Suspension type monorail vehicle body and cross beam connection structure and suspension type monorail vehicle

A connection structure and suspension technology, applied in the field of rail transit, can solve the problems of embedding the inner side of the roof side beam, only overlapping to the upper surface of the roof side beam, the welding structure cannot solve the connection problem, and there are safety risks. Reduce risk, connect reliably, and solve the effect of not matching the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

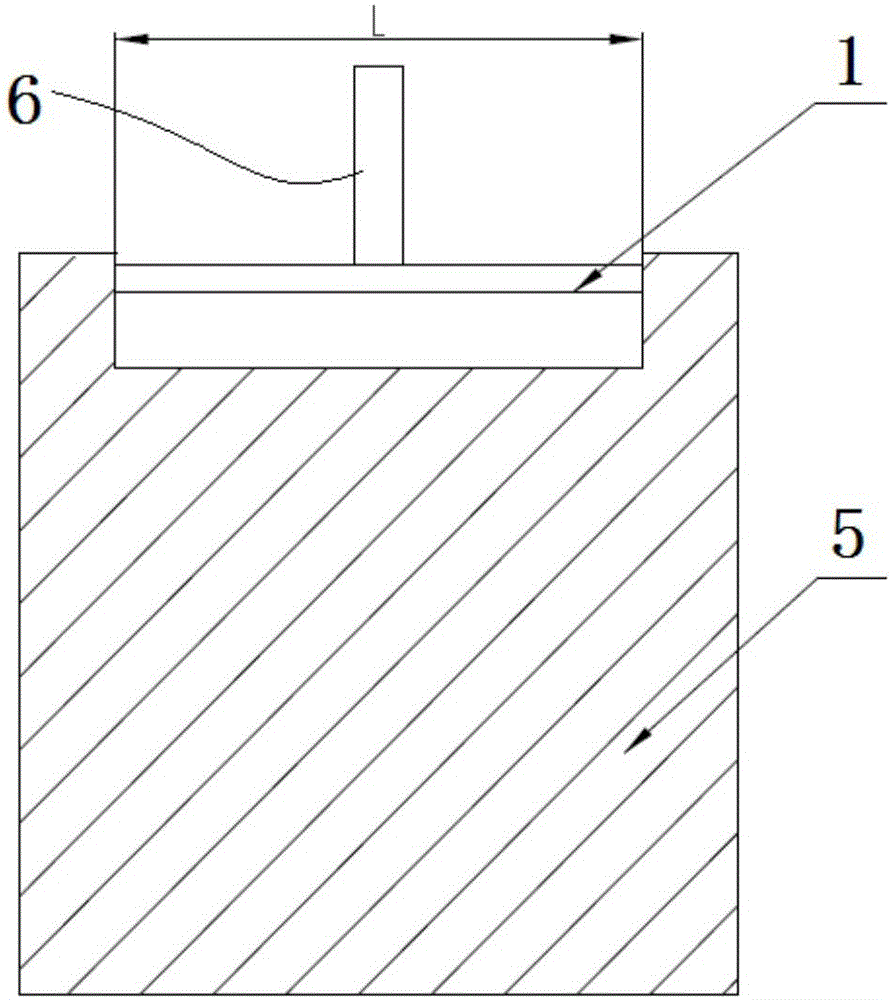

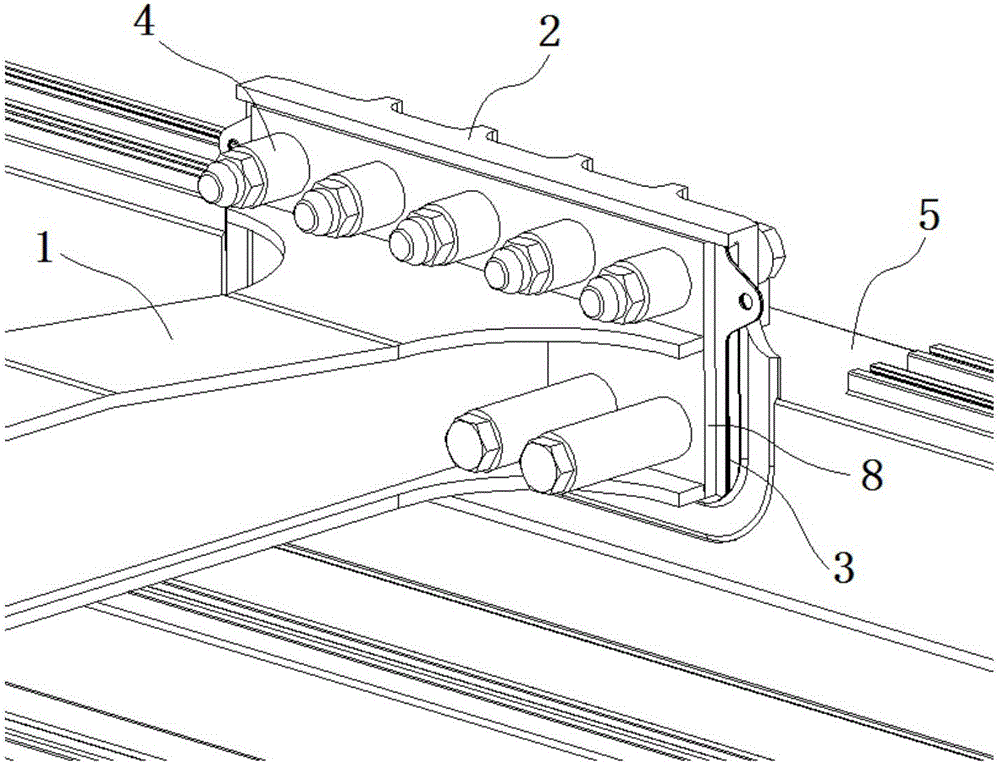

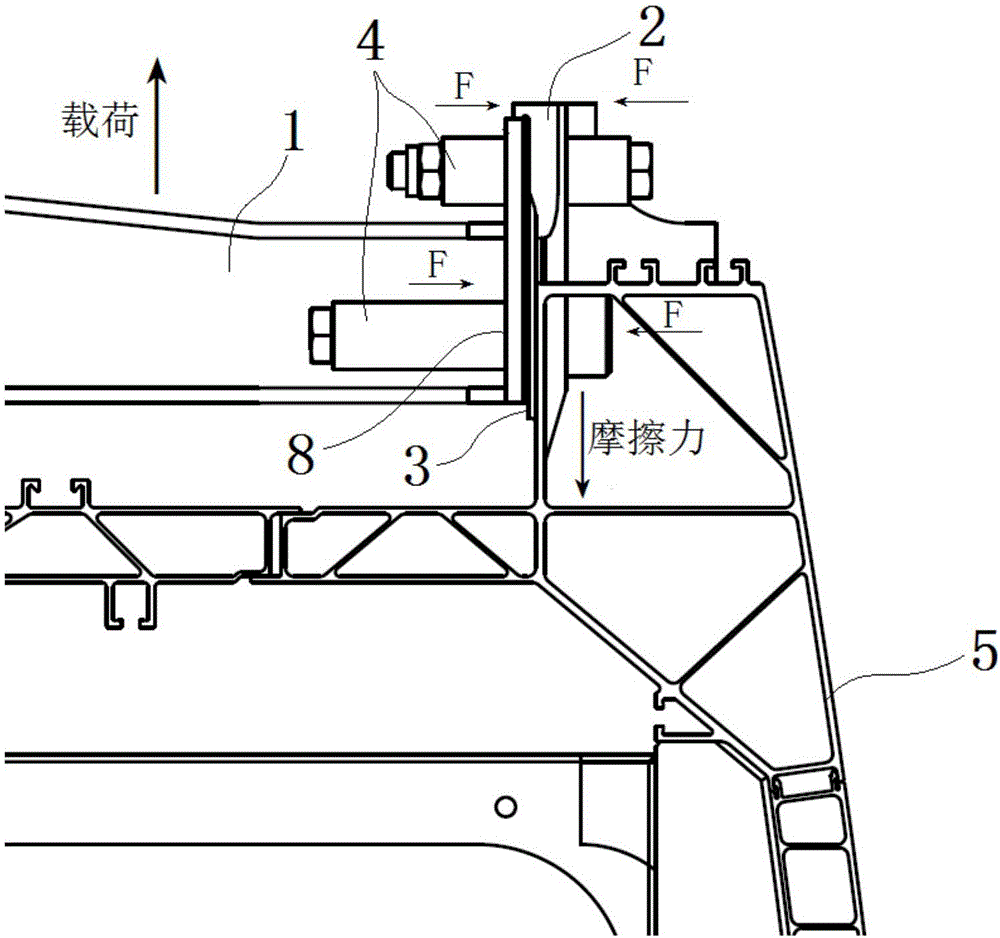

[0048] A suspended monorail car body beam connection structure, such as Figure 1-2 As shown, it is mainly composed of a beam 1, a connecting plate 2, an adjusting plate 3, a connecting fastener 4, and a suspended vehicle body 5. Connection, the load of the vehicle body 5 is transmitted to the running part through the beam 1 and the connecting part 6 connected together, and the traction braking force of the running part is transmitted to the vehicle body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com