Horizontal telescopic suction head taking mechanism and working method thereof

A material retrieving mechanism and horizontal telescopic technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of wasting manpower and material resources, increasing experiment costs, low-level repetitive labor, etc., and achieve fast retrieving speed and box packing The effect of high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

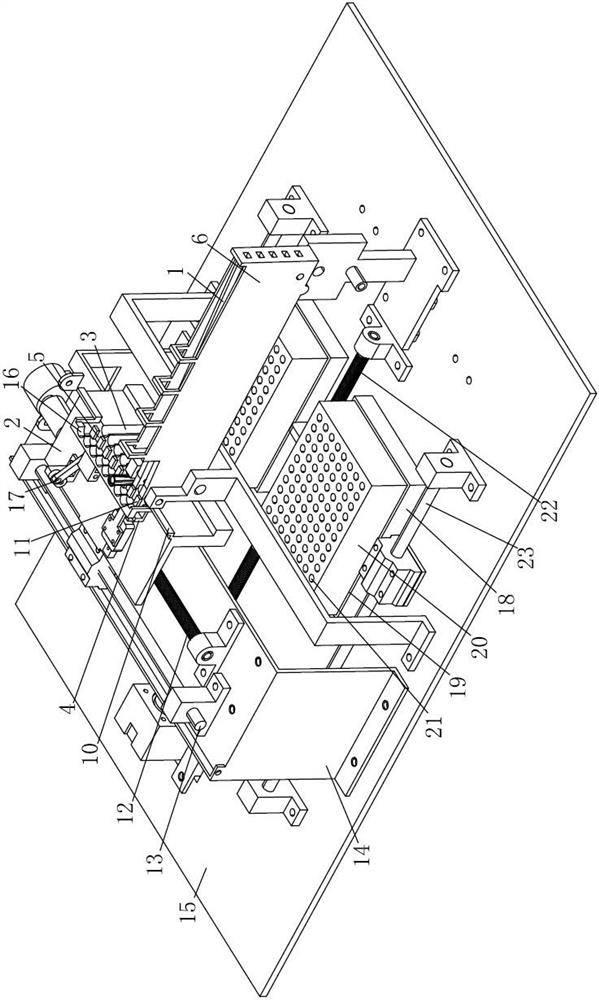

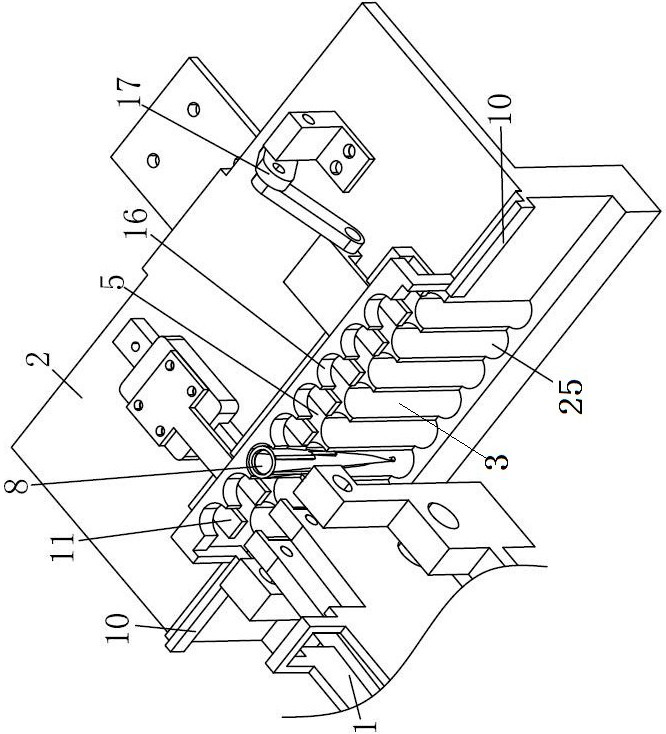

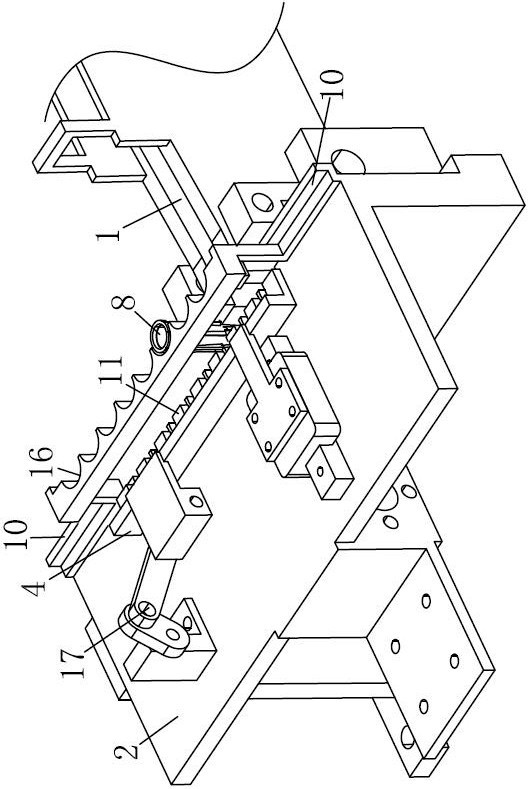

[0032] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0033] Such as Figure 1~8 As shown, a horizontally telescopic suction head retrieving mechanism includes an inclined suction head feeding track 1, and the lower end side of the suction head feeding track is provided with a transmission and retrieving slider driven by the first electric mechanism to reciprocate left and right. 2. The front end of the conveying and retrieving slider is provided with a row of vertical suction head guide half-holes extending evenly from left to right. The retrieving slider 4, the front end of the retrieving slider is provided with a row of suction head suspension grooves 5 for connecting the lower end of the suction head feeding track.

[0034] In the embodiment of the present invention, the tip feeding track is located in the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com