A large racetrack-shaped shaft forging die

A racetrack-shaped and mold technology, applied in manufacturing tools, engine components, forging/pressing/hammer devices, etc., can solve the problems of lack of market competitiveness, influence on strength, low efficiency, etc., to improve the effect of alignment and shaping, improve The accuracy of shaft parts and the effect of improving the reclaiming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

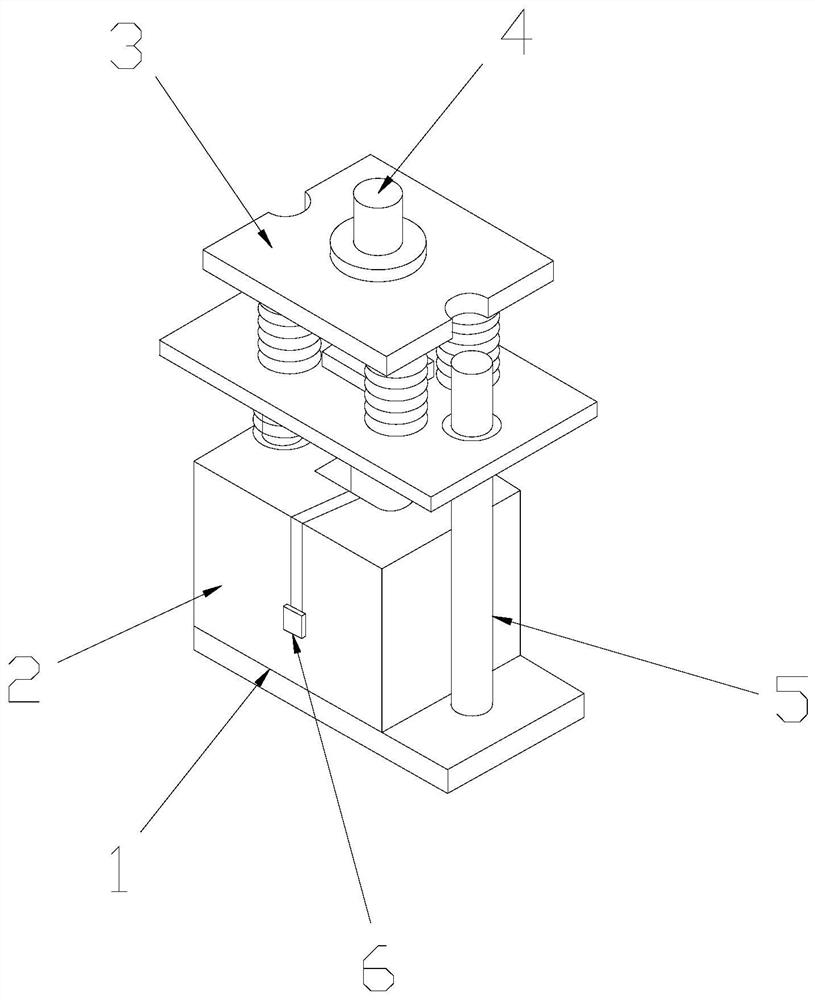

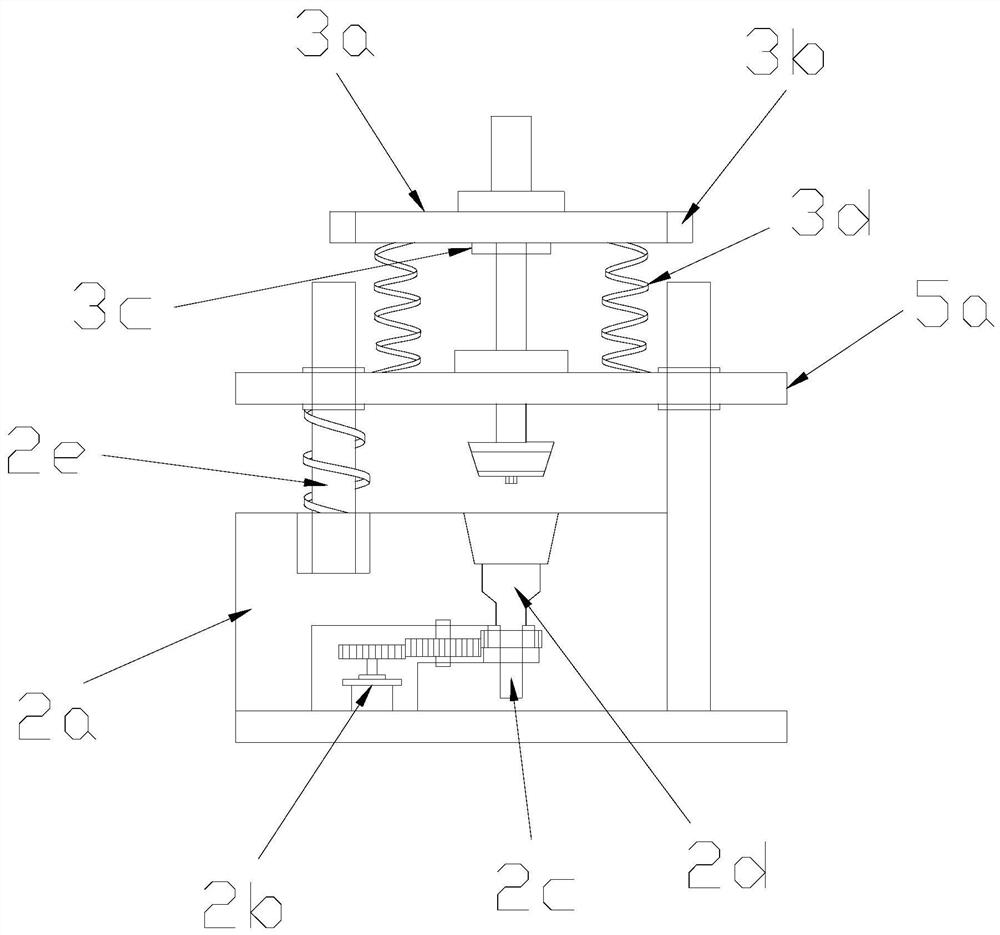

[0028] see Figure 1-Figure 5 , the present invention provides a large racetrack-shaped shaft forging die, the structure of which includes a die base 1, a forging die 2, a balance power mechanism 3, a stamping mechanism 4, a fixed rod 5, and a stripping mechanism 6. The bottom of the forging die 2 There is a die base 1 under the end, the forging die 2 is connected with the die base 1, a balance power mechanism 3 is arranged on the top of the forging die 2, and the forging die 2 and the balance power mechanism 3 pass through the fixed rod 5 Sliding fit, the top of the balance power mechanism 3 is provided with a stamping mechanism 4, the balance power mechanism 3 and the stamping mechanism 4 are mechanically connected, and a stripping mechanism 6 is installed inside the forging die 2.

[0029] The forging die 2 is composed of a die body 2a, a rotating mechanism 2b, a shaft length adjustment column 2c, a shaft mold groove 2d, a support column 2e, and a first spring 2f, and a rot...

Embodiment 2

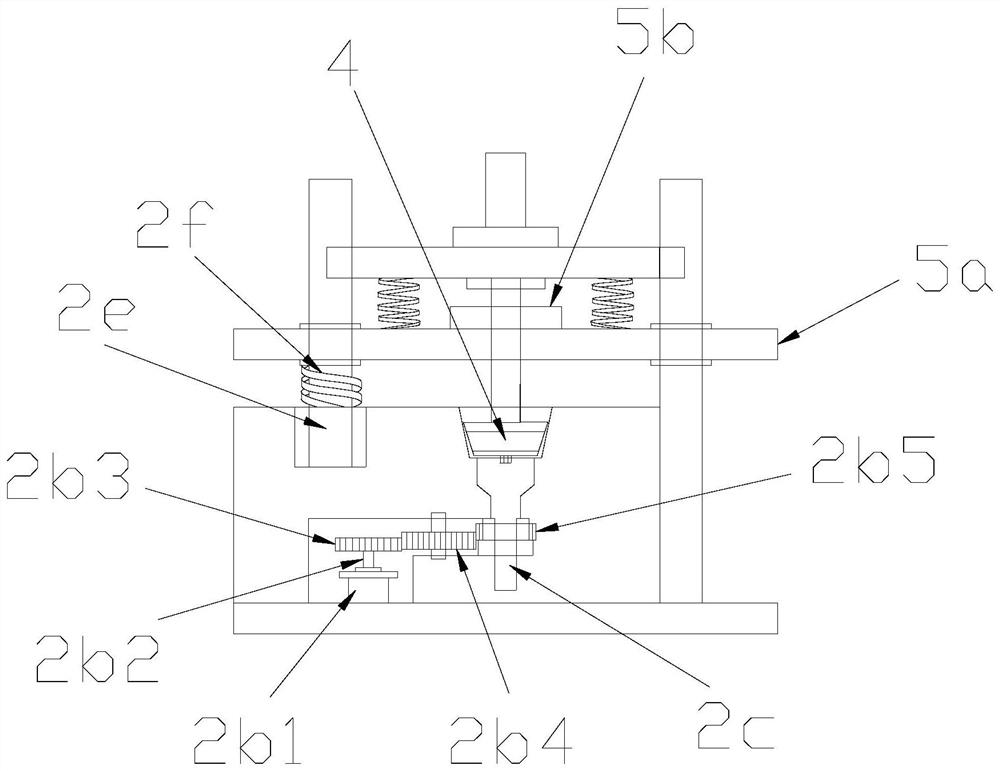

[0036] see Figure 1-Figure 6 , the present invention provides a large racetrack-shaped shaft forging die, the balance power mechanism 3 is composed of a sliding plate 3a, a chute 3b, a gasket 3c, and a second spring 3d, and the left and right ends of the sliding plate 3a are Both are provided with a chute 3b, a spacer 3c is provided under the middle position of the bottom end of the sliding plate 3a, the sliding plate 3a and the spacer 3c are fixedly connected, and two bottom ends of the sliding plate 3a are installed For the second spring 3d, a support plate 5a is provided on the surface of the fixed rod 5, and the fixed rod 5 and the support plate 5a are slidingly fitted.

[0037] Described stripping mechanism 6 is made up of lifting slide block 6a, model block 6b, magnet sheet 6c, and described model block 6b left end is provided with lift slide block 6a, and described model block 6b and lift slide block 6a is an integrated structure, the right side of the model block 6b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com