Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Short afterglow time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

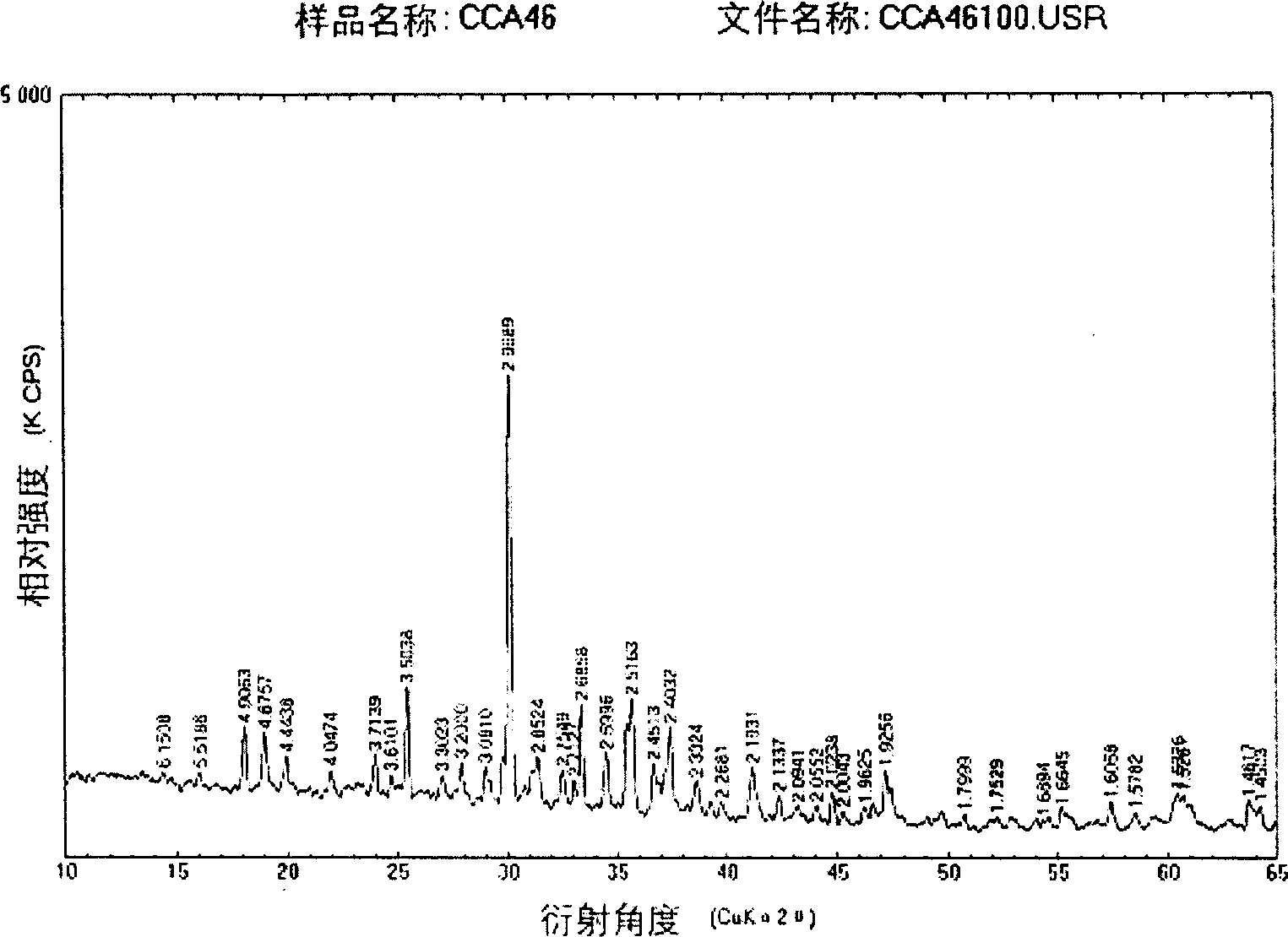

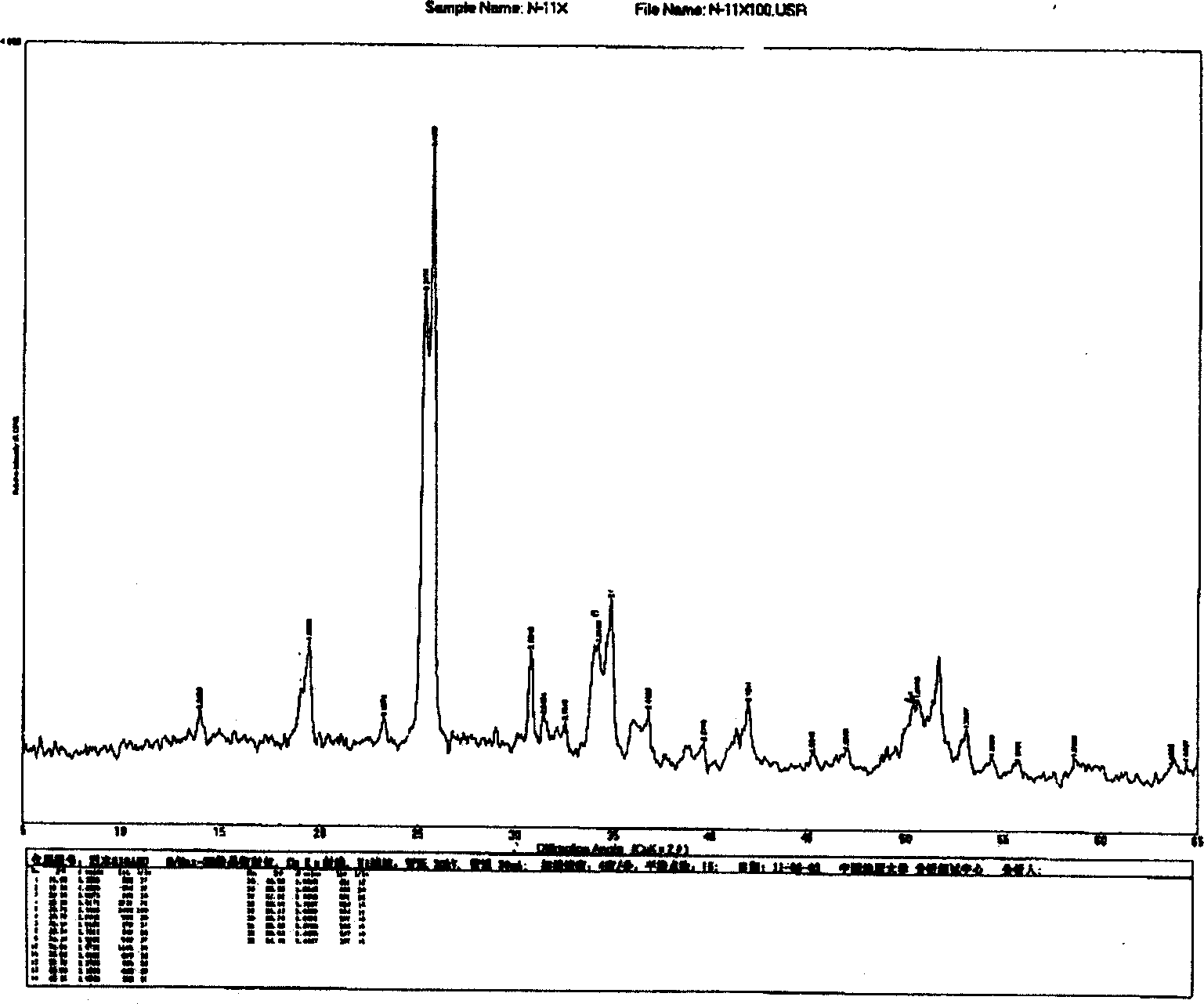

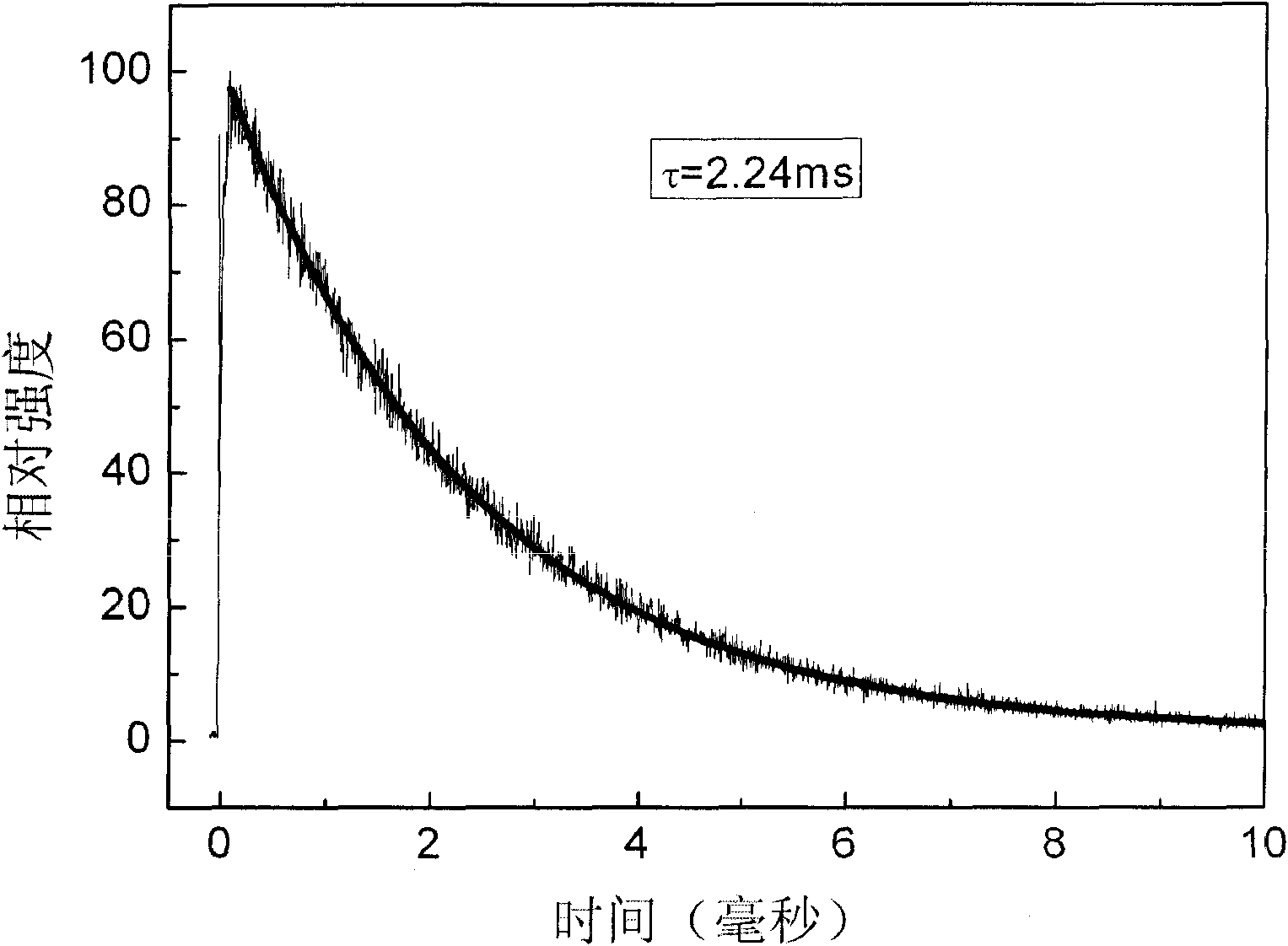

Rare earth oxide solid solution ceramic scintillator and preparation method thereof

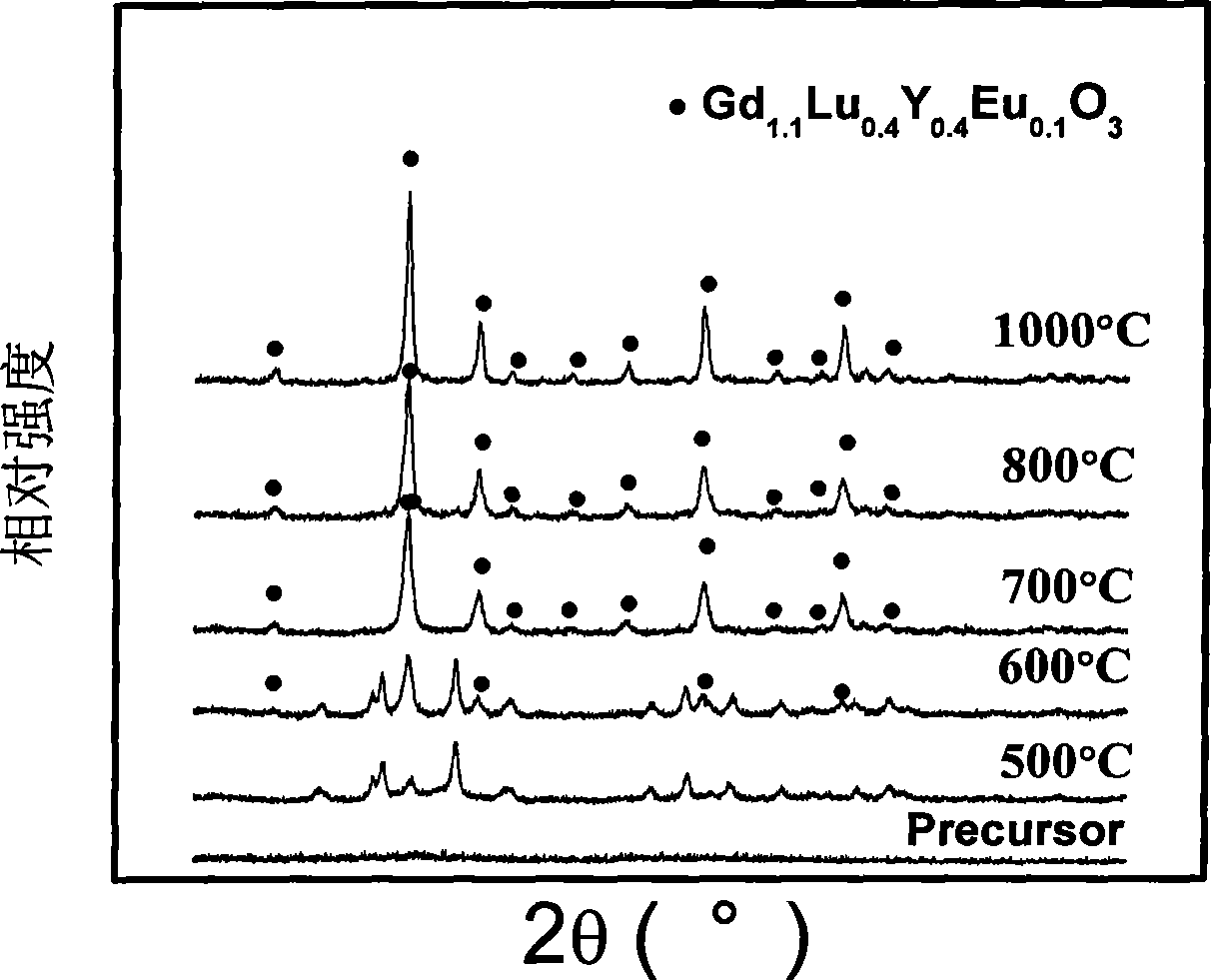

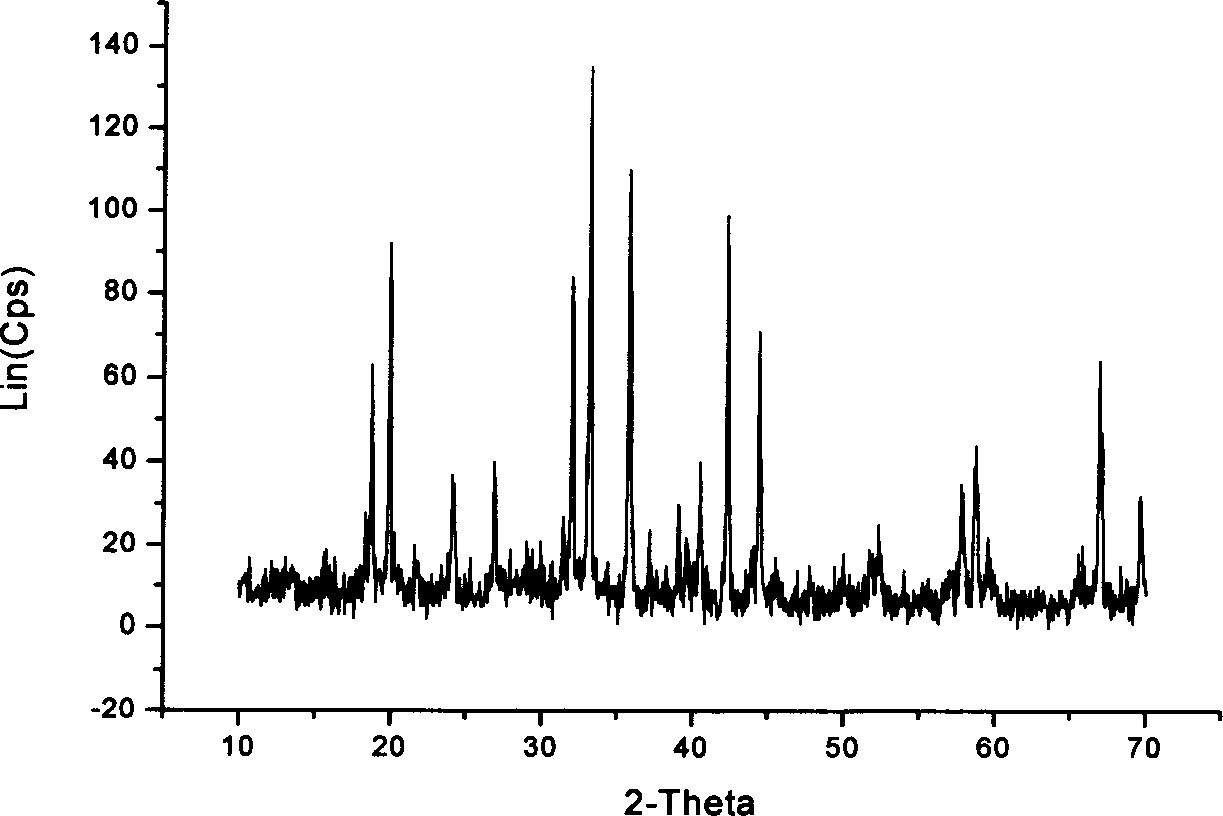

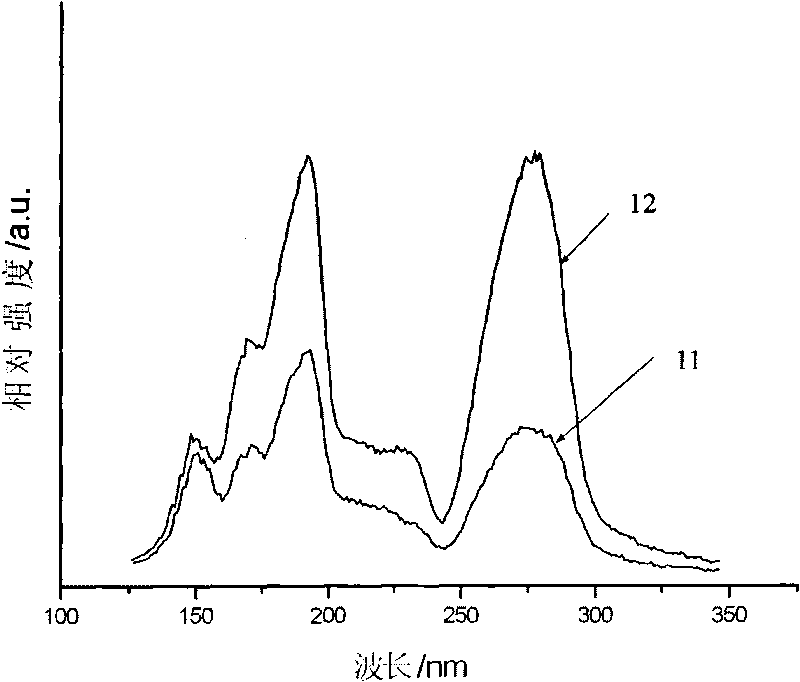

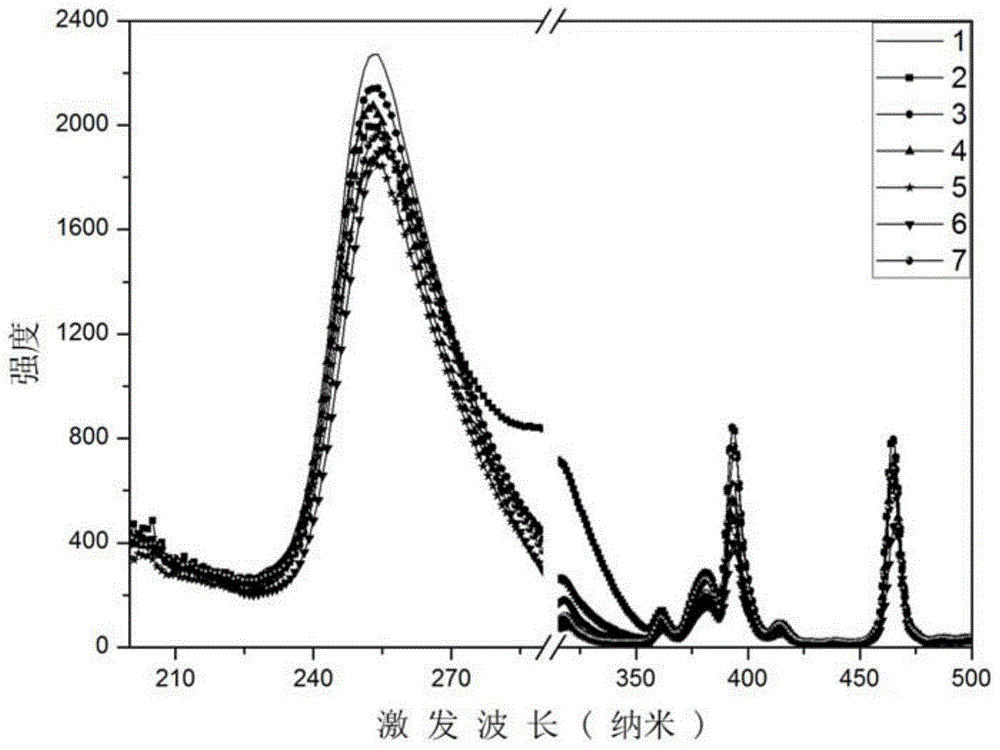

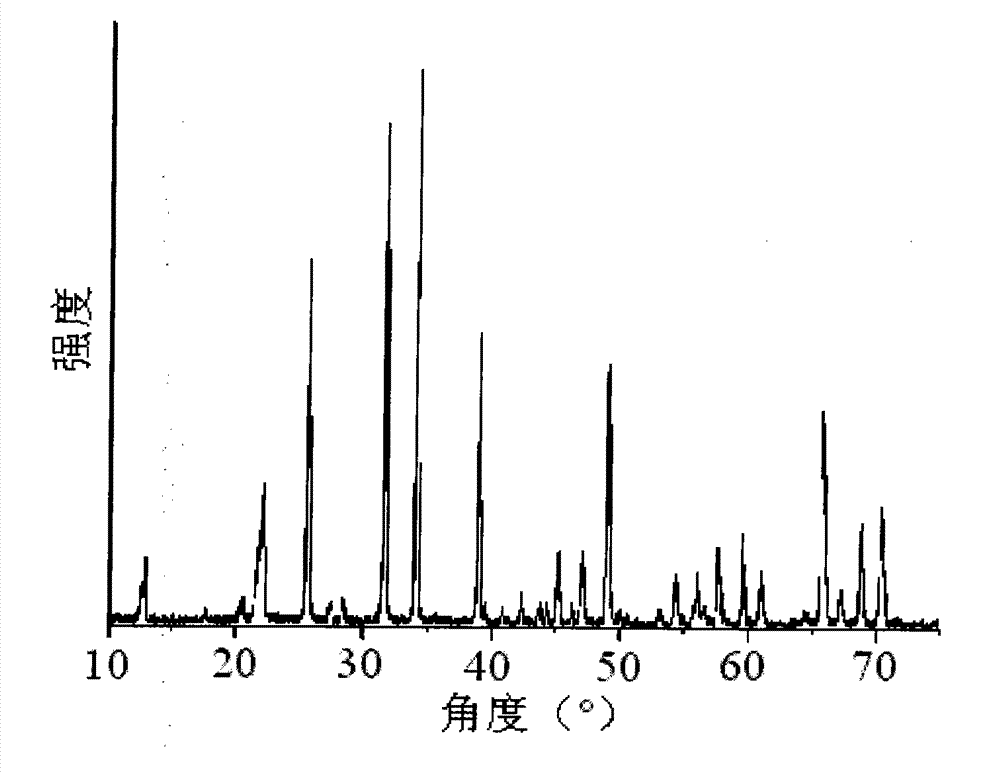

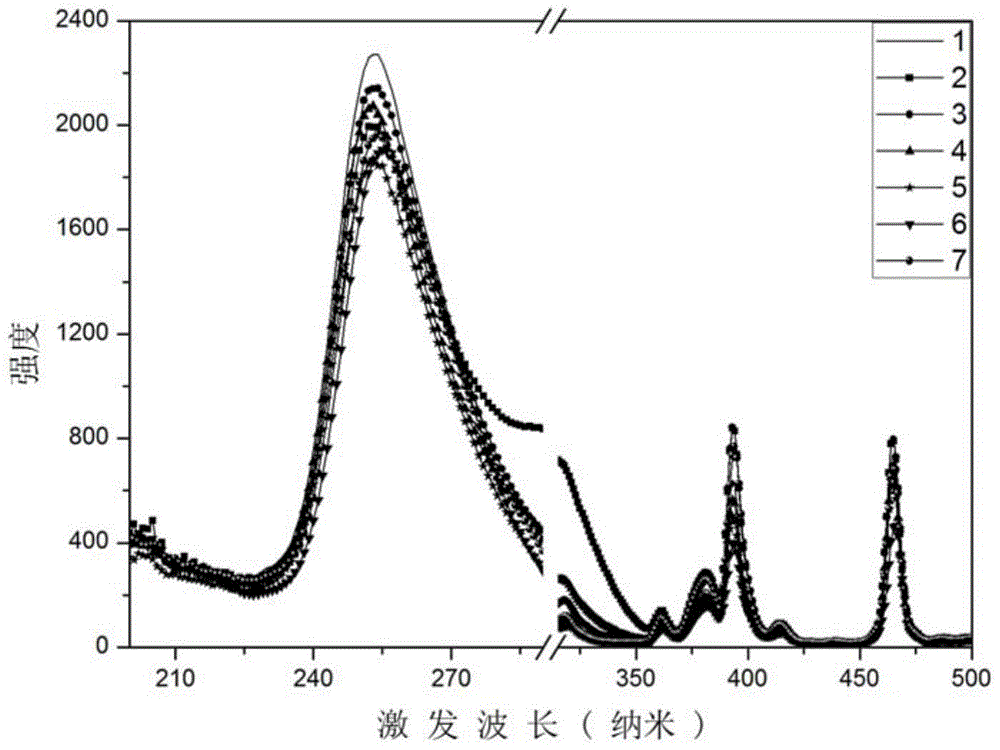

The invention discloses a rare earth oxide solid solution ceramic scintillator and a preparation method thereof. The main component of the ceramic scintillator is Gd2xLu2yY2(1-x-y-z)Eu2zO3 (the x is more than or equal to 0.1 and less than or equal to 0.6, the y is more than or equal to 0.1 and is less than or equal to 0.4, and the z is more than or equal to 0.01 and less than or equal to 0.1), and the ceramic scintillator has a crystal structure with a cubic Ia3 point group. Ceramic powder can be synthesized by a chemical coprecipitation method. The coprecipitation method adopts ammonia, ammonium hydrogen carbonate or a mixed solution of the ammonium water and the ammonium hydrogen carbonate as a precipitating agent, titrates the precipitating agent into a solution of gadolinium nitrate, lutecium nitrate, yttrium nitrate and europium nitrate to obtain a precipitate, and then the precipitate is dried and calcined to obtain nano-powder. The obtained powder is pressed into a ceramic blank through an isostatic compaction method, then the pressureless sintering is performed in vacuum or hydrogen atmosphere, the sintering temperature is between 1,600 and 1,900 DEG C, transparent Gd2xLu2yY2(1-x-y-z)Eu2zO3 ceramic can be obtained, a ceramic product with the needed dimension is prepared after the cutting, grinding and polishing, and the transmission rate of the ceramic in a visible region (400-800 nanometers) is more than or equal to 65 percent. The ceramic scintillator emits red light with a main wavelength of 610 nanometers under the excitation of ultraviolet light or X rays, and can be used for scintillating materials of imaging and detection of medical and industrial X rays.

Owner:CHINA JILIANG UNIV

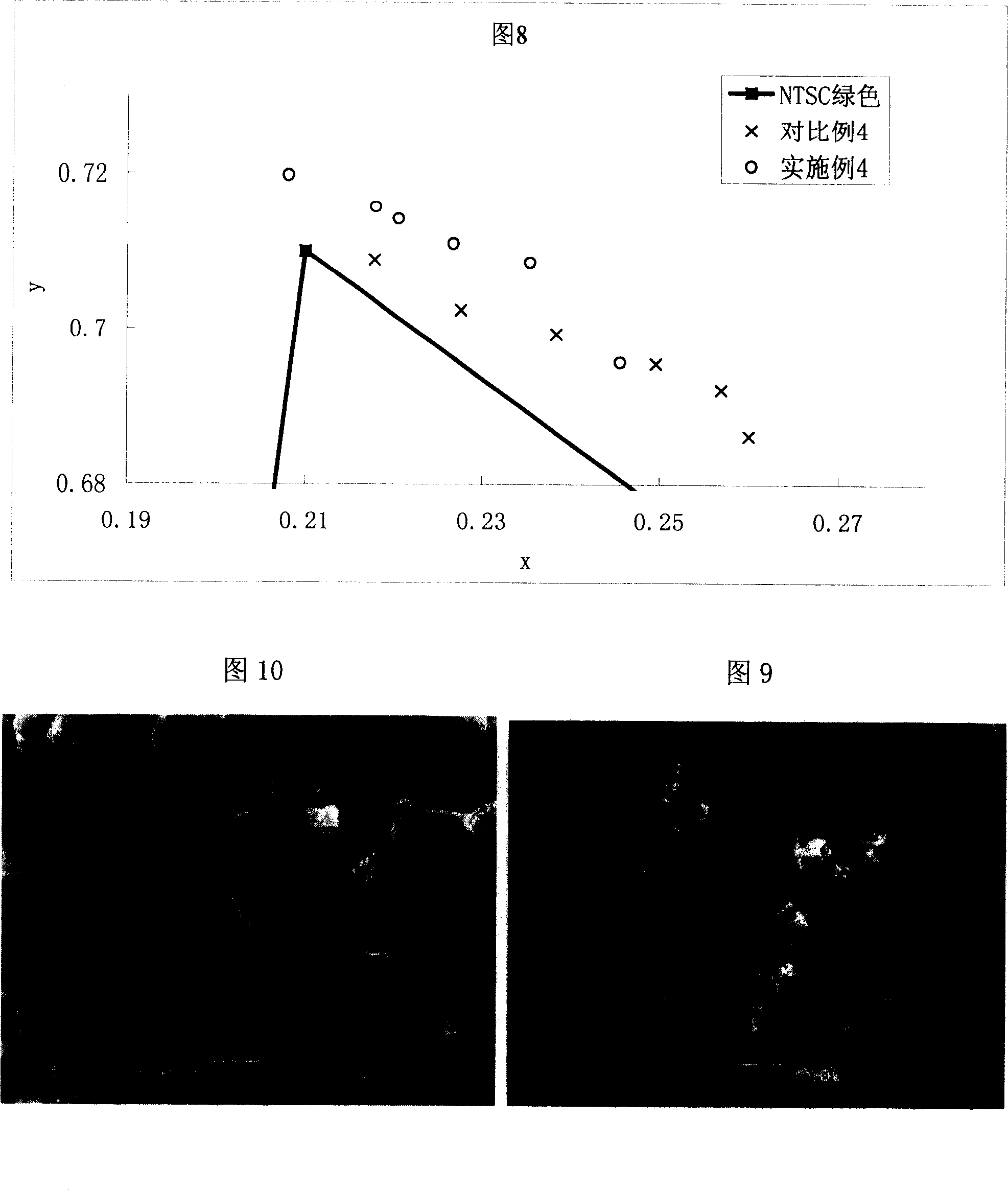

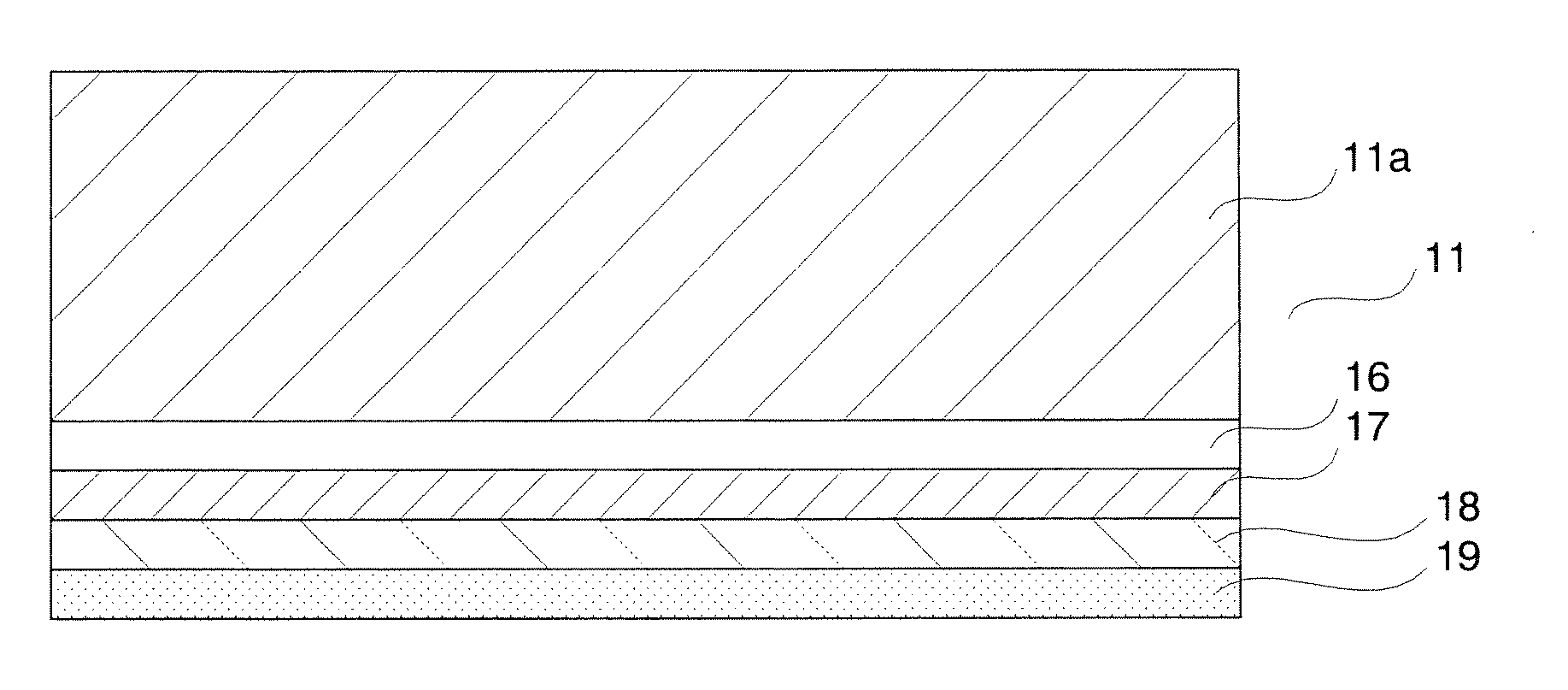

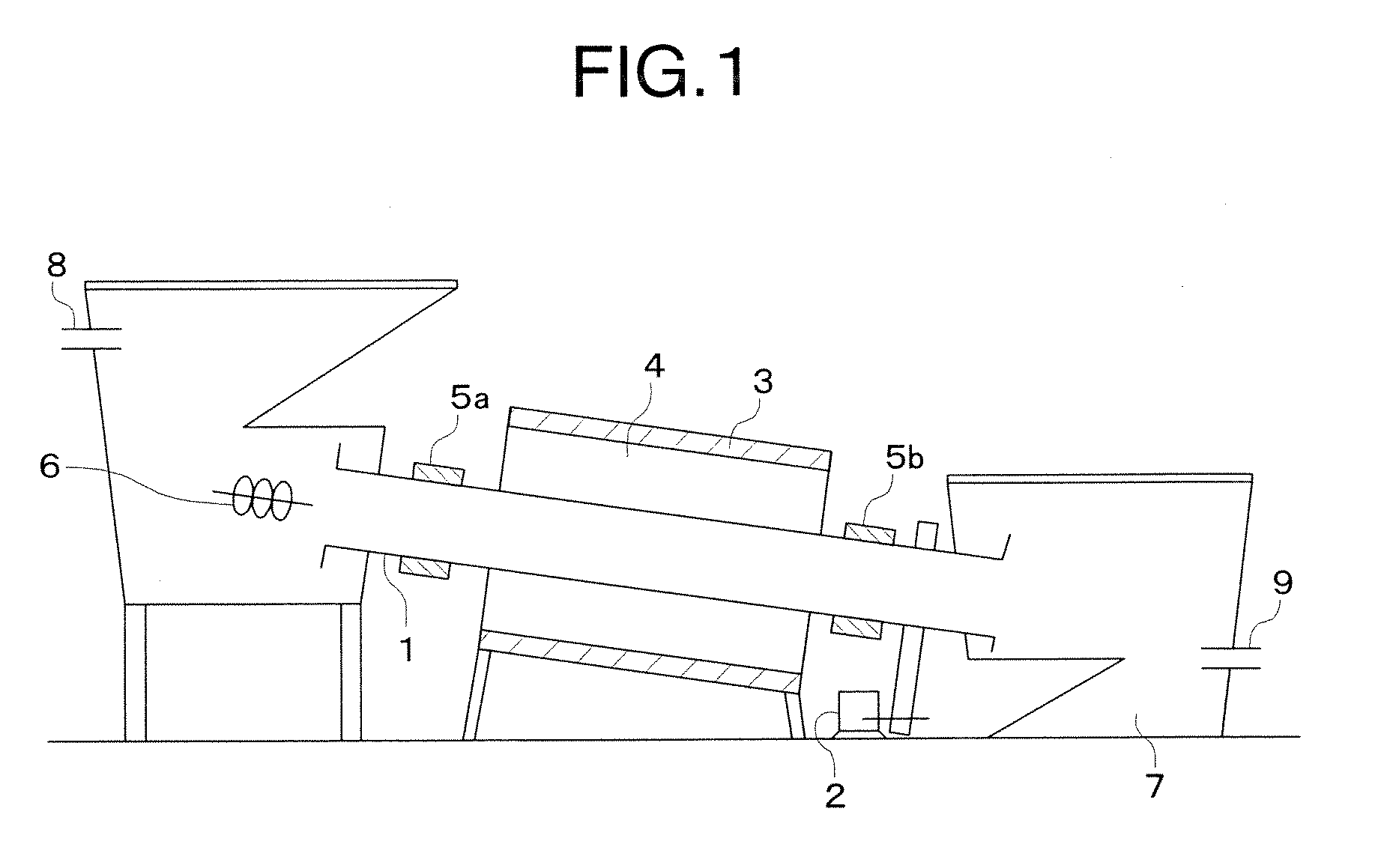

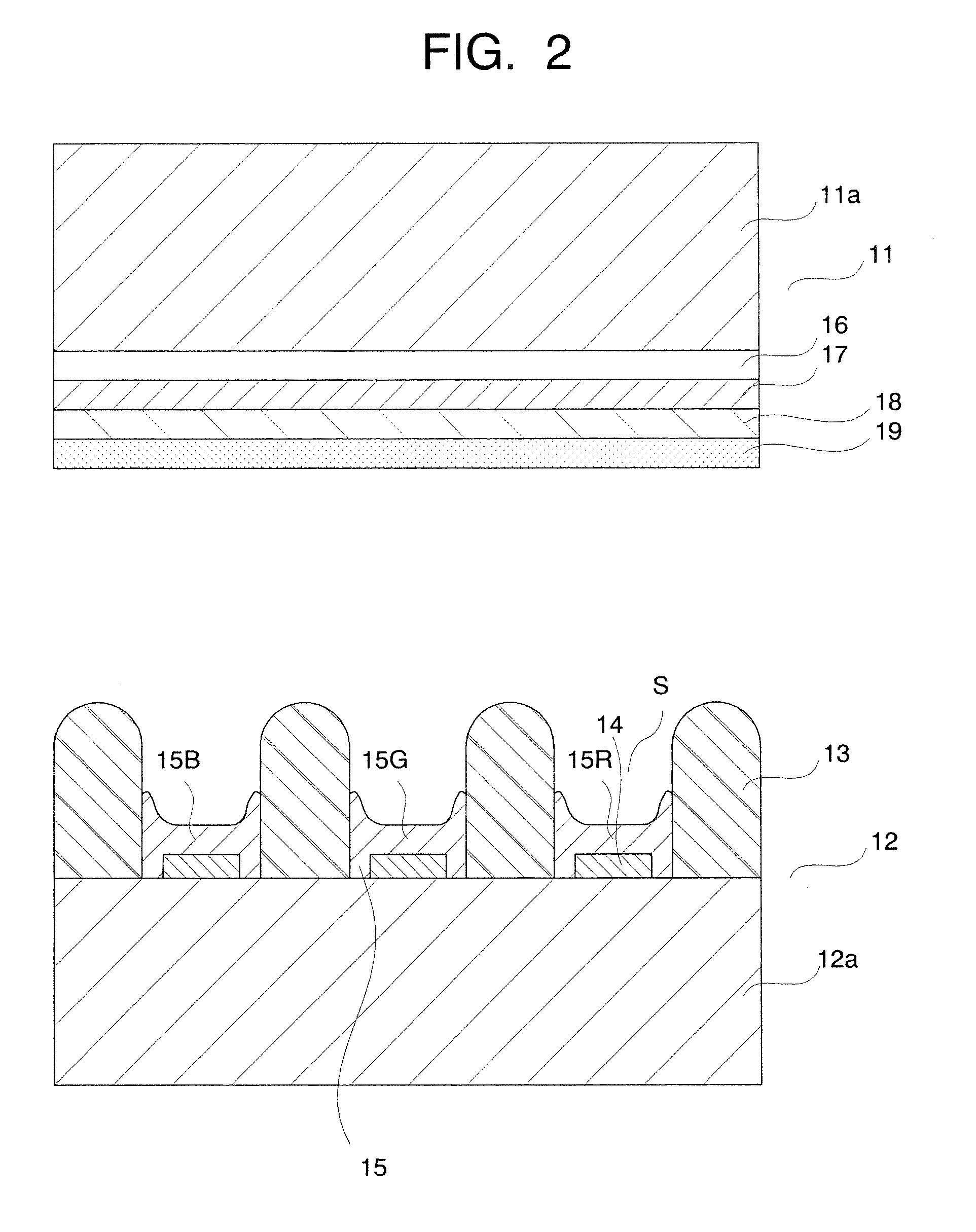

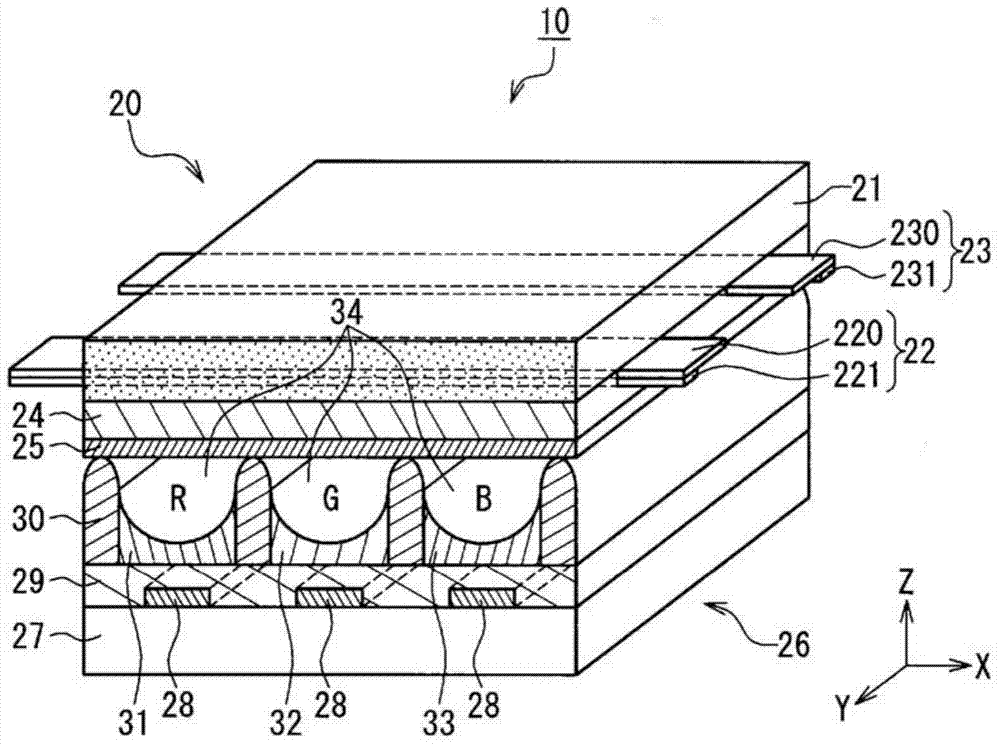

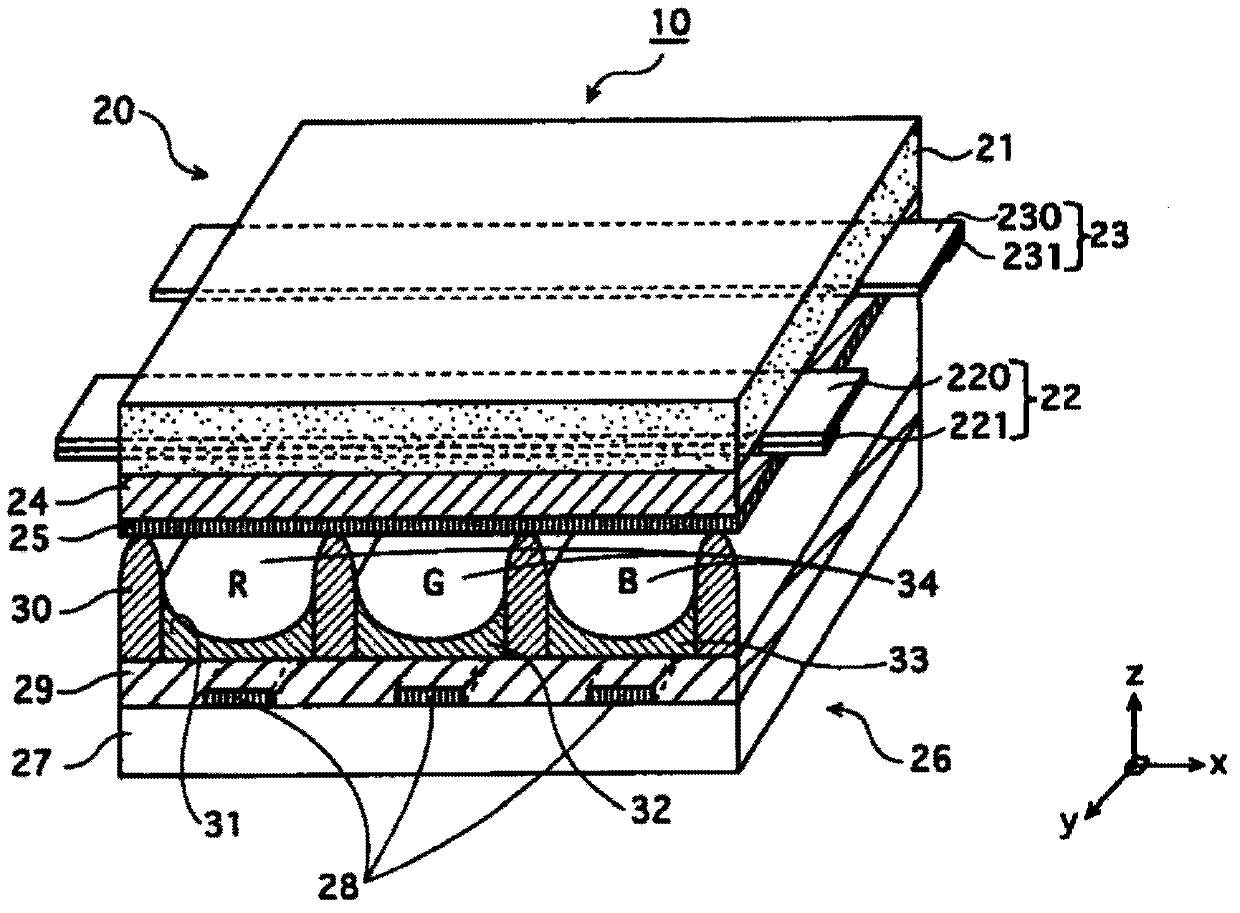

Color display unit

InactiveUS20100188322A1Short afterglow timeHigh unimodal in wavelength rangeStatic indicating devicesNon-linear opticsDisplay deviceTransmittance

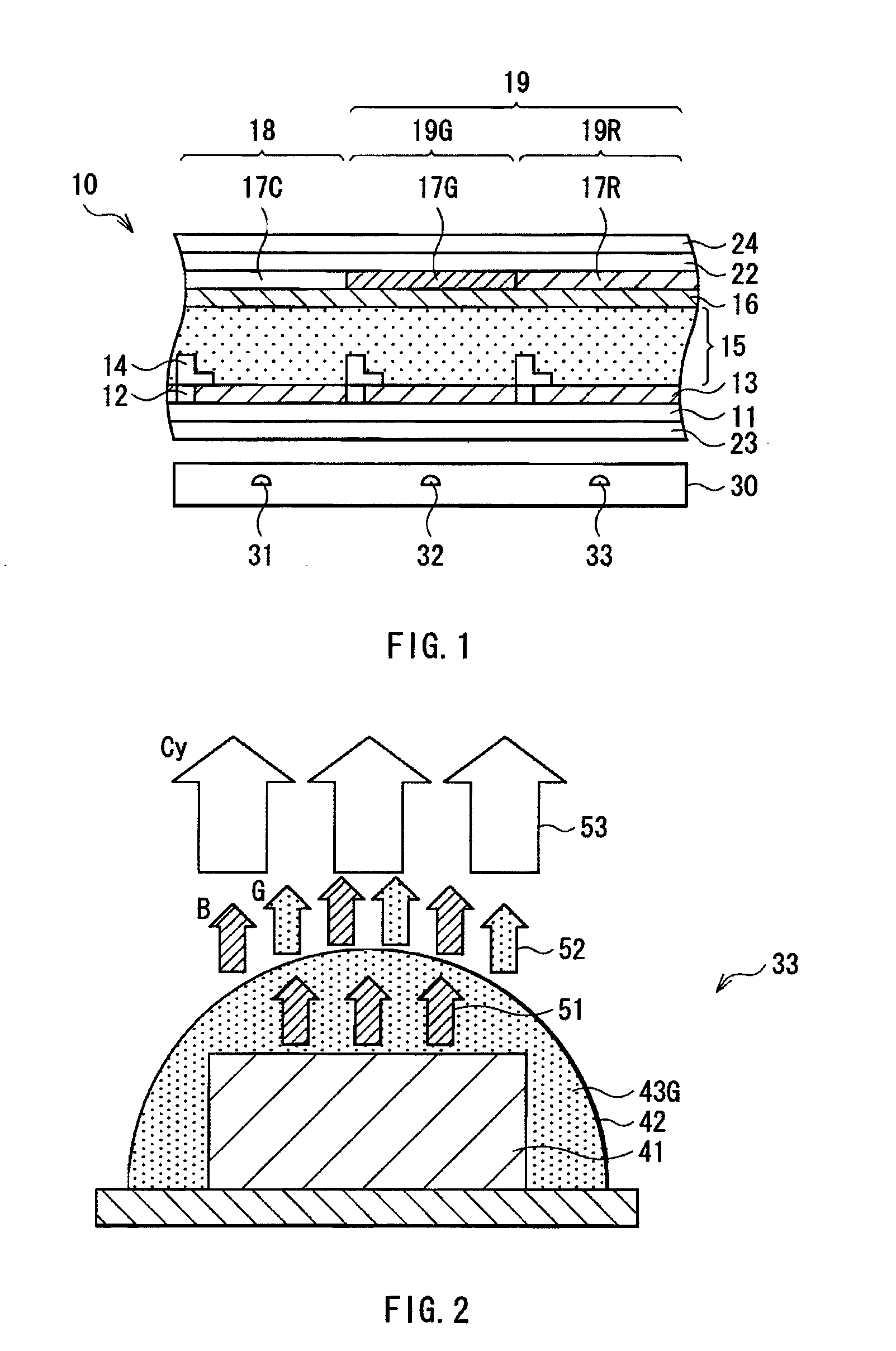

A color display unit is provided, which allows color display to be performed with high efficiency in utilizing light as compared with a prior type using all of RGB color filters. The color display unit includes a light source section having plural kinds of color LEDs, and includes a display section controlling transmissivity of light from the light source section in synchronization with light emission control by the light source section, to achieve desired color display. The display section has a full-color transmittable region and a partially transmittable region. The full-color transmittable region allows all color components of the light to be transmitted, while the partially transmittable region inhibits passage of one or more in the color components of the light. The display section controls the transmissivity of the light independently for each of the full-color transmittable region and the partial transmittable region.

Owner:SONY CORP

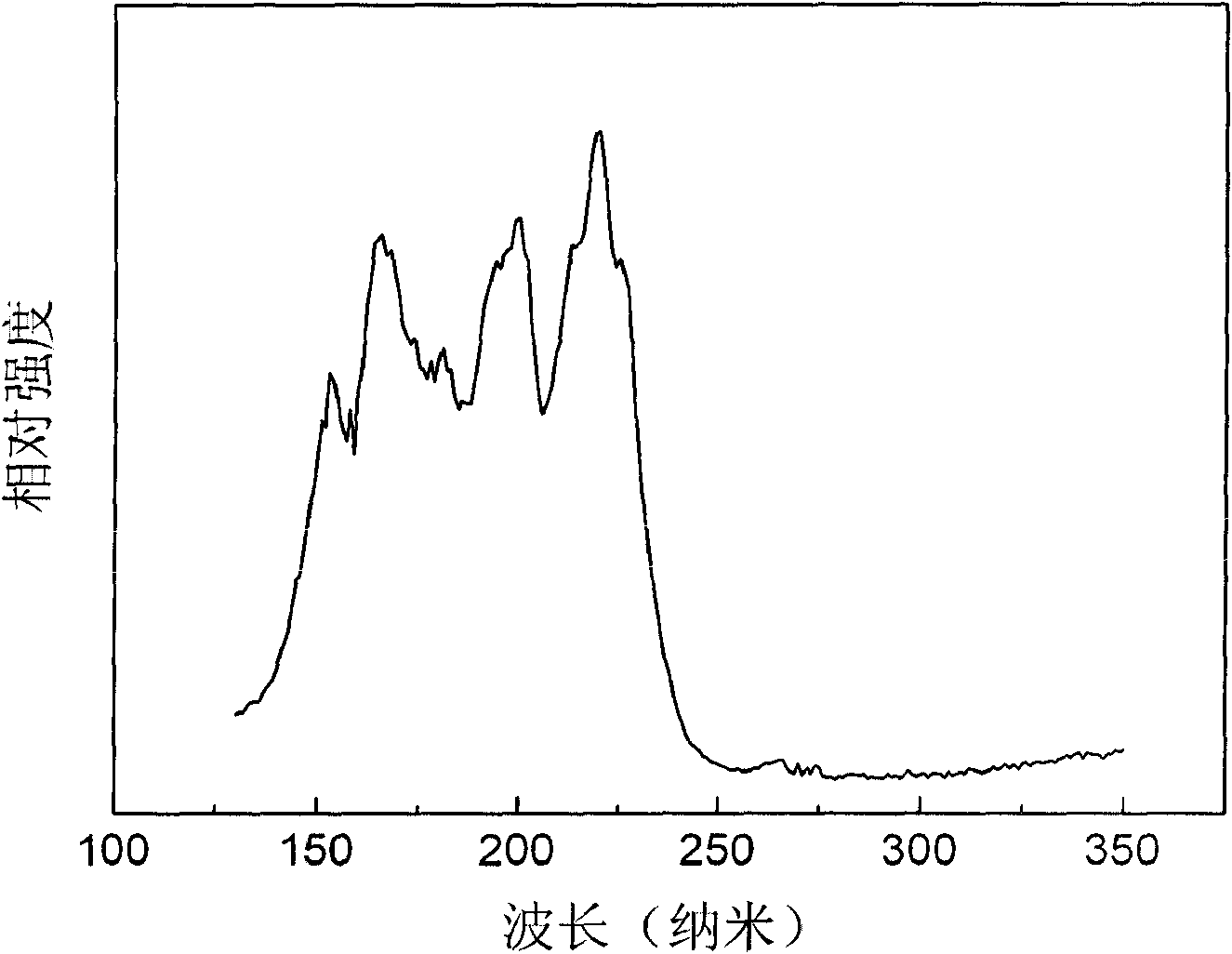

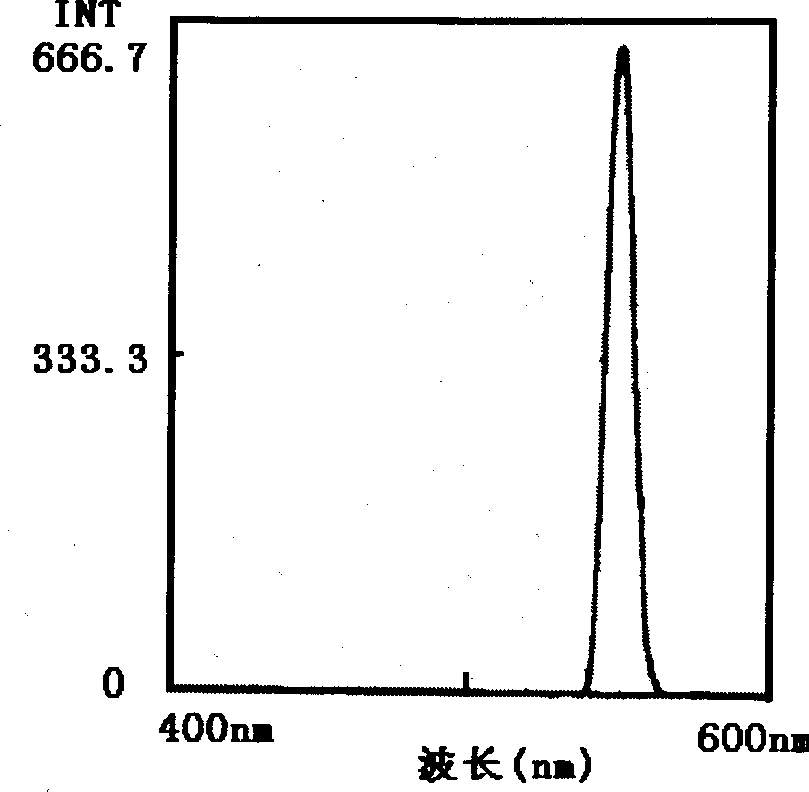

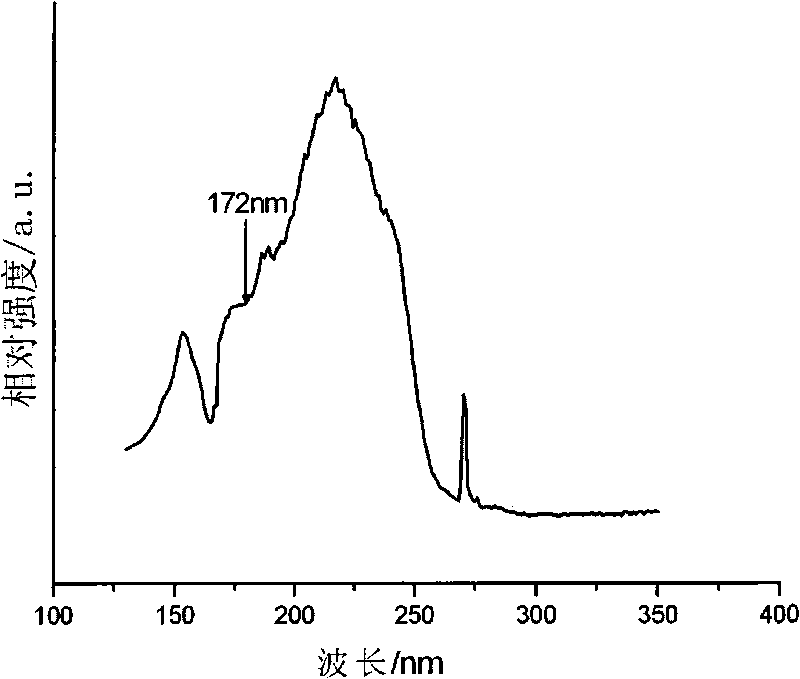

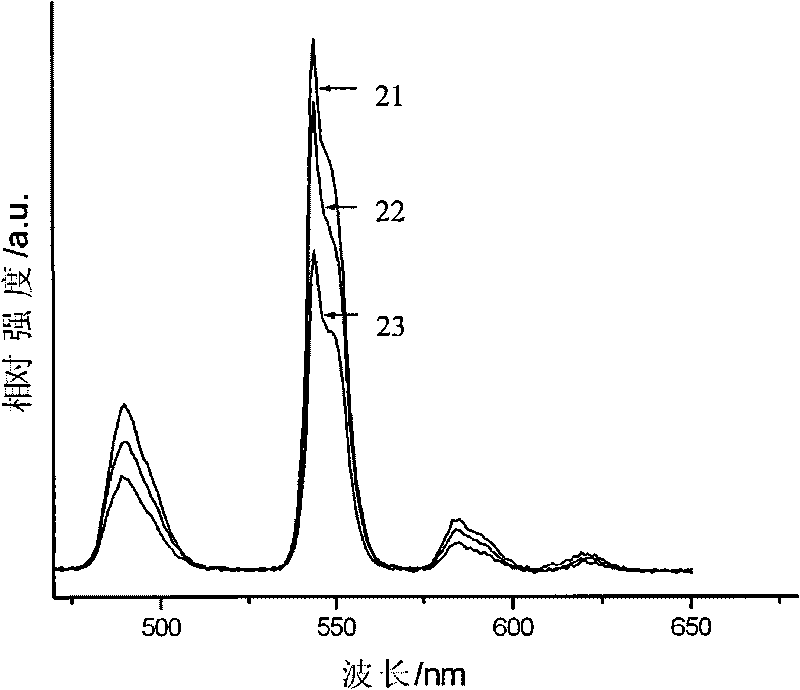

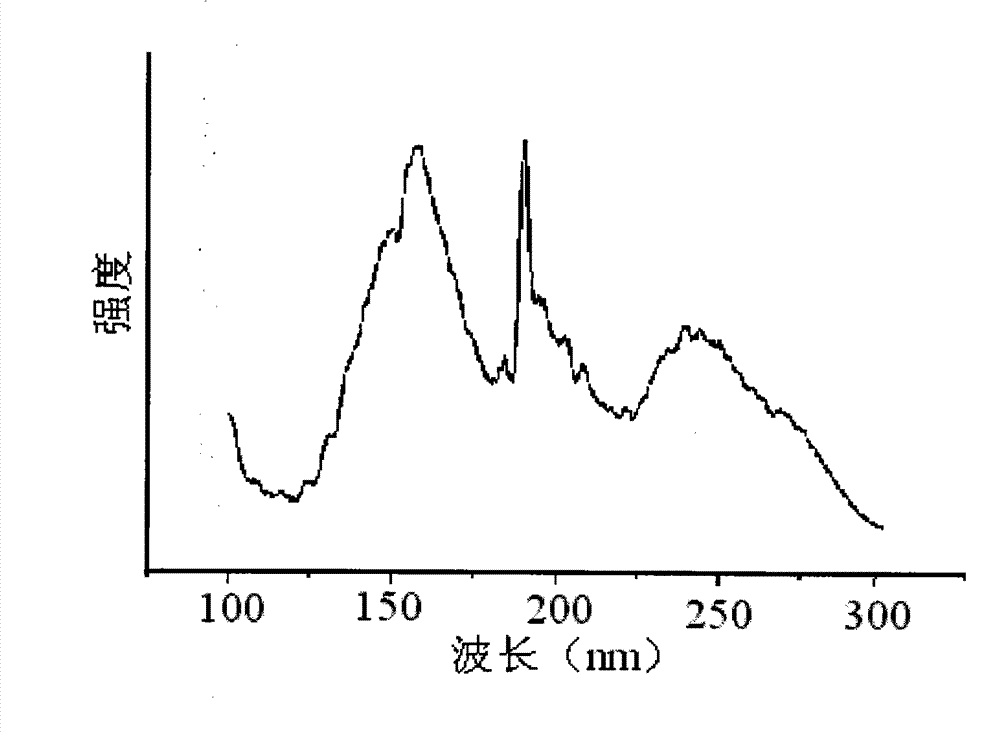

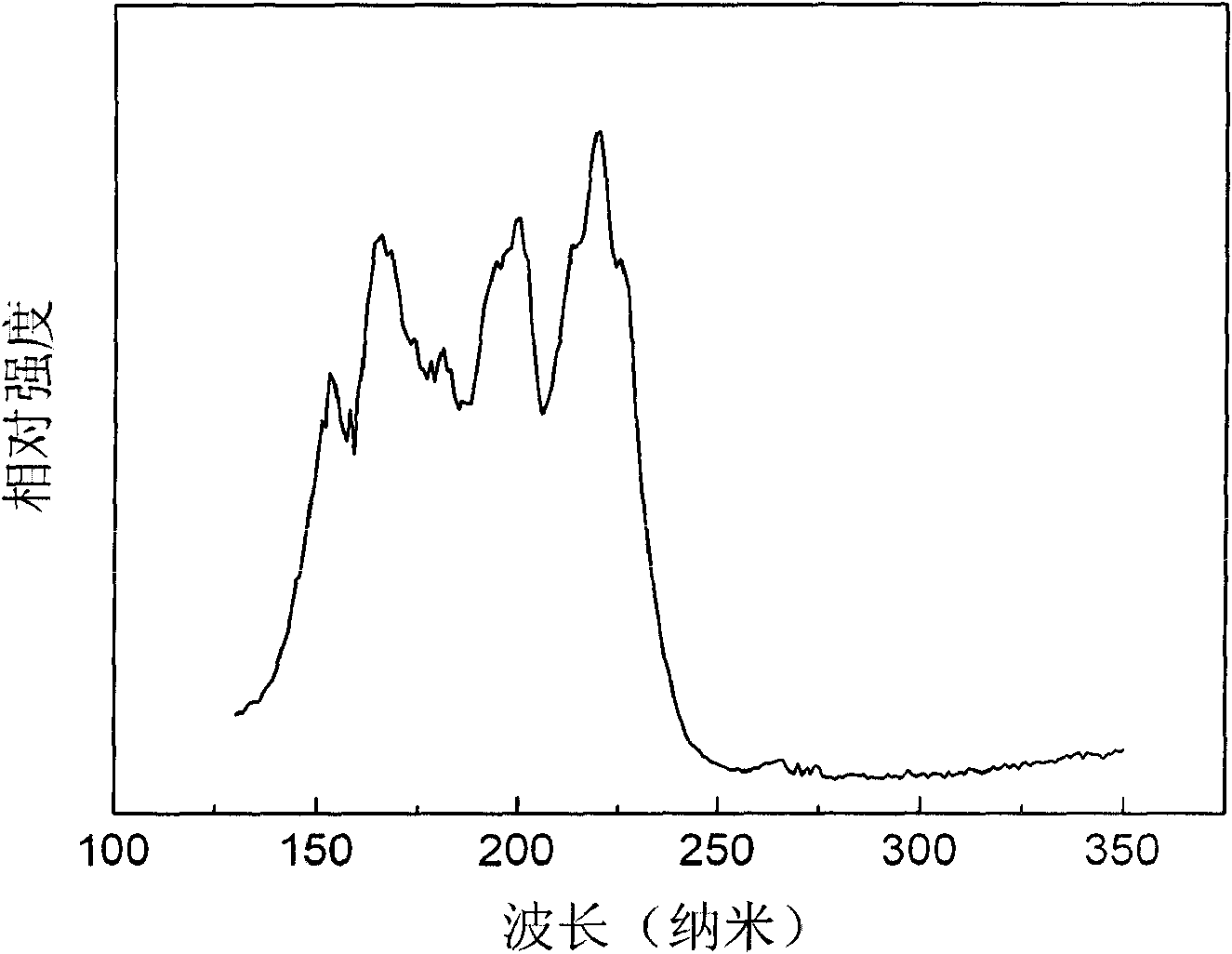

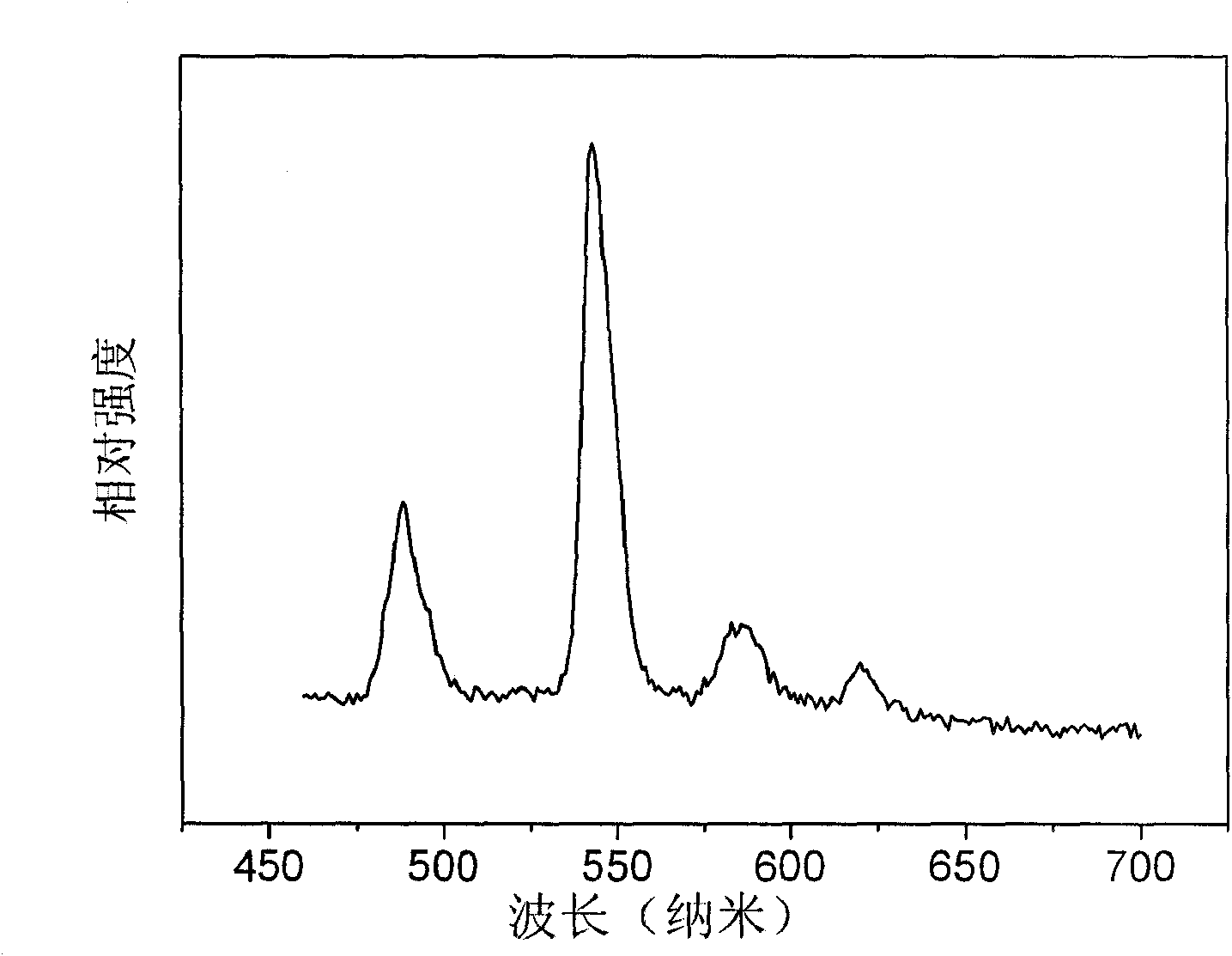

Vacuum ultraviolet induced green emitting phosphor and preparation method thereof

The invention provides vacuum ultraviolet induced green emitting phosphor which is characterized by having the following concrete chemical formula: M3 minus 2xBPO7: Tbx, Rx, wherein x is more than 0 and less than or equal to 0.3, R is one or several of Li, Na and K, and M is one or several of Mg, Zn, Ca, Sr and Ba. The invention also provides a method for preparing the green emitting phosphor, comprising the following steps: firstly, weighing corresponding raw materials according to the weight ratio expressed in the chemical formula; secondly, carrying out high-temperature roasting on the raw materials and rinsing coasted materials; and thirdly, carrying out separation, filtration, size grading and drying on the rinsed materials to obtain the vacuum ultraviolet induced green emitting phosphor having stable chemical property, short after time and excellent luminance.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Zinc, manganese silicate gree luminous fluorescent powder and its preparing method

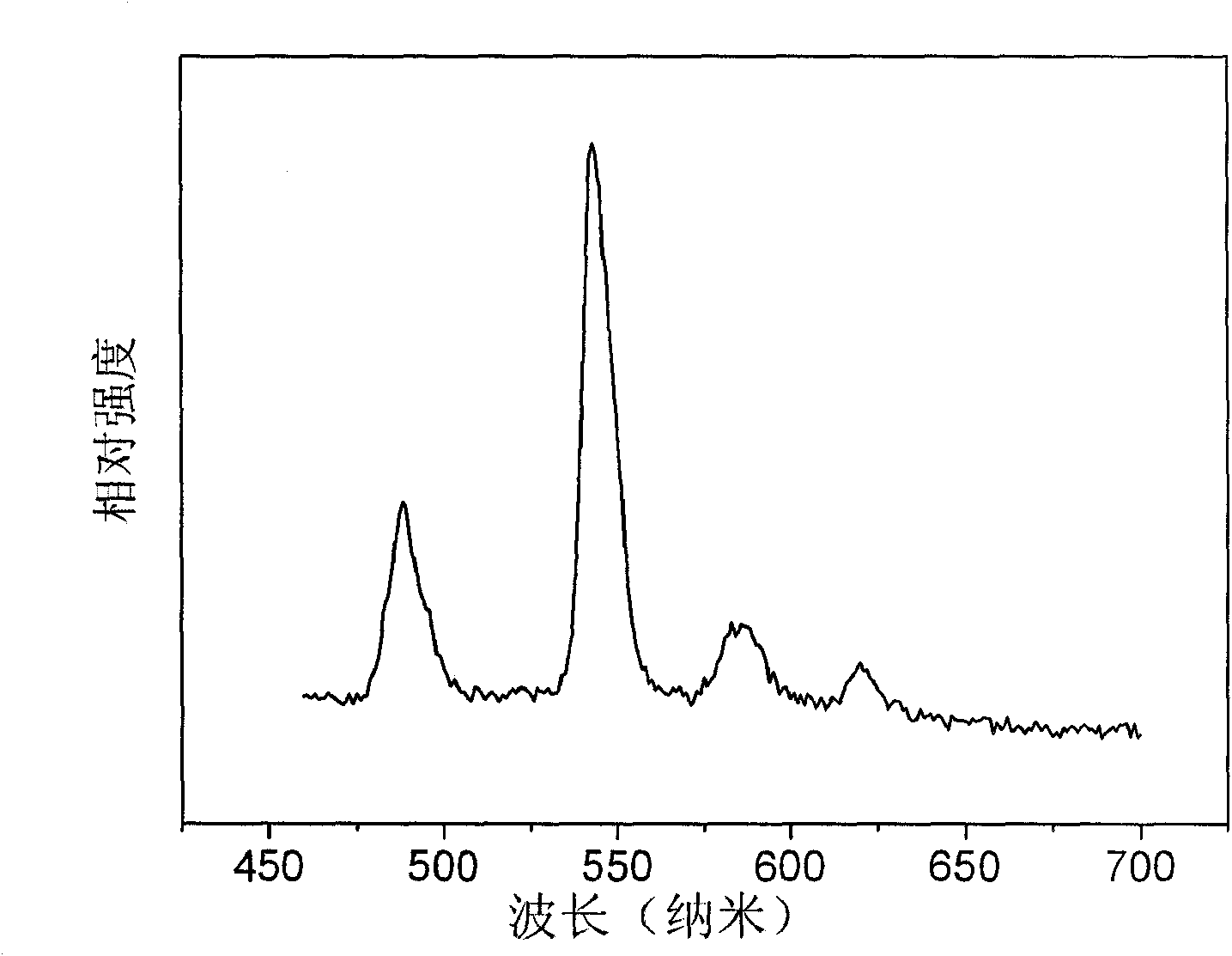

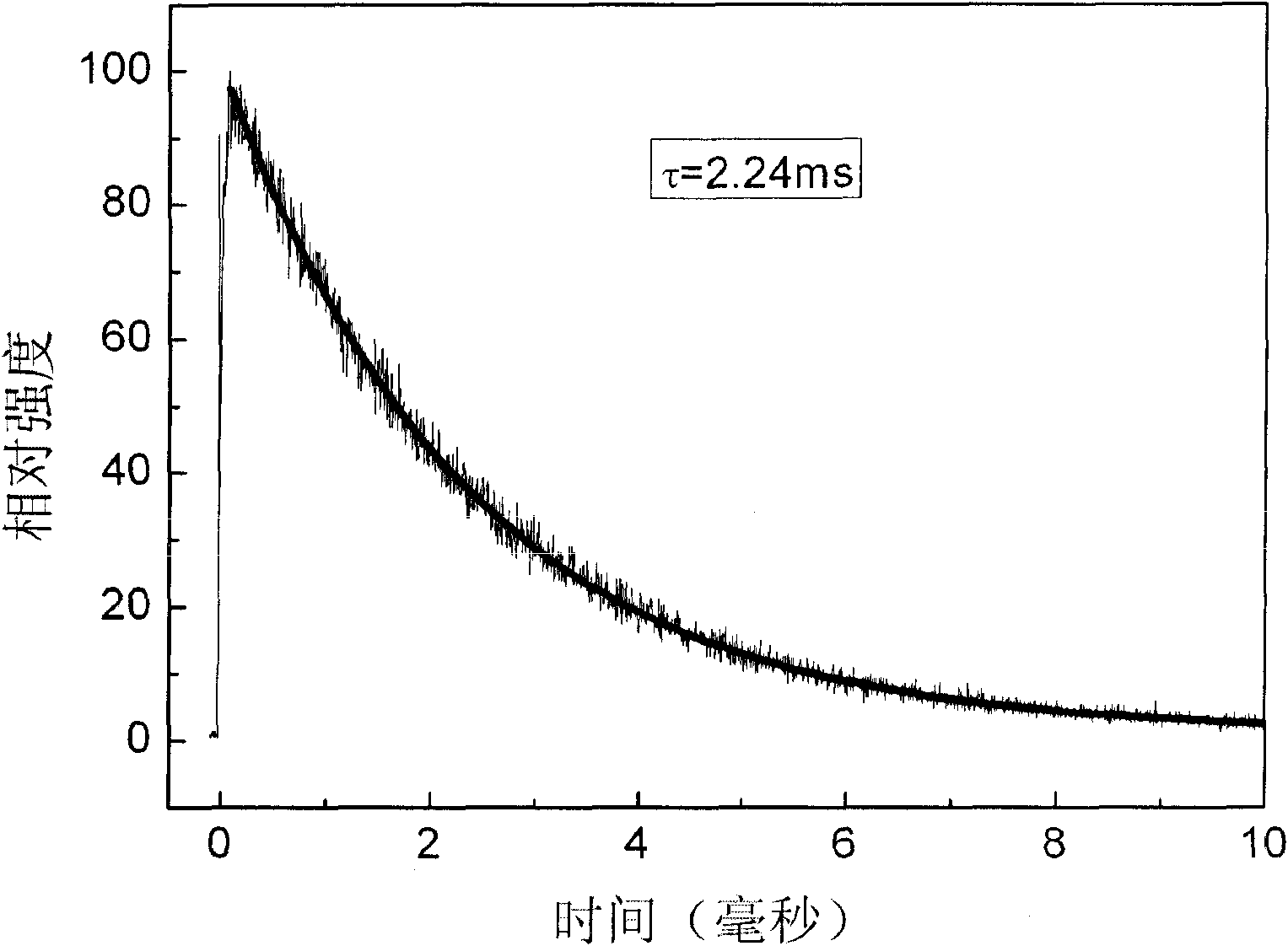

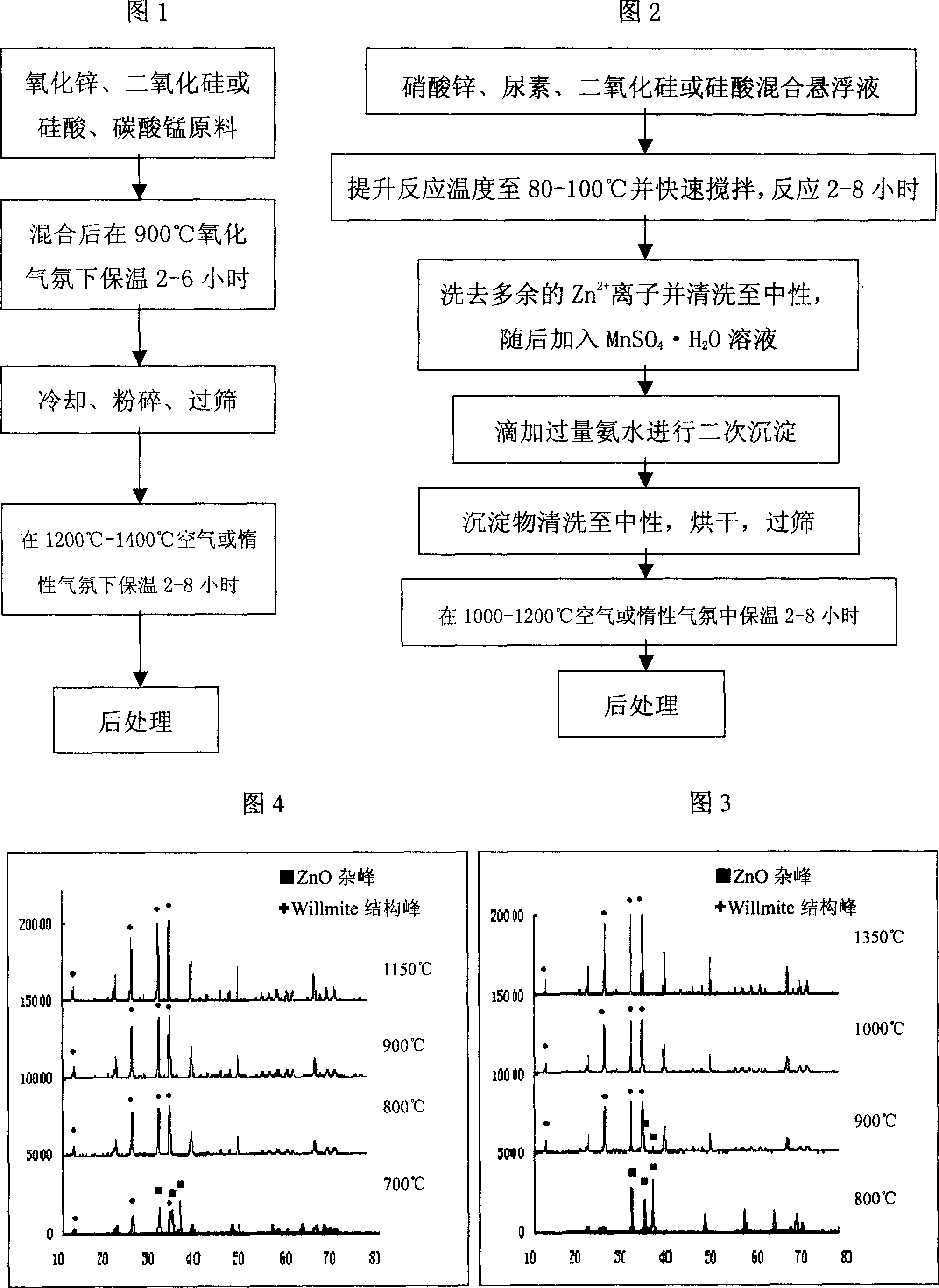

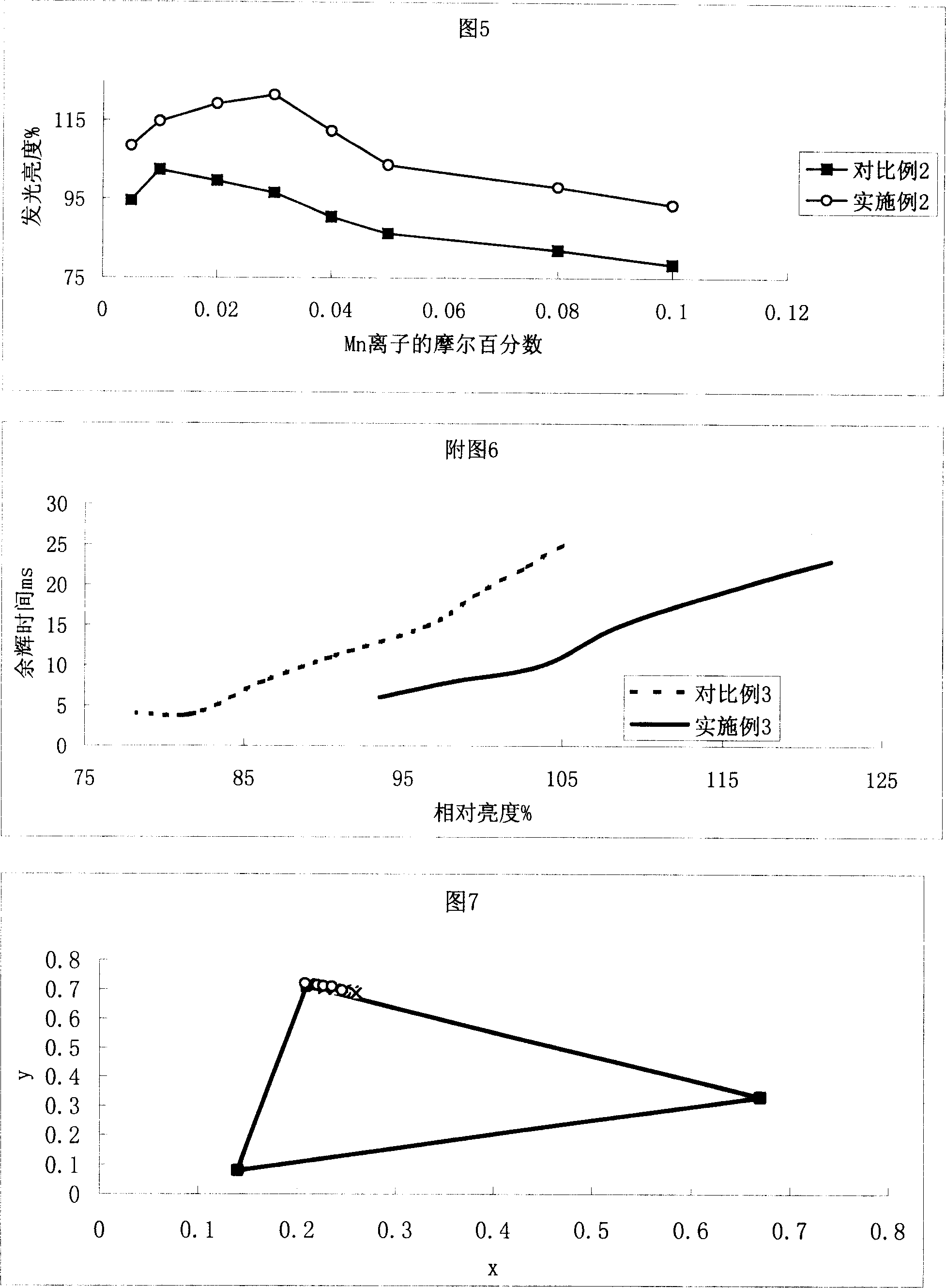

InactiveCN101024768ASynthesis temperature is lowShort afterglow timeLuminescent compositionsIlluminated signsIon distributionManganese

The invention relates to zinc silicate manganese green emitting fluorescent powder and the manufacture method. It includes the following steps: adding SiO2 or silica slurry into zinc nitrate and urea water solution to make suspension, manganese sulfate solution, dropping excessive ammonia to generate precipitate; keeping temperature of precipitate in air or inert gas and gaining the fluorescent powder after processed. The feature is that the grain size is normally 1um, and has equally manganese ion distribution, and the keeping temperature declines about 200 degree centigrade. The invention has good emitting performance and persistent quality.

Owner:YUELONG NEW MATERIAL SHANGHAI

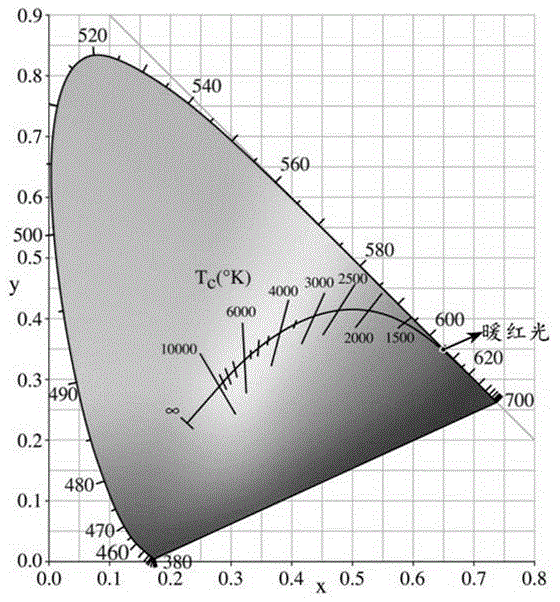

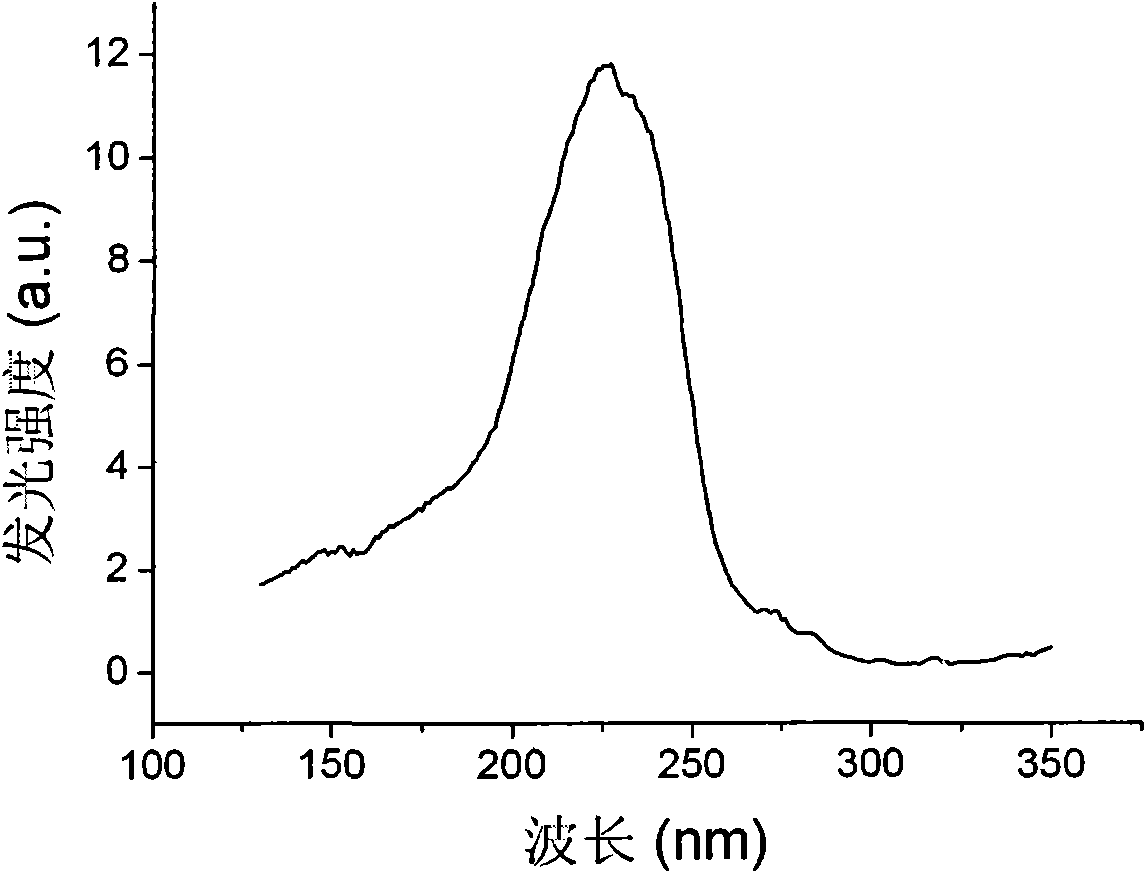

Warm white fluorescent powder excited by ultraviolet LED

ActiveCN105623660AHigh luminous intensitySimple preparation processLuminescent compositionsChemistryLead field

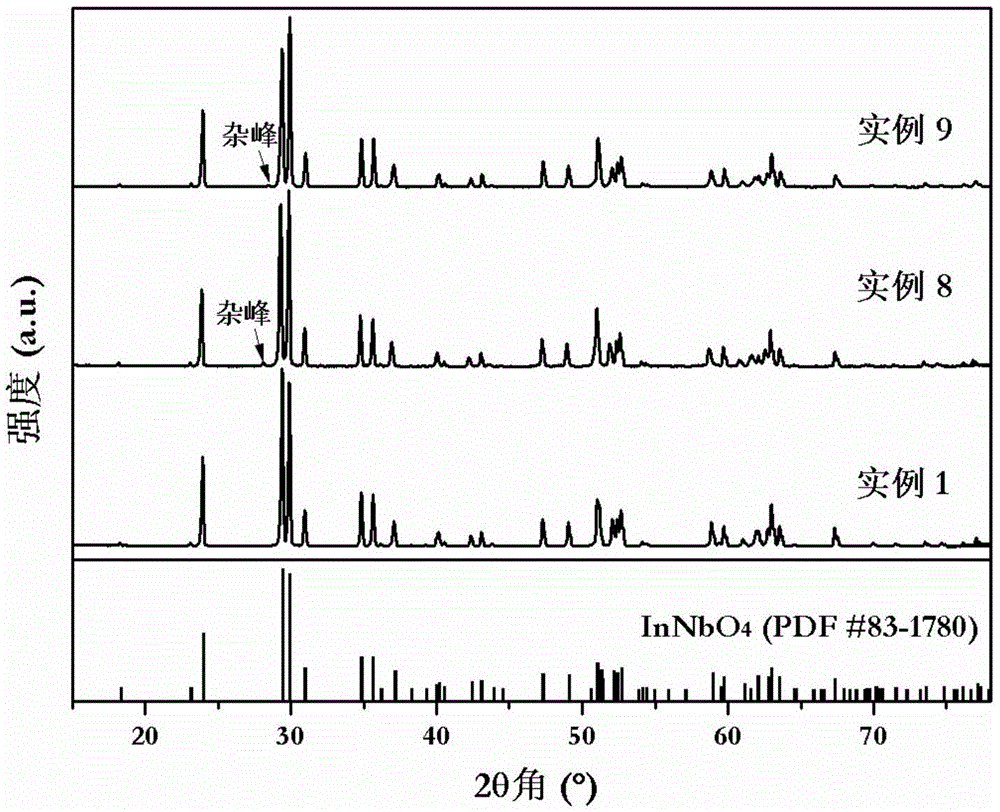

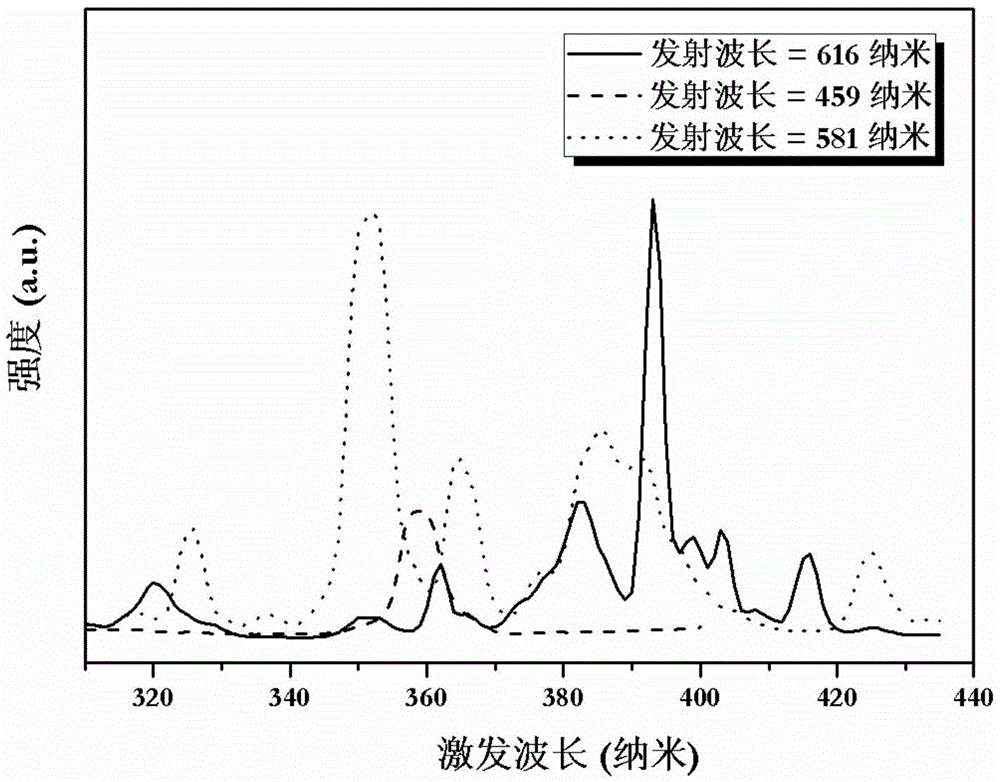

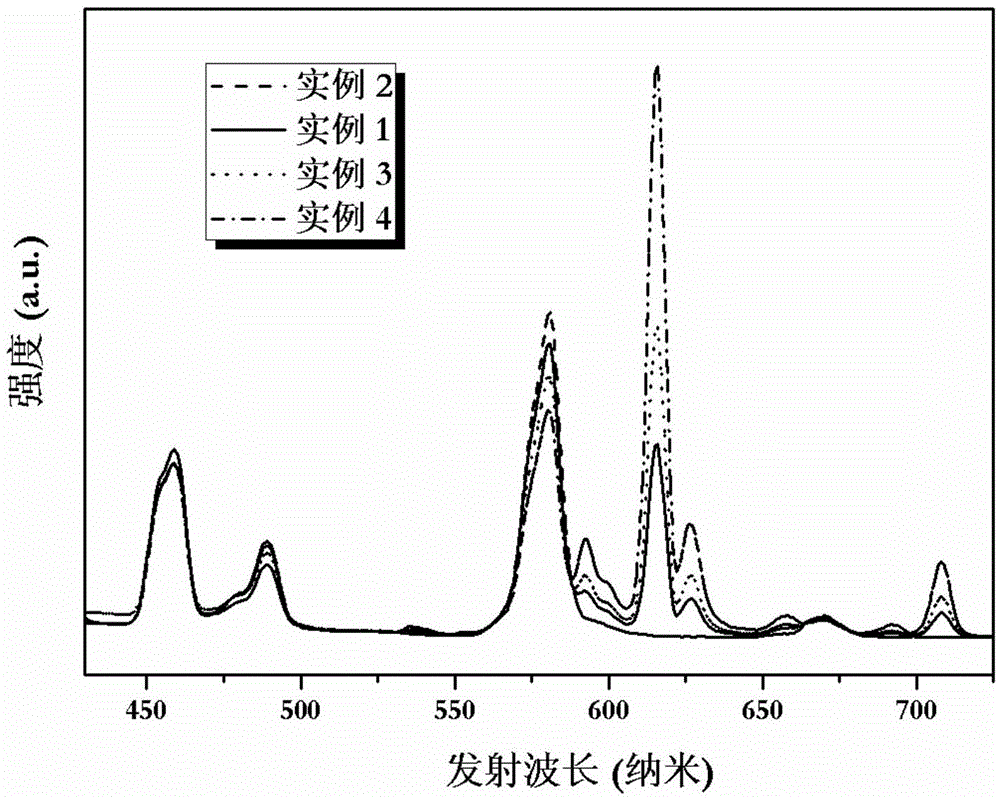

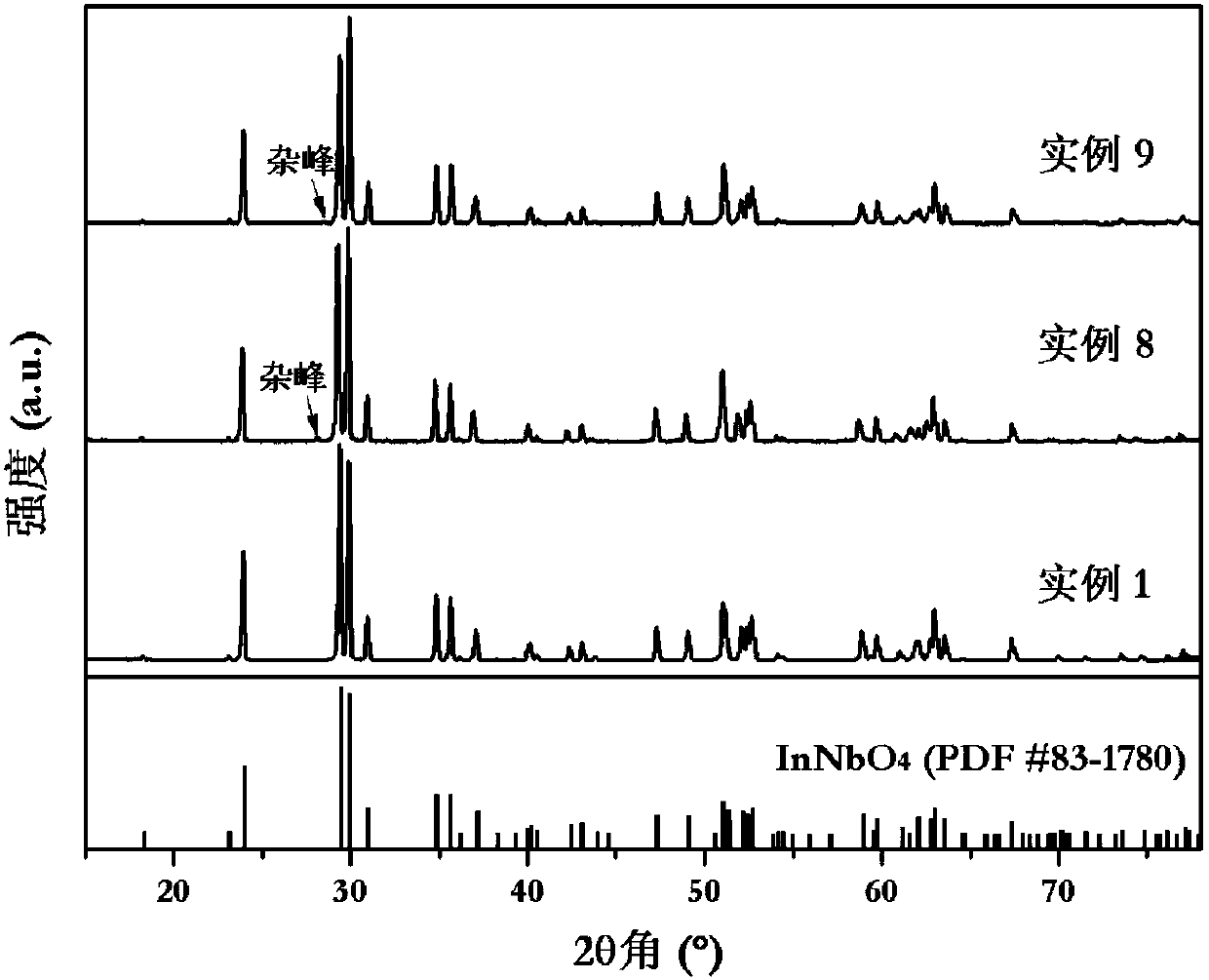

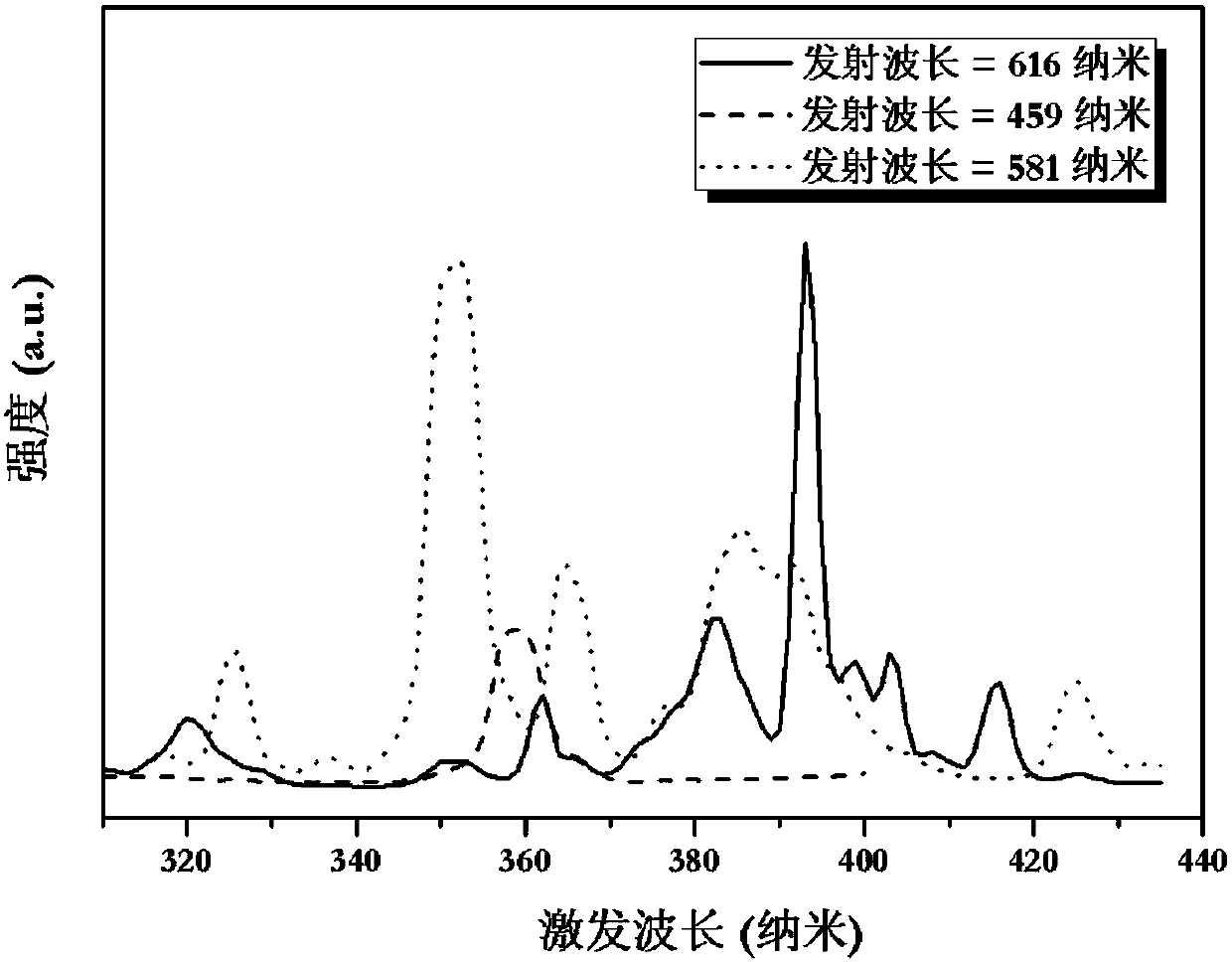

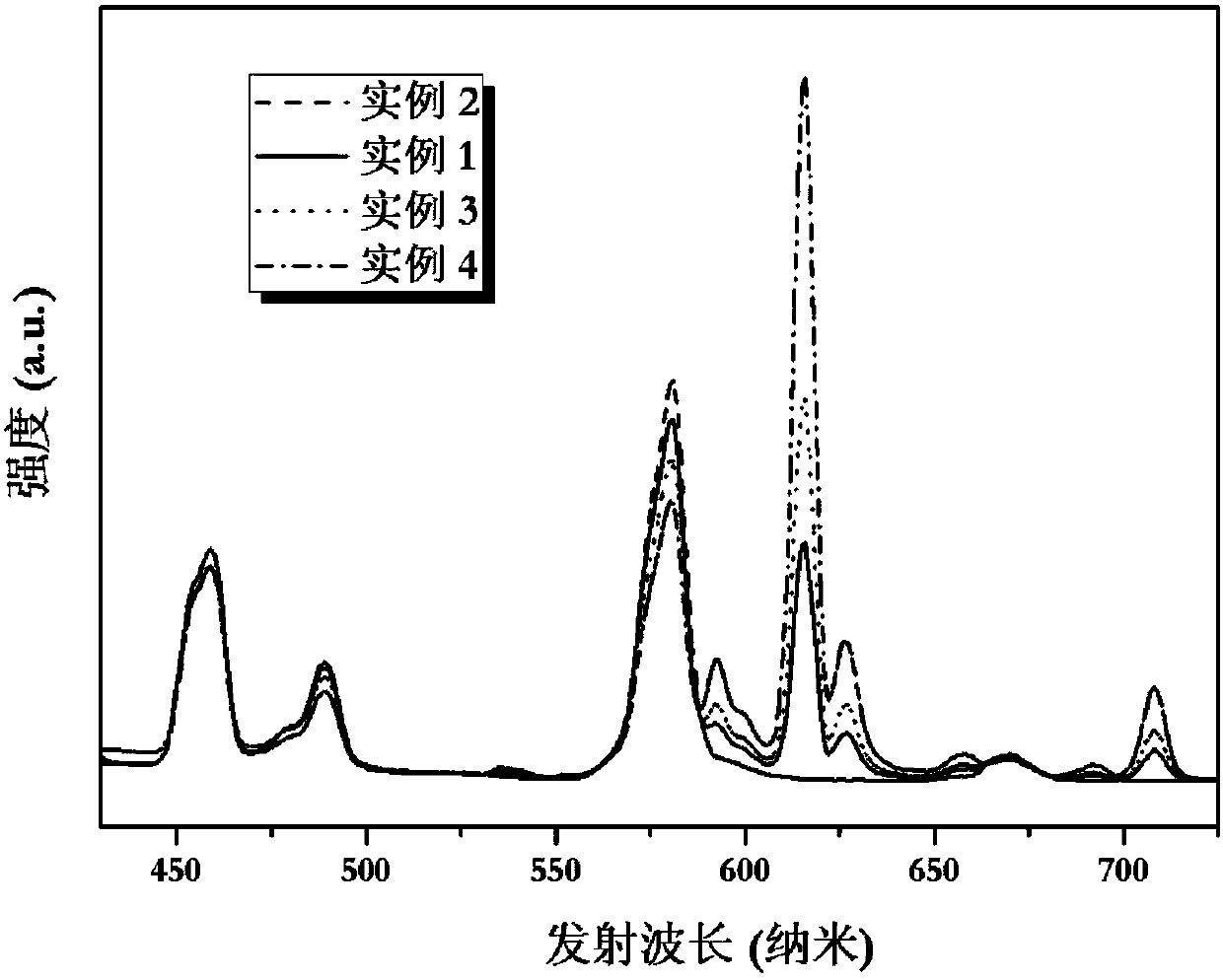

The invention relates to a warm white fluorescent powder excited by an ultraviolet LED. According to the fluorescent powder, InNbO4 serves as a host material, and the warm white fluorescent powder In1-x-y-zDyxTmyEuzNbO4 is obtained by simultaneously doping rare earth ions such as 0.01-0.05at.% of Dy3+, 0.01-0.05at.% of Tm+3+ and 0-0.03at.% of Eu3+ into the In3+ position, wherein x ranges from 0.01 to 0.05, y ranges from 0.01 to 0.05, and z ranges from 0 to 0.03. The rare-earth-doped niobate-based warm white fluorescent powder for the LED has the advantages of being simple in preparing process, high in light-emitting intensity, adjustable in color, capable of achieving a warm color, short in fall time, good in stability and the like, and can be widely applied to the LED field.

Owner:CENT SOUTH UNIV

Self-activated titanoniobate-based fluorescent powder and preparation method thereof

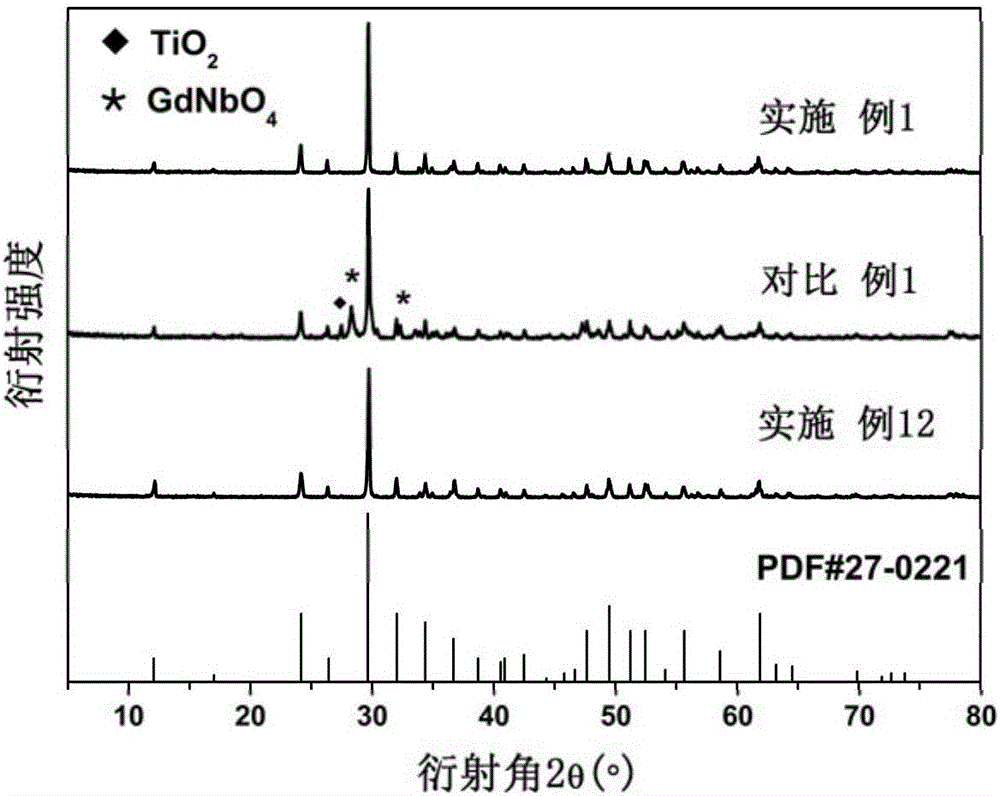

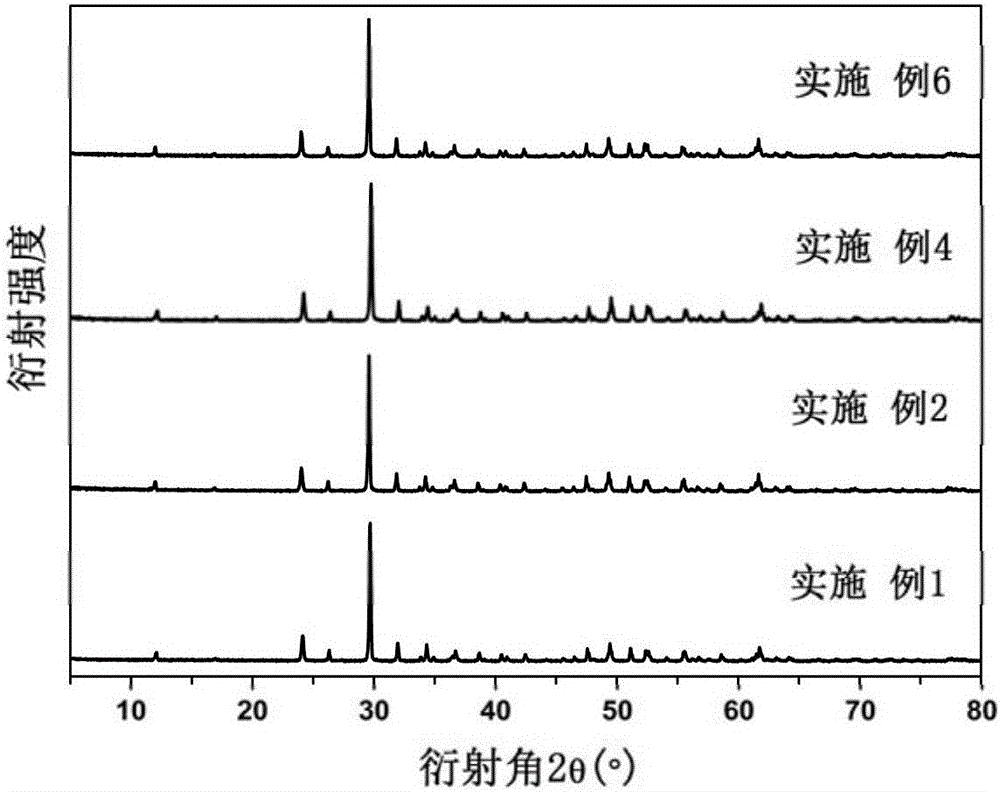

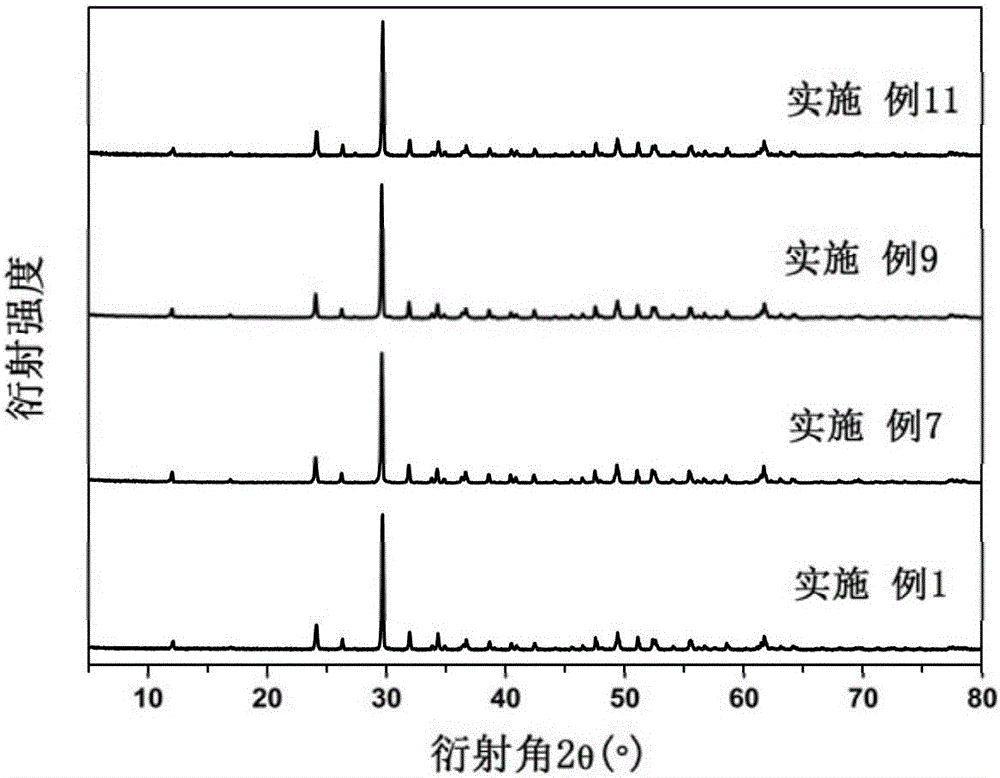

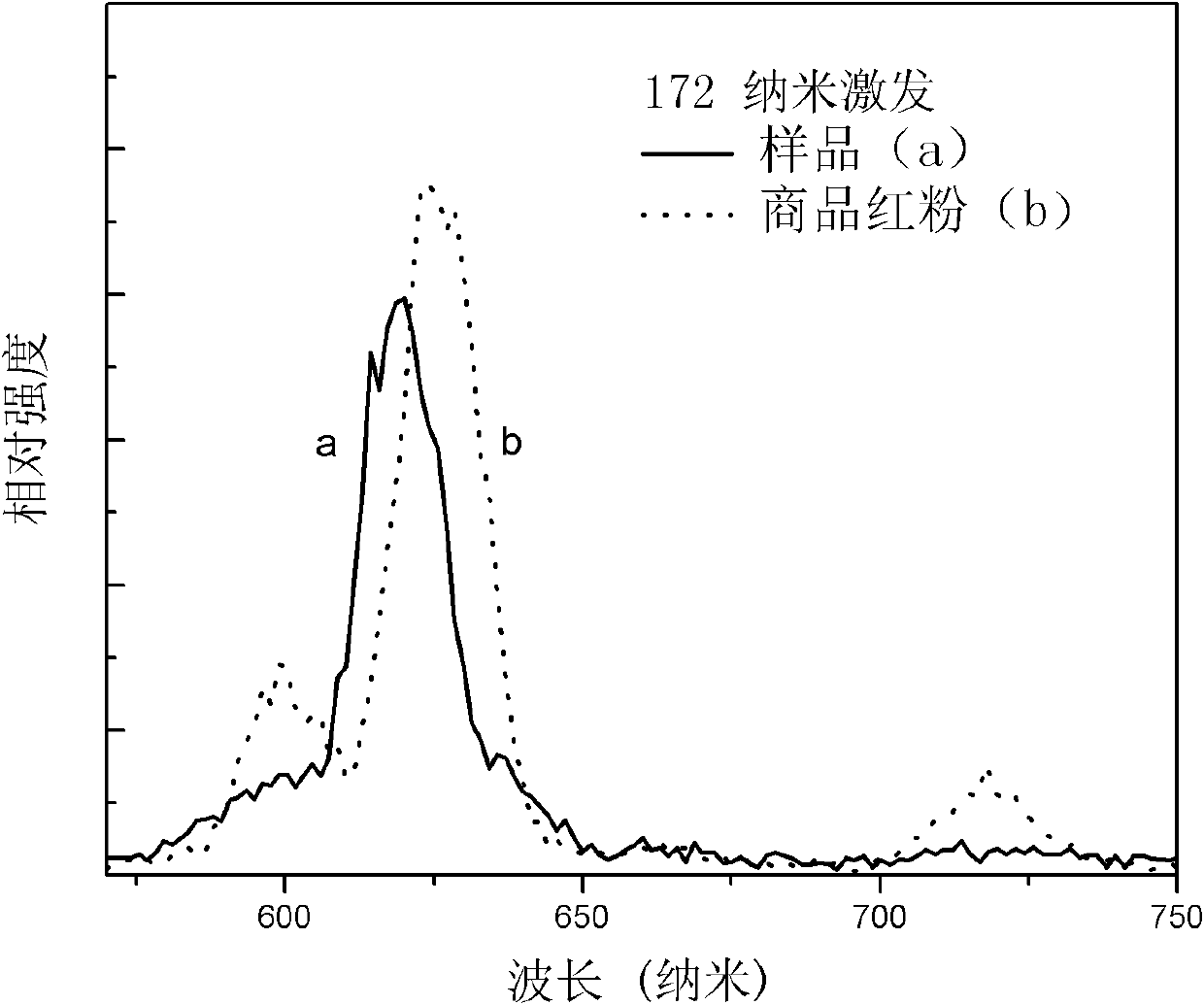

InactiveCN106433642AHigh luminous intensityShort afterglow timeLuminescent compositionsNon toxicityRare earth ions

The invention discloses a self-activated titanoniobate-based fluorescent material and a preparation method thereof. The series of fluorescent powder is prepared by the following steps: taking GdNbTiO6 as a matrix, doping rare earth ions Eu3<+> and Dy<3+>, thereby obtaining a red fluorescent material Gd<1-x>NbTiO6:xEu3<+> and yellow green fluorescent powder Gd<1-y>NbTiO6:yDy3<+>, wherein x is equal to 0.01-0.05, and y is equal to 0.01-0.05. The process flow disclosed by the invention is safe, simple and easy to control. The prepared fluorescent material has the advantages of high chemical stability, non-toxicity, zero radiation, high brightness, high color purity, high conversion efficiency and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Red fluorescent powder for PDP (Plasma Display Panel) and preparation method thereof

The invention discloses a red fluorescent powder for a PDP (Plasma Display Panel) and a preparation method thereof. The chemical formula of the red fluorescent powder is (Y1-x-y-zEuxREyRz)2O3, wherein x is not less than 0.005 and not more than 0.40, y is not less than 0.005 and not more than 0.40, z is not less than 0.005 and not more than 0.10, RE is rare-earth metal and R is alkali metal. The main light-emitting ion in the red fluorescent powder disclosed by the invention is Eu<3+>. Under the excitation of vacuum ultraviolet (VUV) light, after absorbing a certain amount of energy, the red fluorescent powder can transfer the energy to the Eu<3+>; the Eu<3+> produces red emission and an auxiliary ion R results in lattice distortion of the red fluorescent powder, so that the afterglow time of the Eu<3+> can be shortened effectively; moreover, the raw material for synthesis of the red fluorescent powder is non-toxic, the preparation process is simple and the industry production is easily realized.

Owner:SICHUAN COC DISPLAY DEVICES

Preparation method of zinc manganese silicate fluorescent powder with short afterglow

InactiveCN104212443AHigh luminous intensityShort afterglow timeLuminescent compositionsManganese(II) carbonateLuminous intensity

The invention discloses a preparation method of zinc manganese silicate fluorescent powder with short afterglow. The fluorescent powder is prepared by a high temperature solid state method, wherein the source of Mn is ZnMn2O4 instead of conventional manganese oxide or manganese carbonate or other compounds. The zinc manganese silicate green fluorescent powder prepared by the method is high in luminous intensity and short in afterglow time, thus completely meeting the requirement on 3D plasma display. The preparation method does not change existing technology of preparing the zinc manganese silicate fluorescent powder by the high temperature solid state method, thus being easy to implement industrially, and very applicable to scale production.

Owner:SOUTHEAST UNIV

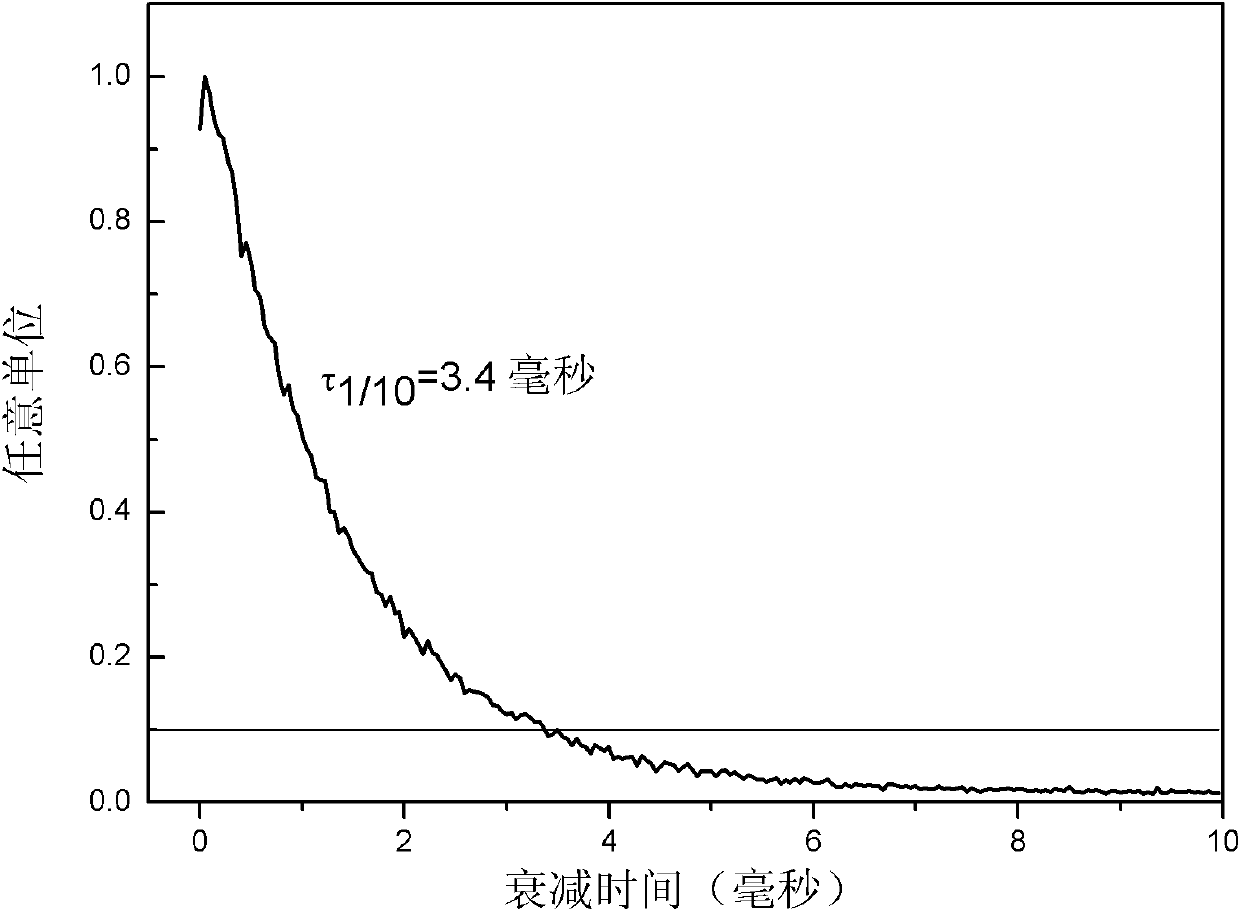

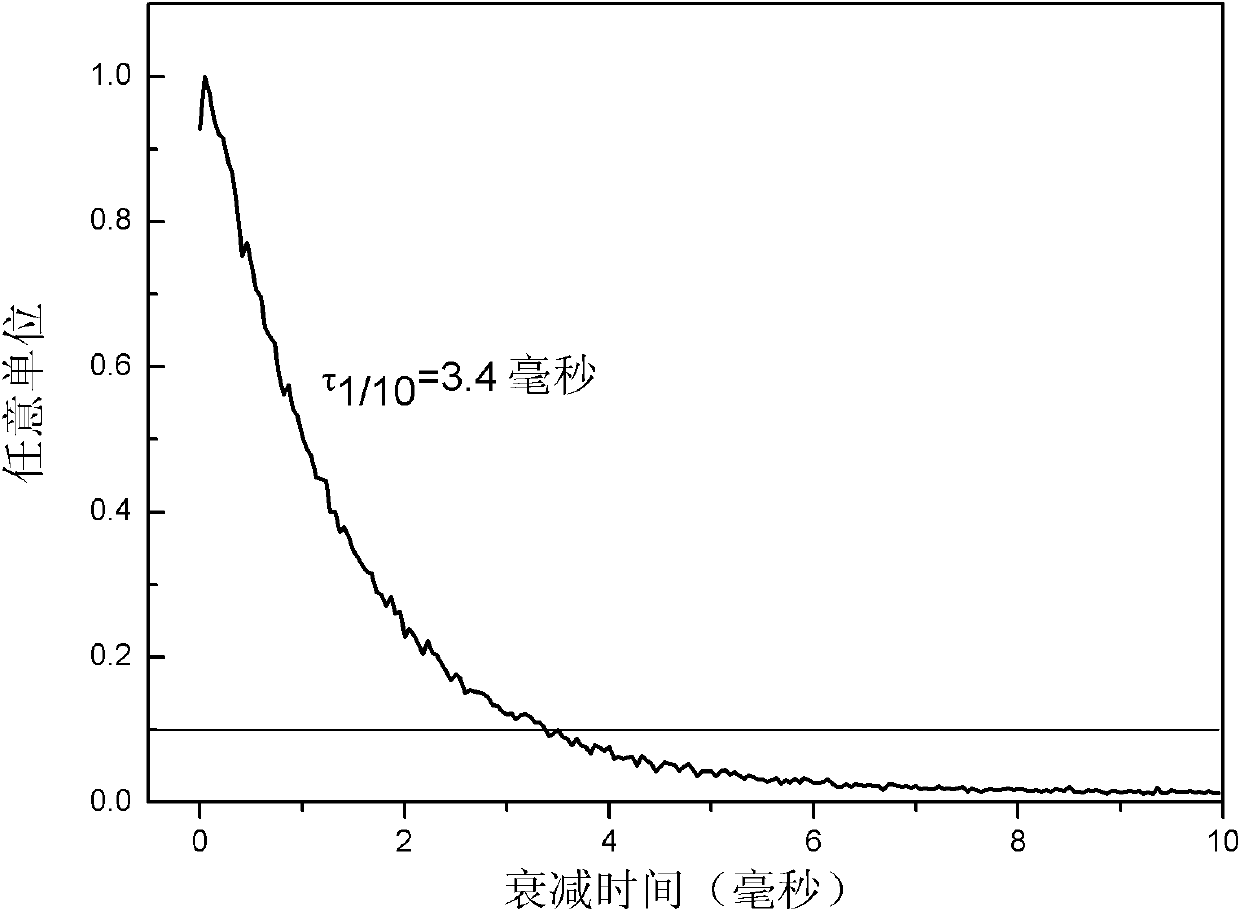

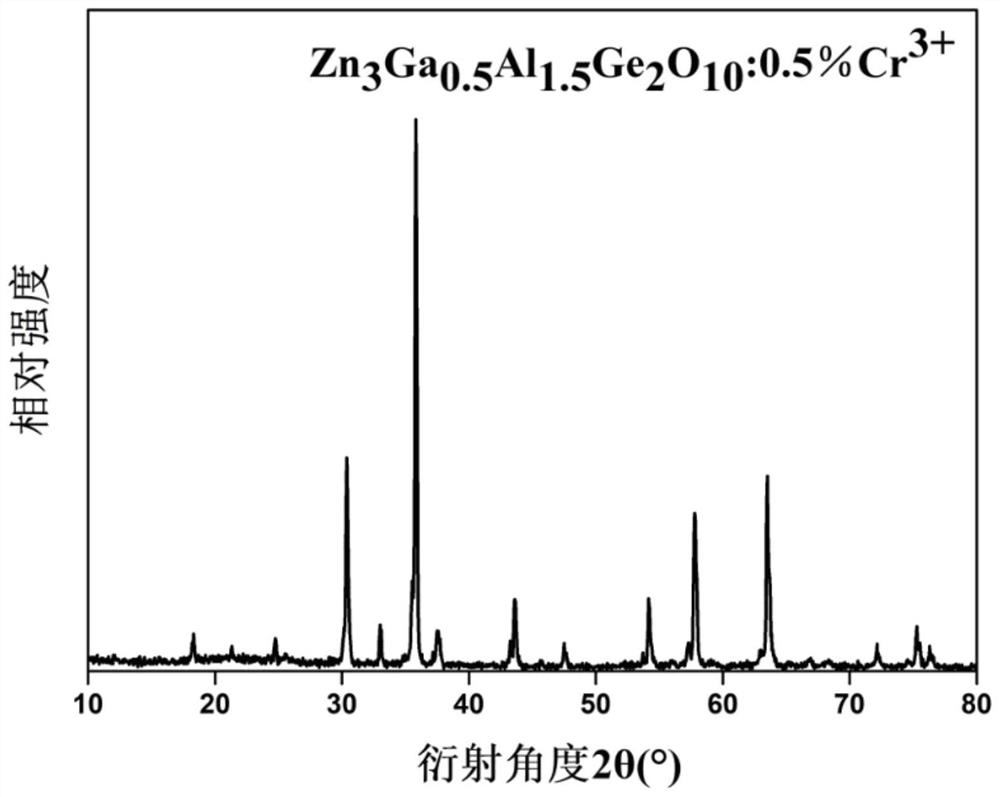

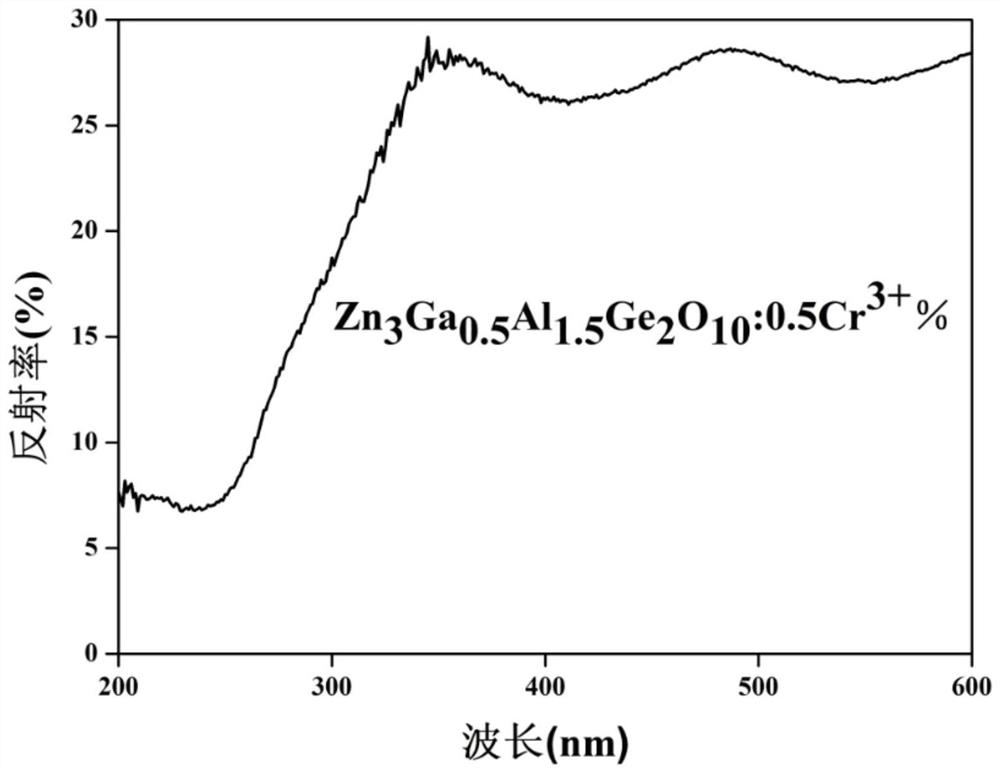

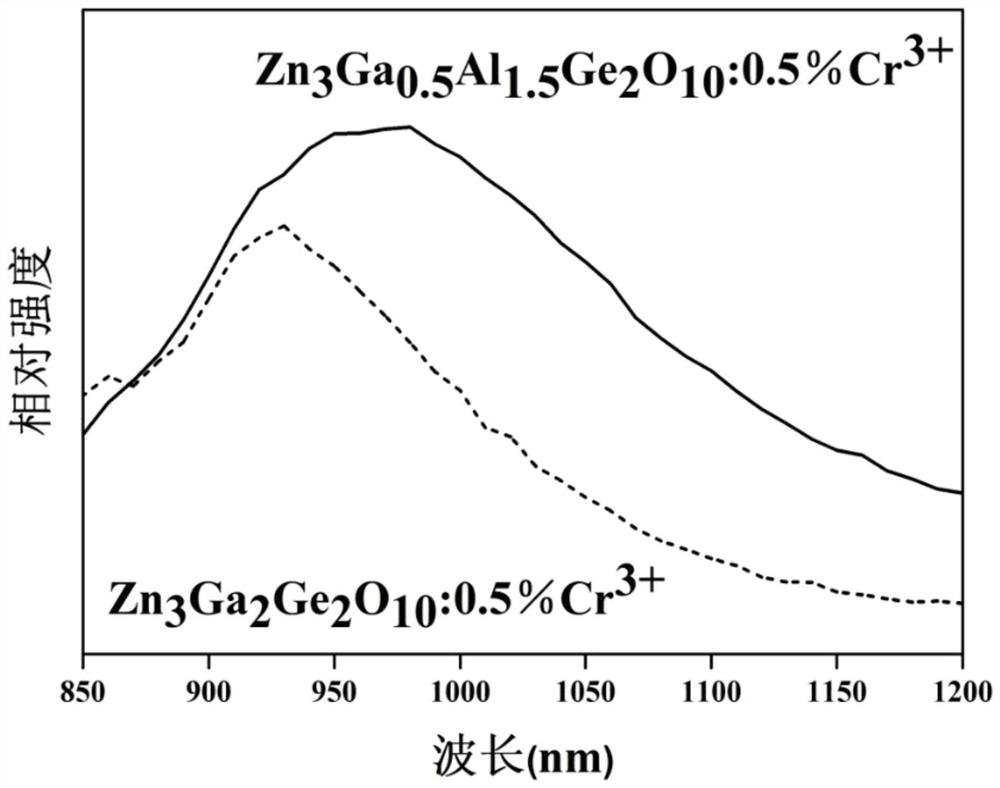

Cr < 3 + >-doped gallium aluminate near-infrared long-afterglow luminescent material and preparation method thereof

The invention discloses a Cr < 3 + >-doped gallium aluminate near-infrared long-afterglow luminescent material and a preparation method thereof. The general chemical formula of the near-infrared long-afterglow luminescent material is Zn3GaxAl2-xGaeTibSn2-a-bO10: yCr < 3 + >. The preparation method comprises the following steps: weighing the raw materials according to the molar ratio of the substances in the equation, adding the fluxing agent, grinding in an agate mortar, and uniformly mixing to obtain a precursor; putting the precursor into an alumina crucible, and pre-sintering in an air or neutral atmosphere; and grinding and uniformly mixing a sample obtained by presintering, and calcining in air or neutral atmosphere to obtain the Cr < 3 + > gallium aluminate near-infrared long-afterglow luminescent material. The near-infrared long-afterglow fluorescent powder disclosed by the invention has the advantages of low raw material cost, simplicity and feasibility in operation, low requirements on equipment and the like. The long-afterglow luminescent material has the advantages that the emission range is located in a near-infrared region, and the long-afterglow luminescent material is long in afterglow time and the like.

Owner:SHANGHAI INST OF TECH

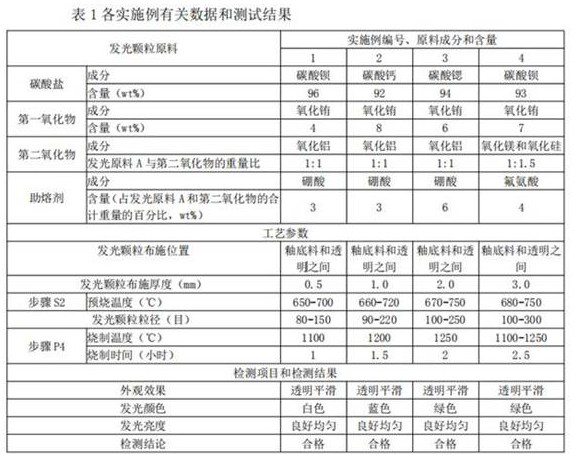

Co-firing method-based luminous ceramic tile preparation process, and luminous ceramic tile prepared by same

InactiveCN112010679AHas a luminous effectAvoid erosionLuminescent compositionsClaywaresMolten stateGlaze

The invention relates to the technical field of ceramics, and discloses a light-emitting ceramic tile based on a co-firing method preparation process, and the preparation process thereof. The preparation process comprises a luminous particle pre-sintering step and a finished product preparation step, wherein the luminous particle pre-sintering step comprises: S1) preparing luminous slurry; S2) putting the luminous slurry into an electric furnace, and presintering at 600-700 DEG C to remove impurities, so as to obtain luminous particles; and the preparation step of the finished product comprises: P1) applying a first viscous material on the surface of a green body to form a lower viscous layer on the green body; P2) applying the luminous particles to form a luminous layer on the green body;P3) applying transparent glaze to form a transparent glaze layer on the green body, and P4) placing the green body in a kiln, and firing at 1100-1250 DEG C to prepare the luminous ceramic tile. The luminous layer can prevent liquid in the transparent glaze from eroding and damaging particles of luminous powder in a fired molten state, and the prepared ceramic product is high in luminous brightness and long in luminous life.

Owner:佛山市东鹏陶瓷发展有限公司

Green photoluminescent phosphor and its prepn

InactiveCN1810922AImprove luminous efficiencyHigh color purityLuminescent compositionsWater bathsPhotoluminescence

The present invention relates to new material, and is especially new type of green photoluminescent phosphor and its preparation. The phosphor is RE Tb activated aluminate green phosphor in the expression of M1-XAl12O19:Tb3+x, where, M is Ba2+, Sr2+ and Ca2+, and x is 0.005-0.06. The phosphor is prepared through either a solid phase process including mixing and grinding materials terbium oxide, alumina, barium carbonate and boron oxide, and roasting for over 2 hr; or a sol-gel process including dissolving barium carbonate, aluminum nitrate a RE nitrate in citric acid solution, heating and stirring in water bath to form sol, drying the sol to form loose black powder, grinding and high temperature roasting. The phosphor has short afterglow, high light emitting strength, high light emitting efficiency, and small and homogeneous grain size.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Phosphor, process for producing phosphor and luminescent device

InactiveUS20070210692A1High bulk densitySuppress luminescenceDischarge tube luminescnet screensElectric discharge tubesLow voltageUltraviolet

A phosphor, comprising a manganese activated zinc silicate phosphor, is comprised of particles having a major-to-minor axis ratio of 1.0 to 1.4. A method for producing the phosphor, comprising burning a phosphor material containing elements constituting a host material of the phosphor and an activator or compounds containing the elements by heating in a heating furnace while flowing or rotating them to manganese activated zinc silicate phosphor particles having a major-to-minor axis ratio of 1.0 to 1.4. Another method for producing the phosphor, comprising burning phosphor material by heating in a heating furnace while flowing or rotating them to obtain a manganese activated zinc silicate phosphor having an afterglow time of less than 9 ms. Thus, a compact phosphor layer with high packing density can be formed, and there can be obtained a phosphor capable of high-luminance green light emission upon excitation by vacuum ultraviolet rays or low-voltage electron beams. Moreover, there can be obtained a manganese-activated zinc silicate phosphor capable of emission of green light of high luminance and short afterglow time upon excitation by vacuum ultraviolet rays or low-voltage electron beams.

Owner:KK TOSHIBA

Green light-emitting fluorescent powder and preparation method thereof

InactiveCN101724398AImprove luminous performanceImprove the display effectLuminescent compositionsLuminous intensityReducing atmosphere

The invention relates to a green light-emitting fluorescent powder, which is characterized in that the chemical formula thereof is M1-x-yRexNyO, wherein M is at least one of Ca, Sr and Ba; Re is at least one of Tb and Gd; N is Li, Na or K; the value of x is more than or equal to 0.001 and less than or equal to 0.3; and the value of y is more than or equal to 0 and less than or equal to 0.3. The preparation method comprises the following steps: weighing raw materials and fluxing agents in proportion; grinding and uniformly mixing the raw materials and the fluxing agents; roasting the mixture at the temperature of between 850 DEG C and 1,300 DEG C in reducing atmosphere for 1 to 24 hours for one to three times; and grinding the roasted mixture after cooling to obtain the green light-emitting fluorescent powder. The green light-emitting fluorescent powder has the advantages of simple preparation method, no pollution, contribution to industrialized production, short afterglow time, high luminous intensity and excellent luminous performance, can be widely used in PDP or mercury-free fluorescent lamps.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

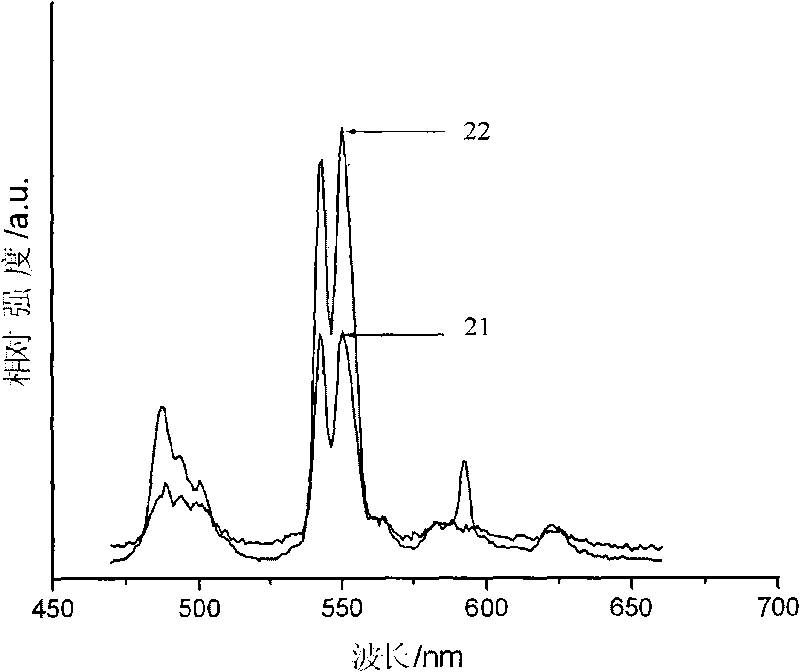

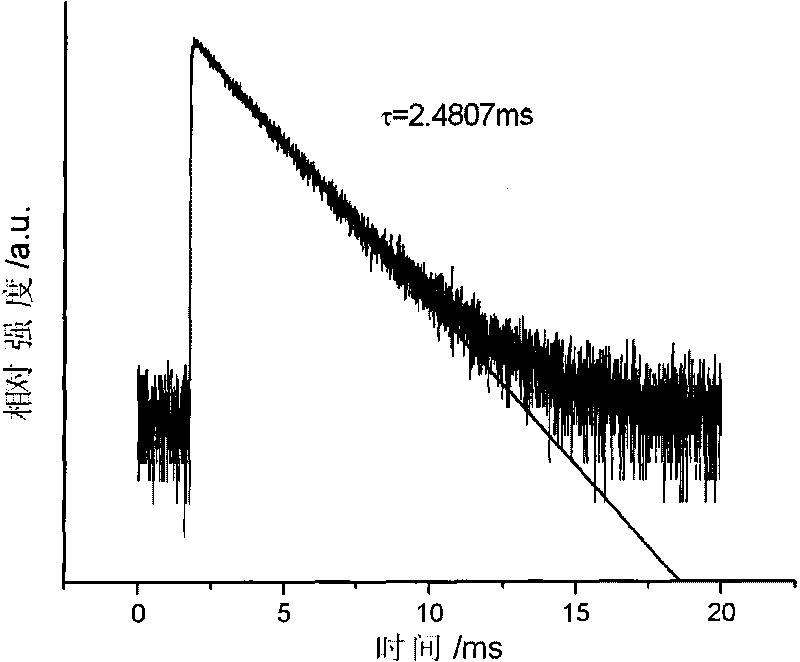

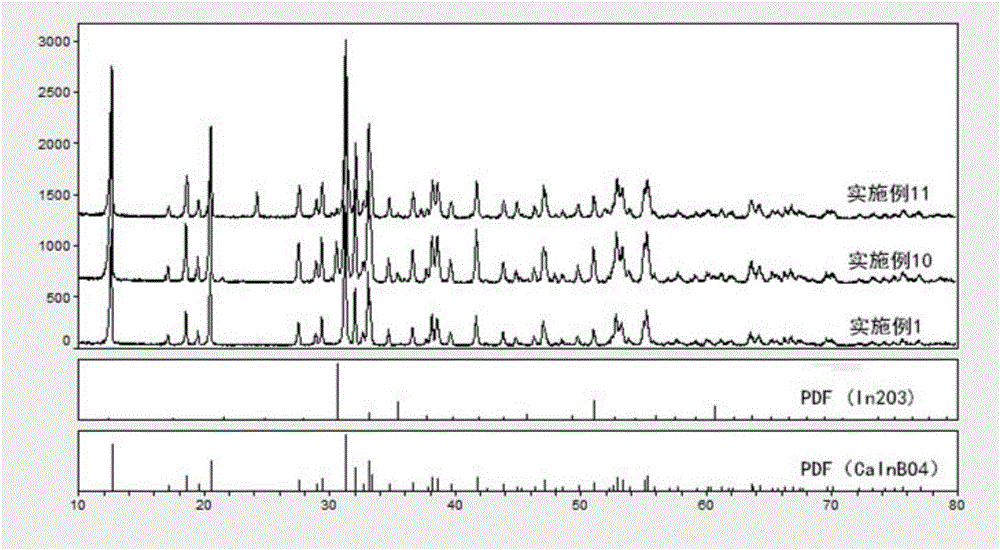

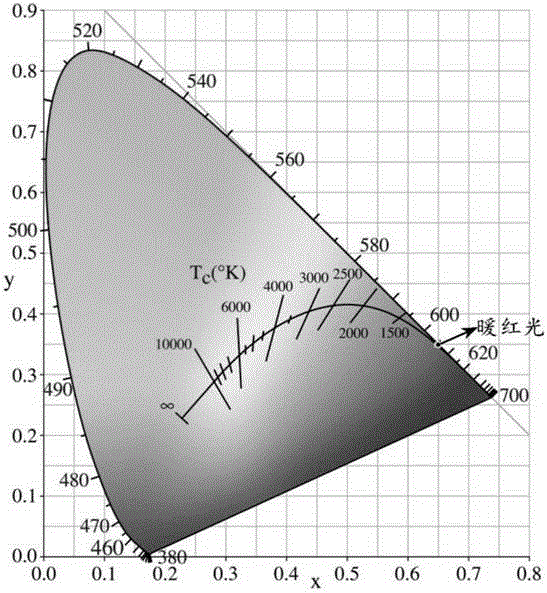

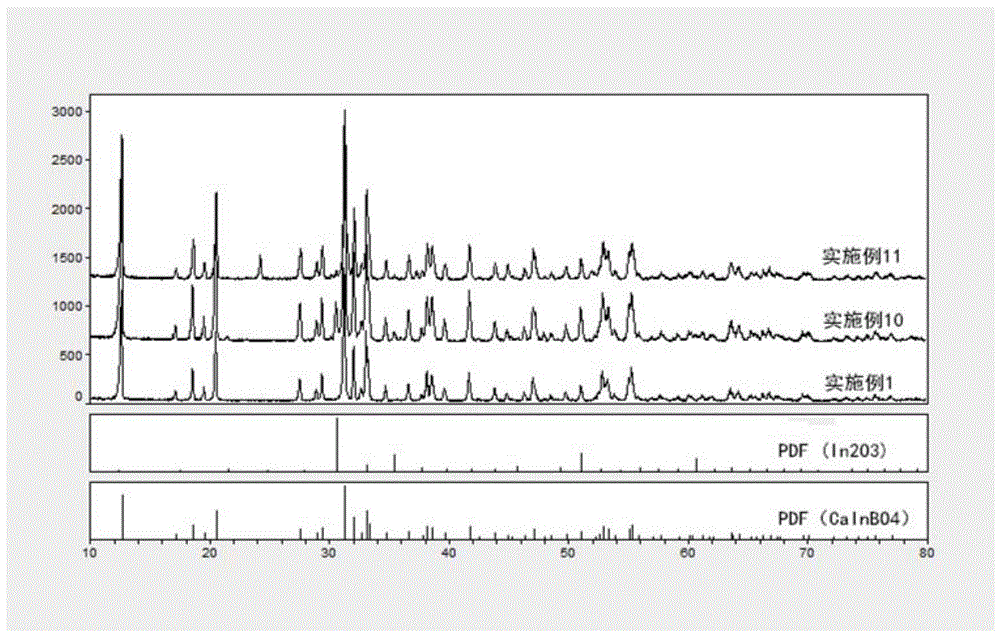

Rare earth borate-based red fluorescent powder

ActiveCN104927855AHigh luminous intensityImprove thermal stabilityLuminescent compositionsLuminous intensityHeat stability

The invention discloses rare earth borate-based red fluorescent powder. According to the fluorescent powder, CaInBO4 is used as a base body, 0.02-0.08 at.% of Al<3+> is doped to enter In<3+> bit, 0.02-0.08 at.% of Ba<2+> is doped to enter Ca<2+> bit and 0.07-0.10 at.% of Eu<3+> is doped to enter In<3+> bit, so that fluorescent powder (In(1-x-z), Alx, Euz)(Ca(1-y), Bay)BO4 is obtained, wherein x is equal to 0.02-0.04, y is equal to 0.05-0.07, and z is equal to 0.07-0.1. The rare earth borate-based red fluorescent powder provided by the invention has excellent properties of high luminous intensity, warm color, rapid decay, short persistence, good heat stability, easiness in long-term preservation and wide application range.

Owner:CENT SOUTH UNIV

Low-pressure gas discharge lamp

InactiveCN101473015AShort decay timeShort afterglow timeLuminescent compositionsGas discharge lamp detailsGas-discharge lampHertz

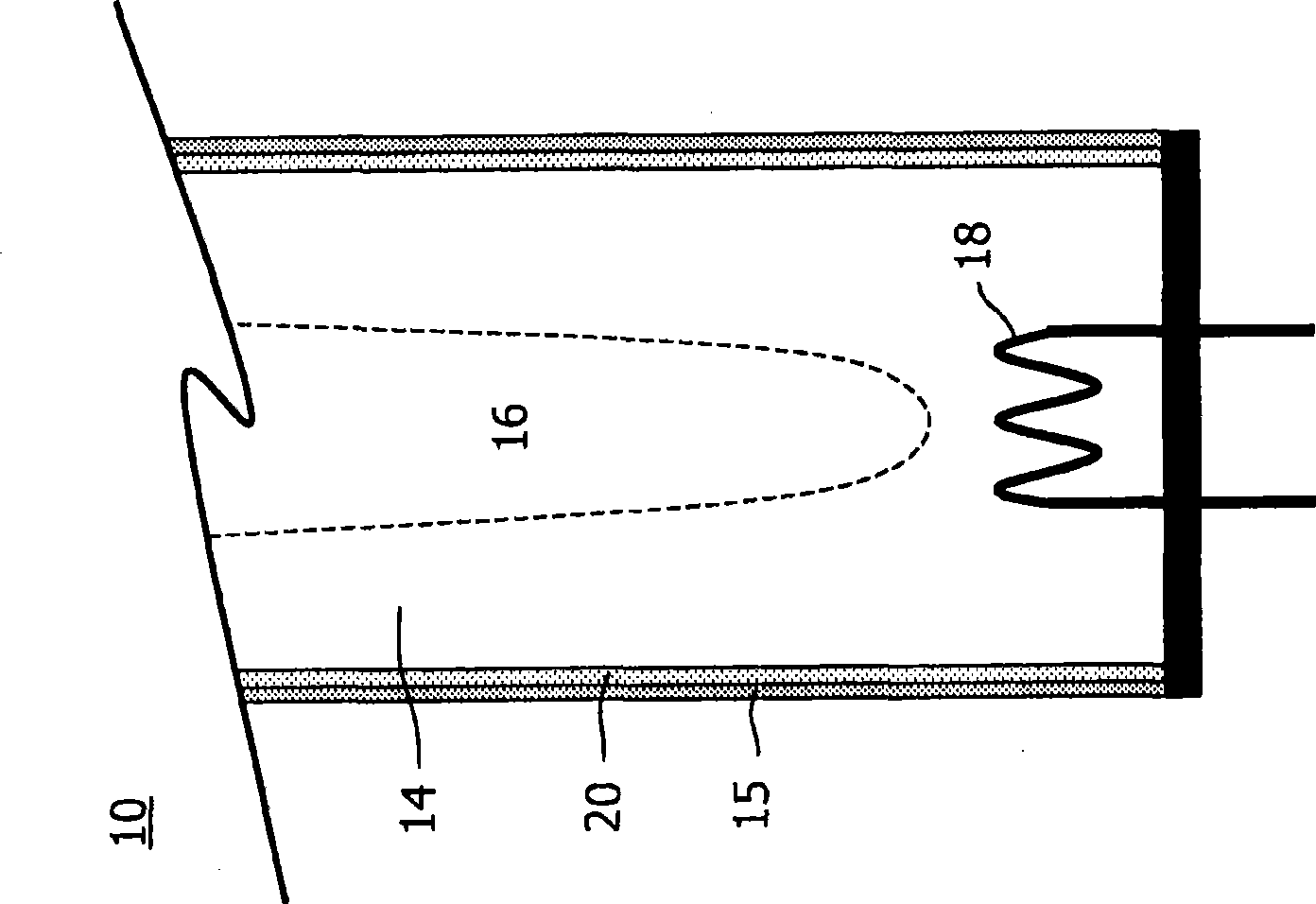

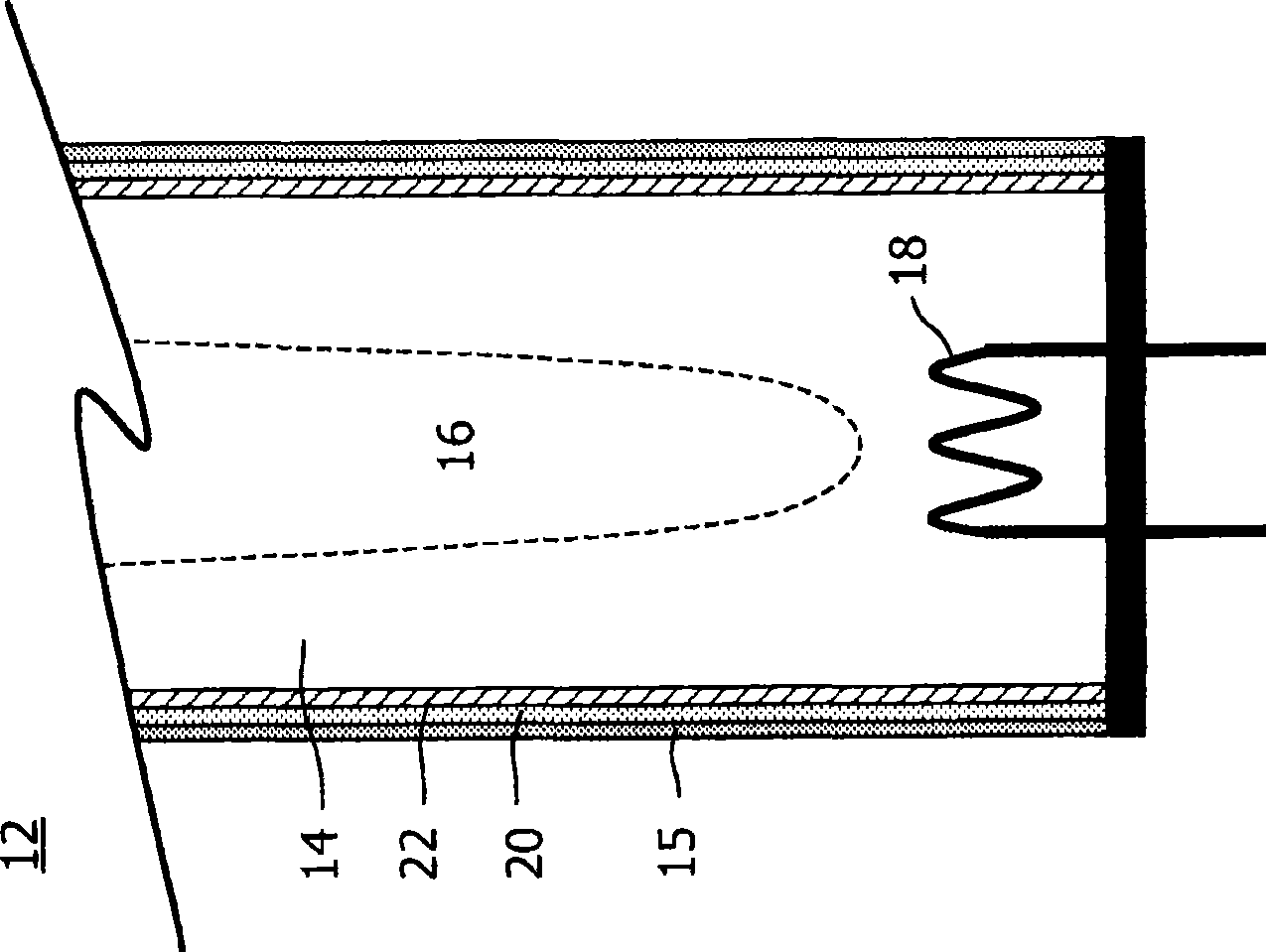

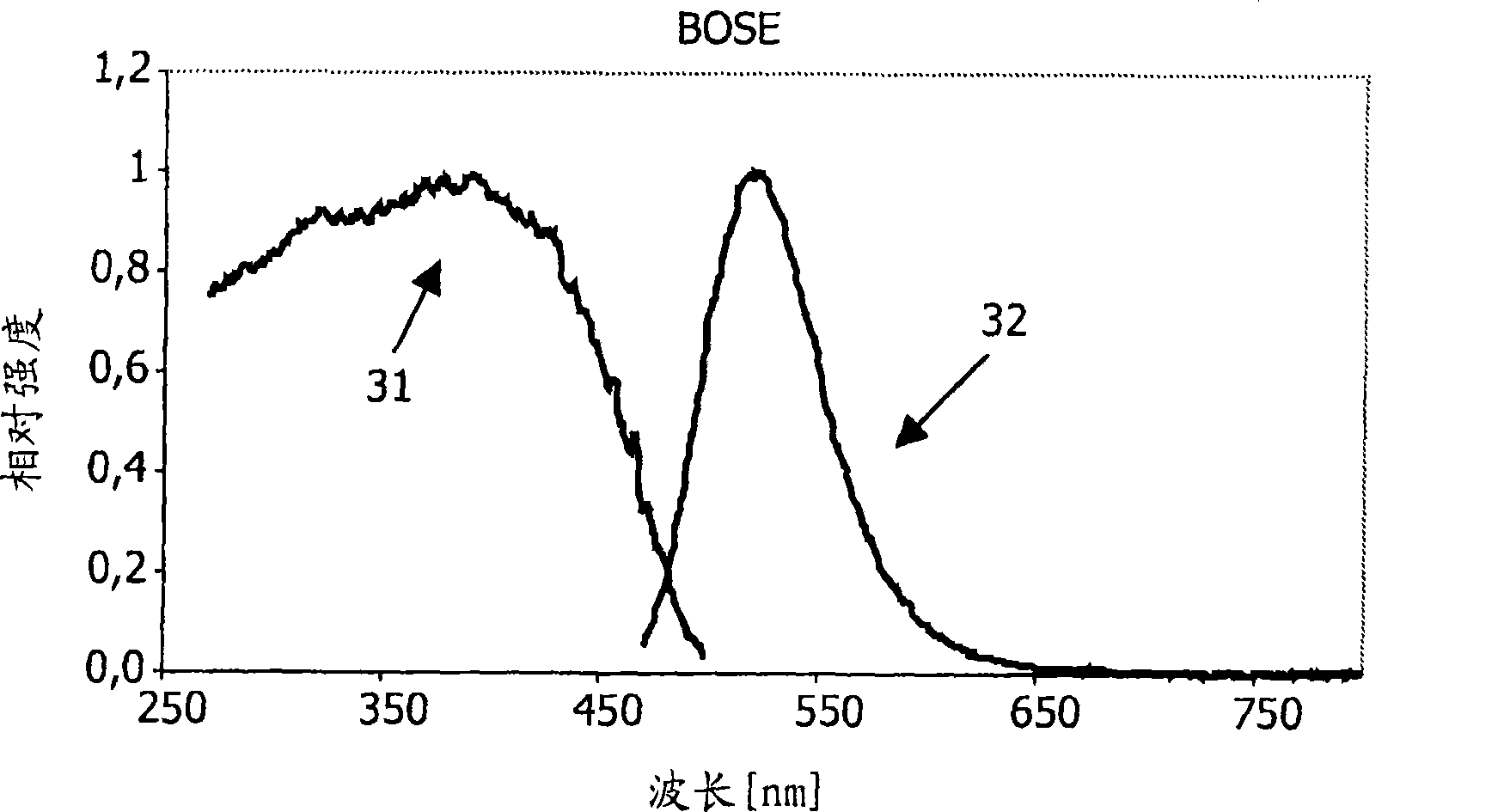

The invention relates to a low-pressure gas discharge lamp (10) for use in a scanning or blinking backlighting system, the low-pressure gas discharge lamp (10) comprising a luminescent layer (20) comprising a luminescent material selected from a group comprising: (Sr1-x-y-z, Bax, Cay, Eu(II)z)2Si04 (also known as XSO), (Sr1-x-y-z, Bax, Cay, Eu(II)z)Si2N2O2 (also known as XSON), and (Sr1-x-y-z, Bax, Cay, Eu(II)z)2Si5N8 (also known as XSN), wherein 0=x<1, 0=y<, 0<z=0.20, and x+y+z=l. The luminescent materials according to the invention have a relatively short decay time (less than 0.5 milliseconds), resulting in a relatively short afterglow time of the low-pressure gas discharge lamp (10) according to the invention. When using known low- pressure gas discharge lamps, for example, comprising the luminescent materials BAM, LAP and YOX in the scanning or blinking backlighting system, the afterglow time of these luminescent materials creates visible motion artifacts, especially when the scanning or blinking time is increased from 50 Hertz or 60 Hertz to, for example, 90 Hertz or 100 Hertz. Replacing the known luminescent materials LAP and / or YOX with luminescent material according to the invention will result in a reduction of the motion artifacts.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Green luminescent material and preparation method thereof

InactiveCN101747895AImprove the display effectShort afterglow timeLuminescent compositionsLuminous intensityReducing atmosphere

The invention relates to a green luminescent material and a preparation method thereof. The green luminescent material adopts a chemical formula of M1-x-y-zGdxTbyNzAl2B2O7, wherein M is at least one component among Ca, Sr and Ba, N is Li, Na and K, the value range of x meets the relationship, i.e., 0.02 Less than or equal x Less than or equal 0.3, the value range of y meets the relationship, i.e., 0.01 Less than or equal y Less than or equal 0.4, z=x+y, and 1-x-y-z>0. The preparation method comprises the following steps: weighing all the raw materials according to the proportion, then fully grinding the raw materials, presintering the ground raw materials at the lower temperature, calcining for 2 to 12 h at the temperature of 800-1200 DEG C under the reducing atmosphere, and then grinding after cooling to obtain the green luminescent material. The preparation method is simple, pollution-free and is beneficial to industrialized production; and the obtained green luminescent material is short in afterglow time and high in luminous intensity, has the excellent luminous performance and can be widely used for a PDP or mercury-free fluorescent lamp.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

High-brightness small blue luminous particle and its preparation method

InactiveCN1252214CImprove luminous efficiencyShort afterglow timeLuminescent compositionsWater bathsLightness

A high-brightness small blue-light fluorescent particle (300 nm) has a formular Ca1-xEuxAlyO4, where x=0.005-0.1 and y=2-2.4. It is prepared through adding oxalic acid as precipitant in an acidic solution of metallic ions, controlling pH value and water bath temp for depositing the metallic ions to become small particles and controlling sintering temp. Its advantages are high luminescent efficiency, long afterglow, and high stability.

Owner:袁曦明

Rare-earth luminescent materials for plasma planar plate display and non-mercury fluorescent light and production thereof

InactiveCN100366704CImprove stabilityLittle change in light colorSolid cathode detailsLuminescent compositionsAlkaline earth metalNoble gas

A rare earth luminescent material for plasma planar displaying device and non-mercury fluorescent light and its production are disclosed. Its chemical formula is XxYy(BO3)2: Cem.Lnn.Nam+n; X and Y are chosen from alkaline metal ion Mg2+, Ca2+, Sr2+ and Ba2+; Ln is chosen from La, Ce, Pr, Nd, Sm, Eu, Gd, Tb and Dy; x+y=3; 0.01<=m<=0.10, 0.00<=n<=0.10. It has better light wavelength coincidence and stability and can reach high-efficient excitation.

Owner:SUN YAT SEN UNIV

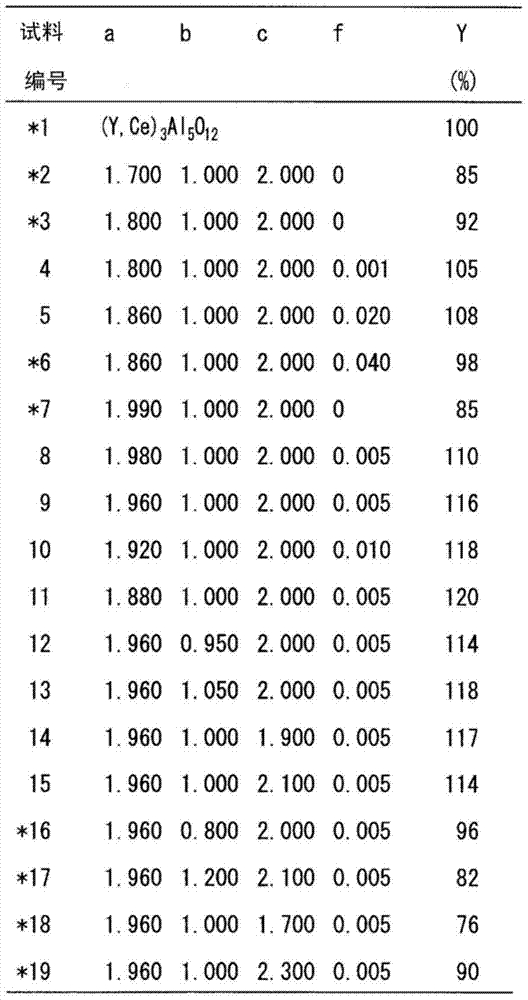

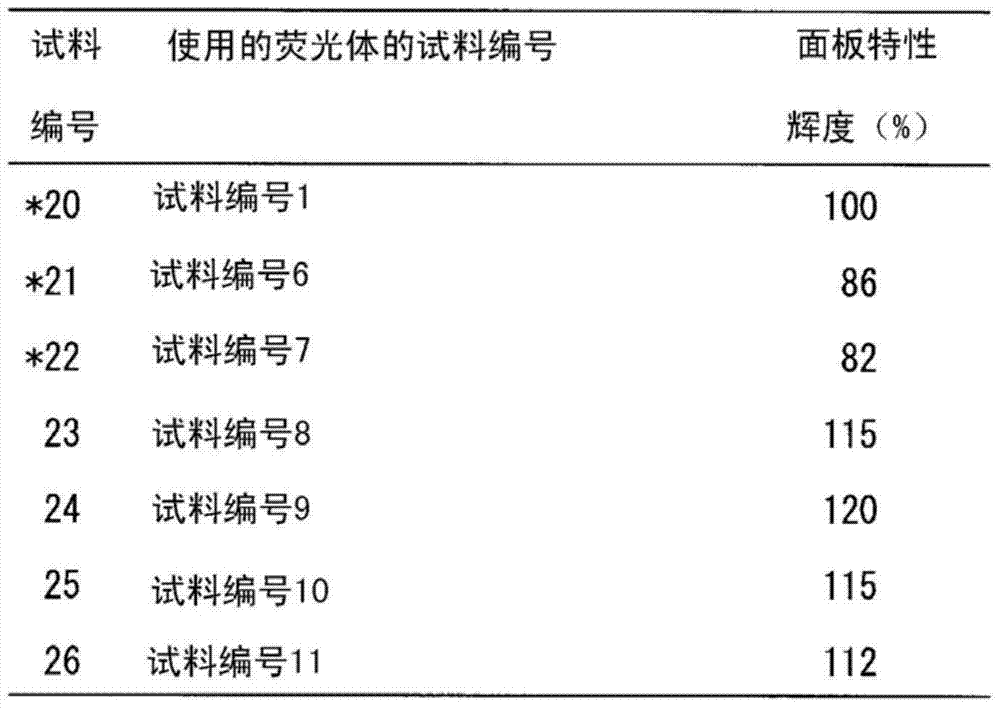

Plasma display panel and phosphor

InactiveCN103717704AShort afterglow timeIncrease brightnessSolid cathodesCathode ray tubes/electron beam tubesFluorescencePhosphor

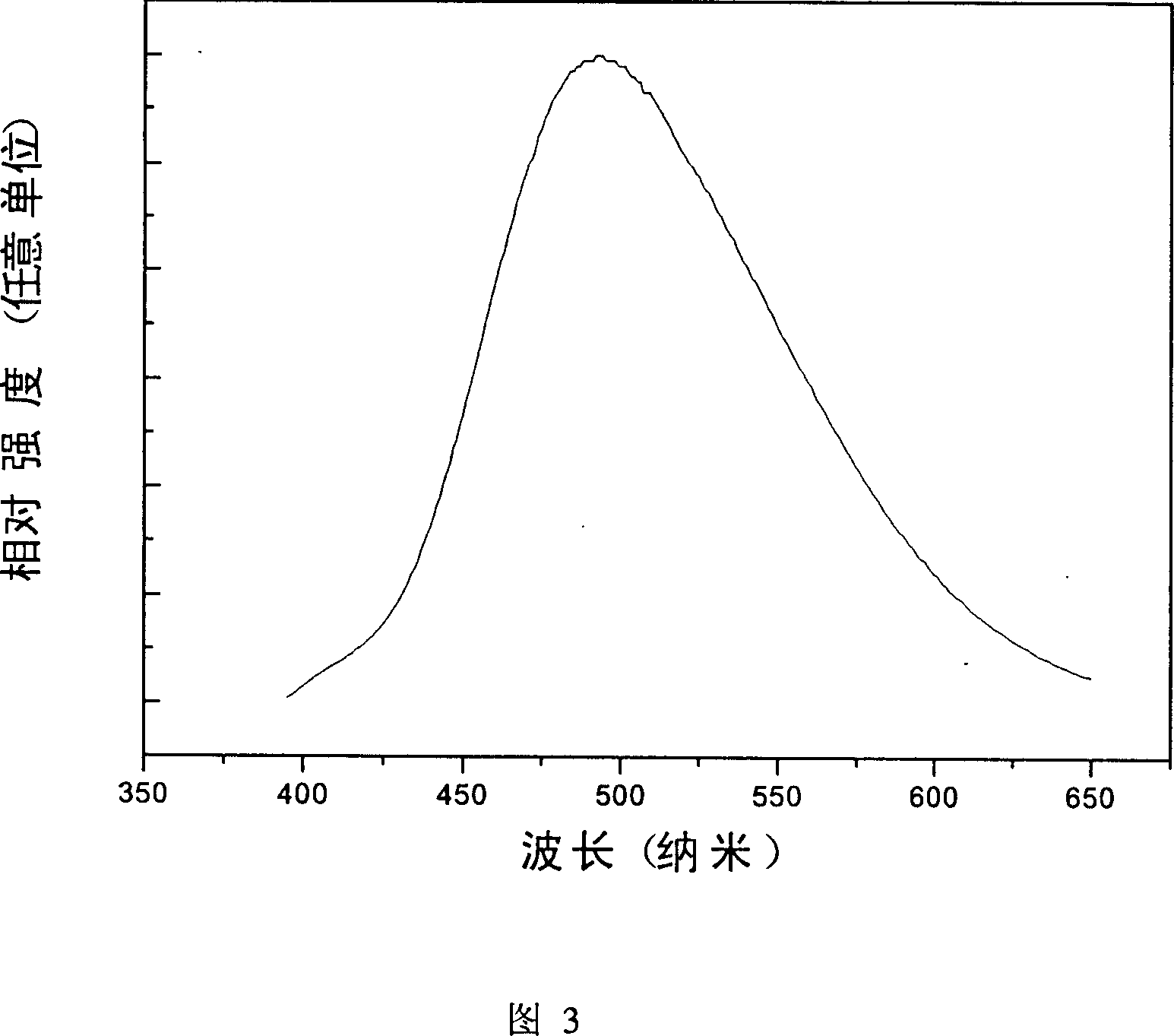

Provided is a high-efficiency plasma display panel which has a short afterglow time and a high level of brightness. The plasma display panel of the present invention comprises a green phosphor layer which emits a visible light from vacuum ultraviolet rays, and the green phosphor layer comprises a green phosphor expressed in the following general formula: aBaO(2-a)EuObMgOcSiO2fCaCl2(1.800<=a<=1.980, 0.950<=b<=1.050, 1.900<=c<=2.100, 0.001<=f<=0.020).

Owner:PANASONIC CORP

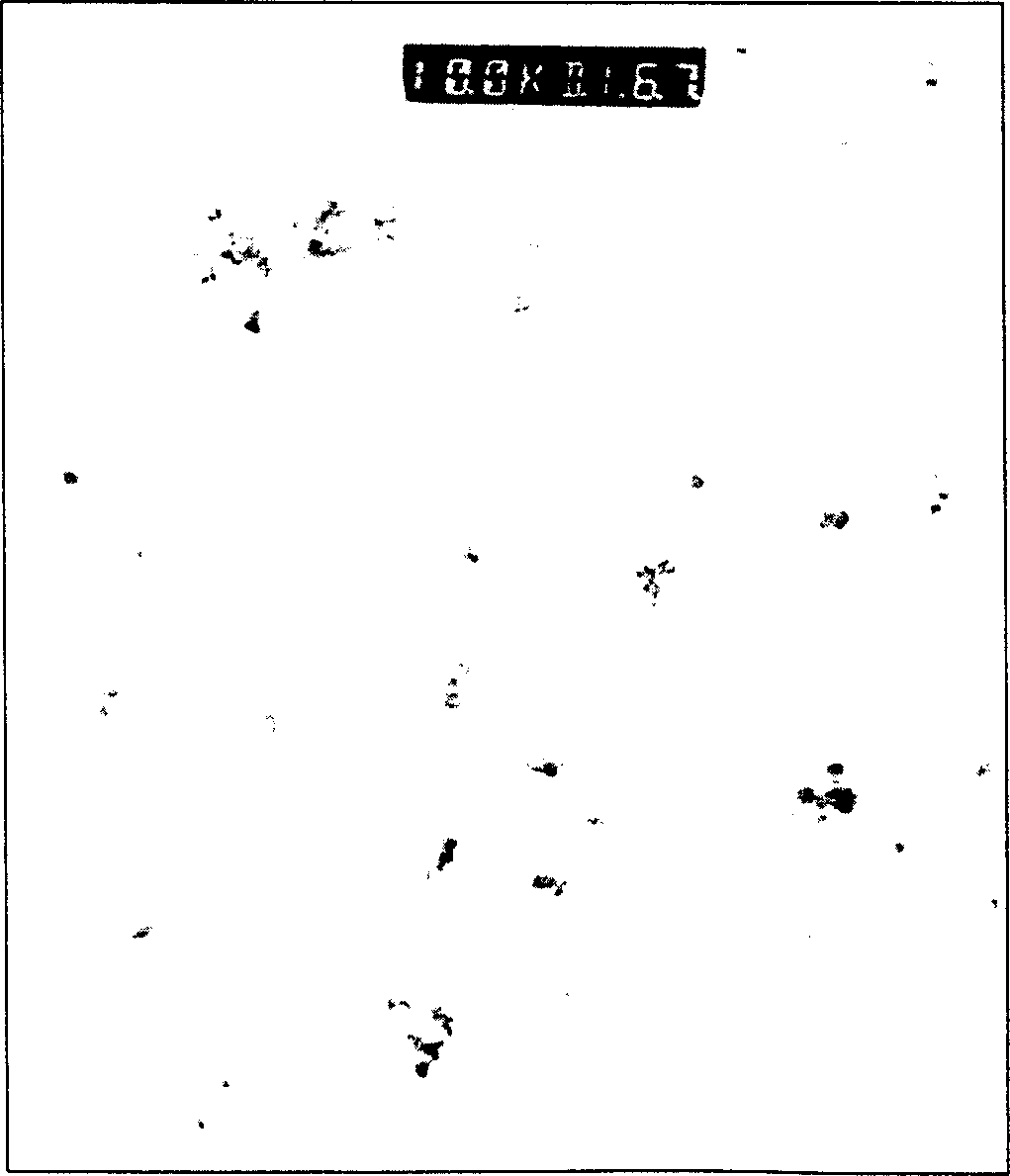

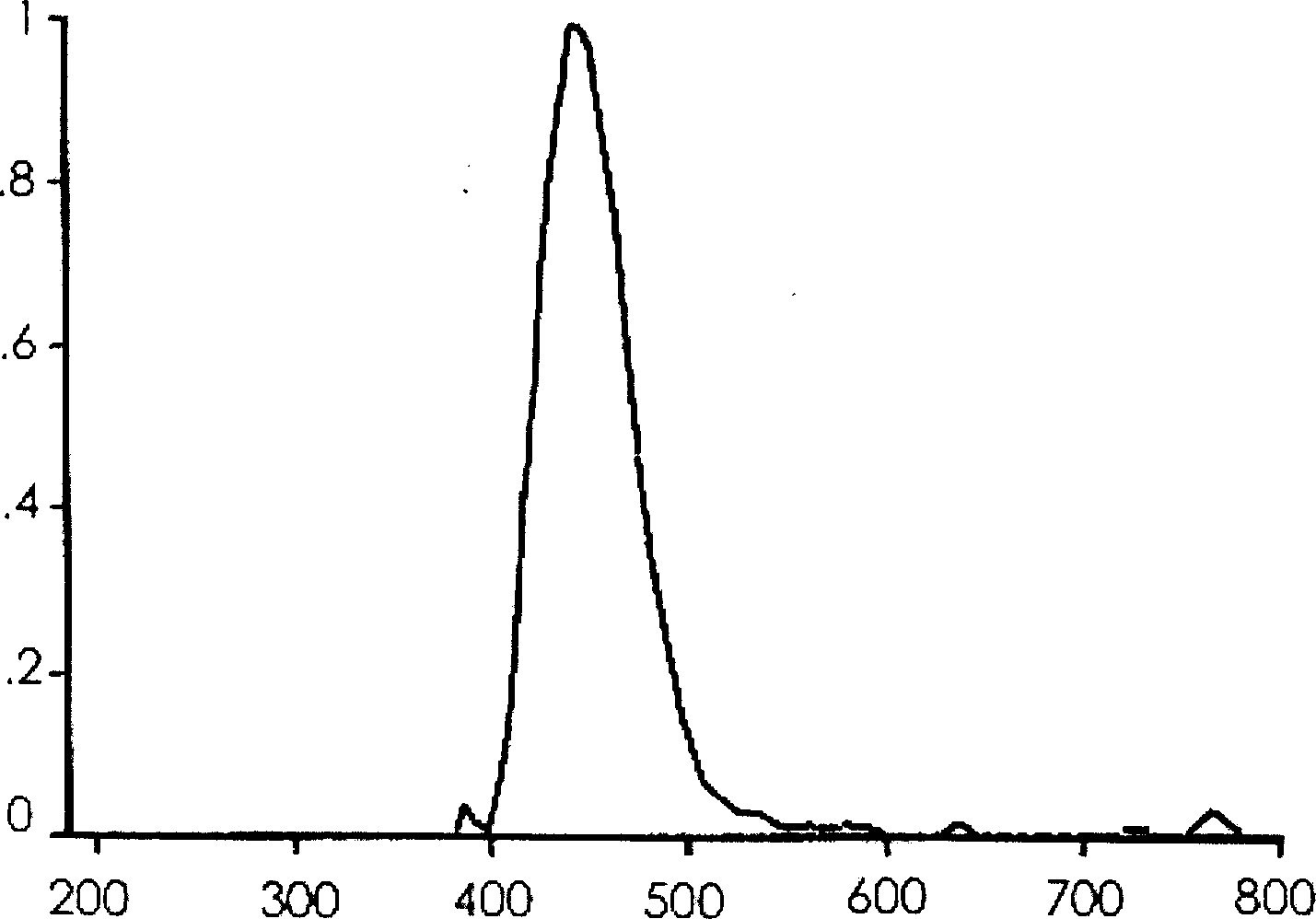

Nano fluorescent powder preparing method

InactiveCN1285704CImprove quantum luminous efficiencyMeet the requirements of luminous performanceLuminescent compositionsPhosphorCombinatorial chemistry

The present invention relates to a kind of preparation method of nano fluorescent powder, nano fluorescent powder is a compound, and its chemical formula is composed of: Zn 2-x-y SiO 4 : xMn, yEr, where, 0.01≤x≤0.15, 0.0001≤y≤0.001. The inventive method adopts Mn 2+ 、Er 3+ As a co-activator, it can greatly improve the quantum luminous efficiency of phosphor products, has good thermal stability and long life, and meets the requirements of color PDP for the luminescence performance of phosphors; at the same time, it also plays a certain role in shortening the afterglow time of phosphors. . The nano fluorescent powder of the present invention has fine particles (particle diameter 30-100nm), good dispersibility and superior luminous performance. For the defect of long afterglow time of traditional green phosphor powder, the present invention adopts the method of increasing Mn 2+ The dosage and the use of Mn 2+ with Er 3+ Co-activation means to overcome, to meet the color PDP on the persistence time performance requirements.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Green photoluminescent phosphor and preparing method thereof

InactiveCN100509999CImprove luminous efficiencyHigh color purityLuminescent compositionsWater bathsLuminous intensity

A novel photoluminescent green phosphor and a preparation method thereof relate to a new material and a preparation method thereof. The phosphor is an aluminate green phosphor activated by rare earth terbium, and the expression is: M1-XAl12O19:Tb3+X where M is Ba2+, Sr2+ and Ca2+, where 0.005≤X≤0.06. The preparation method of phosphor powder adopts two preparation methods: (1) solid phase method: terbium oxide, aluminum oxide, barium carbonate and boron oxide are ground uniformly according to the calculation of 1-5% of the raw material quality, and the green phosphor powder is obtained by roasting for more than 2 hours. (2) Sol-gel method: Dissolve barium carbonate, aluminum nitrate and rare earth nitrate in citric acid solution in turn, heat and stir in a water bath until gelatinization, and dry the gel to a bulky black powder , after grinding, the dry powder was calcined at high temperature to obtain the sample. The prepared phosphor powder has short afterglow time, high luminous intensity, high luminous efficiency, small and uniform particle size.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

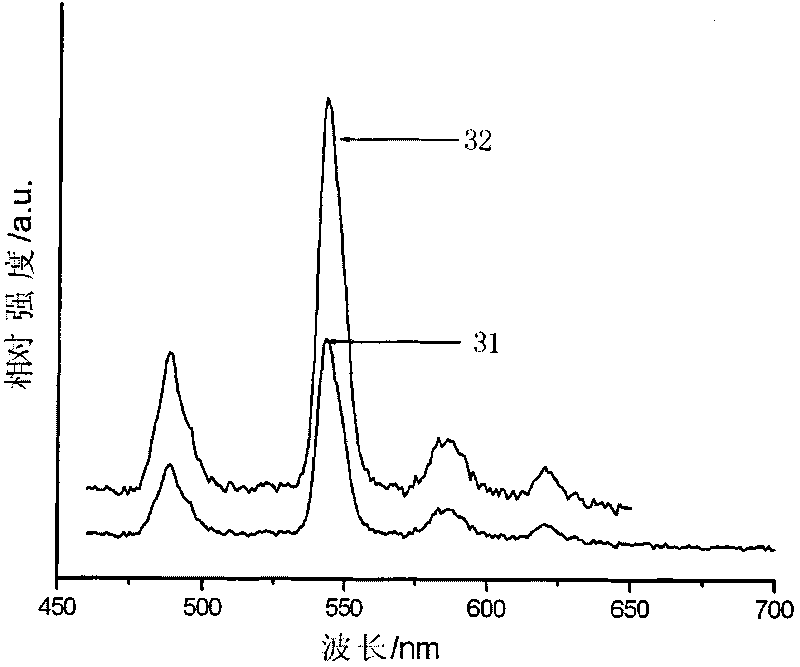

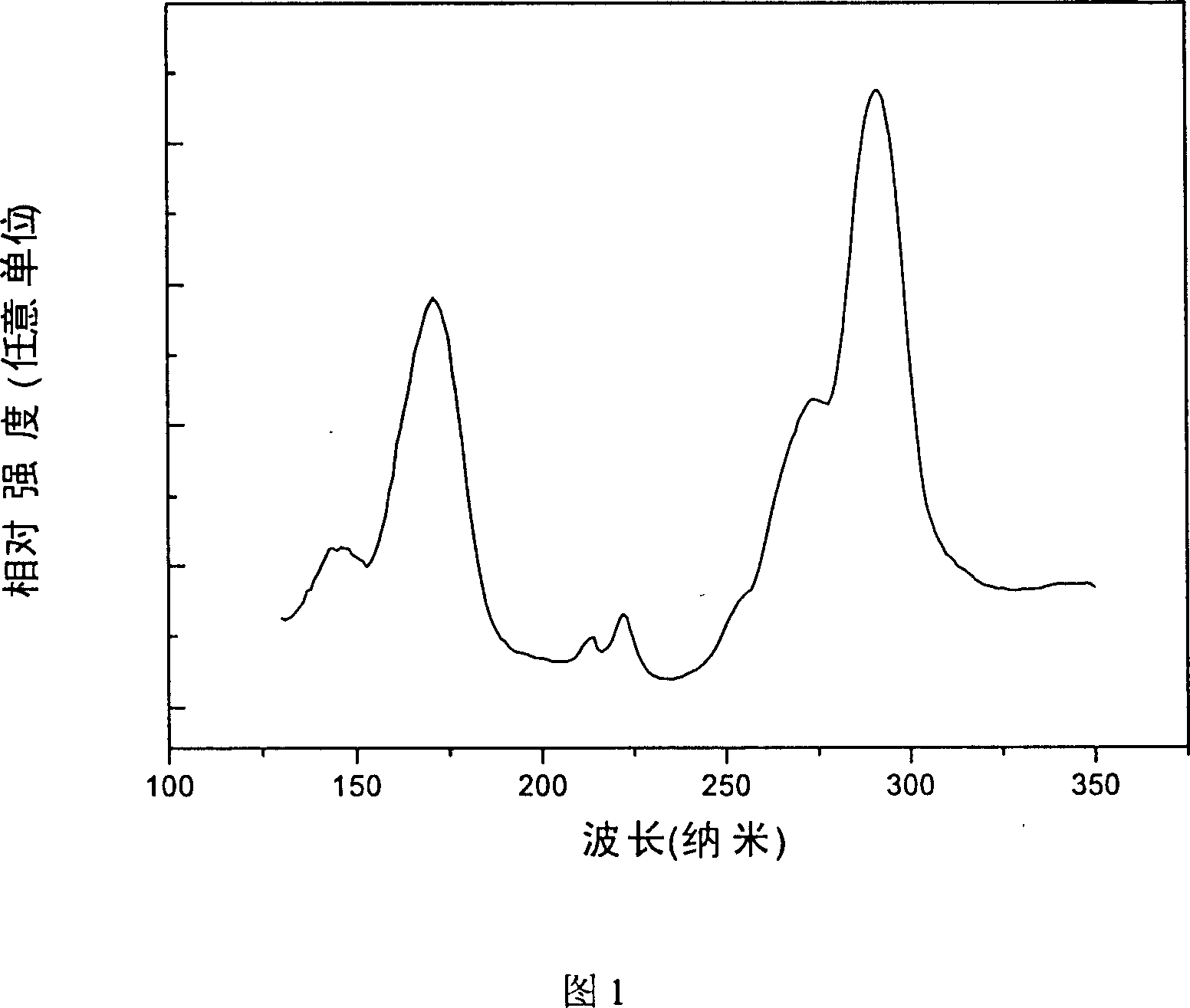

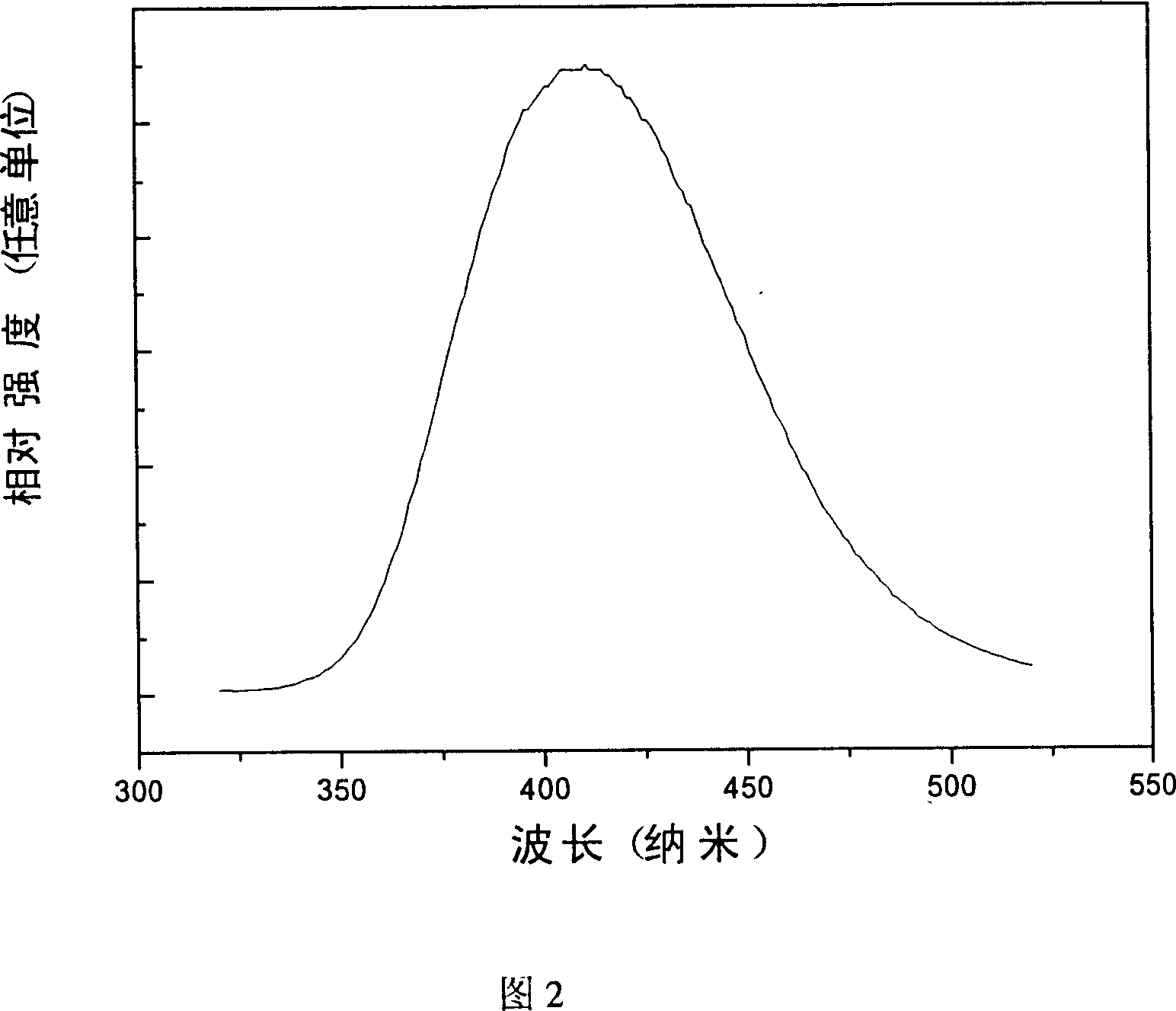

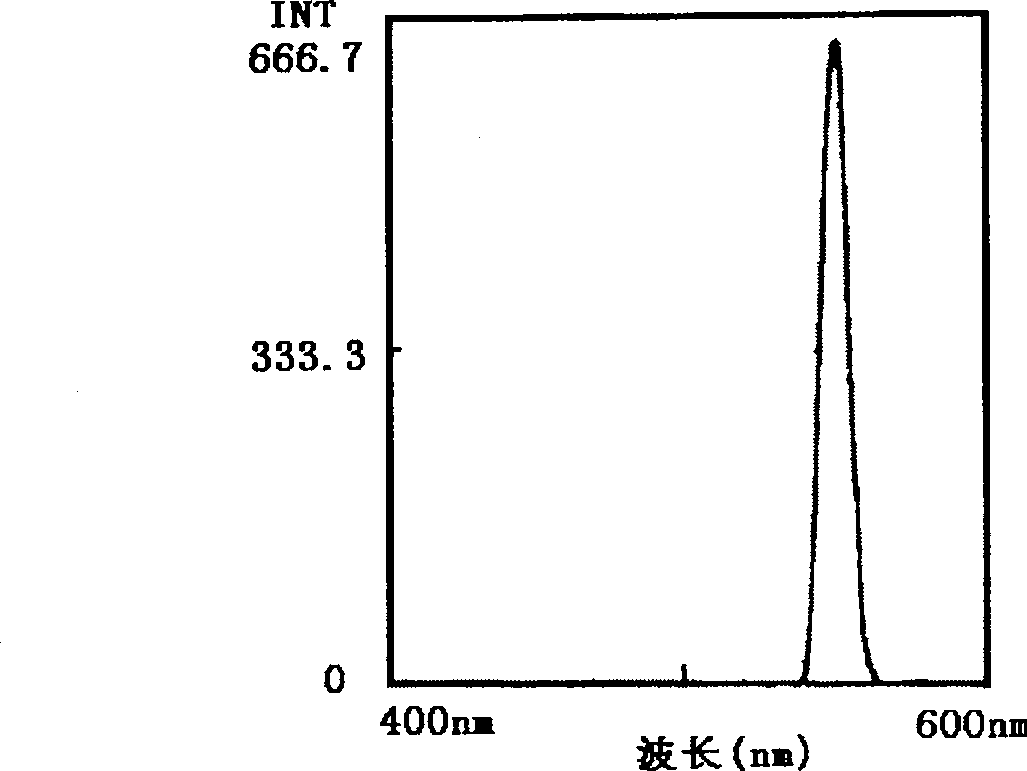

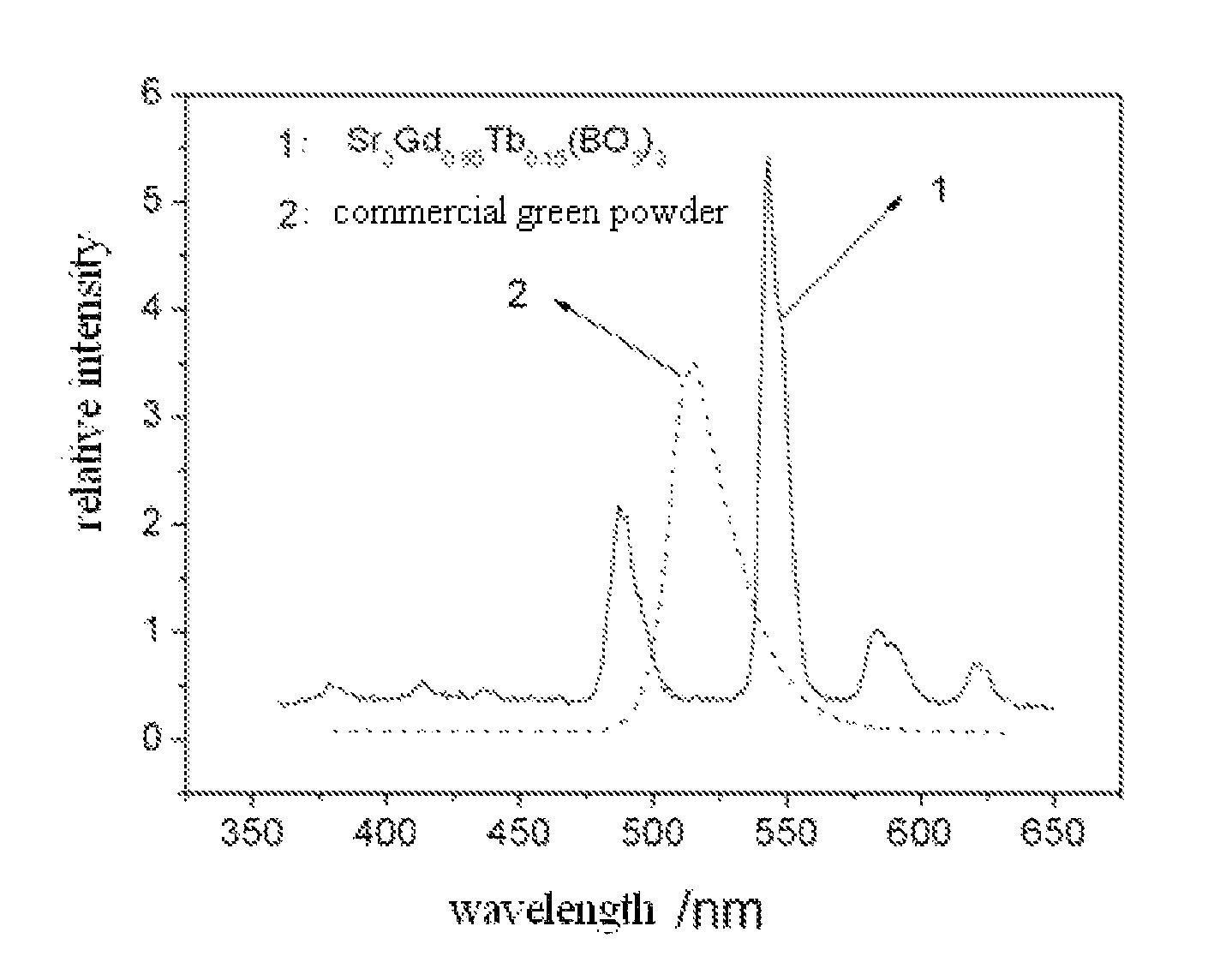

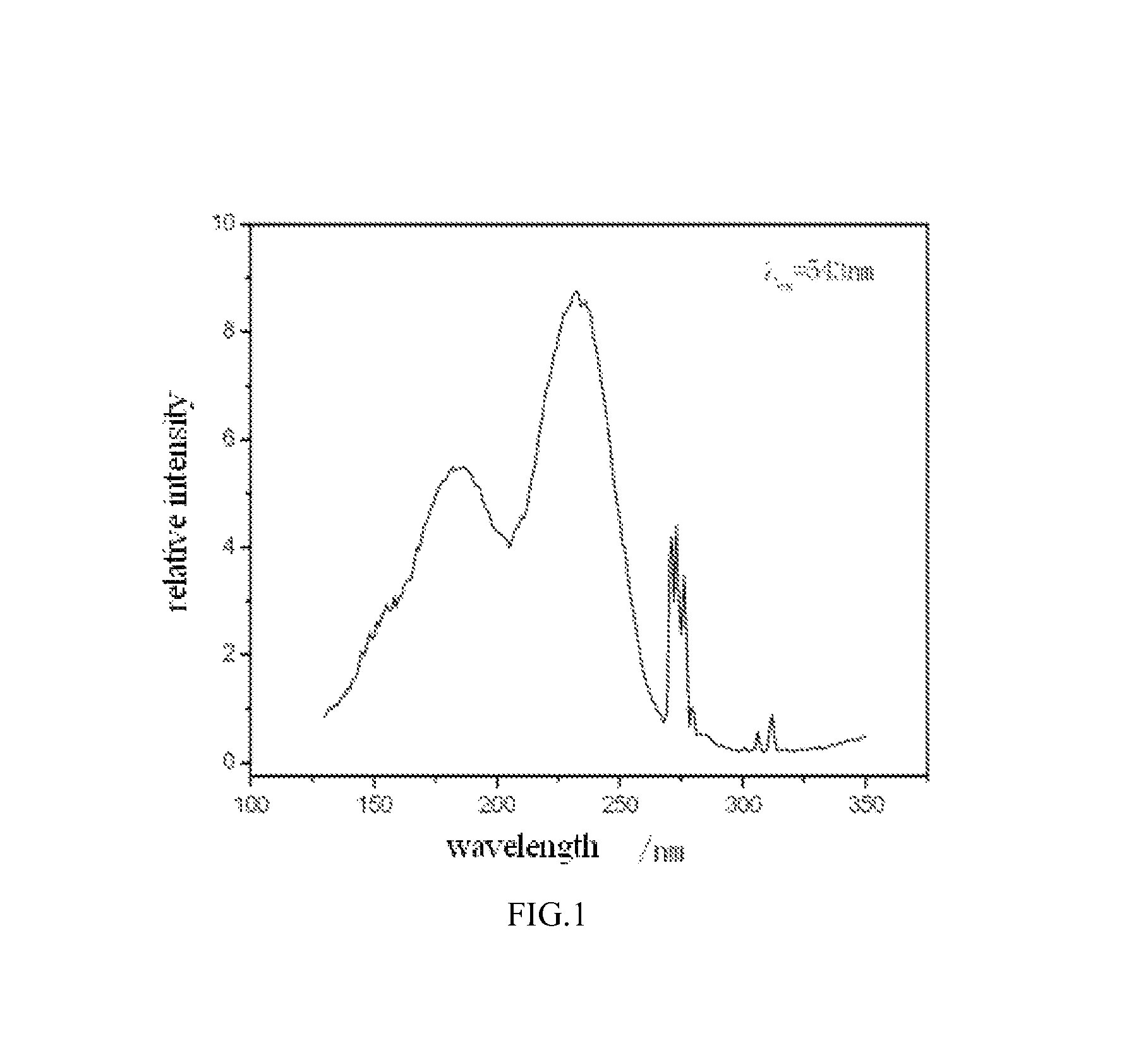

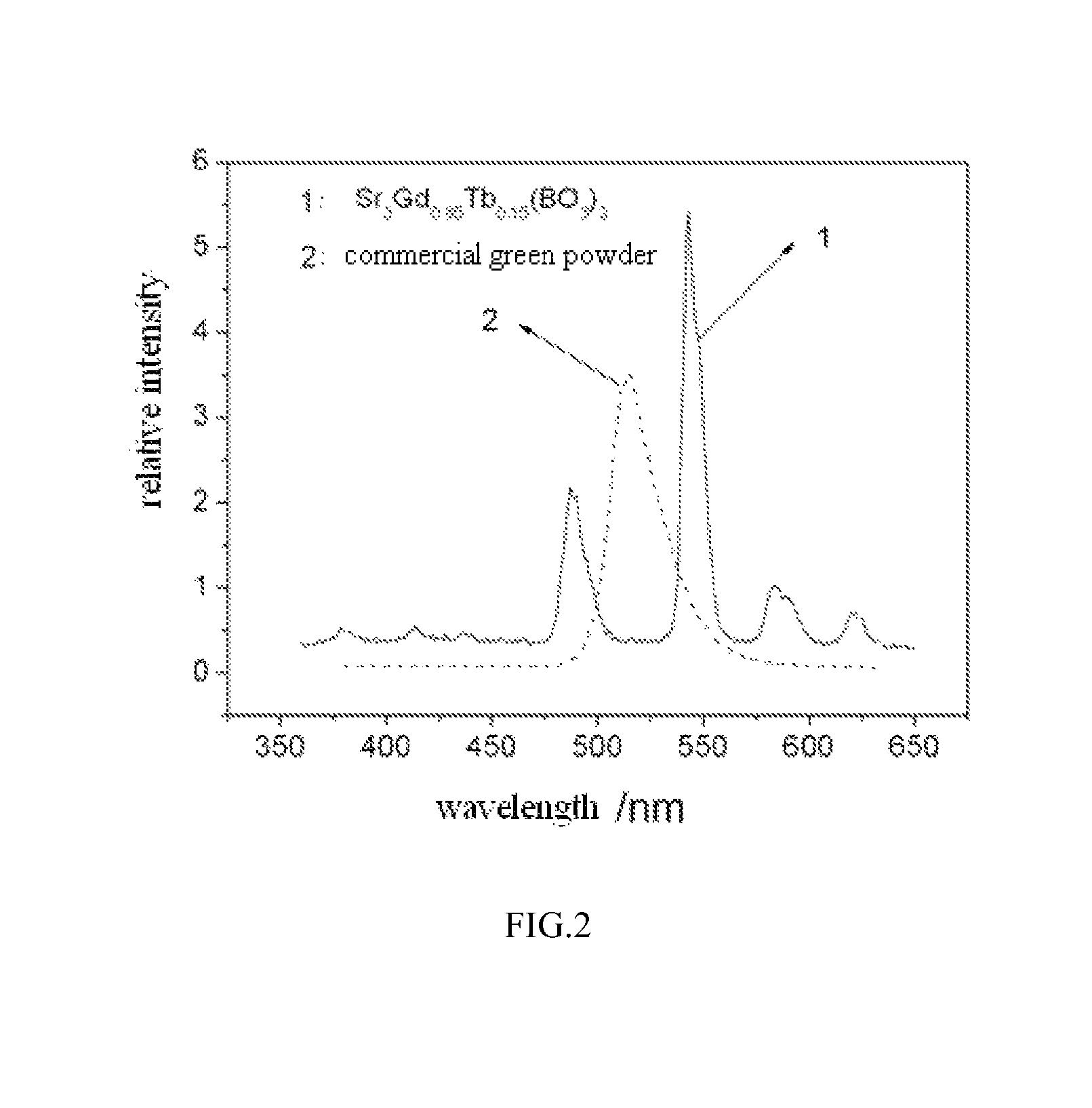

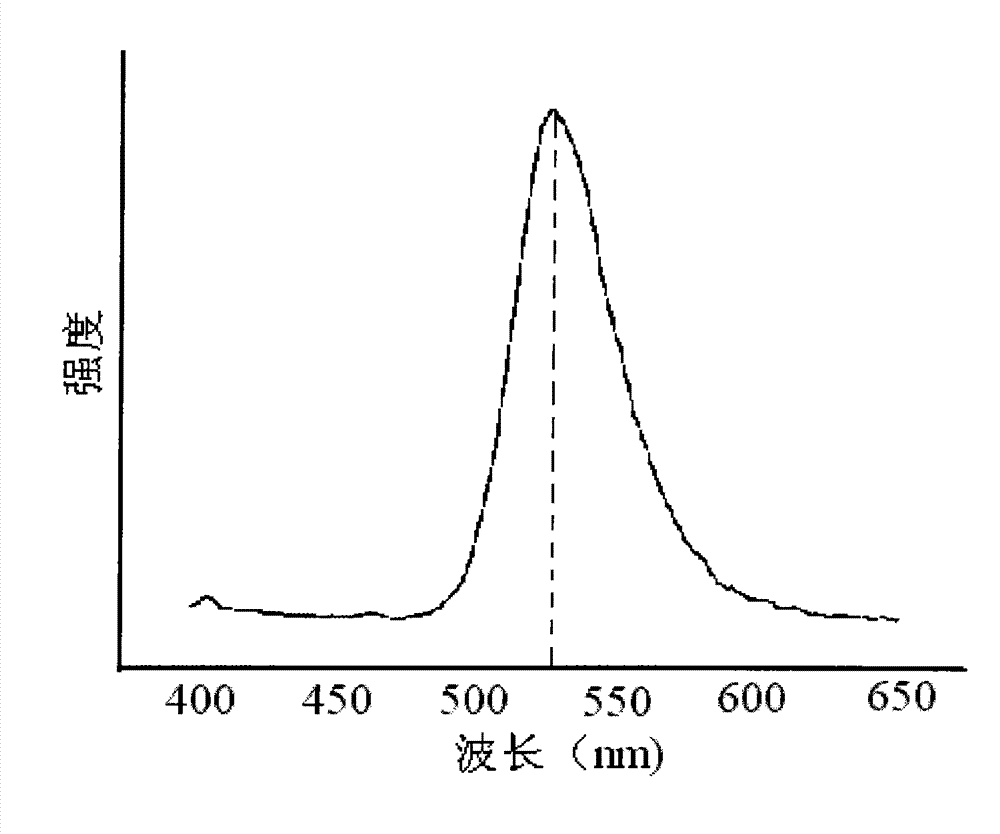

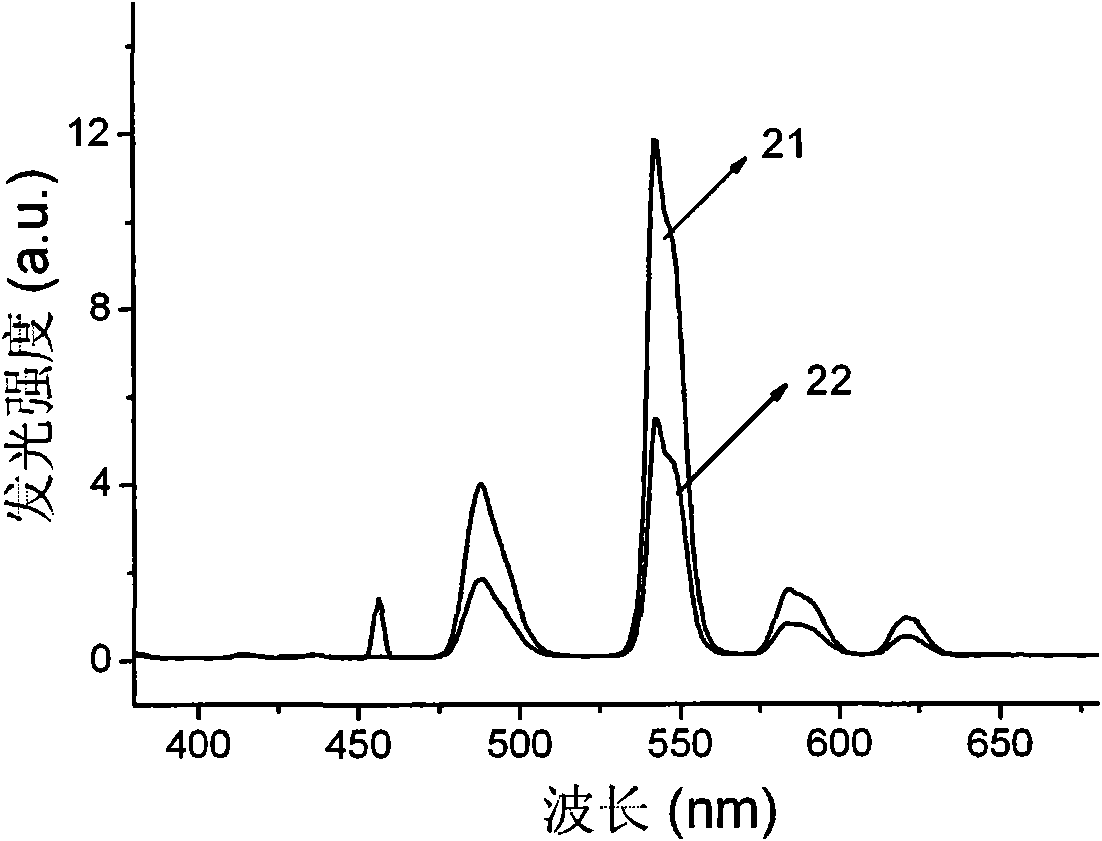

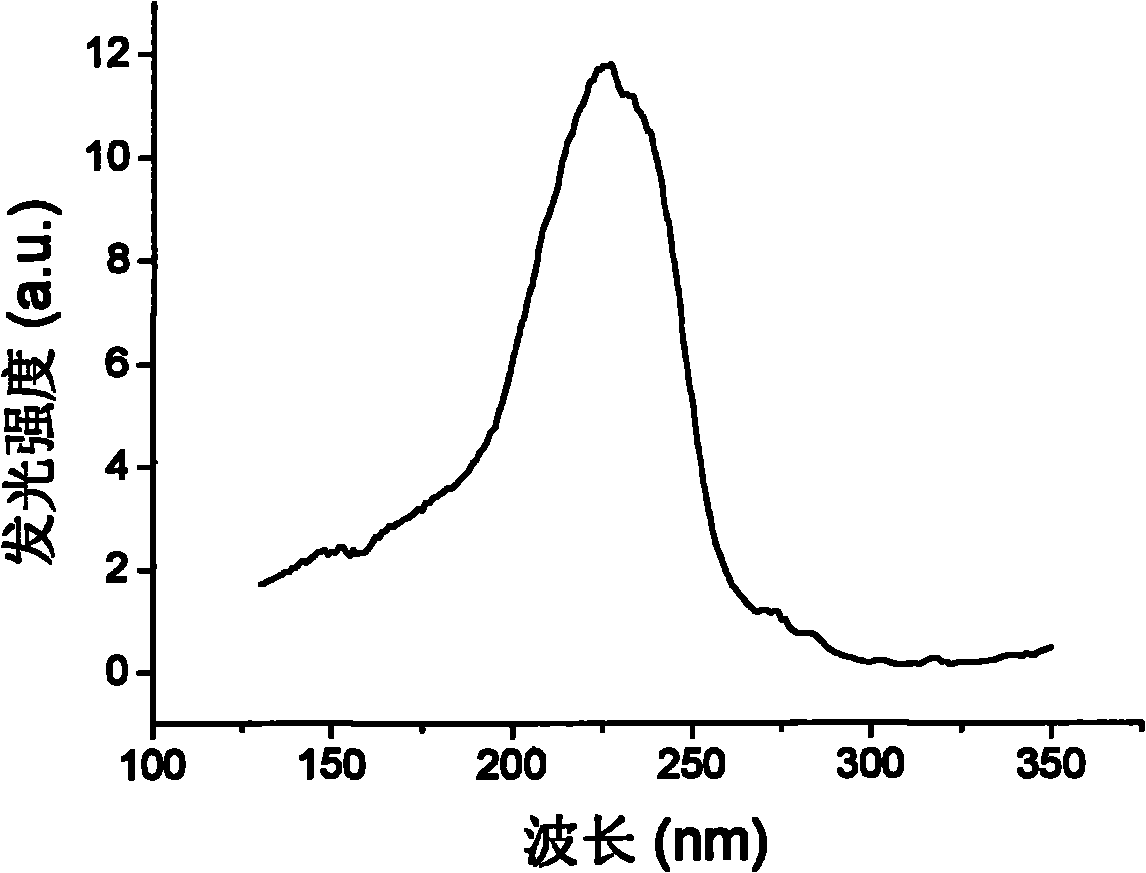

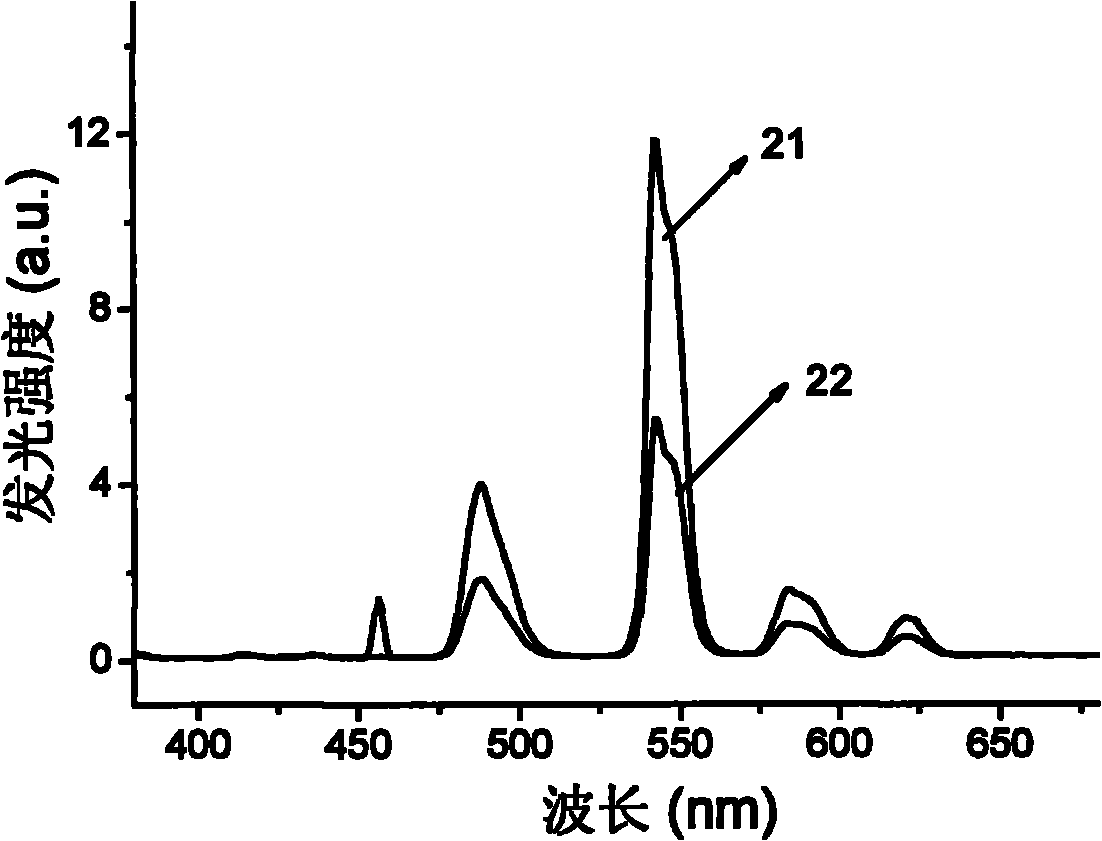

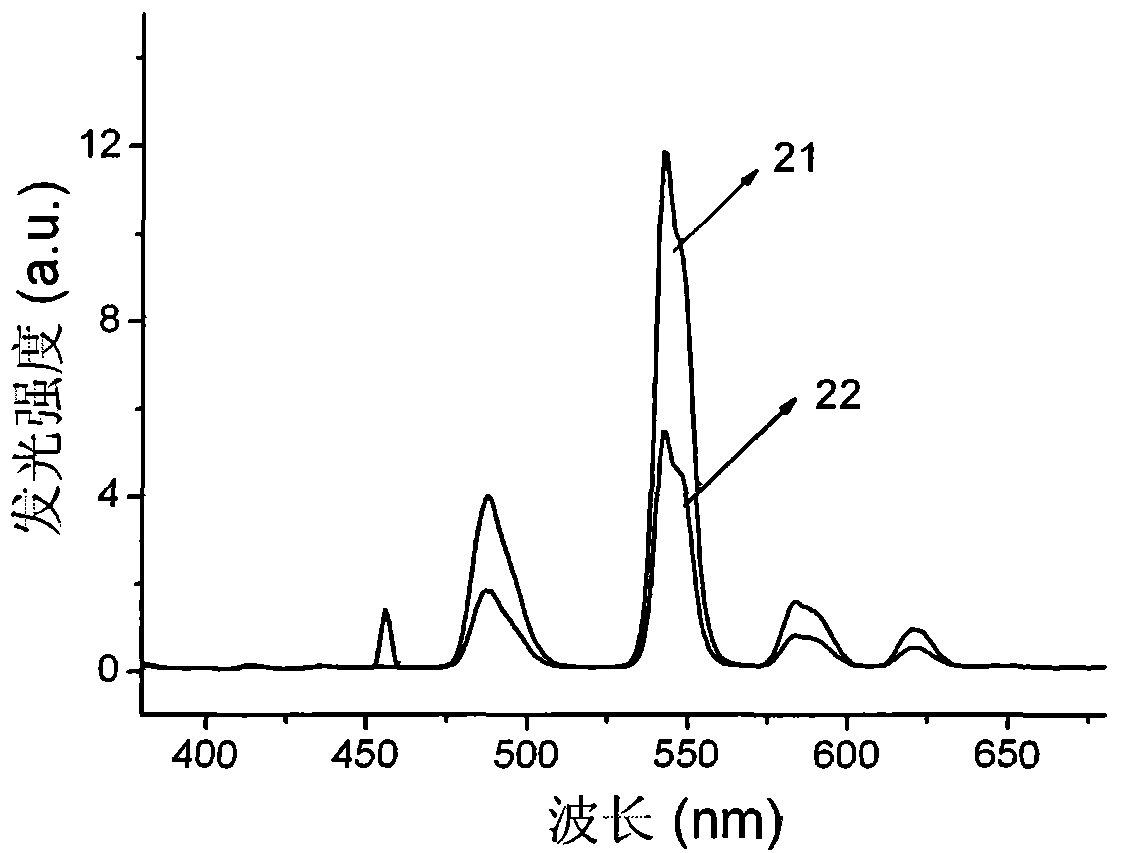

Green luminescent material of terbium doped gadolinium borate and preparing method thereof

ActiveUS8765016B2Convenient lightingShort afterglow timeLuminescent compositionsAlkaline earth metalBorate ion

A green luminescent material of terbium doped gadolinium borate is provided. The luminescent material has a formula of M3Gd1-xTbx(BO3)3, wherein, M is alkaline earth metal element and x is 0.005-0.5. The method for preparing the luminescent material comprises the following steps: selecting the source compounds of alkaline earth metal ion, boric acid radical ion (BO33−), Gd3+ and Tb3+ by the stoichiometric ratio, wherein, the stoichiometric ratio is the molar ratio of the corresponding element in the formula of M3Gd1-xTbx(BO3)3, and the source compound of BO33− is over 10%-30% by the molar ratio; mixing; pre-treatment by sintering; cooling; grinding; calcination; and cooling to obtain the luminescent material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Preparation method of vacuum ultraviolet excited green silicate fluorescent powder

InactiveCN101831296BEnhance and improve luminosityShort afterglow timeLuminescent compositionsMANGANESE ACETATESilicic acid

The invention relates to a preparation method of vacuum ultraviolet excited green silicate fluorescent powder. The formula of the green silicate fluorescent powder is Zn1.92-x-2yMgxYyLiySiO4:0.08Mn2+ (x is greater than or equal to 0 and smaller than or equal to 0.12, y is greater than or equal to 0 and smaller than or equal to 0.03). The preparation method comprises the following steps of: respectively taking silicic acid or silicon dioxide, zinc oxide, manganese acetate, magnesium oxide, yttrium oxide and lithium carbonate, taking absolute ethyl alcohol, and grinding to obtain raw material powder; while introducing nitrogen, calcining the raw material powder, cooling, introducing shielding gas atmosphere, calcining, and cooling in the furnace to obtain the calcined powder; and grinding the calcined powder, washing, drying and screening to obtain the vacuum ultraviolet excited green silicate fluorescent powder. On the premise of not increasing the concentration of Mn2+, the preparation method can prepare the green silicate fluorescent powder with good luminous performance and shorter persistence.

Owner:LANZHOU UNIVERSITY

Boron aluminate luminescent material capable of generating green light and preparation method thereof

InactiveCN102115669BImprove the display effectShort afterglow timeLuminescent compositionsAluminateLuminous intensity

The invention relates to a boron aluminate luminescent material capable of generating green light and a preparation method thereof. The chemical formula of the luminescent material capable of generating green light is M1-x-y-zGdxTbyNzAl3BO7, wherein M is at least one of Ba, Sr, N is Na, Li or K, and x, y, and z satisfy the relations: 0.001 <= x <= 0.20, 0.005 <= y <= 0.50, 0.02 <= z <= 0.30, 1-x-y-z > 0. The preparation method comprises the steps: weighing raw materials and a flux in proportion; grinding and mixing well, then pre-sintering under a lower temperature; then calcining under a temperature of 900 to 1100 DEG C for 1 to 24 hours; grinding after cooling; and obtaining the boron aluminate luminescent material capable of generating green light of the invention. The method of the invention is simple, has no pollution, and is benefit for industrial production. The obtained luminescent material capable of generating green light has short afterglow, high luminous intensity and excellent luminous performance, and can be widely used for PDP or mercury-free fluorescent lamp.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Boron aluminate luminescent material capable of generating green light and preparation method thereof

InactiveCN102115669AShort afterglow timeHigh quenching concentrationLuminescent compositionsAluminateLuminous intensity

The invention relates to a boron aluminate luminescent material capable of generating green light and a preparation method thereof. The chemical formula of the luminescent material capable of generating green light is M1-x-y-zGdxTbyNzAl3BO7, wherein M is at least one of Ba, Sr, N is Na, Li or K, and x, y, and z satisfy the relations: 0.001 <= x <= 0.20, 0.005 <= y <= 0.50, 0.02 <= z <= 0.30, 1-x-y-z > 0. The preparation method comprises the steps: weighing raw materials and a flux in proportion; grinding and mixing well, then pre-sintering under a lower temperature; then calcining under a temperature of 900 to 1100 DEG C for 1 to 24 hours; grinding after cooling; and obtaining the boron aluminate luminescent material capable of generating green light of the invention. The method of the invention is simple, has no pollution, and is benefit for industrial production. The obtained luminescent material capable of generating green light has short afterglow, high luminous intensity and excellent luminous performance, and can be widely used for PDP or mercury-free fluorescent lamp.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

A warm white phosphor excited by UV LEDs

ActiveCN105623660BHigh luminous intensitySimple preparation processLuminescent compositionsRare earth ionsPhosphor

The invention relates to a warm white fluorescent powder excited by an ultraviolet LED. According to the fluorescent powder, InNbO4 serves as a host material, and the warm white fluorescent powder In1-x-y-zDyxTmyEuzNbO4 is obtained by simultaneously doping rare earth ions such as 0.01-0.05at.% of Dy3+, 0.01-0.05at.% of Tm+3+ and 0-0.03at.% of Eu3+ into the In3+ position, wherein x ranges from 0.01 to 0.05, y ranges from 0.01 to 0.05, and z ranges from 0 to 0.03. The rare-earth-doped niobate-based warm white fluorescent powder for the LED has the advantages of being simple in preparing process, high in light-emitting intensity, adjustable in color, capable of achieving a warm color, short in fall time, good in stability and the like, and can be widely applied to the LED field.

Owner:CENT SOUTH UNIV

Method for preparing efficient red small-particle fluorescent powder

InactiveCN1237147CLarge specific surface areaEfficient mixingLuminescent compositionsPhotoluminescenceReaction temperature

The invention refers to a method for producing high efficient red small particles fluorescent powder, the fluorescent powder is Y1-xP1-yVyO4:xEu3+, x=0.06-0.15, y=0.2-0.8. The invention uses supersonic wave to combine with collosol-gelatum method to produce high efficiency red small particle fluorescent powder, the reaction temperature is lower than the temperature in SSR method greatly. The fluorescent powder particle is tiny and even, the shape of particle likes sphere, the purity is high, the quantum efficiency is high. It can be used in color plasma screen, impact energy saving light, mercury-less neon lamp, liquid crystal new background light house.

Owner:CHOW TAI SENG JEWELRY CO LTD

A rare earth borate-based red phosphor

ActiveCN104927855BHigh luminous intensityImprove thermal stabilityLuminescent compositionsLuminous intensityPhosphor

The invention discloses rare earth borate-based red fluorescent powder. According to the fluorescent powder, CaInBO4 is used as a base body, 0.02-0.08 at.% of Al<3+> is doped to enter In<3+> bit, 0.02-0.08 at.% of Ba<2+> is doped to enter Ca<2+> bit and 0.07-0.10 at.% of Eu<3+> is doped to enter In<3+> bit, so that fluorescent powder (In(1-x-z), Alx, Euz)(Ca(1-y), Bay)BO4 is obtained, wherein x is equal to 0.02-0.04, y is equal to 0.05-0.07, and z is equal to 0.07-0.1. The rare earth borate-based red fluorescent powder provided by the invention has excellent properties of high luminous intensity, warm color, rapid decay, short persistence, good heat stability, easiness in long-term preservation and wide application range.

Owner:CENT SOUTH UNIV

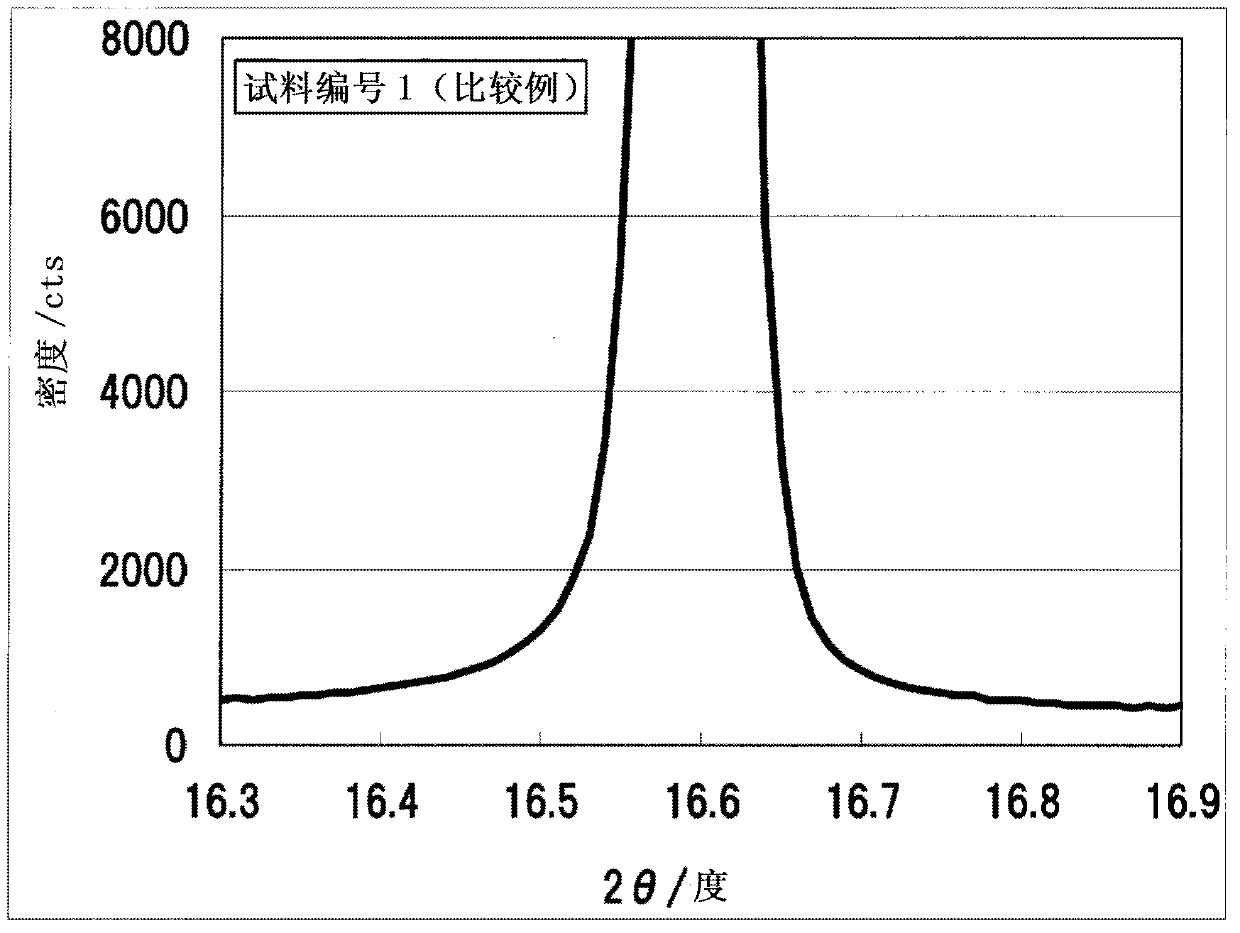

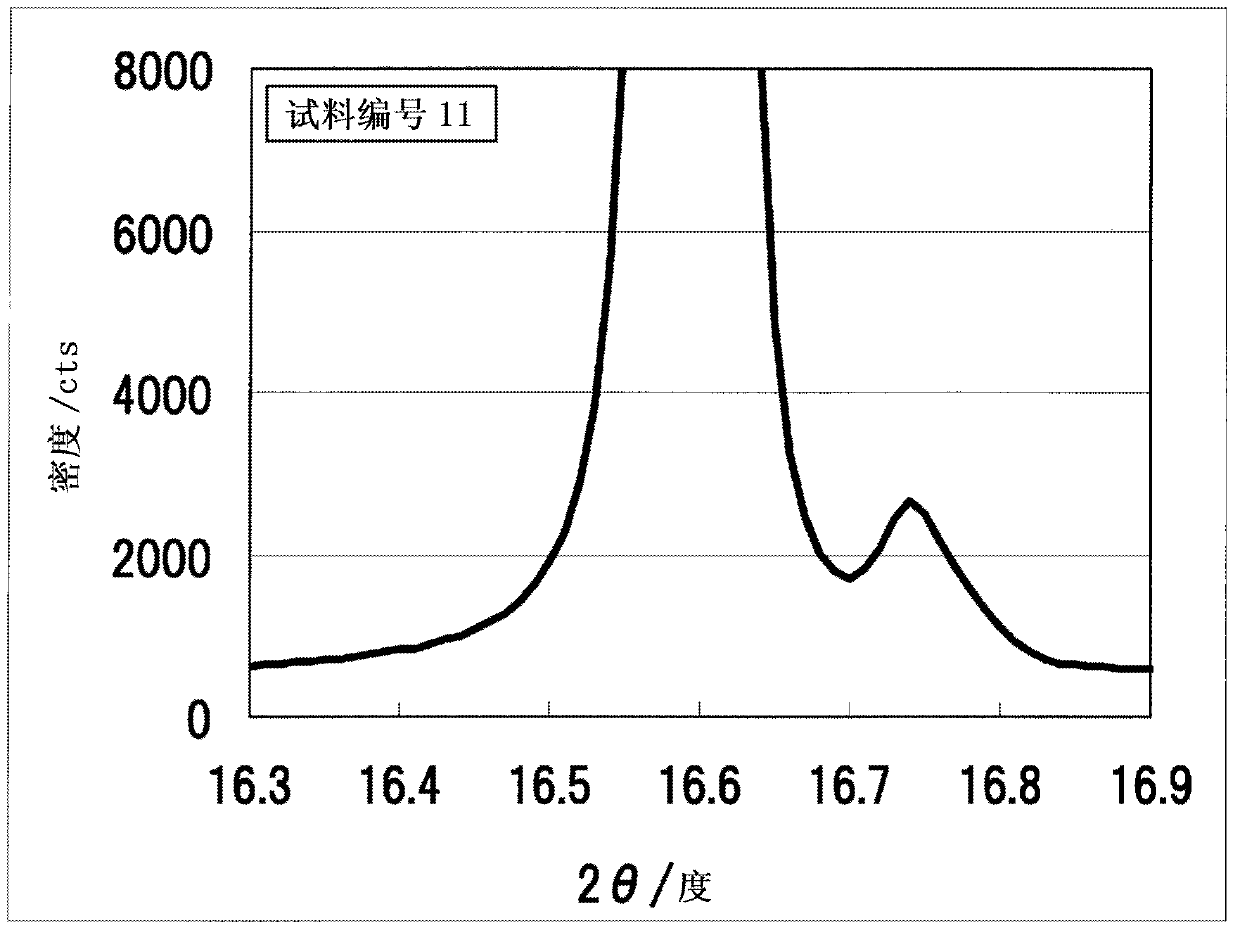

Plasma display panel and green phosphor layer

InactiveCN102754180AShort afterglow timeIncrease brightnessAddress electrodesSustain/scan electrodesFluorescencePhosphor

Disclosed is a highly efficient plasma display panel which has short afterglow time, while achieving high luminance and high color purity. Specifically disclosed is a plasma display panel comprising a green phosphor layer, which is characterized in that the green phosphor layer contains a phosphor that is represented by general formula: aYO3 / 2(3-a)CeO3 / 2bAlO3 / 2cGaO3 / 2 (wherein 2.80 <= a< = 2.99, 1.00 <= b <= 5.00 and 0< = c <= 4.00, provided that 4.00 <= b + c <= 5.00) and has a peak with a peak top at a diffraction angle (2-d) within the range from 16.7 DEG to 16.9 DEG (inclusive) in the X-ray diffraction pattern as determined by an X-ray having a wavelength of 0.774 AA. The plasma display panel is also characterized in that the green phosphor layer additionally contains a phosphor that is represented by general formula: dZnO(2-d)MnO.eSiO2 (wherein 1.80 <= d <= 1.90 and 1.00 <= e <= 1.02) in an amount of 30-80% by weight (inclusive) based on the total weight of the green phosphor.

Owner:PANASONIC CORP

Vacuum ultraviolet induced green emitting phosphor and preparation method thereof

The invention provides vacuum ultraviolet induced green emitting phosphor which is characterized by having the following concrete chemical formula: M3 minus 2xBPO7: Tbx, Rx, wherein x is more than 0 and less than or equal to 0.3, R is one or several of Li, Na and K, and M is one or several of Mg, Zn, Ca, Sr and Ba. The invention also provides a method for preparing the green emitting phosphor, comprising the following steps: firstly, weighing corresponding raw materials according to the weight ratio expressed in the chemical formula; secondly, carrying out high-temperature roasting on the raw materials and rinsing coasted materials; and thirdly, carrying out separation, filtration, size grading and drying on the rinsed materials to obtain the vacuum ultraviolet induced green emitting phosphor having stable chemical property, short after time and excellent luminance.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com