Clamping device and regulating unit

A clamping device and clamping sleeve technology, which can be applied to fixing devices, fluid pressure actuating devices, mechanical equipment, etc., can solve problems such as damage, device damage, clamping jaws, etc., to improve operational reliability and facilitate elasticity. The effect of features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

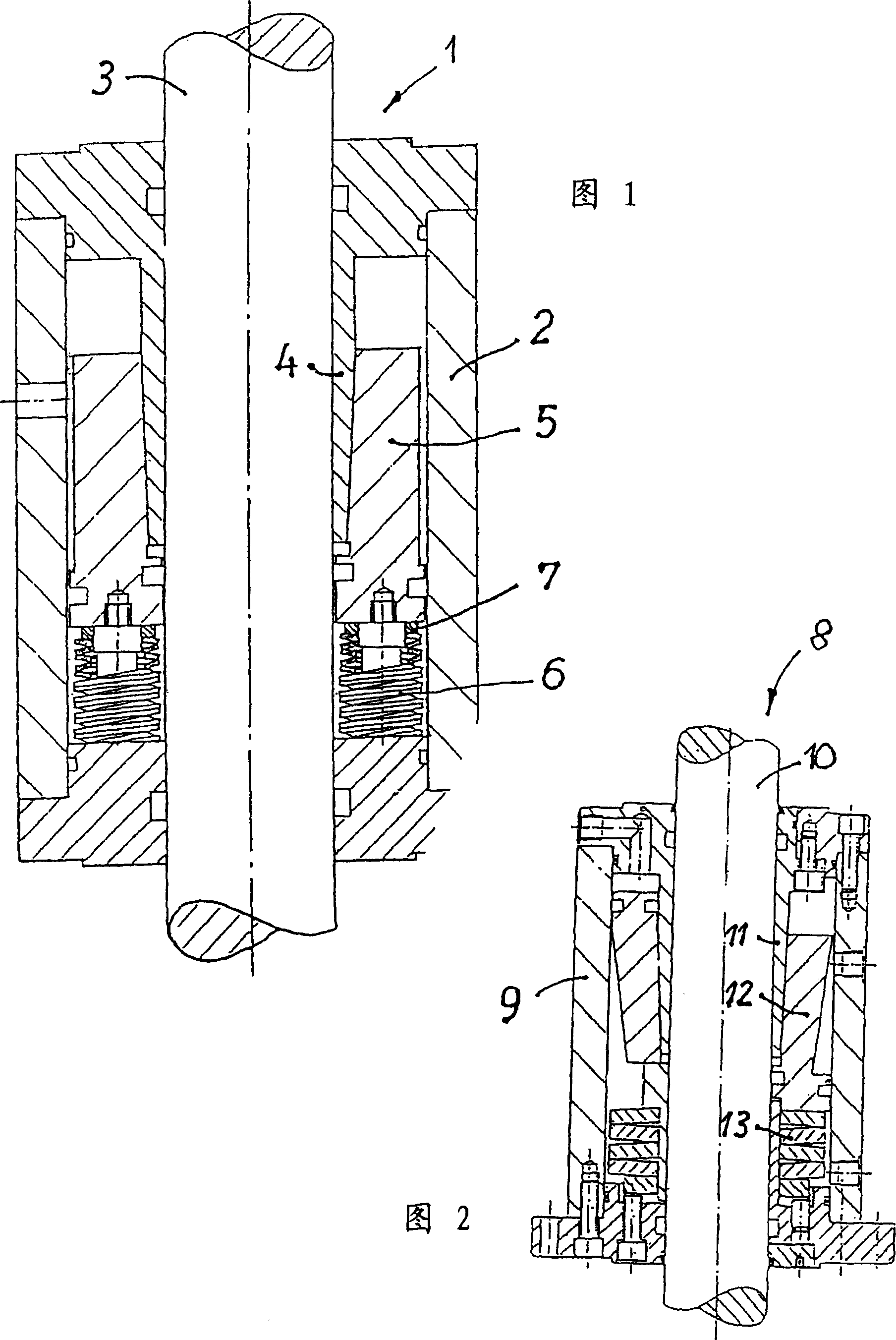

[0036] FIG. 2 shows a clamping device known from the prior art, in particular DE 37 070 46 A1. The known clamping device 8 has a three-part housing, in which a rod 10 can be clamped by means of a clamping sleeve 11 . This clamping takes place by means of a tensioning piston 12 which is provided with a prestressing or biasing force by the action of a coaxially mounted leaf spring unit 13 . The clamping sleeve 11 is released by supplying the tensioning piston 12 with pressure medium, since the force exerted by the pressure medium counteracts the prestressing or biasing force of the elastic unit 13 .

[0037] The leaf spring unit is therefore permanently prestressed in both the clamped and the unclamped position, ie all the leaf springs forming the leaf spring unit are prestressed by the same amount, the prestress being higher in the unclamped position. Since the leaf springs are connected one after the other, in the case of a single layer, each spring applies the total prestres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com