Nano fluorescent powder preparing method

A nano-phosphor, soluble technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of unfavorable display image dynamic display, imperfect color PDP performance, long luminescence afterglow time, etc., to improve quantum luminescence efficiency, Small particles and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0027] Preparation method embodiment 1 of the present invention, its steps are:

[0028] (1) Accurately weigh 7.94 grams of zinc oxide (ZnO) (analytical pure), 0.29 grams of manganese carbonate (MnCO 3 ) (analytically pure), 0.0045 grams of erbium oxide (Er 2 o 3 ) (99.99%), 11.5 mg tetraethyl orthosilicate ((C 2 h 5 ) 4 SiO 4 ) (analytically pure);

[0029] (2) zinc oxide (ZnO), manganese carbonate (MnCO 3 ), erbium oxide (Er 2 o 3 ) mixed into the beaker;

[0030] (3) Add 50 mg of 1:1 nitric acid (HNO 3 ) (analytical pure), heated and stirred to boiling, and fully dissolved the substance in the beaker;

[0031] (4) Add 50 milliliters of distilled water, and add 2 grams of cosolvents—boric acid (H 3 BO 3 ) (analytically pure), the mixed solution in the beaker is diluted; cooling;

[0032] (5) Slowly add 11.5 milliliters of tetraethyl orthosilicate ((C 2 h 5 ) 4 SiO 4 ), stir evenly and put it into a water bath device at 60-90°C to make it peptized until tran...

Embodiment approach 2

[0042] Preparation method embodiment 2 of the present invention, its steps are:

[0043] (1) Accurately weigh 7.94 grams of zinc oxide (ZnO) (analytical pure), 0.58 grams of manganese carbonate (MnCO 3 ) (analytically pure), 0.009 grams of erbium oxide (Er 2 o 3 ) (99.99%), 50 mg of 1:1 nitric acid (HNO 3 ) (analytically pure), 11.5 milligrams of ethyl orthosilicate ((C 2 h 5 ) 4 SiO 4 ) (analytically pure);

[0044] (2) zinc oxide (ZnO), manganese carbonate (MnCO 3 ), erbium oxide (Er 2 o 3 ) mixed into the beaker;

[0045] (3) Add nitric acid (HNO 3 ), heating and stirring until boiling, and fully dissolving the substance in the beaker;

[0046](4) First add 2 grams of boric acid to 50 milliliters of distilled water for dilution, then add boric acid and distilled water to the container to dilute the mixed solution in the beaker; cool;

[0047] Other steps are the same as the preparation method embodiment 1 of the present invention.

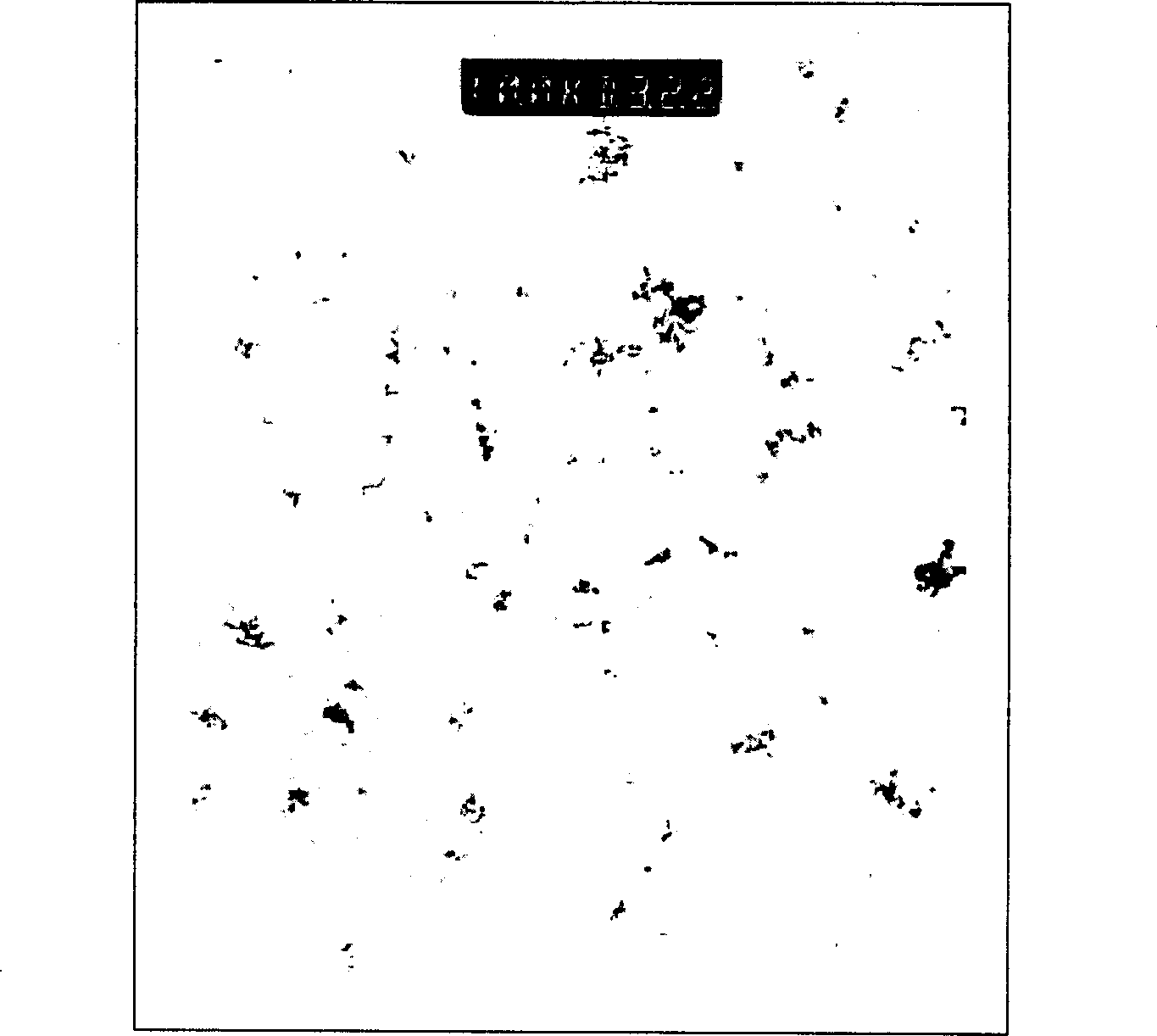

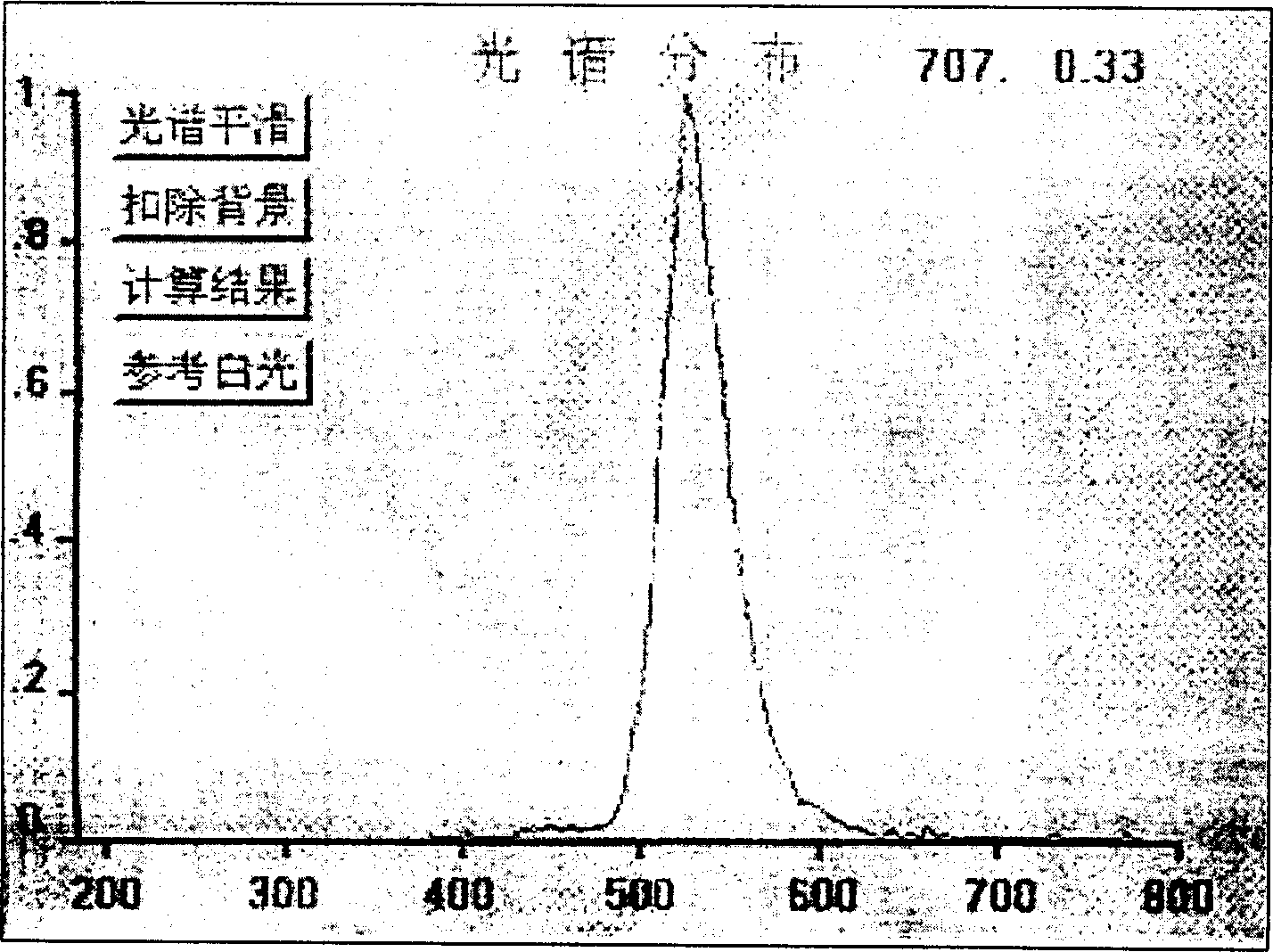

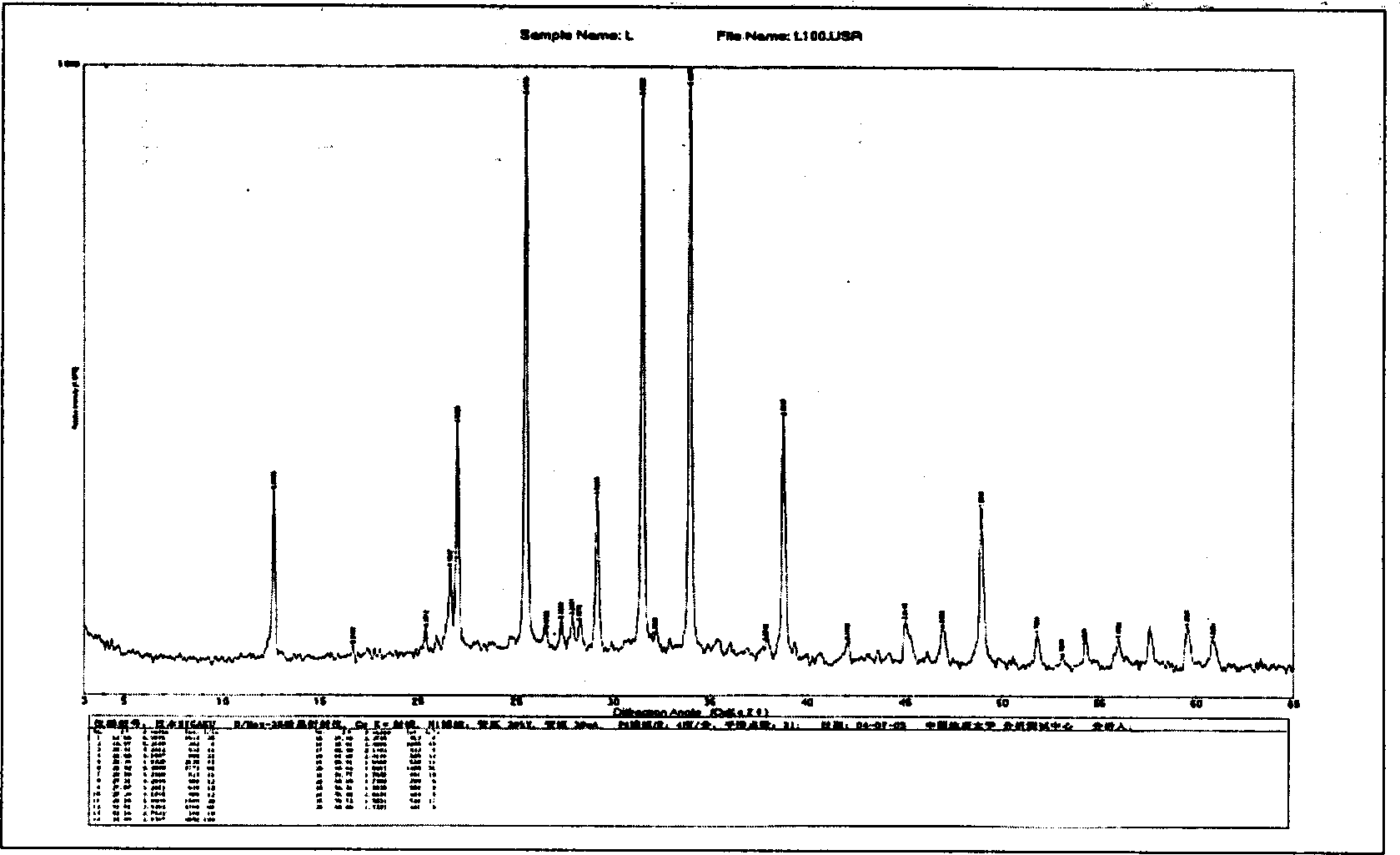

[0048] Such as figure 1 , ...

Embodiment approach 3

[0049] Preparation method embodiment 3 of the present invention, its steps are:

[0050] (1) Accurately weigh 7.94 grams of zinc oxide (ZnO) (analytical pure), 1.15 grams of manganese carbonate (MnCO 3 ) (analytically pure), 0.0023 grams of erbium oxide (Er 2 o 3 ) (99.99%), 50 mg of 1:1 nitric acid (HNO 3 ) (analytically pure), 11.5 milligrams of ethyl orthosilicate ((C 2 h 5 ) 4 SiO 4 ) (analytically pure);

[0051] (2) zinc oxide (ZnO), manganese carbonate (MnCO 3 ), erbium oxide (Er 2 o 3 ) mixed into the beaker;

[0052] (3) Add nitric acid (HNO 3 ), heating and stirring until boiling, and fully dissolving the substance in the beaker;

[0053] (4) Add 50 milliliters of distilled water, and add 4 grams of co-solvent---boric acid (H 3 BO 3 ) (analytically pure), the mixed solution in the beaker is diluted; cooling;

[0054] Other steps are the same as the preparation method embodiment 1 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com