Self-activated titanoniobate-based fluorescent powder and preparation method thereof

A niobate titanate and phosphor technology, applied in the field of rare earth luminescent materials, can solve the problems of reduced luminous efficiency of phosphors, unreported optical properties, low luminous efficiency, etc., and achieves easy long-term storage, high color purity, and chemical stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

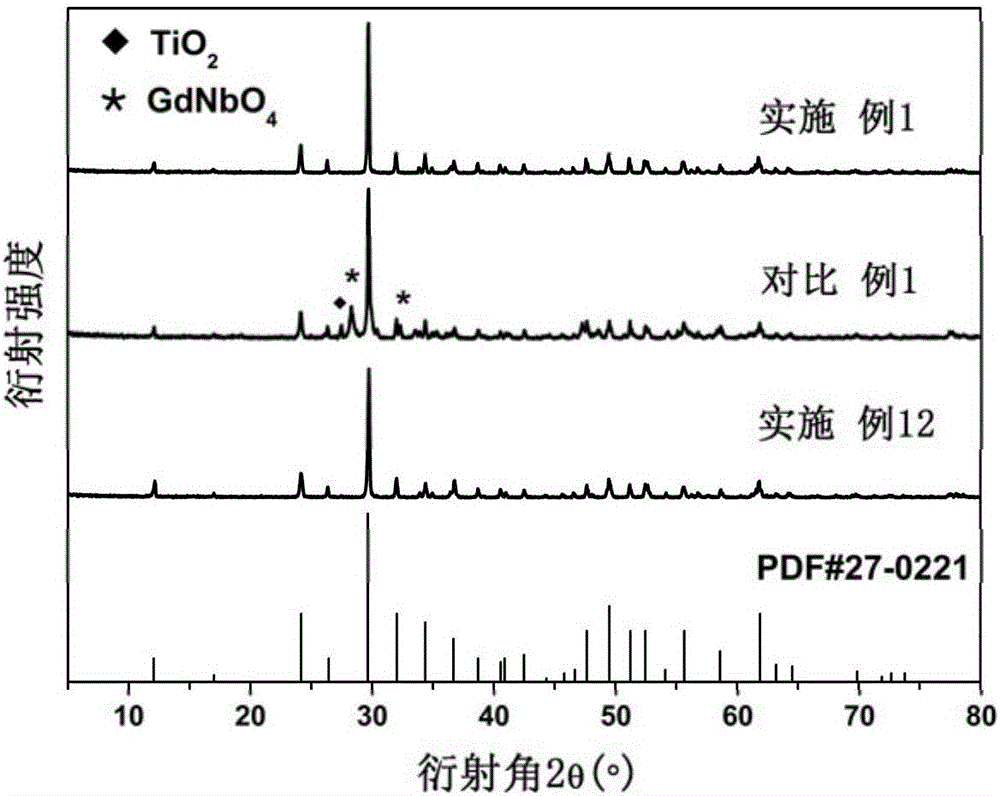

[0045] Example 1: GdNbTiO 6 Preparation of Phosphor Matrix

[0046] Weigh 0.7820gNb 2 o 5 , 1.0059g Gd 2 o 3 and 0.4447g TiO 2 Put it in an agate mortar and grind for 30 minutes to mix the ingredients evenly. Put the raw materials into a crucible and place them in a muffle furnace for two-step sintering (the first stage sintering temperature is 1200°C, heat preservation for 12 hours, then cool to room temperature with the furnace, and grind for 20 minutes; the second stage sintering temperature is 1250°C, heat preservation for 12 hours After cooling to room temperature with the furnace, the heating rate of the two-step sintering is 5°C / min. The fired sample is taken out and ground to prepare GdNbTiO 6 Phosphor matrix.

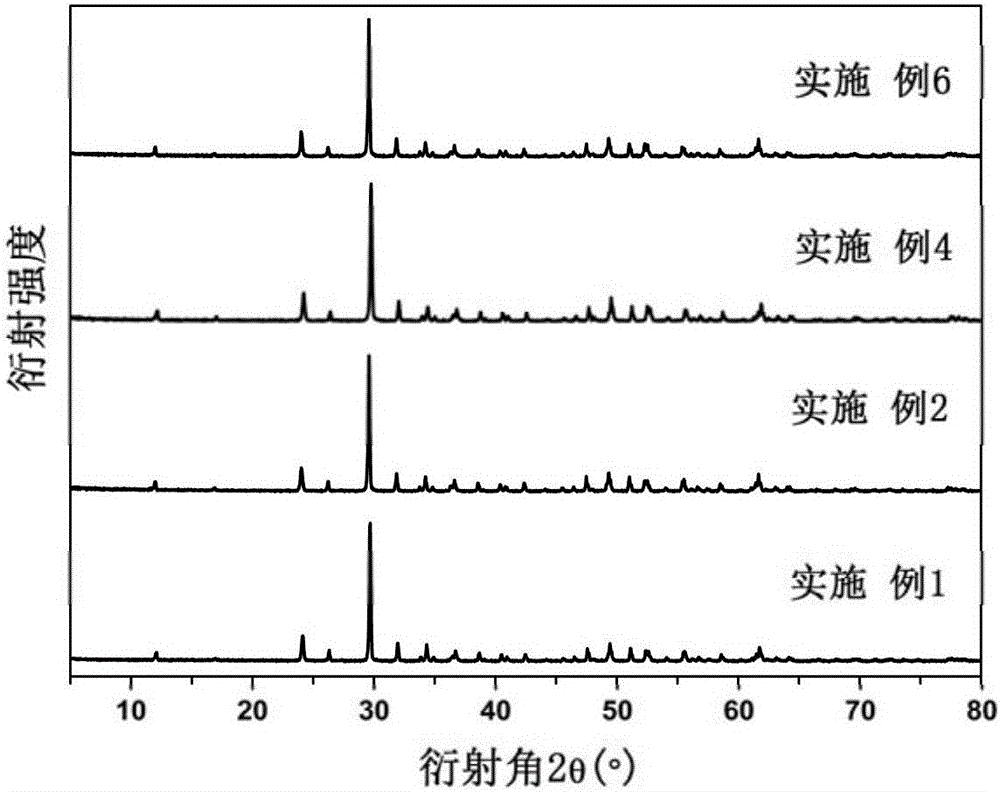

Embodiment 2

[0049] Embodiment 2: (Gd 0.99 Eu 0.01 )NbTiO 6 Phosphor powder preparation

[0050] Weigh 0.7820g Nb 2 o 5 , 0.9959g Gd 2 o 3 , 0.4447g TiO 2 and 0.0098g Eu 2 o 3 , the rest of the steps are the same as in Example 1.

Embodiment 3

[0051] Embodiment 3: (Gd 0.98 Eu 0.02 )NbTiO 6 Phosphor powder preparation

[0052] Weigh 0.7820g Nb 2 o 5 , 0.9858g Gd 2 o 3 , 0.4447g TiO 2 and 0.0195g Eu 2 o 3 , the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com