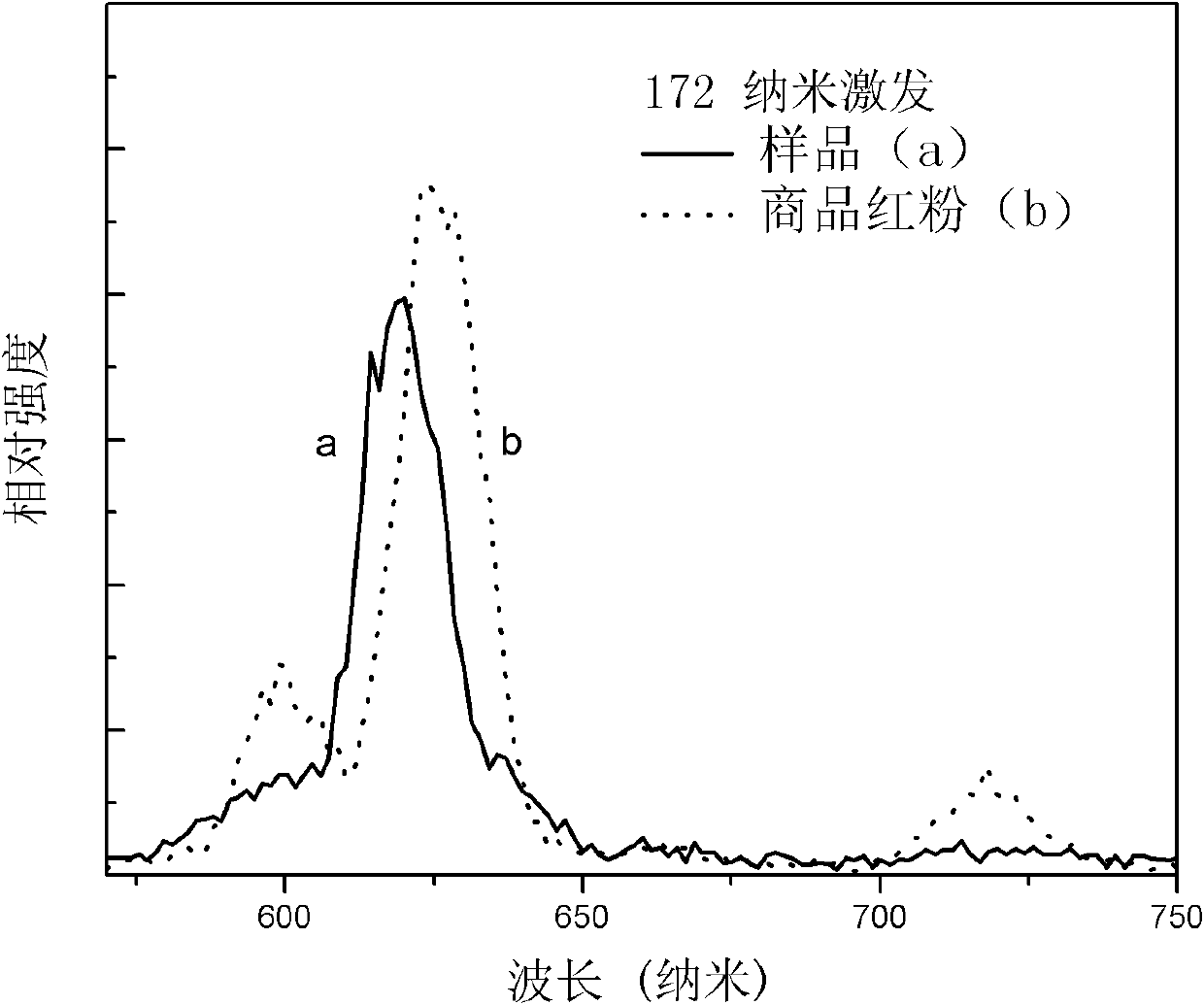

Red fluorescent powder for PDP (Plasma Display Panel) and preparation method thereof

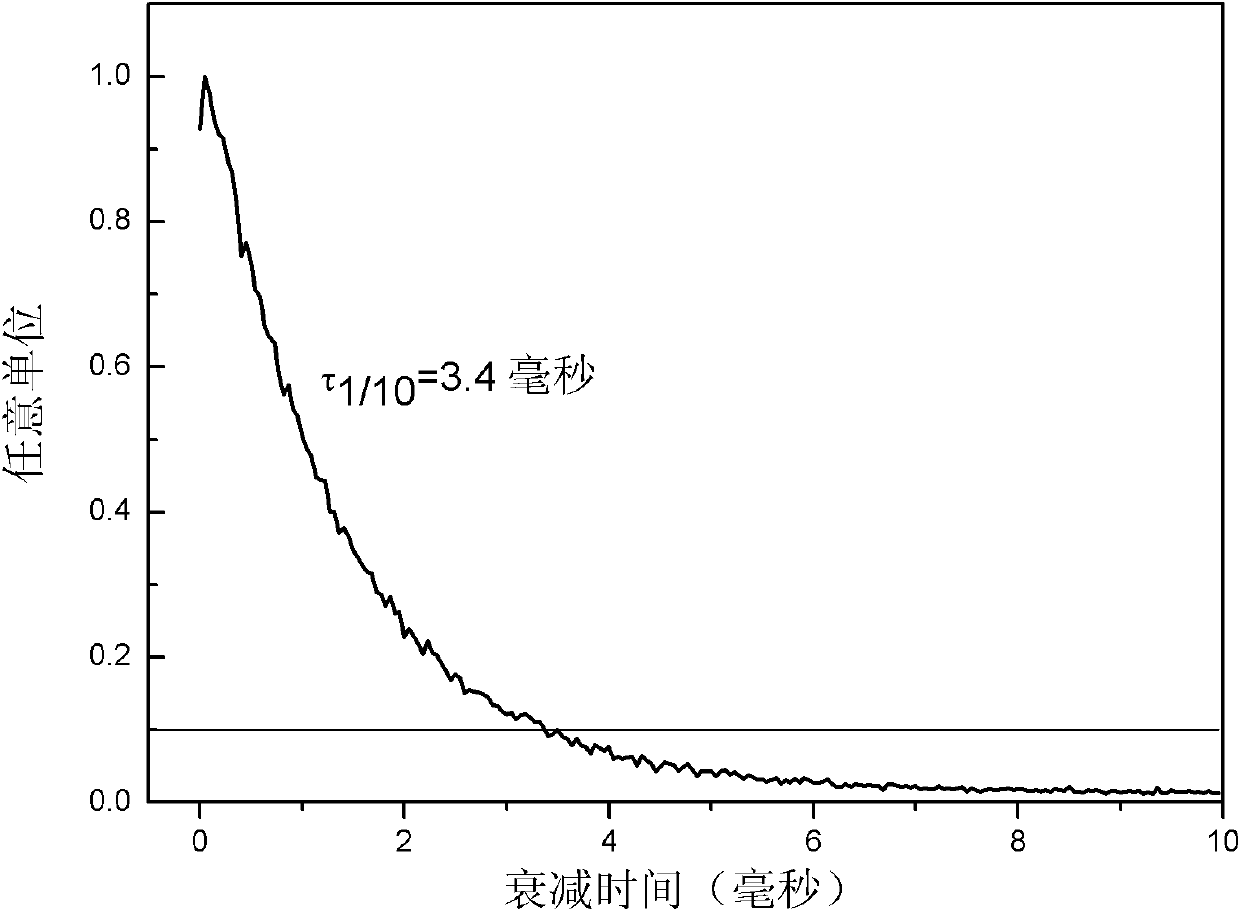

A red fluorescent powder, selected technology, applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of red fluorescent powder long afterglow, environmental pollution, toxic synthetic raw materials, etc., achieve reduction of afterglow time, simple preparation process, easy to use The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] Preferably, RE is selected from La 3+ , Sc 3+ , Gd 3+ , Lu 3+ One or more of these ions have the advantage of being able to effectively adjust the size of the matrix crystal lattice, sensitize the luminescence, and at the same time not affect the luminous color of the phosphor. Preferably, R is selected from Li + , Na + , K + , Rb + , Cs + One or more of these ions have the advantage of being able to effectively adjust the size of the matrix crystal lattice, sensitize the luminescence, and at the same time not affect the luminous color of the phosphor. According to another aspect of the present invention, according to a typical embodiment of the present invention, the preparation method of the red phosphor for PDP includes the following steps: 1) According to the chemical formula (Y 1-x-y-z Eu x RE y R z ) 2 O 3 The molar ratio of each element in is called Y 2 O 3 , Eu 2 O 3 , RE 2 O 3 And R-containing compounds, where 0.005≤x≤0.40, 0.00≤y≤0.40, 0.005≤z≤0.10, and the R-con...

Embodiment 1

[0023] Weigh yttrium oxide (Y 2 O 3 )0.0064mol, gadolinium oxide (Gd 2 O 3 )0.0025mol, europium oxide (Eu 2 O 3 )0.0005mol, lithium carbonate (Li 2 CO 3 ) 0.0006mol, fully ground in an agate mortar and mixed uniformly, sintered at 1300°C for 3 hours, cooled to room temperature, the sample is taken out and ground, washed with deionized water, filtered, and dried to obtain the final product.

Embodiment 2

[0025] Weigh yttrium oxide (Y 2 O 3 )0.0064mol, lanthanum oxide (La 2 O 3 )0.0025mol, europium oxide (Eu 2 O 3 )0.0005mol, lithium carbonate (Li 2 CO 3 ) 0.0006 mol, fully ground in an agate mortar and mixed uniformly, sintered at 1100°C for 5 hours, cooled to room temperature, the sample is taken out and ground, washed with deionized water, filtered, and dried to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com