Co-firing method-based luminous ceramic tile preparation process, and luminous ceramic tile prepared by same

A luminous ceramic and a preparation technology, which is applied in the field of ceramics, can solve the problems of not having the same luminous efficacy, high refractoriness of luminescent powder, and attenuation of luminous performance, so as to achieve less loss of luminous efficacy, high luminous efficiency, and avoid erosion and damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

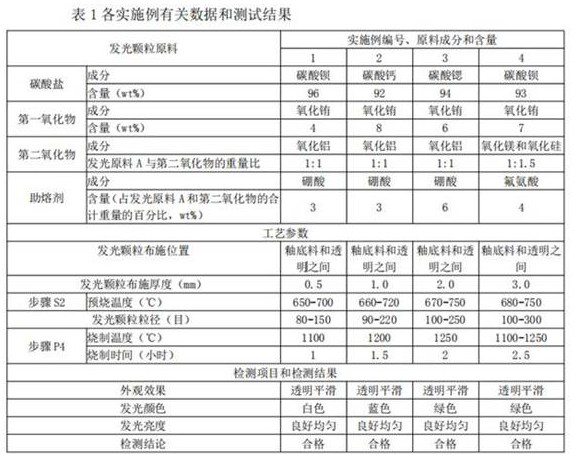

[0041] The technical solutions of the present invention will be further described below with specific embodiments.

[0042] A preparation process for luminescent ceramic tiles based on co-firing method, including the pre-firing steps of luminescent particles and the preparation steps of finished products:

[0043] The step of pre-firing the luminescent particles includes:

[0044] S1) Weigh the carbonate, the first oxide, the second oxide and the flux respectively in proportion, add alcohol and grind and mix them evenly to prepare the luminescent slurry;

[0045] S2) Put the luminescent slurry into an electric furnace and pre-fire at 600-700°C to remove impurities to prepare luminescent particles;

[0046] Described finished product preparation step comprises:

[0047] P1) Applying the first viscous material on the surface of the green body to form a lower sticky layer on the green body;

[0048] P2) distributing the luminescent particles on the surface of the lower adhesiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com