Rare earth oxide solid solution ceramic scintillator and preparation method thereof

A technology of rare earth oxides and scintillators, which is applied in the field of ceramic scintillation materials, can solve the problems of reducing material density and absorbing radiation, reducing detector resolution, and reducing UV emission intensity, achieving excellent scintillation performance, cost reduction, The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

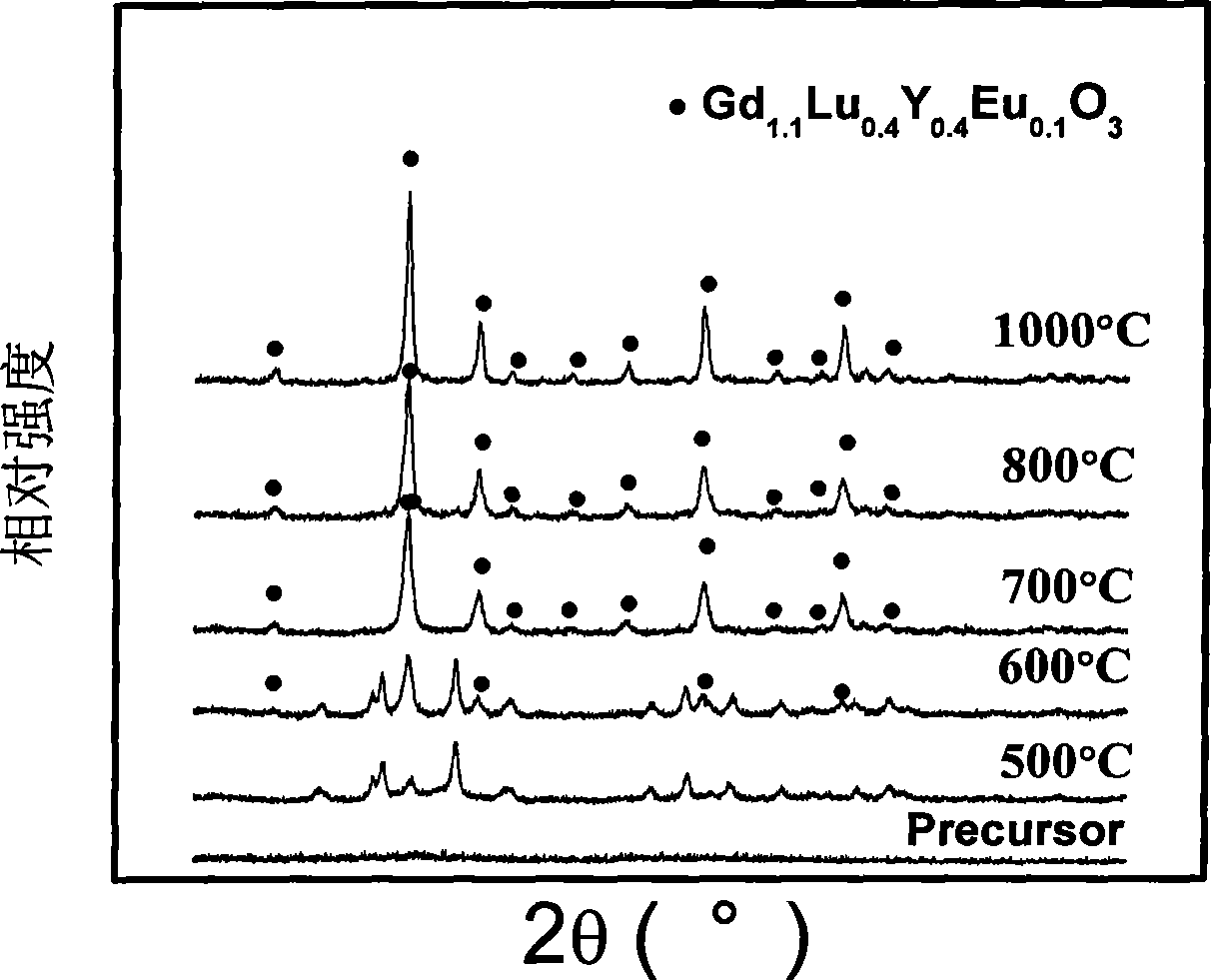

[0034] Preparation of Gd 1.1 Lu 0.4 Y 0.4 Eu 0.1 o 3 Ceramics, Gd(NO 3 ) 3 :Lu(NO 3 ) 3 :Y(NO 3 ) 3 :Eu(NO 3 ) 3 =0.55:0.2:0.2:0.05 Prepare mixed nitrate solution, the total concentration of rare earth ions in the mixed solution is 0.5mol / l. A mixed solution of ammonia water with a concentration of 2 mol / l and ammonium bicarbonate with a concentration of 0.5 mol / l is used as the precipitant. Gradually titrate the precipitant into the mixed rare earth nitrate solution, keep stirring, and continuously produce white flocculent precipitation, stop the titration when the pH of the solution reaches 8, continue stirring for 30 minutes, age, filter, and then use the precipitates separately Ionized water and absolute ethanol were washed 3 times each, dried in an oven for 24 hours, calcined, and ground to obtain a nanoscale cubic rare earth oxide solid solution ceramic powder, as shown in the attached figure 1 Shown is the XRD pattern of the powder, the powder particles are...

Embodiment 2

[0039] Preparation of Gd 1.2 Lu 0.2 Y 0.4 Eu 0.2 o 3 Ceramics, Gd(NO 3 ) 3 :Lu(NO 3 ) 3 :Y(NO 3 ) 3 :Eu(NO 3 ) 3 =0.6:0.1:0.2:0.1 Prepare mixed nitrate solution, the total concentration of rare earth ions in the mixed solution is 0.5mol / l. A mixed solution of ammonia water with a concentration of 2 mol / l and ammonium bicarbonate with a concentration of 0.5 mol / l is used as the precipitant. Gradually titrate the precipitant into the mixed rare earth nitrate solution, keep stirring, and continuously produce white flocculent precipitation, the pH of the solution reaches 9 when the titration ends, continue to stir for 30 minutes, age, filter, and then use the precipitates separately Washing with deionized water and absolute ethanol three times each, drying in an oven for 24 hours, calcining, and grinding to obtain nanoscale cubic rare earth oxide solid solution ceramic powder, the powder particles are nearly spherical and uniform. The calcination temperature is 700° C...

Embodiment 3

[0043] Preparation of Gd 0.2 Lu 0.8 Y 0.98 Eu 0.02 o 3 Ceramics, Gd(NO 3 ) 3 :Lu(NO 3 ) 3 :Y(NO 3 ) 3 :Eu(NO 3 ) 3 =0.1:0.4:0.49:0.01 Prepare mixed nitrate solution, the total concentration of rare earth ions in the mixed solution is 0.5mol / l. A mixed solution of ammonia water with a concentration of 2 mol / l and ammonium bicarbonate with a concentration of 0.5 mol / l is used as the precipitant. Gradually titrate the precipitant into the mixed rare earth nitrate solution, keep stirring, and continuously produce white flocculent precipitation, the pH of the solution reaches 9 when the titration ends, continue to stir for 30 minutes, age, filter, and then use the precipitates separately Washing with deionized water and absolute ethanol three times each, drying in an oven for 24 hours, calcining, and grinding to obtain nanoscale cubic rare earth oxide solid solution ceramic powder, the powder particles are nearly spherical and uniform. The calcination temperature is 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com