A centrifugal casting mold

A centrifugal casting and mold technology, applied in the field of casting molds, can solve problems such as short service life of molds, uneven internal quality, poor product quality, etc., and achieve the effects of fast forming speed, accelerated forming, and fast material retrieving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art.

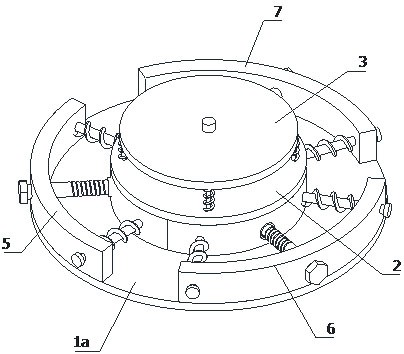

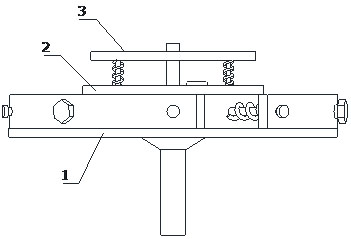

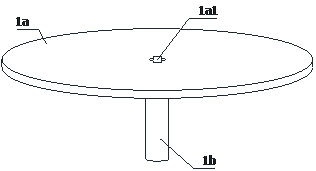

[0043] refer to Figure 1 to Figure 10 As shown, a centrifugal casting mold includes a rotating chassis 1, a pressing component 2, a pushing component 3, a lining component 4, a first wrapping component 5, a second wrapping component 6 and a third wrapping component 7;

[0044] The first wrapping assembly 5, the second wrapping assembly 6 and the third wrapping assembly 7 are all located on the top of the rotating chassis 1, and the first wrapping assembly 5, the second wrapping assembly 6 and the third wrapping assembly 7 are arranged around the axis of the rotating chassis 1 , the push-down assembly 2 is located at the bottom of the push-down assembly 3, and the stressed end of the push-down assembly 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com