Production method for improving rolling stability of thick-specification pipeline steel

A production method and technology for pipeline steel, applied in metal rolling, temperature control, etc., can solve the problems of mismatched production process, large speed variation, unstable performance, etc., to improve market competitiveness, uniform performance, and qualified coiling The effect of rate increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

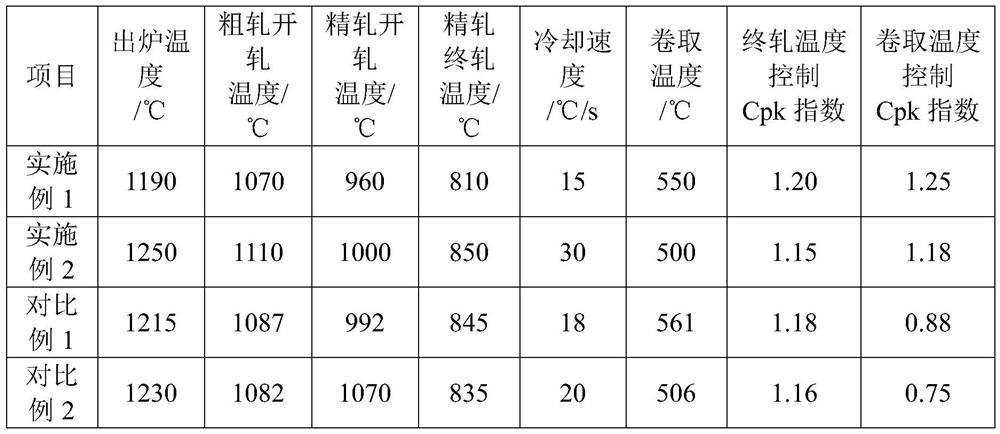

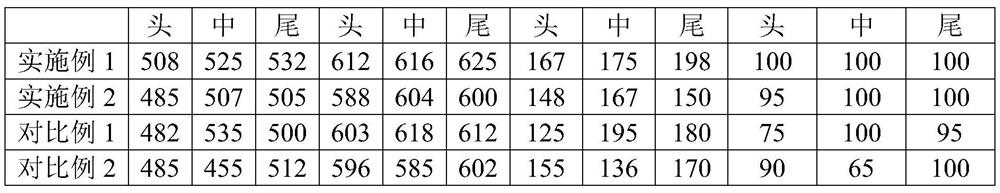

Embodiment 1

[0042] 1. For 15.9mm X65M pipeline steel, the slab thickness is 227mm, the slab reheating temperature is controlled at 1190°C, the strip surface temperature difference is ≤30°C, and the heating time is 210min. The components of the continuous casting slab are: C: 0.07%, Si: 0.20%, Mn: 1.42%, Nb: 0.048%, Ti: 0.023%, and the balance is Fe and unavoidable impurities.

[0043] 2. The starting temperature of rough rolling is 1070°C, 5 rolling passes are adopted, the reduction rate of each pass is 24%, 26%, 25%, 25%, 26%, the thickness of the intermediate billet is 52mm, and the rolling and descaling are fully opened. The temperature of rough rolling and final rolling is controlled at 1000°C, and the rolling speed is 4.0-4.2m / s.

[0044] 3. The starting temperature of finish rolling is 960°C, the finish rolling is seven-stand hot continuous rolling, F2 and F5 are assumed as false, and the reduction rate of each pass is 31%, 0%, 34%, 24%, 0%, 16%, 8%, and the final rolling temperatu...

Embodiment 2

[0048] 1. For 19.1mm X60M pipeline steel, the slab thickness is 227mm, the slab reheating temperature is controlled at 1250°C, the strip surface temperature difference is ≤30°C, and the heating time is 190min. The components of the continuous casting slab are: C: 0.08%, Si: 0.20%, Mn: 1.39%, Nb: 0.042%, Ti: 0.021%, and the balance is Fe and unavoidable impurities.

[0049] 2. The starting temperature of rough rolling is 1110°C, 5 rolling passes are adopted, the reduction rate of each pass is 23%, 24%, 25%, 24%, 25%, the thickness of the intermediate billet is 55mm, and the rolling and descaling are fully opened. The temperature of rough rolling and final rolling is controlled at 1040°C, and the rolling speed is 4.0-4.2m / s.

[0050] 3. The starting temperature of finish rolling is 1000°C, the finish rolling is seven-stand hot continuous rolling, F2 and F5 are assumed as false, and the reduction rate of each pass is 27%, 0%, 25%, 20%, 0%, 15%, 9 %, the final rolling temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com