Green photoluminescent phosphor and preparing method thereof

A green fluorescent powder and photoluminescence technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of limited use, long afterglow time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

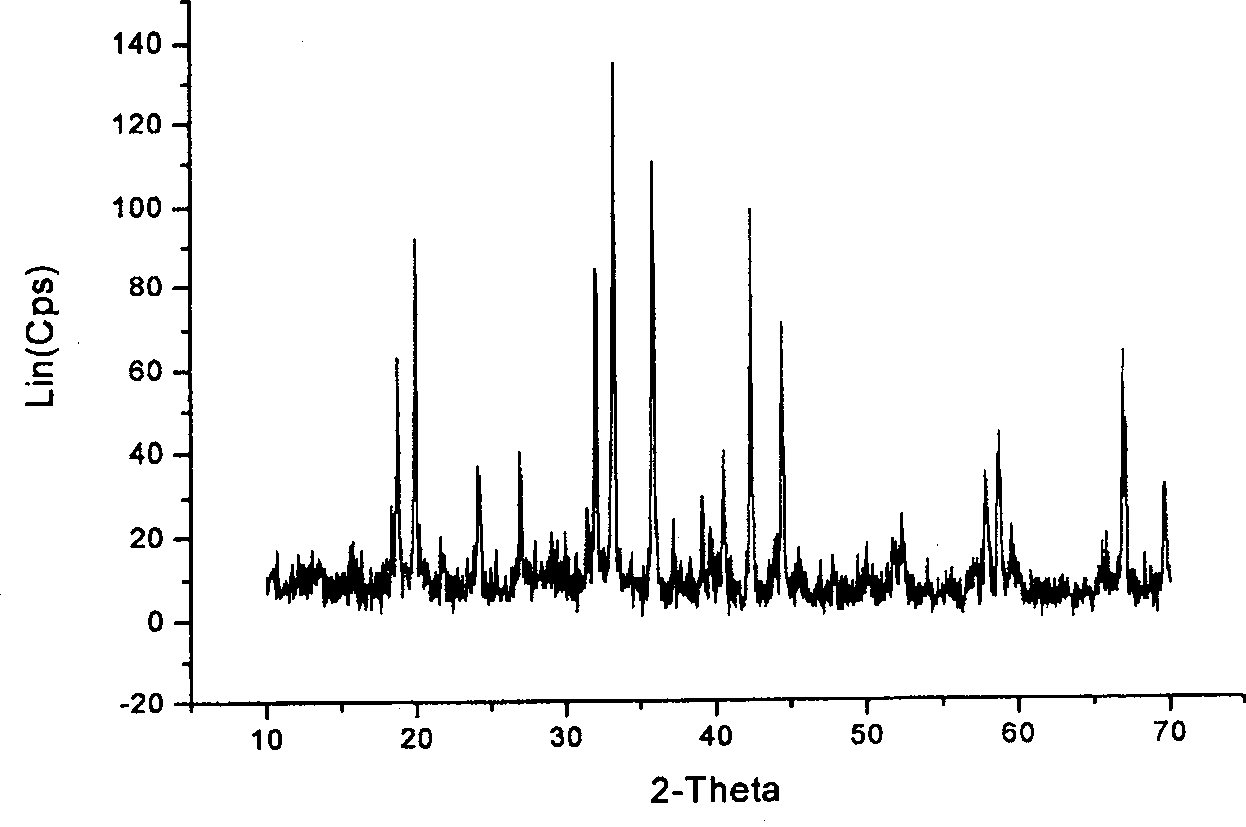

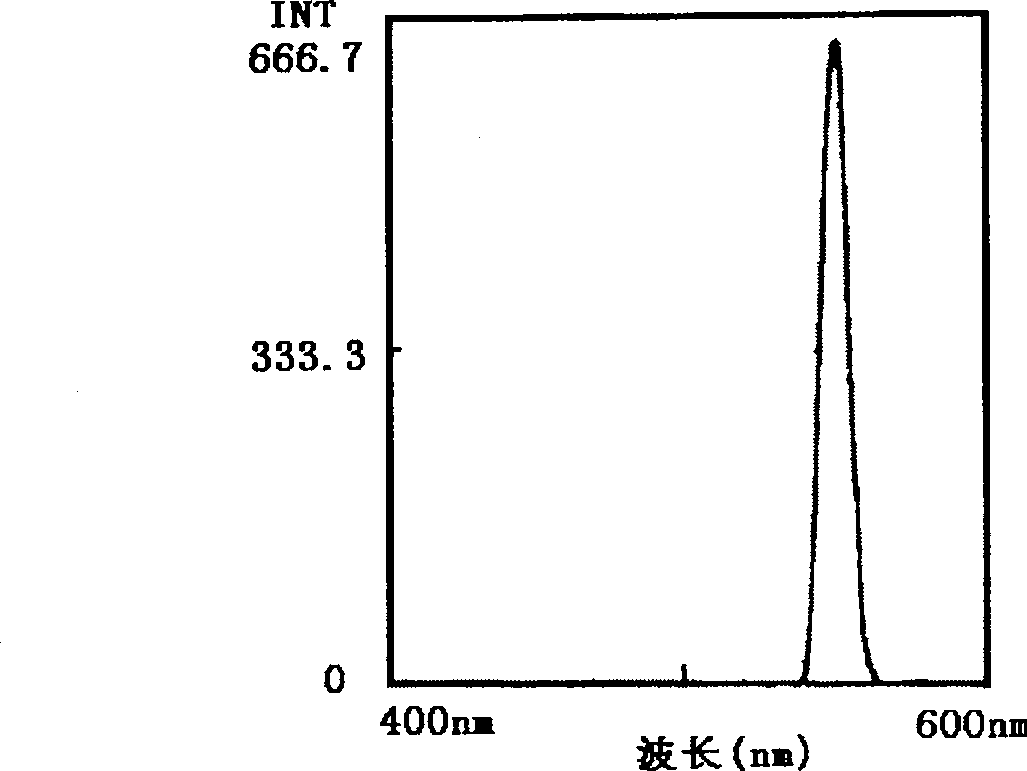

[0015] Embodiment 1: Weigh 0.019g of terbium oxide, 4.5016g of aluminum nitrate, 0.1954g of barium carbonate, and 6g of citric acid. Dissolve citric acid in water to make a citric acid solution. Terbium oxide is dissolved in nitric acid to produce terbium nitrate. Under the condition of heating, successively dissolve barium carbonate, aluminum nitrate and terbium nitrate in citric acid solution, and adjust the pH value to 6-7. Heat and stir at 80°C, and keep the pH value until gelling. The gel was dried for 2h to a bulky black powder. After grinding, the dry powder is calcined at 1200°C for 2 hours, then cooled to 900°C and fired with reducing gas for 2 hours to obtain a white fluorescent powder called Ba 0.99 al 12 o 19 :Tb 0.01 . Under the excitation of 276nm, the fluorescent powder has an emission peak at 550nm and is a single peak, and its luminous intensity is greater than that of the Ba prepared by the solid-phase method in Embodiment 2. 0.99 al 12 o 19 :Tb 0....

Embodiment approach 2

[0017] Embodiment 2: Weigh 0.019g of terbium oxide, 0.6118g of aluminum oxide, 0.1954g of barium carbonate and 0.015g of boron oxide, grind the above medicines with an agate mortar, and burn them at 1300°C for 2 hours in a reducing atmosphere to obtain a white Ba 0.99 al 12 o 19 :Tb 0.01 Phosphor powder, under the excitation of 276nm, a single emission peak at 550nm can be obtained, and the half-peak width is 12.2nm.

Embodiment approach 3

[0018] Embodiment three: take terbium oxide 0.037g, barium carbonate 0.1934g, other conditions are the same as embodiment two, and the white fluorescent powder that makes is Ba 0.98 al 12 o 19 :Tb 0.02 , when the phosphor is excited at 276nm, the emission peak has no change in the shape and position of the emission peak obtained by Scheme 1, the difference is that the luminous intensity is greater than Ba 0.99 al 12 o 19 :Tb 0.01 of luminous intensity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com