A photodetector automatic coupling dispensing curing method and system

A photoelectric detector and automatic coupling technology, which is applied in the coupling of optical waveguides, instruments, optics, etc., can solve the problems of easy deformation under force, low work efficiency, small size of optical dispensing coupling parts, etc., and achieve improved material retrieving Speed, effects against detachment or deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

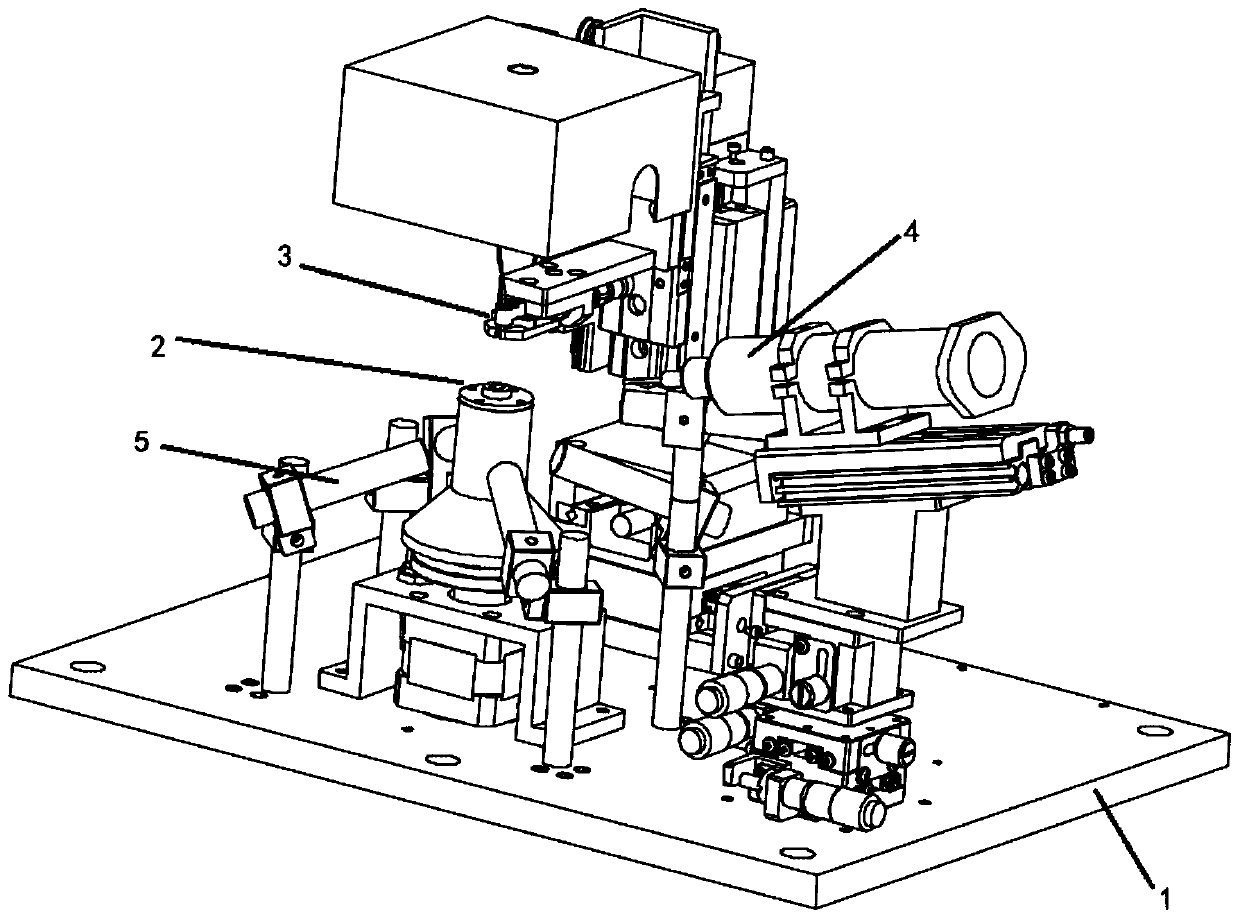

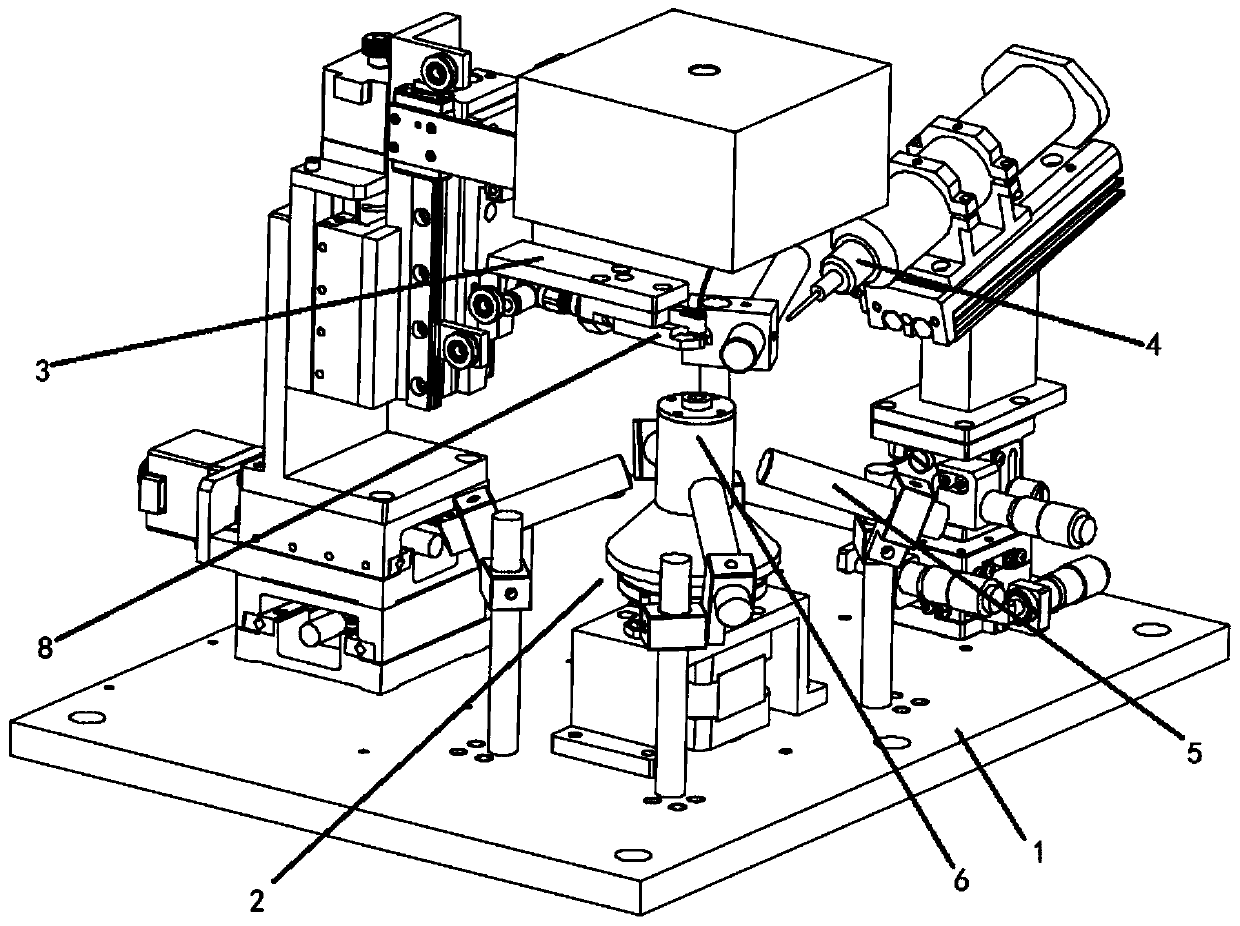

[0043] Such as figure 1 , 2 As shown in, 3, 4, and 5, this embodiment provides a photodetector automatic coupling dispensing curing method, which includes the following steps:

[0044] Step 1: Obtain the coupling requirements between the optical device and the adapter;

[0045] Step 2: Determine the relative positional relationship between the first clamping mechanism 2 and the second clamping structure according to the coupling requirements;

[0046] Step 3: Determine the dispensing mode of the dispensing mechanism 4, the feeding mode of the second clamping structure, the curing mode of the curing structure, and the ejecting mode of the first clamping structure according to the coupling requirements and the relative position relationship;

[0047] Step 4. Convert the movement of each mechanism into preset parameters and perform preset settings in the adjustment control mechanism;

[0048] Step 5. Start the photodetector automatic coupling dispensing curing system, and the adjustment co...

Embodiment 2

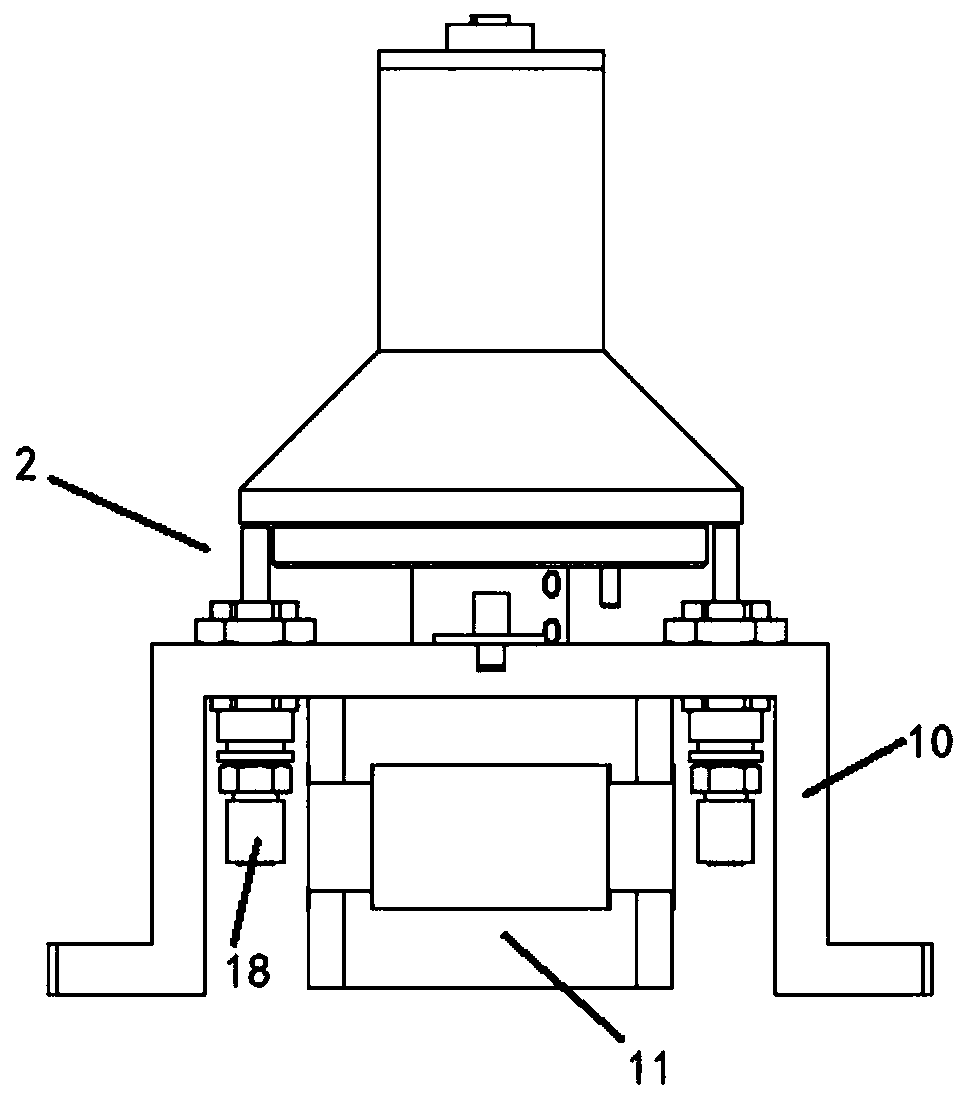

[0058] On the basis of embodiment 1, as shown in 4 and 5, this embodiment further provides a photodetector automatic coupling dispensing curing system, which includes a support base 1, a first clamping mechanism 2, a second clamping mechanism 3. Dispensing mechanism 4, curing mechanism 5, and adjustment control mechanism; the first clamping mechanism 2 includes a first clamping structure 6 for clamping the optical device and a light dispensing coupling for coupling the dispensing The ejector structure 7 ejected from the first clamping structure 6, the second clamping mechanism 3 includes a second clamping structure 8 for clamping the adapter and sending the adapter to a preset Position of the feeding structure; when the optical device is fixed by the first clamping structure 6, the adjustment and control mechanism activates the dispensing structure, and the dispensing structure applies a predetermined method to the upper part of the optical device Glue is dispensed on the end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com