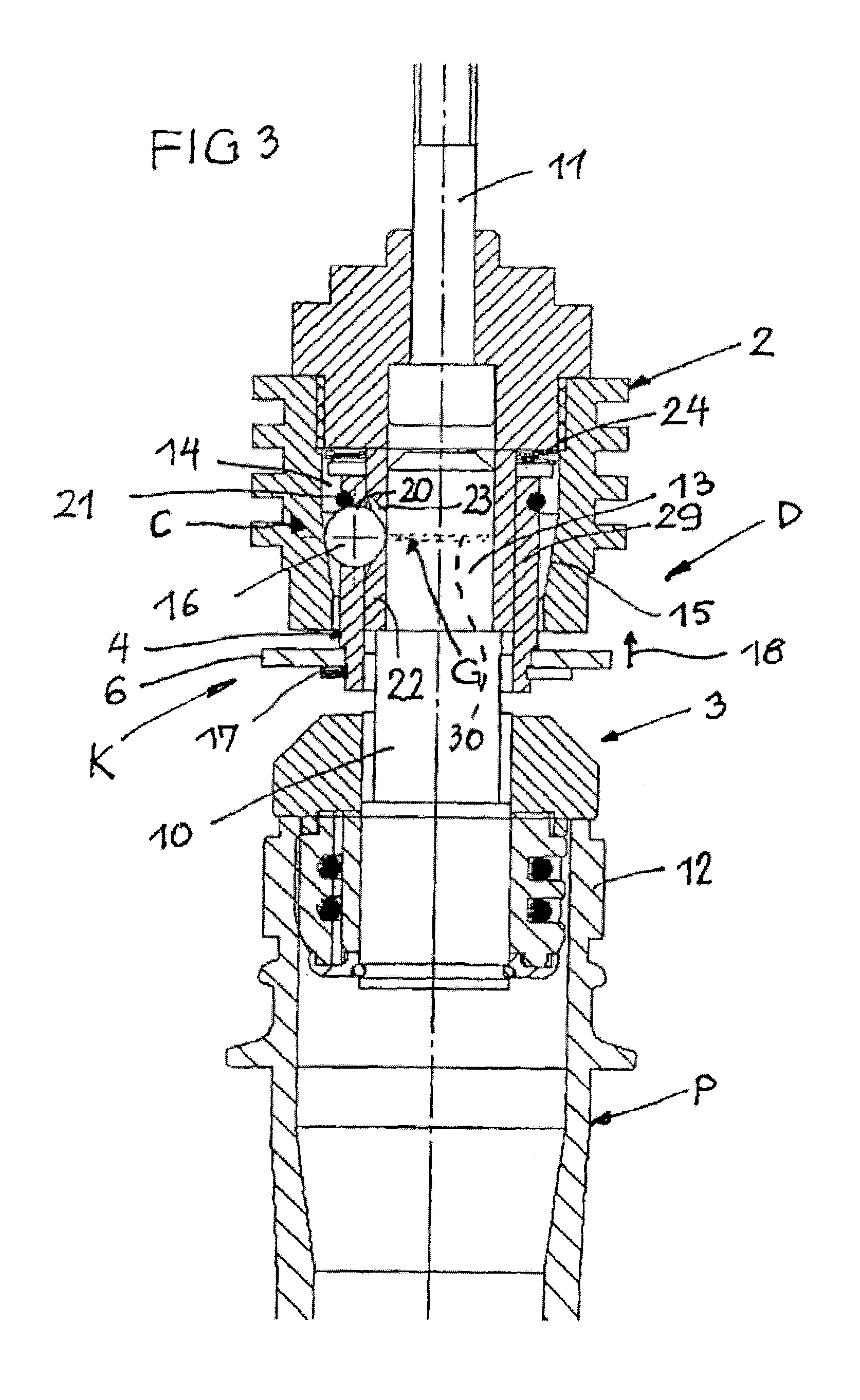

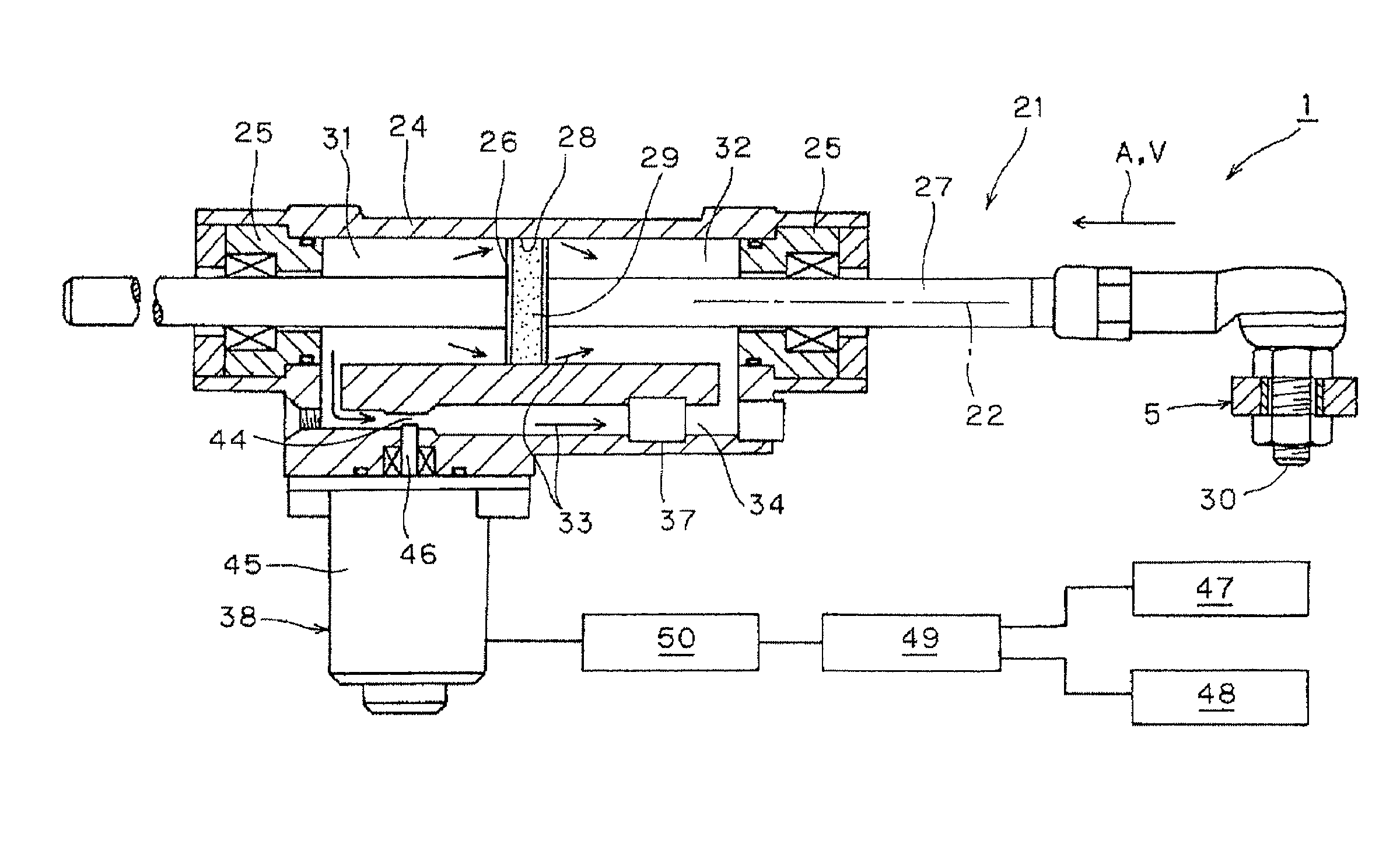

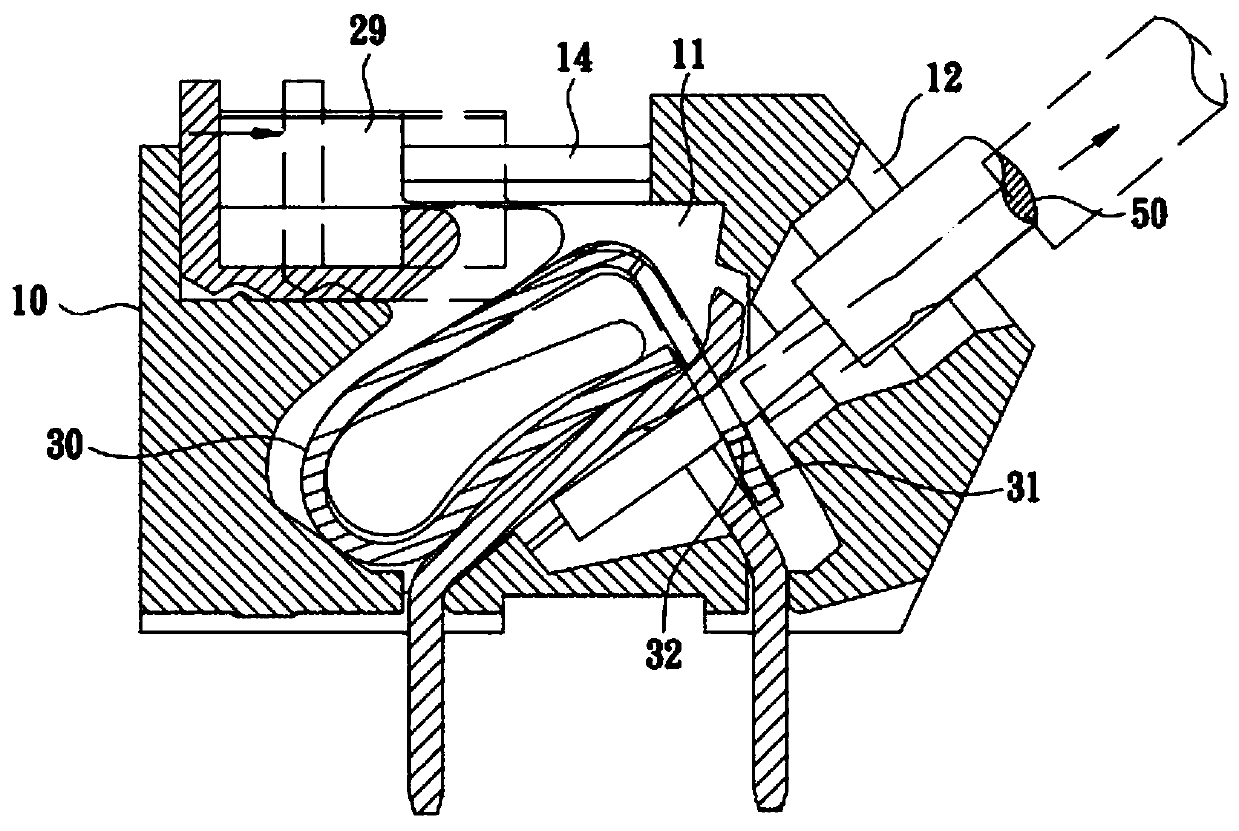

Valve with end position switching

InactiveUS20060272712A1Avoid destructionImprove sealingOperating means/releasing devices for valvesPipeline systemsEngineeringTappet

For detecting closing or opening of a valve activated preferably by a solenoid actuator, a switch activated by a tappet spring mounted on an armature of the actuator is provided. A stop and an associated surface limit the stroke of the tappet with reference to the switch. Preferably, a valve closing element opens the gas flow only when the armature has already executed a part of its opening stroke. The trigger point of the switch is set in this first part of the opening stroke of the armature, in which the valve closing element has not yet opened. The stroke limiting of the tappet for activating the switch is also preferably set in this region of the opening stroke of the armature. However, the stop limits the stroke of the tappet independent of the opening stroke size of the armature, so that the same switch can be used for different valves with different nominal diameters and opening strokes.

Owner:KARL DUNGS

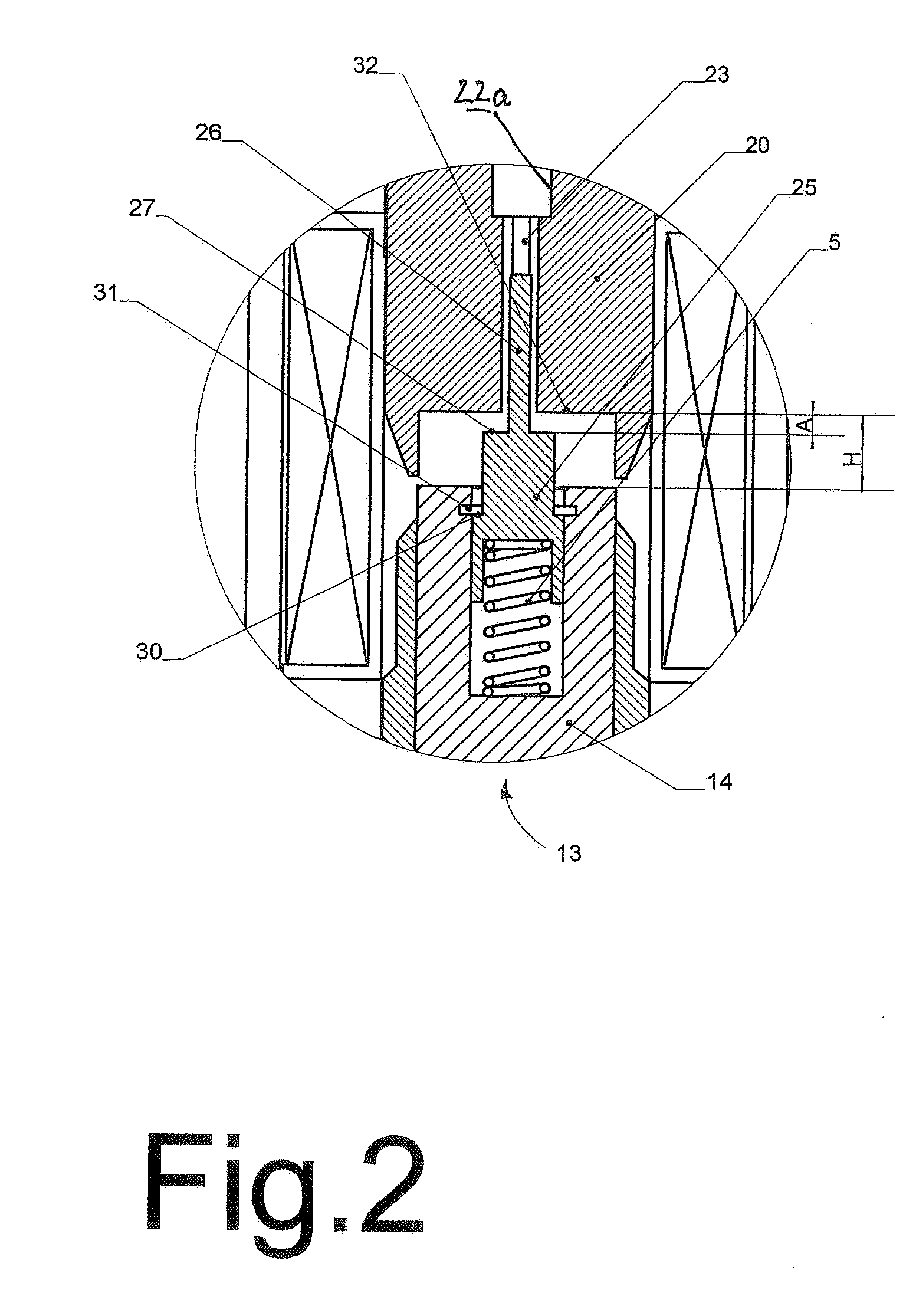

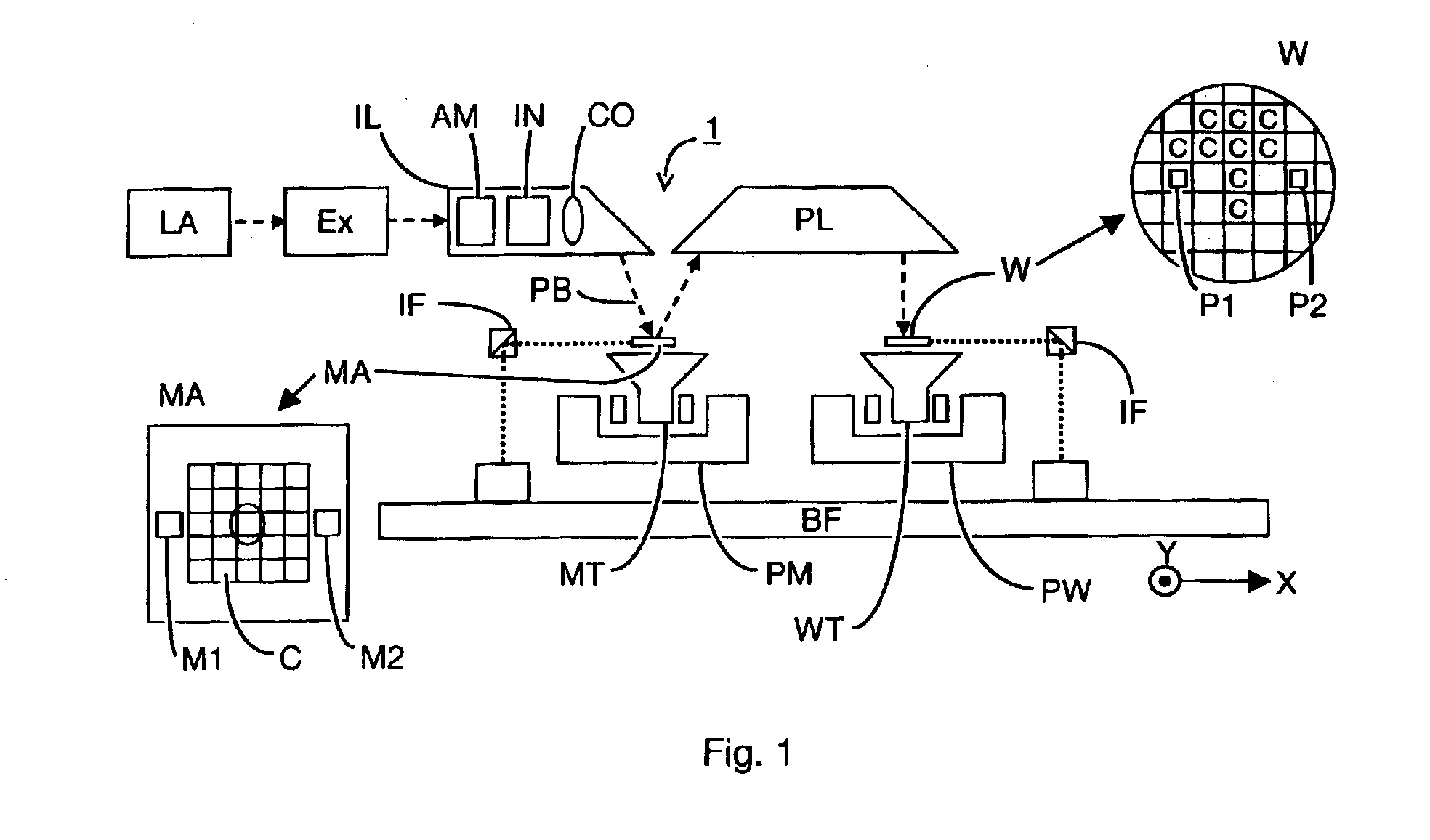

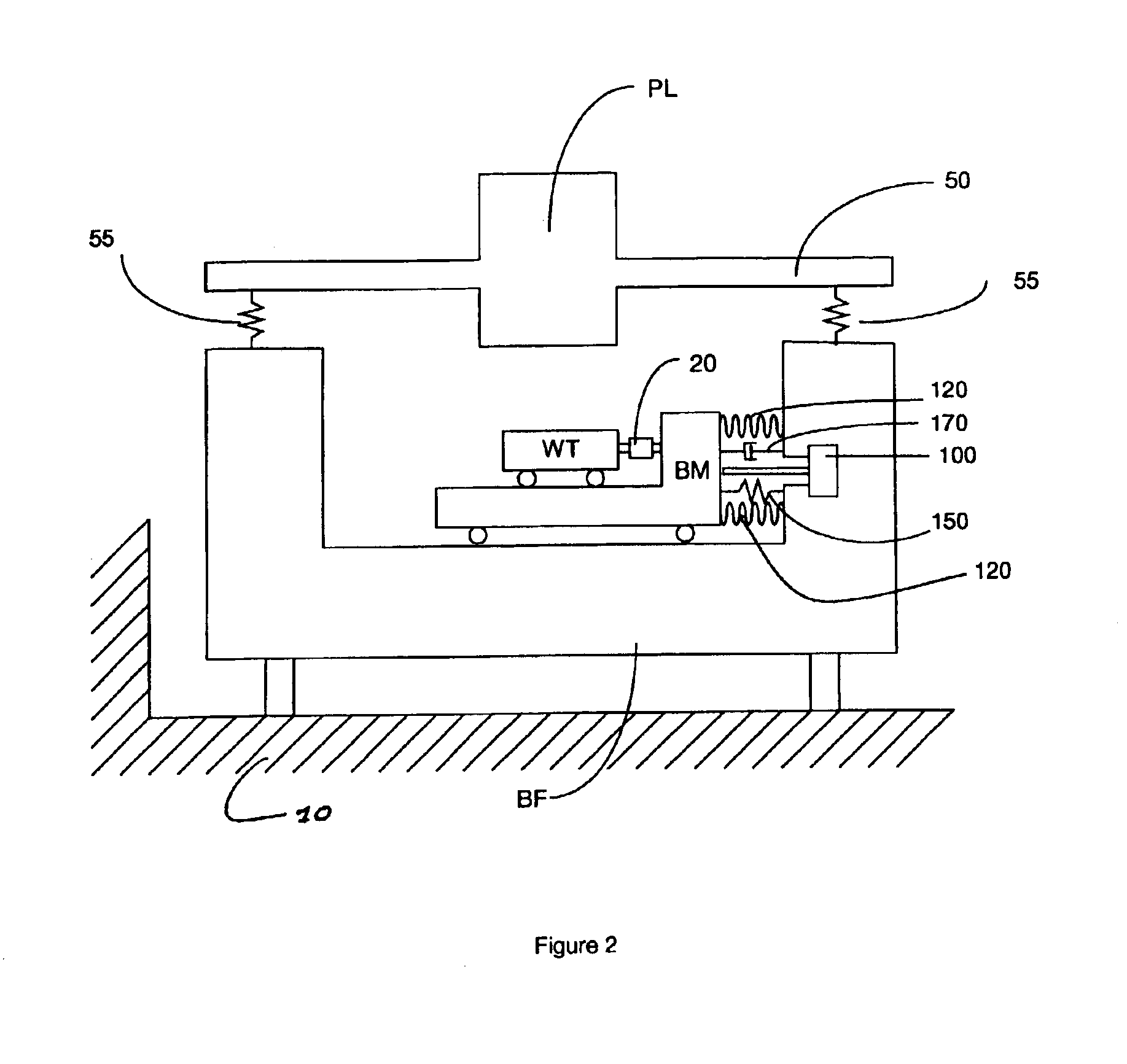

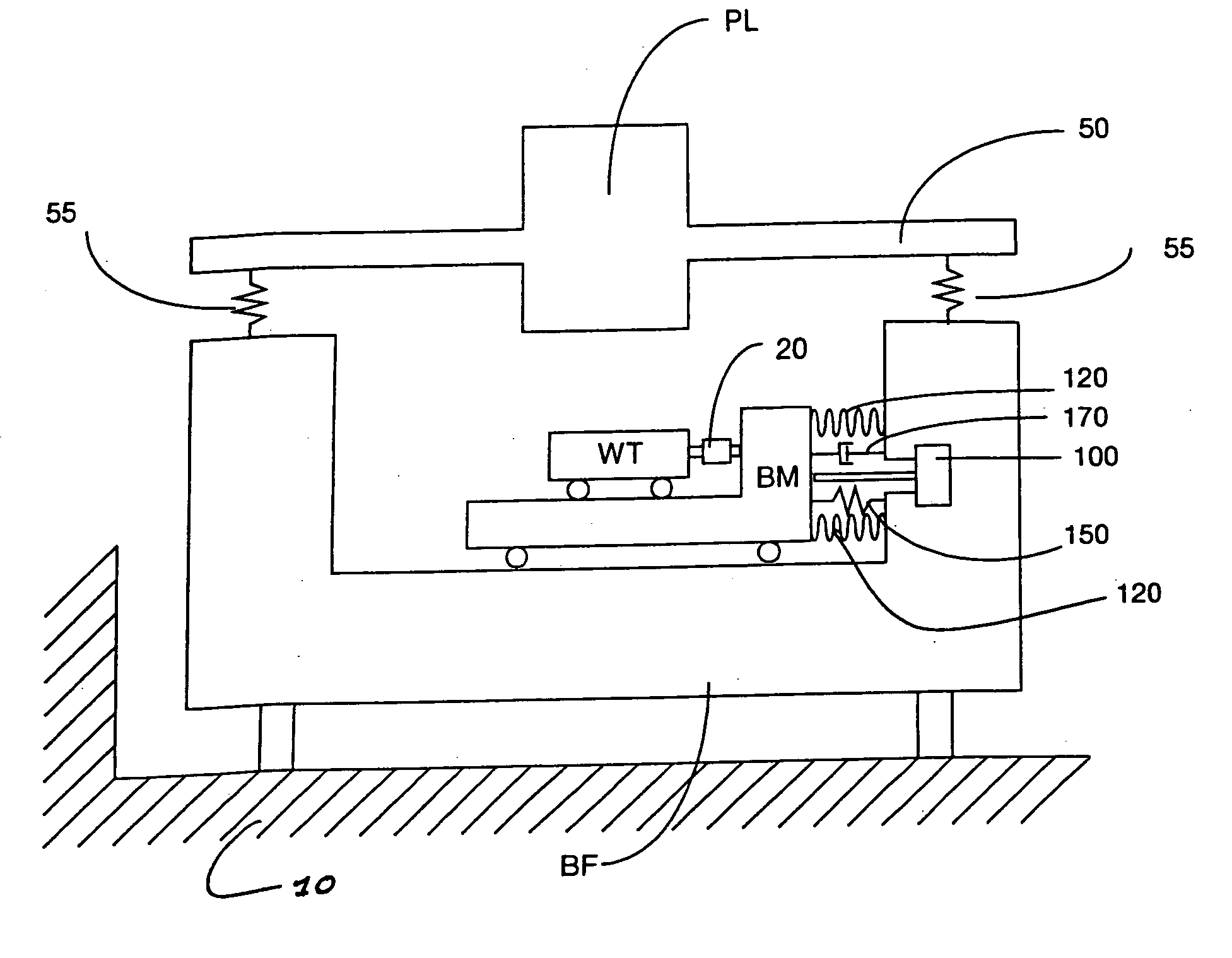

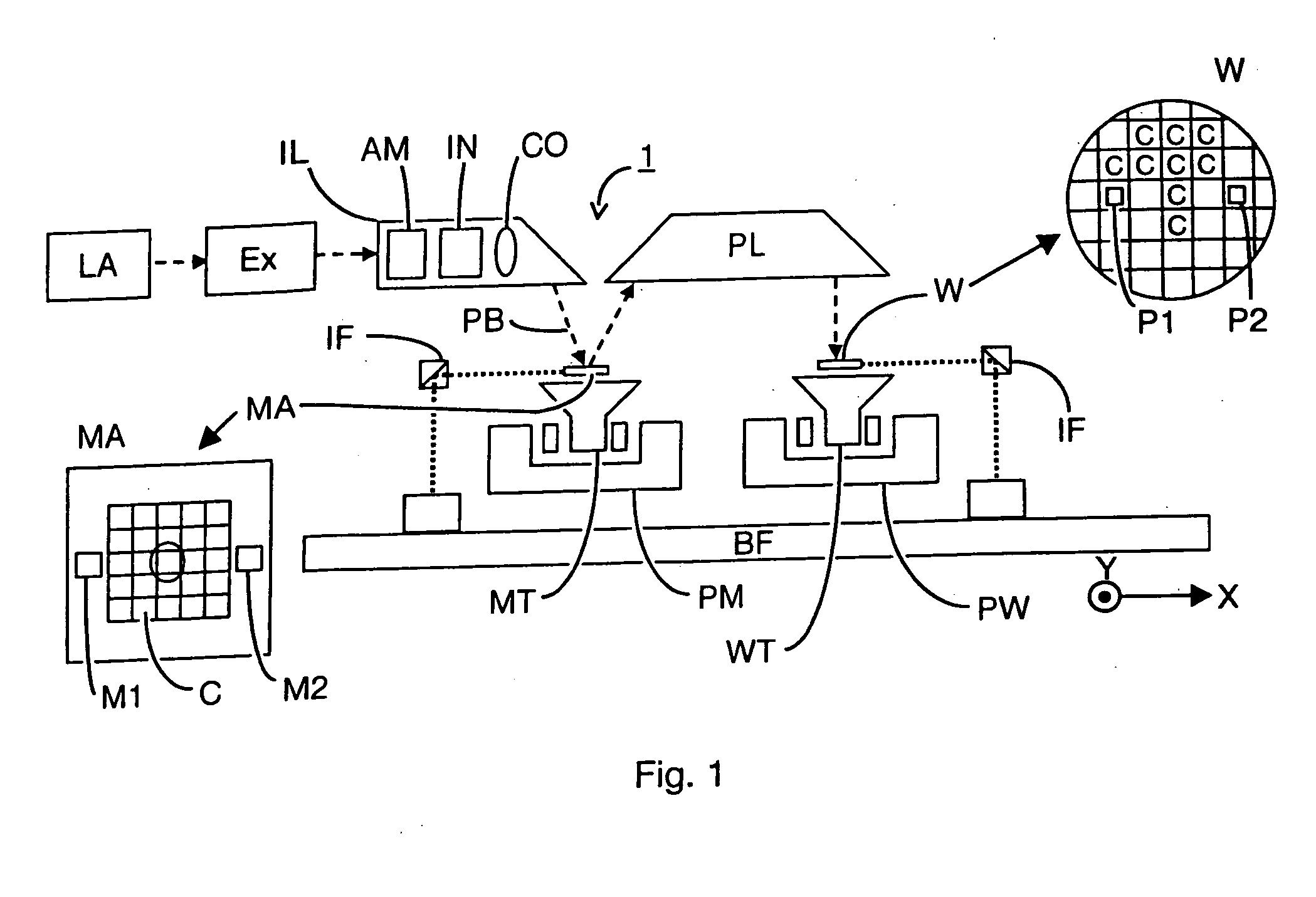

Lithographic apparatus and device manufacturing method

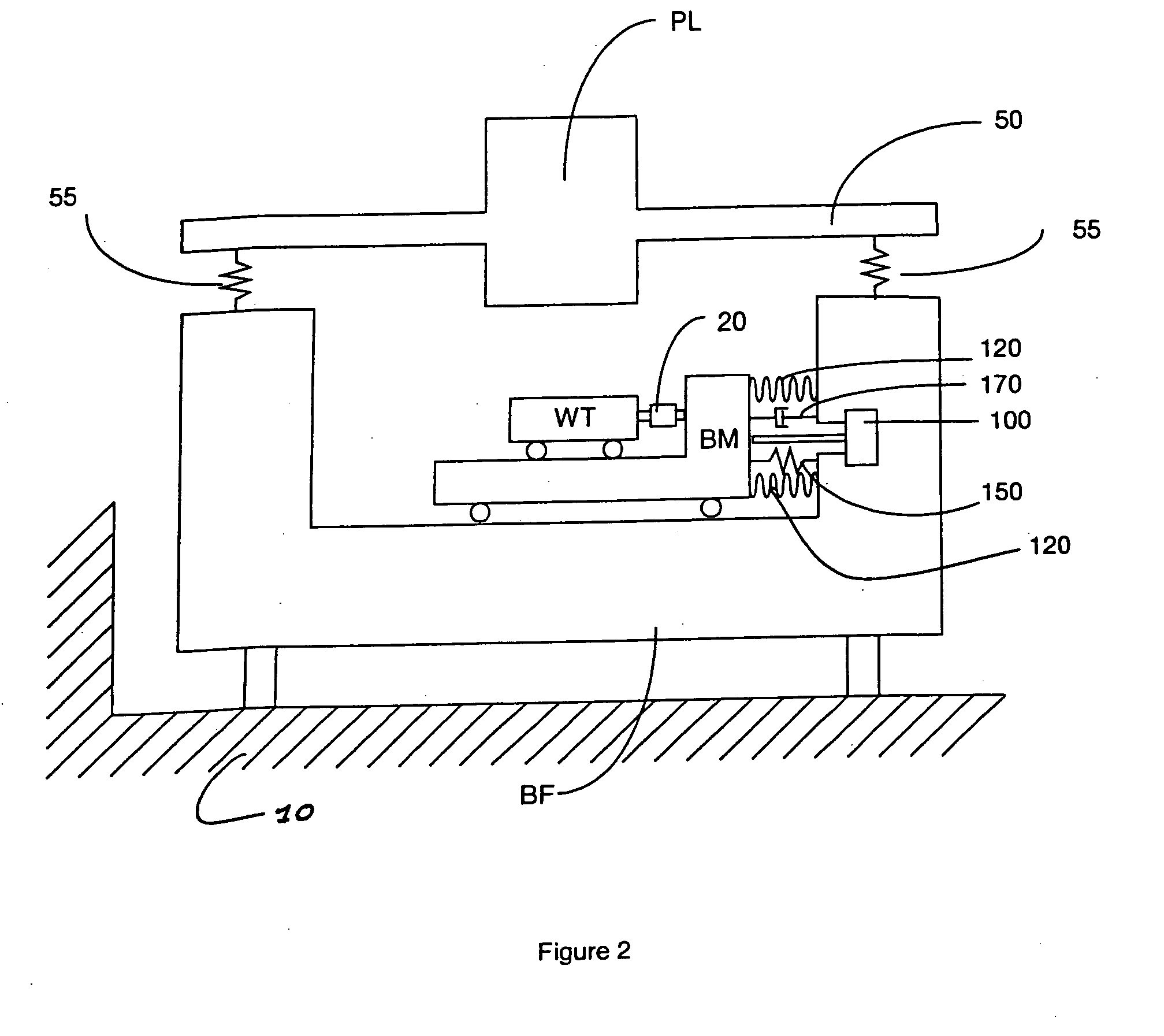

ActiveUS6906786B2Eliminate the problemReduce force transmissionNon-rotating vibration suppressionProjectorsEngineeringGround reaction force

Owner:ASML NETHERLANDS BV

Lithographic apparatus and device manufacturing method

InactiveUS20050190351A1Reduce force transmissionLess expensiveNon-rotating vibration suppressionSemiconductor/solid-state device manufacturingEngineeringGround reaction force

Owner:ASML NETHERLANDS BV

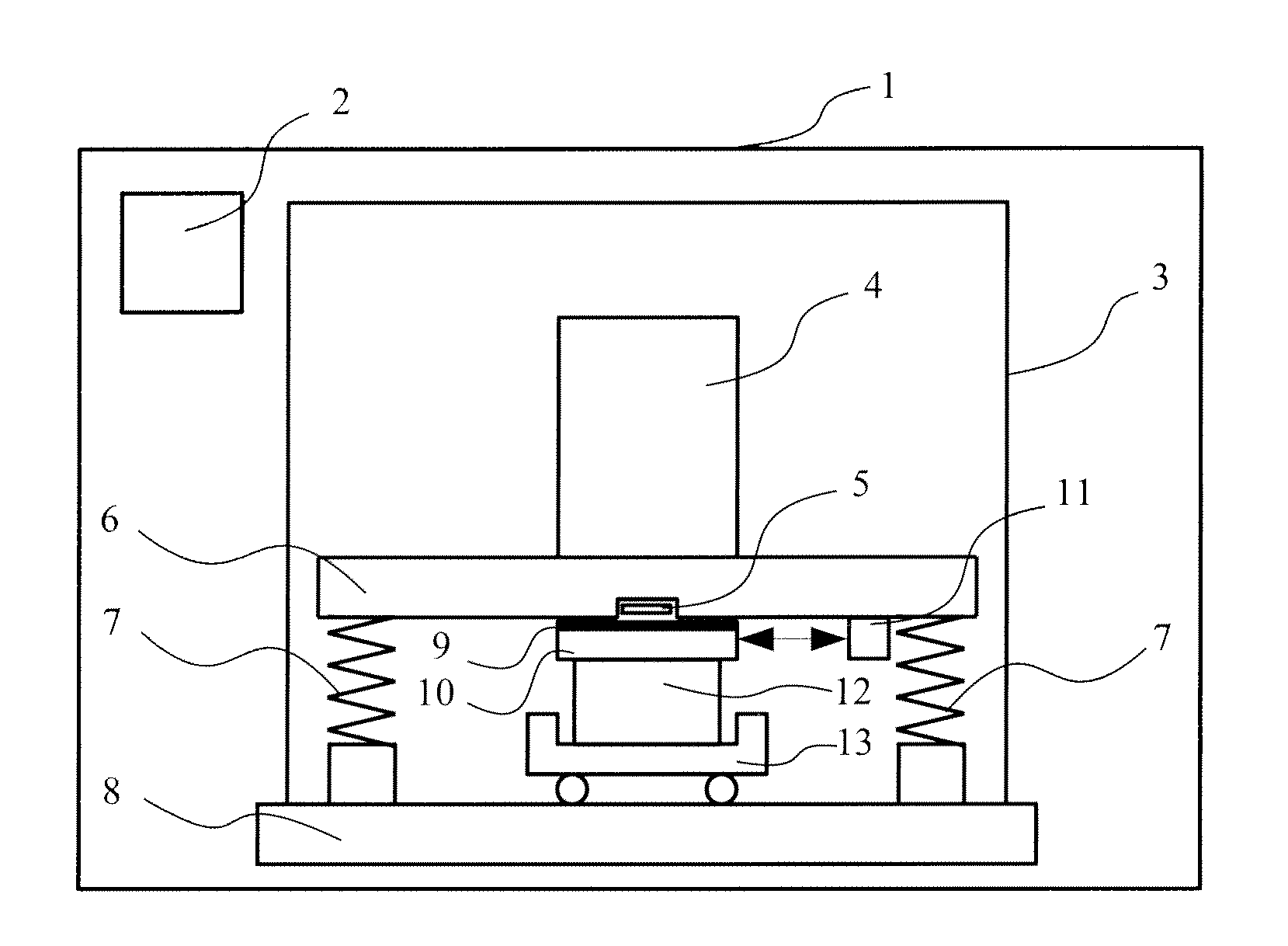

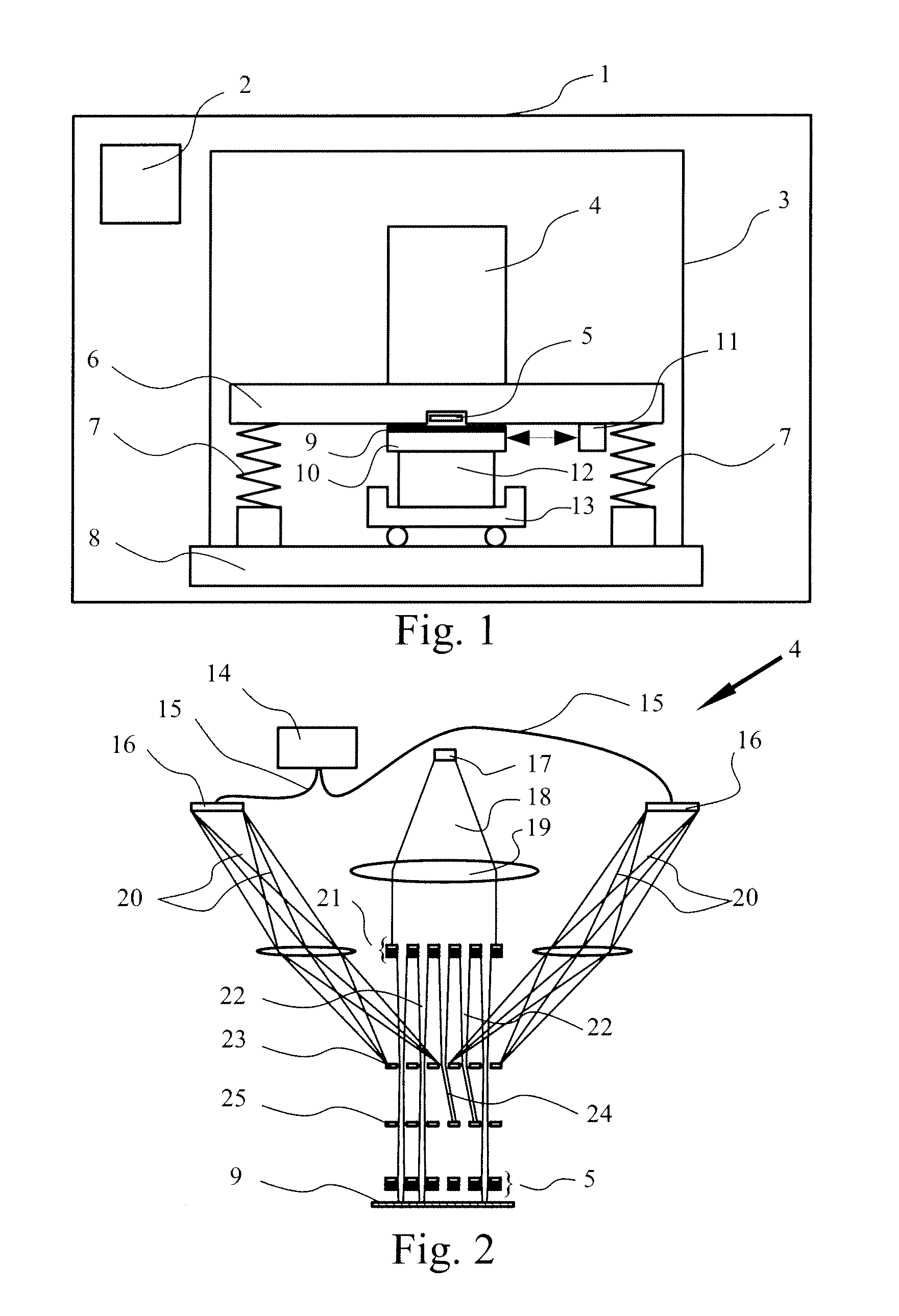

Lithography system with lens rotation

InactiveUS20110174985A1Small strokeReduce needThermometer detailsStability-of-path spectrometersElectron opticsAperture array

The invention relates to a charged particle based lithography system for projecting an image on a target using a plurality of charged particle beamlets for transferring said image to said target, said system comprising a charged particle column comprising:an electron optical subassembly comprising a charged particle source, a collimator lens, an aperture array, a blanking means and a beamstop for generating a plurality of charged particle beamlets; anda projector for projecting said plurality of charged particle beamlets on said target;said projector being moveably included in the system by means of at least one projector actuator for moving said projector relative to said electron optical subassembly;said projector actuator being included for mechanically actuating said projector and providing said projector with at least one degree of freedom of movement;wherein said degree of freedom relates to a movement around an optical axis of the system.

Owner:ASML NETHERLANDS BV

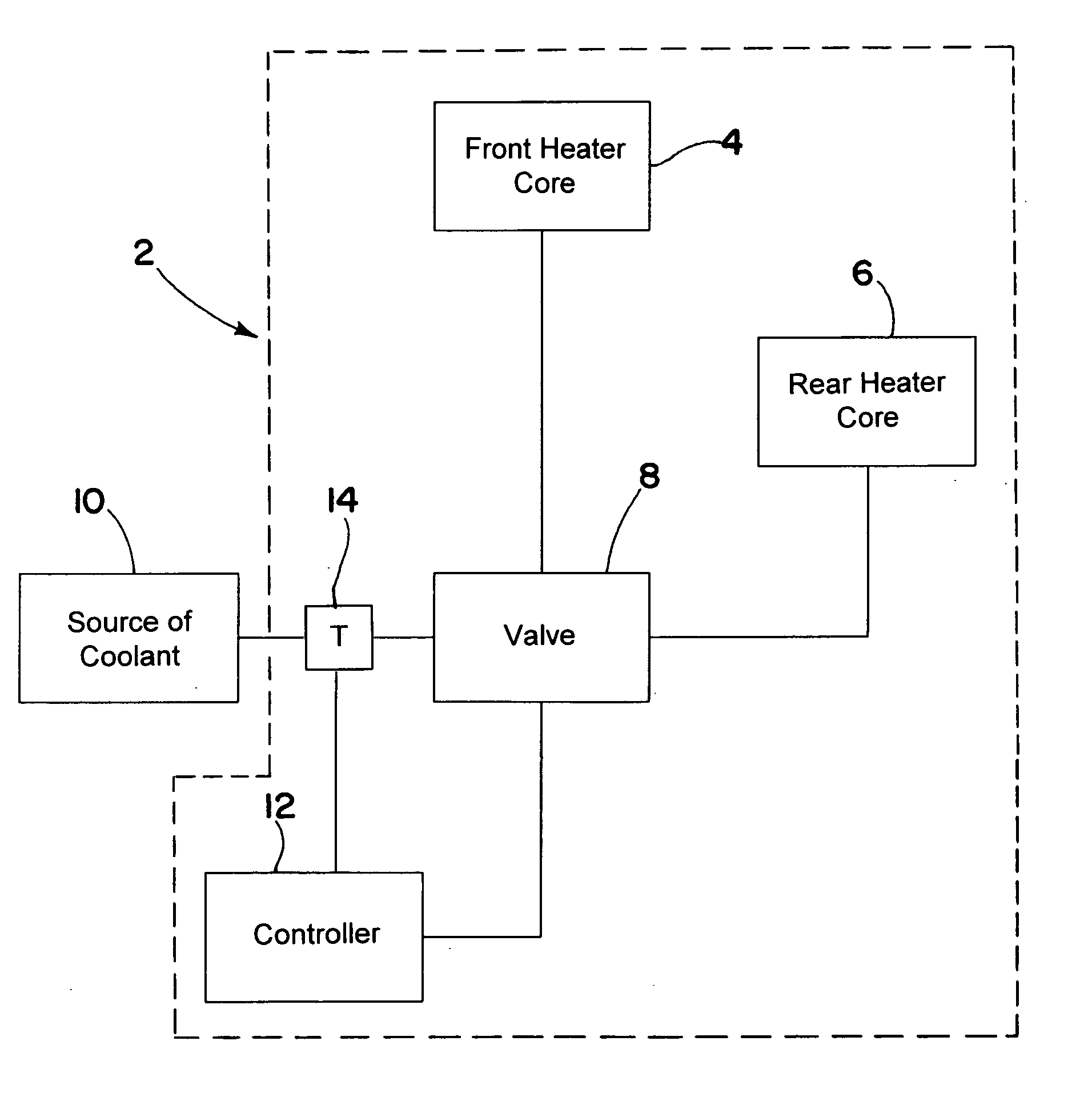

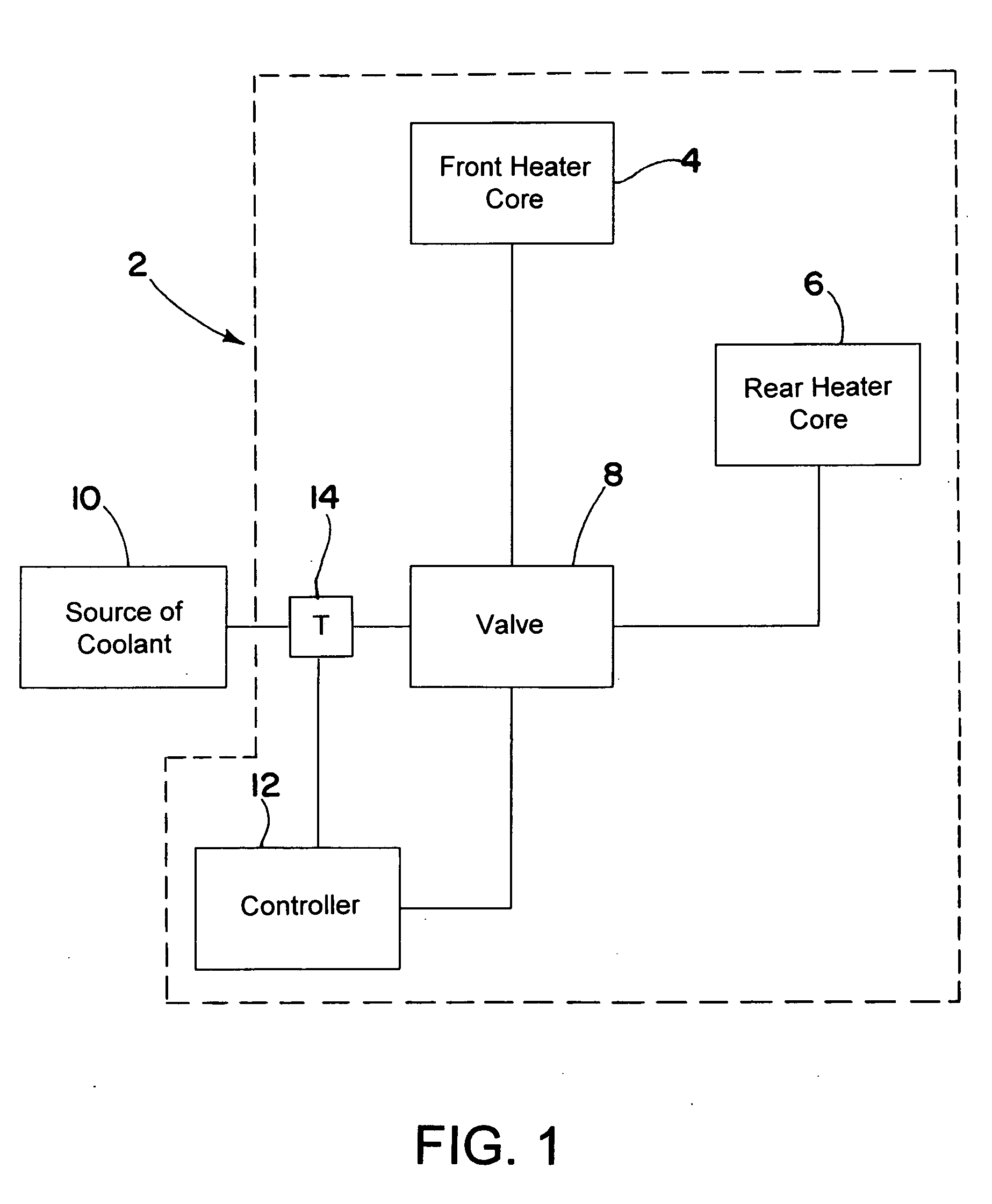

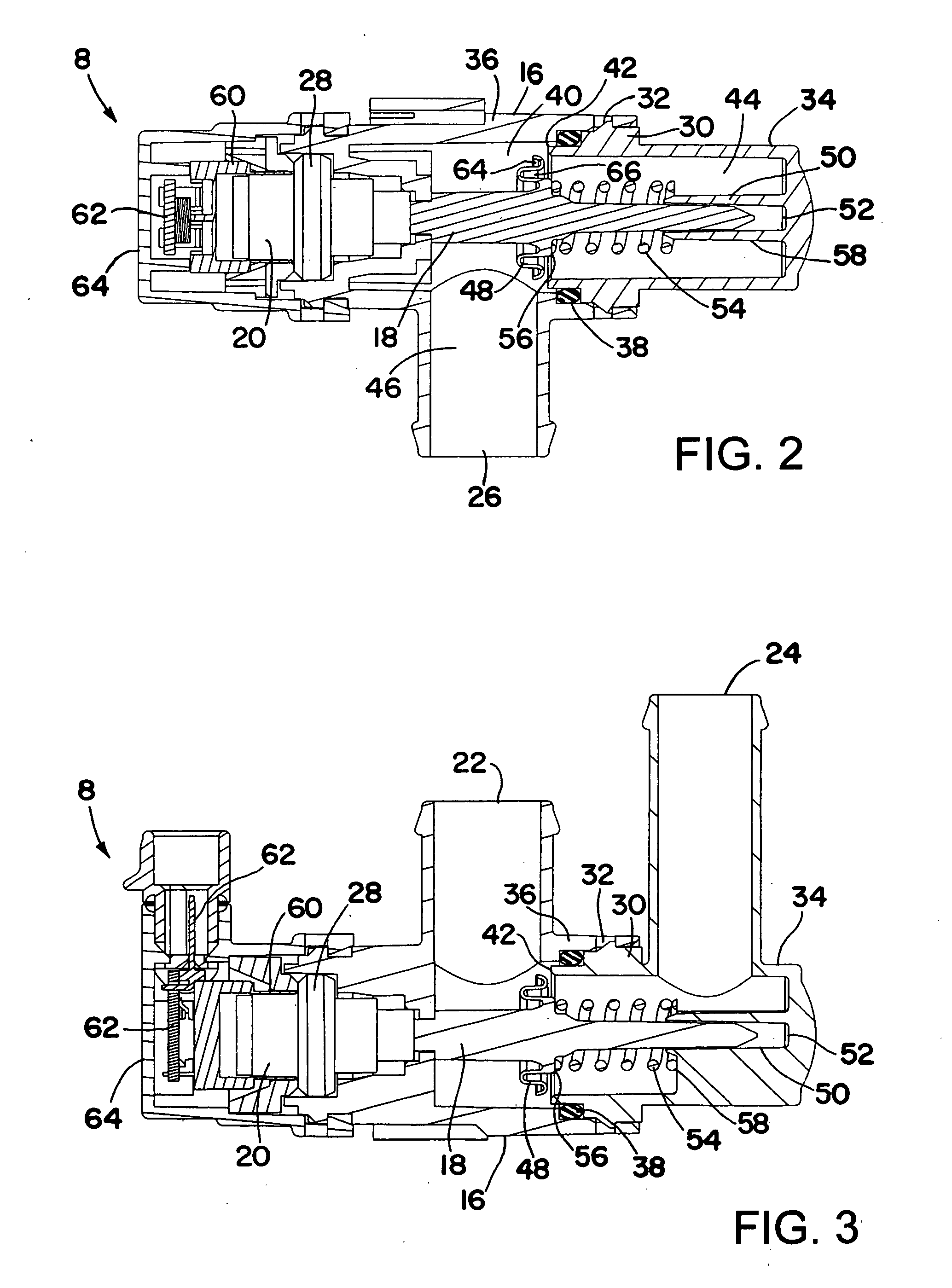

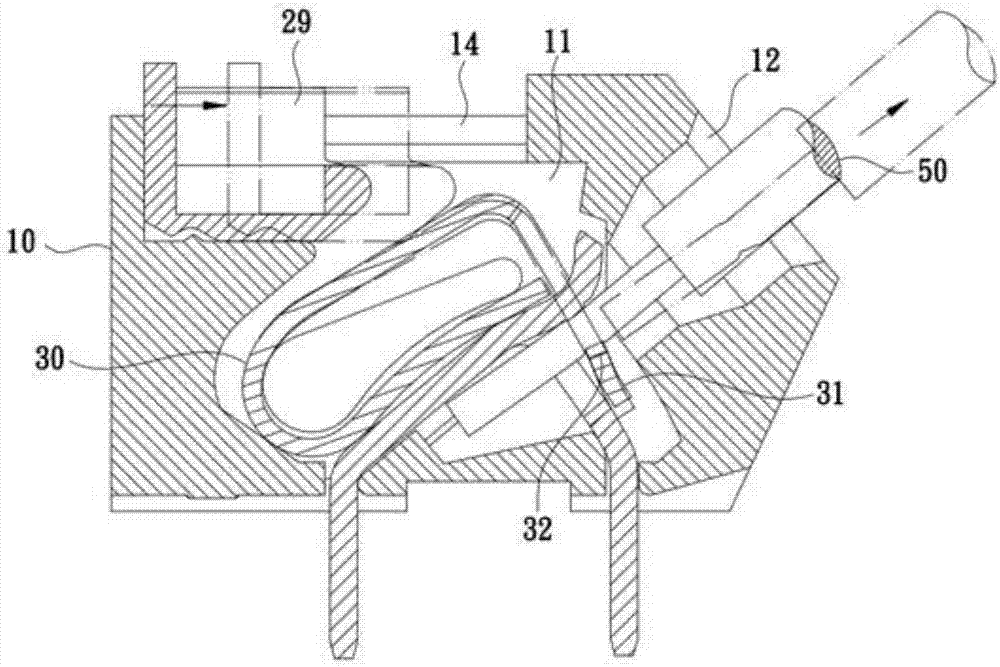

Vehicle cabin heating system with wax motor three-way valve

InactiveUS20050224031A1High strengthSimple moldingAir-treating devicesOperating means/releasing devices for valvesCoolant flowEngineering

The present invention provides a wax motor actuated valve assembly for controlling the flow of coolant to a heater core or cores until the coolant reaches a predetermined operating temperature. The wax motor actuated valve has particular application to vehicle cabin heating systems comprising front and rear heat exchangers (cores) over which air can pass for heating front and rear portions of the cabin, respectively. Initially, flow to the rear heat exchanger is shut off until the temperature of the coolant reaches a predetermined elevated temperature, whereby initial coolant flow is directed to the front heat exchanger for more rapid heating of the forward portion of the vehicle cabin. After the predetermined elevated temperature has been reached, the wax motor valve assembly is actuated to supply coolant to the rear heat exchanger for heating the rear portion of the vehicle cabin.

Owner:PARKER HANNIFIN CORP

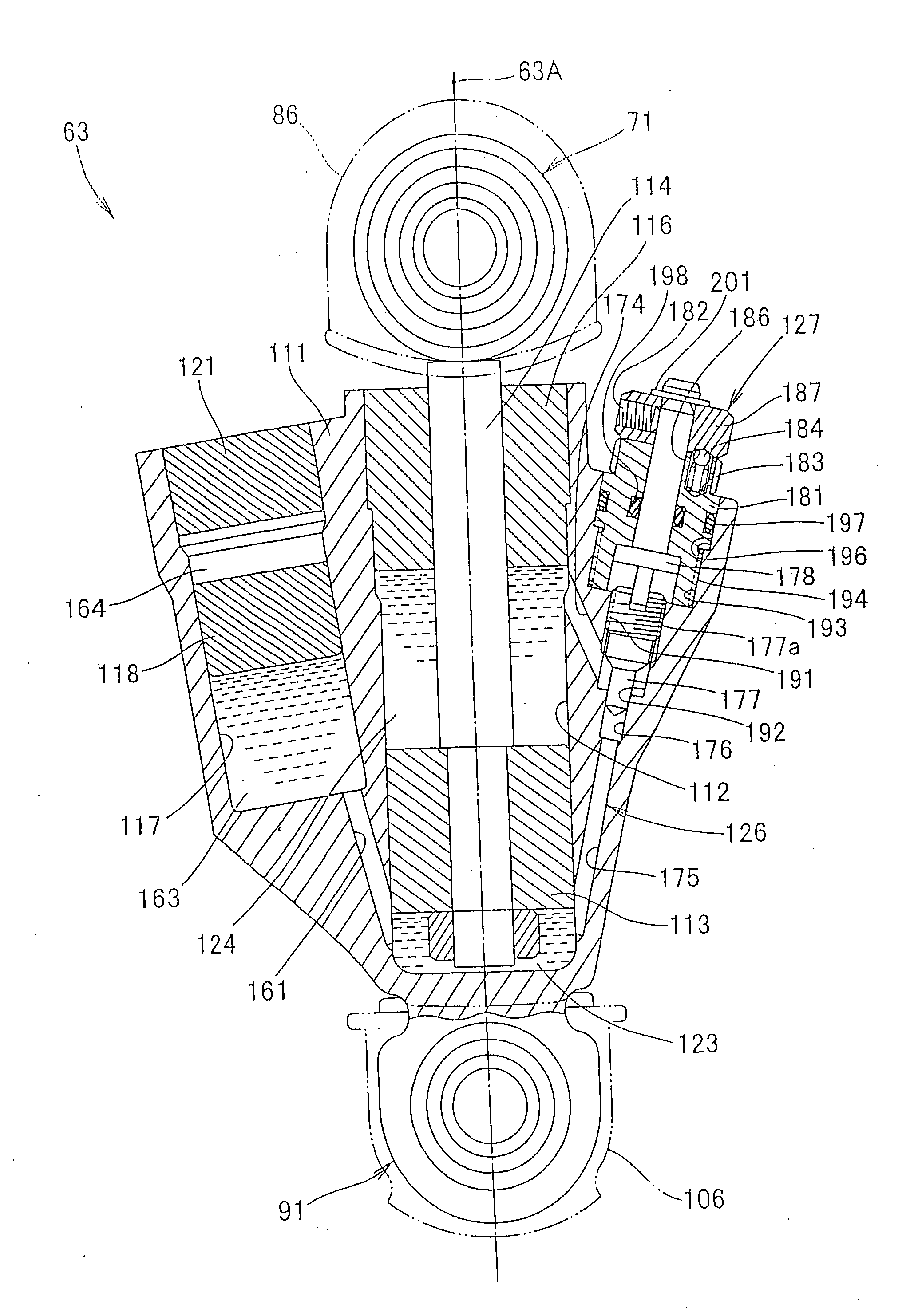

Valve control unit for a fuel injection valve

InactiveUS6244245B1Quantity minimizationIncrease movement speedCombustion enginesFuel injecting pumpsEngineeringPiston

A valve control unit for a fuel injection valve includes a housing body with two valve control chambers that continuously communicate with each other. An end member of a movable valve control piston can be moved inside the first valve control chamber and the first valve control chamber communicates with an inlet conduit for fuel. The second valve control chamber communicates with an outlet conduit that can be closed by a ball valve. The end member is comprised of an inner structural member and an outer structural member that can move in relation to each other. In the movement of the valve control piston, only the outer structural member is moved for a preinjection of fuel and the inner structural member is moved for the main injection. The quantity of preinjected fuel can be further minimized while an increased movement speed of the valve control piston is simultaneously possible during the main injection.

Owner:ROBERT BOSCH GMBH

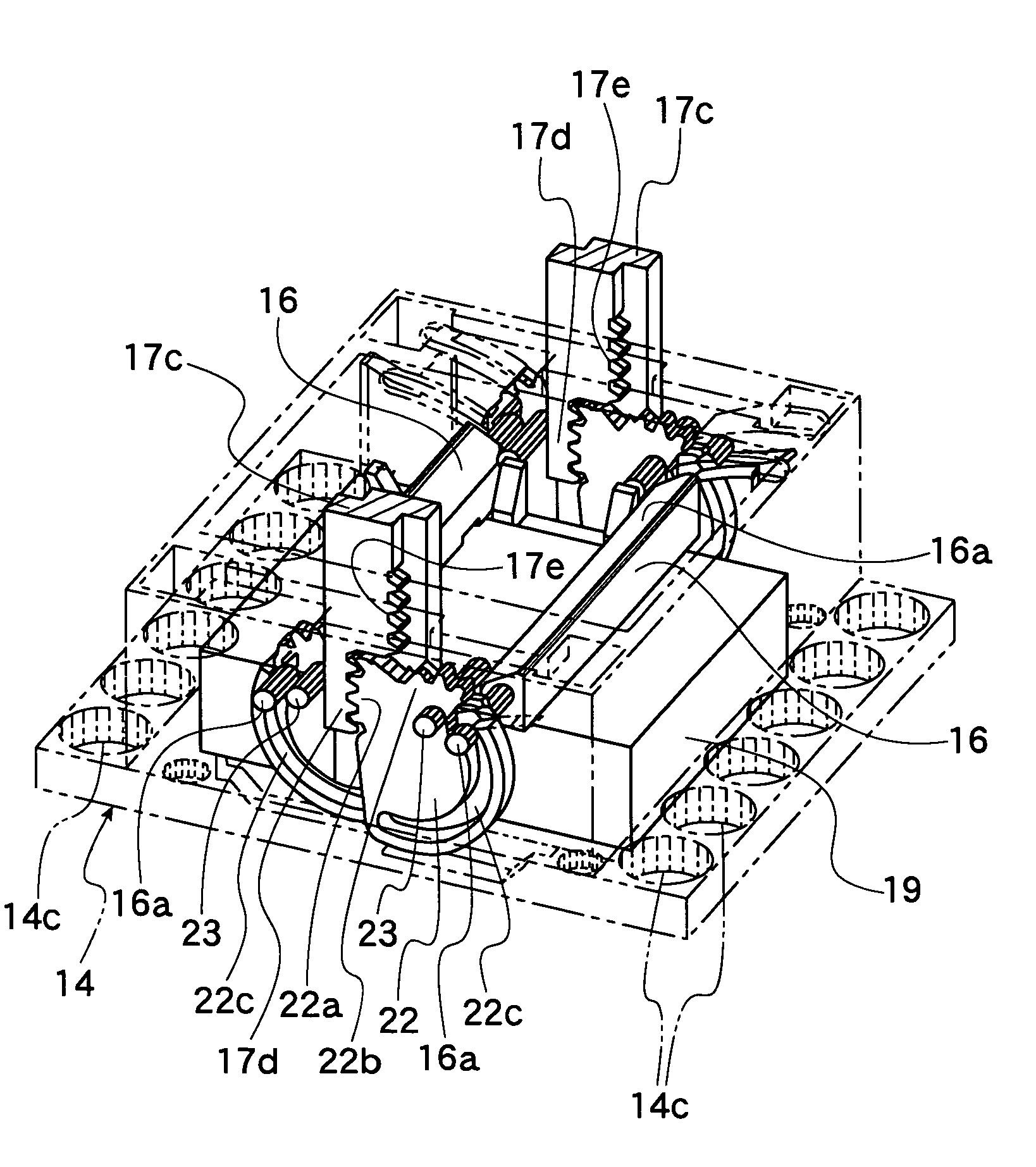

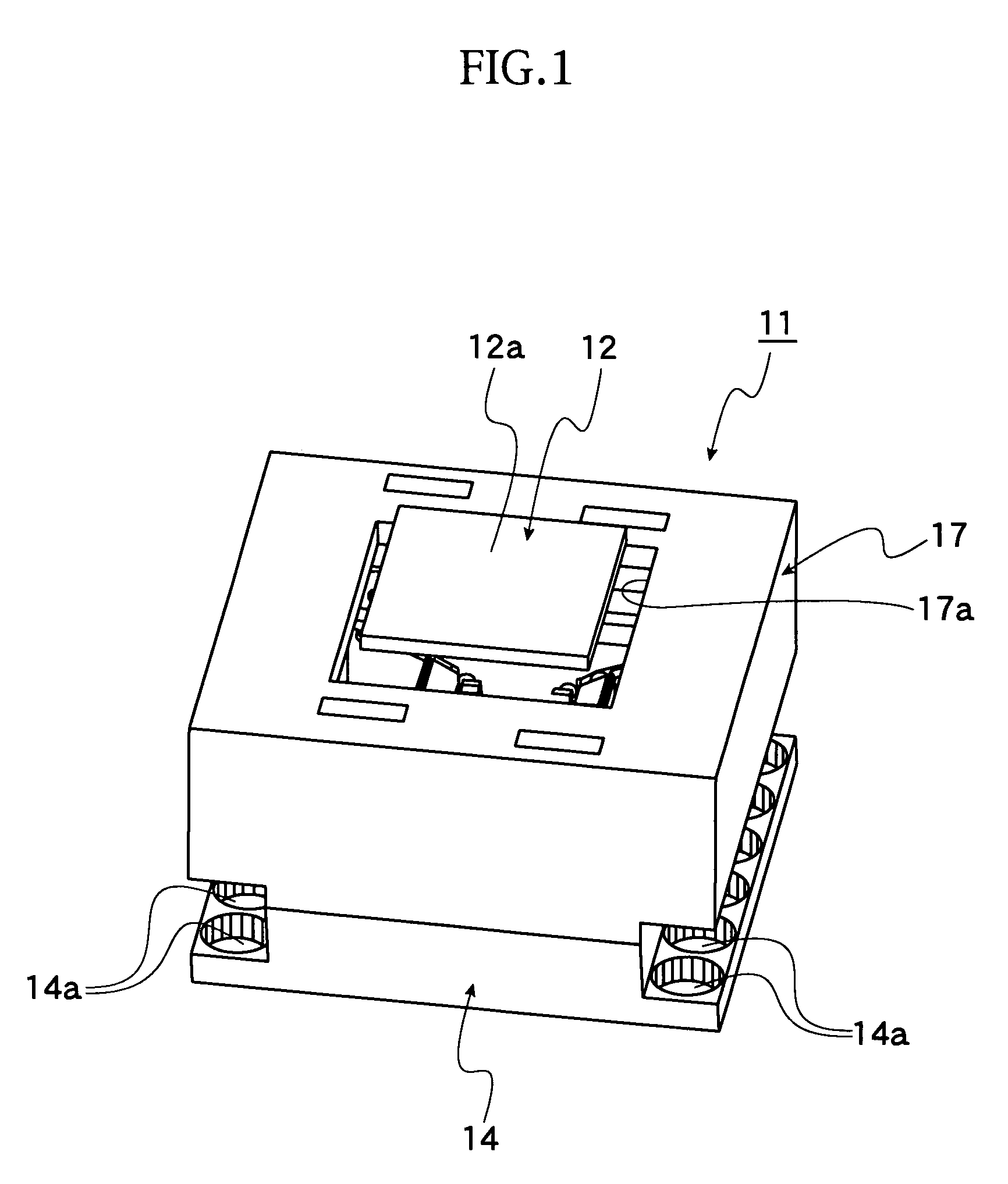

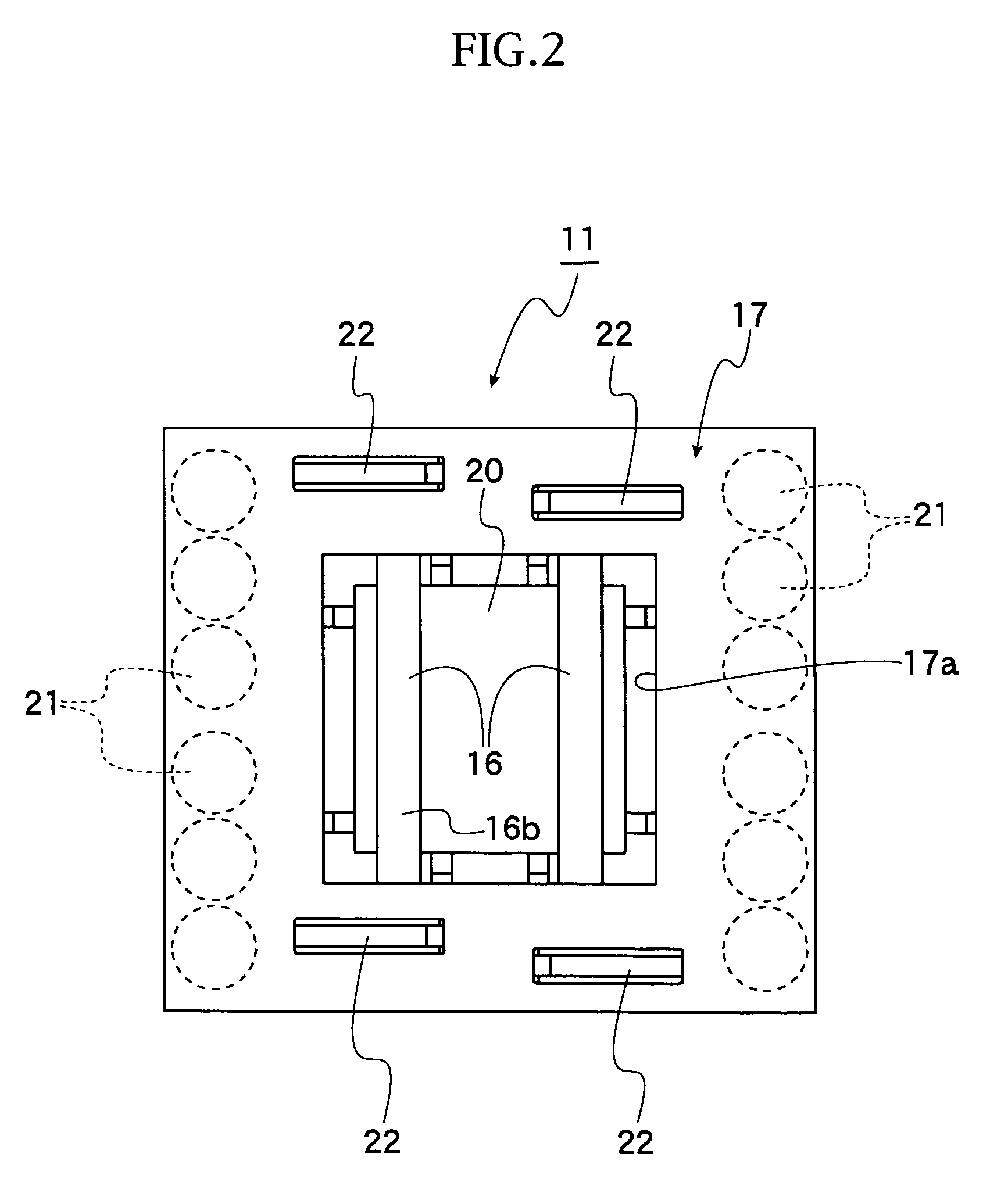

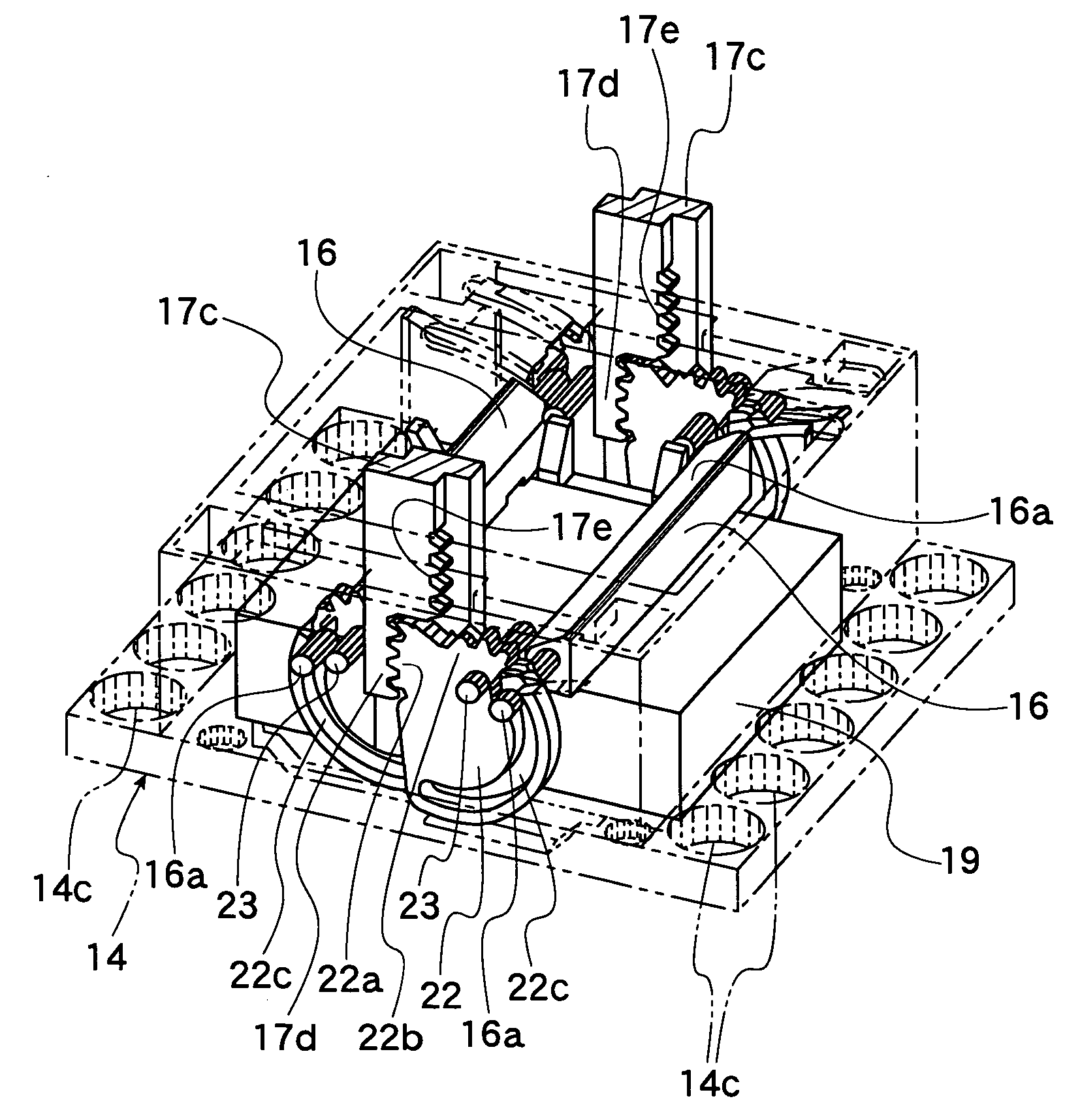

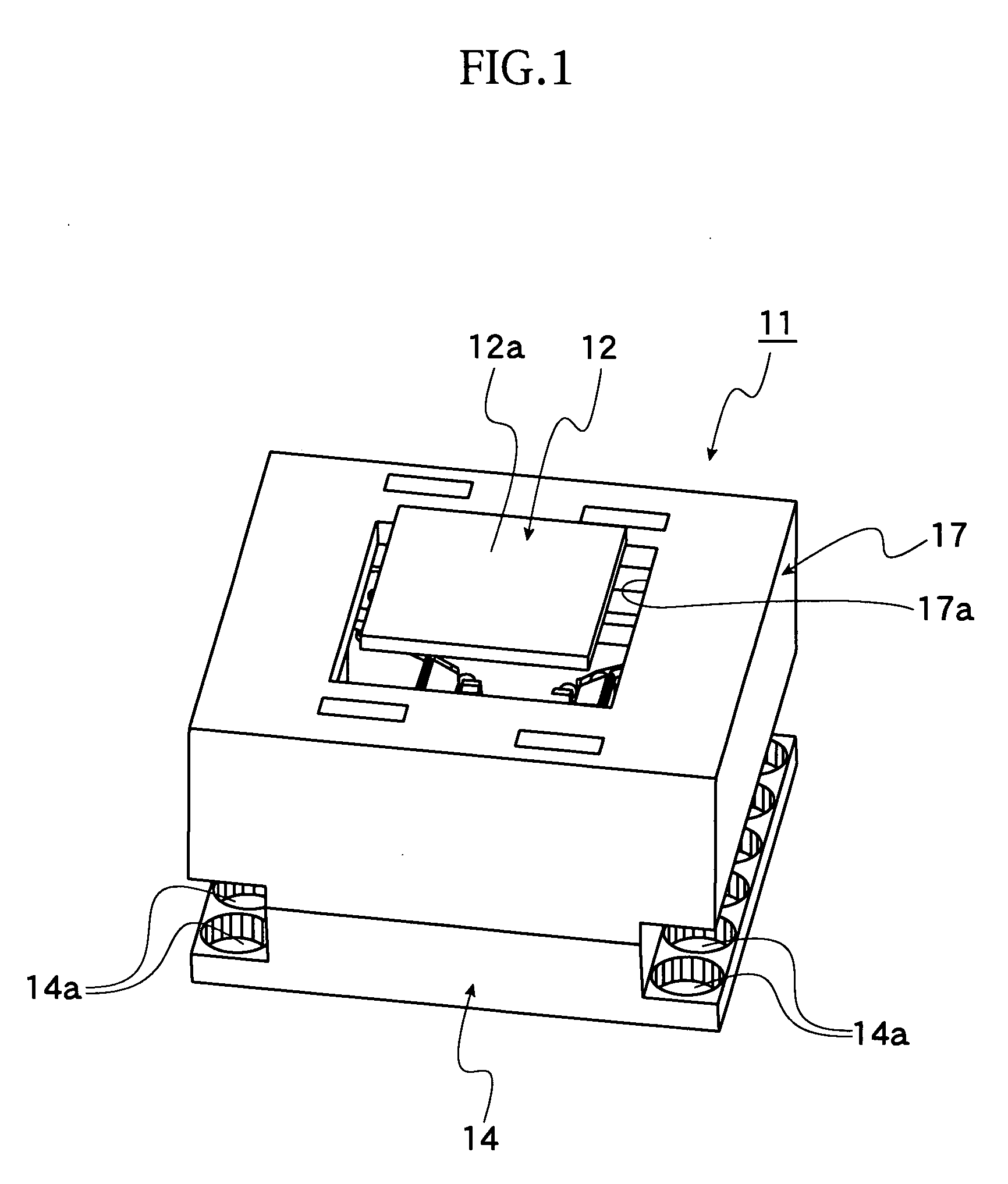

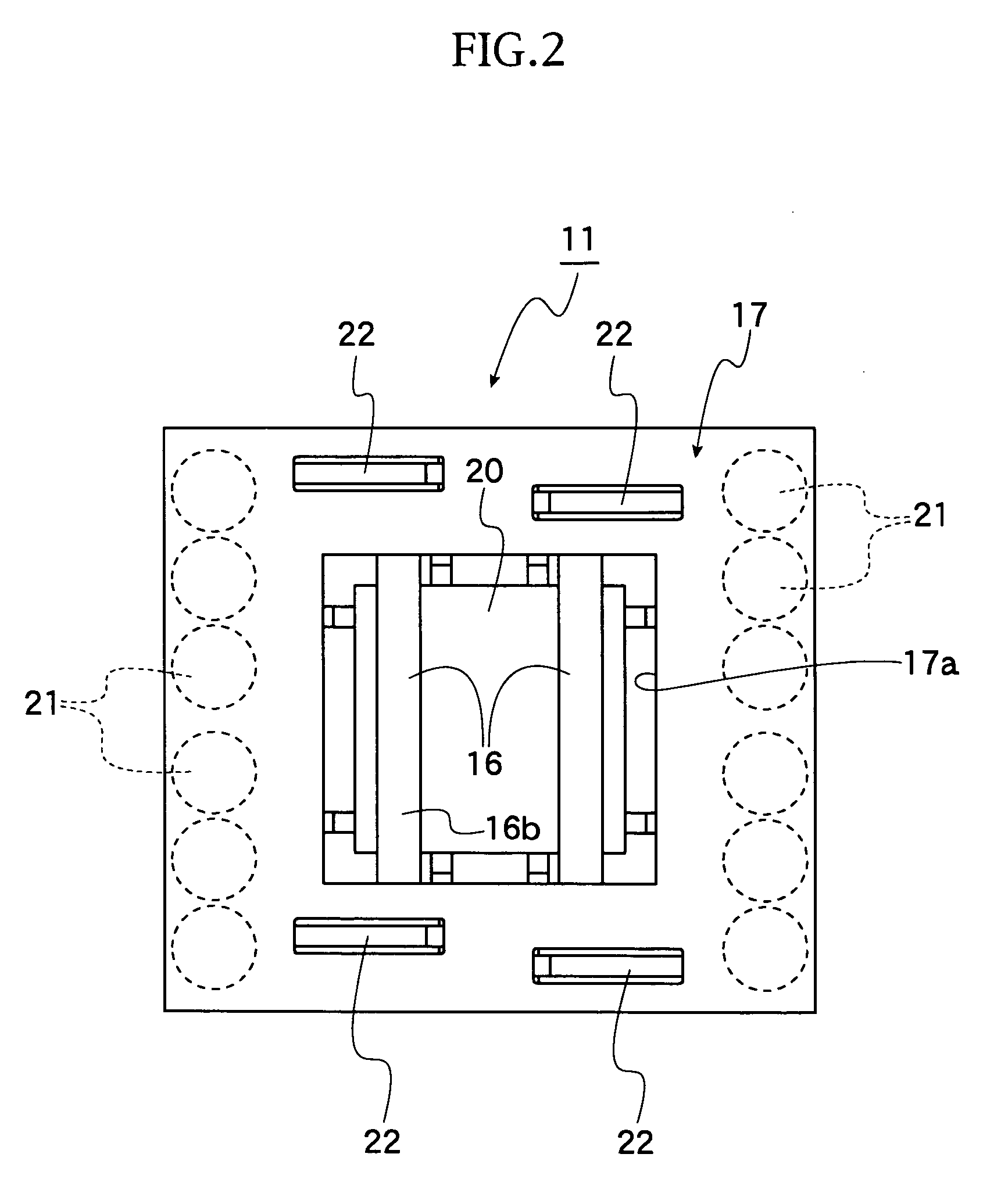

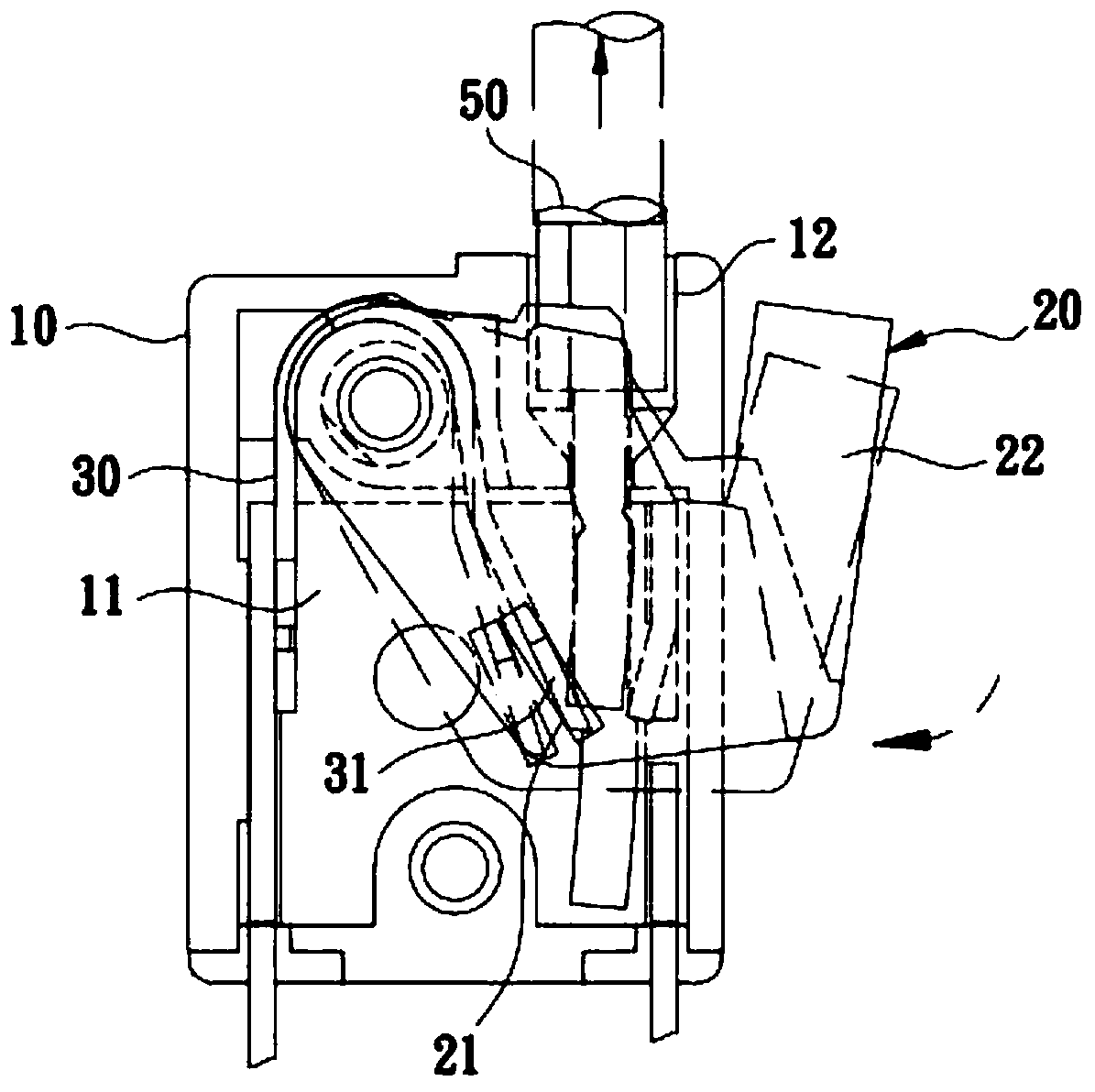

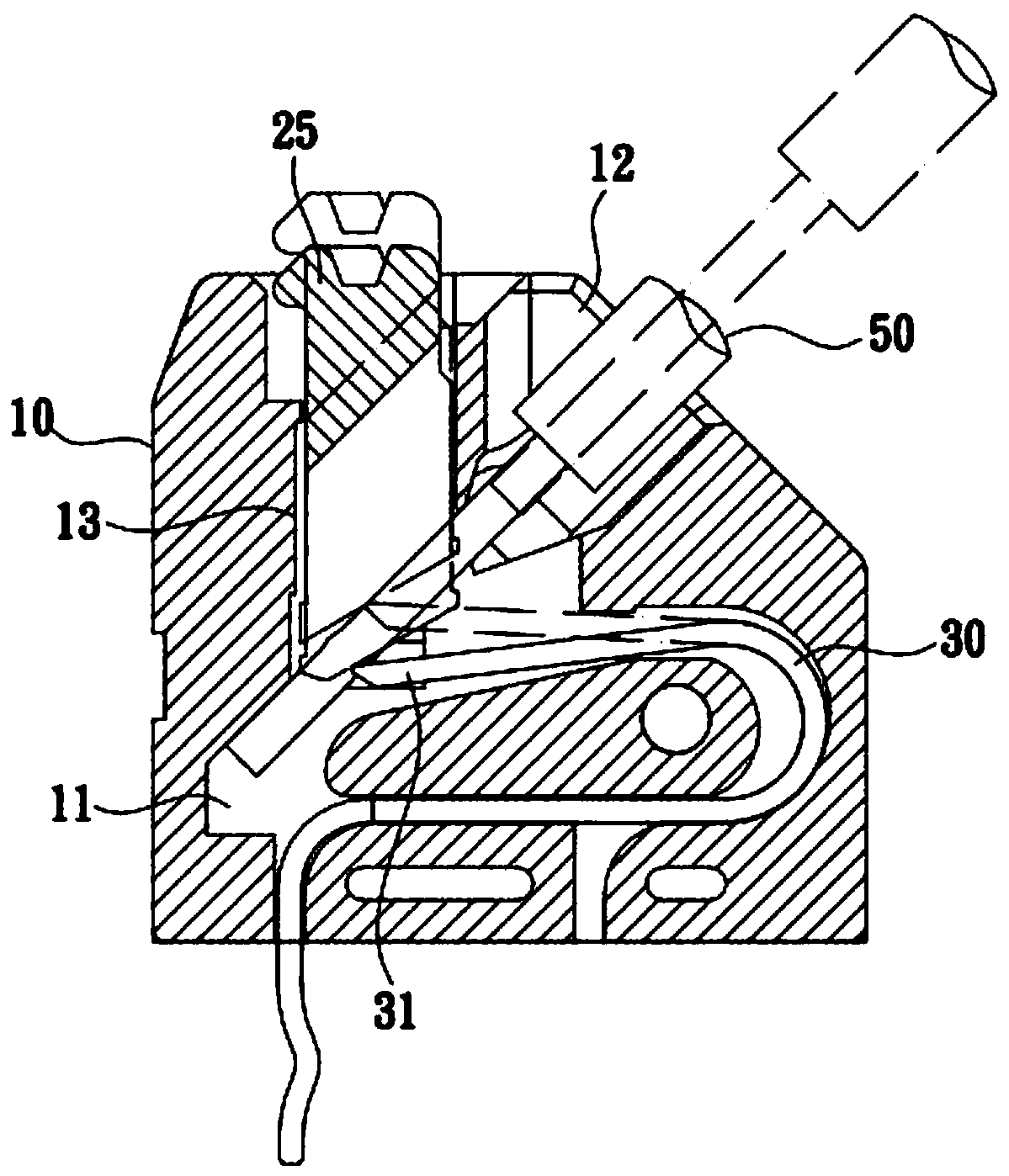

Socket for electrical parts

InactiveUS6976852B2Short strokeShorten the timeCoupling device connectionsElectric discharge tubesEngineeringRack and pinion

A socket for electrical parts includes driving mechanisms that move pressing members from a depressed position to a retired position when an operating member is vertically shifted. The operating member includes racks each of which has rack gears in the vertical direction. Follower gears engageable with the rack gears are also provided. The follower gears have different distances from the rotational pivot to the pitch circle. When the operating member is depressed, the follower gear with a longer distance from the rotational pivot to the pitch circle is engaged with one of the rack gears.

Owner:ENPLAS CORP

Blow molding machine for containers and mandrel holder

InactiveUS20110120840A1Short replacement timeImprove retentionConveyor partsRotary conveyorsBlow moldingCoupling

A blow molding machine for containers, having a conveyor path carrying a mandrel holder and pre-forming mandrels attached to the mandrel holders in an exchangeable manner by means of removable couplings, wherein each coupling has a mandrel clamping mechanism and a releasing element accessible form outside that can be adjusted at least relative to the mandrel holder for releasing the clamping mechanism. In the mandrel holder, particularly for use in a blow molding machine, the mandrel clamping mechanism is designed with a ball joint lock, and the ball joint lock can be released by means of a releasing element in order to exchange a performing mandrel.

Owner:KRONES AG

Blow molding machine for containers and mandrel holder

InactiveUS8567589B2Short replacement timeImprove retentionControl devices for conveyorsMechanical conveyorsBlow moldingCoupling

A blow molding machine for containers, having a conveyor path carrying a mandrel holder and pre-forming mandrels attached to the mandrel holders in an exchangeable manner by means of removable couplings, wherein each coupling has a mandrel clamping mechanism and a releasing element accessible form outside that can be adjusted at least relative to the mandrel holder for releasing the clamping mechanism. In the mandrel holder, particularly for use in a blow molding machine, the mandrel clamping mechanism is designed with a ball joint lock, and the ball joint lock can be released by means of a releasing element in order to exchange a performing mandrel.

Owner:KRONES AG

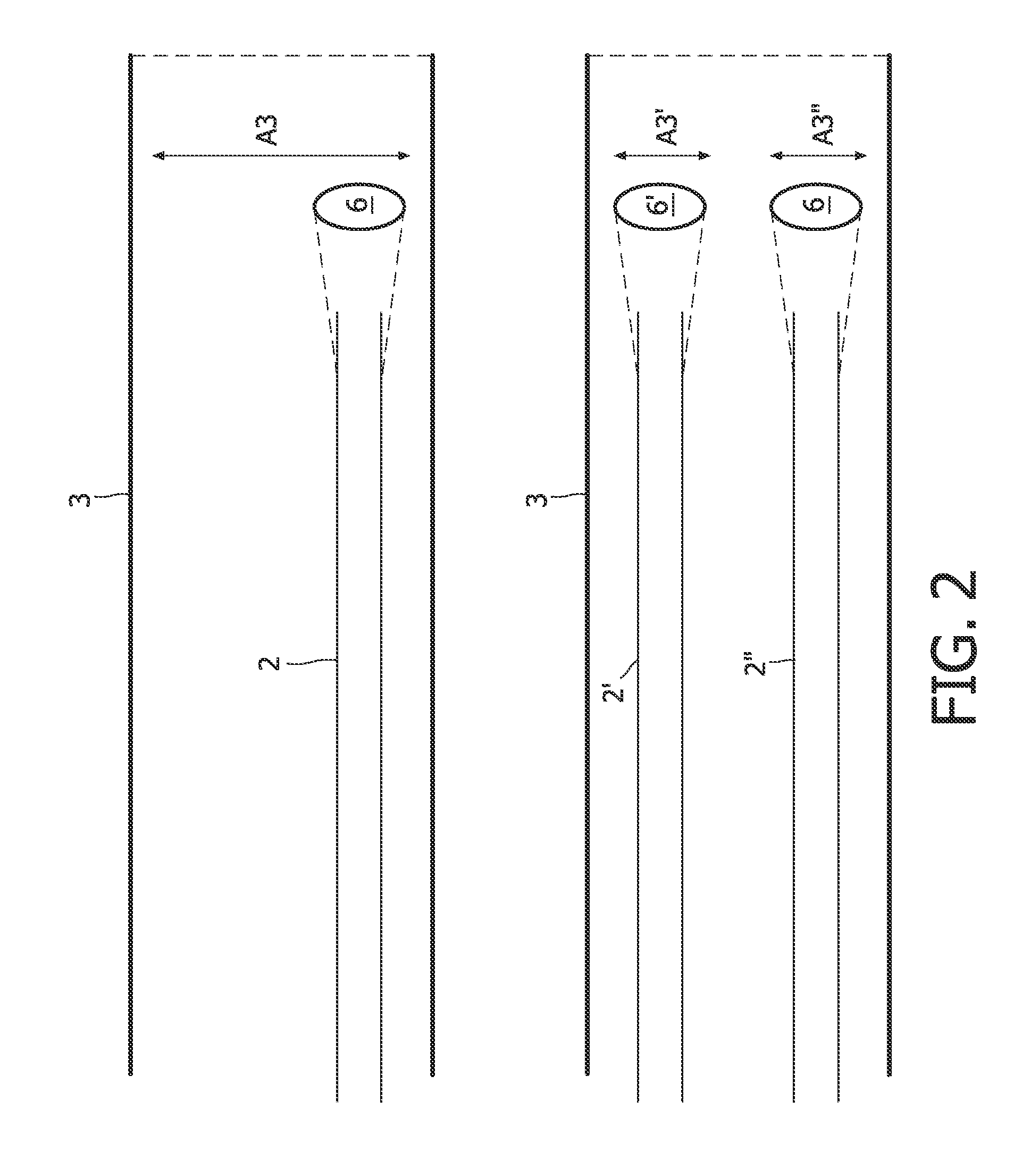

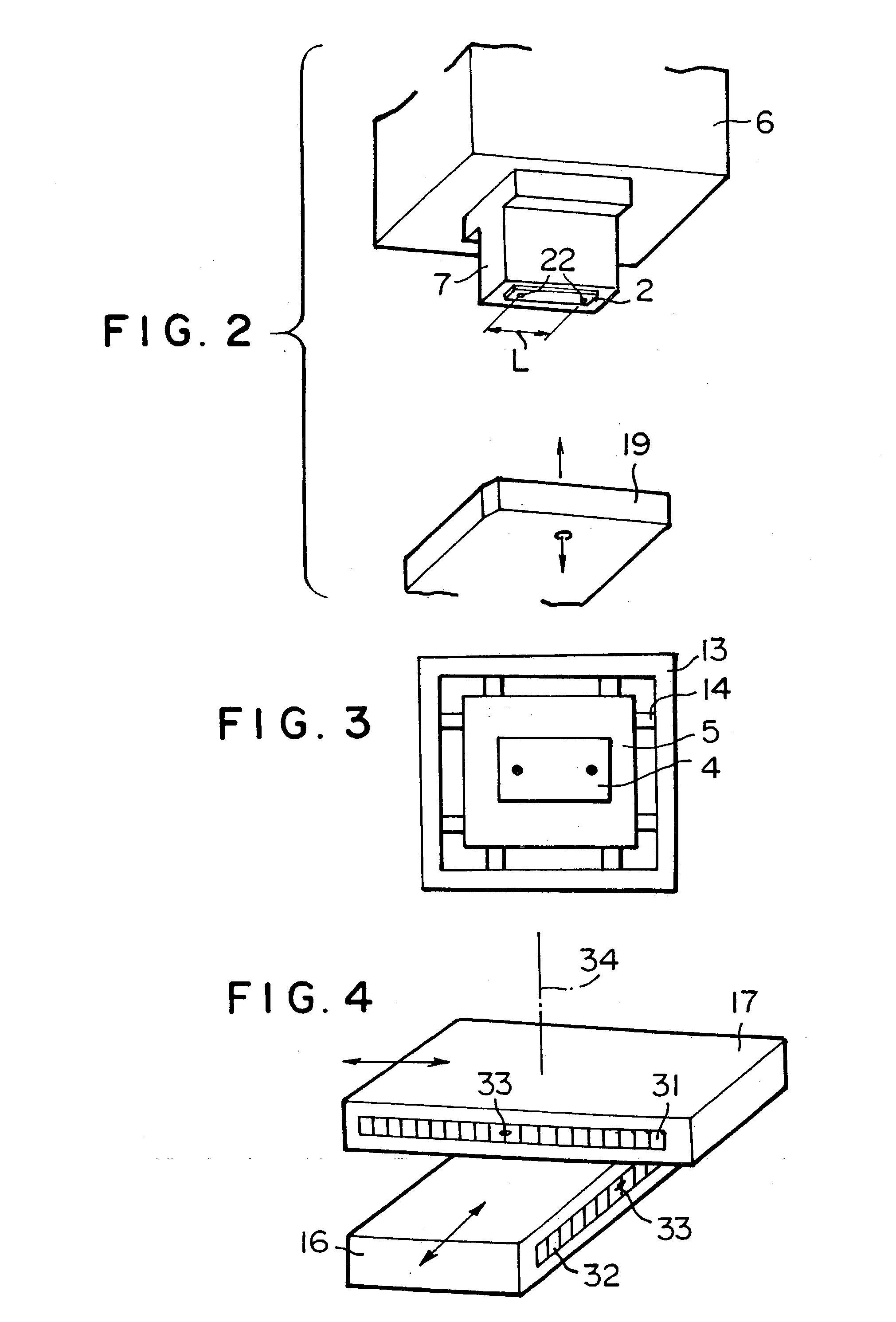

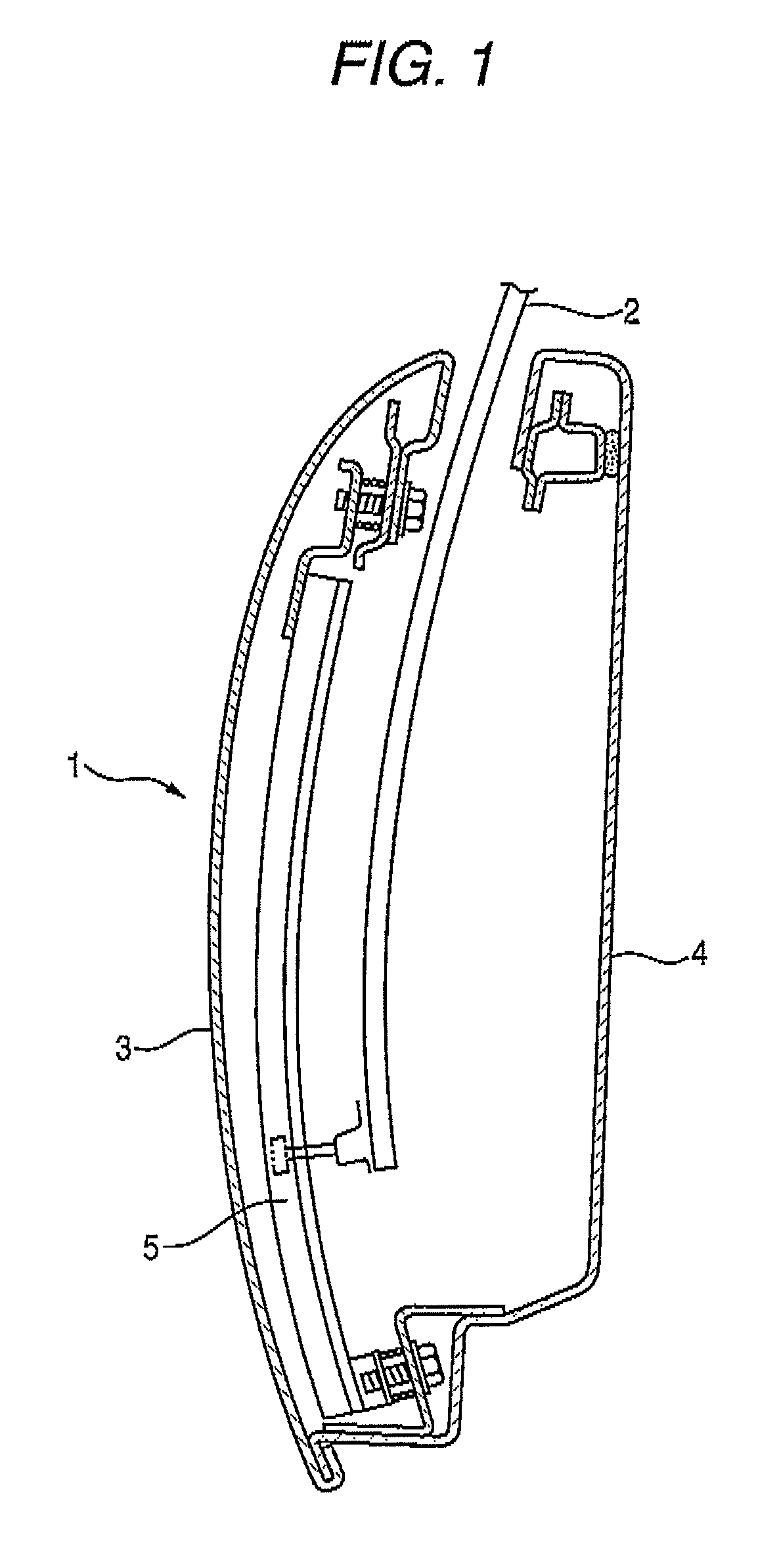

Optical probe

InactiveUS20100282954A1ImproveEfficient and reliableEndoscopesMaterial analysis by optical meansOptical powerRegion of interest

The present invention relates to an optical probe (1) with an optical guide (2), e.g. an optical fibre, and a lens system (6) rigidly coupled to an end portion (2a) of the optical guide. The probe has a housing (3) with a cavity for the optical guide, the housing having at its distal end a transparent window (4), the window having an insignificant optical power as compared to the optical power of the said lens system (6). Actuation means (8) displaces the 5 lens system so as to enable optical scanning of a region of interest (ROI). The invention is particularly suited for miniature applications e.g. for in-vivo medical application. By attaching the lens system (6) to the optical guide (2) via the mount (7), the field of view (FOV) of the optical probe (1) may be determined directly by the transverse stroke of the optical fibre (2). Hence only a relatively small stroke is required. The field of view is thus 10 effectively no longer limited by the transverse stroke. The optical probe is especially advantageous for non-linear optical imaging where the optical guide may be an optical fibre with a relatively low exit numerical aperture.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

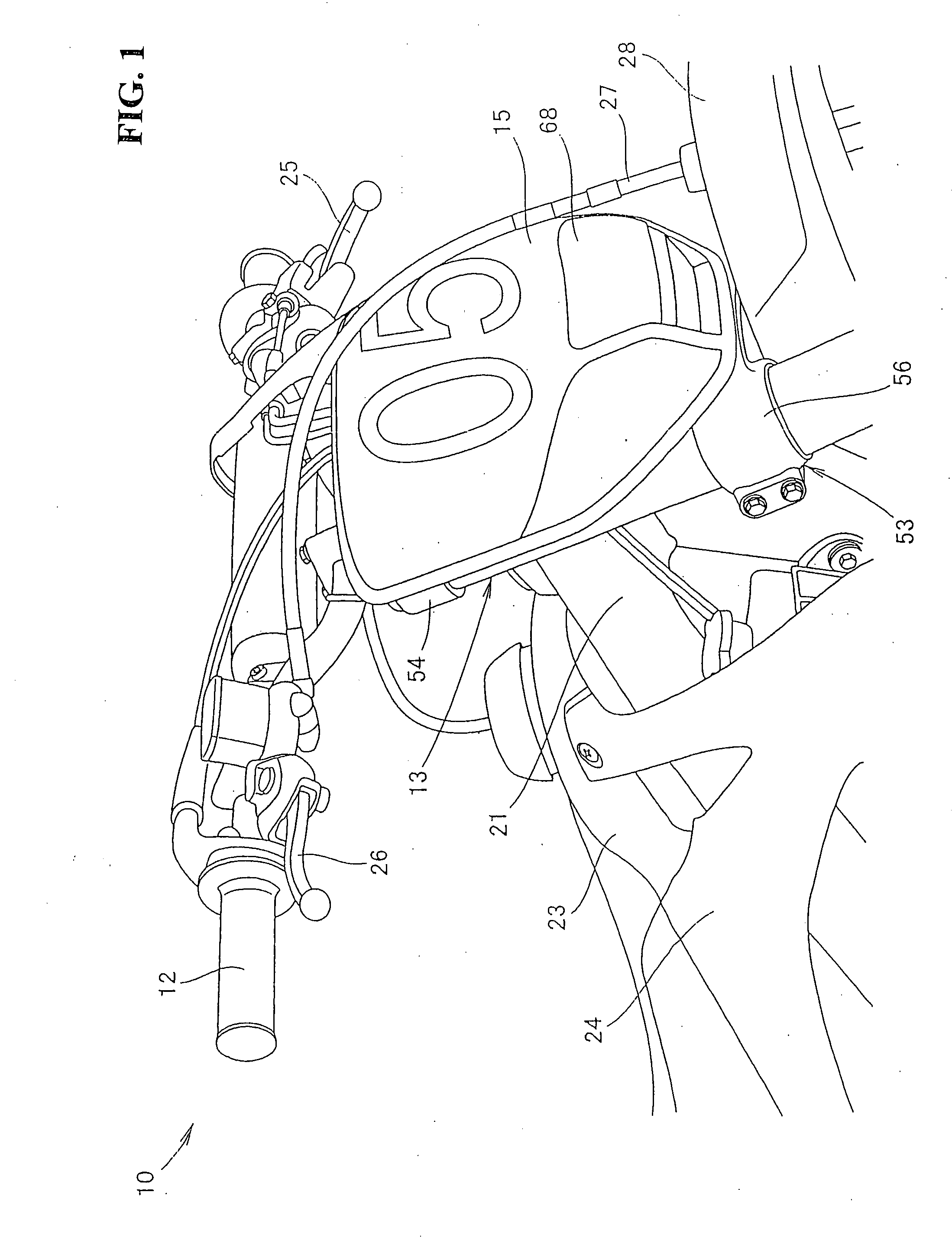

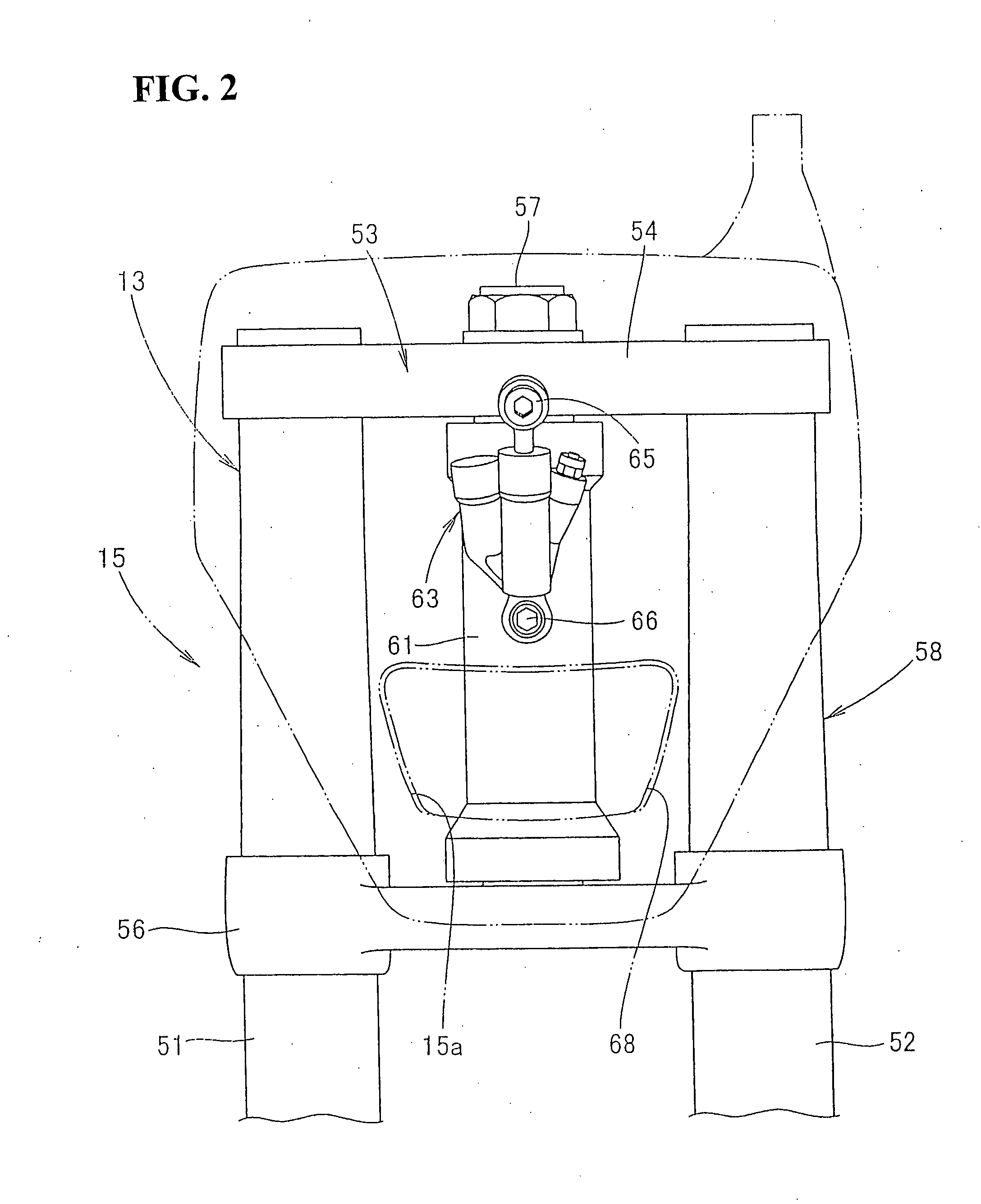

Steering damper mounting structure for vehicle

InactiveUS20080054590A1Small space requirementReduce in sizeFoot-driven leversWheel based transmissionControl theoryRoad surface

A steering damper mounting structure of a vehicle includes a head pipe, a front fork, a fork bridge, and a steering damper. The front fork, which suspends a front wheel, is steerably disposed on the head pipe. The fork bridge connects left and right members of the front fork. The steering damper is mounted on the fork bridge and the head pipe. The steering damper dampens a steering directional movement transmitted from a road surface to a handlebar via the front wheel and the front fork. A lower mounting portion on a side of the head pipe is disposed on a side of an axis as a center of pivotal motion of the front fork relative to the fork bridge, more specifically, an upper mounting portion on a side of the top bridge. The resulting configuration reduces the size of a front portion of a vehicle and a steering damper.

Owner:HONDA MOTOR CO LTD

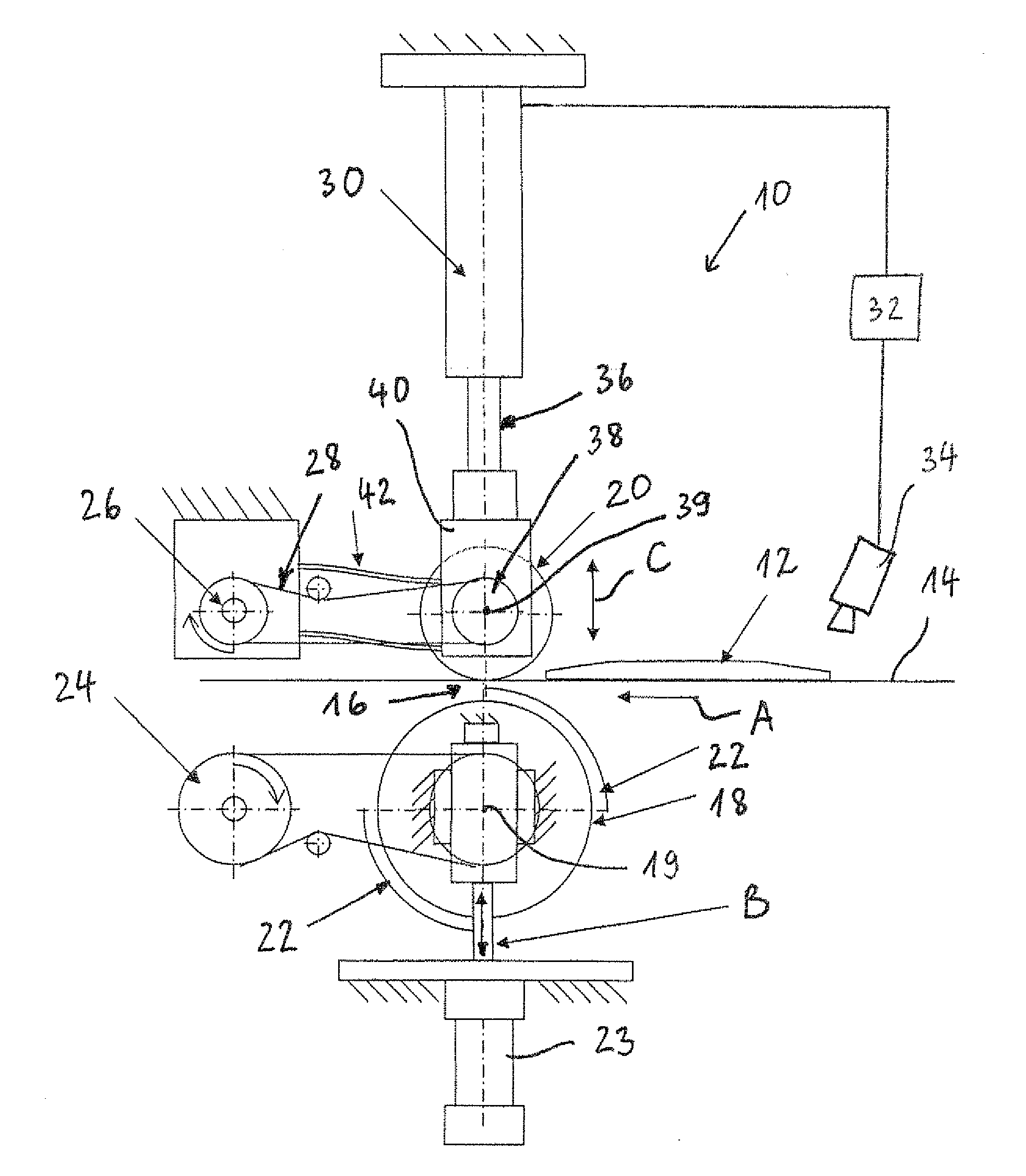

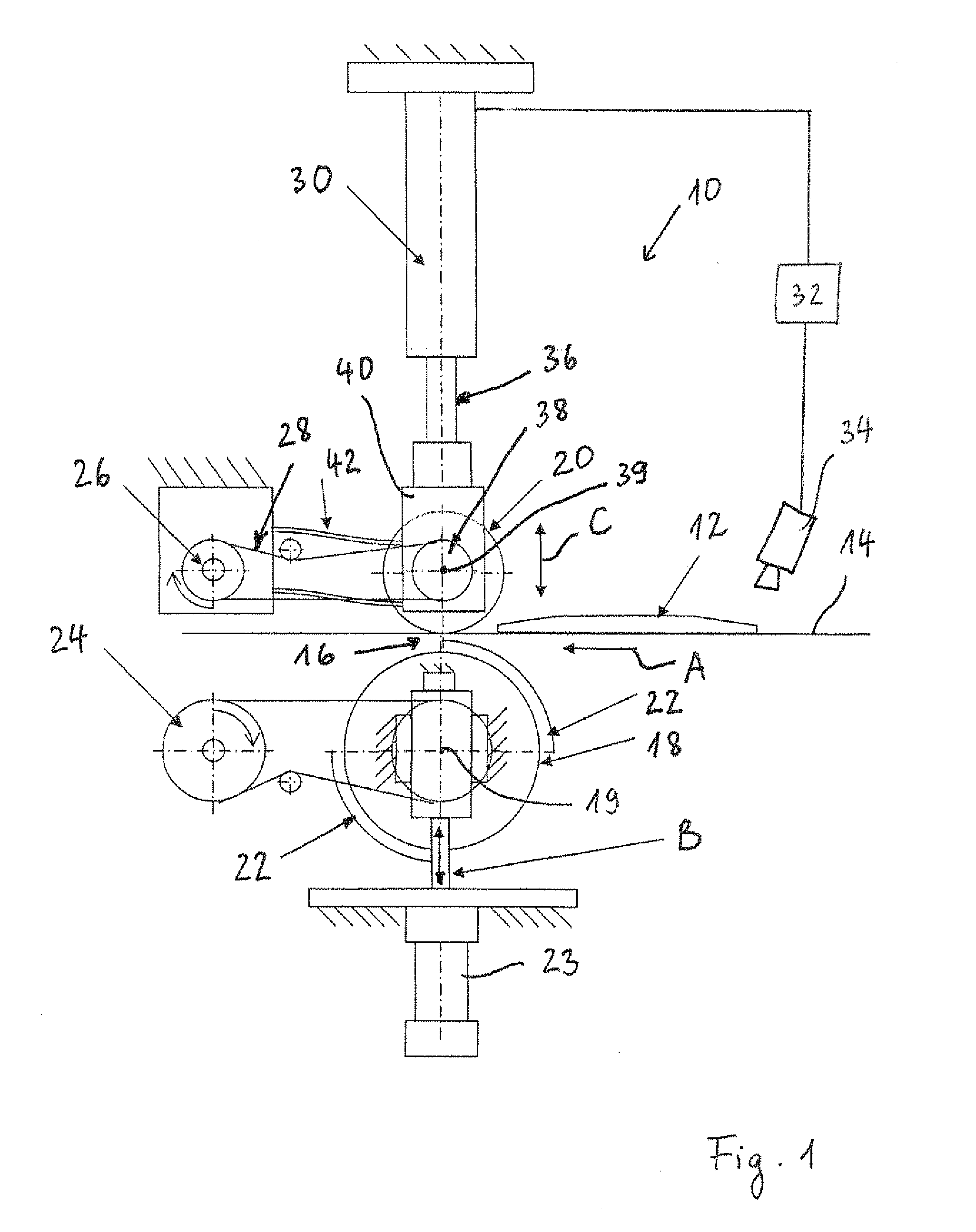

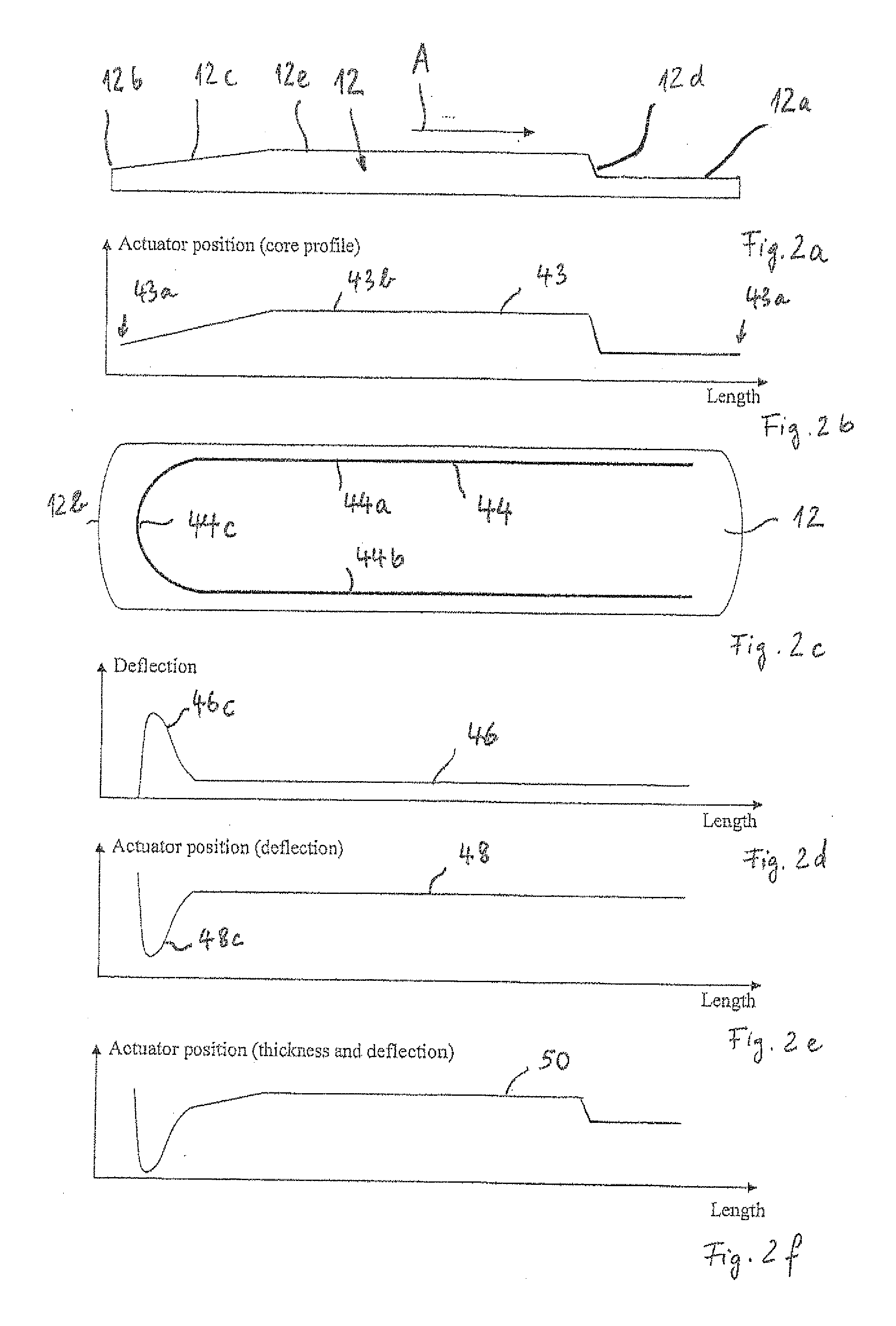

Apparatus and method for treating products

InactiveUS20130042771A1High qualityQuality improvementMechanical working/deformationDecorative surface effectsEngineeringNominal size

An apparatus for treating products continuously fed to the apparatus includes a first roller rotatable around a first rotation axis and a second roller rotatable around a second rotation axis parallel to the first rotation axis. A treatment gap is formed between the first roller and the second roller. The apparatus further includes an adjusting means for in-line adjusting the nominal size of the treatment gap. The adjusting means includes at least one piezoelectric element for shifting the position of the first rotation axis and / or the second rotation axis.

Owner:SCA HYGIENE PROD AB

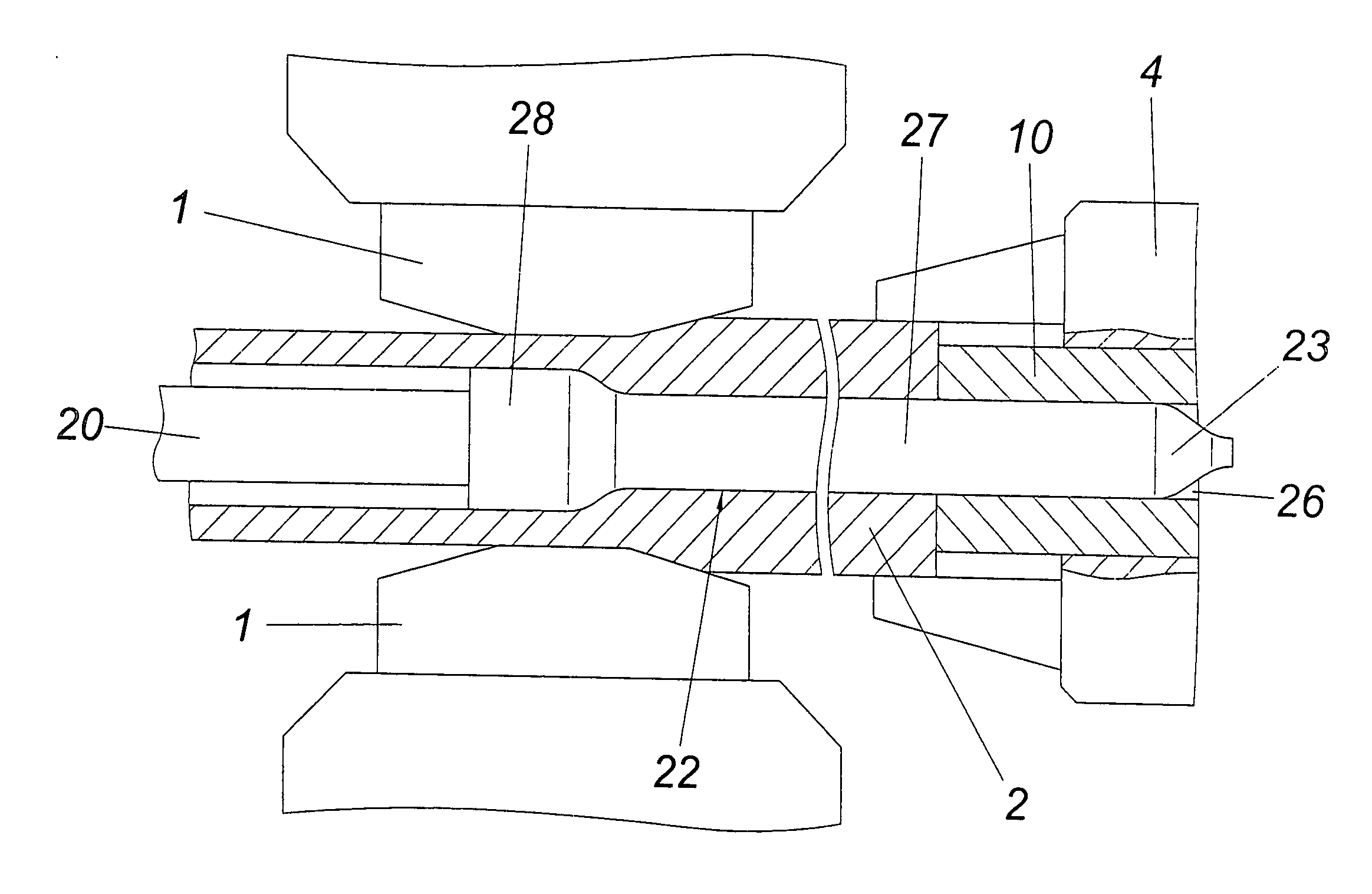

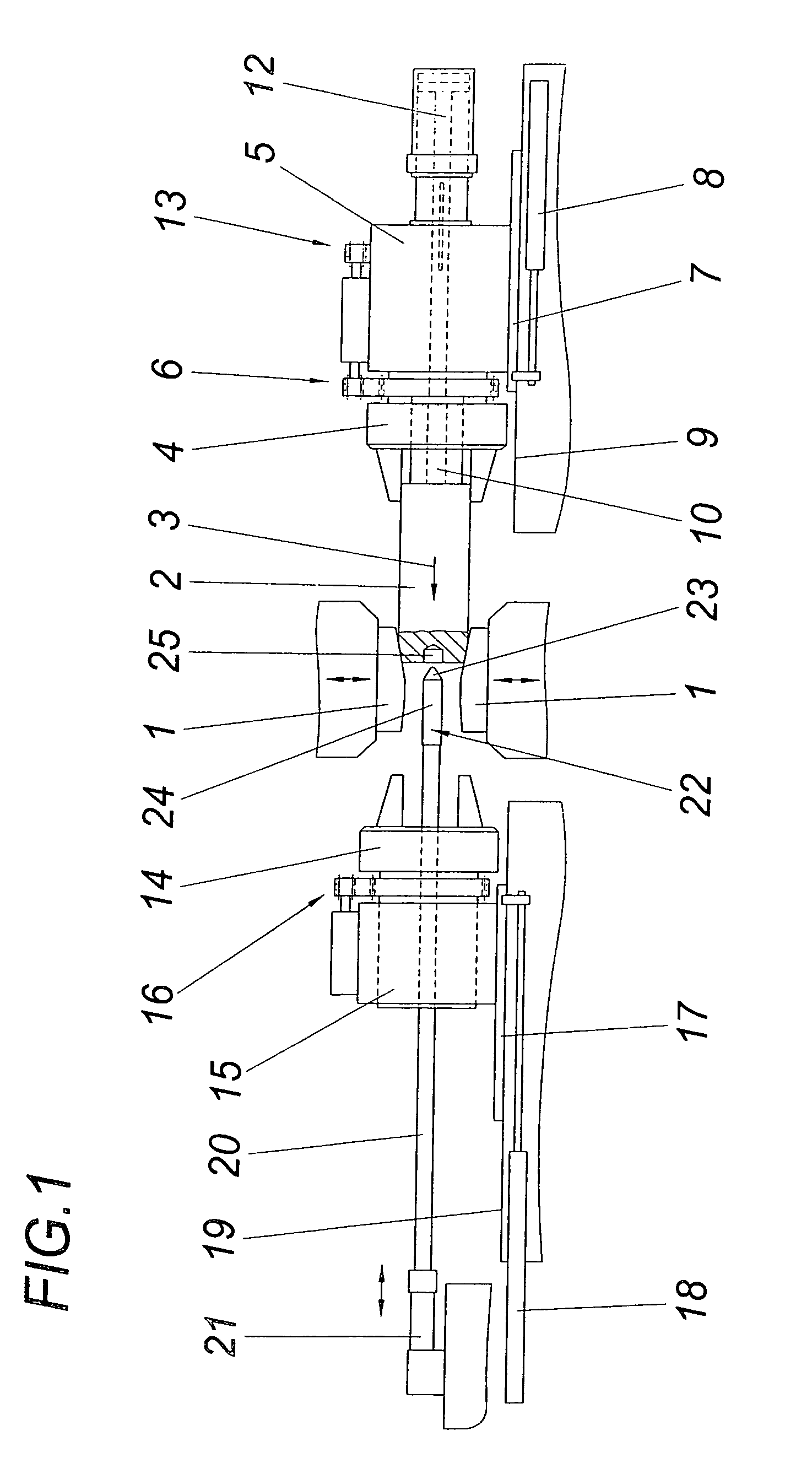

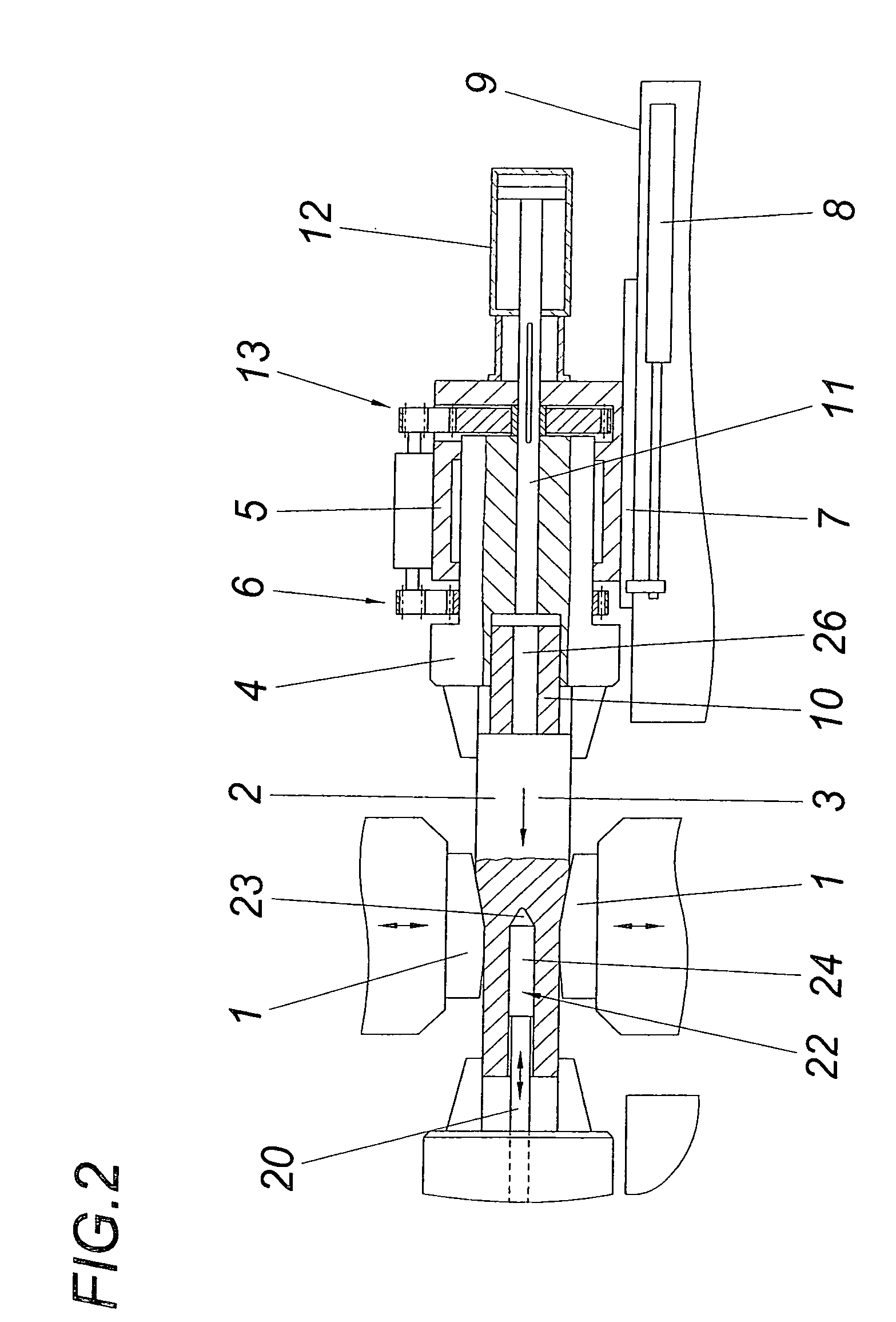

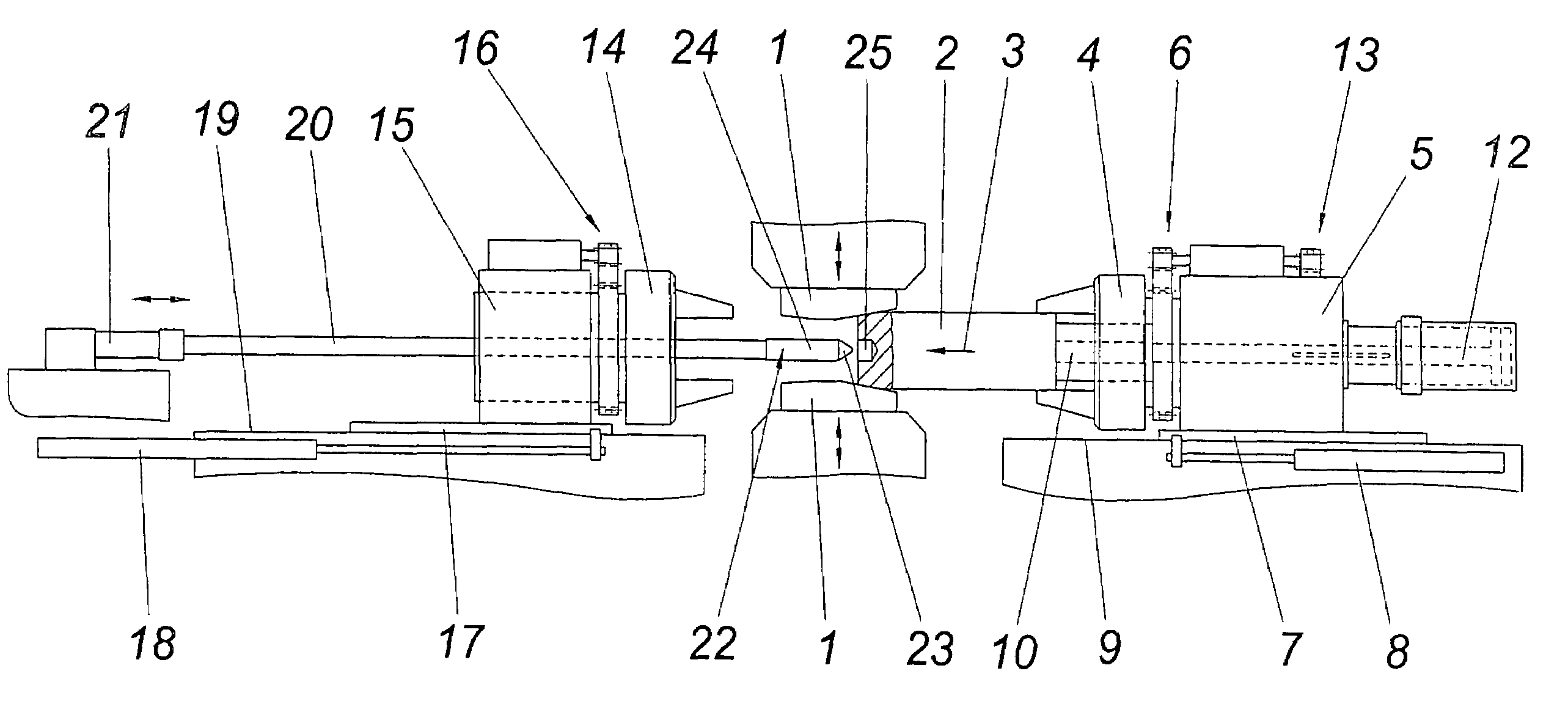

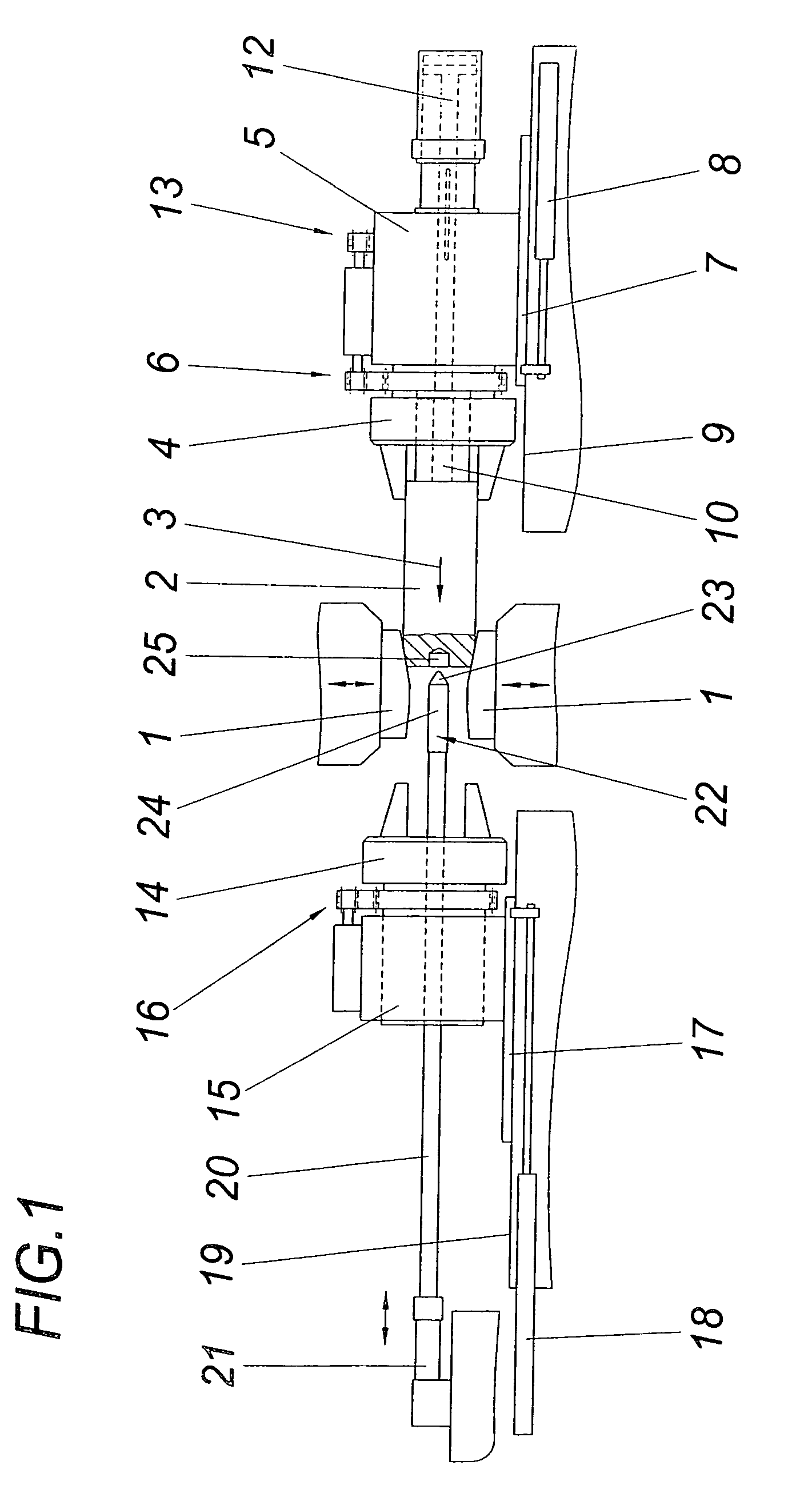

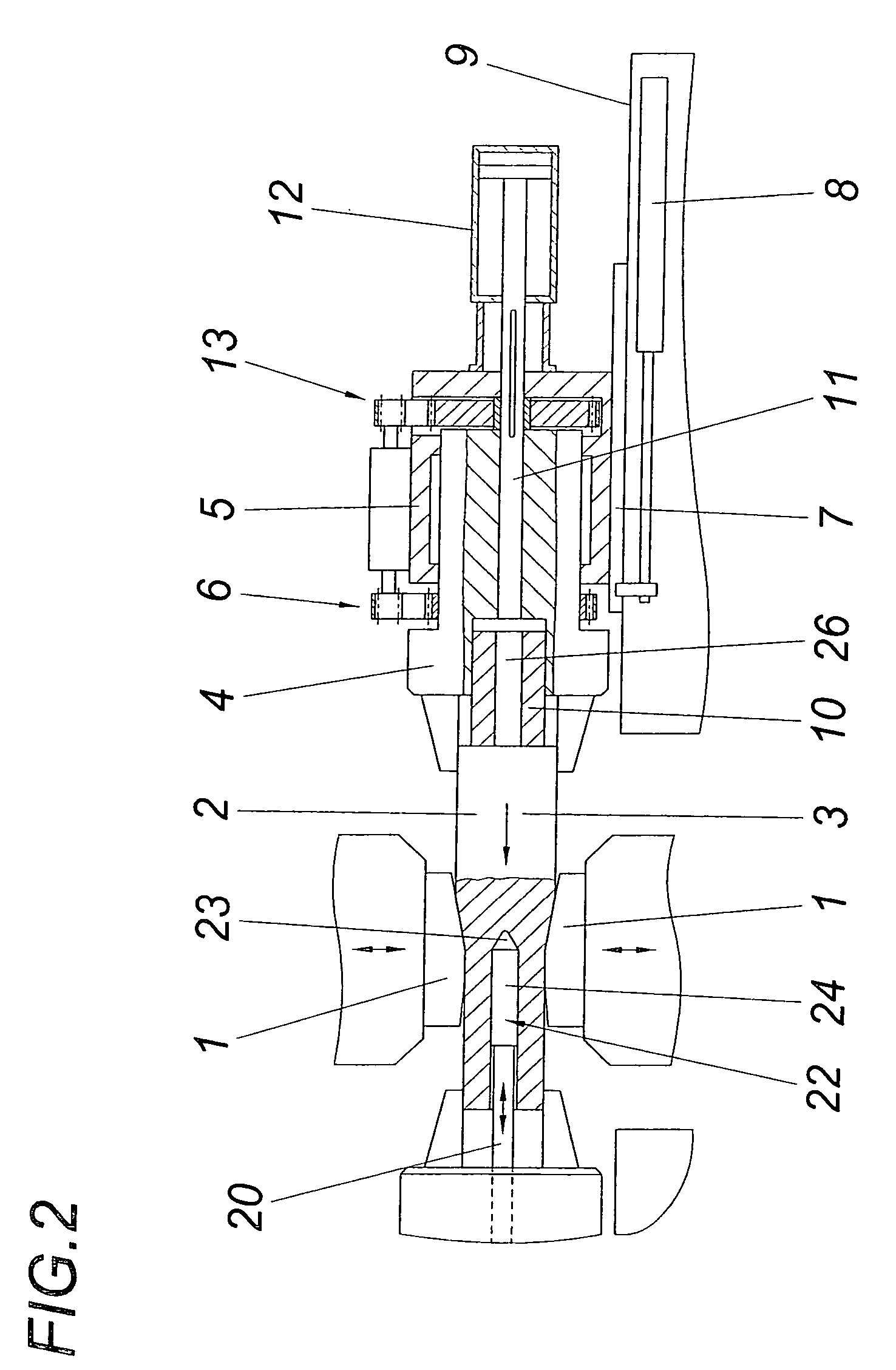

Method and apparatus for producing a cylindriacal hollow body from a blank

ActiveUS20070186604A1Feed of the workpiece can be increased considerablyImprove construction conditionsForging hammersPiercing pressesAxial forceSwaging

A method is described for producing a cylindrical hollow body from a blank, with the workpiece being opened in the core region by successive swaging which is angularly offset against each other about the axis of the workpiece and being simultaneously pushed onto a piercing mandrel. In order to improve the piercing it is proposed that the workpiece is pressed during the swaging with a predeterminable axial force against the piercing mandrel which can be advanced against the workpiece against this axial force, which piercing mandrel is moved back to its initial position synchronous with the axial feed of the workpiece between the successive swaging steps.

Owner:GFM BETEILIGUNGS & MANAGEMENT

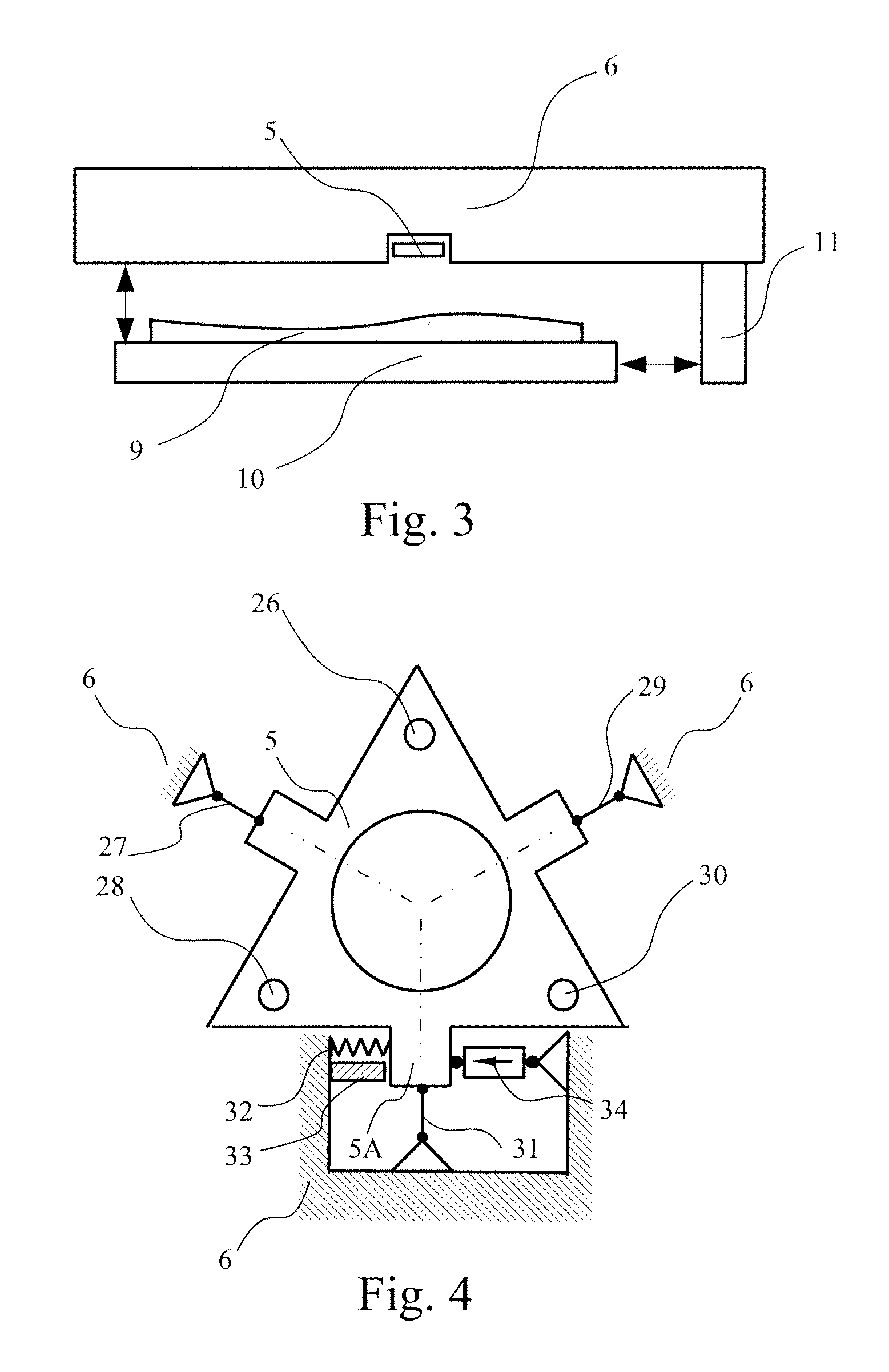

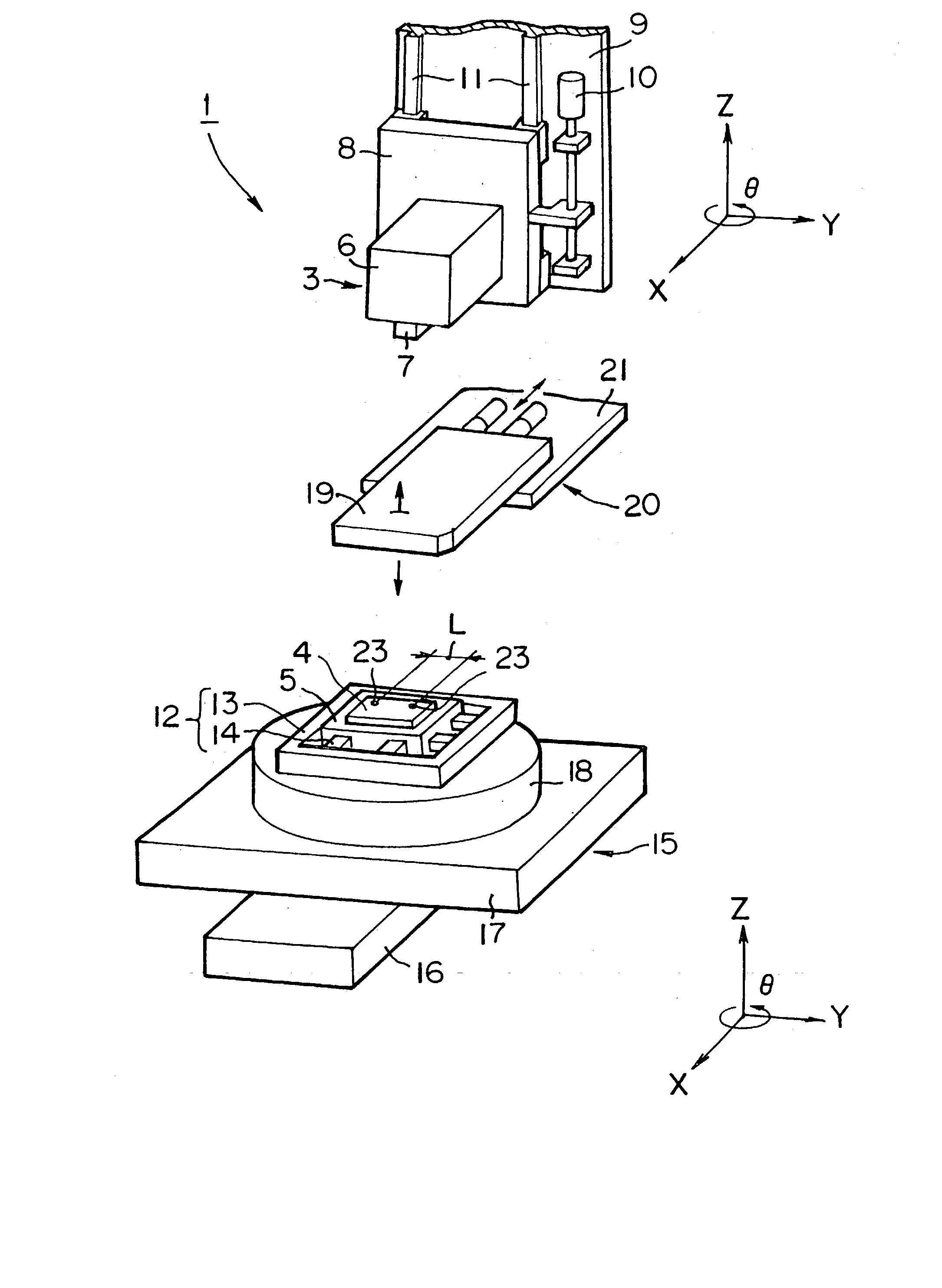

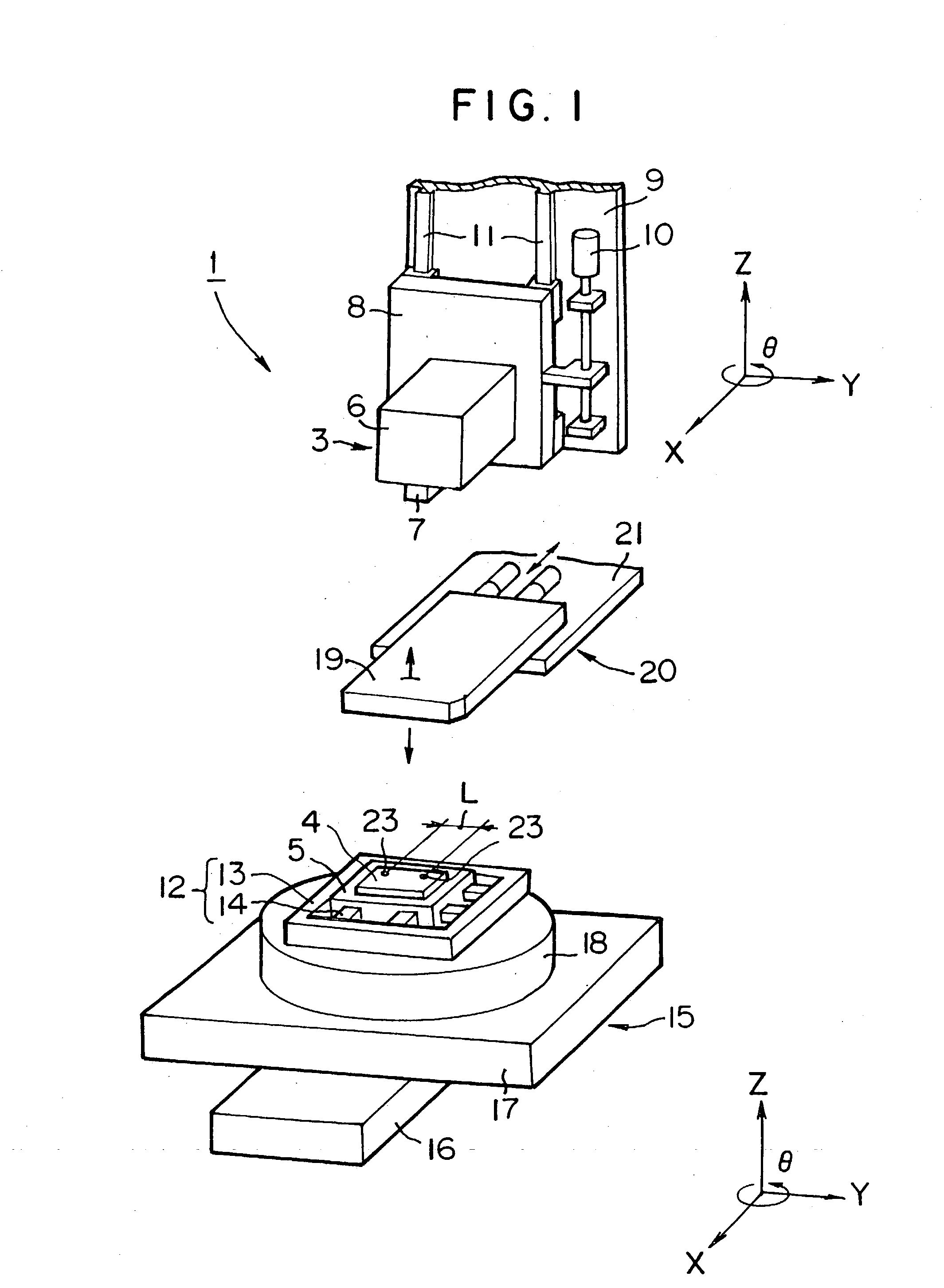

Chip-mounting device and method of alignment

InactiveUS20030106210A1Large range of controlSmall strokePrinted circuit assemblingSolid-state devicesEngineering

A chip-mounting device comprises a chip-holding tool and a substrate-holding stage. At least one of the chip-holding tool and the substrate-holding stage is placed on a coarse adjustment table for coarse positioning of a chip or a substrate. Brake means for fixing the positioned coarse adjustment table is provided on the coarse adjustment table. Fine adjustment means for fine positioning of a chip or a substrate is provided on the coarse adjustment table. The chip-mounting device allows alignment with submicorn accuracy to be performed quickly, shortening tact time in chip mounting remarkably.

Owner:TORAY ENG CO LTD

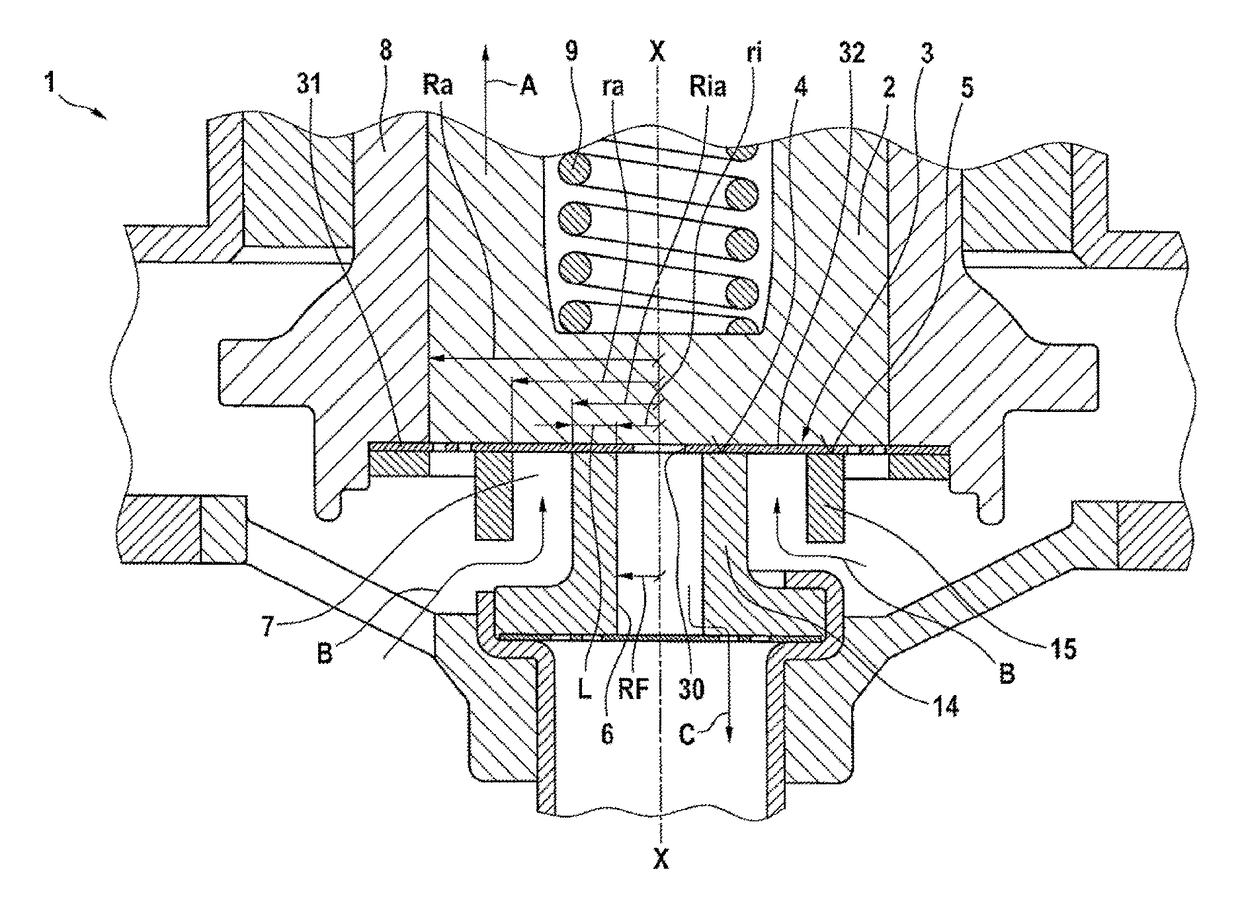

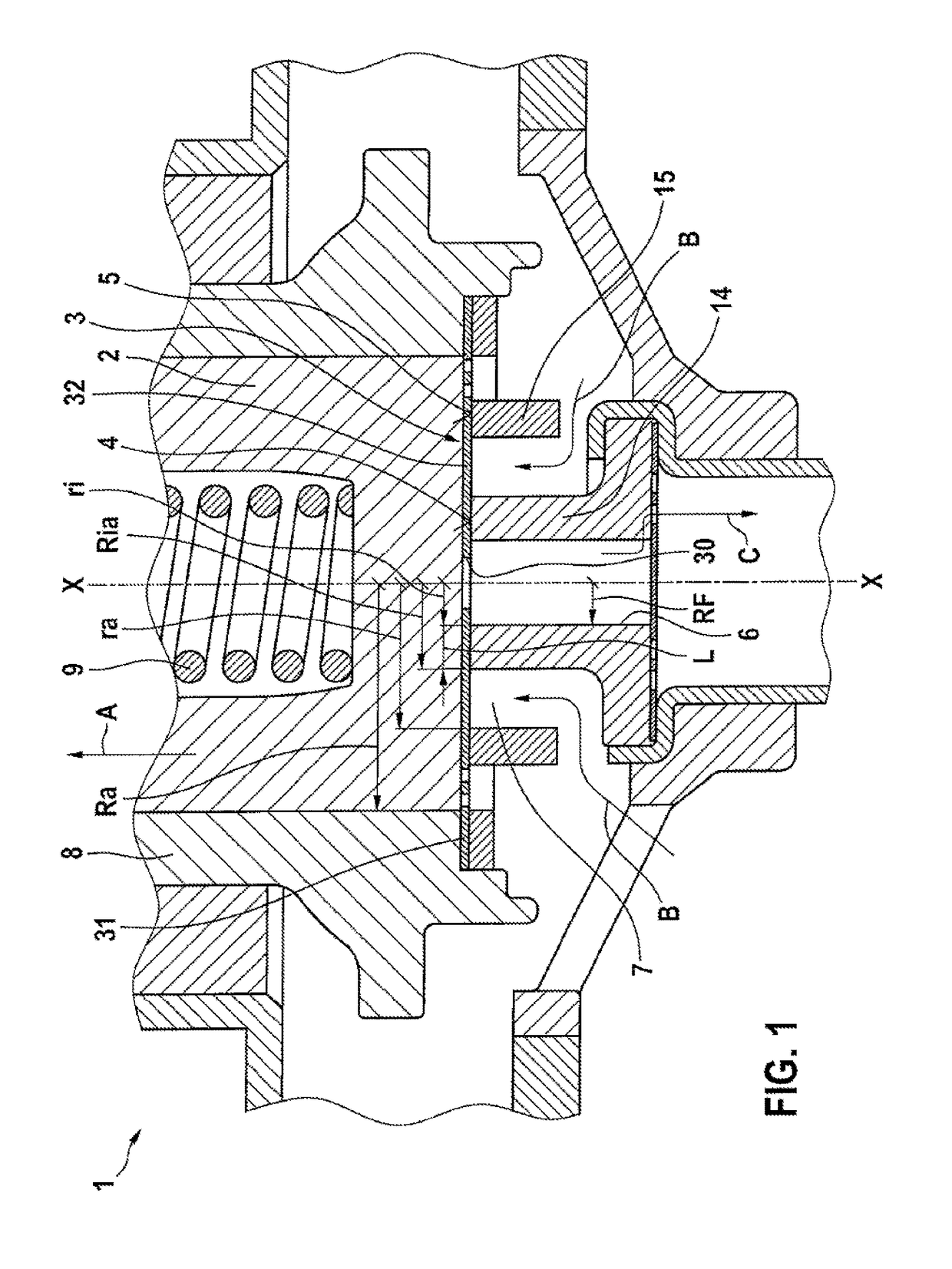

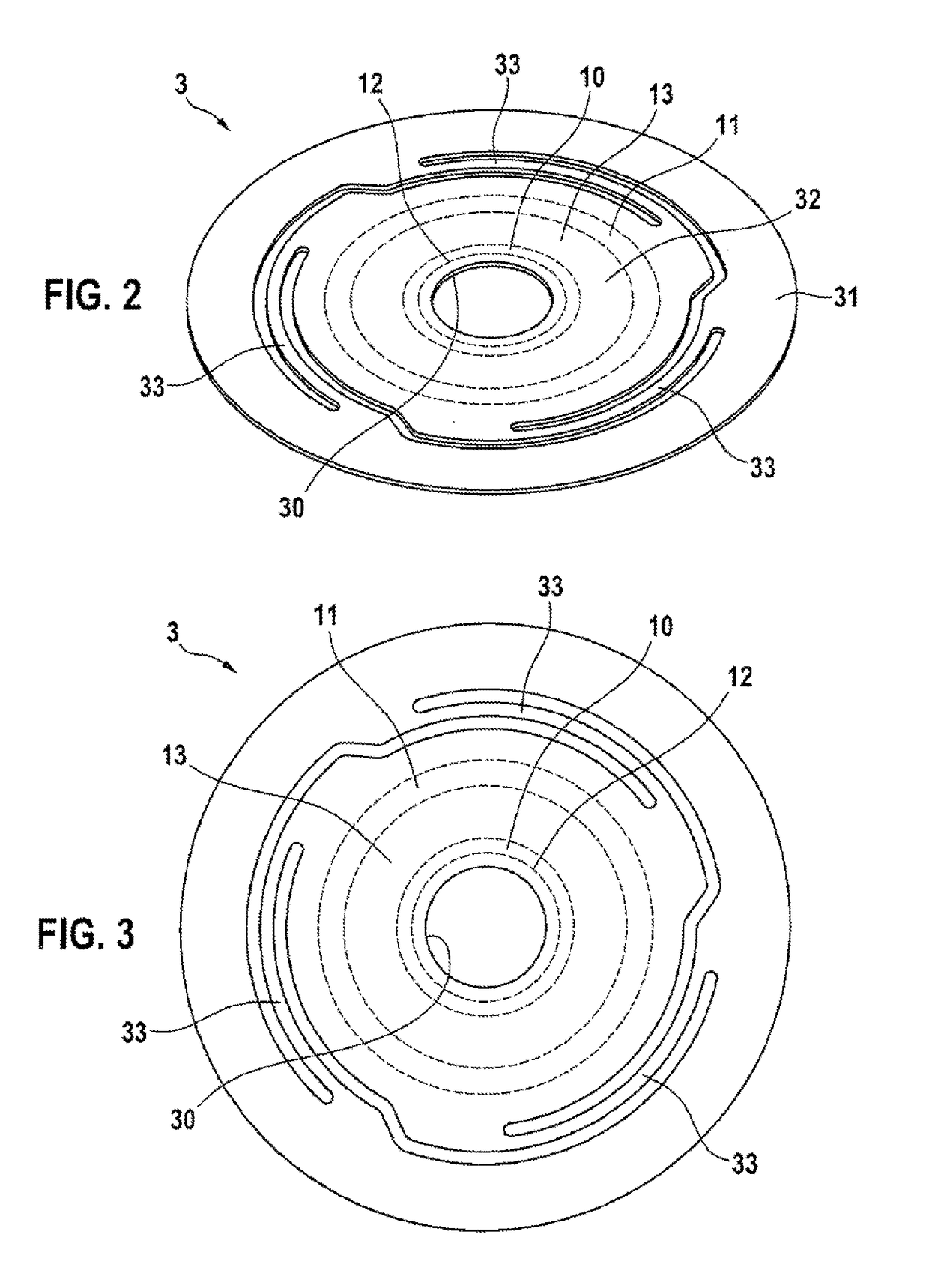

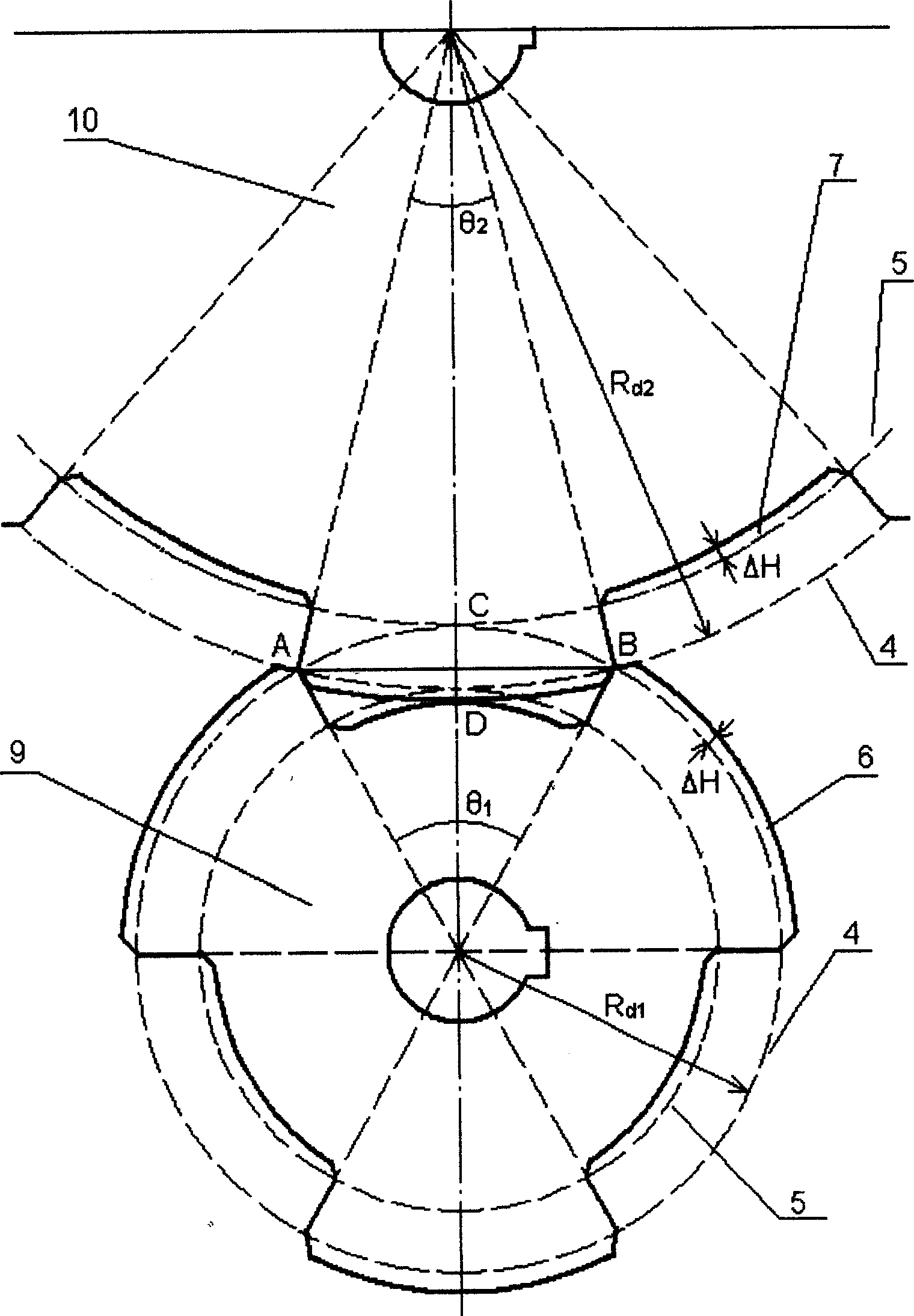

Fuel pump having improved pumping behavior

ActiveUS20170321643A1Improved delivery characteristicLower overall pressure dropPositive displacement pump componentsLow pressure fuel injectionEngineeringDiaphragm seal

The present invention relates to a fuel pump for pumping fuel, comprising a piston (2) and a diaphragm seal element (3), which seals on an inner annular seal seat (4) and an outer annular seal seat (5), wherein the following equation is satisfied: (Ra2−ra2) / (ri+L)2=ra / ri, where ri is the inner radius of the inner seal seat (4), ra is the inner radius of the outer seal seat (5), Ra is the outer diameter of the piston (2) and L is a difference between an outer radius (Ria) of the inner seal seat (4) and the inner radius (ri) of the inner seal seat (4). The invention further relates to a method for operating a fuel pump.

Owner:ROBERT BOSCH GMBH

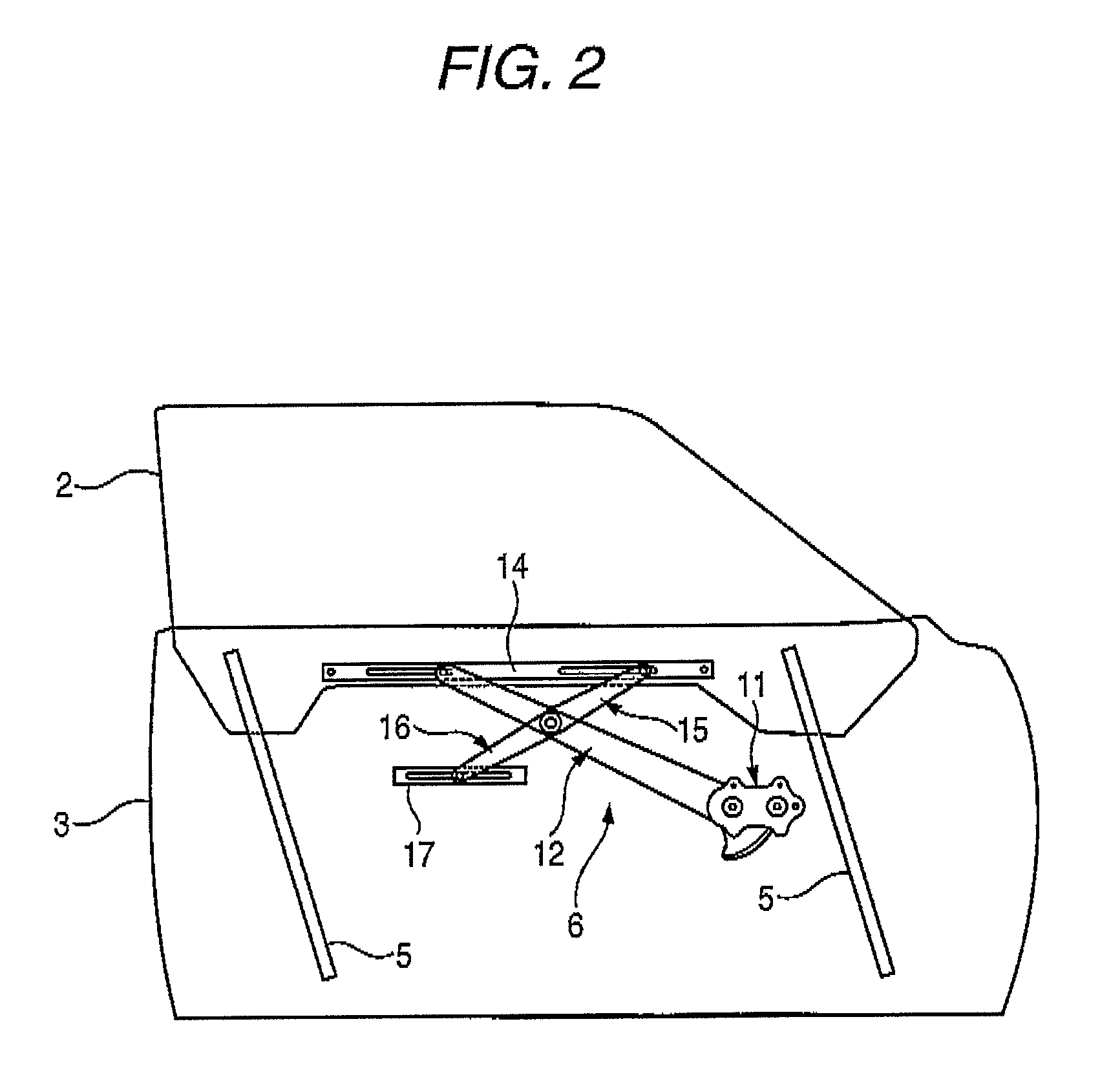

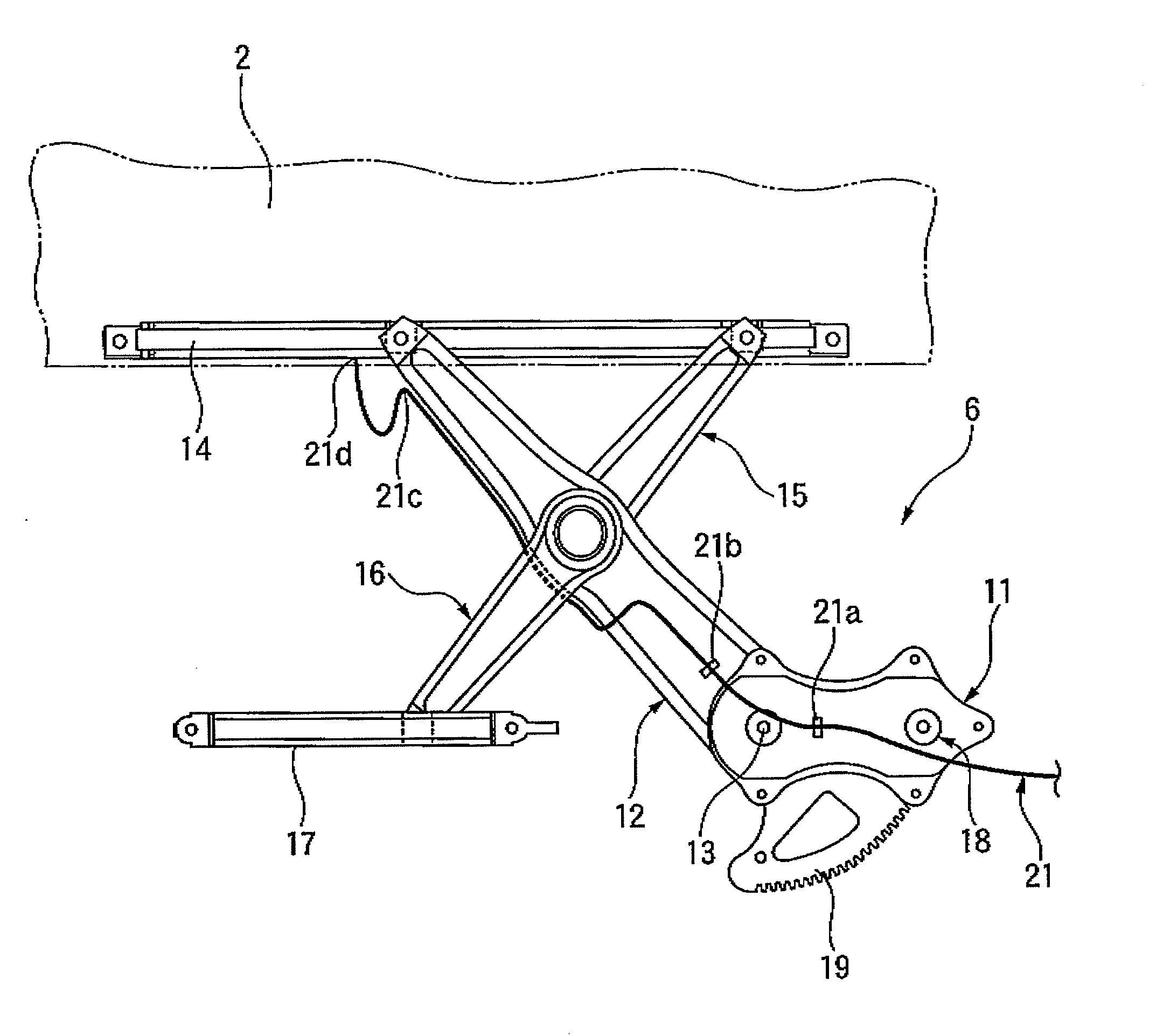

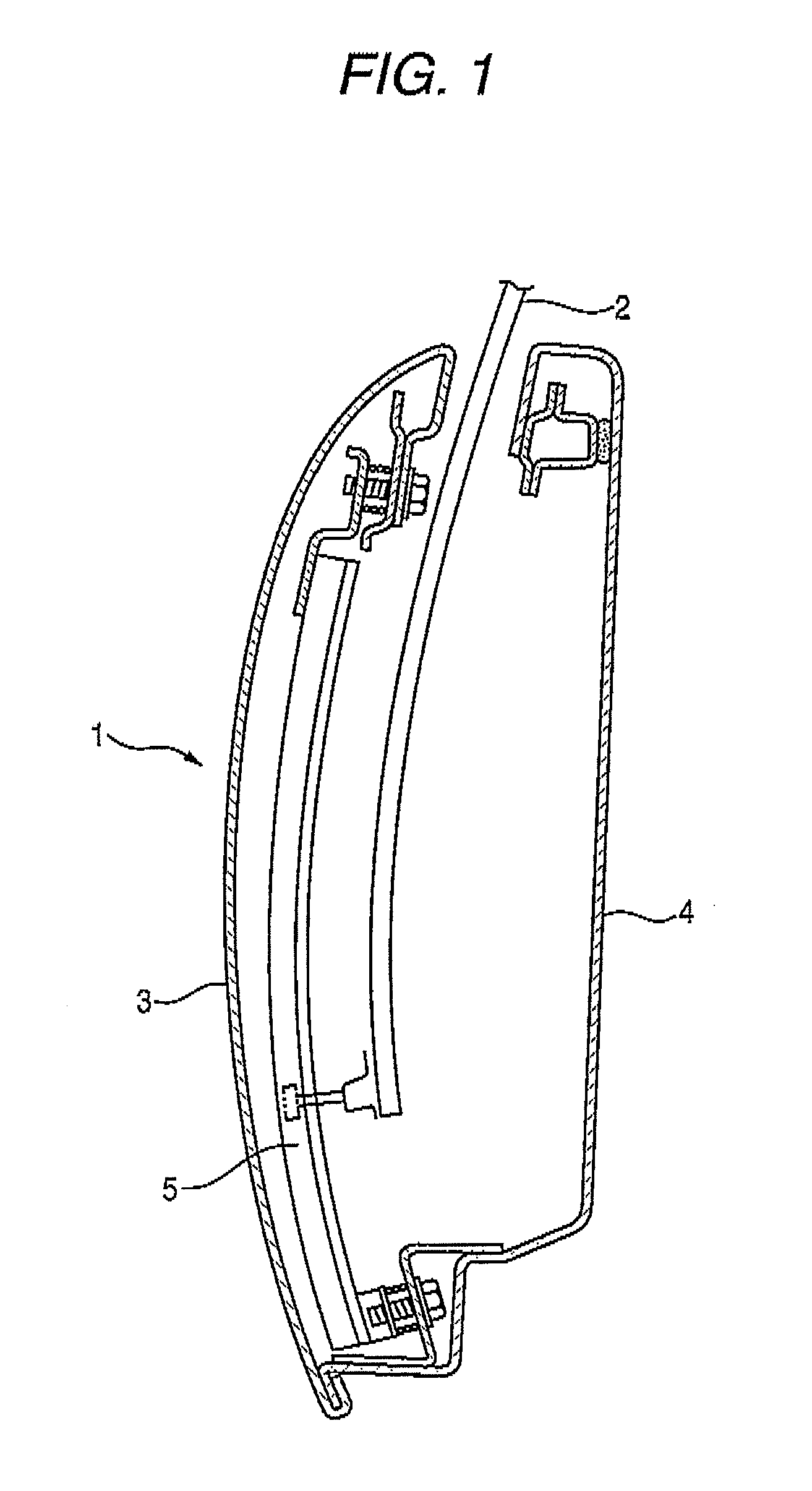

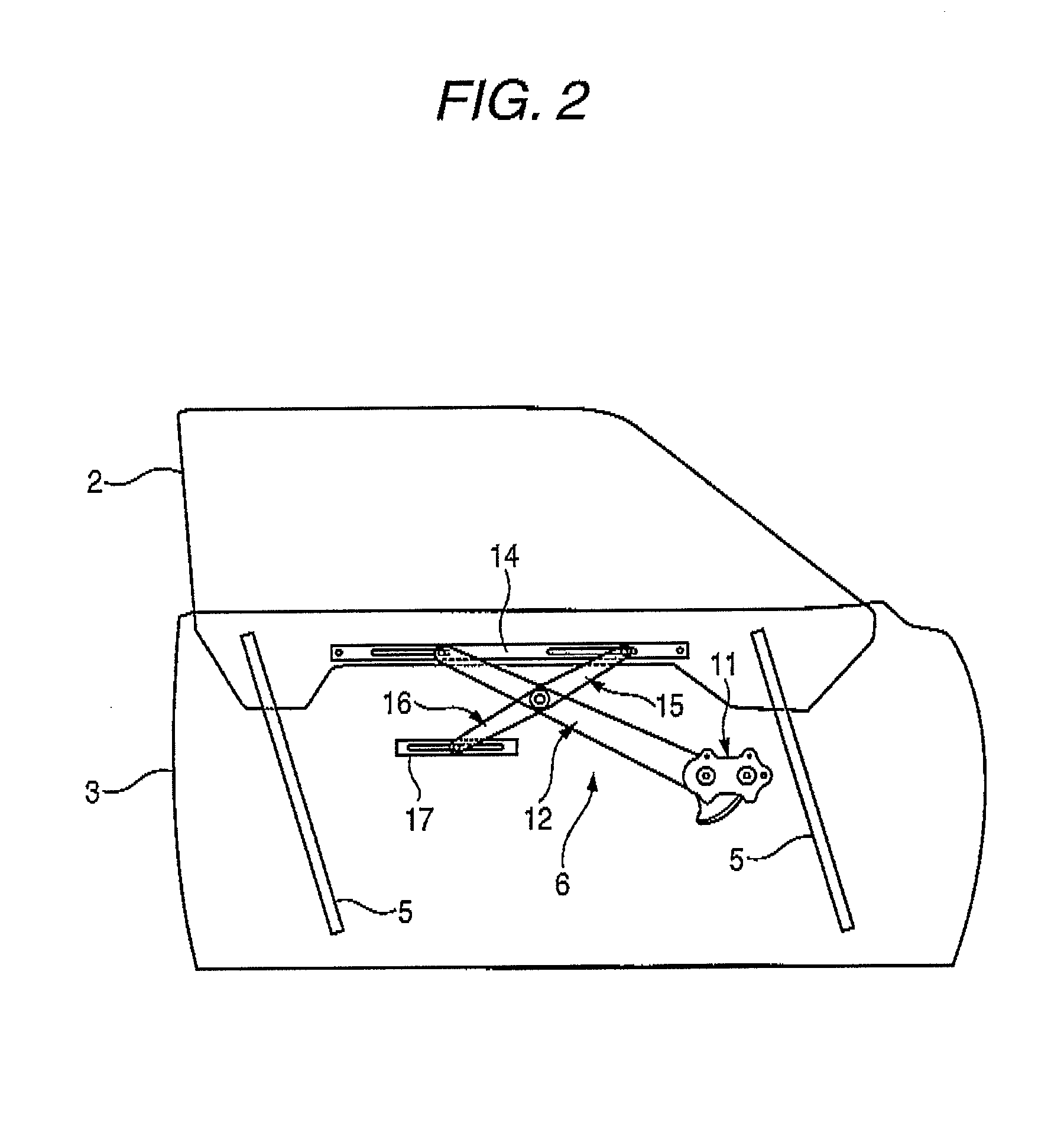

Electric power-feeding structure

ActiveUS7739837B2Made smallLooseness of the electrical wire can be reducedMan-operated mechanismCable arrangements between relatively-moving partsElectric power systemEngineering

An electric power-feeding structure for feeding electric power to a moving body which is driven to be raised or lowered, includes: an arm having a distal end connected to the moving body movably in a horizontal direction and a proximal end rotatably driven to swing, to thereby drive the raising or lowering of the moving body. An electrical wire is routed alongside the arm, and one end of the electrical wire extending from the distal end is connected to the moving body. In a vicinity of a rotating shaft of the arm, the electrical wire is fixed to the arm at a first fixing point and to a base for supporting the arm at a second fixing point. The first fixing point is provided on a straight line defined by the rotating shaft and the second fixing point when the arm is at an intermediate position of its swinging range.

Owner:YAZAKI CORP

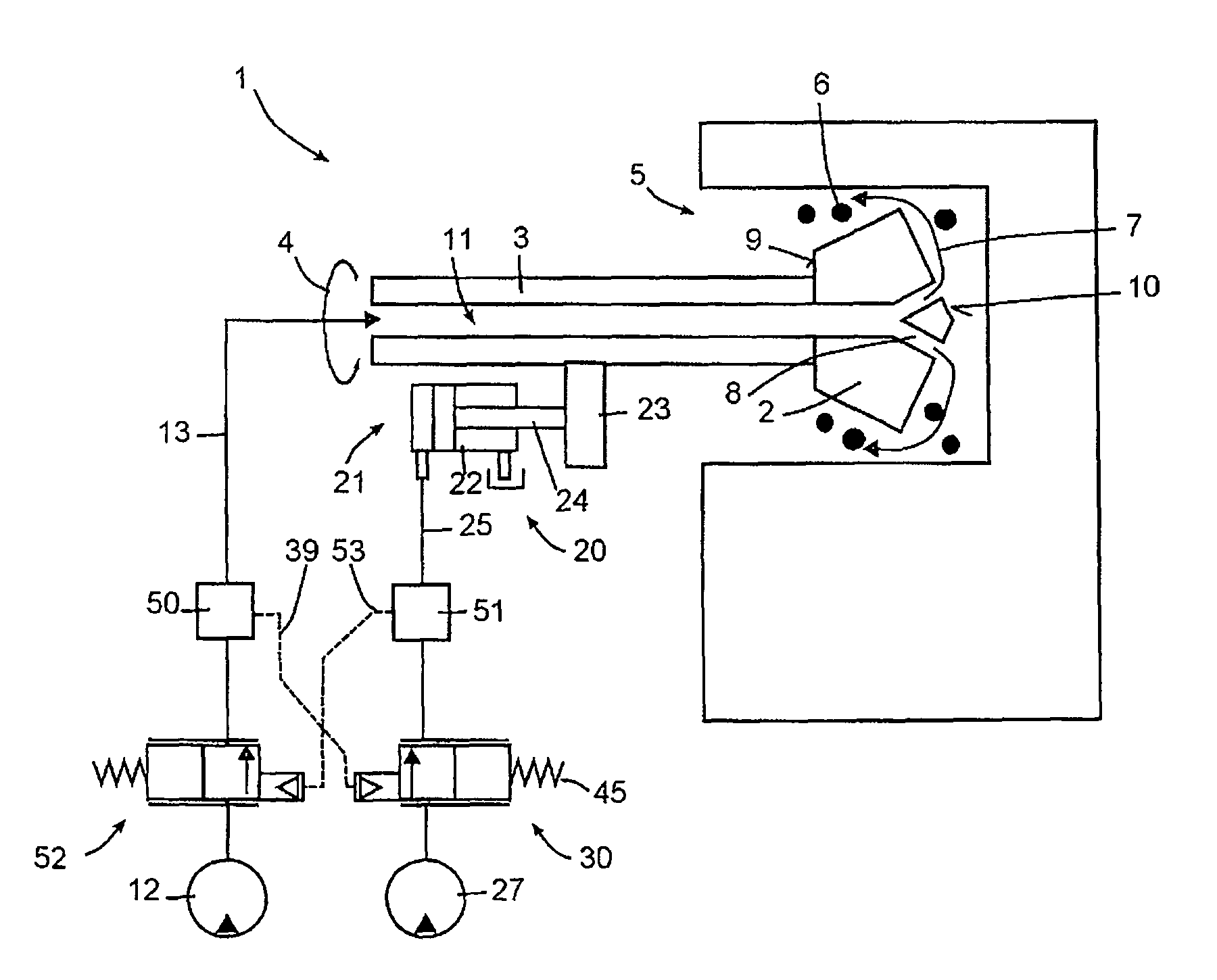

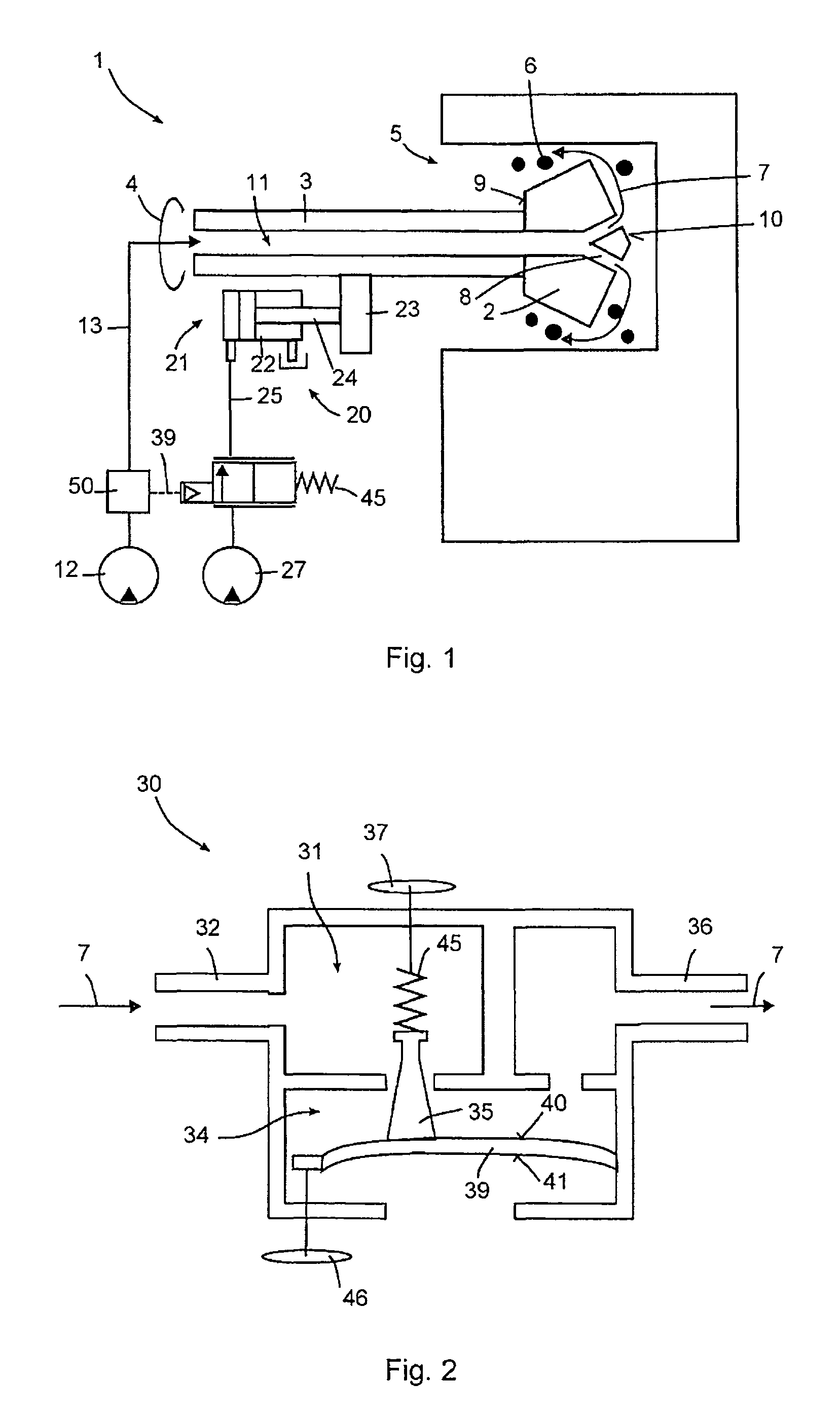

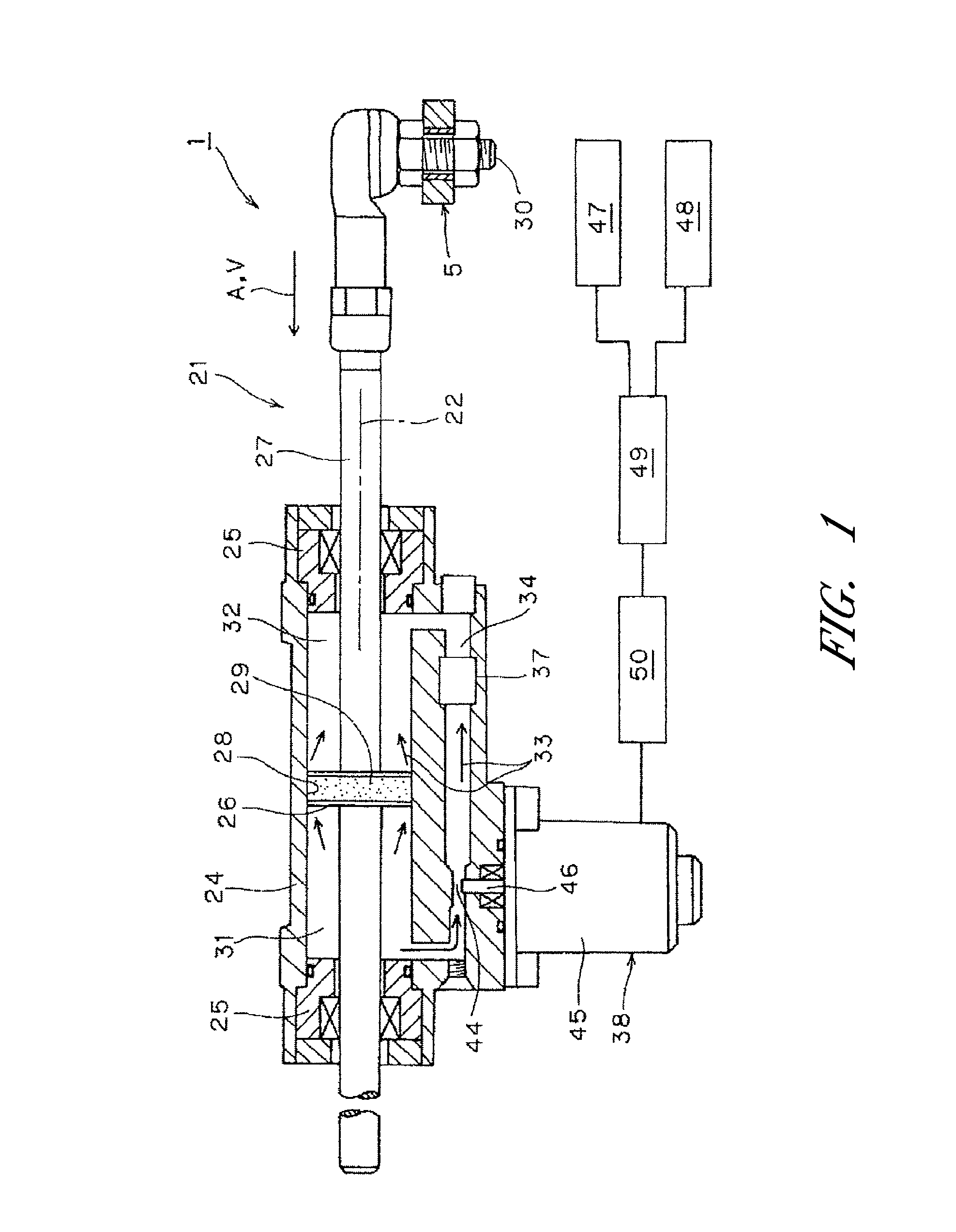

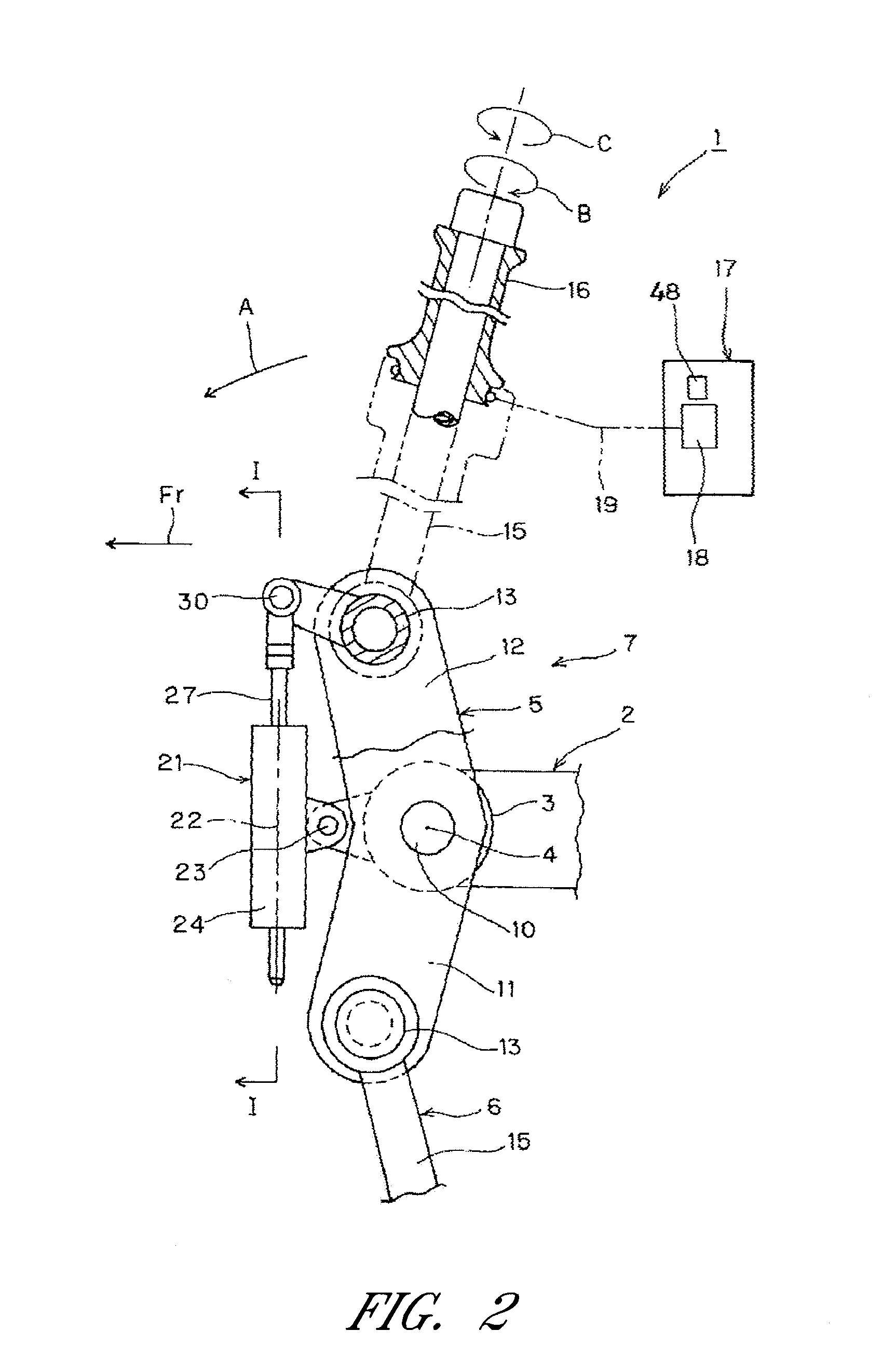

Drilling tool and drilling method

InactiveUS8146681B2Increase pressureReduce deliveryDrilling rodsReciprocating drilling machinesEngineeringHydraulic fluid

A drilling tool includes a hydraulically driven device (21) for advancing a drilling head (2) in a bore (5), and a flow limiter (30) arranged in a hydraulic conduit (25) of the advancing device (21) for adjusting an advancing speed of the drilling head (2) in the bore (5), with the flow limiter (30) having a pressure-actuated adjusting member (38) for adjusting flow of a hydraulic fluid in the hydraulic conduit means (25) in accordance with a flow volume of a rinsing fluid (7) for rinsing the bore.

Owner:HILTI AG

Method and apparatus for producing a cylindrical hollow body from a blank

ActiveUS7434434B2Feed of the workpiece can be increased considerablyImprove construction conditionsForging hammersPiercing pressesEngineeringAxial force

A method is described for producing a cylindrical hollow body from a blank, with the workpiece being opened in the core region by successive swaging which is angularly offset against each other about the axis of the workpiece and being simultaneously pushed onto a piercing mandrel. In order to improve the piercing it is proposed that the workpiece is pressed during the swaging with a predeterminable axial force against the piercing mandrel which can be advanced against the workpiece against this axial force, which piercing mandrel is moved back to its initial position synchronous with the axial feed of the workpiece between the successive swaging steps.

Owner:GFM BETEILIGUNGS & MANAGEMENT

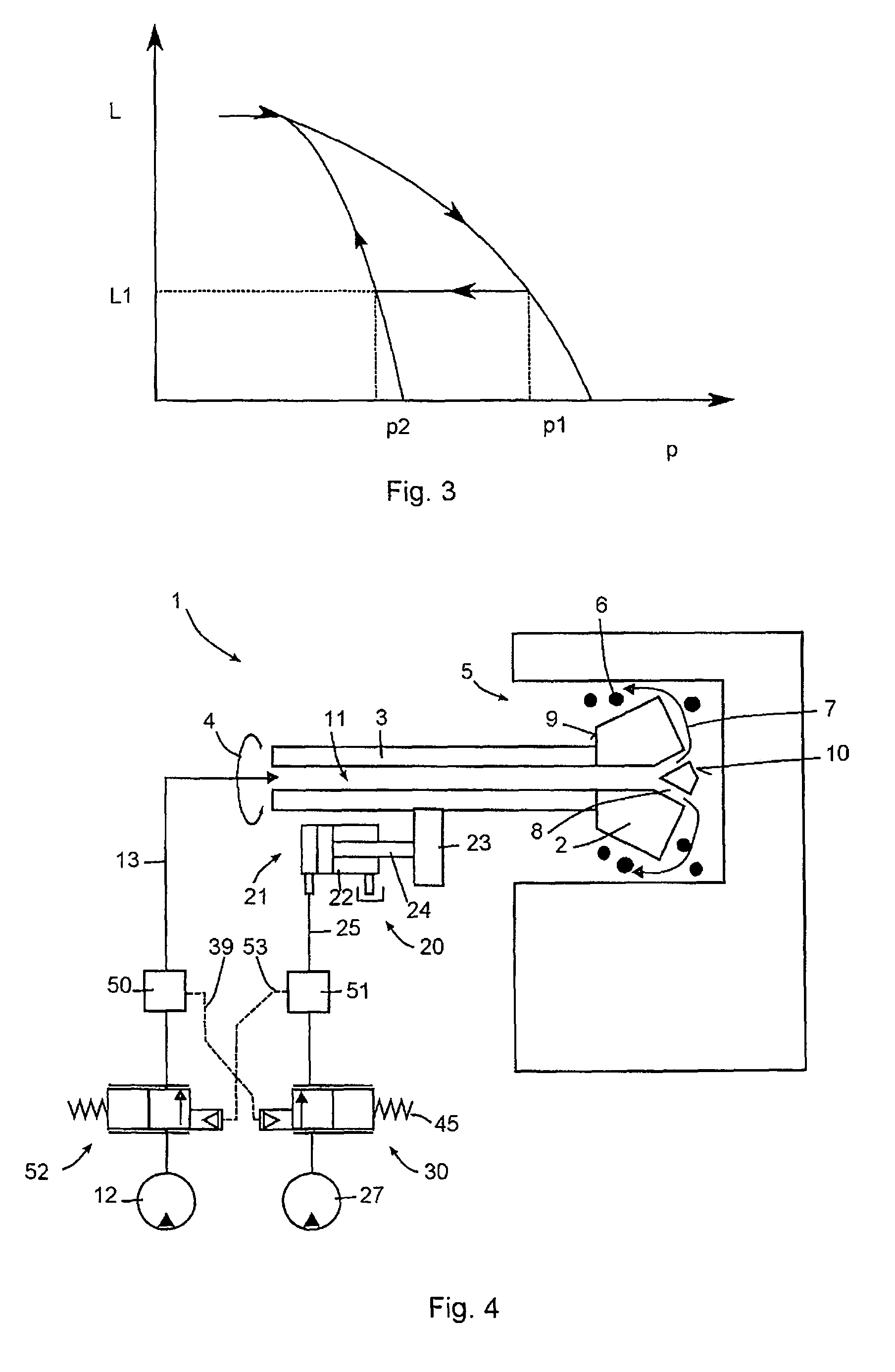

Steering damping method for vehicle and steering damping device for vehicle

InactiveUS8177043B2Small strokeEasy to operateWheel based transmissionFrictional rollers based transmissionEngineeringControl theory

A steering damper can generate a smaller damping force according to a first damping force characteristic or a larger damping force according to a second damping force characteristic by controlling a flow of hydraulic oil during a steering operation of a steering member. When the associated vehicle is running at a relatively low or medium speed and is not accelerating, and if an operational speed of the steering damper is lower than a predetermined value, damping force according to the first damping force characteristic can be generated in the steering damper. On the other hand, when the operational speed of the steering damper is equal to or higher than the predetermined value, damping force according to the second damping force characteristic can be generated in the steering damper. While the vehicle is running at a high speed or is accelerating, the damping force according to the second damping force characteristic can be generated in the steering damper regardless of the operational speed of the steering damper.

Owner:SOQI H S

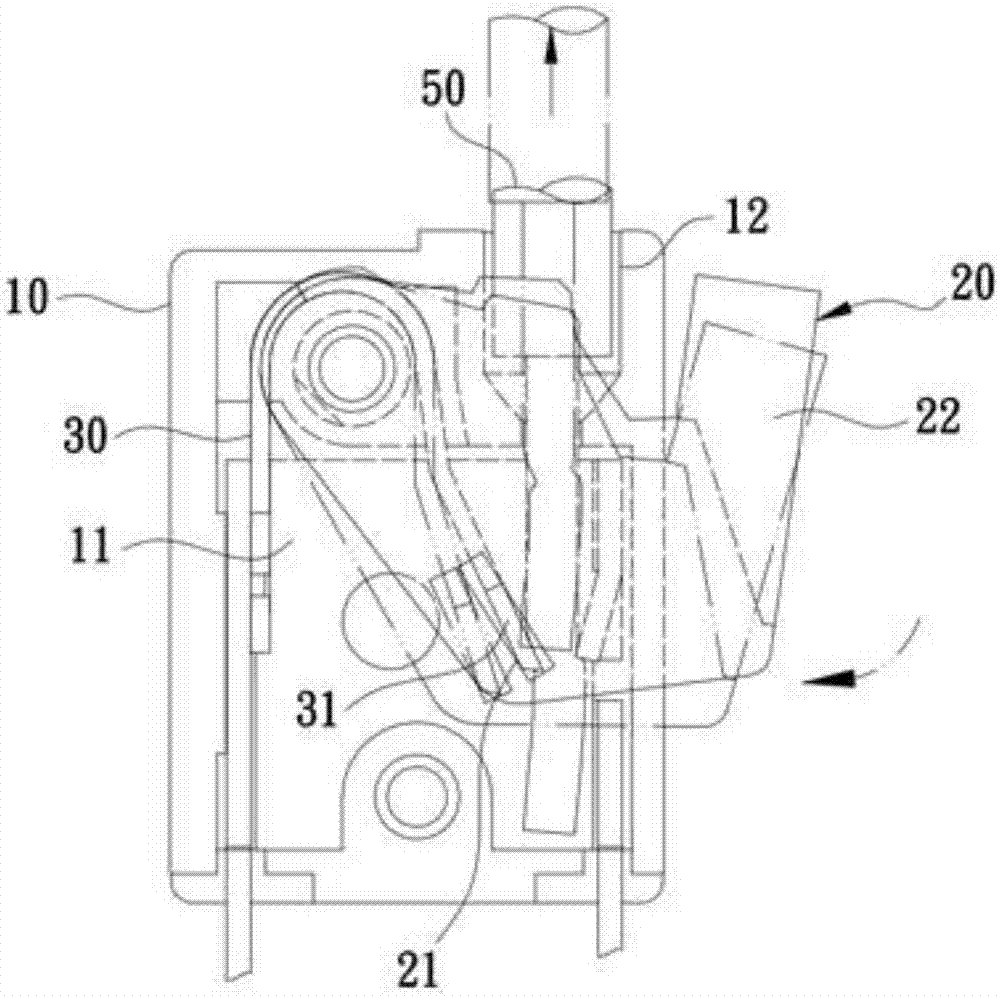

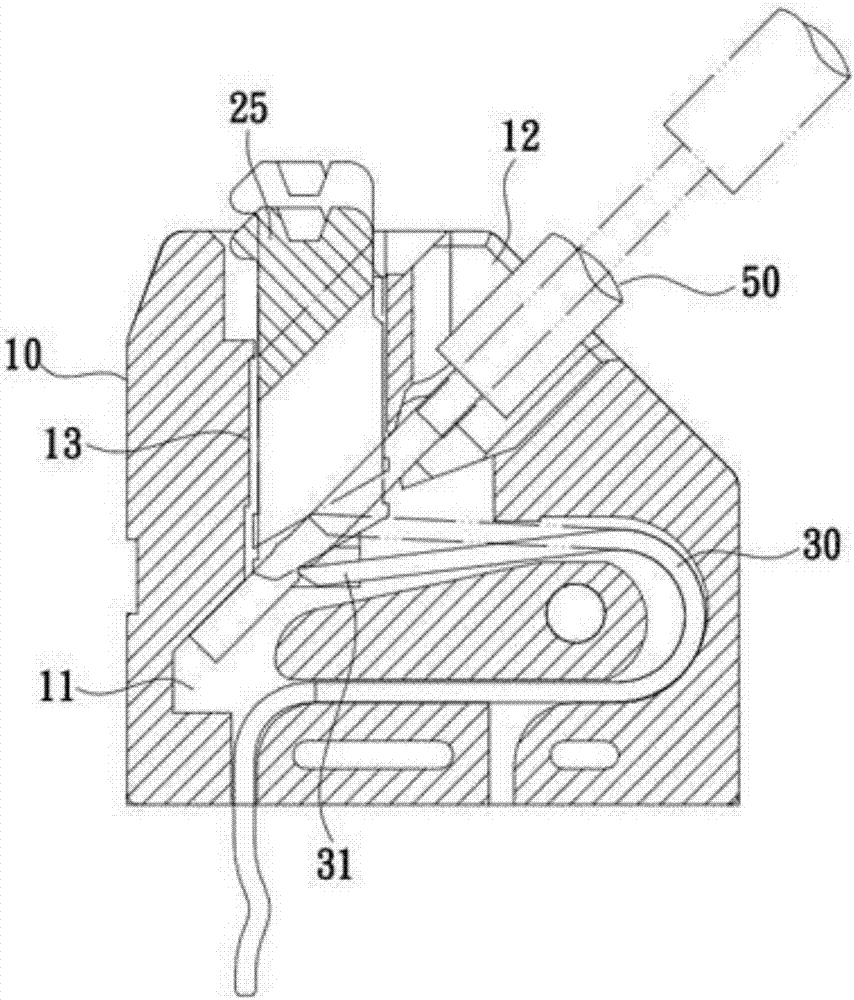

Wire connection terminal device

The invention discloses a wire connection terminal device which comprises a combination of a body and a pressure actuator, wherein the pressure actuator is provided with a coupling part, a convex arm connected with the coupling part, and a force application part and a pressing part which are formed on the convex arm; the convex arm can form a free rotation or swing state in a chamber defined by the body; the chamber of the body is provided with a metal elastic sheet; and the metal elastic sheet can press a wire to form electrical connection or respond to movement of the pressure actuator to release the wire. The wire connection terminal device improves situations such as large housing size, operating space and actuation stroke which are necessary for a structure in the prior art.

Owner:SWITCHLAB SHANGHAI

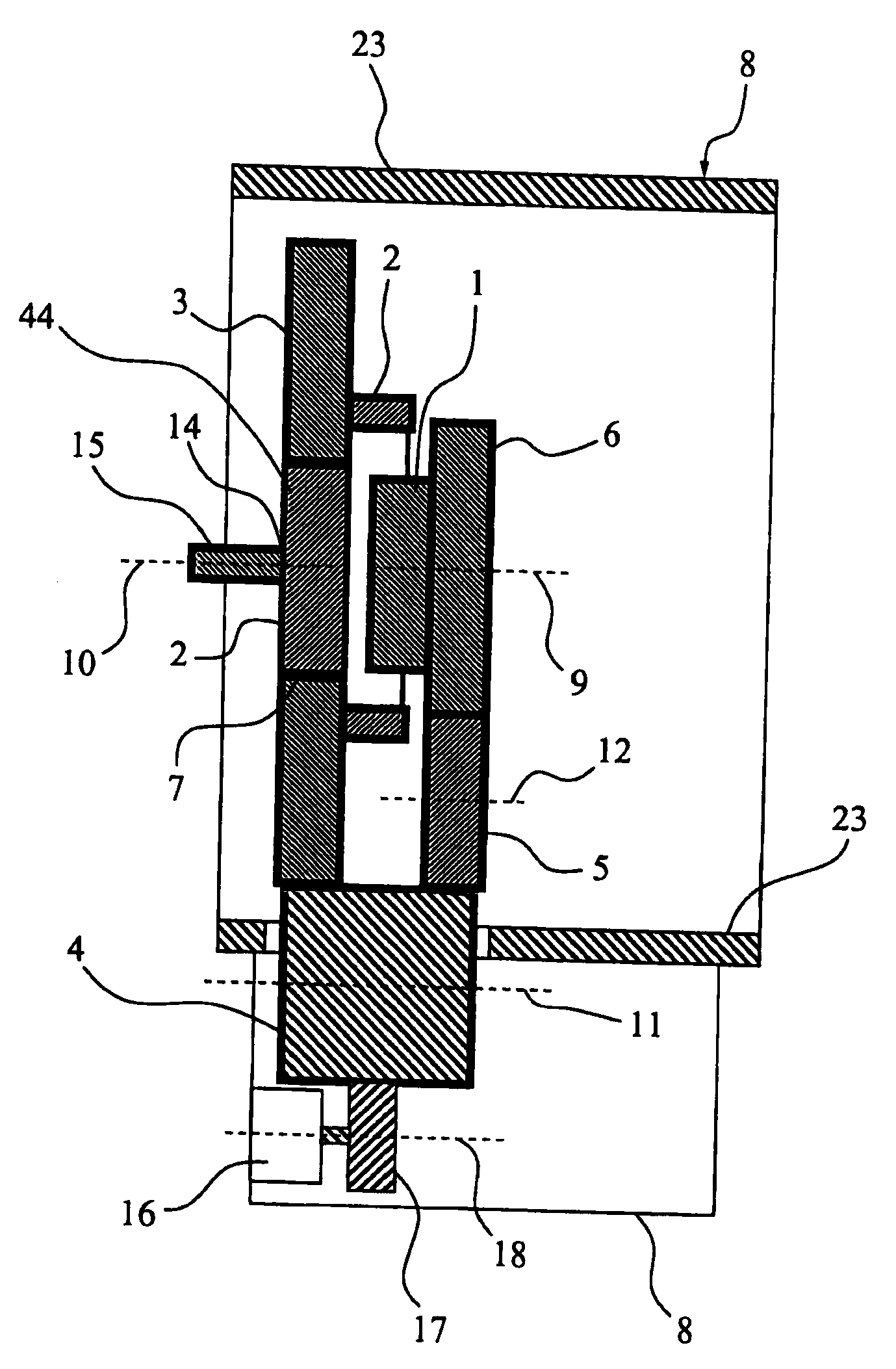

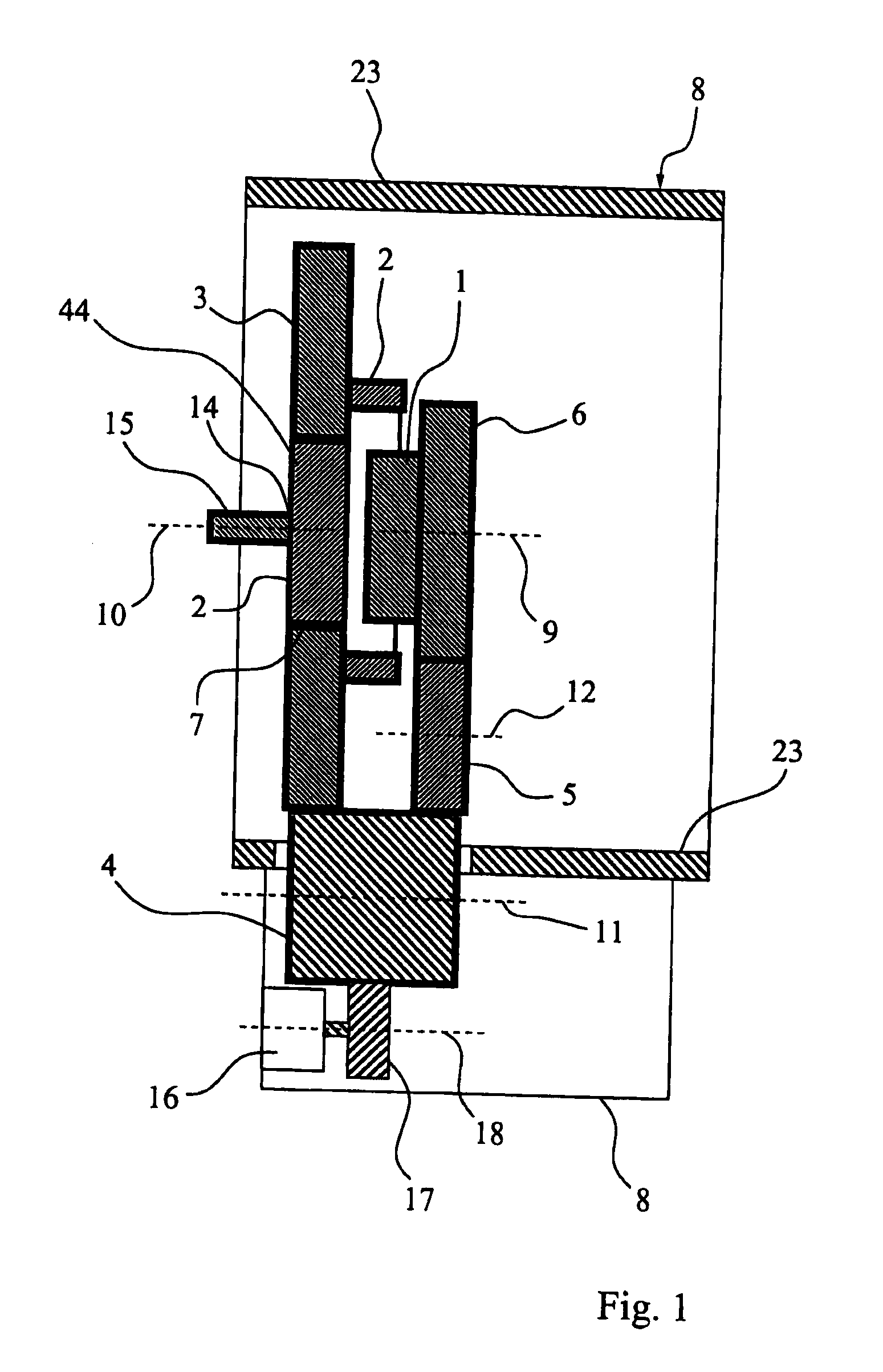

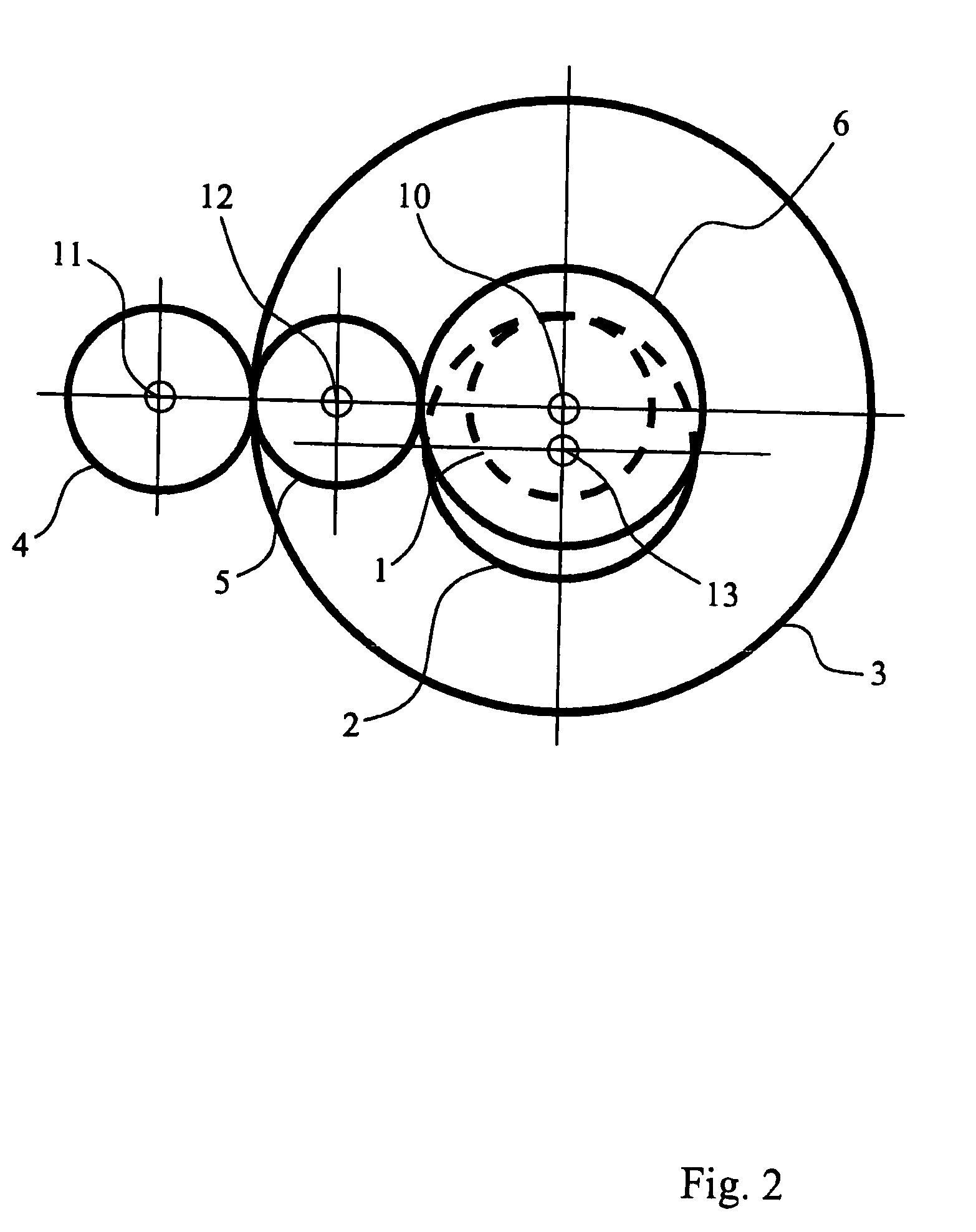

Adjustment drive for the local adjustment of a chassis component

InactiveUS20100066039A1Large caliberSmall strokeToothed gearingsSteering partsEngineeringMechanical engineering

An adjustment drive for local adjustment of a chassis component. The drive including a mounting (8), a first wheel (1) having a common first center line (9) and rotational axis, a second wheel (2), which is eccentric to the first wheel (1), has a second center line (13) that is parallel to the first center line (9), a third wheel (3) having a common third center line (10) and rotational axis. The third center line is either parallel to or coincident with the first center line (9). A drive system (16) is coupled to the mounting (8) and rotates at least the first and third wheels (1, 3). The second wheel (2) is eccentric to the third wheel (3) and is supported thereon so as to rotate about the second center line (13), and the first wheel (1) is coupled to the second wheel (2) for transmitting rotational motion.

Owner:ZF FRIEDRICHSHAFEN AG

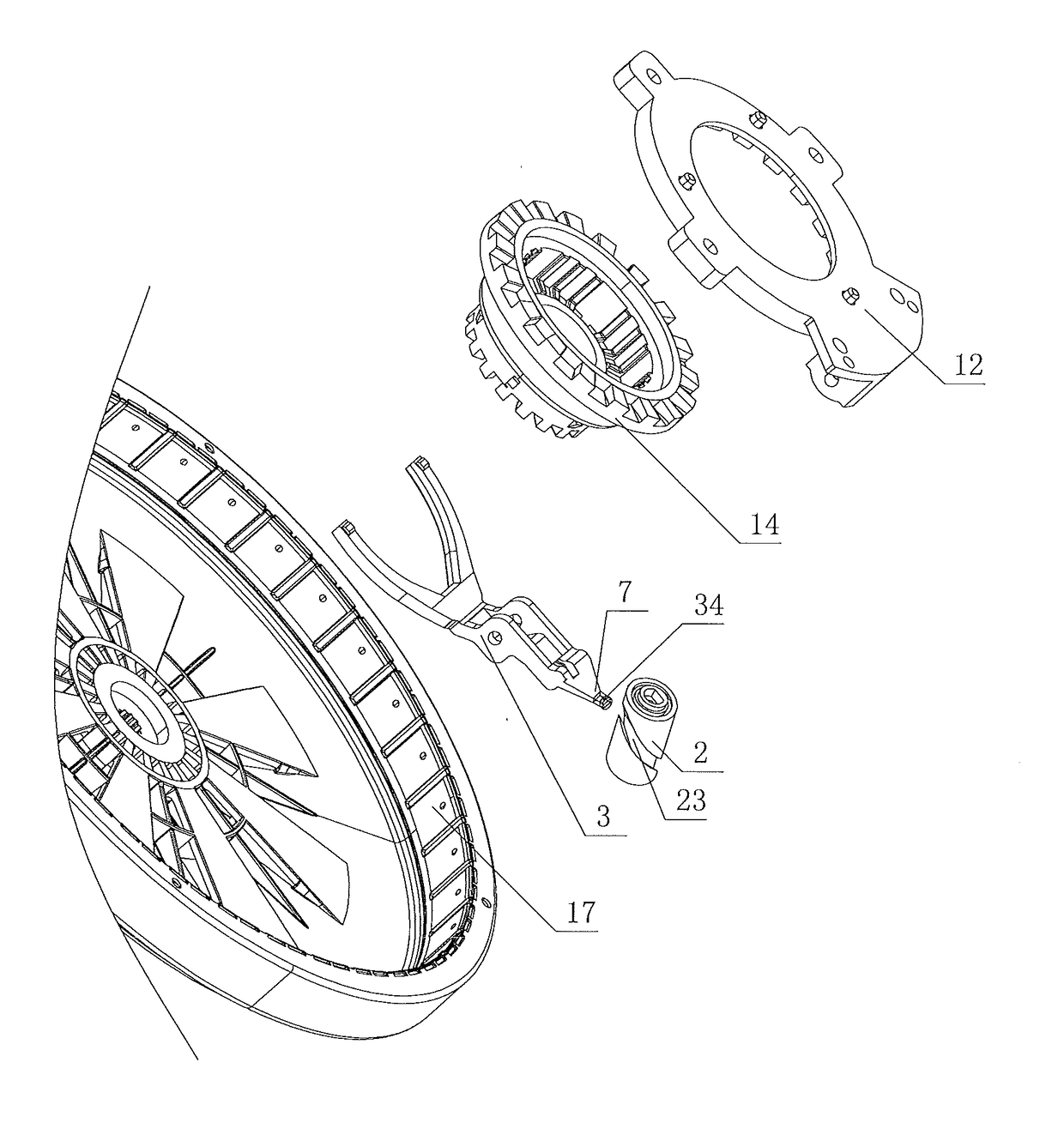

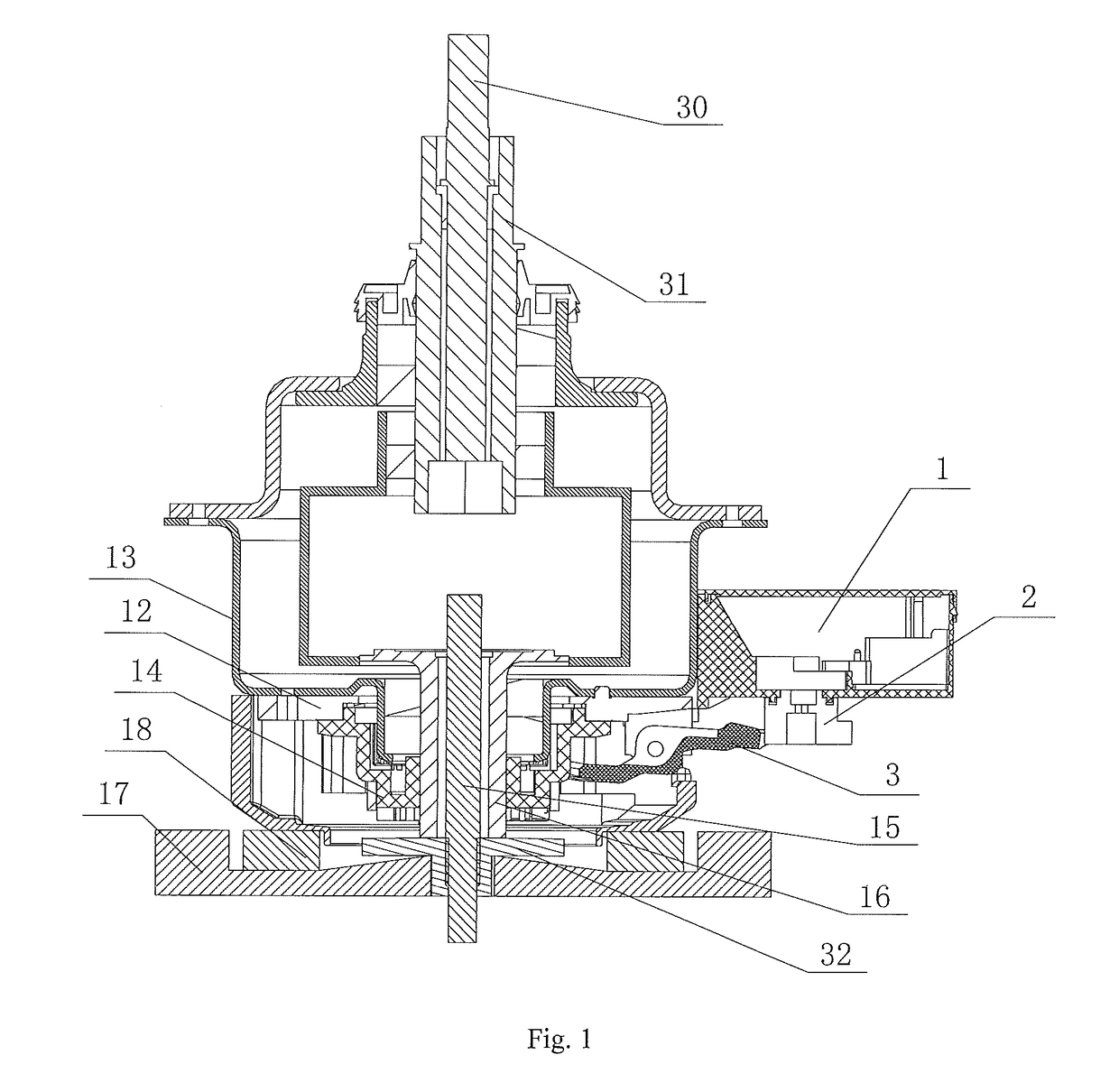

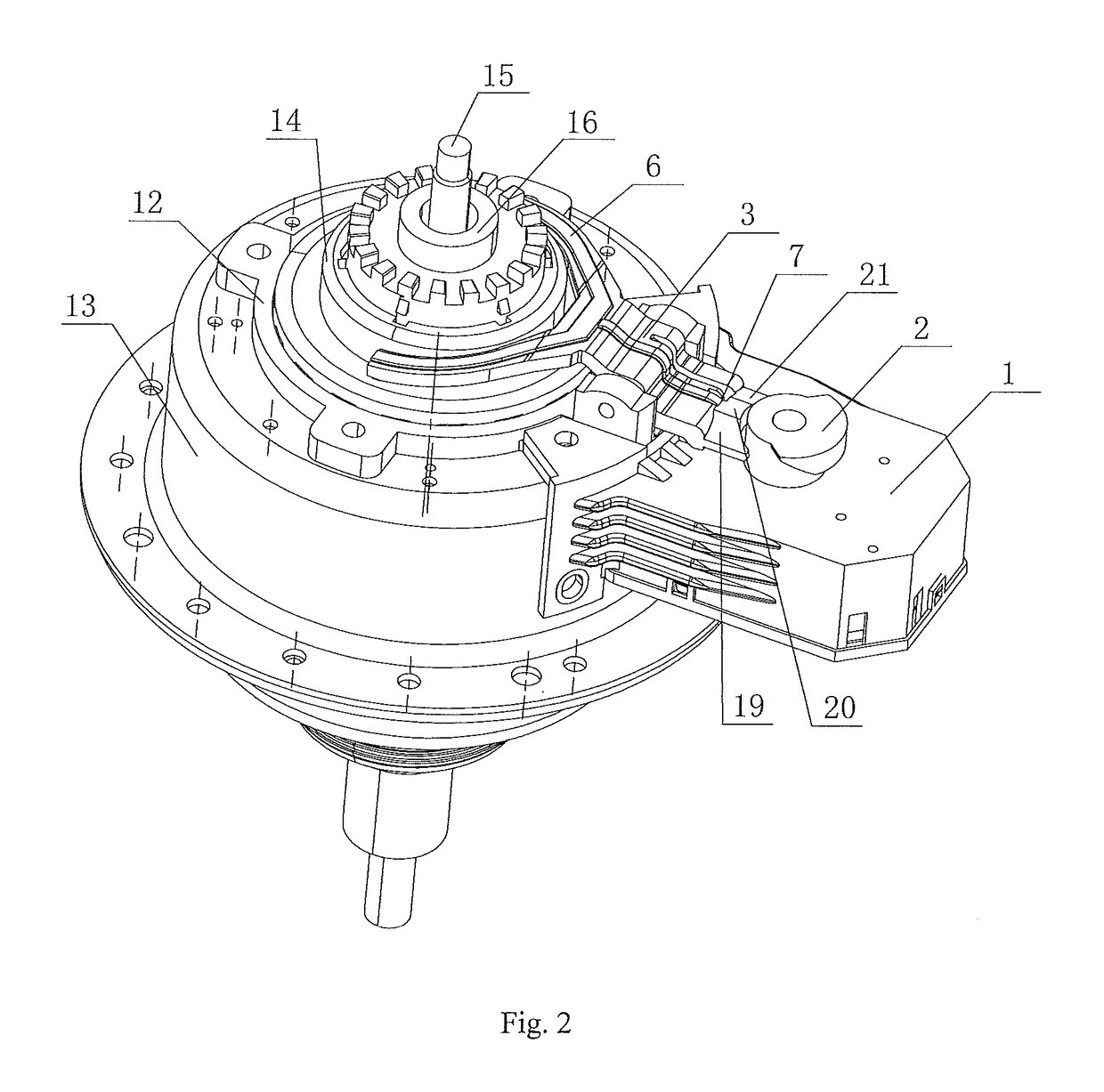

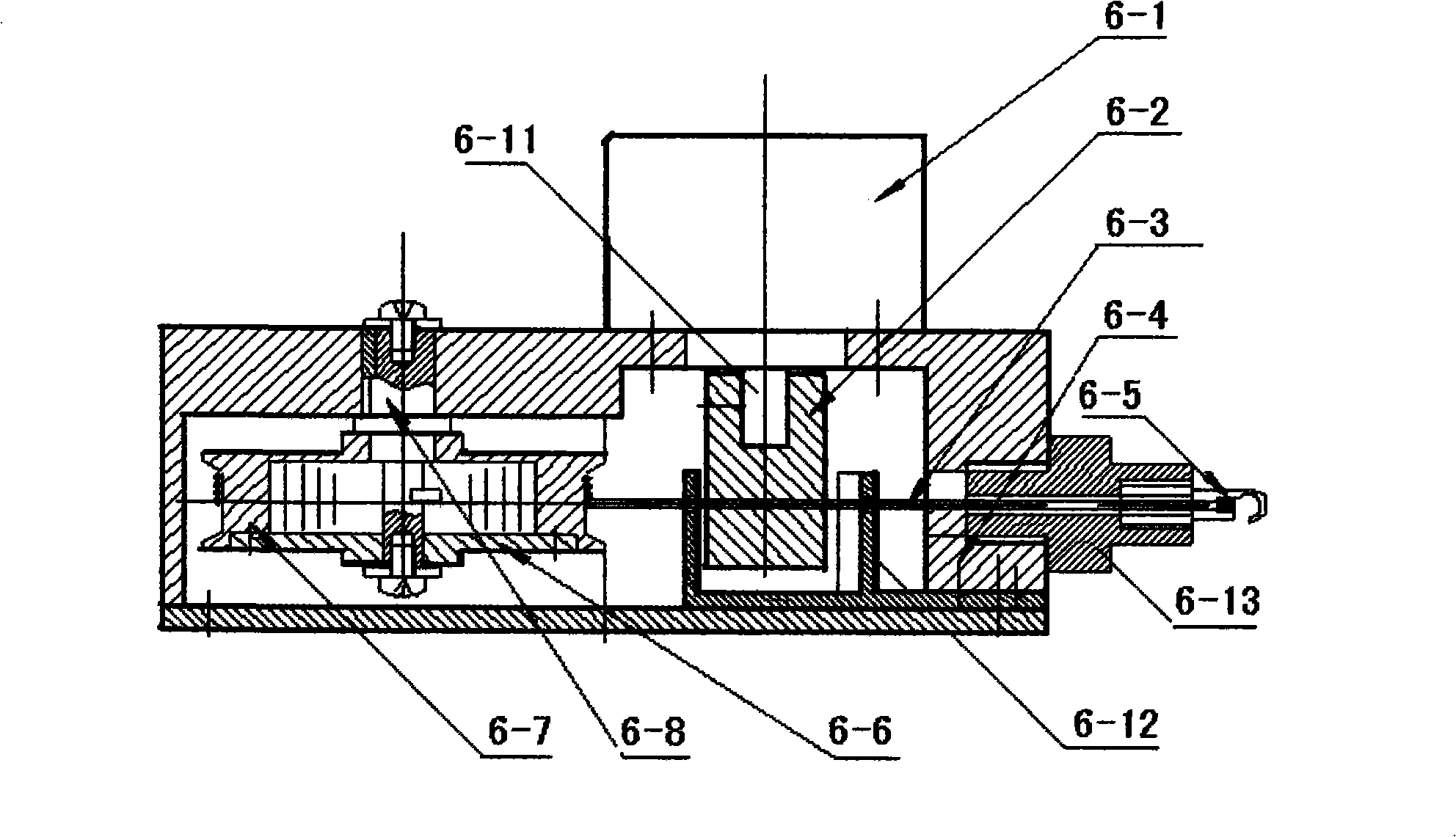

A clutch driving device for deceleration clutch

ActiveUS20170159723A1Simple controlReduce chanceOther washing machinesInterengaging clutchesClutchMotor shaft

A driving device for a deceleration clutch, comprises a on a driving motor shaft. The drive wheel has a supporting surface with a height difference in the axial direction. A head of a shift fork lever controls the clutch sleeve to move up and down. A tail of the shift fork lever is supported on the supporting surface. The tail of the shift fork lever relatively slides on the supporting surface, so that a height of the tail of the shift fork lever changes which drives a height of the head of the shift fork and further drives the clutch sleeve to move up and down. Alternatively, the drive wheel has a supporting slide rail with a height difference in the axial direction, or has cam circumference that is radially gradient, or a bracing rod is eccentrically arranged on an end surface of the drive wheel.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

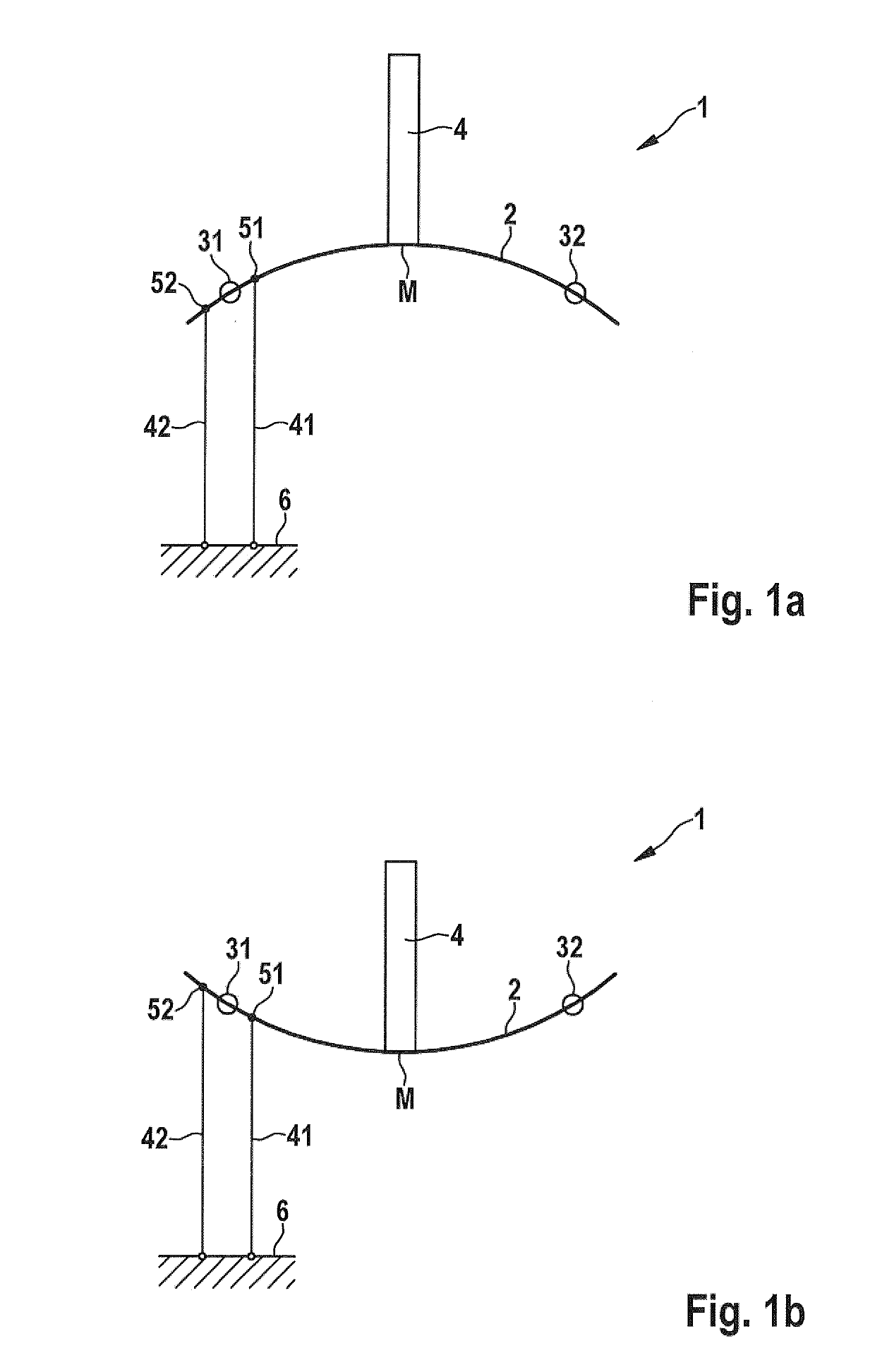

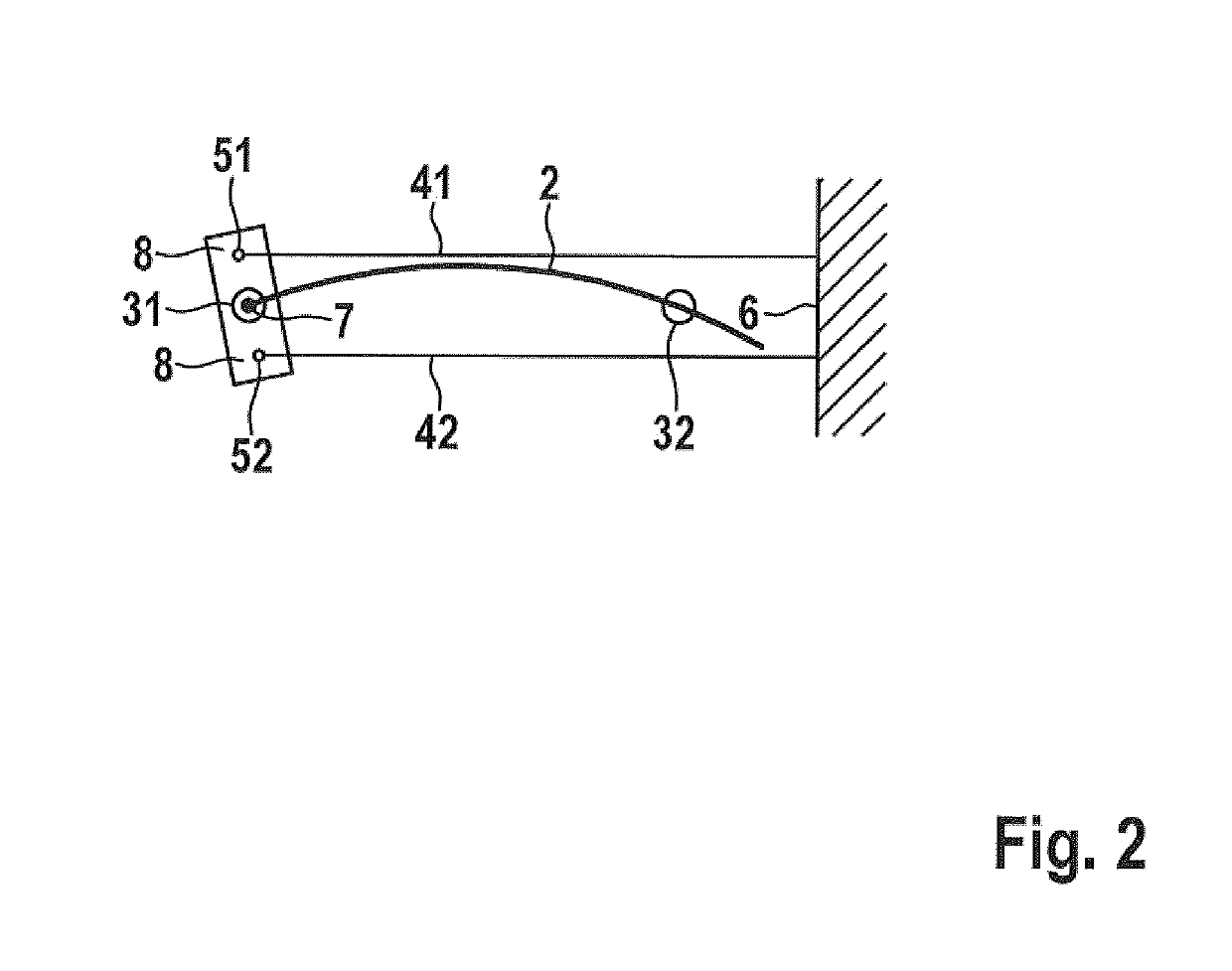

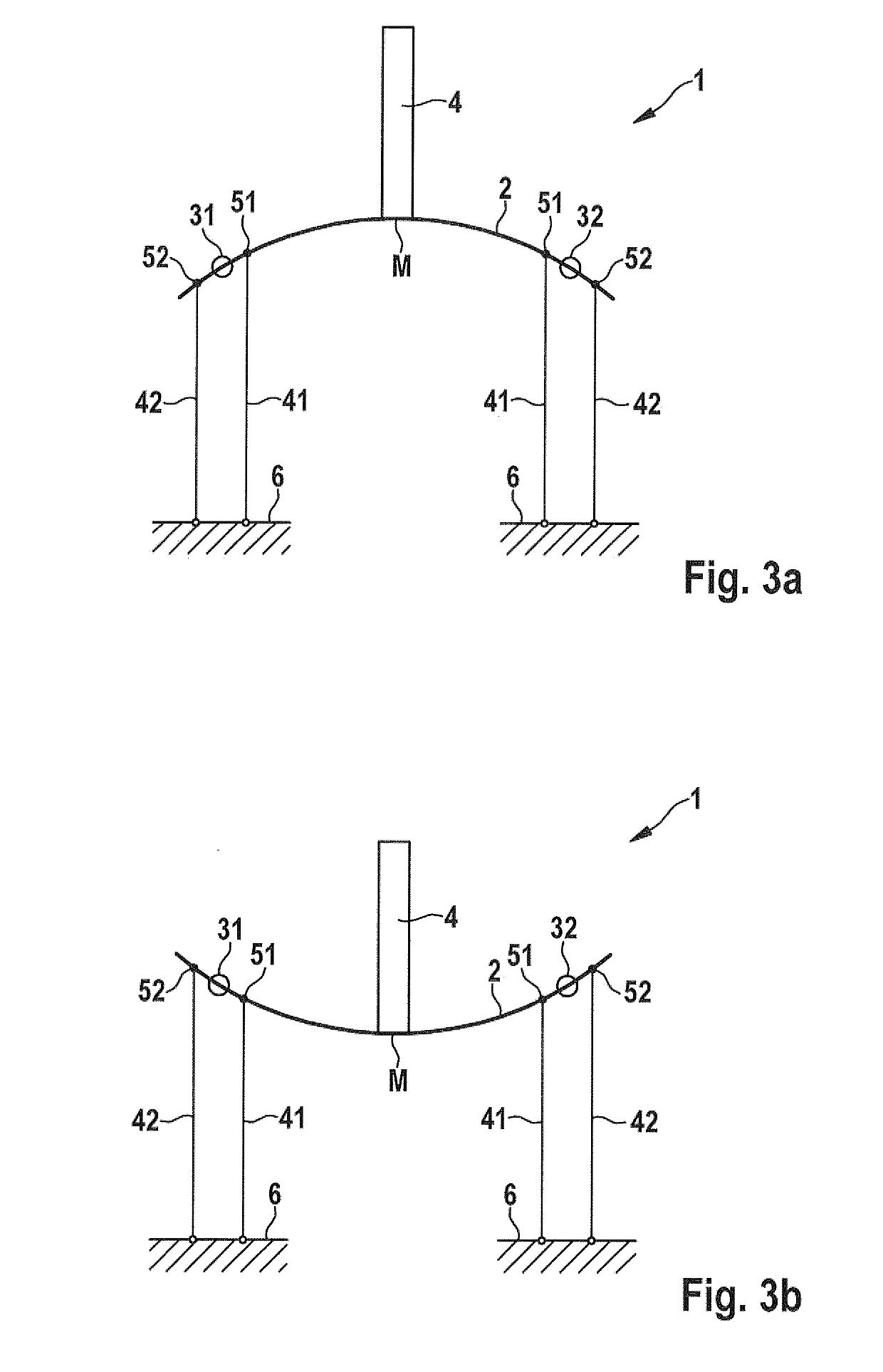

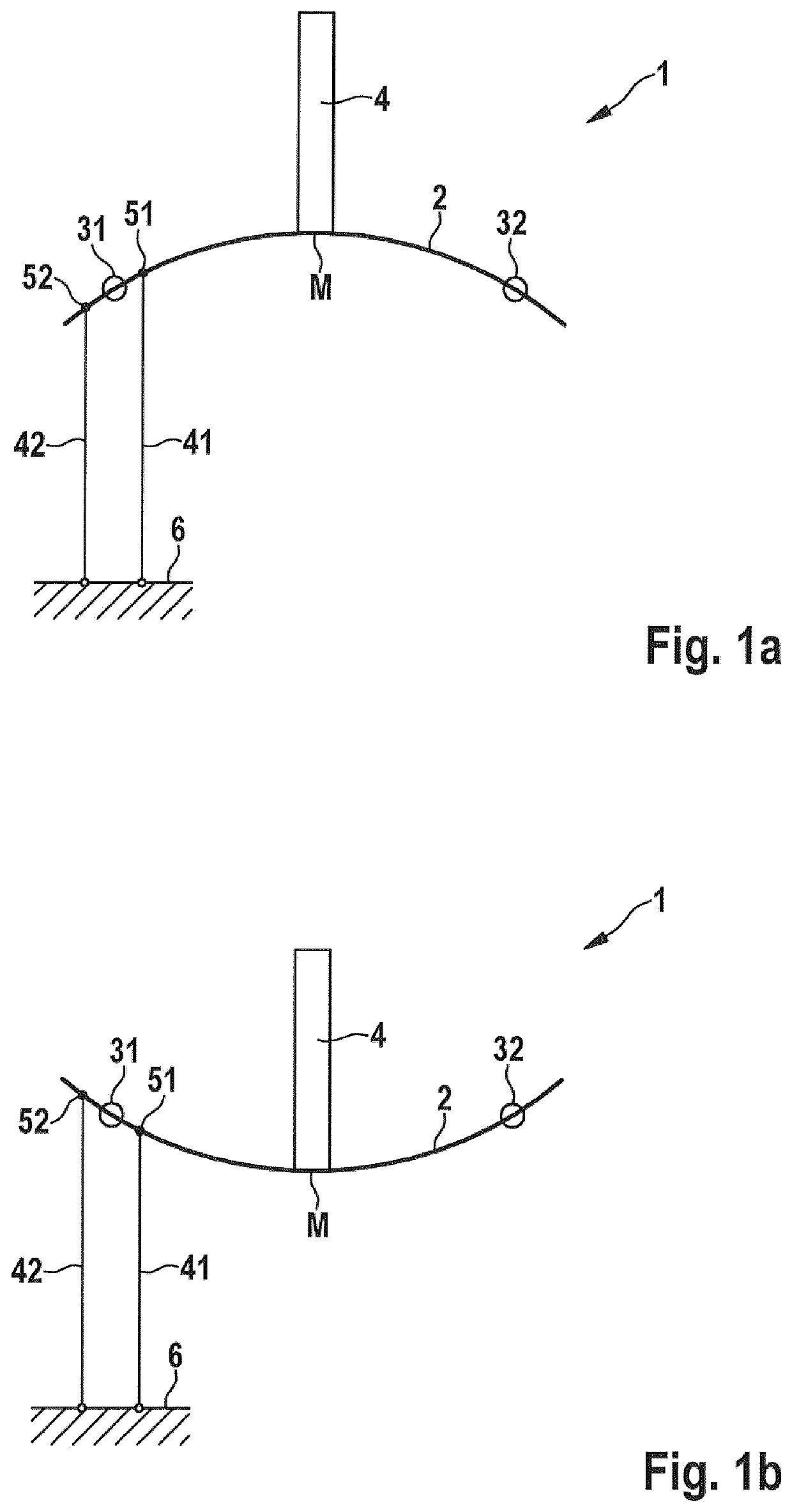

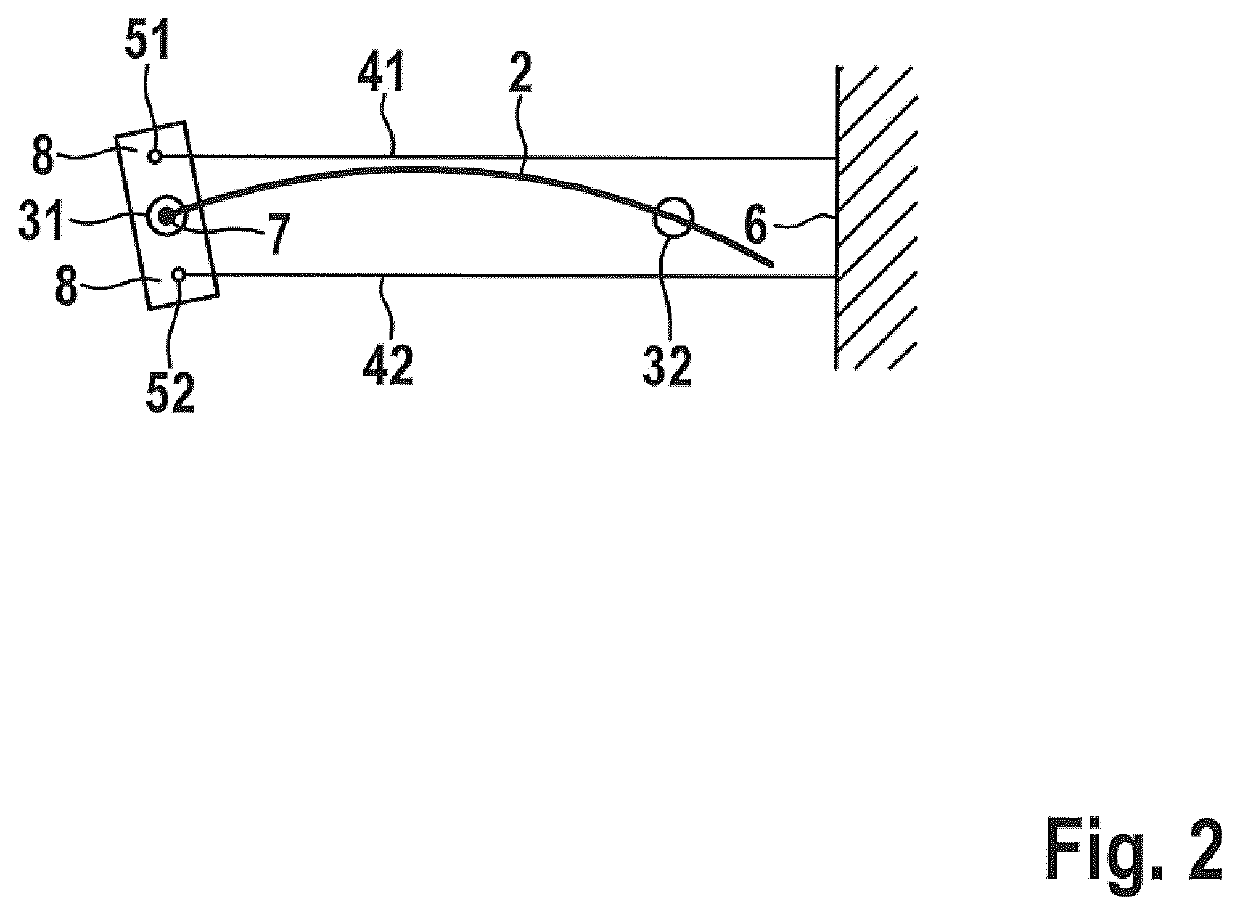

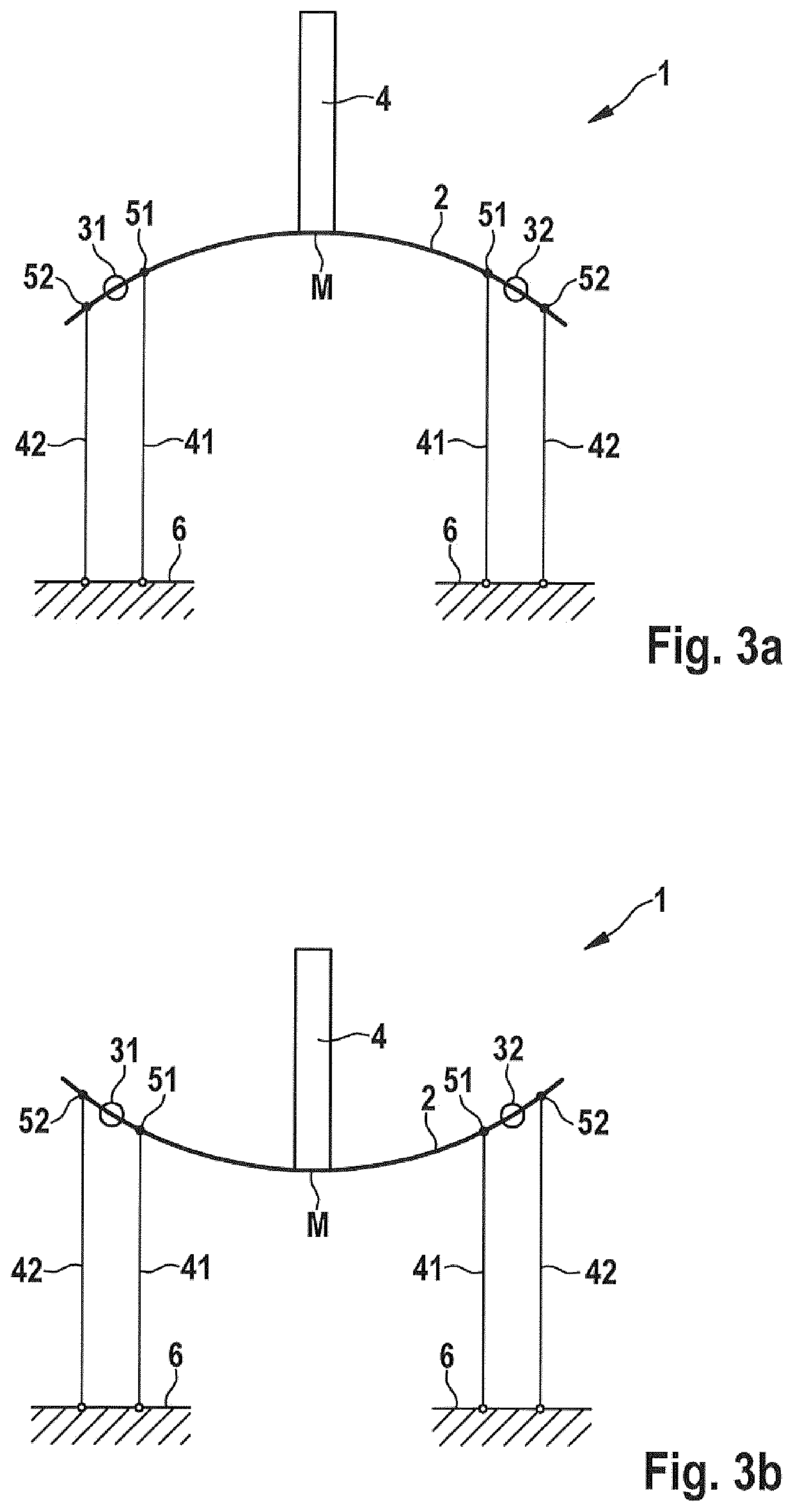

Bistable actuator device having a shape memory element

ActiveUS20190203701A1Eliminate needSave design spaceControlling membersLimiting/preventing/returning movement of partsPull forceActuator

The invention relates to a bistable actuator device (1) for providing at least two actuator positions comprising:an elastic bending element (2) supported at at least one attachment point (31, 32, 34) such that, by applying a switching torque at the attachment point (31, 32, 34), elastic deformation of the bending element (2) results in a change from a first actuator position to a second actuator position; andat least one actuator element (41, 42) formed with a shape memory wire, the shape memory wire causing a pulling force by heating and being coupled to a portion of the bending element (2) at the attachment point (31, 32, 34) so that the pulling force causes the switching torque at the attachment point (31, 32, 34) to move the bending element (2) from the first actuator position to the second actuator position.

Owner:UNIV DES SAARLANDES +1

Large deformation extensometer

InactiveCN101493309ALarge gauge lengthIncrease the itineraryConverting sensor output electrically/magneticallyMechanical solid deformation measurementsCoil springEngineering

The invention provides a large deformation extensometer, comprising a sensor, a regulating bar with a hook, a fixed bar, a scale distance limiting plate and a pair of an upper knife edge group and a lower knife edge group which are eudipleural and arranged at the upper part of the regulating bar and at the lower part of the sensor respectively; the extensometer is characterized in that the sensor which is arranged at the lower part of the fixed bar and articulated with the hook at the lower part of the regulating bar is a draw out type displacement sensor; the draw out type displacement sensor comprises a box body, a steel wire rope and a coil spring type contracting mechanism A and an encoder which are arranged in the box body; the coil spring type contracting mechanism comprises a clockwork spring shaft one end of which is fixedly connected with the box body, a spring plate capable of circuition arranged at an axis body and a disk clockwork spring one end of which is fixed on a locating shaft and the other end of which is fixed in the inside cavity of the spring plate; one end of the steel wire rope is fixed on the spring plate and led out after being sheathed and wound by a winding shaft which is in swing connection with the encoder; the other led out end thereof is directly connected with the hook and forms a large deformation extensometer automatic contracting mechanism with the hook at the lower part of the regulating bar by the hook.

Owner:SHANGHAI HUALONG TEST INSTR

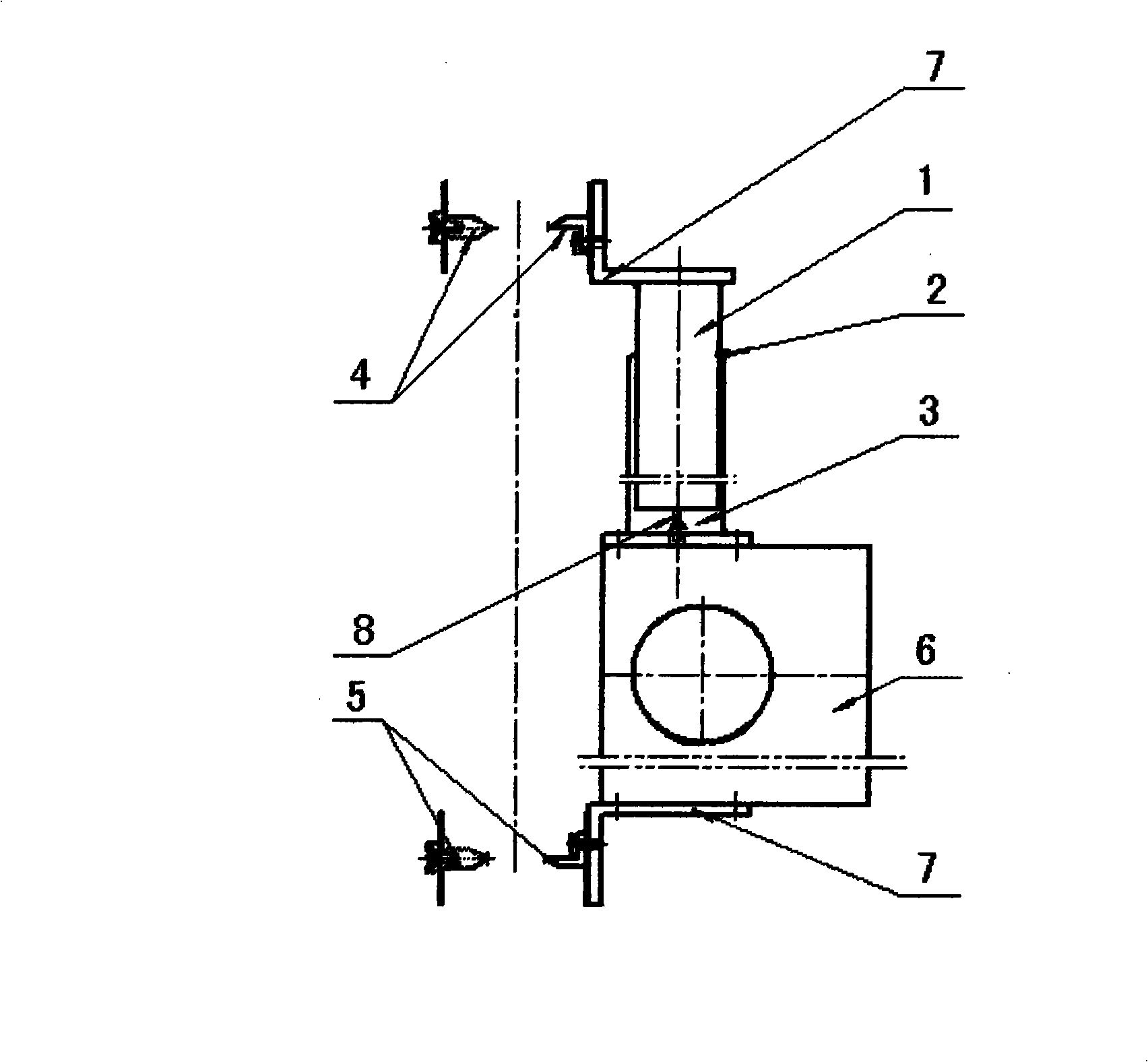

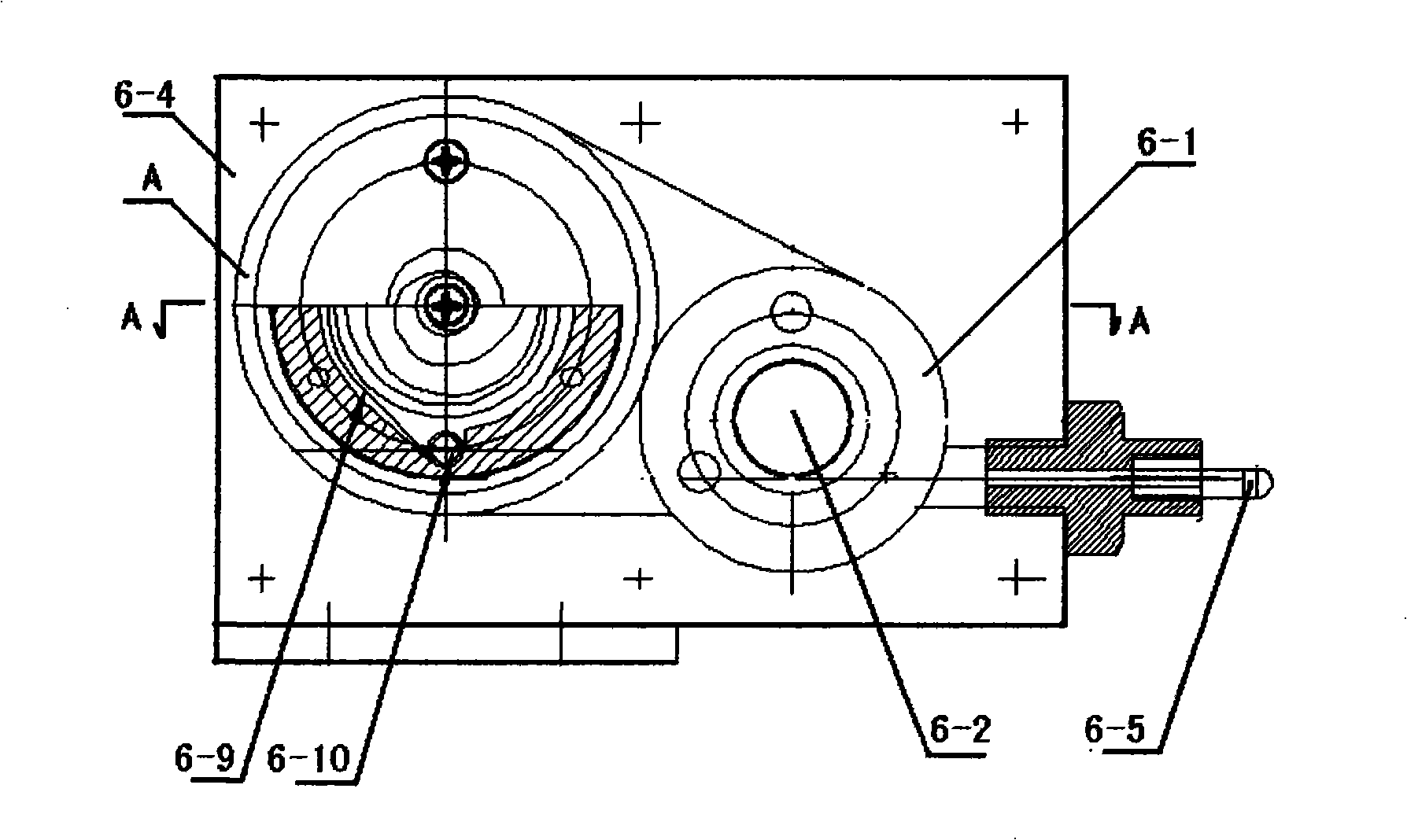

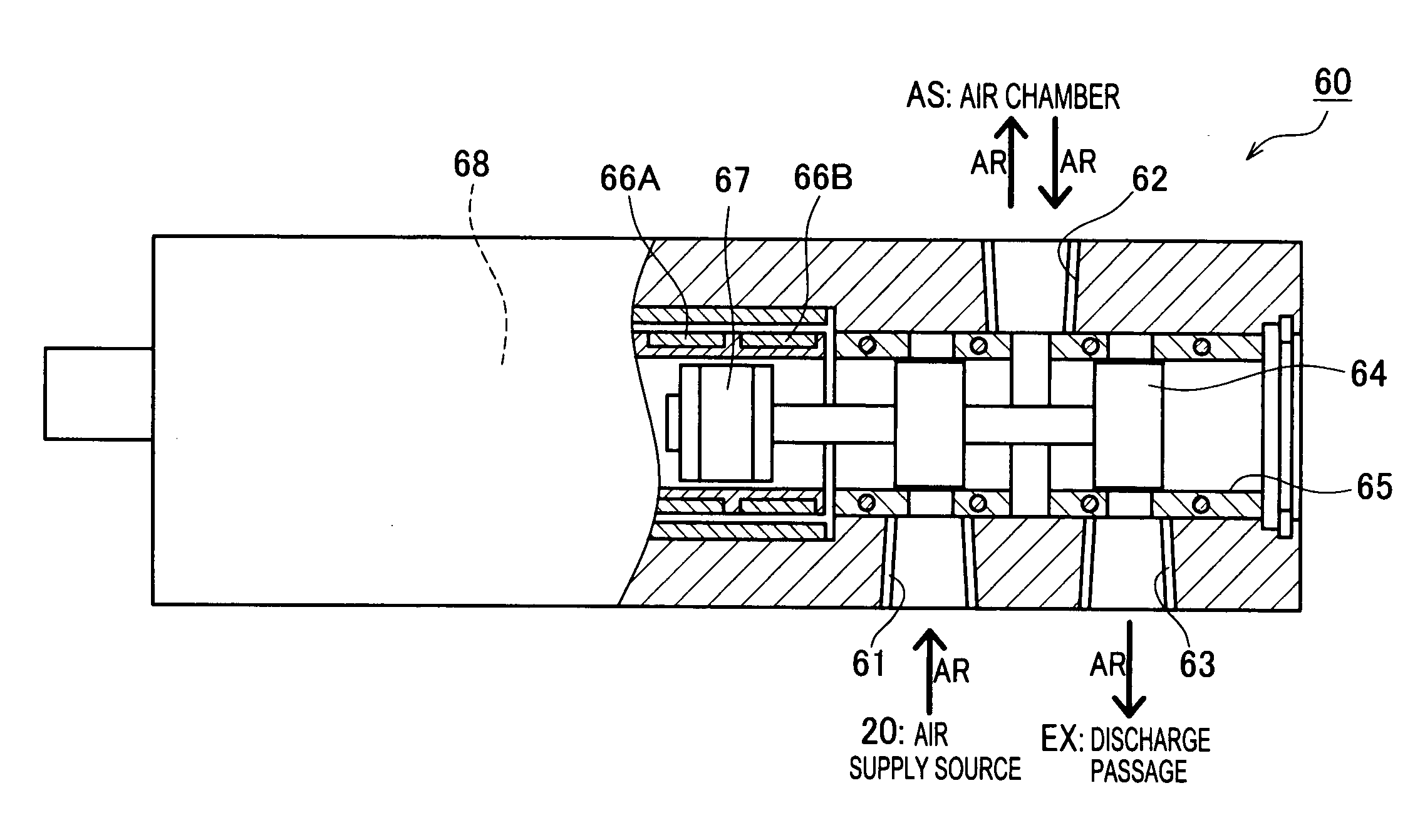

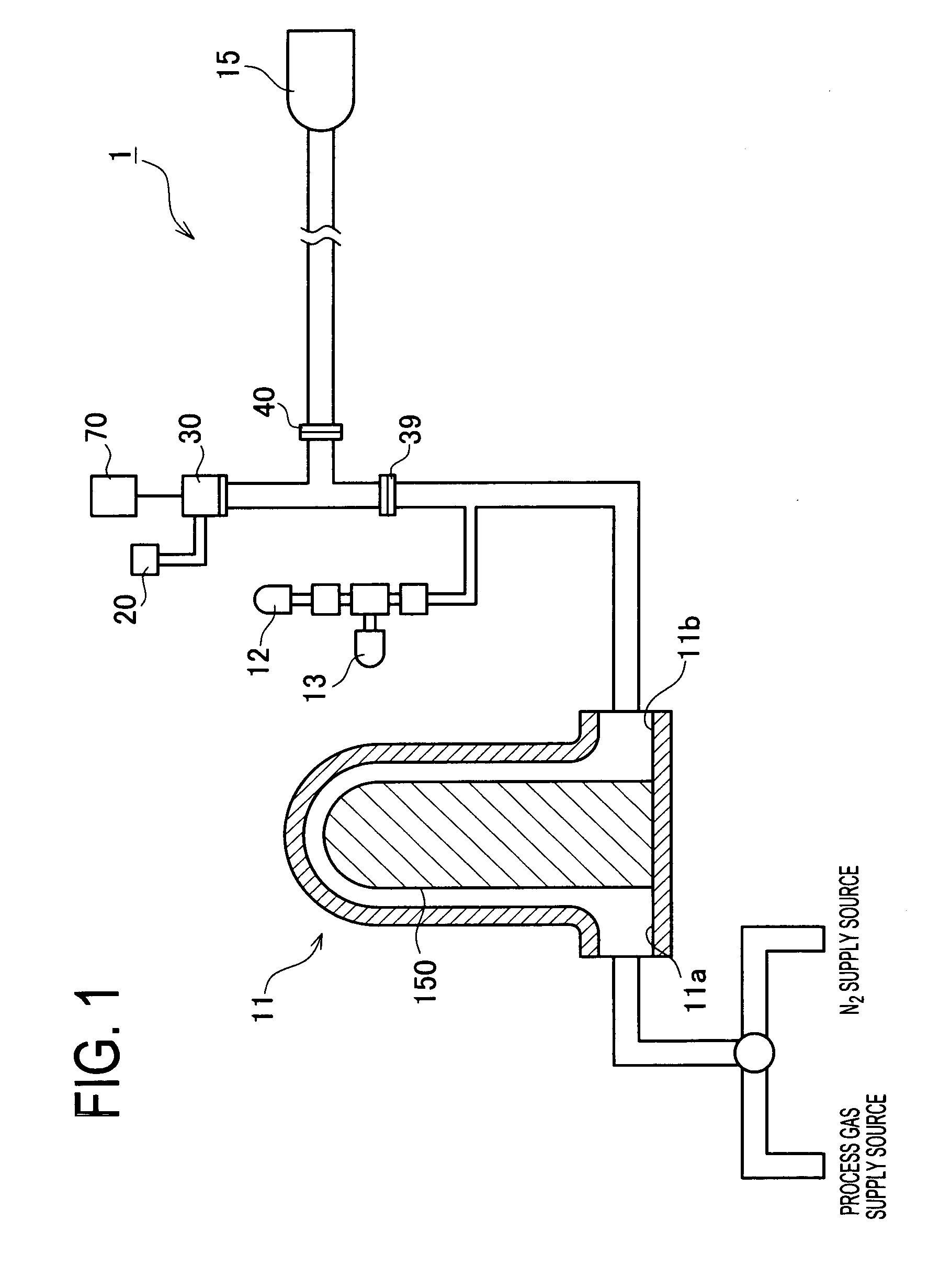

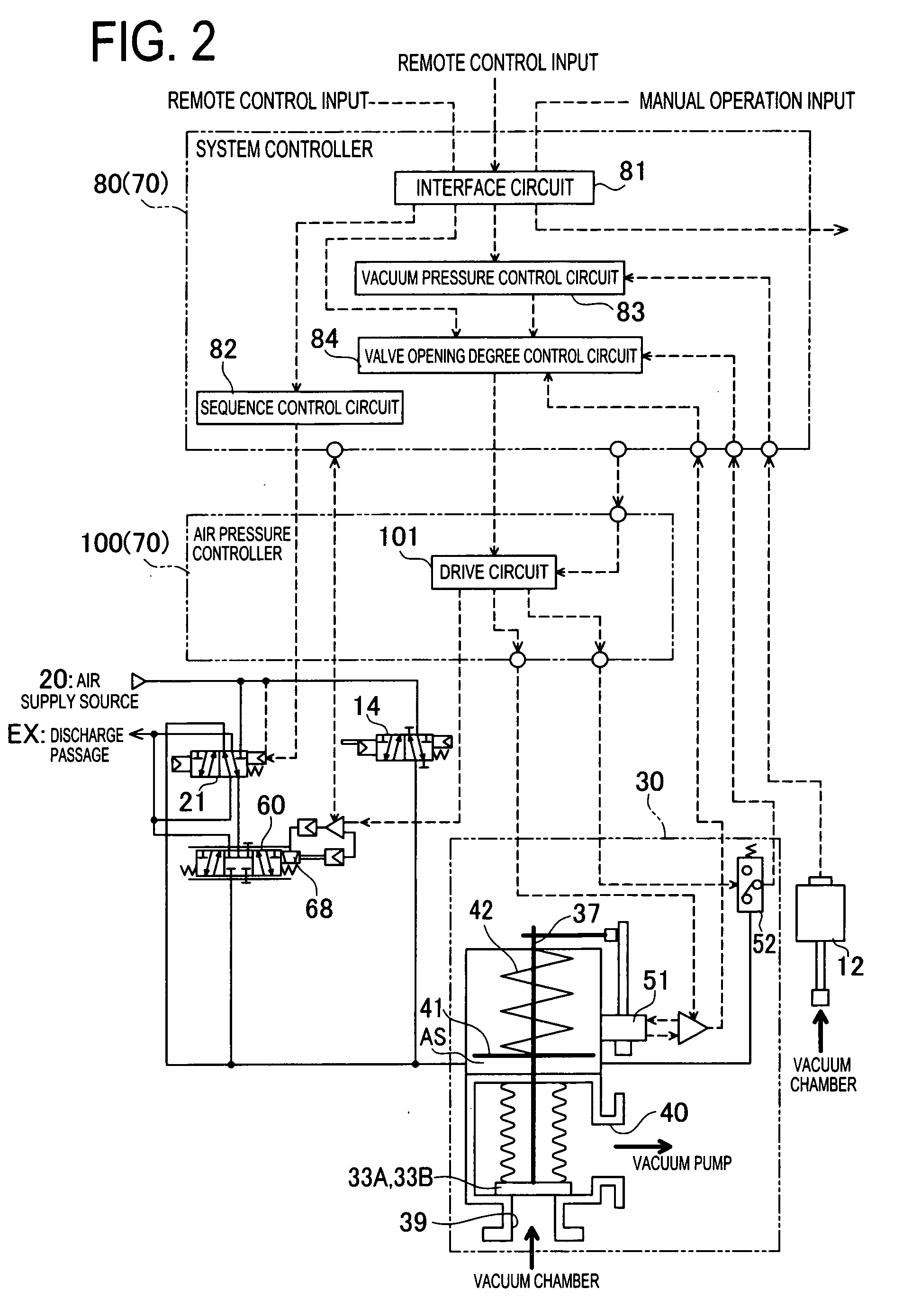

Vacuum pressure control system

InactiveUS20080302427A1Improve responseImprove accuracyOperating means/releasing devices for valvesSemiconductor/solid-state device manufacturingVacuum pressureControl system

A vacuum pressure control system includes a vacuum chamber, a vacuum pump for sucking gas from the vacuum chamber, a vacuum open / close valve for controlling vacuum pressure in the vacuum chamber by changing a opening degree by driving air supplied from an air supply source serving as a power source, a vacuum pressure control device for controlling the vacuum open / close valve, and a servo valve for controlling the opening degree of the vacuum open / close valve.

Owner:CKD

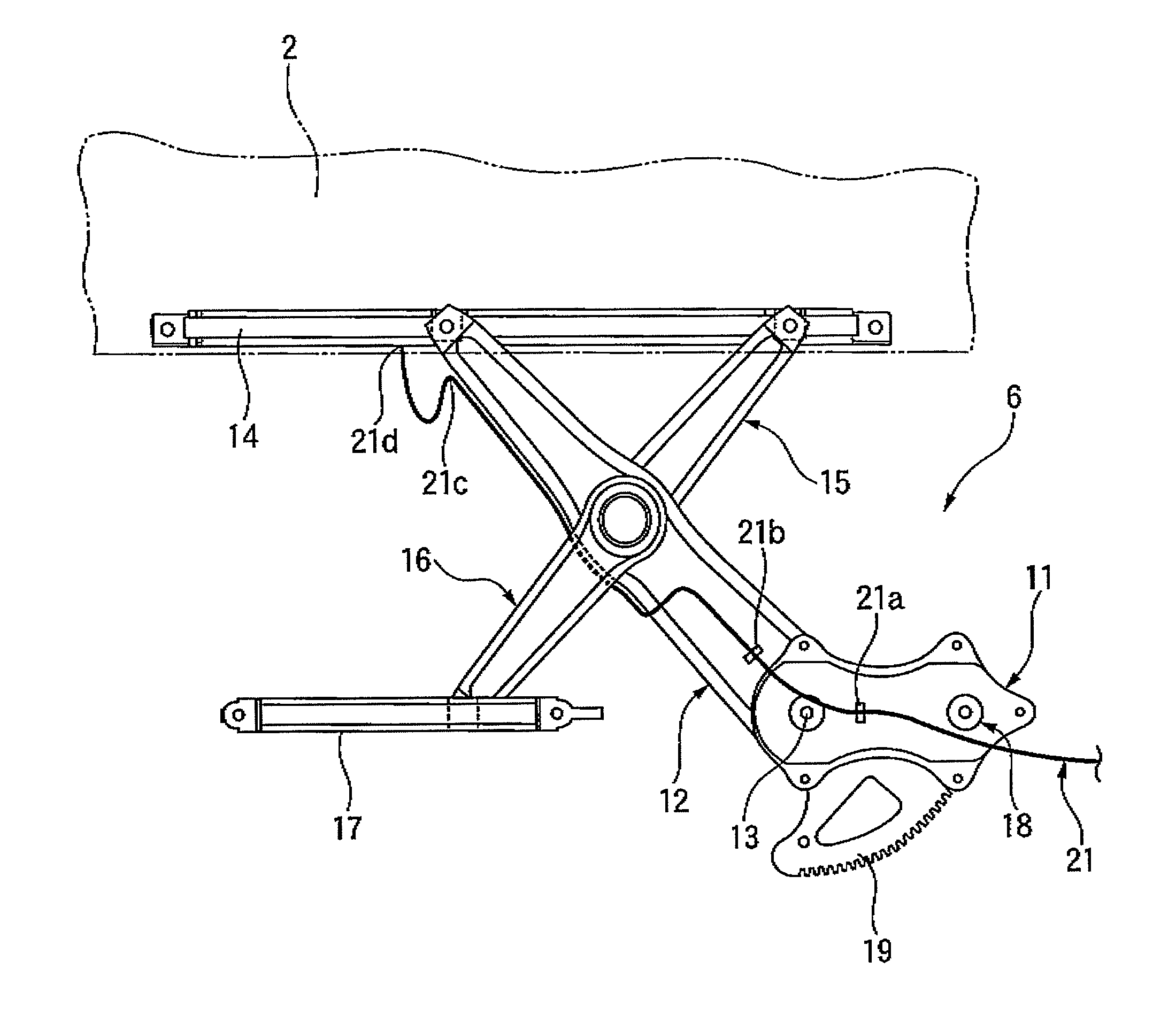

Electric power-feeding structure

ActiveUS20090066156A1Made smallSimple structureElectric devicesMan-operated mechanismEngineeringElectric power

An electric power-feeding structure for feeding electric power to a moving body which is driven to be raised or lowered, includes: an arm having a distal end connected to the moving body movably in a horizontal direction and a proximal end rotatably driven to swing, to thereby drive the raising or lowering of the moving body. An electrical wire is routed alongside the arm, and one end of the electrical wire extending from the distal end is connected to the moving body. In a vicinity of a rotating shaft of the arm, the electrical wire is fixed to the arm at a first fixing point and to a base for supporting the arm at a second fixing point. The first fixing point is provided on a straight line defined by the rotating shaft and the second fixing point when the arm is at an intermediate position of its swinging range.

Owner:YAZAKI CORP

Superposition gear wheel with wide tooth form

InactiveCN1737409AMiniaturizationFacilitate thinningPortable liftingGearing elementsGear wheelEngineering

This invention relates to a long gear superposition gear used in mechanical power actuating device, characterized in that its gear width is three times than the present gear width, and the moment strength a single gear can bear is nine times than the present gear. The design and manufacturing technique of the gear outline is simple with low cost, when it is used in the changeover speed gear of the mechanical power actuating device, it can save raw material above 60%.

Owner:黄振强

Socket for electrical parts

InactiveUS20050014399A1Short strokeShorten the timeCoupling device connectionsElectric discharge tubesEngineeringRack and pinion

A socket for electrical parts includes driving mechanisms that move pressing members from a depressed position to a retired position when an operating member is vertically shifted. The operating member includes racks each of which has rack gears in the vertical direction. Follower gears engageable with the rack gears are also provided. The follower gears have different distances from the rotational pivot to the pitch circle. When the operating member is depressed, the follower gear with a longer distance from the rotational pivot to the pitch circle is engaged with one of the rack gears.

Owner:ENPLAS CORP

Bistable actuator device having a shape memory element

ActiveUS10954925B2Eliminate needSave design spaceControlling membersLimiting/preventing/returning movement of partsWire rodActuator

The invention relates to a bistable actuator device (1) for providing at least two actuator positions comprising:an elastic bending element (2) supported at at least one attachment point (31, 32, 34) such that, by applying a switching torque at the attachment point (31, 32, 34), elastic deformation of the bending element (2) results in a change from a first actuator position to a second actuator position; andat least one actuator element (41, 42) formed with a shape memory wire, the shape memory wire causing a pulling force by heating and being coupled to a portion of the bending element (2) at the attachment point (31, 32, 34) so that the pulling force causes the switching torque at the attachment point (31, 32, 34) to move the bending element (2) from the first actuator position to the second actuator position.

Owner:UNIV DES SAARLANDES +1

Wire connection terminal device

Owner:SWITCHLAB SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com