Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Reclaiming speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

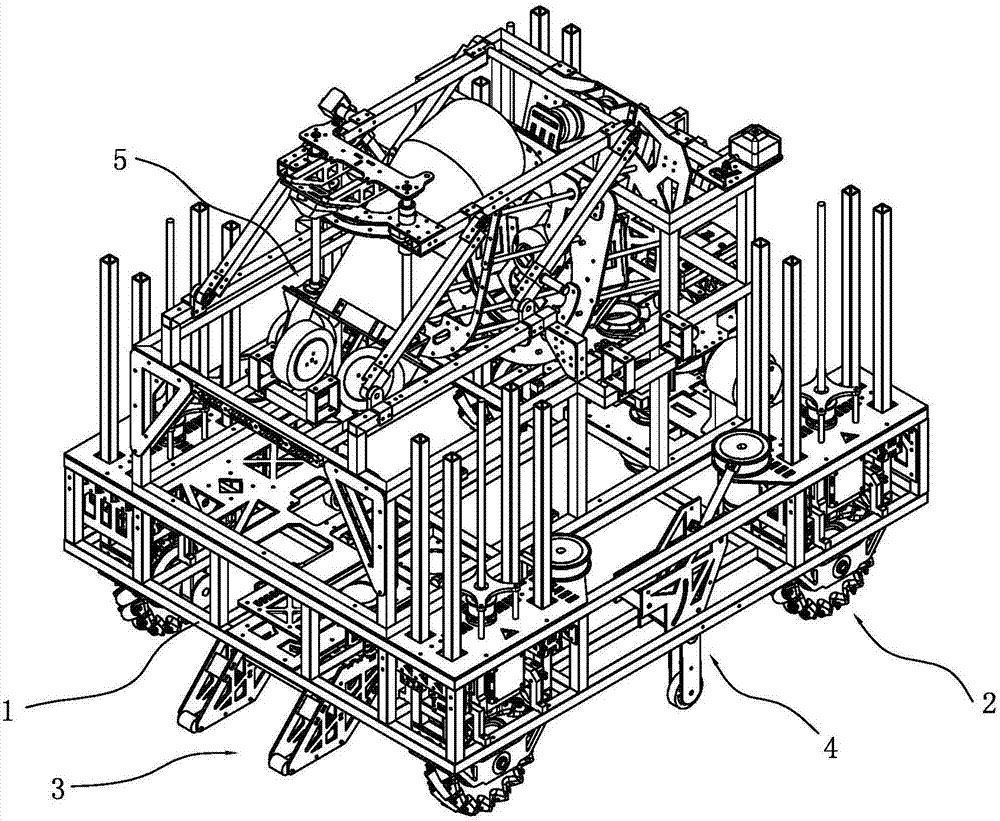

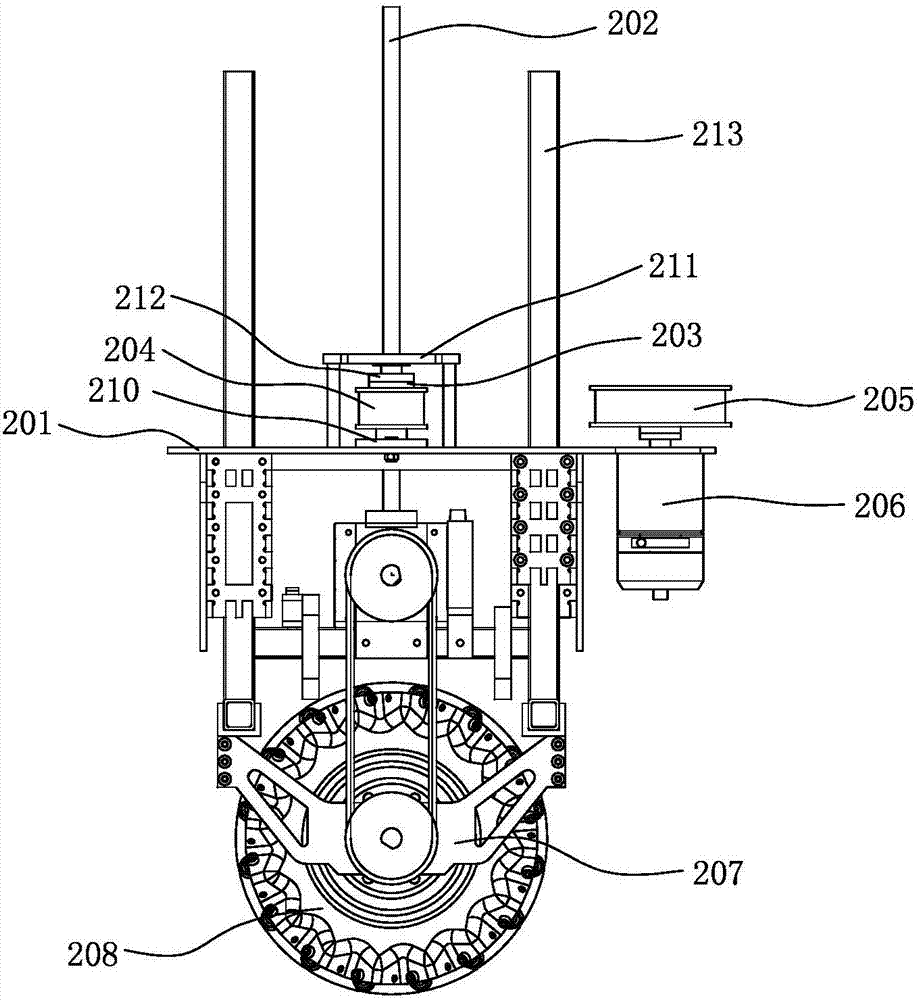

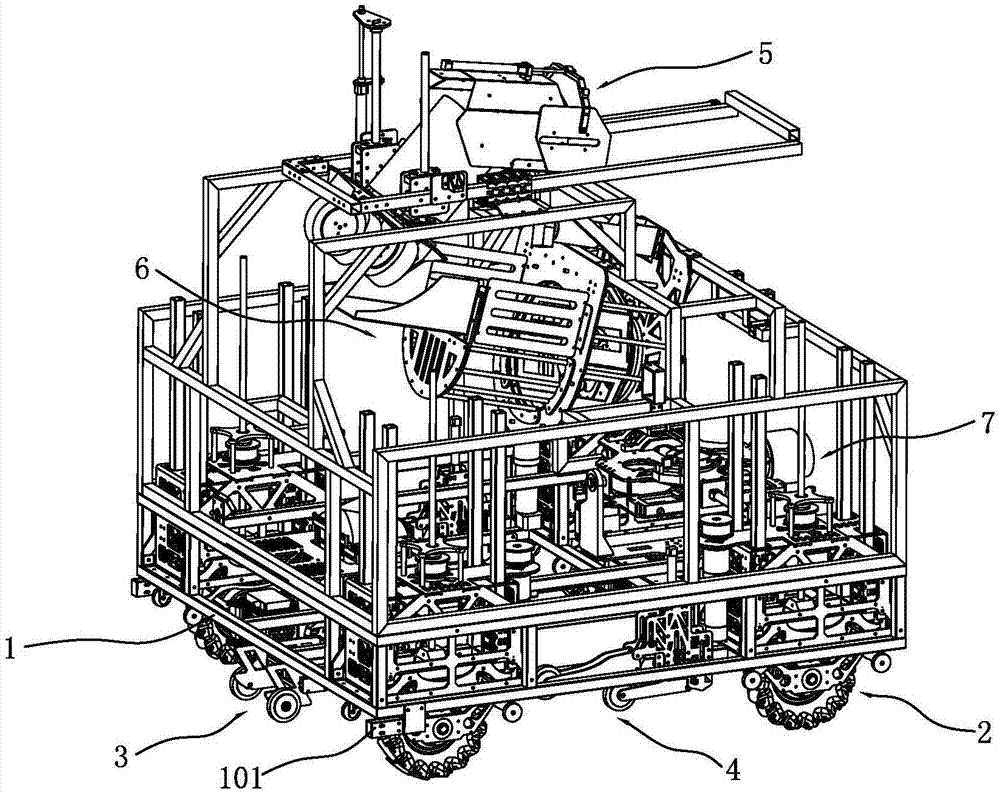

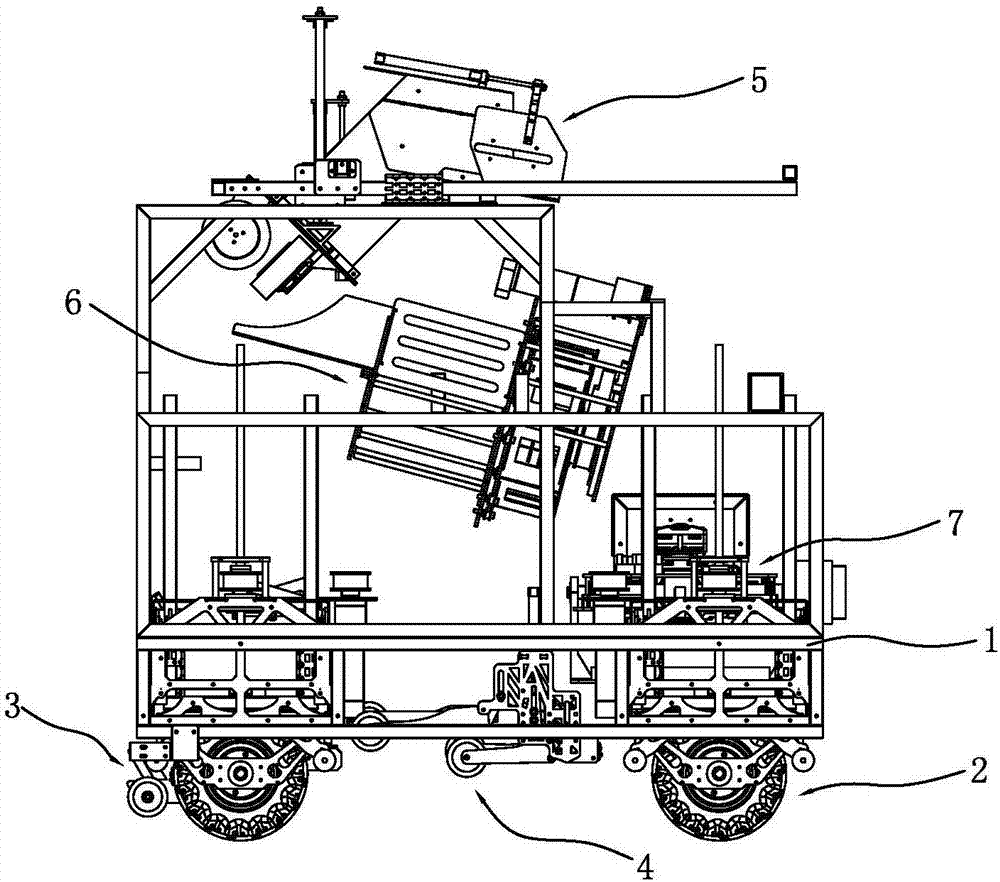

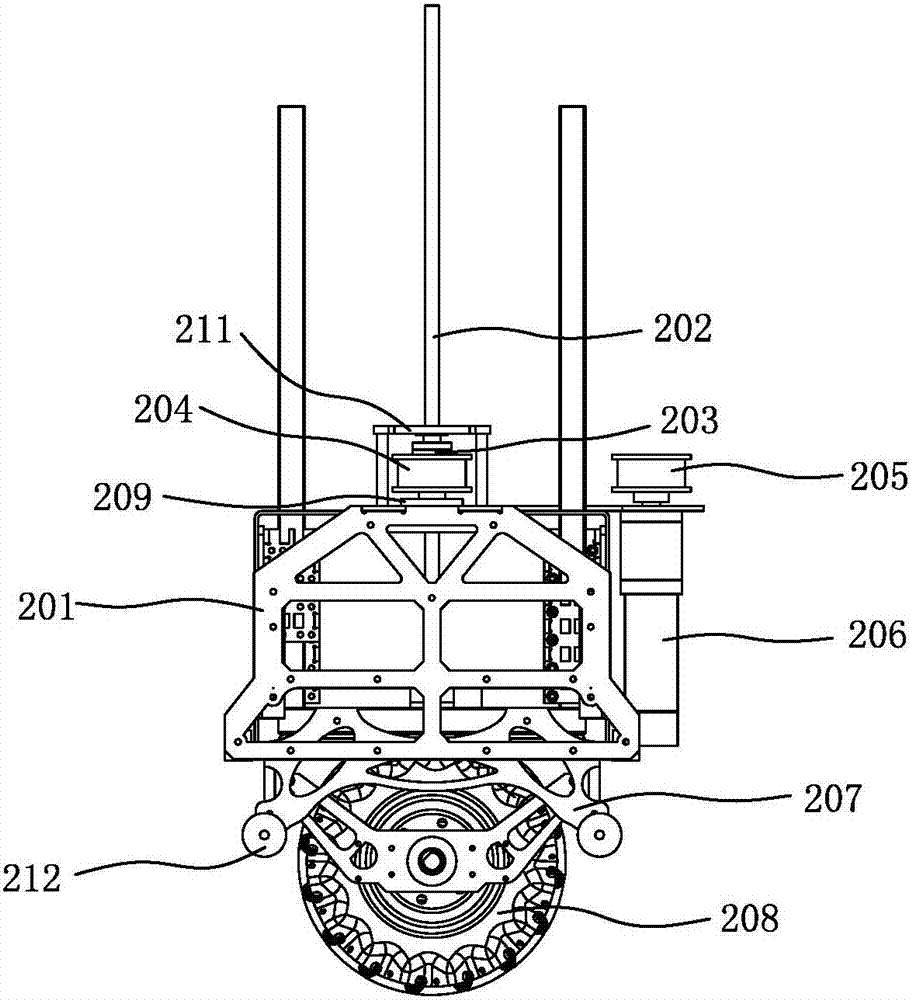

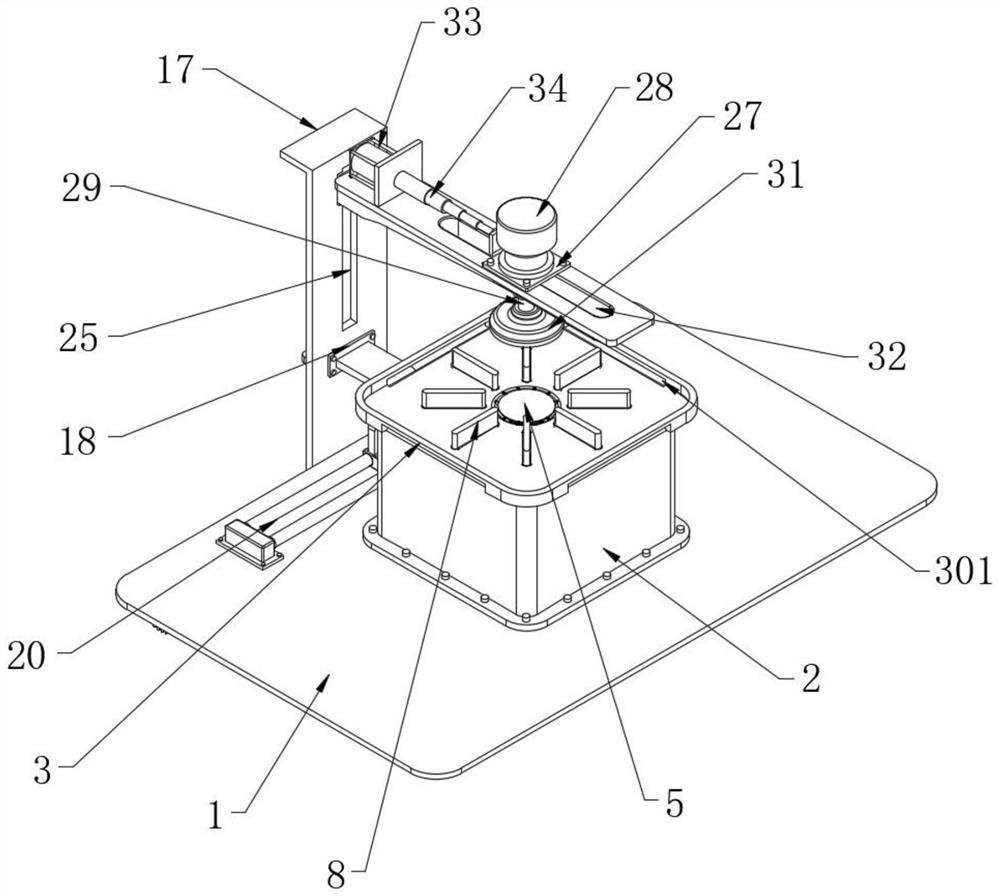

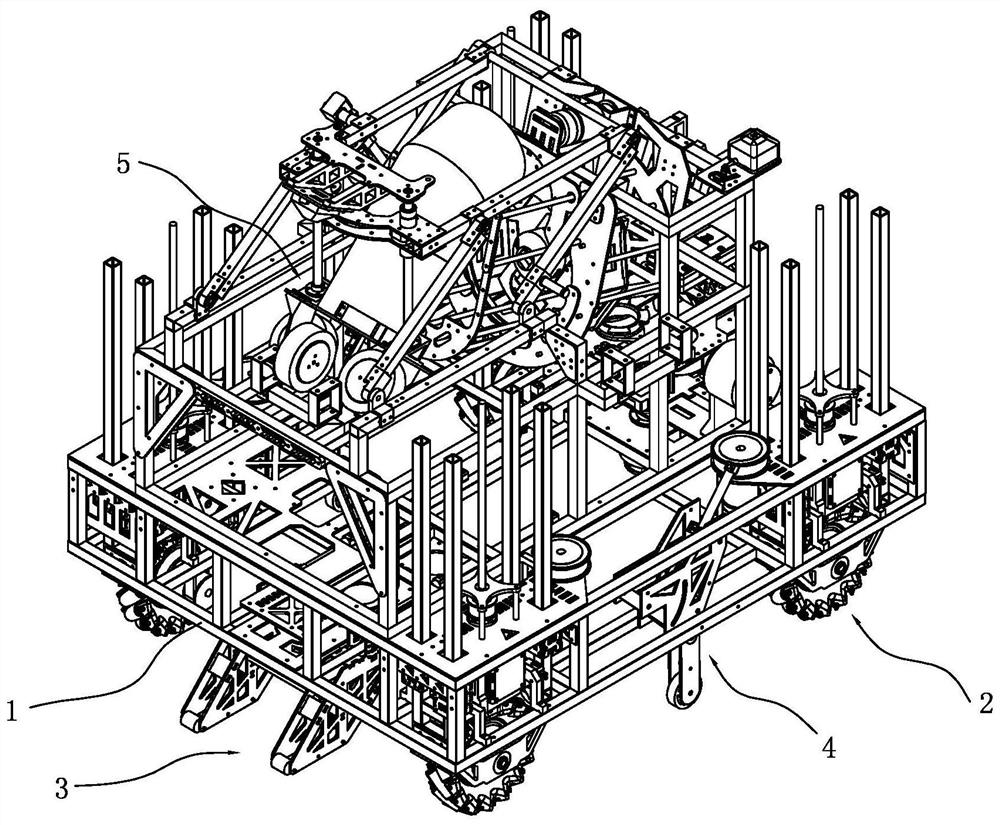

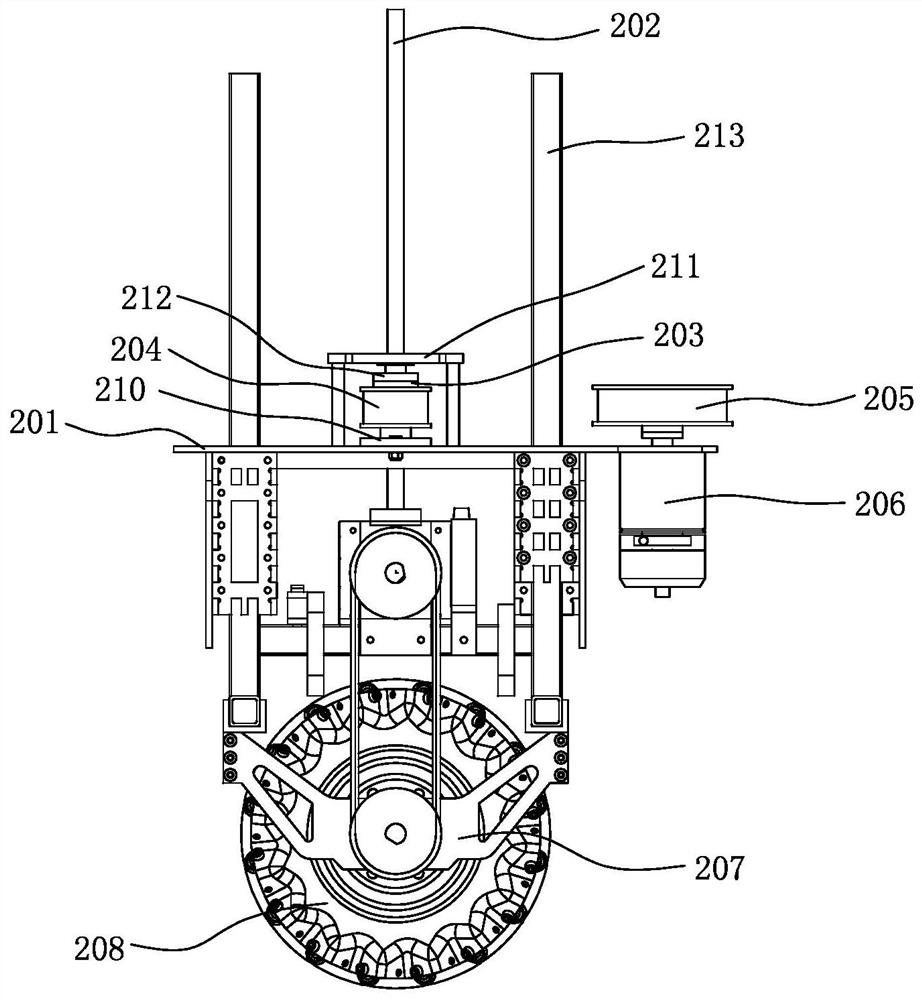

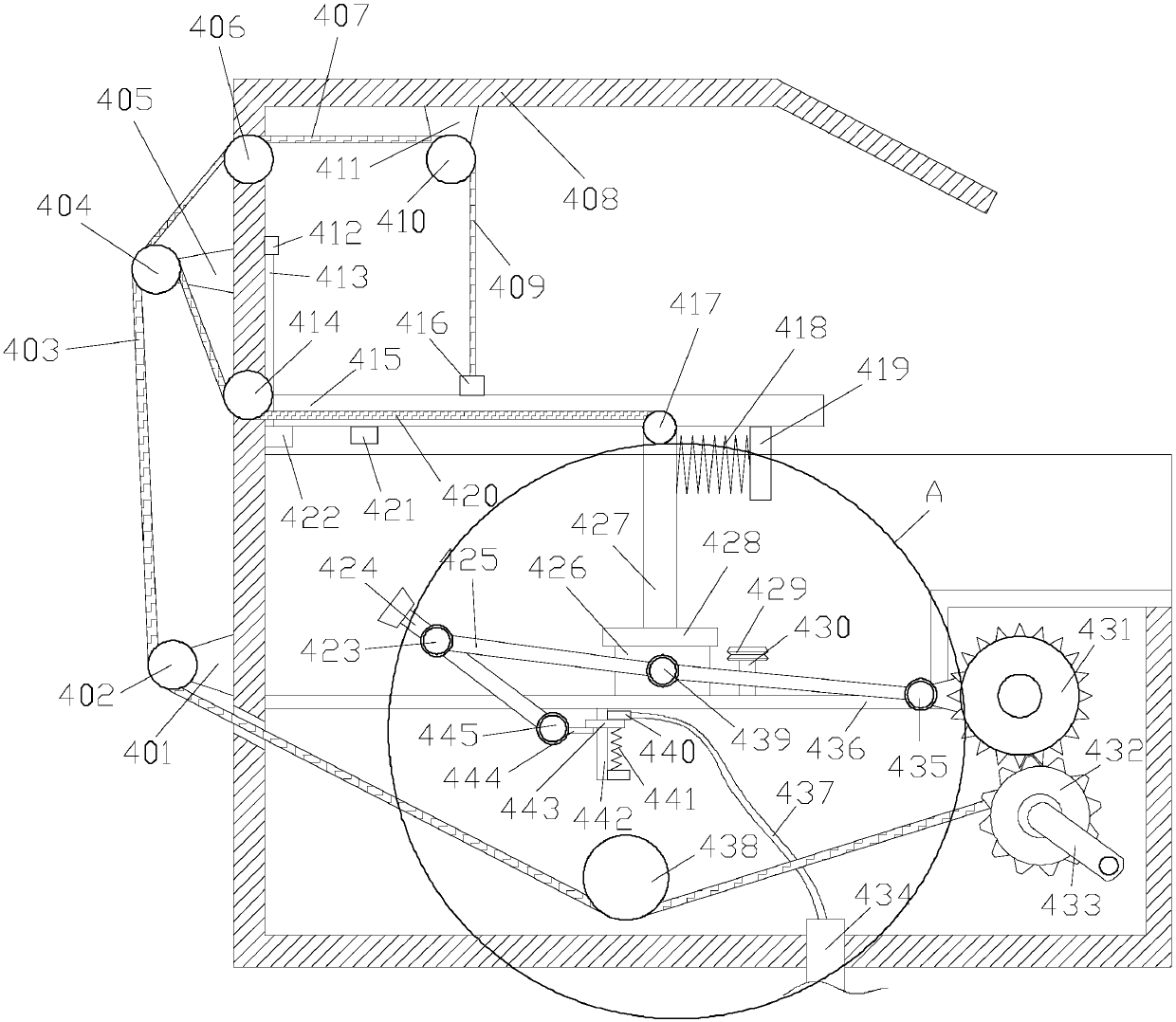

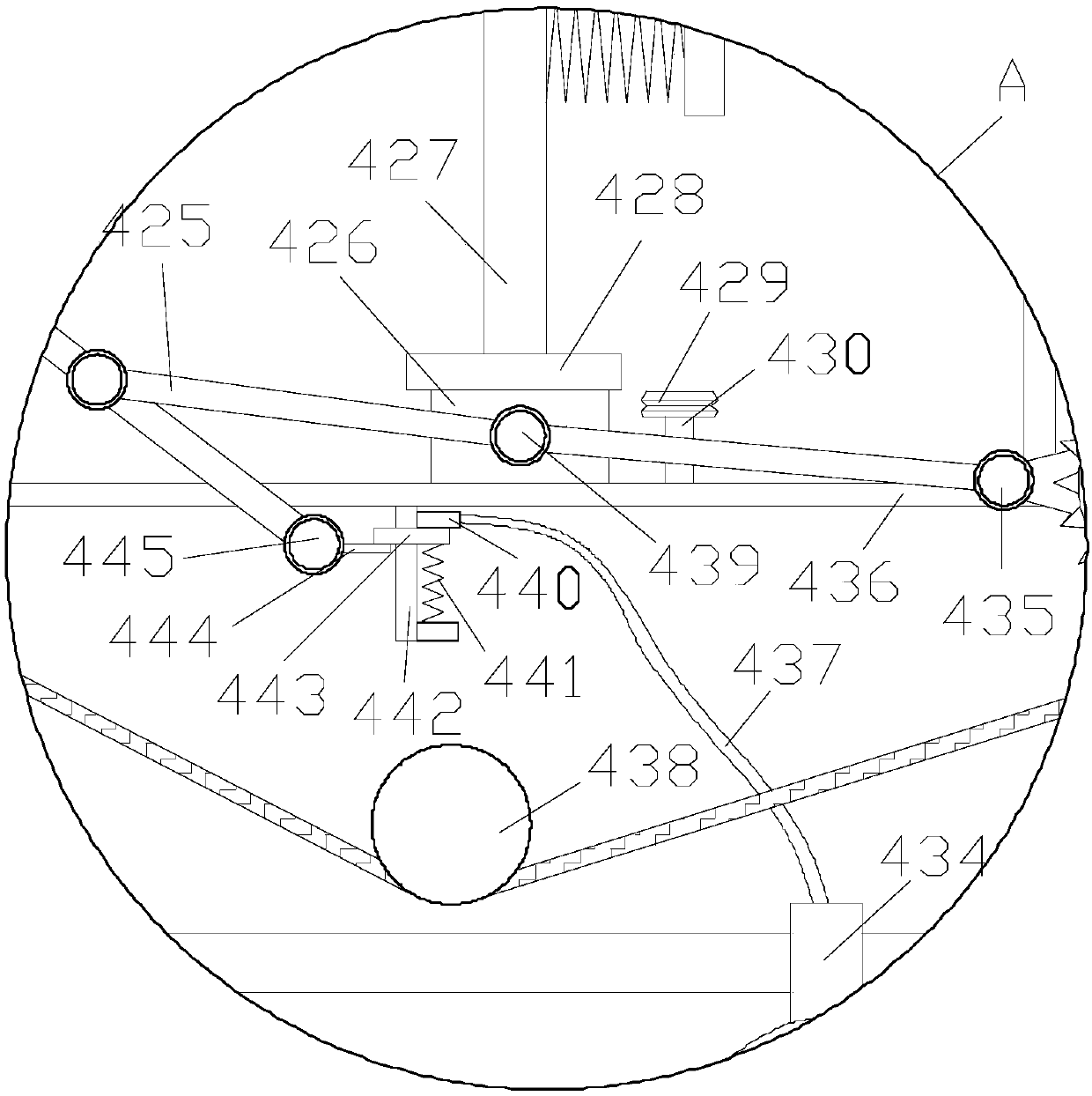

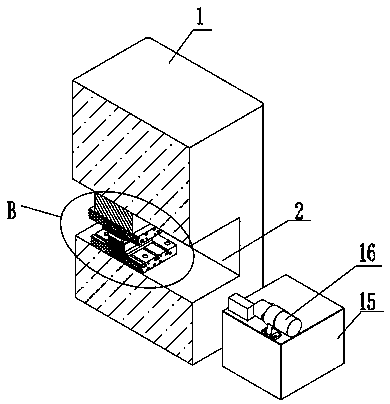

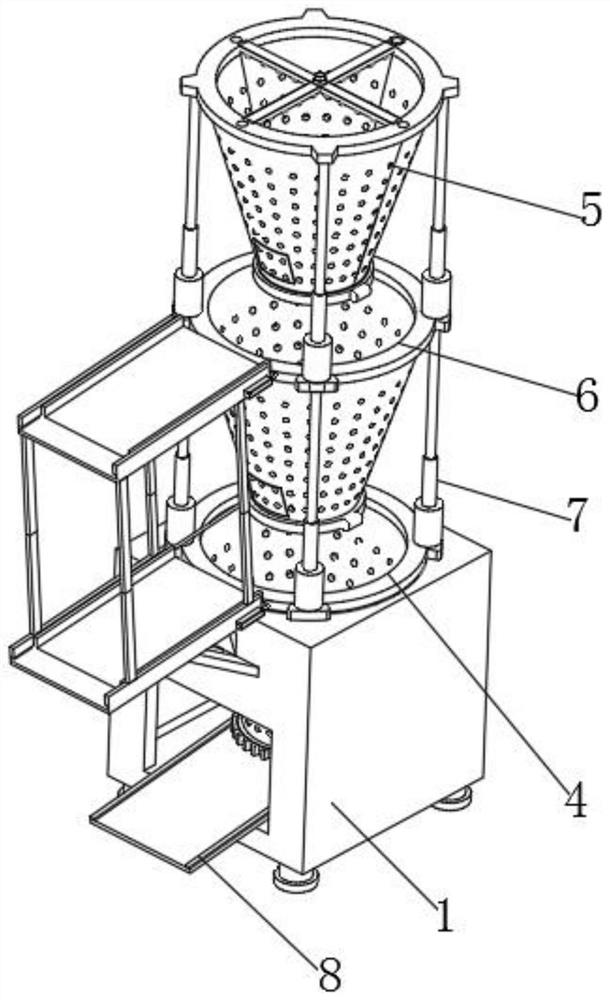

Movable robot for complex terrains

InactiveCN107351932AOvercome the shortcomings of poor adaptabilityImprove reliabilitySievingScreeningTerrainEngineering

The invention discloses a movable robot for complex terrains. The movable robot comprises a movable chassis; a material taking device and a material screening device which are connected in sequence are arranged on the chassis; the material taking device is used for taking materials and conveying the taken materials to the material screening device; and the material screening device is used for screening the materials according to sizes and collecting the screened materials. According to the movable robot for complex terrains, provided by the invention, the height from the chassis to the ground can be dynamically adjusted according to the terrains, so that the movable robot for complex terrains overcomes the defect of poor adaptability of a traditional movable robot platform under complex terrain conditions, has relatively strong passing performance, can meet multiple demands of working in field complex environments, can climb slopes and cross obstacles, can smoothly move forward and move laterally under non-smooth terrains, and has the advantages of simple structure, convenient control, high reliability, strong practicability and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

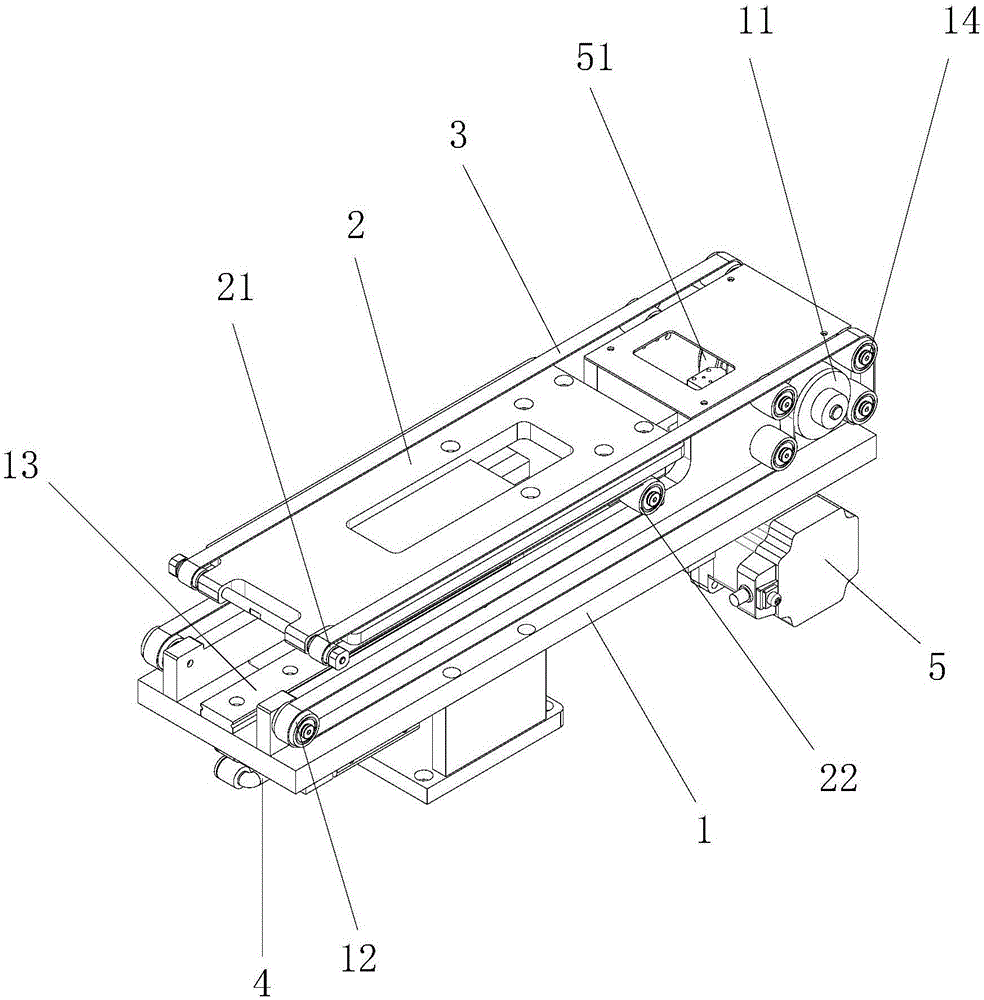

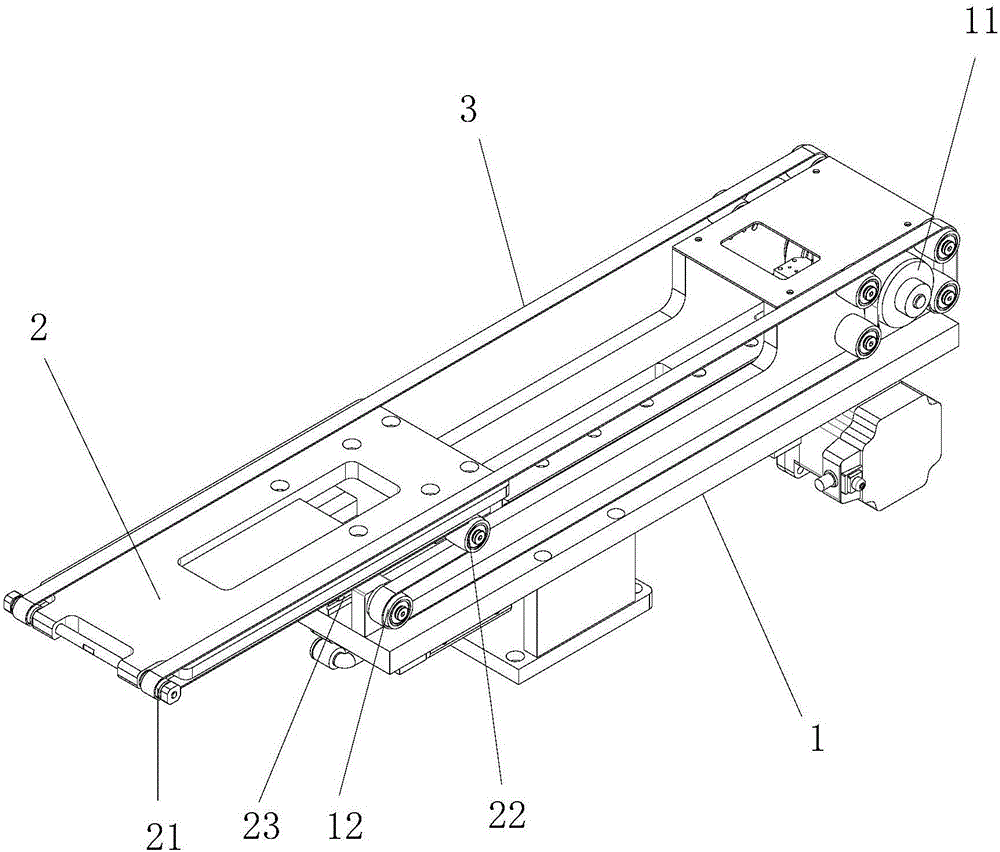

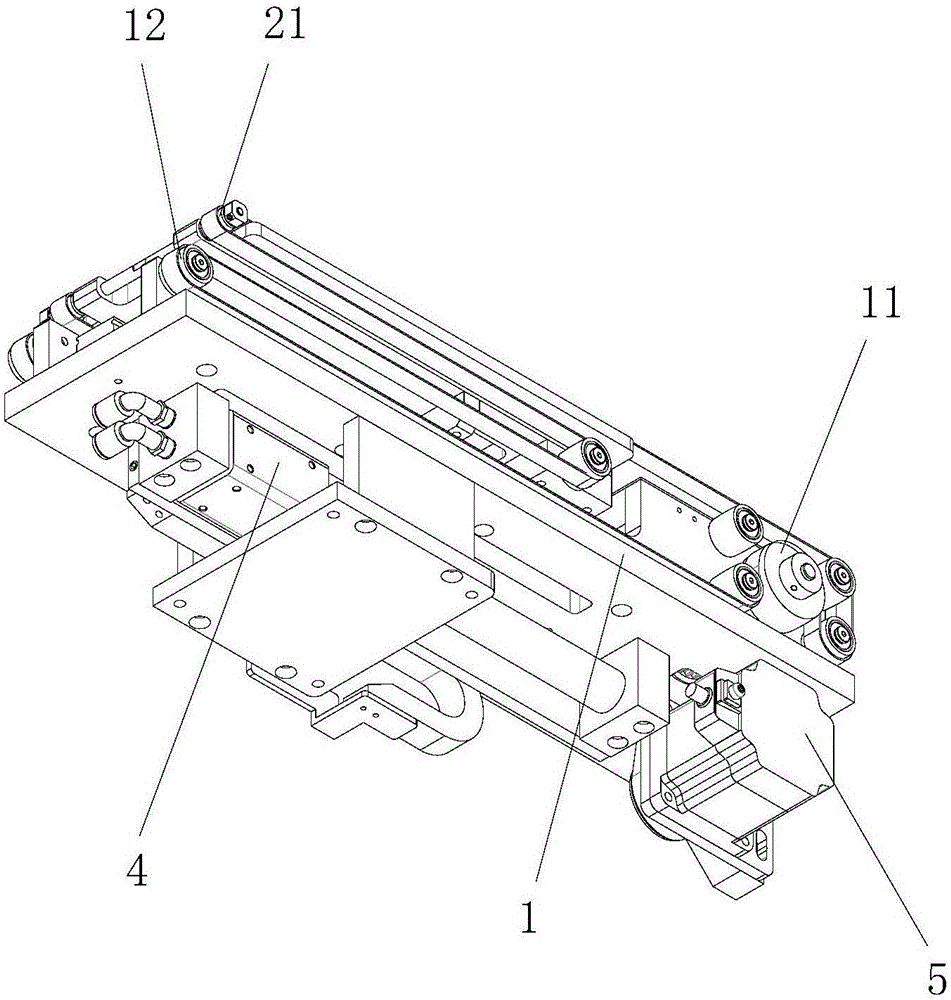

Silicon slice taking mechanism, taking method of silicon slice taking mechanism and silicon slice testing and sorting equipment

InactiveCN106276282AFast transferSimple structureConveyorsDe-stacking articlesEngineeringSlide plate

A silicon slice taking mechanism comprises a rack, a sliding plate and a taking belt; the sliding plate is slidably installed on the rack, the taking belt is connected between the rack and the sliding plate, and the rack is provided with a first driving piece and a second driving piece, wherein the first driving piece is used for driving the sliding plate to stretch and retract, and the second driving piece is used for driving the taking belt to operate. The taking method of the silicon slice taking mechanism comprises the following steps that the first driving piece drives the sliding plate to stretch into a silicon slice box, and the taking belt enters the silicon slice box with the sliding plate; the first driving piece stops to act, the second driving piece drives the taking belt to operate, silicon slices in the silicon slice box sequentially fall onto the taking belt and are conveyed away; and after transporting of the silicon slices in the silicon slice box is completed, the second driving piece stops to act, the first driving piece drives the sliding plate to retract back to the initial position, and the taking belt exits from the silicon slice box with the sliding plate. Silicon slice testing and sorting equipment comprises the silicon slice box, a conveying belt, a positioning mechanism, a testing bench, a sorting mechanism and the silicon slice taking mechanism in sequence; and the taking belt is located between the silicon slice box and the conveying belt.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

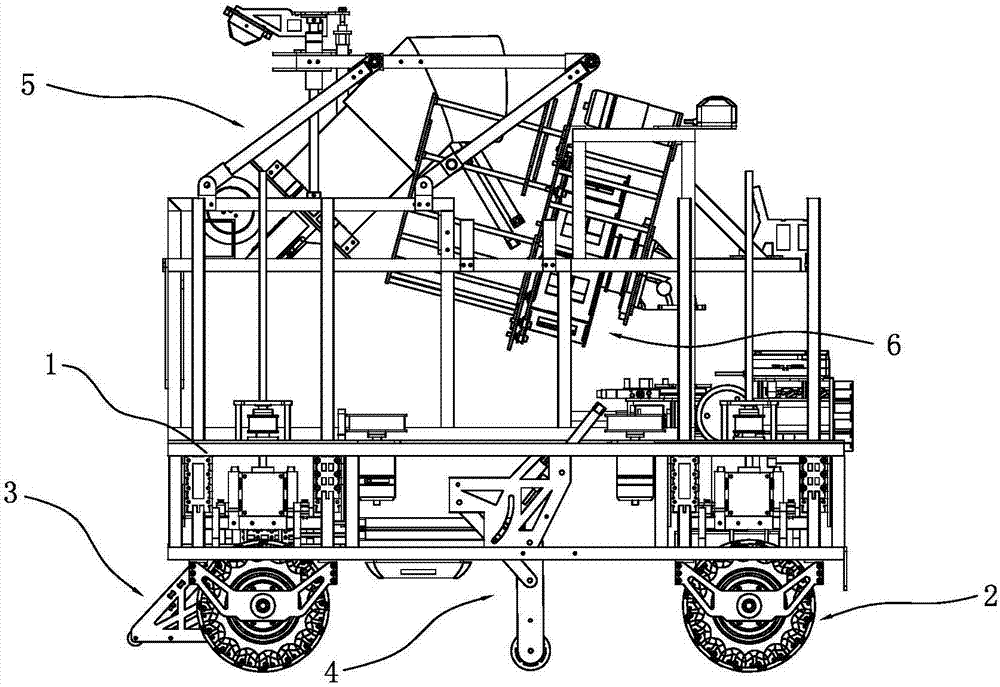

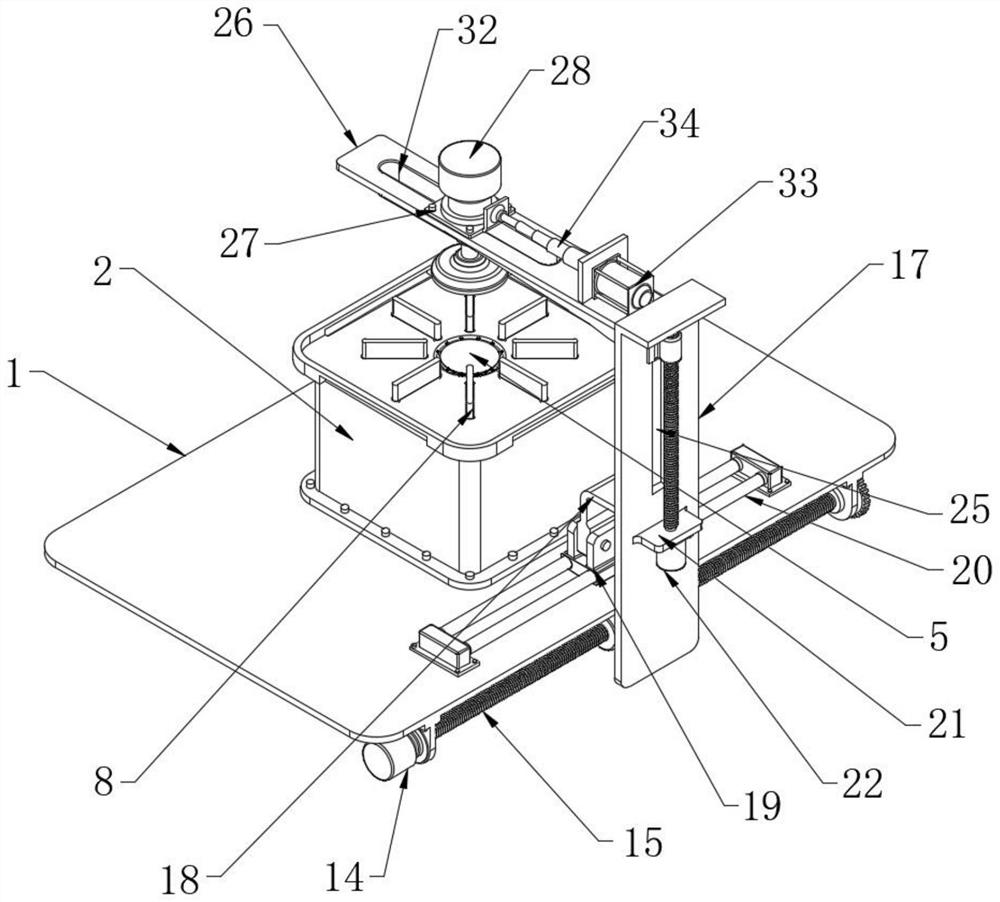

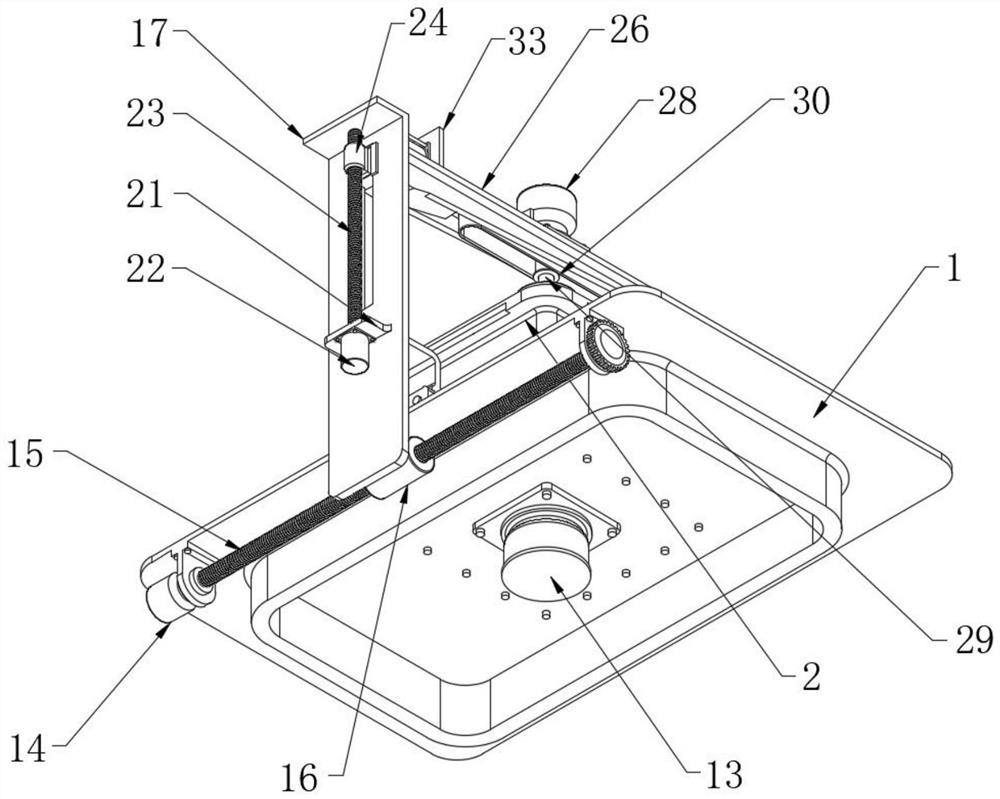

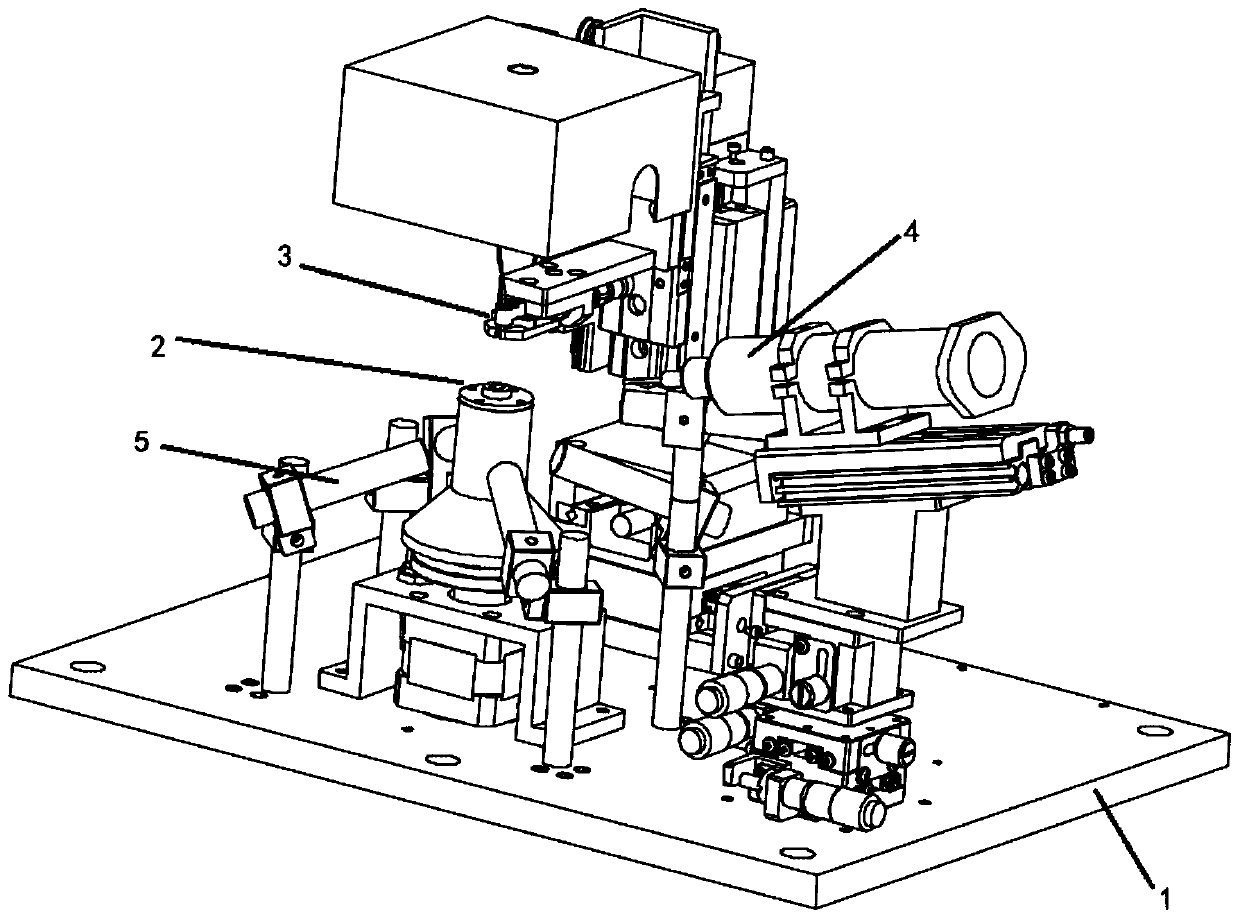

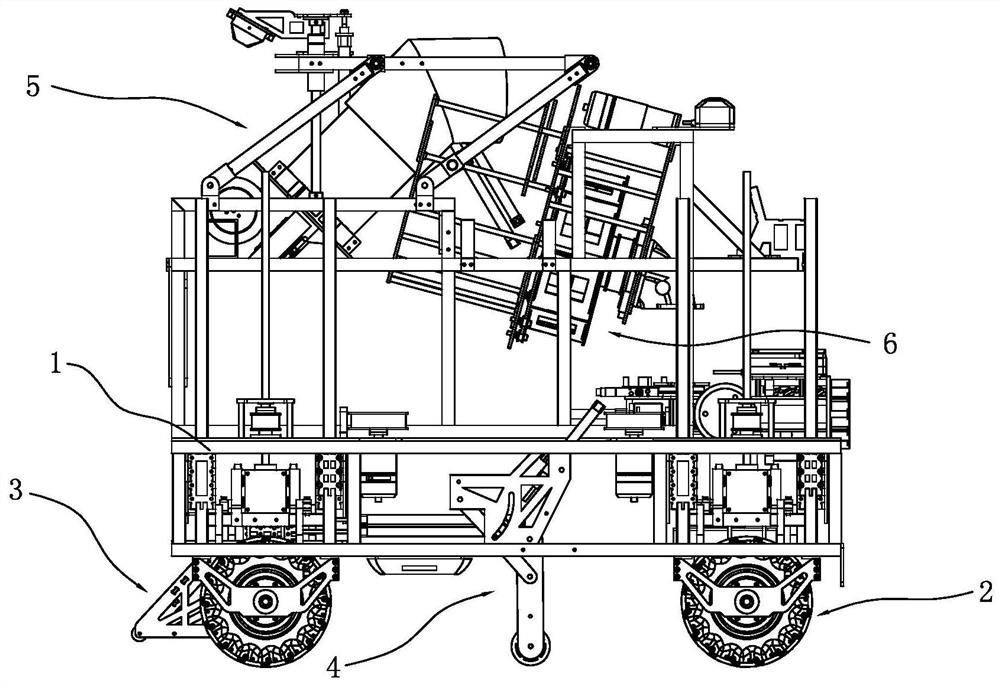

Robot with material taking and feeding functions

InactiveCN107053199AOvercome the shortcomings of poor terrain adaptabilityImprove reliabilityManipulatorTerrainEngineering

The invention discloses a robot with material taking and feeding functions. The robot comprises a bottom disc which can move. A material taking device, a material screening device and a transmitting device are installed on the bottom disc from top to bottom. Lifting wheel modules are arranged at the front portion and the rear portion of the bottom disc correspondingly. The lifting wheel modules are used for driving the bottom disc to descend and ascend. A telescopic guide wheel module is arranged at the front end of the bottom disc and can stretch forwards to support the bottom disc on a climbing object. A folding guide wheel module is arranged at the middle portion of the bottom disc and can be put down to support the bottom disc. By means of the robot with the material taking and feeding functions, the distance between the bottom disc and the ground can be dynamically adjusted according to the terrain, the defect that a traditional moving robot platform is poor in terrain adaptability is overcome, high passing performance is achieved, the material taking device is used for taking materials and conveying the taken materials to the material screening device, the material screening device is used for screening the materials according to the size and conveying the materials to the transmitting device, and the transmitting device is used for throwing the screened materials to a target station.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

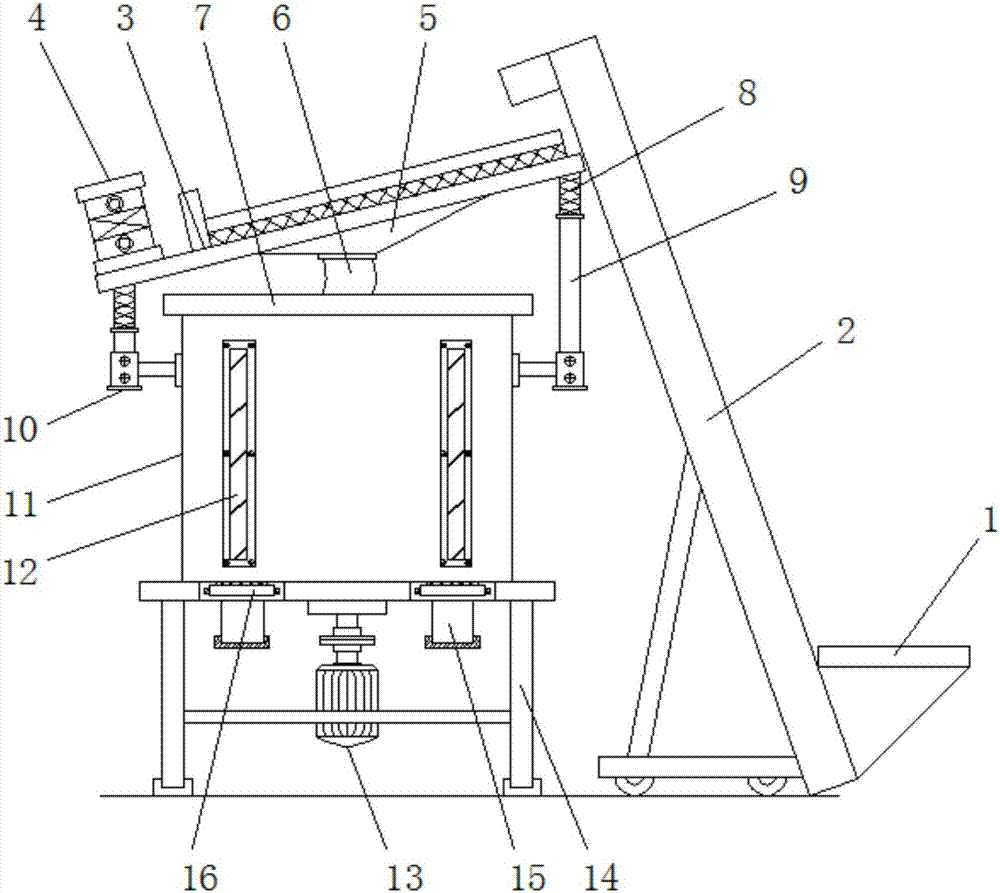

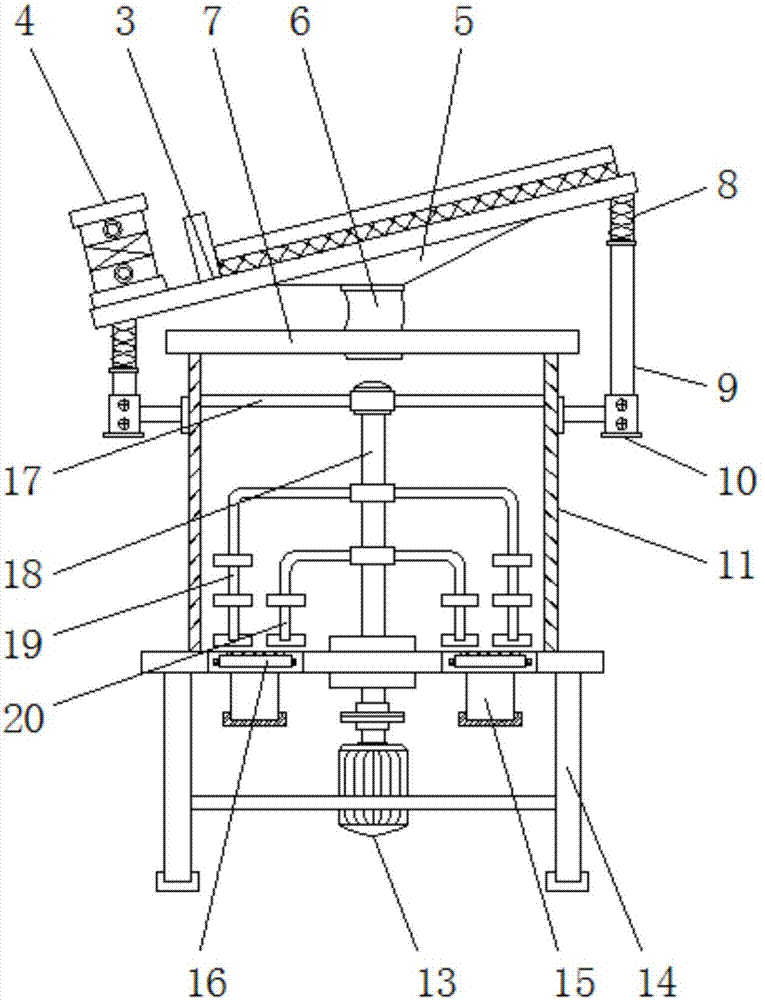

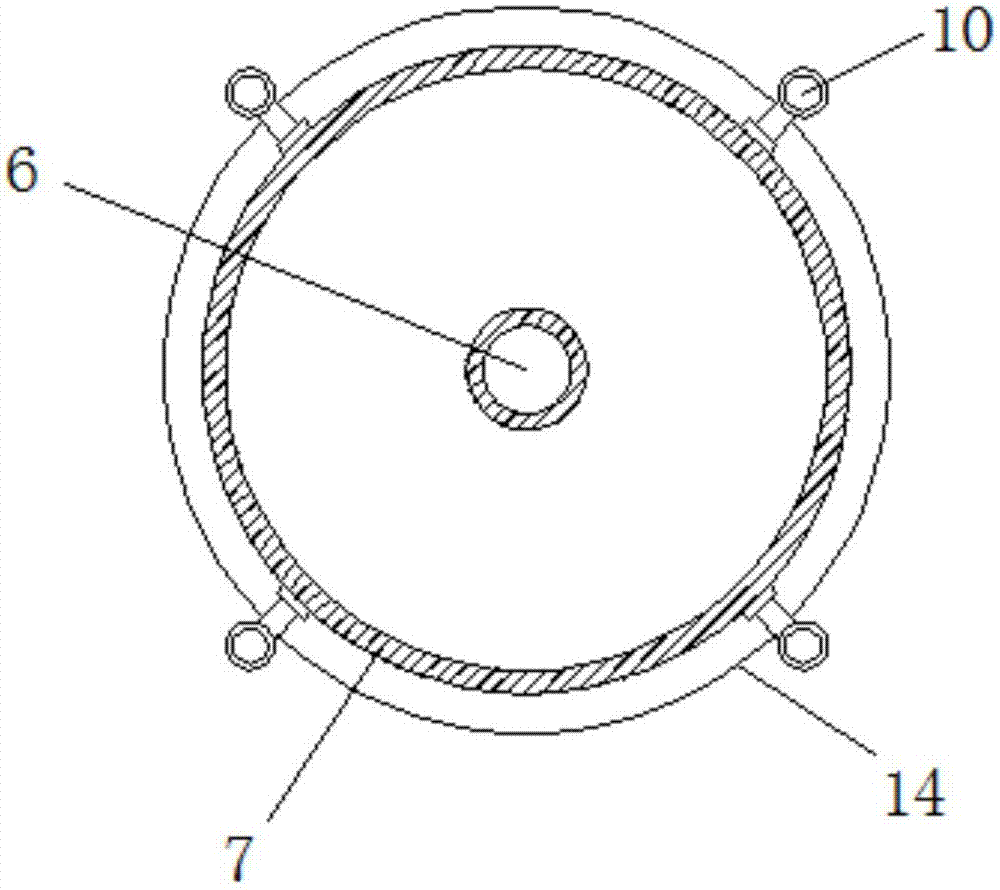

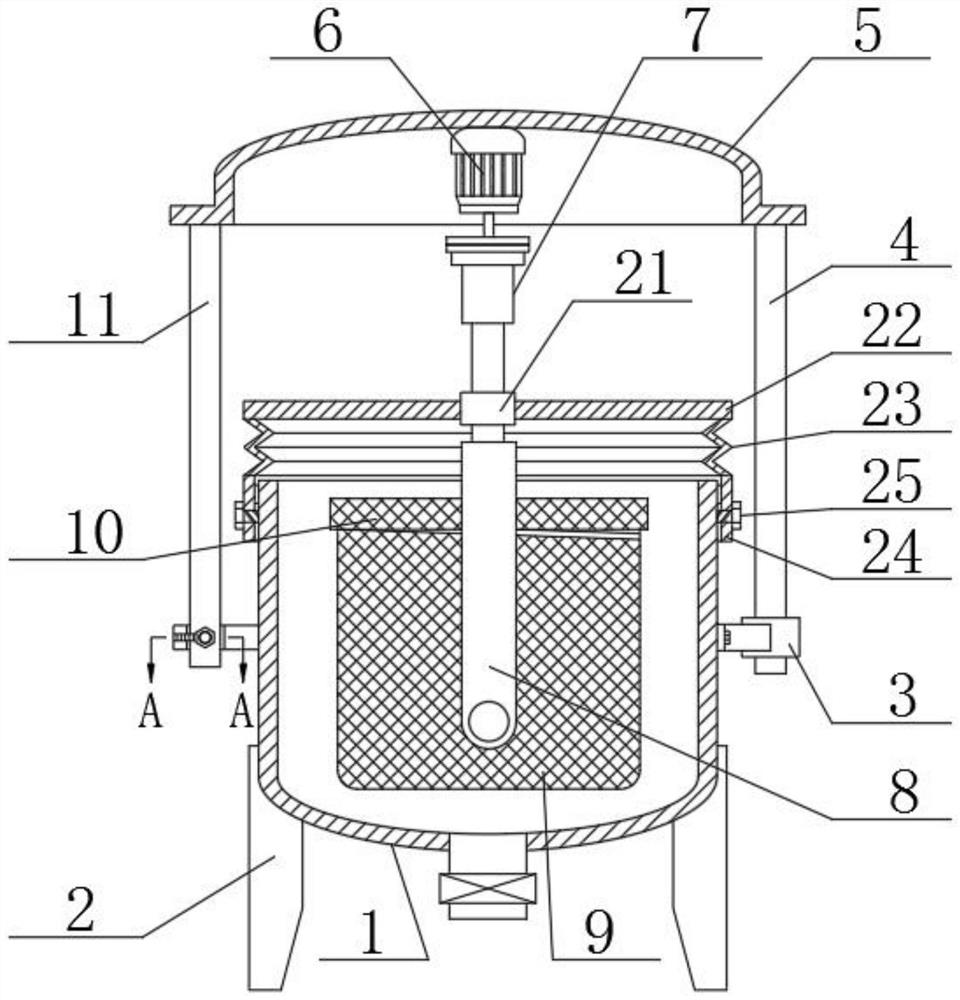

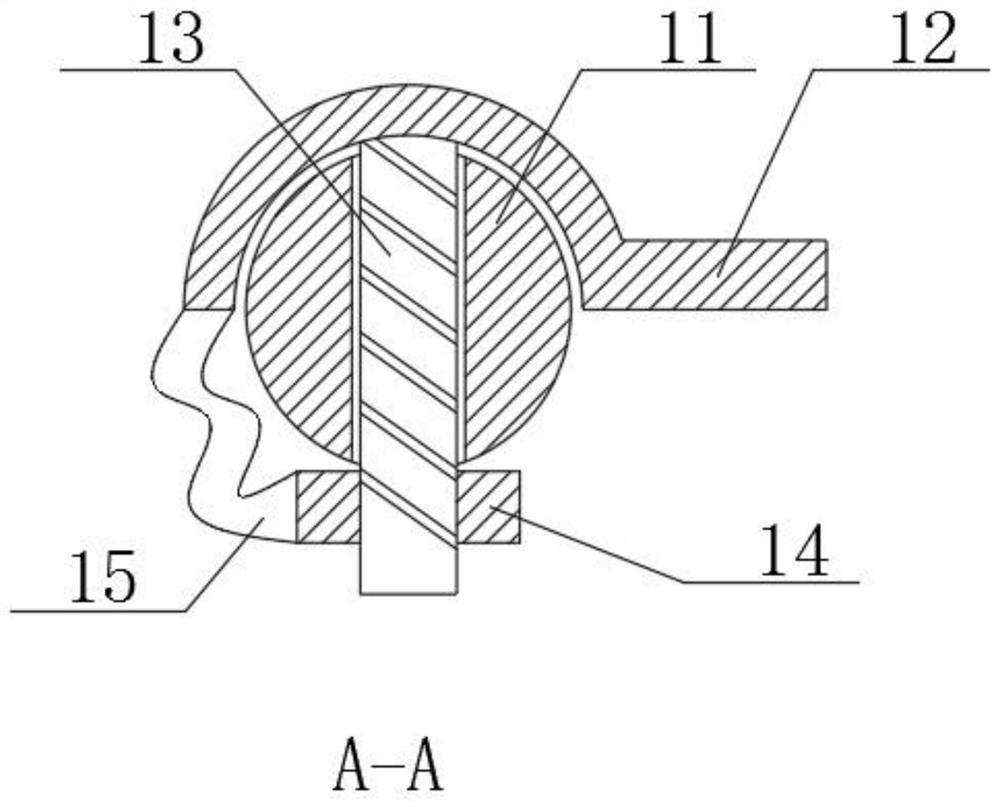

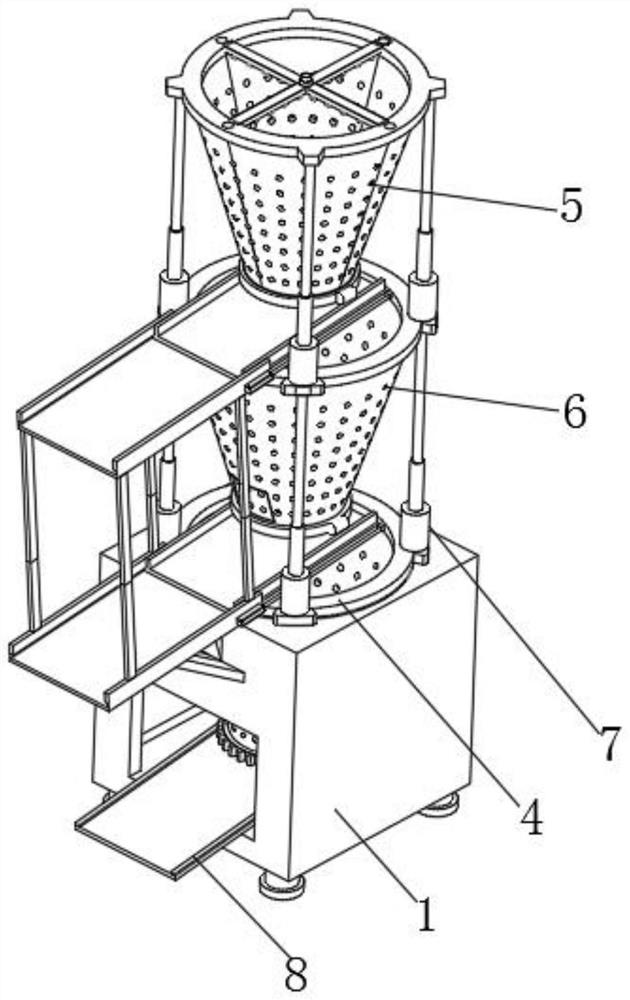

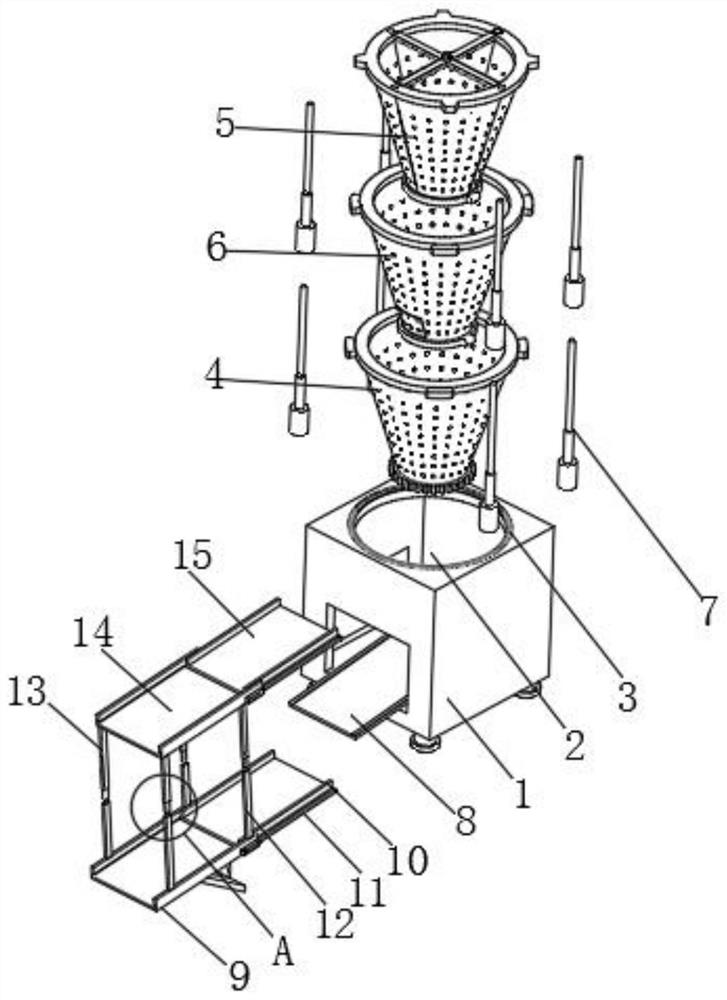

Vertical concrete mixer with screening function

InactiveCN107160556AImprove qualityFully contactedSievingDischarging apparatusFixed frameArchitectural engineering

The invention discloses a vertical concrete mixer with a screening function. The vertical concrete mixer comprises a spiral conveyor, a mixing motor, a slide plate, a first mixing rod and a second mixing rod; a feed hopper is arranged at the lower end of the spiral conveyor; a vibration motor is fixed at one end of a screening plate; two ends of the screening plate are connected through a vibration reducing spring and a support column; an observation window is mounted on a mixing barrel; the slide plate is fixed rightly above a discharge port; the mixing motor is positioned under the mixing barrel; a mixing shaft on the mixing motor penetrates through the mixing barrel to connect with a mixing shaft fixed frame; and the first mixing rod and the second mixing rod are both mounted on the mixing shaft. The vertical concrete mixer with the screening function needs no manual loading, is simple in operation, can remove impurities and large-size particles in raw materials, improves the concrete quality, can perform all-directional mixing to enable the raw materials to fully contact with water so as to achieve high mixing efficiency, and is convenient to quickly take the materials.

Owner:安徽新兴翼凌机电发展有限公司

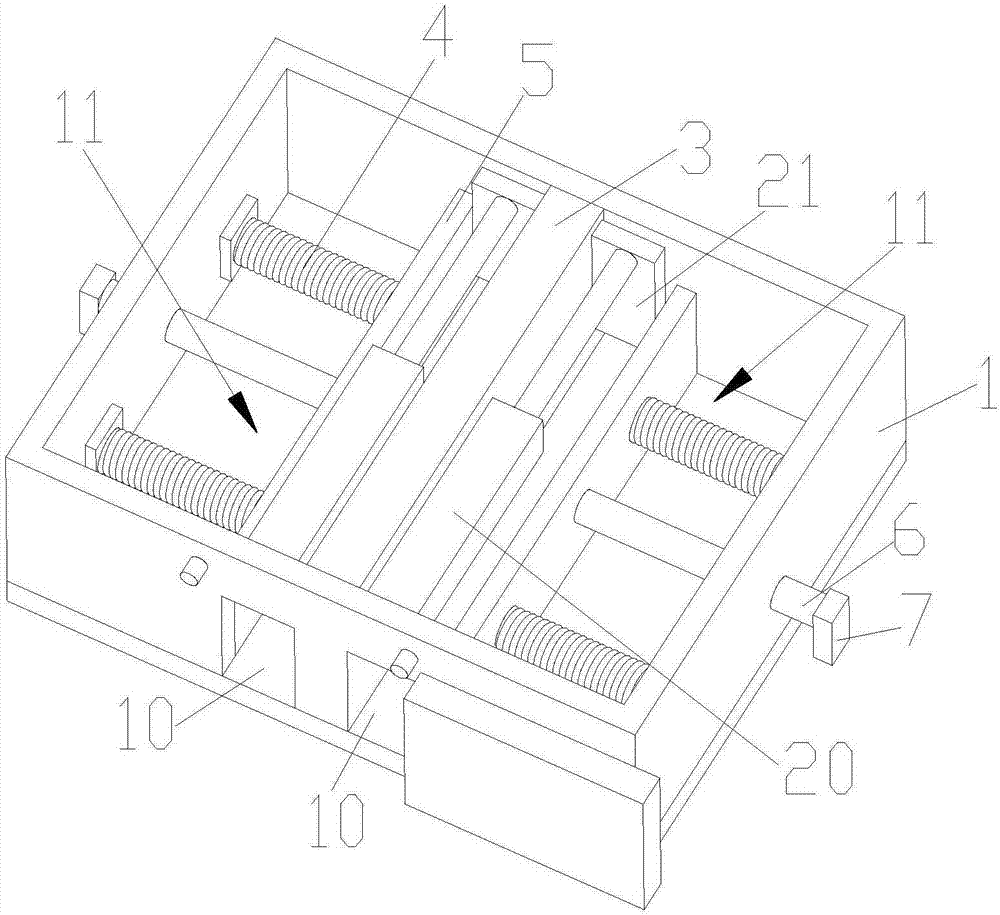

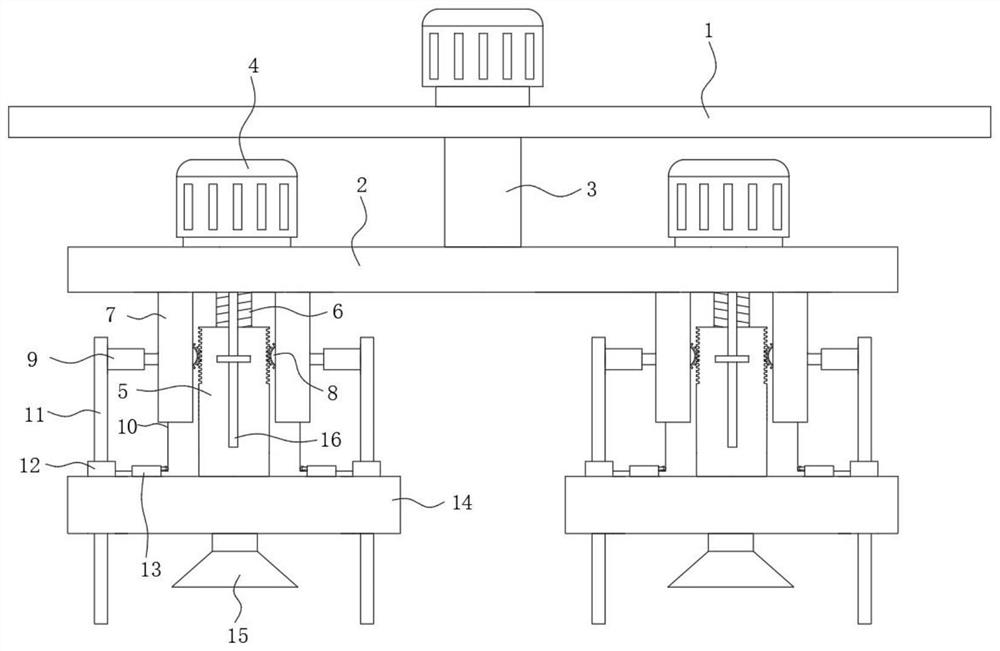

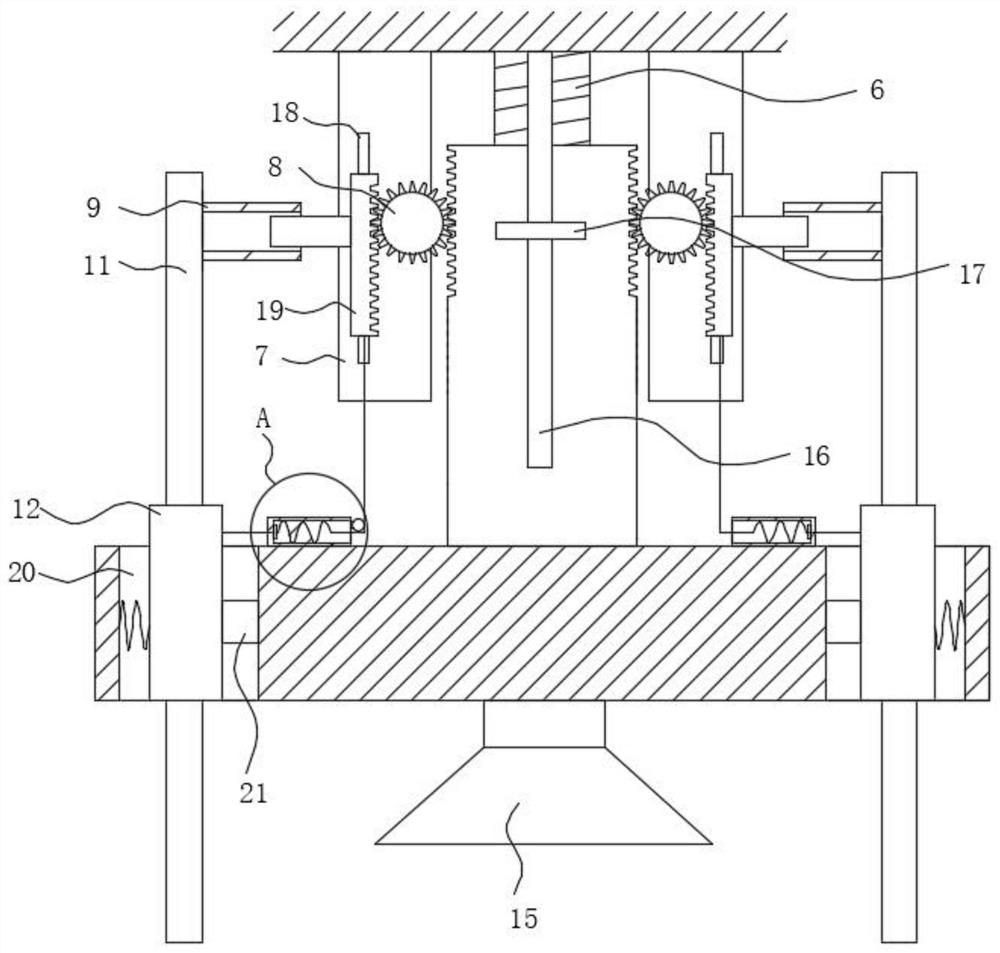

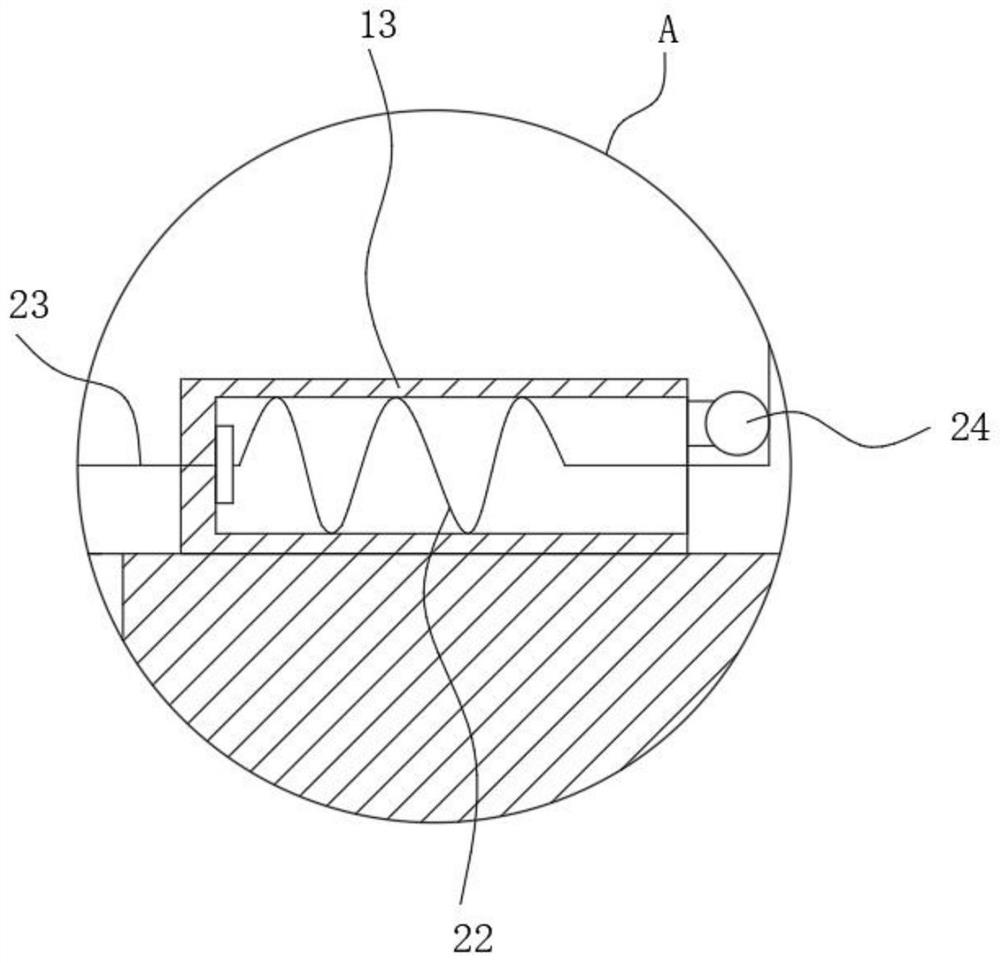

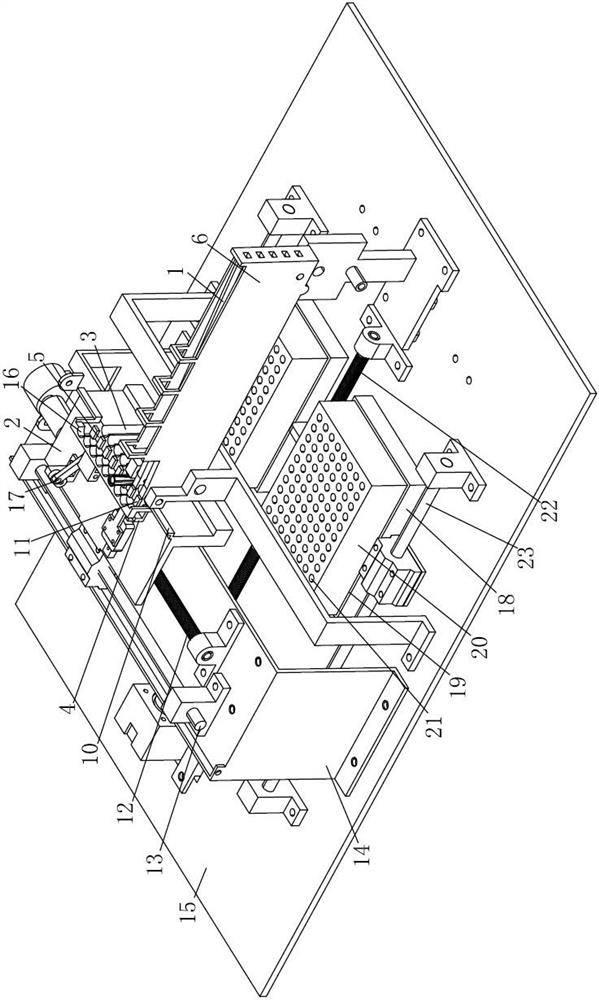

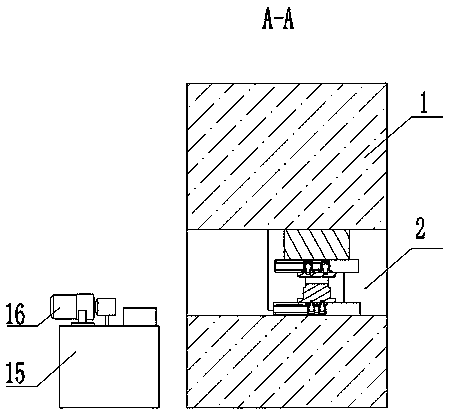

Automatic material discharging mechanism of bush press-in machine

The invention discloses an automatic material discharging mechanism of a bush press-in machine. A workpiece placement platform is fixed on a workbench of the automatic material discharging mechanism. Multiple hexagon prisms are fixed on the lower end face of the workbench and fixed on a base plate. A thin air cylinder is fixed on the lower end face of the base plate. A piston rod of the thin air cylinder penetrates through the base plate and is fixed on a lifting supporting frame plate. A linear bearing is fixed on the lifting supporting frame plate. A guide shaft is inserted in the linear bearing in a sleeved mode. The two ends of the guide shaft are fixed on the workbench and the base plate respectively. Two sets of ejector rods are fixed on the upper end face of the lifting supporting frame plate. The top ends of the ejector rods penetrate through the workbench and are fixedly connected with L-shaped material discharging plates. The L-shaped material discharging plates are located on the left and the right of the workpiece placement platform respectively. An air cylinder installation supporting frame is fixed on the workbench on the rear side of the workpiece placement platform. A guide rod air cylinder is fixed on the air cylinder installation supporting frame. By means of the automatic material discharging mechanism of the bush press-in machine, manual material taking below a punching device is not needed, the labor intensity of operators is relieved and meanwhile, the safety accidents of bruising the hands are avoided.

Owner:XIONG HUA MACHINERY SUZHOU CO LTD

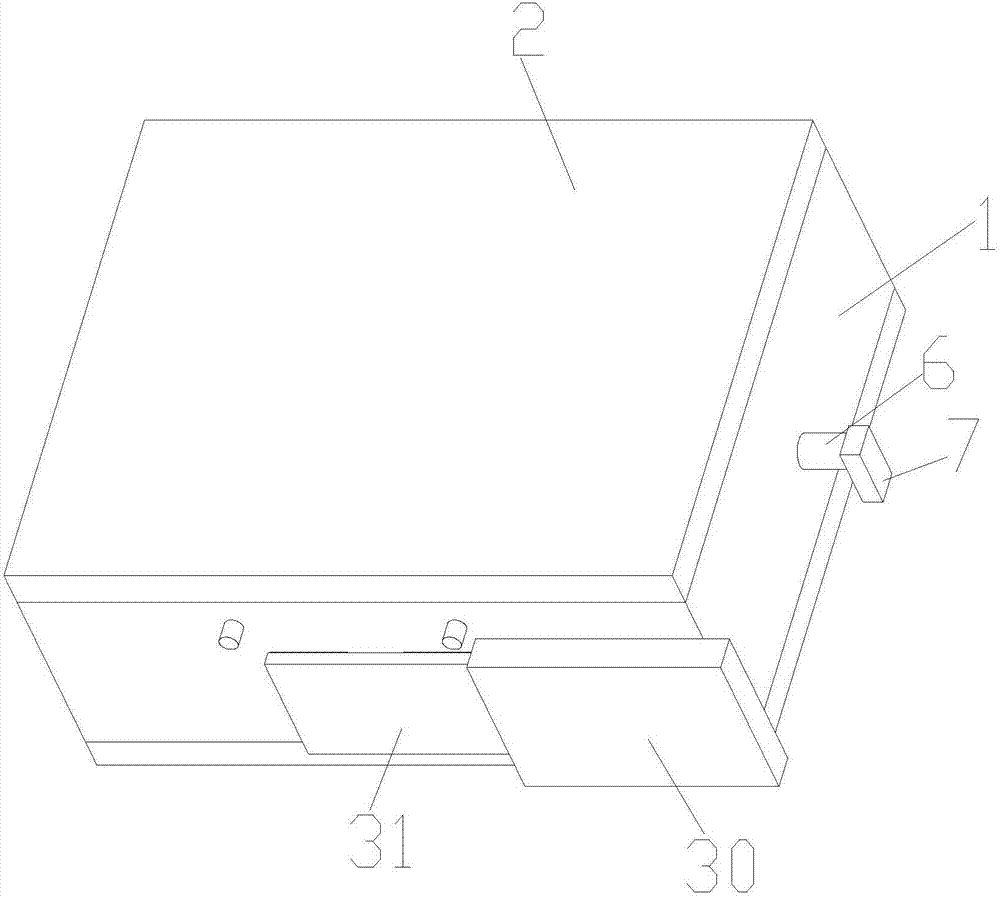

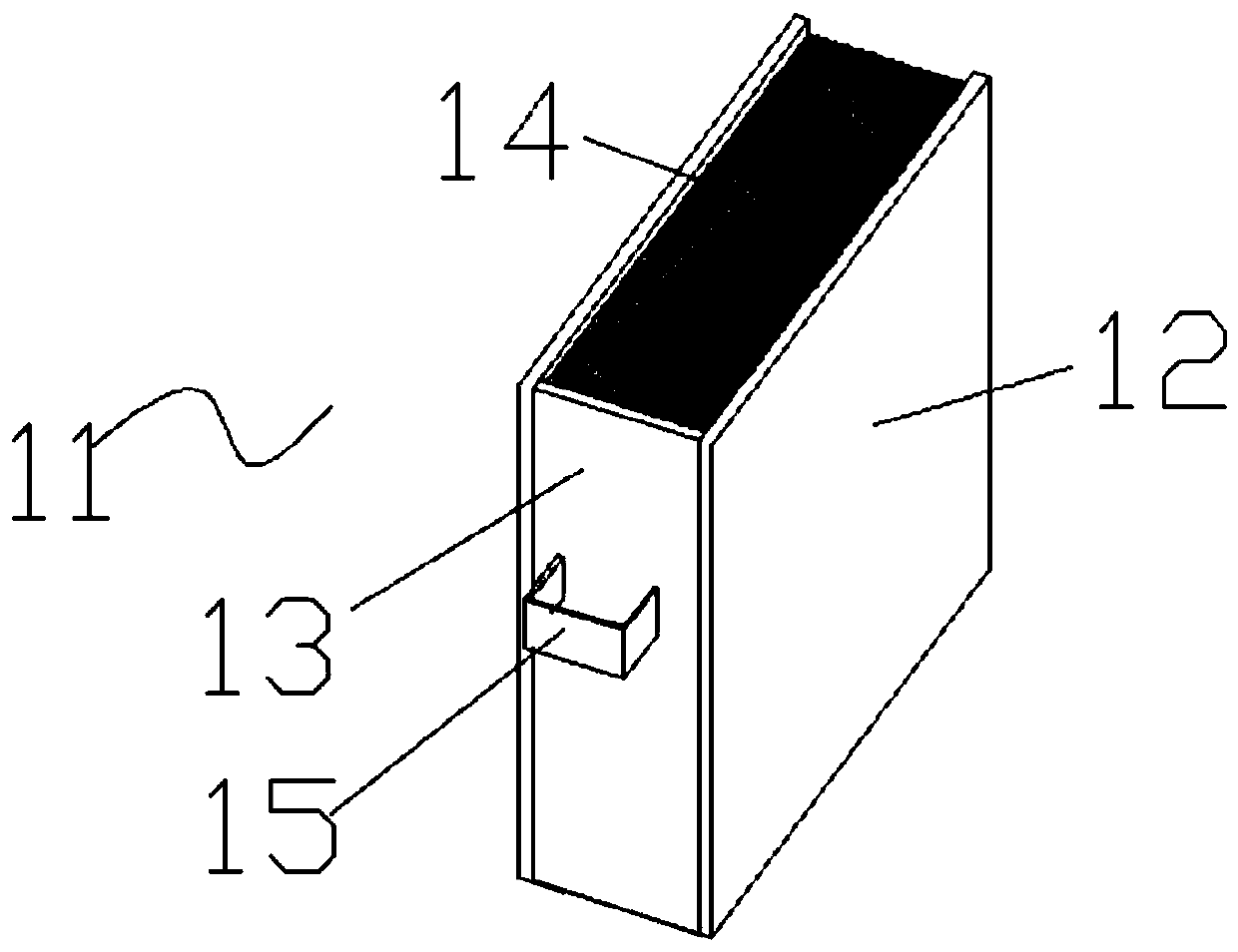

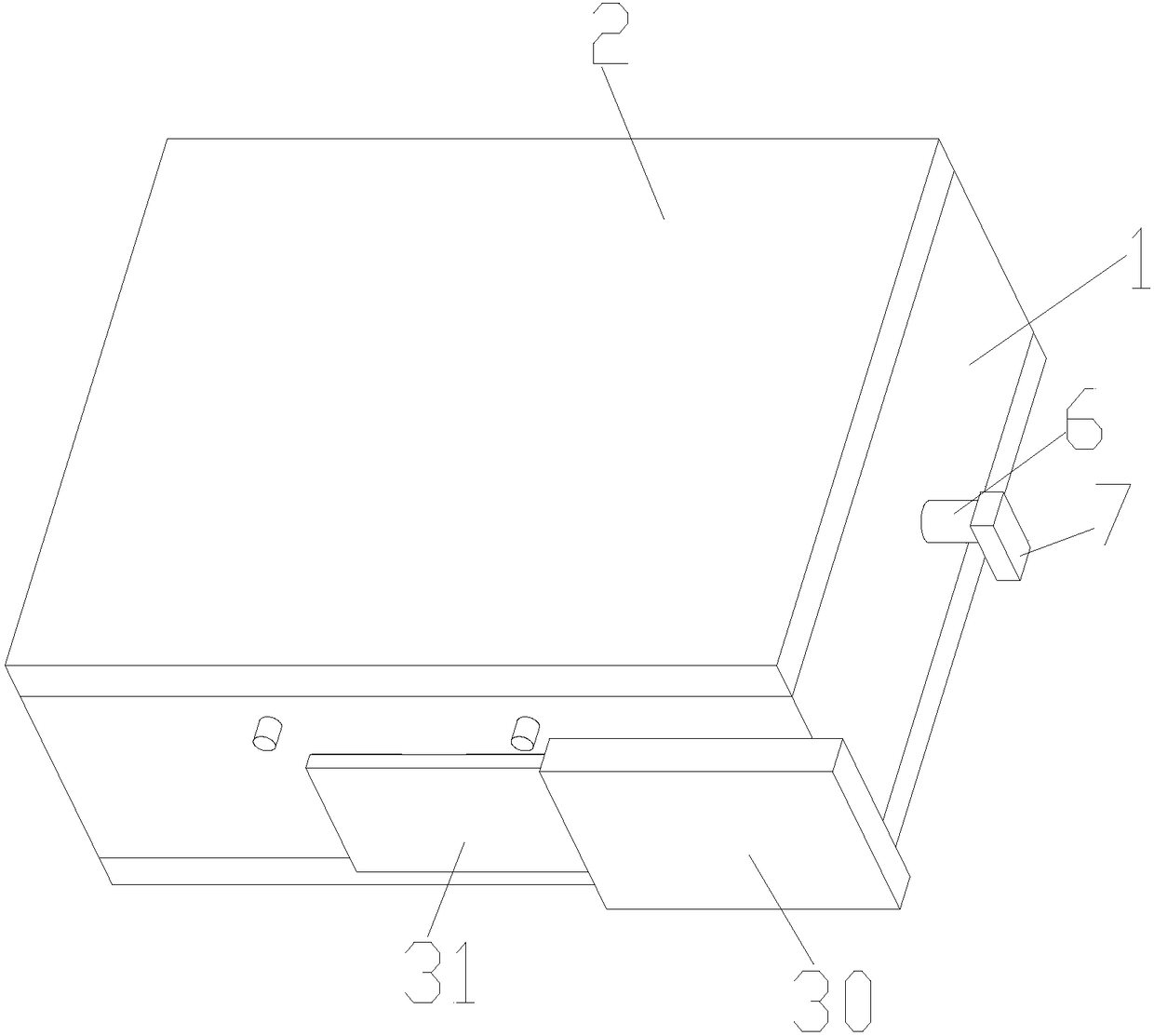

Hardware storage box

The invention discloses a hardware storage box. A detachable box cover is arranged at the upper end of a box frame; a separation plate is arranged in the box frame for dividing the box frame into two accommodating cavities; multiple springs are arranged on one sides of the inner walls of the accommodating cavities; the front ends of the multiple springs are connected through pressing plates; the pressing plates are parallel to the separation plate; a pull rod is arranged on the separation plate; the other end of the pull rod penetrates out of the accommodating cavities to connect with a pull block; outlets are formed in one sides of the accommodating cavities, and are positioned between the pressing plates and the separation plate; mobile modules positioned in the accommodating cavities are arranged between the pressing plates and the separation plate for pushing out hardware from the outlets; and a sealing module is arranged on one side of the box frame for sealing the outlets. The hardware storage box is simple in overall structure, can prevent damage of the hardware during transporting, meanwhile, can conveniently take out the corresponding hardware from the outlets, reduces the labor intensity of workers, accelerates the taking speed, satisfies actual machining demands, and is better in practicability.

Owner:铜陵常江传动工具有限公司

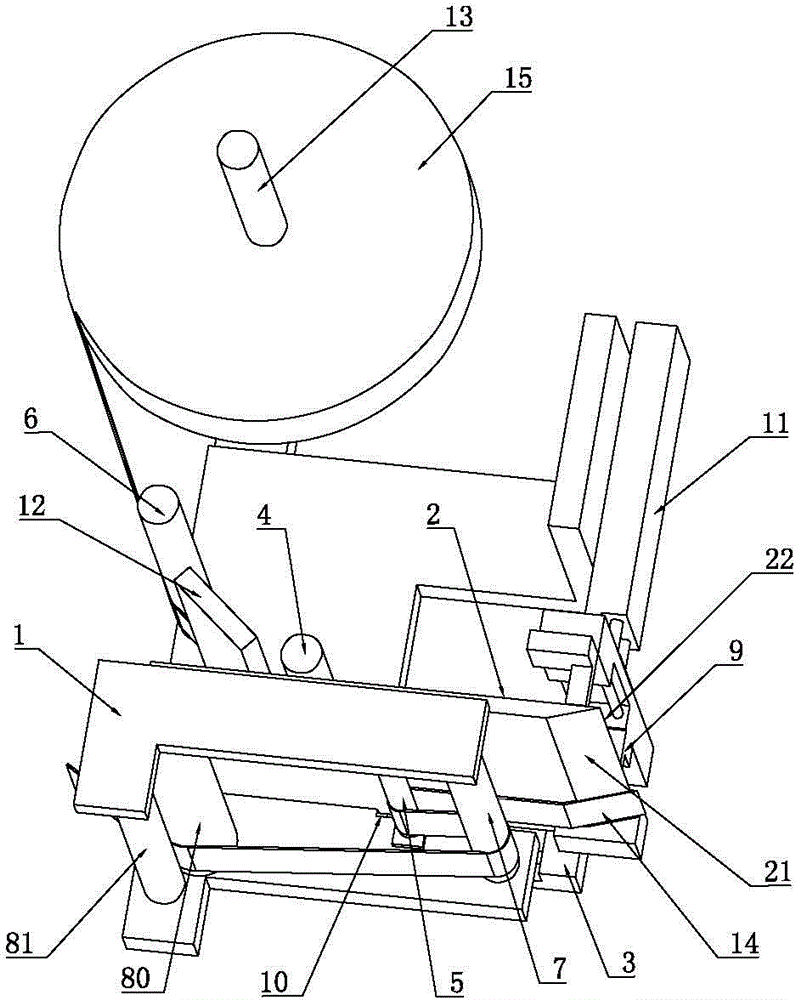

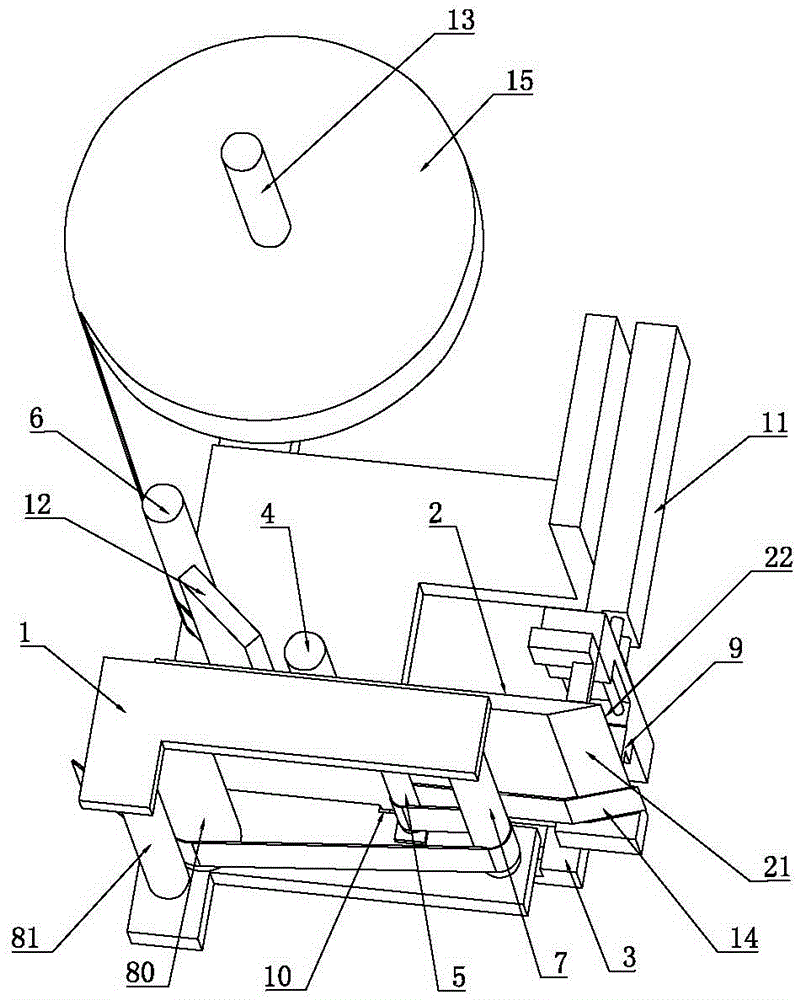

Automatic adhesive pasting device

An automatic adhesive pasting device structurally comprises a suction nozzle and a taking platform, wherein the suction nozzle and the taking platform are arranged on a rack, a first tensioning roller is arranged above the taking platform, a second tensioning roller is arranged below the taking platform, adhesive tape is pre-tightened to the taking platform through the first tensioning roller and the second tensioning roller, the taking platform is provided with a taking position, the suction nozzle sucks foam at the taking position under the action of external driving force and is in a static state at the moment, and then the taking platform moves in the direction far from the suction nozzle under the action of the external driving force to make the adhesive tape aligned with the suction nozzle in a suspended state; meanwhile, the second tensioning roller drives the adhesive tape on the back of the taking platform to move along with the taking platform so that the adhesive tape in the suspended state can move towards the back of the taking platform and be stripped off from the foam to be taken. According to the automatic adhesive pasting device, in the taking process, the situation that the foam drives the adhesive tape to move can be effectively prevented, and the adhesive tape is made to keep constant tension all the time; as a result, the production efficiency can be improved, and a good adhesive pasting effect is ensured.

Owner:东莞华誉精密技术有限公司

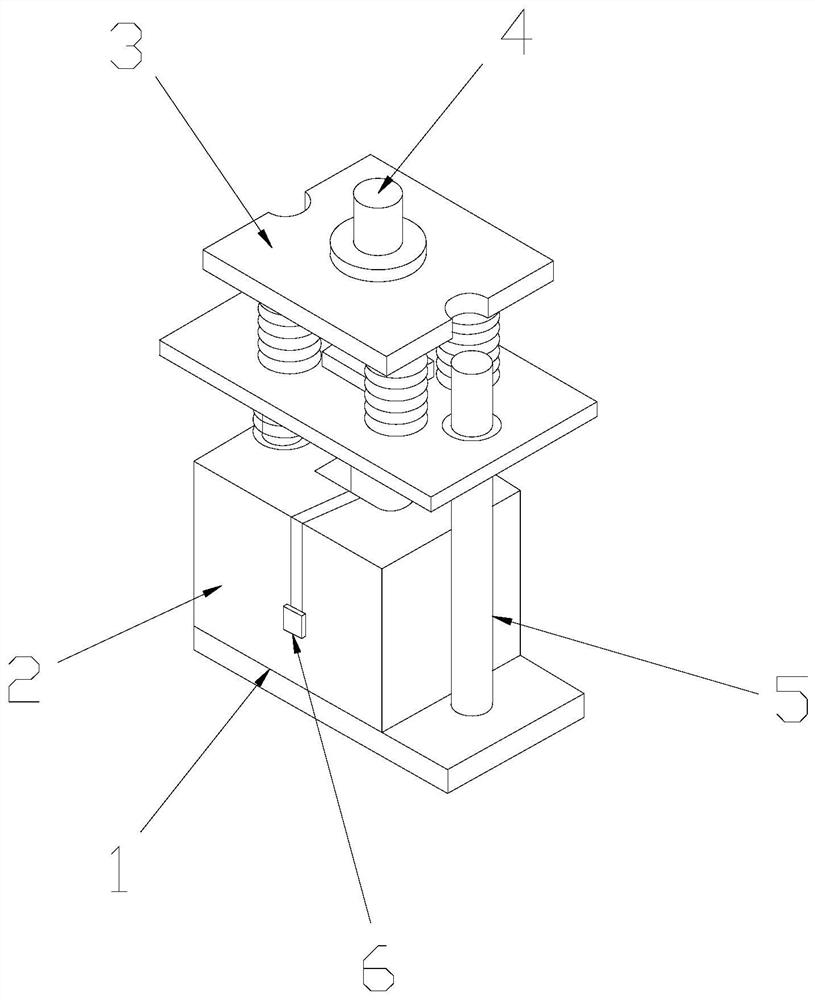

Material ejecting device facilitating metal mold processing

The invention belongs to the technical field of mold processing and particularly relates to a material ejecting device facilitating metal mold processing. The material ejecting device comprises a boxbody. A refrigeration box is fixedly connected to the top of the box body. A hydraulic cylinder is fixedly connected to the top of the box body. A working box is fixedly connected to the inner bottomwall of the box body. A lower mold is fixedly connected to the top of the working box. Sliding rods are correspondingly and fixedly connected to the top of the lower mold. An upper mold is slidably connected to the outer surfaces of the sliding rods. The top of the upper mold is fixedly connected with the bottom end of the hydraulic cylinder. A gas outlet pipe is fixed to the bottom of the refrigeration box in a communicated manner. The top of the lower mold is movably connected with a mold plate. A moving block is fixedly connected to the bottom of the mold plate. According to the material ejecting device, the function of lifting the moving block can be played through a button, a push rod, a first spring, a rolling wheel and a triangular block, the quick automatic material ejecting purpose is achieved, the material taking speed is increased, and the production efficiency is improved greatly.

Owner:江苏金科森电子科技有限公司

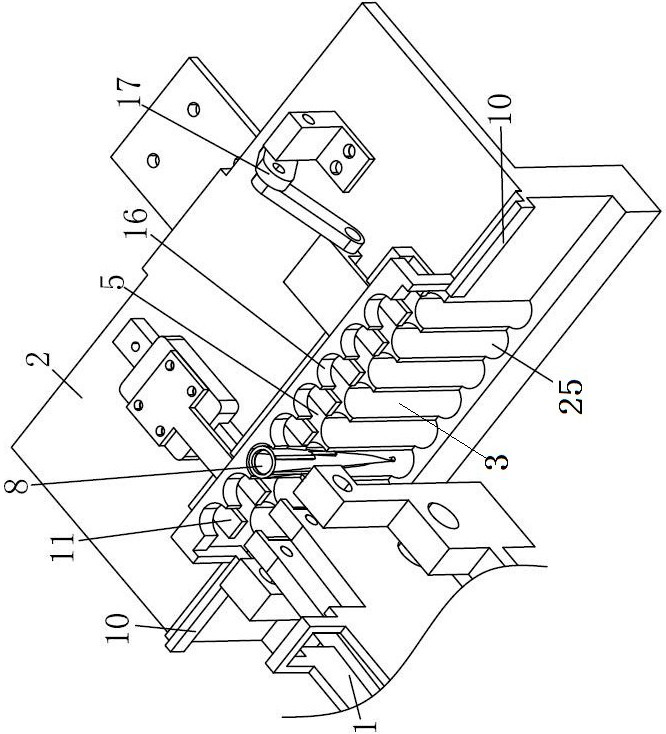

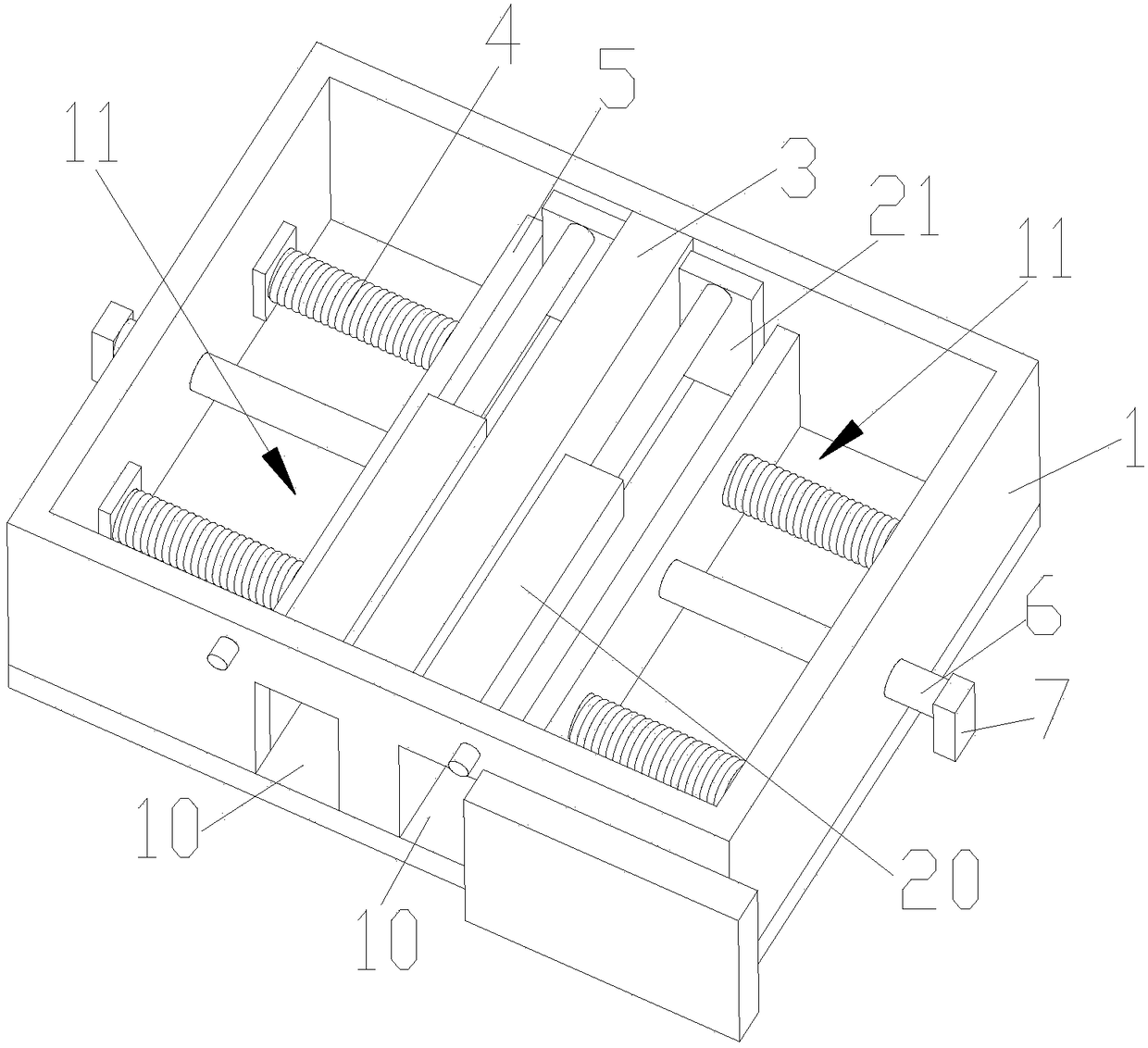

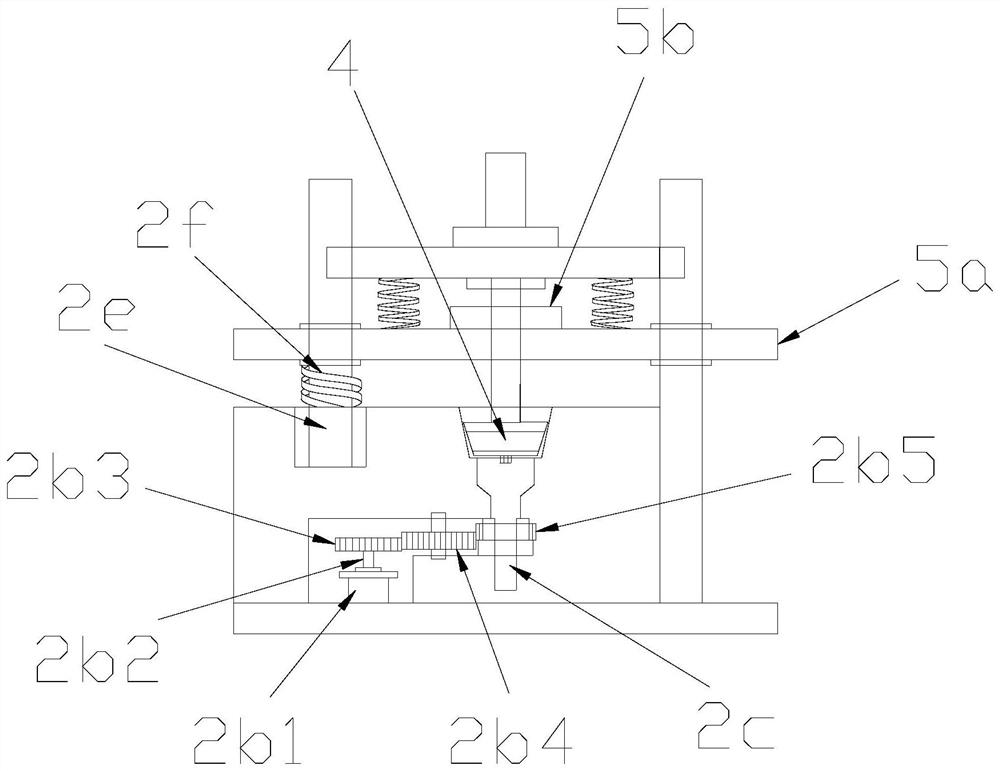

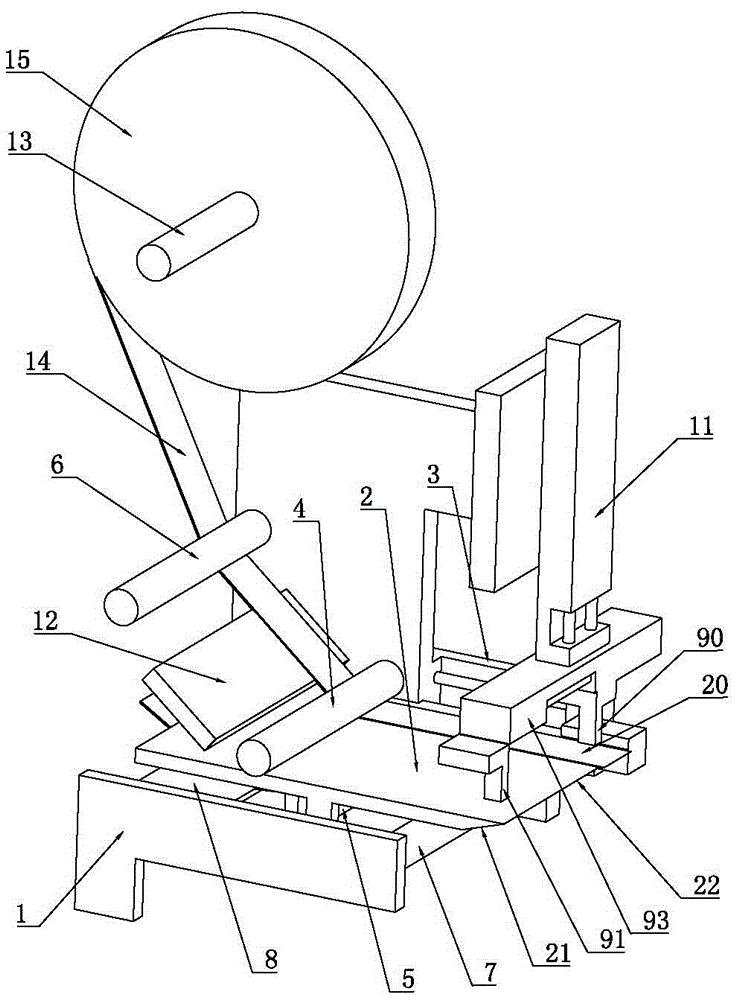

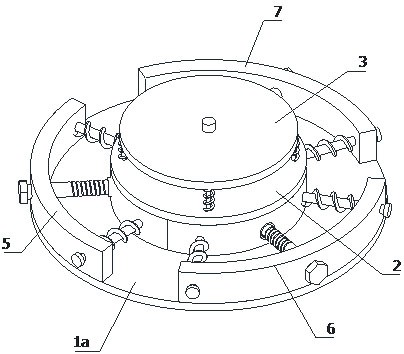

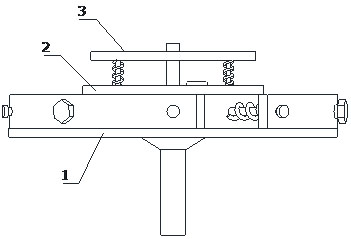

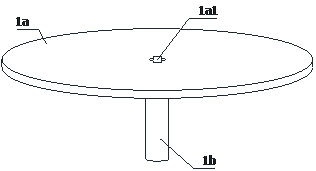

Material taking mechanism of LED chip mounter

ActiveCN113347870AConvenient to get close to each otherEasy to toggleElectrical componentsSurface mountingEngineering

The invention relates to the technical field of LED chip mounters and particularly relates to a material taking mechanism of an LED chip mounter, and aims to solve a problem that an LED chip mounter in the prior art is easy to cause inaccurate material suction positions during material taking. The material taking mechanism comprises a turntable, a driving mechanism mounted at the top of the turntable and two material taking mechanisms symmetrically mounted on a bottom surface of the turntable, wherein the material taking mechanism comprises a lifting motor, a longitudinally-arranged lifting assembly and a material suction base installed at the bottom of the lifting assembly, the lifting motor drives the lifting assembly to move in the longitudinal direction through a threaded column, a material suction nozzle is installed in the middle of the bottom face of the material suction base, and two longitudinally-arranged clamping plates are installed on the material suction base. The material taking mechanism is reasonable in structure and easy to operate, materials can be stirred to the position under the material suction nozzle when the materials are sucked, so accuracy of material suction is guaranteed, then precision of surface mounting is guaranteed, and the material suction mechanism is easy to popularize and use.

Owner:安徽德浦照明科技有限公司

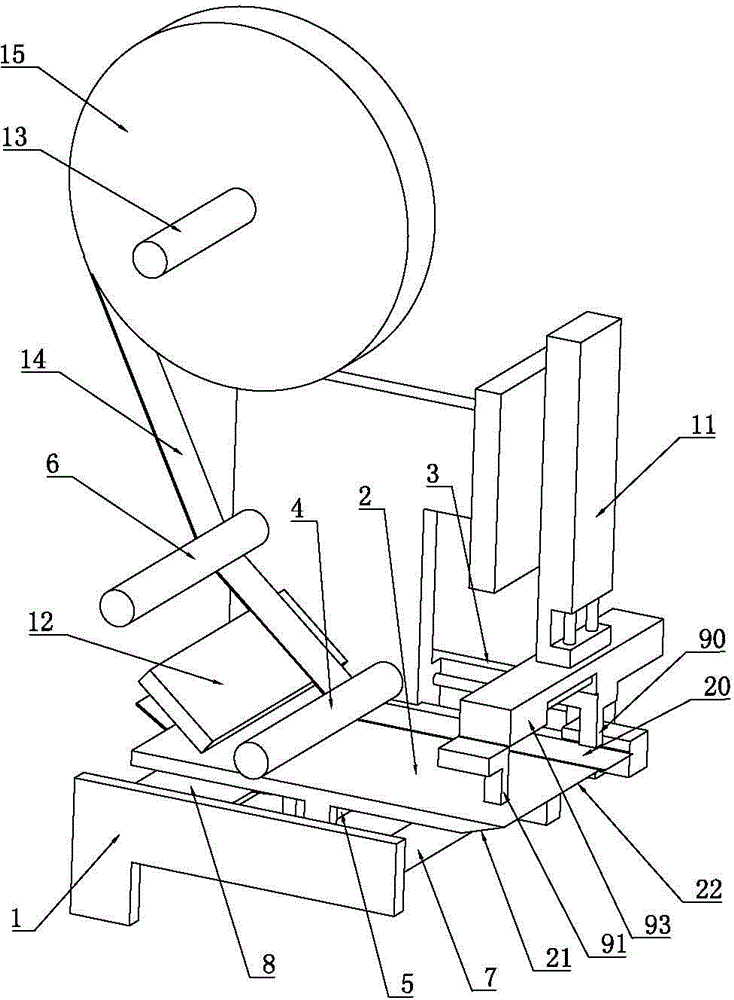

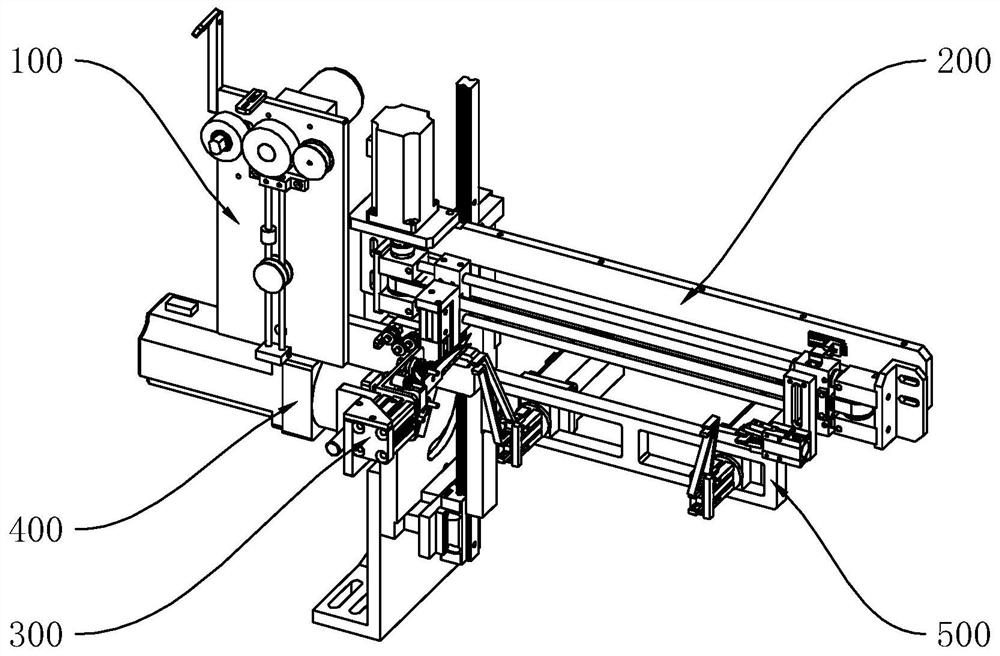

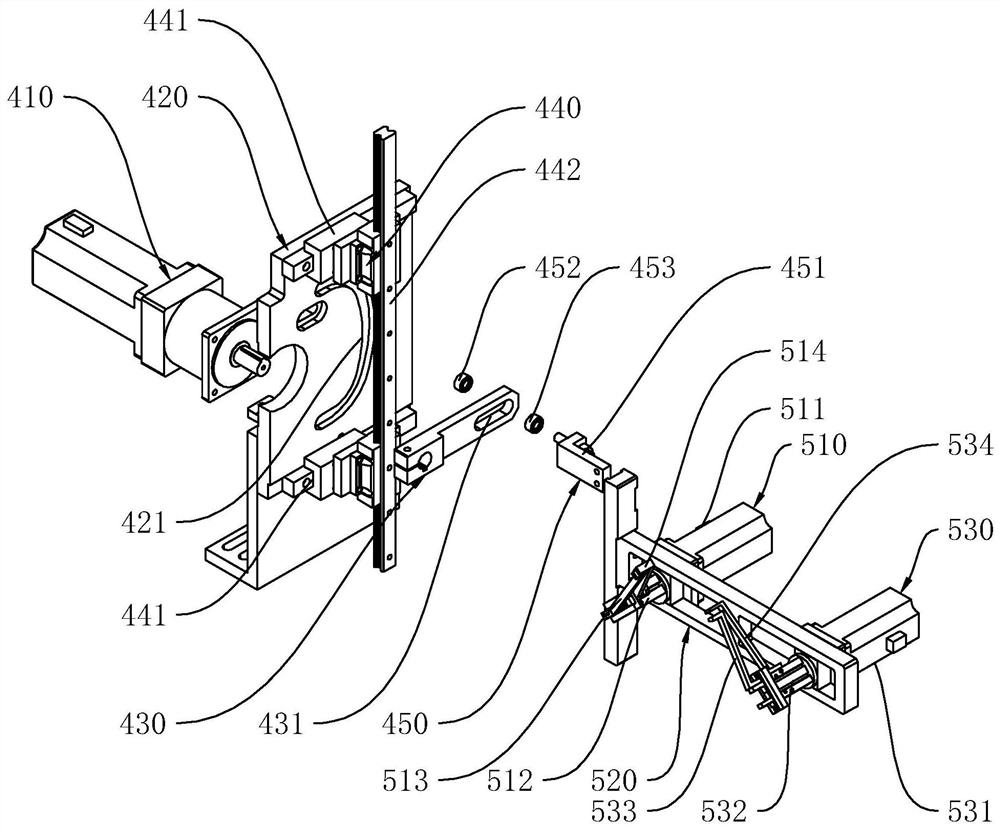

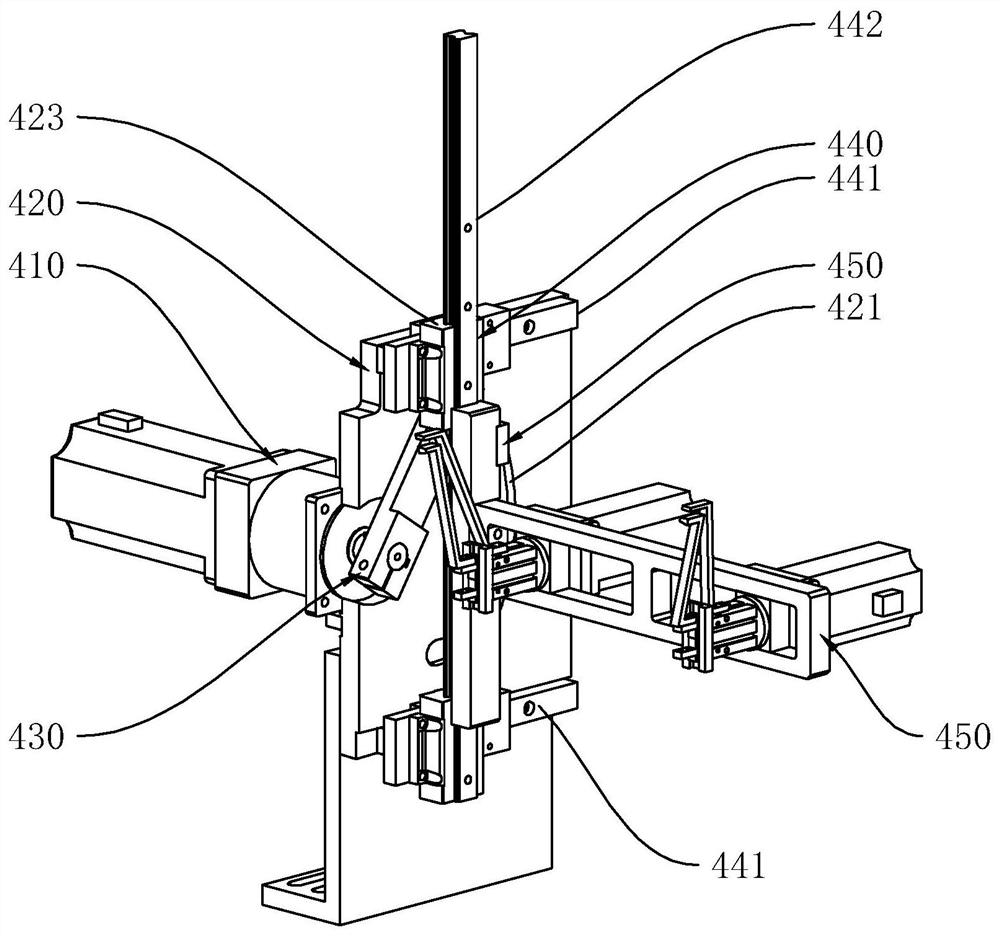

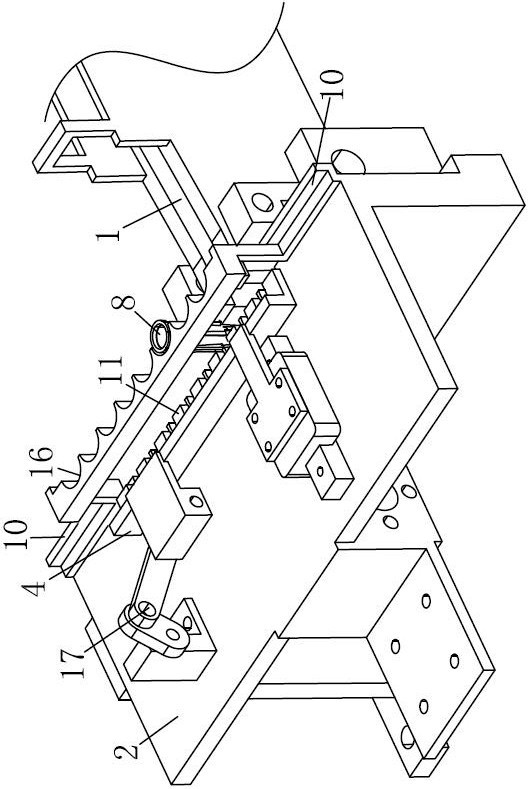

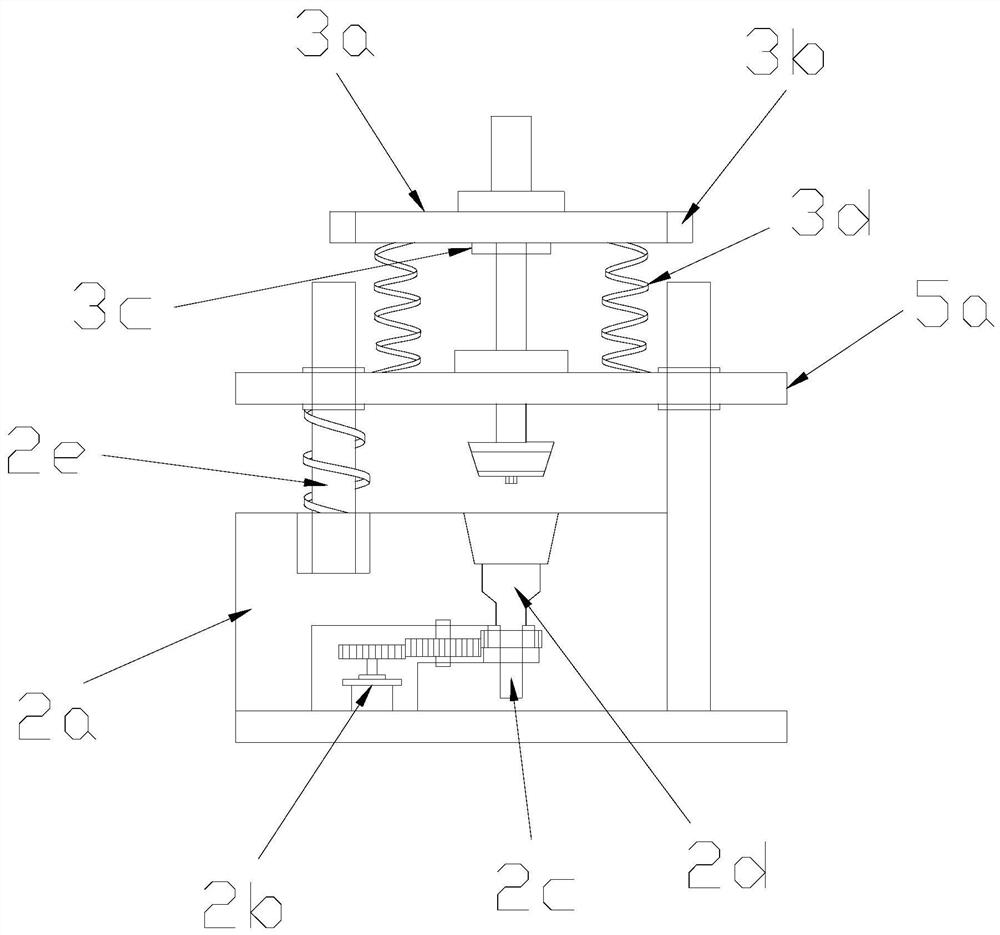

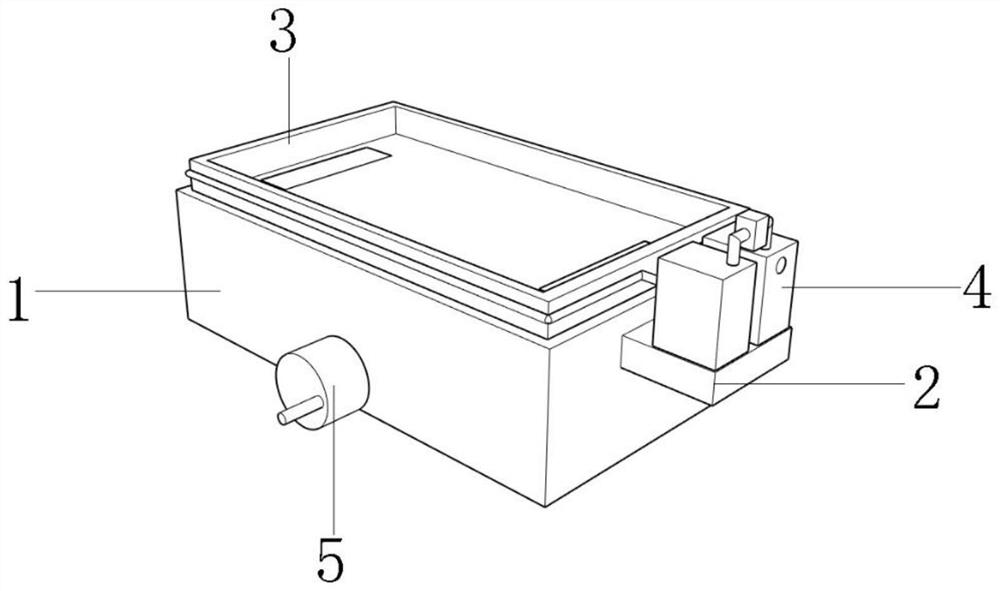

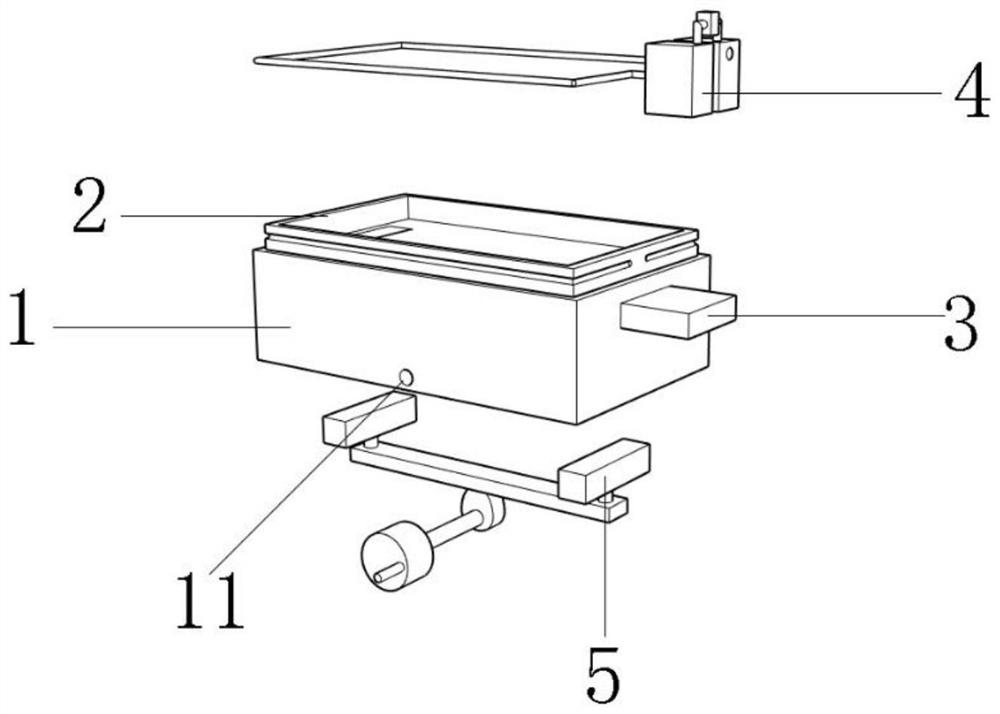

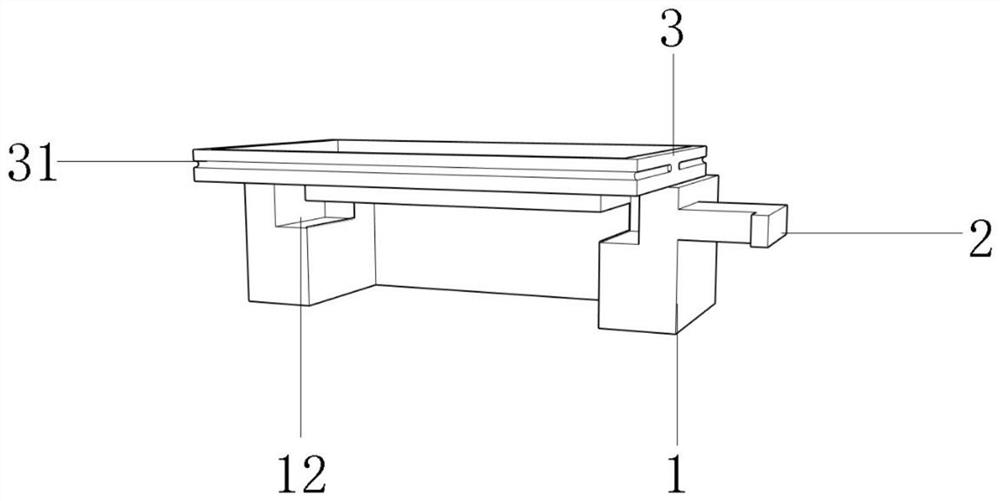

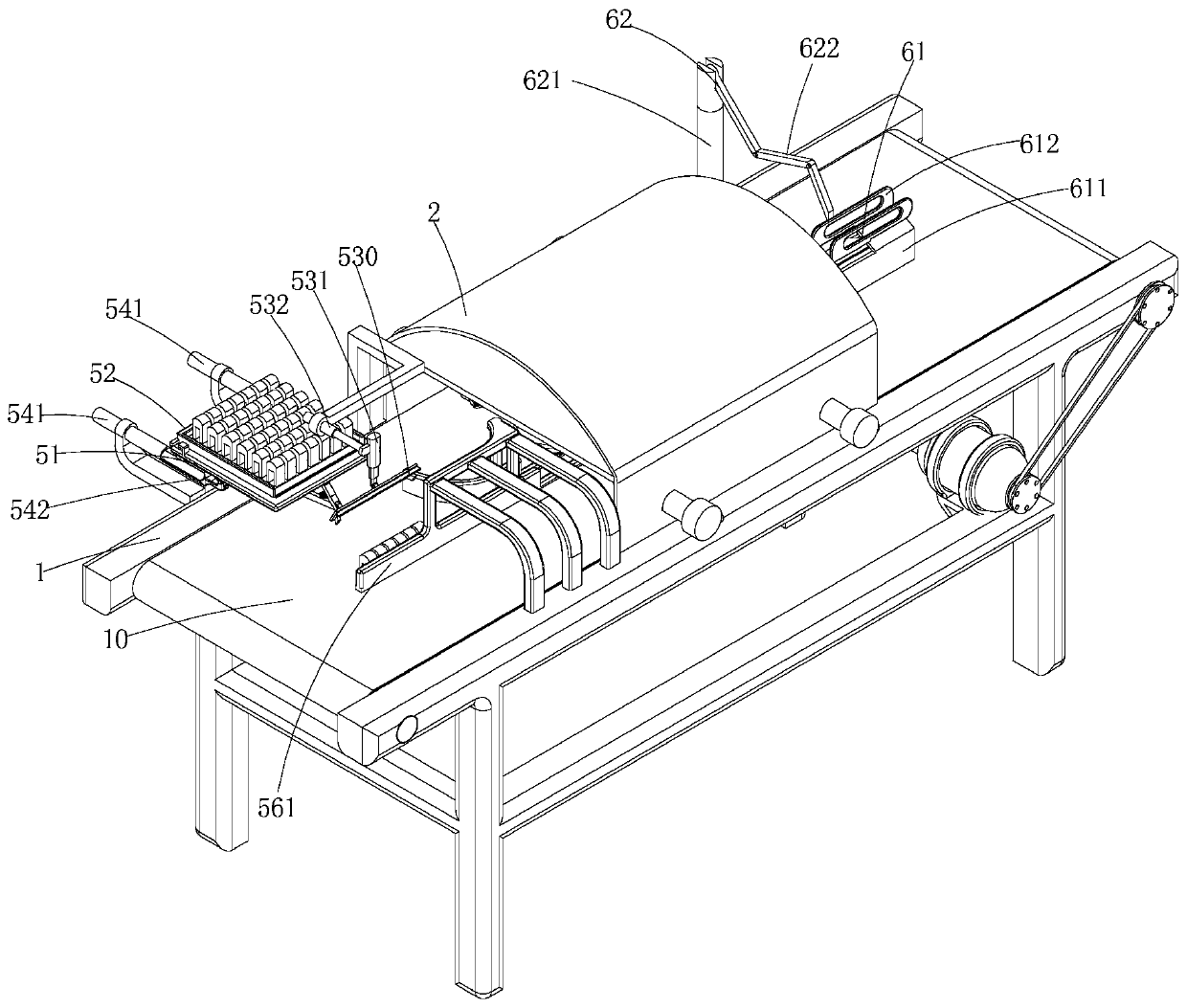

Ear band feeding device

PendingCN112120331AReclaiming speed is fastIncrease the feeding speedProtective garmentClothes making applicancesBand bendingControl system

The invention discloses an ear band feeding device, which comprises an ear band bending device, a connecting mechanism, an ear band conveying device and a control system. The connecting mechanism comprises a connecting block, a first bearing follower and a second bearing follower; the connecting block is connected with the ear band bending device; the first bearing follower and the second bearingfollower are respectively connected with the connecting block; the ear band conveying device comprises a power device, a mounting plate, a connecting rod and a limiting guide mechanism for limiting rotation of the ear band bending device; a curved groove is formed in the mounting plate; a first sliding groove is formed in the connecting rod; the first bearing follower is connected with the curvedgroove in a sliding manner; the second bearing follower is connected with the first sliding groove in the sliding manner; and a power device is connected with the connecting rod and used for driving the connecting rod to rotate so that the ear band bending device can horizontally move along the track of the curve groove. According to the technical scheme, movement is stable, the feeding speed is high, the positioning precision is high, and the production efficiency of a three-dimensional mask is greatly improved.

Owner:广东瀚迪科技有限公司

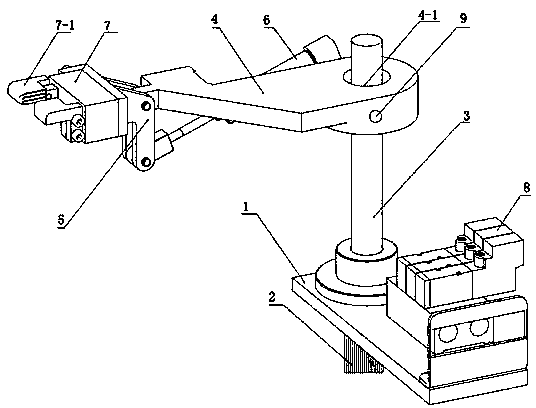

Welding material taking mechanical arm

InactiveCN103506781ASimple structureSimple motion trackProgramme-controlled manipulatorWelding/cutting auxillary devicesCost effectivenessElectric machinery

The invention discloses a welding material taking mechanical arm which comprises a machine base, a motor, a connecting rod, a hanging arm, a connecting block, an air cylinder, a pneumatic finger, pneumatic pipelines and a solenoid directional valve. The connecting rod is vertically arranged on the machine base. The bottom of the connecting rod is in transmission linkage with the motor. The top of the connecting rod is provided with the hanging arm. The end portion of the hanging arm is hinged to the connecting block. One end of the connecting block is provided with the pneumatic finger. A clamping block of the pneumatic finger is made of heat-resisting materials. The air cylinder used for driving the connecting block to turn is connected between the other end of the connecting block and the hanging arm. The air cylinder and the pneumatic pipeline are connected with the solenoid directional valve through the pneumatic pipelines. The welding material taking mechanical arm has the advantages of being simple in structure, high in cost-effectiveness ratio and the like.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

LED pick and place machine reclaiming mechanism

ActiveCN113347870BConvenient to get close to each otherEasy to toggleElectrical componentsControl engineeringElectric machinery

Owner:安徽德浦照明科技有限公司

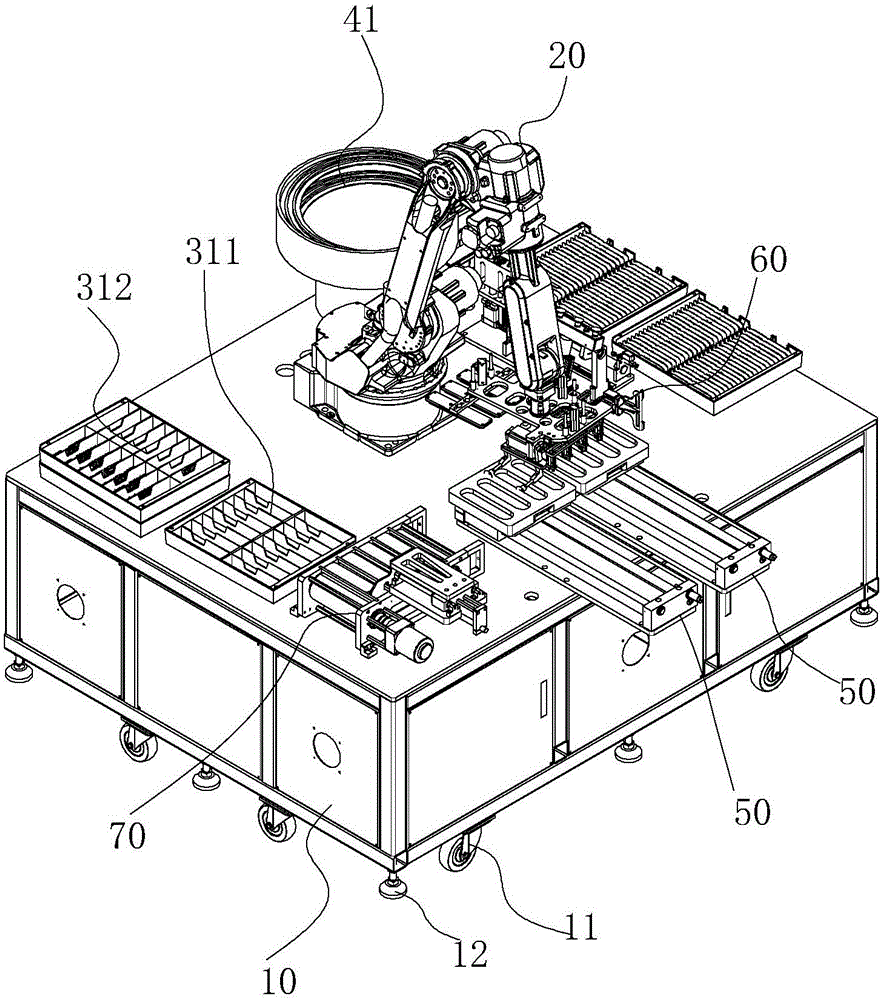

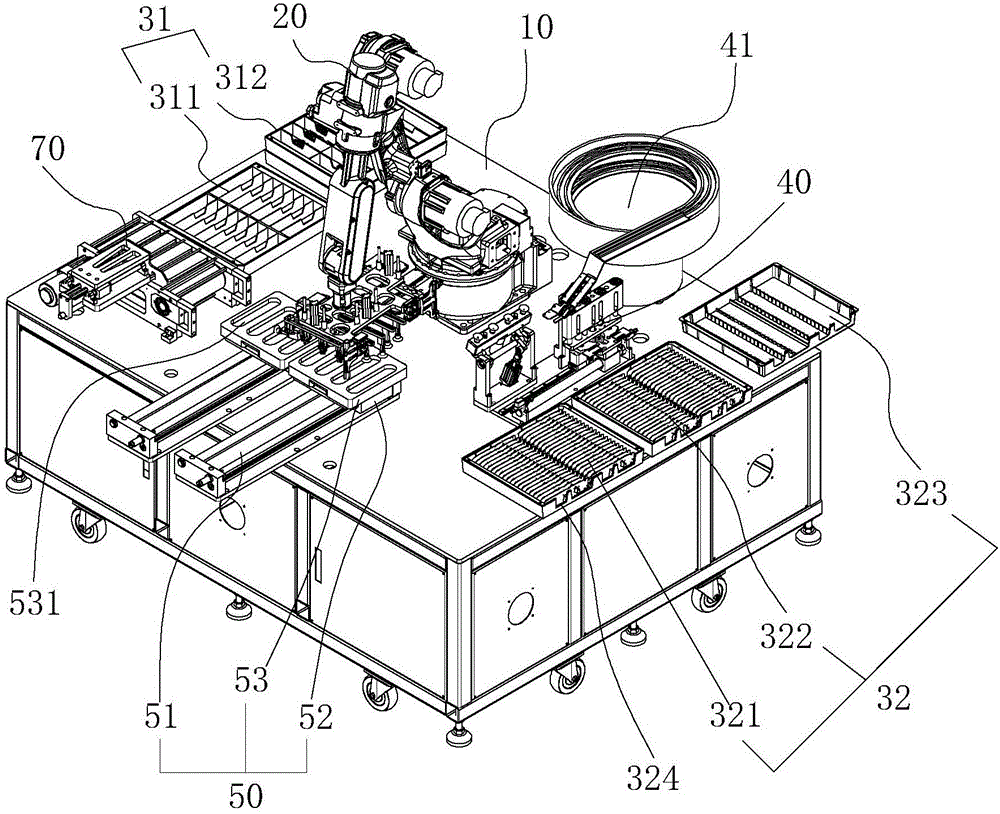

Remote control assembly equipment

ActiveCN103722376BReduce in quantityReduce positioning accuracyGripping headsAssembly machinesRemote controlEngineering

The invention discloses remote-control unit assembling equipment which comprises a machine base. A robot, a silica gel feeding area on the side edge of the robot, a PCB feeding area, a direction key feeding device and running table mechanisms are arranged on the machine base, and assembling jigs used for assembling a remote-control unit are arranged on the running table mechanisms. A clamp device used for clamping a workpiece and a material box is arranged at the movable end of the robot. One operator mounts a face cover on the jigs of the running table mechanisms, then direction keys, silica gel and a PCB are assembled through the robot, the number of operation personnel is greatly reduced, labor cost is lowered, precise mounting is achieved through the robot, and poor products or the difference of product quality cannot occur easily. In addition, a silica gel secondary locating device is arranged, the locating precision of the robot is lowered, and the work efficiency of the robot is improved. Clamping and feeding of various parts and the material box are achieved through the robot. The direction key feeding device is arranged, the robot can fast clamp the direction keys, and the material taking speed of the robot is further improved.

Owner:SHENZHEN RAPOO TECH

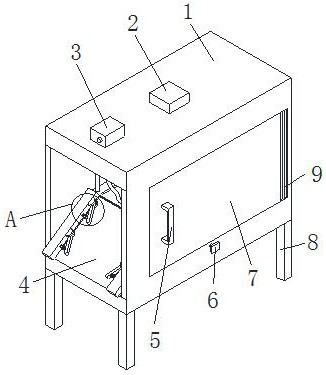

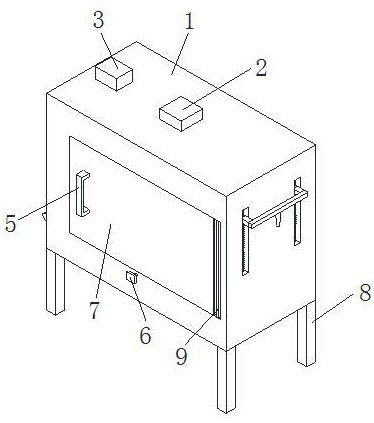

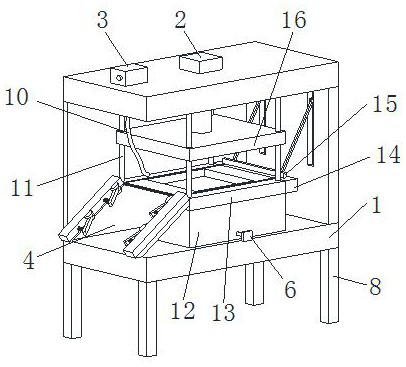

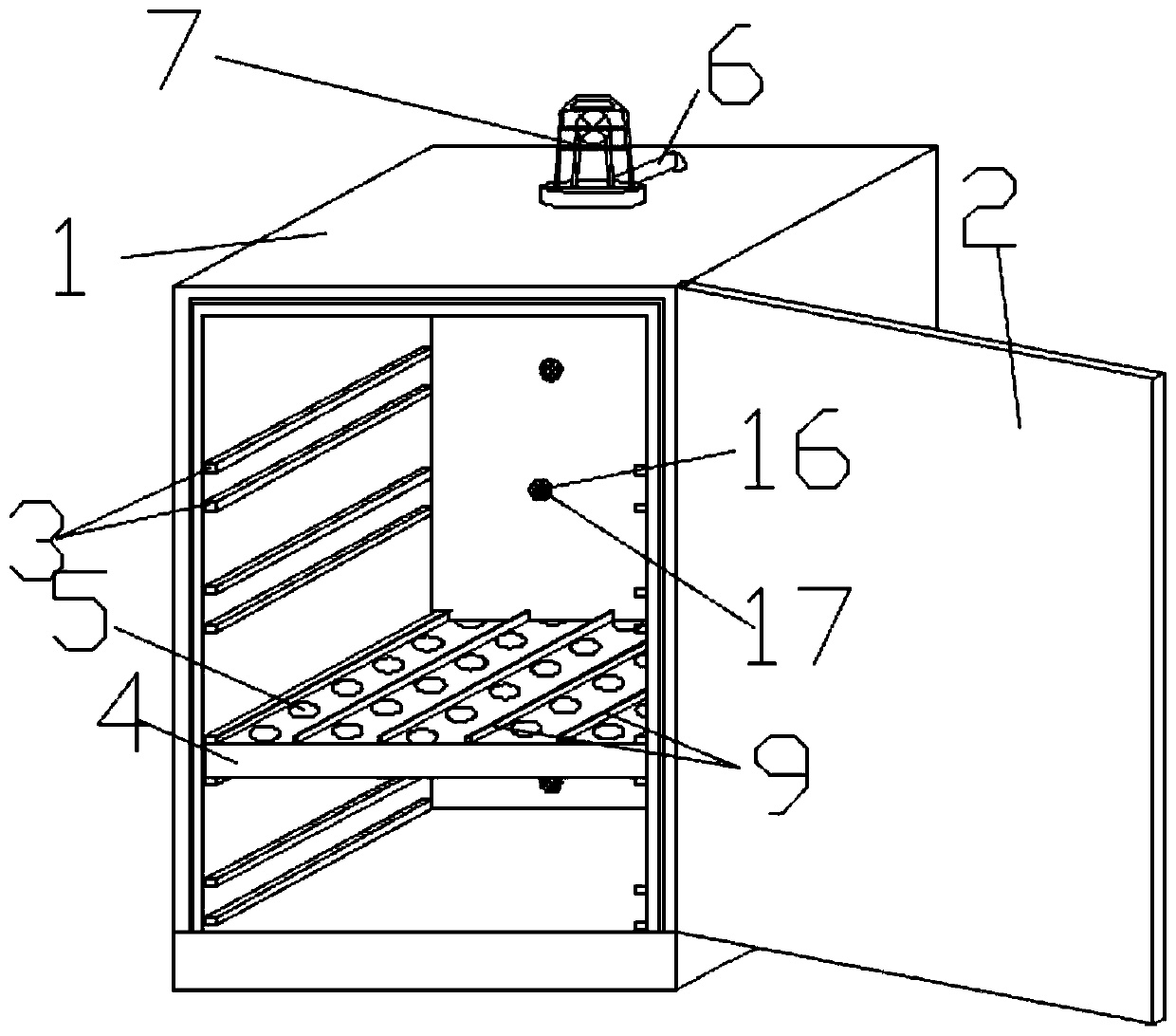

Tea drying box

InactiveCN110822834AOvercome the disadvantage of needing to bend down and then fabricateReclaiming speed is fastPre-extraction tea treatmentDrying gas arrangementsStructural engineeringAir blower

The invention discloses a tea drying box. The tea drying box comprises a housing, wherein a door is hinged to the housing; a plurality of box bodies are sequentially mounted in the housing from top tobottom; air outlet holes are uniformly formed in the upper surfaces and the lower surfaces of the box bodies; the box bodies communicate with a hot air blower through communicating pipes; a pluralityof longitudinal spacing bars which are arranged in parallel are formed on two sides of the upper surface and the lower surface of each box body; a drawer is mounted between the longitudinal spacing bars; each drawer comprises two side plates; the front ends of the two side plates are connected with each other through a front end plate; and a plurality of net plates are sequentially fixed betweenthe two side plates from top to bottom. The tea drying box is simple in structure and convenient to use, facilitates distributing and discharging, is uniform in drying and good in drying effect, and guarantees the drying quality and the drying speed of tea.

Owner:石门梦健生态农业开发有限公司

Disposable packaging bag facilitating material taking

The invention discloses a disposable packaging bag facilitating material taking. The disposable packaging bag facilitating material taking comprises a plastic film and a plastic sheet which is connected with the plastic film. A sealed cavity for padding is formed between the plastic film and the plastic sheet. The plastic sheet is provided with a tearable line for the padding to be extruded out of the sealed cavity. According to the disposable packaging bag facilitating material taking, the plastic sheet is provided with the tearable line, during material taking, the padding is directly extruded out, the padding can be taken out after the tearable line is broken, the material taking speed is high, and it is not need to shear or tear the packaging bag open.

Owner:SICHUAN HUILI IND

A gear processing surface grinding device

ActiveCN113245944BReclaiming speed is fastImprove convenienceEdge grinding machinesGrinding carriagesMachined surfaceGear wheel

The invention discloses a gear processing surface grinding device, which comprises a bottom plate and a top cover. A top case is installed on the top of the bottom plate, and the center line of the top case and the center line of the bottom plate are on the same vertical straight line; The top of the shell is provided with a processing groove, and the inner center of the processing groove is provided with a top groove; the top cover is arranged inside the top groove, and a push rod is installed at the bottom of the top cover; Convenience, and can be adjusted by itself following the inner diameter of the gear. Second, during the process of returning the material after processing, the push rod moves down to drive the ejector plate to move, and the processed gear is ejected from the processing tank. In the traditional grinding device, the bottom of the gear will always be in close contact with the surface of the processing platform, which is inconvenient in the process of retrieving the material. However, after the gear is set out of the processing tank, the speed of retrieving the material after the gear processing is completed can be greatly improved. .

Owner:JIANGSU AIRSHIP GEAR

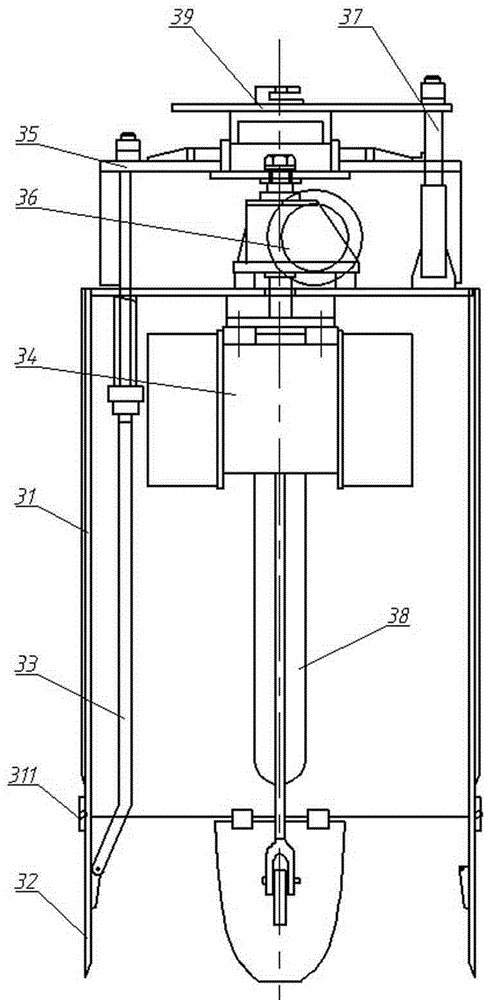

Cylinder machine

ActiveCN103979425BImprove proficiencyFully automatedTrolley cranesEnvironmental resistanceDrive wheel

The invention relates to a wine pouring machine, which solves the problem of time and energy waste, as well as low efficiency due to manual operation during a pouring process for Fenyang wine. The wine pouring machine comprises two lower end beams provided with a driven wheel and a driving wheel, a main column and an elevating guide pillar are provided on each lower end beam, a suspension beam support is fixed on the elevating guide pillar in an oblique mode, a vibration capturing device is suspended below a suspension beam by using a chain electric hoist, the vibration capturing device comprises a cylindrical shell with edge hinged to several petals, a vibration exciter is fixed at top in the cylindrical shell, and an elevator is fixed between the cylindrical shell and a petal collection plate. The wine pouring machine uses an elevating system by cooperating with a material taking apparatus ingeniously, and realizes the mechanization and automation of the pouring process, under the prerequisite that the lifting is guaranteed by the elevating system, a structure is simplified as possible, a material collection mechanism employs a vibration petals-collection mode, compared with other material collection schemes, the wine pouring machine saves more space and lowers the cost. The wine pouring machine is the Fenyang wine brewage equipment which has the advantages of economic, advanced, reliable, safe, environmentally friendly performances.

Owner:王新民 +1

A hardware storage box

ActiveCN106927127BAvoid damageEasy to take outDischarging meansInternal fittingsEngineeringUltimate tensile strength

The invention discloses a hardware storage box. A detachable box cover is arranged at the upper end of a box frame; a separation plate is arranged in the box frame for dividing the box frame into two accommodating cavities; multiple springs are arranged on one sides of the inner walls of the accommodating cavities; the front ends of the multiple springs are connected through pressing plates; the pressing plates are parallel to the separation plate; a pull rod is arranged on the separation plate; the other end of the pull rod penetrates out of the accommodating cavities to connect with a pull block; outlets are formed in one sides of the accommodating cavities, and are positioned between the pressing plates and the separation plate; mobile modules positioned in the accommodating cavities are arranged between the pressing plates and the separation plate for pushing out hardware from the outlets; and a sealing module is arranged on one side of the box frame for sealing the outlets. The hardware storage box is simple in overall structure, can prevent damage of the hardware during transporting, meanwhile, can conveniently take out the corresponding hardware from the outlets, reduces the labor intensity of workers, accelerates the taking speed, satisfies actual machining demands, and is better in practicability.

Owner:铜陵常江传动工具有限公司

A large racetrack-shaped shaft forging die

ActiveCN111230025BAvoid damageImprove alignment shaping effectForging/hammering/pressing machinesEngine componentsStructural engineeringMachine

The invention discloses a large racetrack-shaped shaft forging die. Its structure includes a die seat, a forging die, a balance power mechanism, a stamping mechanism, a fixing rod and a stripping mechanism. The accuracy of the shaft parts is improved, and the forging blank is clamped and rotated by driving the fitting convex ring through the rotating mechanism, which improves the alignment and shaping effect of the forging blank during forging. It is formed once, and the density of the shaft is solidified during the forming process. The buffer head is used to reduce the anti-vibration force when pressing the forging blank, avoid the damage to the mechanical power source caused by the anti-vibration force, and improve the use of the machine. The forging die uses the balanced power mechanism to provide a stable and accurate sliding trajectory for the power rod during stamping and forging, so as to avoid the damage of the shaft due to deviation during stamping. The forging die needs to be disassembled again.

Owner:威海区域创新中心有限责任公司

Motor accessory production mold facilitating material taking

PendingCN113953491AIncrease cooling rateEase of workFoundry mouldsManufacturing dynamo-electric machinesEngineeringCooling pipe

The invention discloses a motor accessory production mold facilitating material taking. The mold comprises a workbench, wherein a supporting table is fixedly mounted on a side surface of the workbench, a mold plate frame is detachably mounted at the top of the workbench, a cooling groove is formed in an outer surface of the mold plate frame, a cooling assembly is detachably mounted in the cooling groove, a circular groove is formed in a side surface of the workbench, a movable groove is formed in the bottom of the workbench, an ejection device is movably mounted in the circular groove, the cooling assembly comprises a cooling pipe, and one end of the cooling pipe fixedly communicates with a first box body. According to the scheme, an ejection assembly is arranged, a finished product can be subjected to demolding by means of a holding rod, direct manual demolding of workers is not needed, a material taking speed is increased, working difficulty of the workers is reduced, an effect of improving creativity of equipment is achieved, the cooling assembly is arranged, the cooling pipe surrounds a periphery of the mold plate frame, an interior of the mold plate frame can be rapidly cooled, a cooling rate of finished products is increased, and an effect of improving working efficiency of equipment is achieved.

Owner:苏州任翔金属制品有限公司

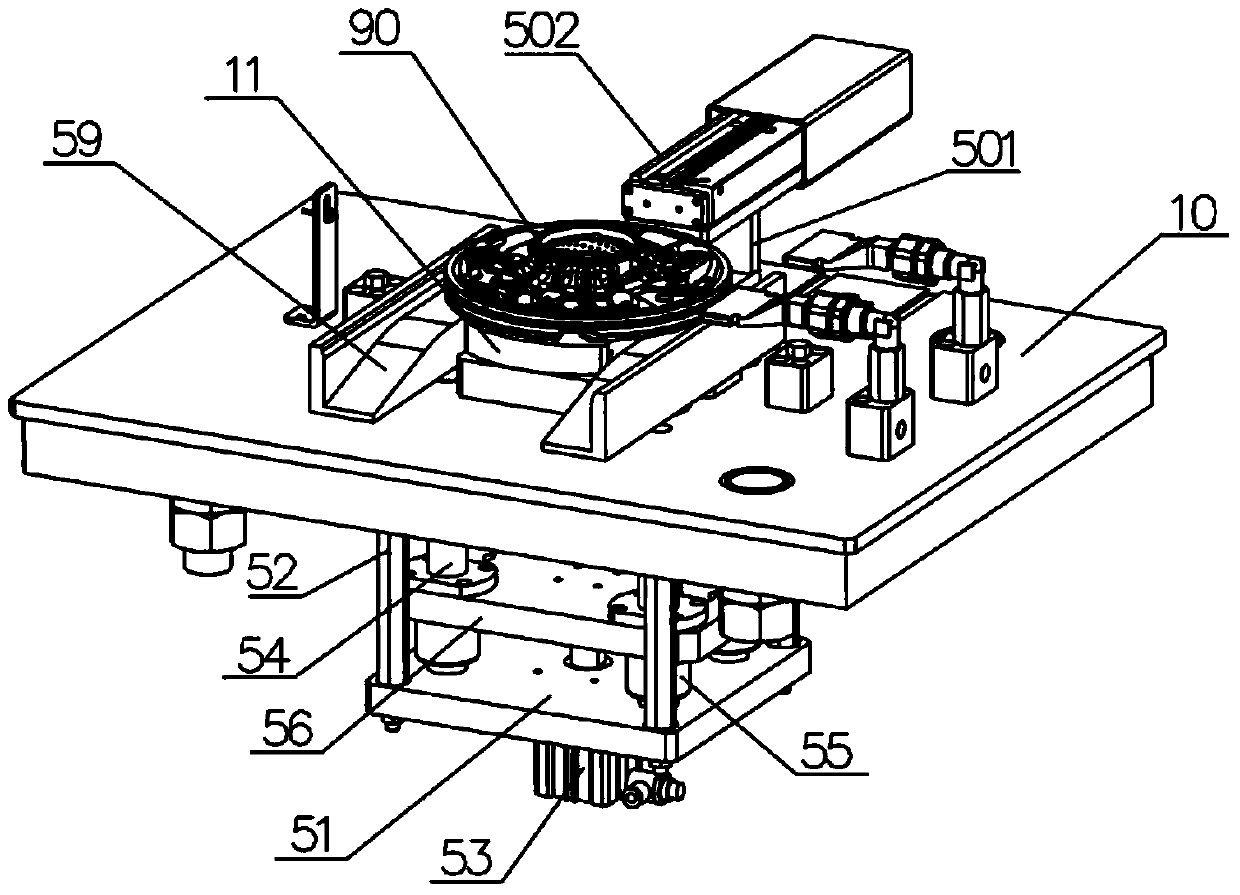

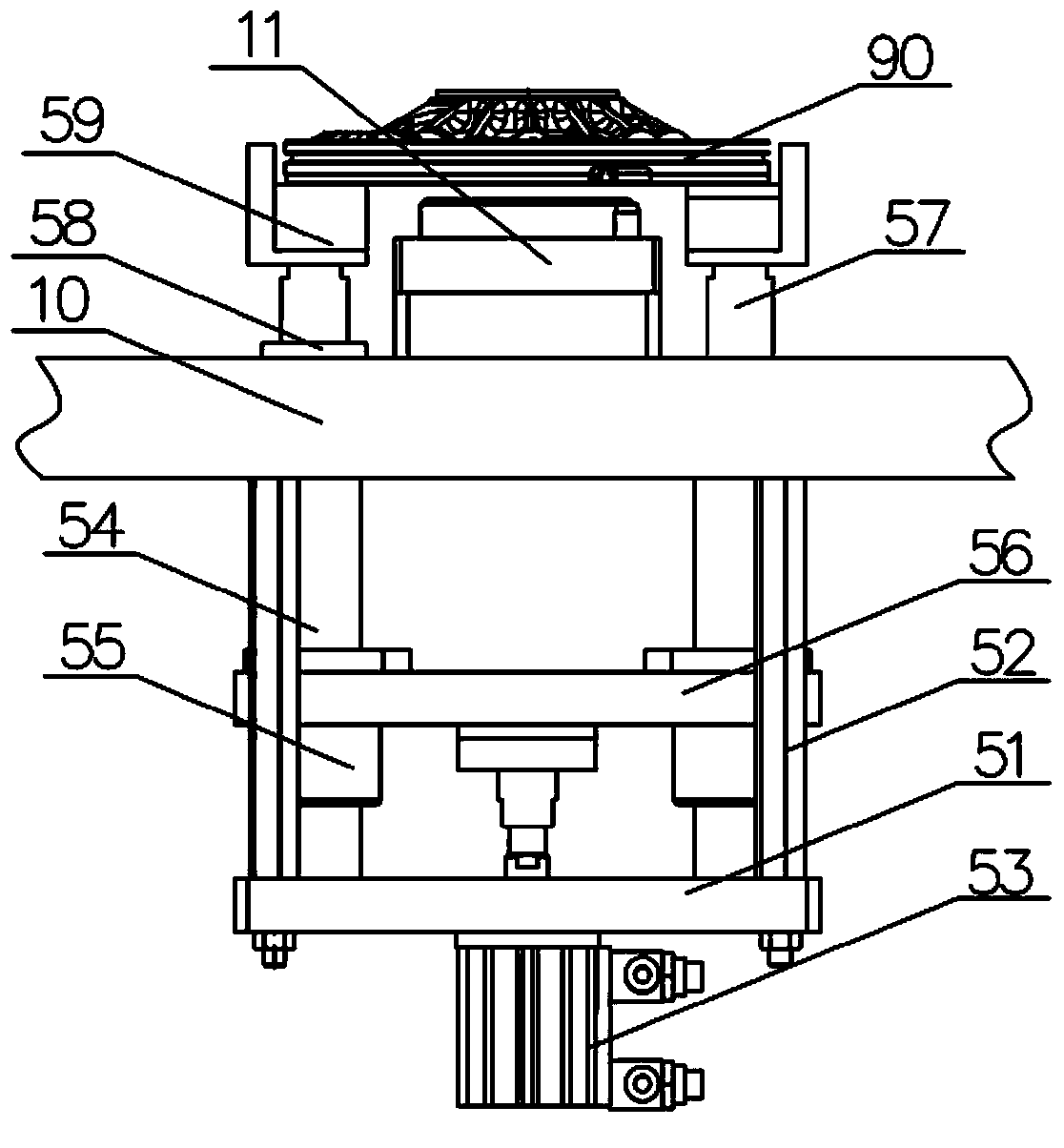

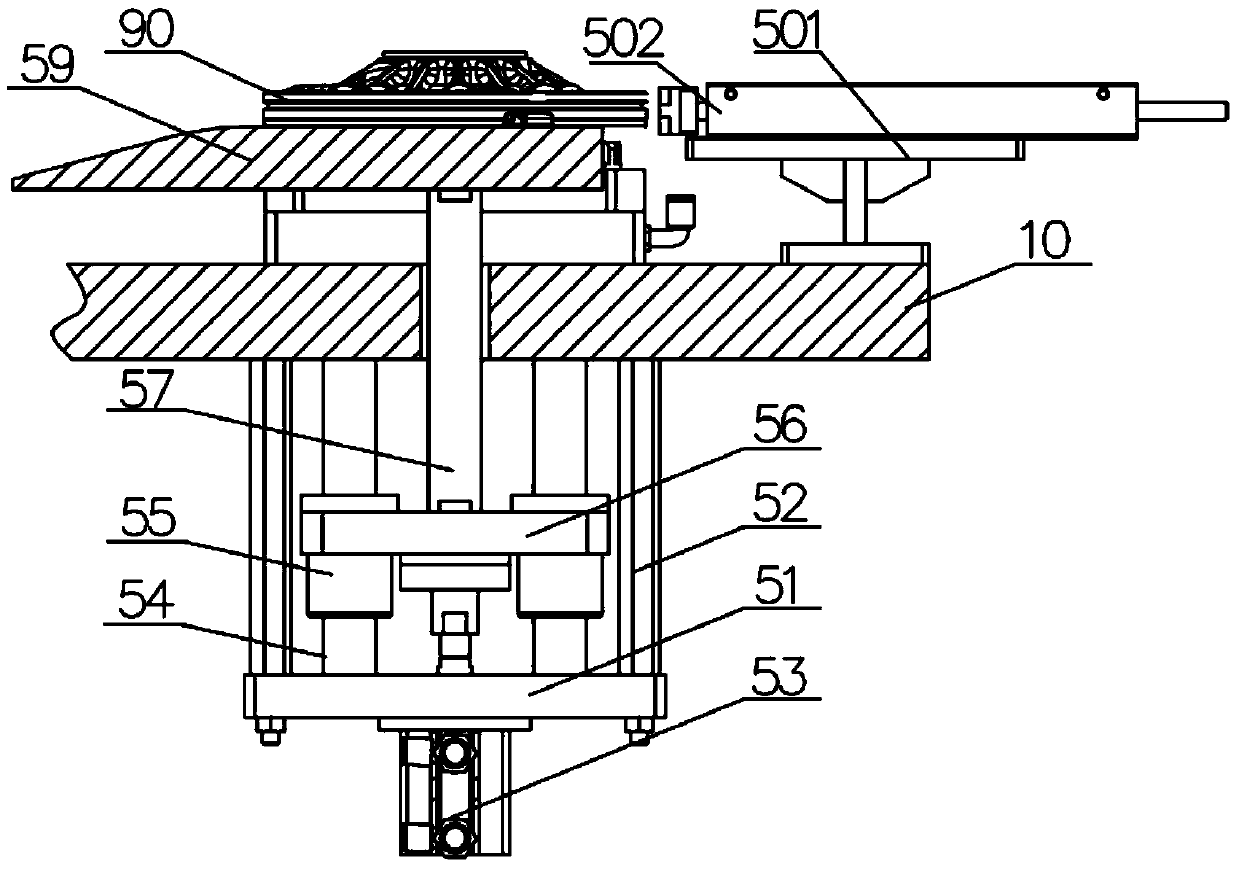

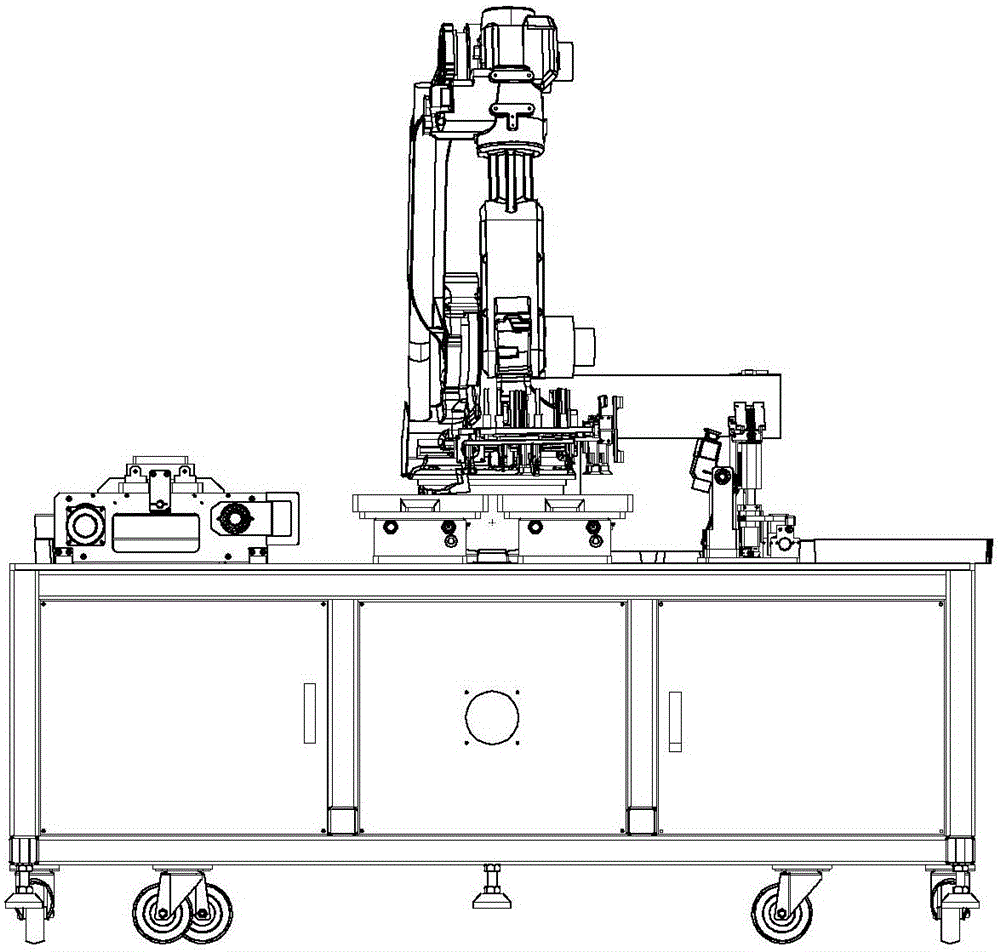

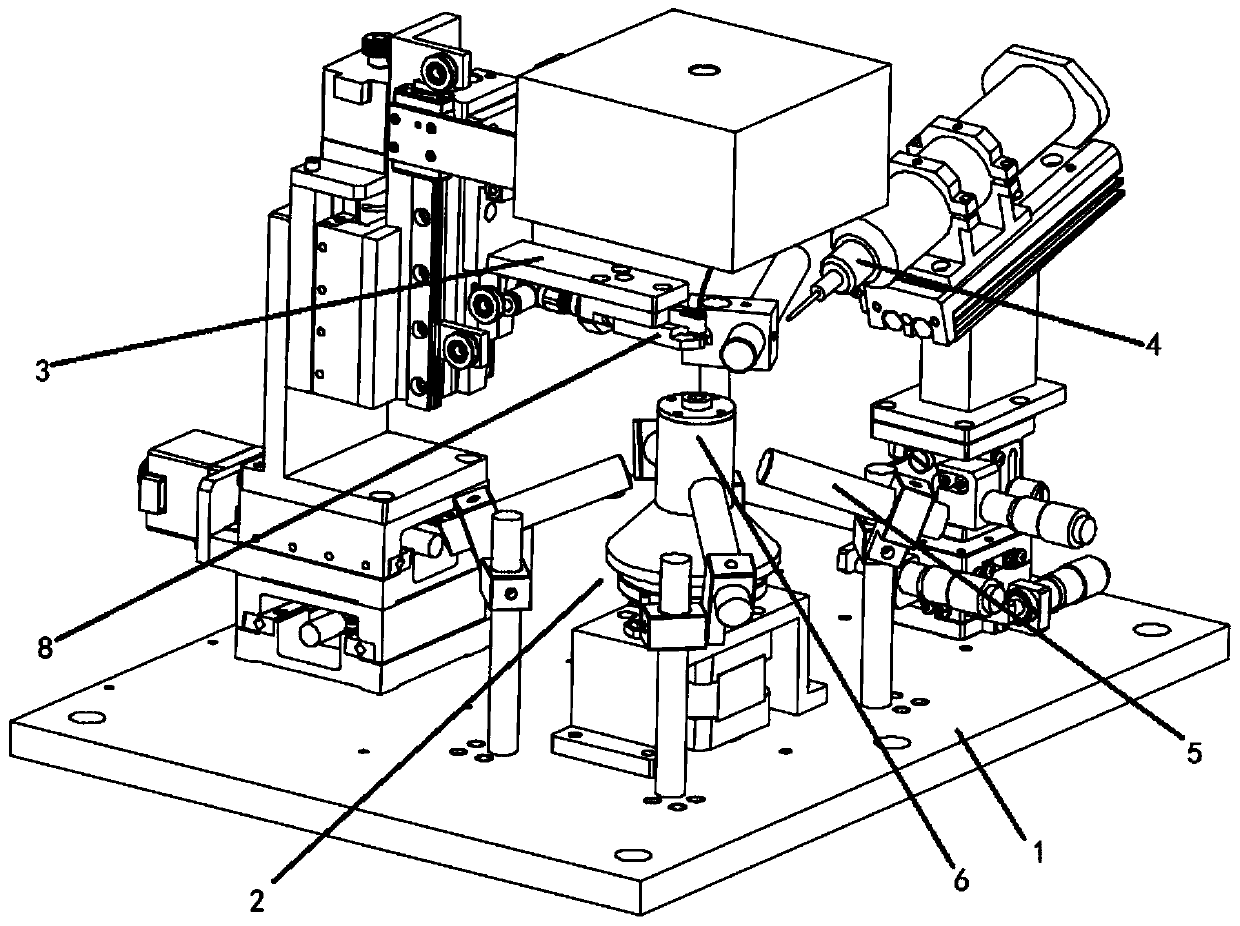

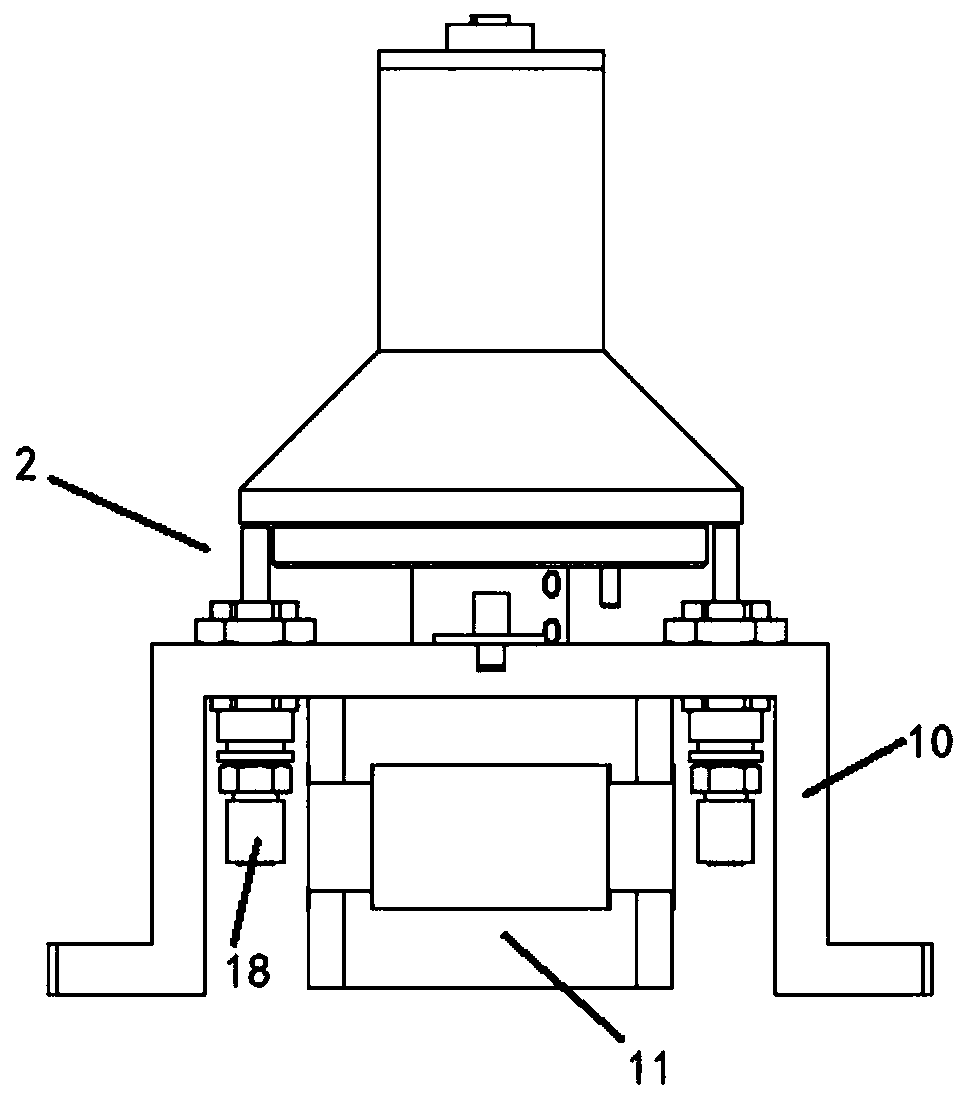

A photodetector automatic coupling dispensing curing method and system

ActiveCN109158262BPrevent disengagementAvoid deformationPretreated surfacesCoupling light guidesPhotovoltaic detectorsPhotodetector

The invention discloses a photodetector autocoupling glue dispensing and solidifying method. The photodetector autocoupling glue dispensing and solidifying method comprises the following steps: acquiring a coupling requirement of an optical device and an adapter; determining the relative position relation of a first clamping mechanism and a second clamping mechanism according to the coupling requirement; determining a glue dispensing mode of a glue dispensing mechanism, a feed mode of the second clamping structure, a solidifying mode of a solidifying structure, and a material ejecting mode ofthe first clamping structure according to the coupling requirement and the relative position relation; transforming motions of various mechanisms into preset parameters, and presetting in a regulationcontrol mechanism; starting a photodetector autocoupling glue dispensing and solidifying system, enabling the regulation control mechanism to sequentially control the operations of the first clampingmechanism, the glue dispensing mechanism, the second clamping mechanism and a solidifying mechanism according to the preset value in sequence until the whole process of automatic glue dispensing is finished.

Owner:CENT SOUTH UNIV

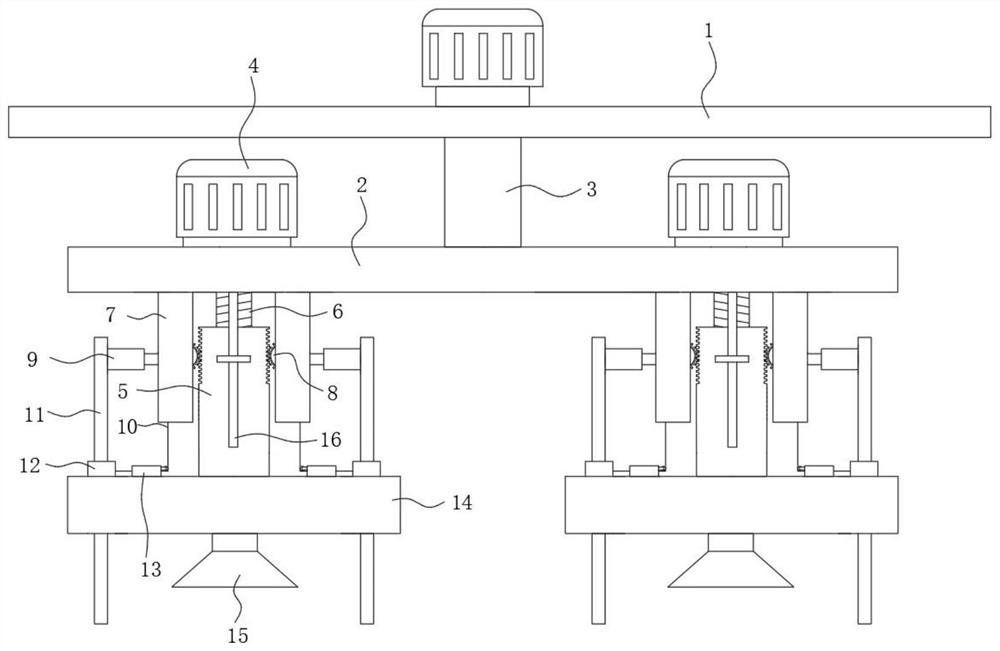

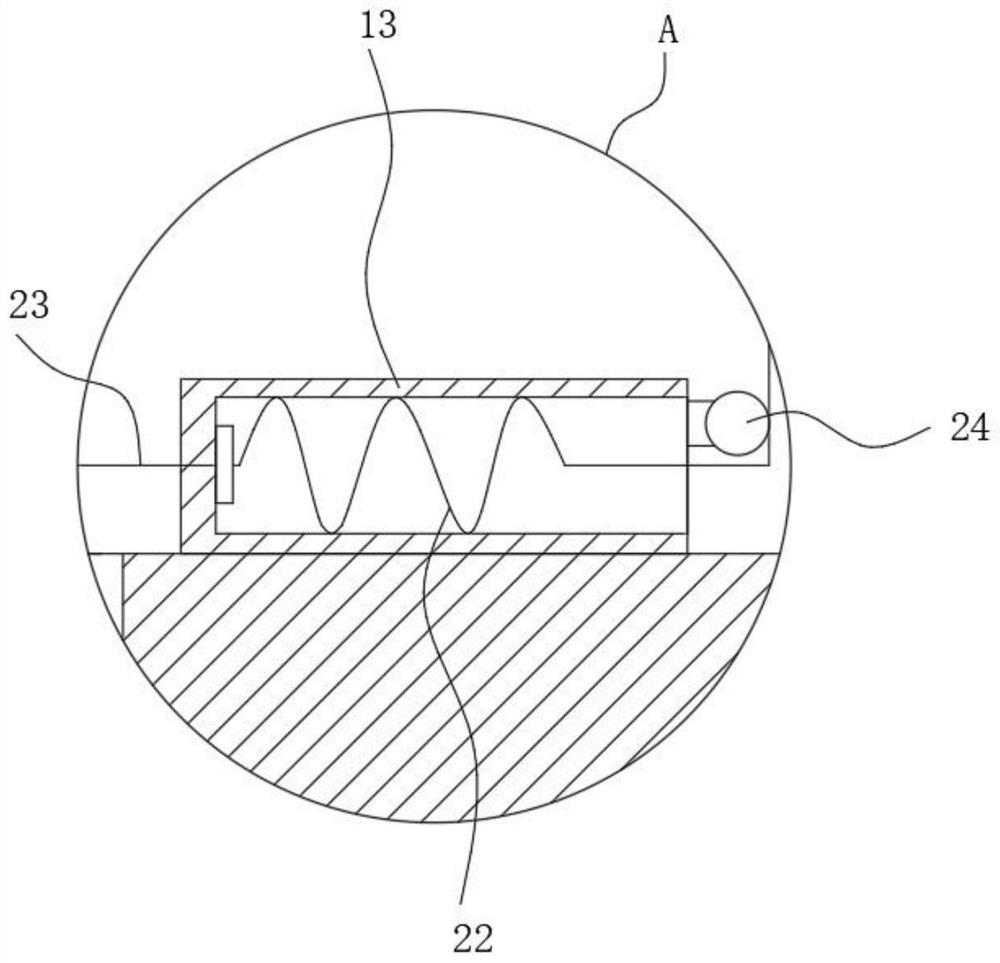

A device for grinding magnetic cores

ActiveCN110480458BSmooth motionUninterrupted movementGrinding wheel securing apparatusGrinding drivesEngineeringMechanical engineering

The invention discloses equipment for grinding a magnetic core. The equipment comprises a frame, a feeding device and a material taking device, wherein the feeding device is used for pushing the magnetic core to a conveying device and comprises a support, a tray detachably connected with the support, a pushing component and a driving component for driving the support to move forwards and backwards; the magnetic core is placed on the tray; when the support moves forward, the support is changed from horizontal to inclined, and then parts of the magnetic cores are pushed by the pushing componentto fall onto the conveying device; and the material taking device is used for clamping the polished magnetic core from the conveying device. According to the equipment for grinding a magnetic core, the material taking device is arranged and can clamp the polished magnetic core, therefore, when the magnetic core is taken, a worker can use the material taking device to clamp the material quickly, the material taking speed is high, the material taken out is kept in a whole row, and the material taking efficiency is high.

Owner:浙江冶泰软磁科技有限公司

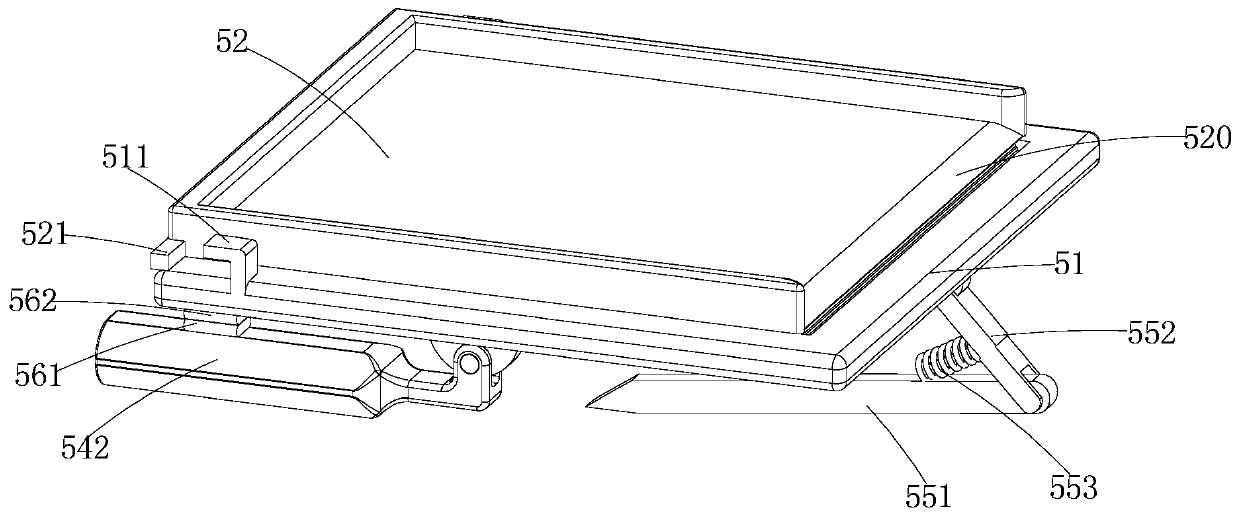

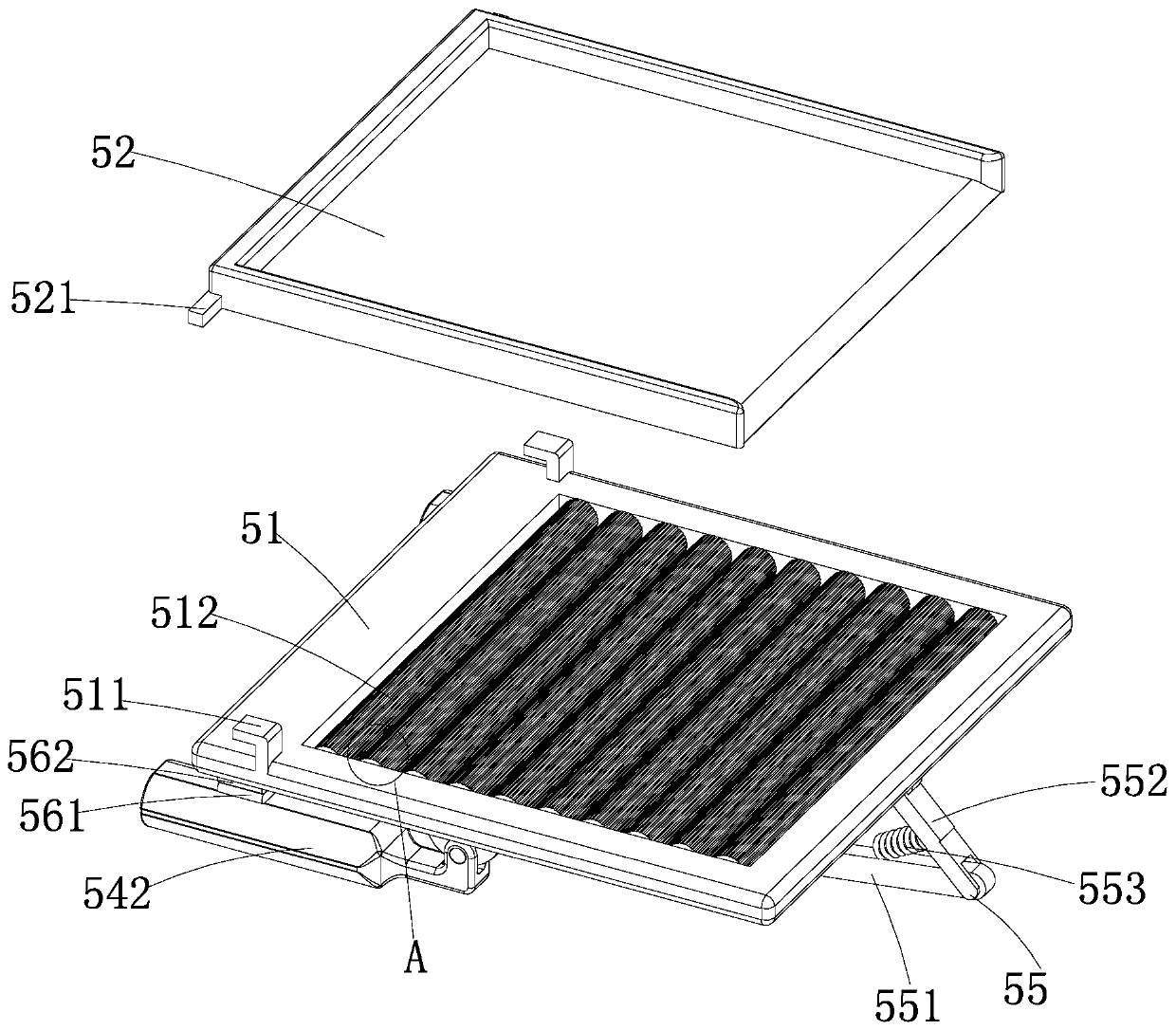

A complex terrain mobile robot

InactiveCN107351932BOvercome the shortcomings of poor adaptabilityImprove reliabilitySievingScreeningReal-time computingRolling chassis

The invention discloses a complex-terrain mobile robot, which comprises a movable chassis. The chassis is provided with a sequentially connected feeding device and a screening device. The feeding device is used for picking up materials and transporting the taken materials to the screening materials. The sieving device is used to sieve and collect materials according to their size. The complex terrain mobile robot provided by the present invention can dynamically adjust the height of the chassis from the ground according to the terrain, overcomes the shortcomings of poor adaptability of the traditional mobile robot platform under complex terrain conditions, has strong passing performance, and can meet the needs of working in complex outdoor environments. It can climb slopes, overcome obstacles, advance steadily and move sideways in uneven terrain. It has the advantages of simple structure, convenient control, high reliability and strong practicability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Automatic gluing device

Owner:东莞华誉精密技术有限公司

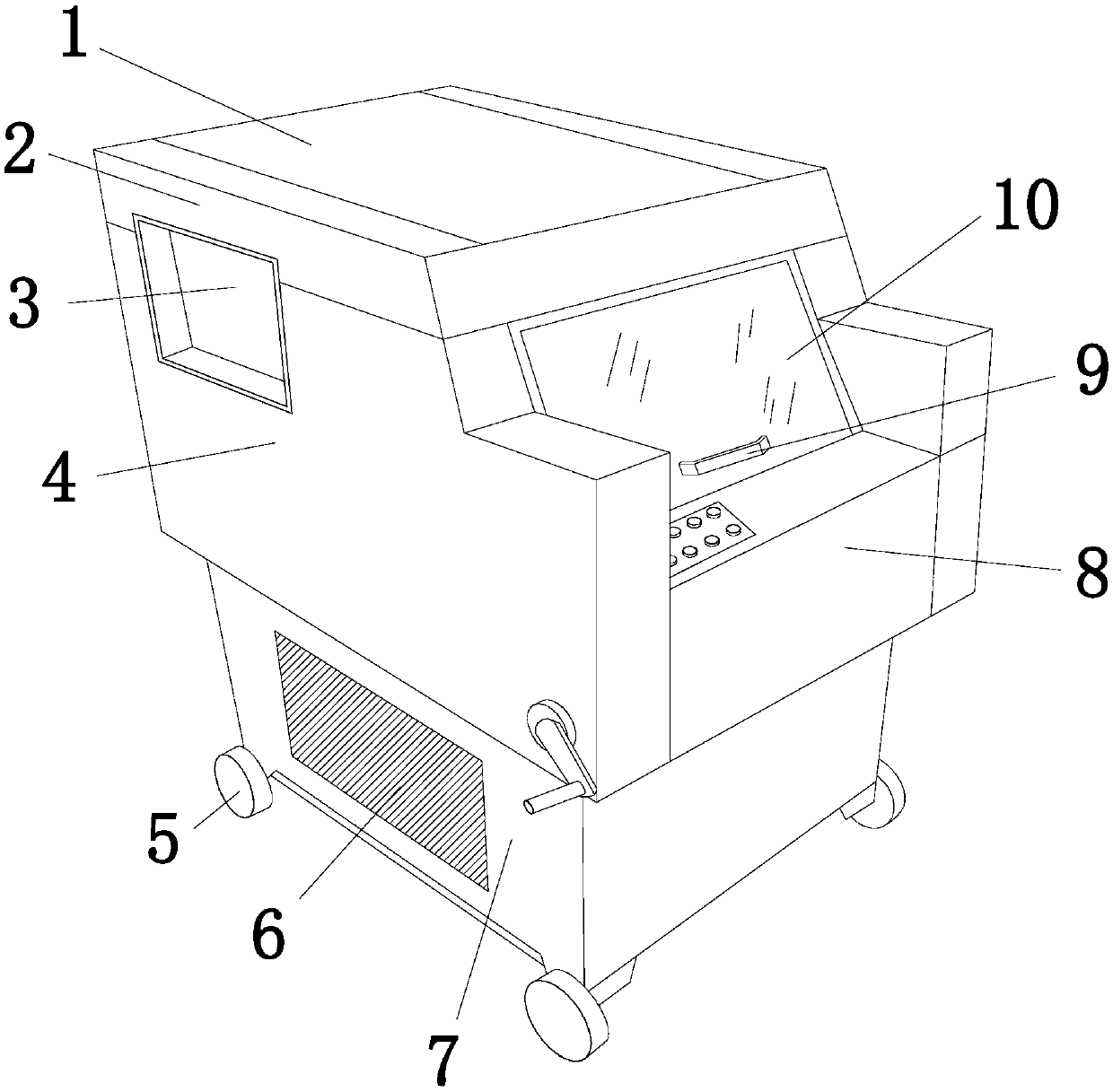

A serpentine spring bending device

The invention discloses a serpentine spring bending device. The serpentine spring bending device comprises an artistic plate, a top fixing frame, a taking port, a machining box, moving wheels, a heatdissipating groove, an electric control cabinet, a controller, a protection door handle and a protection door. The serpentine spring bending device has the following beneficial effects: serpentine springs are fixed on the front side of a bending disc through a batching template in the machining box; and then, a hand wheel rod is used for controlling a second distribution shaft to drive the batching template to flatly move forwards, so that multiple serpentine springs on the template are matched with the bending disc for quick bending; in addition, the serpentine springs are absorbed through amagnetic plate; and second gears synchronously drive a main transmission rope; a movable guide rail and a lifting rod are synchronously withdrawn, so that the magnetic plate is driven to the taking port of a box, the taking speed is accelerated during multi-station bending, and the working efficiency is greatly improved.

Owner:ZHEJIANG TUYUAN INTELLIGENT EQUIP TECH CO LTD

Novel 500-ton punch press oil-pressure die pad

The invention discloses a novel 500-ton punch press oil-pressure die pad. The novel 500-ton punch press oil-pressure die pad comprises a punch press body, an upper die pad, a lower die pad and lower press material cylinders, wherein the punch press body is provided with a cavity, and a mounting block is fixedly connected to the top end of the cavity; the upper die pad is fixedly connected to the bottom end of the mounting block, the upper die pad is provided with counterbores, and protective sleeves are installed in the counterbores; sealing plates are installed at the bottom ends of the protective sleeves, upper press material cylinders are installed in the protective sleeves, an upper die is fixedly connected to the ends, extending out of the sealing plate, of the upper press material cylinders; and the low die pad is fixedly connected to the bottom end of the cavity, and the low die pad is further provided with counterbores. According to the novel 500-ton punch press oil-pressure die pad, the positions of the dies can be conveniently adjusted to adapt to different product processing, a plurality of sets of cylinders are arranged, and the cylinders occupy small space, installation and maintenance are easy, the recoil speed can further be adjusted to facilitate taking materials, the sound made by a punch press is effectively reduced, the hearing health of workers is facilitated, the service life of the punch press is prolonged, and the practicability is higher.

Owner:DAIFONG PRECISION IND

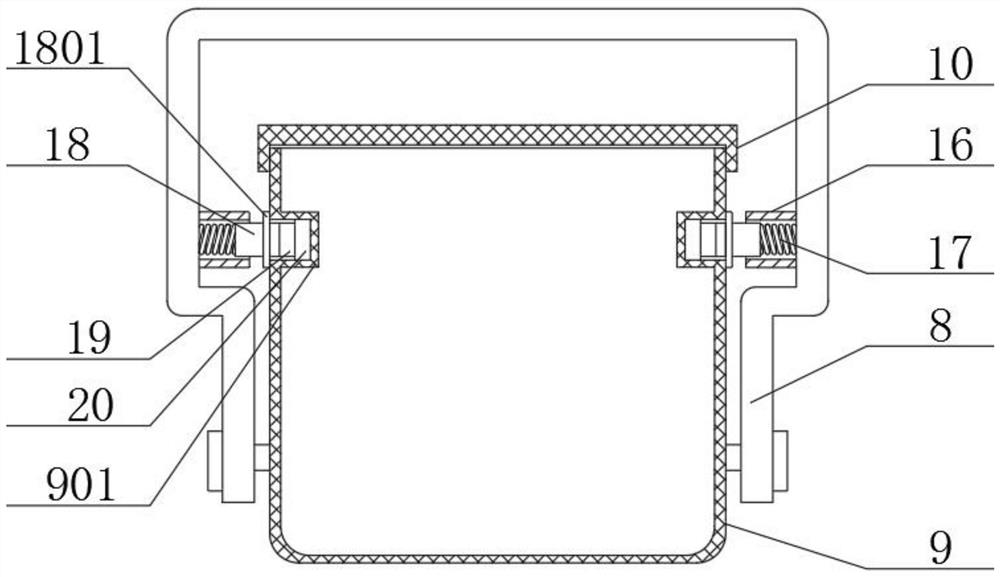

Straw wetting and softening equipment for straw tableware production

InactiveCN112411228APrevent floatingFaster immersionRaw material pretreatmentWater flowPulp and paper industry

The invention relates to the technical field of straw tableware production, in particular to straw wetting and softening equipment for straw tableware production. A discharging pipe is connected to the lower end of a tank body in a penetrating mode, a control valve is arranged on the discharging pipe, three supporting legs which are annularly distributed at equal intervals are connected to the lower end of the tank body, and a bearing is connected to the outer wall of the tank body; and a rotating shaft is fixedly inserted into the bearing, the upper end of the rotating shaft is connected withan upper cover, the upper cover is connected with a long rod, and the long rod is connected with the outer wall of the tank body through a fixing mechanism. According to the straw wetting and softening equipment for straw tableware production, a wetting and softening barrel body rotates in water, so that water flow passes through the space between straw, the speed of soaking the straw by water isincreased, the wetting and softening efficiency is improved, the straw is located in the wetting and softening barrel body and pressed into the water, the straw is prevented from floating on the water surface, and the contact area between the straw and the water is increased.

Owner:安徽谷瑞琪新材料科技有限公司

A centrifugal casting mold

The present invention relates to the technical field of casting molds, in particular to a centrifugal casting mold, which includes a rotating chassis, a pressing component, a pushing component, a lining component, a first wrapping component, a second wrapping component and a third wrapping component, The first wrapping assembly, the second wrapping assembly and the third wrapping assembly are located on the top of the rotating chassis, the first wrapping assembly, the second wrapping assembly and the third wrapping assembly are arranged around the axis of the rotating chassis, and the pressing assembly is located on the pushing assembly The bottom of the pressing assembly, and the force-bearing end of the pressing assembly runs through the pushing assembly, the lining assembly is located at the bottom of the pressing assembly, and the lining assembly and the pressing assembly are rotatably connected. This technical solution can perform centrifugal Casting molding, and the molding speed is fast, and the material retrieving speed is fast, which greatly improves the production efficiency.

Owner:德州卓尔科技有限公司

Cleaning, separating and recycling circulating system for residual concrete and multi-channel screening method

ActiveCN114669531AHigh degree of automationSave human effortGas current separationSolid waste managementStructural engineeringProcess engineering

The invention discloses a cleaning, separating and recycling circulating system for residual concrete and a multi-channel screening method, and relates to the field of engineering machinery. The cleaning, separating and recycling circulating system for the residual concrete comprises a storage box; the three drum screens are matched with one another to complete screening work of different materials in concrete, the second screening assembly and the third screening assembly are stacked together and finally stored in the first screening assembly, a whole formed by a second support, a third flow guide plate and a second telescopic guide plate is separated from a first support, the size of the device is reduced, and the screening efficiency is improved. And the second screening assembly is mainly composed of a mounting base, an auxiliary material discharging assembly and a plurality of screening plates, the screening plates can be detached and replaced after being damaged after being used for a long time, the screening plates with different filtering holes can be replaced according to the particle size of stones in concrete, and therefore the concrete screening device can be suitable for screening of concrete of various specifications.

Owner:杭州鼎昌混凝土有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com