Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Reduce the frequency of opening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

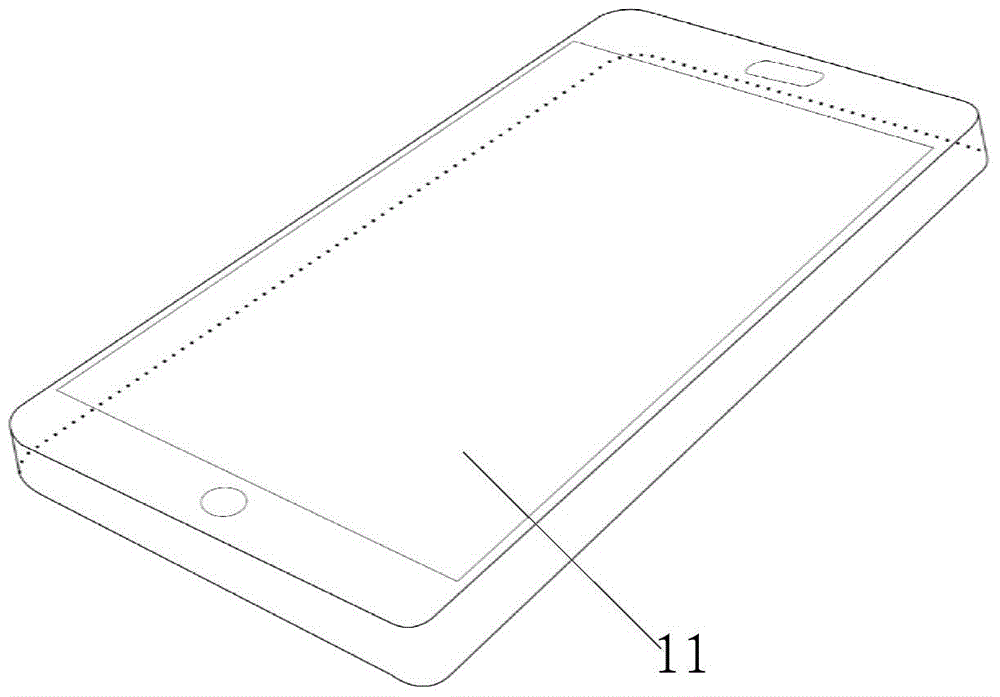

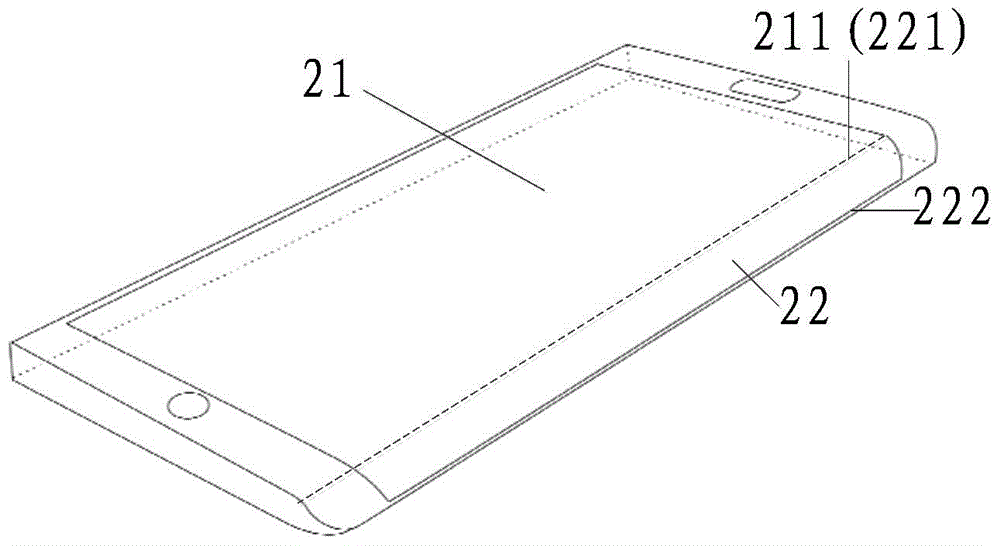

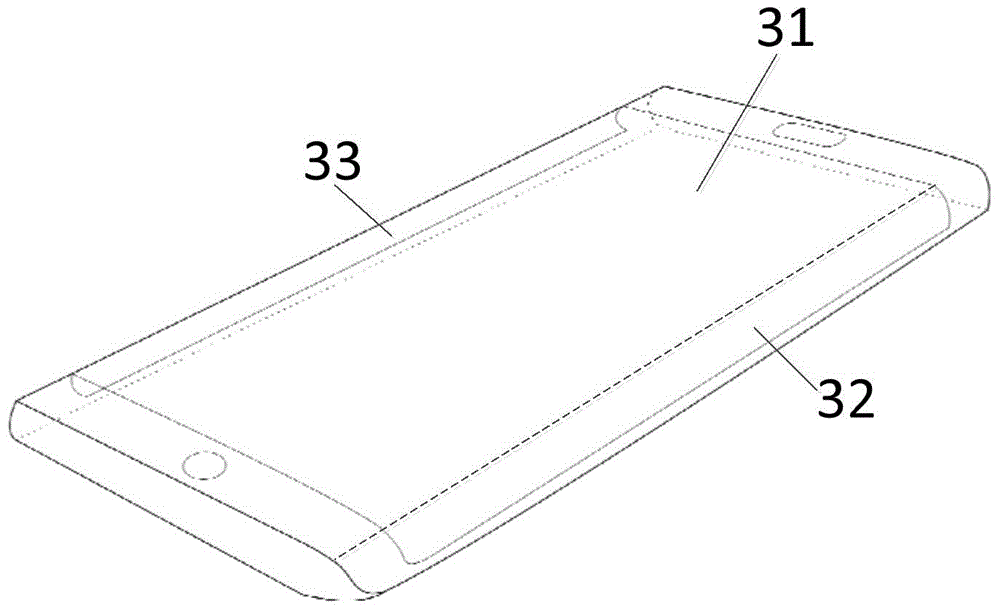

Mobile terminal

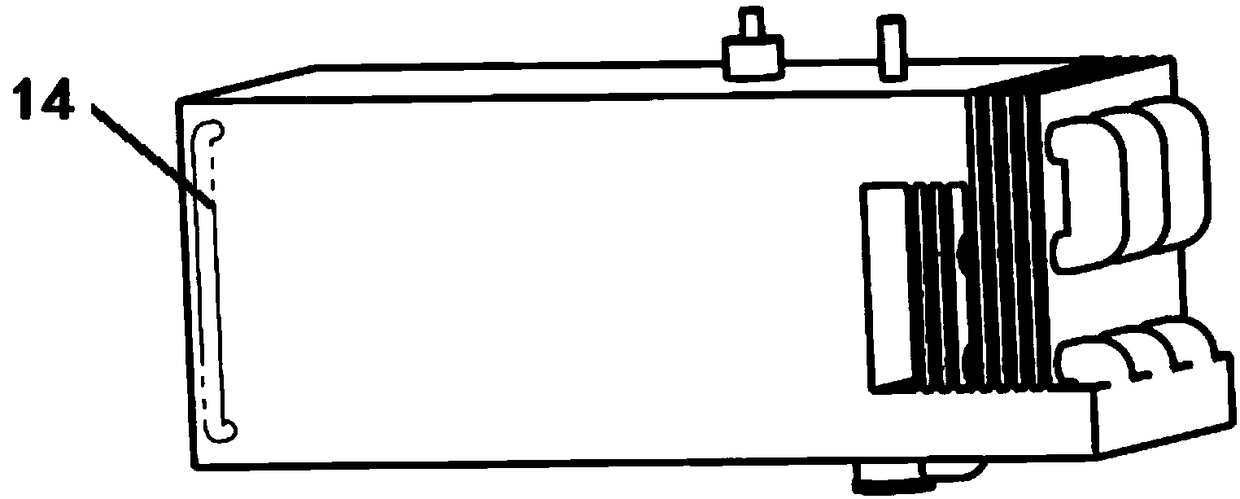

InactiveCN104902038AReduce the frequency of openingGood value for moneyCurrent supply arrangementsTelephone set constructionsElectricityComputer terminal

The invention discloses a mobile terminal. The mobile terminal comprises: a first screen which is made of an LCD material, is disposed at the upper surface of the mobile terminal and is provided with a rectangular plane comprising a first side edge; a second screen which is made of an OLCD material and is provided with an arc surface comprising a first straight edge and a second straight edge parallel to each other, wherein the first straight edge is adjacent to the first side edge, and the second straight edge is arranged at the side surface of the mobile terminal; a first circuit which is connected with the first screen for controlling displaying of the first screen; and a second circuit which is connected with the second screen for controlling the displaying of the second screen. The mobile terminal provided by the invention can enable the operation of the mobile terminal o be simpler and faster and saves more electricity under the condition that high cost performance of a main screen is guaranteed.

Owner:TRULY OPTO ELECTRONICS

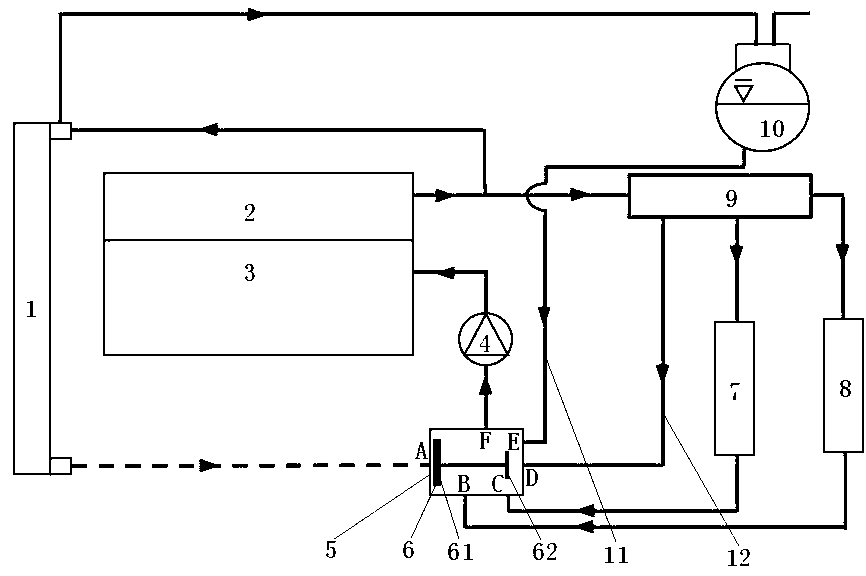

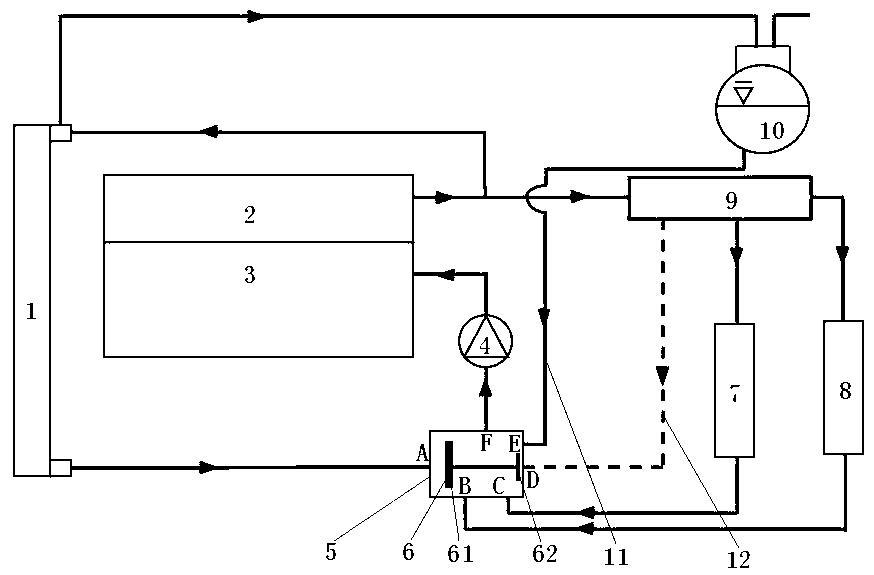

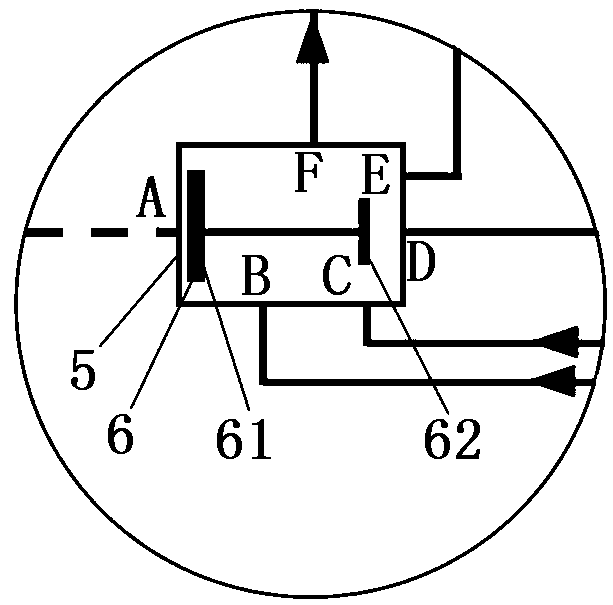

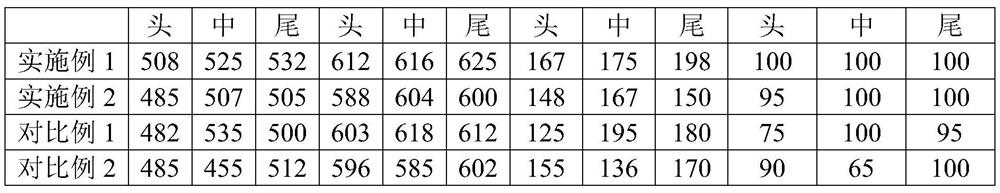

Gasoline engine cooling system

ActiveCN102705055AAvoid cavitationImprove cooling performanceLiquid coolingCoolant flow controlExpansion tankThermal shock

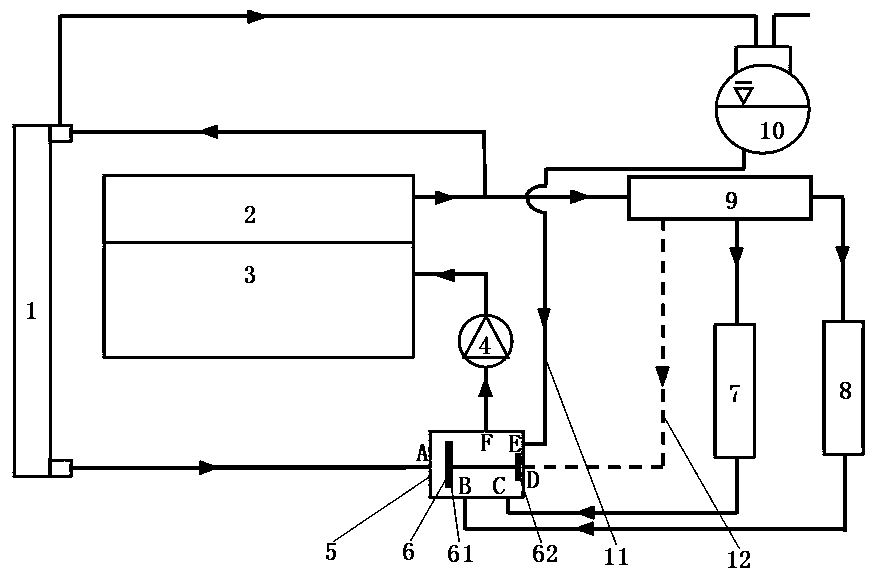

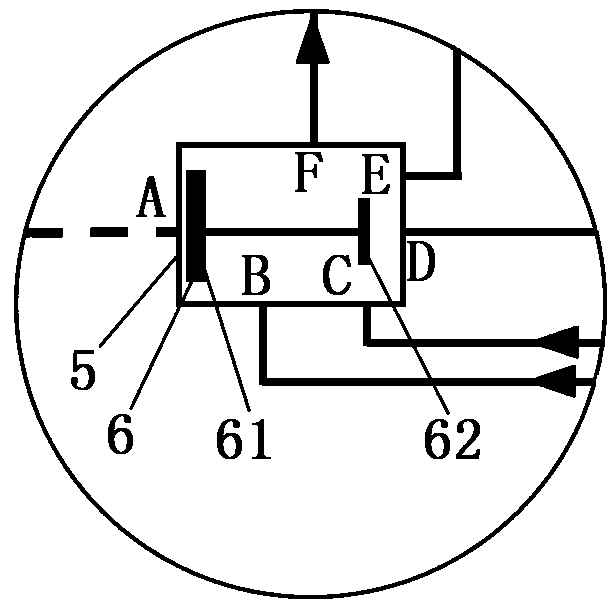

The invention discloses a gasoline engine cooling system, which comprises a radiator, a cylinder cover water jacket, a cylinder body water jacket, a water pump, an expansion tank and a thermoregulator valve seat, wherein a thermoregulator is arranged in the thermoregulator valve seat; the thermoregulator valve seat is provided with five inlets and one outlet F; the first inlet A is communicated with a lower water chamber of the radiator; the second inlet B is communicated with the outlet of a fan heater; the third inlet C is communicated with the outlet of an air damper; the fourth inlet D is communicated with the outlet of a distributive pipe via a small circulation circuit; the fifth inlet E is communicated with the expansion tank via a water replenishing circuit; the outlet F is communicated with the water inlet of the water pump; the thermoregulator is a double-valve wax type thermoregulator and comprises a main valve and an auxiliary valve, wherein the main valve is installed on the first inlet A of the thermoregulator valve seat; and the auxiliary valve is just against the fourth inlet D of the thermoregulator valve seat. According to the gasoline engine cooling system disclosed by the invention, gas in cooling liquid can be removed to protect the water pump from cavitation, the cooling performance of the cooling system is improved, an engine is prevented from overheating, and thermal shock is prevented from generating in the cooling system.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

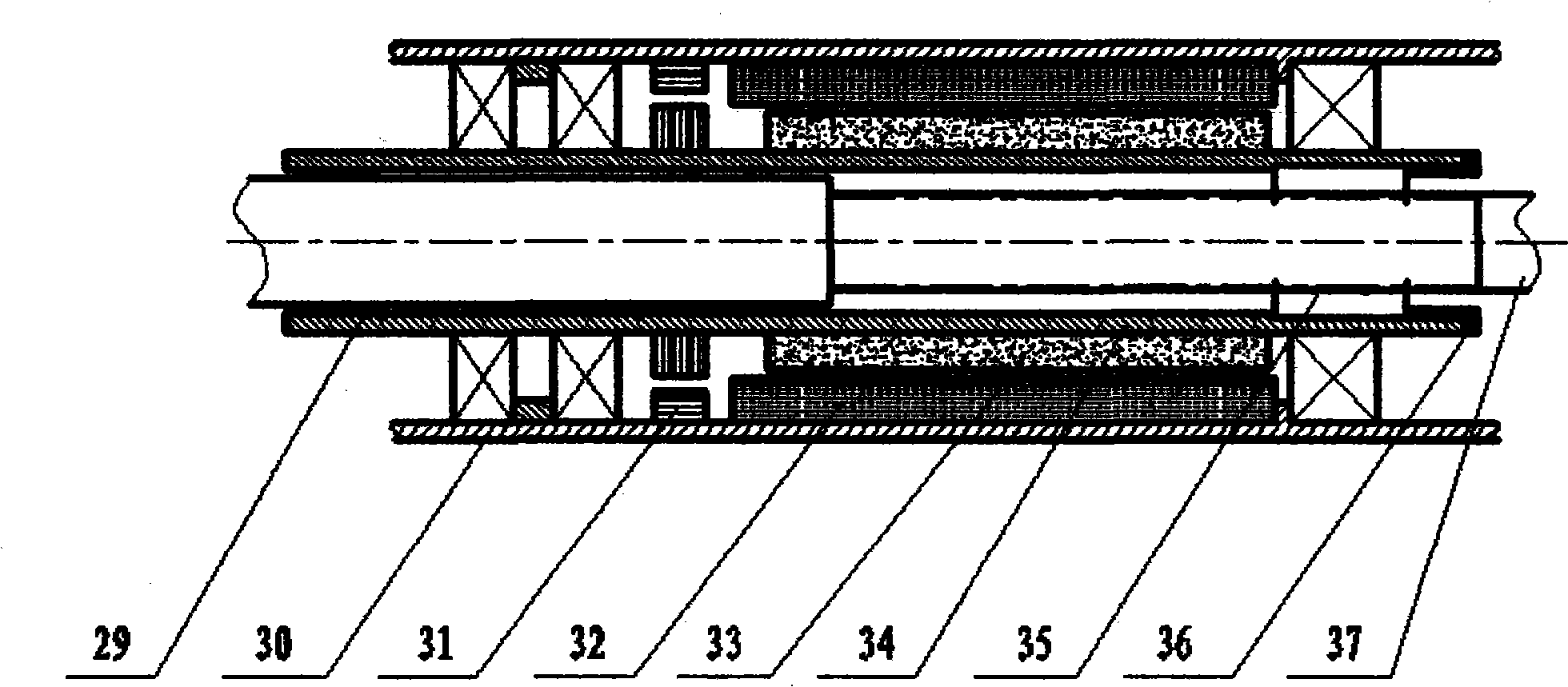

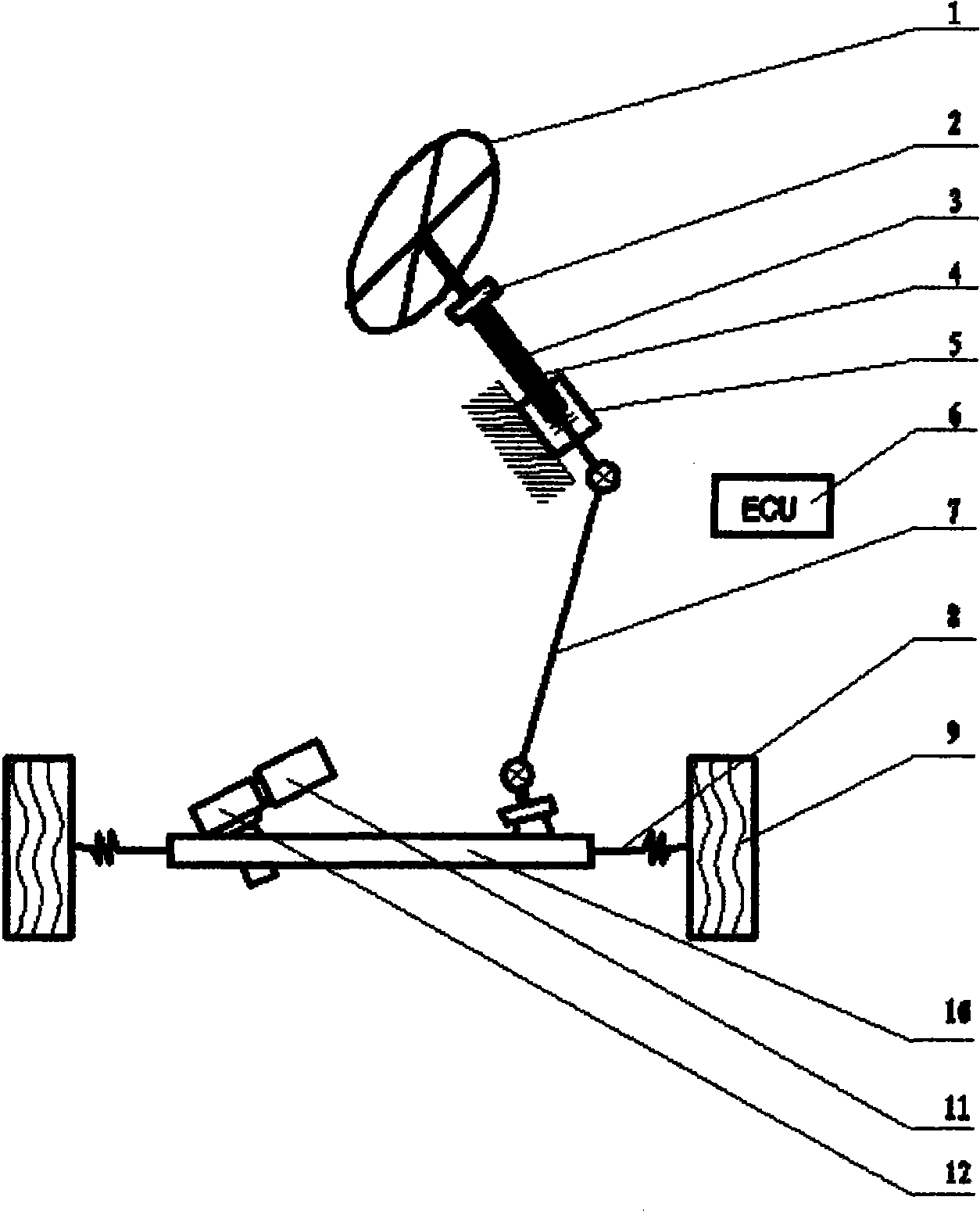

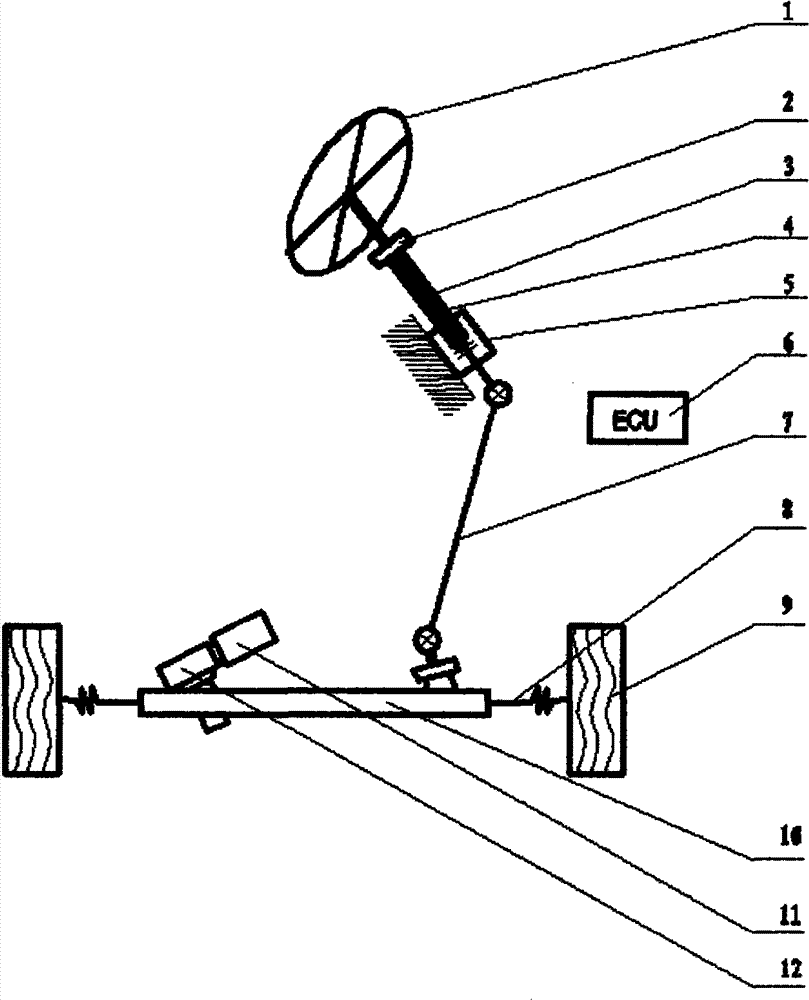

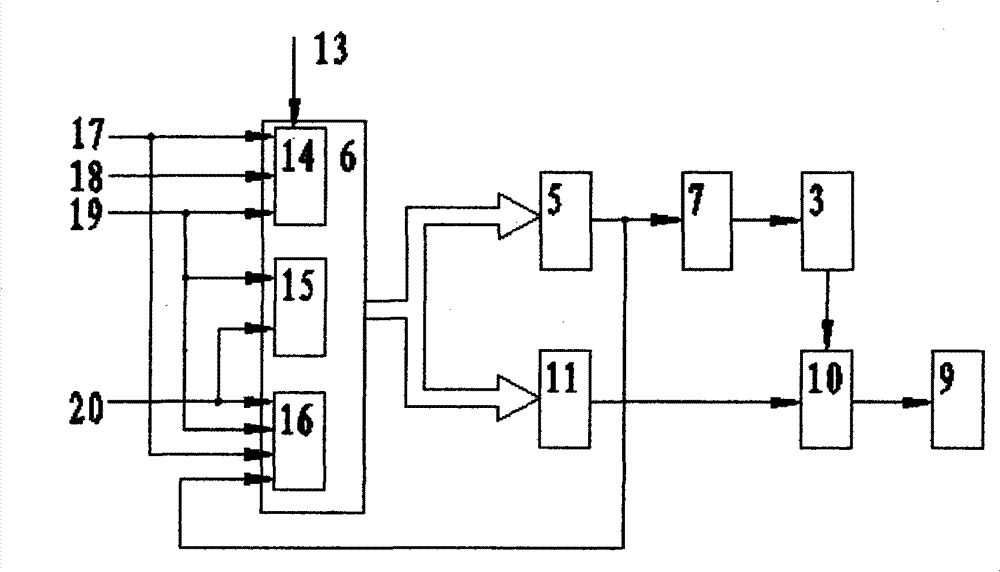

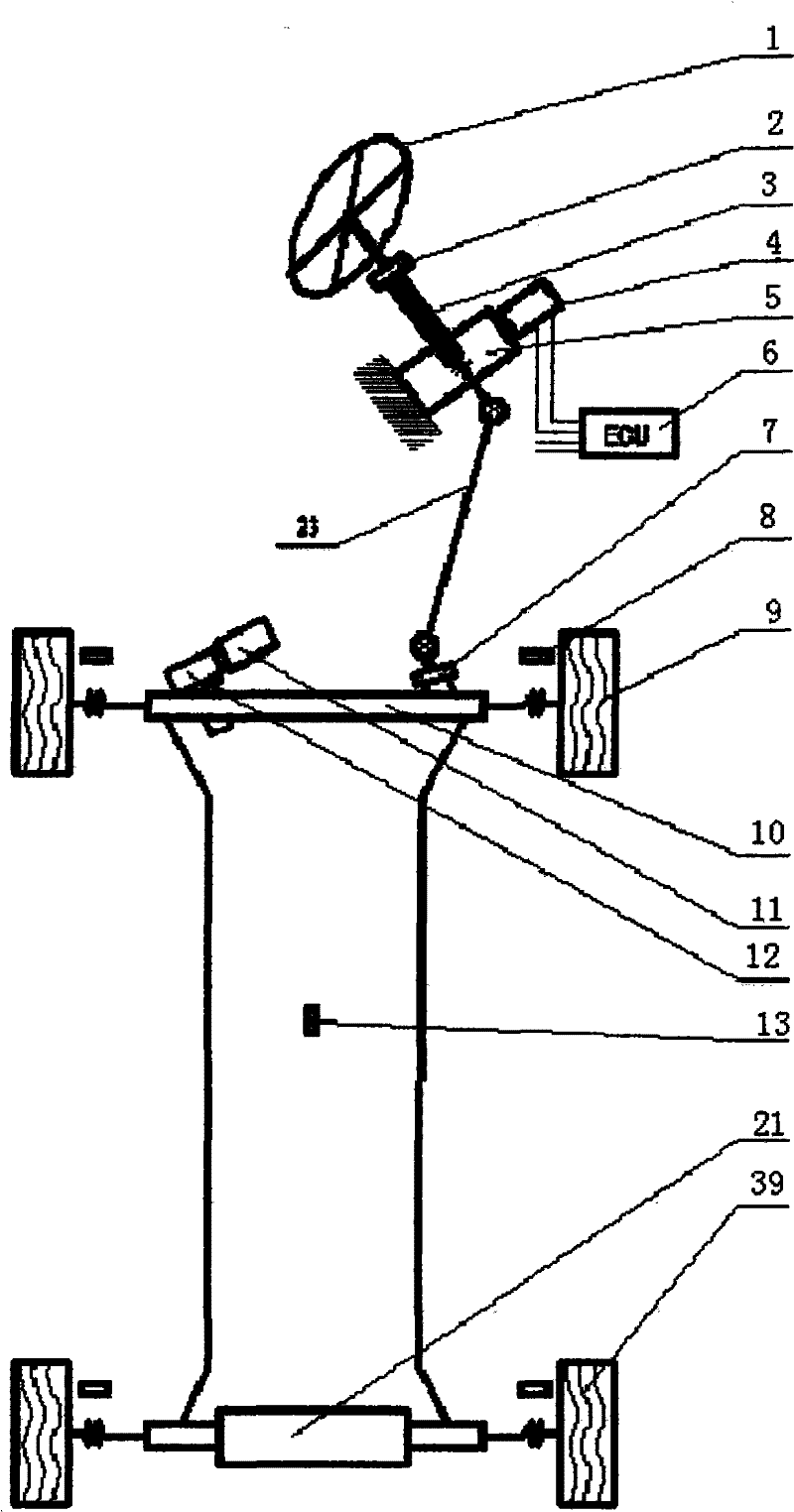

Integral active electric power-assisted steering mechanical structure

InactiveCN101973311AImprove securityImprove stabilityMechanical steering gearsElectrical steeringElectric power steeringPermanent magnet rotor

The invention discloses an integral active electric power-assisted steering mechanical structure. The structure comprises an electric power-assisted steering system, a steering system gear ratio system and a back wheel steering system, wherein the electric power-assisted steering system and the steering system gear ratio system are realized by a steering system variable-gear ratio electric power-assisted steering system; the back wheel steering system is a special device system for supplying steering force to a back wheel; the steering system variable-gear ratio electric power-assisted steering system is realized by an electronically-controlled harmonic gear transmission between a steering wheel and a lower transmission shaft; and the back wheel steering system consists of a support shaft ring, an outer shell, a motor stator coil, a permanent magnet rotor, a motor angle sensor, a central hollow shaft, a recirculating ball retarding mechanism, a lock sleeve and a rack shaft. In a steering process, an adjusting motor and a power assisting motor are controlled flexibly and compensate for each other, so that steering sensitivity, portability and operation stability are combined perfectly and operation performance and safety performance are enhanced.

Owner:ZHUZHOU ELITE ELECTRO MECHANICAL

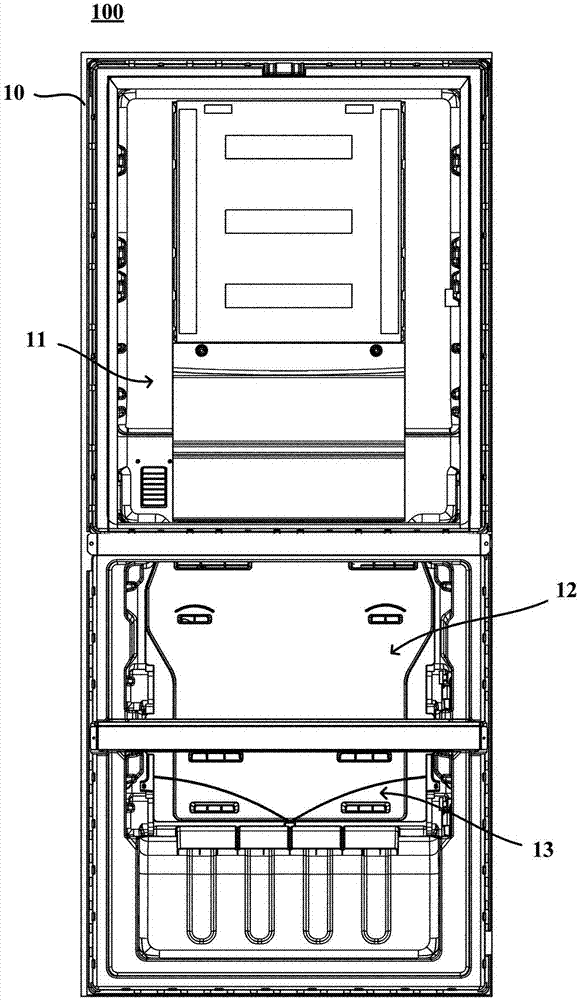

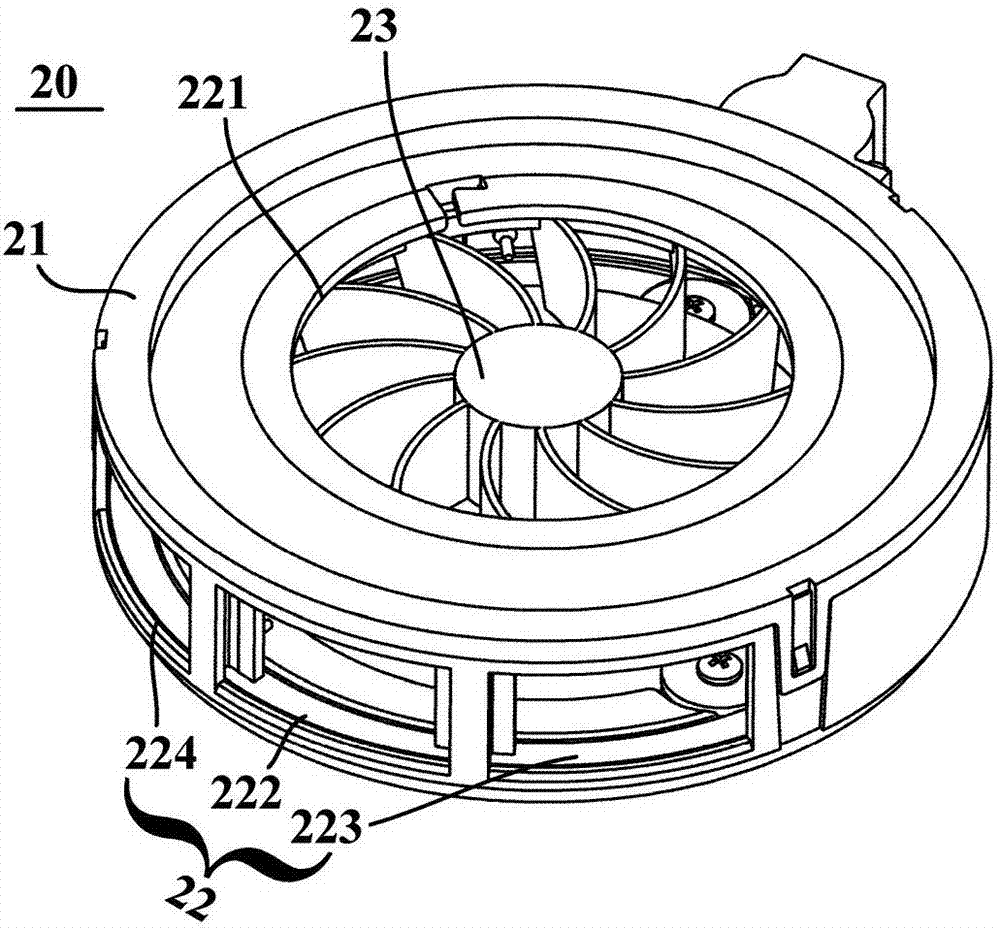

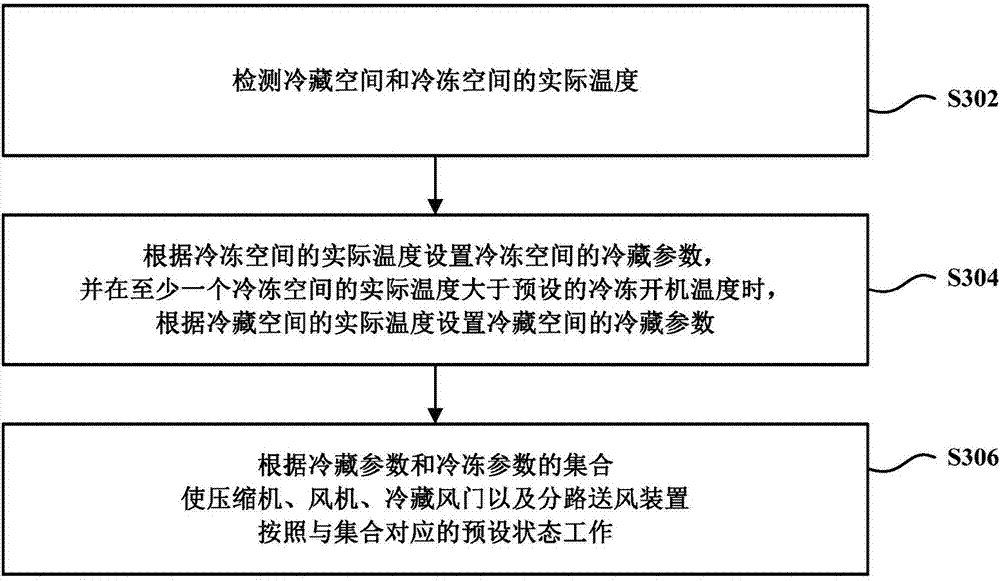

Refrigeration control method of refrigerator and computer storage medium

ActiveCN107388686AReduce the frequency of openingRealize individual coolingCompression machines with non-reversible cycleDomestic refrigeratorsRefrigerated temperatureEnergy consumption

The invention provides a refrigeration control method of a refrigerator and a computer storage medium. The refrigeration control method of the refrigerator comprises the steps of detecting the actual temperatures of refrigerating cells and the actual temperatures of freezing cells; setting the freezing parameters of the freezing cells according to the actual temperatures of the freezing cells, and setting the refrigerating parameters of the refrigerating cells according to the actual temperatures of the refrigerating cells when the actual temperature of at least one freezing cell is higher than the preset freezing startup temperature, specifically, the refrigerating parameters and the freezing parameters each comprise the first parameter and the second parameter; and enabling a compressor, a draught fan, a refrigerating air door and a split air delivery device to operate in a preset state corresponding to the set of the refrigerating parameters and the freezing parameters according to the set of the refrigerating parameters and the freezing parameters. According to the scheme, the actual temperature conditions of the refrigerating cells and the freezing cells are taken into consideration comprehensively, the start frequency of the facilities like the compressor can be reduced, and energy consumption is effectively reduced.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

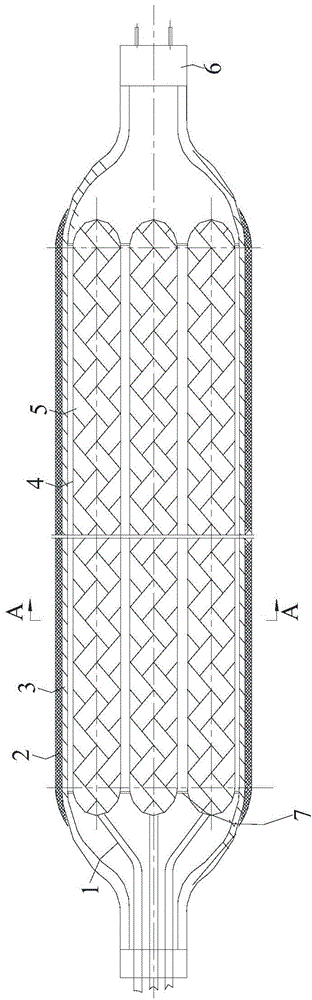

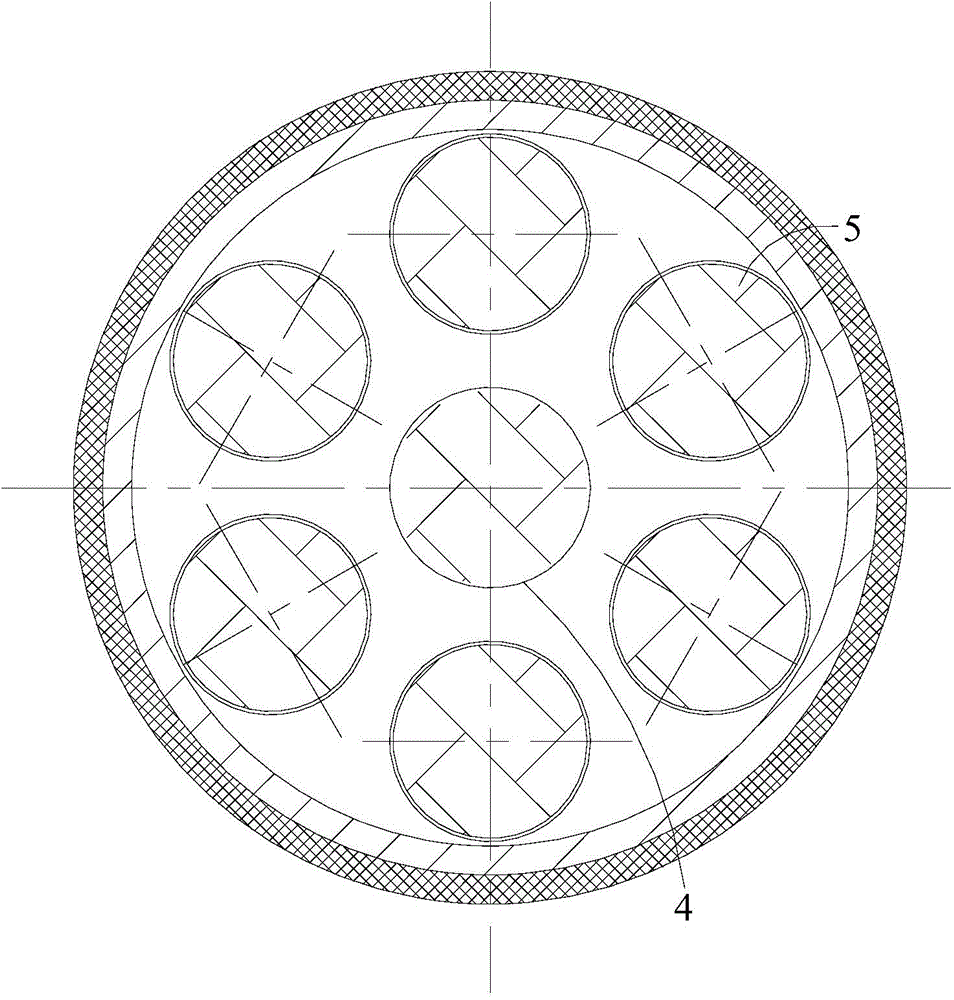

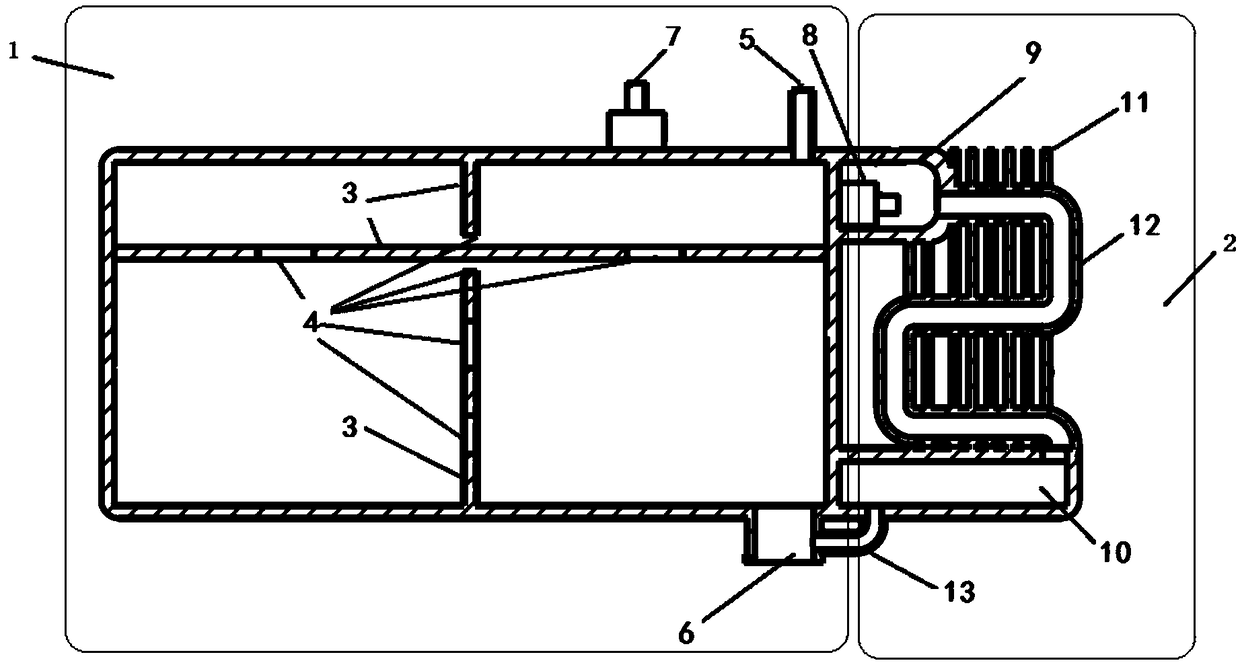

Solid-state high-pressure mixed hydrogen storage device

PendingCN106151869AUniform and rapid heatingUniform and rapid coolingContainer filling methodsFixed capacity gas holdersHeat conductingProcess engineering

A solid-state high-pressure mixed hydrogen storage device comprises a main tank and multiple sub tanks. An opening in one end of the main tank is a gas inlet / outlet, and an opening in the other end of the main tank is provided with heat exchange pipes. The sub tanks are mounted in the main tank. All the sub tanks are filled with a block-shaped hydrogen storage alloy material. The heat exchange pipes are connected into the corresponding sub tanks and can heat or cool the hydrogen storage material in the corresponding sub tanks. All the sub tanks communicate with an inner cavity of the main tank. Through the sub tanks with the diameter being far smaller than that of the main tank, the radius of heat conducting of each heat exchange pipe to an alloy in the corresponding sub tank is small, the heat exchange pipes can quickly and evenly heat or cool the corresponding block-shaped hydrogen storage alloys, the heat exchange effect is better, and the hydrogen storage performance of the hydrogen storage device better meets the process requirements; and the storage amount of the hydrogen storage alloys of the whole hydrogen storage device is larger due to the sub tanks, and more hydrogen storage alloys are arranged, so that the hydrogen storage efficiency of the hydrogen storage device is higher under the same pressure.

Owner:SHIJIAZHUANG ENRIC GAS EQUIP +2

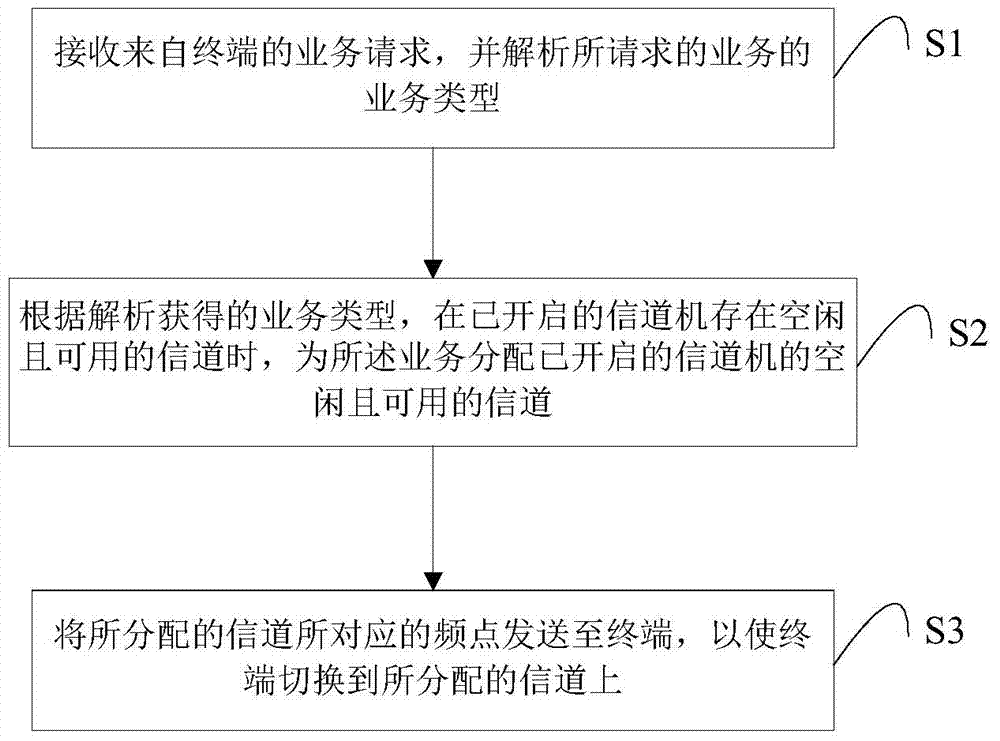

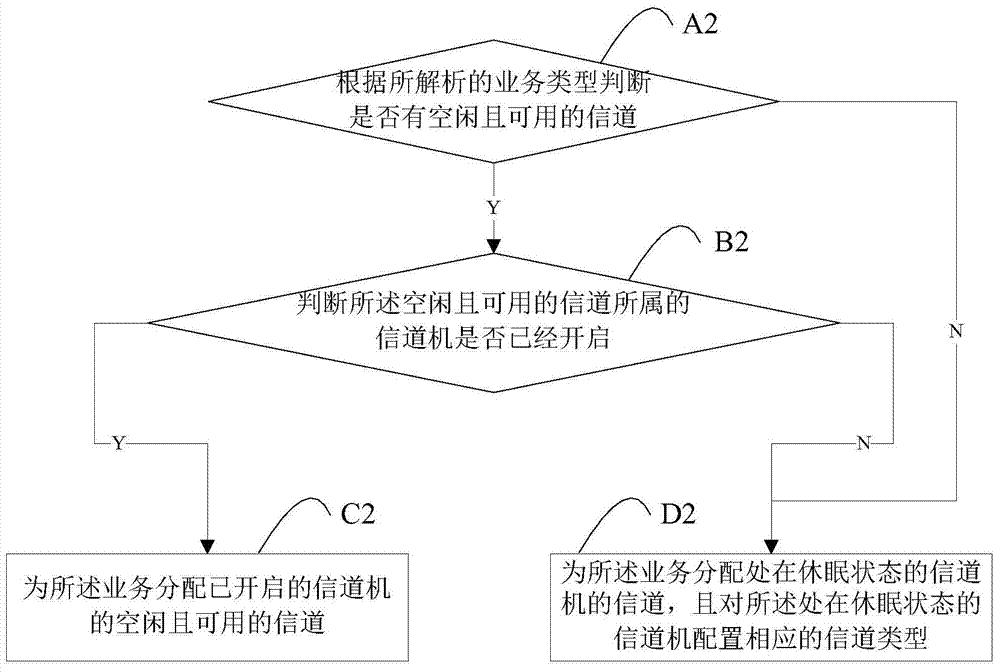

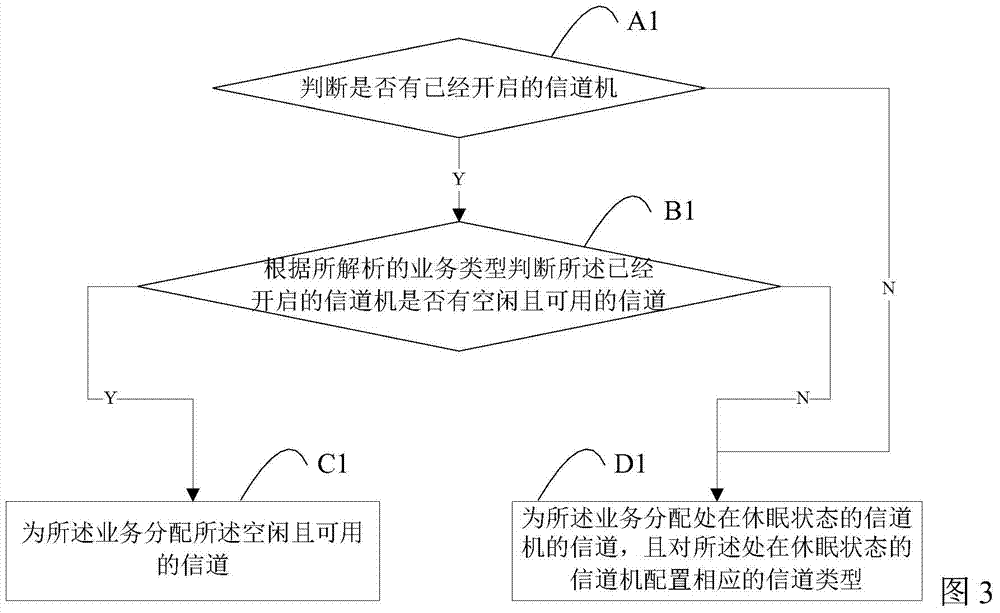

Trunked communication system adopting time division multiple access, device and channel allocation method

ActiveCN103796322AReduce the frequency of openingAvoid wastingBroadcast service distributionHigh level techniquesTime division multiple accessCommunications system

The invention discloses a trunked communication system adopting time division multiple access, a device and a channel allocation method. The channel allocation method comprises the steps that a service request from a terminal is received, and the service type of the requested service is analyzed; according to the obtained service type through analysis, when an idle and available channel exists in a started channel machine, the idle and available channel of the started channel machine is allocated to the service, a frequency point corresponding to the allocated channel is sent to the terminal, and therefore the terminal is switched to the allocated channel. According to the technical scheme, the idle and available channel of the started channel machine is allocated to the new service preferentially, so that the starting frequency of the channel machine is lowered, waste of channel resources is avoided, electric energy is saved, the access rate of base station service is greatly improved, the service life of a base station is prolonged, and the service access capacity of the base station is improved.

Owner:HARBIN HYTERA TECH CORP

Water-saving valve element and fluid supply system thereof

ActiveCN106151595ARealize the most humaneFacilitateOperating means/releasing devices for valvesMultiple way valvesWater savingFluid supply

The invention discloses a water-saving valve element and a fluid supply system thereof. Valve element modes include the single cooling mode and the single heating mode. Control handle placement positions include the regulating area and the lower stop position. Valve element states include the opening state and the closing state. The water-saving valve element is characterized in that when a control handle is located in the lower stop position in the single cooling mode, the water-saving valve element is in a saving state or a critical state in the single cooling mode, and when the control handle is located in the lower stop position in the single heating mode, the water-saving valve element is in the closing state; and alternately, when the control handle is located in the lower stop position in the single heating mode, the water-saving valve element is in the saving state or the critical state in the single heating mode, and when the control handle is located in the lower stop position in the single cooling mode, the water-saving valve element is in the closing state. The water-saving valve element is beneficial for saving water, can facilitate control over a fluid supply device through a valve, can particularly facilitate control over the supply temperature of hot fluid of the hot fluid supply device, and can facilitate normal use of the hot fluid supply device.

Owner:安徽领克自控设备有限公司

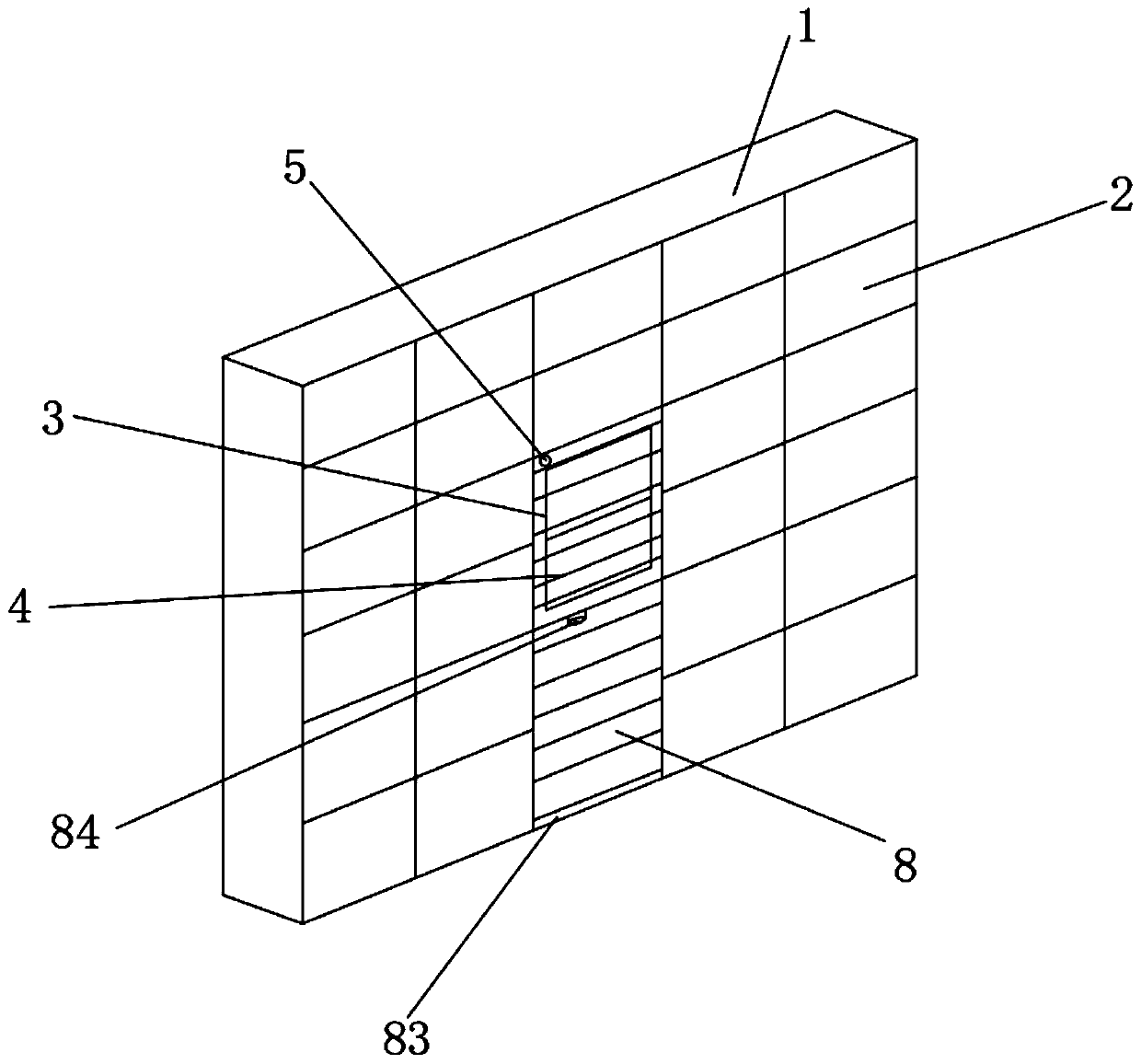

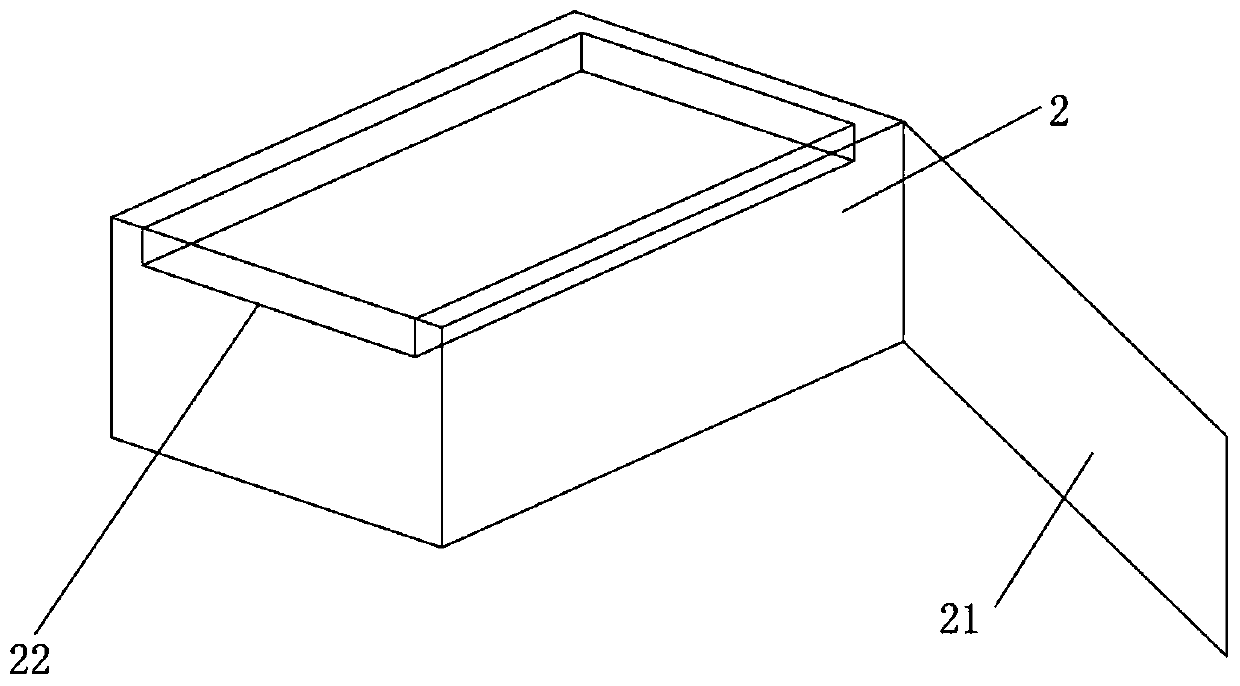

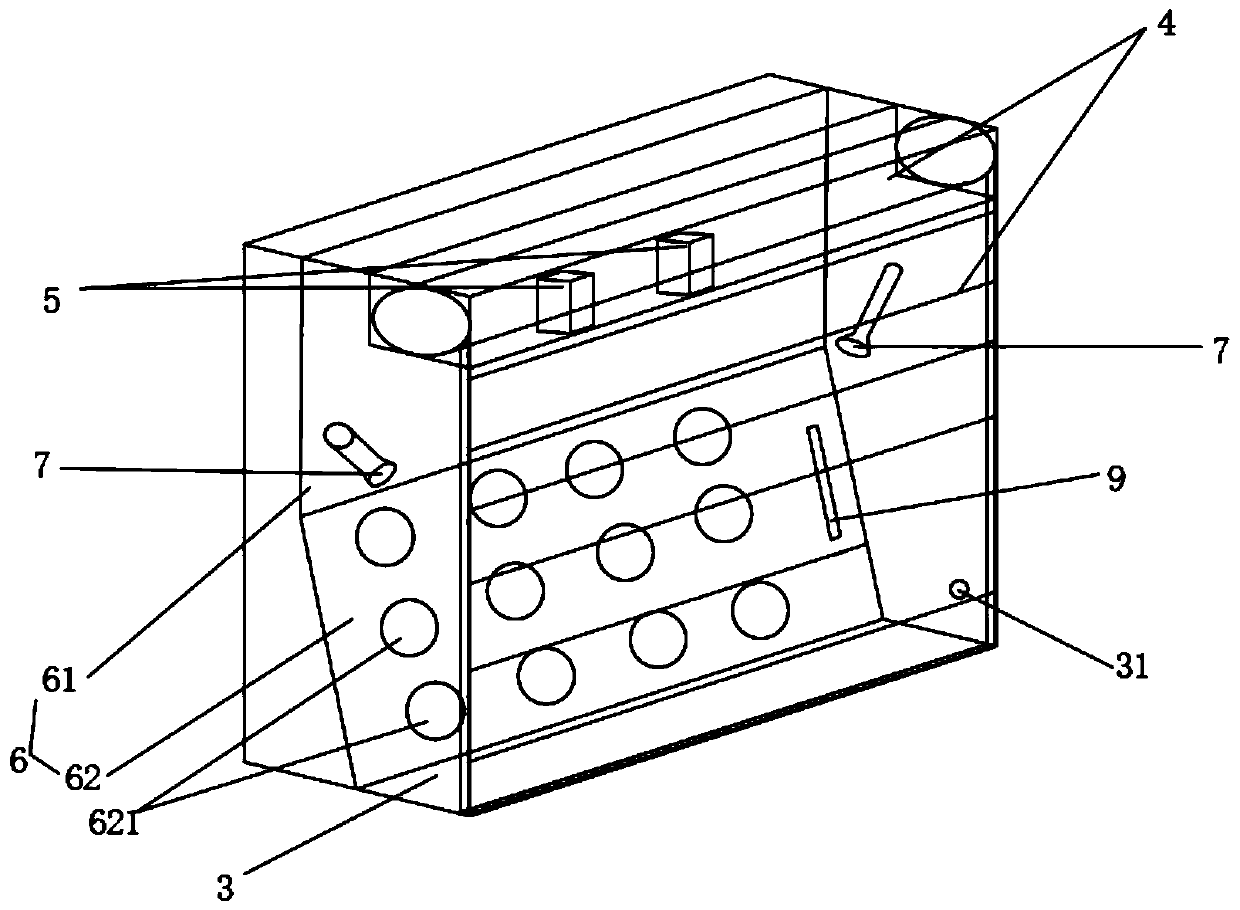

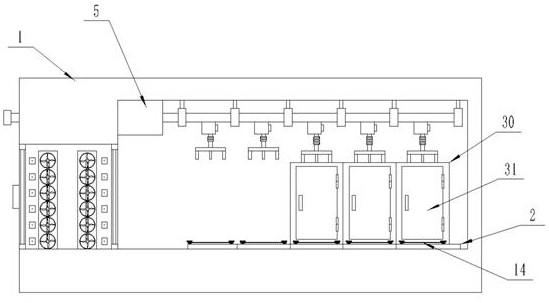

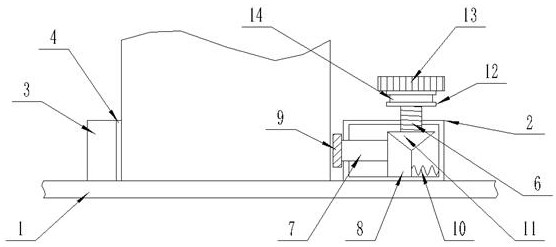

E-commerce express cabinet, express sending method thereof and express delivery and pickup method of E-commerce express cabinet

InactiveCN111280880AEasy to disinfectReduce the frequency of openingShutters/ movable grillesLavatory sanitoryComputer hardwarePersonal computer

The invention discloses an e-commerce express cabinet. The cabinet comprises a cabinet body, an industrial personal computer, an operation panel, a payment device, first disinfection equipment, seconddisinfection equipment, third disinfection equipment, a proximity switch, a detection device and a measurement device, the cabinet body is provided with a storage grid, an operation panel grid and ameasurement grid; the storage grid, the operation panel grid and the measurement grid are respectively provided with electric doors for sealing and covering openings of the storage grid, the operational panel grid and the measurement grid, the operation panel, the payment device and the first disinfection equipment are arranged in the operation panel grid, the measurement device and the second disinfection equipment are arranged in the measurement grid, the third disinfection equipment is arranged in the storage grid, and the proximity switch is arranged on the outer wall of the cabinet body to control the door of the operation panel equipment. The invention further discloses an express sending method and an express delivery and pickup method adopting the e-commerce express cabinet. According to the e-commerce express cabinet, the express sending method and the express delivery and pickup method thereof, contact transmission and droplet transmission of viruses in the express receivingand pick-up process can be effectively blocked, and the health of express sending and pickup personnel and deliverymen is guaranteed.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

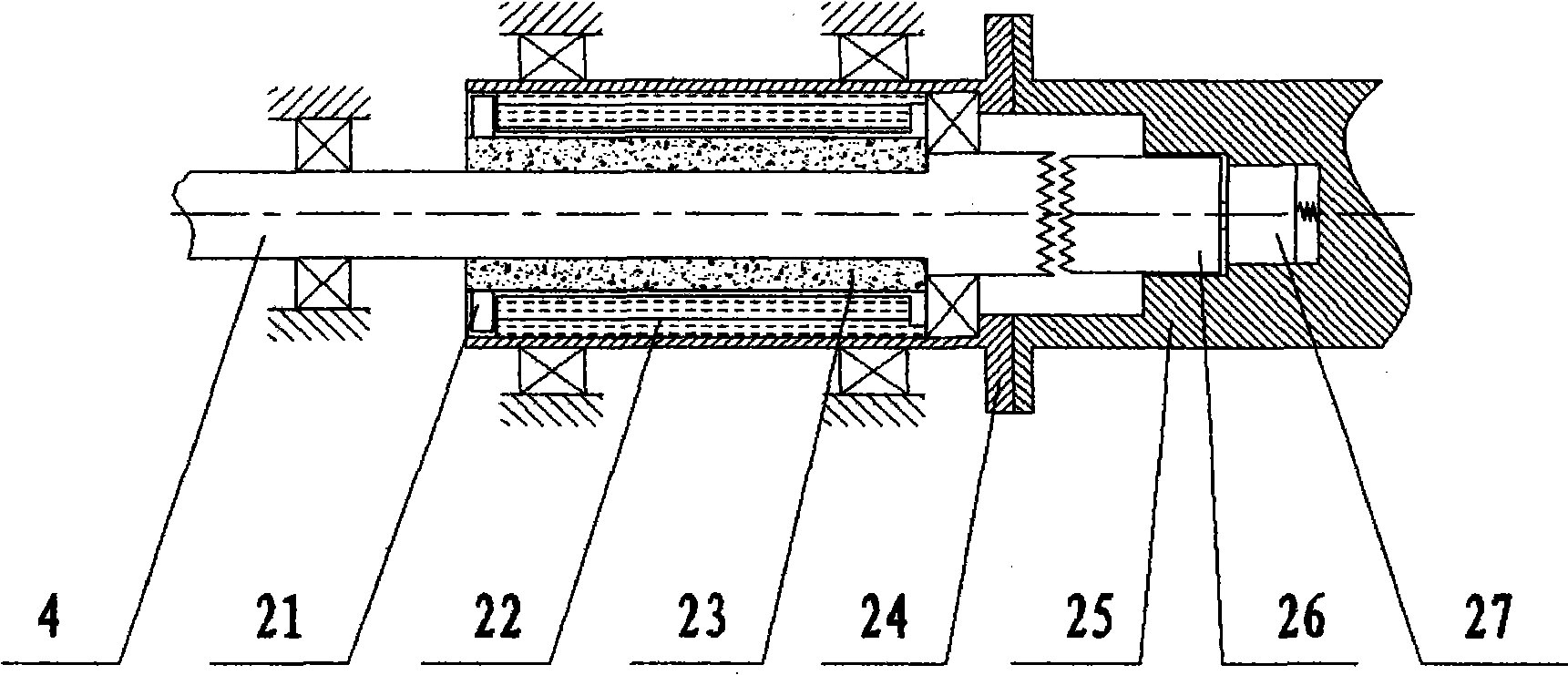

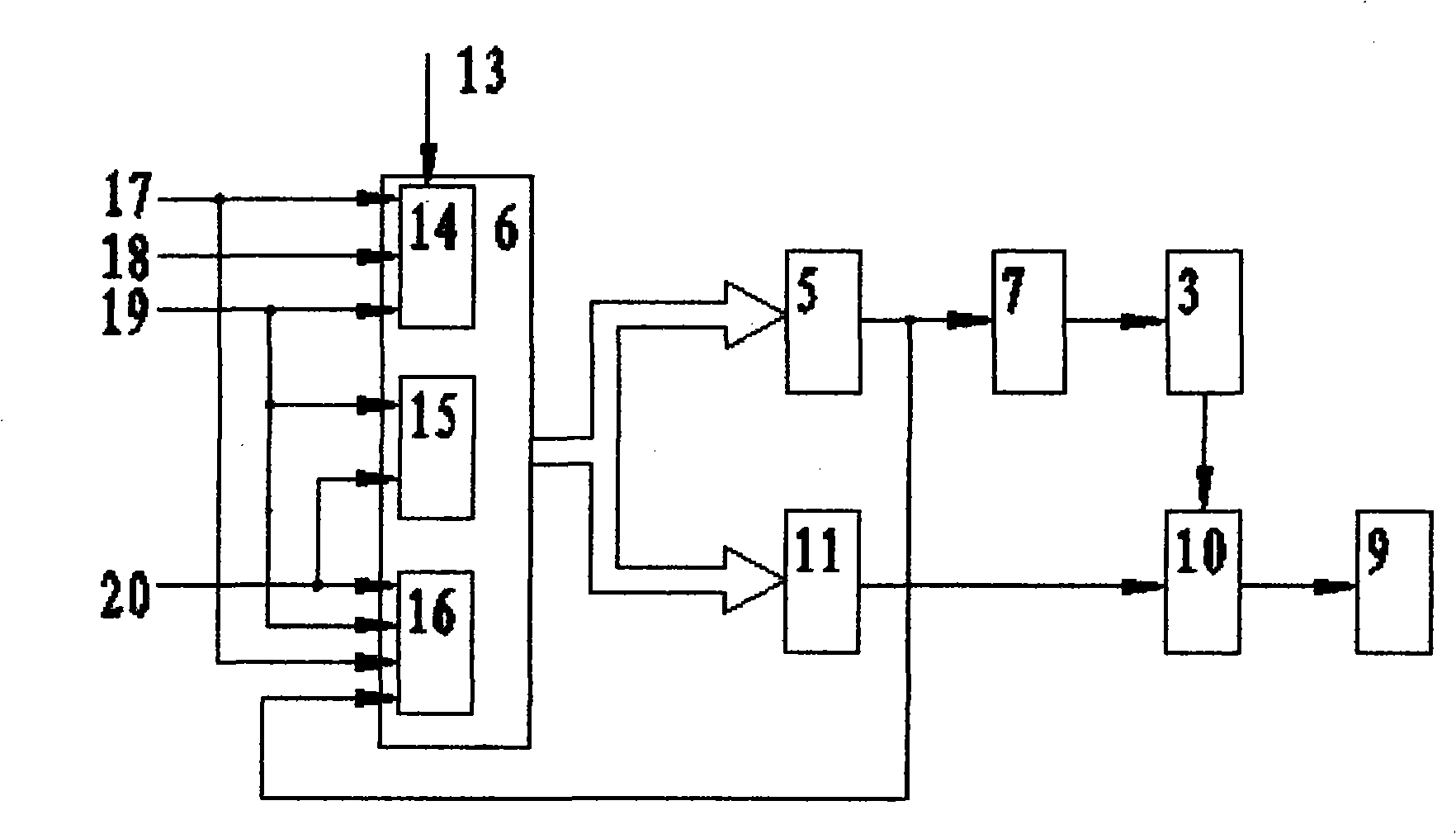

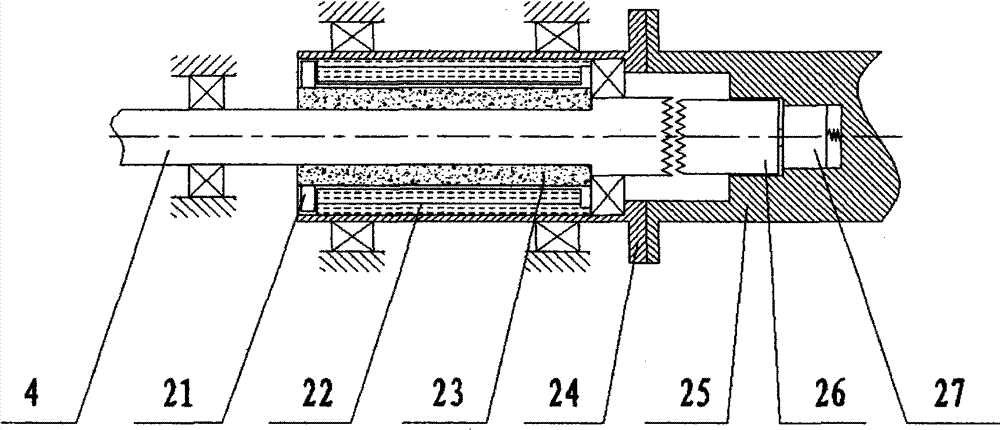

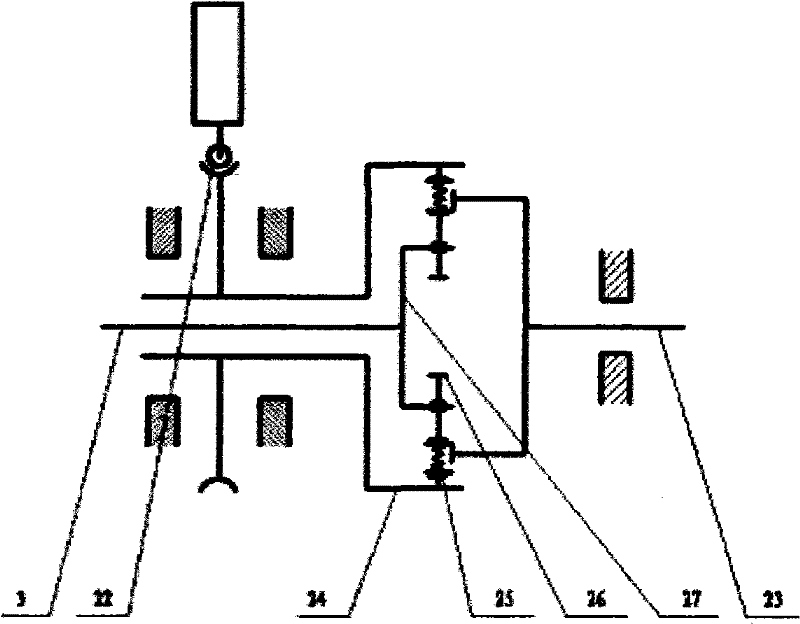

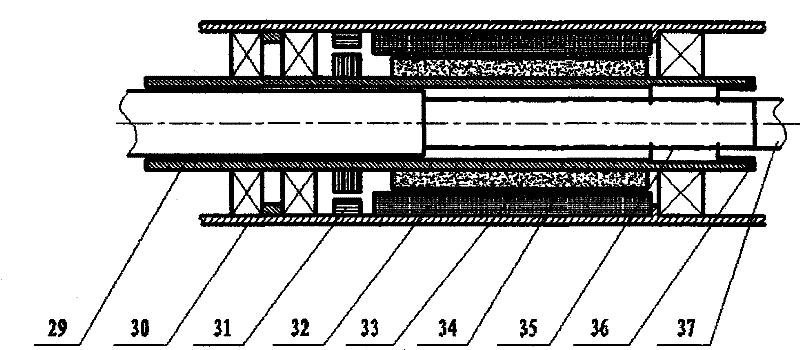

Electric power-assisted steering system with VTMS (Variable Transmission Motor System) speed variable transmission ratio

ActiveCN101973312ALow costSimple structureMechanical steering gearsElectrical steeringElectric power steeringElectric power system

The invention relates to an electric power-assisted steering system with VTMS (Variable Transmission Motor System) variable speed transmission ratio and provides an electronic controlled electric power-assisted steering stability safety device which is realized by arranging a VTMS between a steering wheel and a transmission shaft and connecting an electric power-assisted steering system with variable transmission ratio, wherein the VTMS consists of eight basic parts of a middle transmission shaft, a motor angle sensor, a motor stator coil, a rotor permanent magnet, a stator framework, an output shaft, a protection shaft sleeve and a relay. In the invention, by monitoring various signal values of the VTMS, the torque quantity of a steering column of a vehicle can be worked out, thereby omitting torque sensors, torque bars and other crucial parts used in traditional technology and achieving the advantages of cost saving and simple assembling and manufacturing; in addition, during the process of steering, the VTMS and a power-assisted motor are under flexible control and mutually compensate, and therefore, the sensitivity, the portability and the stability of steering can be combined perfectly, and the operation performance and the safety can also be improved.

Owner:ZHUZHOU ELITE ELECTRO MECHANICAL

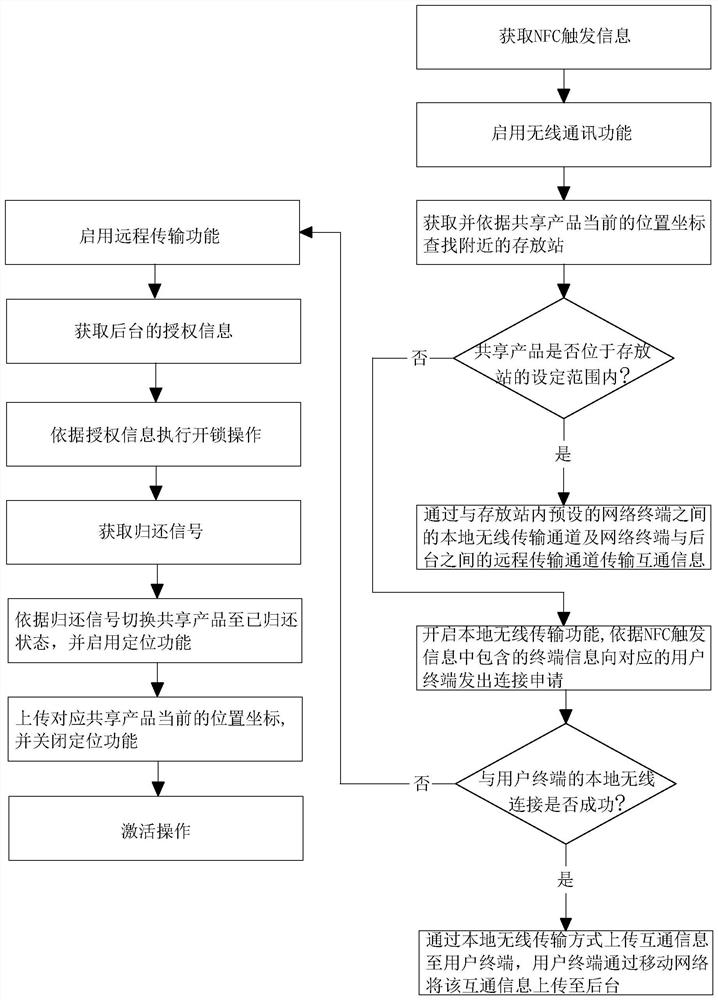

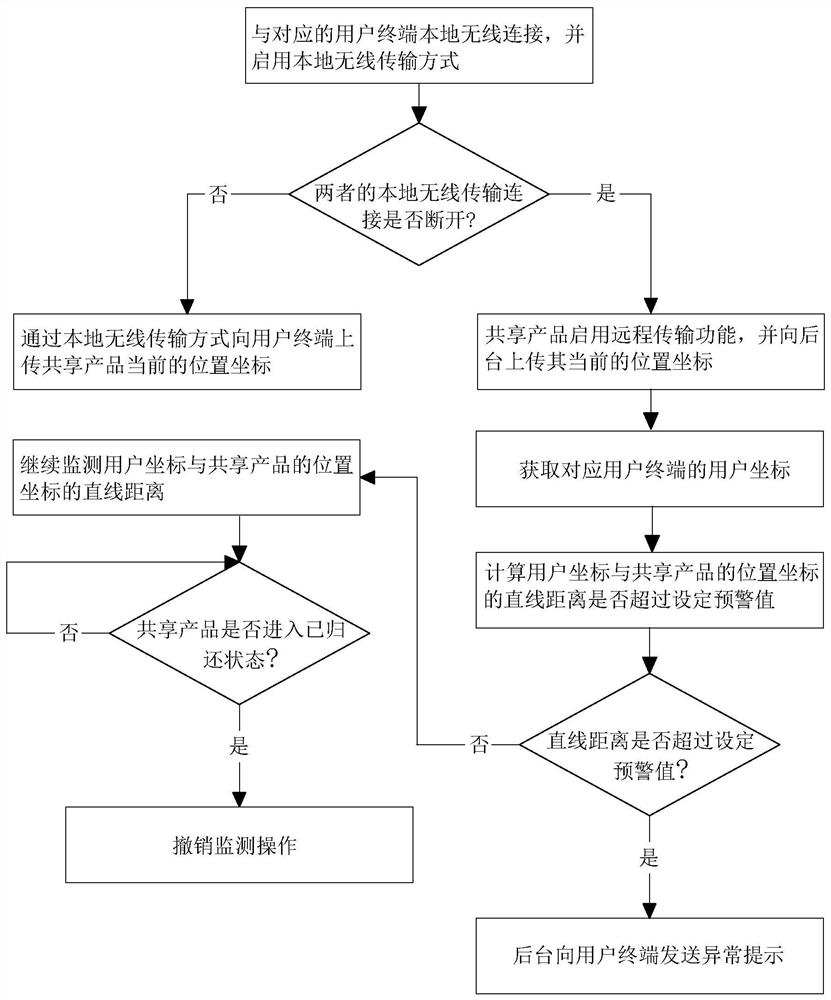

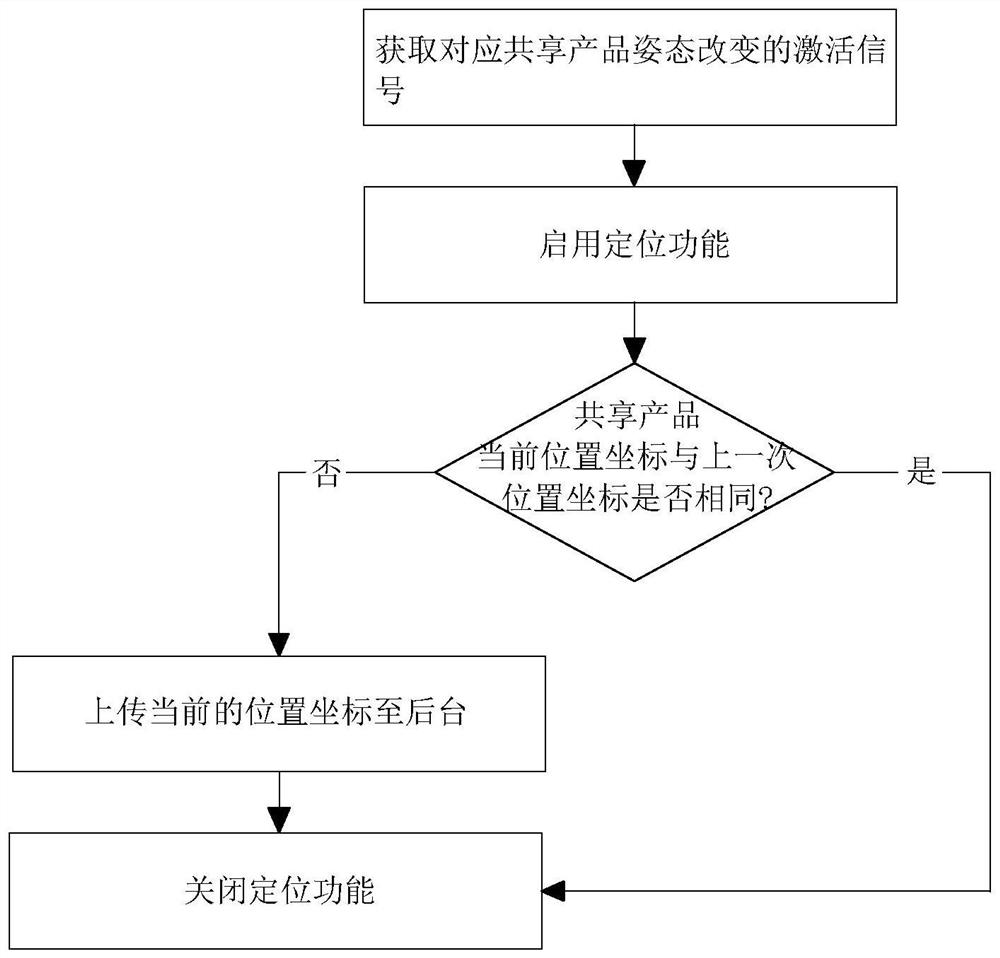

Communication method and system applied to sharing economy

InactiveCN113554819AReduce turn-on timeReduce consumptionApparatus for meter-controlled dispensingShort range communication serviceInformation interoperabilityEngineering

The invention relates to a communication method and system applied to sharing economy. The method comprises the steps of: obtaining NFC trigger information obtained through NFC induction with a user terminal; starting a wireless communication function according to the NFC trigger information, and transmitting intercommunication information between the shared product and a background through the wireless communication function, the intercommunication information including authorization information and position coordinates of the shared product; executing unlocking operation according to the authorization information; obtaining a return signal; switching the shared product to a returned state according to the return signal, starting a positioning function, and uploading a current position coordinate of the corresponding shared product; and closing the positioning function. The method has the effects of reducing the battery maintenance frequency of the shared product and reducing the maintenance cost.

Owner:杨迎卯

Valve device with fixed flow on single side and fluid supply system thereof

ActiveCN106151596ARealize the most humaneFacilitateOperating means/releasing devices for valvesValve members for heating/coolingEngineeringFluid supply

The invention discloses a valve device and a fluid supply system thereof. The valve device is provided with a first fluid inlet end, a second fluid inlet end and a fluid outlet end. An operation area of an operation mechanism is divided into a mixing degree adjusting area for adjusting the mixing degree of first fluid and second fluid, and a flow adjusting area capable of always adjusting the fluid outlet end flow of the whole mixing degree adjusting area. The mixing degree adjusting area is divided into a first fluid area with a fluid outlet end only discharging the first fluid, a mixing area with a fluid outlet discharging a mixture of the first fluid and the second fluid, and a second fluid area with a fluid outlet end only discharging the second fluid. The flow of the minimum stop position of a flow adjusting area in the first fluid area of the operation mechanism is larger than zero, and the flow of the minimum stop position of a flow adjusting area in the second fluid area of the operation mechanism is equal to zero. The valve device and the hot fluid supply system thereof are beneficial for saving fluid passing through the valve device and can facilitate normal use of a hot fluid supply device.

Owner:安徽领克自控设备有限公司

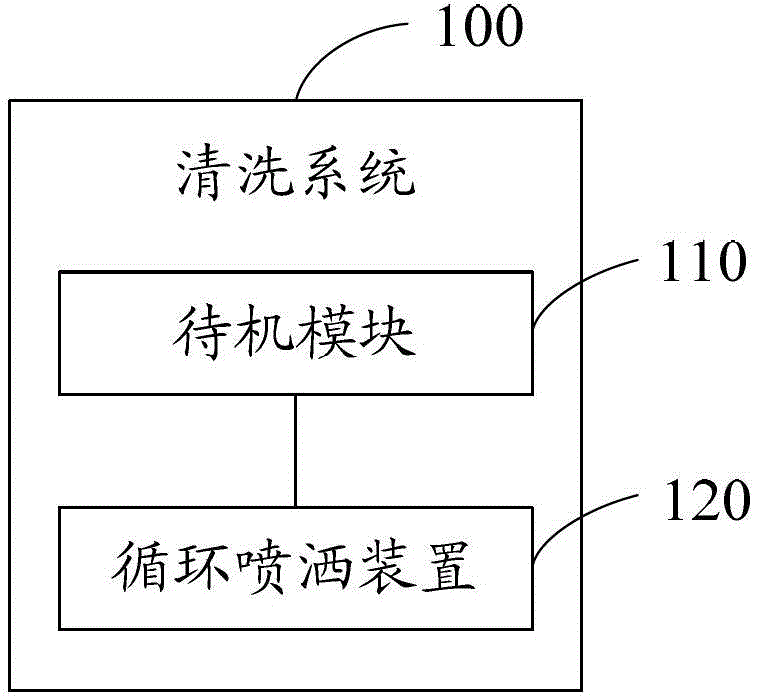

Cleaning method and cleaning system

InactiveCN102974583AImprove wetting effectImprove stabilityHollow article cleaningSemiconductor/solid-state device manufacturingWettingEngineering

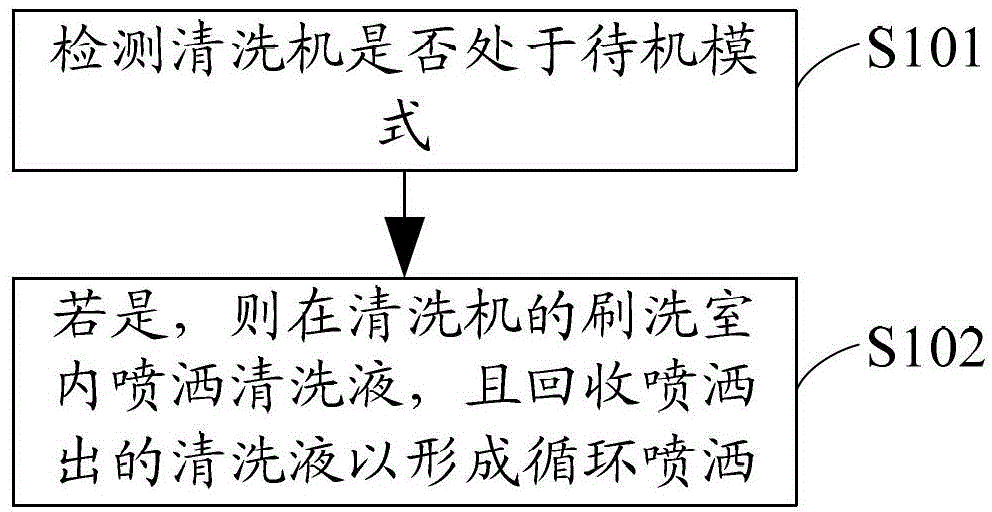

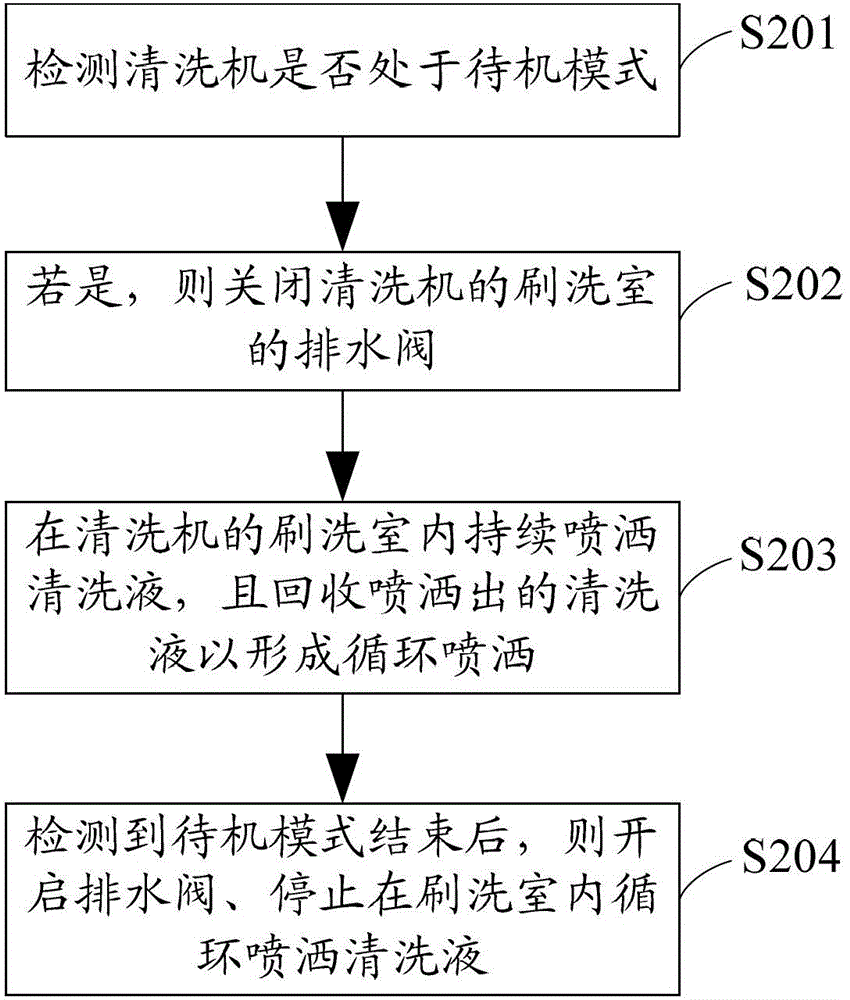

The invention discloses a cleaning method and a cleaning system of a cleaning machine. The cleaning method comprises the following steps of: detecting whether the cleaning machine is in a standby mode; and if so, spraying a cleaning liquid into a scrubbing chamber of the cleaning machine, and recovering the sprayed cleaning liquid to realize circular spraying. The scrubbing chamber is controlled independently, and the cleaning liquid is sprayed into the scrubbing chamber separately, so that the spraying frequency of the cleaning liquid sprayed into the scrubbing chamber can be increased, even the cleaning liquid can be sprayed continuously, the wetting effect of a hair brush is enhanced, and the stability of a cleaning procedure is further enhanced; meanwhile, the startup frequency of a gas supply pipeline can be lowered when the cleaning machine is in the standby mode, so that gas consumption is lowered; and moreover, the sprayed cleaning liquid is recovered during spraying of the cleaning liquid into the scrubbing chamber to realize circular spraying, so that the cleaning liquid is used circularly in the scrubbing chamber, waste of the cleaning liquid is prevented, and the cost is lowered.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

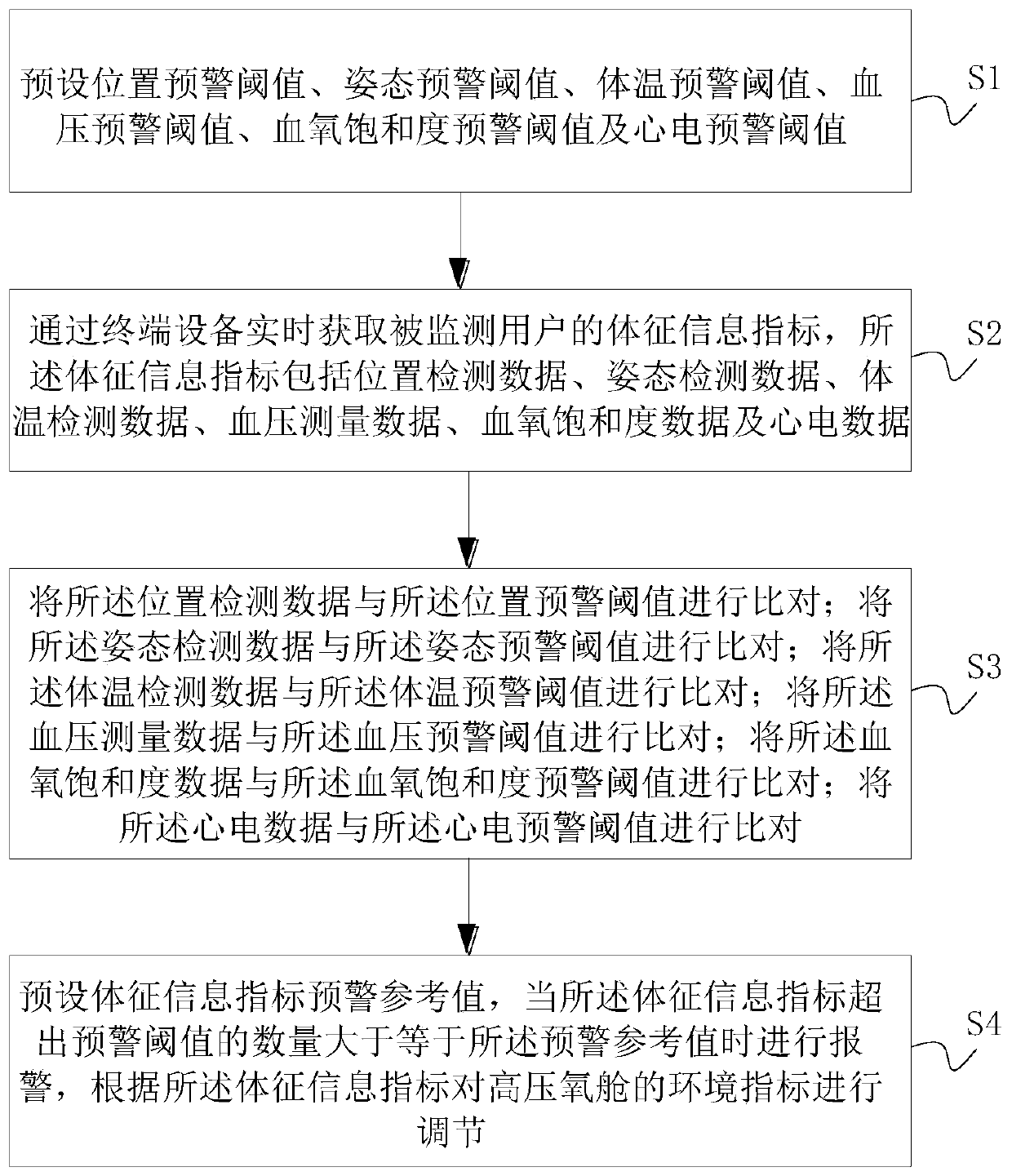

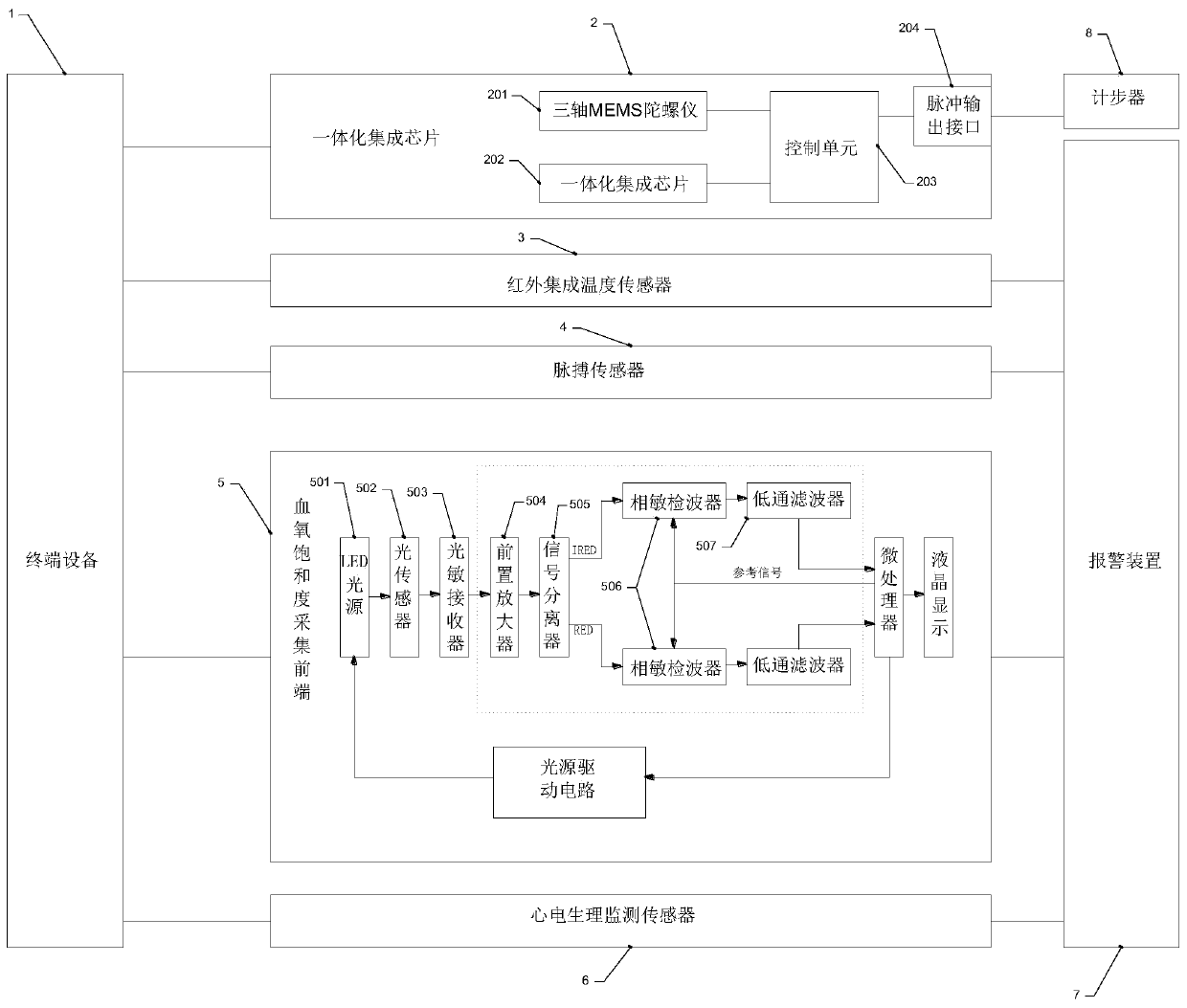

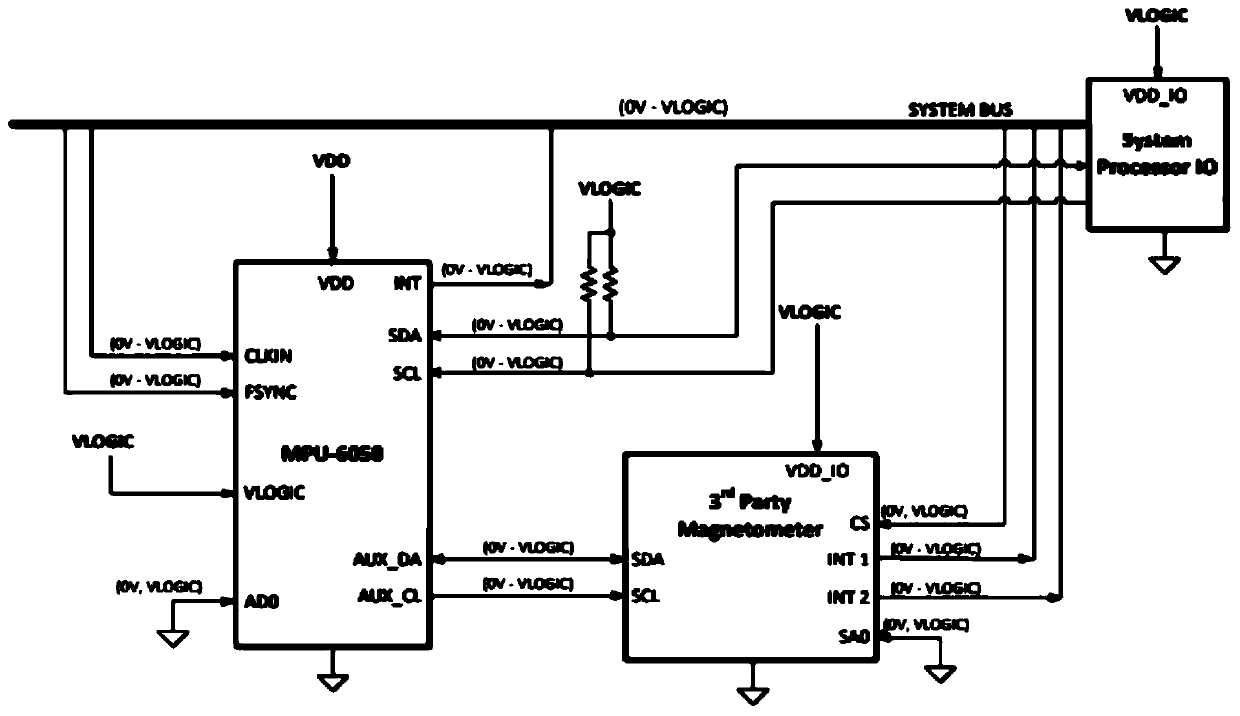

Hyperbaric oxygen chamber vital sign monitoring method and system

PendingCN110013246AReduce the frequency of openingRealize remote real-time monitoringSensorsBlood characterising devicesEnvironmental indexEnvironmental indicator

The invention discloses a hyperbaric oxygen chamber vital sign monitoring method and system. The method comprises the steps of performing real-time obtaining on sign information indexes of users to bemonitored by terminal equipment, and comparing position detection date with position pre-warning threshold; comparing posture detection date with posture pre-warning threshold; comparing body temperature detection date with body temperature pre-warning threshold; comparing blood pressure measuring date with blood pressure pre-warning threshold; comparing blood oxygen saturation date with blood oxygen saturation pre-warning threshold; comparing electrocardio data with electrocardio pre-warning threshold; presetting sign information index pre-warning reference value, when the quantity that thesign information index exceeds the pre-warning threshold is greater than or equal to the pre-warning reference value, performing warning, and according to the sign information indexes, adjusting the environmental index of a hyperbaric oxygen chamber. Under the condition that patient rest and noninvasive condition cannot be influenced, various data indexes of human bodies can be accurately obtained, and through feedback and self-adapting, intelligent chamber body environment can be provided for patients.

Owner:烟台宏远氧业股份有限公司

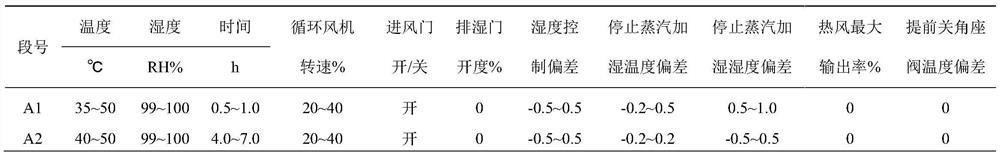

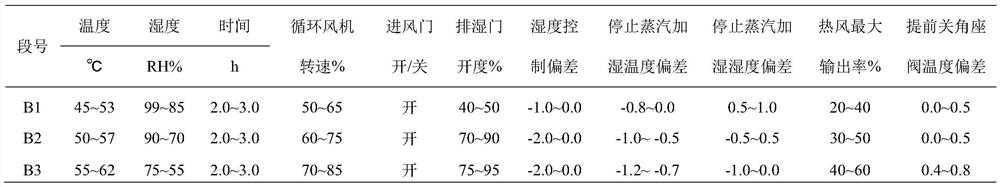

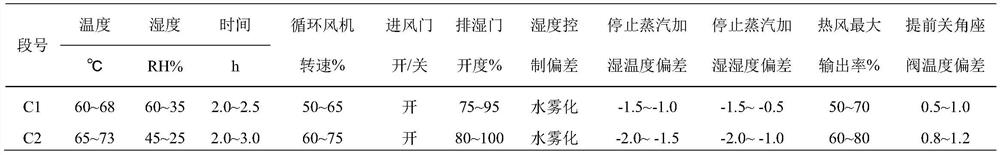

Process for quickly curing and drying negative green plate

ActiveCN111697202AUniform moistureSufficient humidityLead-acid accumulator electrodesLead carbonateManufacturing cost reduction

The invention belongs to the field of lead-acid storage batteries and particularly relates to a process for quickly curing and drying a negative electrode plate. The process at least comprises the following program steps of (1) a curing constant-temperature high-humidity maintaining stage, (2) a curing heating constant-speed dehumidifying stage, (3) a curing heating rapid dehumidifying stage, (4)a drying heating rapid dehumidifying stage, (5) a drying high-temperature rapid enhancing stage and (6) a drying cooling rapid strength stabilizing stage. According to the green polar plate cured anddried according to the process, the content of basic lead carbonate of the green polar plate is increased, the falling strength of the green polar plate is further improved, lead plaster looseness isreduced after falling, and the floating powder amount on a surface of the green polar plate is reduced, improvement of the strength of the green plate reduces a reject ratio of subsequent slicing andwrapping of the green plate. The process is advantaged in that the floating powder amount is small, lead powder flying dust in the subsequent polar plate production process is reduced, and environmental pollution is reduced, and the rapid curing and drying process can reduce the use amount of steam and electricity in the process, reduce curing and drying energy consumption and reduce manufacturingcost.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU +3

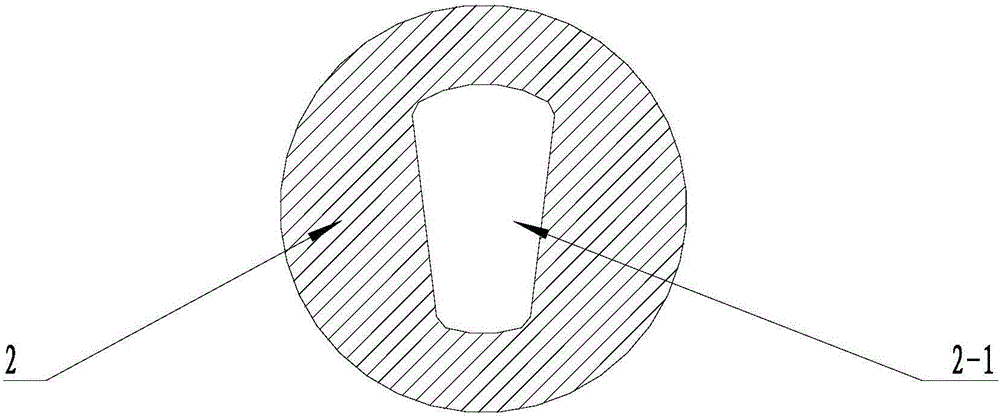

Condensing-type expanding water tank

InactiveCN108915841AReduce the frequency of openingReduce lossMachines/enginesEngine cooling apparatusLiquid waterPiping

The invention provides a condensing-type expanding water tank comprising a primary expanding water tank and a secondary expanding water tank which are in left-right arrangement. A partition and a liquid passageway are arranged inside the primary expanding water tank, an air incoming pipe and a high-pressure air release valve are arranged on the primary expanding water tank, and a water replenishing pipe is arranged below the primary expanding water tank; an upper water collection chamber is arranged on the upper portion of the secondary expanding water tank, a lower water collection chamber isarranged at the bottom of the secondary expanding water tank, multiple broken-line-shaped water pipes communicating the upper water collection chamber with the lower water collection chamber are arranged in the middle of the secondary expanding water tank, and fins are arranged around each water pipe; an exhaust pipe is arranged on the side face of the primary expanding water tank and positionedin the upper water collection chamber, and a water outgoing pipe communicated with the water replenishing pipe is arranged at the bottom of the lower water collection chamber. The condensing-type expanding water tank has the advantages that the expanding water tank can quickly condense water vapor discharged by an engine cooler into liquid water to flow back into the water tank through circulation; frequency of opening a water tank air release valve in a conventional cooling water tank is lowered, and loss of cooling liquid in a cooling system is reduced.

Owner:CHINA NORTH ENGINE INST TIANJIN

Electric power-assisted steering system with VTMS (Variable Transmission Motor System) speed variable transmission ratio

ActiveCN101973312BShift to Nimble and AgileImprove securityMechanical steering gearsElectrical steeringElectric power steeringElectric power system

The invention relates to an electric power-assisted steering system with VTMS (Variable Transmission Motor System) variable speed transmission ratio and provides an electronic controlled electric power-assisted steering stability safety device which is realized by arranging a VTMS between a steering wheel and a transmission shaft and connecting an electric power-assisted steering system with variable transmission ratio, wherein the VTMS consists of eight basic parts of a middle transmission shaft, a motor angle sensor, a motor stator coil, a rotor permanent magnet, a stator framework, an output shaft, a protection shaft sleeve and a relay. In the invention, by monitoring various signal values of the VTMS, the torque quantity of a steering column of a vehicle can be worked out, thereby omitting torque sensors, torque bars and other crucial parts used in traditional technology and achieving the advantages of cost saving and simple assembling and manufacturing; in addition, during the process of steering, the VTMS and a power-assisted motor are under flexible control and mutually compensate, and therefore, the sensitivity, the portability and the stability of steering can be combined perfectly, and the operation performance and the safety can also be improved.

Owner:ZHUZHOU ELITE ELECTRO MECHANICAL

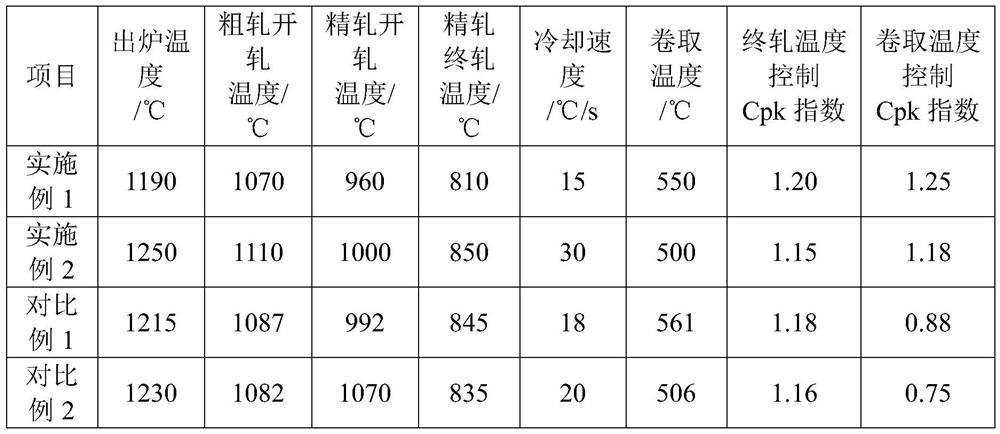

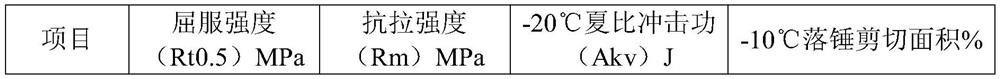

Production method for improving rolling stability of thick-specification pipeline steel

InactiveCN112058910ASimple processEasy to operateTemperature control deviceMetal rolling arrangementsProduction lineTemperature control

The invention discloses a production method for improving the rolling stability of thick-specification pipeline steel. The production method comprises the following steps including plate blank heating, rough rolling, finish rolling, cooling after rolling and coiling, in the plate blank heating step, the in-furnace time is 170-230 min, and the heating temperature is 1,190 DEG C-1,250 DEG C; in therough rolling step, the rough rolling biting temperature is 1,070-1,110 DEG C, five passes are adopted for rough rolling of a plate blank, the accumulated reduction rate is 60-80%, the final pass speed of rough rolling is 4.0-4.3 m / s, and the final rolling temperature of rough rolling is controlled to be 1,000-1,040 DEG C; in the finish rolling step, the temperature of a finish rolling inlet is controlled to be 960-1,000 DEG C, finish rolling is seven-rack hot continuous rolling dummy F2 and F5, and the accumulated rolling reduction is larger than or equal to 60%; the final rolling temperatureis 810-850 DEG C; after threading, the acceleration is set to be 0.003-0.008 m / s <2>; and the cooling after rolling is laminar cooling, a front-section cooling mode is selected, the cooling speed is15-30 DEG C / s, and the final cooling temperature is controlled to be 500-550 DEG C. Compared with the prior art, the rolling stability of thick-specification pipeline steel of a conventional hot continuous rolling production line can be obviously improved.

Owner:RIZHAO STEEL HLDG GROUP

Gasoline engine cooling system

ActiveCN102705055BAvoid cavitationImprove cooling effectLiquid coolingCoolant flow controlExpansion tankWax

The invention discloses a gasoline engine cooling system, which comprises a radiator, a cylinder cover water jacket, a cylinder body water jacket, a water pump, an expansion tank and a thermoregulator valve seat, wherein a thermoregulator is arranged in the thermoregulator valve seat; the thermoregulator valve seat is provided with five inlets and one outlet F; the first inlet A is communicated with a lower water chamber of the radiator; the second inlet B is communicated with the outlet of a fan heater; the third inlet C is communicated with the outlet of an air damper; the fourth inlet D is communicated with the outlet of a distributive pipe via a small circulation circuit; the fifth inlet E is communicated with the expansion tank via a water replenishing circuit; the outlet F is communicated with the water inlet of the water pump; the thermoregulator is a double-valve wax type thermoregulator and comprises a main valve and an auxiliary valve, wherein the main valve is installed on the first inlet A of the thermoregulator valve seat; and the auxiliary valve is just against the fourth inlet D of the thermoregulator valve seat. According to the gasoline engine cooling system disclosed by the invention, gas in cooling liquid can be removed to protect the water pump from cavitation, the cooling performance of the cooling system is improved, an engine is prevented from overheating, and thermal shock is prevented from generating in the cooling system.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Double-mode valve device and fluid supply system thereof

The invention discloses a valve device and a fluid supply system thereof. The valve device comprises a valve unit controlling the passing state of fluid during passing, and an operation mechanism operating in an operation area of the operation mechanism to achieving the control. The valve unit is provided with a first fluid inlet end, a second fluid inlet end and a fluid outlet end. The operation area of the operation mechanism is divided into a mixing degree adjusting area adjusting the mixing degree of first fluid and second fluid, and a flow adjusting area adjusting the flow of the fluid outlet end in the mixing degree adjusting area. The mixing degree adjusting area comprises a necessary first fluid area with a fluid outlet end through which only the first fluid flows out, a necessary second fluid area with a fluid outlet end through which only the second fluid flows out, and a dispensable mixing area with a fluid outlet end through which mixed fluid of the first fluid and the second fluid flow out. The flow of the operation mechanism in the maximum stop position of the flow adjusting area of the first flow area and the flow of the maximum stop position of the flow adjusting area of the second flow area are unequal. Through the valve device and the fluid supply system thereof, the fluid flowing through the valve device can be saved, and normal use of a hot fluid supply device can be facilitated.

Owner:CHENGDU JINGYI TECH CO LTD

Automatic cut-off temperature adjusting device for truck air conditioner temperature controller

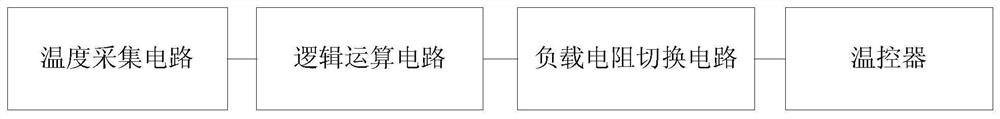

PendingCN113928083AReduce energy consumptionReduce the frequency of openingAir-treating devicesVehicle heating/cooling devicesLoad resistanceResistive switching

The invention discloses an automatic cut-off temperature adjusting device for a temperature controller of an air conditioner of a truck. The main design concept of the device is that a temperature acquisition circuit, a logic operation circuit, a load resistance switching circuit and a temperature controller for pre-calibrating a corresponding relation between an input load resistance value and a cut-off temperature construct a cut-off temperature self-adaptive adjustment mechanism of the temperature controller of the truck air conditioner, specifically, according to the acquired different environment temperatures, the temperature acquisition circuit outputs corresponding electric signals to the logic operation circuit, the logic operation circuit controls the load resistance switching circuit to convert different load resistors according to a preset logic rule and in combination with the electric signals input by the temperature acquisition circuit, and the temperature controller changes different preset cut-off temperatures according to the input load resistors. The cut-off temperature of the temperature controller is automatically adjusted through the environment temperature, the starting frequency of a compressor can be reduced under the condition that the environment temperature is low, and therefore the energy consumption of the truck air conditioner can be remarkably reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

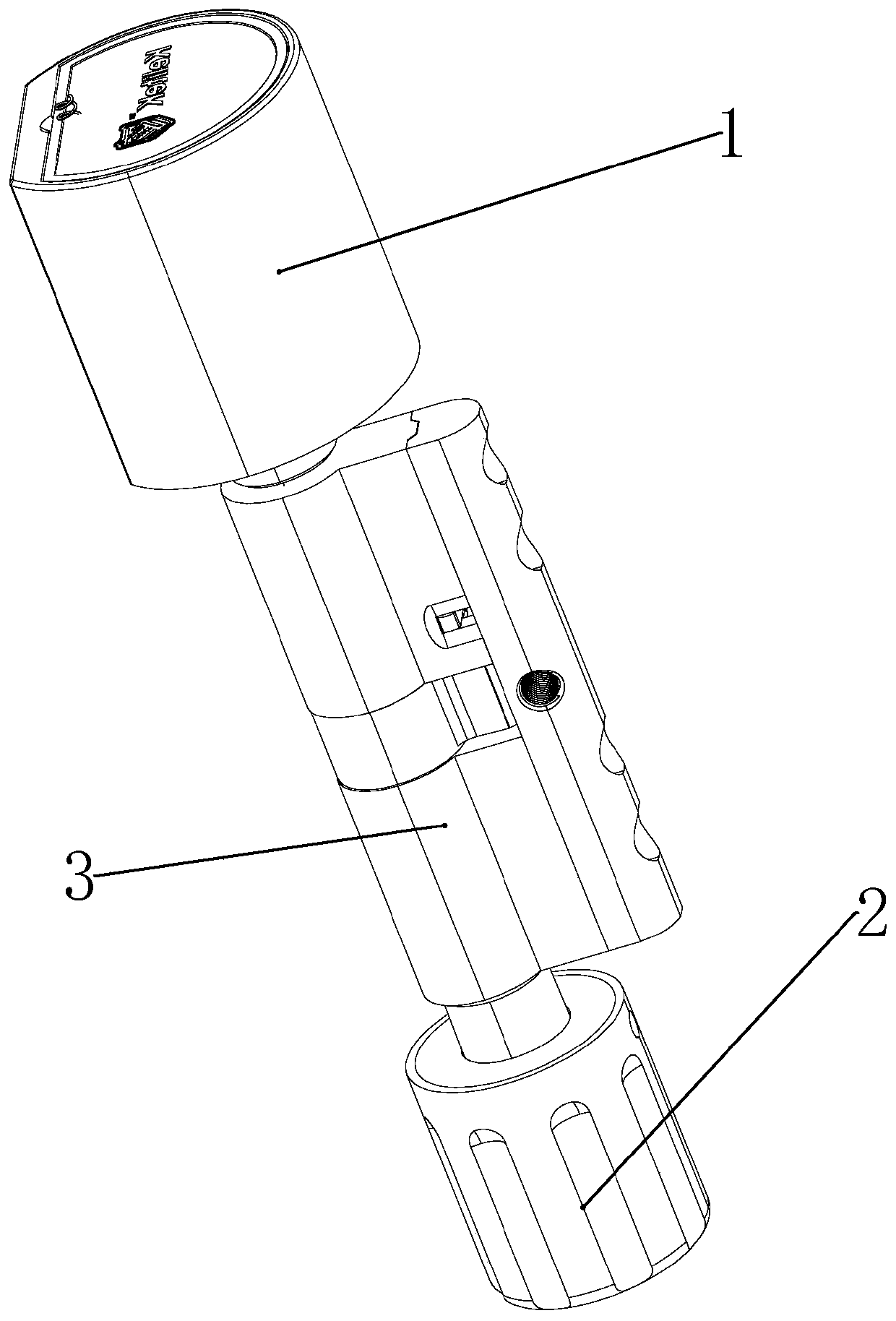

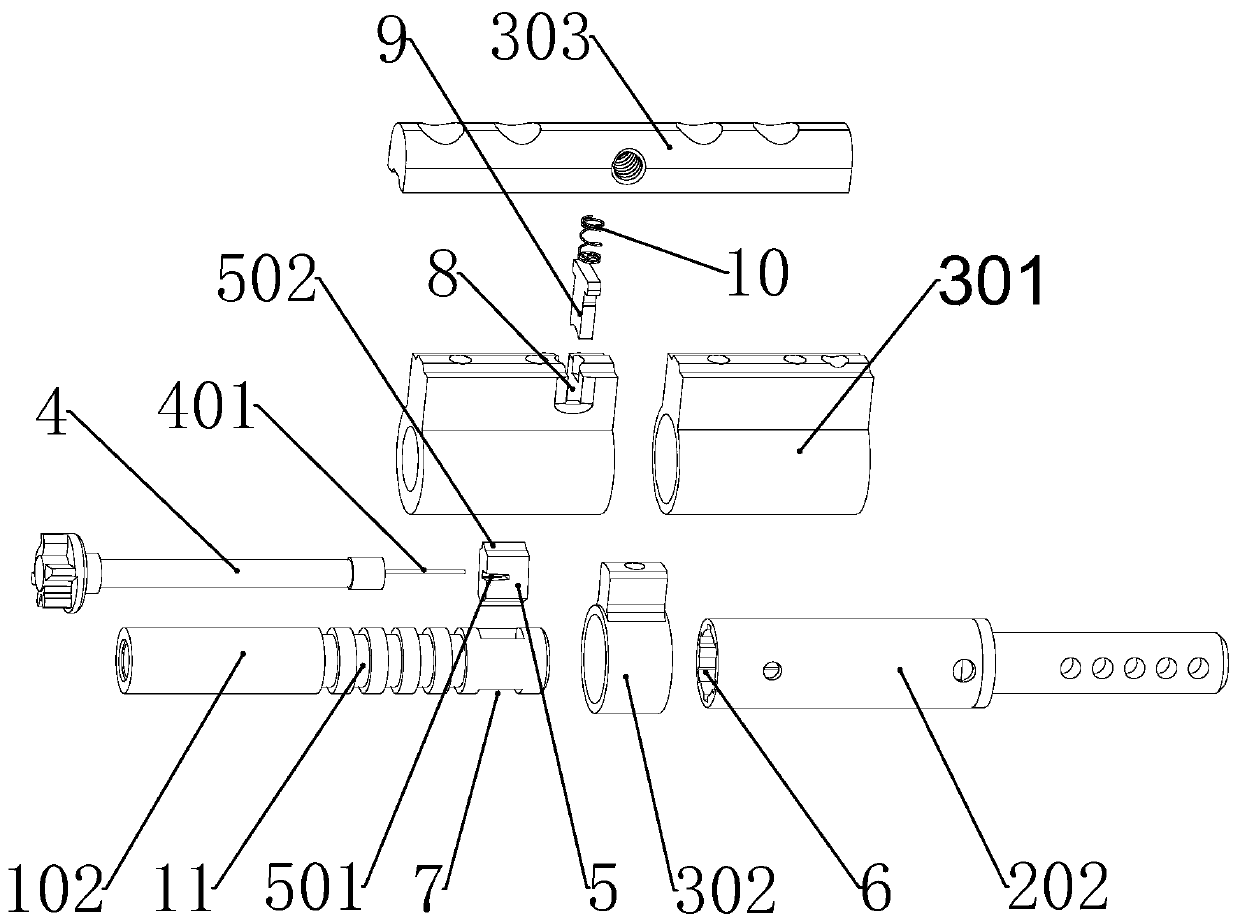

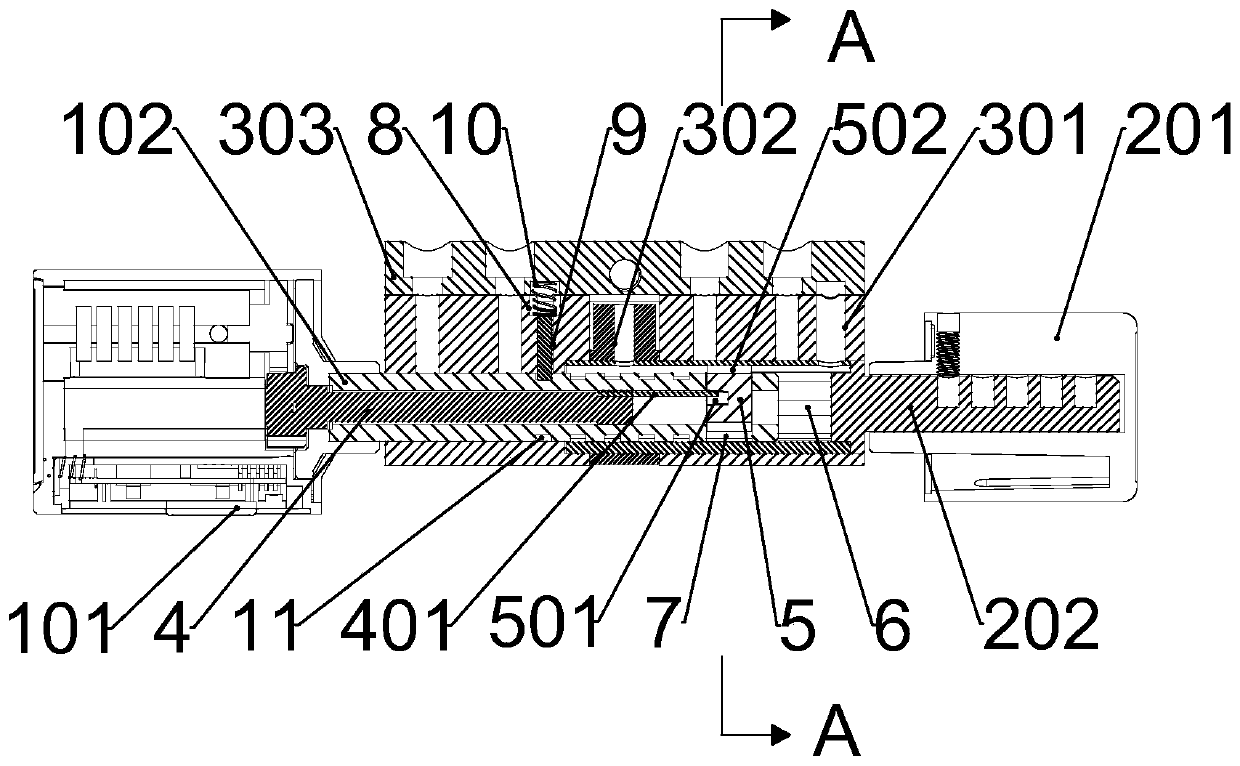

Clutch mechanism of electronic lock cylinder

The invention discloses a clutch mechanism of an electronic lock cylinder. The clutch mechanism comprises a front handle assembly, a rear handle assembly and a lock cylinder body, wherein the rear handle assembly comprises a front spindle and a rear spindle. The front spindle and the rear spindle each comprise a front handle and a rear handle, the front spindle and the rear spindle are arranged ina synchronous rotation mode, the rear spindle sleeves the front spindle, the front spindle is internally provided with a clutch mechanism body, the clutch mechanism body includes a lock cylinder shaft and a pawl, a poke rod is eccentrically arranged at one end of the lock cylinder shaft, a through hole is provided on the side wall of one end of the front spindle, the claw is slidably disposed inthe through hole, clamping protrusions are symmetrically arranged on the two sides of the pawl, a plurality of racks are symmetrically arranged on the inner wall of the rear spindle, the clamping protrusions on one side of the rear spindle can be engaged with the racks to realize one-way driving of the rear spindle, and the poke rod drives the clamping protrusions on the other side of the claw tobe engaged with the reversing of the racks after the lock cylinder shaft rotates reversely. The clutch mechanism has the effects that locking is convenient and fast, the structure is simple, and the electric quantity is saved.

Owner:浙江科利智能科技有限公司

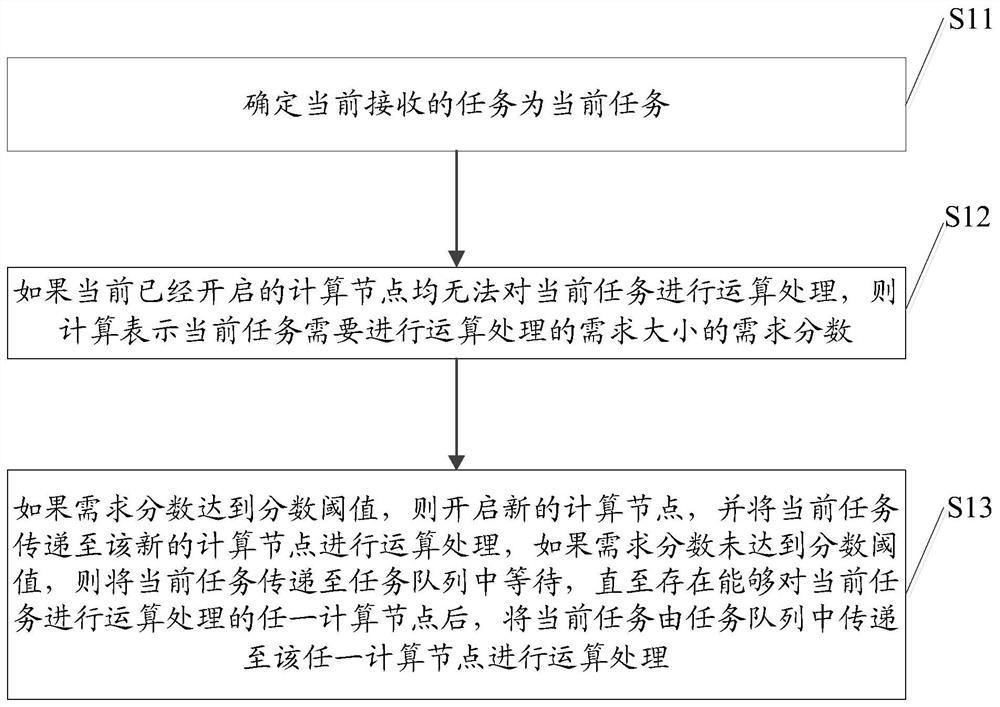

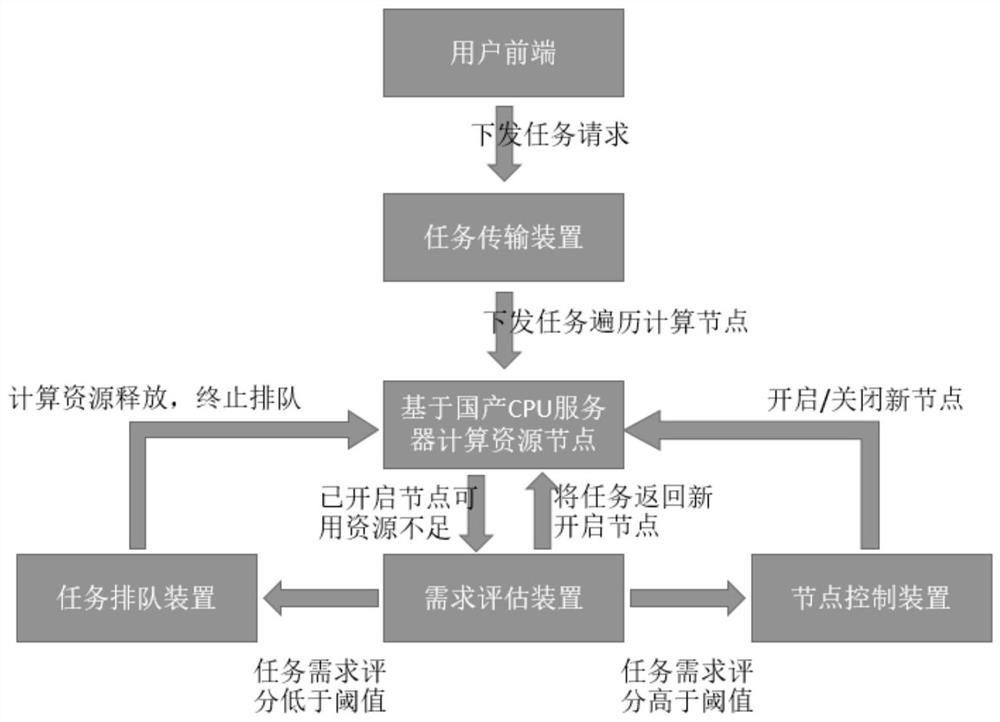

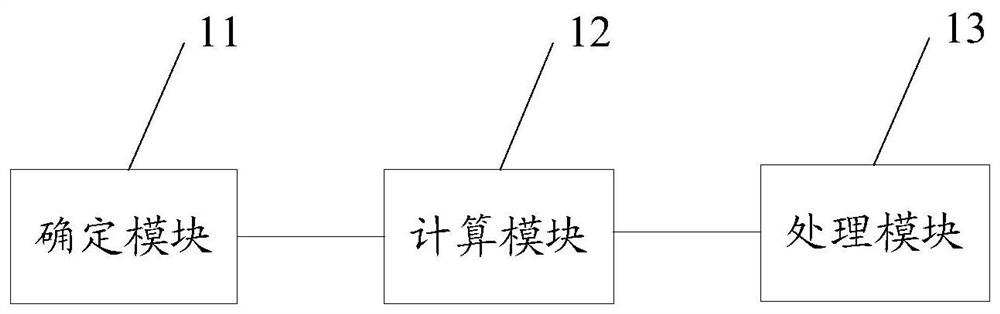

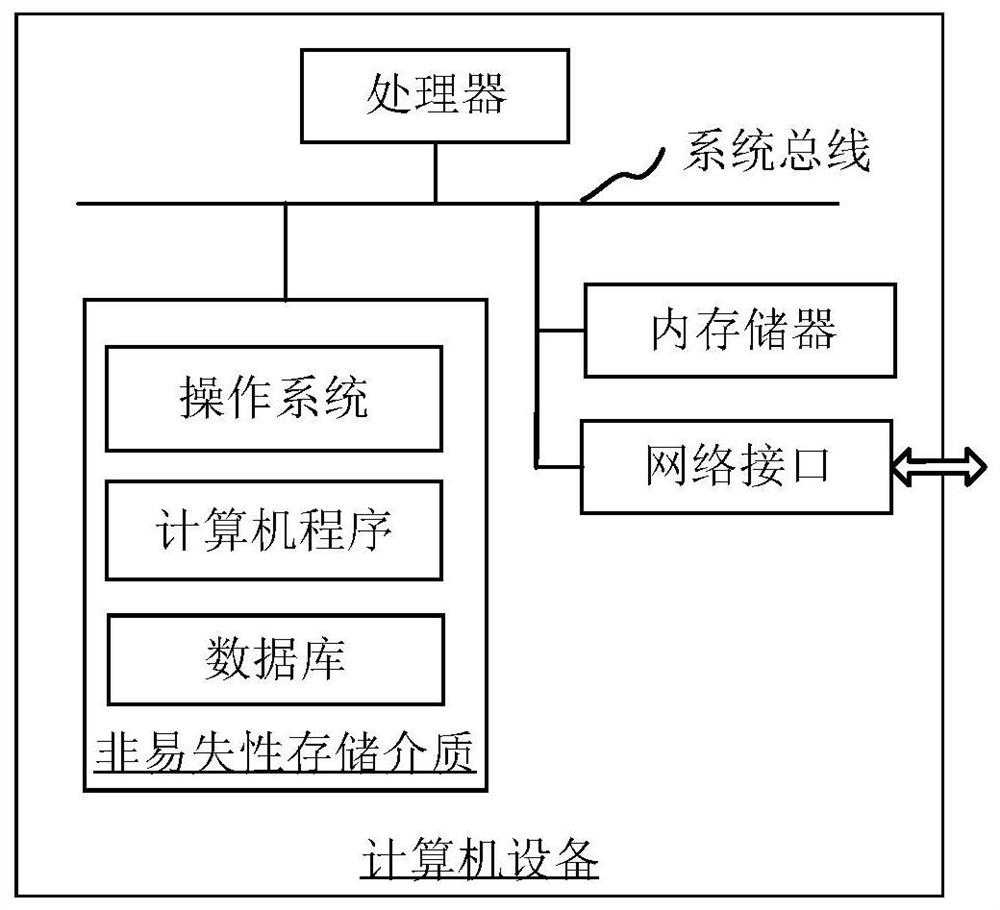

Task processing method, device and equipment and storage medium

InactiveCN111858005AReduce the frequency of openingProgram initiation/switchingDigital data processing detailsServerComputer engineering

The invention discloses a task processing method, apparatus and device, and a storage medium. The method comprises the steps of determining a currently received task as a current task; if the currently opened computing nodes cannot perform operation processing on the current task, calculating a demand score representing the demand size of the current task needing operation processing; if the demand score reaches a score threshold, starting a new computing node, and transmitting the current task to the new computing node for operation processing; and if the demand score does not reach the scorethreshold, transmitting the current task to a task queue for waiting until any computing node capable of performing operation processing on the current task exists, and transmitting the current taskfrom the task queue to the any computing node for operation processing. Therefore, the starting frequency of the new computing node is effectively reduced, and the power consumption of the server is effectively reduced on the premise of meeting the service requirements.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Integral active electric power-assisted steering mechanical structure

InactiveCN101973311BImprove securityImprove stabilityMechanical steering gearsElectrical steeringElectric power steeringPermanent magnet rotor

The invention discloses an integral active electric power-assisted steering mechanical structure. The structure comprises an electric power-assisted steering system, a steering system gear ratio system and a back wheel steering system, wherein the electric power-assisted steering system and the steering system gear ratio system are realized by a steering system variable-gear ratio electric power-assisted steering system; the back wheel steering system is a special device system for supplying steering force to a back wheel; the steering system variable-gear ratio electric power-assisted steering system is realized by an electronically-controlled harmonic gear transmission between a steering wheel and a lower transmission shaft; and the back wheel steering system consists of a support shaftring, an outer shell, a motor stator coil, a permanent magnet rotor, a motor angle sensor, a central hollow shaft, a recirculating ball retarding mechanism, a lock sleeve and a rack shaft. In a steering process, an adjusting motor and a power assisting motor are controlled flexibly and compensate for each other, so that steering sensitivity, portability and operation stability are combined perfectly and operation performance and safety performance are enhanced.

Owner:ZHUZHOU ELITE ELECTRO MECHANICAL

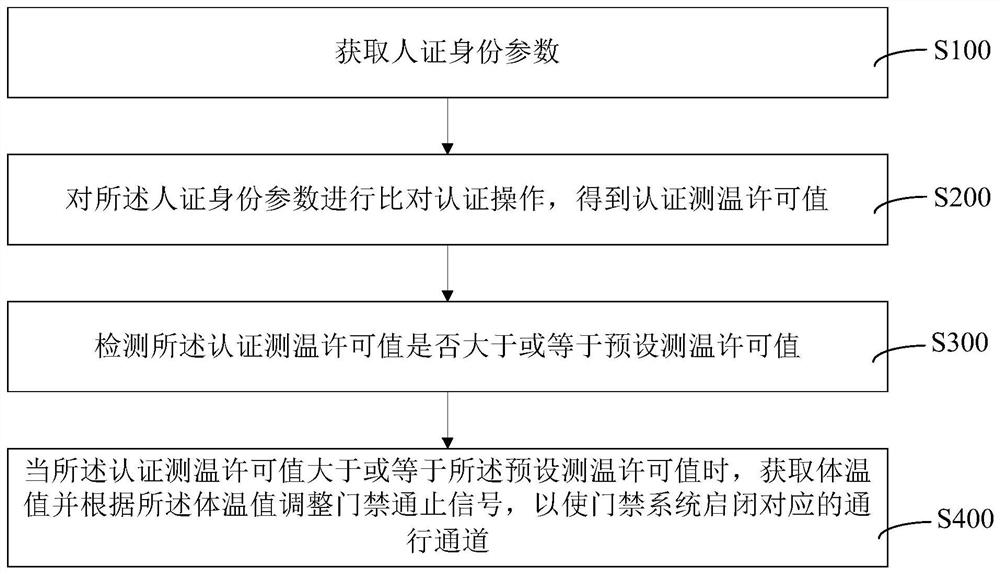

Temperature measurement access control monitoring method and device, computer equipment and storage medium

PendingCN113205630AReduce the temperature measurementReduce the frequency of openingSensing radiation from moving bodiesIndividual entry/exit registersComputer equipmentReal-time computing

The invention provides a temperature measurement access control monitoring method and device, computer equipment and a storage medium. The method comprises the following steps of: acquiring human-certificate identity parameters; performing comparison authentication operation on the human-certificate identity parameters to obtain an authentication temperature measurement permission value; detecting whether the authentication temperature measurement permission value is greater than or equal to a preset temperature measurement permission value; and when the authentication temperature measurement permission value is greater than or equal to the preset temperature measurement permission value, acquiring a body temperature value and adjusting an access control on-off signal according to the body temperature value so as to enable an access control system to open and close a corresponding passage channel. According to the temperature measurement access control monitoring method and device, the computer equipment and the storage medium, the body temperature of the human body is measured only after the authentication temperature measurement permission value reaches the preset temperature measurement permission value, namely temperature measurement is started, so that the condition that the temperature of a person with unqualified identity authentication is measured is reduced, the frequency of starting temperature measurement is reduced, the starting frequency of a temperature detector of the access control system is reduced, and the power consumption of the access control system is reduced.

Owner:惠州空间信息技术研究院

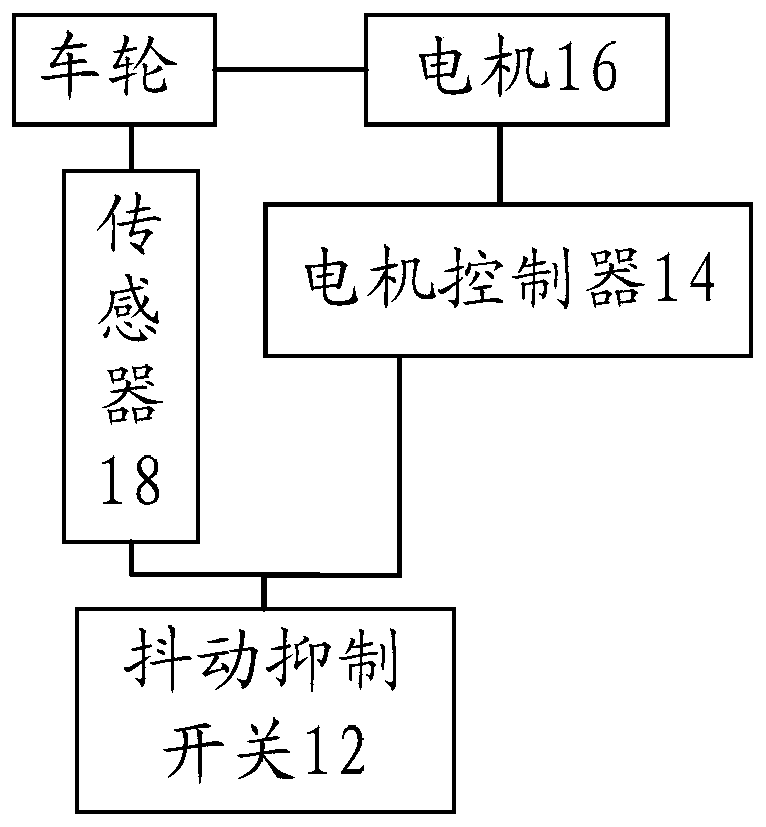

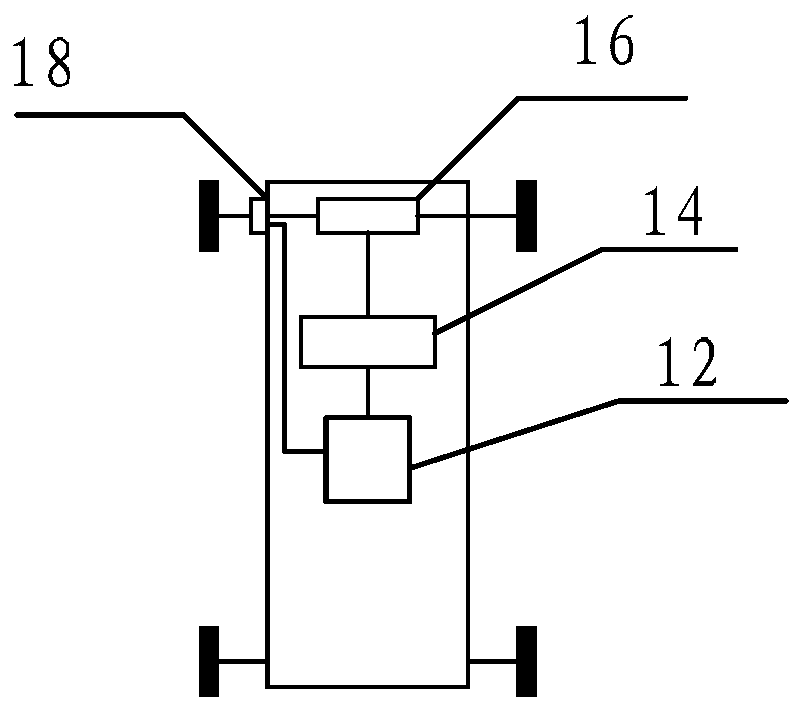

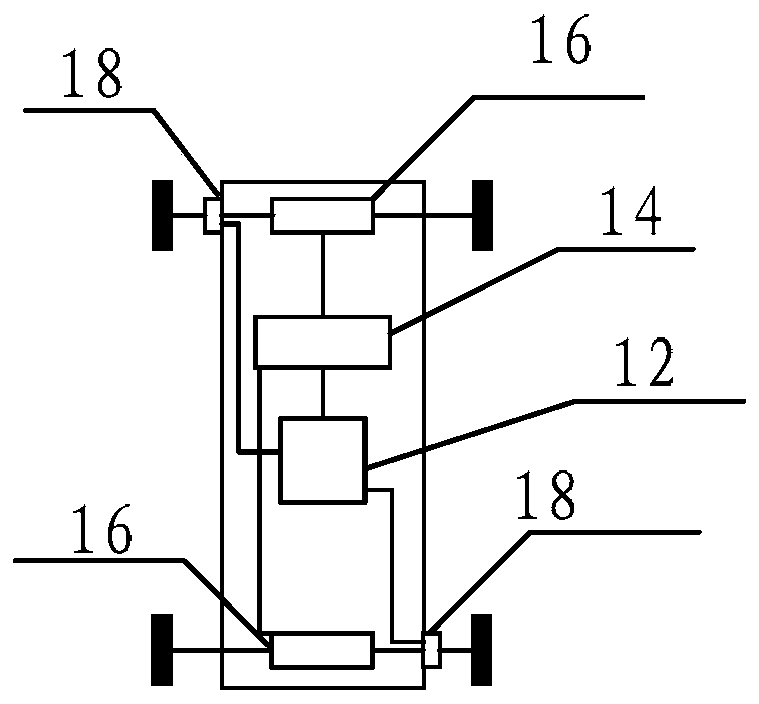

Control method, system and vehicle for suppressing body shake

InactiveCN108032768BImprove torque control accuracySolve the technical problem of low torque control accuracySpeed controllerElectric energy managementControl signalElectric machinery

The invention discloses a control method and system for suppressing automobile body shaking and an automobile. According to the control method for suppressing automobile body shaking, a shaking suppression switch, a motor controller, a drive motor and sensors are arranged; the sensors are arranged on wheels and used for acquiring the accelerated speed of the wheels; the motor controller is connected with the drive motor and used for acquiring the accelerated rotation speed of the drive motor corresponding to the wheels; and the shaking suppression switch is connected with the sensors and the motor controller and used for outputting a shaking suppression control signal according to the accelerated speed of the wheels and the accelerated rotation speed of the drive motor. The technical problem that in the automobile body shaking suppression treatment process in the prior art, the fluctuation of the rotation speed of the motor is suppressed through superposition of the torque, and thus the whole automobile torque control accuracy is low is solved.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

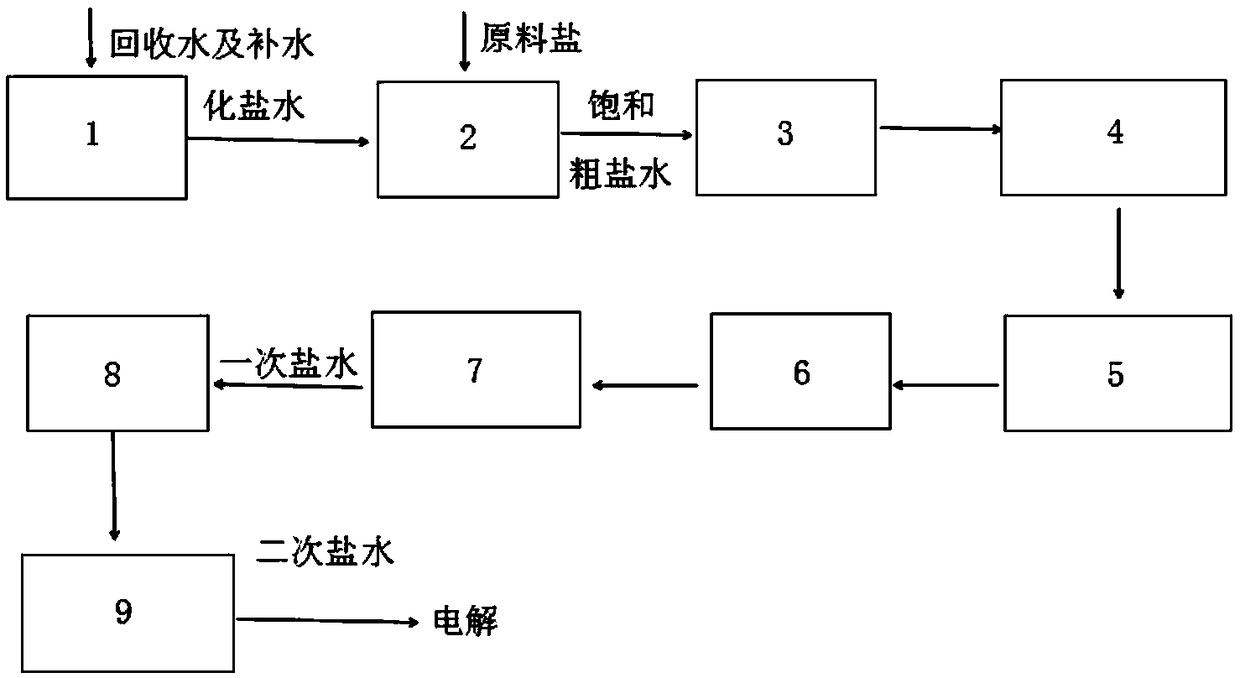

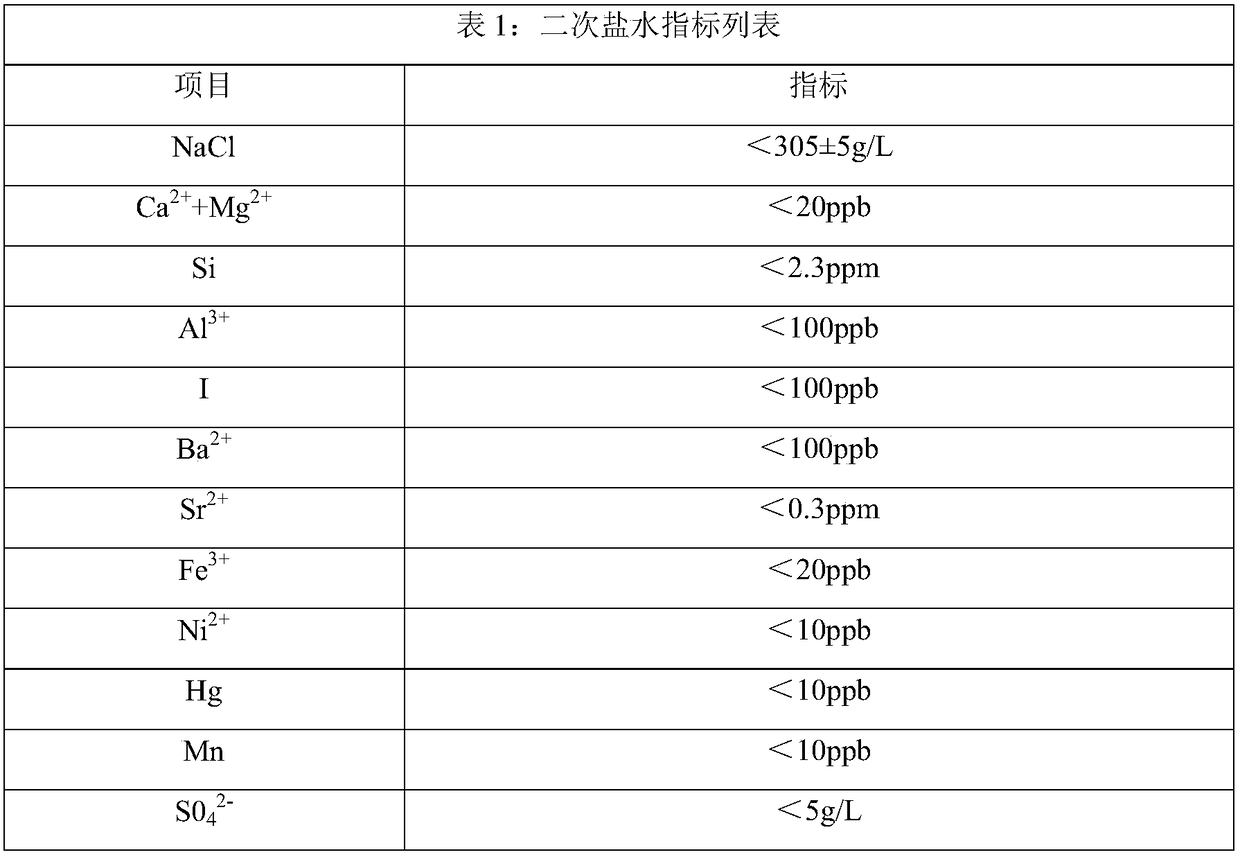

Production process for refining secondary brine by replacing sun-dried sea salt with well and rock salt

ActiveCN108996773AReduced salt consumption per ton of alkaliReduce turn-on frequencyWater contaminantsWater/sewage treatment by ion-exchangeSea saltChemistry

The invention discloses a production process for refining secondary brine by replacing sun-dried sea salt with well and rock salt. The production process for refining secondary brine with sun-dried sea salt uses the sea salt and the well and rock salt as raw material salts, wherein the raw material salts contain not less than 25% by mass of sea salt; the content of the well and rock salt in the raw material salts is not zero. The production process provided by the invention can replace the sea salt with the well and rock salt to improve production capacity and reduce cost.

Owner:DEZHOU SHIHUA CHEM

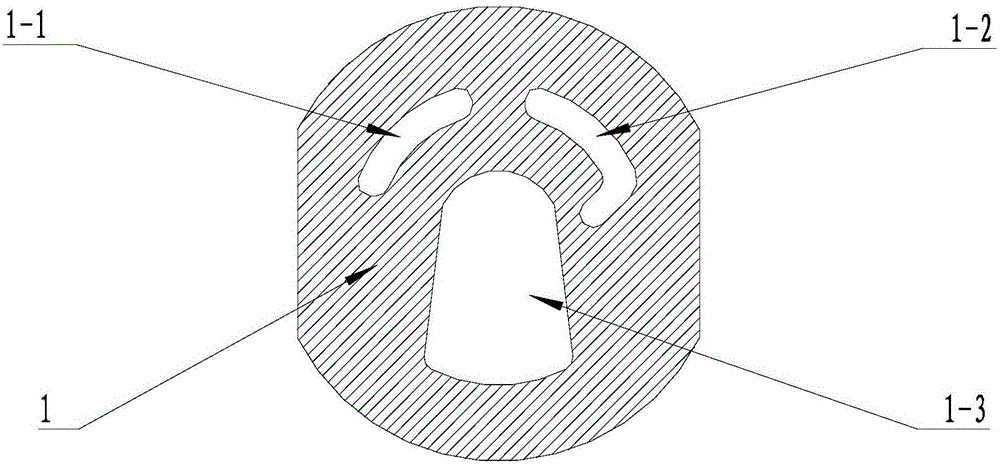

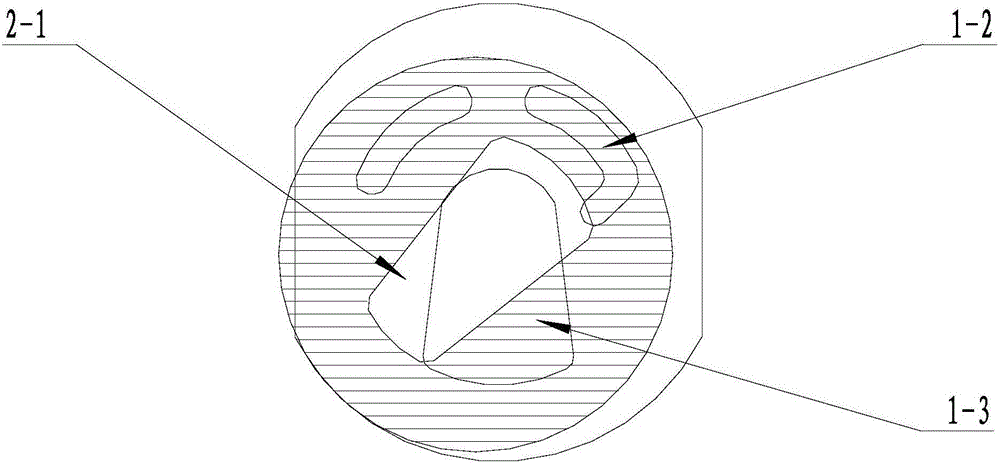

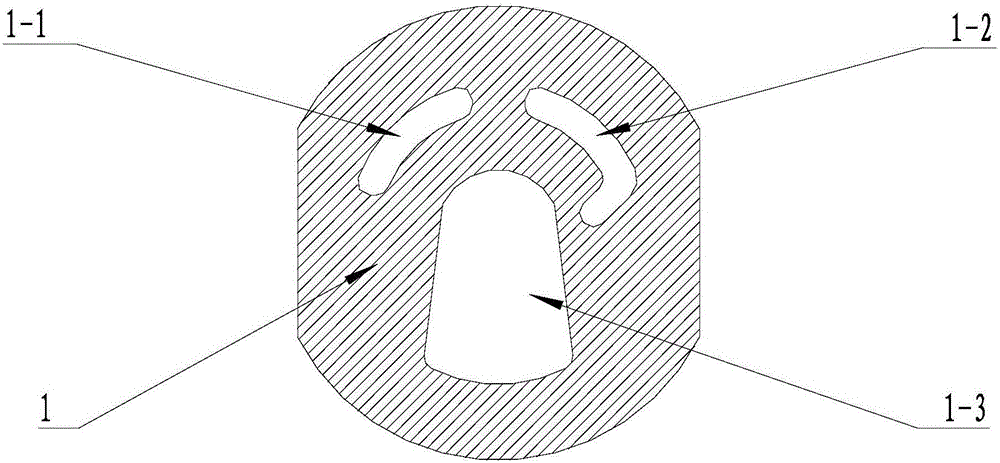

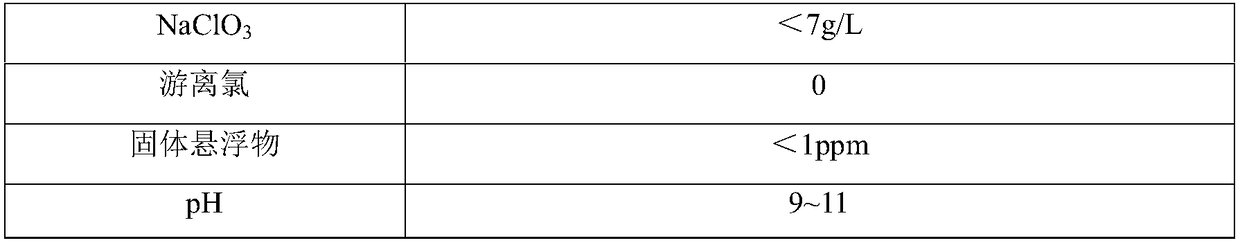

Single side constant flow valve device and its fluid supply system

ActiveCN106151596BSave fluidEasy to controlOperating means/releasing devices for valvesValve members for heating/coolingEngineeringFluid supply

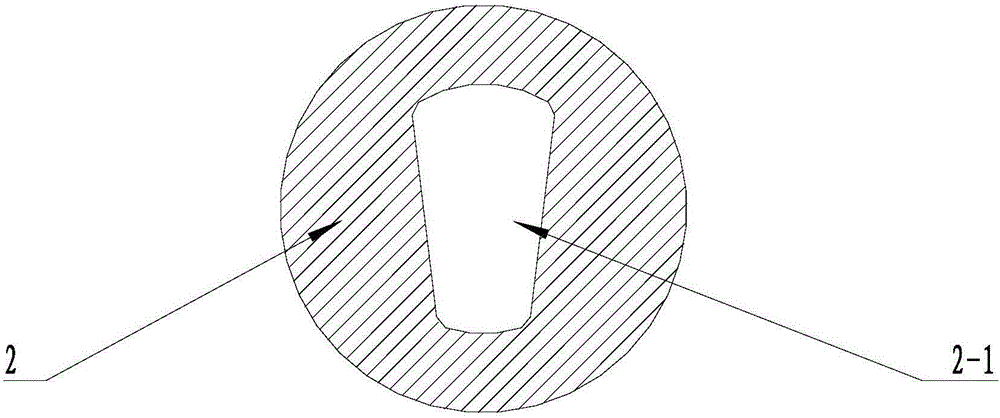

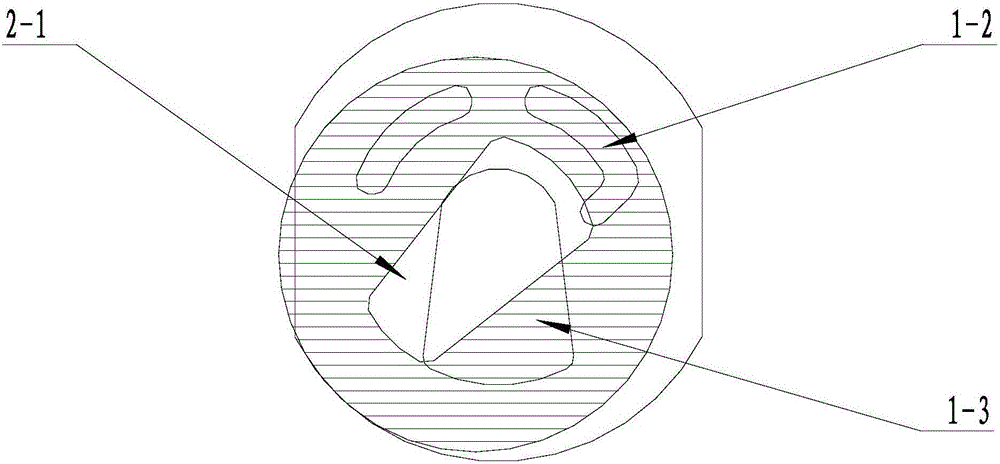

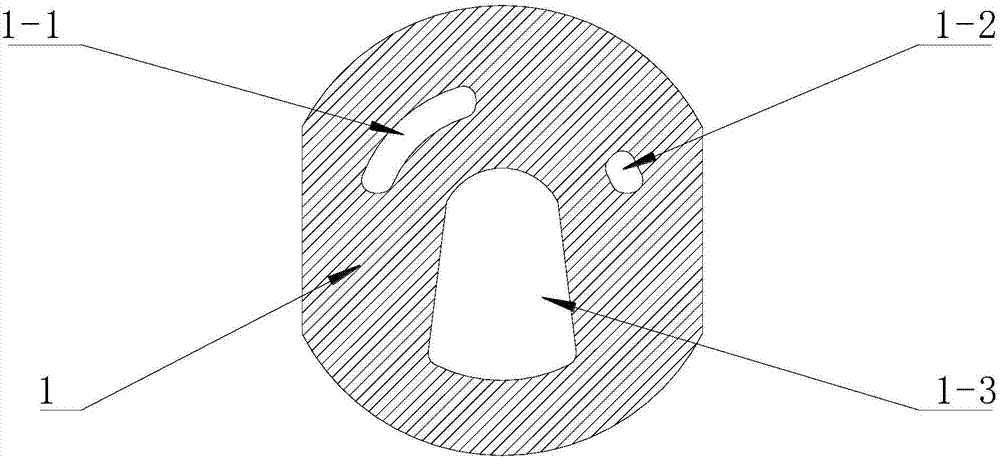

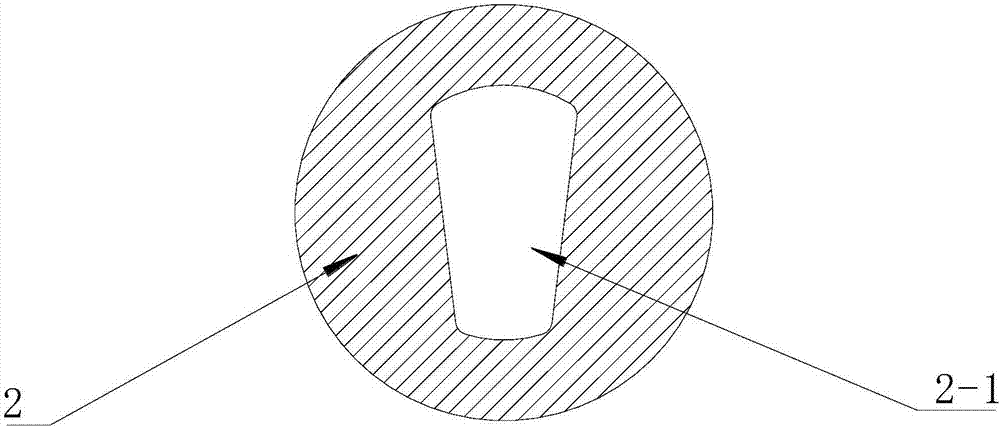

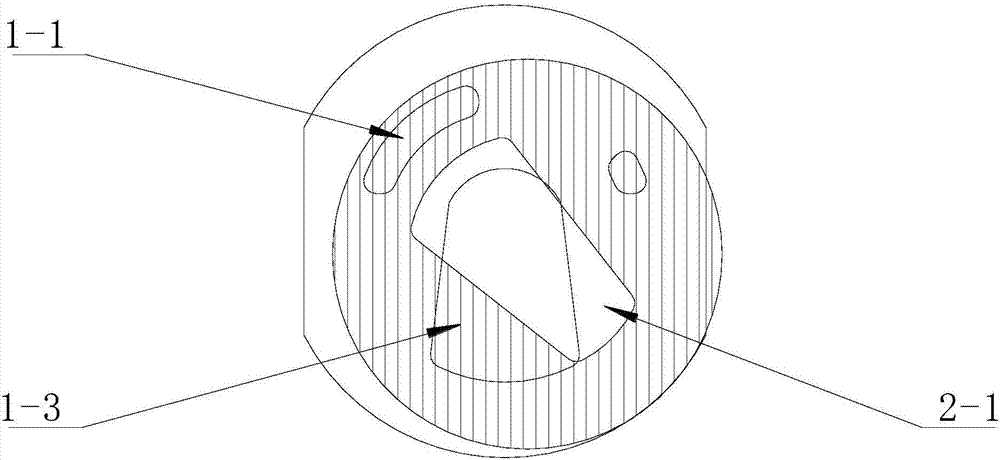

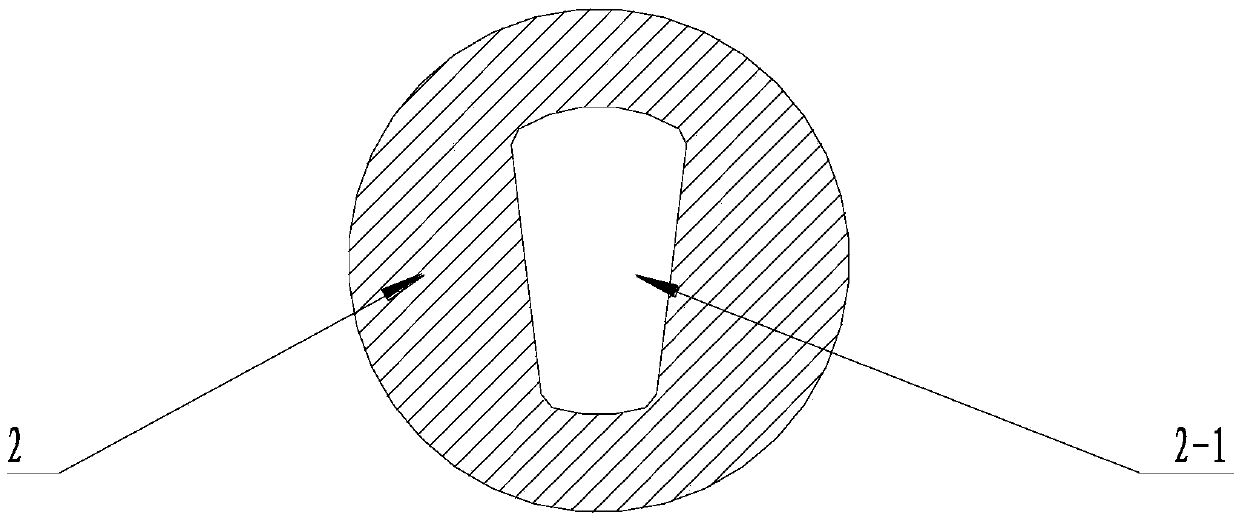

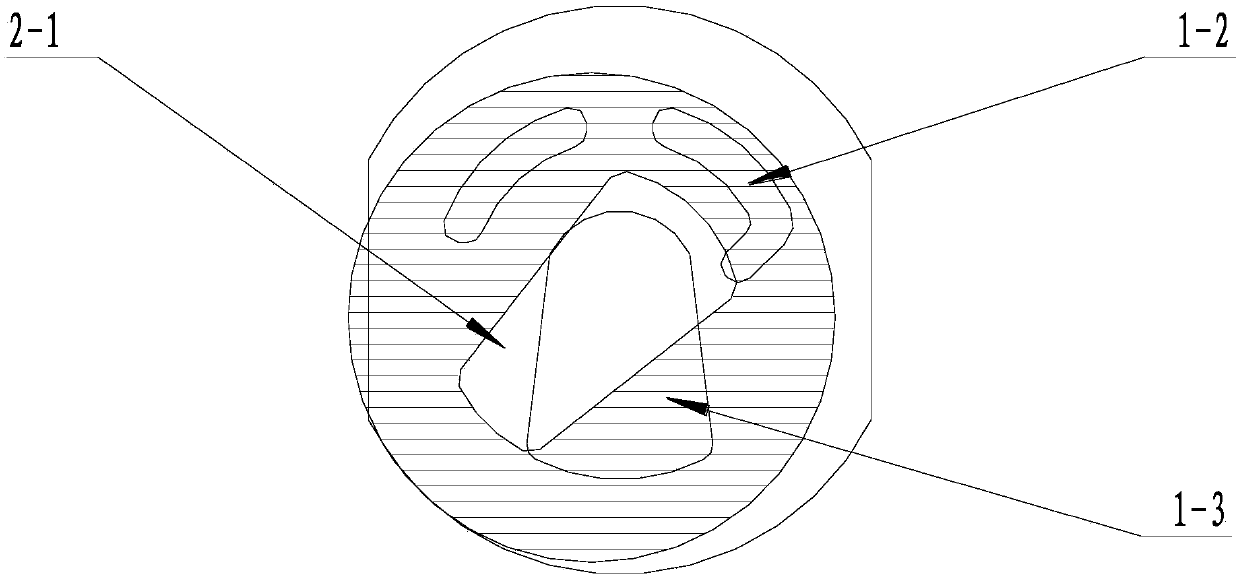

A valve device and a fluid supplying system thereof. The valve device is provided with a first fluid inlet end (1-2), a second fluid inlet end (1-1) and a fluid outlet end (1-3); an operating area of an operating mechanism is divided into a mixing degree adjusting area for adjusting the mixing degree of a first fluid and a second fluid and a flow adjusting area that is always capable of adjusting the flow of the fluid outlet end (1-3) of the valve device in the whole mixing degree adjusting area; the mixing degree adjusting area is divided into a first fluid area in which the first fluid is only drained from the fluid outlet end (1-3), a mixing area in which a mixed fluid of the first fluid and the second fluid is drained from the fluid outlet end (1-3) and a second fluid area in which the second fluid is only drained from the fluid outlet end (1-3); and the flow of the operating mechanism at a minimum stop position in the flow adjusting area of the first fluid area is greater than zero, and the flow of the operating mechanism at a minimum stop position in the flow adjusting area of the second fluid area is equal to zero. The valve device and the thermal fluid supplying system thereof facilitate the conservation of fluid passing through the valve device, and facilitate normal use of a thermal fluid supplying device.

Owner:安徽领克自控设备有限公司

Functional modular partition type cloud data machine room

PendingCN114375140AEasy to useImprove the stability of useDispersed particle filtrationTransportation and packagingRubber ringTemperature control

The invention discloses a function modular partition type cloud data machine room, the machine room comprises a room body and a cabinet, the front end position of the cabinet is movably provided with a door plate through a hinge, the upper end position of the room body is provided with a temperature control mechanism, and the left side end position of the room body is provided with a dust removal mechanism. A plurality of penetrating holes are evenly formed in the upper end of the cabinet, rubber rings are horizontally and fixedly installed in the penetrating holes, and a plurality of hollow blocks are fixedly installed at the bottom end of the interior of the room body. A user pulls the U-shaped pipes downwards according to the number of cabinets needing heat dissipation until the U-shaped pipes and the vacuum pipes penetrate into the center of the rubber ring and extend into the cabinets, then the first fan is started, negative pressure is formed in the second connecting pipe through the first fan, gas is exhausted through the first connecting pipe, and heat dissipation is achieved. Therefore, hot air in the cabinet is pumped out through the U-shaped pipe, so that heat dissipation and temperature control are carried out on the interior of the cabinet, and the service life of the cabinet is prevented from being shortened due to too high temperature.

Owner:谭东敏

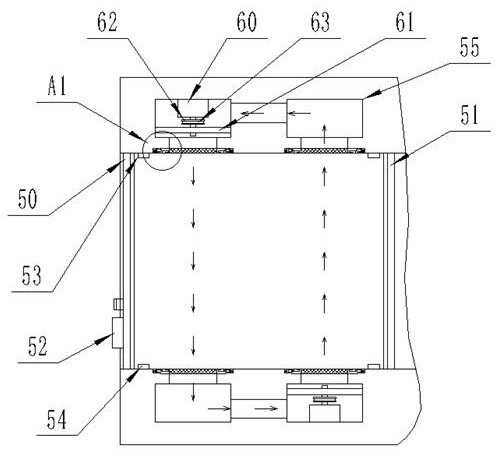

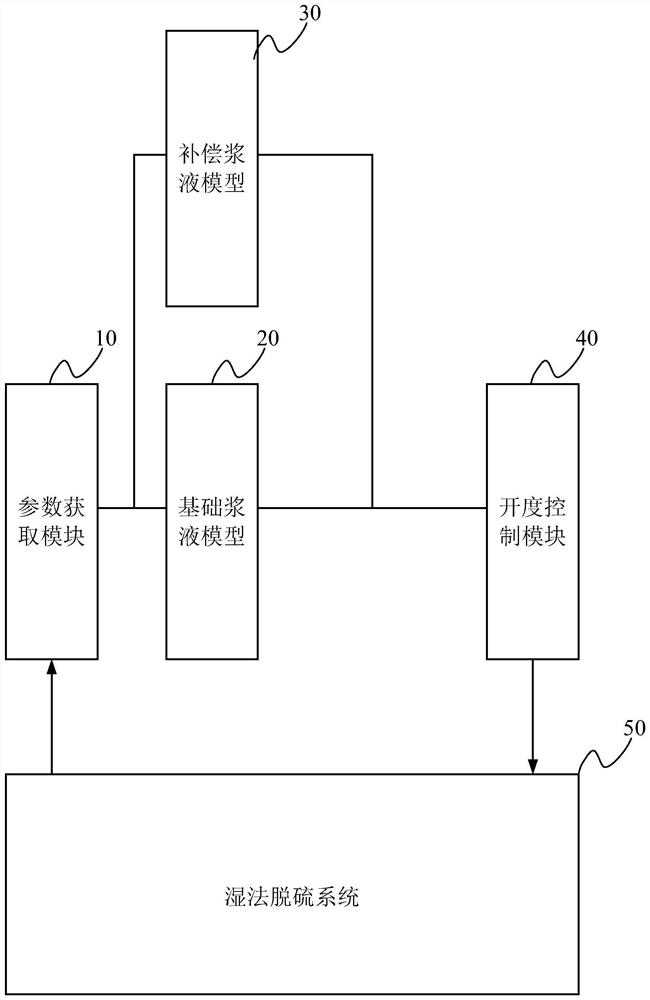

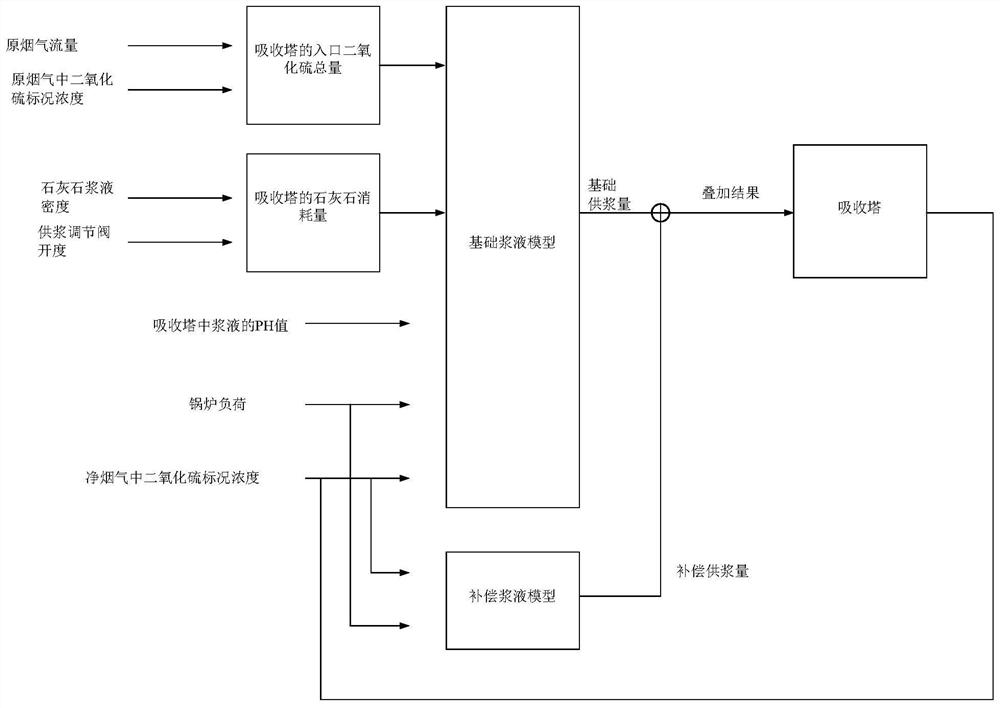

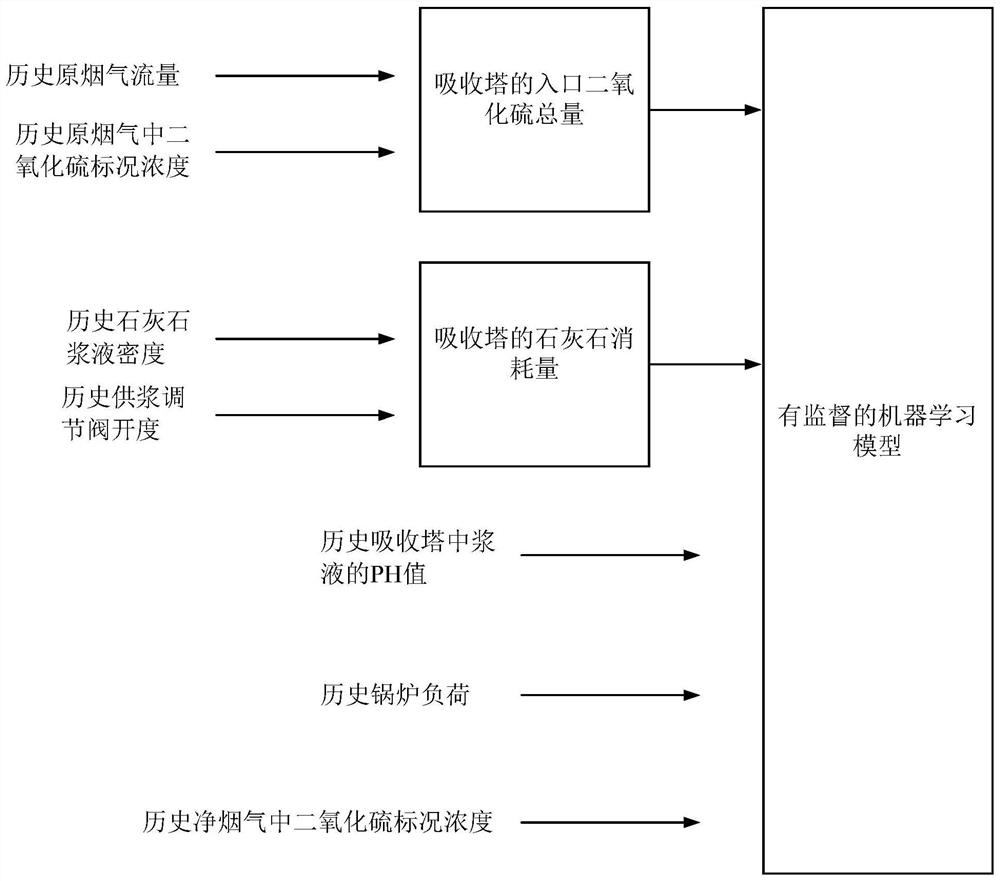

An opening degree control system and opening degree control method of a slurry supply regulating valve

ActiveCN111229010BReduce the frequency of openingReduce labor intensityGas treatmentOperating means/releasing devices for valvesFlue gasControl system

This application discloses an opening control system and an opening control method for a slurry supply regulating valve. The system realizes the target value based on the sulfur dioxide in the net flue gas through the parameter acquisition module, the basic slurry model, the compensation slurry model and the opening control module. For the purpose of closed-loop control of the opening of the slurry supply regulating valve, the system has better control over the opening of the slurry supply regulating valve than the PID control strategy based on the pH setting value of the slurry in the absorption tower in the prior art. The given slurry supply volume (the superimposed value of the basic slurry supply volume and the compensation slurry supply volume) is more conducive to controlling the concentration of sulfur dioxide in the outlet of the absorption tower below the limit value, which is operationally replaceable for the on-site staff and has improved The control effect of the opening degree control system of the slurry supply regulating valve on the wet desulfurization system can reduce the frequency of staff manually controlling the opening of the slurry supply regulating valve, reduce the labor intensity of the staff, and avoid energy and material that may be caused by manual operation. wasteful situation.

Owner:FUJIAN LONGKING

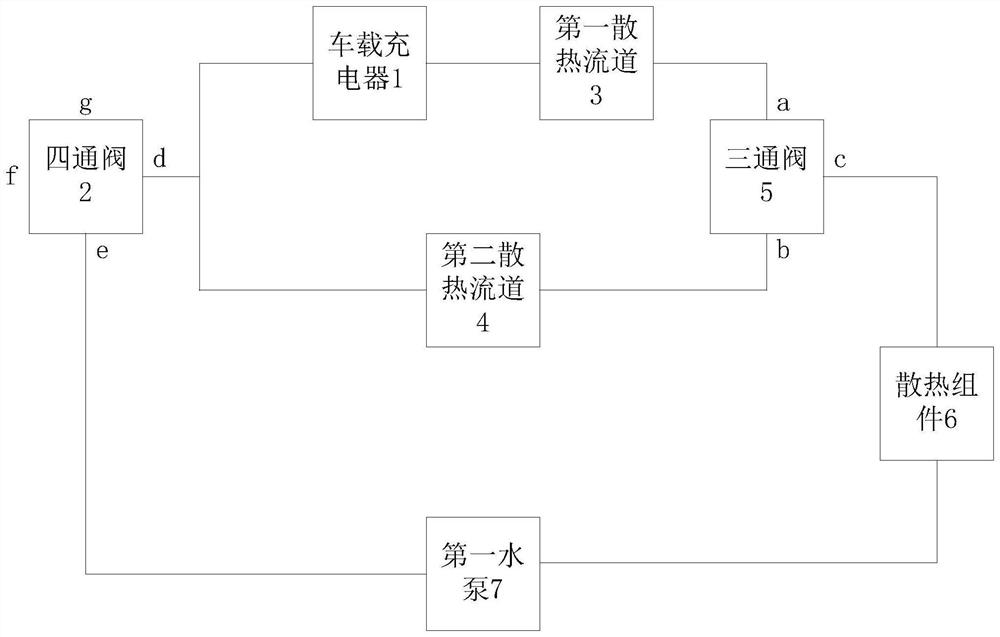

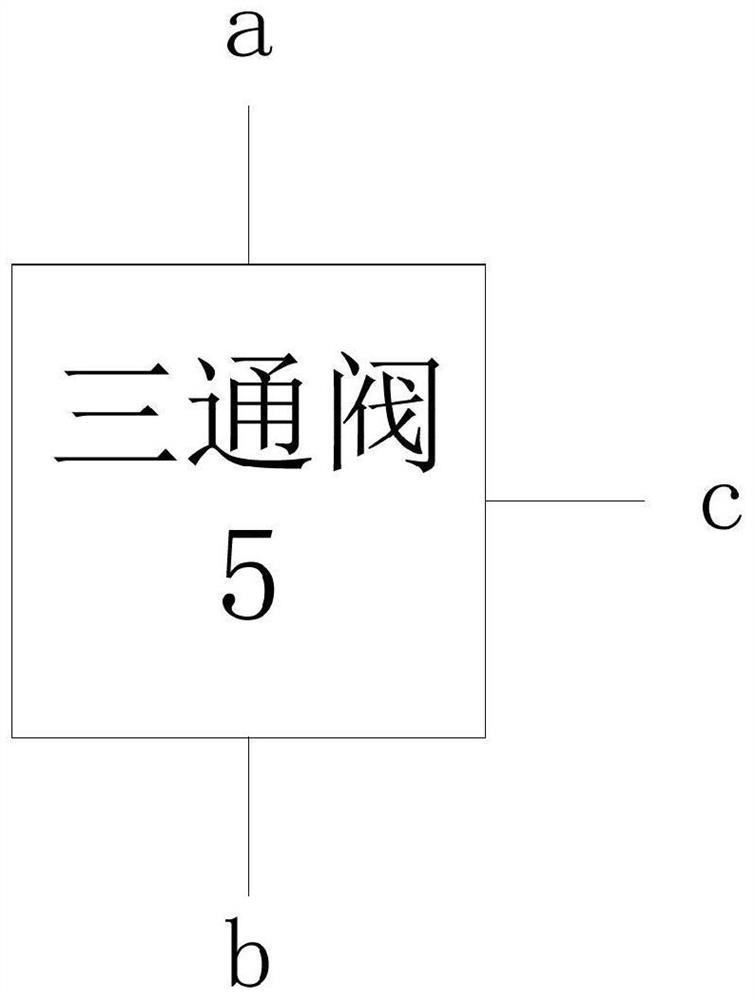

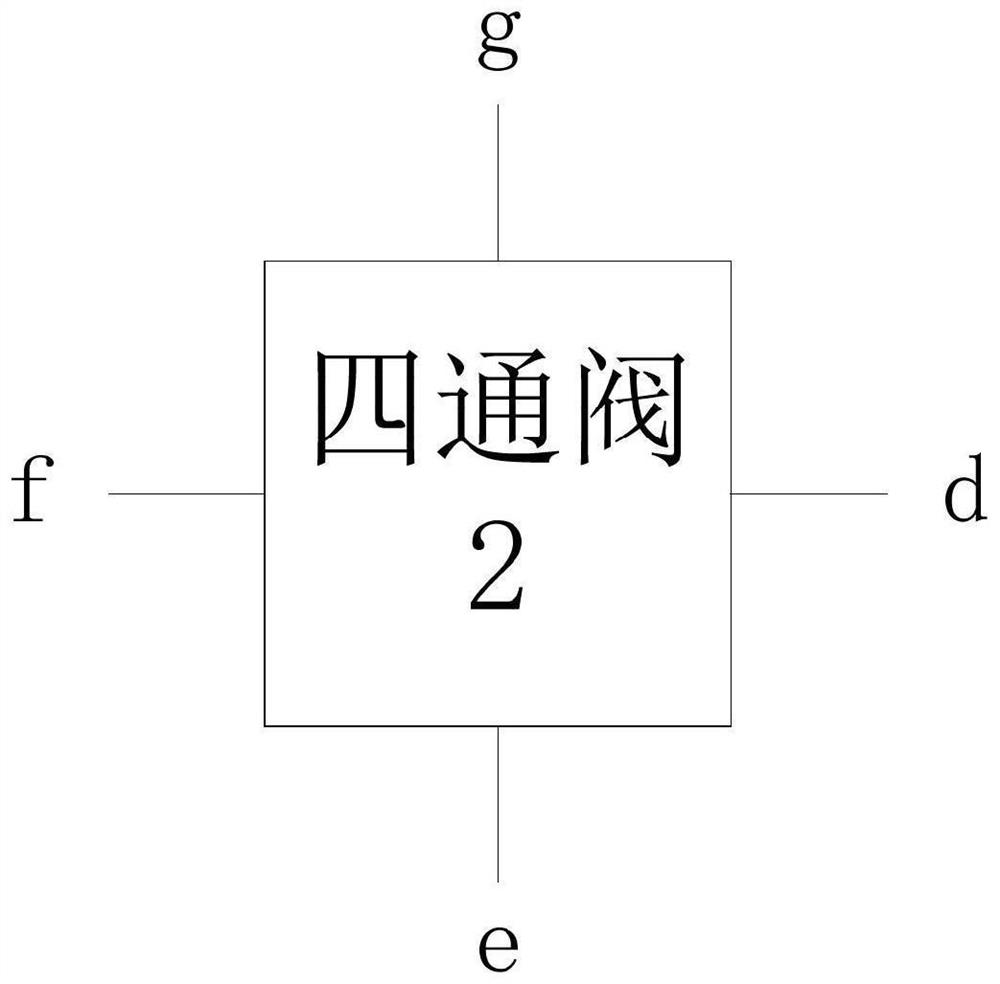

Thermal management system of electric automobile

PendingCN114161923AReasonable layoutClear structureSecondary cellsVehicular energy storageThermodynamicsFour-way valve

The invention discloses a thermal management system of an electric vehicle, which comprises a vehicle-mounted charger, a controller, a four-way valve, a first motor, a second motor, a three-way valve, a heat dissipation assembly and a first water pump, and is characterized in that the first motor is provided with a first heat dissipation flow channel, and the second motor is provided with a second heat dissipation flow channel; the vehicle-mounted charger, the controller, the four-way valve, the first heat dissipation flow channel, the second heat dissipation flow channel, the three-way valve, the heat dissipation assembly and the first water pump are specifically connected through water pipes to form heat dissipation waterway circulation. And the controller is configured to realize heat dissipation through an auxiliary heat dissipation mode, an alternate heat dissipation mode and a dual heat dissipation mode. According to the thermal management system of the electric vehicle provided by the embodiment of the invention, the final heat dissipation effect is improved by constructing a specific heat dissipation system structure.

Owner:HUMAN HORIZONS (JIANGSU) TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com