Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Reduce prestress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Twin-shelled artificial hip joint and its manufacture

InactiveUS6045583AHigh degree of polymerizationReduce wear rateJoint implantsCoatingsArtificial hip jointsCoxal joint

The invention shows a hip joint socket and its manufacture, with the hip joint socket including a thin walled metallic outer shell with anchoring pins which is firmly connected to an inner shell of plastic. Since the bearing surface of the inner shell is not produced until after the assembly, a high accuracy of shape of the bearing surface results together with a relatively elastic outer shell and with good anchoring aids for a primary anchoring.

Owner:SULZER ORTHOPAEDIC

Low-shrinkage early-strength mine filling gel material for superfine iron tailings

The invention provides a low-shrinkage early-strength mine filling gel material for superfine iron tailings and belongs to the technical field of metal mine underground filling. The low-shrinkage early-strength mine filling gel material comprises, by weight, 50-90% of mineral residue powder, 5-25% of cement clinker, 1-30% of slag powder, 0-15% of gypsum, 0.5-10% of an alkaline activator, 0-10% ofan early strength agent, 0.1-10% of an anti-cracking material, and 0.5-10% of a suspending agent. Low-shrinkage early-strength mine filling slurry with effectively reduced usage of additives, good mobility and high early strength is finally acquired by: studying the functionality of mine filling gel materials, selecting mineral residue powder, cement clinker, slag powder, gypsum, the alkaline activator, the early strength agent, the anti-cracking material and the suspending agent as the mine filling gel materials, and adaptively studying their ratio. The low-shrinkage early-strength mine filling slurry has the advantages of good strength, good size stability and the like, and all the properties exceed those of a cement material.

Owner:HEBEI JINTAICHENG BUILDING MATERIAL

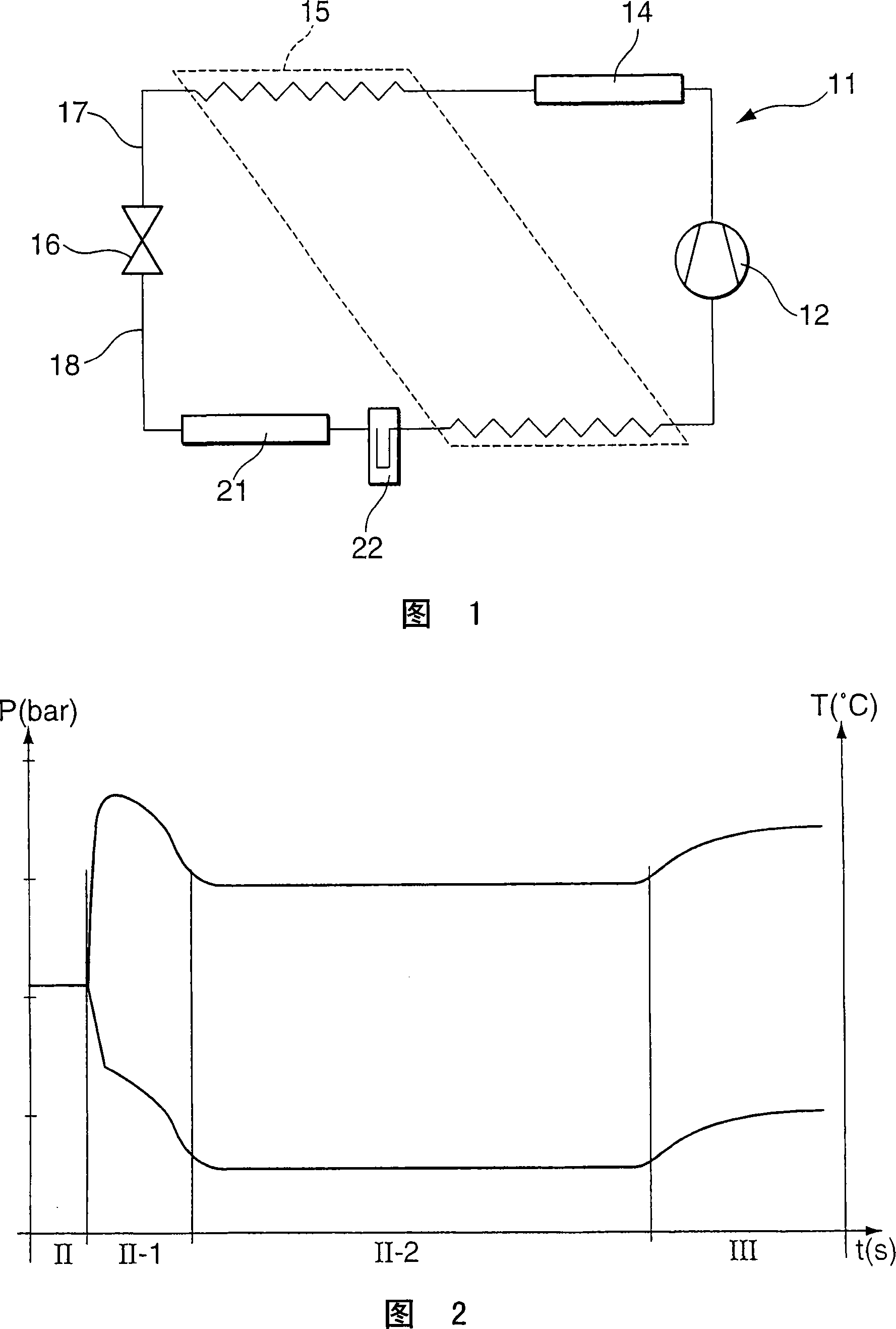

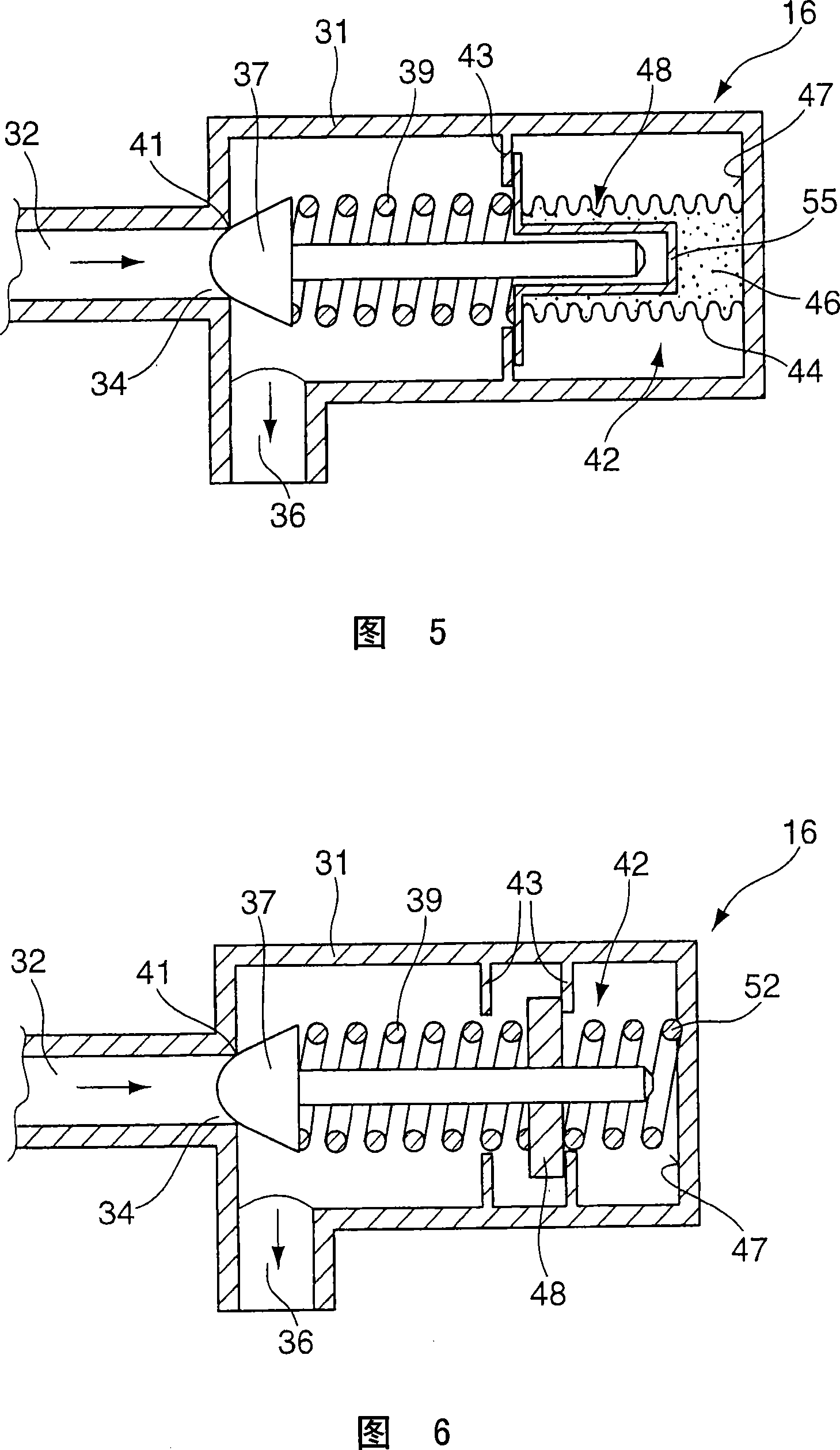

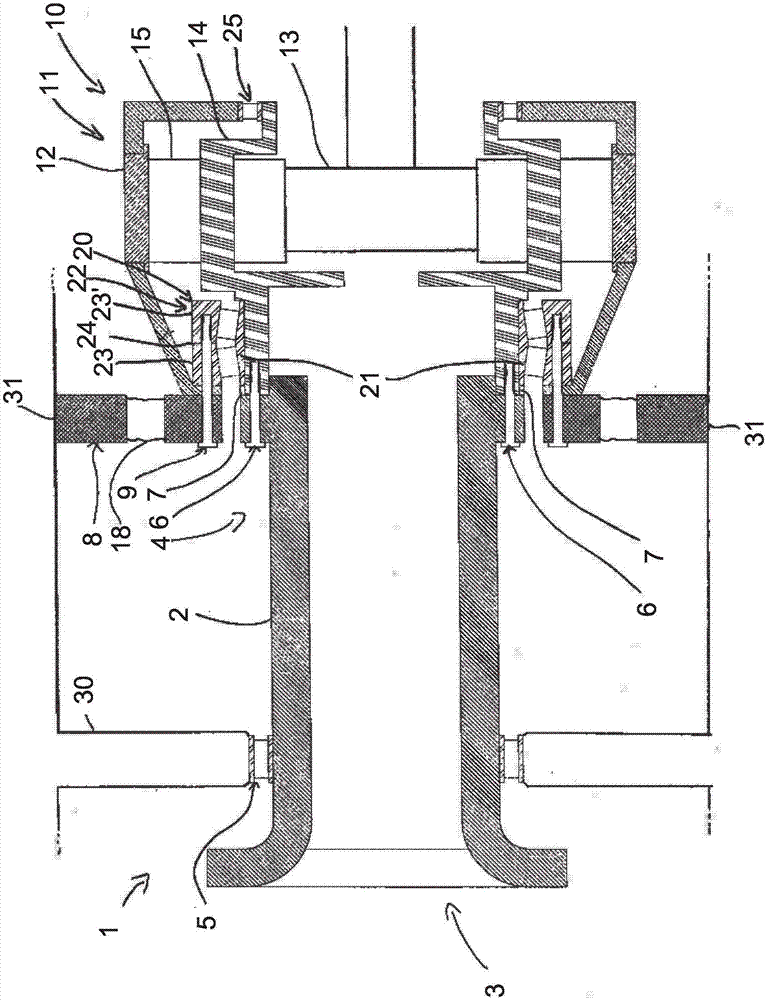

Expansion valve control method, and expansion valve

InactiveCN101135387AImprove responsivenessLow mass flowOperating means/releasing devices for valvesCompression machinesPressure riseEngineering

The invention relates to a method for controlling an expansion valve, in particular for vehicle air-conditioning systems operated with CO2 as the refrigerant, with a valve housing which has a feed opening and a removal opening, with a valve-closing member which closes a valve seat of a passage opening arranged between the feed and removal openings, and with a resetting device which acts in the closing direction of the valve-closing member, an adjusting element, which is assigned to the valve-closing member, on the low-pressure side being activated via a predetermined threshold value as the low pressure rises or as the temperature on the low-pressure side rises and actuates at least one actuating element by means of which a closing force of the resetting device acting on the valve-closing member is reduced such that a passage opening is enlarged or a passage of a bypass valve arranged on the low-pressure side, which passage is arranged parallel to the passage opening, is opened.

Owner:OTTO EGELHOF GMBH & CO KG

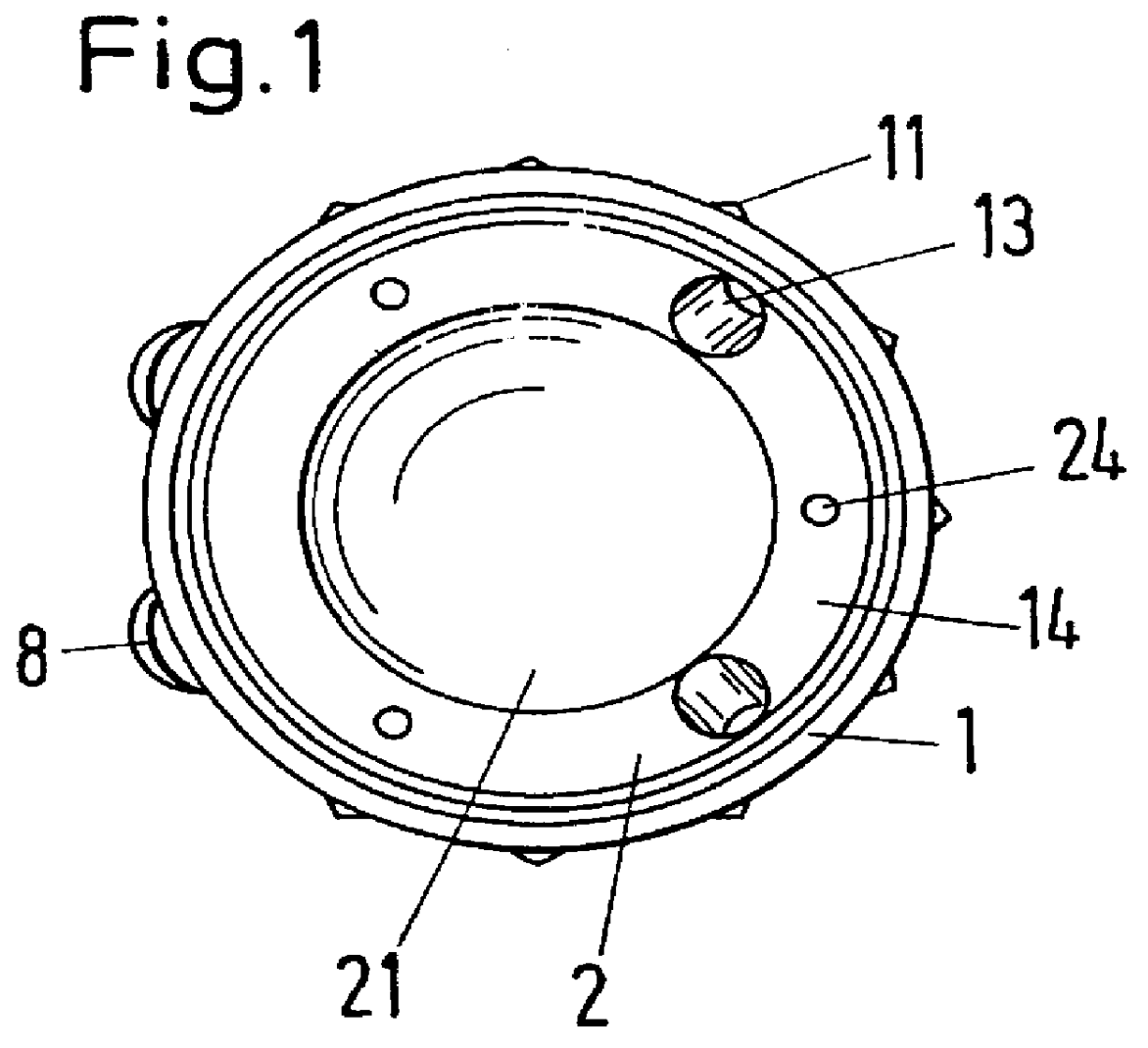

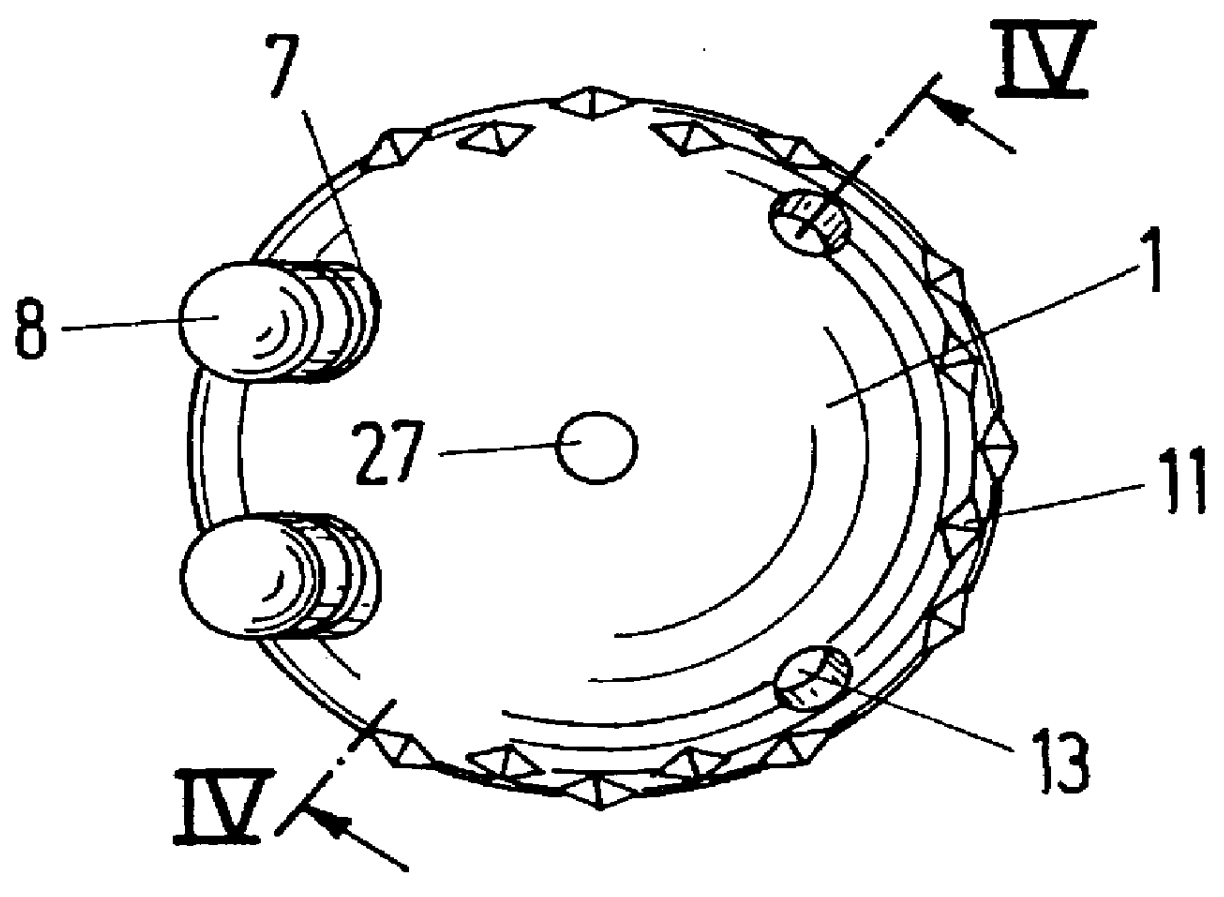

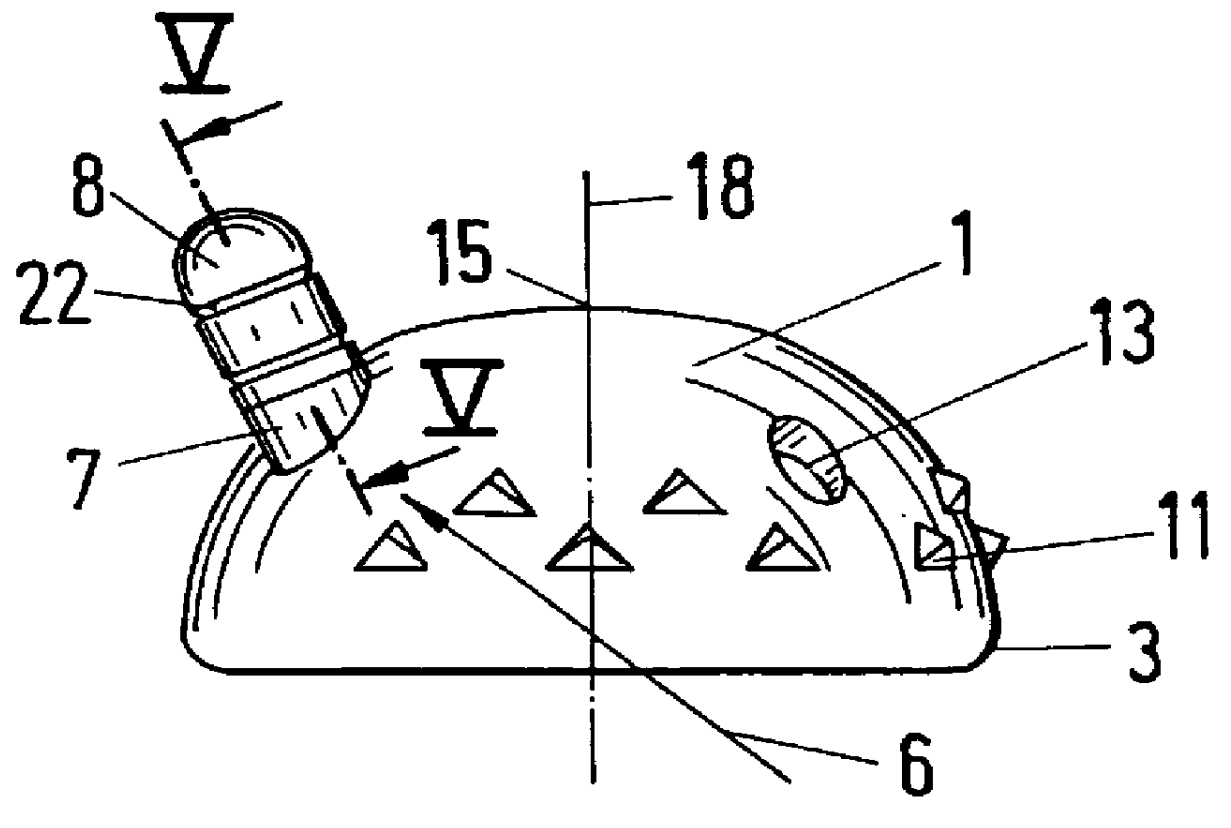

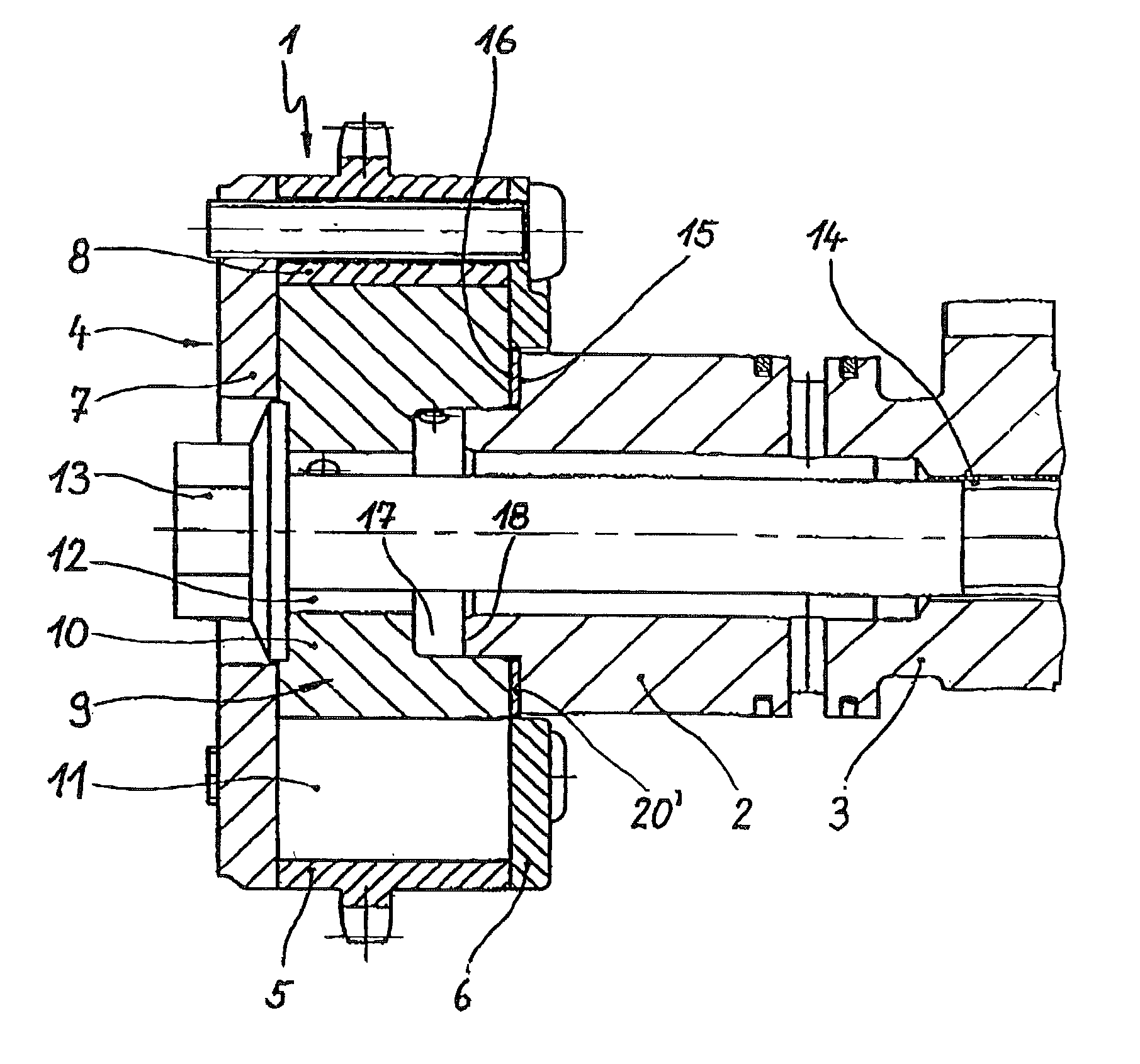

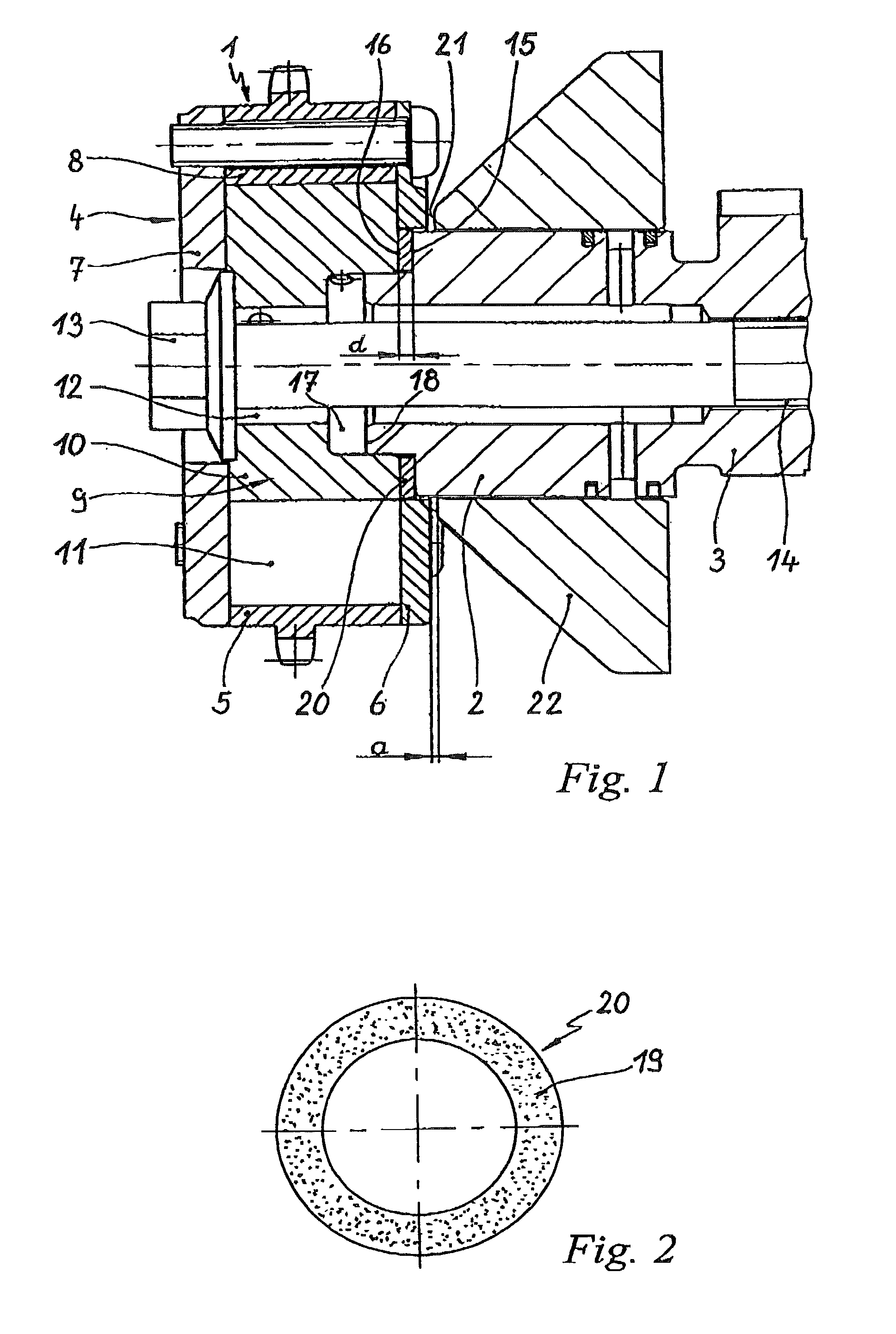

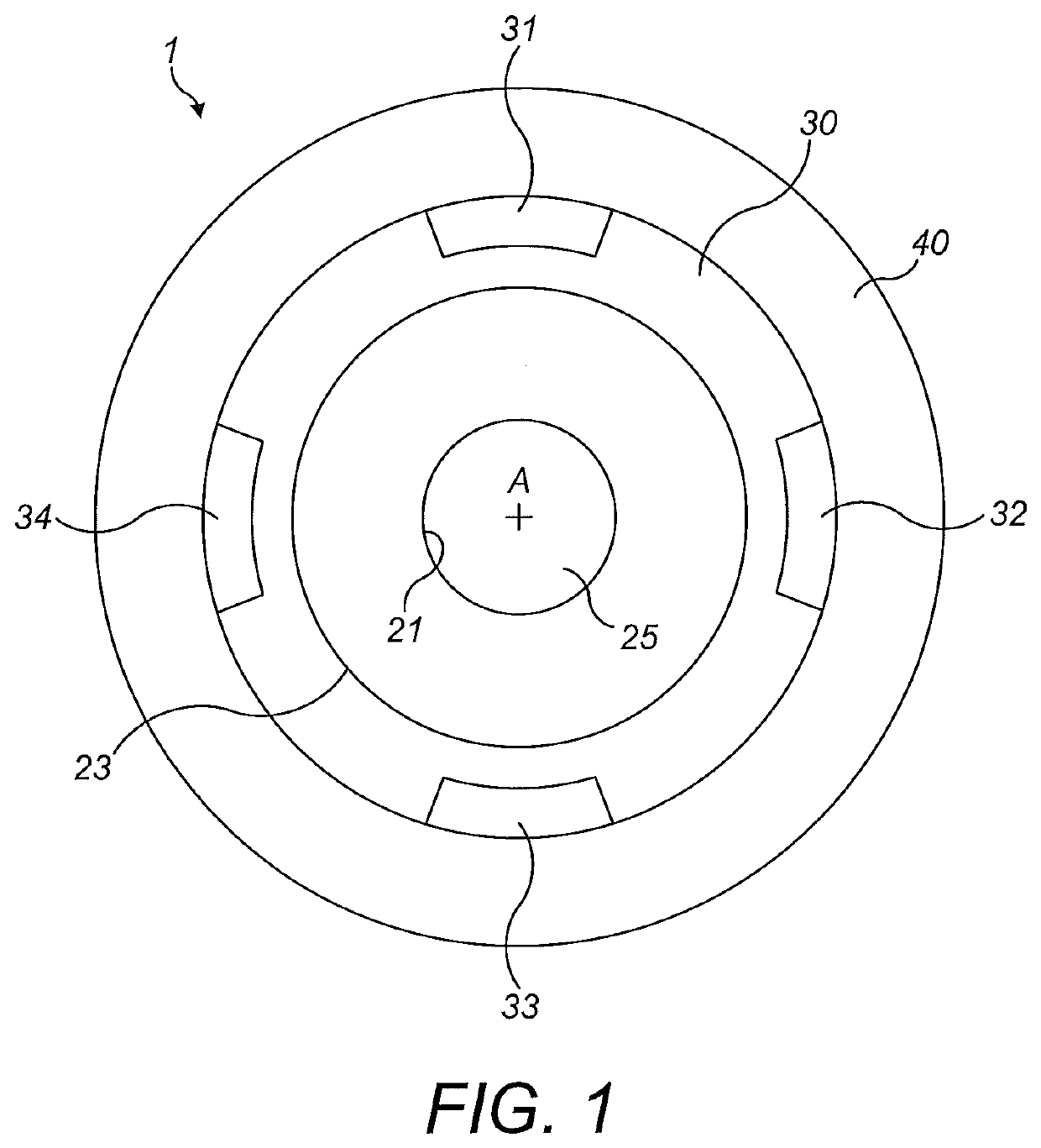

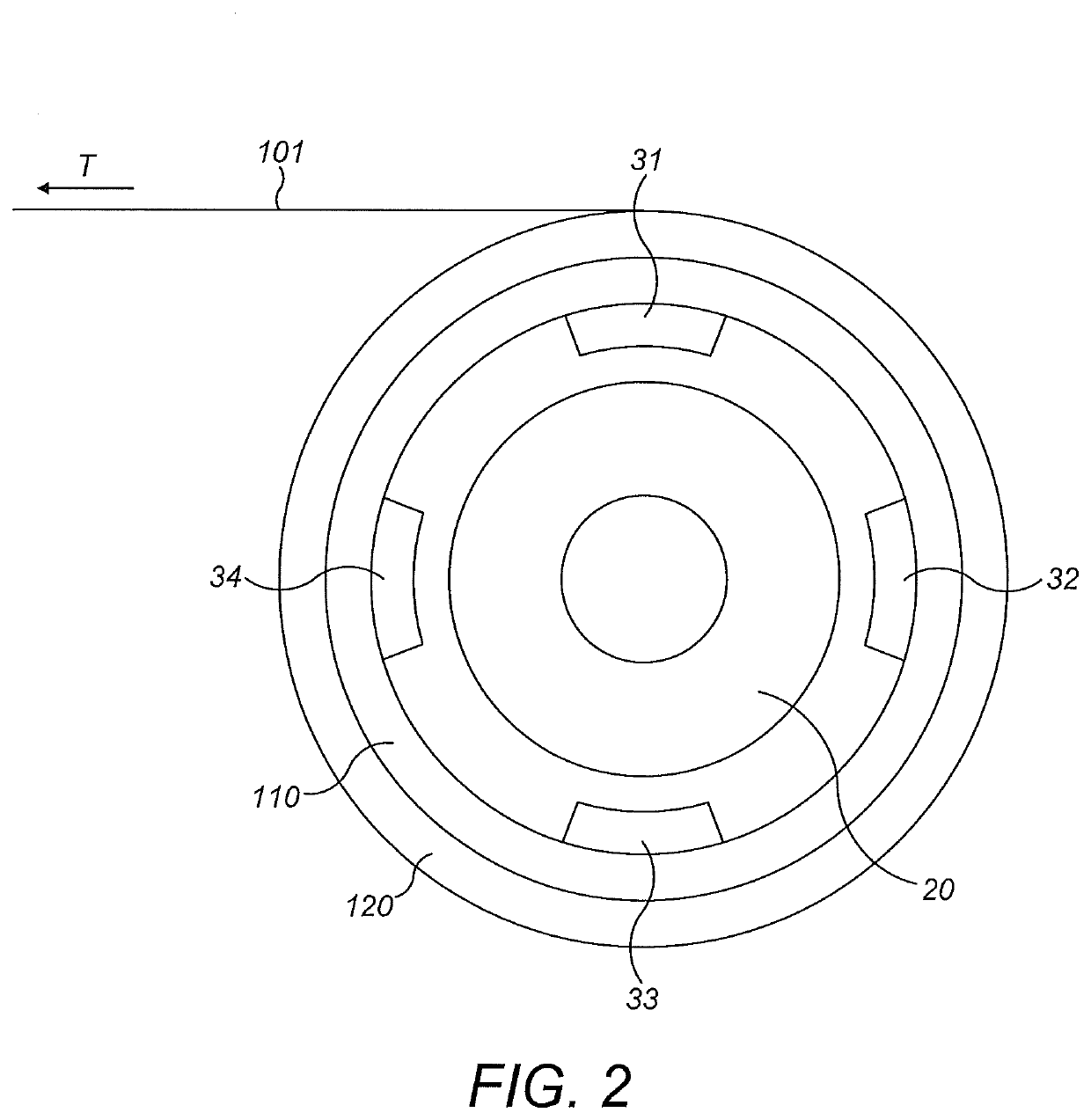

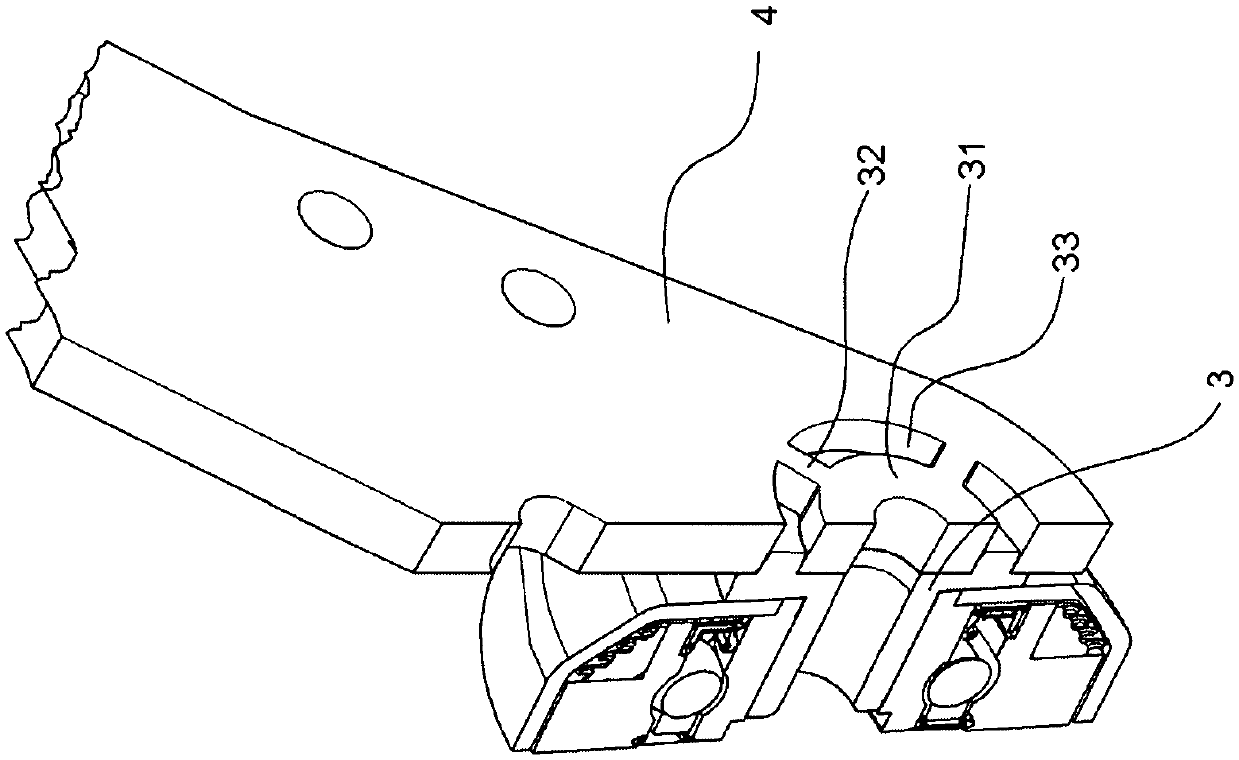

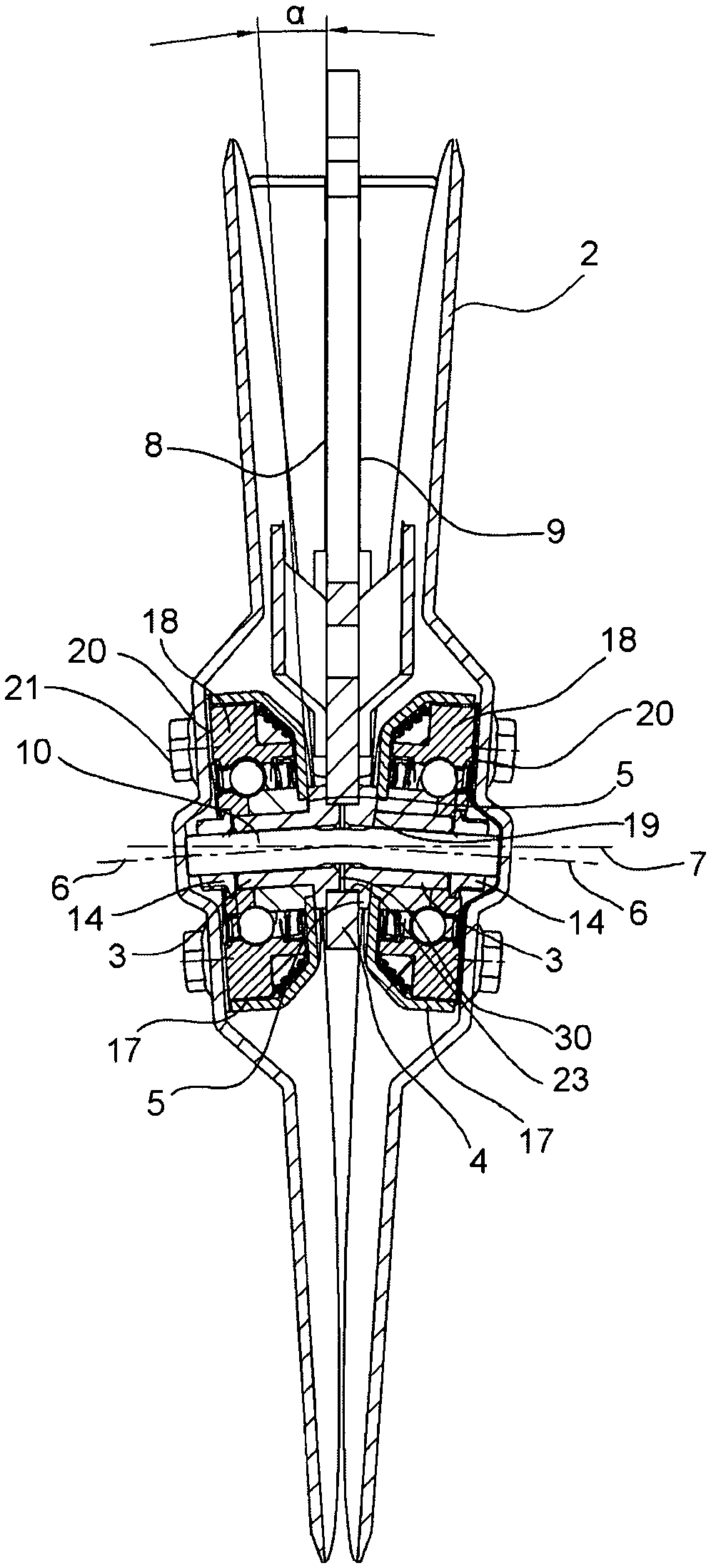

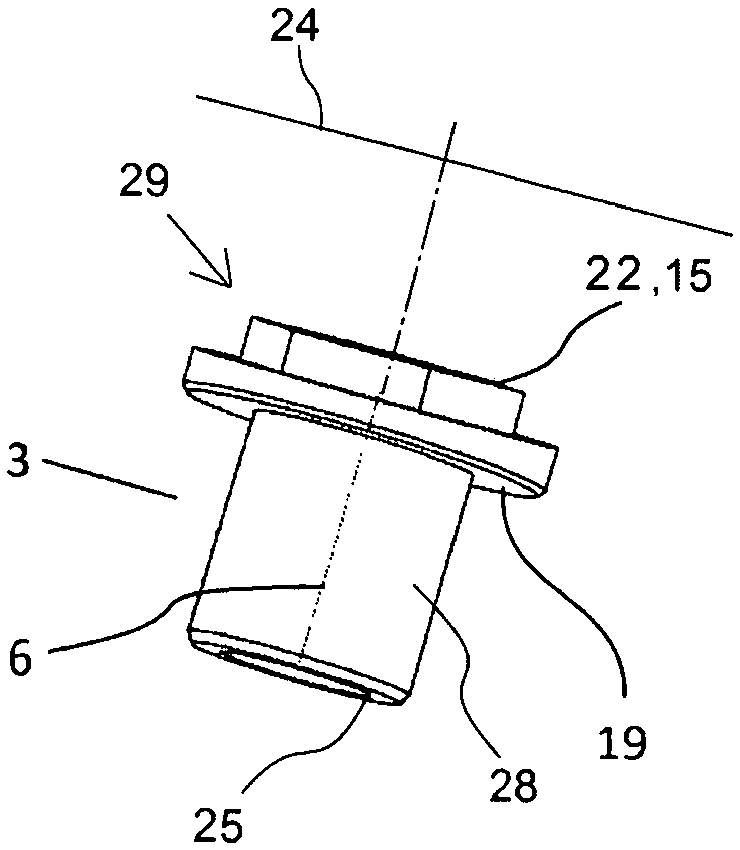

Internal combustion engine adjusting the rotation angle of a camshaft with respect to a crankshaft

InactiveUS20030116110A1Disadvantageous consequenceIncrease forceValve arrangementsYielding couplingPre stressPre stressing

A device for hydraulically adjusting the rotation angle of a camshaft with respect to a crankshaft of an internal combustion engine: A drive unit connected to a crankshaft and an output unit connected to a camshaft, having radially extending, axially facing sides secured by the pre-stressing force of a central securing bolt. The drive unit is rotably mounted to the output unit and they are so connected that at least two hydraulic pressure chambers transmit relative rotation forces. An annular disk with coating on opposite sides increases the frictional force between the end face of the output unit which faces the camshaft and the end of the camshaft and enables reduction of the pre-stressing force on the bolt. The character of visually detectable elements on the disk enable detection of the presence or absence of the disk.

Owner:SCHAEFFLER TECH AG & CO KG

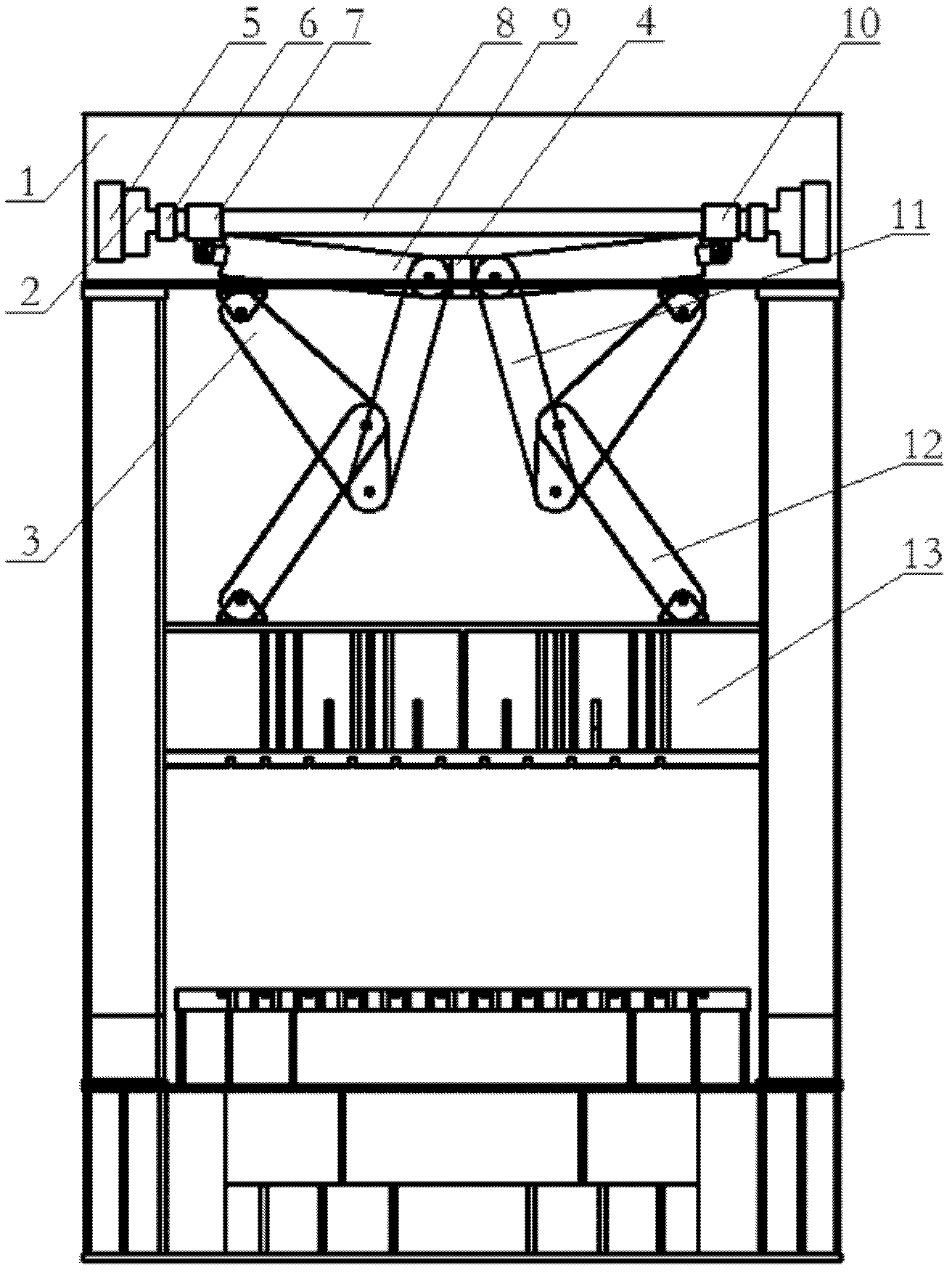

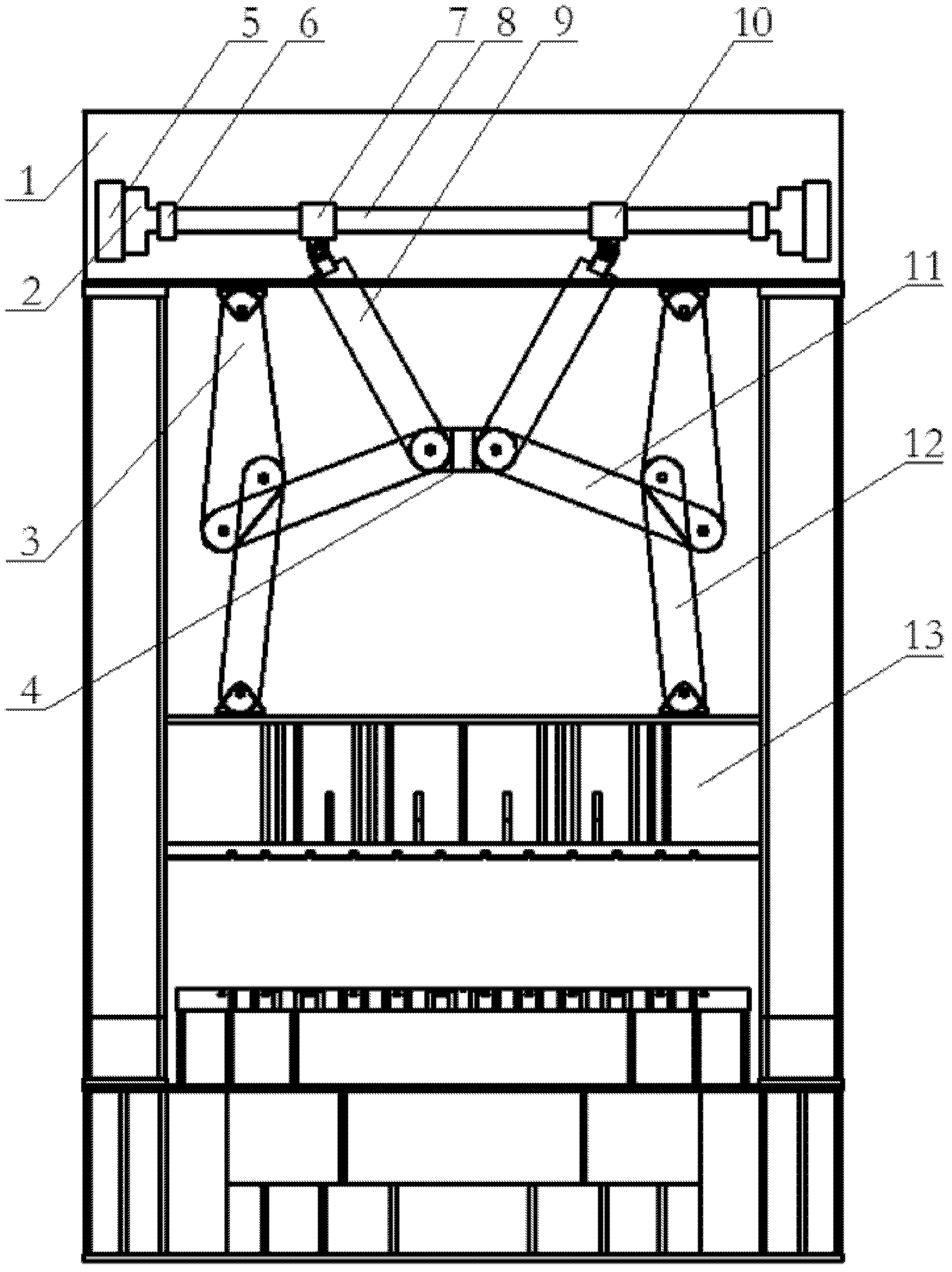

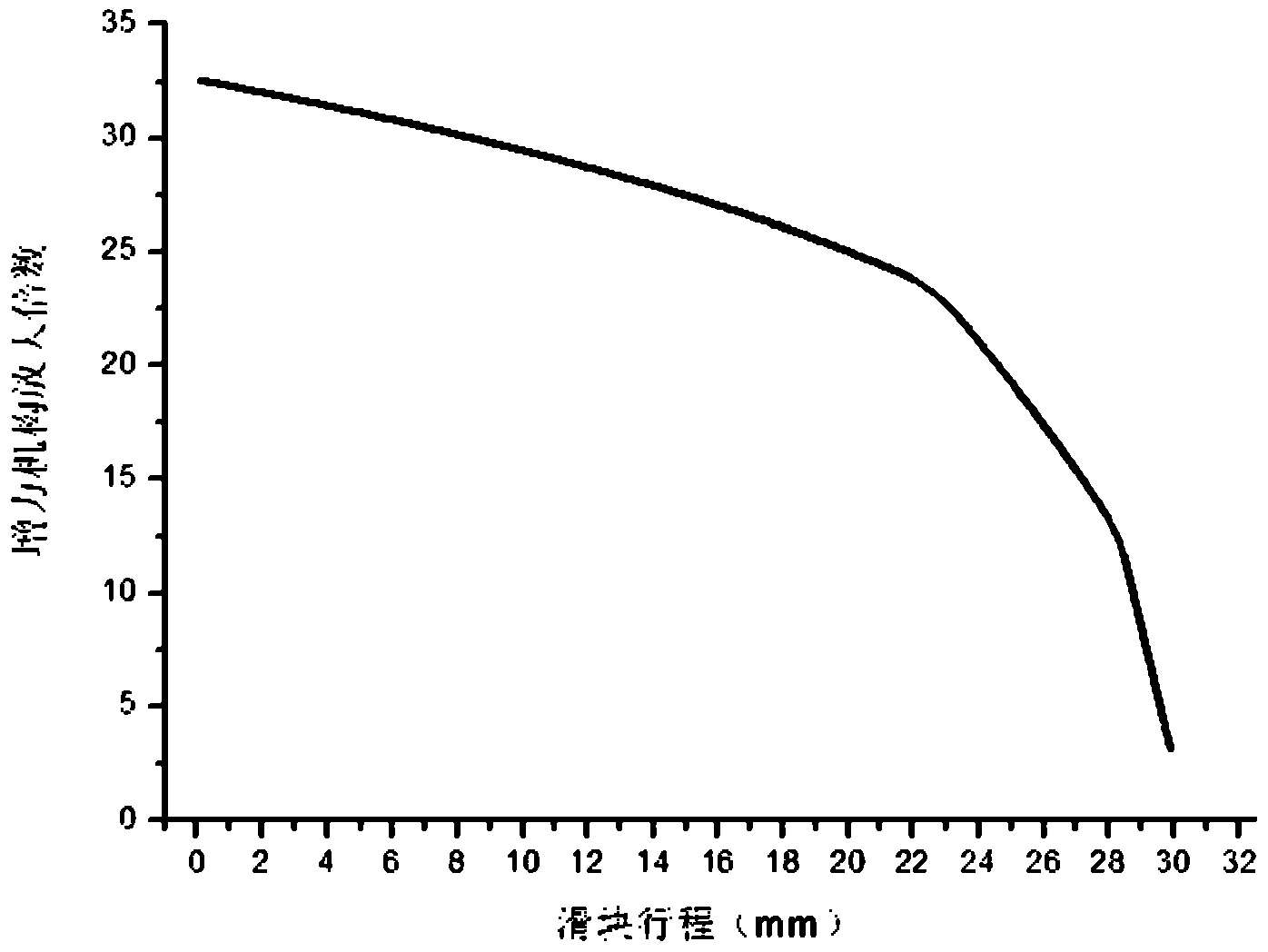

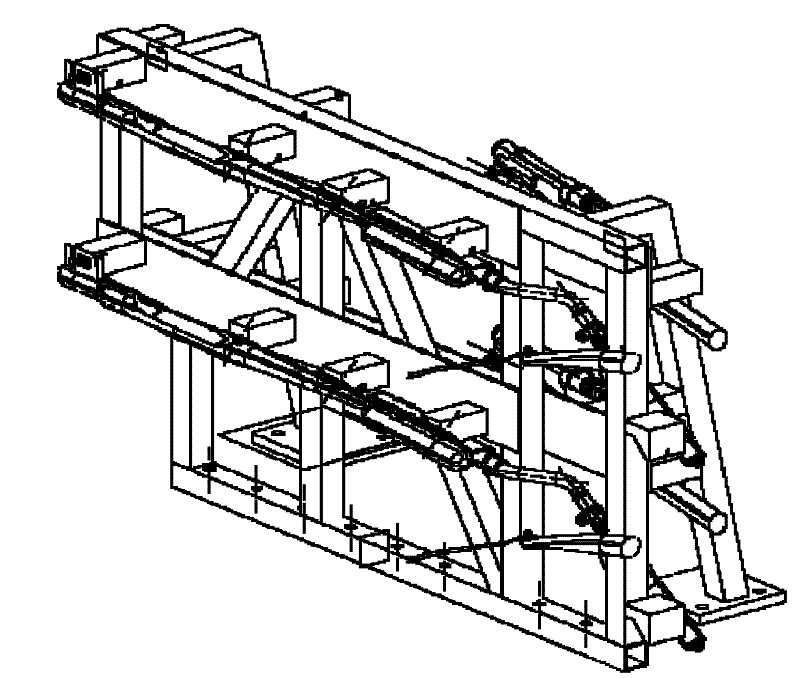

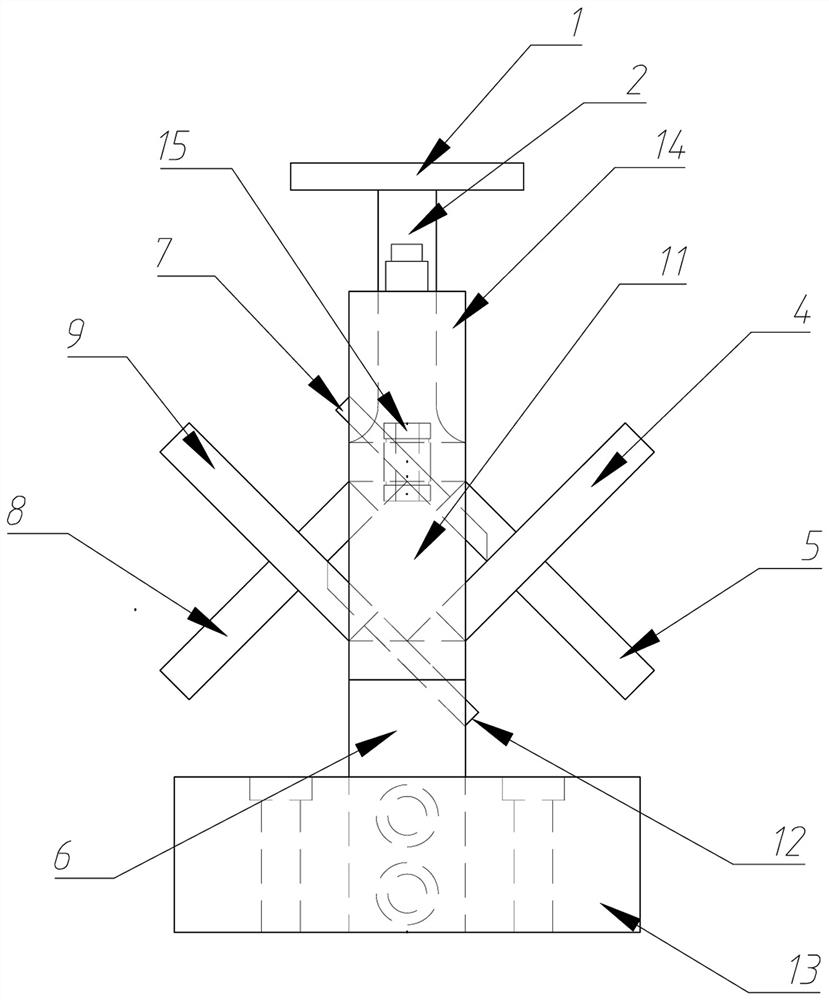

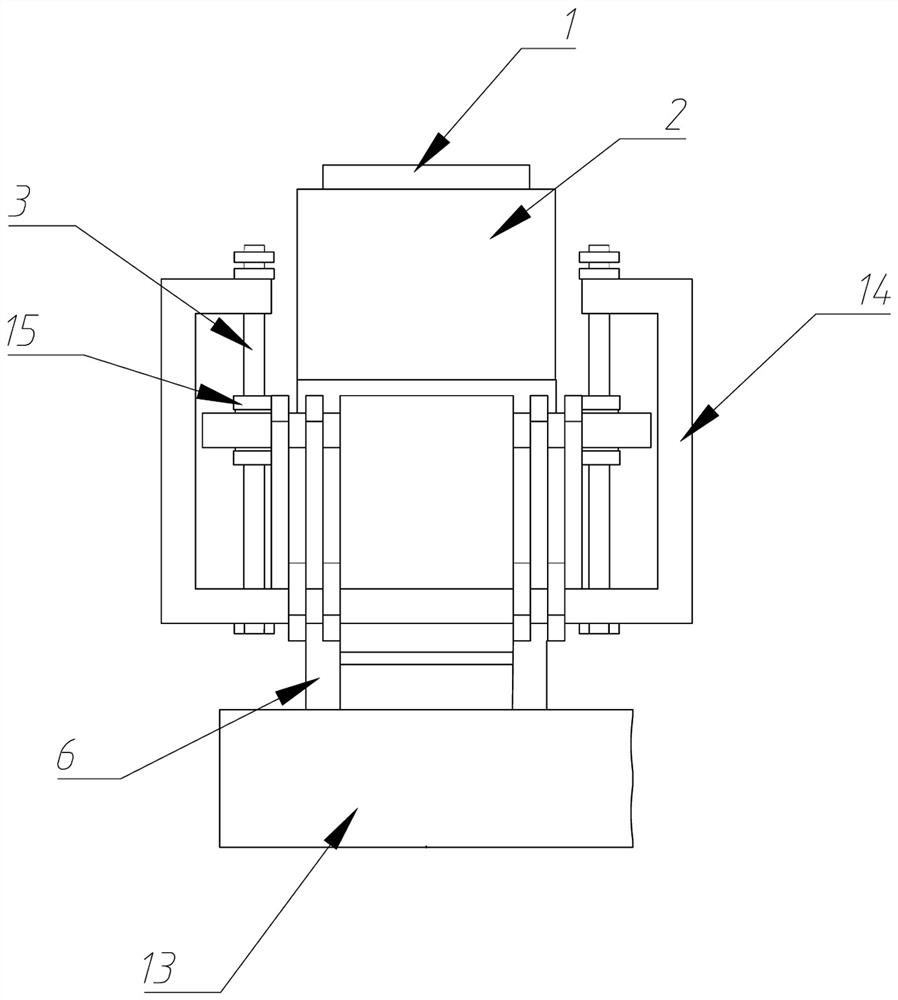

Transmission system suitable for large-tonnage alternating current servo press

ActiveCN102320153AOvercome the disadvantage of small magnificationLow powerGearingPressesThree levelBall screw

The invention discloses a transmission system suitable for a large-tonnage alternating current servo press. The output shaft of a disk-type permanent magnet synchronous servo motor and a planet gear speed reducer are made into integral structure; the screw of a driving mechanism and two nuts arranged on the nut form a ball screw structure; the screw is connected with the planet gear speed reducer; the left and the right of a top bar as well as the front and the back of the top bar are symmetrically provided with double toggle rod boosting mechanisms; a symmetrical oscillating rod input type boosting mechanism is arrange between the top bar and the double toggle rod boosting mechanisms; a three-level boosting mechanism causes the amplification multiple of the boosting mechanisms in the beginning stage to be above 15 times; and the amplification multiple is bigger and bigger along with the shaping process to lower the power of the disk-type permanent magnet synchronous servo motor. The transmission system can provide large amplification multiple and has the advantages of obvious boosting effect, large effective boosting travel, small integral structural size, big sliding block travel, quick virtual travel, high working efficiency, quick feeding, low shaping speed and the like, and unbalance loading is simultaneously eliminated.

Owner:XI AN JIAOTONG UNIV

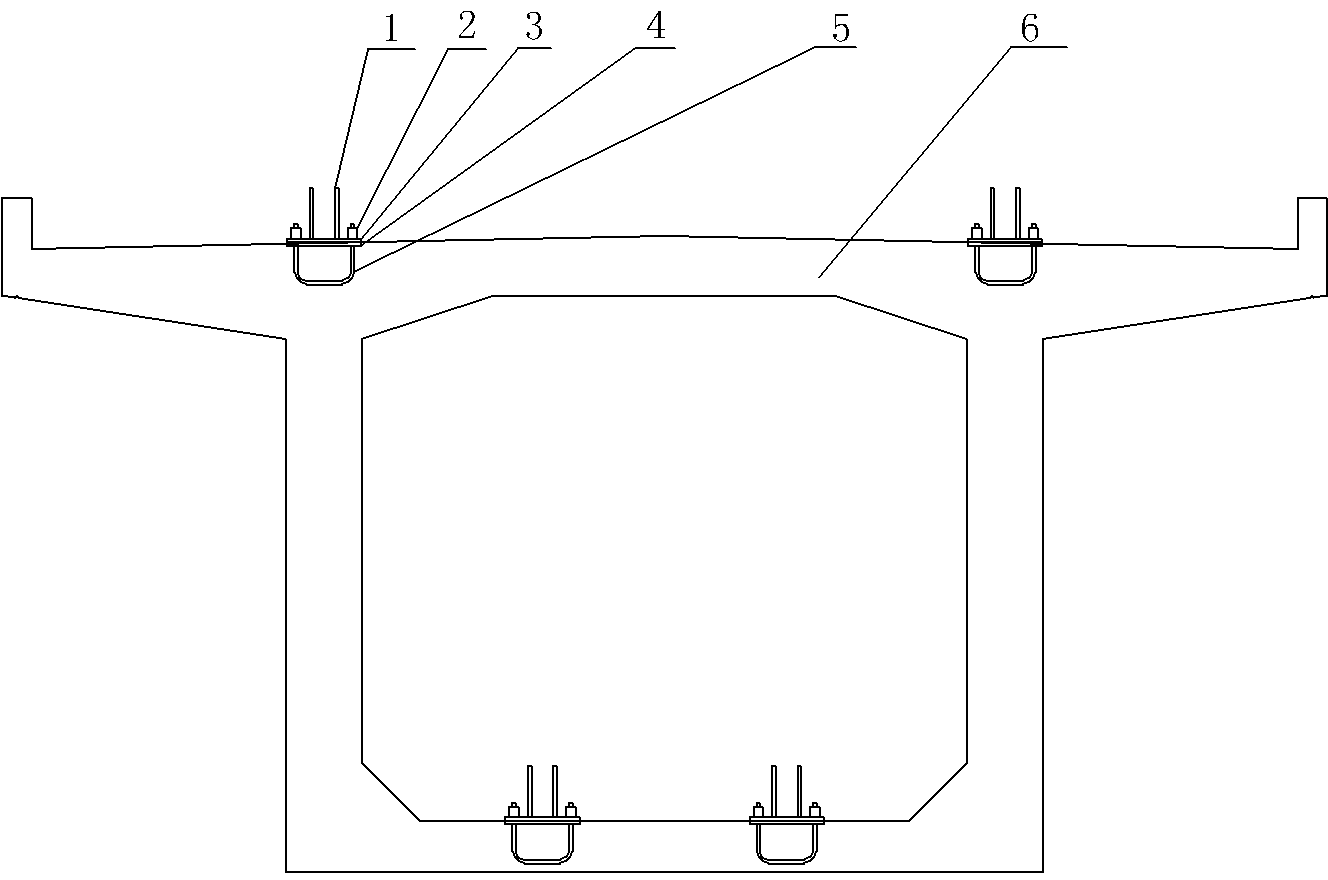

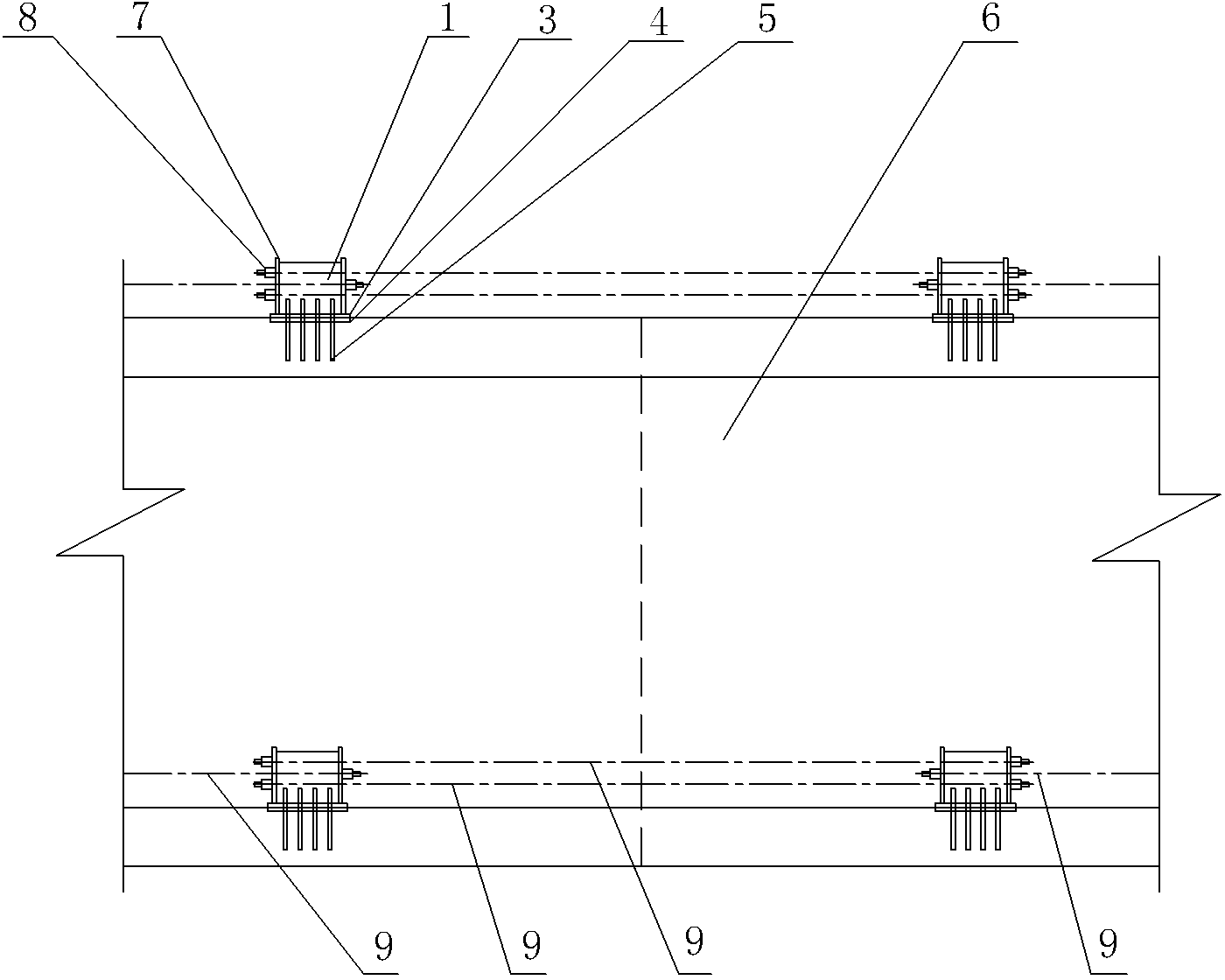

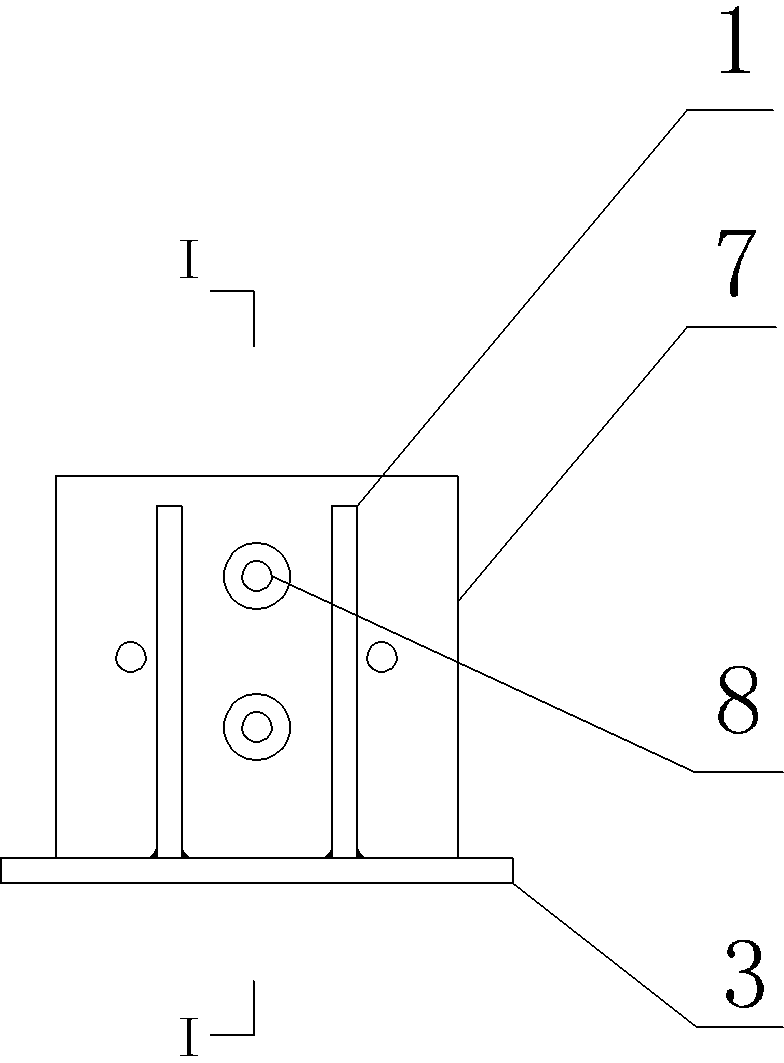

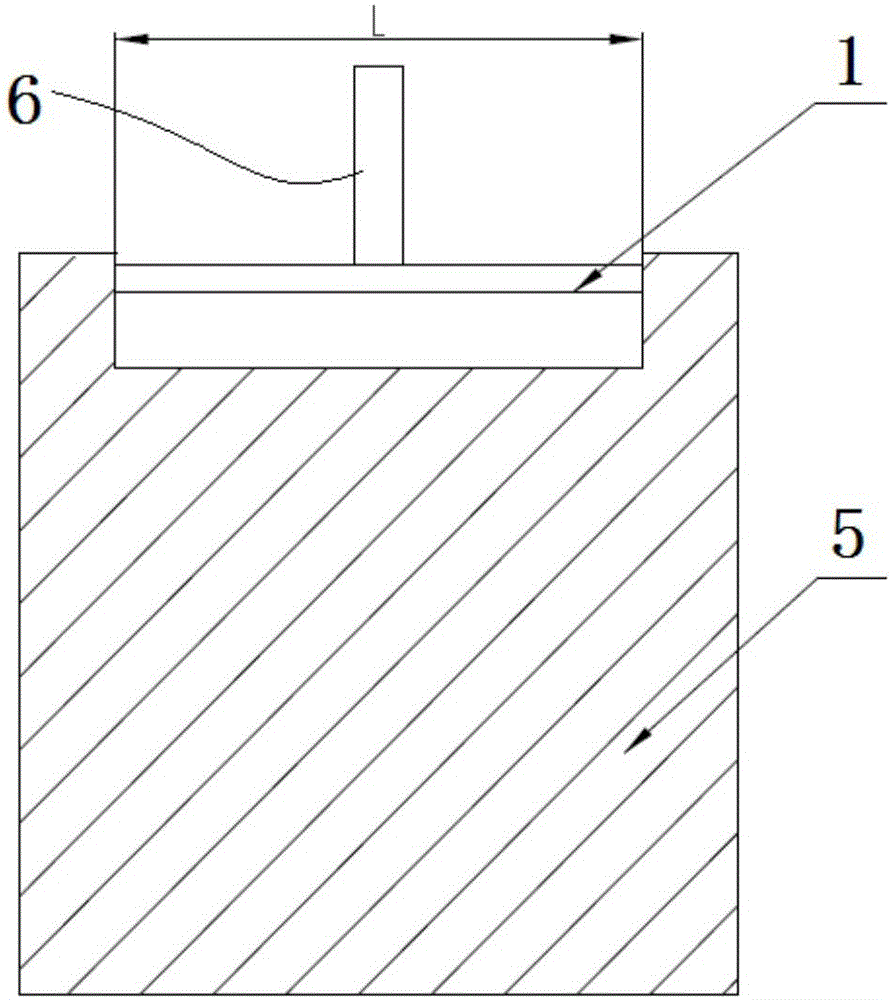

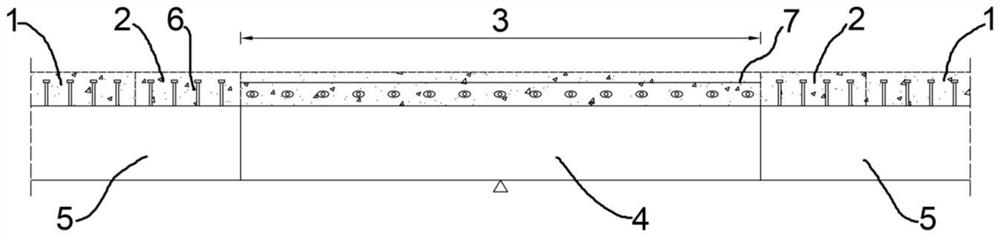

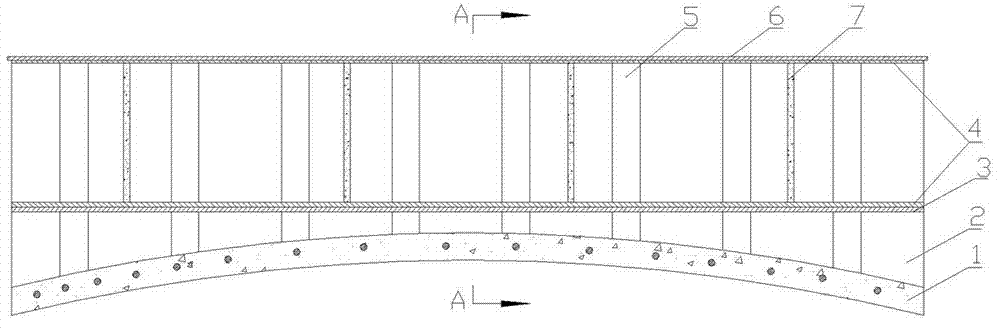

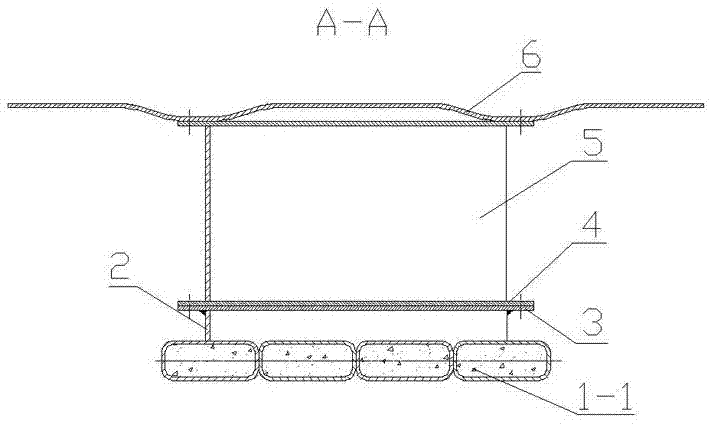

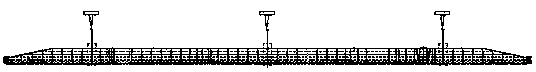

Mobile temporary prestress tension anchor block

ActiveCN103215894ASimple structureIncrease stiffnessBridge erection/assemblyPre stressArchitectural engineering

The invention relates to a mobile temporary prestress tension anchor block. A concrete anchor block is adopted for conventional segmented precast assembled bridge temporary prestress tension, can not be used repeatedly, and is large in weight and unfavorable for stress of a segmented precast assembled beam. The mobile temporary prestress tension anchor block is provided with a base plate which is fixed on a precast segmented box beam through embedded fixed parts. Two opposite anchor plates are vertically welded on the upper surface of the base plate. Two rib plates perpendicular to the anchor plates are welded between the anchor plates. The anchor plates are provided with anchor plate through holes for enabling prestress thick reinforcing steel bars to penetrate through. The prestress thick reinforcing steel bars are arranged in the four anchor plates of two anchor blocks on the two adjacent precast segmented box beams in a penetrating mode. The ends of the prestress thick reinforcing steel bars are fixed on the anchor plates at the far ends of the two adjacent anchor blocks through prestress thick reinforcing steel bar binding anchorage devices. The mobile temporary prestress tension anchor block is simple in structure, large in rigidity, low in cost, convenient to construct, and capable of being disassembled, assembled, moved, and utilized repeatedly, and has good universality.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Transfer ring beam for concrete cylinder and steel cylinder combined tower and construction method thereof

ActiveCN105971827AImprove the uniformity of stress distributionReduce prestressEngine manufactureWind motor assemblyPre stressMaterial consumption

The invention provides a transfer ring beam for a concrete cylinder and steel cylinder combined tower and a construction method thereof. The transfer ring beam is arranged between the concrete tower cylinder and the steel tower cylinder and is formed by defining an annular bottom plate horizontally arranged, ring beam webs fixe to the annular bottom plate and a flange covering the top of the ring beam webs. The annular bottom plate serves as a lower flange plate of an annular box girder, and the flange serves as an upper flange plate. The ring beam web is welded to the annular bottom plate. The upper surface of the flange is fixed to the steel tower cylinder. The positions, corresponding to the two ring beam webs, of the lower surface of the flange protrude to form a protruding opening. The protruding opening is correspondingly connected with the top ends of the wing beam webs. The annular bottom plate and the flange are provided with prestressing tendon preformed holes correspondingly. Internal prestressing tendons penetrate through the concrete tower cylinder and the transfer ring beam from bottom to top and then are fixed through prestressed anchorage devices. By adopting the transfer ring beam, extra prestressing pressure in the concrete section of the tower cylinder can be reduced, the section thickness of the concrete tower cylinder can be decreased, concrete material consumption is reduced, and the hoisting and installation difficulty of the precast concrete tower cylinder is lowered.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

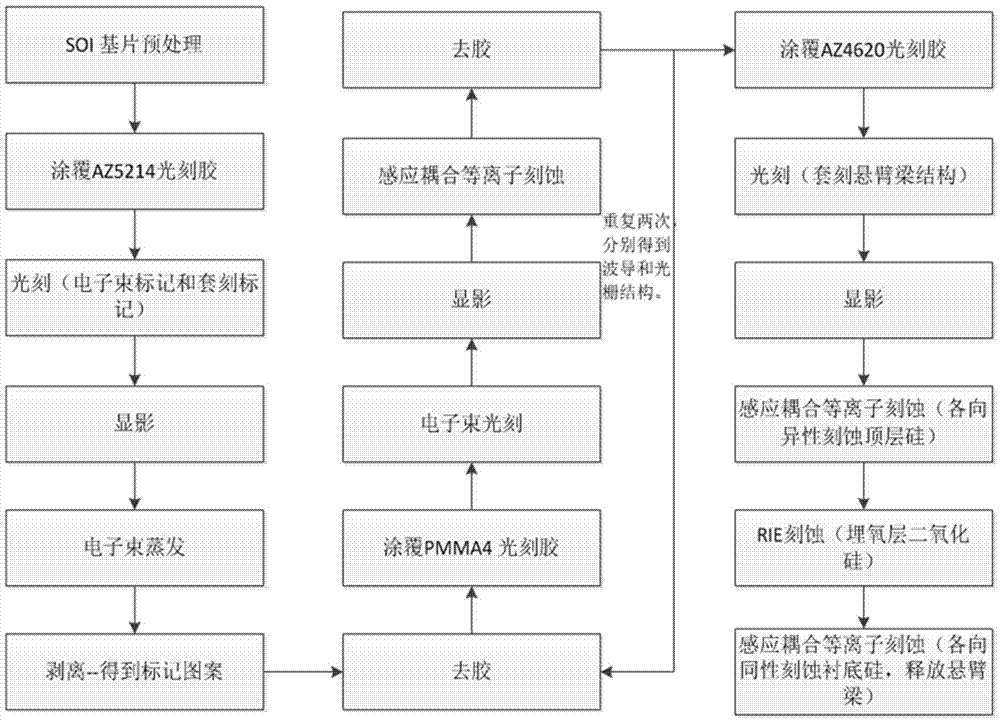

MOEMS accelerometer based on planar ring cavity, and manufacturing method of the same

InactiveCN105445494AHigh sensitivityHigh measurement accuracyDecorative surface effectsAcceleration measurementGratingAccelerometer

The invention belongs to the optical field and the micro-electro-mechanical system field, and specifically relates to an MOEMS accelerometer based on a planar ring cavity, and a manufacturing method of the same. The accelerometer comprises a substrate, a cantilever beam, gratings, a straight waveguide and a micro-ring resonant cavity. The basic operating principle of the accelerometer includes: an incident light is coupled with the straight waveguide through the gratings; the light transmitted in the straight waveguide is coupled with the micro-ring resonant cavity in an evanescent field mode; the light satisfying a resonance condition generates resonance in the micro-ring resonant cavity and generates a transmission peak corresponding to the resonance; and when the system is impacted by external forces, under the effect of the accelerated speed, the cantilever beam is deformed because of the effect of inertia force to enable the micro-ring resonant cavity integrated on the cantilever beam to be lightly deformed, so that the effective refractive index of the micro-ring resonant cavity is changed and then the resonance peak of the micro-ring resonant cavity offsets and the corresponding accelerated speed value can be calibrated by means of the offset generated through measurement of a resonant point.

Owner:ZHONGBEI UNIV

Quick-setting filling cementing material

The invention discloses a quick-setting filling cementing material and a preparation method thereof. The composition comprises the following components in parts by weight: 40-90 parts of slag powder;6-24 parts of cement clinker; 2-18 parts of bentonite, 2-28 parts of steel slag powder; 0-15 parts of modified gypsum; 0.5-10 parts of an alkaline excitant; 0-10 parts of a coagulant; 1-3 parts of a water reducing agent; 0.2-8 parts of an anti-cracking material; and 0.5-10 parts of a suspension agent. The quick-setting filling cementing material can effectively reduce the dosage of an additive, has good flowing property and relatively high early strength, has good retention strength and volume stability, is short in cementing time, quick in early strength increase and slow in later strength increase, and is simple in process and wide in material source.

Owner:TAIYUAN UNIV OF TECH

Testing apparatus of impact vibration of general CAB

ActiveCN102226734AStructural stabilitySimple structureVibration testingShock testingFrequency coverageEngineering

The invention relates to the mechanical technology field, more particularly to a testing apparatus of impact vibration of general curtain air bag (CAB). The apparatus comprises a main body structure consisting of a base plate and a main substrate, stiffeners, a connection block, bolts. The apparatus is characterized in that: the base plate and the main substrate are connected vertically to form the main body structure of an inverted T shape; Fixed orifices are arranged on the main substrate, and the connection block is fixed on the fixed orifices by bolts; and the main body structure of an inverted T shape is provided with the stiffeners. Compared with the prior art, the technology employed in the invention is characterized in that: a T-shaped or a double T-shaped main body structure is employed; and a plurality of stiffeners are combined. In addition, the apparatus with a simple structure enables a center of gravity of combination of the to-be-tested CAB and a clamp to pass an axis of a vibration table easily. Moreover, according to the invention, a frequency coverage range is extended, a processing cycle is effectively shortened, and the modification cost is low; an integrated framework is stable; an assembly structure of the connection block can be adjusted according to an actual demand; Welding deformation is effectively reduced because of the focus of utilization of connection by bolts.

Owner:SHANGHAI LINGANG JOYSON SAFETY SYST CO LTD +1

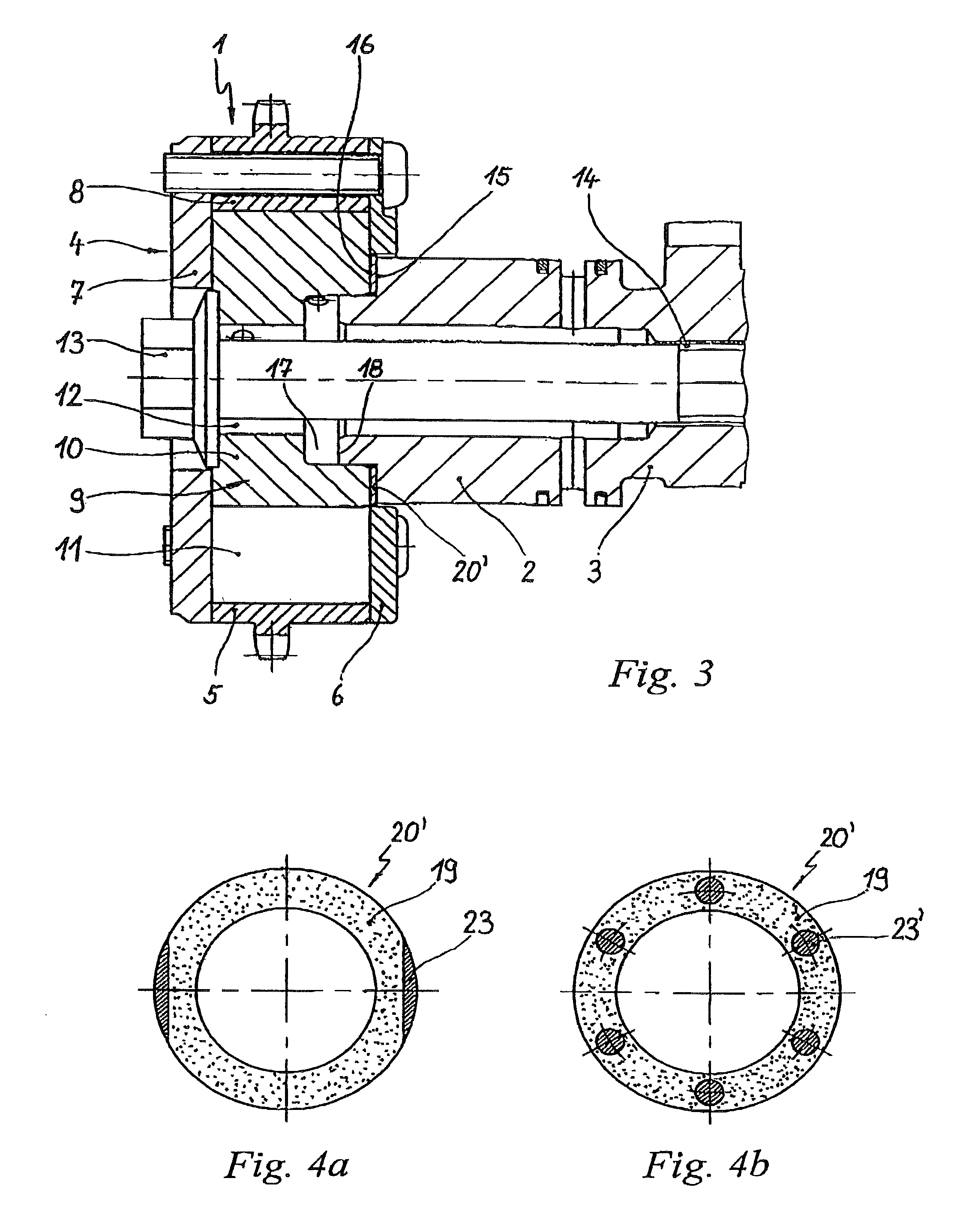

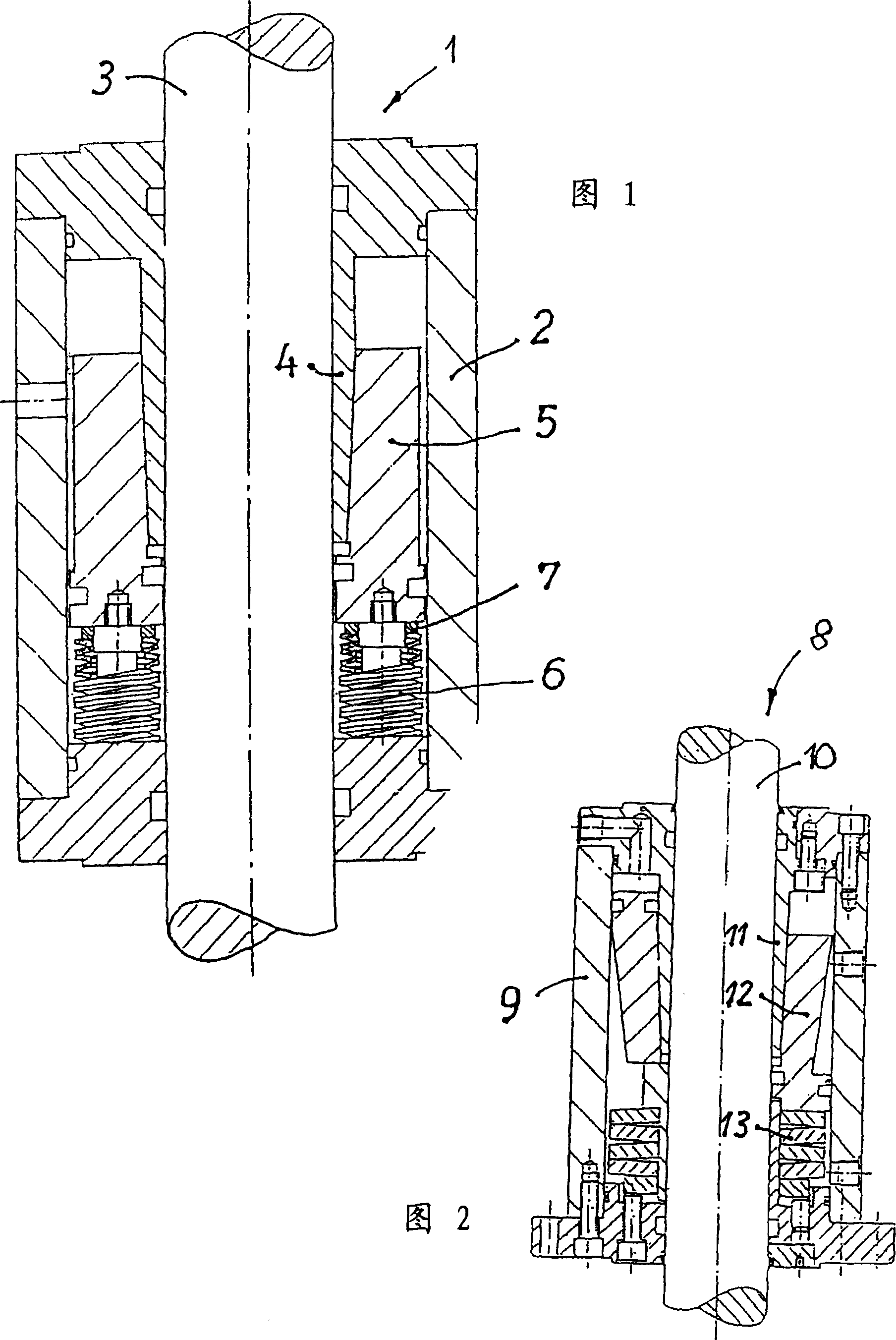

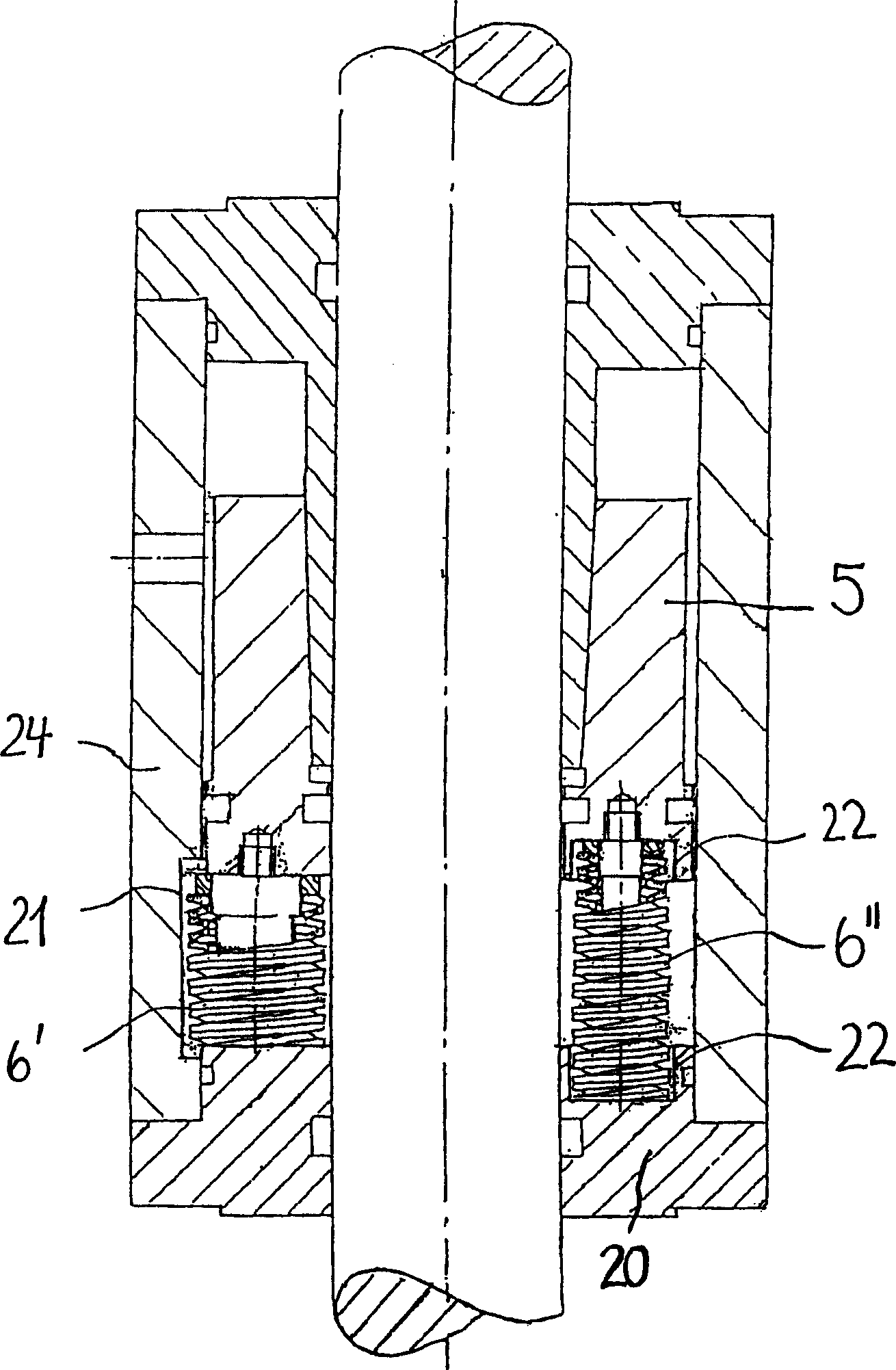

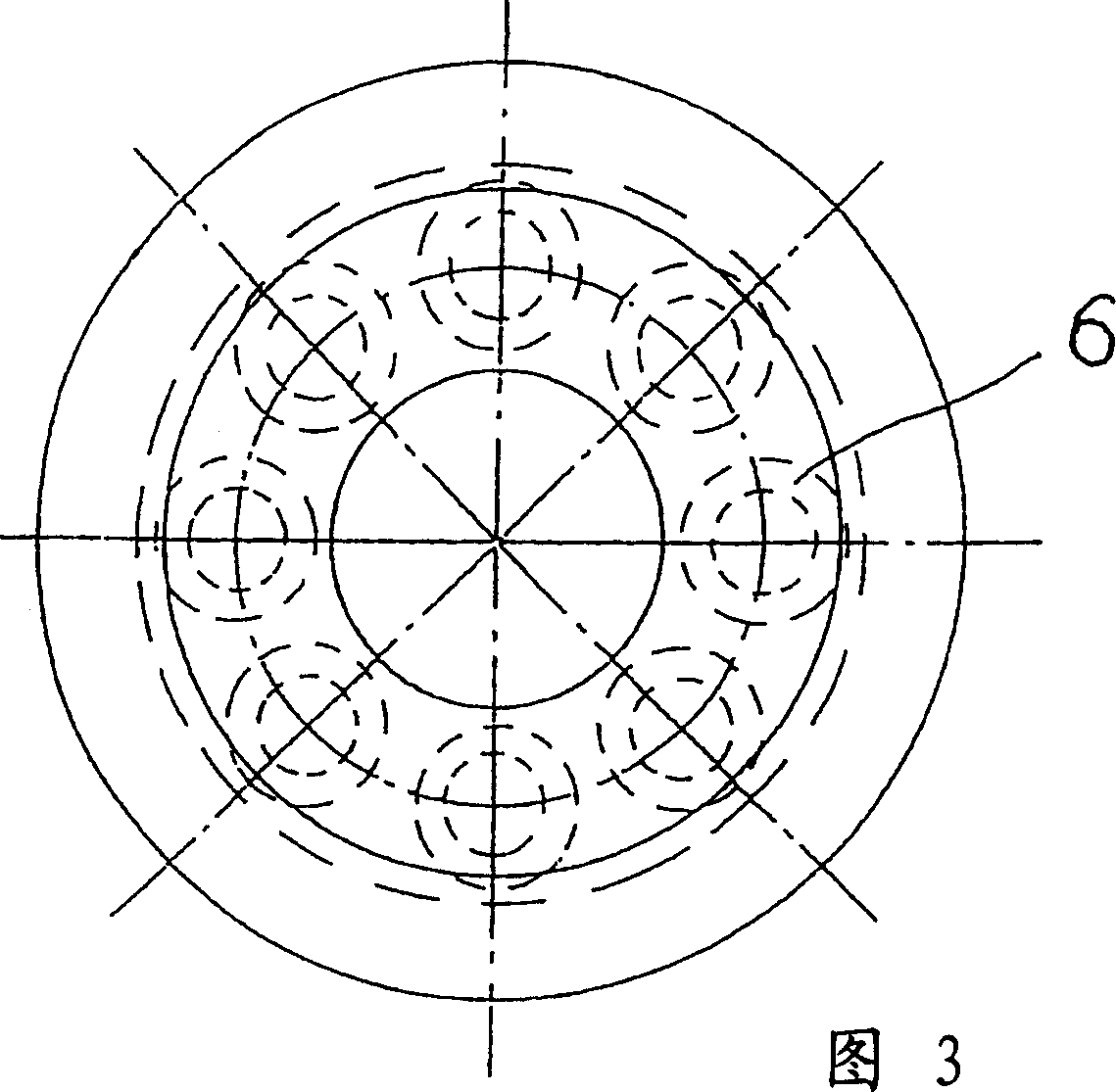

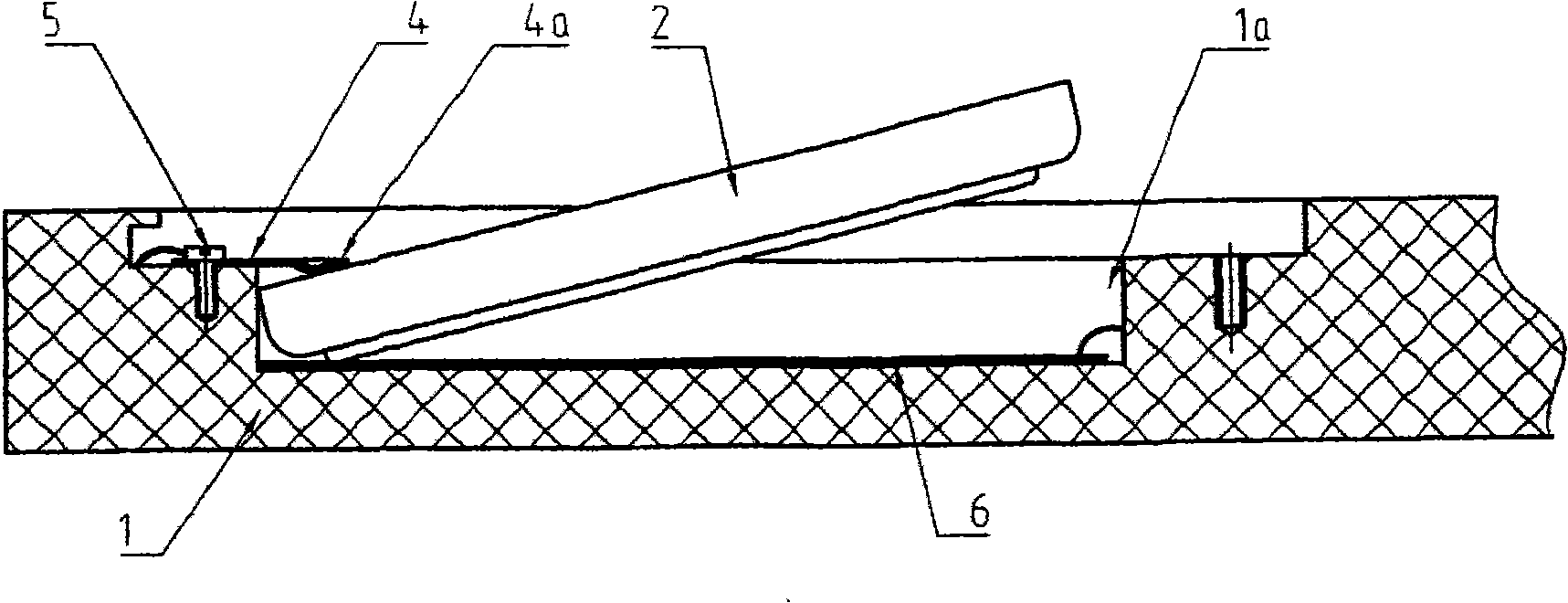

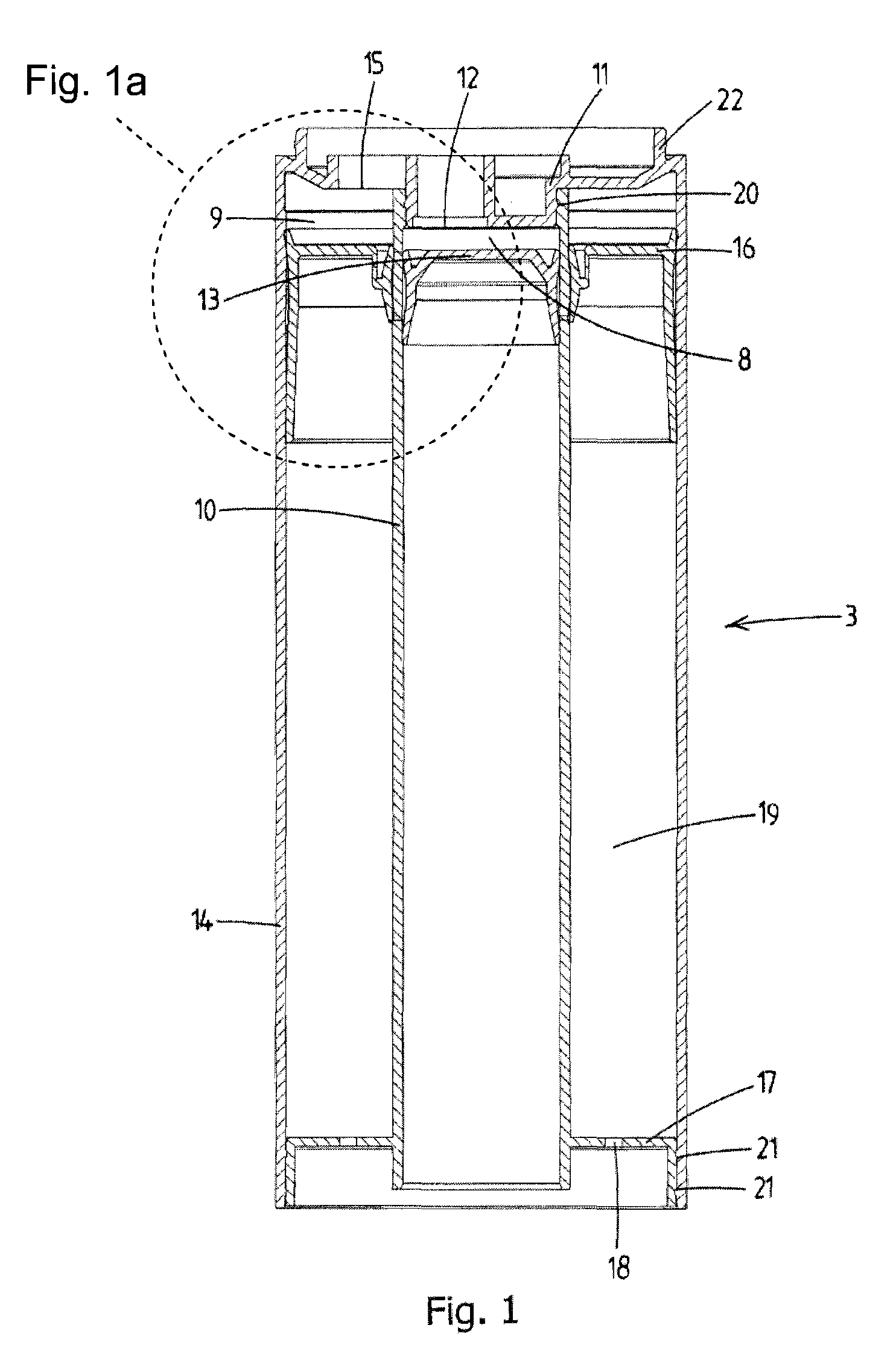

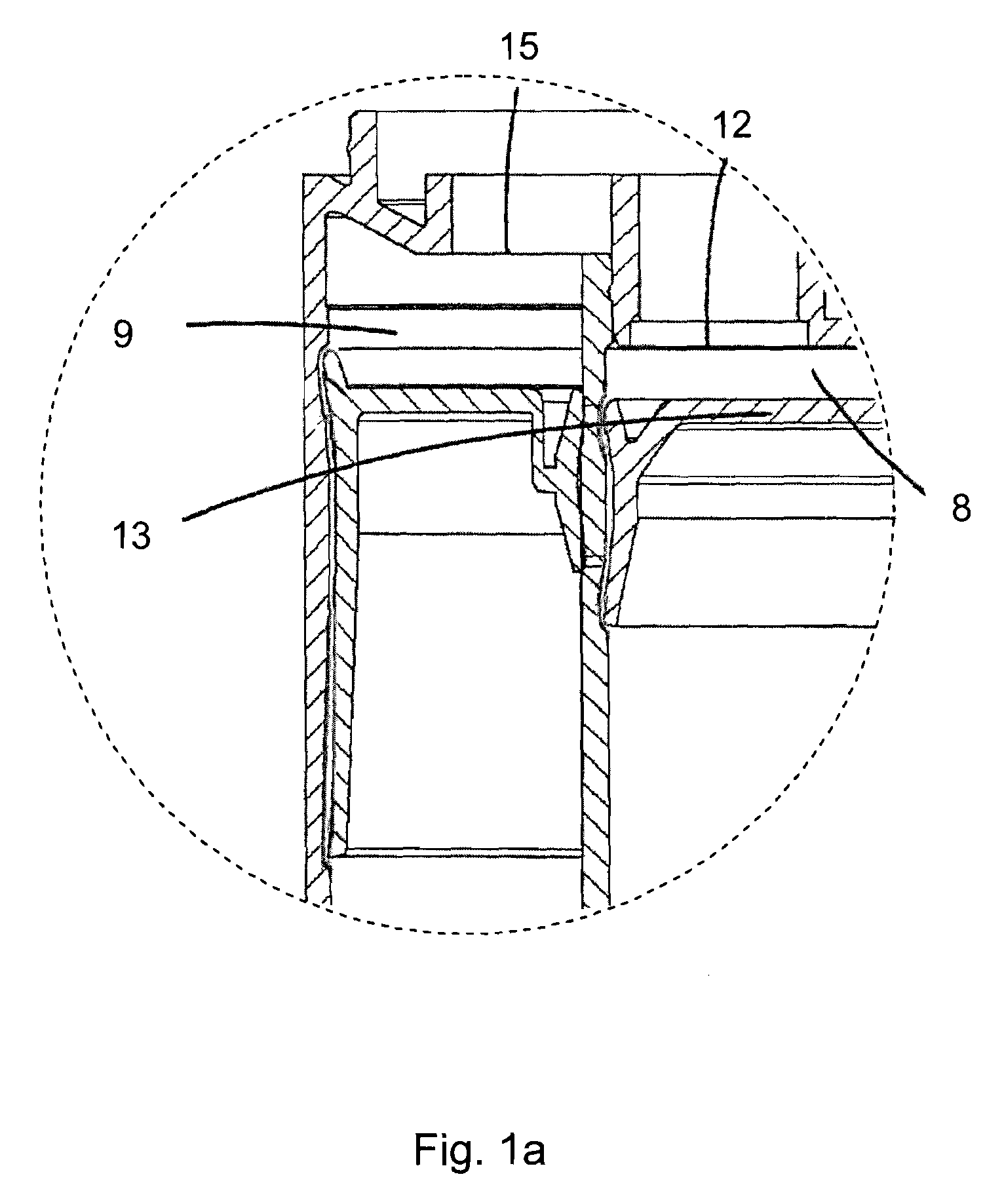

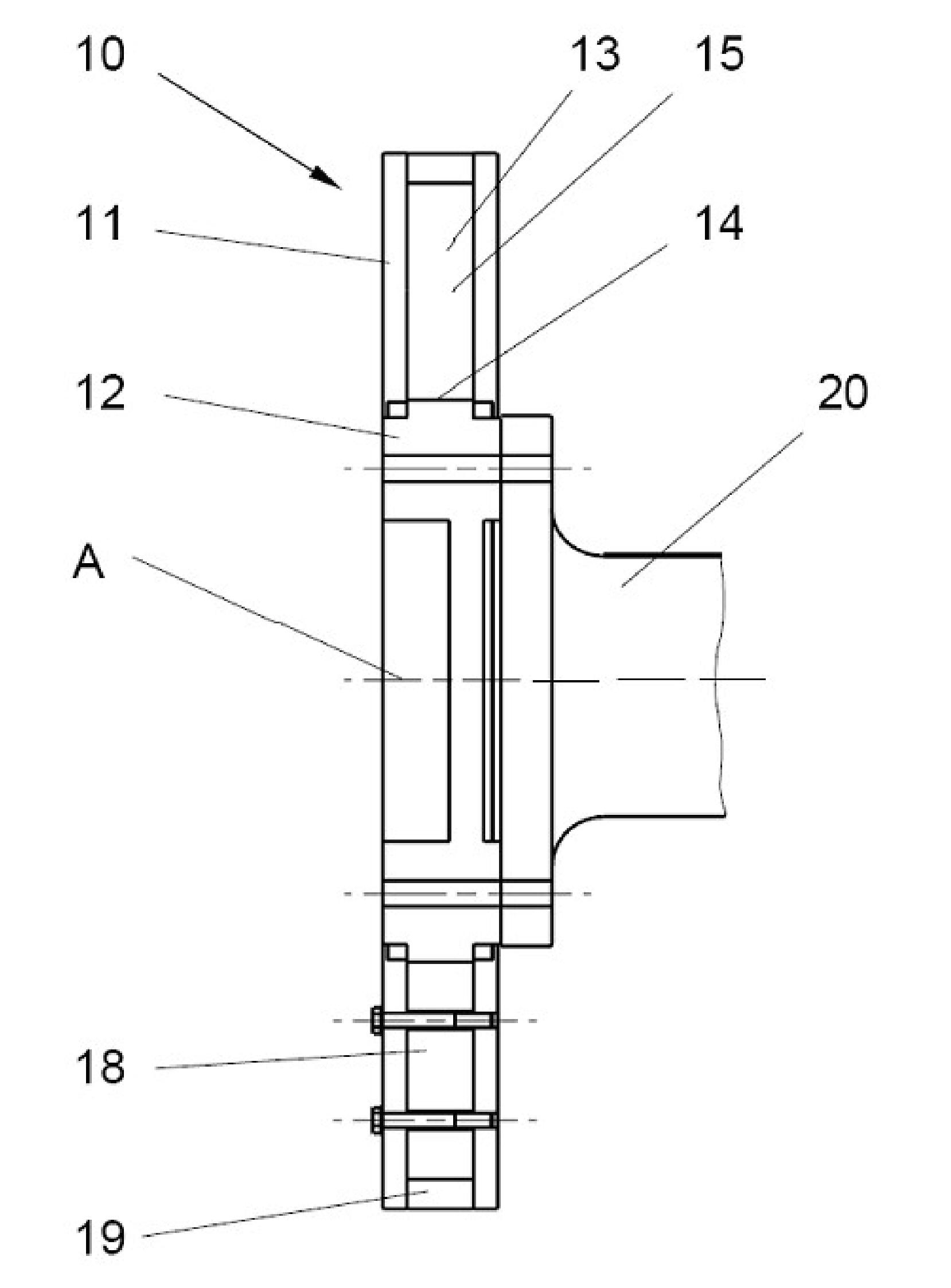

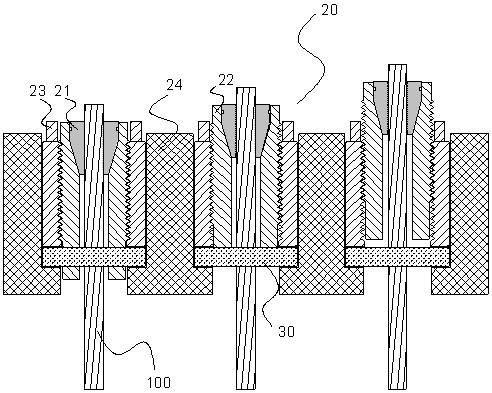

Clamping device and regulating unit

InactiveCN1596344AFavorable elastic characteristicsReduce prestressSecuring devicesFluid-pressure actuatorsMechanical engineeringPiston

The invention relates to a clamping device for a rod (3) which moves in an axial translatory or rotating manner. Said device comprises a housing (2), a clamping sleeve (4) which is axially fixed in said housing, a tensioning piston (5) which can be displaced in the housing embodied as a cylinder, and a spring device for pre-tensioning the piston (5) in the direction of the clamping sleeve (4) in the locking state. Said spring device is embodied as at least one helical plate spring (6, 6', 6', 19) which, in the event of a fracture, preserves the holding force and the dynamic course of the same. In a first form of embodiment, the at least one helical plate spring (19) is coaxially arranged in relation to the rod (3) to be clamped. In a second form of embodiment, a plurality of helical plate springs (6, 6', 6') are arranged on the circumference of the rod (3) in such a way that they are parallel to the axis thereof, for the distribution of a pre-tensioning force acting on the spring device.

Owner:HERBERT HANCHEN

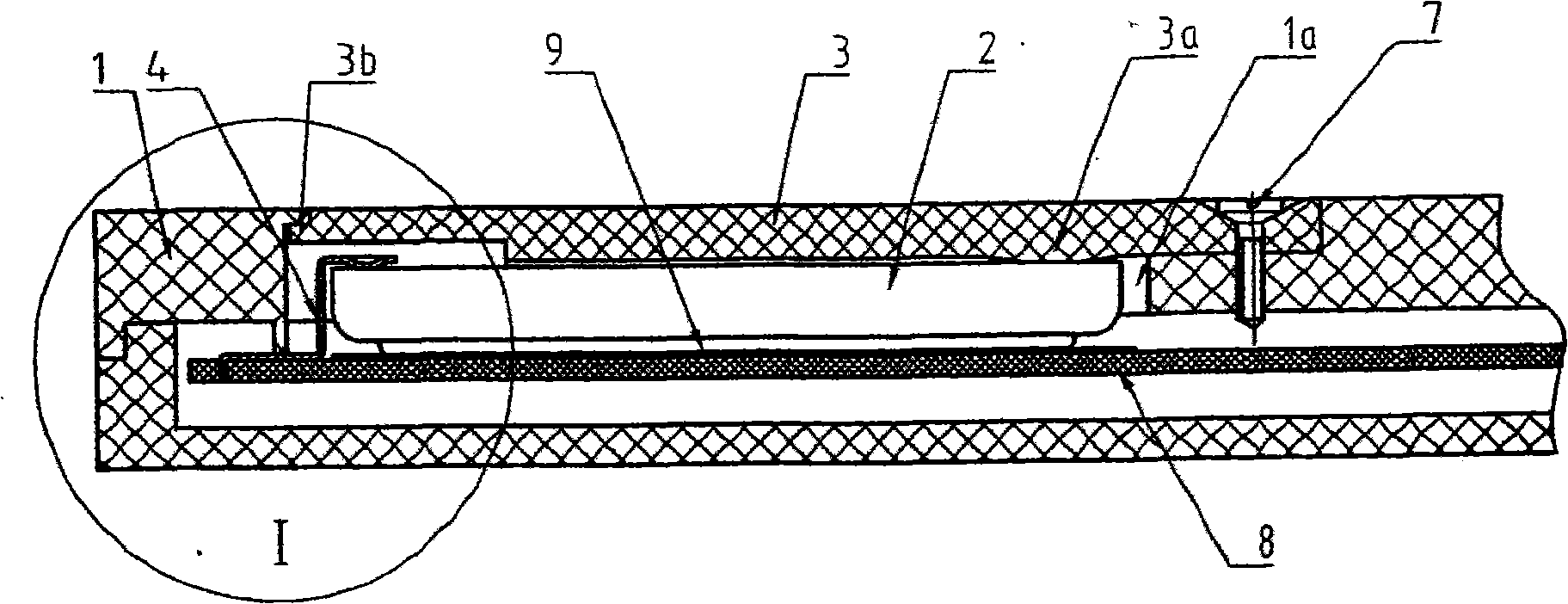

Electronic apparatus power supply output end structure

InactiveCN101299503AReduce distortionReduce prestressElectric discharge tubesCoupling contact membersButton batteryEngineering

The invention discloses a power output structure of the electronic apparatus, including an electronic apparatus case, a PCB circuit board, a button cell as the power, a first power output end and a second power output end. A battery storehouse with an open outwards is arranged on the case, wherein the outside of the battery storehouse is closed by the battery storehouse cover. The first power output end is a metal shrapnel, with one end fixed on the case or the PCB circuit board, and the other end pressed on the part near the battery edge of the epiboly extremeness of the button cell by the bounce of the metal shrapnel. The second power output end is contacted with the central pole of the button cell. The invention is a power output structure with convenient assemble and unassemble of the button cell and reliable conduction.

Owner:卢润侨 +1

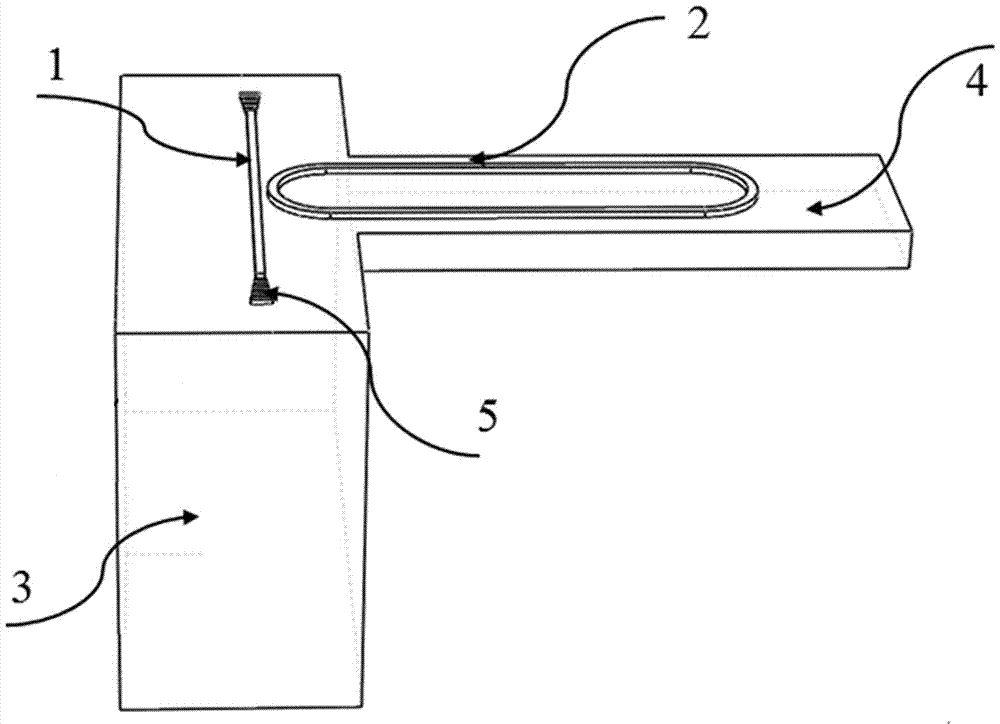

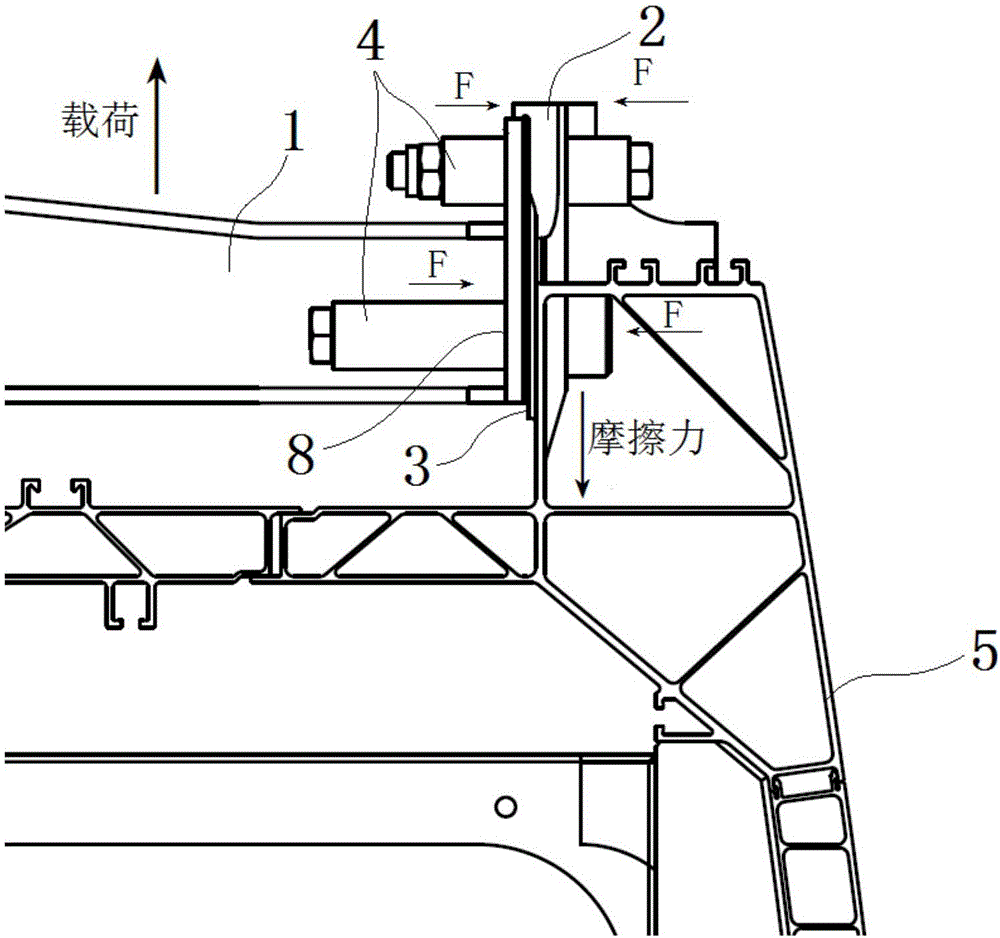

Suspension type monorail vehicle body and cross beam connection structure and suspension type monorail vehicle

ActiveCN106218648ASolve the problem of degrees of freedomFreedom releaseMonorailsRailway transportEngineeringMonorail

The invention discloses a suspension type monorail vehicle body and cross beam connection structure and a suspension type monorail vehicle. The suspension type monorail vehicle body and cross beam connection structure comprises connection plates fixed to the two ends of an edge beam of a top cover of a suspension type vehicle body, and a cross beam used for being fixedly connected with a traveling component. Barbs are arranged on the inner side faces of the tops of the connection plates. End plates are arranged at the two ends of the cross beam. The top of each end plate is located in the barb of the corresponding connection plate. Each end plate is fixedly connected with the corresponding connection plate. Preferably, the cross beam and the end plates are of an integrally formed structure. Through the arrangement of the barb structure, the cross beam is matched with the barbs of the connection plates, so that connection between the cross beam and the suspension type vehicle body is more reliable, and meanwhile the independence on the welding mode is avoided.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

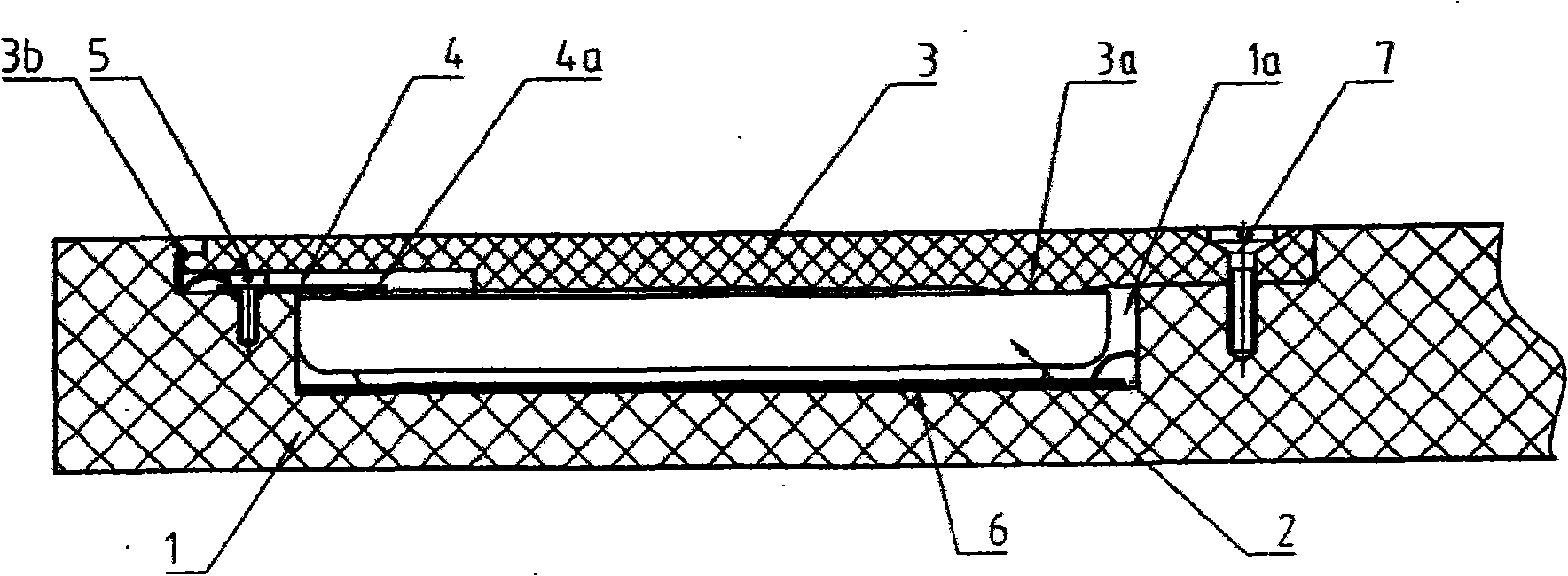

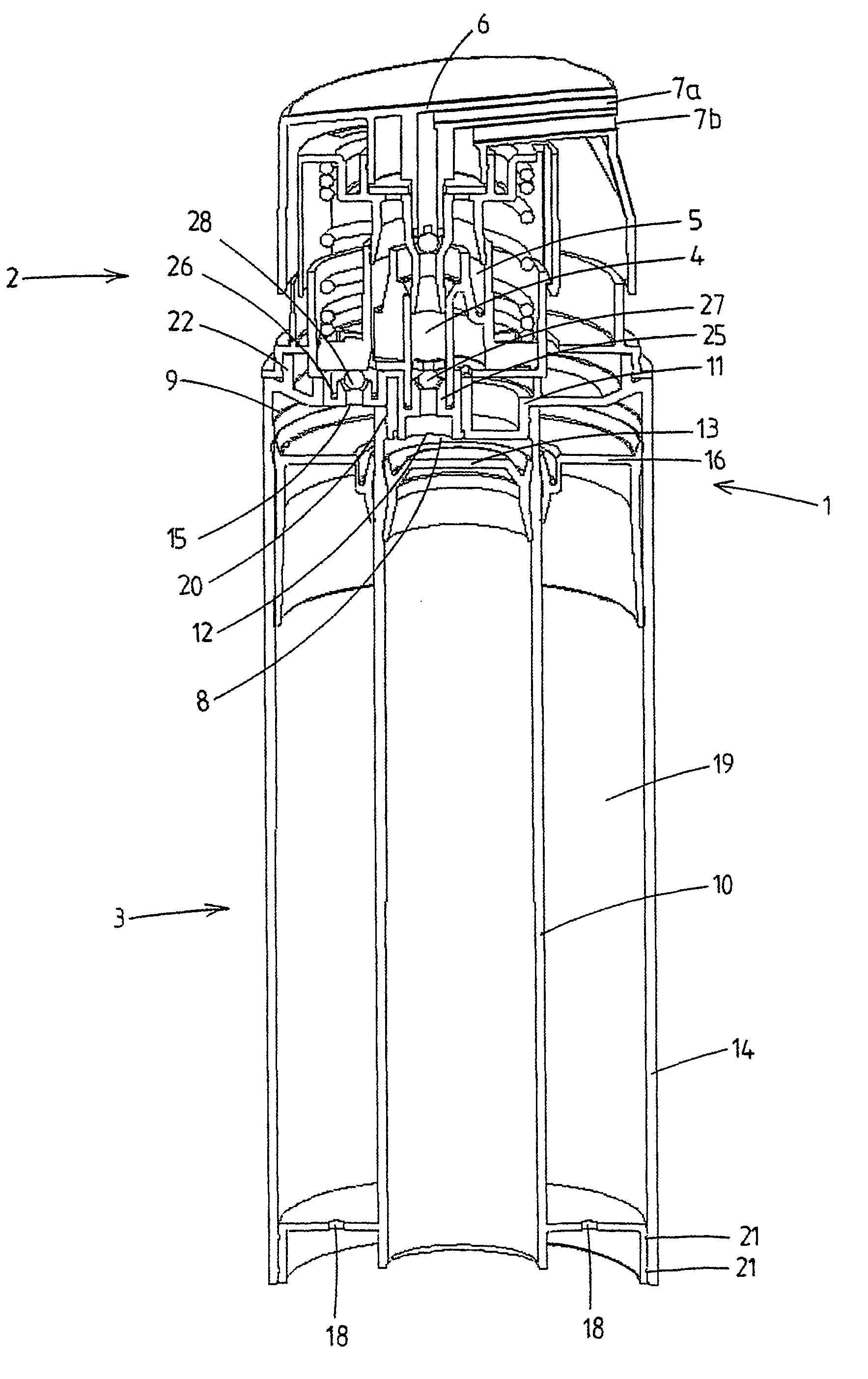

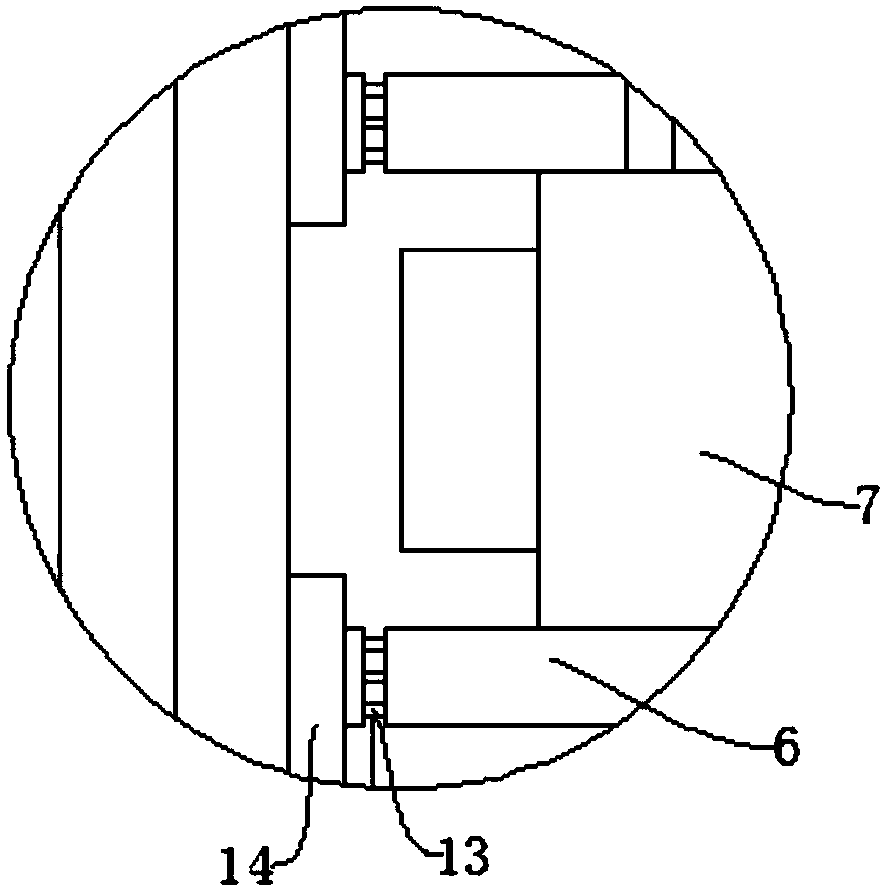

Dispensing unit

InactiveUS7588170B2Volume of reservoir can be reducedLower the volumeLiquid transferring devicesSolid materialEngineeringFluid - substance

The invention relates to a dispensing unit for dispensing two fluid substances. The dispensing unit comprises a pump assembly (2) having a first (4) and a second pump (5) which can be actuated by common, manually operable operating means (6) in order to simultaneously dispense the two fluid substances. The dispensing unit also comprises a reservoir assembly (3), the reservoir assembly comprising two reservoirs which are each provided at an outlet side with an outlet and are each delimited by a movable piston (13, 16) on the other side from the outlet, which pistons, during the dispensing of the fluid substances, move toward the respective outlets. According to a first aspect of the invention, the reservoir assembly (3) and the pump assembly (2) are separate assemblies which can be coupled to one another, in such a manner that in the uncoupled state each reservoir can be filled through the outlet of the reservoir, after which the pump assembly and the reservoir assembly are coupled to one another.

Owner:AIRSPRAY INT

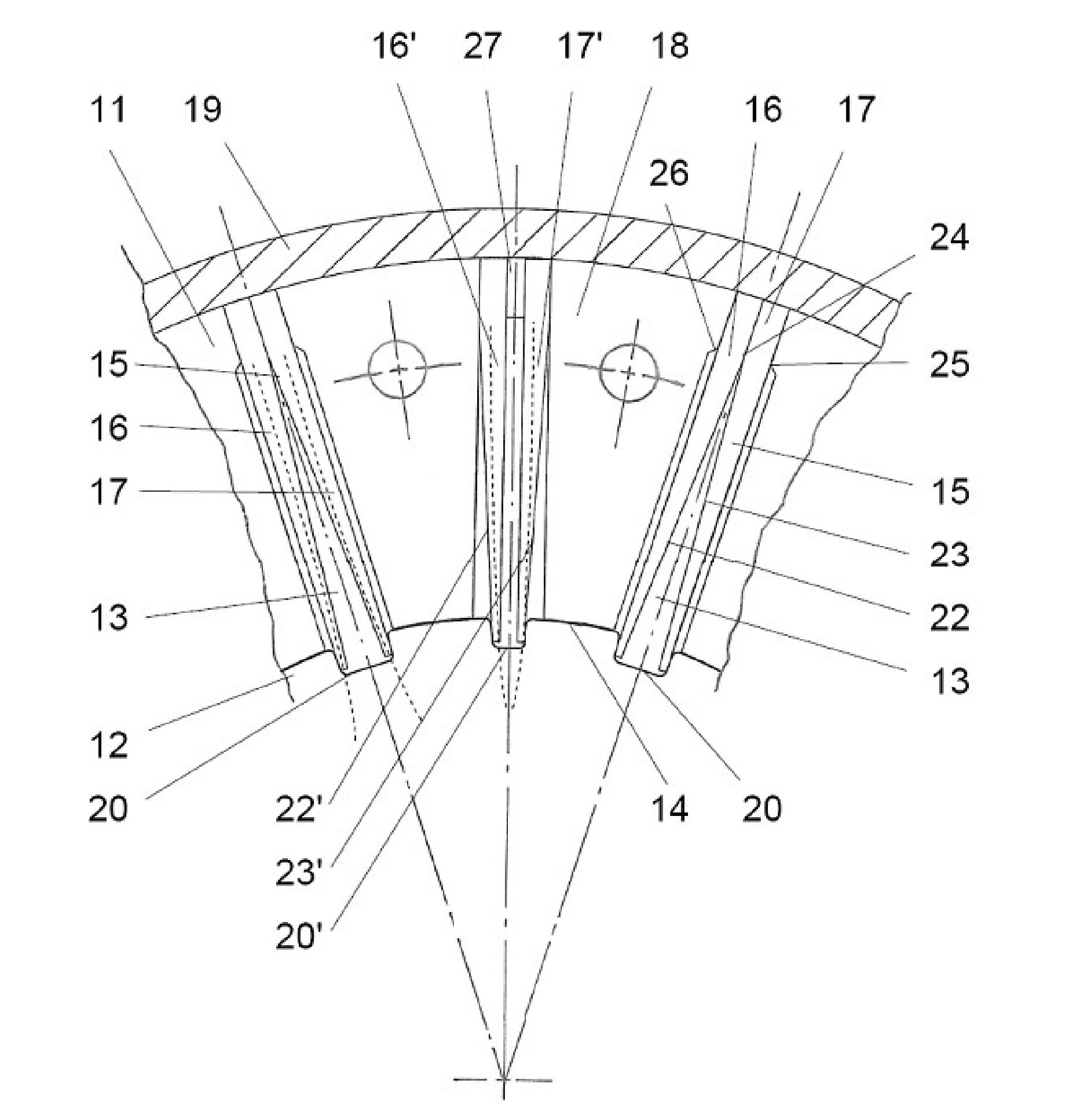

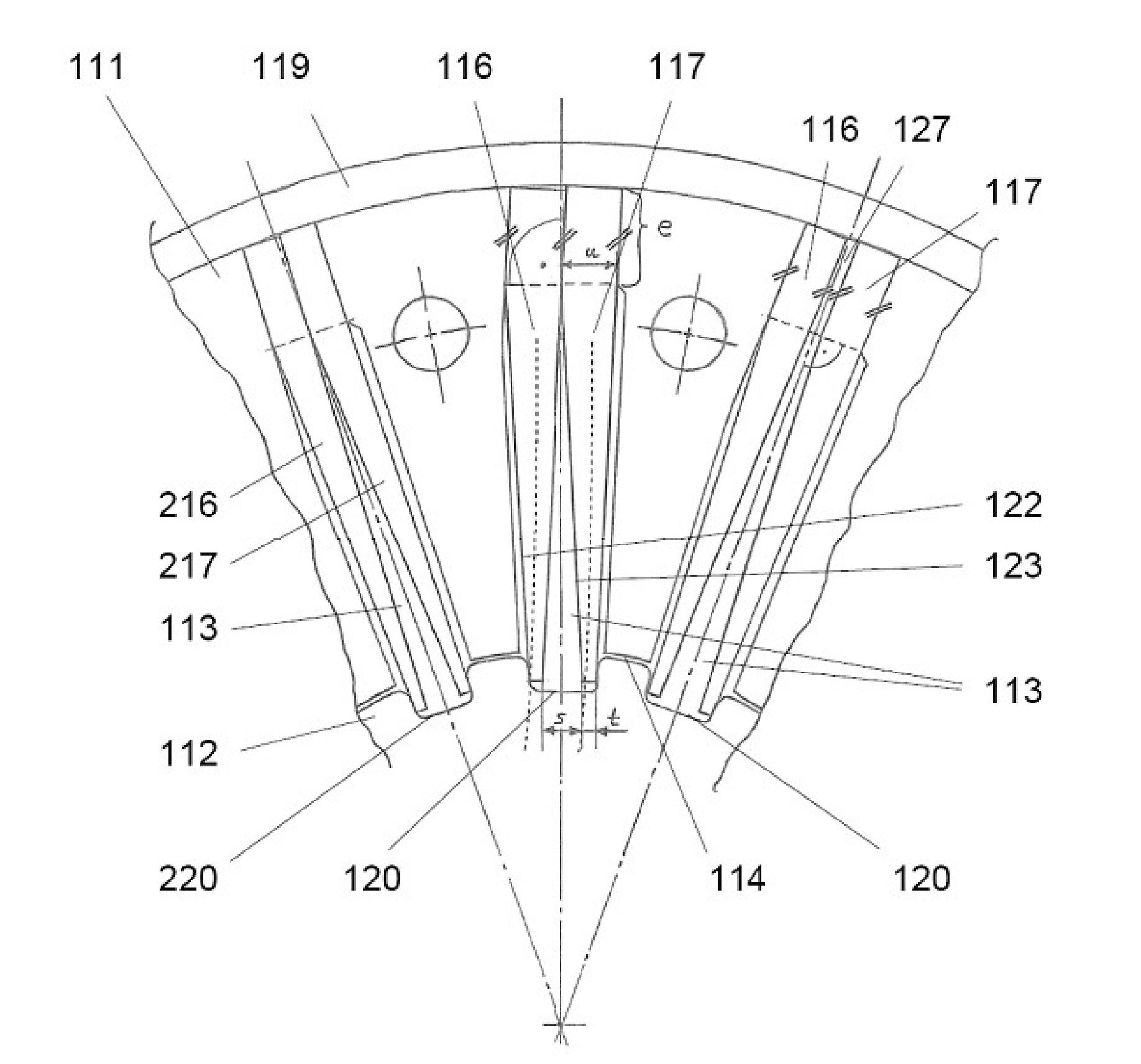

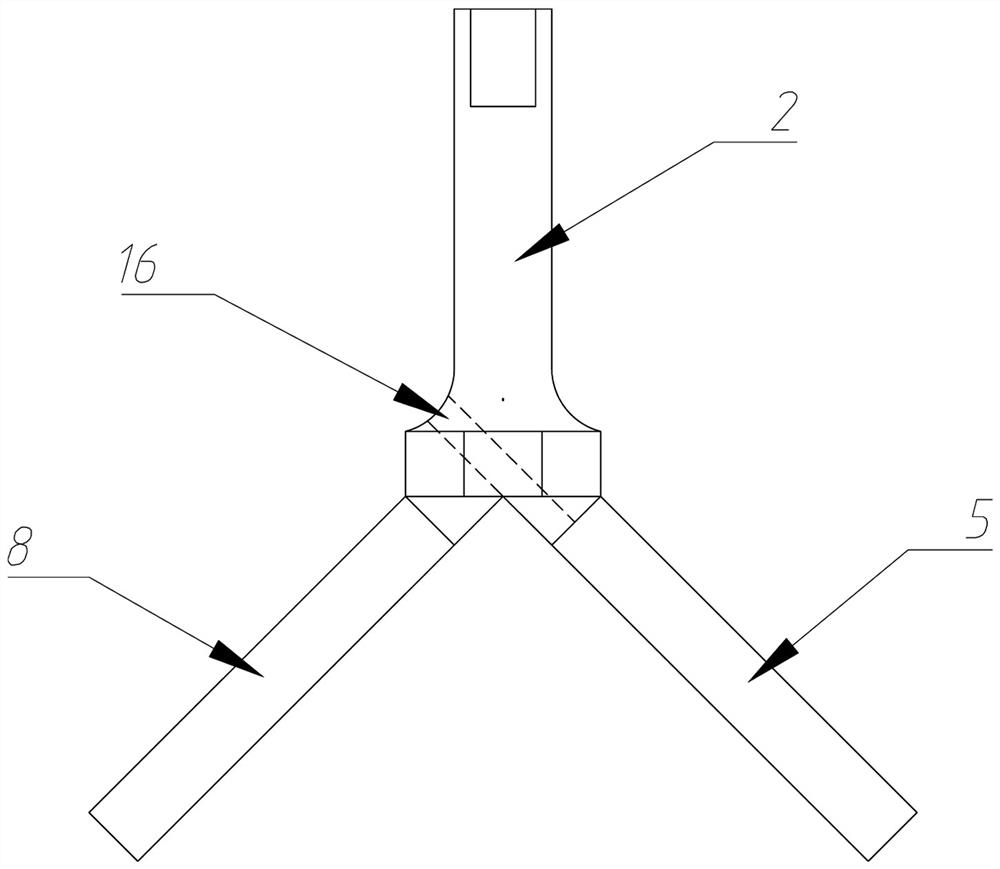

Torsional vibration damper

ActiveCN102072277AMaintain mean stressEasy to processRotating vibration suppressionEngineeringTorsional vibration

A torsional vibration damper comprises an outer housing (11), an inner part (12) that is concentric relative to the outer housing (11), a plurality of chambers (13) formed between the outer housing (11) and the inner part (12), which arc filled with a damping medium and are connected to one another through overflow channels (14), and a plurality of leaf spring configurations (16, 17, 16', 17') that are arranged in the chambers (13) and join the outer housing (11) and the inner part (12) with one another in a torsionally flexible manner. The leaf spring configurations (16, 17, 16', 17') have machining-induced deflections. Two leaf springs with substantially similar deflections are each arranged within a chamber (13). The leaf spring pairs may be arranged in a mirror-image array or in parallel to one another. Thus, the manufacturing cost of a torsional vibration damper can be reduced, while its compact outer dimensions can be maintained.

Owner:ELLERGON ANTRIEBSTECHN

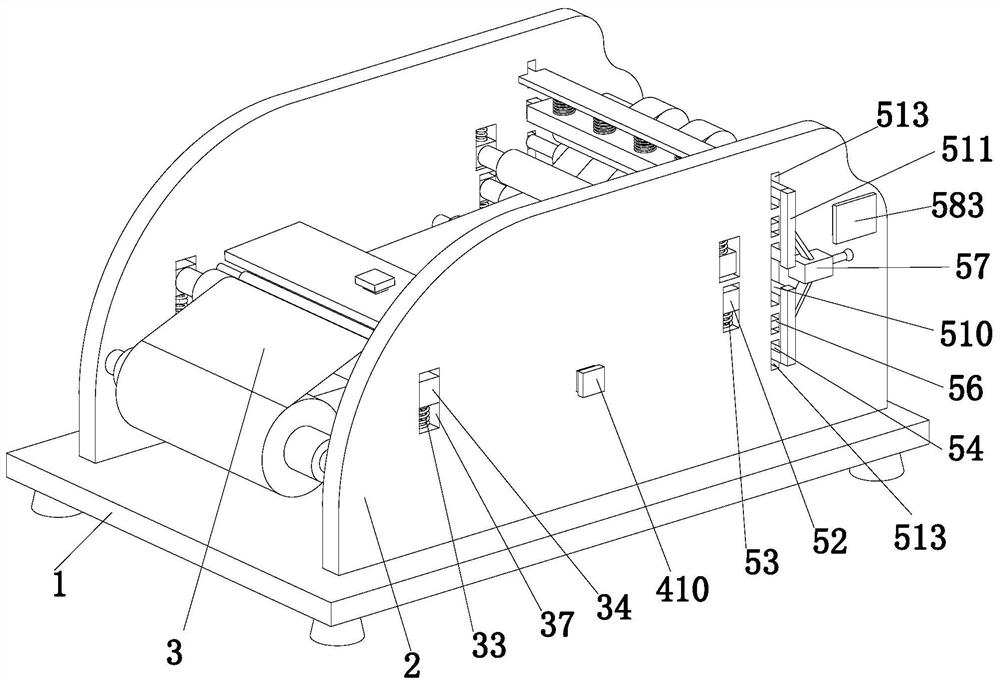

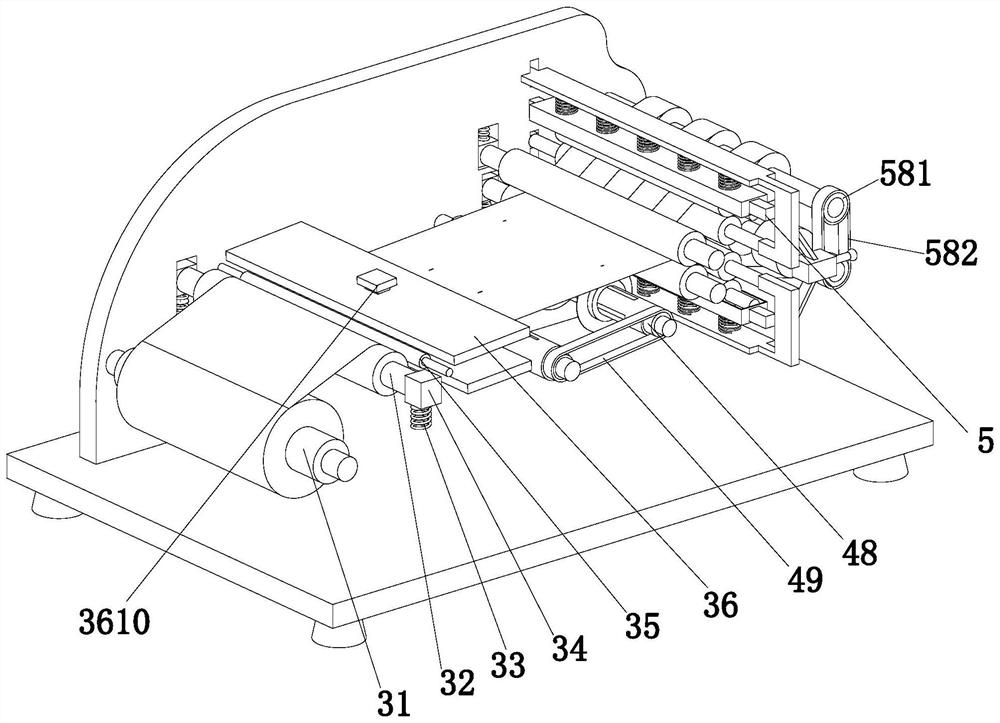

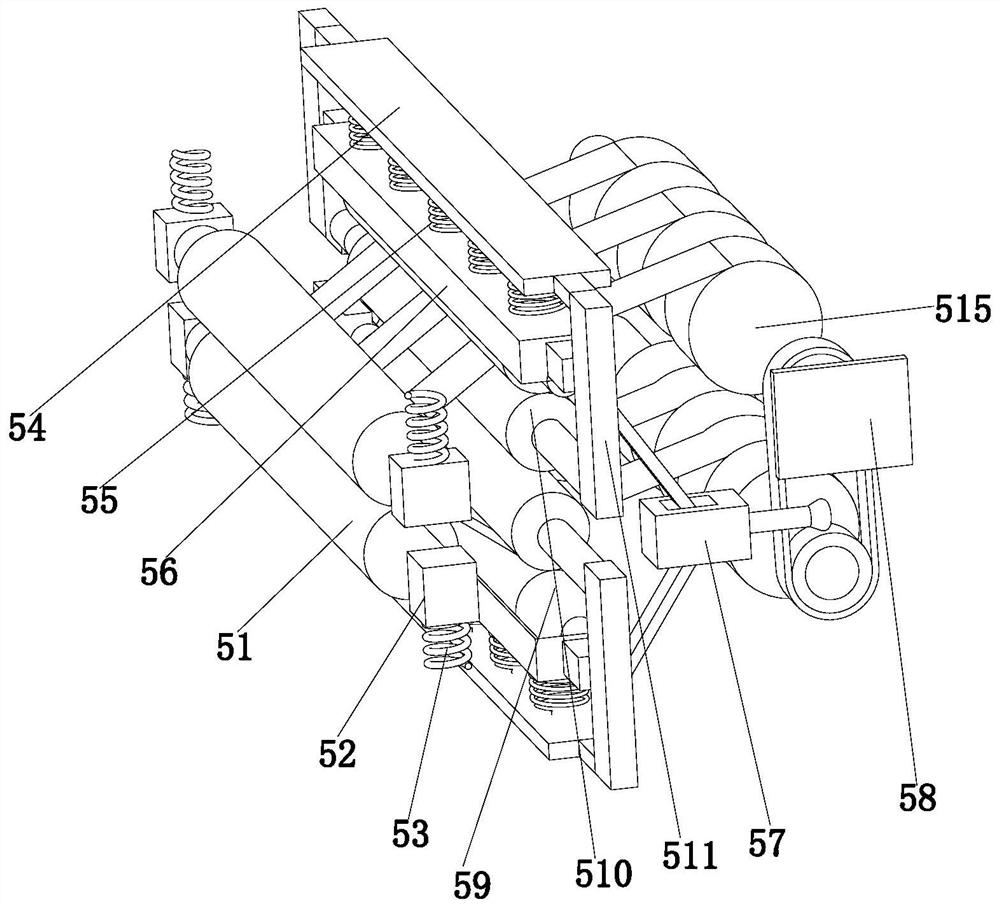

Polymer plastic film preparing processing system

PendingCN113071947ASolve the disadvantages of slittingNot prone to tearingArticle deliveryWebs handlingPolymer scienceThin membrane

The invention provides a polymer plastic film preparing processing system. The polymer plastic film preparing processing system comprises a base, a wall base, an unwinding mechanism, a slitting mechanism and a winding mechanism. The invention provides the polymer plastic film preparing processing system which can overcome the defects existing in current polymer plastic film slitting: a, in the polymer plastic film slitting process, a film vibrates due to some objective factors such as artificial real objects and air flow, in the film slitting process, the film does not make contact with slitting tools, and film slitting failure is caused; b, when the film is subjected to multi-section slitting, due to the fact that the tools are distributed too densely, the film is torn due to the fact that prestress generated by the film is too large, and the ideal slitting effect cannot be achieved; and c, the film is of an elastic structure, the film is prone to shrinkage after being cut excessively, and the phenomena of wrinkling and edge deviation are prone to occurring in the film rolling operation.

Owner:刘雁燕

Wind energy facility with drive train

InactiveCN107288825ASmall torque receiving capacityImprove securityEngine fuctionsShaftsFixed bearingEnergy facilities

The invention relates to a wind energy facility with a drive train (1). The invention relates to a wind turbine with a drive train (1) comprising a rotor shaft (2) and a planetary gear (10). The rotor shaft (2) is fixed and play-free with the planet carrier (14) of the first gear stage (11). Furthermore, the rotor shaft (2) on the side facing away from the first gear stage (11) side (3) with a roller bearing (5) on a support structure (30) is mounted. The planetary carrier (14) connected to the rotor shaft (2) is mounted with a double-row roller bearing (20) in an X arrangement as a fixed bearing in a transmission housing (16), wherein the transmission housing (16) on at least one opposite the support structure (30 ) fixed support (31) is attached.

Owner:森维安有限公司

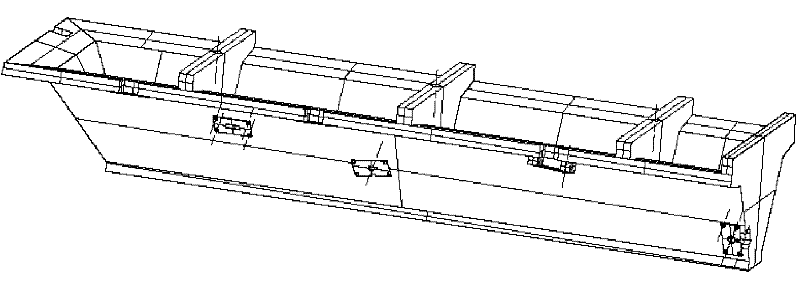

Steel-concrete composite continuous beam, connecting piece of hogging moment area of steel-concrete composite continuous beam and construction method

InactiveCN112376386AEnsure safetyIncreased durabilityBridge structural detailsBridge erection/assemblyBridge deckContinuous beam

The invention discloses a steel-concrete composite continuous beam, a connecting piece of a hogging moment area of the steel-concrete composite continuous beam and a construction method. The connecting piece comprises a perforated plate, transverse steel bars and a foam filling material; the perforated plate is fixedly welded to a top plate of a hogging moment area steel beam, the length extendingdirection of the perforated plate is parallel to the bridge direction of a bridge, a row of oval holes are formed in the perforated plate in the length extending direction of the perforated plate, and the long axis direction of each oval hole is parallel to the length extending direction of the perforated plate. The number of the transverse steel bars is consistent with that of the oval holes; the length extension direction of each transverse steel bar is parallel to the transverse bridge direction of the bridge, and the transverse steel bars penetrate through the oval holes in a one-to-one correspondence mode; and the foam filling material is a filling block body with a complete circular through hole in the middle. Therefore, the steel beam in the hogging moment area and the concrete topplate in the hogging moment area can longitudinally slide, the tensile stress of a bridge deck slab in the area is effectively reduced, meanwhile, the transverse anti-shearing effect and the verticalanti-pulling capacity are reserved, and the safety and durability of the bridge are improved.

Owner:SOUTHEAST UNIV

Active-control-based deep foundation pit profile steel supporting system

The invention discloses an active-control-based deep foundation pit profile steel supporting system. The active-control-based deep foundation pit profile steel supporting system comprises concrete poured deep foundation pit walls and embedded parts buried in the deep foundation pit walls. Steel supporting seats fixedly connected with the embedded parts are tightly arranged on the sidewalls of thedeep foundation pit walls. Multiple steel enclosing purlins are detachably connected between the steel supporting seats on the deep foundation pit walls of the two sides, wherein a steel support pouring jacket is detachably mounted between one end of each steel enclosing purlin and the corresponding steel supporting seat; and a jack is mounted in each steel support pouring jacket. The active-control-based deep foundation pit profile steel supporting system has the beneficial effects that prestressing force of a steel supporting system can be actively adjusted according to deformation of a foundation pit so as to generate stable supporting stress to an underground diaphragm wall to guarantee no deformation of a foundation pit enclosure structure, an enclosure wall body and an underground diaphragm wall body; and the safety of facilities on the periphery of the foundation pit is protected.

Owner:重庆建工第八建设有限责任公司

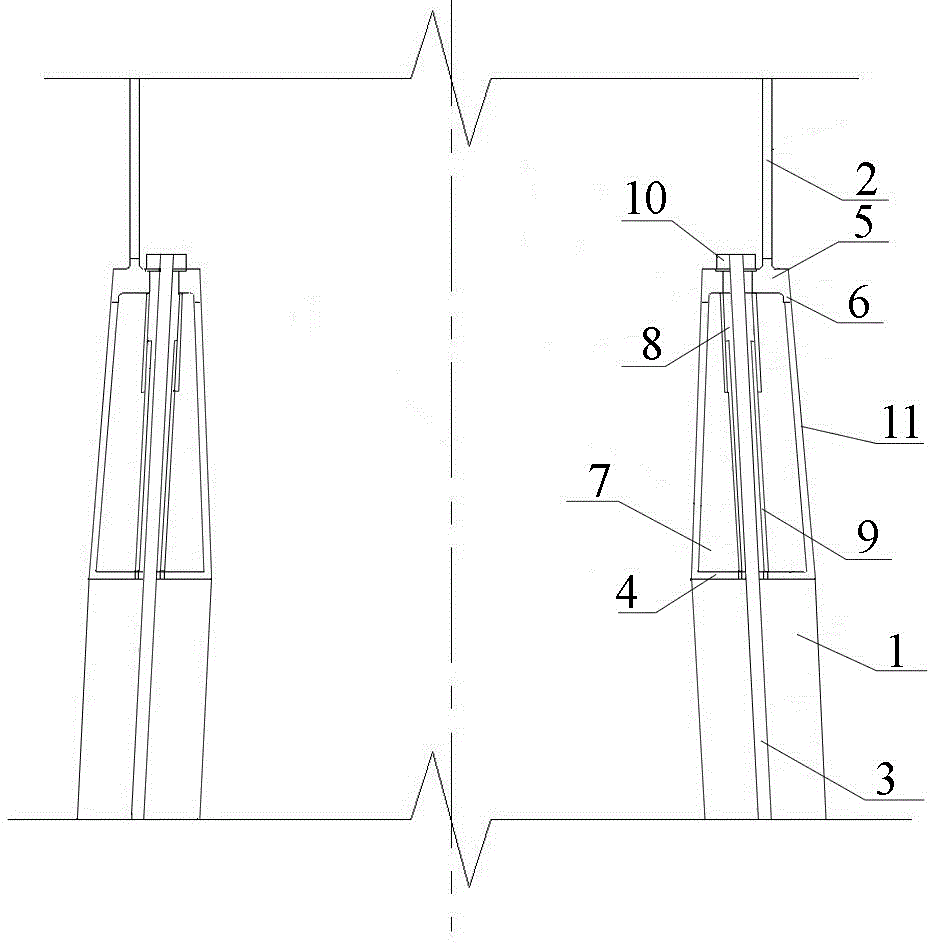

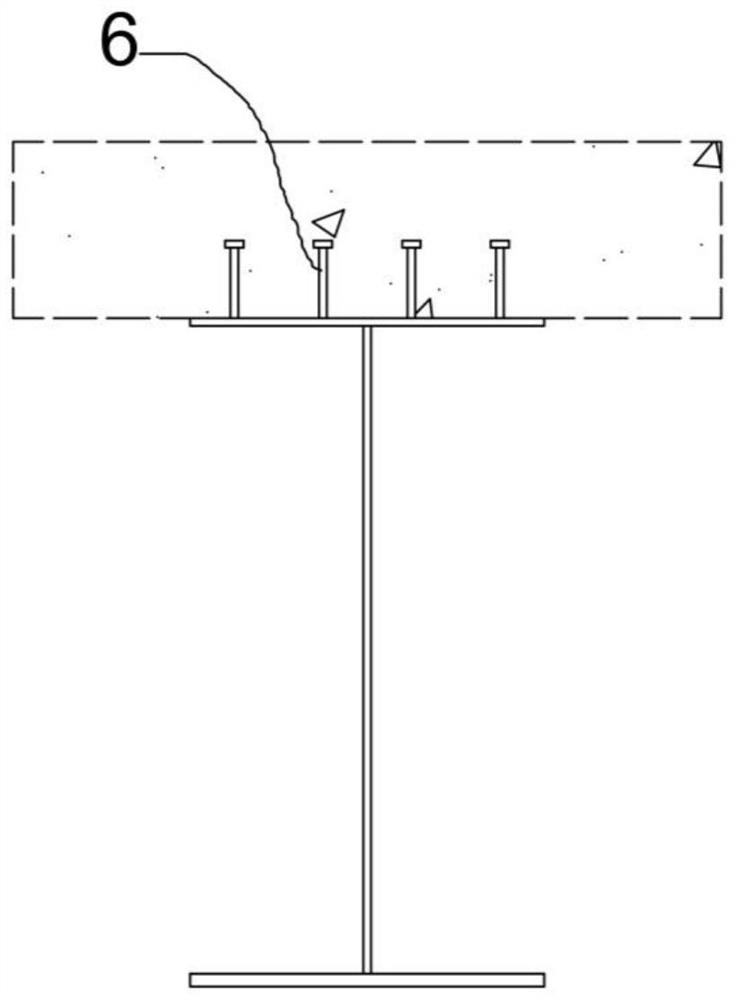

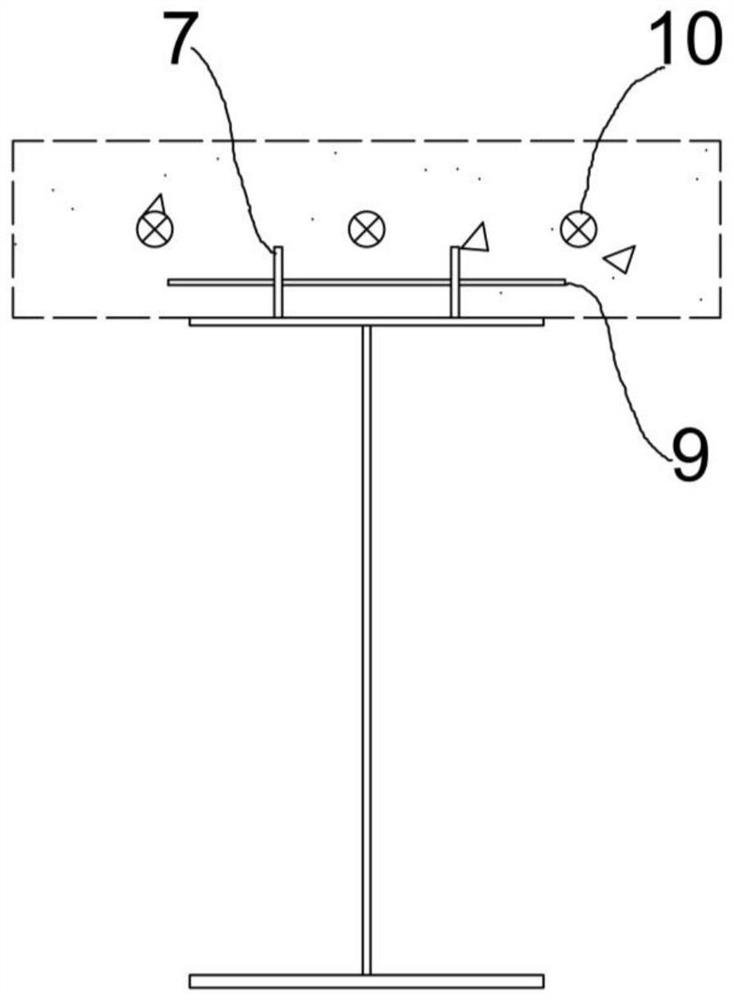

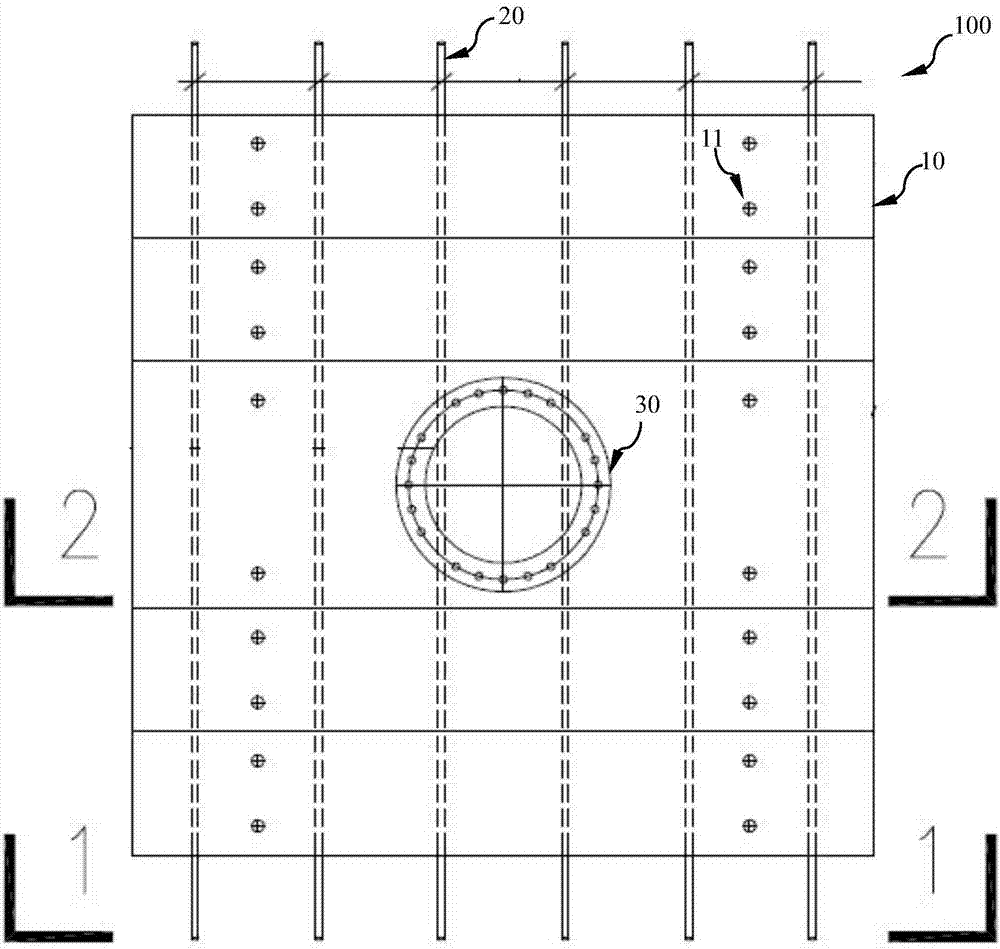

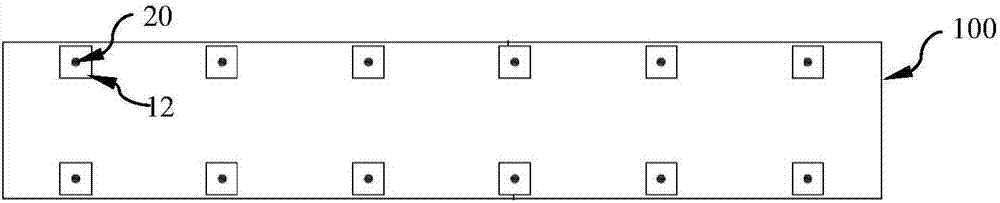

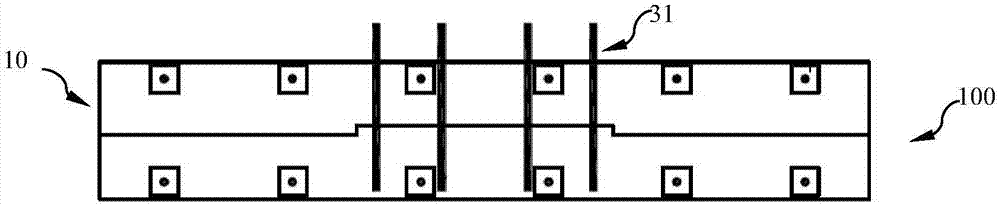

Limited prestressed precast concrete foundation, communication tower building and construction method

A limited prestressed prefabricated concrete foundation, comprising: a plurality of strip-shaped prefabricated concrete blocks arranged side by side, a single strip-shaped prefabricated concrete block is provided with a plurality of through holes in the cross section, and adjacent strip-shaped prefabricated concrete blocks are in contact with each other And the through holes are in the corresponding positions; a plurality of prestressed steel strands equal to the number of through holes, the prestressed steel strands pass through the through holes; two anchors are respectively connected to the two ends of the prestressed steel strands Fixed, prestressed strands are limited prestressed strands. Under the action of limited prestress, the precast concrete blocks will not be disengaged under normal wind loads and will remain in close contact; under design wind loads, although the limited prestress is not enough to ensure that the concrete blocks will not be disengaged, it can pass through the concrete The mutual pressure between blocks and the tension of a layer of steel strands ensure the safety of the basic structure. Therefore, the foundation of the invention not only ensures the overall structure, but also reduces the prestress of the steel strands and improves the reliability of the structure.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

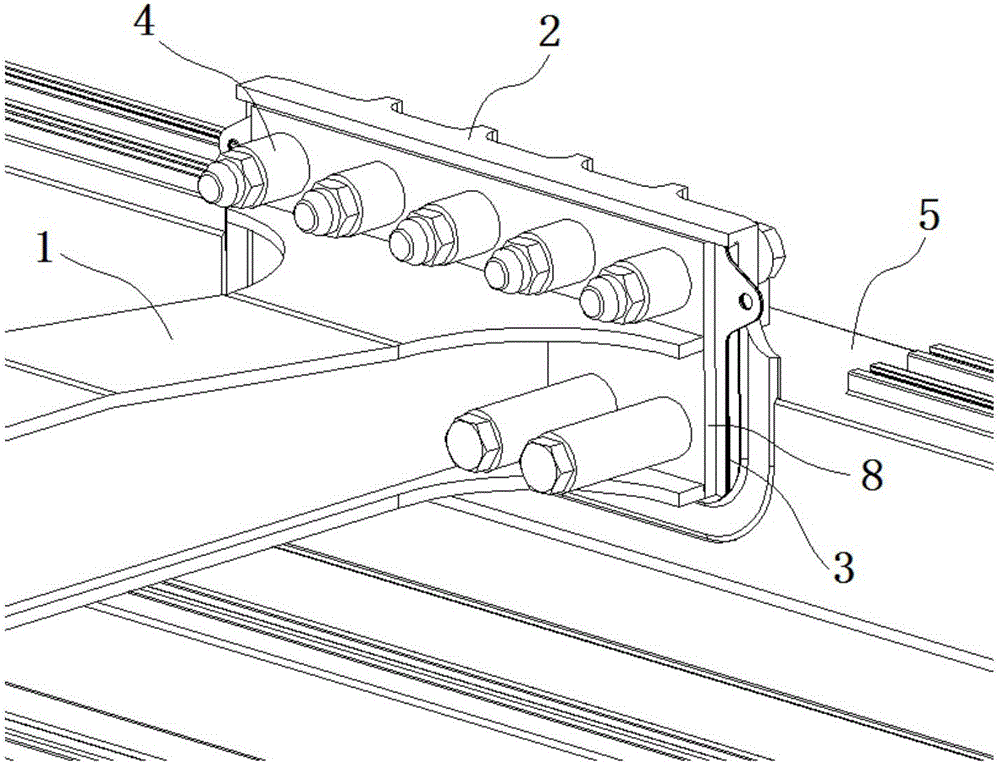

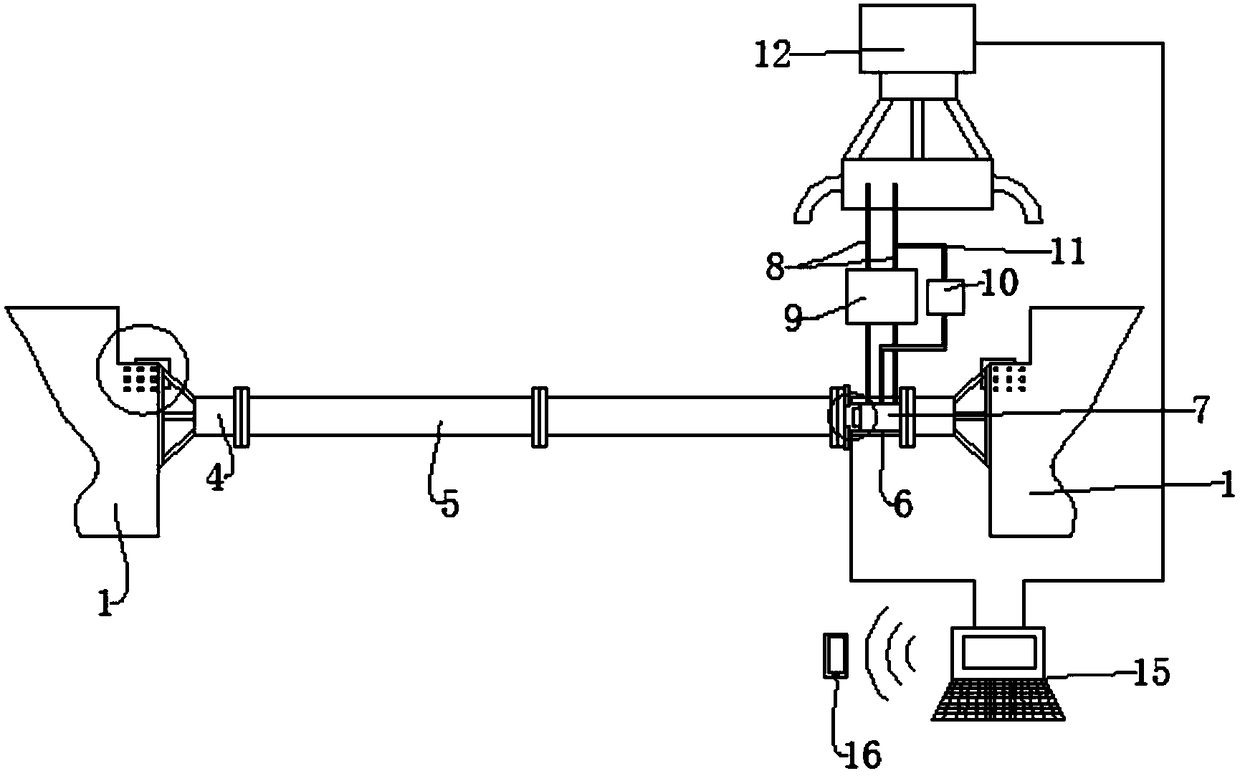

Anchor cable prestress control device and using method

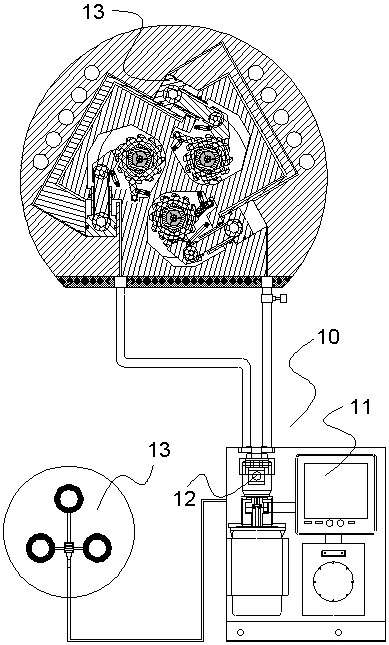

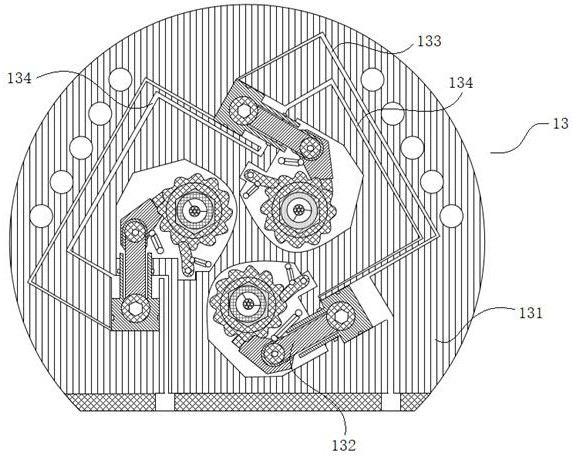

ActiveCN114738024ATime-consuming and laborious to solvePrestressedWind energy generationAnchoring boltsManipulatorElectrical connection

The invention relates to an anchor cable prestress control device and a using method, and the anchor cable prestress control device comprises a prestress adjusting assembly which comprises a control structure, a driving structure and an execution structure, the control structure is electrically connected with the driving structure, the driving structure is connected with the execution structure, and the execution structure comprises a manipulator shell and a manipulator; the lock assembly comprises a clamping piece, an inner anchor ring, an outer anchor ring and a lock shell, the clamping piece clamps the anchor cable, the clamping piece is fixed in the inner anchor ring, the inner anchor ring is located in the outer anchor ring and matched with the outer anchor ring through threads, and the outer anchor ring is rotatably installed in the lock shell; the prestress detection structure is electrically connected with the control structure, and the prestress detection structure is arranged on the lock shell; the manipulator is matched with the outer anchor ring to drive the outer anchor ring to rotate, and the rotation of the outer anchor ring drives the inner anchor ring to move axially. The anchor cable solves the problem that in the prior art, time and labor are wasted in stress compensation of anchor cables.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

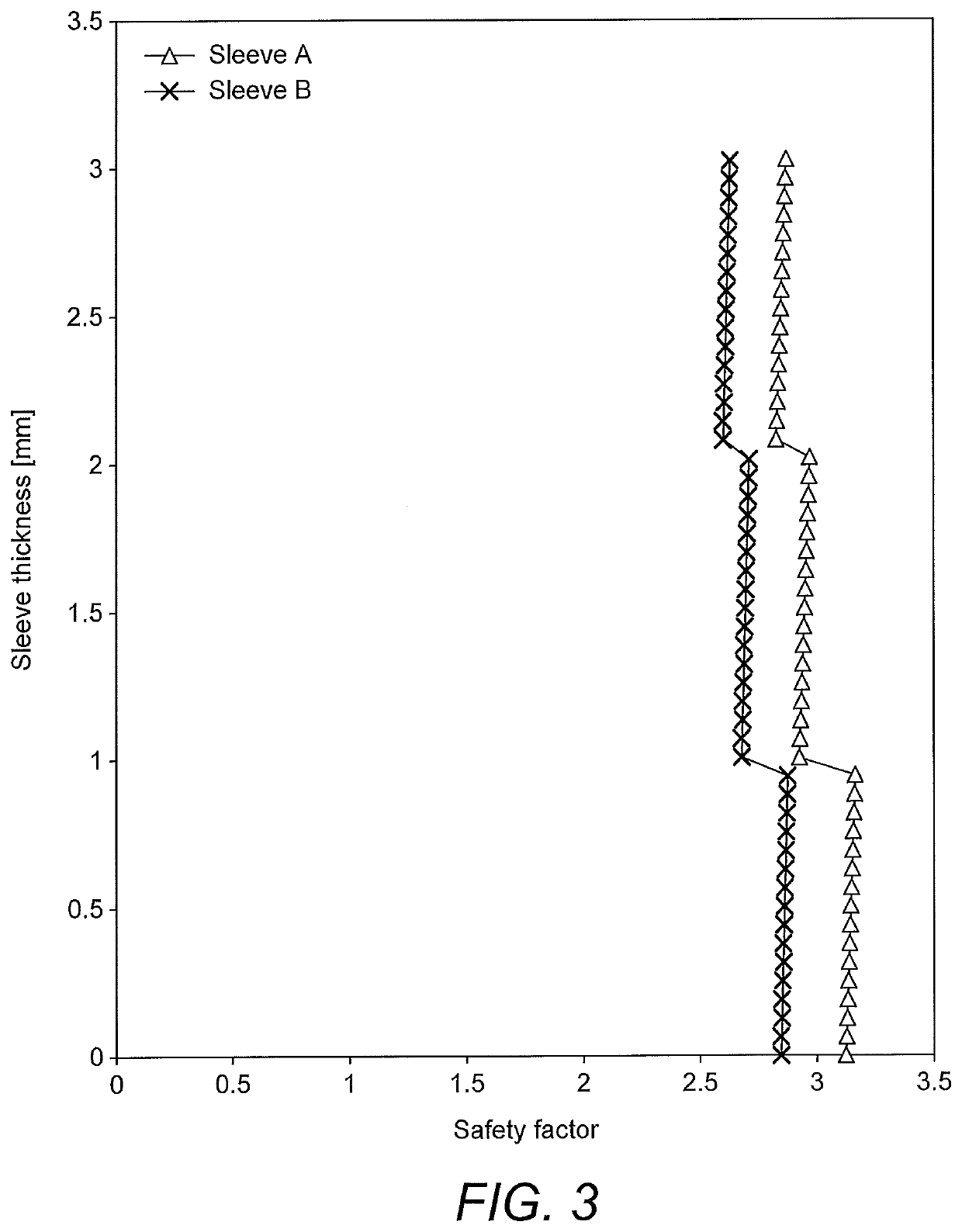

Improved method for manufacturing a rotor

PendingUS20220190660A1Reduce prestressIncreased riskMagnetic circuit rotating partsManufacturing stator/rotor bodiesFiber-reinforced compositeElectric generator

A method of manufacturing a rotor for a generator of an aircraft engine. The method includes providing a rotor body; mounting at least one magnet on the rotor body; wrapping a tow around the rotor body and the at least one magnet to form a wrapped tow having a plurality of layers overlaid in the radial direction; and curing the wrapped tow to form at least a part of a fibre-reinforced composite sleeve configured to retain the at least one magnet on the rotor body. The step of wrapping includes applying a controlled tension to the tow during wrapping. The controlled tension is varied according to the radial position of the layer being wrapped.

Owner:SAFRAN ELECTRICAL & POWER

Assembly type steel and concrete arch bridge T beam plate

ActiveCN104727213AIncrease resistance to load deflectionSimple structureBridge structural detailsArch-type bridgeWave shapeT-beam

The invention discloses an assembly type steel and concrete arch bridge T beam plate. The assembly type steel and concrete arch bridge T beam plate comprises a bottom plate, a top plate and wave-shaped steel webs arranged between the bottom plate and the top plate. The bottom plate is in an arch shape along a bridge in the axial direction, connecting vertical plates are arranged on the arch-shaped bottom plate, the lower end faces of the connecting vertical plates are welded to the arch-shaped bottom plate, the upper end faces of the connecting vertical plates are planes, and longitudinal connecting plates with threaded holes are welded to the upper end faces of the connecting vertical plates. Longitudinal steel plates are welded to the upper end faces and the lower end faces of the wave-shaped steel webs respectively, and the upper end faces and the lower end faces of the wave-shaped steel webs are connected with the longitudinal connecting plates and the top plate through connecting parts. Split manufacturing and transporting are adopted, it is only needed to perform connecting and fastening through bolts or screws, the assembly type steel and concrete arch bridge T beam plate is simple in structure, easy to construct, short in construction period and reliable in quality because the T beam plate is produced by the adoption of factory standardization; because the arch-shaped structure or the parabolic-arch-shaped structure is adopted for the bottom plate, resistance to load deflection of the bridge type can be substantially improved, and compared with a slab bridge, pre-stress can be omitted under the same span.

Owner:邢台路桥千山桥梁构件有限责任公司

Novel mine filling quick-setting enhanced additive

The invention provides a novel mine filling quick-setting enhanced additive and belongs to the technical field of underground filling of metal mines. The novel mine filling quick-setting enhanced additive comprises the following components in percentage by weight: 10-40wt% of a slurry rheological agent, 20-35wt% of an alkaline activator, 15-35wt% of an accelerator and 15-30wt% of an early strengthagent. According to the invention, the function of mine filling slurry is studied, the slurry rheological agent, the alkaline activator, the accelerator and the early strength agent are selected as raw materials, the ratio of the raw materials is adaptively researched, and finally, the novel mine filling quick-setting enhanced additive which enables mine filling slurry to have good flowing property, quick setting time and high early strength is obtained. And under the condition that the additive is used, the performance of a filling material can be effectively improved, it is guaranteed thatthe filling slurry can keep good rheological property, rapid hardening effect, high strength, good volume stability, low settling shrinkage rate and other characteristics under large-volume and different-concentration conditions, and all the properties are excellent.

Owner:HEBEI JINTAICHENG BUILDING MATERIAL

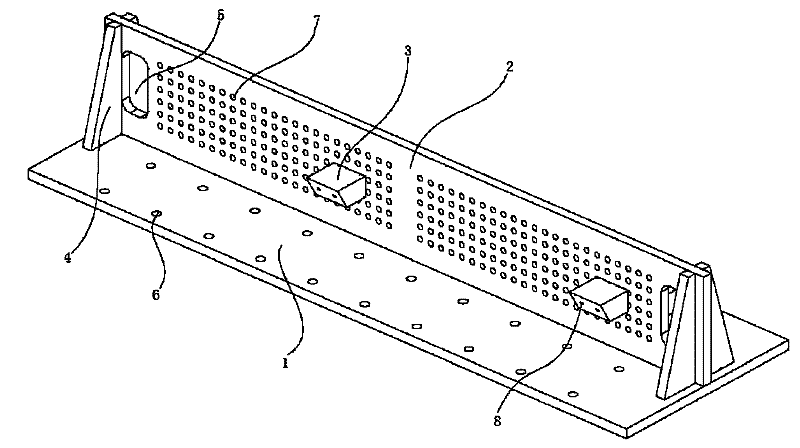

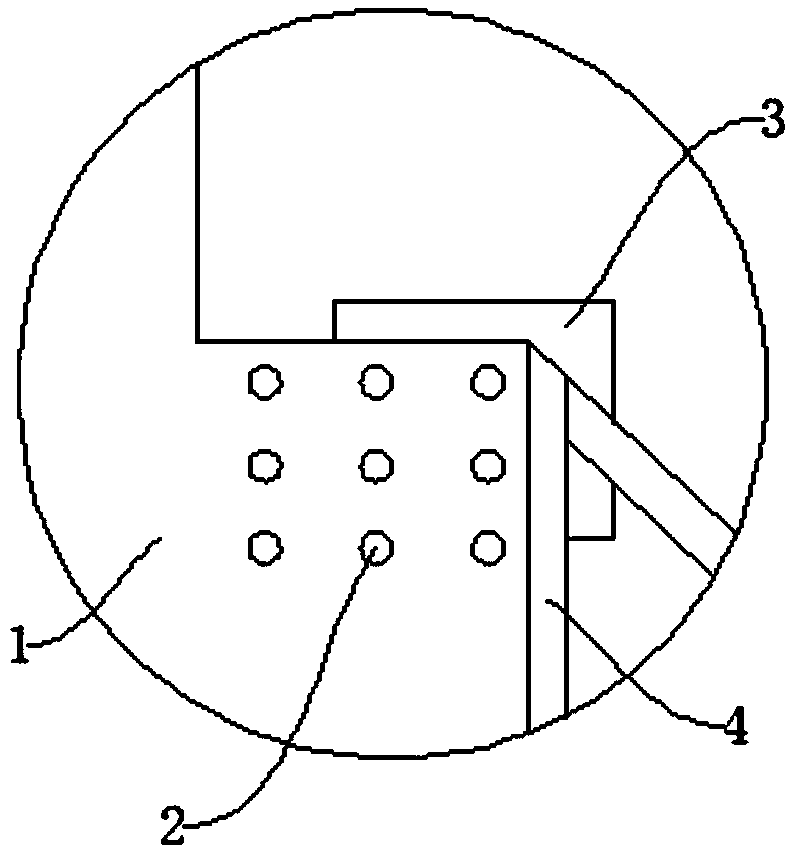

Elastic foil piece bearing top layer foil piece heat treatment tool capable of controlling shape and performance

ActiveCN108251631AGuaranteed radius of curvatureTo achieve the effect of shape controlFurnace typesHeat treatment furnacesDot matrixSurface oxidation

An elastic foil piece bearing top layer foil piece heat treatment tool capable of controlling the shape and performance comprises an inner mold which is loaded into an outer mold, a plurality of through grooves for allowing elastic foil pieces to be stored can be formed by the inner mold and the outer mold, and a bottom layer cover plate and a top layer cover plate arranged at the two ends of theinner mold and the outer mold are fixed to the outer mold through fastening bolts; in the heat treatment process, the elastic foil pieces are inserted into the through grooves formed by the outer moldand the inner mold, a preset curvature is formed, the curvature is fixed after heat treatment is conducted, and the effect of shape controlling is achieved; and the inner side of the outer mold and the outer side of the inner mold are provided with rectangular pit dot matrix in a manufactured mode, the ends of the outer mold and the inner mold are provided with through holes in a manufactured mode, and the through holes communicate with the rectangular pit dot matrix, and aluminum oxide powder added into the through holes makes contact with the elastic foil pieces through the rectangular pitdot matrix to reduce surface oxidation of the elastic foil pieces. The elastic foil piece bearing top layer foil piece heat treatment tool capable of controlling shape and performance can control heatdeformation of the foil pieces and meanwhile prevent surface oxidation of the foil pieces.

Owner:XI AN JIAOTONG UNIV

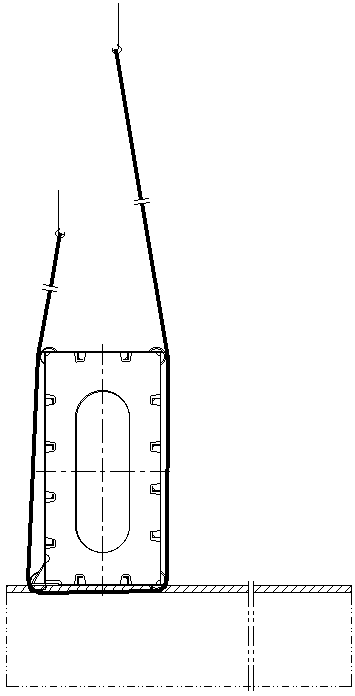

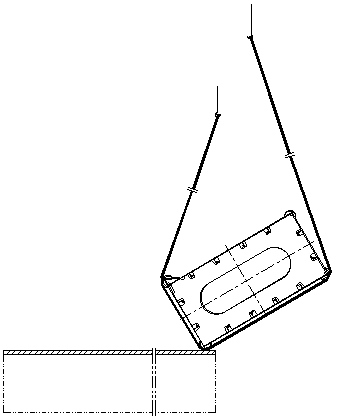

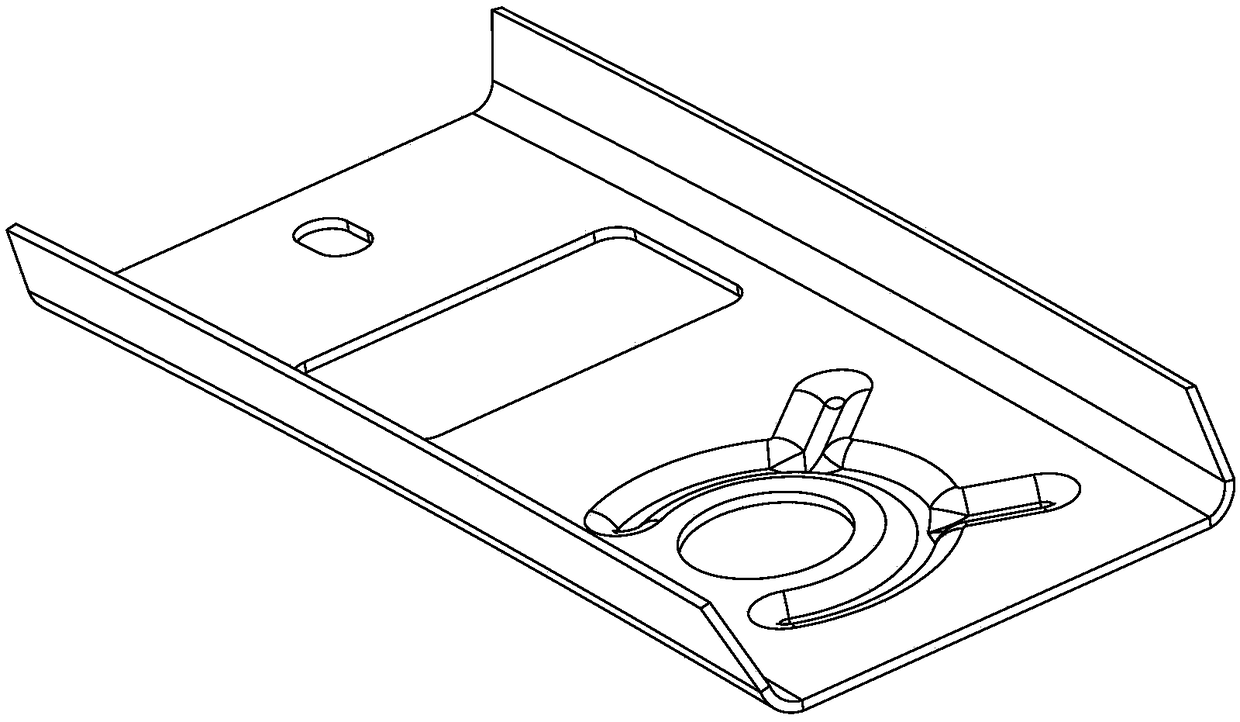

Overturning technology for ultra-large rail-mounted gantry crane girder structure in workshop

ActiveCN110835052AGuaranteed assembly accuracy and deformation controlReduce the generation of prestressLoad-engaging elementsGantry craneWire rope

The invention relates to an overturning technology for an ultra-large rail-mounted gantry crane girder structure in a workshop. The overturning technology is characterized by comprising the followingspecific technological steps that S1, assembling and welding of an auxiliary tool are conducted; S2, penetrating and inserting of a steel wire rope are conducted; S3, crane lifting and overturning areconducted; and S4, girder detection is conducted. According to the overturning technology, steel wire rope baffles used for containing steel wire ropes and main beam end corner protection tools are installed and welded to the center position and the four end corners of the two end positions of a girder, the steel wire ropes are matched with three cranes for simultaneous lifting and overturning, and therefore compared with the manner that a single crane is adopted for overturning, the manner of the technology can better ensure the assembling precision and the deformation control of the girderstructure; meanwhile generation of prestress is reduced, and torsion resistance can be better controlled; and the process time of subsequent overproof correction is shortened.

Owner:SHANGHAI ZHENHUA HEAVY IND

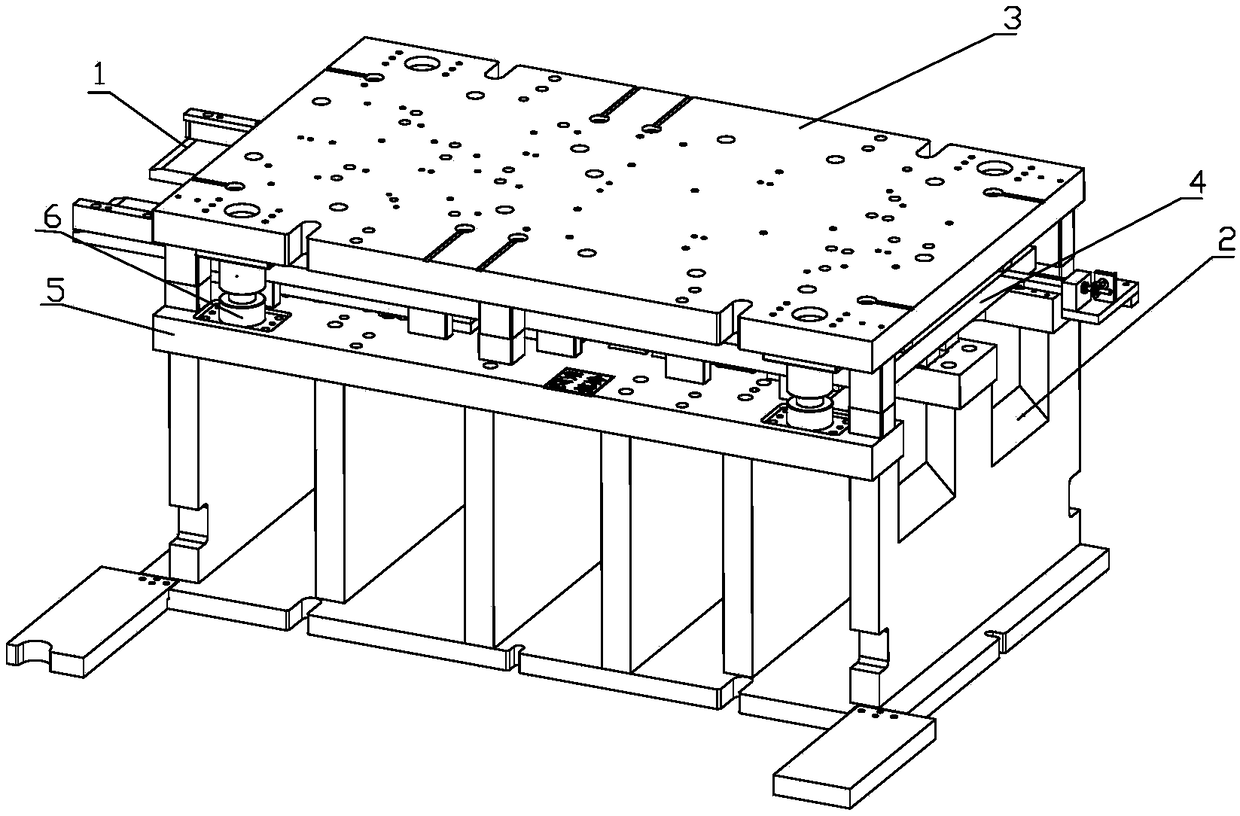

Car bumper accessory progressive die

The invention discloses a car bumper accessory progressive die. The progressive die includes an upper die body fixing plate used for fixing an upper die body, a material pressing plate and a lower diebody fixing plate used for fixing a lower die body, wherein the upper die body fixing plate, the material pressing plate and the lower die body fixing plate are arranged from top to bottom. Accordingto a machining procedure, the upper die body sequentially includes a concave mold used for machining C-shaped reinforcing ribs, a flanging forming mold and a macroporous stamping mold. The concave mold is positioned in the middle of the lower surface of the upper die body fixing plate, the macroporous stamping mold is positioned on one side of the upper die body fixing plate, and the flanging forming mold is positioned between the concave mold and the macroporous stamping mold; the material pressing plate is movably connected with the upper die body fixing plate and provided with through holes which correspond to the concave mold, the flanging forming mold and the macroporous stamping mold and are used for being penetrated by the concave mold, the flanging forming mold and the macroporousstamping mold. The lower die body includes a convex mold used for machining the C-shaped reinforcing ribs, a flanging forming convex mold and a macroporous discharge mold which are matched with the upper die body for use. According to the progressive die, multiple work procedures are combined, the space can be saved, the production time is shortened, the production efficiency is improved, and thestamping precision is improved.

Owner:CHONGQING LINGYUN AUTO PARTS

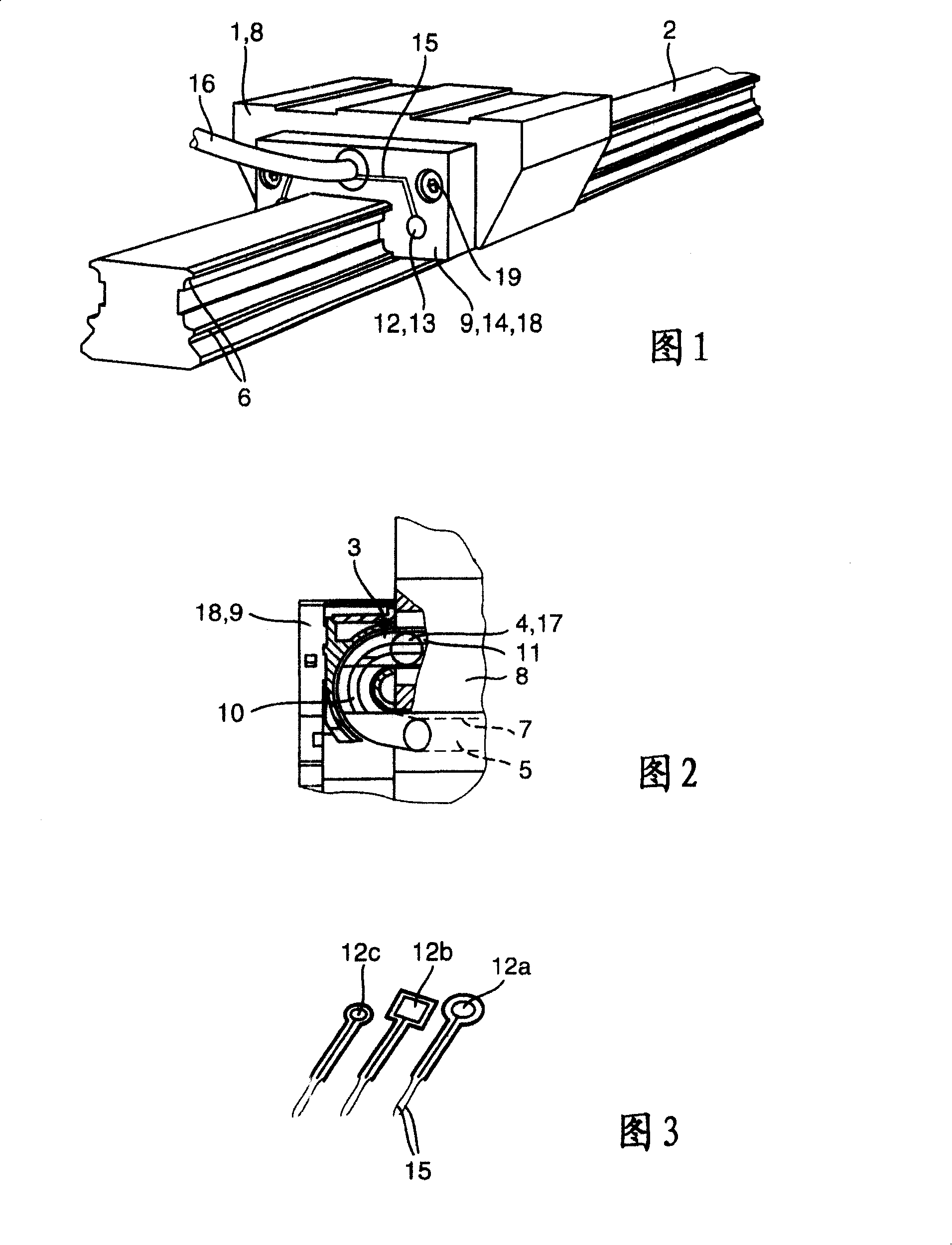

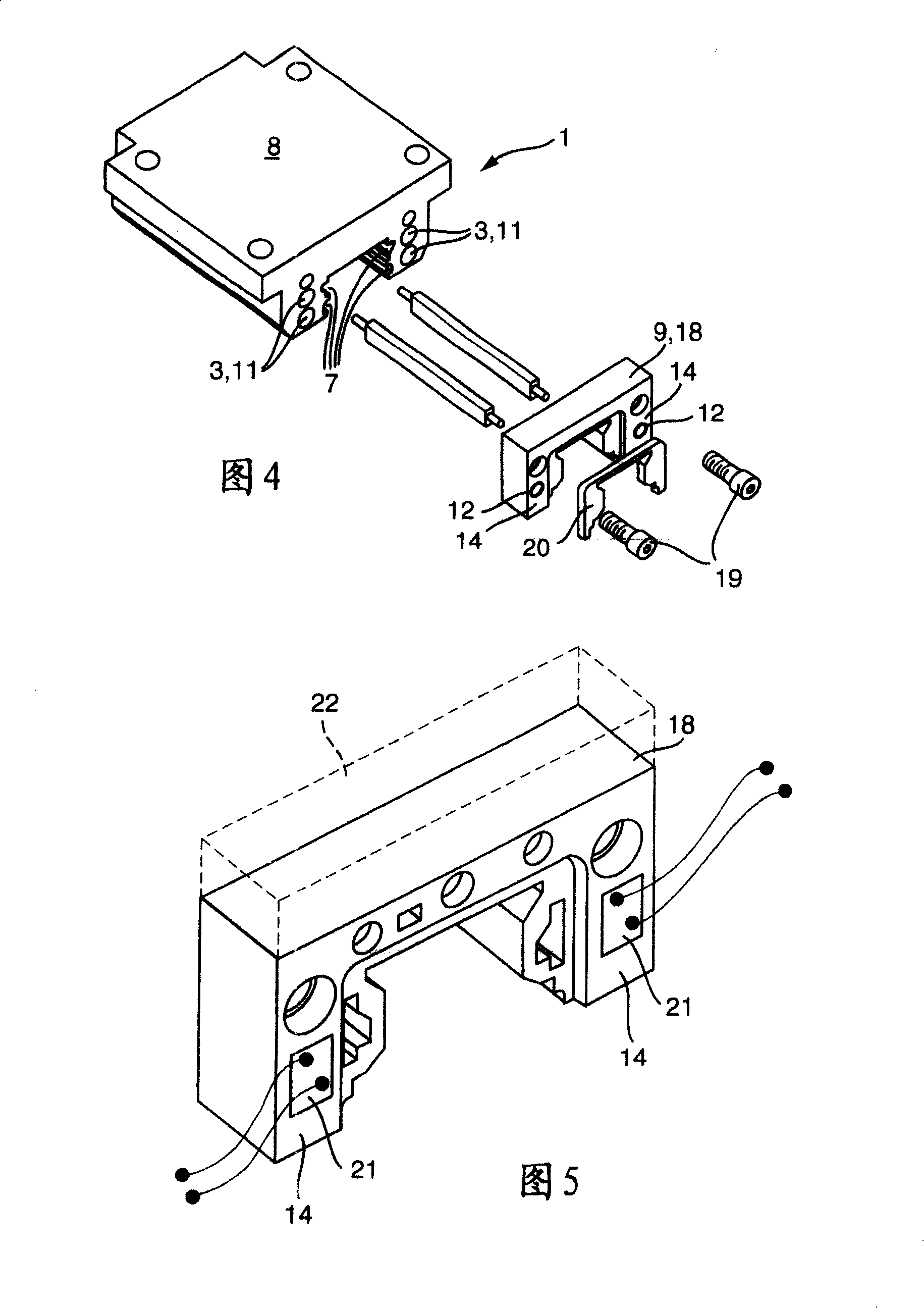

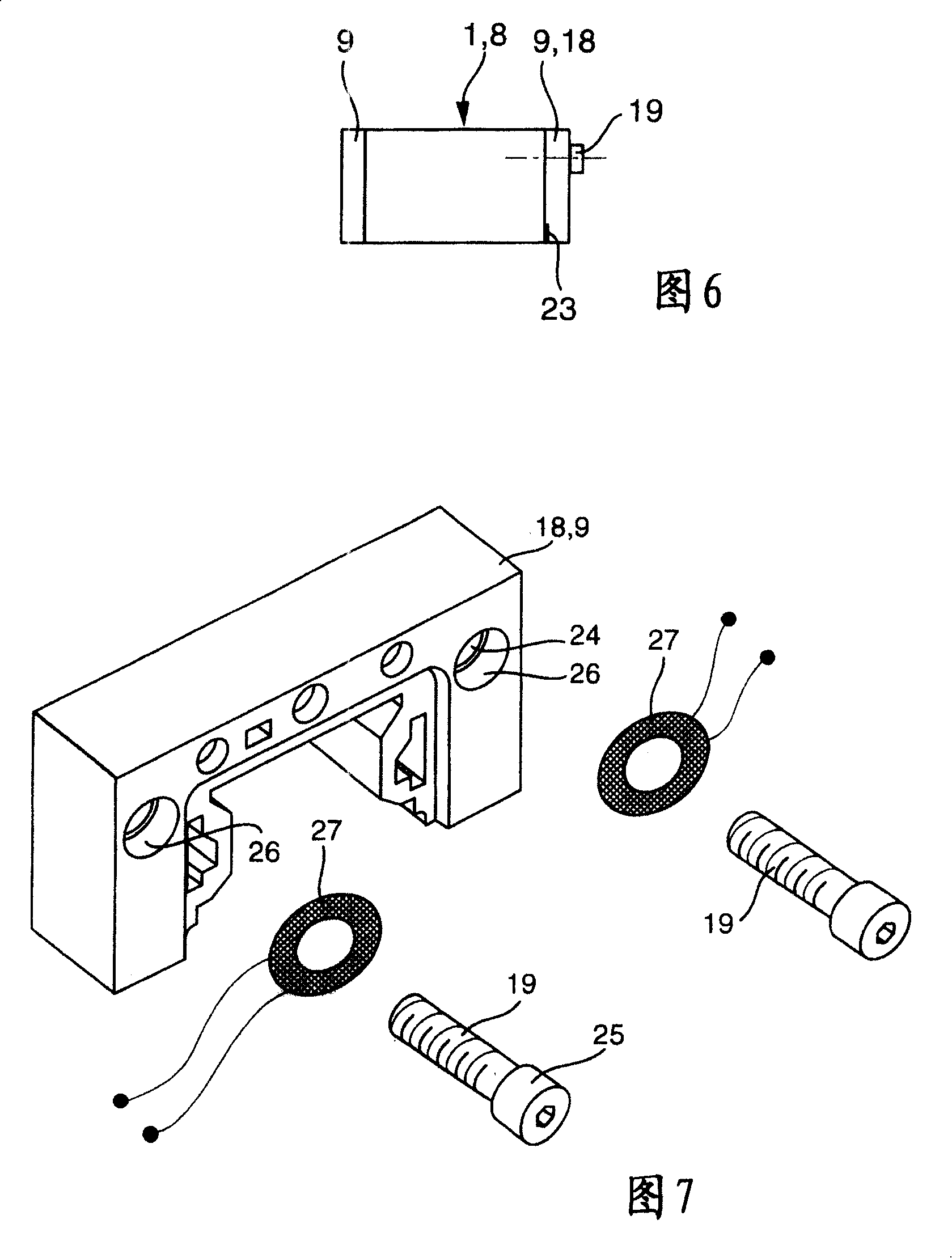

Linear roller bearing provided with a sensor for determining displacement resistance

InactiveCN100384586CPrevent production downtimeFree from outside influenceLinear bearingsBearing assemblyEngineeringReturn channel

The invention relates to a linear roller bearing provided with a guide carriage (1) which can be mounted on a guide rail (2) in a rolling manner by means of roller bearings (4). Said guide carriage is provided with at least one continuous roller bearing channel (3) for the roller bearings (4). The roller bearing channel (3) comprises a support channel (5) for supporting the roller bearings (4), a return channel (11) for returning the roller bearings (4), and deflecting channels (10) which connect the support channel (5) to the return channel (11). The deflecting channels (10) are provided on the end elements (9) of the guide carriage (1), and the roller bearings (4) in the roller bearing channel (3) are subject to displacement resistance in the direction of rotation. The end elements (9) are respectively provided with a sensor (12), whereby the preferably electrical signal thereof is dependent on the displacement resistance.

Owner:SCHAEFFLER TECH AG & CO KG

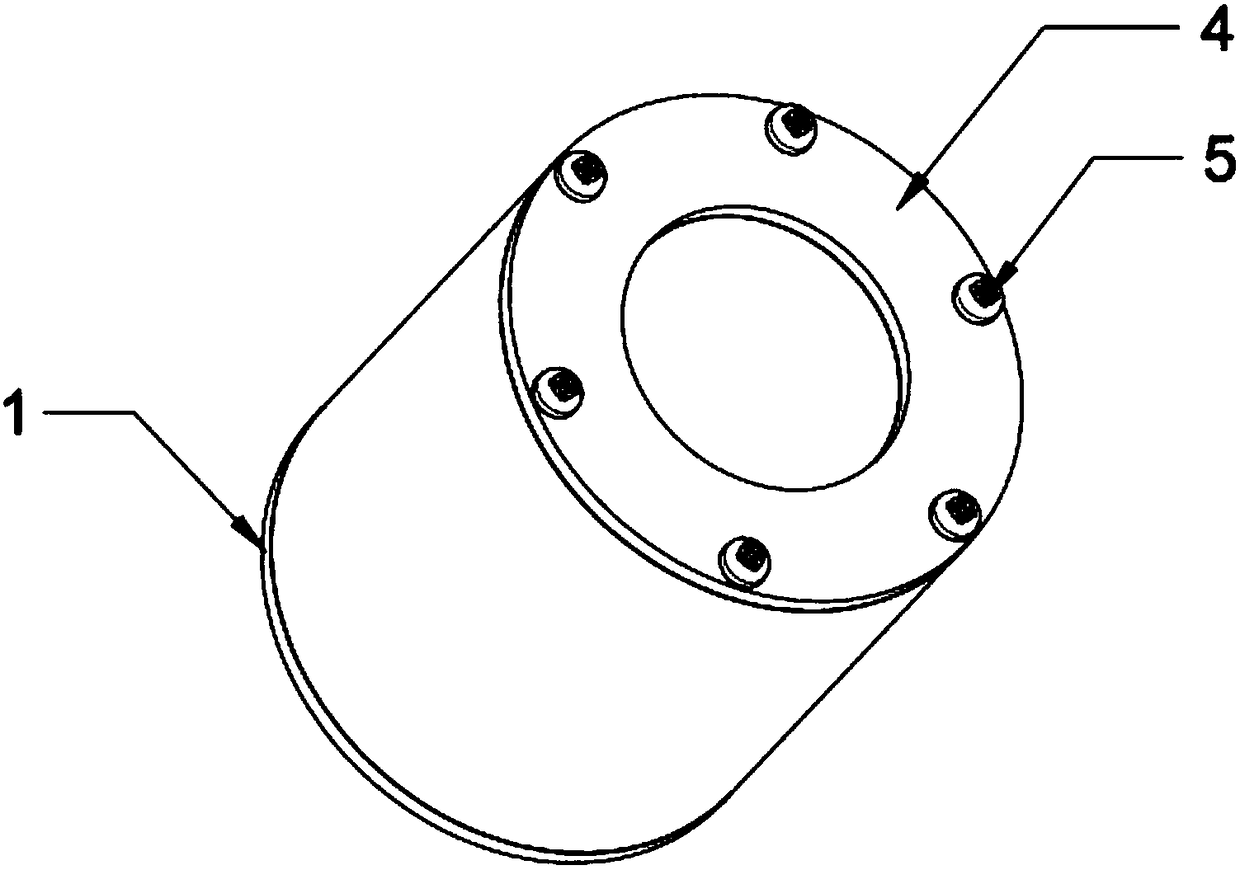

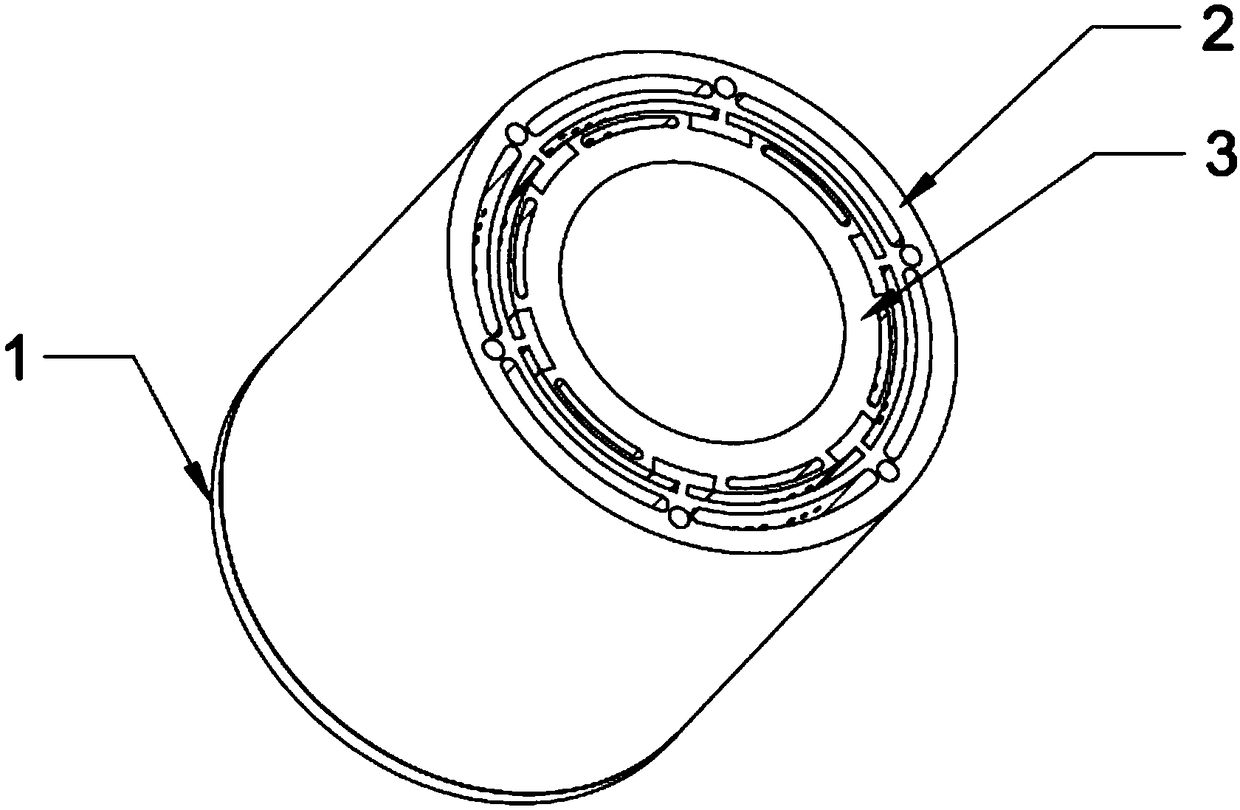

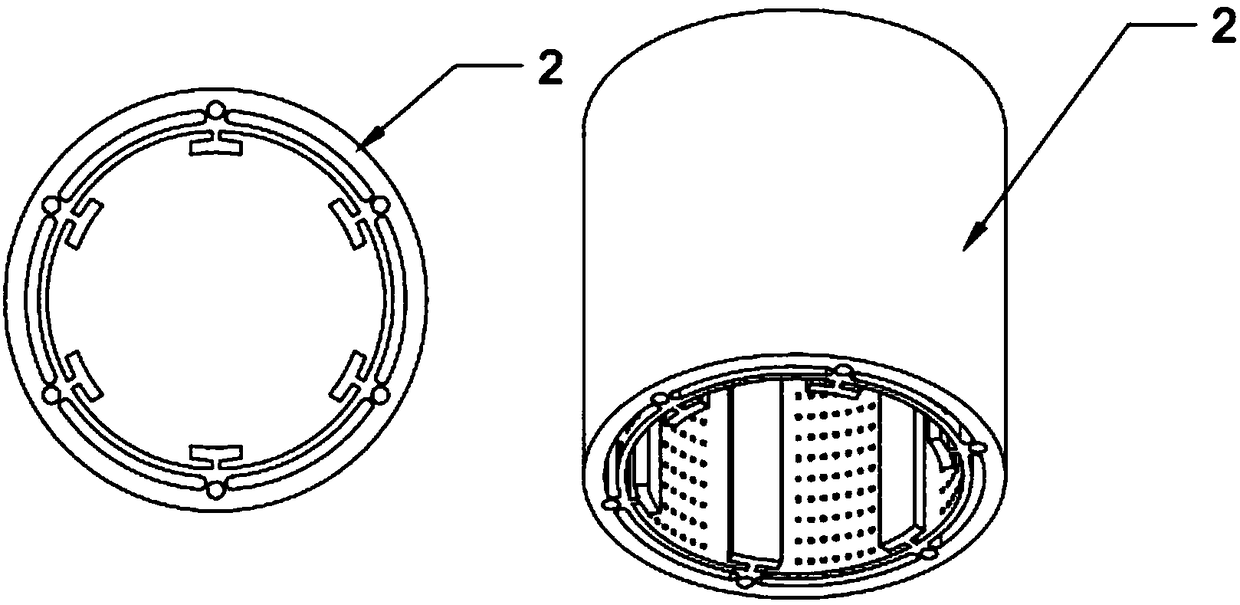

Double disc coulter

ActiveCN105517426AReduce prestressImprove cutting effectAgricultural machinesPlantingRotational axisVertical plane

A double disc coulter (1) has two disc coulters (2) which are angled in a V-shaped manner with respect to each other and are mounted rotatably on hollow axle stubs (3) by means of bearing units (18). A hollow axle stub (3) is arranged with a flange surface (5), which faces the coulter carrier (4), at an angle with respect to the vertical plane of the axis of rotation (6) of the hollow axle stub. At the same time, the hollow axle stub defines the angular position of the plane (13) which intersects the axis of rotation (6) and an axis (7) which is perpendicular to the flange surface (8, 9) of the coulter carrier (4).

Owner:LEMKEN

Loading device and loading method for dynamic biaxial compression of solid propellant

PendingCN113466030AReduce stepsReduce prestressMaterial strength using tensile/compressive forcesCircular discClassical mechanics

The invention relates to the technical field of material mechanical property tests, in particular to a loading device and a loading method for dynamic biaxial compression of a solid propellant. The loading device comprises an upper clamp and a lower clamp which are connected in a matched mode, the upper clamp comprises an upper clamp body and an upper loading table, and a disc-shaped upper pressing disc is fixedly connected to the upper loading table; the lower clamp comprises a lower clamp body and a lower loading table, and the lower loading table is fixedly connected with a bottom fixing sleeve seat; and the upper clamp body and the lower clamp body are buckled with each other, and the area between the upper clamp body and the lower clamp body is a clamping area. According to the clamp designed by the invention, biaxial compression loading test such as dynamic loading with the loading ratio of 1: 1, and the strain rate covering 1-100S <-1 > can be realized on a high-strain-rate hydraulic servo testing machine. The clamp is in micro contact with the surface of the test piece through a suspension structure composed of a double-hole wire locking device and a thin rope, direct operation on a test piece is avoided, and prestress and damage caused by the dead weight of a fixed test piece and the clamp are reduced.

Owner:ROCKET FORCE UNIV OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com