Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Realize secondary heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

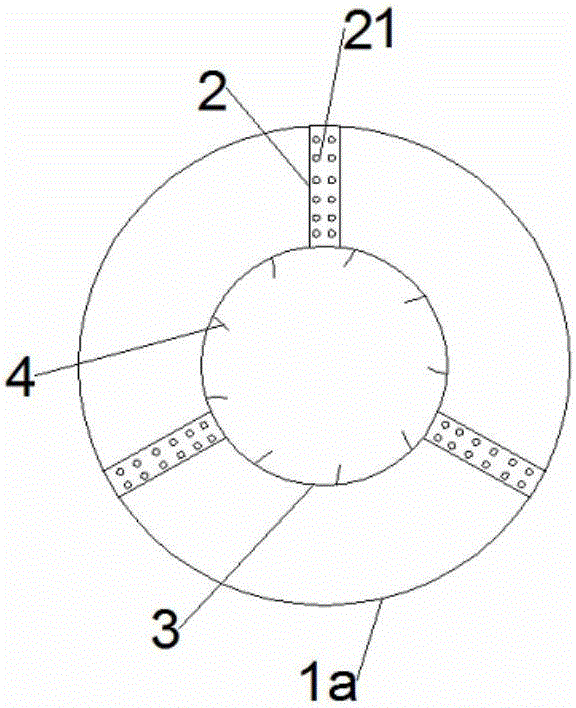

Double-barrel rotary kiln for flue gas backflow

ActiveCN106247810AAchieve heatingRealize secondary heatingPreheating chargesCeramicwareFlue gasEngineering

The invention discloses a double-barrel rotary kiln for flue gas backflow. The double-barrel rotary kiln for flue gas backflow comprises a kiln body which is arranged in an inclined manner, wherein the kiln body comprises an outer barrel and an inner barrel positioned in the outer barrel; the inner barrel and the outer barrel are coaxially and fixedly arranged; one end, close to the kiln tail, of the inner barrel is equipped with a material inlet; the position, at a kiln head, of the outer barrel is equipped with a finished product outlet; a flue gas outlet of the outer barrel is connected to a dust settling chamber; a desulfurization dust collector and a flue gas backflow air blower are connected onto the dust settling chamber; inlet air of the flue gas backflow air blower is hot flue gas of the dust settling chamber; and an air outlet of the flue gas backflow air bower extends into a charge hole of the inner barrel. The double-barrel rotary kiln for flue gas backflow disclosed by the invention has the advantages that hot flue gas introduced out from the outer barrel partially flows back into the inner barrel through the air blower, so that heating for materials in the inner barrel can be realized, polluted gas generated in the inner barrel is forced to move towards a high-temperature section of the kiln head, and polluted air us subjected to sufficient high-temperature incineration disposal, and therefore, pollution of harmful gases such as dioxin and stink is prevented, and waste heat is efficiently utilized.

Owner:NINGBO UNIV

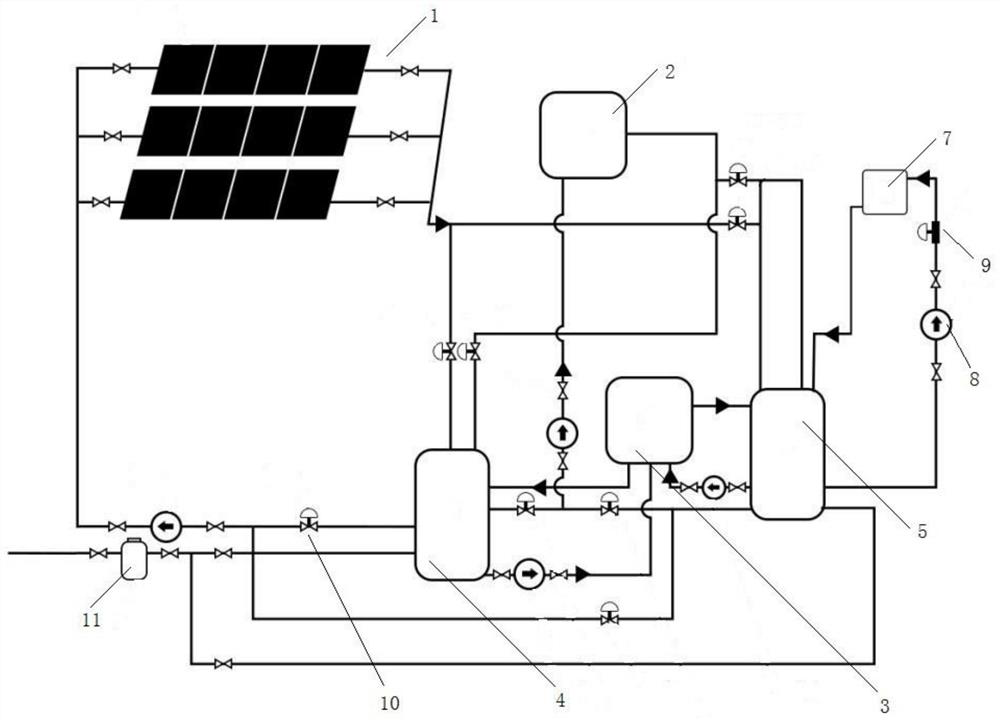

Heating equipment for crude oil gathering and transferring and heating method therefor

InactiveCN1670422ARealize automatic heatingRealize thermal storage controlPipeline systemsElectricityWater storage tank

This invention provides heating equipment and its heating method of crude oil concentrated output. It includes water route equipment, oil transmitting equipment and control equipment. The control equipment is connected to water route equipment and oil transmitting equipment, the water route equipment is connected to oil transmitting equipment through water / oil heat exchanger, solar heating unit is set in water route equipment. Water in water storage tank is sent to solar collector to heated, then the high temperature water heated by the collector is sent to water / oil exchanger, and oil is sent to water / oil exchanger at the same time, the heat exchange between high temperature water and low temperature crude oil is realized in water / oil exchanger, finally the low temperature water flows back to storage tank. Solar energy is successfully used to industrial manufacture. Solar energy used in crude oil concentrated transmits and heat, it is propitious to generalize in crude exploitation and transmission field.

Owner:SOUTH CHINA UNIV OF TECH

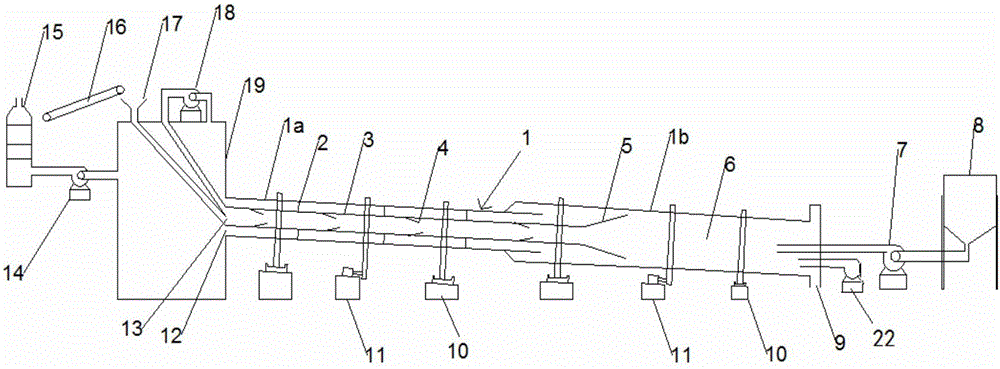

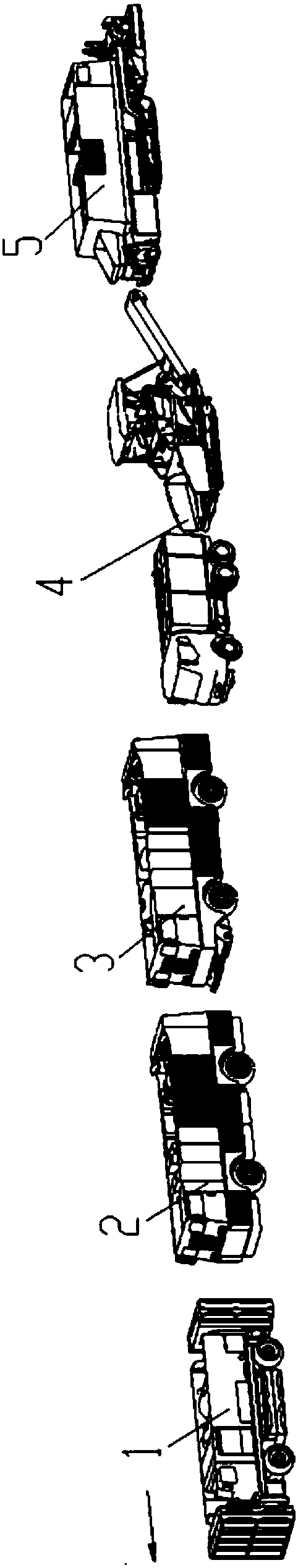

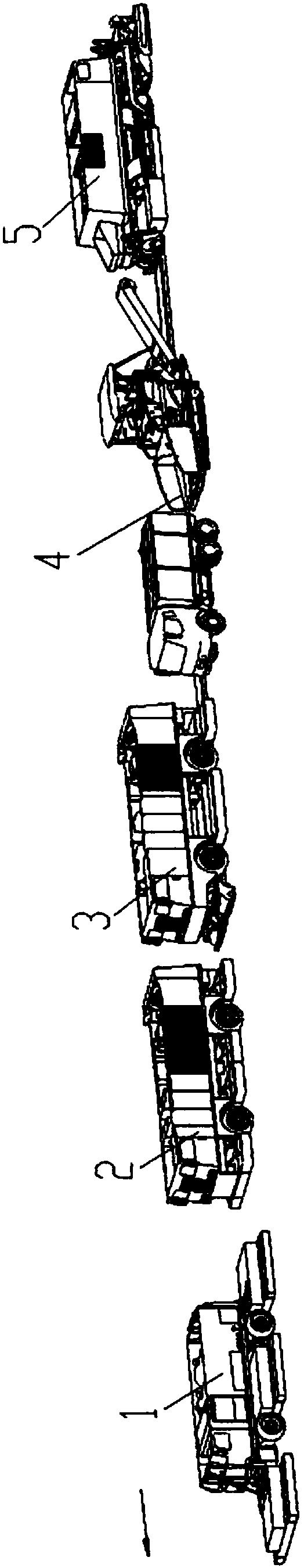

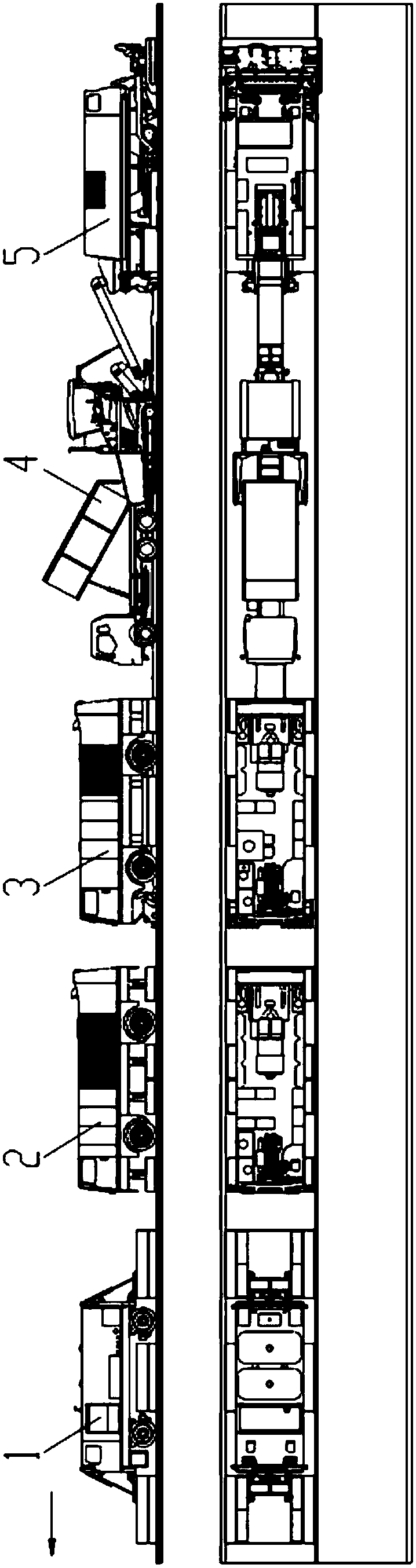

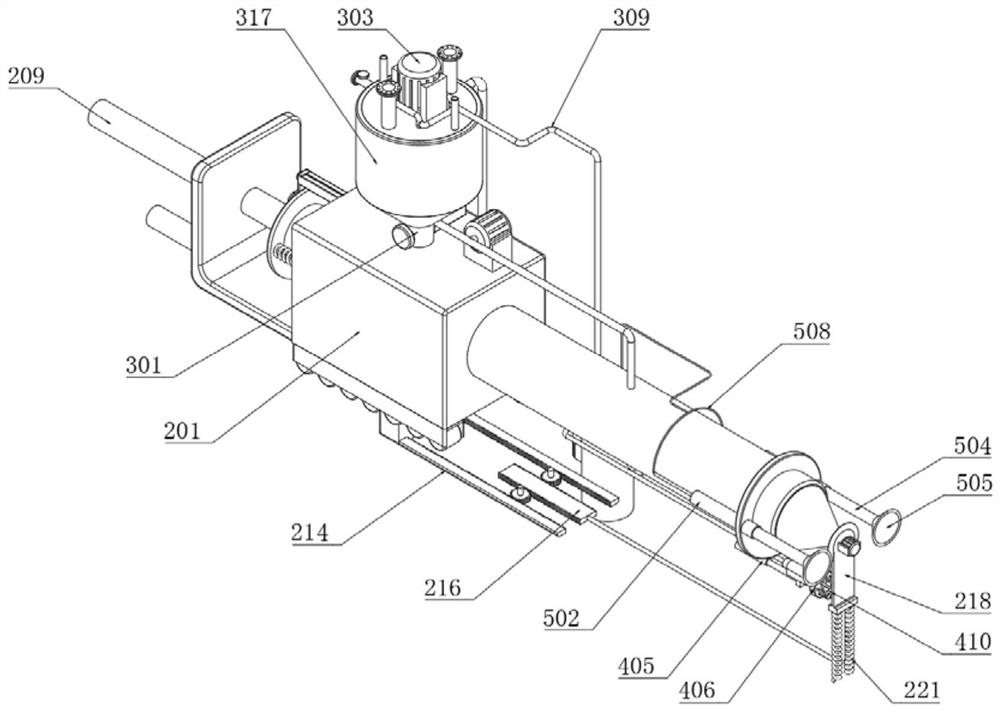

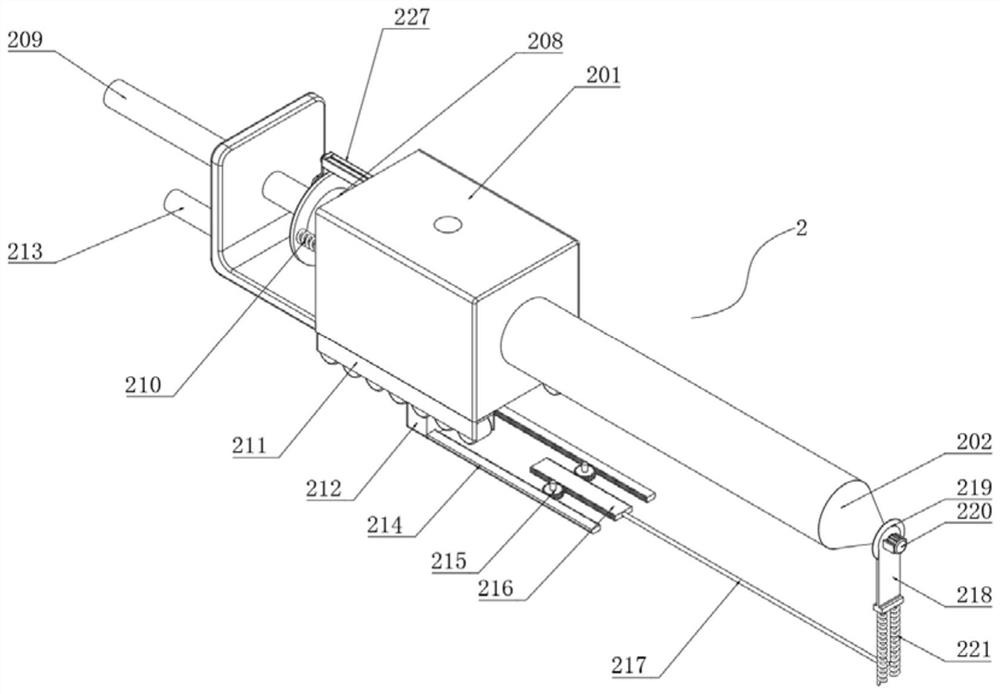

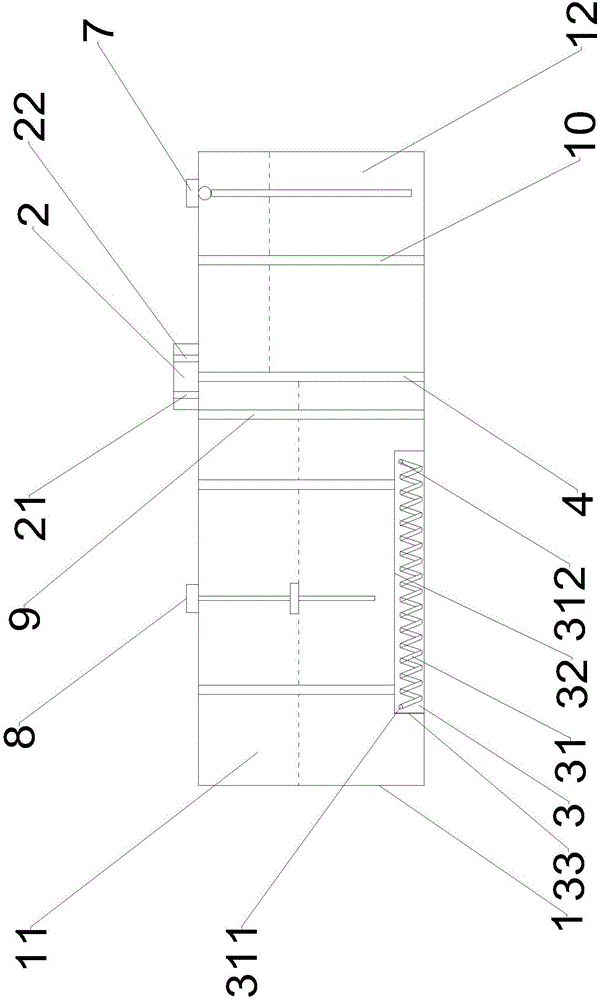

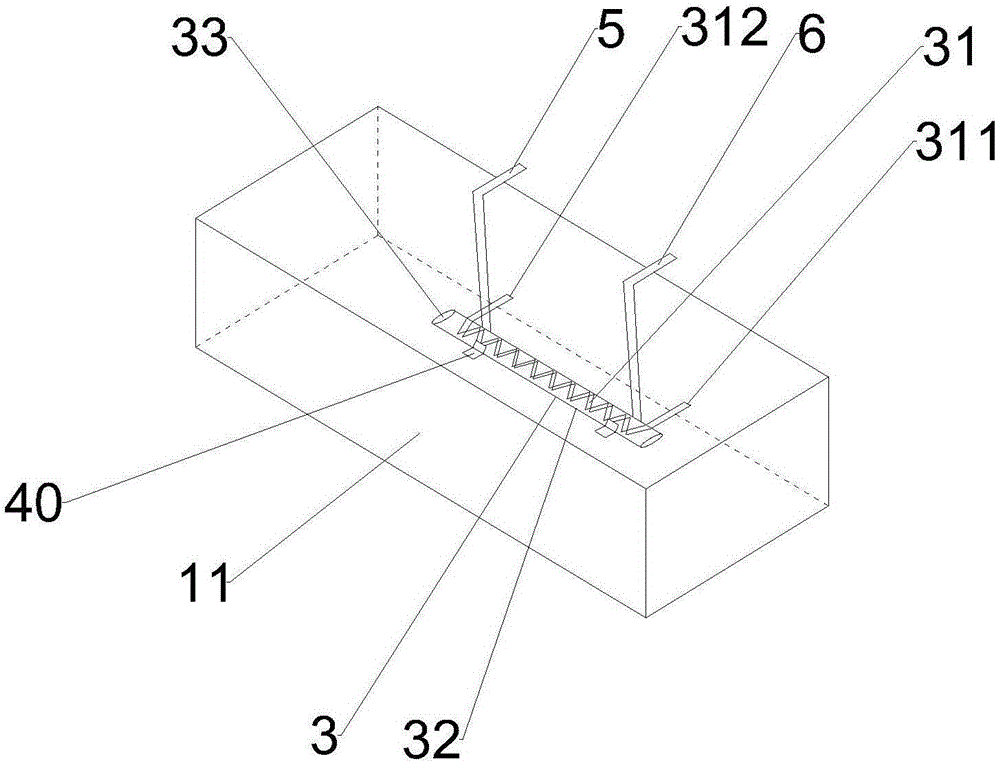

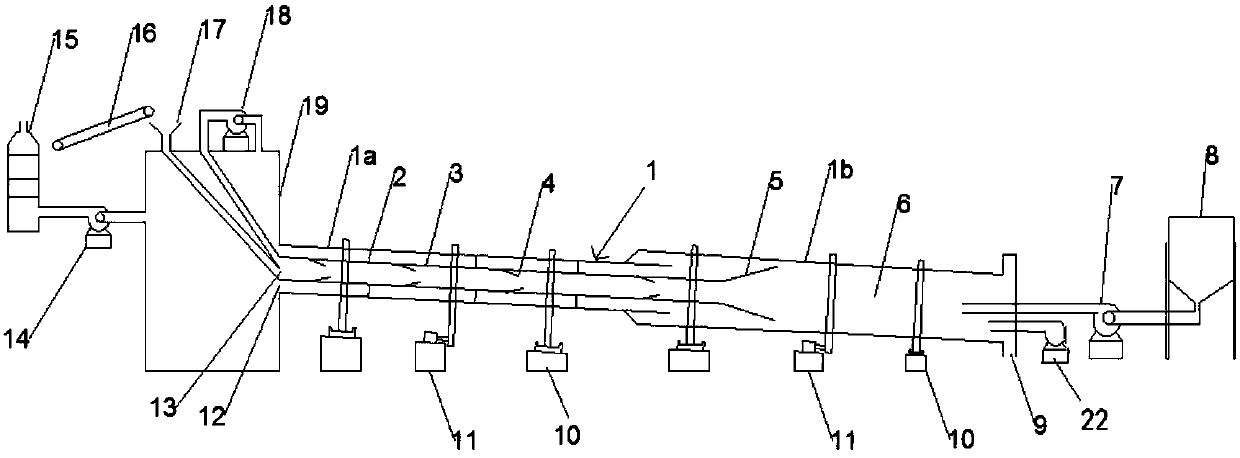

Novel hot air-microwave composite in-place hot recycling complete set and construction technology thereof

PendingCN108252188ASolve pollutionSolve the problem of road performance degradationRoads maintainenceMicrowaveEngineering

The invention discloses a novel hot air-microwave composite in-place hot recycling complete set. The novel hot air-microwave composite in-place hot recycling complete set comprises a hot air heater (1) arranged at the foremost end of the complete set, wherein a microwave heater (2) is arranged at the back end of the hot air heater (1); a microwave heating milling machine (3) is arranged at the back end of the microwave heater (2); a dump truck and multifunctional feeder adding combination (4) is arranged at the back end or on the side surface of the microwave heating milling machine (3); a remixing recycling machine (5) is arranged at the foremost end of the complete set. The invention further discloses a construction technology of the novel hot air-microwave composite in-place hot recycling complete set. Through the novel hot air-microwave composite in-place hot recycling complete set and the construction technology thereof, provided by the invention, accurate control of the modular zone heating temperature is achieved and the uniformity of a whole heating surface is guaranteed; the novel hot air-microwave composite in-place hot recycling complete set has good adaptability to large-bend construction, large-angle climbing, transfer transportation and the like; power-variable and intermittent heating of a modular heating wall and machine group control are achieved, the heating efficiency is high, the heating depth is high and adaptability to the disease condition is strong.

Owner:JIANGSU JITRI ROAD ENG TECH & EQUIP RES INST CO LTD

Fritted porcelain forming baking oven

InactiveCN105222535AConsistent temperatureExtended staySolar heat devicesDrying gas arrangementsCooking & bakingEngineering

A fritted porcelain forming baking oven comprises an oven body made of heat insulating materials, an air heating device arranged on the outer top surface of the oven body, two heat radiation cavities symmetrically distributed on a bottom plate inside the oven body, and a recycling cavity arranged in the middle of a top plate inside the oven body. Heat radiation holes are formed in the surfaces of the heat radiation cavities. Recycling holes are formed in the surface of the recycling cavity. The air heating device comprises a primary heating cavity, a heating electric wire arranged in a wall of the primary heating cavity, an exhaust fan and a secondary heating cavity, wherein the exhaust fan is communicated with the primary heating cavity through the secondary heating cavity; the heat radiation cavities are communicated with the exhaust fan through heat radiation pipes; the recycling cavity is communicated with the primary heating cavity through a recycling pipe; a plurality of metal rods are embedded in the wall of a cavity body of the secondary heating cavity; one end of each of the metal rods extends into the secondary heating cavity, and the other end of each of the metal rods is located outside the secondary heating cavity; the diameter of the heat radiation pipes is larger than that of the recycling pipe. The fritted porcelain forming baking oven has the advantages of being simple in structure, carrying out baking in a hot air circulating heating mode, and being high in baking efficiency.

Owner:HUBEI YAOMEI FLEXIBLE CERAMICS

Anti-blocking injection molding machine

The invention discloses an anti-blocking injection molding machine is characterized in that an injection molding gun barrel is welded to one end of a supporting entering box, a conveying auger is welded to the side end of a movable transmission rod, a movable supporting barrel is welded to one end of a clamping sealing block, a reset spring is welded to one end of the movable supporting barrel, and an auxiliary moving block is welded to the bottom end of the supporting entering box; and a driving rack is welded to one end of the auxiliary moving block, a cleaning plate is rotationally connected to one end of a sliding moving plate, a pushing electromagnet is installed on the inner side of a sliding cavity, a pushing spring is welded to one end of the inner side of the sliding cavity, and an anti-blocking column is welded to one end of the pushing spring. The conveying auger and a reverse flow preventing threaded column drive a raw material to move and prevent the raw material from backflow, the hollow situation is avoided, and a contact switch controls the opening and closing of the pushing electromagnet, so that the anti-blocking column can be quickly reset when needing to be reset, and the discharge port is sealed while the requirement for discharging solidified raw materials at the discharge port position is met.

Owner:姚新耿

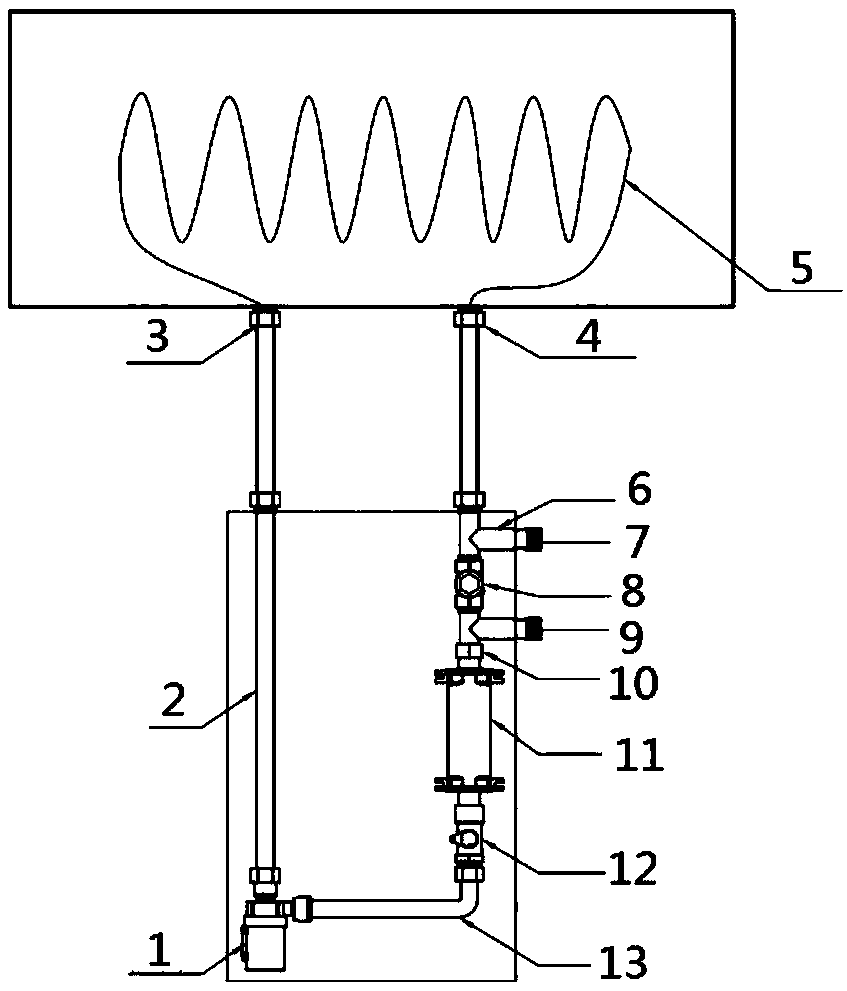

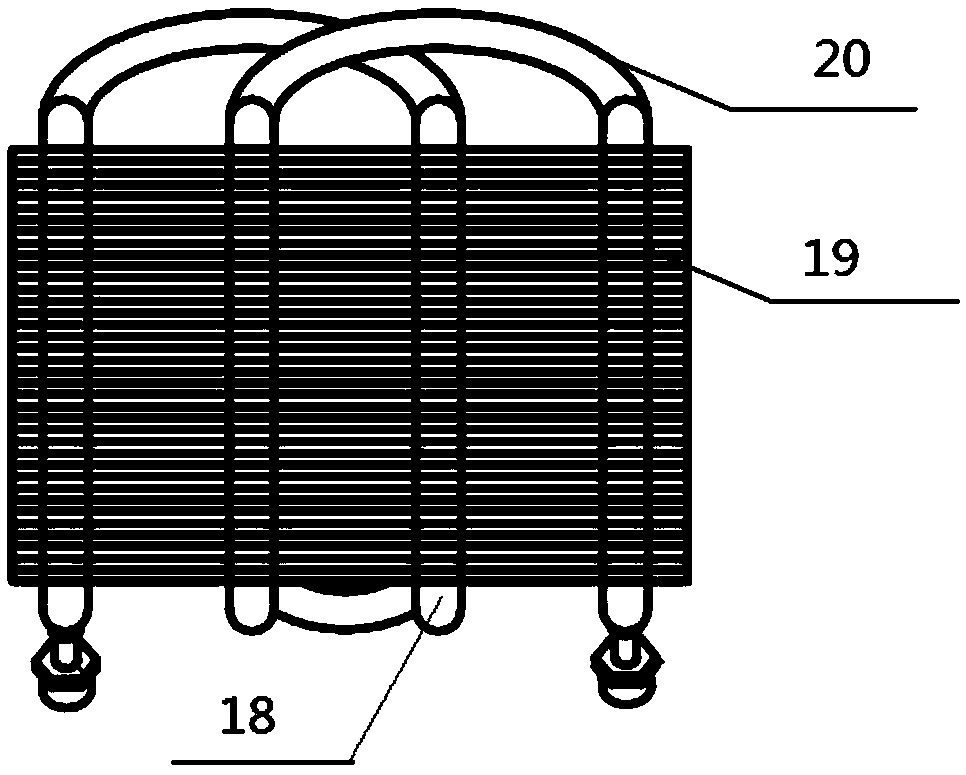

Integral double-use water-circulating heating diesel tank

ActiveCN105863908ARealize secondary heatingSolve the problem of not being able to use low-type fuelMachines/enginesThermal treatment of fuelFuel tankHeating effect

The invention discloses an integral double-use water-circulating heating diesel tank. Inside a heater, an integral helical tube design is adopted to realize no splicing and no welding line of the heater, so water cannot leak from a heating tube; the heater adopts a horizontal type design, so the heating effect of the heater is not weakened when oil level is relatively low; meanwhile, by adopting a design of a main oil tank and a secondary oil tank, a diesel engine can be supplied with oil from the main oil tank or the secondary oil tank according to different conditions. The integral double-use water-circulating heating diesel tank comprises a tank body, an oil tank cover and the heater, wherein the oil tank cover is arranged on the tank body; the tank body comprises the main oil tank and the secondary oil tank; the main oil tank and the secondary oil tank are isolated by a first partition; the heater is arranged inside the main oil tank and is positioned at the bottom of the main oil tank; the length direction of the heater is parallel to that of the main oil tank.

Owner:赵幸芝

High-temperature steam generator and steam cooking equipment applying same

PendingCN110367835AAchieve heatingRealize secondary heatingSteam cooking vesselsRoasters/grillsWater vaporSteam cooking

The invention belongs to the technical field of steam generators and discloses a high-temperature steam generator. The high-temperature steam generator comprises a steam generating assembly and a steam heating assembly; the steam heating assembly comprises a steam heating shell, a second heating assembly, a high-temperature steam outlet pipe and a water vapor separation component; a cavity of thesteam heating shell is a steam heating chamber; the second heating assembly is arranged on a side wall of the steam heating shell; steam generated by the steam generating assembly enters the steam heating chamber; hot air in the steam heating chamber is used for heating the steam generated by the steam generating assembly; the high-temperature steam outlet pipe is arranged on the steam heating shell; and the water vapor separation component is located below a steam inlet of the high-temperature steam outlet pipe and is used for re-heating the steam heated by the hot air. The invention furtherdiscloses steam cooking equipment applying the high-temperature steam generator. According to the steam generator, the generated steam is heated for multiple times, so that the problem that an existing steam generator cannot generate high-temperature steam is solved.

Owner:VATTI CORP LTD

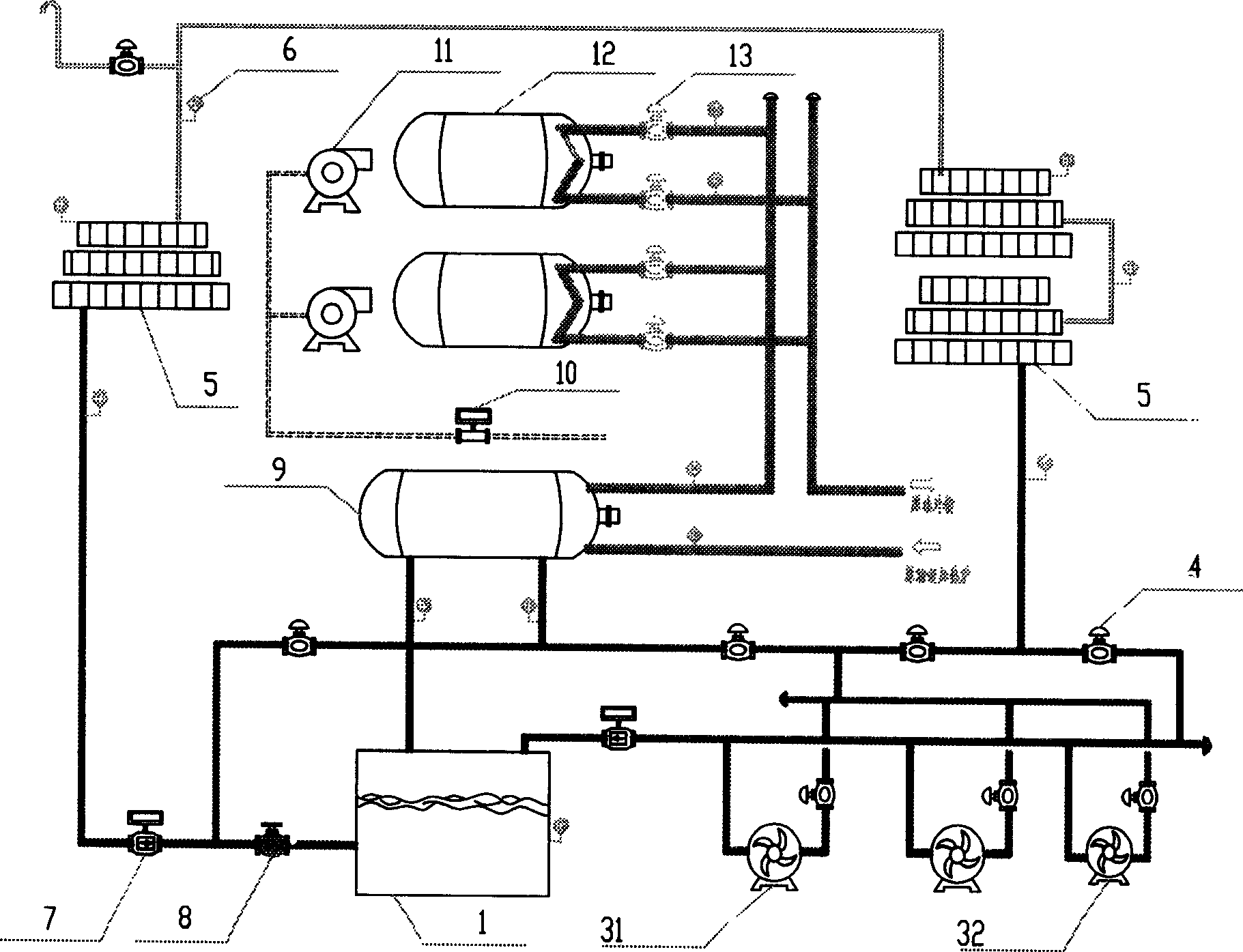

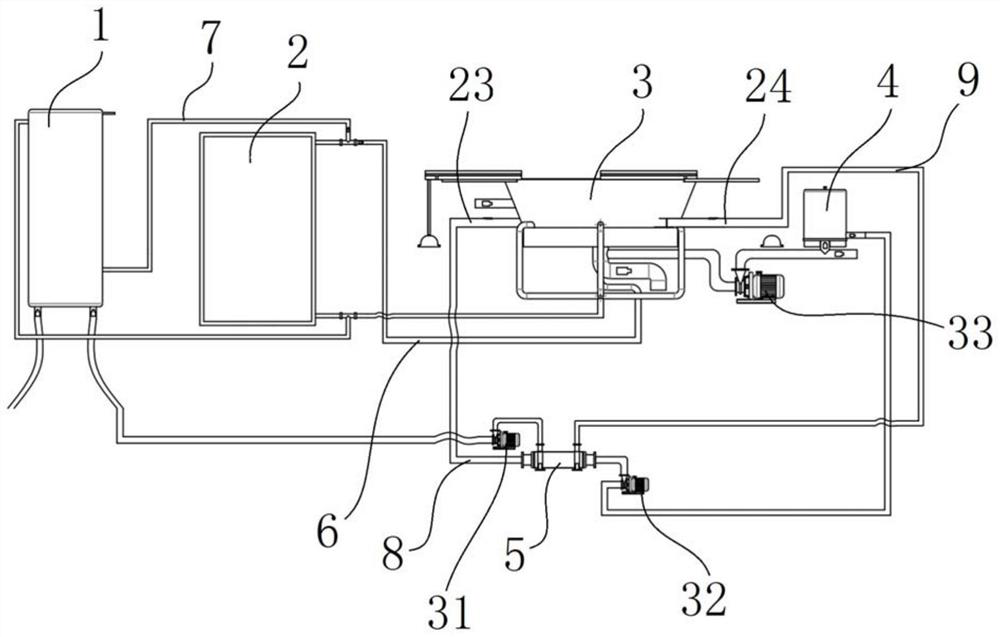

Nighttime warming drip irrigation system

InactiveCN112075324ARealize secondary heatingImprove hydrothermal conditionsSolar heating energySolar heat collector controllersDrip irrigationHeat conservation

The invention provides a nighttime warming drip irrigation system, and belongs to the technical field of agricultural irrigation. The nighttime warming drip irrigation system involves a water storagepool, a solar heat collector, and a heat preservation water tank, wherein the interior of the water storage pool is suitable for accommodating irrigation water and is provided with an irrigation wateroutlet, the solar heat collector is connected with the water storage pool and is suitable for heating the irrigation water inside the water storage pool, and the heat preservation water tank is connected with the water storage pool and the solar heat collector correspondingly. According to the nighttime warming drip irrigation system, the solar heat collector is used for heating the water insidethe water storage pool and the water inside the heat preservation water tank, the heat preservation water tank is supplemented to the water storage pool according to the water amount and temperature at the nighttime, nighttime warming irrigation is achieved, the hydrothermal condition of a crop root zone is improved, and water absorption of the crop root zone is facilitated; and meanwhile, nighttime irrigation can avoid the phenomenon of water evaporation caused by over-high air temperature, and the water-saving effect is achieved.

Owner:SHIHEZI UNIVERSITY

Machining equipment

PendingCN112519195AImprove finished product qualityReduce axial stretch rate instabilityPhysicsHeat-shrink tubing

The invention discloses machining equipment. The machining equipment comprises a pipe releasing structure, a heating structure, an expanding die, a traction device and a pipe collecting structure, wherein the pipe releasing structure is provided with a pipe releasing roller, the heating structure comprises a retracting mechanism and a heating furnace arranged on the retracting mechanism, the heating furnace is provided with a heating cavity and an inlet communicating with the heating cavity, the retracting mechanism is provided with a retracting cavity and an outlet communicating with the retracting cavity, the heating cavity communicates with the retracting cavity, the expansion die is arranged at the outlet and used for expanding a heat shrink tube, the traction device is provided with atraction channel right opposite to the expansion mold, the pipe collecting structure and the traction device are arranged adjacently, and the pipe collecting structure is provided with a pipe collecting roller. According to the machining equipment, the defect that the axial stretching rate of the heat shrink tube is unstable can be overcome or reduced, the stretching rate of the heat shrink tubecan be effectively controlled through the machining equipment, and the finished product quality of the heat shrink tube is improved.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

Reducing roasting flue gas and roasting finished product waste heat comprehensive recovery device and method

InactiveCN111623641AAchieve recyclabilityIncrease waste heatIncreasing energy efficiencySteam generation using hot heat carriersFlue gasProcess engineering

The invention discloses a reducing roasting flue gas and roasting finished product waste heat comprehensive recovery device and method. The device comprises a reducing roasting rotary kiln, a heat exchange rotary cylinder, a flue gas waste heat boiler and a flue gas post-processing system, wherein the heat exchange rotary cylinder is arranged obliquely, the front end of a cylinder body is higher than the rear end of the cylinder body, the front end of the cylinder body communicates with a discharge port of a kiln head of the reducing roasting rotary kiln, the rear end of the cylinder body communicates with a kiln tail flue gas outlet of the reducing roasting rotary kiln, the communication is used for reducing roasting low-temperature flue gas and a high-temperature roasting product for heat exchanging in the cylinder, the flue gas waste heat boiler communicates with the front end of the heat exchange rotary cylinder body and is used for producing steam by using the waste heat of flue gas, and the flue gas post-processing system communicates with the flue gas waste heat boiler and is used for removing dust and cooling. The device and the method comprehensively recover the reductionroasting low-temperature flue gas waste heat and the roasted finished product waste heat to produce the steam, the steam can be used for subsequent power generation, heating in the production processor domestic heating, and the purposes of effective recovery of secondary energy, energy saving and emission reduction are achieved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

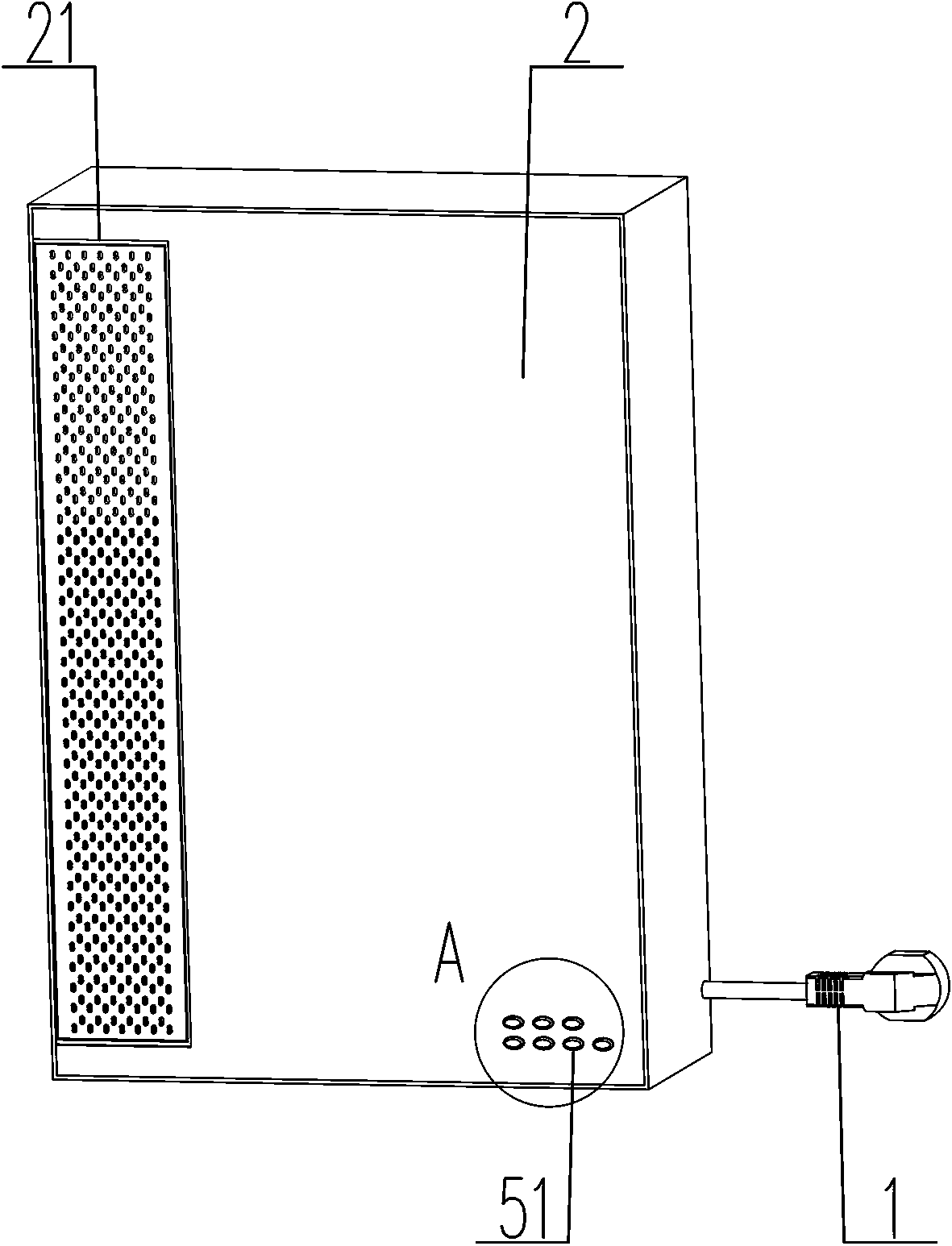

NMP steam condensate recovery system for lithium battery production

InactiveCN114367123AImprove condensation effectRealize secondary heatingPrimary cell manufactureFinal product manufactureThermodynamicsEngineering

The invention discloses an NMP (N-Methyl Pyrrolidone) steam condensate recovery system for lithium battery production, which comprises a shell placed above the horizontal ground, a first partition plate and a second partition plate are arranged on the inner side of the shell, and the first partition plate and the second partition plate sequentially divide the interior of the shell into a steam inlet layer, a collection layer and a condensation layer from bottom to top; the first gear is in shaft connection with the inner side of the first partition plate, the outer side of the first gear is in meshed connection with a second gear, and a cam is fixed to the outer side of the shaft end of the second gear; and the movable plate is in shaft connection with the outer wall of the heat exchange tube. According to the NMP steam condensate recovery system for lithium battery production, the condensation pipe can be driven by steam to vibrate in multiple directions, so that the condensation effect of the steam is effectively improved, meanwhile, heat in the steam can be recycled, secondary heating of condensate is achieved, subsequent secondary rectification is facilitated, and practicability is high.

Owner:宋超

Body drying device

PendingCN108013826ASolve the defects of large limitations in useAddresses more restrictive flawsDomestic applicationsWhole bodyEngineering

The invention discloses a body drying device which comprises a shell, a power supply connecting piece, a first heating assembly and an air inlet assembly. The body drying device also comprises an airguide assembly and a control assembly, wherein an accommodating space is formed in the shell; an air outlet and an air inlet are formed in the shell; the air inlet assembly is located in the accommodating space and is close to the air inlet; the air guide assembly is located in the accommodating space and is close to the air outlet; the tail end of the air inlet assembly is connected to the head end of the air guide assembly; the first heating assembly is located in the air inlet assembly; the control assembly is arranged on the shell and is separately connected to the power supply connectingpiece, the air inlet assembly, and the first heating assembly. The body drying device is simple to operate and obvious in heating effect; people can dry the full body smoothly by way of blowing hot air, so that the defect that an existing body drier which is often an accessory apparatus of a shower device is relatively great in limit during use is overcome effectively, and the body drying device is relatively high in heat energy utilization ratio and relatively low in energy consumption during use, meets the demand on daily life of people well and is conveniently popularized in the market.

Owner:浙江潇源工贸有限公司

Water cycle integrated dual-purpose heating diesel tank

ActiveCN105863908BRealize secondary heatingSolve the problem of not being able to use low-type fuelMachines/enginesThermal treatment of fuelFuel tankHeating effect

Owner:赵幸芝

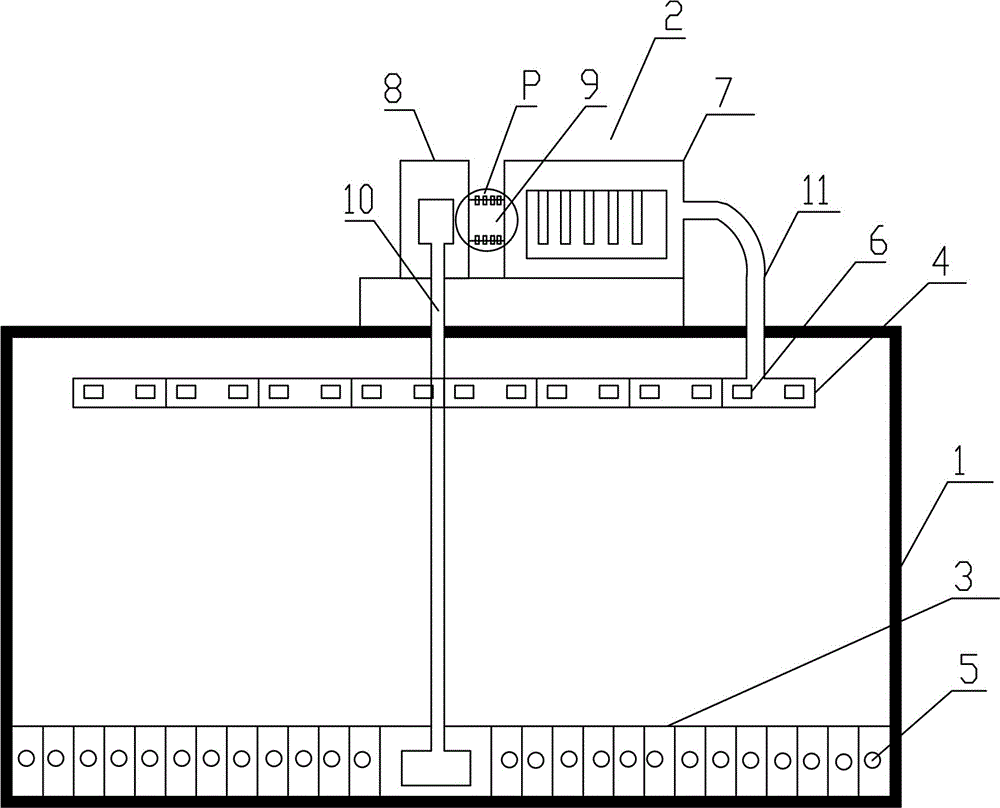

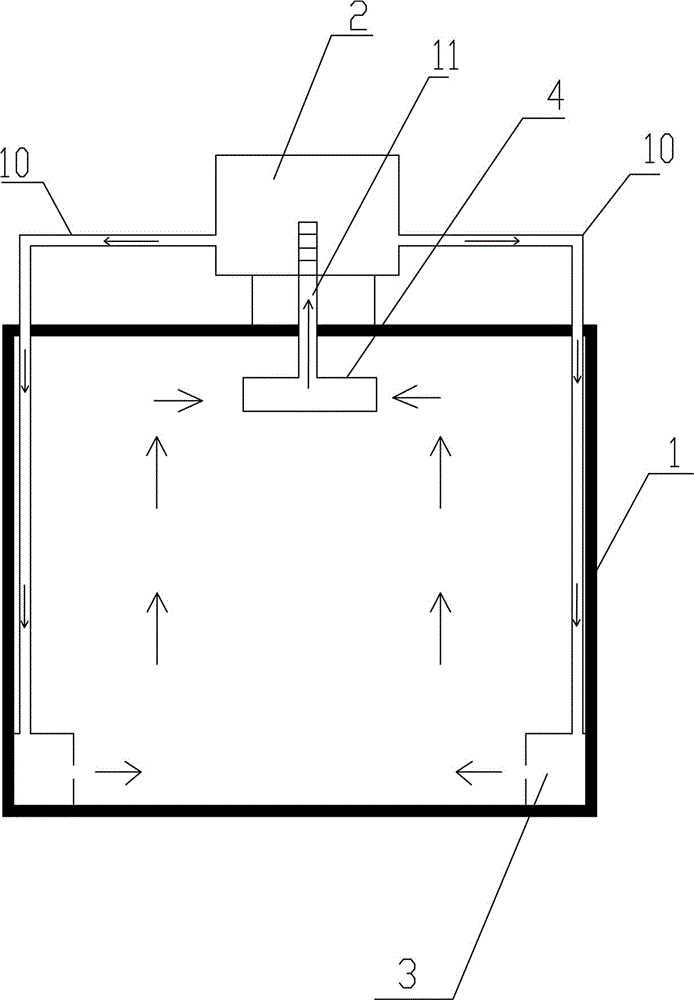

Aging room

InactiveCN105674467AEffective temperature controlSimple structureLighting and heating apparatusElectrical testingEngineeringHot blast

The invention provides an aging room which comprises an aging room body and a hot blast stove mounted outside the aging room. A main air duct is formed in the aging room body, and an air inlet of the main air duct is connected with an air outlet of the hot blast stove. The aging room body is provided with an air return port, an air return pipeline located outside the aging room body is arranged in the position of the air return port, and an air outlet of the air return pipeline is connected with an air inlet of the hot blast stove. The main air duct is connected with an exhaust air duct and an air supply duct, and the exhaust air duct and the air supply duct penetrate through the top end of the aging room body. An exhaust fan is arranged at the top end of the exhaust air duct, and an air supply fan is arranged at the top end of the air supply duct. The top end of the exhaust air duct and the top end of the air supply duct are open. The aging room is simple in structure and good in using effect and has an energy saving function; the hot blast stove is used for quickly increasing the temperature in the aging room, meanwhile, the temperature in the aging room also can be quickly lowered, the temperature in the aging room is effectively kept at a constant value, and therefore smooth aging testing is guaranteed.

Owner:SHAANXI ZIZHU ELECTRON

A semi-embedded 8-shaped cavity solar heat absorber and its working method

InactiveCN105841363BReduce convective heat lossEfficient heat absorptionSolar heating energySolar heat collector controllersLight reflectionHeat losses

The invention discloses a semi-embedding type eight-shaped cavity type solar receiver and a working method thereof. The solar receiver comprises a regular hexagonal convex mirror, a glass housing, a heat insulation vacuum layer, a steel inner shell, a soft heat transfer layer, a helical heat exchange coil tube, a heat conductive fluid, light reflection type wind shields and a cavity mouth convex mirror, wherein different from the traditional heat absorber, the solar receiver is in an eight shape, and independent feeding and discharge holes are formed in a low-temperature heating part and a high-temperature heating part and can be used for heating working media with different temperature requirements in a middle-high temperature solar heat utilization system and transporting the media with different temperatures respectively; the media can be secondarily heated by utilizing the focusing action of the regular hexagonal convex mirror; semi-embedding type connection between the soft heat transfer layer and the helical heat exchange coil tube makes the coil tube more uniformly heated, and thus heat spots are prevented from occurring; and through the focusing and closing actions of the cavity mouth convex mirror, the effects of efficiently absorbing heat and reducing convective heat loss can be reached.

Owner:SOUTH CHINA UNIV OF TECH

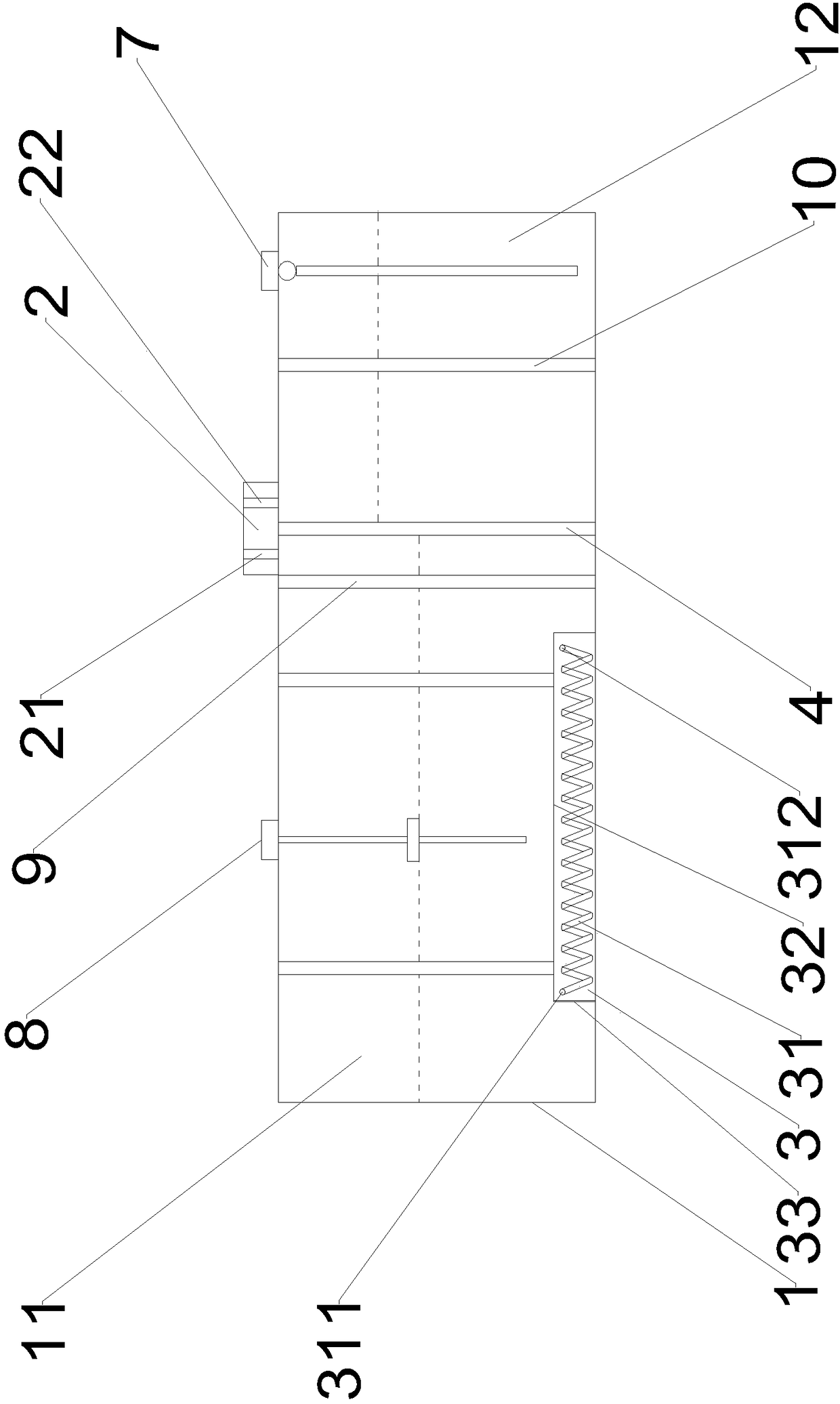

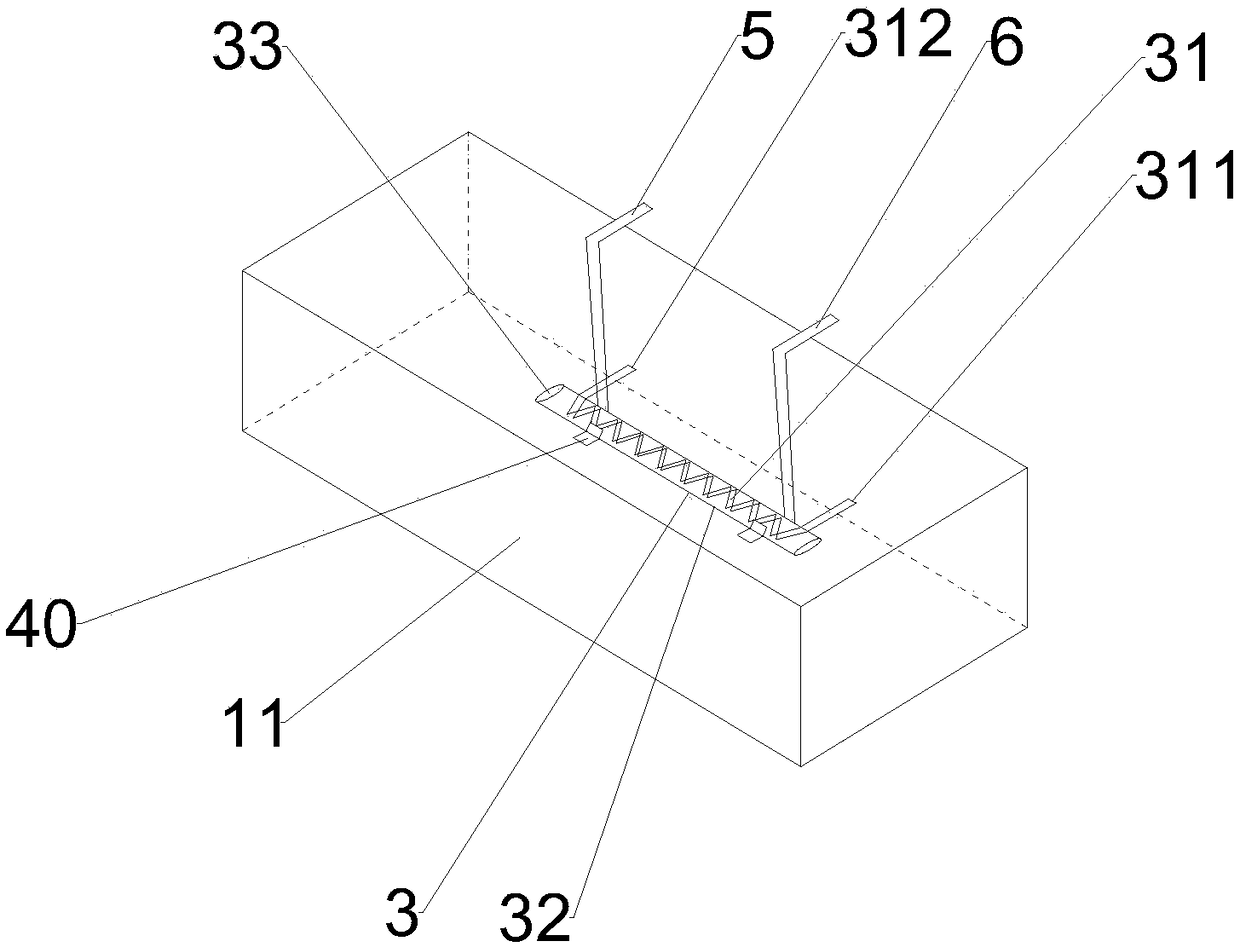

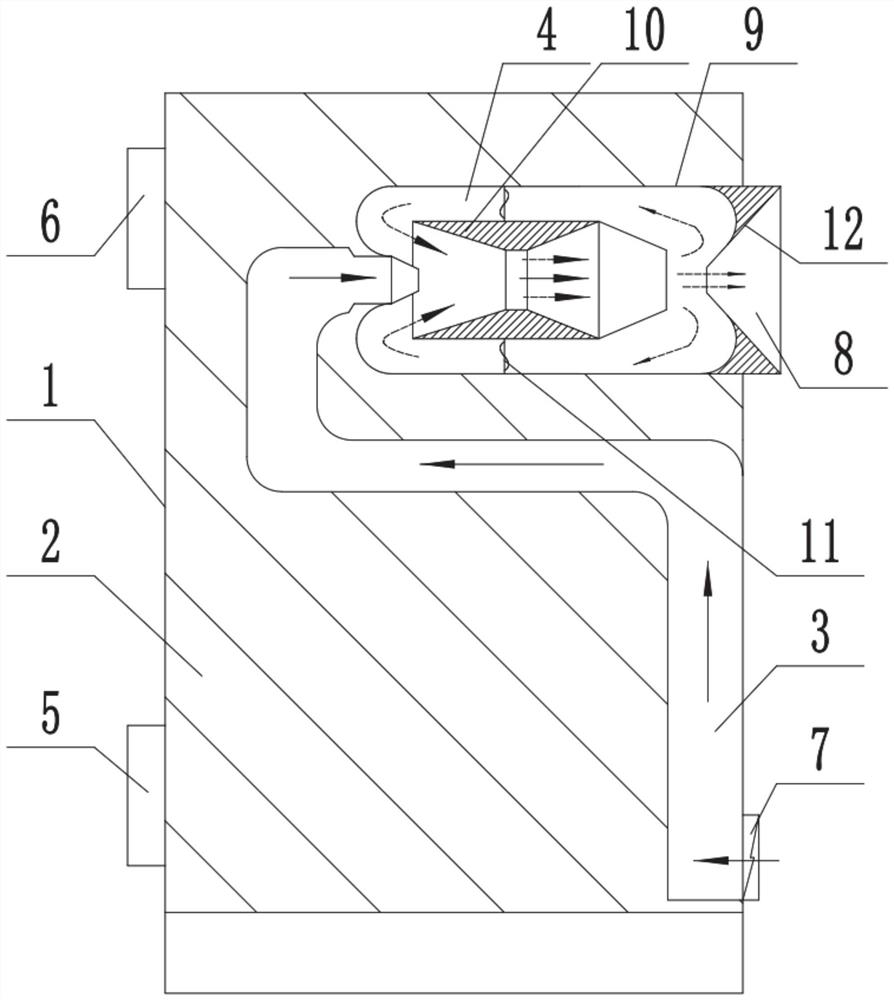

Circulating heat exchange device and method for improving heat exchange efficiency

ActiveCN111947300AImprove heat transfer efficiencyMeet the need for a quick startAir heatersEngineeringHearth

The invention provides a circulating heat exchange device and method for improving heat exchange efficiency, and relates to the field of hot air equipment. The circulating heat exchange device comprises a stove body, a heat conduction pipe and a circulating pipe; the heat conduction pipe and the circulating pipe are arranged in a furnace of the stove body, the circulating pipe comprises a venturipipe and a return pipe arranged outside the venturi pipe in a sleeving mode, and one end of the return pipe is connected with the stove body to form an air outlet; the other end of the return pipe isconnected with the heat conduction pipe, a circulation channel is formed between the outer wall of the venturi pipe and the interior of the return pipe, one end of the circulation channel and one endof the heat conduction pipe jointly communicate with an inlet of the venturi pipe, and the air outlet and the other end of the circulation channel jointly communicate with an outlet of the venturi pipe, the furnace communicating with the outside is arranged to heat the heat conduction pipe and the circulating pipe together, indoor oxygen is not consumed while hot air is output, heat exchange is conducted without air exchange, a circulation heating channel is formed inside the circulating pipe, airflow output by the backflow part is subjected to secondary heating, sufficient mixing is conductedin cooperation with the venturi pipe structure, the heat exchange efficiency is improved, and the requirement for rapid starting is met.

Owner:SHANDONG HUAYU UNIV OF TECH

A kind of flue gas backflow double cylinder rotary kiln

ActiveCN106247810BImprove utilization efficiencyRealize secondary heatingPreheating chargesCeramicwareFlue gasEngineering

The invention discloses a double-barrel rotary kiln for flue gas backflow. The double-barrel rotary kiln for flue gas backflow comprises a kiln body which is arranged in an inclined manner, wherein the kiln body comprises an outer barrel and an inner barrel positioned in the outer barrel; the inner barrel and the outer barrel are coaxially and fixedly arranged; one end, close to the kiln tail, of the inner barrel is equipped with a material inlet; the position, at a kiln head, of the outer barrel is equipped with a finished product outlet; a flue gas outlet of the outer barrel is connected to a dust settling chamber; a desulfurization dust collector and a flue gas backflow air blower are connected onto the dust settling chamber; inlet air of the flue gas backflow air blower is hot flue gas of the dust settling chamber; and an air outlet of the flue gas backflow air bower extends into a charge hole of the inner barrel. The double-barrel rotary kiln for flue gas backflow disclosed by the invention has the advantages that hot flue gas introduced out from the outer barrel partially flows back into the inner barrel through the air blower, so that heating for materials in the inner barrel can be realized, polluted gas generated in the inner barrel is forced to move towards a high-temperature section of the kiln head, and polluted air us subjected to sufficient high-temperature incineration disposal, and therefore, pollution of harmful gases such as dioxin and stink is prevented, and waste heat is efficiently utilized.

Owner:NINGBO UNIV

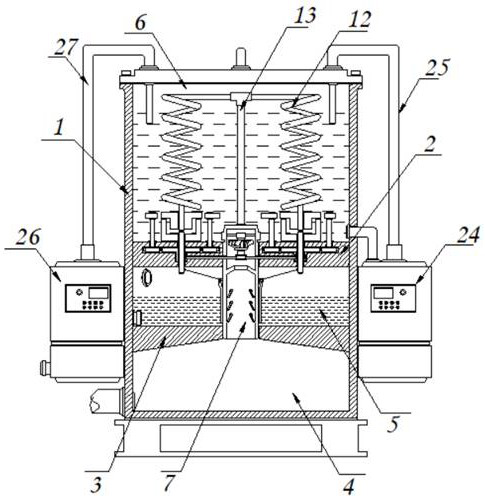

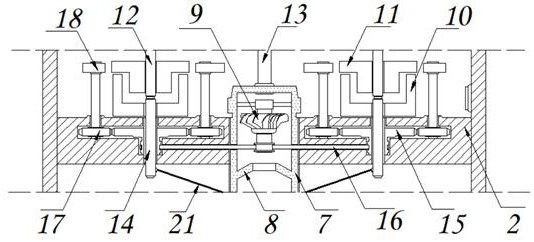

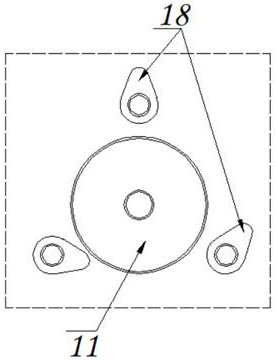

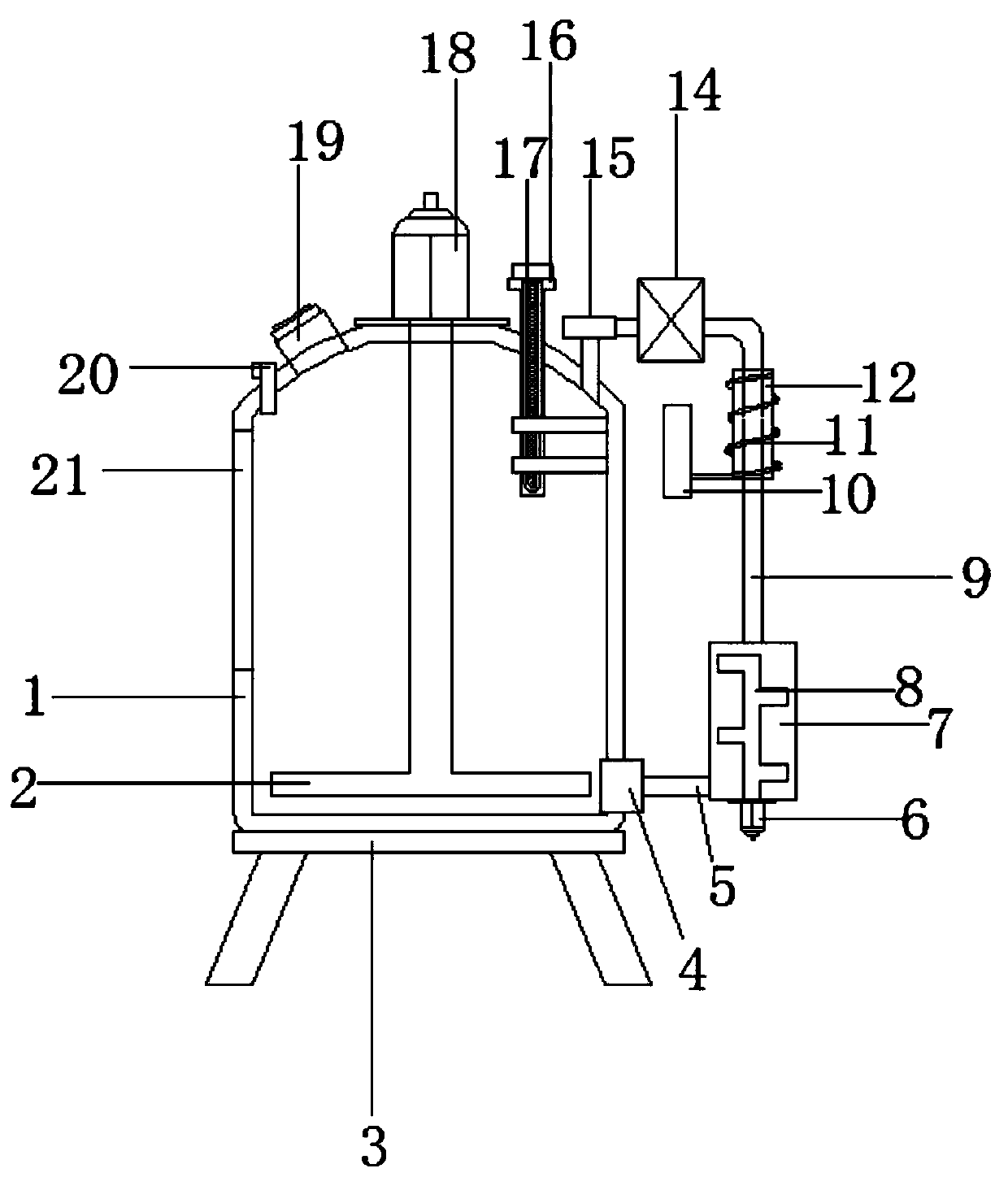

Multifunctional stainless steel heating reaction kettle

PendingCN111495302ARealize secondary heatingAvoid Mixed EffectsTransportation and packagingMixersElectric machineryEngineering

The invention discloses a multifunctional stainless steel heating reaction kettle which is characterized in that a bottom material opening is formed in the side end of the bottom of a reaction kettlebody and is communicated with the interior of the reaction kettle body; a crushing box is provided, the side end of the bottom of the crushing box communicates with the bottom material opening througha pipeline, and materials in the reaction kettle body can enter the crushing box through the bottom material opening; a second stirring motor is arranged at the bottom of the crushing box; a transmission shaft of the second stirring motor extends into the crushing box, a second stirring paddle is further arranged in the crushing box, the lower end of the second stirring paddle is connected with the transmission shaft of the second stirring motor, the other end of the second stirring paddle extends into the middle of the crushing box, and a plurality of stirring blades extending to the side end are evenly distributed at the side end of the second stirring paddle; and a material return port is provided, the material return port is formed in the top of the reaction kettle body, the materialreturn port is communicated with the top of the crushing box through a pipeline, and materials in the crushing box can enter the reaction kettle body from the material return port through the pipeline.

Owner:江门市鹏昇五金制品有限公司

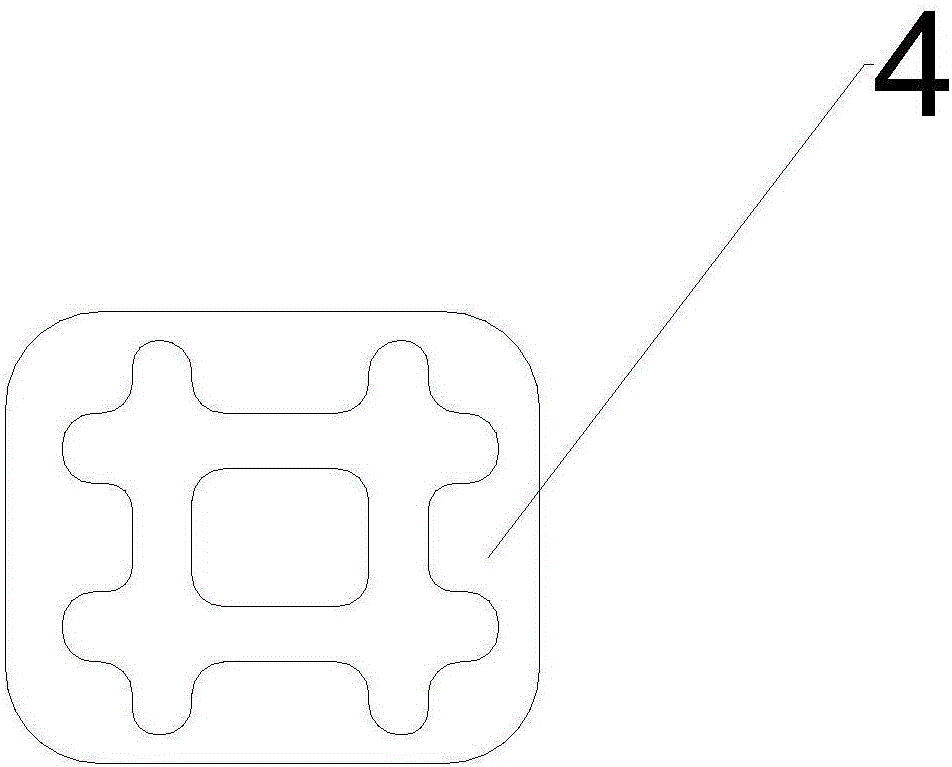

Extrusion-screw puffing cavity structure

ActiveCN110101014ARealize the second heatingFully gelatinizedFood scienceElectrical resistance and conductanceCavity wall

The invention provides an extrusion-screw puffing cavity structure. The structure comprises a puffing cavity and a screw accommodating in the cavity and is characterized in that the puffing cavity comprises a feeding conveying cavity, a first-segment high-temperature heating cavity, a second-segment high-temperature heating cavity, a low-temperature heating cavity and a third-segment high-temperature heating cavity which are distributed from a feeding end to a discharging end in sequence; a first-segment high-temperature heating resistance wire, a second-segment high-temperature heating resistance wire and a third-segment high-temperature heating resistance wire are arranged outside the cavity walls of the first-segment high-temperature heating cavity, the second-segment high-temperature heating cavity and the third-segment high-temperature heating cavity respectively, a refrigerant cavity is formed outside the cavity wall of the low-temperature heating cavity, and cavity wall of the low-temperature heating cavity is sunken inwards to be provided with a material passage the diameter of which is gradually decreased at first and then gradually increased. The cavity structure comprises the four segments of heating cavities including the first-segment high-temperature heating cavity, the second-segment high-temperature heating cavity, the low-temperature heating cavity and the third-segment high-temperature heating cavity, in this way, materials discharged from the cavity structure are subjected to heating processes of temperature increasing, temperature decreasing, temperatureincreasing and temperature decreasing, secondary temperature increasing and secondary temperature decreasing of the materials can be achieved, and puffed products with better quality are convenientlyobtained.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Energy saving and environment protecting system for changing thermal-chemical bond energy

PendingCN108278603ARealize energy saving and environmental protectionHigh heat releaseIndirect carbon-dioxide mitigationAir/fuel supply for combustionHigh frequency powerAir volume

The invention discloses an energy saving and environment protecting system for changing thermal-chemical bond energy and aims to solve the problems that a current combustor is low in thermal-chemicalreaction speed, small in heat release enthalpy, too large in entropy value and too large in thermo-technical combustion waste. The energy saving and environment protecting system for changing the thermal-chemical bond energy comprises a control system, a high-temperature combustor, a water electrolysis device, a plasma generator, an oxygen generating device, a cooling system, an IGBT high-frequency power source, a nitrogen making machine and a frequency converting air volume control device; the control system is connected with the high-temperature combustor, the water electrolysis device, theplasma generator, the oxygen generating device, the cooling system, the IGBT high-frequency power source and the nitrogen making machine; the IGBT high-frequency power source is connected with the water electrolysis device and the plasma generator; the water electrolysis device, the oxygen generating device and the frequency converting air volume control device are communicated with a first-time heating input port of the high-temperature combustor through pipelines; and the plasma generator is communicated with a second-time heating input port of the high-temperature combustor through a pipeline.

Owner:GUANGZHOU MPC INT ELECTRIC ENG

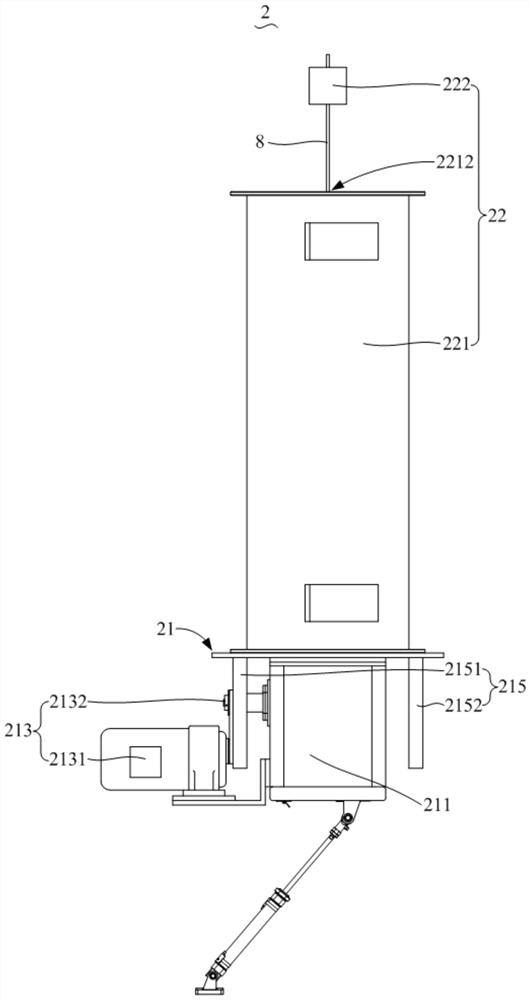

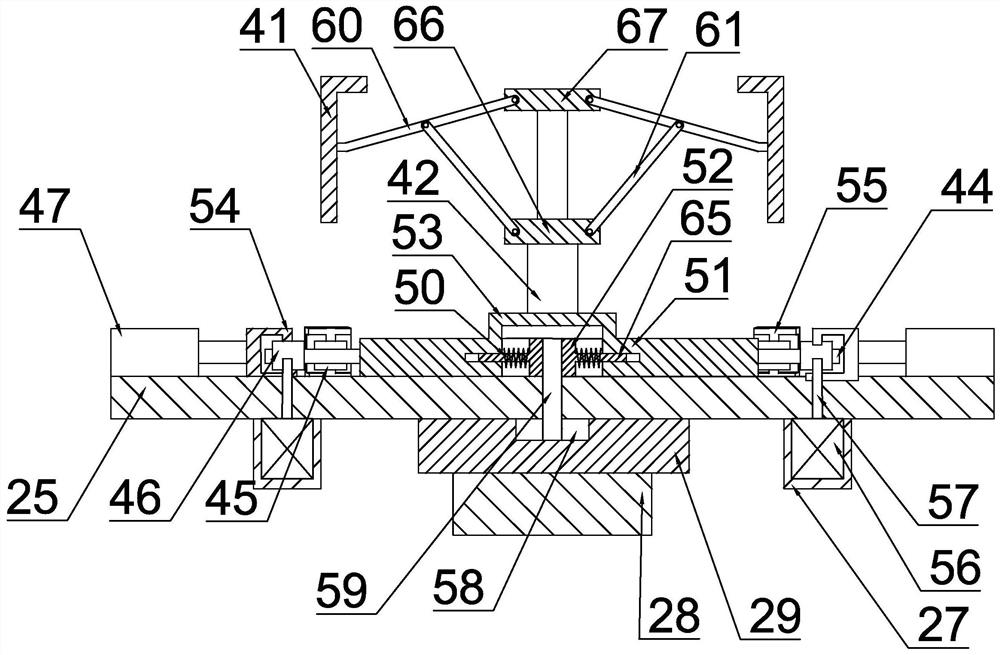

A rotating and oscillating automobile wheel hub painting and baking system

ActiveCN113499922BRealize secondary heatingEfficient dischargePretreated surfacesCoatingsRotary stageEngineering

Owner:金世纪(江苏)智能科技有限公司

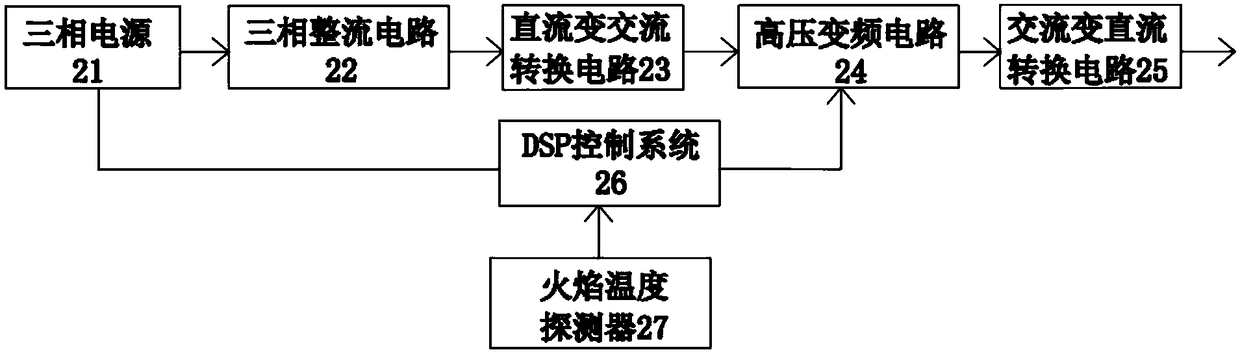

High-frequency IGBT power supply of plasma and water electrolytic separation equipment

PendingCN108343962AImprove utilization efficiencyEasy to useCellsBurner material specificationsChemical reactionControl system

The invention discloses a high-frequency IGBT power supply of plasma and water electrolytic separation equipment, relates to the field of chemical reaction burners, and aims to provide a high-frequency IGBT power supply which is easy to use and high in power supply utilization efficiency of plasma and water electrolytic separation equipment. The high-frequency IGBT power supply of the plasma and water electrolytic separation equipment comprises a three-phase supply, a rectified three-phase circuit, a direct current-to-alternating current converting circuit, a high-frequency transformation circuit and an alternating current-to-direct current converting circuit which are connected in sequence. The high-frequency IGBT power supply further comprises a control system and a flame temperature detector for inputting signals to the control system, wherein the control system is connected with the high-frequency transformation circuit.

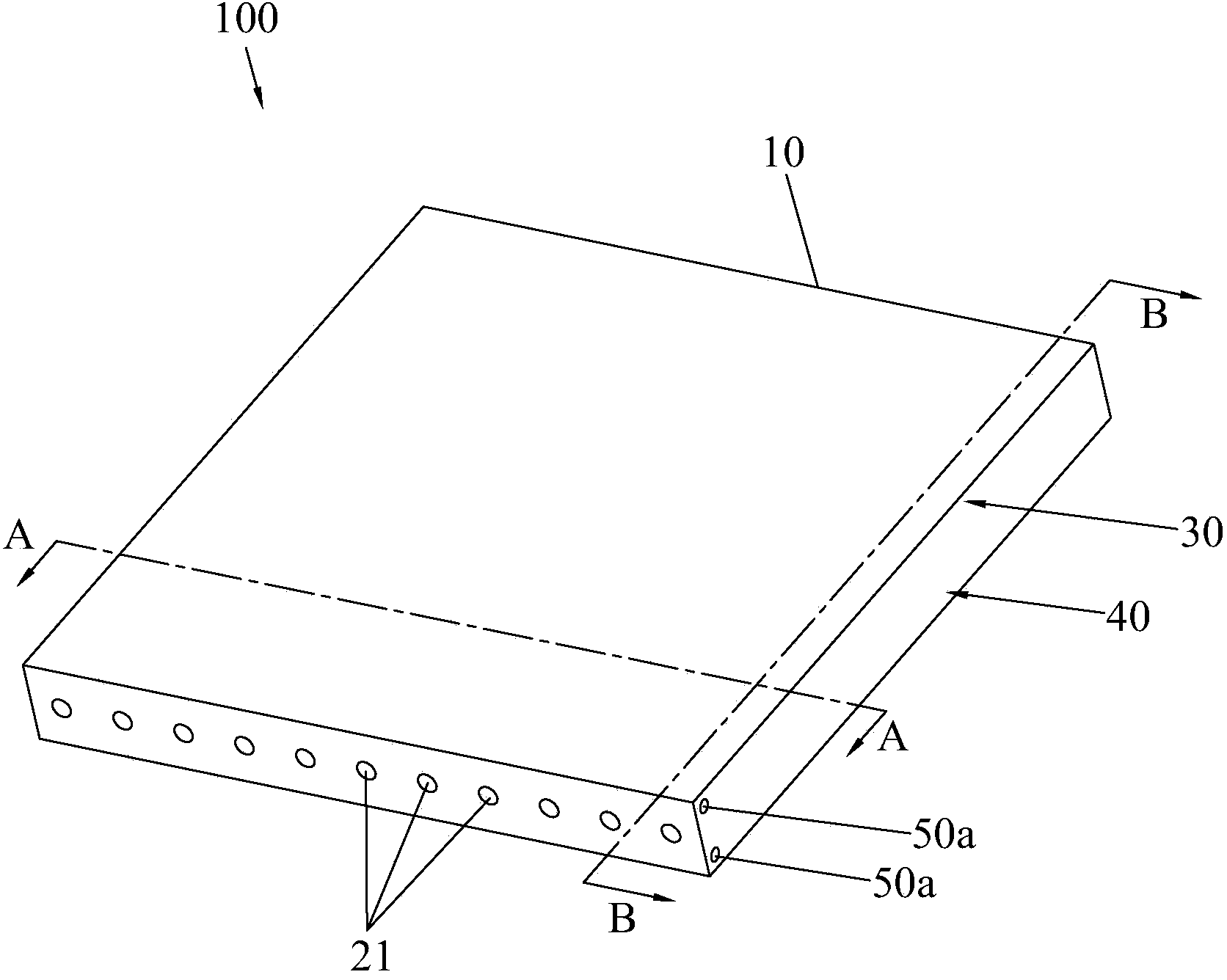

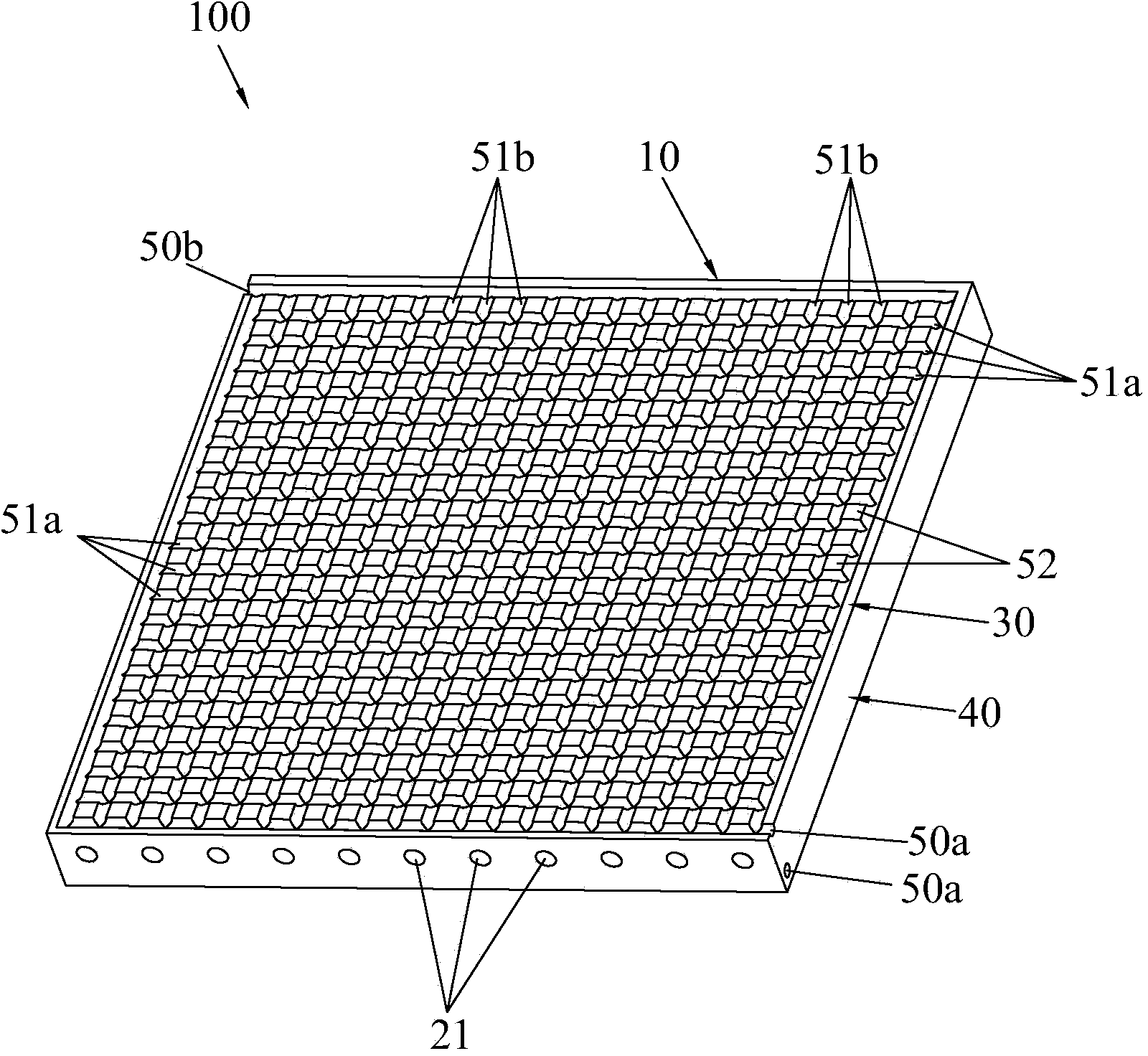

double heated laminate

InactiveCN103533757BAchieve independent controlImplement loop sectionOhmic-resistance heatingPrinted circuit manufactureElectricityEngineering

The invention discloses a double-heating laminated board, which includes a board body and electric heating wires. The fluid channel forms a grid-shaped fluid heating layer, which communicates with the high-temperature fluid outside, and the fluid heating layer at the upper end of the plate body is symmetrically located on both sides of the electric heating layer with the fluid heating layer at the lower end of the plate body; On the basis of electric heating for heating by electricity, it also has a fluid heating layer for heating by fluid. The fluid can be injected into the fluid heating layer quickly and uniformly. Combined with its grid-like design, the heat of the fluid can be quickly and efficiently Uniform and continuous transfer to the plate body, so that the invention can be heated evenly, can quickly rise to the specified maximum temperature and can maintain the maximum temperature for a long time, and also has a variety of heating modes for actual needs, and also has rapid cooling function.

Owner:GUANGDONG SHENGYI SCI TECH

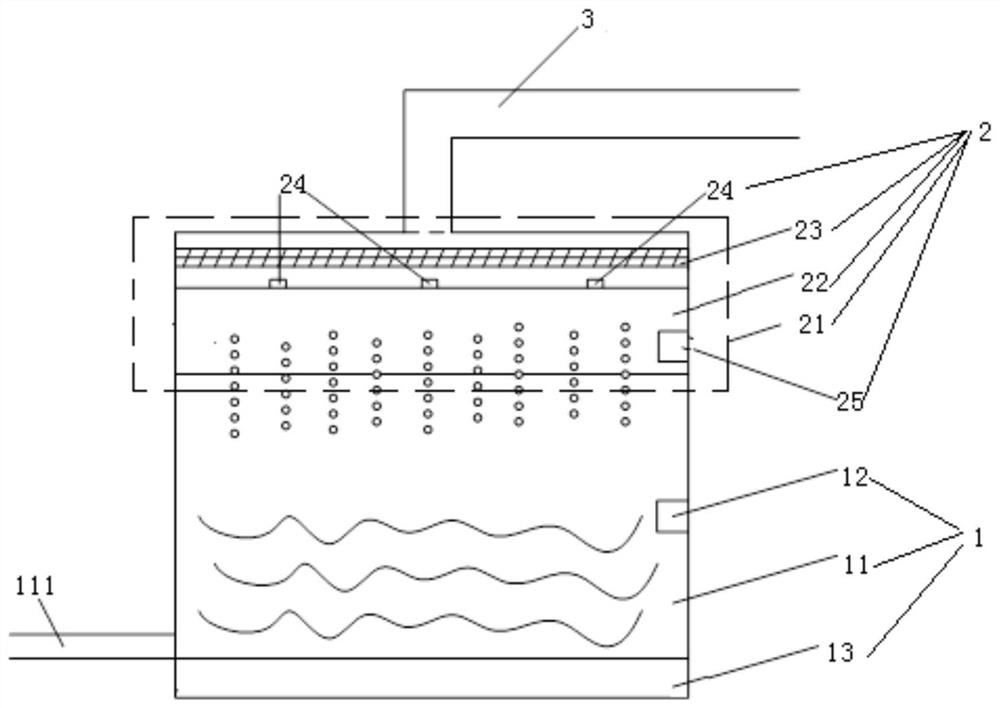

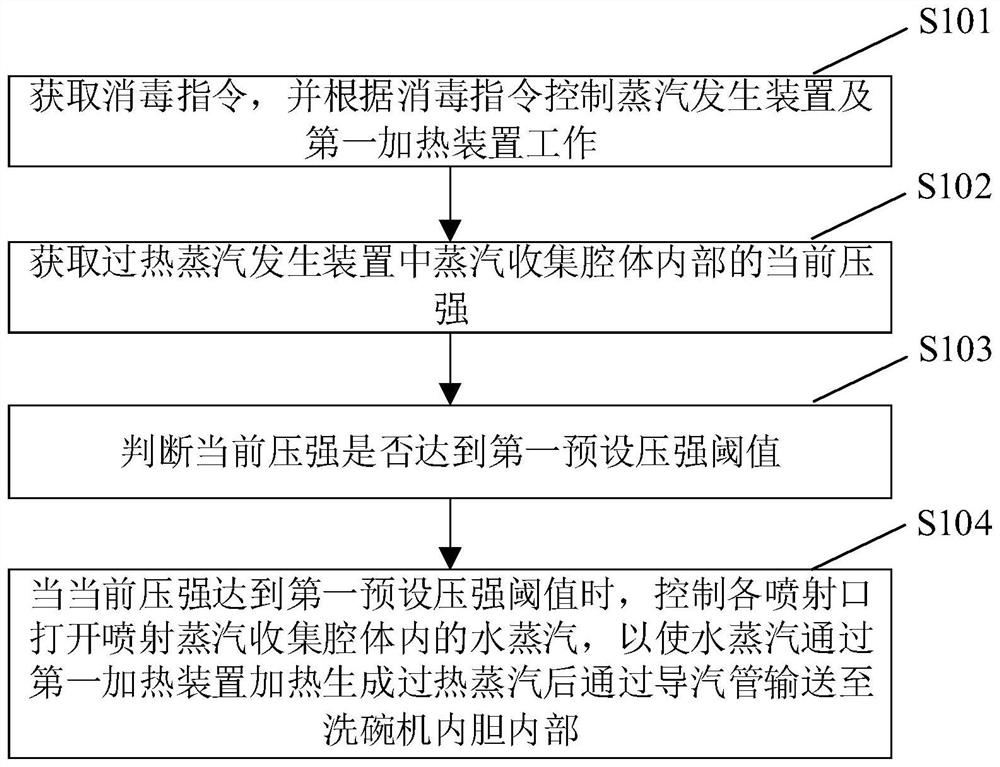

Superheated steam generating device and method for disinfection of dish-washing machine and dish-washing machine

InactiveCN112471993AImprove disinfection effectSolve UtilizationTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionThermodynamicsProcess engineering

The invention provides a superheated steam generating device and method for dish-washing machine disinfection and a dish-washing machine. The superheated steam generating device comprises a steam generating device and a superheated steam generating device, wherein the superheated steam generating device comprises a superheated steam generating device body, the steam collecting cavity is formed inthe superheated steam generating device body; the steam collecting cavity is communicated with the steam generating device and is used for collecting steam generated by the steam generating device; the steam collection cavity is provided with a plurality of jet orifices; the first heating device is arranged at the position, close to each jet orifice, in the superheated steam generation device body, and is used for heating water steam jetted from each jet orifice to form superheated steam; the superheated steam generating device body is connected with a dish-washing machine inner container through a steam guide pipe. The device is advantaged in that the tableware in the inner container of the dish-washing machine is disinfected through the superheated steam, problems that an existing dish-washing machine is poor in disinfection effect and energy utilization rate are solved, and the user experience is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Phase change energy storage water heater

InactiveCN108800570ARealize secondary heatingImprove utilization efficiencyStorage heatersEngineeringPhase change

The invention discloses a phase change energy storage water heater. The phase change energy storage water heater comprises a phase change energy storage heat exchange device and a valve control combination; the valve control combination comprises a water pipe I connected with a hot water outlet of the phase change energy storage heat exchange device, and a water pipe II connected with a water inlet of the phase change energy storage heat exchange device; a circulating water pump is connected between the water pipe I and the water pipe II; the water pipe I is connected with a cold water inlet pipe and a hot water outlet pipe through a tee joint; the hot water outlet pipe is arranged near the circulating pump; a one-way valve is mounted on the water pipe I between the cold water inlet pipe and the hot water outlet pipe; and a pipe heater is mounted on the water pipe I between the hot water outlet pipe and the circulating pump. The water way circulation is realized through the pipe heaterand the circulating pump during heating of the phase change energy storage water heater. When hot water is used, cold water enters from a cold water pipe for heat exchange through a heat exchanger, and passes through the circulating pump and the pipe heater; and hot water is discharged from a hot water pipe. Secondary heating of water for the phase change energy storage water heater and sharing of one water way with the phase change water heater can be realized. The product utilization efficiency is improved; and the purposes of energy conservation and environmental protection are achieved.

Owner:BEIJING SIJI MICOE SOLAR ENERGY TECH

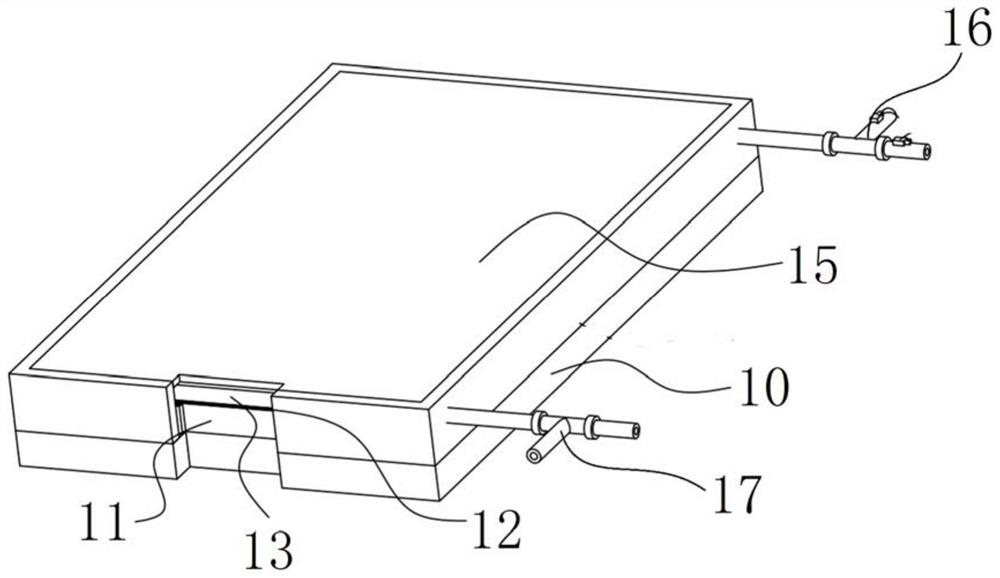

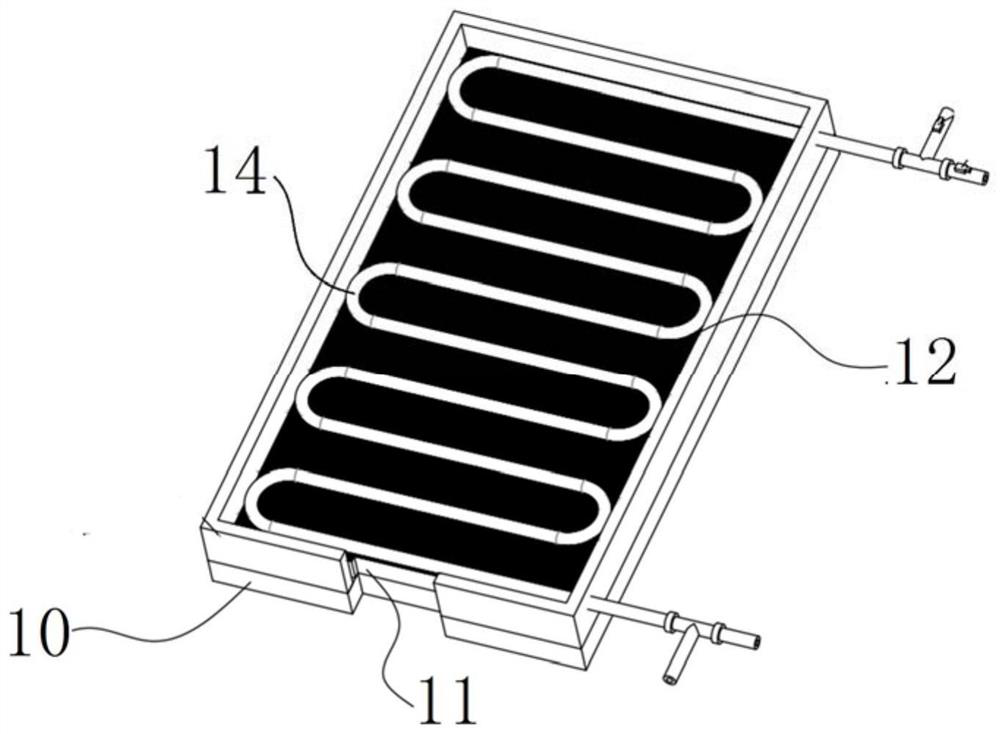

Heating equipment for crude oil gathering and transferring, and heating method thereof

InactiveCN100489373CRealize secondary heatingIncrease profitPipeline systemsWater storage tankCollector device

This invention provides heating equipment and its heating method of crude oil concentrated output. It includes water route equipment, oil transmitting equipment and control equipment. The control equipment is connected to water route equipment and oil transmitting equipment, the water route equipment is connected to oil transmitting equipment through water / oil heat exchanger, solar heating unit is set in water route equipment. Water in water storage tank is sent to solar collector to heated, then the high temperature water heated by the collector is sent to water / oil exchanger, and oil is sent to water / oil exchanger at the same time, the heat exchange between high temperature water and low temperature crude oil is realized in water / oil exchanger, finally the low temperature water flows back to storage tank. Solar energy is successfully used to industrial manufacture. Solar energy used in crude oil concentrated transmits and heat, it is propitious to generalize in crude exploitation and transmission field.

Owner:SOUTH CHINA UNIV OF TECH

Multi-energy complementary park cold and heat combined supply device and control system thereof

PendingCN113790468AImprove qualityReduce power consumptionSolar heating energyEnergy industryWater source heat pumpThermodynamics

The invention relates to a multi-energy complementary park cold and heat combined supply device and a control system thereof, belongs to the technical field of energy supply, and solves the technical problems that an industrial park only uses an air source heat pump, cold and heat combined supply power consumption is high, the park voltage is low due to high-power equipment, even the service life of various devices in the park is affected, and the heating requirement cannot be met sometimes by only using the solar heating technology. According to the solution, the multi-energy complementary park cold and heat combined supply device comprises a solar heat collection system, an air source heat pump unit, a water source heat pump unit, a heat collection water tank and a constant-temperature water tank, seven loops are formed by connecting the solar heat collection system, the air source heat pump unit, the water source heat pump unit, the heat collection water tank and the constant-temperature water tank with park cold and heat user terminals, and the seven loops form four modes of heating in winter and two modes of cooling in summer. Solar energy, air energy and other green energy sources are used for supplying (heat and cold) energy sources to the park, meanwhile, the control system is used for controlling the multi-energy complementary park cold and heat combined supply device, finally, safe, clean, efficient and low-carbon utilization of the energy sources is achieved, and the energy source quality is comprehensively improved.

Owner:SHANXI DERUNXIANG ELECTRIC POWER TECH CO LTD +1

A circulating heat exchange device and method for improving heat exchange efficiency

ActiveCN111947300BImprove heat transfer efficiencyMeet the need for a quick startAir heatersEngineeringHot blast

The disclosure provides a circulation heat exchange device and method for improving heat exchange efficiency, which relate to the field of hot air equipment, including a furnace body, a heat conduction pipe, and a circulation pipe. Both the heat conduction pipe and the circulation pipe are arranged in the furnace of the furnace body. The inner tube and the return tube sleeved outside the Venturi tube. One end of the return tube is connected to the furnace body to form an air outlet, and the other end is connected to the heat pipe. A circulation channel is formed between the outer wall of the Venturi tube and the inside of the return tube. One end of the circulation channel and One end of the heat pipe is connected to the inlet of the Venturi tube, and the other end of the air outlet and the circulation channel are connected to the outlet of the Venturi pipe. The furnace connected to the outdoor is set to heat the heat pipe and the circulation pipe together, and the hot air is output without consuming indoor oxygen. Heat exchange without air exchange, a circulation heating channel is formed inside the circulation tube, and the airflow output from the return part is heated twice, and it is fully mixed with the Venturi tube structure, which improves the efficiency of heat exchange and meets the needs of quick start.

Owner:SHANDONG HUAYU UNIV OF TECH

Dual-heating laminated board

ActiveCN103533757AAchieve independent controlImplement loop sectionOhmic-resistance heatingPrinted circuit manufactureElectricityLattice fluid

The invention discloses a dual-heating laminated board, which comprises a board body and electric heating wires, wherein the electric heating wires are arranged in the board body, and form an electric heating layer; a plurality of fluid passages are formed at an equal interval in each of the upper and lower ends of the board body in a staggered way; the staggered fluid passages form latticed fluid heating layers which are communicated with external high-temperature fluid; the fluid heating layers at the upper and lower ends of the board body are symmetrically positioned on the two sides of the electric heating layer. According to the dual-heating laminated board, the fluid heating layers for performing heating through the fluid are additionally arranged on the basis of electric heating, the fluid can be rapidly and uniformly injected into the fluid heating layers, and the heat of the fluid can be rapidly, uniformly and continuously transferred to the board body by combining a latticed design, so that the dual-heating laminated board can be uniformly and rapidly heated to specified highest temperature, and can be kept at the highest temperature for a long time; moreover, a plurality of heating modes can be selected according to actual needs, and meanwhile, the dual-heating laminated board also has a rapid cooling function.

Owner:GUANGDONG SHENGYI SCI TECH

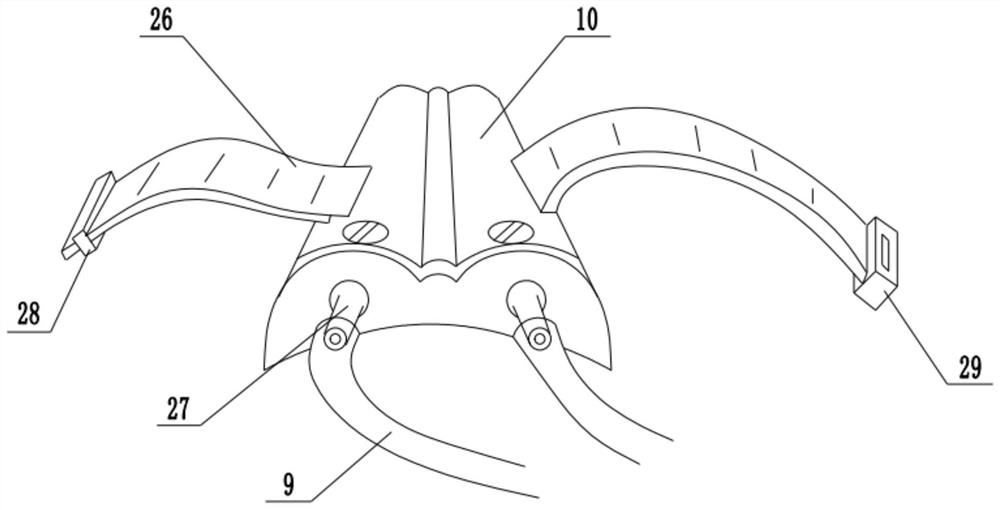

Medicine fumigation device for rhinitis nursing treatment

InactiveCN112402228AReasonable structureInnovative designMedical devicesBathing devicesMedical equipmentNursing care

The invention relates to the technical field of medical equipment, and discloses a medicine fumigation device for rhinitis nursing treatment. The medicine fumigation device comprises a fixed bottom plate, wherein a heating box is arranged on the right side of the upper end of the fixed bottom plate; an air guide box is arranged inside the bottom end of the heating box; a stirring shaft is rotationally arranged in the middle of the upper end of the air guide box through a sealing ring; the interior of the stirring shaft is of a hollow structure; the top end of the stirring shaft penetrates through the middle of the upper end of the heating box and is connected with a cam; the left side of the cam is in contact with a pushing ball; a pushing rod is arranged at the left end of the pushing ball; a pushing block is arranged on the left side of the pushing rod; the inclined section of the left side of the pushing block is in contact with a lifting ball; a lifting rod is arranged at the lowerend of the lifting ball; a lifting plug is arranged at the bottom of the lifting rod; and the air guide box is arranged on the outer side of the lifting plug. According to the medicine fumigation device, effective circulation of medicine fumigation gas is realized, secondary heating is realized, and the medicine fumigation effect is ensured; the stirring shaft and the lifting plug are arranged, so that rapid generation and drainage effects of steam are ensured; and the whole device only has one power source, so that the cost is further reduced.

Owner:安徽森林风生活用品股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com