Hardware storage box

A hardware and storage box technology, applied in the field of hardware storage boxes, can solve the problems of high labor intensity, easily damaged workpieces, cumbersome operation, etc., and achieve the effects of reducing labor intensity, avoiding damage, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

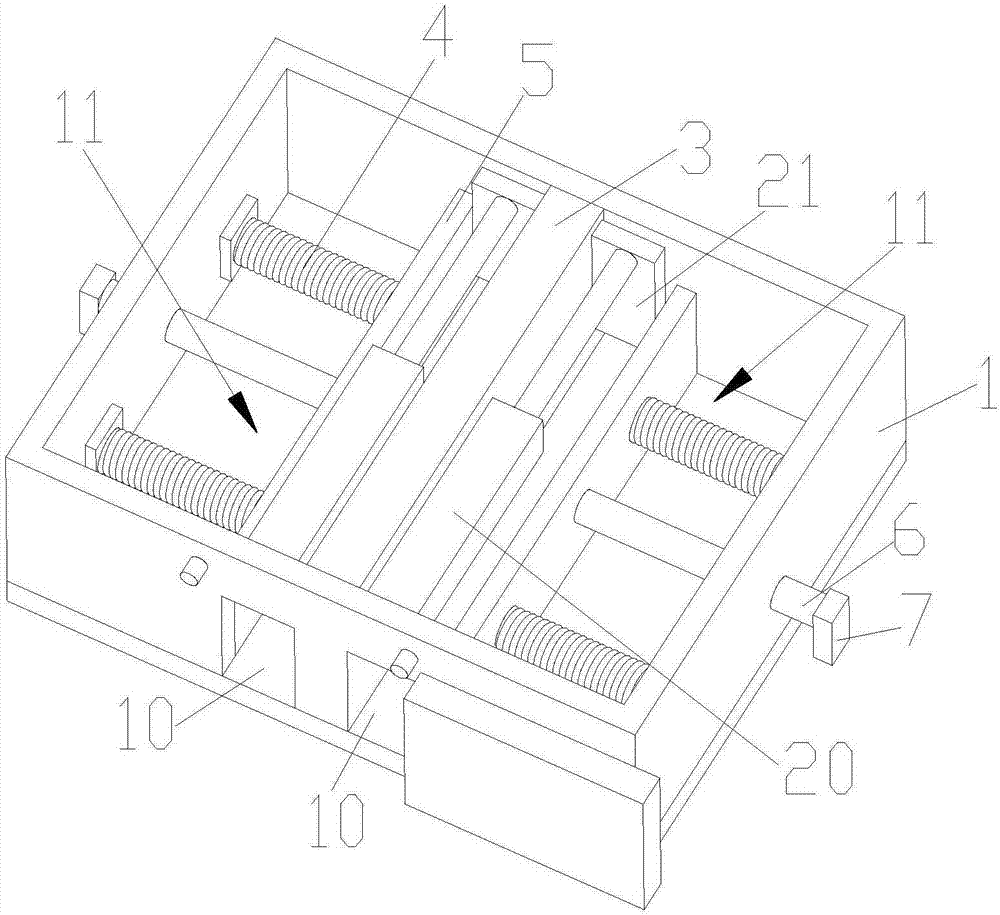

[0014] The present invention will be described below with reference to the accompanying drawings.

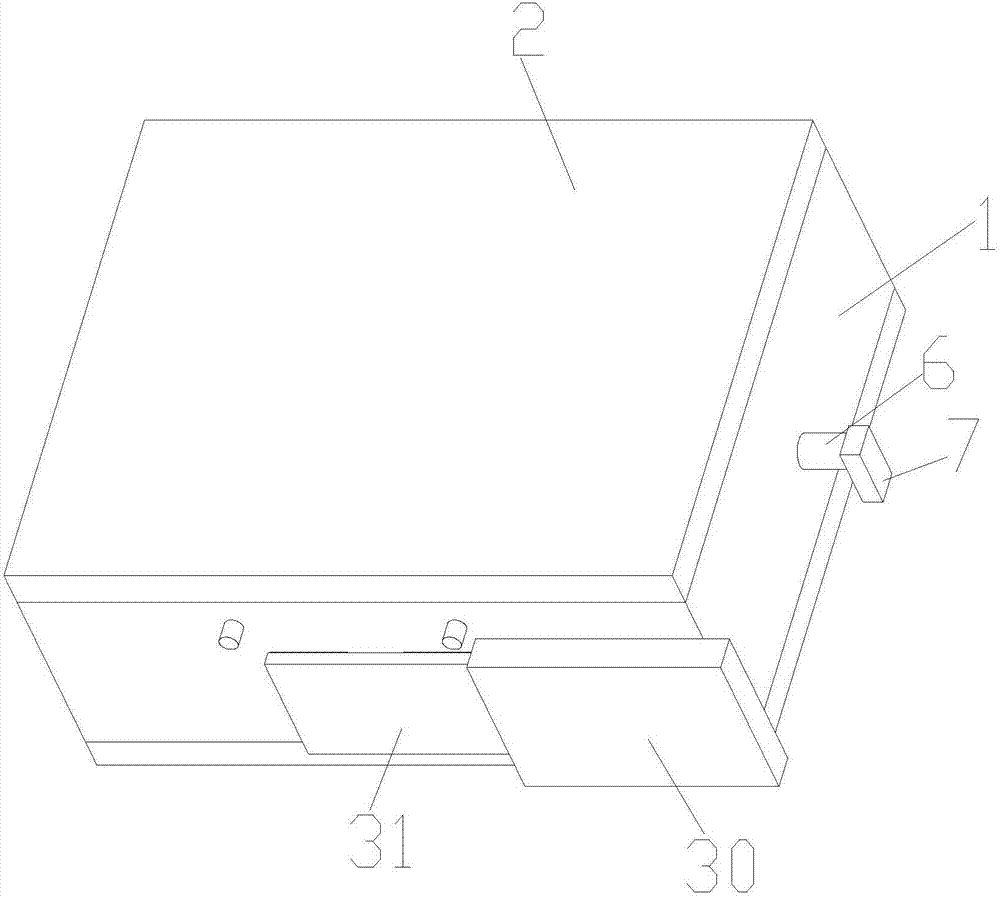

[0015] as attached Figure 1-2 The illustrated hardware storage box of the present invention includes a box frame 1, a box cover 2, a partition 3, a spring 4, a pressure plate 5, a pull rod 6, a pull block 7, a moving assembly and a sealing assembly; the box The upper end of the frame 1 is provided with a detachable box cover 2; the box frame 1 is provided with a partition 3, and the partition 3 divides the box frame 1 into two accommodating cavities 11; There are a plurality of springs 4 on the side, and the front ends of the plurality of springs 4 are connected by a pressure plate 5, and the pressure plate 5 is arranged in parallel with the partition plate 3; The cavity 11 is connected with the pull block 6; an outlet 10 is provided on one side of the accommodating cavity 11, and the above-mentioned outlet 10 is located between the pressing plate 5 and the partition plate 3; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com