Carrier positioning device, material conveying device and full-automatic production line

A technology of positioning device and conveying device, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problem of inability to effectively judge the loading position of the workpiece, and achieve the effect of convenient loading and unloading, ensuring stability and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

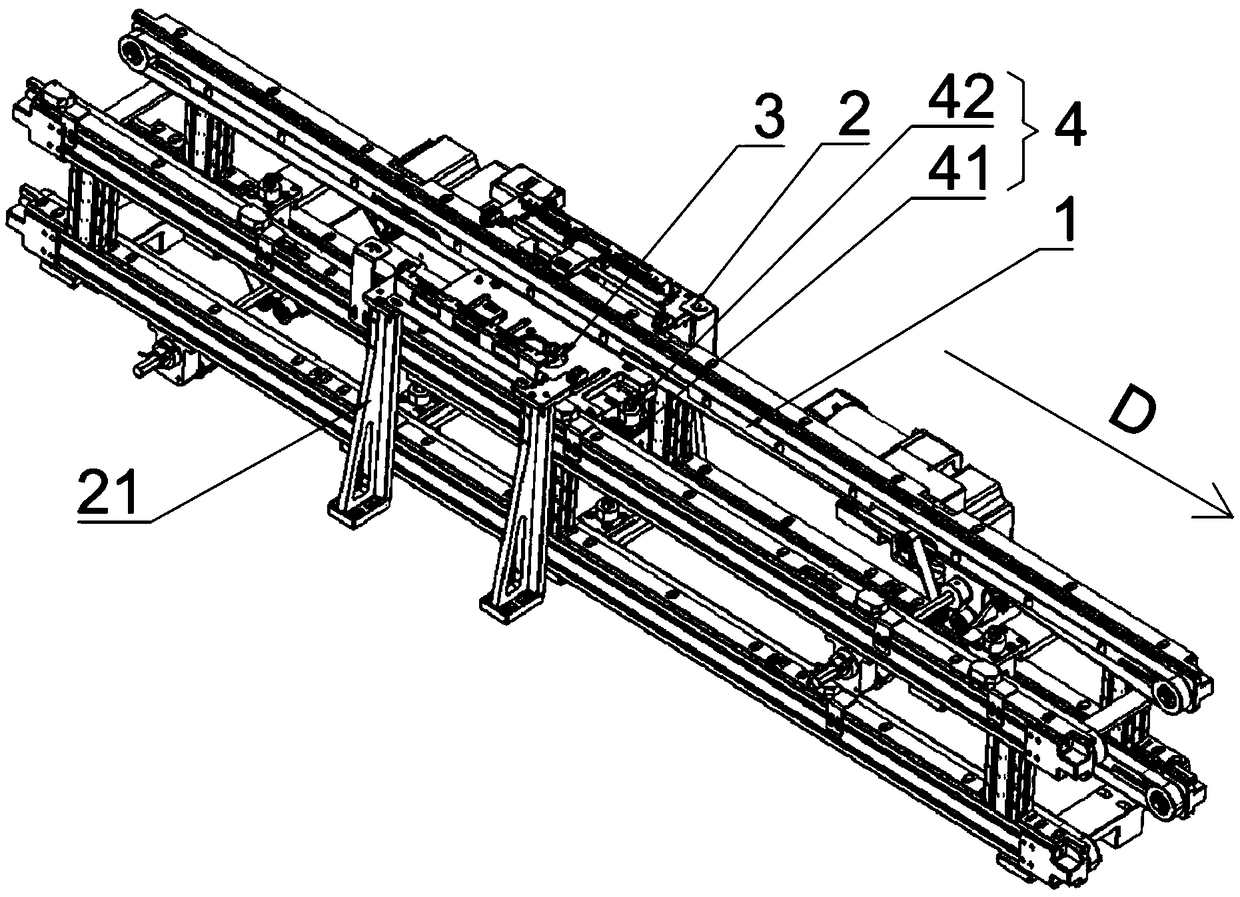

[0045] This embodiment provides a carrier positioning device, the structure of which is as follows: figure 1 As shown, it includes a jacking mechanism 3 , a blocking mechanism 4 and a positioning mechanism 2 . The jacking mechanism 3 is provided between the conveyor belts 1 that are transported in parallel. Between the conveyor belts 1, it can move up and down relative to the conveyor belt 1, and is used to lift the carrier (not shown) from the conveyor belt 1 to the working position. The positioning mechanism 2 is arranged on both sides of the conveyor belt 1 symmetrically to the conveying direction, and is used to temporarily park the carrier at the working position so that the processing equipment can operate it. The blocking mechanism 4 is arranged downstream of the jacking mechanism 3 and has a liftable blocking rod 42 , which is used to prevent the carrier from moving further.

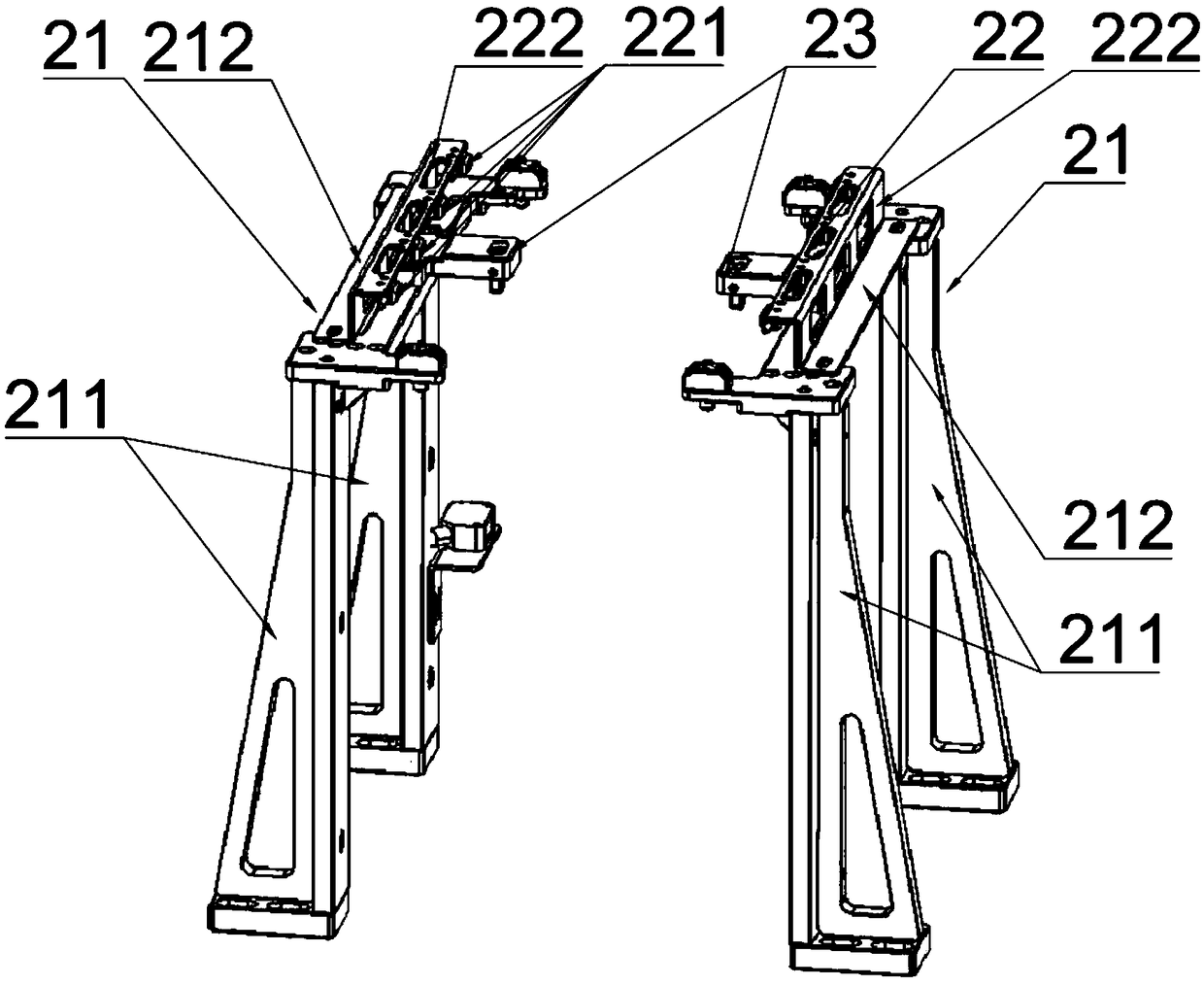

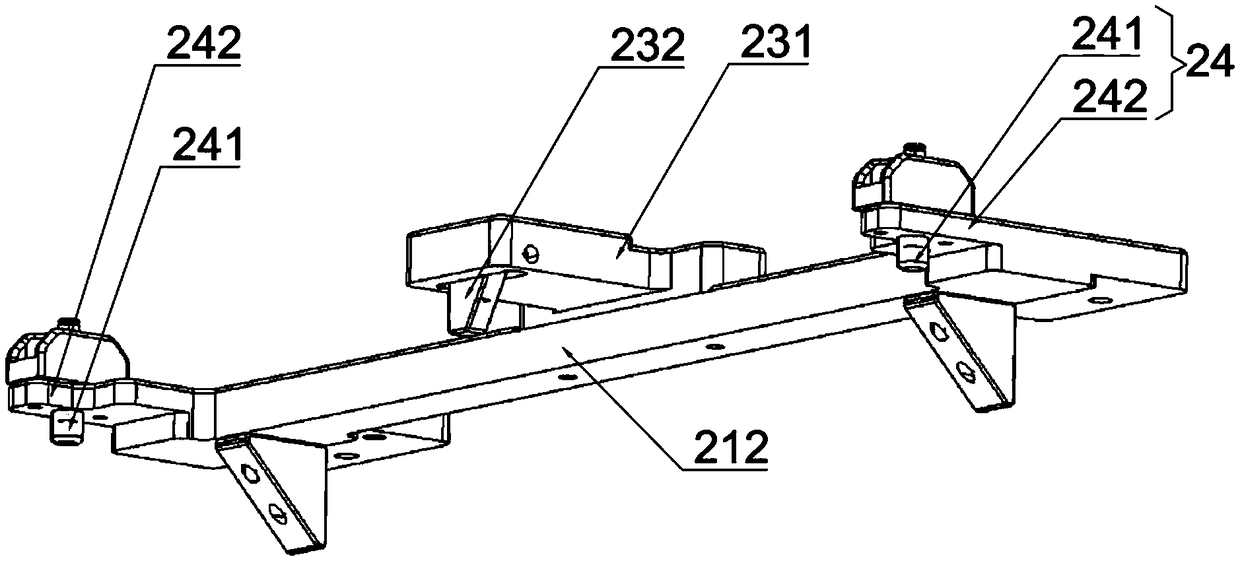

[0046] Positioning mechanism 2 among the present embodiment is symmetrical to conveying dire...

Embodiment 2

[0056] This embodiment provides a material conveying device, which includes two conveyor belts 1 arranged in parallel, and the upper surfaces of the conveyor belts 1 are in the same horizontal plane. A drive motor is arranged beside the conveyor belt 1 to drive the conveyor belt 1 to move towards the conveying direction. On both sides of the conveyor belt 1, for example, in the area where loading or unloading is required on the conveyor belt, multiple carrier positioning devices in Embodiment 1 are provided to temporarily position the carrier so that the workpiece on the carrier can be processed or moved up and down. material.

Embodiment 3

[0058] This embodiment provides a fully automatic production line, including several stations, each station is connected with the material conveying device in Embodiment 2, and the material conveying device is provided with a carrier for transporting workpieces to each station , each station is provided with at least one carrier positioning device in Embodiment 1, so as to facilitate the operation of the processing equipment on each station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com