Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Reduce the amount of hydrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monocrystalline silicon wafer precleaning liquid and cleaning method thereof

ActiveCN103087850AReduce concentrationReduce Fragmentation RateInorganic non-surface-active detergent compositionsCleaning using liquidsHydrogenWater rinsing

The invention relates to monocrystalline silicon wafer precleaning liquid and a cleaning method thereof. The invention is characterized in that the precleaning liquid comprises the following compositions: hydrogen peroxide, sodium hydroxide or potassium hydroxide, and water. The cleaning method of the monocrystalline silicon wafer precleaning liquid as in claim 1 is characterized in that the method comprises the following steps: putting a silicon wafer inserted into a flower basket into a uniformly mixed monocrystalline silicon wafer precleaning liquid at a temperature of 55-80 DEG C, performing ultrasonic cleaning for 60-600 seconds, after ultrasonic cleaning, rinsing with deionized water at 60 DEG C for 1 min, after deionized water rinsing, taking the silicon wafer out, and drying. The advantages of the invention are that with the hydrogen peroxide process, the alkali concentration is reduced; the hydrogen generation amount is low; no bubble trace is generated on the silicon wafer surface; no basket rinsing is caused; no obvious boundary is generated. Since the alkali concentration is reduced, the thickness reduction amount is effectively decreased, which facilitates the reduction of the fragment rate of battery pieces in subsequent procedures.

Owner:徐州鑫宇光伏科技有限公司 +1

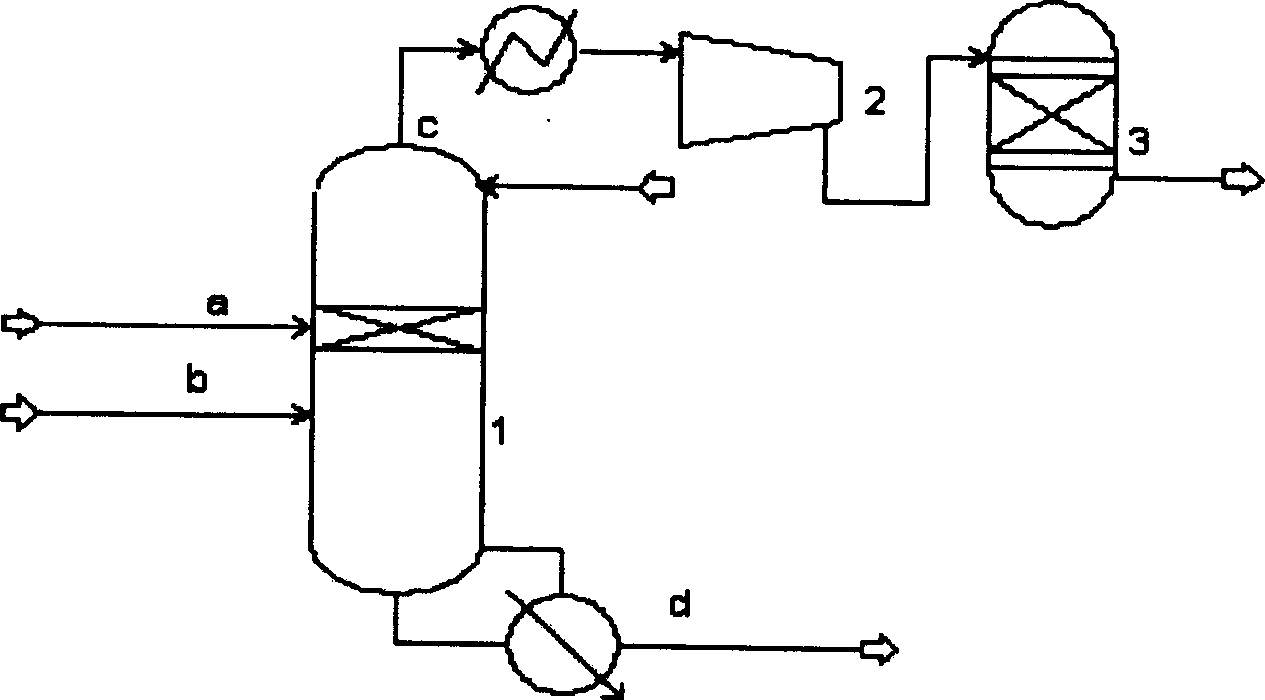

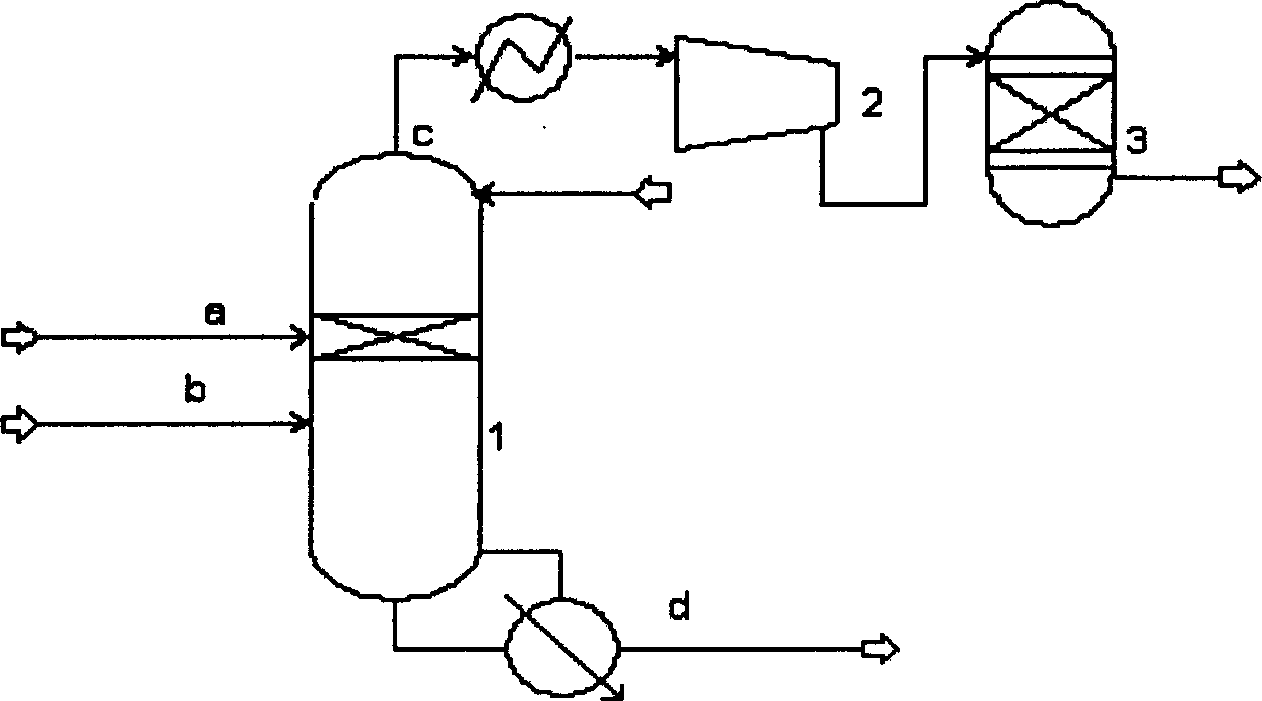

Catalytic distillation process for olefin production device

ActiveCN1690028AReduce loadReduce energy consumptionHydrocarbon by hydrogenationChemical industryHydrogenAlkyne

The catalytic rectification method for olefin production includes setting catalytic reaction area in the pre-depropanizing column of the olefin producing apparatus; selectively hydrogenating C3- acetylene hydrocarbons and diene while separating C3, C3-, C4 and C4+ fractions; making top gaseous matter flow into gaseous hydrogenating reactor for further eliminating C3- acetylene hydrocarbons and diene; and feeding the cauldron liquid C4+ to the further separation area. The said method of the present invention can convert most of the C3- acetylene hydrocarbons and diene into corresponding olefin, reduce the hydrogen amount into the deeply freezing system, lower the power consumption, simplify technological process, reduce investment, raise the selectivity of catalytic hydrogenation and raise olefin yield, and has prolonged catalyst operating period, stable operation and no loss of butadiene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Recirculation unit for a fuel cell system

InactiveCN103563147AImprove reliabilityHigh resolutionFuel cell auxillariesVapor condensationFuel cellsEngineering

The invention relates to a recirculation unit (14) for a fuel cell system (I) comprising at least one fuel cell (2) which has an anode region (3) and a cathode region (4), comprising a recirculation line (12) which connects the outlet (11) of the anode region (3) to the inlet (10) thereof, comprising a liquid separator (15), which is arranged in the area of the recirculation line (12), and which comprises a discharge line (16) having a discharge valve (17) for liquid and / or gases. The invention is characterized in that a bubble sensor (18) for controlling the discharge valve (17) is arranged in the area of the discharge line (16). A method for discharging liquid and / or gases from such a recirculation unit (14) provides for the discharge valve (17) to be opened and then closed as a function of an event detected by the bubble sensor (18).

Owner:DAIMLER AG

Carbon black

Provided is a carbon black which improves the electrical conductivity and flowability of a resin composition. Carbon black characterized by having the following characteristics: 24M4DBP absorption: At least 130 cm 3 / 100 g (1,500 DEG C 30 min) dehydrogenation amount: At most 1.2 mg / g rystallite size Lc: From 10 to 17AA More preferably, it has the following characteristics: itrogen adsorption specific surface area: from 150 to 300 m 2 / g Average particle diameter: from 14 to 24 nm TAB adsorption specific surface area: from 120 to 220 m 2 / g DBP absorption: from 150 to 400 cm 3 / 100 g oxygen-containing functional group density: at most 3 mol / m 2.

Owner:MITSUBISHI RAYON CO LTD

Method for producing diamond-like carbon film

InactiveCN105937022AHigh hardnessHigh hardness and high qualityChemical vapor deposition coatingCarbon filmDiamond-like carbon

A method for producing a diamond-like carbon film is disclosed and comprises the following steps: base material is placed in a reaction chamber, an aromatic ring hydrocarbon is guided into the reaction chamber. The aromatic ring hydrocarbon is used as a reaction precursor, the carbon-like carbon film is grown on the substrate. The step of growing the diamond-like carbon film comprises controlling the temperature of the base material at 200 DEG C to 800 DEG C. Since the aromatic ring hydrocarbon has a benzene ring structure and a high hydrocarbon ratio, a carbon-like carbon film having a high content of sp3 and a low hydrogen content can be obtained when the diamond-like carbon film is grown at a high base material temperature, and the hardness of the diamond-like carbon film can be improved A problem that the diamond-like carbon film decreases in hardness in a high-temperature application environment is solved.

Owner:CREATING NANO TECH INC

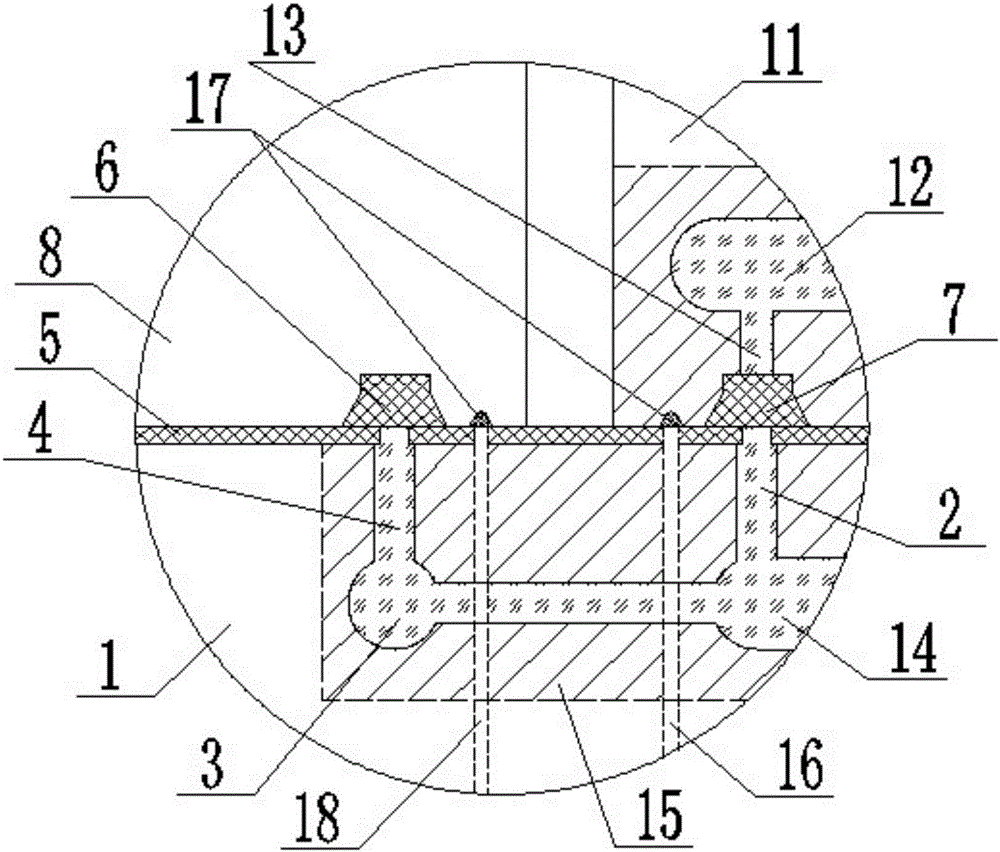

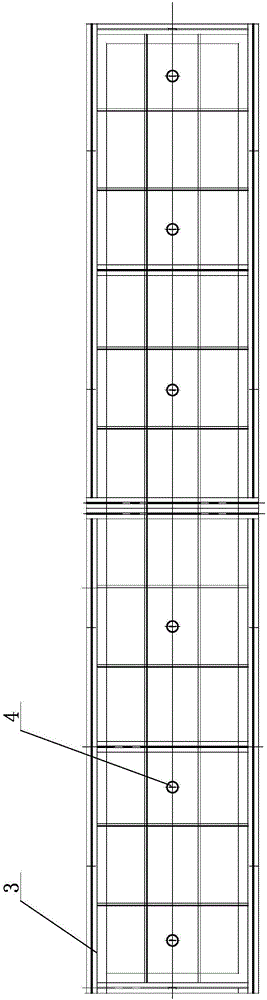

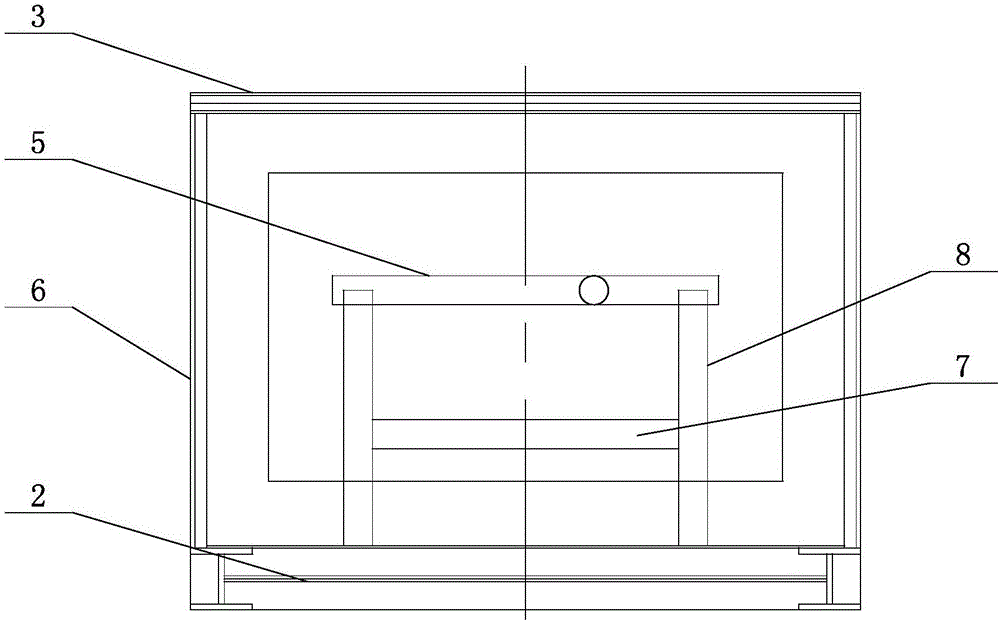

Rectangular-ambulatory-plane oil sealing structure of steam turbine generator

ActiveCN106787375ABarrier leakReduce the amount of hydrogenHydro energy generationCooling/ventillation arrangementHydrogenAmbulatory

The invention provides a rectangular-ambulatory-plane oil sealing structure of a steam turbine generator. The rectangular-ambulatory-plane oil sealing structure comprises a transition ring, an end cover and a sealing seat, wherein the transition ring forms sealing structures respectively with the end cover and the sealing seat by a sealing plate, a first branch oil passage and a second branch oil passage are formed in the transition ring and communicate with each other, the first branch oil passage and the second branch oil passage respectively penetrates through the sealing plate, an installation groove is formed in the end cover, a second sealing strip is embedded into the installation groove, an installation groove is formed in the sealing seat, a first sealing strip is embedded into the installation groove, the first branch oil passage and the second branch oil passage are filled with sealing oil, and the first branch oil passage, the second branch oil passage, the sealing plate, the second sealing strip and the first sealing strip jointly form the rectangular-ambulatory-plane oil sealing structure. By the rectangular-ambulatory-plane oil sealing structure, the hydrogen supplement quantity during running of the steam turbine generator can be greatly reduced, the application cost of the steam turbine generator is reduced, and the running safety and reliability of the steam turbine generator can be effectively improved.

Owner:DONGFANG ELECTRIC MACHINERY

Anaerobic fermentation hydrogen production method using excess sludge as raw material, and additive

InactiveCN111518843AAchieve reductionReduce pollutionFermentationBiological sludge treatmentActivated sludgeMethanobacter

The invention relates to an anaerobic fermentation hydrogen production method using excess sludge as raw material, and an additive. The hydrogen production method comprises the following steps: S1, using excess activated sludge generated by a sewage treatment plant as raw material, settling and removing supernatant of the excess activated sludge to obtain anaerobically fermented raw material; s2,adding the anaerobically fermented raw material into a fermentation reactor, adding ferrate, stirring uniformly, and keeping an anaerobic environment in the fermentation reactor; and S3, controlling the temperature, continuously carrying out a fermentation reaction, and continuously outputting or intermittently outputting generated hydrogen. Compared with the prior art, the hydrogen production method adopts the ferrate, which not only can destroy the structure of the excess sludge and promote the release of a large quantity of biodegradable organic matters in the sludge, but also can significantly inhibit and reduce the activity and abundance of hydrogen-consuming microorganisms such as hydrogen-phagocytosis methanogens, and thereby significantly promotes the amount of hydrogen produced byfermentation of the excess sludge; the operation is simple, and the long-term operation management is facilitated; and the hydrogen production quantity of the residual sludge resources can be obviously increased.

Owner:TONGJI UNIV

Catalytic distillation process for olefin production device

ActiveCN1274649CReduce loadReduce energy consumptionHydrocarbon by hydrogenationChemical industryHydrogenCatalytic distillation

The catalytic rectification method for olefin production includes setting catalytic reaction area in the pre-depropanizing column of the olefin producing apparatus; selectively hydrogenating C3- acetylene hydrocarbons and diene while separating C3, C3-, C4 and C4+ fractions; making top gaseous matter flow into gaseous hydrogenating reactor for further eliminating C3- acetylene hydrocarbons and diene; and feeding the cauldron liquid C4+ to the further separation area. The said method of the present invention can convert most of the C3- acetylene hydrocarbons and diene into corresponding olefin, reduce the hydrogen amount into the deeply freezing system, lower the power consumption, simplify technological process, reduce investment, raise the selectivity of catalytic hydrogenation and raise olefin yield, and has prolonged catalyst operating period, stable operation and no loss of butadiene.

Owner:CHINA PETROLEUM & CHEM CORP +1

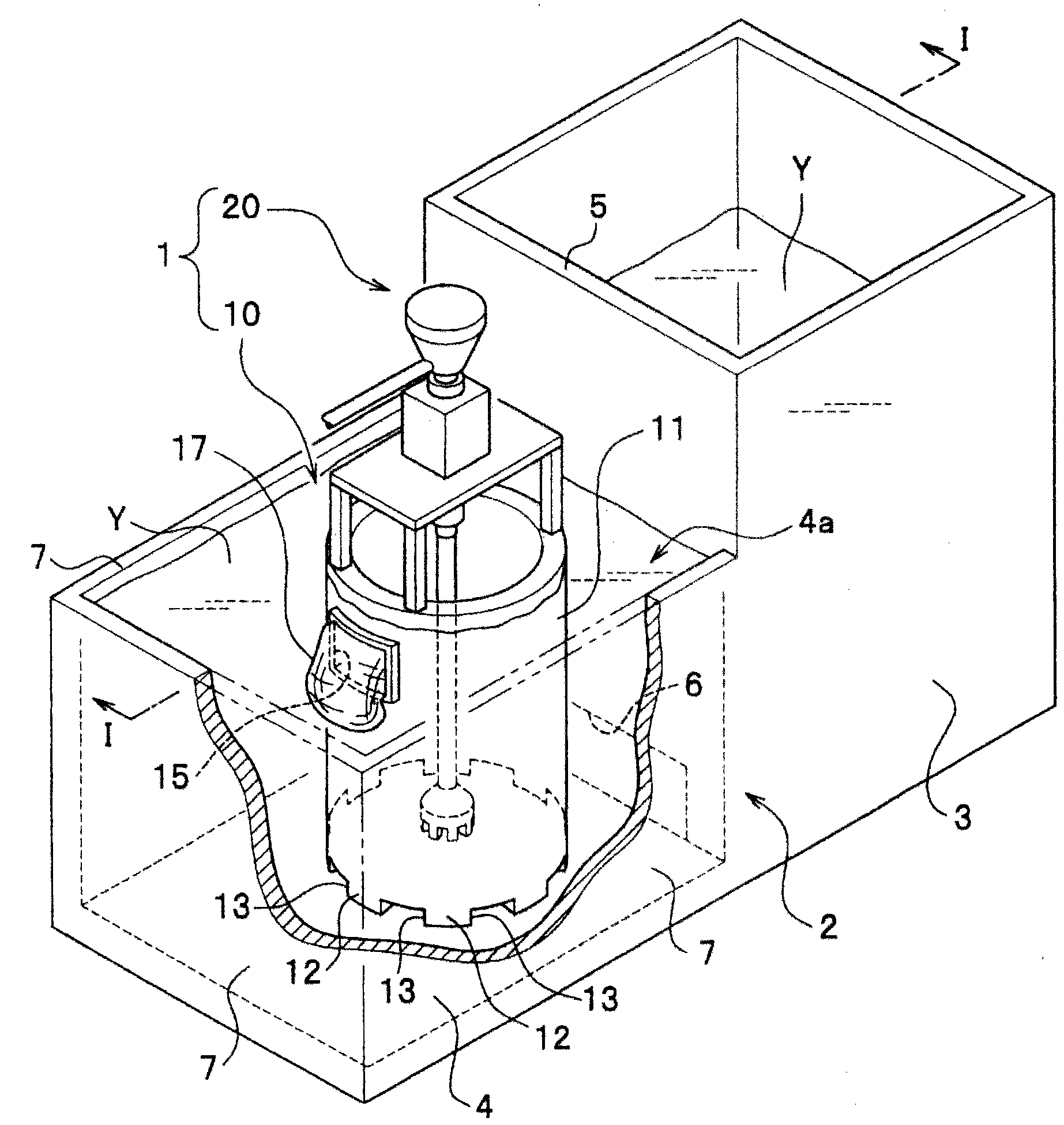

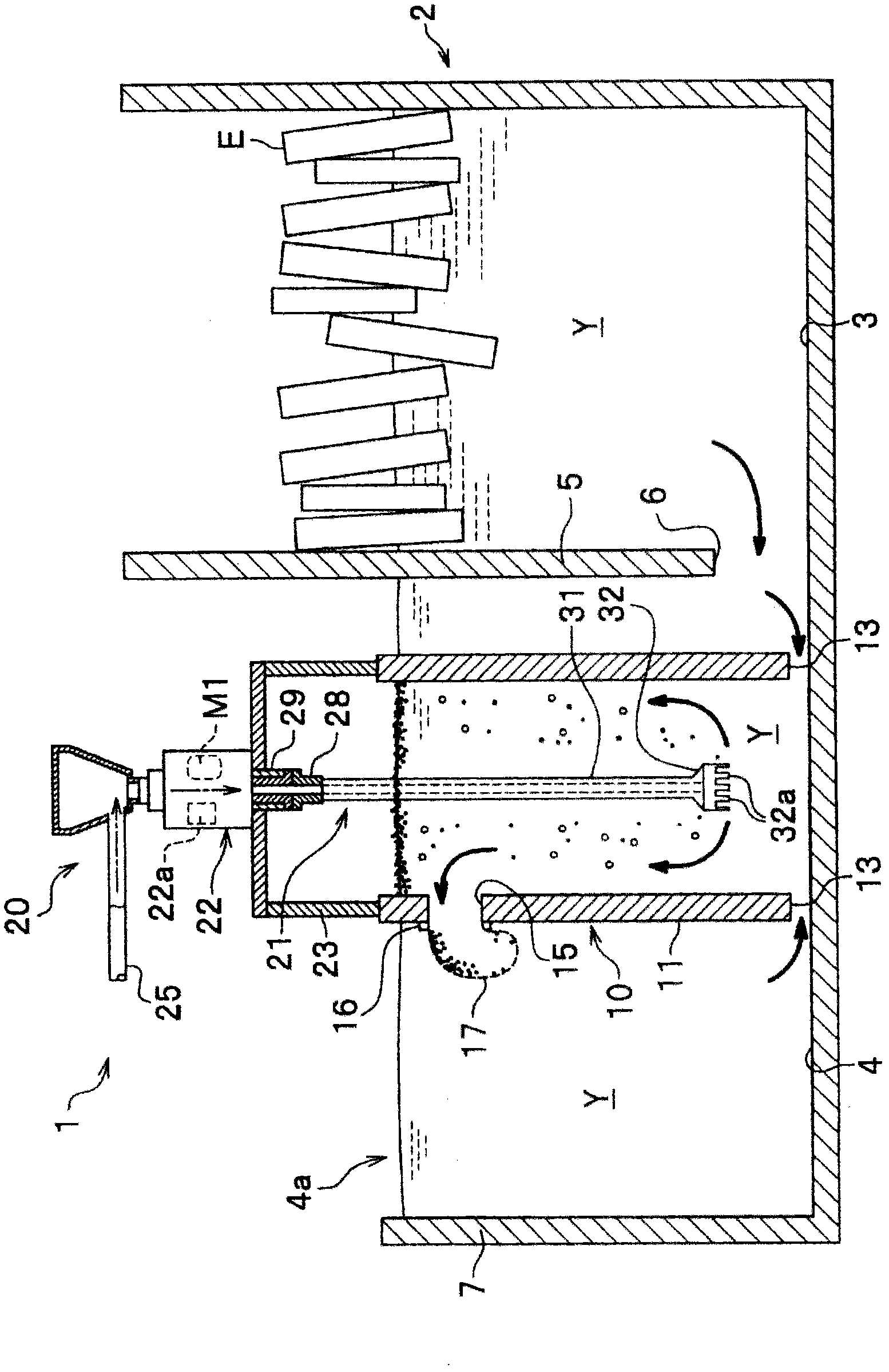

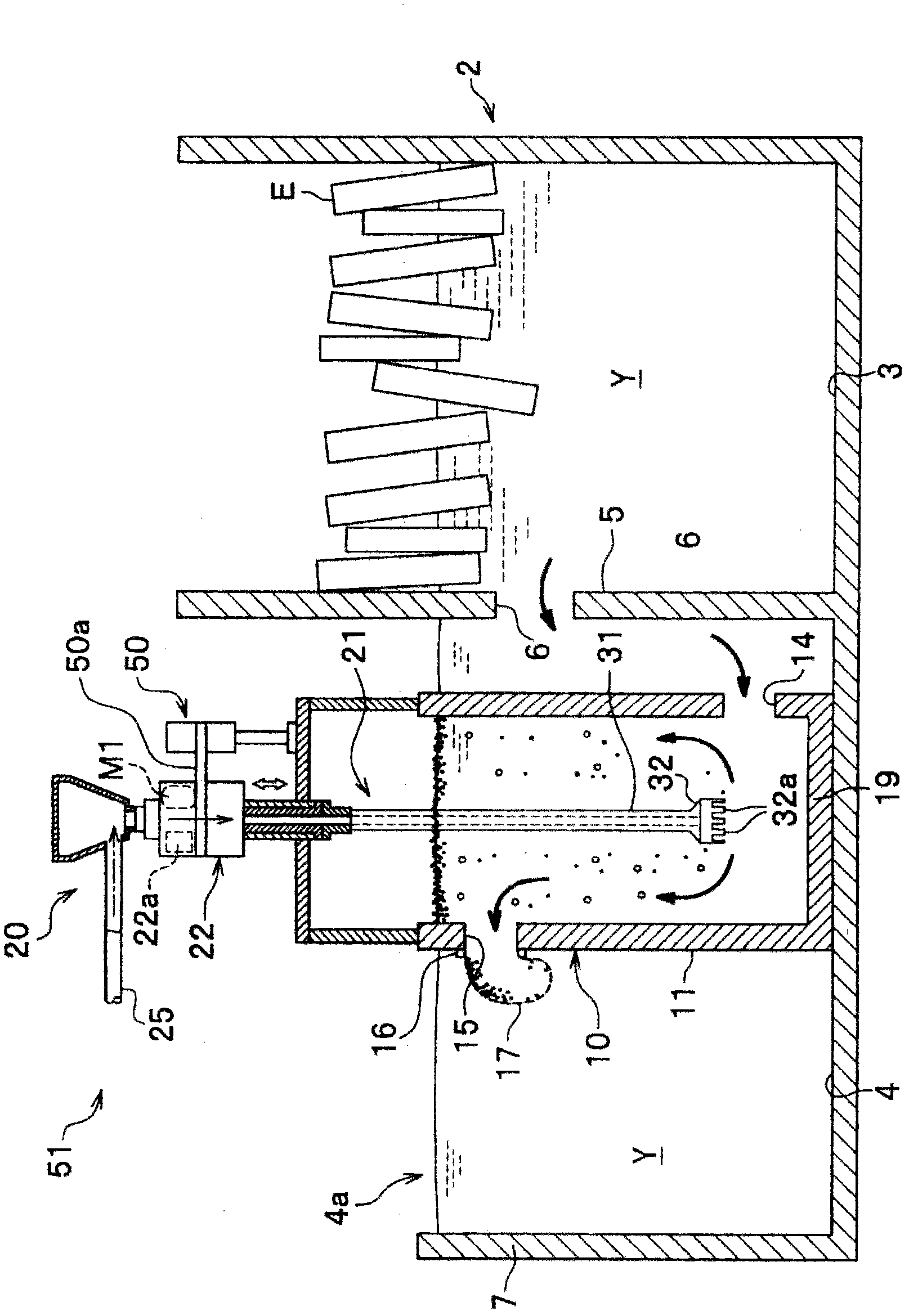

Melt refiner

InactiveCN102149832AReduce the possibility of mixingImprove qualityStirring devicesCharge manipulationHydrogenSlag

A melt refiner (1) which is for use in a ladling chamber (4) (holding chamber) that holds a metal melt (Y) therein and in which the metal melt is subjected to degassing and deslagging to heighten the degree of cleanliness of the metal melt and keep the amount of hydrogen gas small. With the melt refiner (1), the possibility that a slag generated is drawn up with a ladle or the like is low. The refiner is characterized by comprising: a cylindrical treating part (10) which is to be disposed in the ladling chamber (4) and has an opening (inlet hole) (13) through which the metal melt (Y) is caused to flow inward and an outlet hole (15) for discharging the melt outward; and a purifier (20) with which the metal melt (Y) inside the cylindrical treating part (10) is subjected to at least either degassing or deslagging. The refiner is further characterized in that the top of the cylindrical treating part (10) protrudes from the surface of the metal melt (Y) held in the ladling chamber (4).

Owner:NIPPON LIGHT METAL CO LTD

Power system of fuel cell car with ultra-low-temperature cold starting function

PendingCN108808035AReduce the amount of hydrogenShort cold start timeFuel cell auxillariesFuel cell detailsExhaust gasEngineering

The invention discloses a power system of a fuel cell car with an ultra-low-temperature cold starting function. The power system comprises a proton exchange membrane fuel cell and a lithium cell, thefeeding end of the proton exchange membrane fuel cell is connected with a power generation hydrogen input pipe and a power generation air input pipe, the power generation hydrogen input pipe is communicated with a hydrogen cylinder, the power generation air input pipe is communicated with an air compressor, a coolant circulation pipe is arranged between the feeding end and the discharging end ofthe proton exchange membrane fuel cell, an air and exhaust gas pipe, a hydrogen circulation pipe, a condensate water outer discharging pipe and a heating exhaust gas pipe are connected at the discharging end of the proton exchange membrane fuel cell, a plurality of heating units are arranged in the proton exchange membrane fuel cell, each heating unit is arranged between one pair of adjacent mono-cells, an exhaust gas heat insulation pipe is arranged outside the lithium cell, and the heating exhaust gas pipe is communicated with the input end of the exhaust gas heat insulation pipe. The powersystem has the advantages that the system can be started at the ultra-low temperature, hydrogen consuming amount of the system is low when cold starting of the system is implemented, the cold starting time is short, and the system is good in running stability.

Owner:ZHANGJIAGANG RES INST OF HYDROGEN ENERGY CO LTD

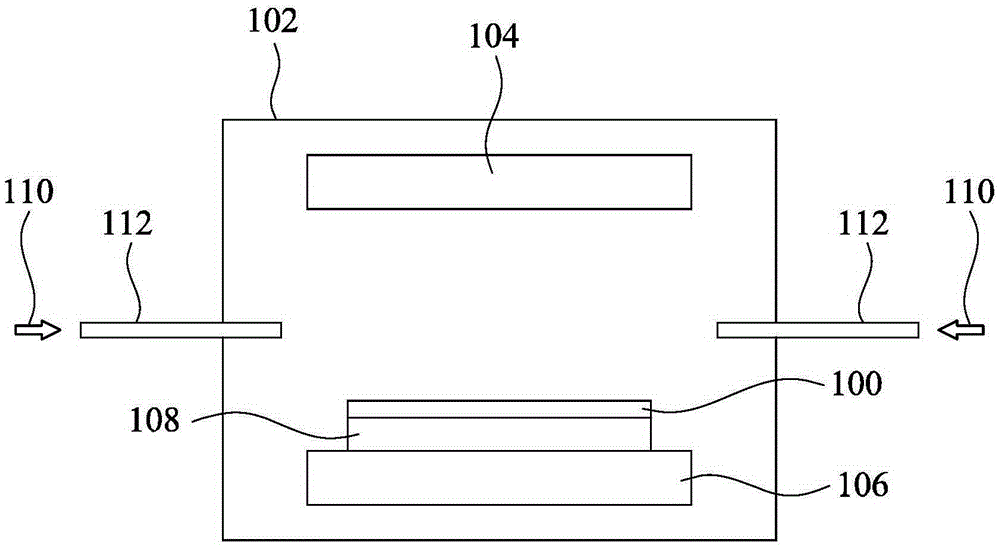

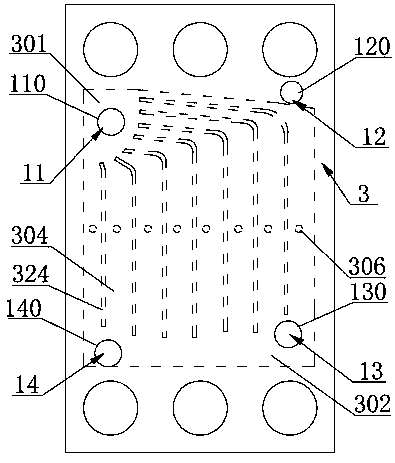

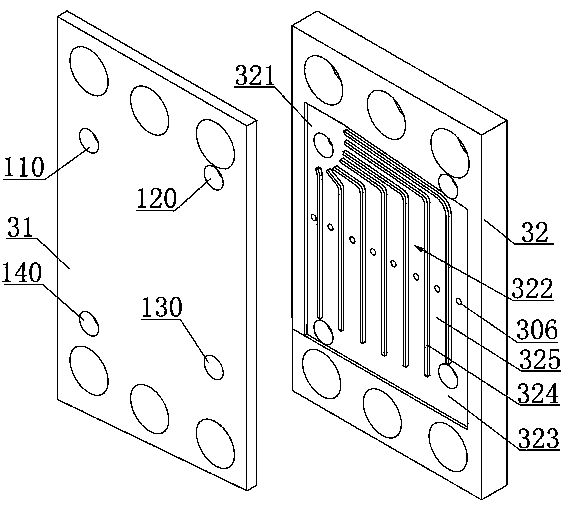

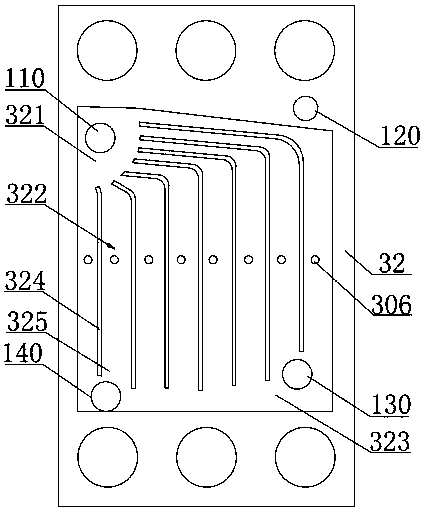

Heating devices in proton exchange membrane fuel cell stacks

PendingCN108987765AReliable startCompact and ingenious structureFuel cell heat exchangeCombustionHydrogen

The invention discloses a heating device in a proton exchange membrane fuel cell stack. The device includes a heating body, An air collecting and distributing cavity, a collecting cavity, a hydrogen collection and distribution chamber, a plurality of air passages and a plurality of hydrogen passages are arranged in the heating body. An inlet end and an outlet end of the air flow passage are respectively communicated with an air collecting and distributing cavity and a collecting cavity, The inlet end of the hydrogen gas flow passage is communicated with the hydrogen gas collecting and distributing cavity, and a combustion port communicated with the corresponding hydrogen gas flow passage is arranged on the flow passage wall of each air flow passage, the hydrogen gas in each hydrogen gas flow passage can enter into the corresponding air flow passage through the combustion port, and an igniter is arranged at the combustion port of each air flow passage; The air collecting and distributing cavity is communicated with the heating air channel; The hydrogen gas collecting and distributing cavity is communicated with the heating hydrogen gas channel; The collecting chamber is communicatedwith the exhaust passage and the drain passage. The invention has the advantages that the heating effect is good, and the proton exchange membrane fuel cell can be reliably started under the ultra-low temperature condition.

Owner:ZHANGJIAGANG RES INST OF HYDROGEN ENERGY CO LTD

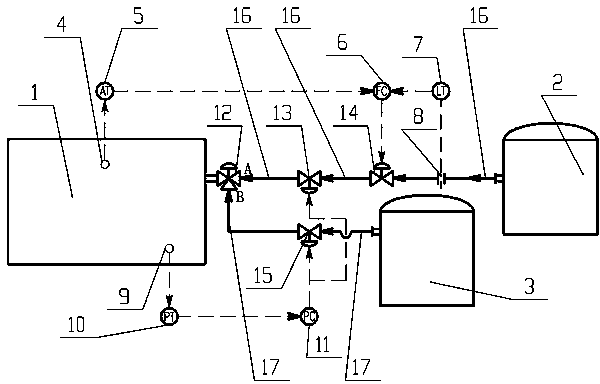

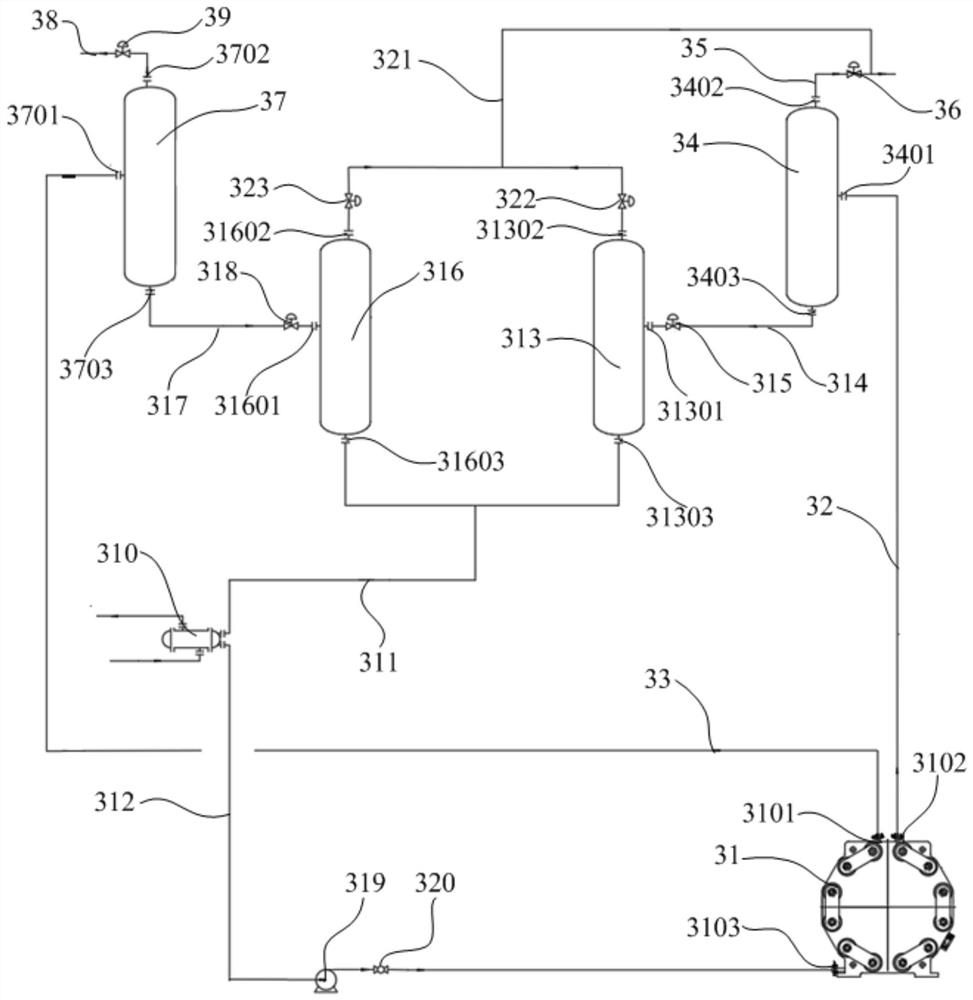

Calculating method of volume of hydrogen storage tank in hydrogen cyclic fatigue test system

ActiveCN108225470AReduce the amount of hydrogenImprove test securityContainer/cavity capacity measurementEngineeringHigh pressure

The invention relates to a calculating method of the volume of a hydrogen storage tank in a hydrogen cyclic fatigue test system. The calculating method comprises the steps of calculating the volume ofa high-pressure storage tank and calculating the volume of a low-pressure storage tank. By means of the calculating method of the volume of the hydrogen storage tank in the hydrogen cyclic fatigue test system, the minimum volumes of the high-pressure storage tank and the low-pressure storage tank in the hydrogen cyclic fatigue test system can be calculated, it is achieved that the hydrogen use amount in a hydrogen cyclic fatigue test is minimum on the condition of guaranteeing the normal run of the hydrogen cyclic fatigue test to improve the test safety, and besides, the running cost of the test is lowered.

Owner:HEFEI GENERAL MACHINERY RES INST +1

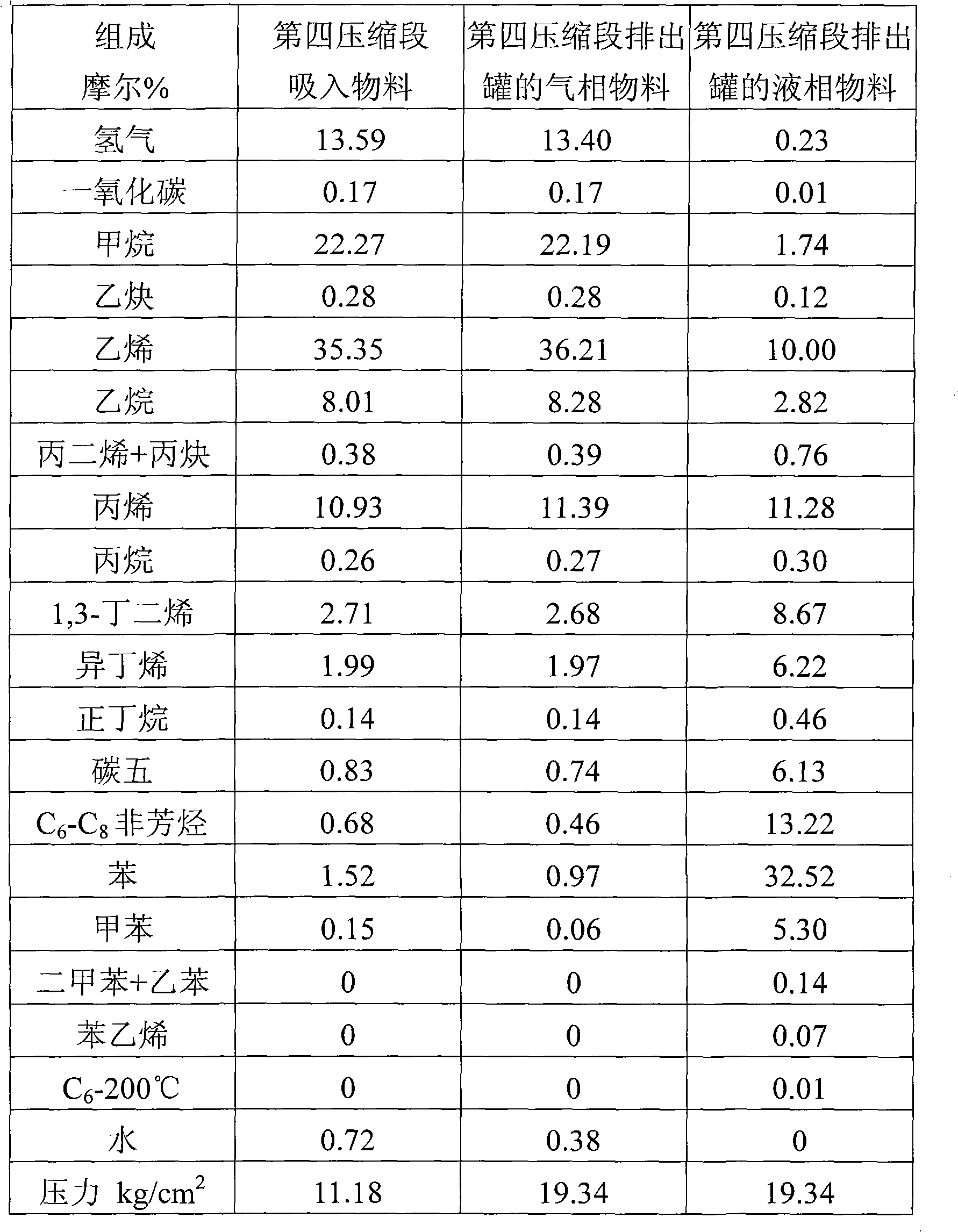

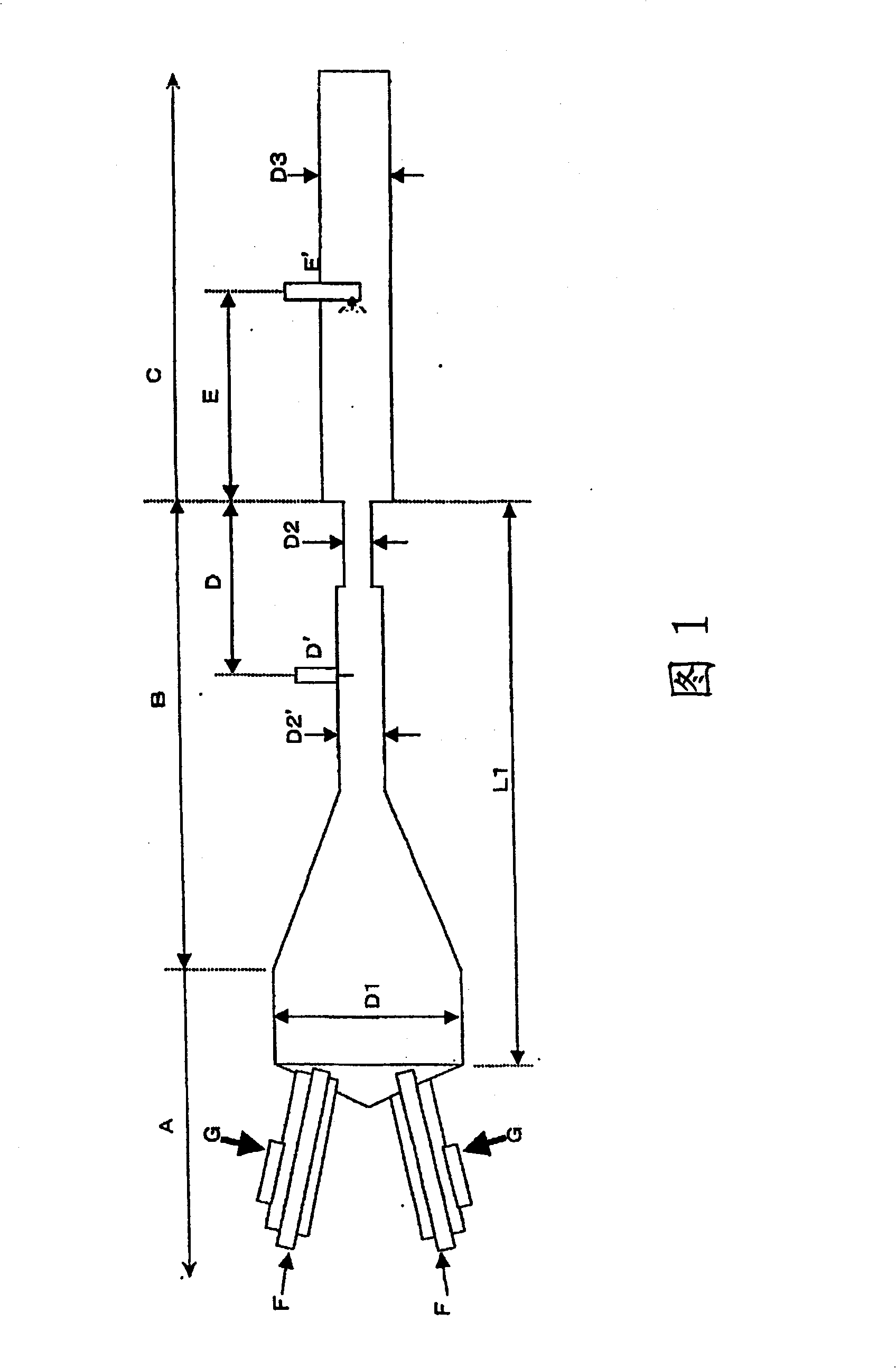

Cracked gas compression interstage selective hydrogenation method

ActiveCN101844959ACleaningCoolingHydrocarbon purification/separationEthylene productionUnsaturated hydrocarbonHydrogenation reaction

The invention discloses a cracked gas compression interstage selective hydrogenation method, belonging to the selective hydrogenation technical field. Aiming at reducing energy consumption and cocking of separation and hydrogenation flows in ethylene unit while reducing energy consumption and coking of cracked gas compressing machine stage and improving application universality and easy operationof the method, mixed phase hydrogenation reaction is carried out between stages of cracked gas compression machine, compressed condensate is taken as liquid phase material flow, hydrogenation is carried out under the presence of catalyst to reduce alkyne and dialkene content in cracked gas, and the material after hydrogenation is cooled and fed into the suction tank at a fourth compression stage.The method of the invention reduces high unsaturated hydrocarbon while consuming part of hydrogen, thus not only reducing energy consumption and coking amount of separation and hydrogenation flows but also reducing coking and energy consumption of compression stage. The method of the invention has wide application and can be used in various cracking separating flows.

Owner:CHINA PETROLEUM & CHEM CORP +1

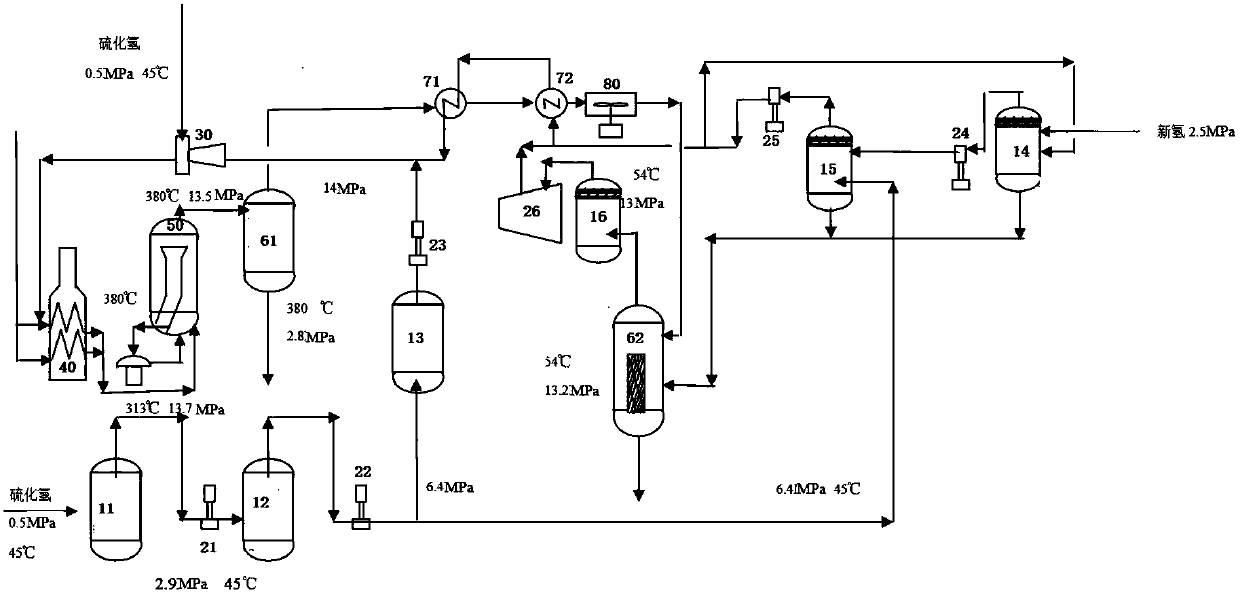

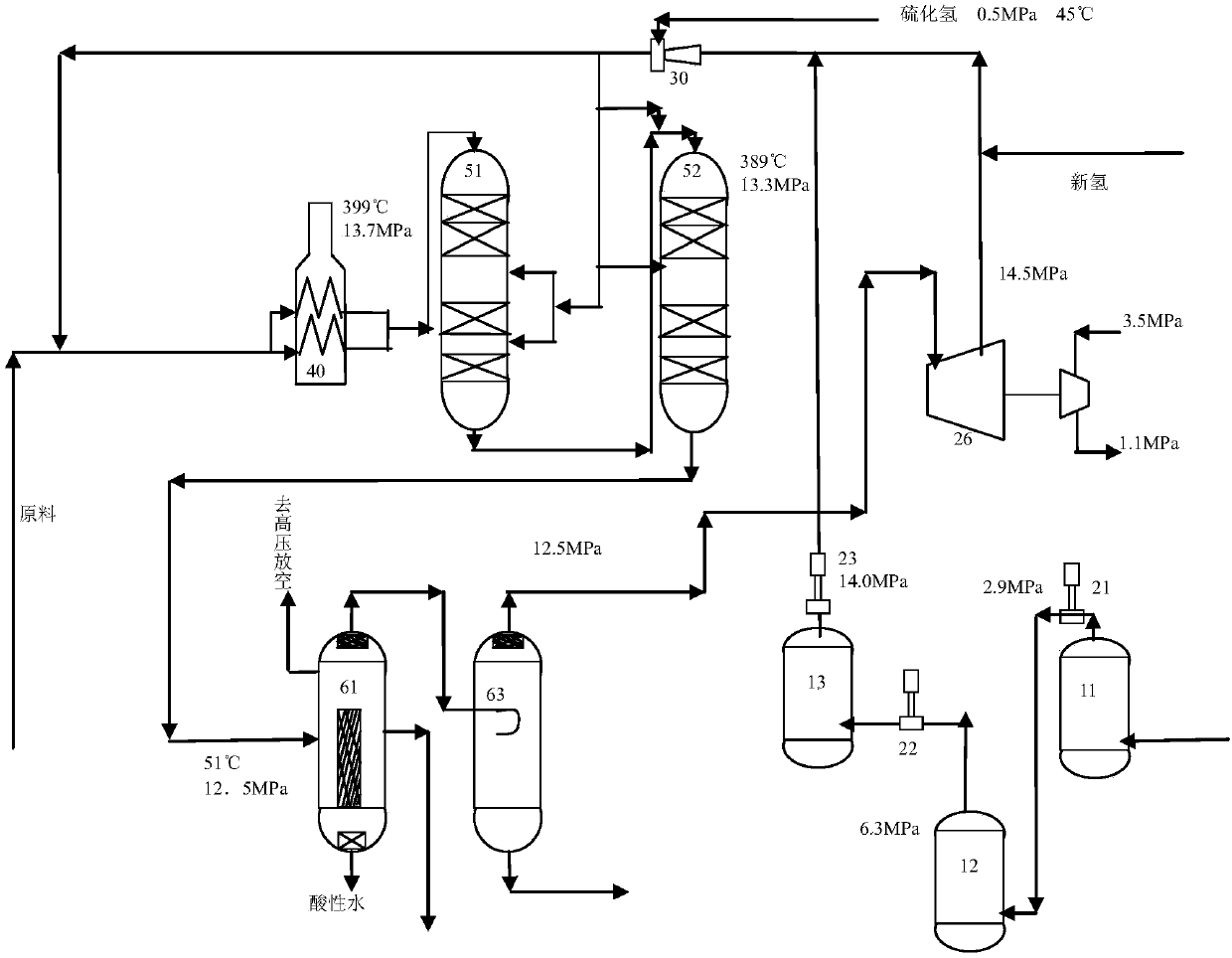

Device and method of reclaiming and processing tail gas of sulfur

InactiveCN100544807CWide applicabilityReduce the amount of hydrogenDispersed particle separationEnergy inputHydrogenation reactionGas cooler

A sulfur recovery and offgas processing device and a method therefor is characterized in that the device comprises a thermal reaction section, a catalytic reaction section and a reducing absorption section. In the thermal reaction section, hydrogen sulfide acid gas is partly burnt in a main burner (1) to convert into sulfur dioxide, hydrogen sulfide and sulfur dioxide proceed claus reaction to generate process gas such as elemental sulphur, the process gas is cooled by a waste-heat boiler (2) and a primary condensate cooler (3) to obtain liquid sulfur; in the catalytic reaction section, the process gas is reacted through a primary reheat hydrogen furnace (4), a secondary steam reheater (7), two stage reactor (5, 8), then separating liquid sulfur is cooled by two stage condensate cooler (6, 9) then enters into the reducing absorption section; in the reducing absorption section, the process gas is heated by a steam heater (10) then hydrogenizated in a hydrogenation reactor (11), cooled in a process gas cooler (12) and enters into a quench tower (13) which top connecting with bottom of a absorber (16), top of the absorber connects with a incinerator (18), the incinerator connects with a chimney (19).

Owner:东营科瑞泛能油气技术服务有限公司

A kind of single crystal silicon chip pre-cleaning liquid and cleaning method thereof

ActiveCN103087850BReduce concentrationReduce Fragmentation RateInorganic non-surface-active detergent compositionsCleaning using liquidsPotassium hydroxideSingle crystal

Owner:徐州鑫宇光伏科技有限公司 +1

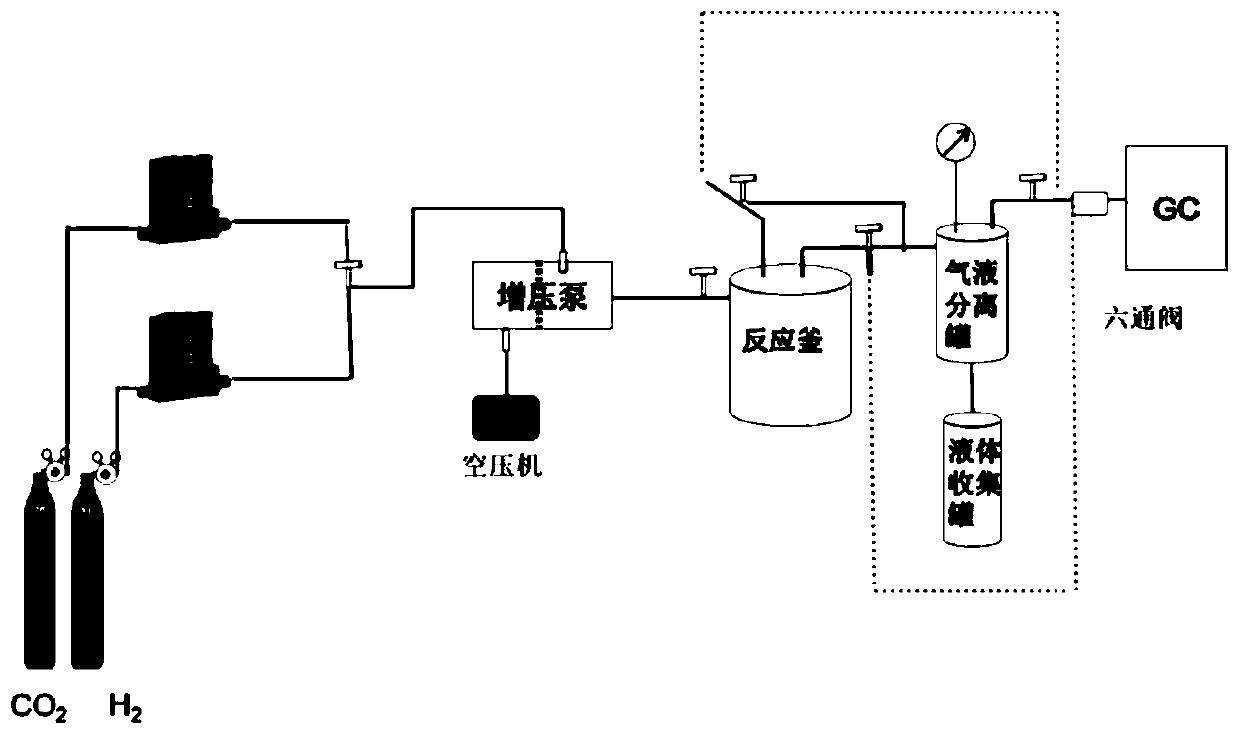

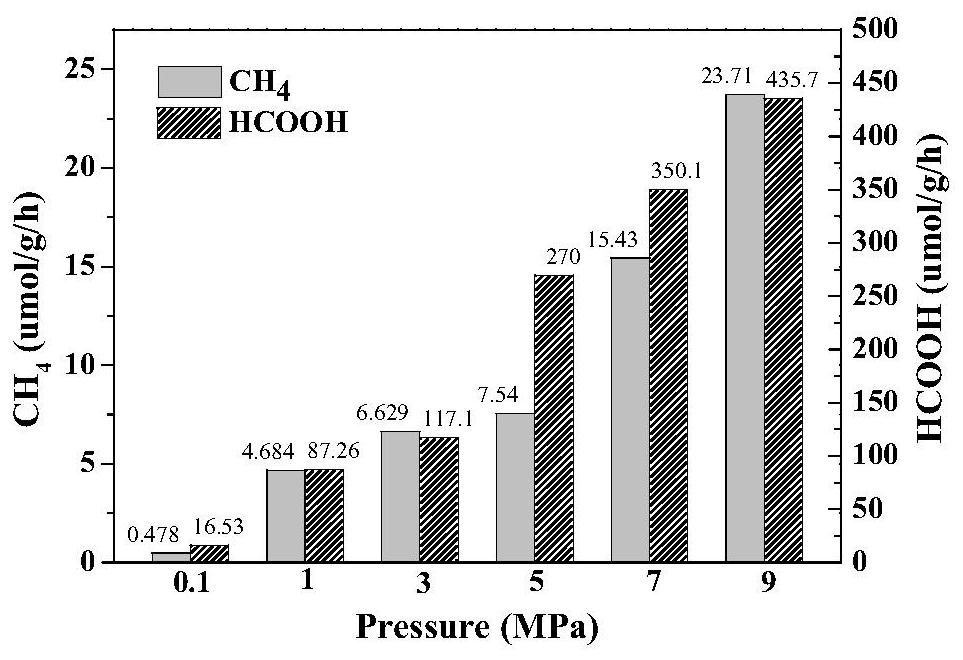

Process for supercritical CO2 hydrogenation based on amorphous alloy

ActiveCN111116346APossess chemical industry valueReduce the amount of hydrogenHydrocarbon from carbon oxidesOrganic compound preparationAlkanePtru catalyst

The invention relates to a process for supercritical CO2 hydrogenation based on amorphous alloy. The method comprises the following steps: mixing a solvent and organic amine in a reaction kettle to form a solution, selecting amorphous alloy as a catalyst, adding H2 and CO2 at a low temperature, heating the mixture until the partial pressure of CO2 reaches a supercritical state, and carrying out areaction in the state to obtain the products, formic acid and alkane compound. Compared with the prior art, the low hydrogen-carbon ratio and the low reaction temperature are different from those of atraditional CO2 hydrogenation catalytic reaction system, and more H2 energy consumption and temperature cost are saved.

Owner:SHANGHAI NORMAL UNIVERSITY +1

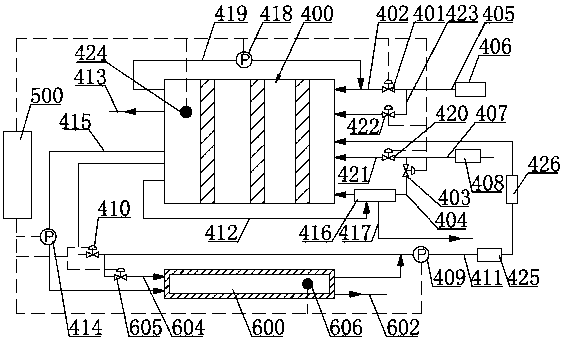

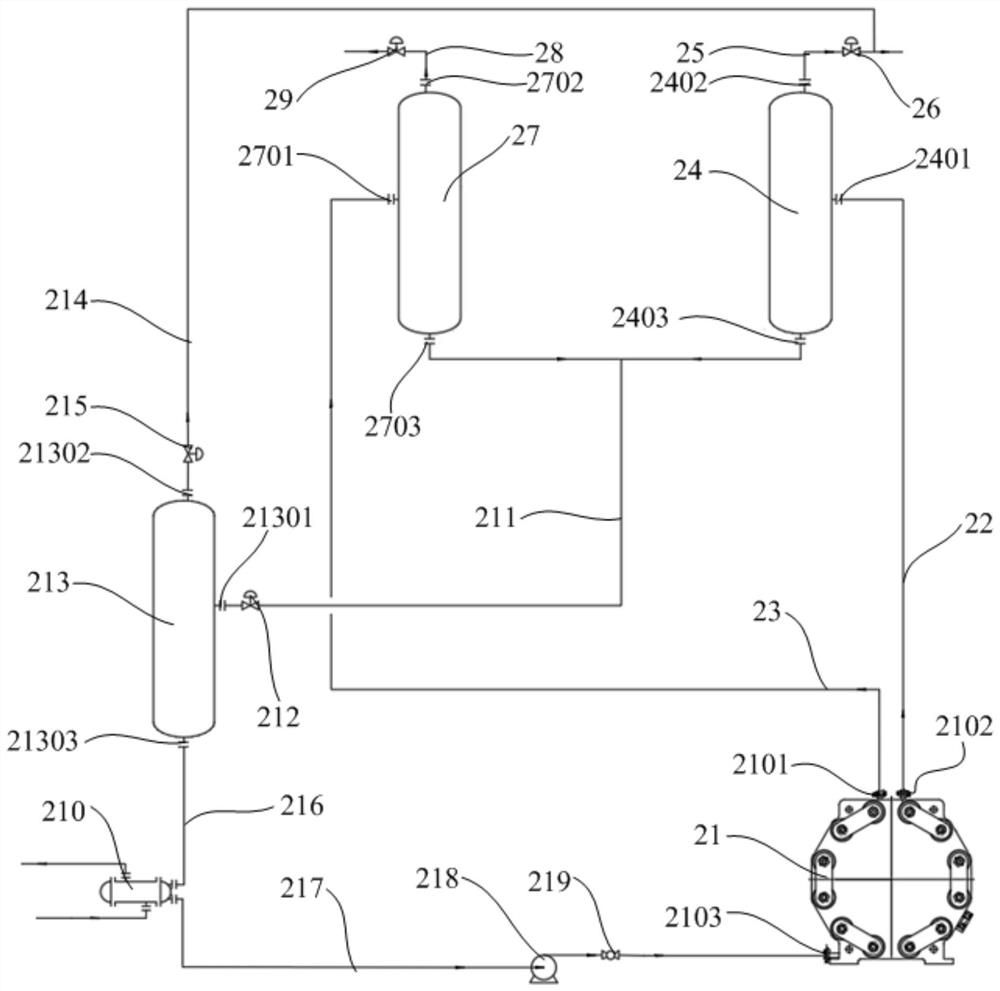

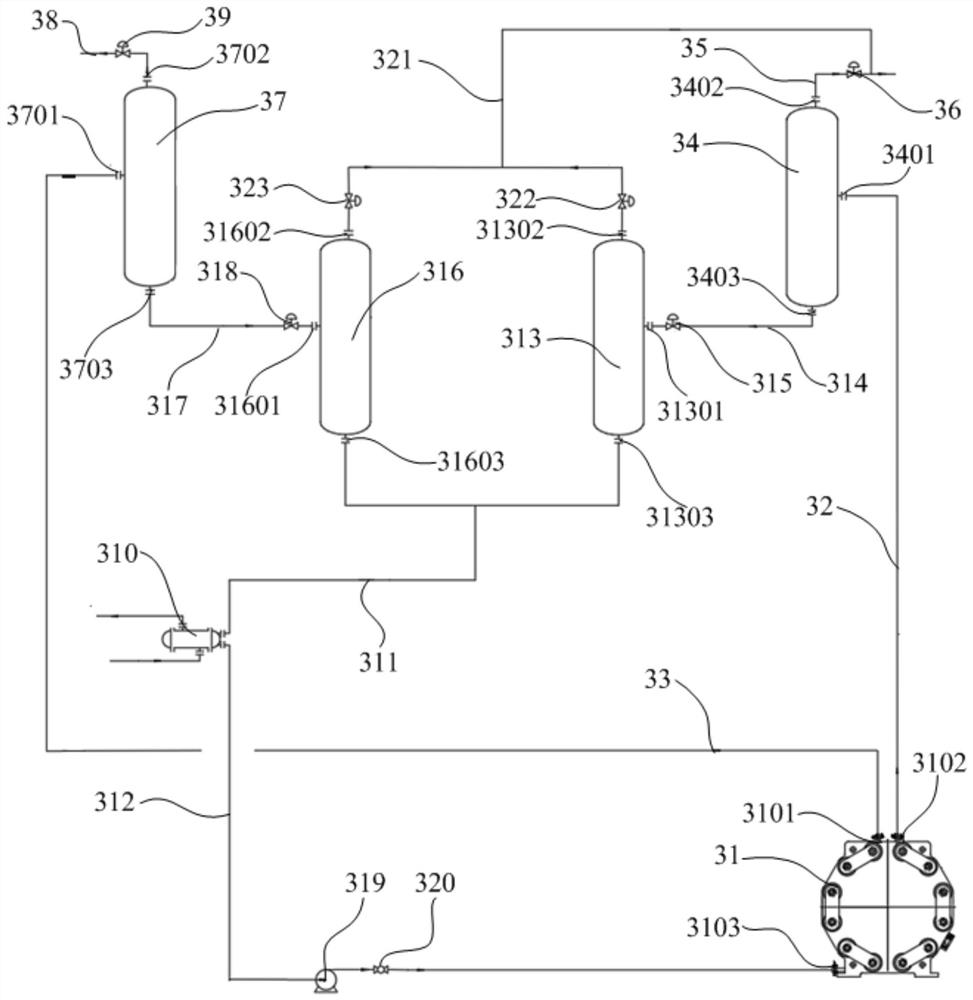

Hydrogen production method, hydrogen production system, and circulating method and circulating device of hydrogen production electrolyte

The invention discloses a hydrogen production method, a hydrogen production system, and a circulating method and circulating device of hydrogen production electrolyte. The circulating method comprises an oxygen side electrolyte circulating method and / or a hydrogen side electrolyte circulating method. The oxygen side electrolyte circulating method comprises the following steps: carrying out gas-liquid separation on a gas-liquid mixture discharged from the oxygen side of an electrolytic bath to obtain an oxygen side separated electrolyte; carrying out depressurization gas-liquid separation on the oxygen side separated electrolyte to obtain oxygen side depressurization separated electrolyte; and boosting the oxygen side depressurization separated electrolyte and inputting the oxygen side depressurization separated electrolyte into an electrolytic bath. The hydrogen side electrolyte circulating method comprises the following steps: carrying out gas-liquid separation on a gas-liquid mixture discharged from the hydrogen side of the electrolytic bath to obtain a hydrogen side separated electrolyte; carrying out depressurization gas-liquid separation on the hydrogen side separated electrolyte to obtain a hydrogen side depressurization separation electrolyte; and boosting the hydrogen side depressurization separation electrolyte and inputting the electrolyte into the electrolytic cell. According to the circulating method, the purity of hydrogen and oxygen obtained by hydrogen production through water electrolysis can be improved, and high system pressure can also be guaranteed.

Owner:阳光氢能科技有限公司

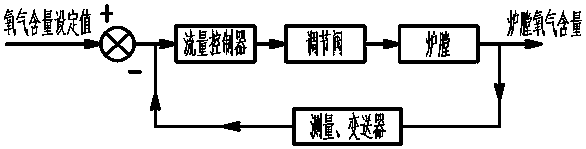

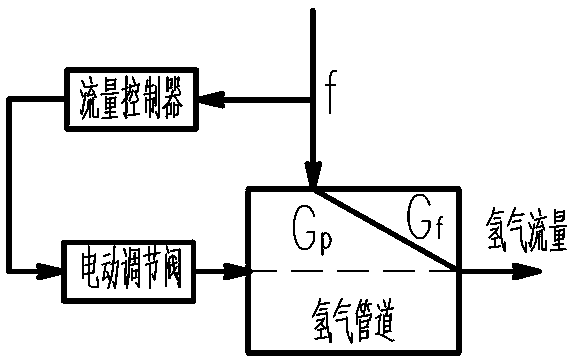

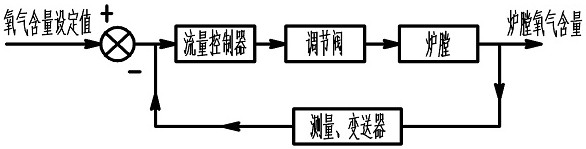

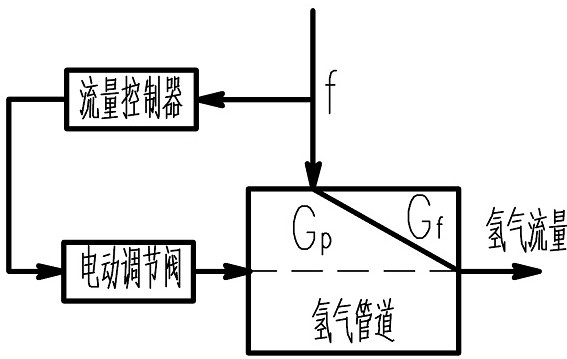

Oxidation-reduction protector of stainless steel pipe thermal treatment furnace

ActiveCN110777242APrevent oxidationEliminate residualFurnace typesHeat treatment process controlFeedback controlHelium gas

The invention discloses an oxidation-reduction protector of a stainless steel pipe thermal treatment furnace and belongs to the technical field of gas protection of thermal treatment furnace devices.The oxidation-reduction protector comprises a thermal treatment furnace, a hydrogen storage tank, a helium storage tank, a hydrogen pipeline, a helium pipeline and a control loop, wherein the hydrogenstorage tank is connected with the inlet A of a three-way valve through the hydrogen pipeline; the helium storage tank is connected with the inlet B of the three-way valve through the helium pipeline; the outlet end of the three-way valve communicates with a thermal treatment furnace; an electric brake valve A and an electric adjusting valve are sequentially arranged on the hydrogen pipeline between the three-way valve and the hydrogen storage tank; an electric brake valve B is arranged on the helium pipeline; the control loop comprises a feedback control system for controlling oxygen contentin the furnace, a feedforward control system for controlling the flow gate of hydrogen in the hydrogen pipeline and a split control system; through comprehensive adjustment and control of the three control systems, the oxidation-reduction protector can ensure that the stainless steel pipe is not oxidized during the thermal treatment process and ensures hydrogen application economy according to the oxygen content in the furnace to eliminate the possibility of hydrogen explosion.

Owner:上泰科技(内蒙古)有限责任公司

A redox protection device for stainless steel tube heat treatment furnace

ActiveCN110777242BPrevent oxidationEliminate residualFurnace typesHeat treatment process controlEngineeringFeedback control

The invention discloses a redox protection device for a stainless steel tube heat treatment furnace, which belongs to the technical field of gas protection for heat treatment furnace devices, and includes a heat treatment furnace, a hydrogen storage tank, a helium storage tank, a hydrogen pipeline, a helium pipeline and a control circuit; The storage tank is connected to the A inlet of the three-way valve through the hydrogen pipeline; the helium storage tank is connected to the B inlet of the three-way valve through the helium pipeline; the outlet end of the three-way valve is connected to the heat treatment furnace; the connection between the three-way valve and the hydrogen storage tank An electric gate valve A and an electric regulating valve are arranged in sequence on the hydrogen pipeline between them; an electric gate valve B is arranged on the helium pipeline; the control loop includes a feedback control system for controlling the oxygen content in the furnace, a feedforward control system for controlling the hydrogen flow in the hydrogen pipeline, and Split-range control system, through the comprehensive regulation of three control systems, the invention can ensure that the stainless steel tube will not be oxidized during heat treatment, ensure the economical use of hydrogen according to the oxygen content in the furnace, and eliminate the possibility of hydrogen explosion.

Owner:上泰科技(内蒙古)有限责任公司

Hydrogen production method, hydrogen production system, circulation method and circulation device of hydrogen production electrolyte

The invention discloses a hydrogen production method, a hydrogen production system, a hydrogen production electrolyte circulation method and a circulation device. The circulation method includes an oxygen side electrolyte circulation method and / or a hydrogen side electrolyte circulation method; an oxygen side electrolyte circulation method The method comprises the steps of: performing gas-liquid separation on the gas-liquid mixture discharged from the oxygen side of the electrolytic cell to obtain an oxygen-side separation electrolyte; performing step-down gas-liquid separation on the oxygen-side separation electrolyte to obtain a step-down separation electrolyte on the oxygen side; The electrolytic solution is depressurized and separated on the side to boost the pressure and input to the electrolytic cell; the electrolyte circulation method on the hydrogen side includes the steps of: performing gas-liquid separation on the gas-liquid mixture discharged from the hydrogen side of the electrolytic cell to obtain the hydrogen-side separated electrolyte; The electrolytic solution is decompressed and gas-liquid separated to obtain the decompressed and separated electrolyte on the hydrogen side; the depressurized and separated electrolyte on the hydrogen side is boosted and input to the electrolytic cell. The above circulation method can improve the purity of hydrogen and oxygen obtained by electrolyzing water to produce hydrogen, and can also ensure a relatively high system pressure.

Owner:阳光氢能科技有限公司

Carbon black

Provided is a carbon black which improves the electrical conductivity and flowability of a resin composition. Carbon black characterized by having the following characteristics: 24M4DBP absorption: At least 130 cm 3 / 100 g (1,500 DEG C 30 min) dehydrogenation amount: At most 1.2 mg / g rystallite size Lc: From 10 to 17AA More preferably, it has the following characteristics: itrogen adsorption specific surface area: from 150 to 300 m 2 / g Average particle diameter: from 14 to 24 nm TAB adsorption specific surface area: from 120 to 220 m 2 / g DBP absorption: from 150 to 400 cm 3 / 100 g oxygen-containing functional group density: at most 3 mol / m 2.

Owner:MITSUBISHI RAYON CO LTD

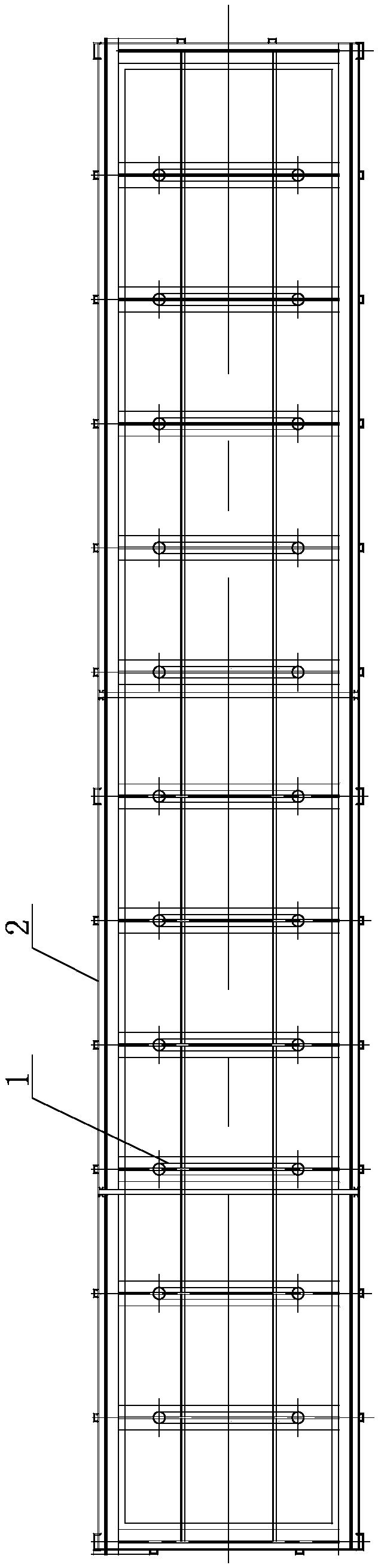

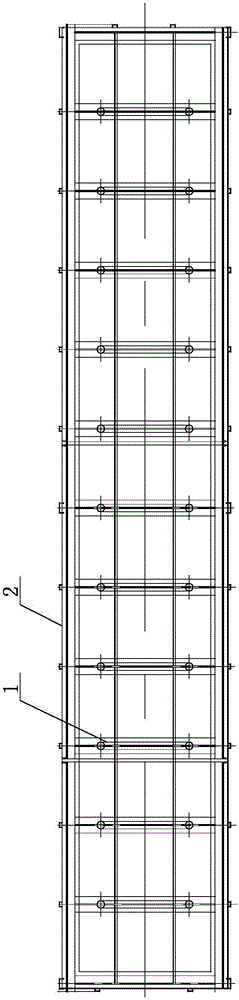

Cracking Furnace Tube In-Situ Coating Processing Heat Treatment Furnace

ActiveCN106403599BMeet the requirements of heat treatment processShorten heat treatment timeFurnace typesElectric heating for furnacesElectricityThermocouple

The invention is mainly applied to the technical field of furnace pipe heating, and in particular, relates to a cracking furnace pipe in-situ coating treatment heat treatment furnace. The cracking furnace pipe in-situ coating treatment heat treatment furnace comprises a bottom frame, wall plates and a top cover plate to form a furnace cavity; portal frames are distributed in the furnace cavity; the portal frames are mounted on the bottom frame; two layers of cross beams are arranged on the portal frames; bottom electric heating chips are arranged between the adjacent portal frames, and are fixed on the bottom frame; the periphery of the bottom frame is the wall plates; the top cover plate is arranged at the tops of the wall plates; the wall plates on the front and back two sides and the top cover plate are provided with fire observing holes; staff access ports and process pipe outlets are respectively formed in the wall plates at the left and right two ends; and thermocouples, electric wire sleeves and side electric heating chips are respectively arranged on the inner sides of the wall plates on the front and back two sides. The cracking furnace pipe in-situ coating treatment heat treatment furnace can be used for heat treatment of pressure containers, can perform the heat treatment for equipment with different lengths and specifications through such forms as adding of separation plates and heightening, and can achieve multiple purposes.

Owner:CHINA PETROLEUM & CHEM CORP +2

High-performance uniformity aluminium alloy ingot production method

Owner:YE CHIU METAL RECYCLINGCHINALTD

Method for selective hydrogenation between cracked gas compression sections

ActiveCN101844959BReduce energy consumptionReduce the amount of hydrogenHydrocarbon purification/separationEthylene productionHydrogenation reactionUnsaturated hydrocarbon

Owner:CHINA PETROLEUM & CHEM CORP +1

Cracking furnace pipe in-situ coating treatment heat treatment furnace

ActiveCN106403599AMeet the requirements of heat treatment processShorten heat treatment timeFurnace typesElectric heating for furnacesElectricityMetallurgy

The invention is mainly applied to the technical field of furnace pipe heating, and in particular, relates to a cracking furnace pipe in-situ coating treatment heat treatment furnace. The cracking furnace pipe in-situ coating treatment heat treatment furnace comprises a bottom frame, wall plates and a top cover plate to form a furnace cavity; portal frames are distributed in the furnace cavity; the portal frames are mounted on the bottom frame; two layers of cross beams are arranged on the portal frames; bottom electric heating chips are arranged between the adjacent portal frames, and are fixed on the bottom frame; the periphery of the bottom frame is the wall plates; the top cover plate is arranged at the tops of the wall plates; the wall plates on the front and back two sides and the top cover plate are provided with fire observing holes; staff access ports and process pipe outlets are respectively formed in the wall plates at the left and right two ends; and thermocouples, electric wire sleeves and side electric heating chips are respectively arranged on the inner sides of the wall plates on the front and back two sides. The cracking furnace pipe in-situ coating treatment heat treatment furnace can be used for heat treatment of pressure containers, can perform the heat treatment for equipment with different lengths and specifications through such forms as adding of separation plates and heightening, and can achieve multiple purposes.

Owner:CHINA PETROLEUM & CHEM CORP +2

Injection method and injection equipment of hydrogenation reactor sulfur replenishing agent in direct coal liquefaction process

ActiveCN106047403BShort processReduce energy consumptionHydrocarbon oil crackingHydrocarbon oils refiningHydrogenInjection device

The invention discloses a method and device for injecting a sulfur supplementing agent into a hydrogenation reactor in a direct coal liquefaction process. The injecting method comprises the following steps that hydrogen sulfide produced in the direct coal liquefaction process serves as the sulfur supplementing agent to be injected into the hydrogenation reactor. According to the technical scheme, the intermediate raw material hydrogen sulfide from a whole factory directly serves as a vulcanizing agent to be injected into a hydrogenation catalytic cracking reactor in the direct coal liquefaction process. On one hand, the process is shortened, and the energy consumption is reduced; on the other hand, the hydrogen amount consumed when elemental sulfur is adopted as the sulfur supplementing agent to react with hydrogen in the hydrogenation reactor to generate the hydrogen sulfide in the prior art is saved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Production method of high-purity stabilized aluminum alloy ingot

Owner:YE CHIU METAL RECYCLINGCHINALTD

A kind of high-performance flame-retardant electrolyte and preparation method thereof

ActiveCN107230550BImprove liquidityReduce viscosityElectrolytic capacitorsPhosphoric acidPolyethylene glycol

The invention discloses a high-performance flame-retardant electrolyte. The high-performance flame-retardant electrolyte is prepared from the following raw materials in parts by weight: 80-90 parts of ethylene glycol, 5-10 parts of methylbenzene sulfonate, 5-10 parts of trifluoroacetate, 5-8 parts of polyethylene glycol, 1-2 parts of mannitol, 10-16 parts of silicon dioxide, 20-30 parts of boric acid, 5-15 parts of phosphoric acid, 25-35 parts of acid ammonium mixture, 1-2 parts of hydrogen eliminating agent and 1-3 parts of hydrolysis inhibitor. The high-performance flame-retardant electrolyte is resistant to high temperature and high voltage, and also capable of reducing hydrogen amount generated in the electrolyte working process and lowering electrolyte vapor pressure and hydrolysis reaction, and has flame retardancy; by virtue of the proper amount of added and deposited silicon dioxide, the fluidity of the electrolyte is improved, the adhesive property is lowered and difficulty in electrolyte pouring is effectively lowered; and meanwhile, the high-performance flame-retardant electrolyte is relatively low in cost of the preparation method, easily available in raw materials, simple and concise in process, and has high application prospect.

Owner:贵州云睿电子科技有限公司

An amorphous alloy based supercritical co 2 hydrogenation process

ActiveCN111116346BPossess chemical industry valueReduce the amount of hydrogenHydrocarbon from carbon oxidesOrganic compound preparationAlkanePtru catalyst

The present invention relates to a method based on amorphous alloys for supercritical CO 2 In the process of hydrogenation, the solvent and the organic amine are mixed to form a solution in the reactor, the amorphous alloy is selected as the catalyst, and H is added at low temperature 2 with CO 2 , and then warmed to CO 2 The partial pressure reaches a supercritical state, where the reaction produces formic acid and alkane compounds as products. Compared with the prior art, in the present invention, the lower hydrogen-to-carbon ratio and lower reaction temperature are different from traditional CO 2 Hydrogenation catalytic reaction system saves more H 2 Energy and temperature costs.

Owner:SHANGHAI NORMAL UNIVERSITY +1

Degassing process for low-gas-content centrifugal composite roll

Owner:QIANAN FUCHENG IND & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com