Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Realize processing operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

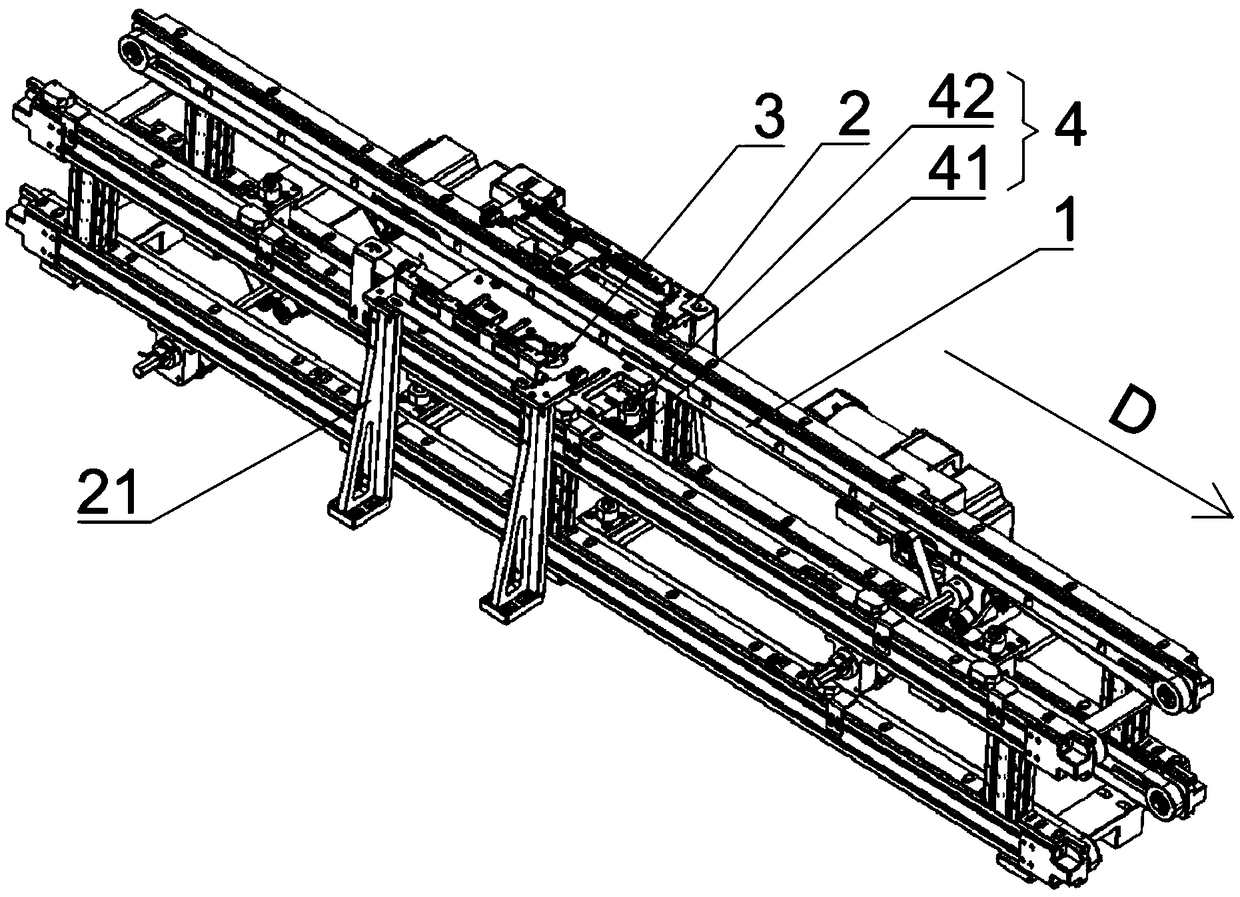

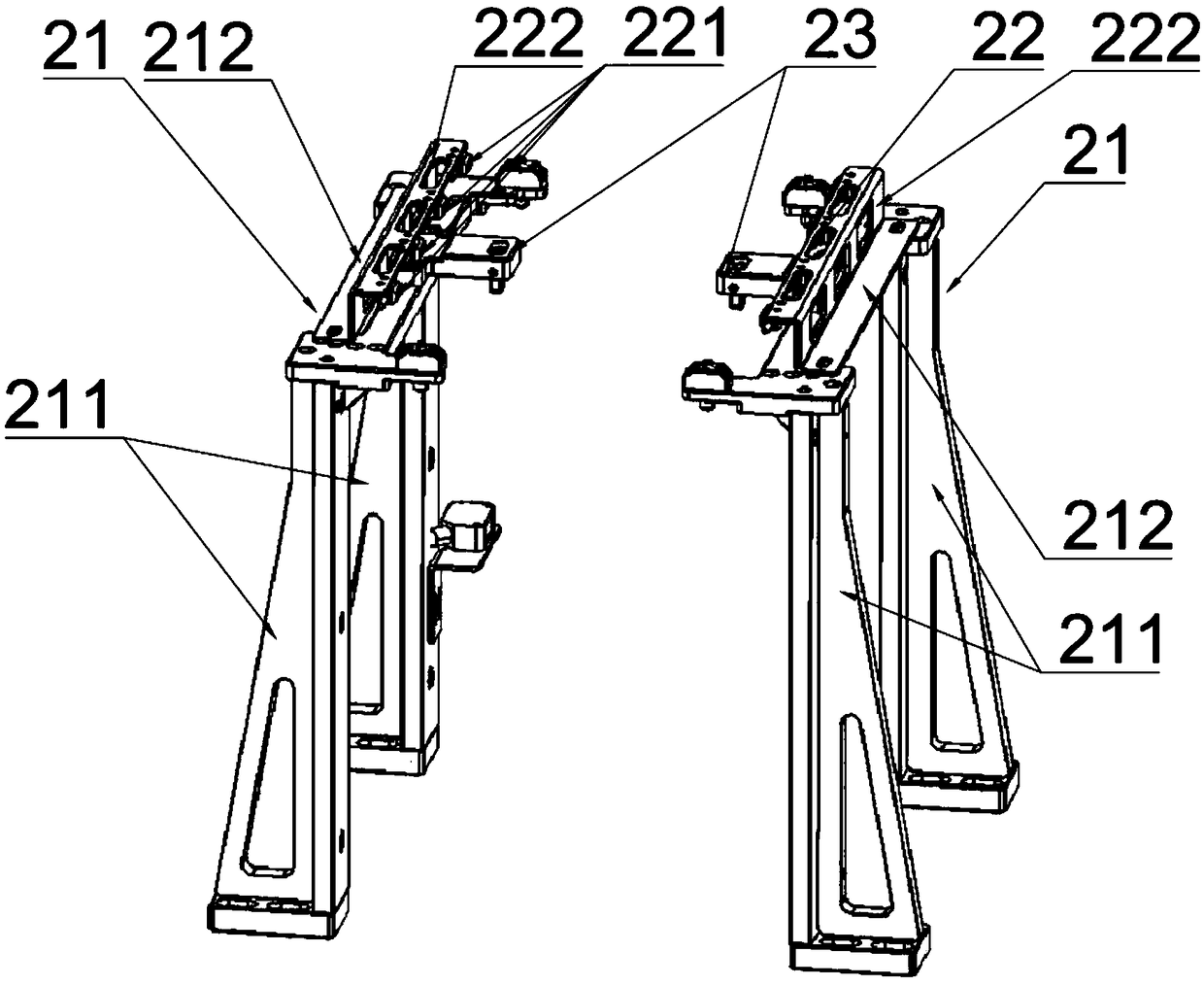

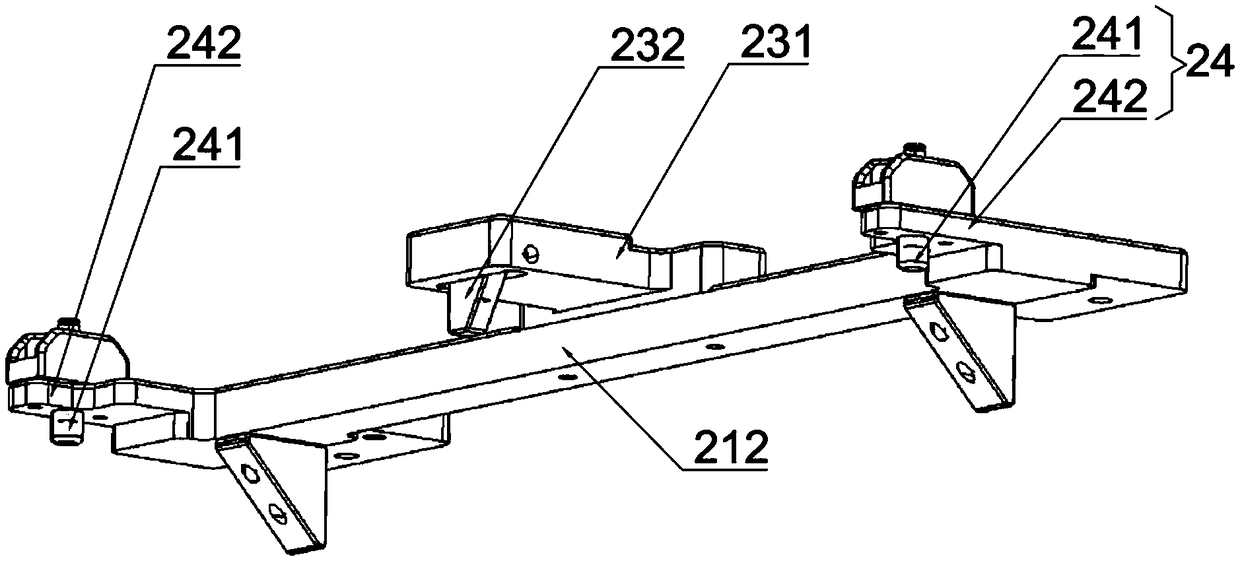

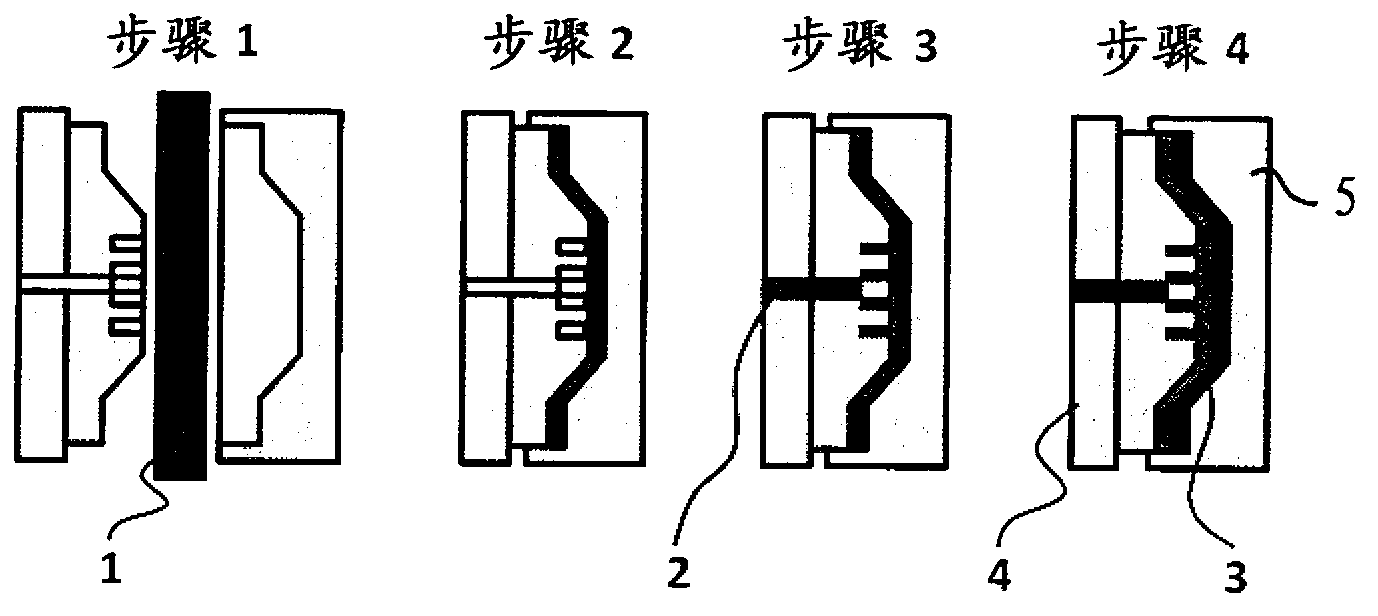

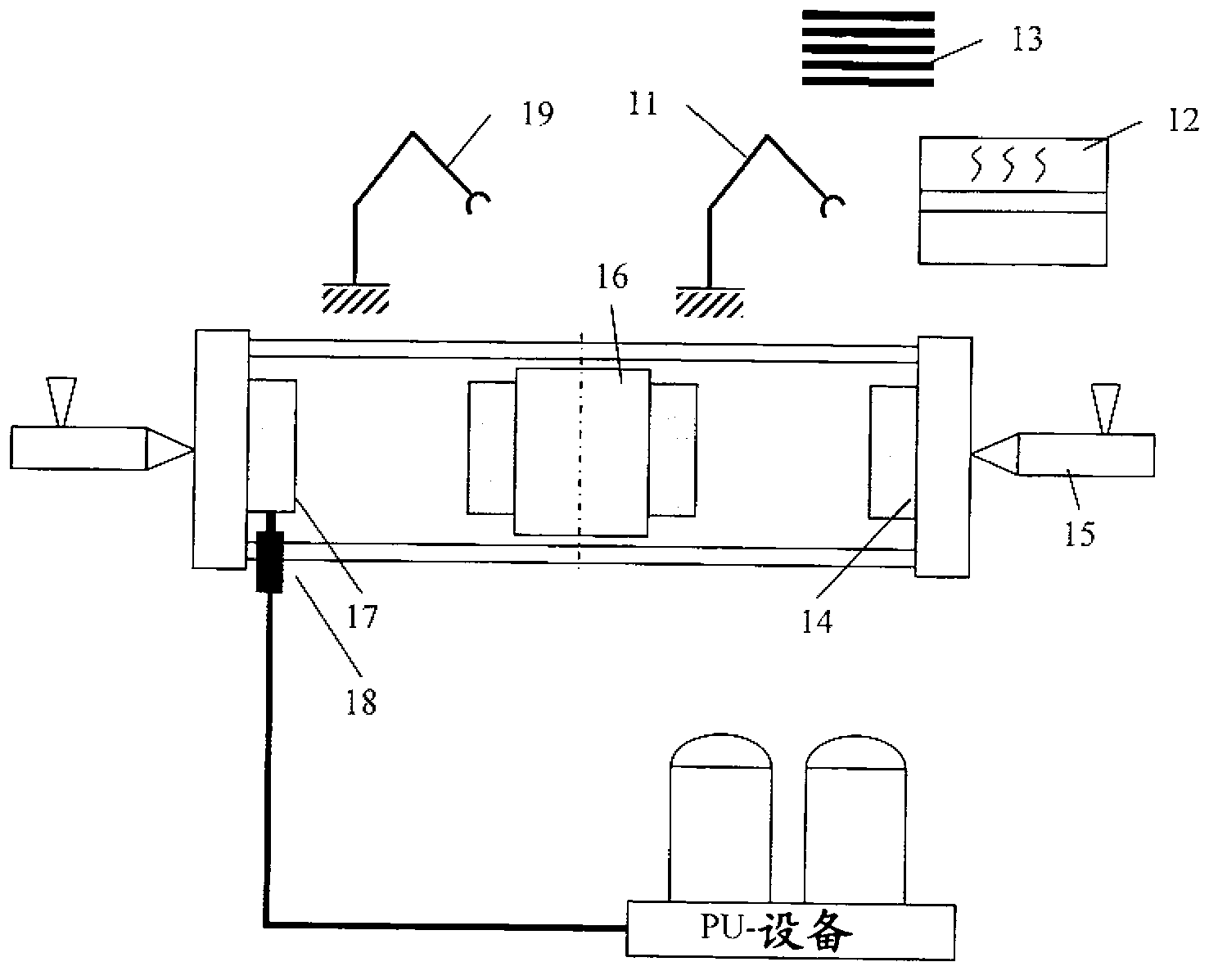

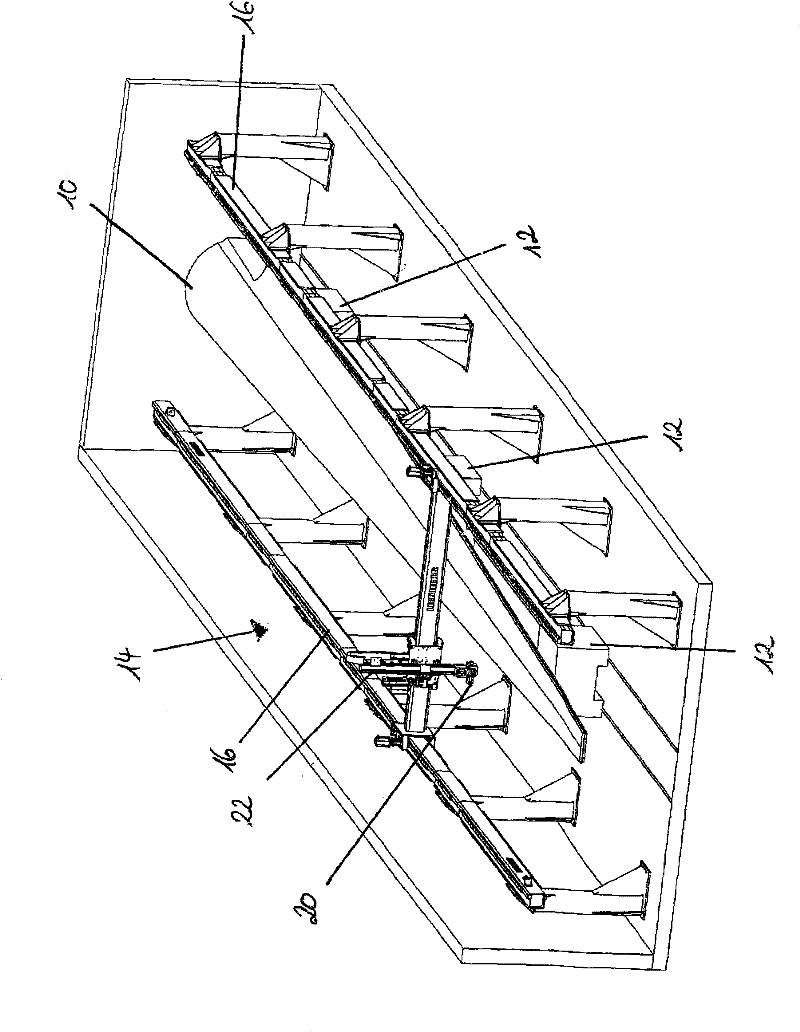

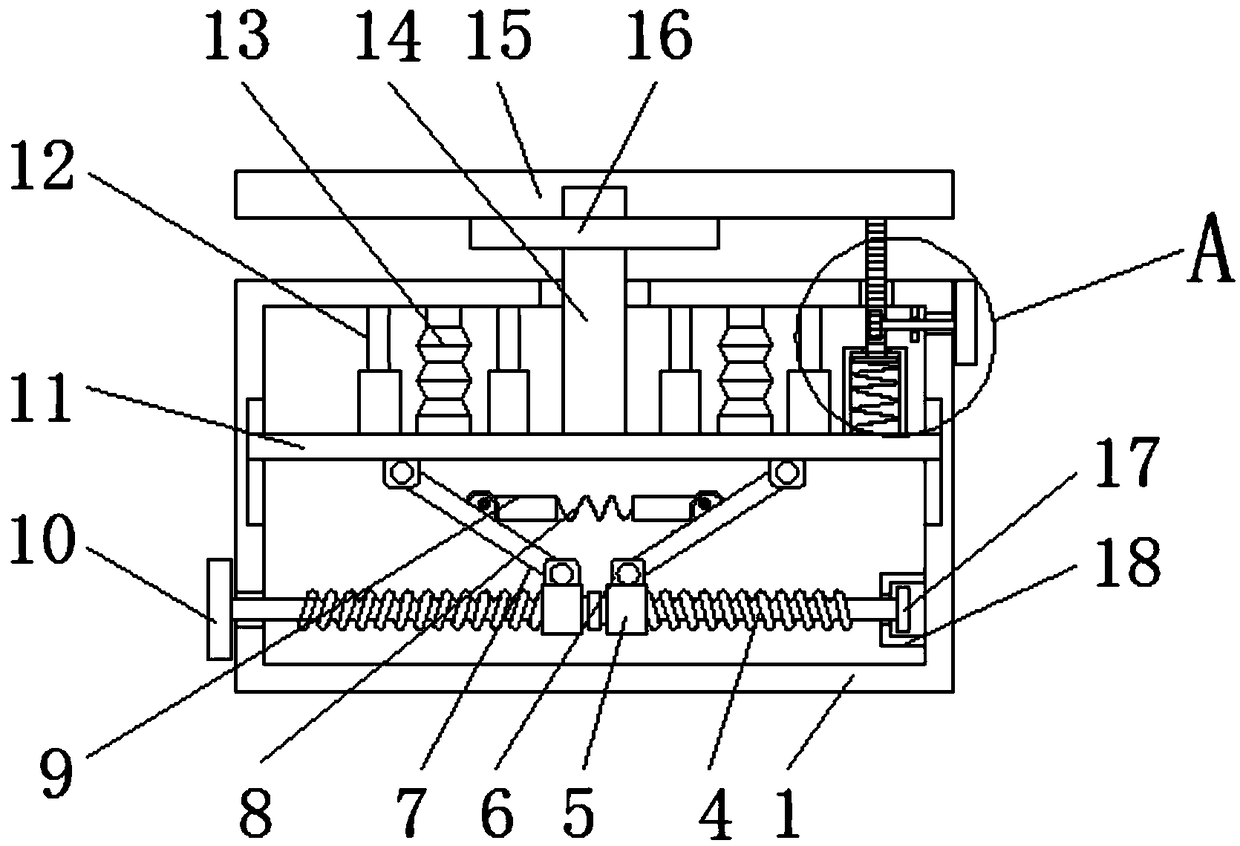

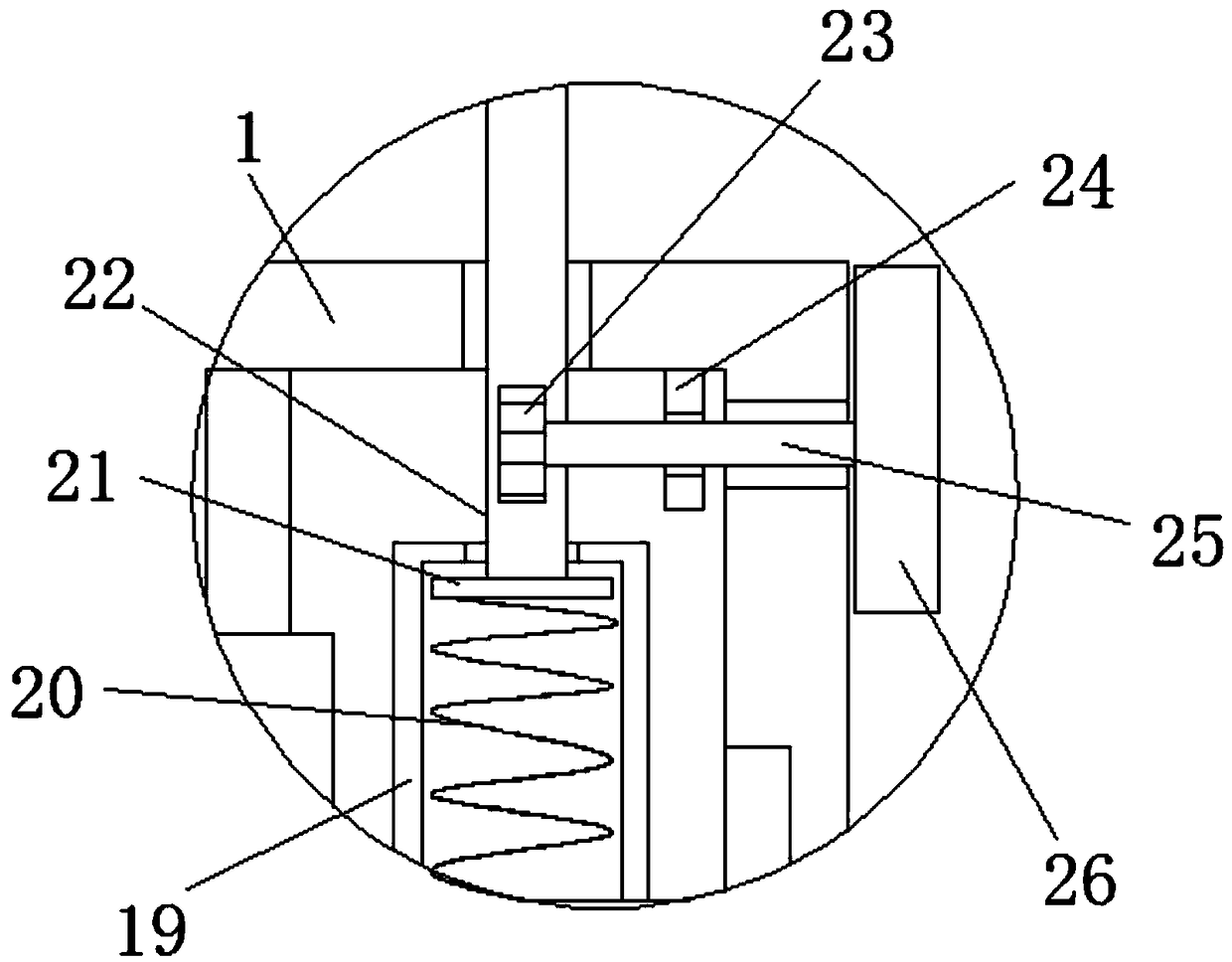

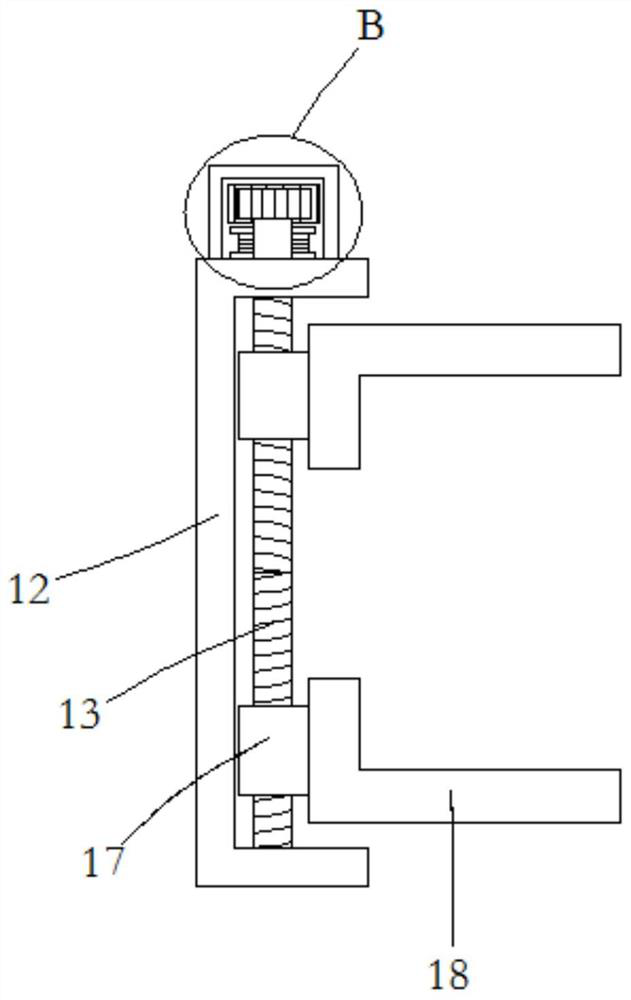

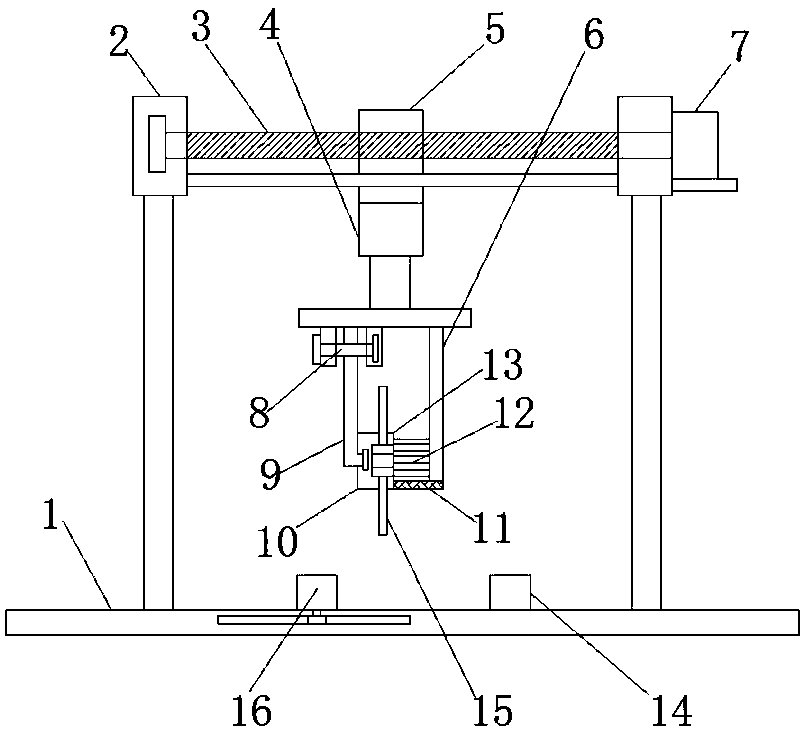

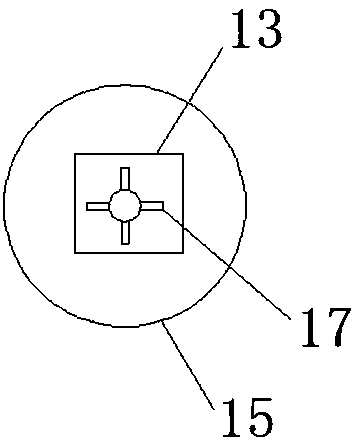

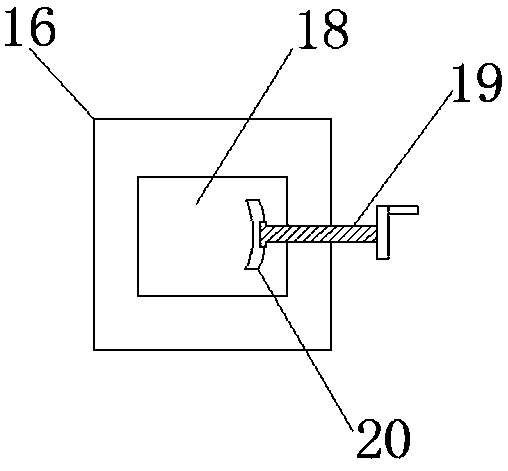

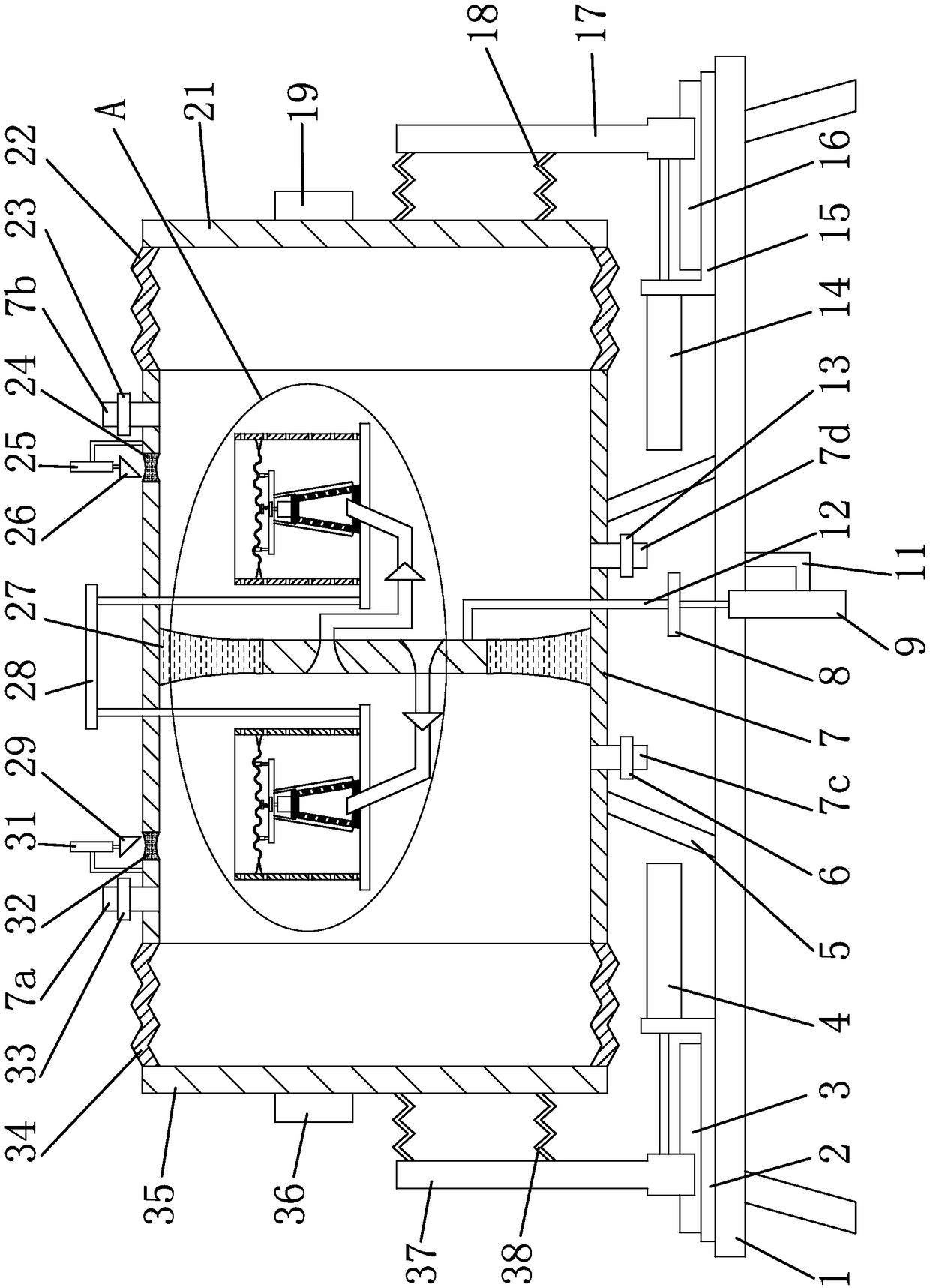

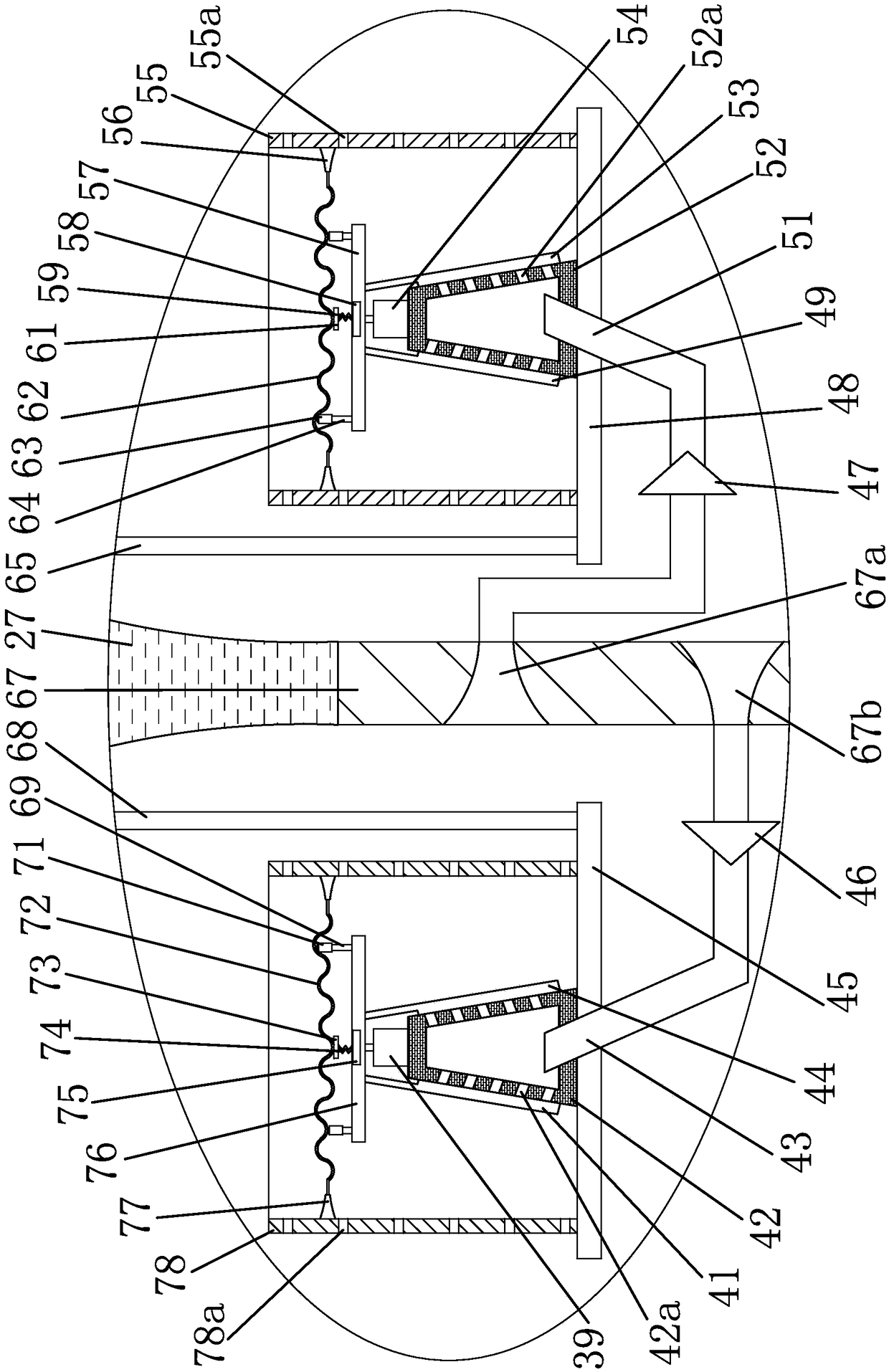

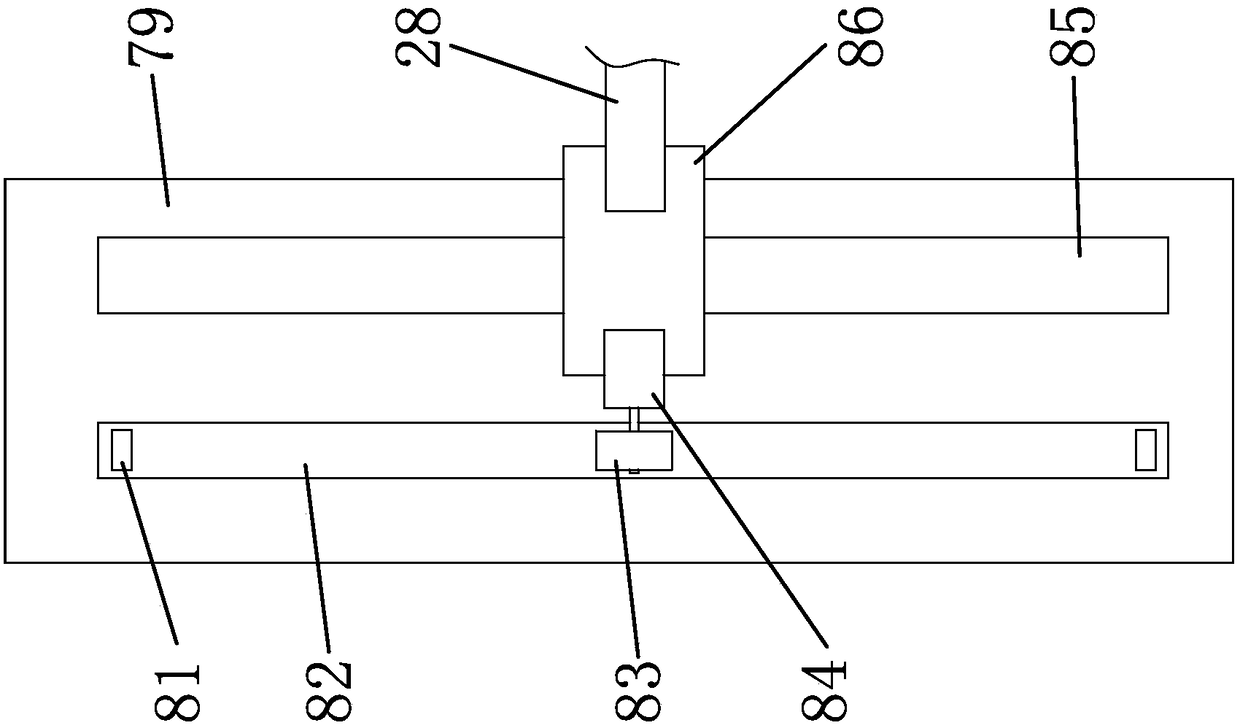

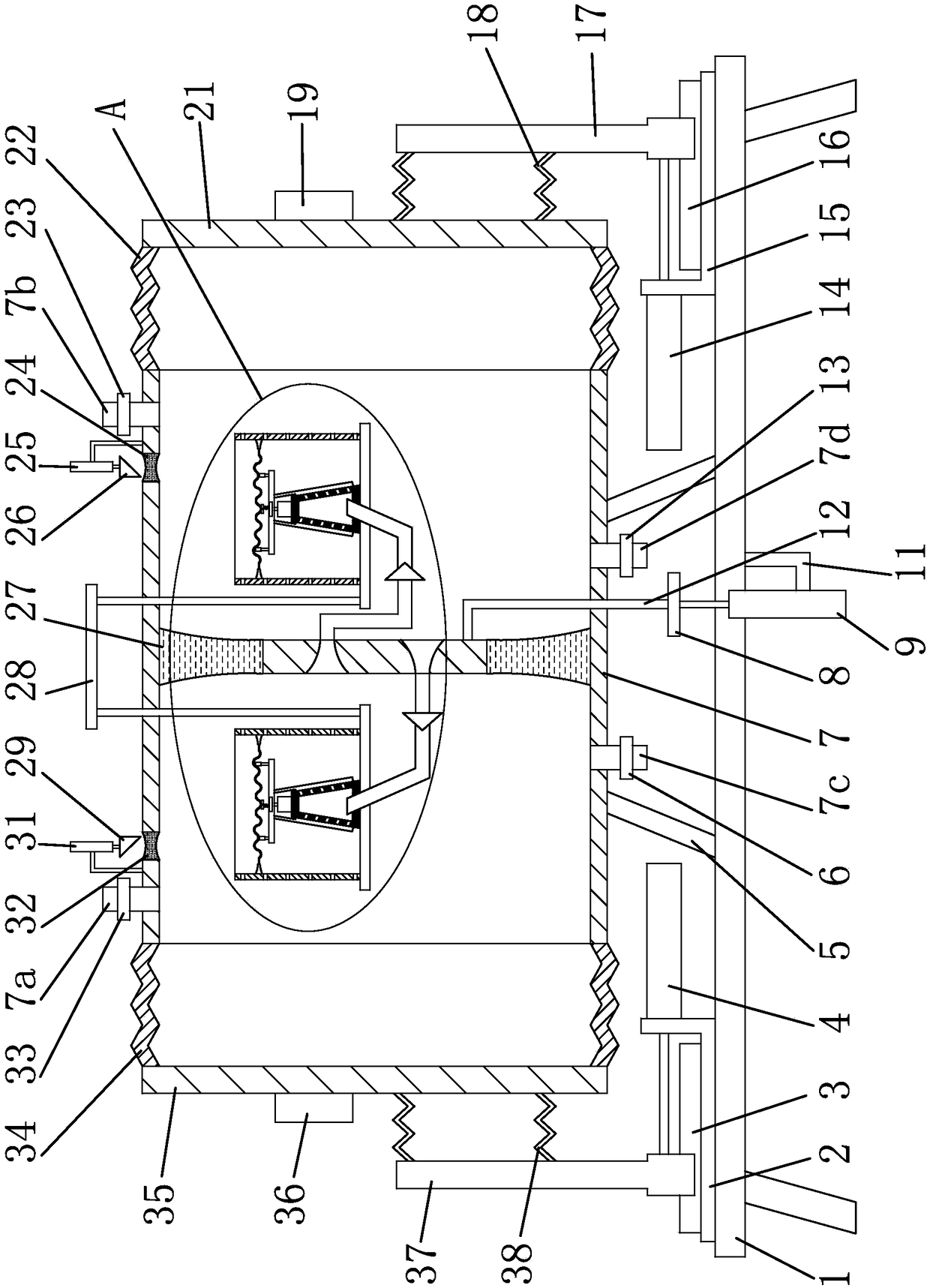

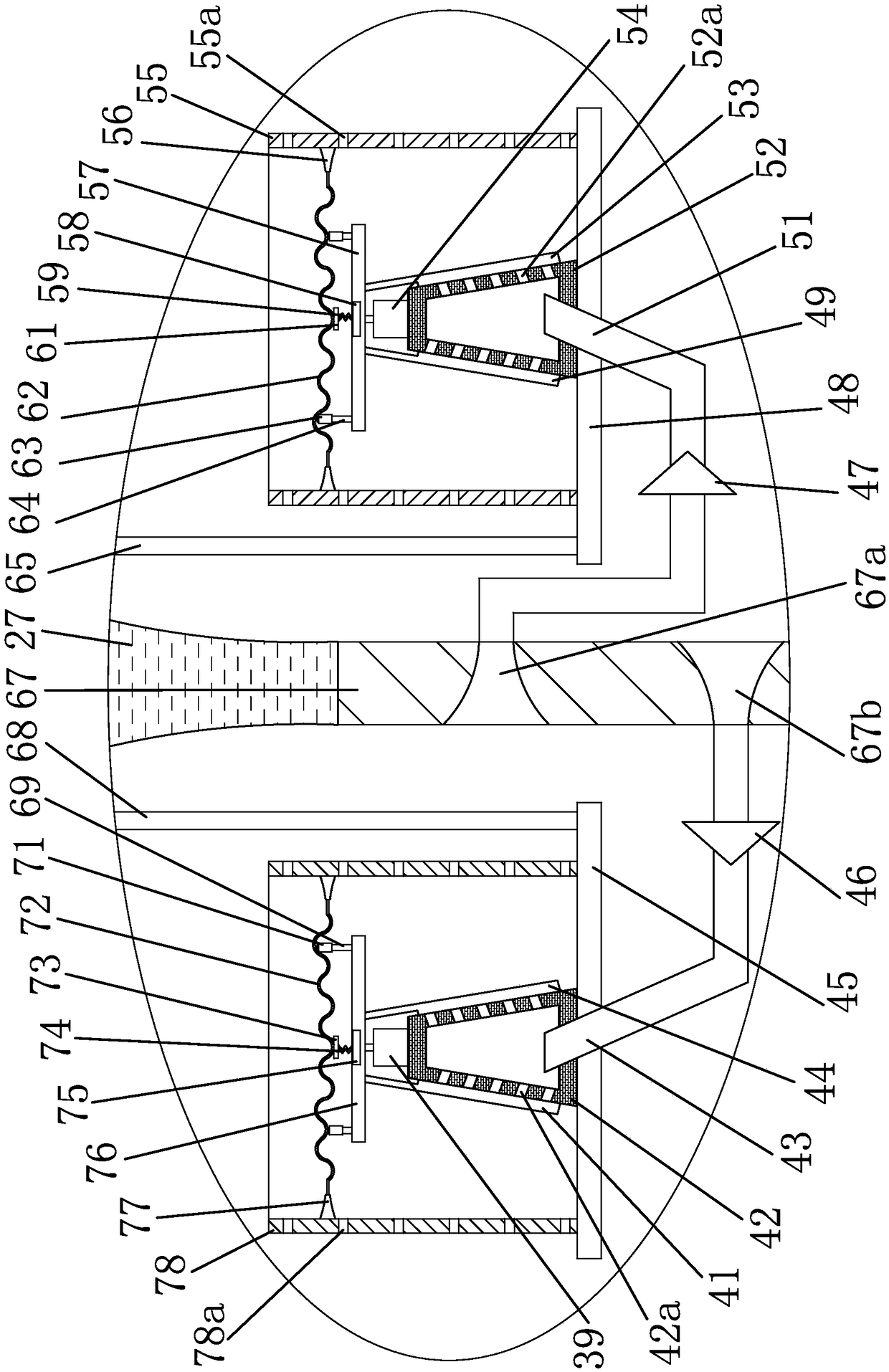

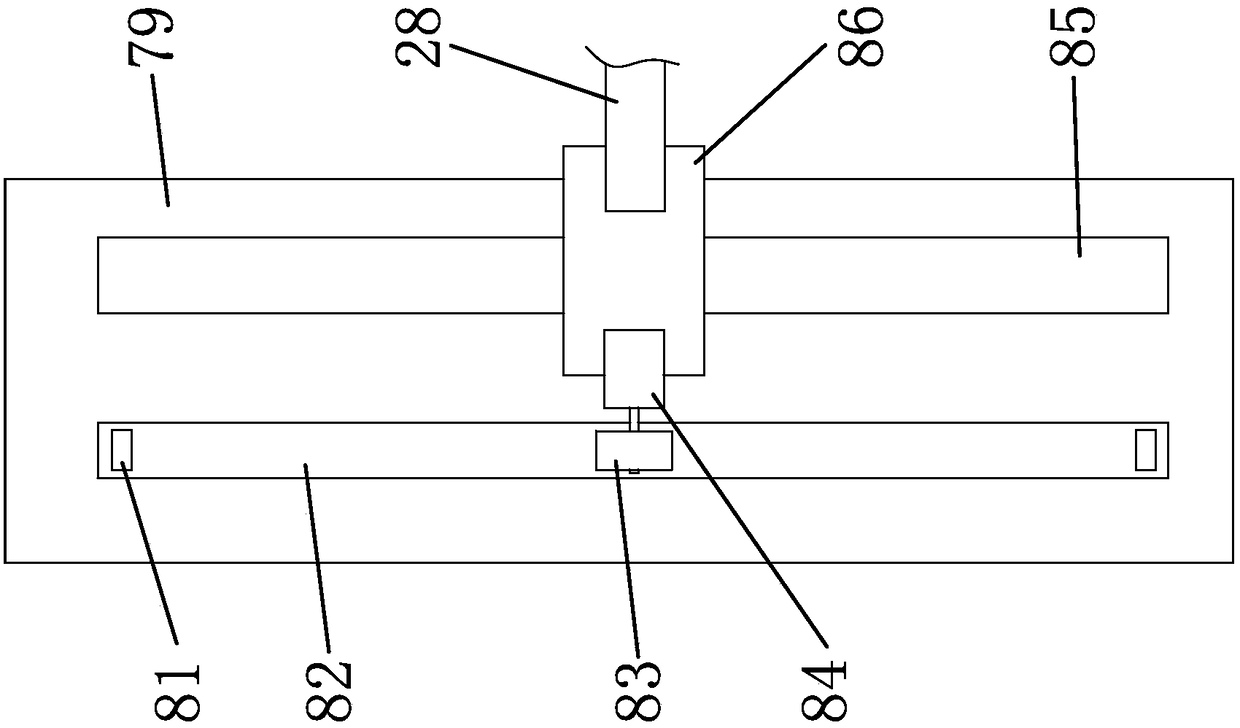

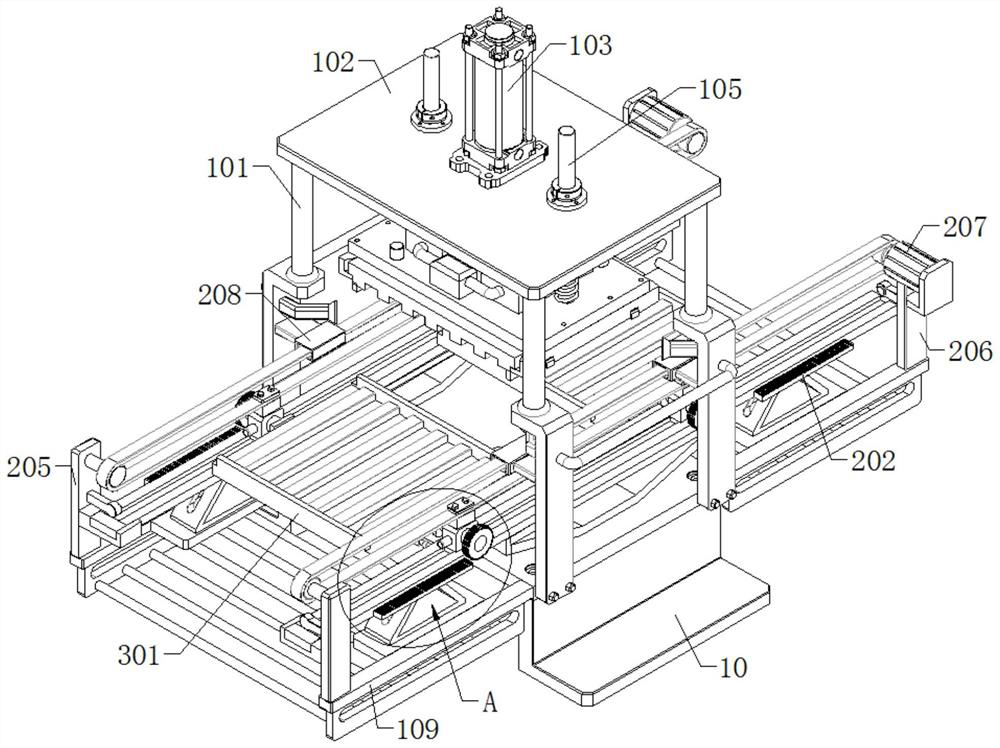

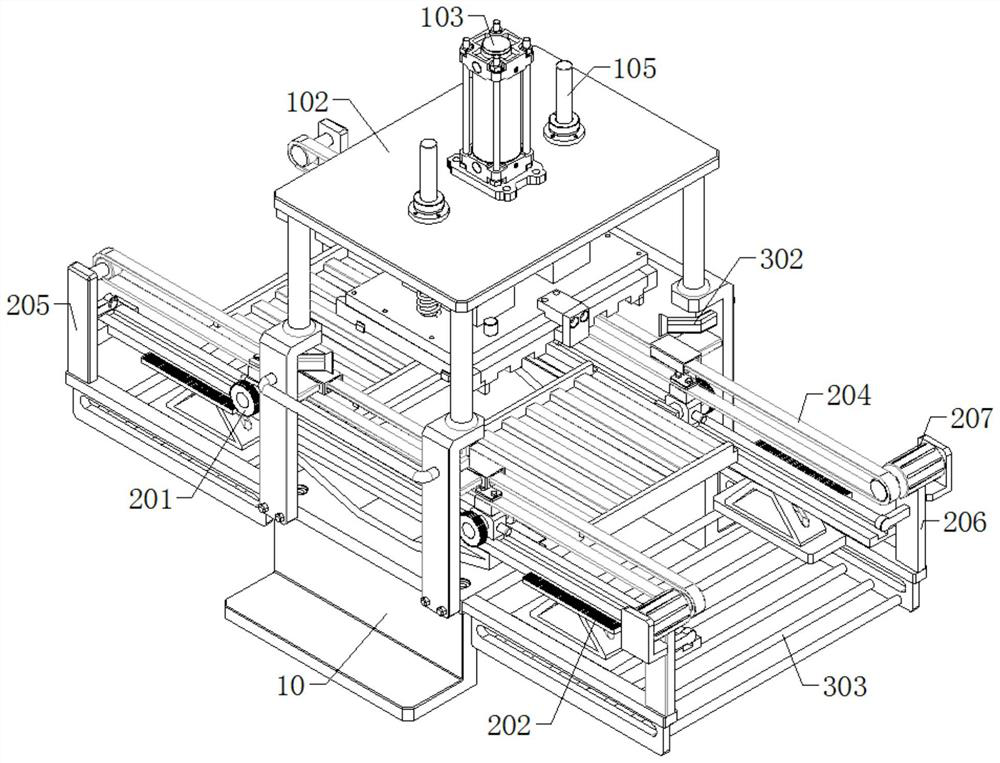

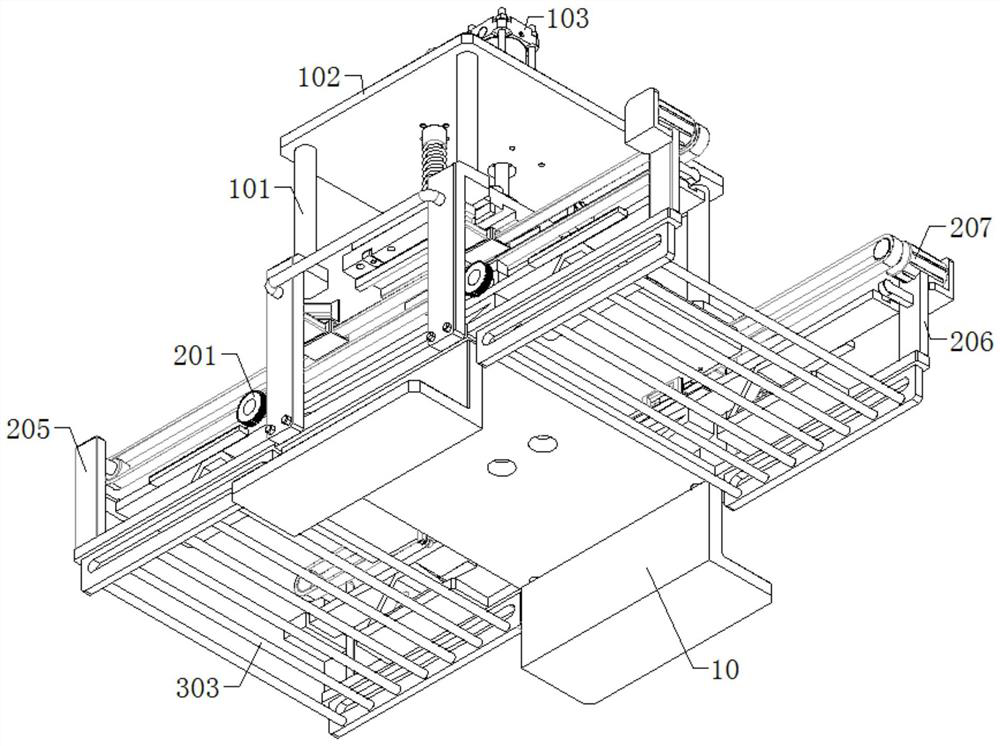

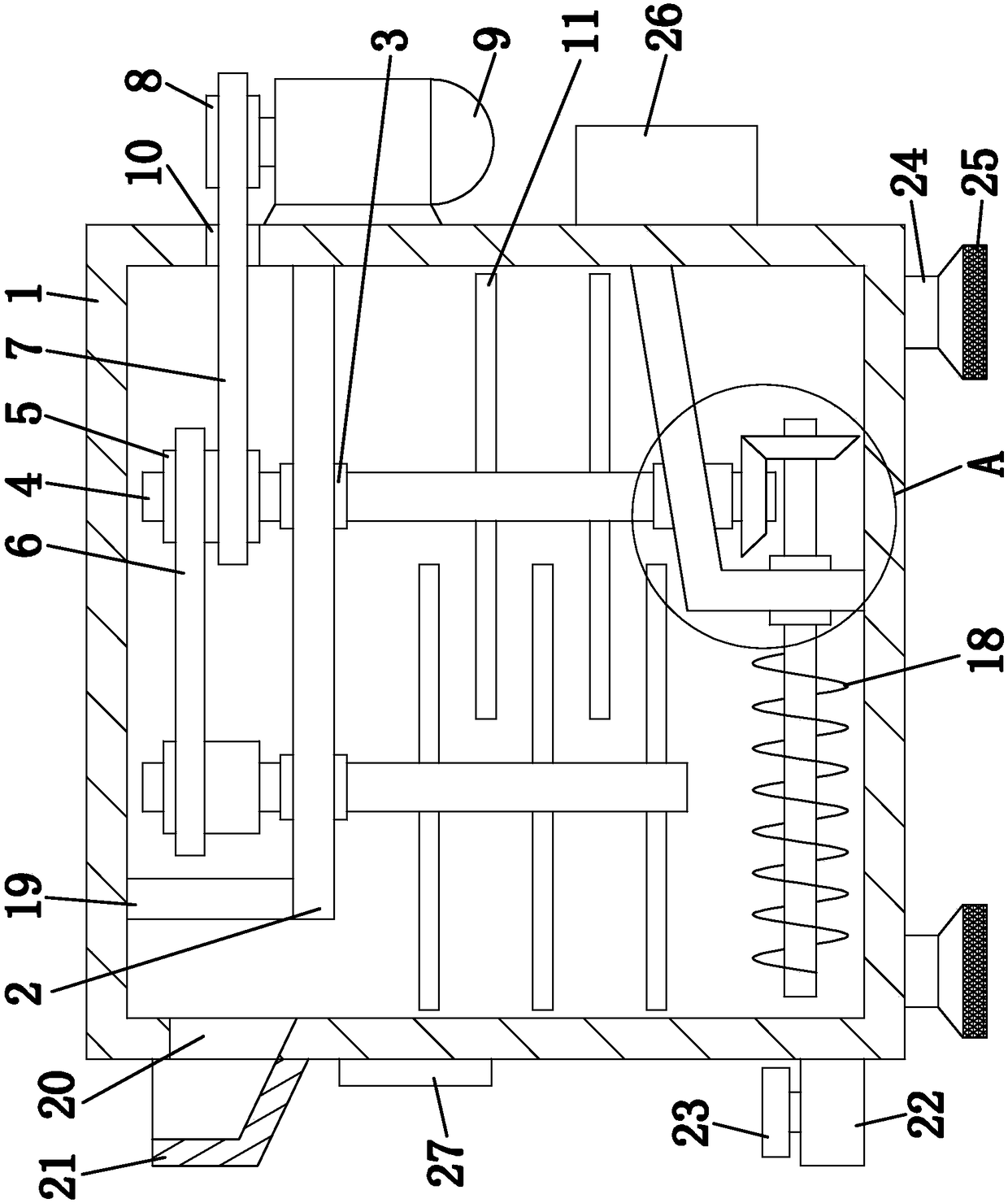

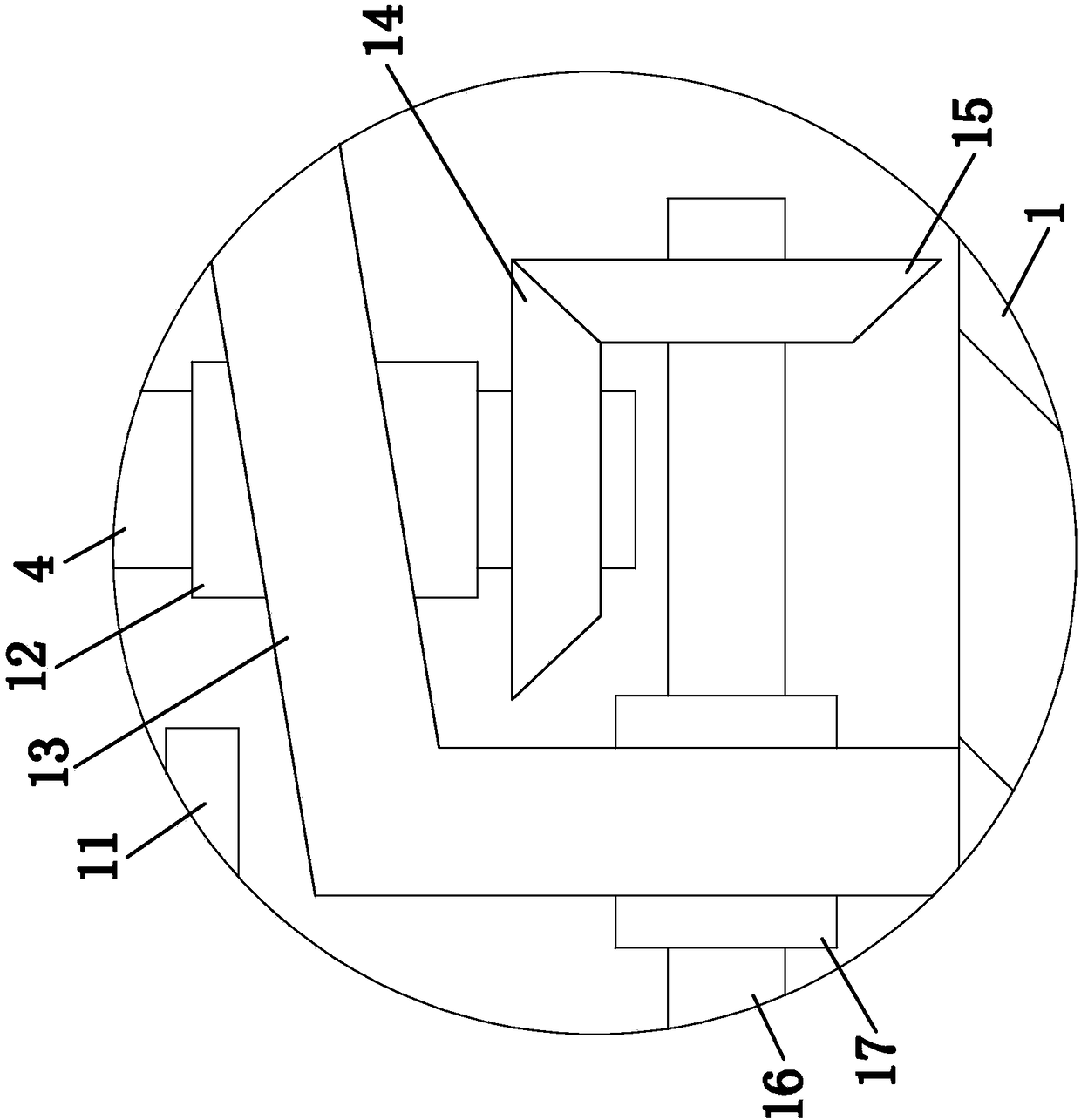

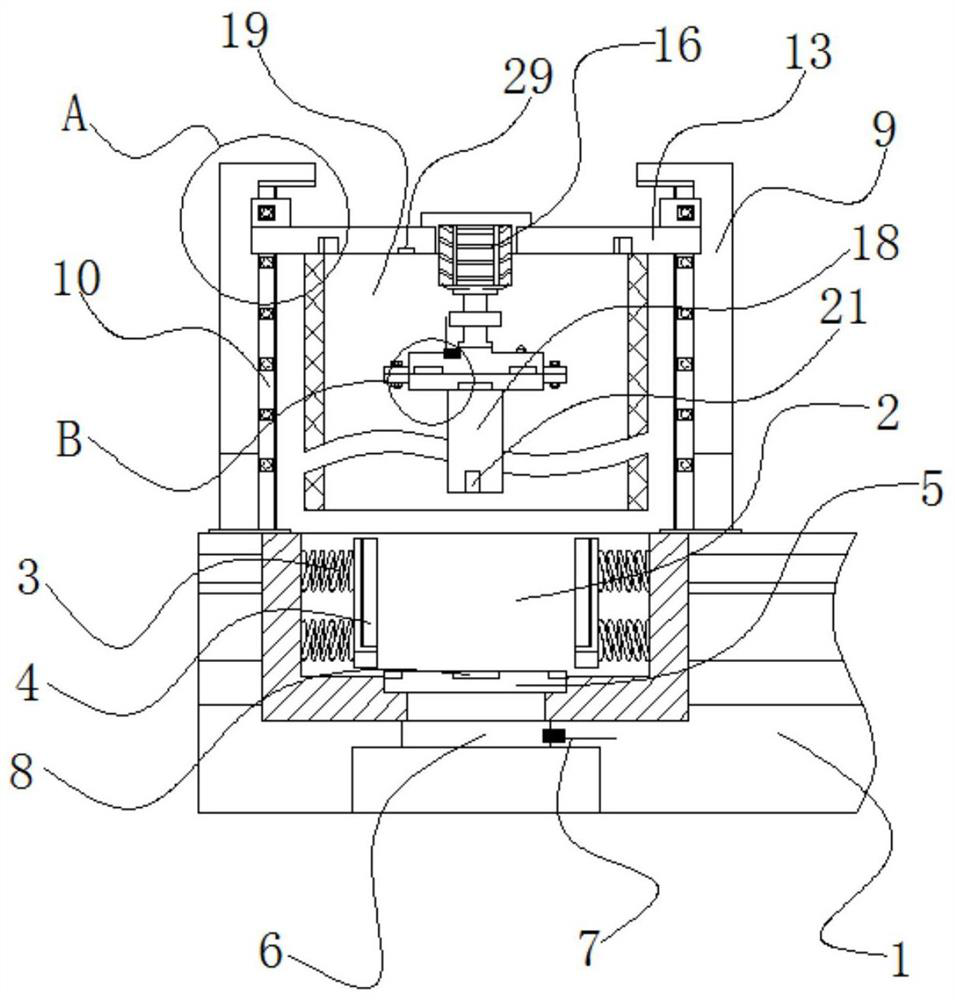

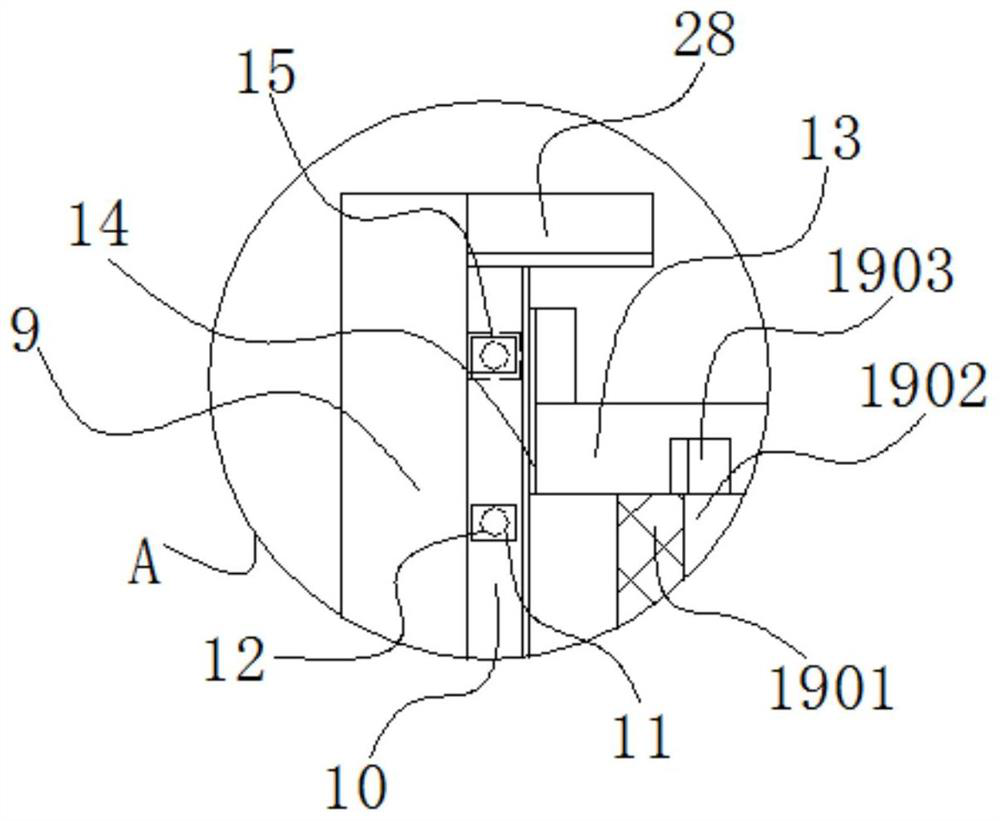

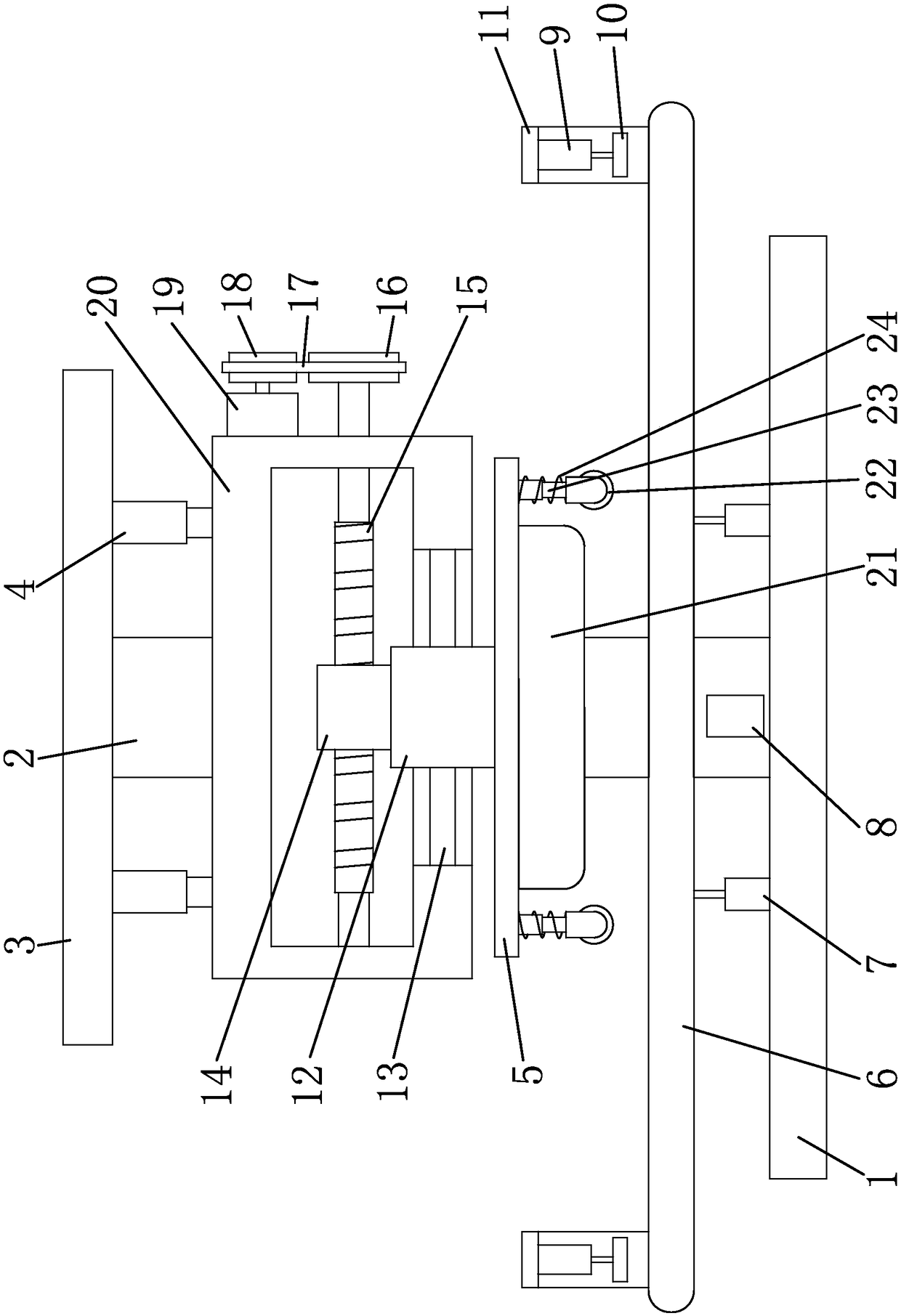

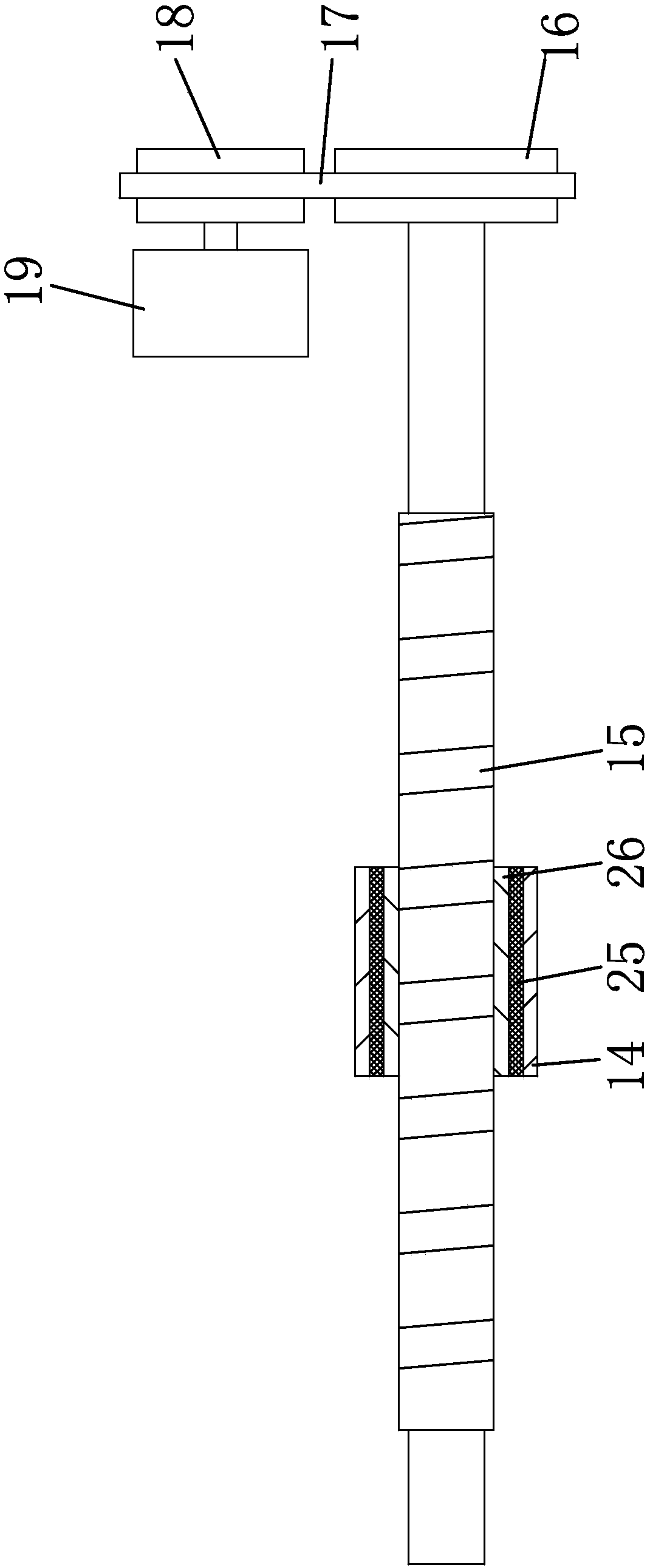

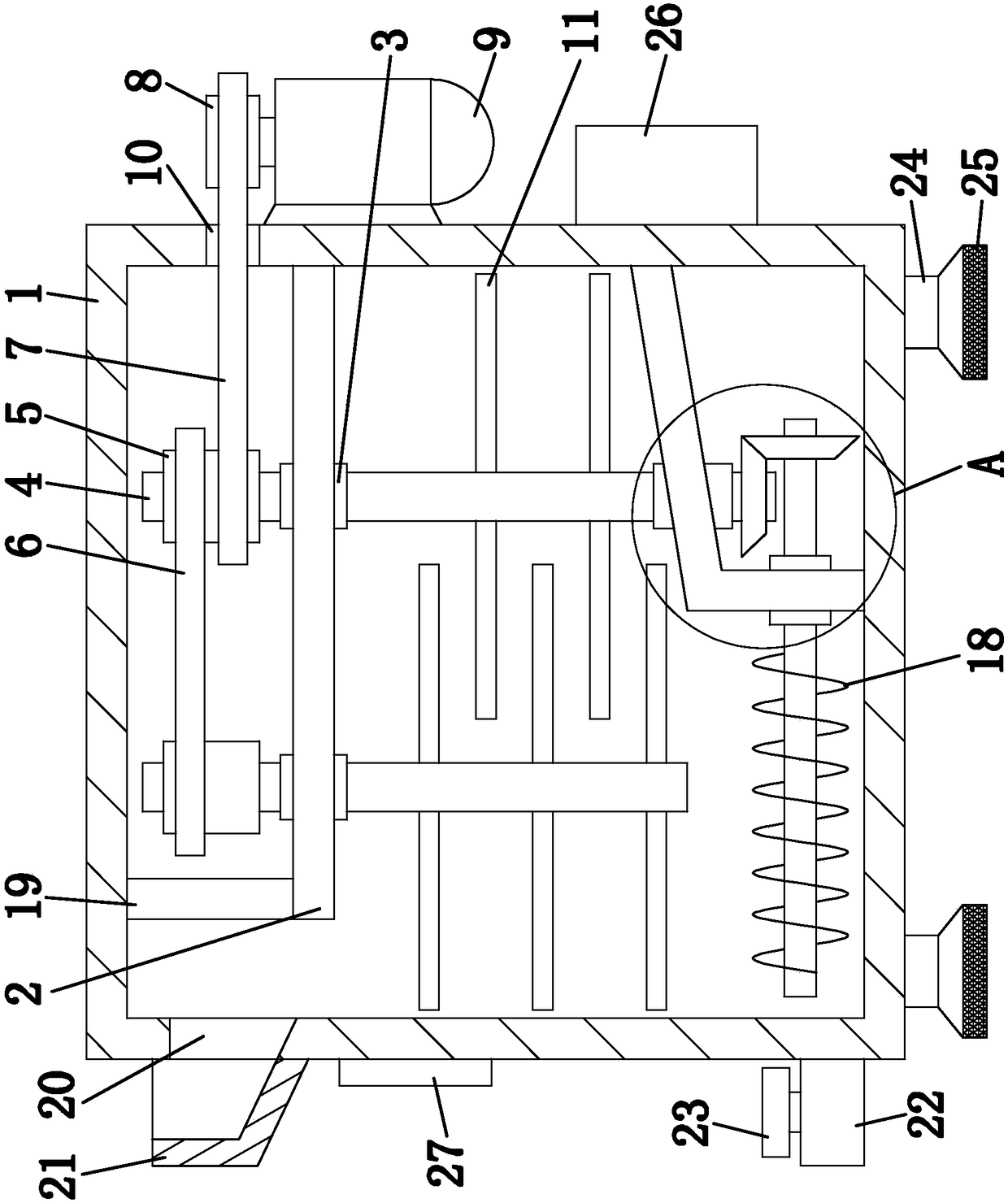

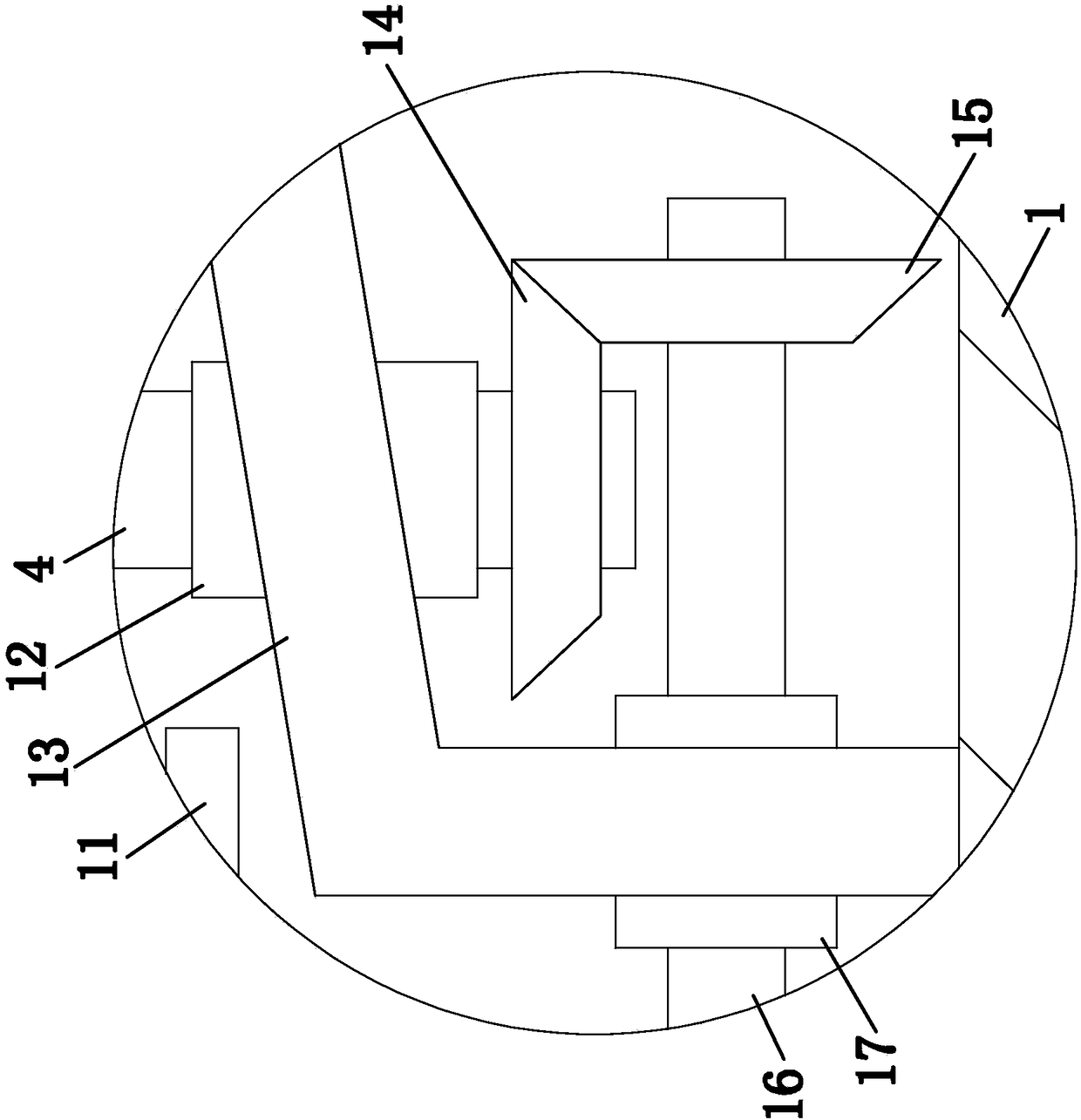

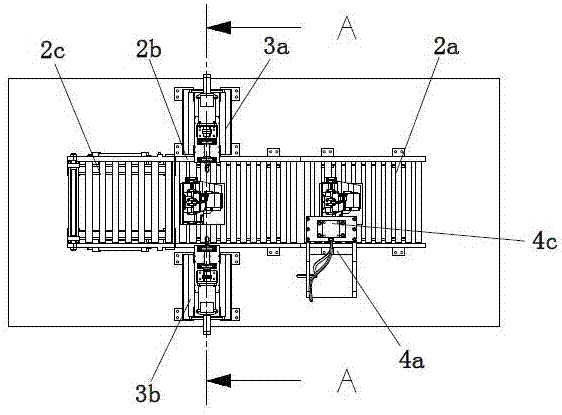

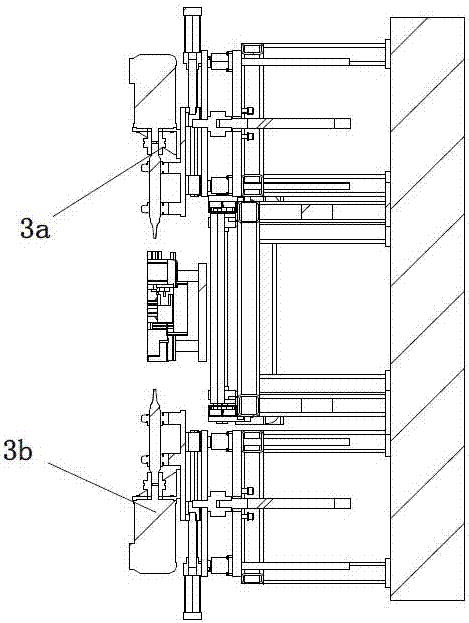

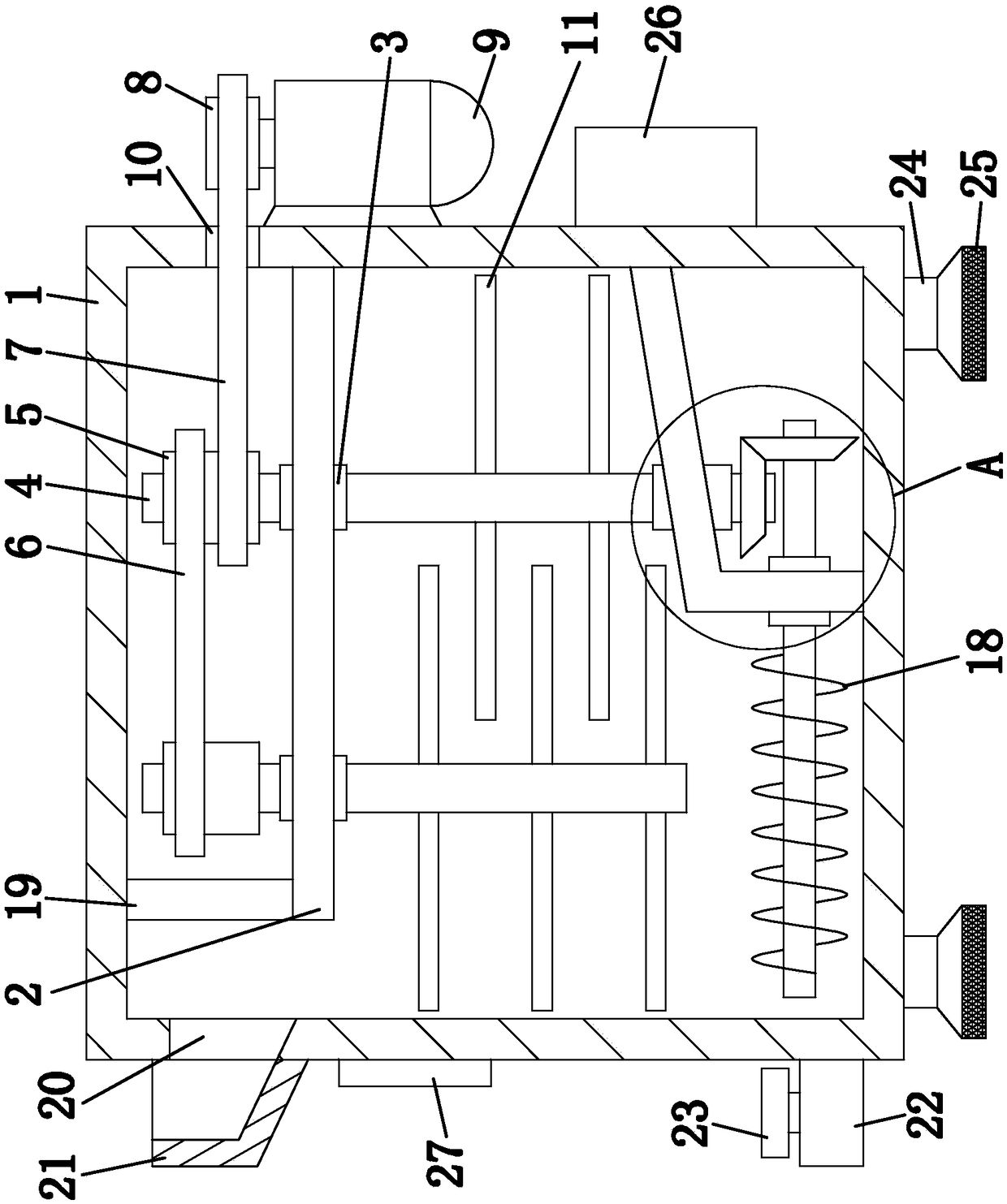

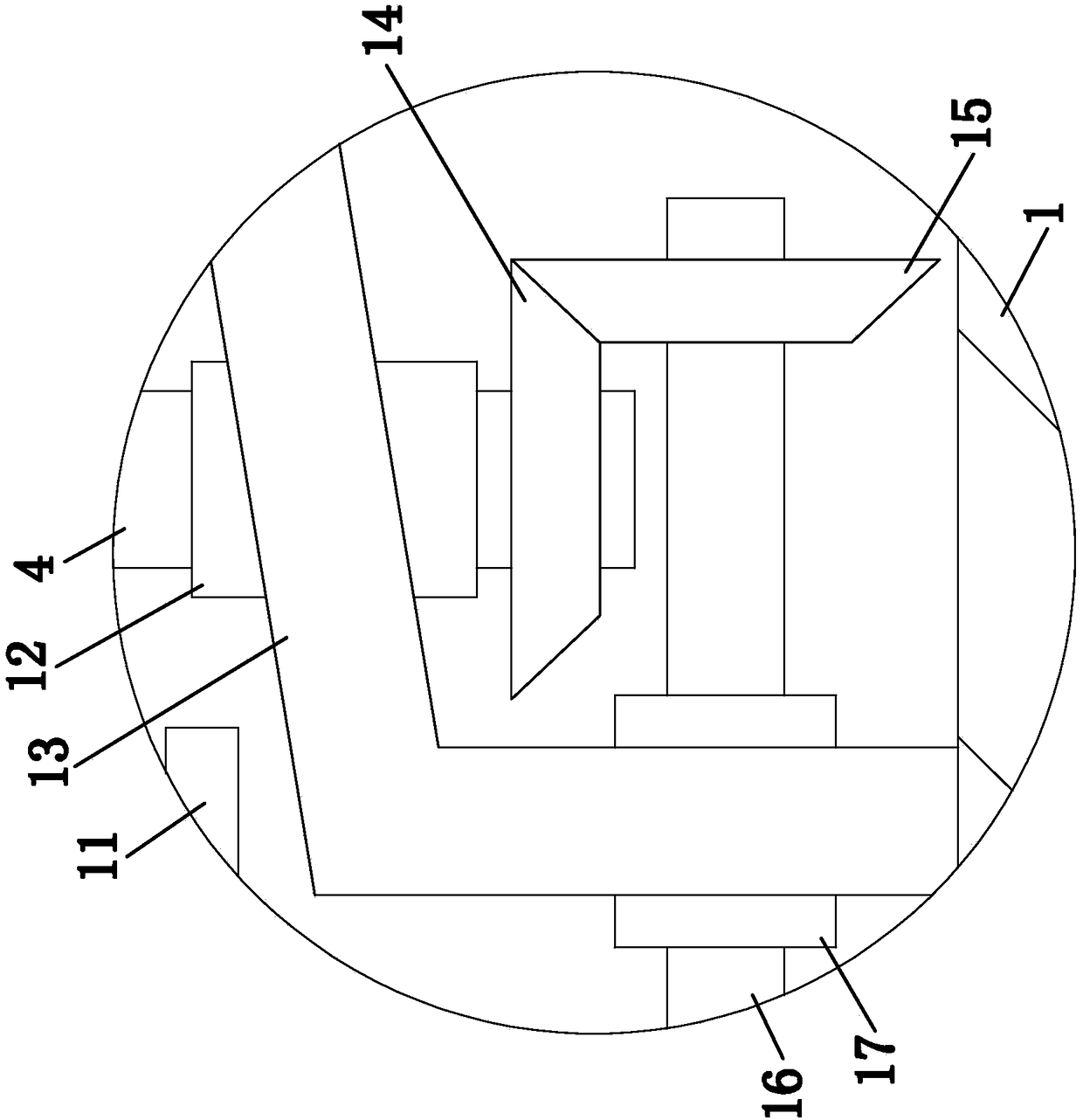

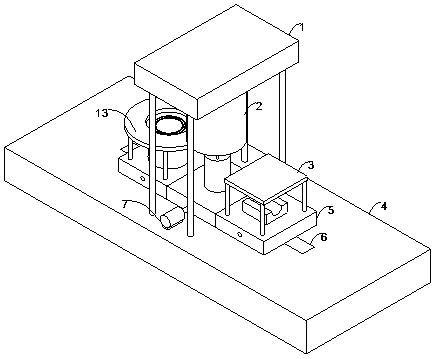

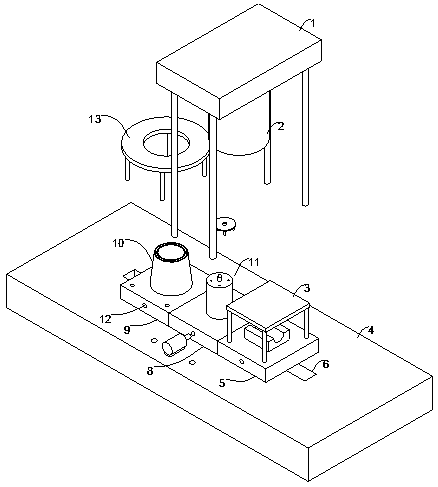

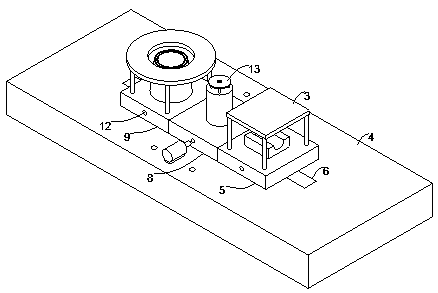

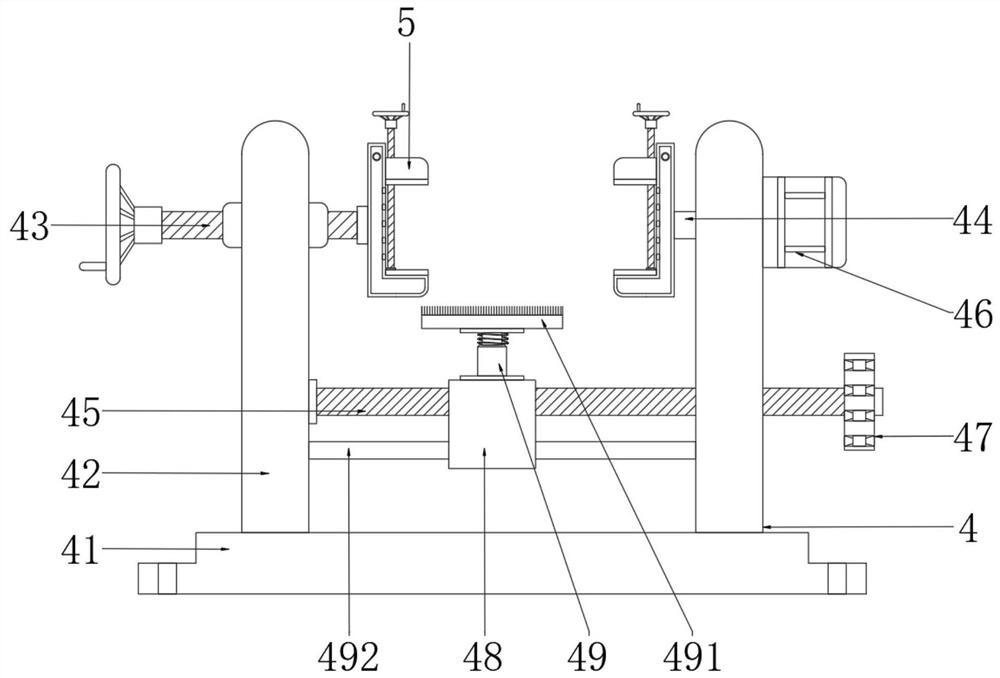

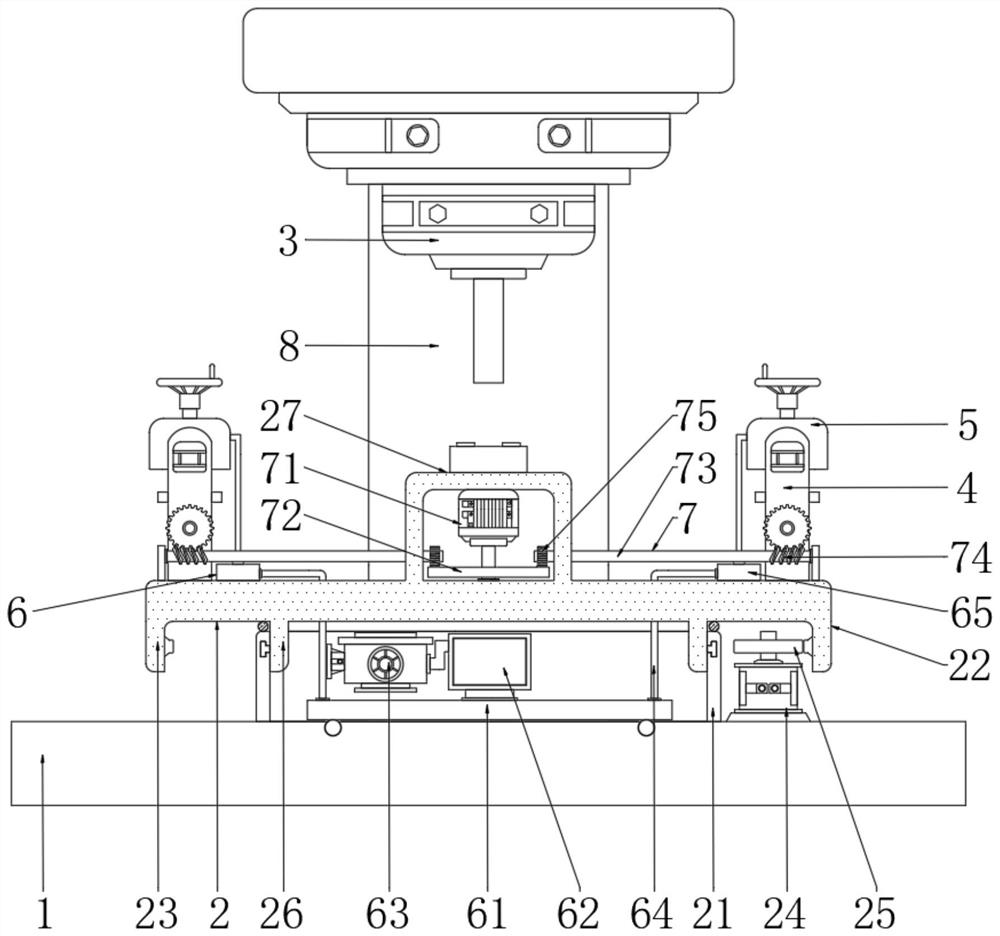

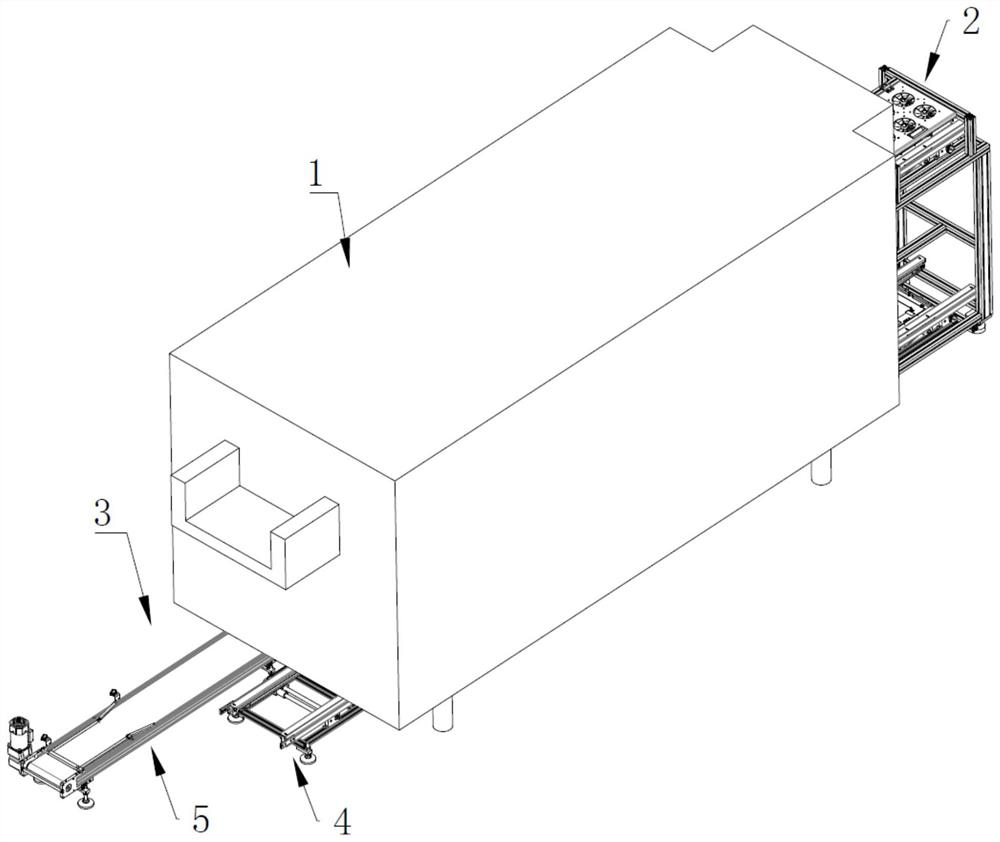

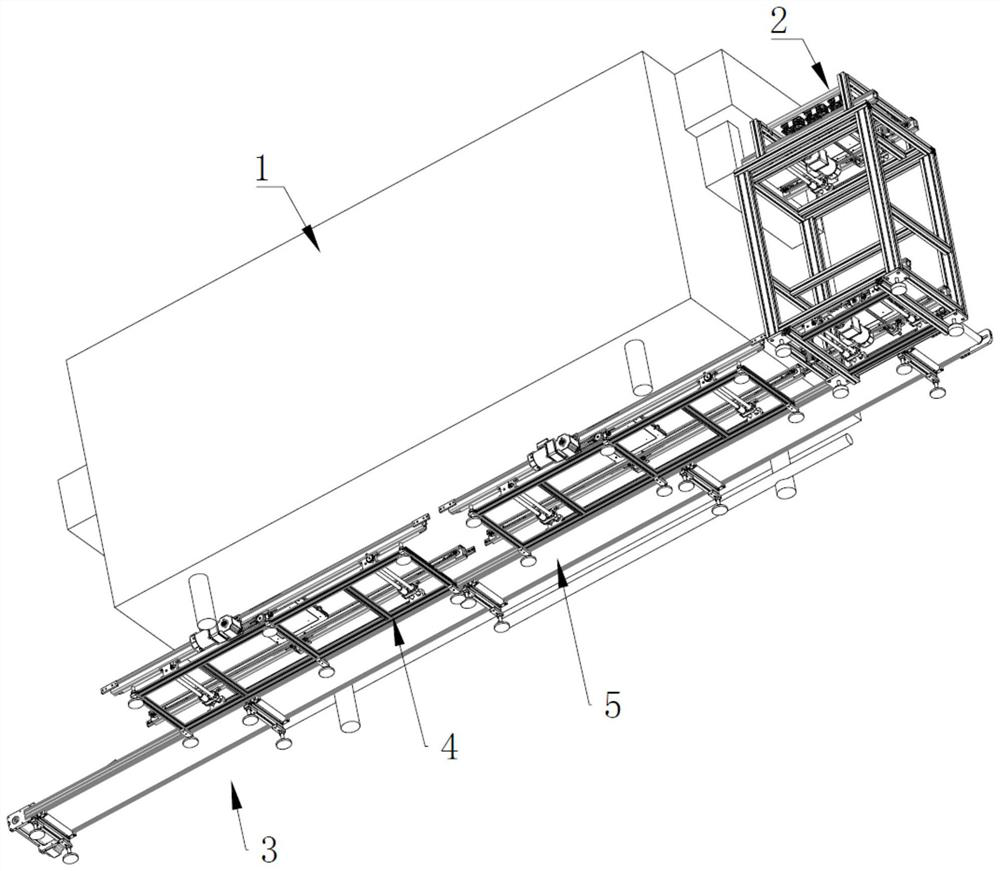

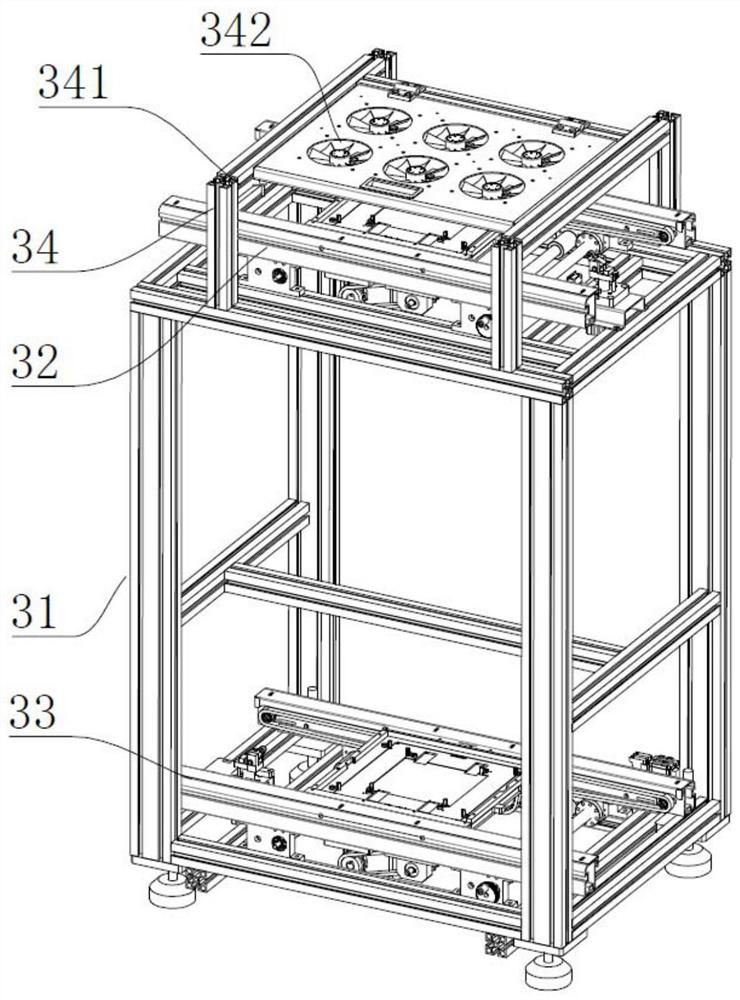

Carrier positioning device, material conveying device and full-automatic production line

ActiveCN109132405ARealize processing operationsEasy loading and unloadingControl devices for conveyorsMechanical conveyorsProduction lineEngineering

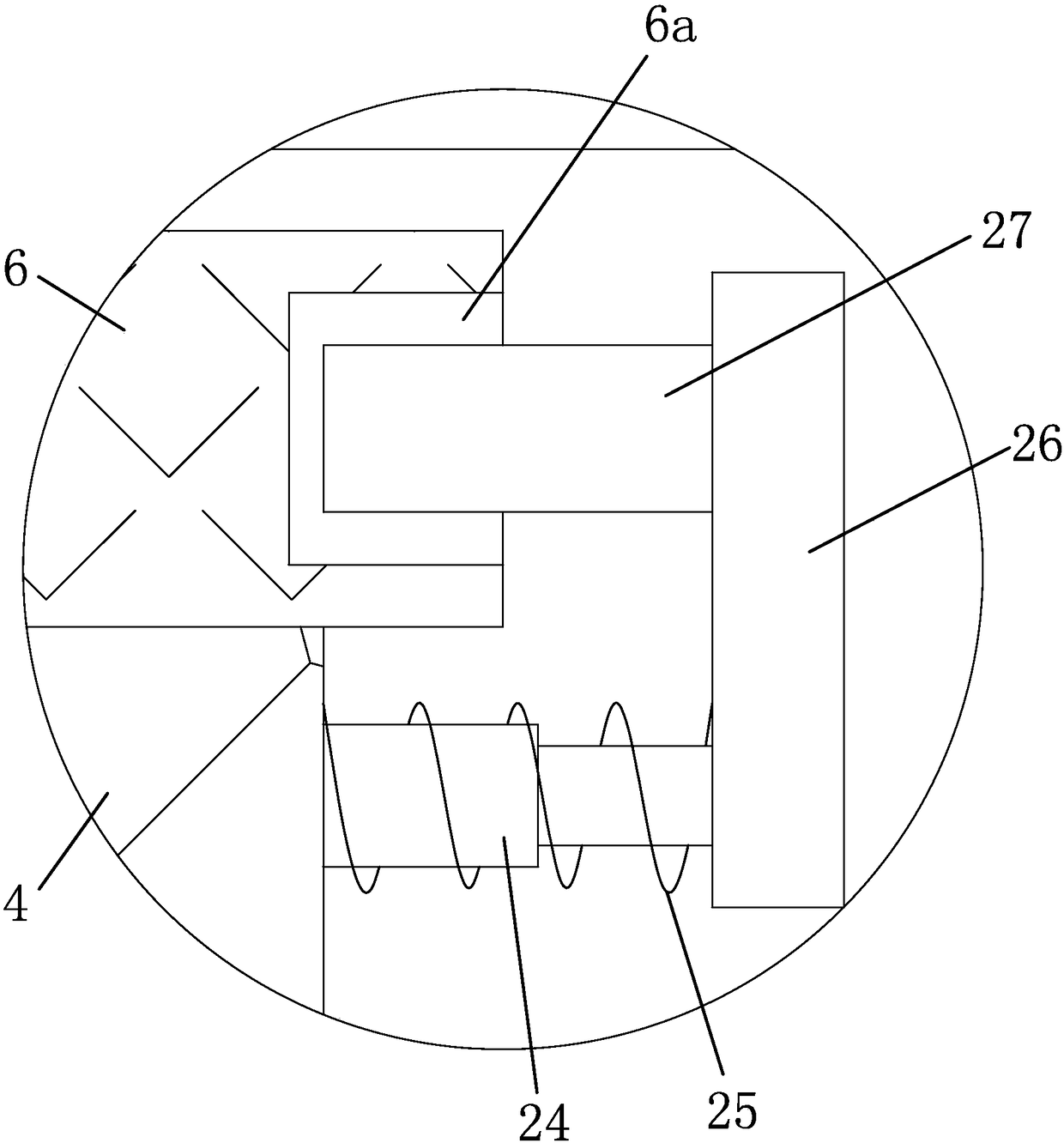

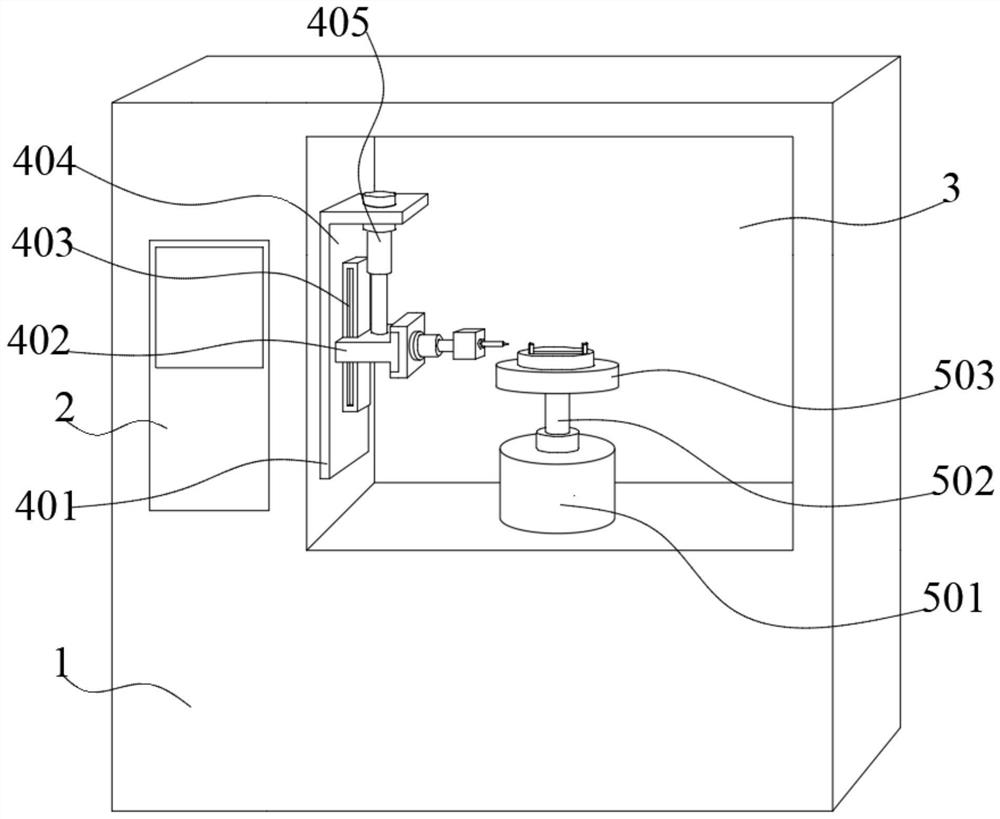

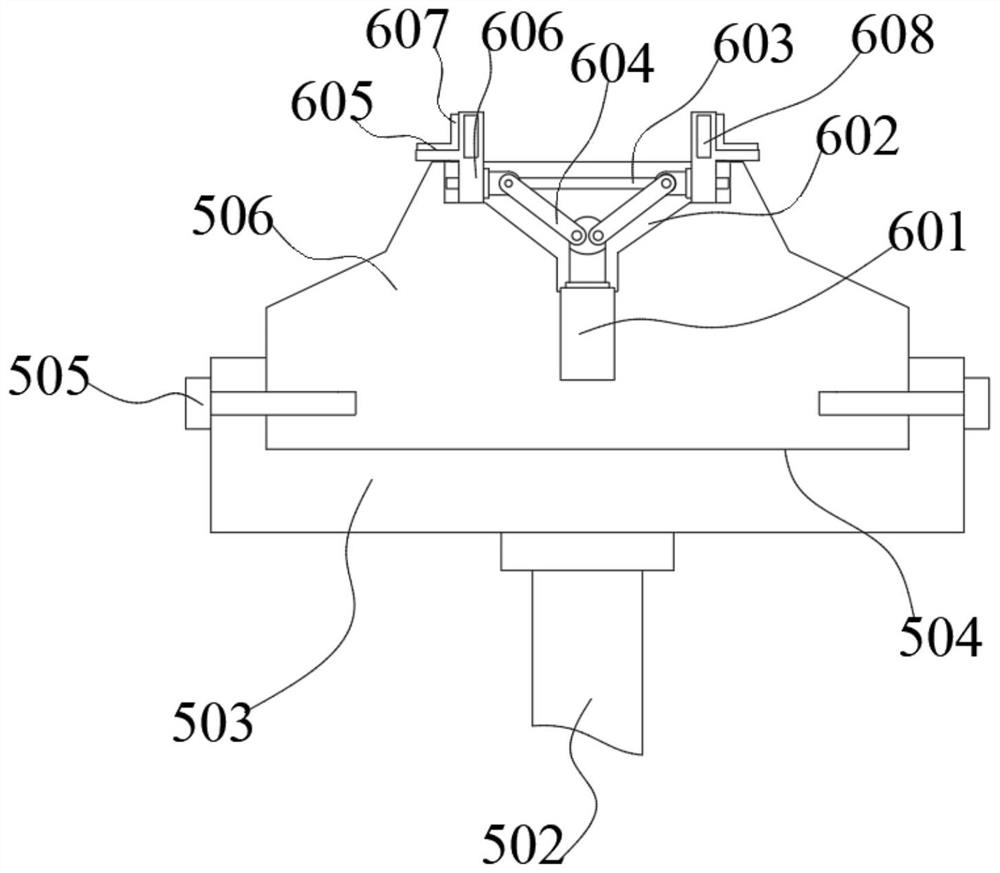

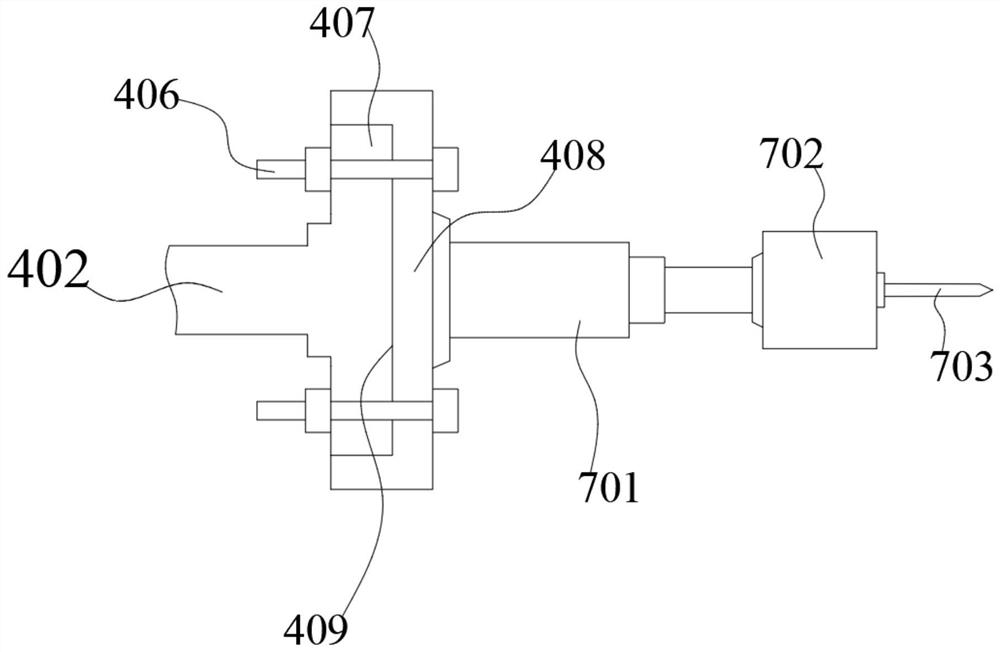

The invention provides a carrier positioning device which comprises a jacking mechanism and a blocking mechanism and further comprises positioning mechanisms. The jacking mechanism is arranged betweenconveying belts which conduct conveying in parallel, can move vertically relative to the conveying belts and is used for jacking a carrier to make the carrier disengaged from the conveying belts andmove to the work position. The blocking mechanism is arranged on the downstream part of the jacking mechanism in the conveying direction and is provided with a lifting blocking rod which is used for preventing the carrier from moving. The positioning mechanisms are symmetrically arranged on the two sides of the conveying belts in the conveying direction. Each positioning mechanism comprises a detecting device and a carrier unlocking device, wherein the detecting device is used for detecting the position of the carrier and the position of a workpiece in the carrier, and the carrier unlocking device is used for unlocking the workpiece in the carrier when the carrier is in the working position so as to achieve unloading of the workpiece. By means of the carrier positioning device, the position of the workpiece can be detected in the unloading process. The invention further provides a material conveying device with the carrier positioning device and a full-automatic production line.

Owner:SUZHOU RS TECH

Process for producing surface-finished lightweight components with high natural fibre content and integrated fastening elements

InactiveCN103260843AIntrinsic stress is smallImproved shape stabilityCoatingsSurface finishEngineering

A process is described for producing a lightweight component comprising natural fibres (FRP component), which has a visible side and a fastening side. In order to manufacture a lightweight FRP component with a high degree of design freedom, any desired type of surface, and substantially reduced cost for downstream operations, the following production steps are proposed according to the invention: a) insertion of a semifinished natural fibre product into an injection mould, b) a pressing and / or forming process, and also consolidation of the semifinished natural fibre product, to give a moulding in the injection mould, c) injection to add functional elements, in particular fastening elements, and / or reinforcing structures, onto the moulding on the fastening side of the lightweight component, into unoccupied spaces in the injection mould, the functional elements, in particular the fastening elements and / or the reinforcing structures being injected only onto a portion of the area of the fastening side, and d) applying the surface component in a prescribed region of the visible side of the moulding.

Owner:KRAUSSMAFFEI TECH GMBH

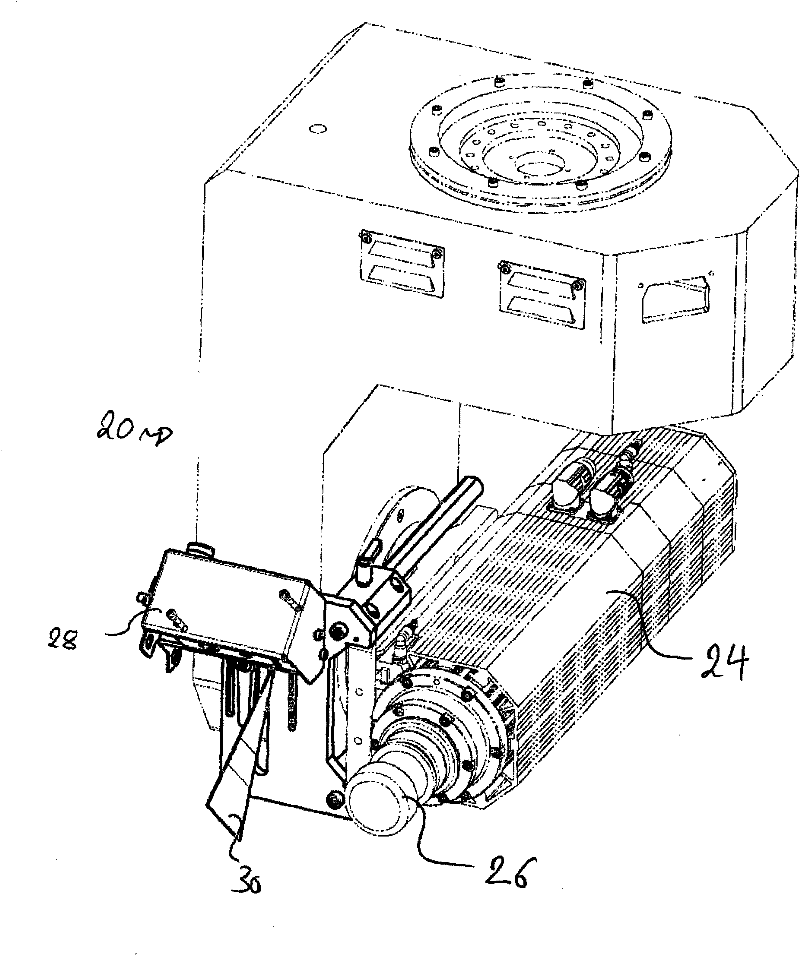

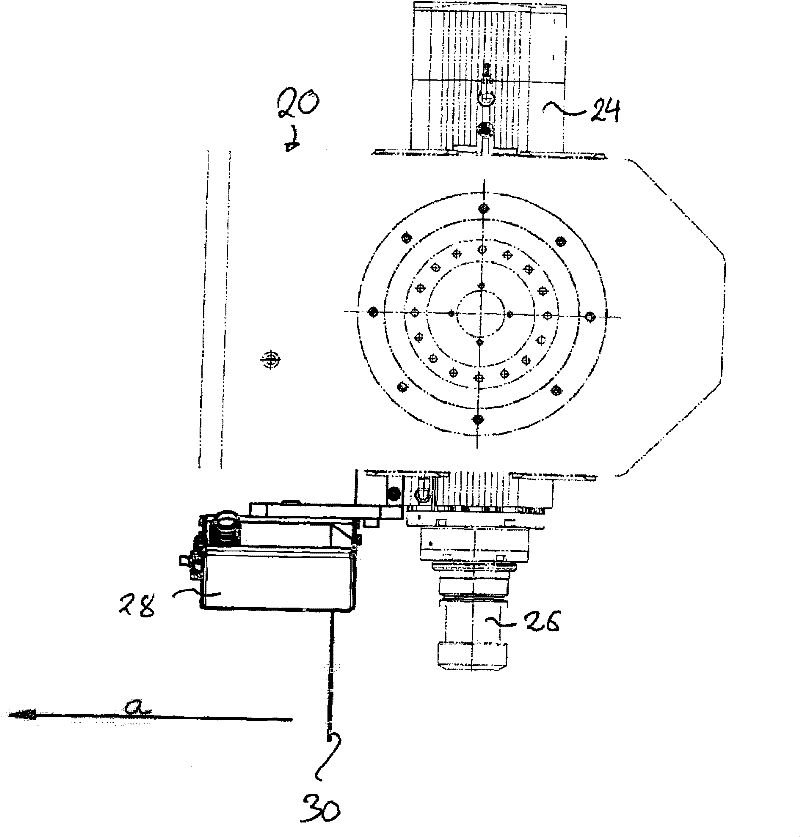

Method for machining composite components

InactiveCN102331742ARealize processing operationsTo achieve the purpose of processingProgramme-controlled manipulatorNumerical controlEngineeringMachine tool

The present disclosure relates to a method for machining composite components in a CNC controlled machining station. In accordance with the present disclosure, a machining tool is guided along a preset tool edge by means of a measuring system, wherein it simultaneously carries out the machining operation, while the CNC control program to control the machining tool is generated in accordance with the measured result. The present disclosure furthermore relates to an apparatus for the carrying out of the method.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

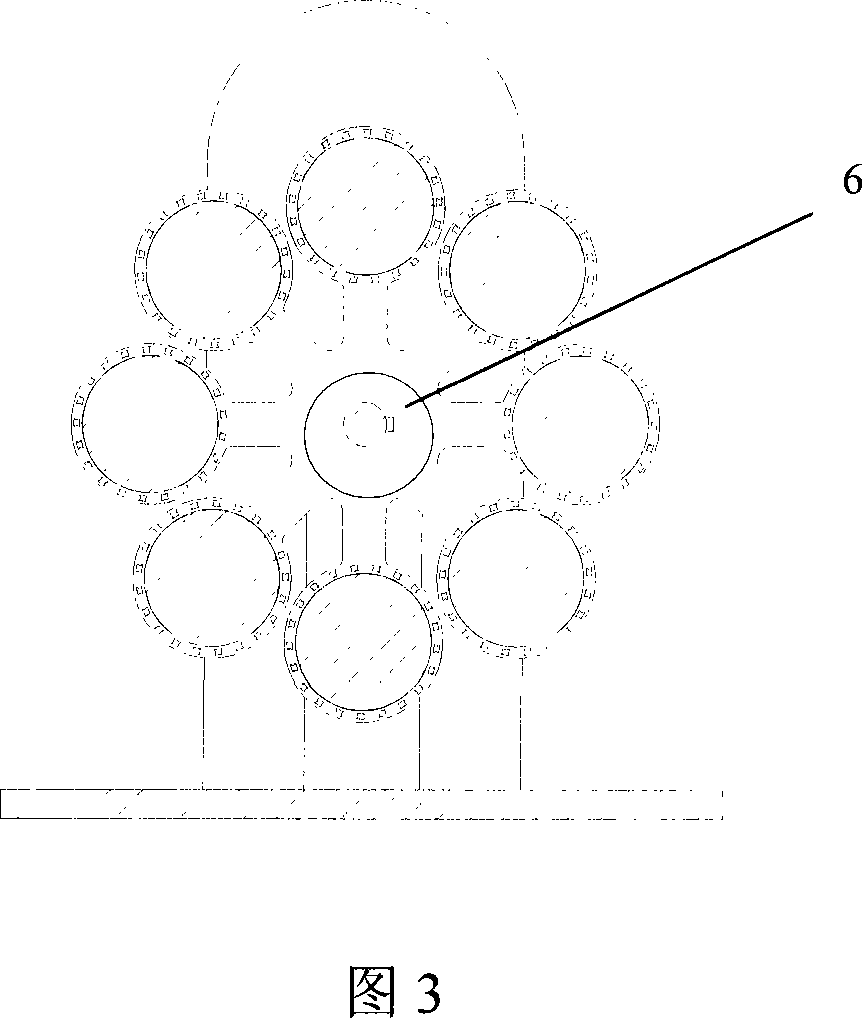

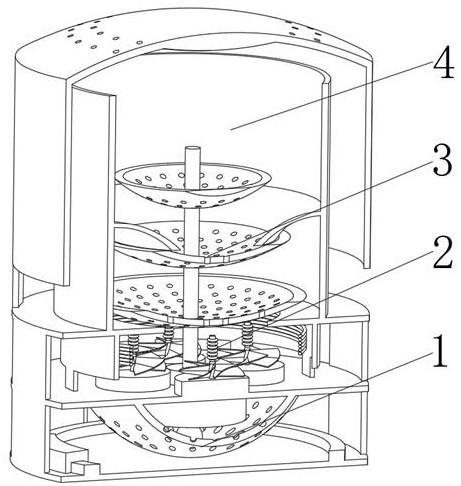

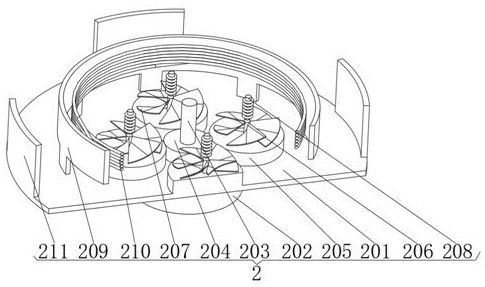

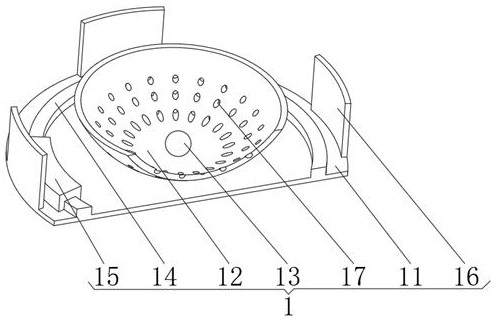

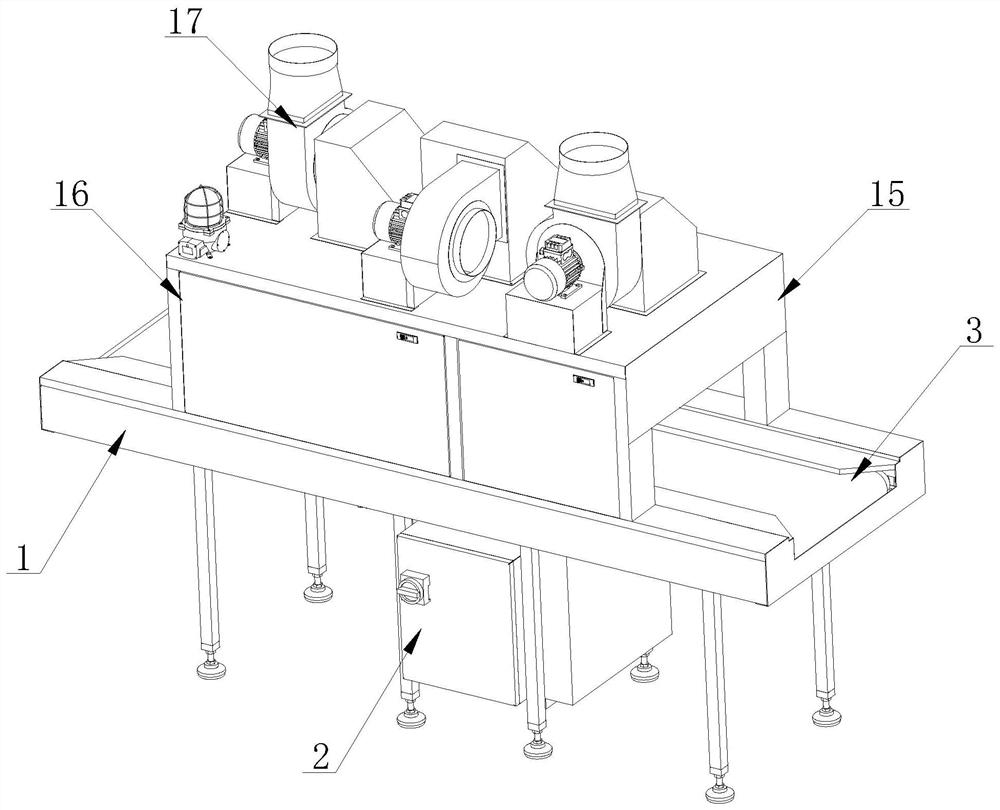

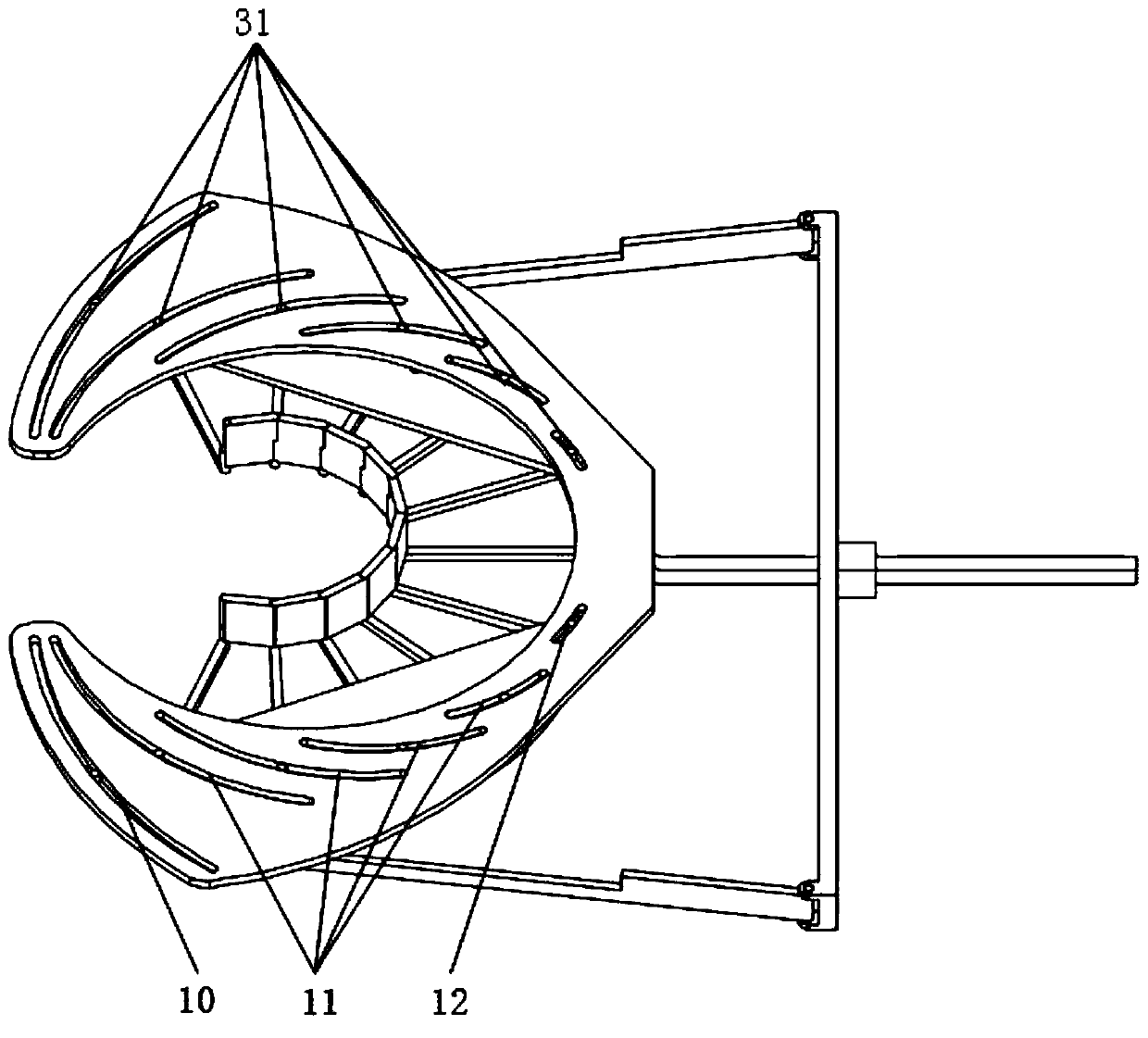

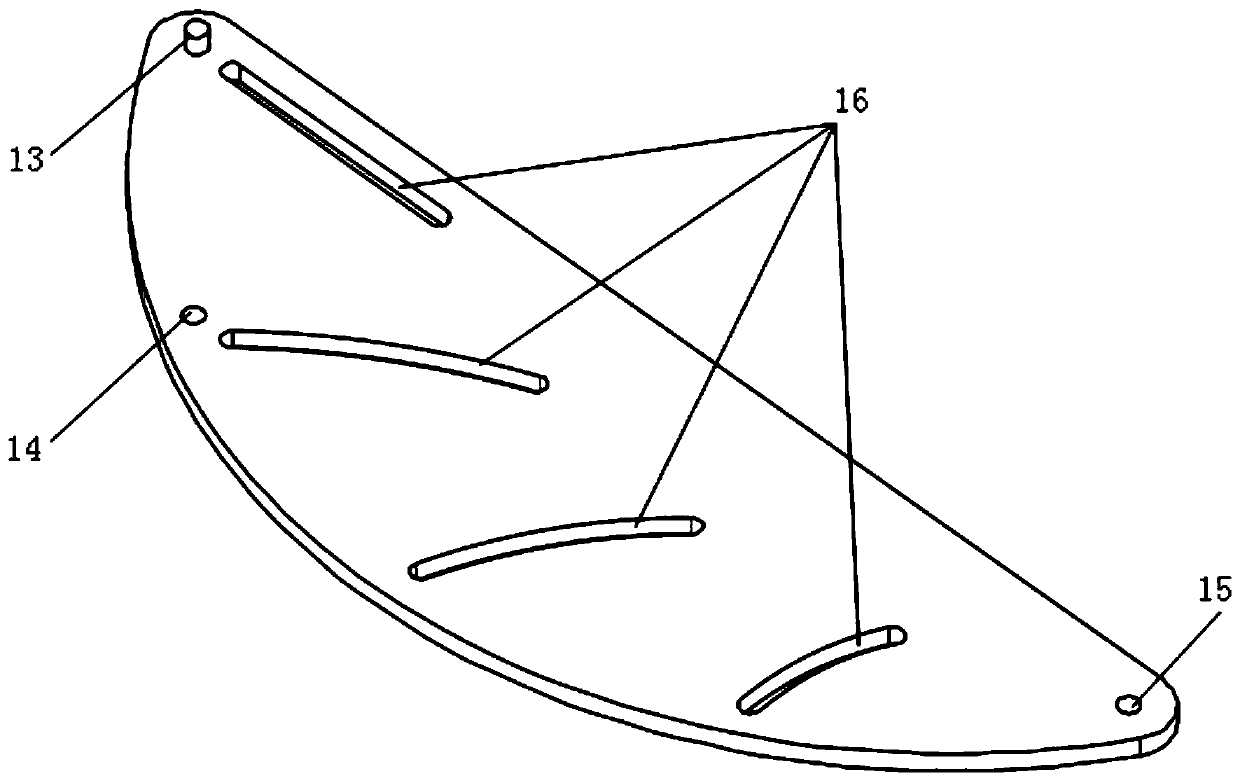

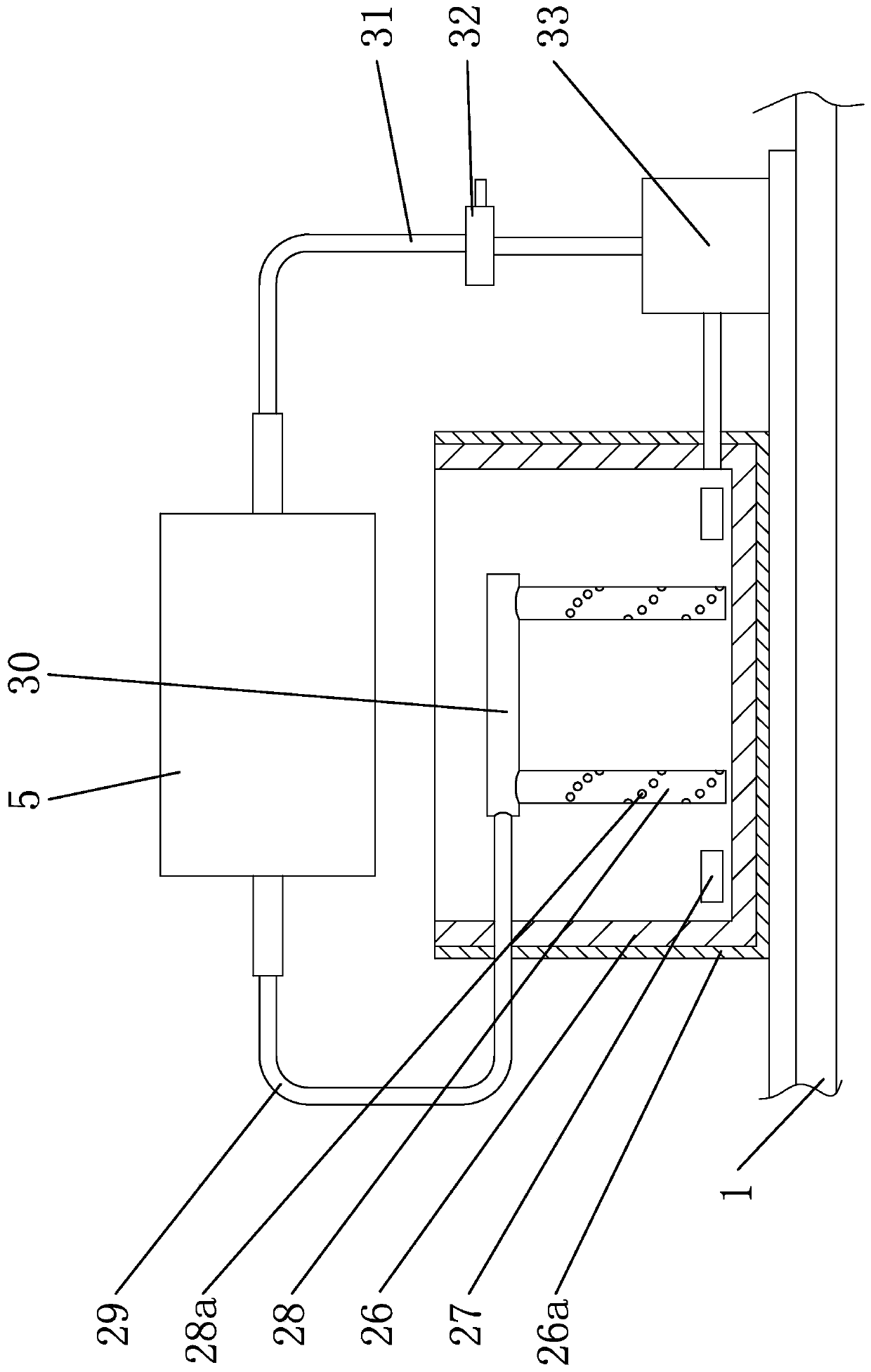

Continuous high-pressure cooking device used for seed nut food

PendingCN109566964AGood cooking effectImprove cooking efficiencyFood scienceFood processingSnack foodEngineering

The invention discloses a continuous high-pressure cooking device used for seed nut food. A top cover is rotatably connected with the top of a pot in a clamped mode, top cover lifting air cylinders are connected with the outer portion of the pot, a top cover fixing frame with a rotating shaft is connected with the top cover lifting air cylinders, a driven gear A is installed at the top end of therotating shaft, a rotating power mechanism is installed on the top cover fixing frame, a driving gear A is installed on a power output shaft of the rotating power mechanism, and the bottom end of therotating shaft is fixed to the top of the top cover; a walking motor is fixedly installed on the top of a walking fixing frame, a driving gear B is installed on a power output shaft of the walking motor, a driven gear B is fixed to the end portion of one end of a walking axle, a walking wheel is fixed to the end portion of the other end of the walking axle, the walking wheel is installed on a guiding rail in a walking matched suspended mode, and a netted material bucket is arranged in an inner cavity of the pot. By means of the continuous high-pressure cooking device used for the seed nut food, multi-station continuous cooking treatment can be conducted on the seed nut snack food, and the problems that kernels can hardly be tasty, shells are hard to crack, energy consumption is high, baking time is long, the efficiency is low, and the like are solved.

Owner:WUHAN XUDONG FOOD +1

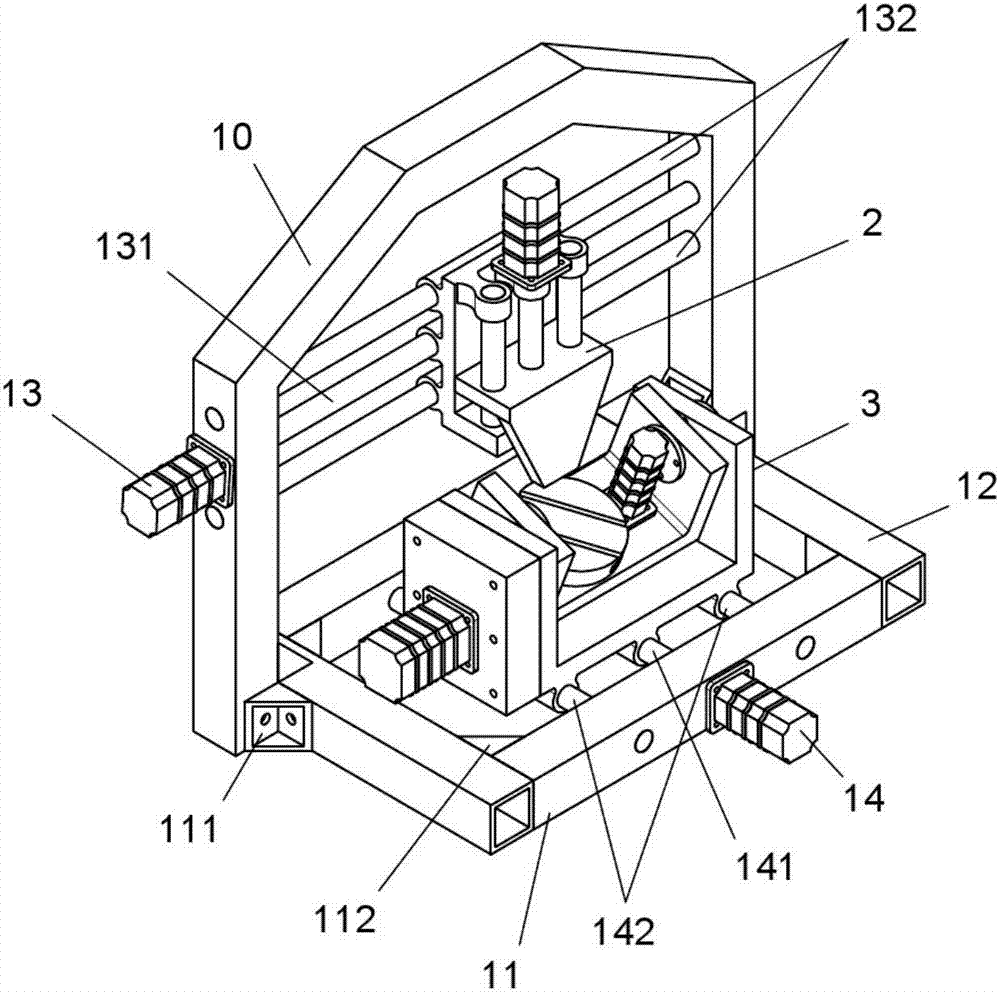

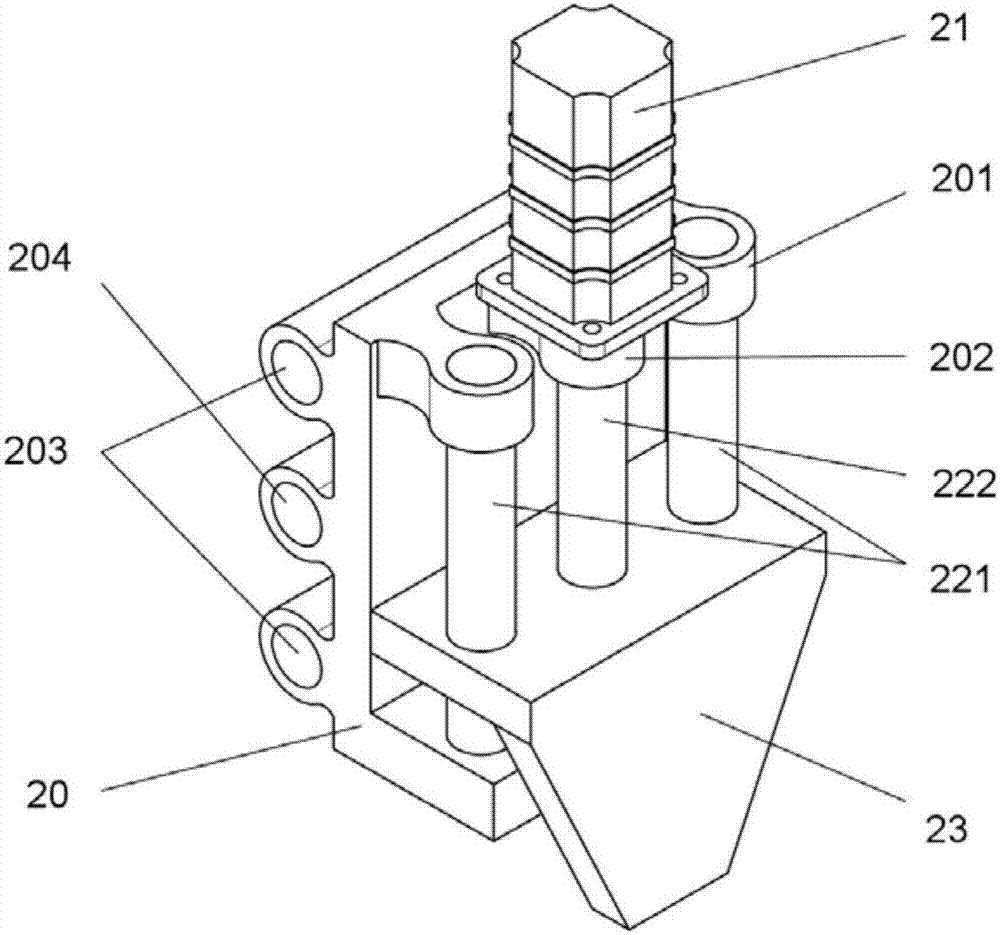

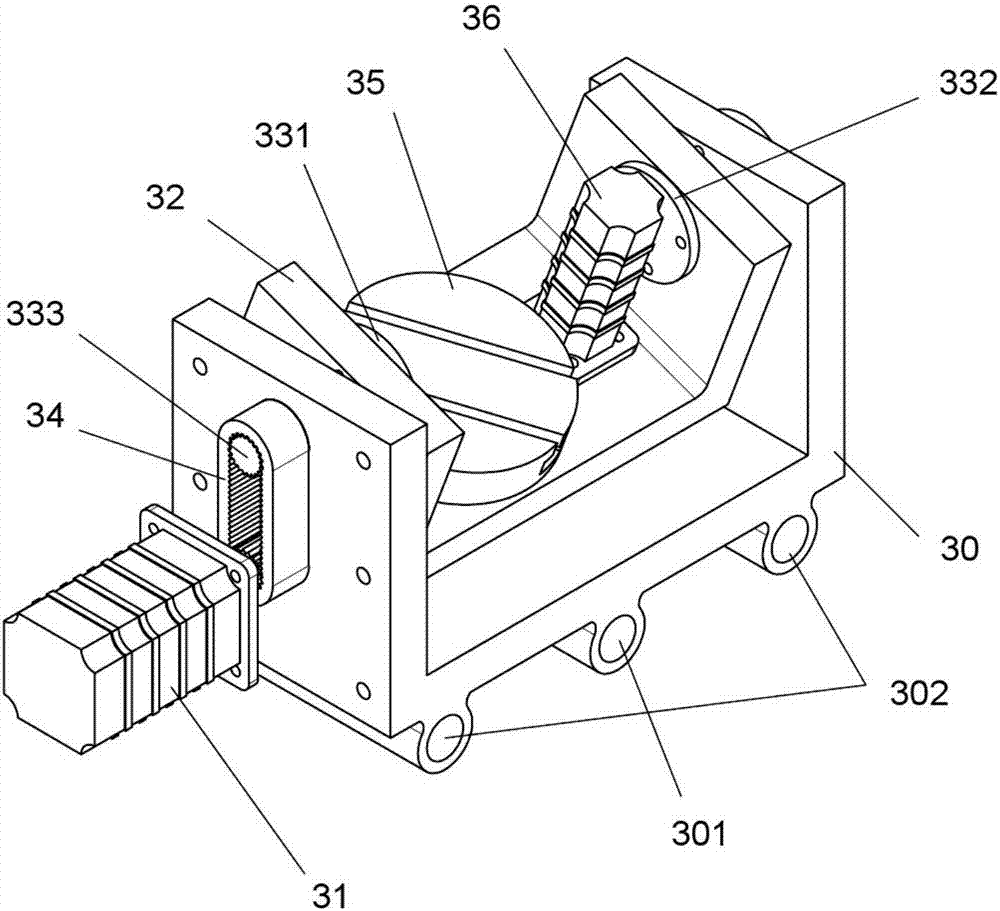

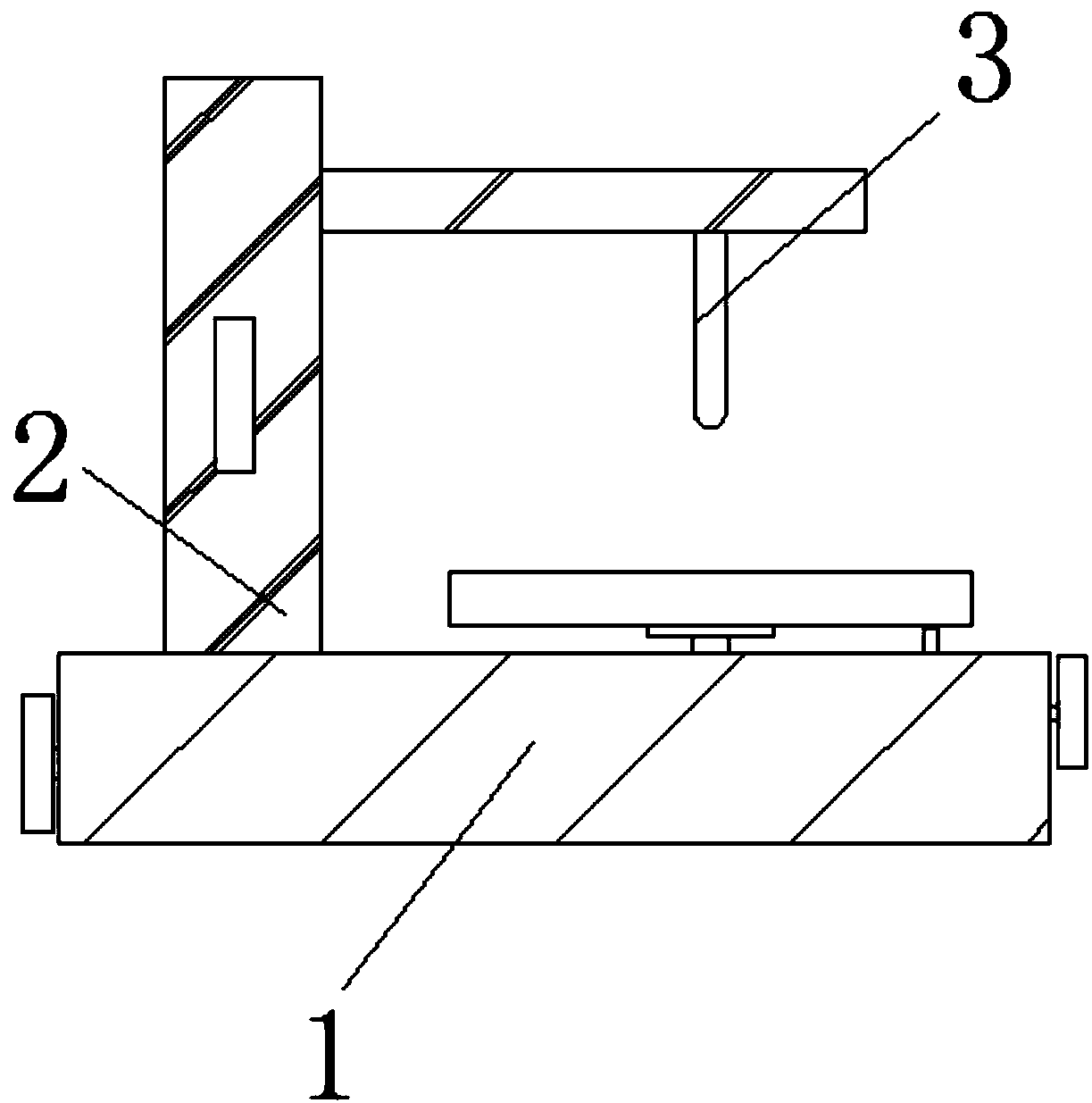

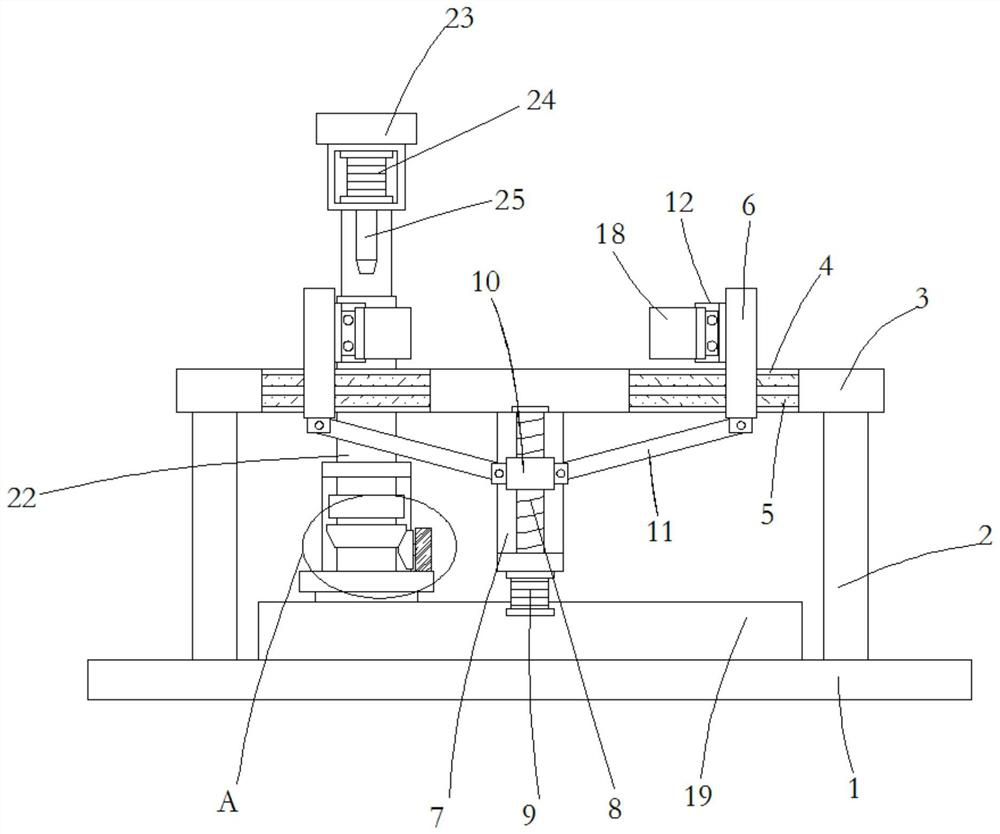

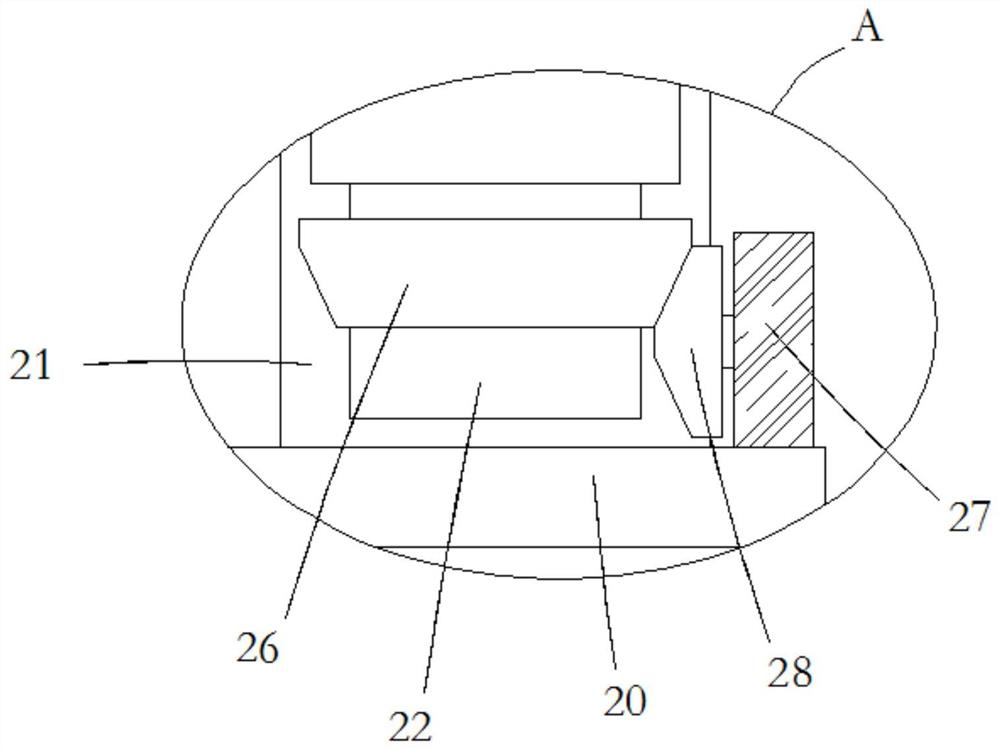

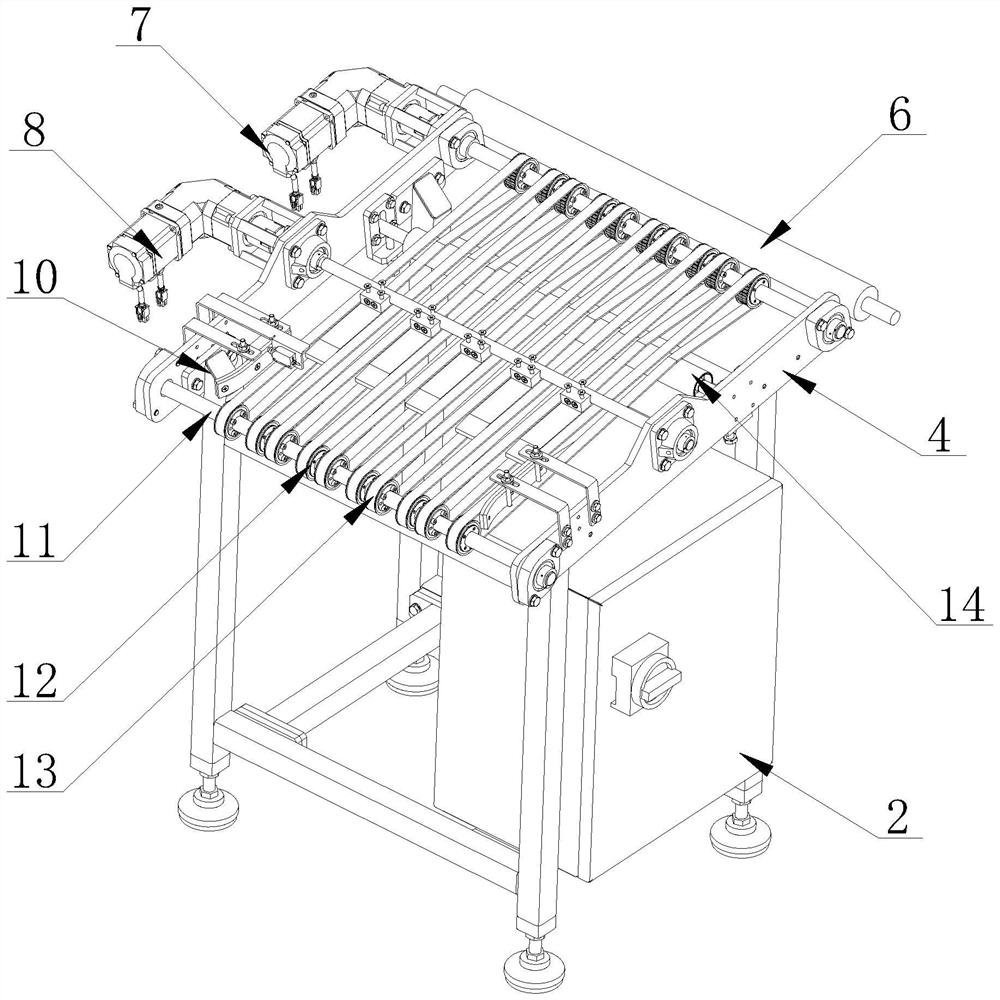

Five-degrees-of-freedom numerical control machining device

InactiveCN107052460ARealize processing operationsSimple structureLarge fixed membersHorizontal transmissionNumerical control

The invention discloses a five-degrees-of-freedom numerical control machining device. The five-degrees-of-freedom numerical control machining device comprises a machine frame; a machining head and a workpiece fixing mechanism are arranged at the upper part of the machine frame; both the machining head and the workpiece fixing mechanism are electrically connected with a controller; the machine frame comprises a horizontal frame body and a vertical frame body; the horizontal frame body comprises two first supporting beams which are arranged opposite to each other and two second supporting beams which are arranged opposite to each other; the first supporting beams and the second supporting beams form a square horizontal frame body; the vertical frame body comprises a door-shaped frame body; the lower part of the door-shaped frame body is fixedly connected with the horizontal frame body through a fixing piece; a horizontal transmission piece is arranged at the upper part of the door-shaped frame body; one end of the horizontal transmission piece is connected with a horizontal driving piece; the machining head is arranged on the horizontal transmission piece; a horizontal guide piece which is parallel to the horizontal transmission piece is also arranged on the door-shaped frame body. The five-degrees-of-freedom numerical control machining device is simple in structure, can realize machining operation of a workpiece on five degrees-of-freedom; the machining efficiency is improved; the occupied area and the energy consumption of the device can also be reduced.

Owner:SUZHOU RUIDAJU AUTOMATIC EQUIP CO LTD

Operating floor used for sponge processing

InactiveCN109291126AHeight adjustableIncreased operating comfortMetal working apparatusEngineeringThreaded rod

The invention discloses an operating floor used for sponge processing. The operating floor comprises a supporting base. A supporting arm is welded to a position, close to the edge, of the top of the supporting base in the vertical direction. A cutting knife is embedded into the position, located above the supporting base, of the bottom of the supporting arm in the vertical direction. According tothe operating floor, a first handle can be rotated, the first handle is made to drive a bidirectional threaded rod to rotate, two threaded bushings move in opposite directions, the inclinations of twoslanting rods are changed, the other ends of the two slanting rods are fixed on a supporting plate, the two slanting rods support the supporting plate, the supporting plate moves upwards, a turnplateis driven to move upwards, and accordingly, the height of the operating floor is adjusted; and according to the operating floor, a second handle can be rotated, a gear is made to drive a rod rack tomove downwards, the rod rack is separated from the bottom of the turnplate, the turnplate is not fixed anymore, the turnplate can be rotated, and processing can be performed on different positions ofsponges.

Owner:ANQING RUIXIA MECHINERY CO LTD

Square timber high-efficiency automatic processing device

InactiveCN111923150AImprove processing efficiencyQuick fix limitFlat surfacing machinesBall bearingElectric machinery

The invention relates to the technical field of timber processing and discloses a square timber high-efficiency automatic processing device. The square timber high-efficiency automatic processing device comprises a base. Supporting columns are fixedly connected to the four corners of the upper end of the base. The upper ends of the four supporting columns are fixedly connected with a working table. The surface of the working table is symmetrically provided with two rectangular openings. Two guide sliding rods are symmetrically and fixedly connected with the inner walls, corresponding to the rectangular openings, of the working table. Moving blocks are slidably sleeved on the outer sides of the two guide sliding rods. A U-shaped supporting plate is fixedly connected to the center of the lower end of the working table. An adjusting screw rod is rotatably connected with the upper end of a horizontal part of the U-shaped supporting plate and the lower end of the working table through a ball bearing. The lower end of the U-shaped supporting plate is fixedly connected with an adjusting motor. The square timber high-efficiency automatic processing device has the advantages of being capable of implementing rapid fixing and limiting on different sizes of square timbers and greatly improving the processing efficiency of the square timbers.

Owner:马鞍山市泰隆家具有限公司

Large-caliber special pipeline processing device

PendingCN108381221AEasy to adjustImprove cutting efficiencyLarge fixed membersPositioning apparatusEngineeringMechanical engineering

The invention discloses a large-caliber special pipeline processing device which comprises a base plate. The top end of the base plate is connected with a clamping block in a sliding mode. A limitingblock is arranged on one side of the clamping block and is further fixed to the base plate. Four supporting rods which are evenly distributed and further vertically arranged are fixed to the top end of the base plate. Two symmetrical transverse pillars are fixed to the top ends of the supporting rods. The transverse pillars are both located between every two supporting rods and are further disposed on the two sides of the position where the clamping block and the limiting block are away from each other. A horizontal lead screw is connected between the two transverse pillars in a rotating mode.A first motor is arranged on one side of one of the transverse pillars, and an output shaft of the first motor is connected to one end of the lead screw. The lead screw is connected with a threaded block in a threaded mode, and a horizontal guide rod is arranged between the two transverse pillars. The large-caliber special pipeline processing device is simple in structure and reasonable in design, multi-section processing of pipelines can be achieved, there is no need to adjust the pipeline positions repeatedly, and cutting efficiency is improved; and meanwhile, the pipelines of different lengths can be processed, flexibility is high and the large-caliber special pipeline processing device is suitable for being popularized.

Owner:贵州枫叶管业有限公司

Method for processing nanometer self-cleaning blended fabrics

InactiveCN108411628ARealize processing operationsImprove self-cleaning effectStain/soil resistant fibresSucessive textile treatmentsSilane couplingPolyester

The invention provides a method for processing nanometer self-cleaning blended fabrics. By the aid of the method, the problem of excessively detailed and complicated steps of existing preparation methods can be solved. The method for processing the nanometer self-cleaning blended fabrics includes steps of blending and interweaving, by weight, 40-60 parts of polyester fibers, 20-30 parts of cottonfibers, 8-18 parts of bamboo fibers and 4-12 parts of modal fibers to obtain blended fabrics; b, weighing 2-8% of organic fluorine resin, 1.2-2.3% of nanometer titanium dioxide, 0.3-0.9% of nanometersilicon dioxide, 1.8-4.6% of silane coupling agents, 0.7-1.5% of triethanolamine, 1-4% of propylene glycol and 80-90% of water; c, placing various raw materials into a stirring device together and preparing treating fluid; d, adding the treating fluid into a pad-roll device and placing the blended fabrics into the pad-roll device; e, placing pad-rolled blended fabrics into a drying oven; f, placing dried blended fabrics into a baking machine; g, rolling baked blended fabrics by the aid of packaging devices. The method has the advantage of short processing time.

Owner:俞祖林

Improved nano self-cleaning blended fabric processing method

InactiveCN108547025ARealize processing operationsImprove self-cleaning effectStain/soil resistant fibresSucessive textile treatmentsPolyesterPolymer science

The invention provides an improved nano self-cleaning blended fabric processing method, and solves the problem that an existing preparation method has complicated steps. The method comprises the following steps of a, blending 50 parts of polyester fiber, 25 parts of cotton fiber, 13 parts of bamboo fiber and 11 parts of modal fiber for interweaving into blended fabric; b, weighing 6 % organic fluororesin, 1.7% nano titanium dioxide, 0.6% nano silica, 3.1% silane coupling agent, 1.1% triethanolamine, 3.5% propylene glycol and 84 % water; c, putting the raw materials together into a stirring device for stirring evenly to obtain treatment liquid; d, adding the treatment liquid to a padding device, and putting the blended fabric into the padding device; e, putting the padding blended fabric inan oven; f, placing the dried blended fabric in a baking machine; g, rolling the baked blended fabric through a packaging device. The method has the advantage of short processing time.

Owner:俞祖林

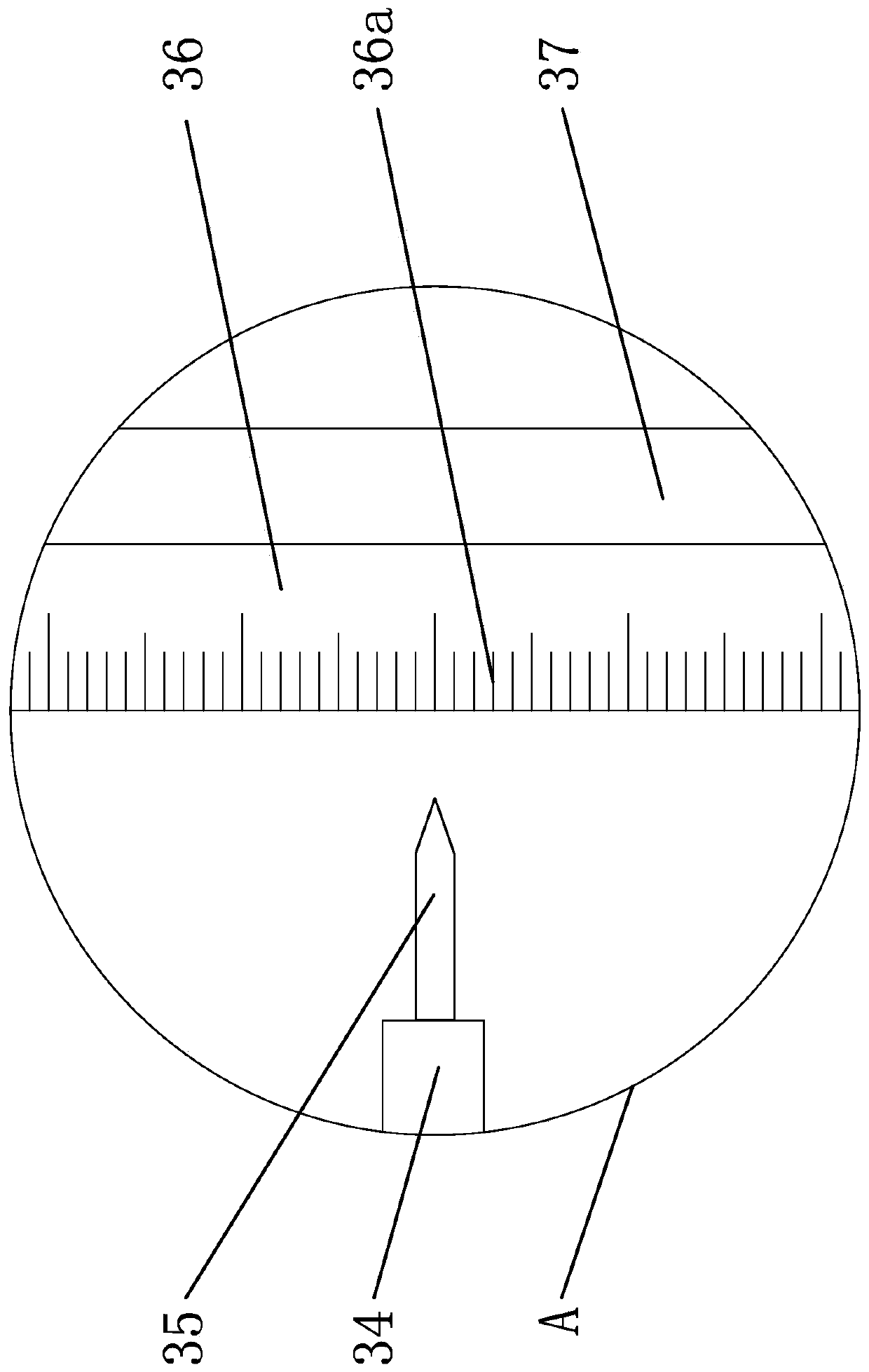

Turning device for chamfer at gear tooth end

The invention discloses a turning device for a chamfer at a gear tooth end. The device comprises a motor, a three-jaw chuck, a chamfering tool, tool rests and a base, wherein a cooling unit is arranged at the front end of the three-jaw chuck and can spray a coolant to a cutting area; the three-jaw chuck rotates around its axis under the driving of the motor; a workpiece is clamped in the three-jaw chuck; and according to a pair of tool rests capable of adjusting the relative position of the tool and the workpiece axis, the angle and position of the tool can be adjusted conveniently, the tool can be controlled to rotate for operation stably, flying chips can be washed away when the coolant is sprayed, and cleanness of a working environment is guaranteed. Therefore, the device has the advantages of being high in efficiency, convenient to use, high in processing quality, good in safety and the like.

Owner:CHIZHOU UNIV

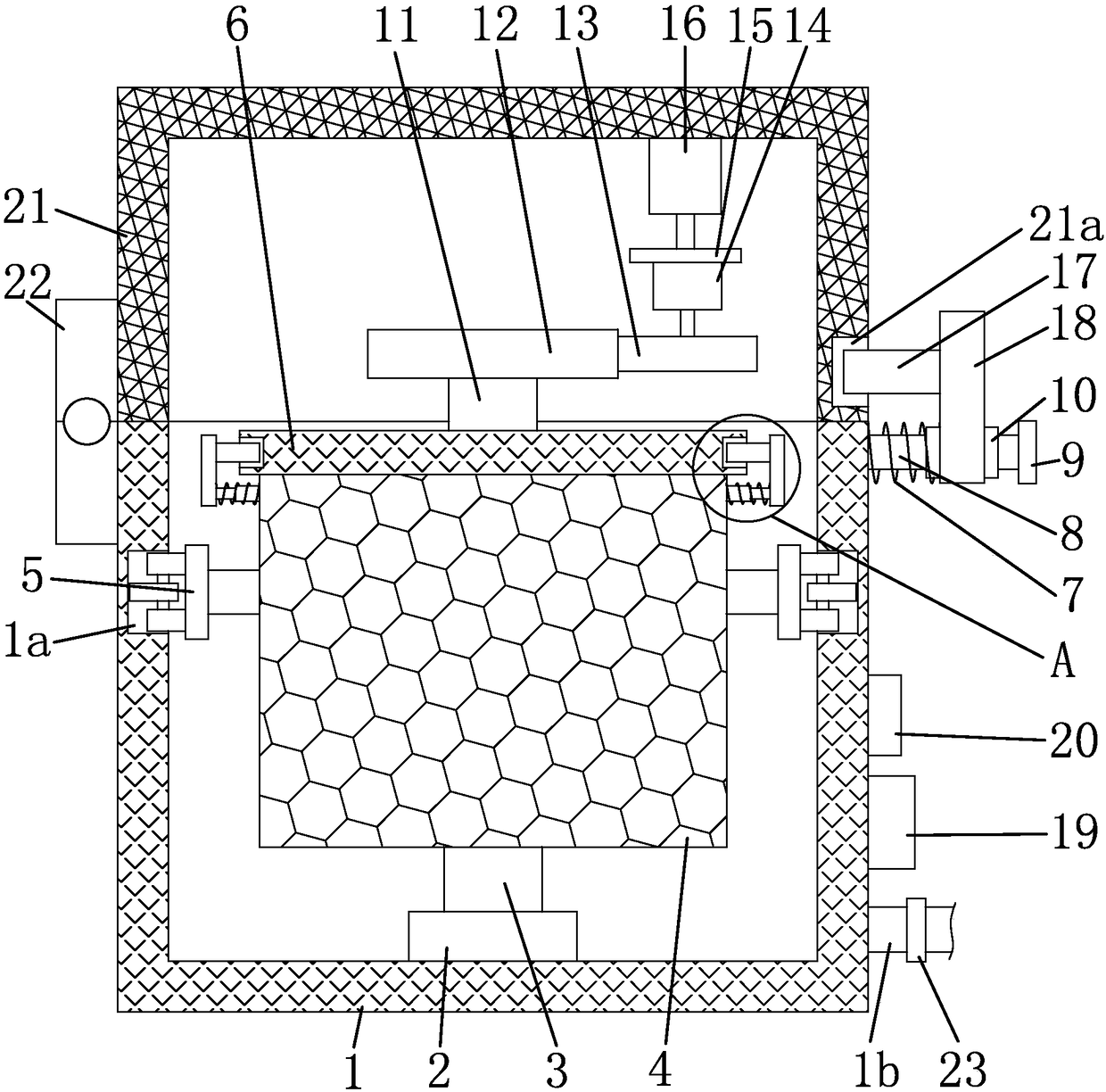

Manufacturing mold of honeycomb filler for water supply and drainage and use method of manufacturing mold

PendingCN114161651AReduce processing costsImprove work efficiency and practicalityMoulding deviceProcess engineering

The invention provides a water supply and drainage honeycomb filler manufacturing mold and a using method thereof.The water supply and drainage honeycomb filler manufacturing mold comprises a workbench and further comprises a supporting platform fixedly connected to the top of the workbench through a connecting column, an air cylinder is arranged at the top of the supporting platform, the telescopic end of the air cylinder penetrates through the supporting platform and is connected with a heat dissipation assembly through a fixing base, and the bottom wall of the heat dissipation assembly is connected with an upper mold; the upper die is matched with the supporting platform through a sliding part; the placing plate is fixedly connected to the side wall of the workbench, the inner wall of the sliding rail is provided with two sets of sliding forming devices, the two sets of sliding forming devices are arranged along the interior of the sliding rail, and the atomization device is arranged in the workbench, matched with the upper mold and the sliding forming devices and used for completing spraying of a release agent. The device is simple in structure and convenient to operate, continuous model machining operation and automatic material taking and placing are achieved, the production efficiency of the device is greatly improved, the production cost of an enterprise is reduced, meanwhile, the cold cutting effect of the device is enhanced, and the molding effect and forming quality of a mold are guaranteed.

Owner:袁燚

Processing method of anti-ultraviolet clothing fabric

InactiveCN108560100ARealize processing operationsEasy to processLiquid/gas/vapor treatment machines driving mechanismsProtective fabricsFiberUltraviolet

The invention provides a processing method of anti-ultraviolet clothing fabric. The technical problems are solved that a corresponding processing method for existing anti-ultraviolet clothing fabric does not exist, and processing is complicated. The processing method of the anti-ultraviolet clothing fabric comprises the following steps that a, by weight, 20-40 parts of cotton fibers, 15-35 parts of modal fibers, 10-20 parts of chitin fibers and 6-12 parts of spandex fibers are blended and woven into clothing fabric; b, the woven clothing fabric is soaked and cleaned; c, the cleaned clothing fabric is pulled open and subjected to oil removal; d, the clothing fabric after the oil removal is dyed by dyeing equipment; e, the dyed clothing fabric is dried; f, the dried clothing fabric is soakedin water for washing; g, the washed clothing fabric is put into a color fixing chamber for steam color fixing; h, the clothing fabric after the color fixing is soaked into anti-ultraviolet finishingliquid for pad-rolling; i, the pad-rolled clothing fabric is dried. The processing method has the advantage of convenient processing.

Owner:海宁市博展经编有限公司

Double-row deep groove ball bearing inner ring outer raceway machining device and using method thereof

PendingCN113275634AAvoid damageReduce procurement costsAutomatic control devicesFeeding apparatusBall bearingStructural engineering

The invention discloses a double-row deep groove ball bearing inner ring outer raceway machining device and a using method thereof. The double-row deep groove ball bearing inner ring outer raceway machining device comprises a base, an adjusting mechanism, a steering mechanism, a clamping mechanism and a milling mechanism, a controller is arranged on the outer surface of the base, a machining groove with a forward opening end is formed in the outer surface of the base, an adjusting mechanism is fixedly connected to the inner wall of the left side of the machining groove, and the adjusting mechanism is detachably connected with a cutting mechanism. A double-row deep groove ball bearing inner ring is clamped and fixed in an adjustable clamping and fixing mode through the clamping mechanism, and the clamping mechanism is suitable for fully clamping and fixing the double-row deep groove ball bearing inner rings of various different sizes or different models; and through the adjusting mechanism, the steering mechanism and the milling mechanism, the double-row deep groove ball bearing inner ring is subjected to outer raceway machining operation in a transverse milling mode, the double-row deep groove ball bearing inner ring is prevented from shaking in the machining process, and the double-row deep groove ball bearing inner ring outer raceway machining device is suitable for being widely popularized and used.

Owner:JIANGSU QIANCHAO BEARING

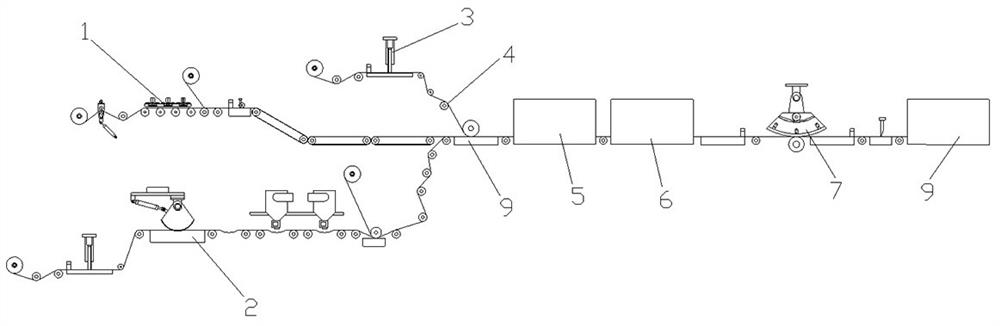

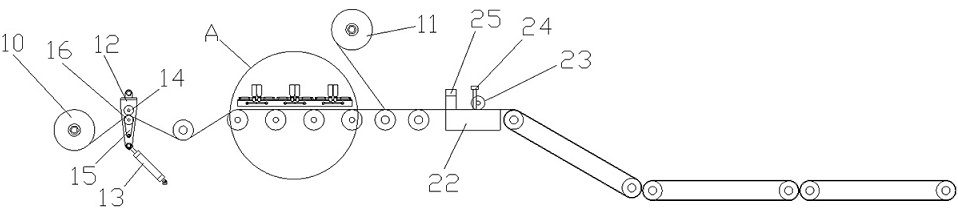

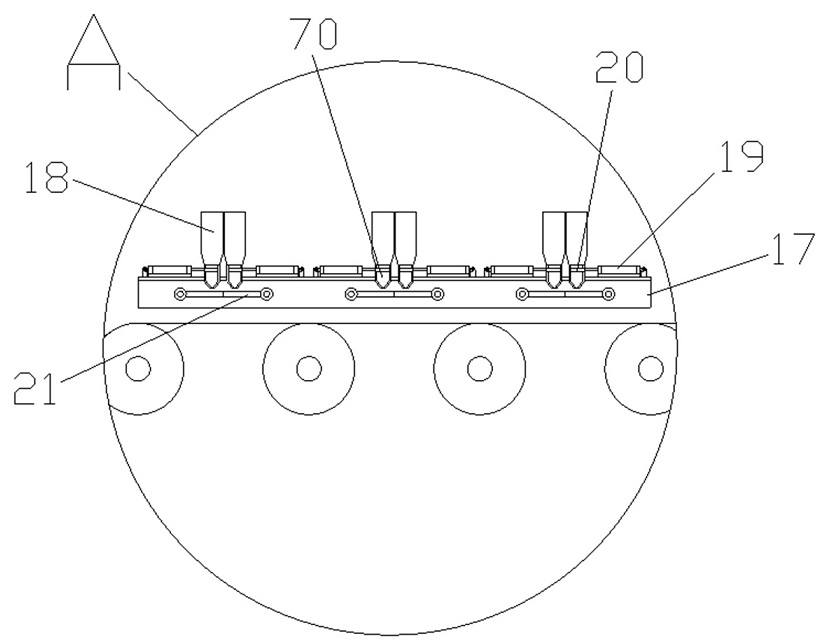

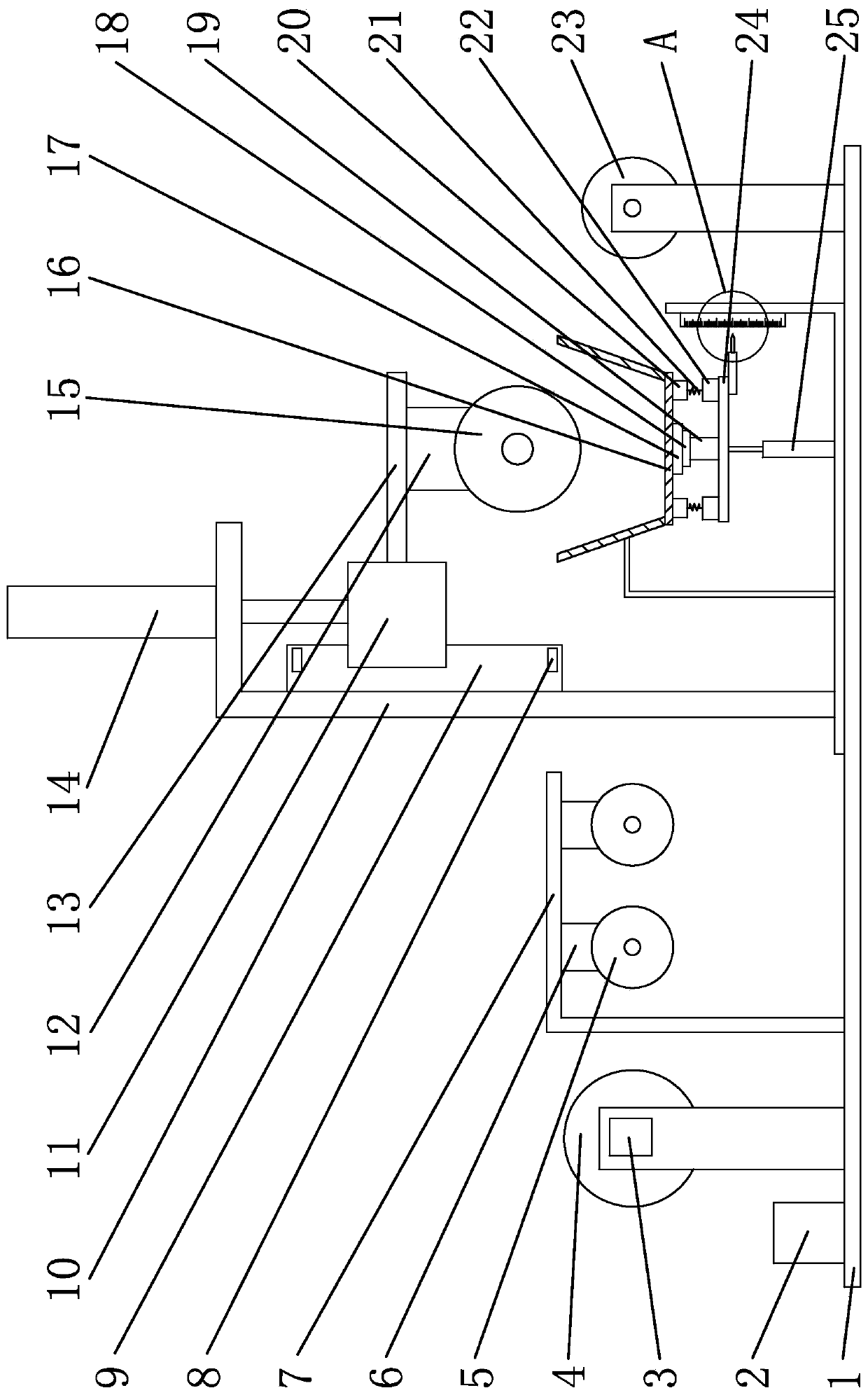

Diaper type pet pants processing equipment

ActiveCN114452086AImprove processing efficiencyRealize processing operationsAbsorbent padsBaby linensWoven fabricHot press

The invention discloses diaper type pet pants processing equipment which comprises an absorption core body processing mechanism, a pants body processing mechanism, an inner-layer non-woven fabric trepanning mechanism, a conveying mechanism, an elastic partition edge processing mechanism, an elastic waistline processing mechanism, a cutting mechanism and a packaging mechanism. A hot pressing mechanism is arranged at the intersection of the absorption core body processing mechanism, the pants body processing mechanism and the inner-layer non-woven fabric trepanning mechanism, and the elastic partition edge processing mechanism, the elastic waistline processing mechanism, the cutting mechanism and the packaging mechanism are sequentially arranged behind the hot pressing mechanism; the conveying mechanism is arranged among the core collecting processing mechanism, the pants body processing mechanism, the inner-layer non-woven fabric trepanning mechanism, the conveying mechanism, the elastic partition edge processing mechanism, the elastic waistline processing mechanism, the cutting mechanism, the hot-pressing mechanism and the packaging mechanism and used for conveying materials, and the absorption core processing mechanism is composed of a plurality of conveying rollers. The pet trousers processing equipment can automatically realize the processing operation of the pet trousers, and the processing efficiency of the pet trousers is improved.

Owner:贵州卡布国际生物科技有限公司

Device for operating planet rotation

ActiveCN101176958ARealize processing operationsReasonable structureWelding/cutting auxillary devicesAuxillary welding devicesSmall footprintPush out

Owner:上海电气企业发展有限公司

Antibacterial wrapping paper processing method

The invention provides an antibacterial wrapping paper processing method. In the prior art, the special processing method for wrapping paper does not exist, the processing of the wrapping paper is inconvenient, and other technical problems exist. A purpose of the present invention is to solve the technical problems in the prior art. The antibacterial wrapping paper processing method comprises: a,fluffing: taking pure wood pulp, carrying out fluffing treatment by using a hydraulic pulp breaking machine, and adjusting the concentration of the pulp to 4.5-5.5%; b, beating: carrying out beating treatment for 40-60 min by using a beating device after adjusting the pH value of the pulp to 6.5-7.0; c, pulp adjusting: placing the obtained pulp into a pulp preparing pool, sequentially adding rosin, an enhancer, an antibacterial agent, titanium dioxide and aluminum sulfate, stirring for 30-40 min, adjusting the pH value of the pulp to 5.5-6.0, and diluting to achieve the concentration of the pulp of 0.45-0.65%; and d, papermaking: conveying the adjusted pulp to a paper machine, carrying out papermaking, dewatering, pressing, drying, and calendering to obtain the antibacterial wrapping paper. The antibacterial wrapping paper processing method of the present invention has the advantages of the processing method.

Owner:浙江鑫墨香科技有限公司

Drying device for plastic granules

ActiveCN113623979BSpeed up dryingQuick changeDrying solid materials with heatDrying gas arrangementsDrive wheelThermal fatigue

Owner:赛纬精密电子科技江苏有限公司

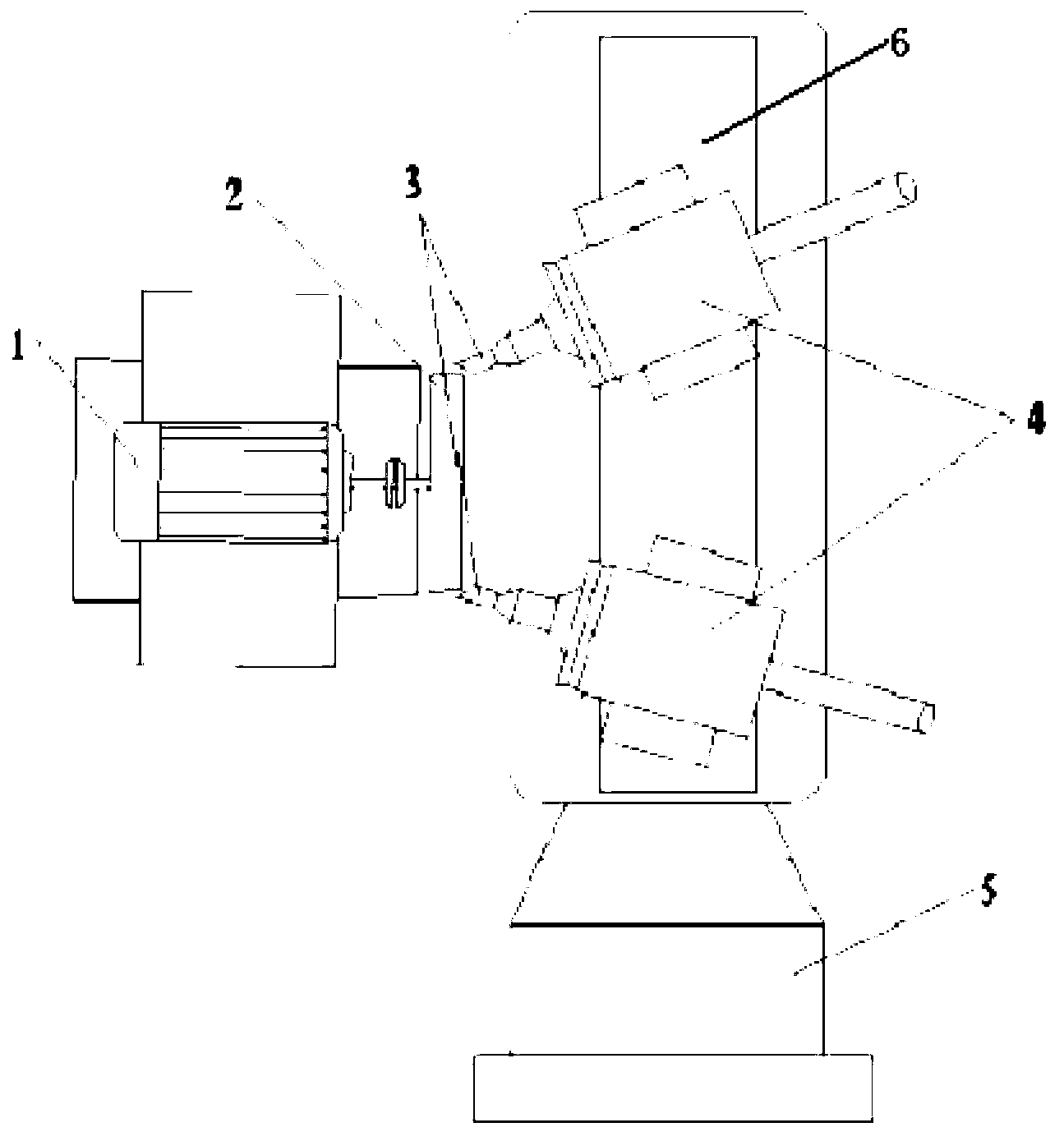

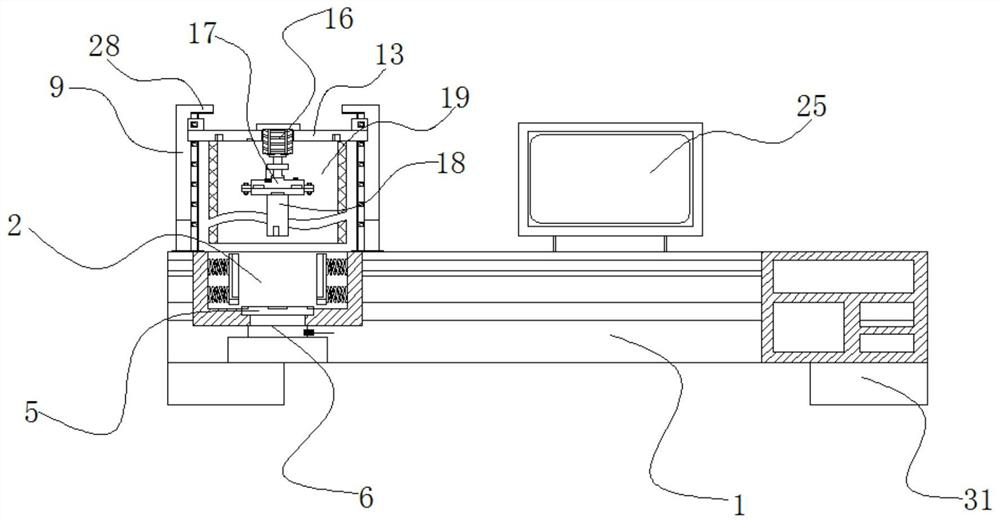

Numerical control machine tool capable of monitoring and feeding back machining cutter in real time

InactiveCN112935871ARealize processing operationsReduce the impact of interferenceAutomatic control devicesMeasurement/indication equipmentsNumerical controlDisplay device

The invention discloses a numerical control machine tool capable of monitoring and feeding back a machining cutter in real time. The numerical control machine tool comprises a machine tool body, a working groove is formed in one side of the machine tool body, a group of vertical blocks is installed on the upper side of the working groove and located on the end face of the machine tool body, a mounting transverse block is installed between the vertical blocks, and a motor is installed on the mounting transverse block; an output shaft of the motor is connected and provided with a mounting disc, the mounting disc is provided with a machining tool in a combined mode through bolts, a sound insulation mechanism is installed on the outer side of the machining tool and located on the lower end face of the mounting transverse block, a metal contact piece is installed on the end face of the fixed end of the machining tool, and an audible and visual alarm is installed on the other side of the mounting disc; and a displayer is installed on the right side of the working groove, and a control module and a wireless transmitting module are installed in the machine tool body. Real-time monitoring on the machining tool during machining and using is achieved through related sensors, so that the machining precision of the machining tool is guaranteed, and abnormity can be handled in time when occurring.

Owner:JINING TECHNICIAN COLLEGE

Processing technology for flame-retardant anti-radiation fabric

InactiveCN108468133AEasy to processRealize processing operationsHeating/cooling textile fabricsLiquid/gas/vapor removalPolyesterCotton fibre

The invention provides a processing technology for a flame-retardant anti-radiation fabric. The technical problems that corresponding processing technologies are not used in an existing anti-radiationfabric, and processing is inconvenient are solved. The processing technology for the flame-retardant anti-radiation fabric includes the following steps that a, warp yarn and weft yarn are woven intoa required fabric, wherein the warp yarn adopts blended yarn of sliver fibers and cotton fibers, and the weft yarn adopts blended yarn of bamboo fibers and polyester fibers; b, 5-10 parts by weight ofmagnesium hydrate, 4-6 parts by weight of aluminum hydroxide, 1-3 parts by weight of antifoaming agent and 50-70 parts by weight of water are weighed and put into a stirring machine together, and spraying liquid is prepared; c, the stirred spraying liquid is sprayed to the surface of the woven fabric through a spraying machine; d, the sprayed fabric is put into a drying oven; e, the hot-dried fabric is put into a baking machine; f, the baked fabric is put into a shaping machine, and the flame-retardant anti-radiation fabric is prepared. The processing technology for the flame-retardant anti-radiation fabric has the advantage that processing is convenient.

Owner:HAINING TIANFU WARP KNITTING

Processing method of food packaging paper

InactiveCN108532353AStir wellAvoid accumulationVegetable material additionRosin additionWater ChestnutsRapid processing

The invention provides a processing method of food packaging paper, aiming at solving the technical problems of existing packaging paper that production steps are too complicated, the production speedis slow and the like. The processing method of the food packaging paper comprises the following steps: a, weighing the following components in parts by weight: 30 to 40 parts of herba celastri angulati, 2.5 to 4.5 parts of calcium carbonate, 10 to 20 parts of cedarwood powder, 22 to 26 parts of water chestnut flour, 5 to 10 parts of straw powder, 3.2 to 4.8 parts of dispersed rosin size and 80 to120 parts of water; b, putting stems and peels of the herba celastri angulati and water into a pulping device and carrying out pulping; stirring for 20 to 30min to obtain original paper pulp; c, adding calcium carbonate, the cedar powder, the water chestnut flour, the straw powder and the dispersed rosin size into the original paper pulp and heating to 90 to 120 DEG C to prepare pulp; d, moldingthe pulp through a mold and drying to obtain the finished-product food packaging paper. The processing method has the advantage of rapid processing.

Owner:浙江鑫墨香科技有限公司

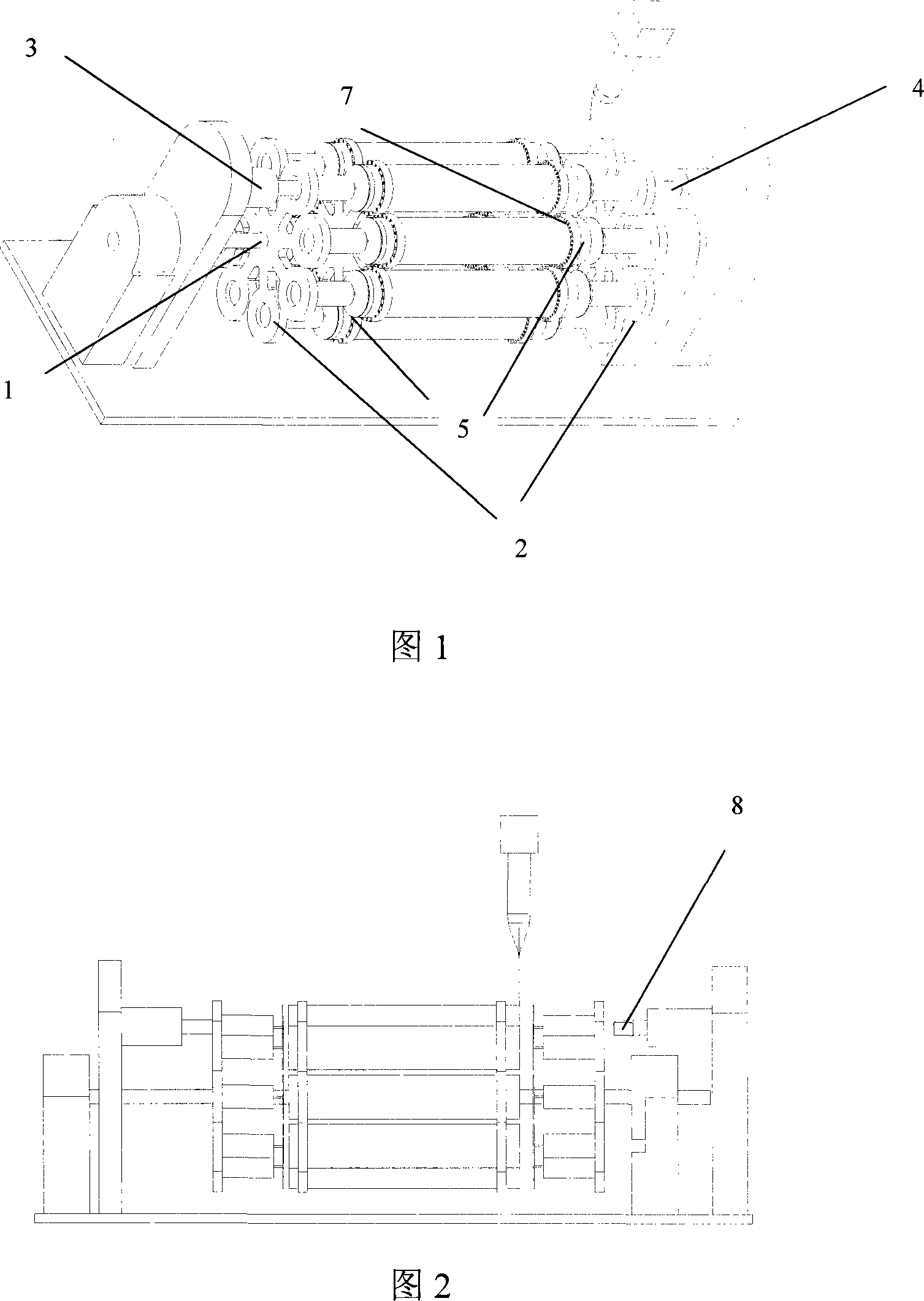

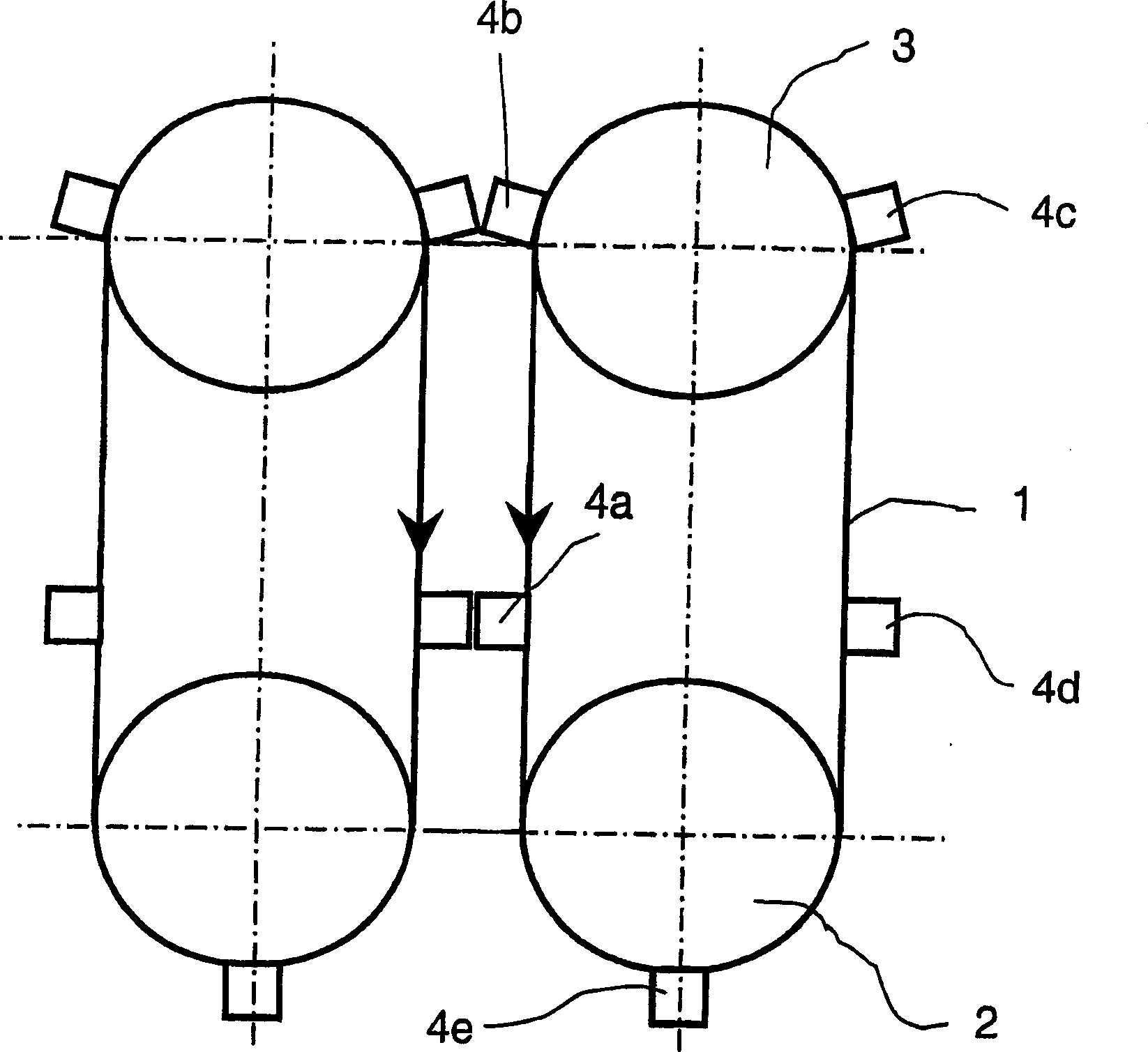

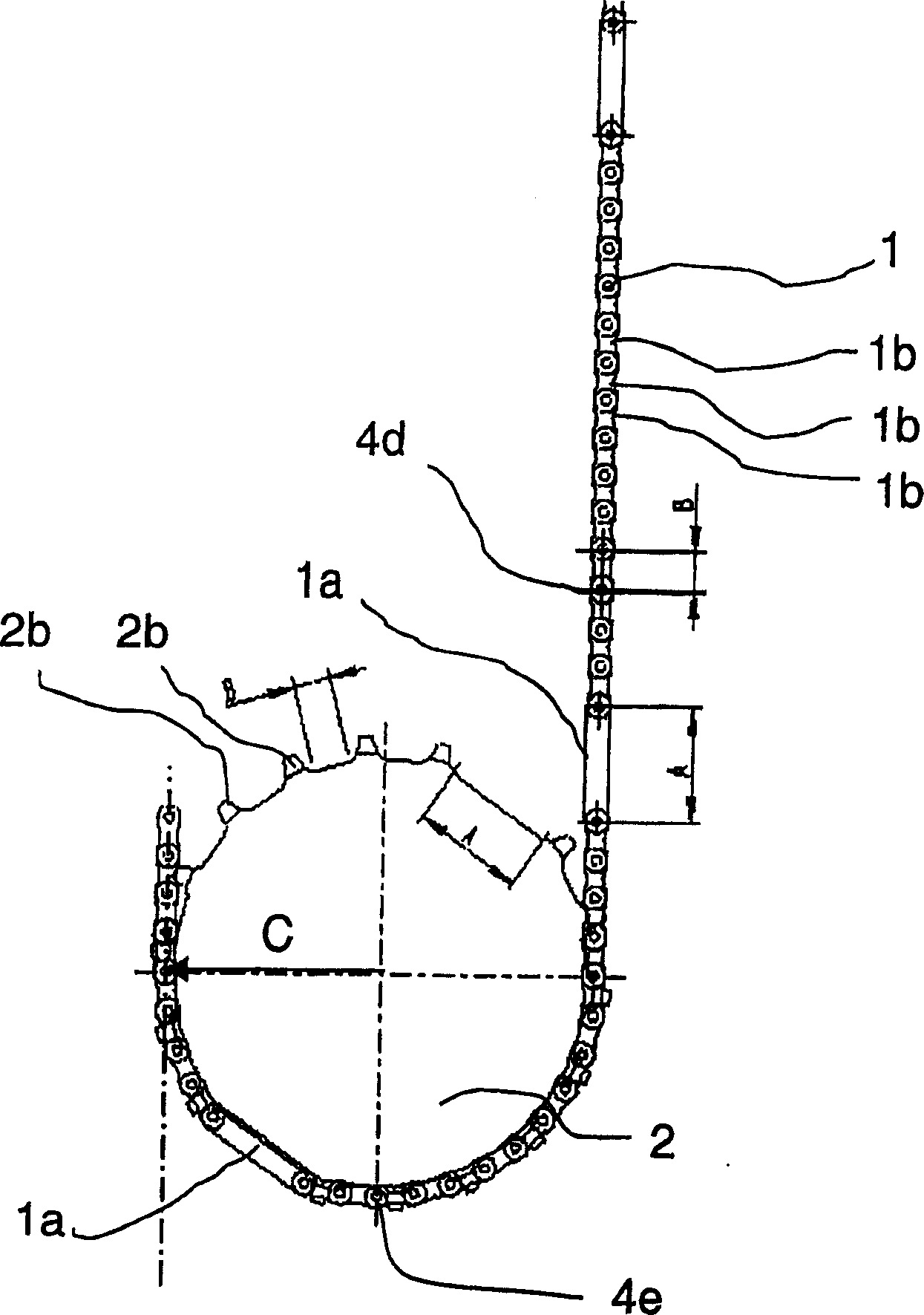

An apparatus for driving one or more processing stations, and a chain for use in the apparatus

ActiveCN1745025ASteplessly variable for different distancesChange lengthConveyorsGearingBiomedical engineering

The present invention relates to an apparatus for driving one or more processing stations, comprising an endless path (1) which includes a plurality of links (1b) of a first predetermined length (B) and at least one pinion (2) which is disposed to engage with said links (1b) and drive said endless path (1), the path (1) being disposed to support said one or more processing stations at a number of predetermined positions along the extent of the path (1), characterised in that each section of the path (1) extending between said positions, comprises at least one link (1a) of a second length (A) deviating from the first length (B). The present inThe present invention relates to an apparatus for driving one or more processing stations, comprising an endless path (1) which includes a plurality of links (1b) of a first predetermined length (B) and at least one pinion (2) which is disposed to engage with said links (1b) and drive said endless path (1), the path (1) being disposed to support said one or more processing stations at a number of predetermined positions along the extent of the path (1), characterised in that each section of the path (1) extending between said positions, comprises at least one link (1a) of a second length (A) deviating from the first length (B). The present invention further relates to a chain of the above mentioned type.

Owner:TETRA LAVAL HLDG & FINANCE SA

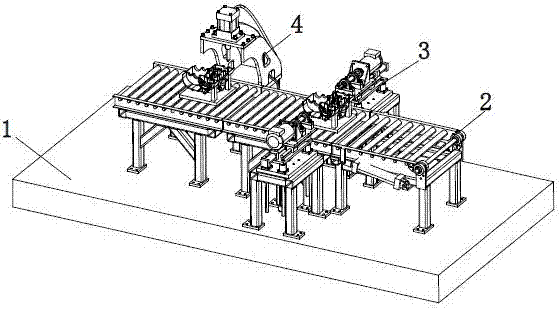

Engine part processing machine

InactiveCN107876830ARealize batch processing operationsSimple structural designMetal working apparatusBoring/drilling machinesEngineeringHigh volume manufacturing

The invention relates to the technical field of engine component processing, in particular to an engine component processing machine. It includes a working base, a processing transfer table installed on the working base, a first processing device and a second processing device, the processing transfer table includes a first transfer table, a second transfer table and a third transfer table, and the first processing The device is arranged on the side of the junction of the first transfer table and the second transfer table, the second processing device is arranged on the side of the third transfer table, the first processing device includes the first processing component and the second processing device The second processing unit on the other side of the second transmission table, the second processing device includes a third processing unit arranged on the third transmission table and on the same side as the first processing unit, the first processing unit and the second processing unit The structure is the same. The invention has a simple structural design, can replace the multi-axis box assembly and the drilling template according to different types of bodies to meet the processing requirements of different bodies, has a wide range of processing, and satisfies mass production.

Owner:胡志会

Processing technology of edible wrapping paper

InactiveCN108740851AStir wellAvoid accumulationFlexible coversWrappersPulp and paper industryFruits and vegetables

The present invention provides a processing technology of edible wrapping paper. A purpose of the present invention is to solve the technical problems of too complicated steps, time consumption, laborconsumption and the like of the existing preparation method. The processing technology comprises: a, washing: placing fruit-and-vegetable raw materials into a washing machine, and washing for 6-10 min at a temperature of 15-25 DEG C; b, boiling: boiling the fruit-and-vegetable raw materials for 20-30 min in water, wherein a mass ratio of the fruit-and-vegetable raw materials to the water is 1:6-1:15; c, pulping: pulping the boiled fruit-and-vegetable raw materials by using a pulping device to obtaining a fruit-and-vegetable pulp; d, papermaking: papermaking the fruit-and-vegetable pulp by using a papermaking machine to obtain wet paper; and e, drying: transferring the wet paper into a dryer, and drying at a temperature of 68-76 DEG C to obtain edible wrapping paper. According to the present invention, the process is simple.

Owner:浙江鑫墨香科技有限公司

Saxophone processing equipment

ActiveCN111203477BAvoid wastingImprove work efficiencyShaping toolsEngineeringMechanical engineering

The invention discloses the technical field of saxophone processing equipment. The equipment comprises a main lower die plate and a main upper die plate arranged in the middle of the top end of the main lower die plate, wherein a first auxiliary lower die plate, a second auxiliary lower die plate and a third auxiliary lower die plate are transversely arranged between the main upper die plate and the main lower die plate side by side from right to left, a sliding groove is formed in the top end of the main lower die plate, a moving mechanism is arranged in an inner cavity of the sliding grooveand connected with the first auxiliary lower die plate, the second auxiliary lower die plate and a third auxiliary lower die plate through a connecting frame, and an auxiliary upper die plate limitedby a guide column and a guide sleeve is arranged at the top end of the first auxiliary lower die plate. According to the equipment, horn mouth stretching processing, elbow semicircular pipe wall processing and sound hole processing of a saxophone are creatively integrated, meanwhile, the elbow semicircular pipe wall processing can achieve full-automatic operation, the operation time of workers isobviously shortened, ascending and descending of the main upper die plate is controlled by only one driving system, the overall equipment is low in manufacturing cost, and popularization and application are facilitated.

Owner:YANTAI NANSHAN UNIV

A convenient mechanical parts processing equipment and using method

ActiveCN112008475BAvoid damageImprove cleaning qualityLarge fixed membersPositioning apparatusWorking environmentProcess engineering

The invention discloses a convenient-to-use mechanical parts processing equipment in the technical field of mechanical parts processing, comprising a base and a processing equipment main body, a continuous operation workbench is arranged on the top of the base, and an annular array is arranged on the top of the continuous operation workbench There are four groups of parts receiving and cleaning mechanisms with the same structure. The parts receiving and cleaning mechanisms of the four groups are symmetrically equipped with clamping and removing chips with the same structure. Connected chip removal mechanism, the present invention is equipped with a chip removal mechanism, the exhaust fan will extract the air in the dust collection case, and the exhaust gas sucked in will be purified by the influence of the filter plate in the dust collection case, so that the sucked waste chips, etc. will be filtered The plate block remains in the dust collection case, reducing the impact on the working environment and staff while avoiding damage to the main body of the processing equipment, and at the same time improving the cleaning quality of the parts by the subsequent cooperation of the connecting drive mechanism and the parts receiving and cleaning mechanism.

Owner:浙江汇丰汽车零部件股份有限公司

A green and environment-friendly infrared sterilizing fruit and vegetable drying device

ActiveCN113973907BReasonably adjust the degree of heat sterilizationHigh degree of integrationFood processingFruits/vegetable preservation by heatingConveyor beltHorticulture

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

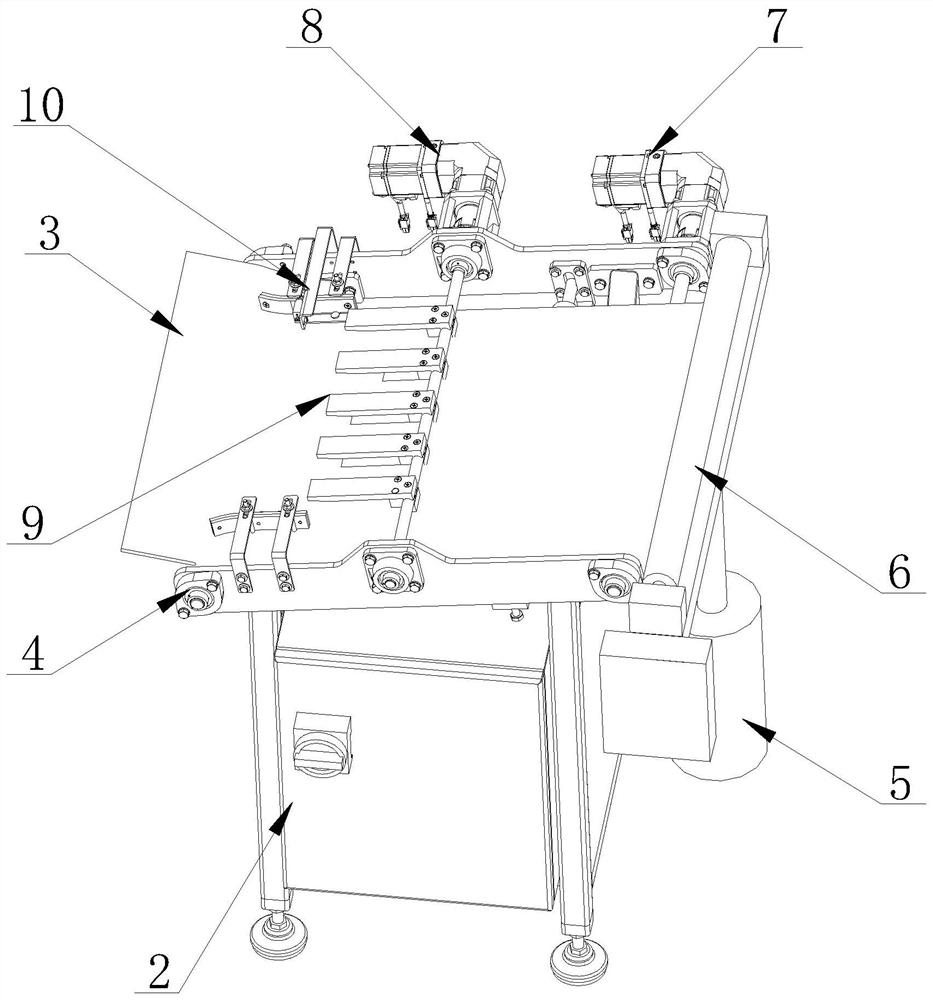

Furnace carrier cover plate backflow line

PendingCN113263240AHigh degree of automationSimple and reliable structureMechanical conveyorsSoldering auxillary devicesPhysicsEngineering

The invention relates to the technical field of carrier cover plate backflow, in particular to a furnace carrier cover plate backflow line. The furnace carrier cover plate backflow line comprises a wave-soldering mechanism, a cooling mechanism connected to the discharging position of the wave-soldering mechanism and a backflow mechanism located below the cooling mechanism, the backflow mechanism comprises a plurality of jig backflow devices and a cover plate backflow device located on one side of the jig backflow devices, and the jig backflow devices are connected with one another to form a jig backflow line. The backflow mechanism is arranged below the wave soldering mechanism and the cooling mechanism and used for conducting backflow on the carrier and the cover plate which are subjected to wave soldering and cooling, the carrier and the cover plate can be conveniently recycled, the automation degree is high, the structure is simple and reliable, and practicability is high.

Owner:DONGGUAN GUANJIA ELECTRONICS EQUIP

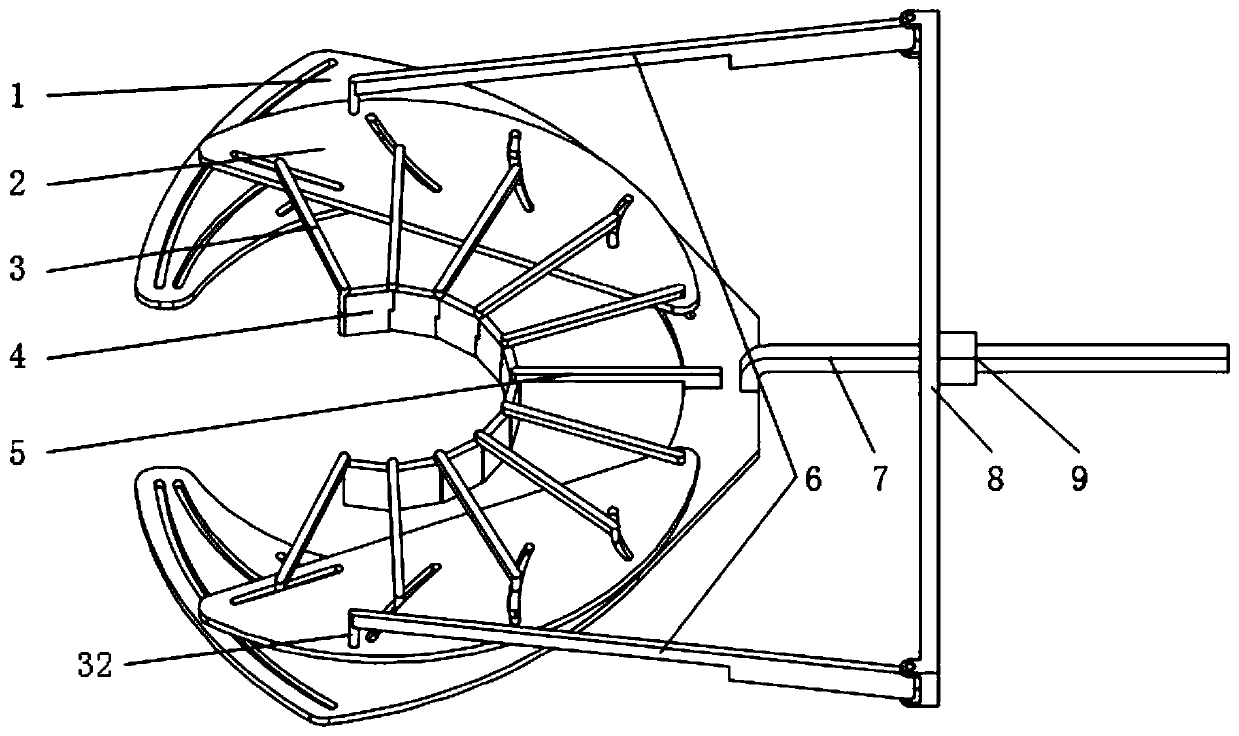

A variable arc mechanism

ActiveCN107598603BRealize processing operationsEffective controlWork holdersPositioning apparatusEnergy consumptionFixed Slide

The invention discloses a variable circular arc mechanism comprising fixed sliding pieces, movable sliding pieces, movable variable circular arc supporting rods, a rigid arc piece, a movable pair guiding rod, a movable pair sliding block, a driving pushing rod and driving transmission rods. The mechanism is divided into two functional parts of the executive part and the driving part. According tothe mechanism, the radian and radius of a circular arc are changed mainly through the mode that the fixed sliding pieces and the movable sliding pieces are matched with sliding grooves to drive terminal executive parts, in the rotating process of the movable pair sliding block, variable diameter adjustment of the circular arc composed of the rigid arc piece can be completed, research and development of the variable circular arc mechanism with the exterior as the entity and the core being hollow are achieved, and the purpose of variable control over the circular arc is achieved. The variable circular arc mechanism is small in overall size, simple in structure, easy to control, high in reliability, high in circular arc precision, large in variable diameter range, wide in application range and low in energy consumption cost.

Owner:SOUTH CHINA AGRI UNIV

A kind of processing method of anti-fouling advertising inkjet material

InactiveCN108527899BRealize processing operationsEasy to processPretreated surfacesFlat articlesKnurlingPurchasing

The invention provides a processing method of an antifouling advertising inkjet material, aiming at solving the technical problems that an existing advertising inkjet material has no antifouling performance, a corresponding processing method is also not provided and the like. The processing method of the antifouling advertising inkjet material comprises the following steps: a, purchasing; b, preparing materials; c, coating; d, laminating; e, knurling. The processing method provided by the invention has the advantage of convenience for processing.

Owner:吴江市斌缘纺织喷绘材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com