Method for manufacturing semiconductor element with concave-convex base plate

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as complex process procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

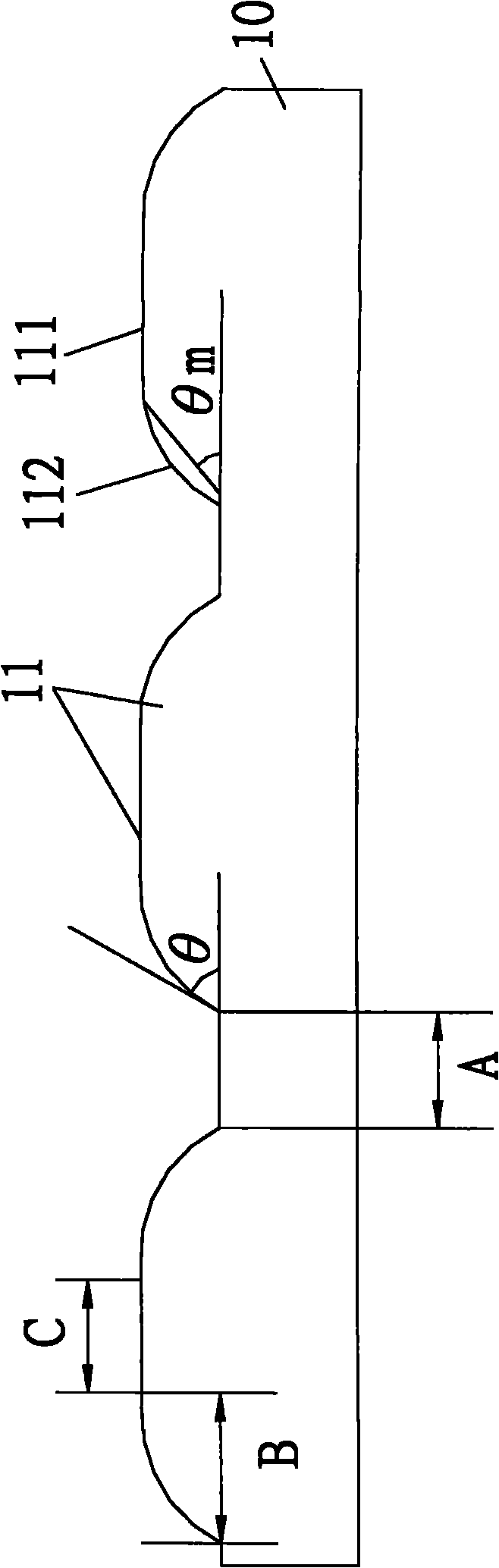

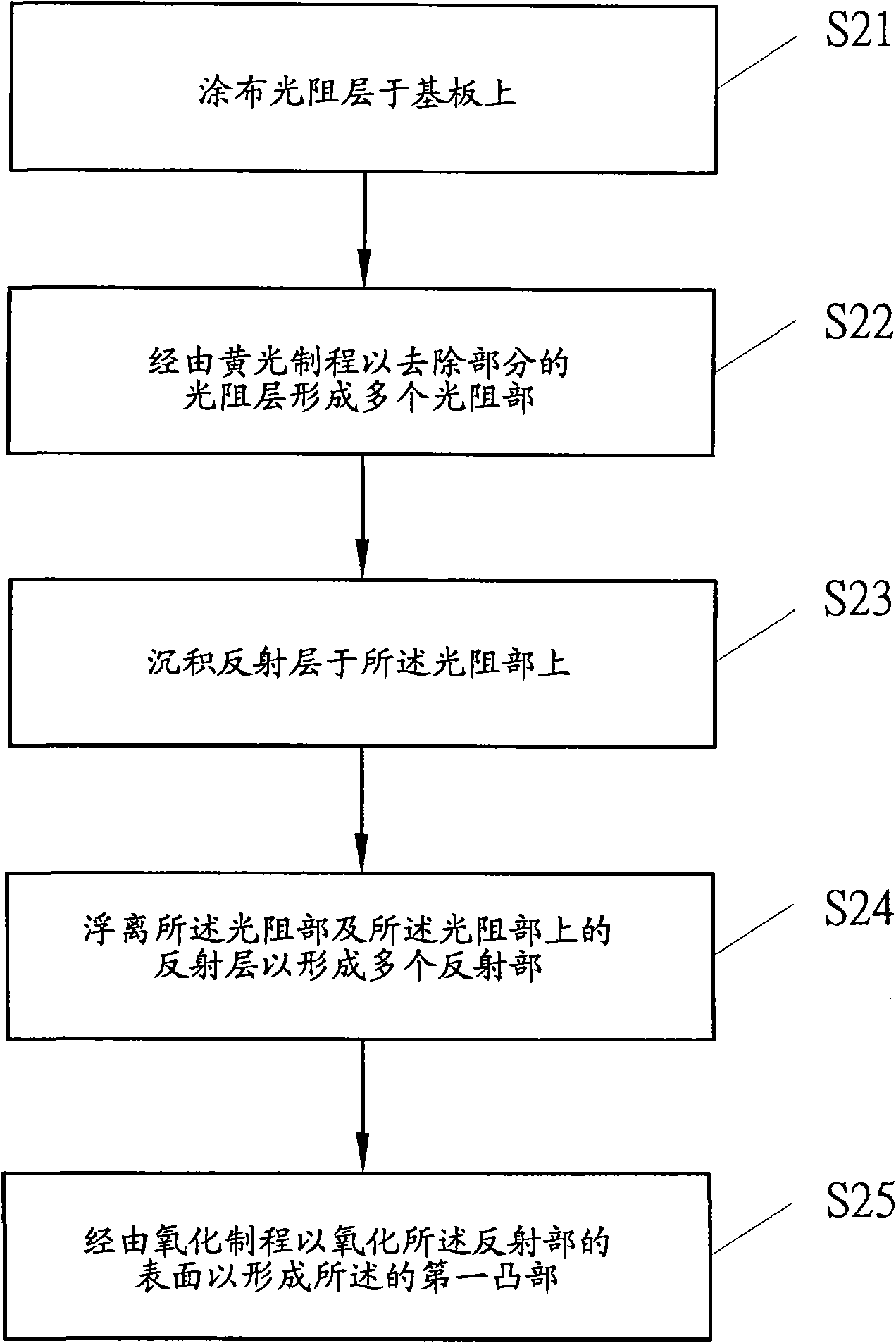

[0025] The method for manufacturing a semiconductor device with a concave-convex substrate according to an embodiment of the present invention will be described below with reference to related drawings. For ease of understanding, the same components in the following embodiments are described with the same symbols.

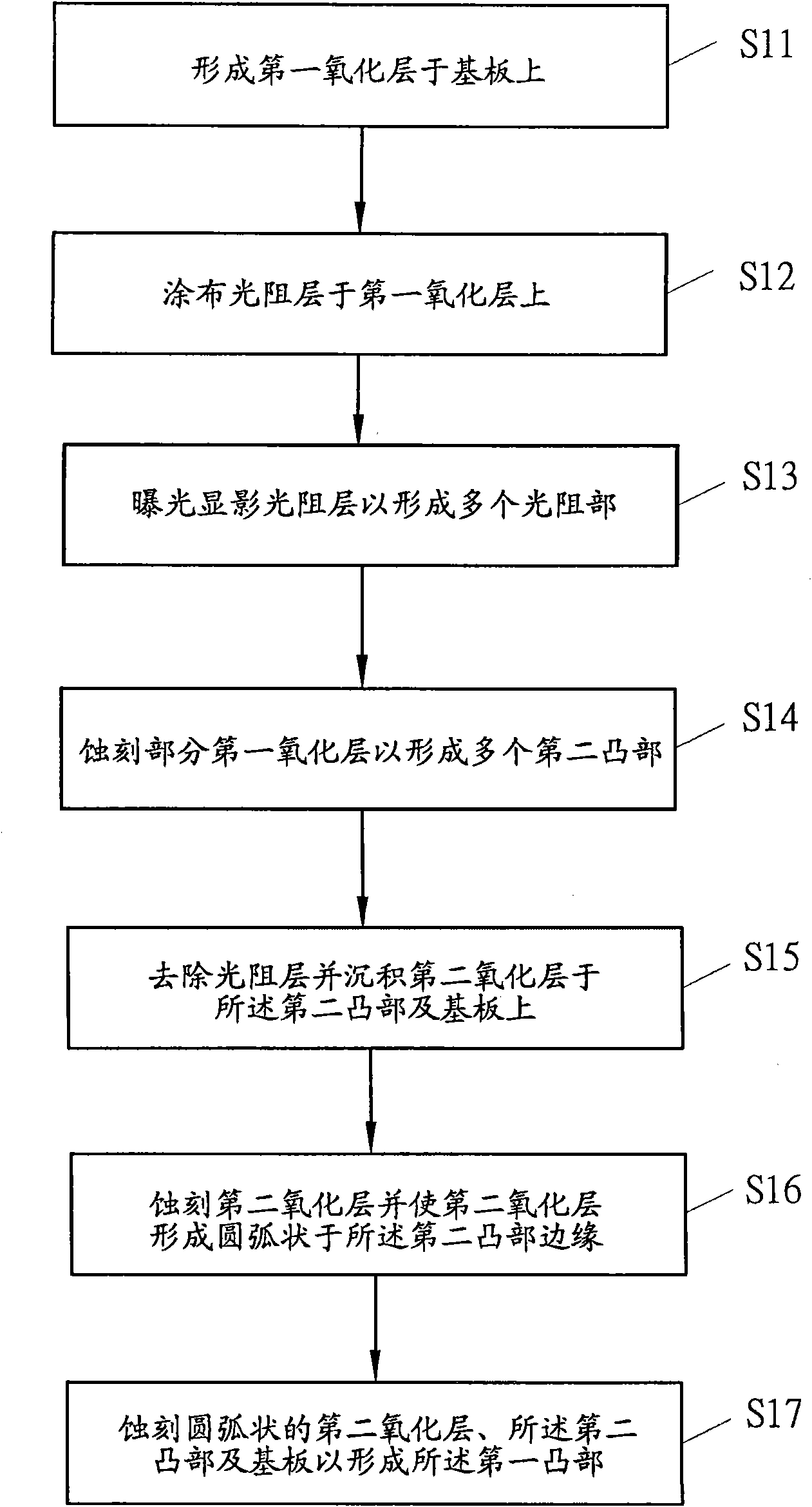

[0026] Figure 1A It is a flow chart of the first embodiment of the method for manufacturing a semiconductor element with a concave-convex substrate of the present invention. The semiconductor element has a substrate and a plurality of semiconductor layers, and the substrate includes a plurality of first protrusions, such as Figure 1A As shown, the manufacturing method includes: in step S11, forming a first oxide layer on the substrate; in step S12, coating a photoresist layer on the first oxide layer; in step S13, exposing and developing the photoresist layer to form multiple a photoresist; in step S14, etching the first oxide layer not covered by the photoresist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com