Device for operating planet rotation

An operating device and planetary technology, applied in auxiliary devices, workbenches, auxiliary welding equipment, etc., can solve the problems of low operation efficiency of multi-workpiece tooling, and achieve the effects of small footprint, reduced working intensity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

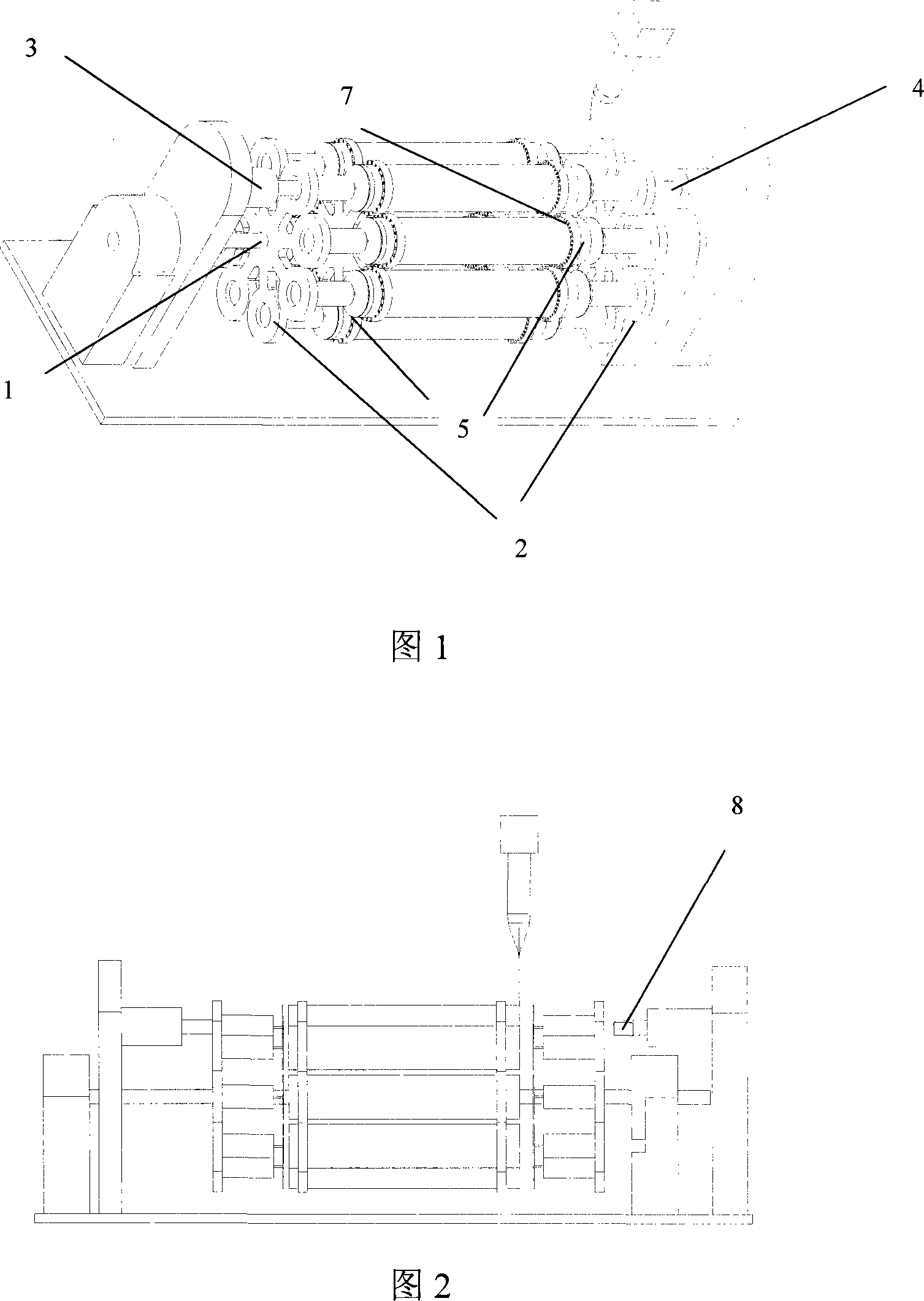

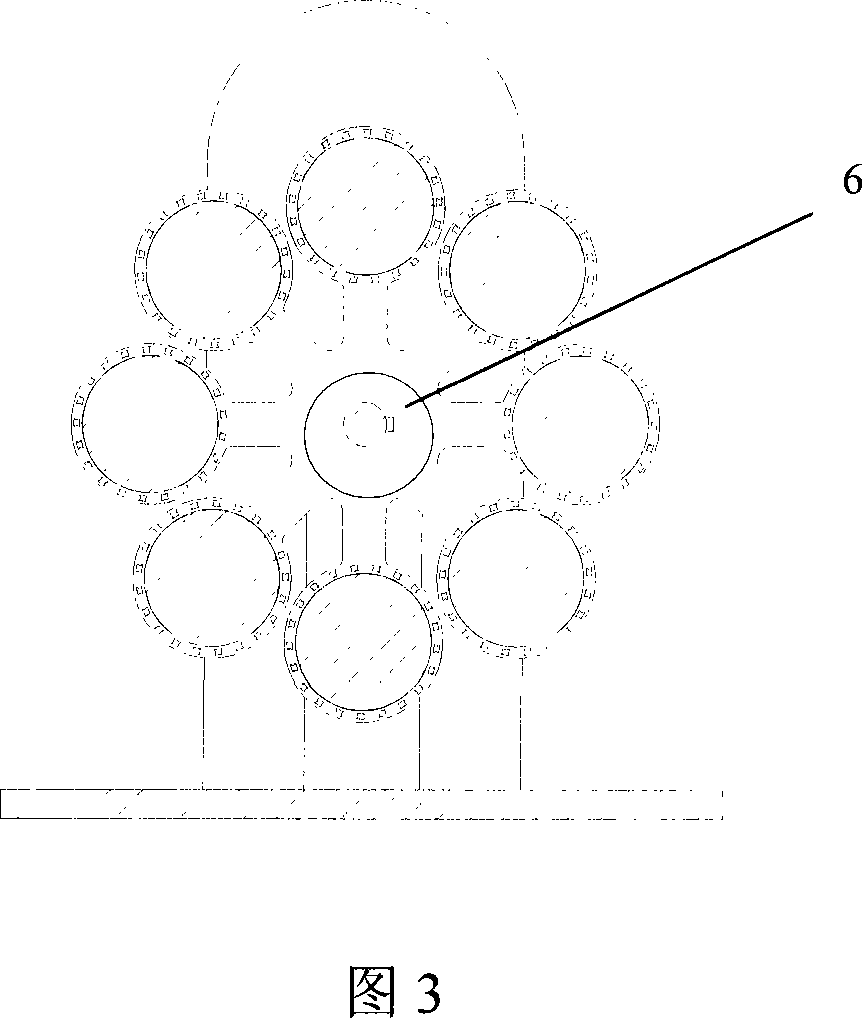

[0015] The main rotating shaft and the secondary rotating shaft are made of hard alloy carbon steel, and the top stalk is made of 304 stainless steel. The stepping motor drives the main rotating shaft and the secondary rotating shaft to rotate. There are eight workpiece holders on the workpiece disk, the workpiece holders are in the shape of a circular sleeve, and sliding bearings are arranged in the circular sleeve to strengthen sliding.

[0016] When in use, the eight workpieces to be operated are placed in the workpiece holder, the main rotating shaft rotates to drive the workpiece plate and drives the workpiece placed in the workpiece holder to rotate to the position of the secondary rotating axis, the ejector rod is pushed out, and fixed with the fixed tenon groove at the top For the workpiece, the rotation of the secondary rotating shaft drives the workpiece to rotate to perform laser processing on the workpiece.

[0017] After the processing is completed, the ejector ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com