Ultraviolet light emitting diode, ultraviolet LED epitaxial layer structure and preparation method thereof

A technology of light-emitting diodes and epitaxial layers, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of high density, slow lateral closure rate of AlGaN, and inability to annihilate dislocations, so as to improve crystal quality, increase luminous intensity, and promote Effects of Diagonal Climbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] One aspect of the present invention provides a method for preparing an ultraviolet LED epitaxial layer structure, which includes the following steps:

[0035] Provide a nano-patterned sapphire substrate with a chamfer angle on the c-plane, the angle of the chamfer angle is 0.5°~8°;

[0036] growing an AlN epitaxial layer on the substrate;

[0037]Al growth on AlN epitaxial layer x Ga 1-x N epitaxial layer;

[0038] in Al x Ga 1-x n-Al growth on N epitaxial layer y Ga 1-y N contact layer;

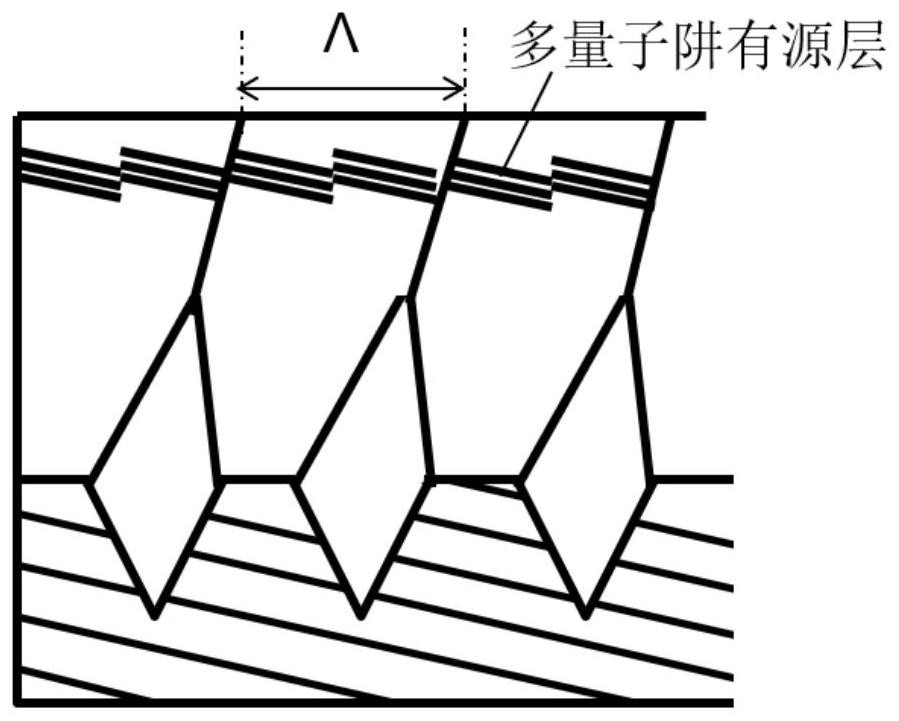

[0039] in n-Al y Ga 1-y Al growth on the N contact layer m Ga 1-m N / Al n Ga 1-n N multiple quantum well active layer; and

[0040] in Al m Ga 1-m N / Al n Ga 1-n A p-type contact layer is grown on the N multi-quantum well active layer, wherein the p-type contact layer is p-Al g Ga 1-g N / p-GaN superlattice contact layer, p-Al g Ga 1-g At least one of an N contact layer and a p-GaN contact layer;

[0041] Wherein, 0.5≤x≤1, 0.5≤y≤1, 0.3≤m≤0.7, 0.3≤n≤0.7, and x≥y≥m≥n;...

Embodiment 1

[0060] Embodiment 1 Preparation of UV LED Epitaxial Layer Structure

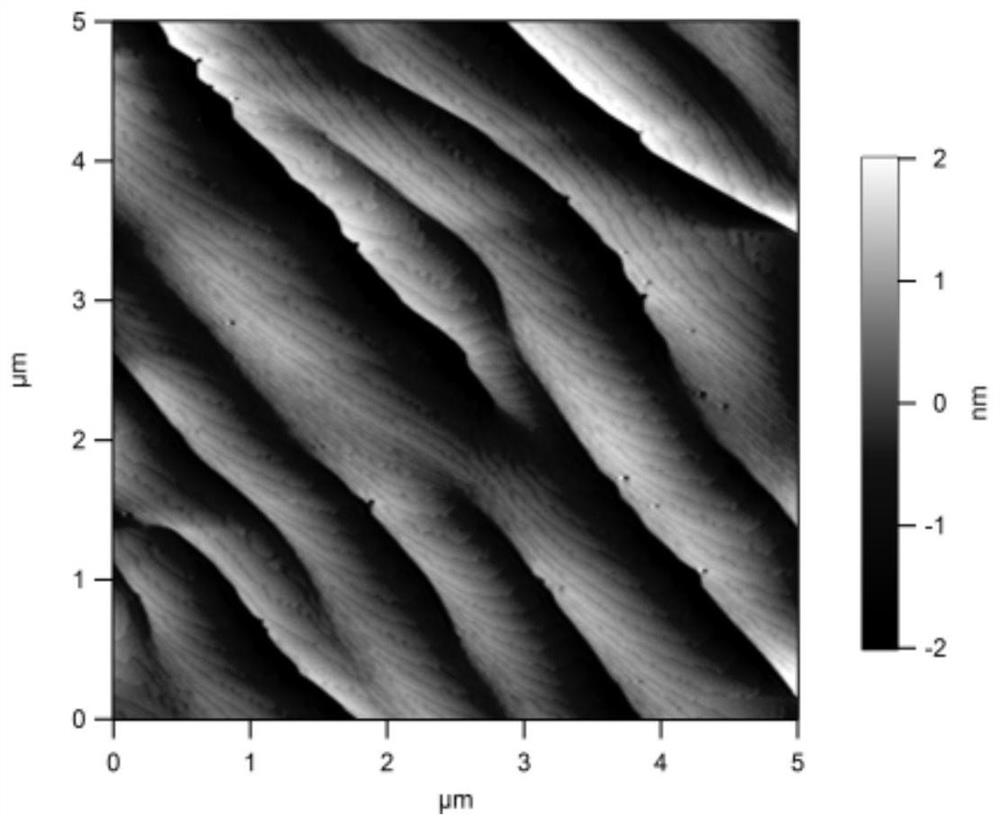

[0061] (1) Adopt a 2-inch c-plane sapphire substrate, and make a sapphire substrate in which the c-plane is inclined 0.5° toward the m-plane through a cutting process;

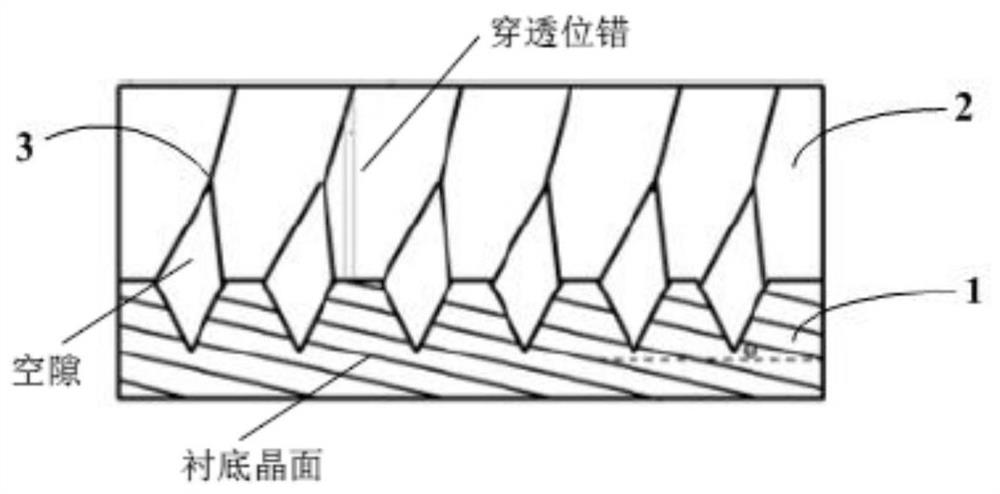

[0062] (2) Prepare a nano-patterned sapphire substrate with an inverted pyramid structure on the sapphire substrate in step (1) by nanoimprinting technology. The period of the nanopatterned structure on the nanopatterned sapphire substrate is 2 μm, and the depth of the inverted pyramid structure is 1 μm;

[0063] (3) Place the nanopatterned sapphire substrate in step (2) in an MOCVD device, and grow a 2 μm thick AlN epitaxial layer, an 800 nm thick Al 0.7 Ga 0.3 N epitaxial layer, 500nm thick n-Al 0.65 Ga 0.35 N and 300nm thick n-Al 0.55 Ga 0.45 The contact layer composed of N together, and further grow 80nm thick Al on the contact layer 0.6 Ga 0.4 N / Al 0.5 Ga 0.5 N multi-quantum well active layer, this layer includes 5 pairs of Al...

Embodiment 2

[0065] Embodiment 2 Preparation of UV LED Epitaxial Layer Structure

[0066] (1) Adopt a 2-inch c-plane sapphire substrate, and make a sapphire substrate in which the c-plane is inclined 2° toward the a-plane through a cutting process;

[0067] (2) Prepare a nano-patterned sapphire substrate with an inverted pyramid structure on the sapphire substrate in step (1) by nanoimprinting technology. The period of the nanopatterned structure on the nanopatterned sapphire substrate is 1 μm, and the depth of the inverted pyramid structure is 500nm;

[0068] (3) Place the nanopatterned sapphire substrate in step (2) in an MOCVD device, and grow a 2 μm thick AlN epitaxial layer, an 800 nm thick Al 0.8 Ga 0.2 N epitaxial layer, 500nm thick n-Al 0.65 Ga 0.35 N and 300nm thick n-Al 0.55 Ga 0.45 The contact layer composed of N together, and further grow 50nm thick Al on the contact layer 0.6 Ga 0.4 N / Al 0.5 Ga 0.5 N multi-quantum well active layer, this layer includes 3 pairs of Al ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com