Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Readily forced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

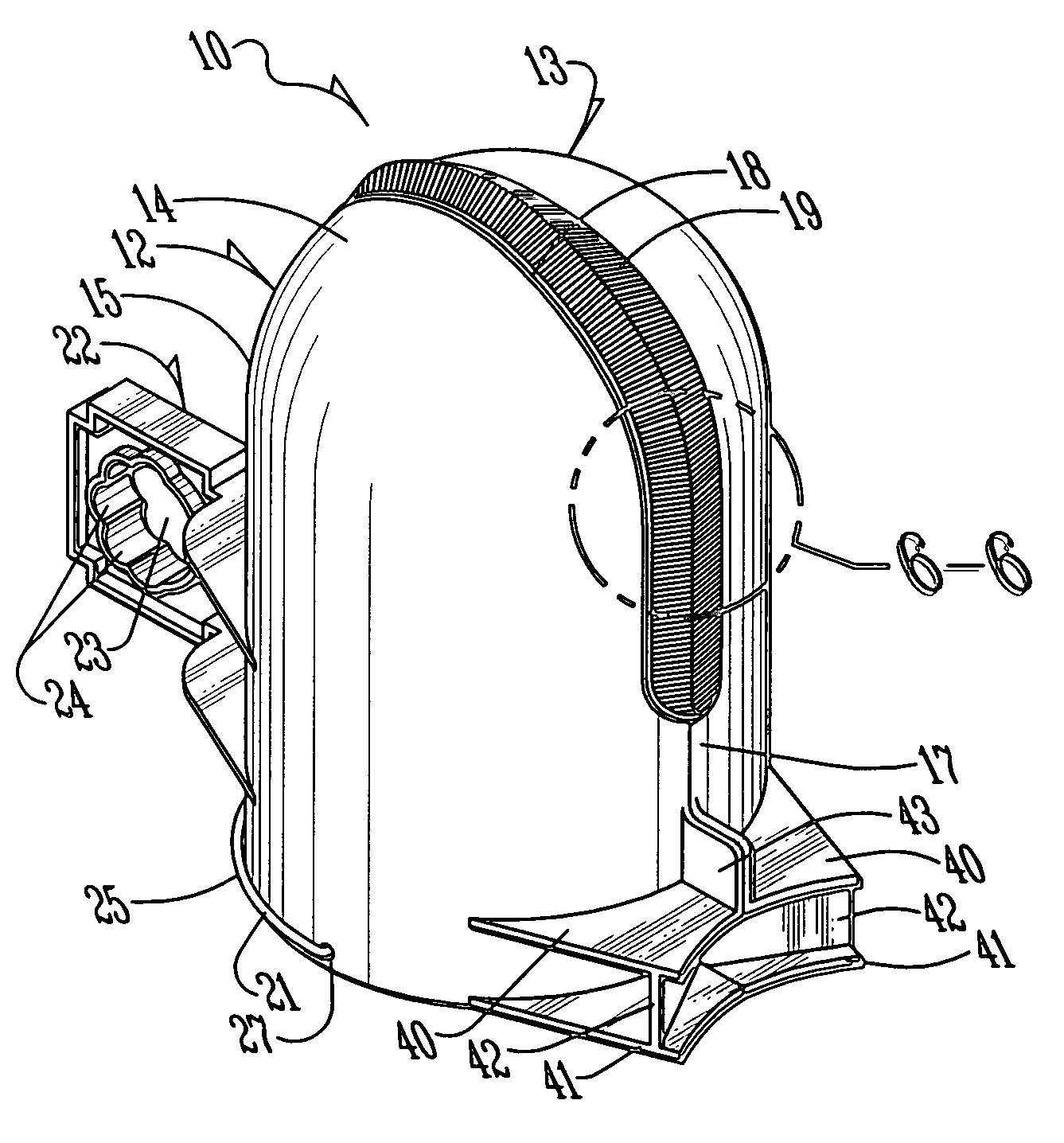

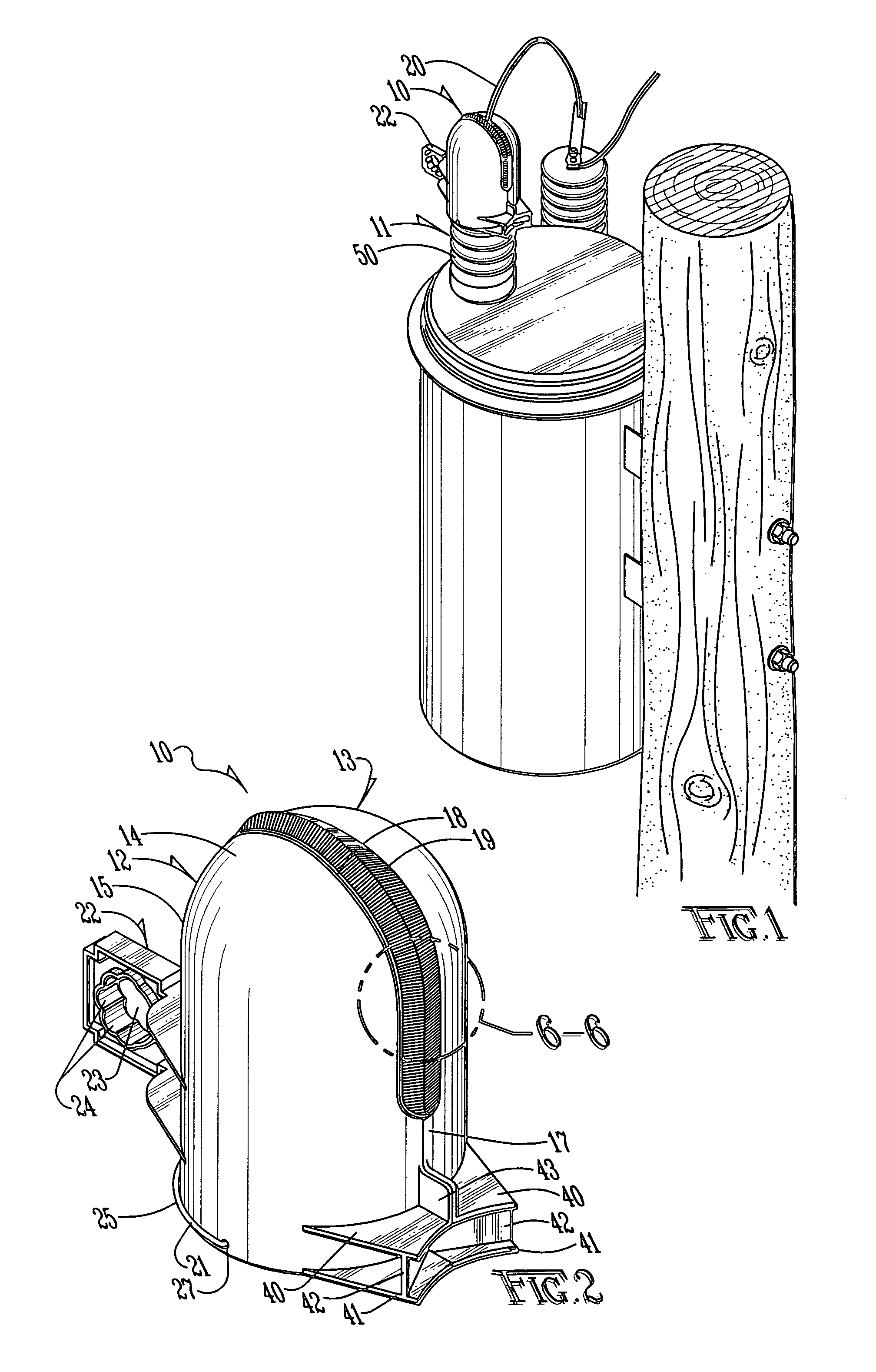

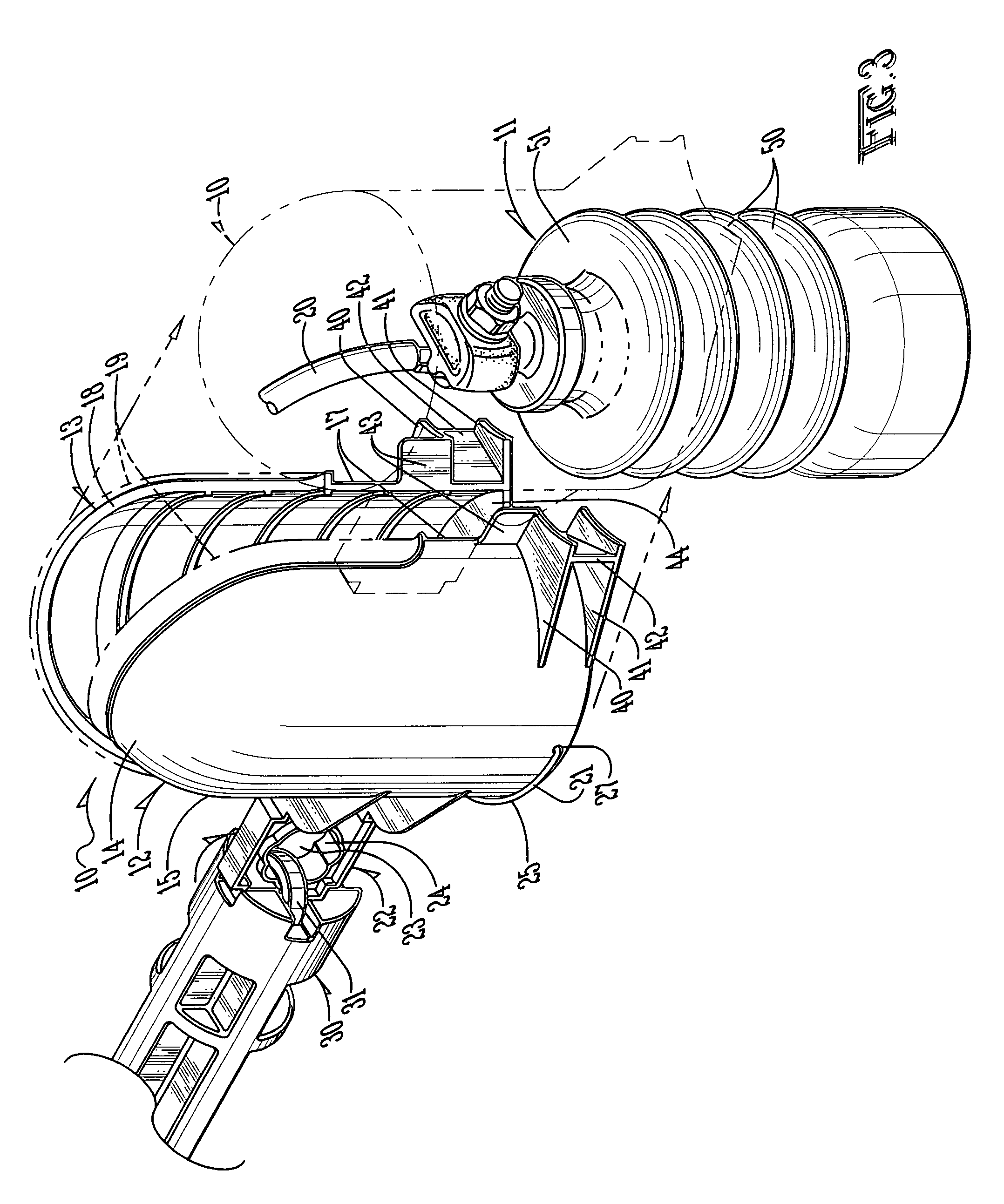

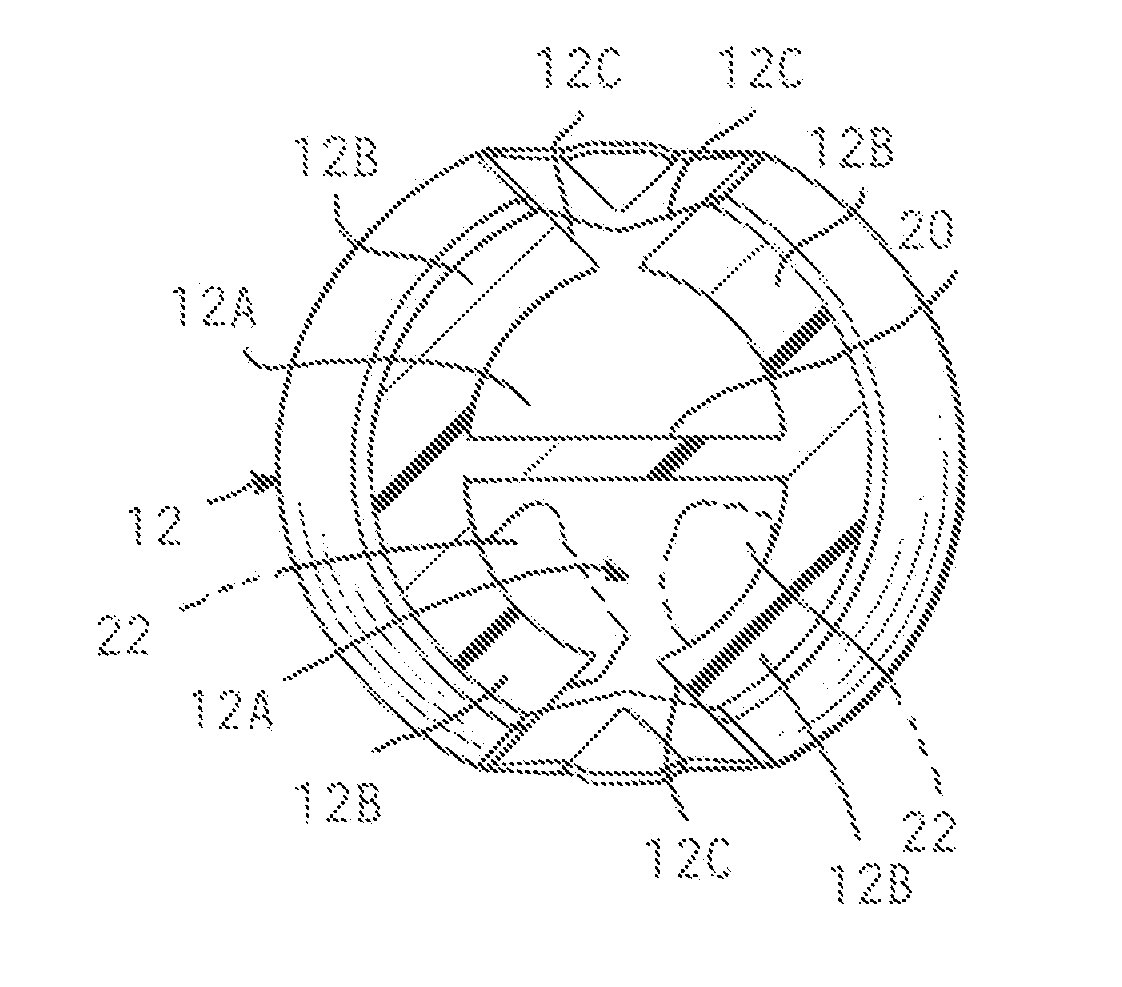

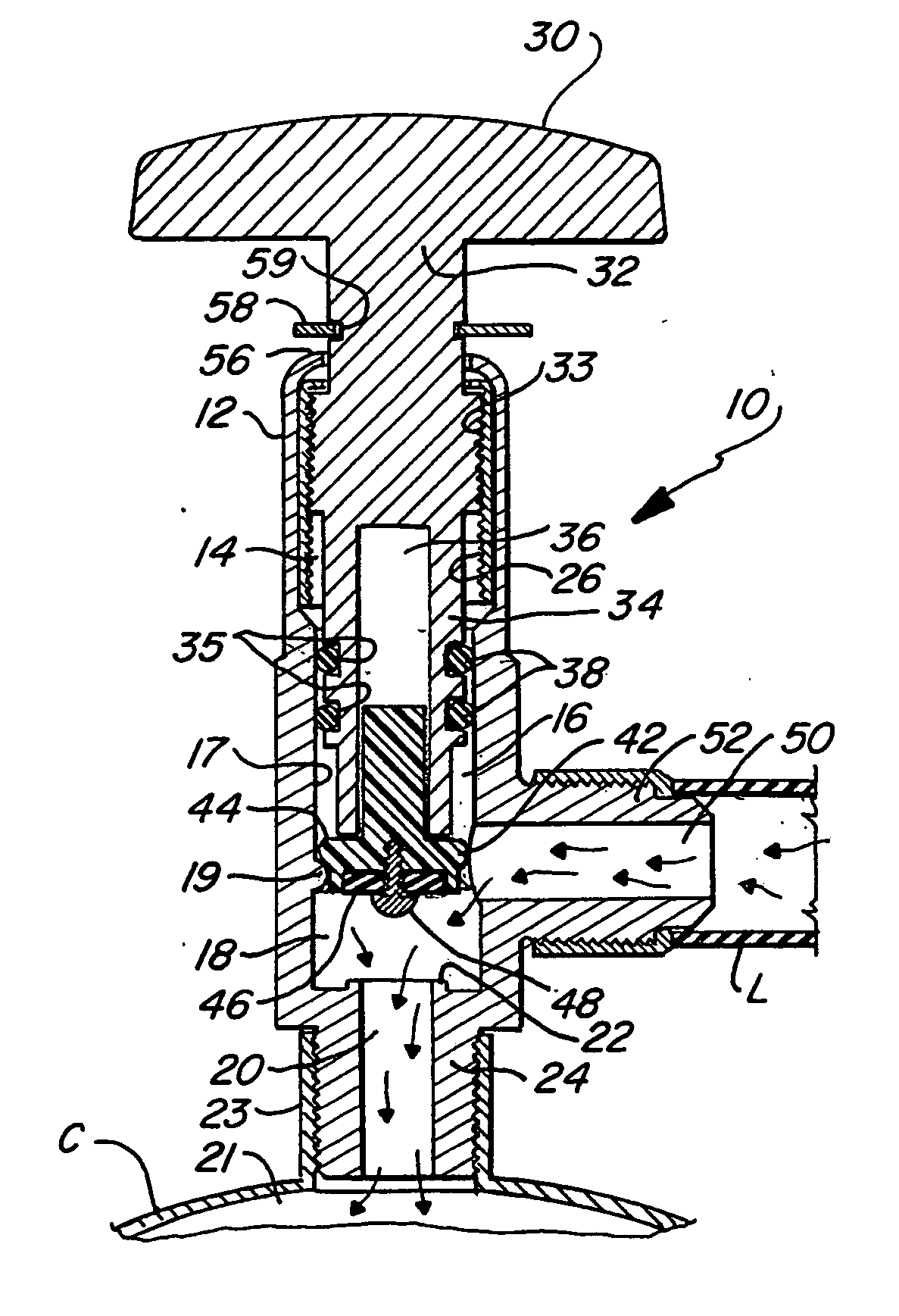

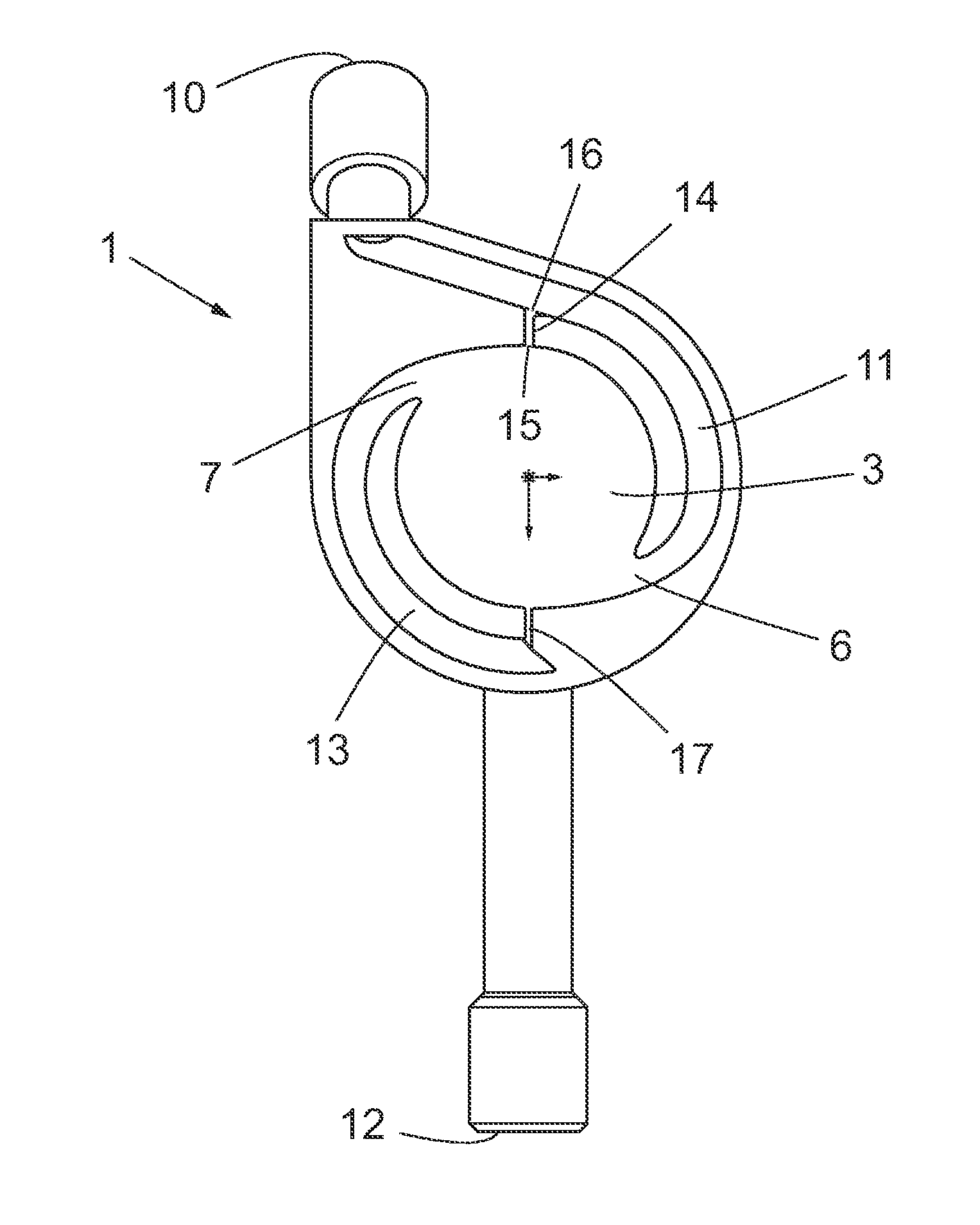

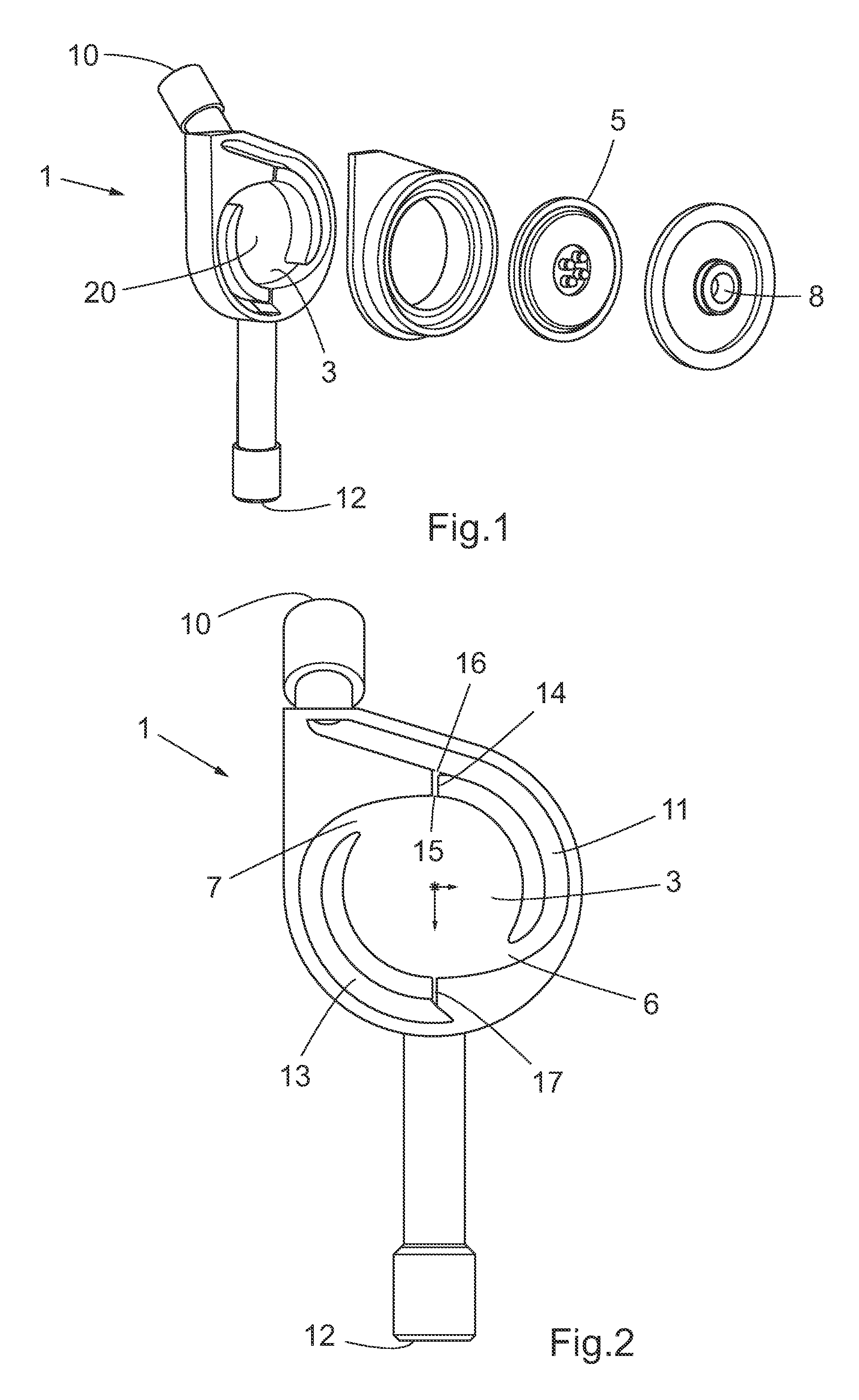

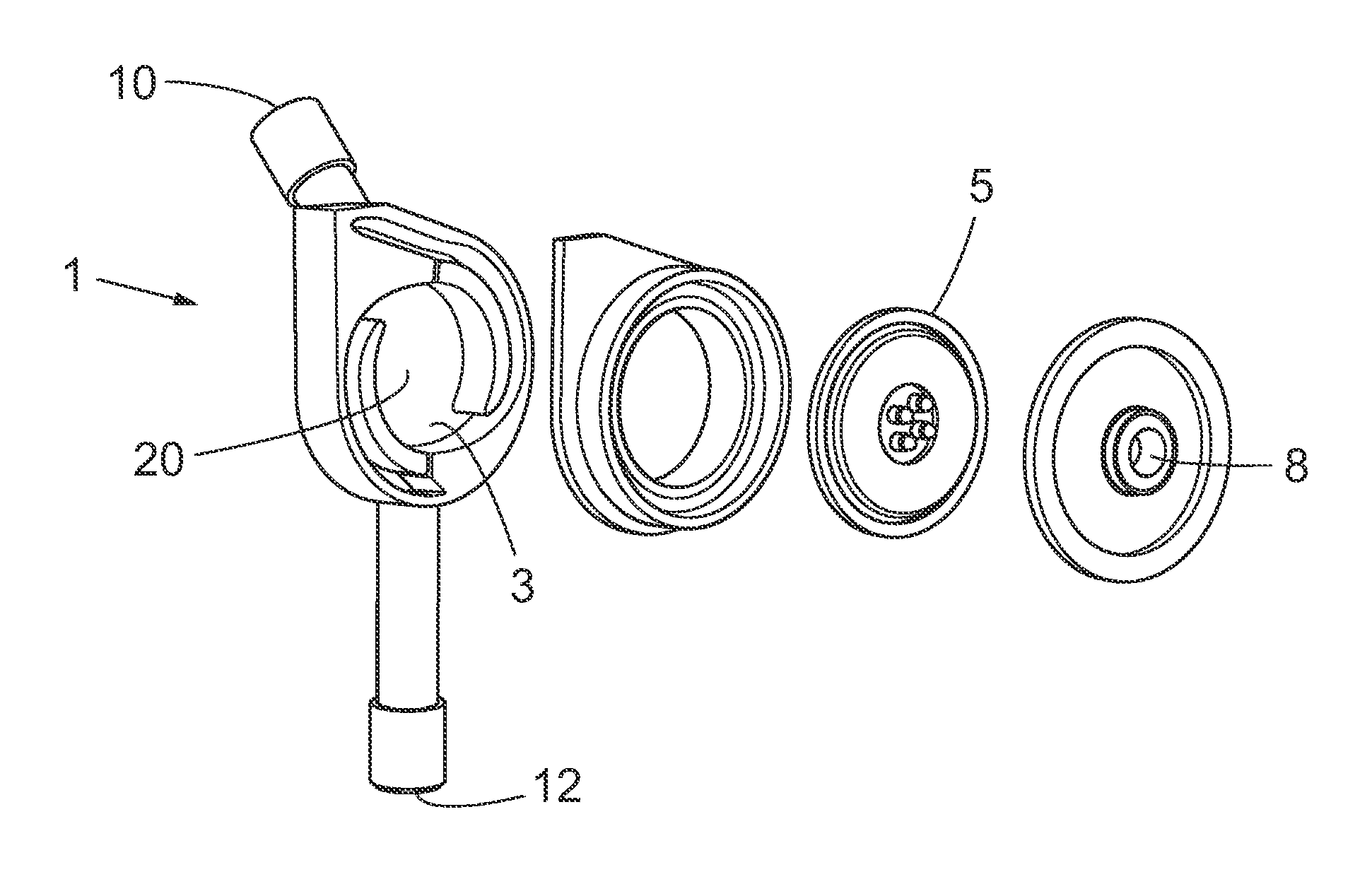

Insulator bushing wildlife guard

ActiveUS6995313B1Easy to grasp and manipulateEasy alignmentSuspension arrangements for electric cablesInsulatorsWildlifeElectrical conductor

An insulator bushing wildlife guard having features for easier alignment and installation of the guard on the bushing. The guard has two hinged body sections of insulating material. An outer edge of each body section is provided with a plurality of flexible fingers that allow conductors to pass through from the interior to the exterior of the enclosure when the two portions of the guard are engaged. In one embodiment, the guard is spring biased toward a closed position. A handle on the back has inner grooves to make it easier to grasp and manipulate the guard using a shotgun stick. On a lower front side of each portion of the guard, spaced-apart, curved, horizontal upper and lower flanges help align the guard with the topmost skirt of a bushing. Medial walls having a curved, sloped, concave or otherwise inwardly-directed configuration between the two flanges facilitate forcing the guard open by pushing it against the bushing. An external tab limiter, disposed above the upper flange, makes it difficult to install the guard over any part of the bushing other than the topmost skirt of the bushing. An alternative version of the guard has a releasable trigger, which is used to hold the two portions in an open position until the bushing or power line displaces the trigger and allows the biasing spring to close the two cover portions. The guard is provided with a handle for grasping by a manipulator tool. In one embodiment the handle is provided with inner grooves for grasping by a shotgun stick. In another embodiment, an adapter releasably engages the handle and provides means for attachment to a hotstick.

Owner:CENT MOLONEY

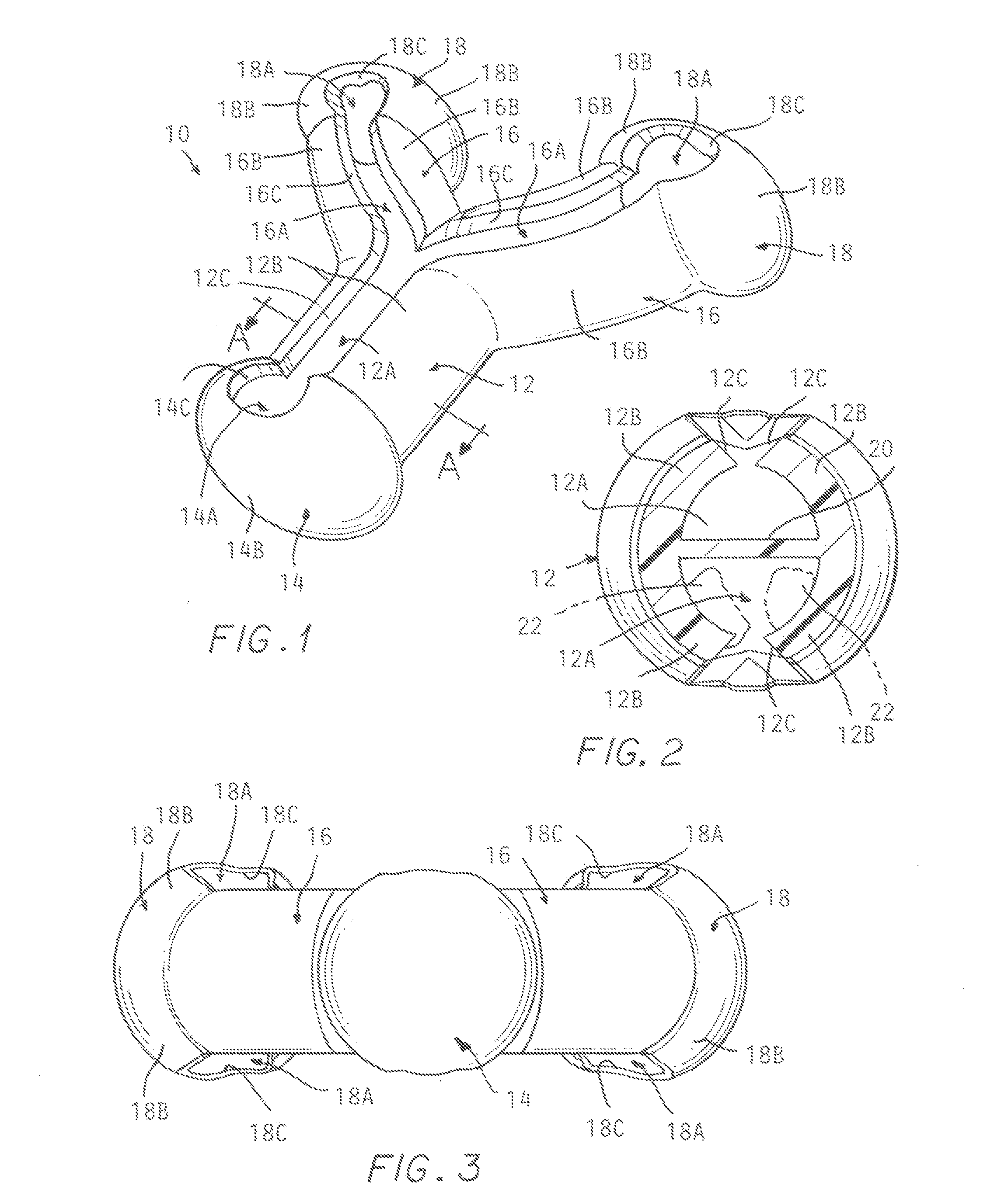

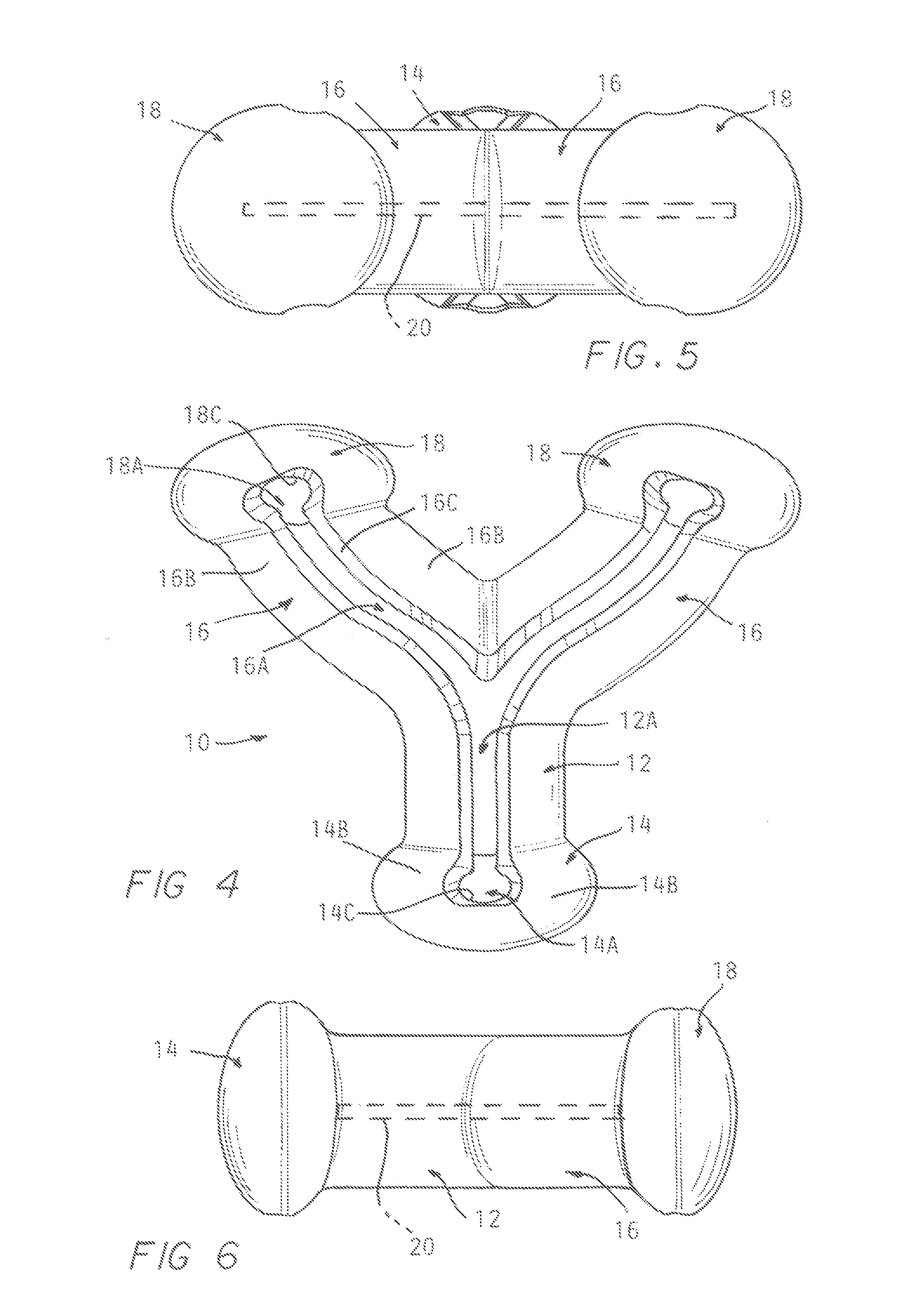

Pet Chew Toy

InactiveUS20140209038A1Effective cleaningReadily forcedOther apparatusTaming and training devicesInternal cavitySmall fragment

A pet chew toy has a body which is formed from an elastic plastic / elastomer and has an opening extending into an associated internal cavity in the body into which treats larger than the opening can be inserted due to the elasticity of the material and returned therein due to the relaxed size of the opening. Chewing by the pet fragments the treats and allows the smaller fragments to fall out through the opening. The opening can be slots, rounded holes, or other openings to vary the technique needed to extract the treats from the toy.

Owner:SIMON DAVID F

Protective hoods and neck seals for use therein

InactiveUS6892725B2Improve protectionReadily forcedChemical protectionHeat protectionPolyesterElastomer

A neck seal for use in a protective hood includes an inner section including a passage for donning. The inner section is fabricated from an elastomeric material to form a seal around a neck of a user. The neck seal also includes an outer section adhered to the inner section. The outer section is fabricated from a material heat sealable to a hood covering material. In one embodiment, the elastomeric material of the inner section is a latex material. The outer section can, for example, be fabricated from a thermoplastic material. In one embodiment the thermoplastic material is a polyurethane such as a polyester-based polyurethane.

Owner:MINE SAFETY APPLIANCES CO

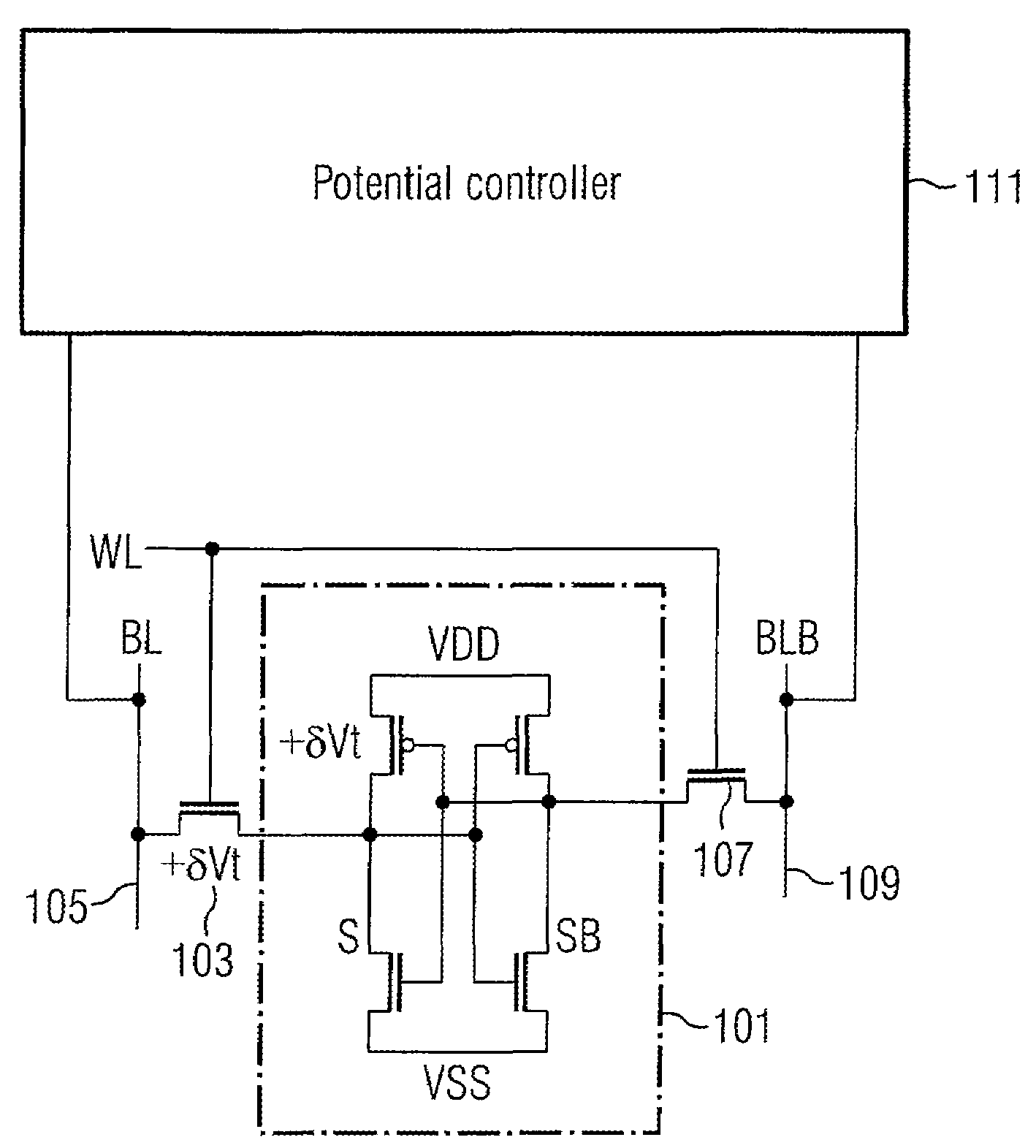

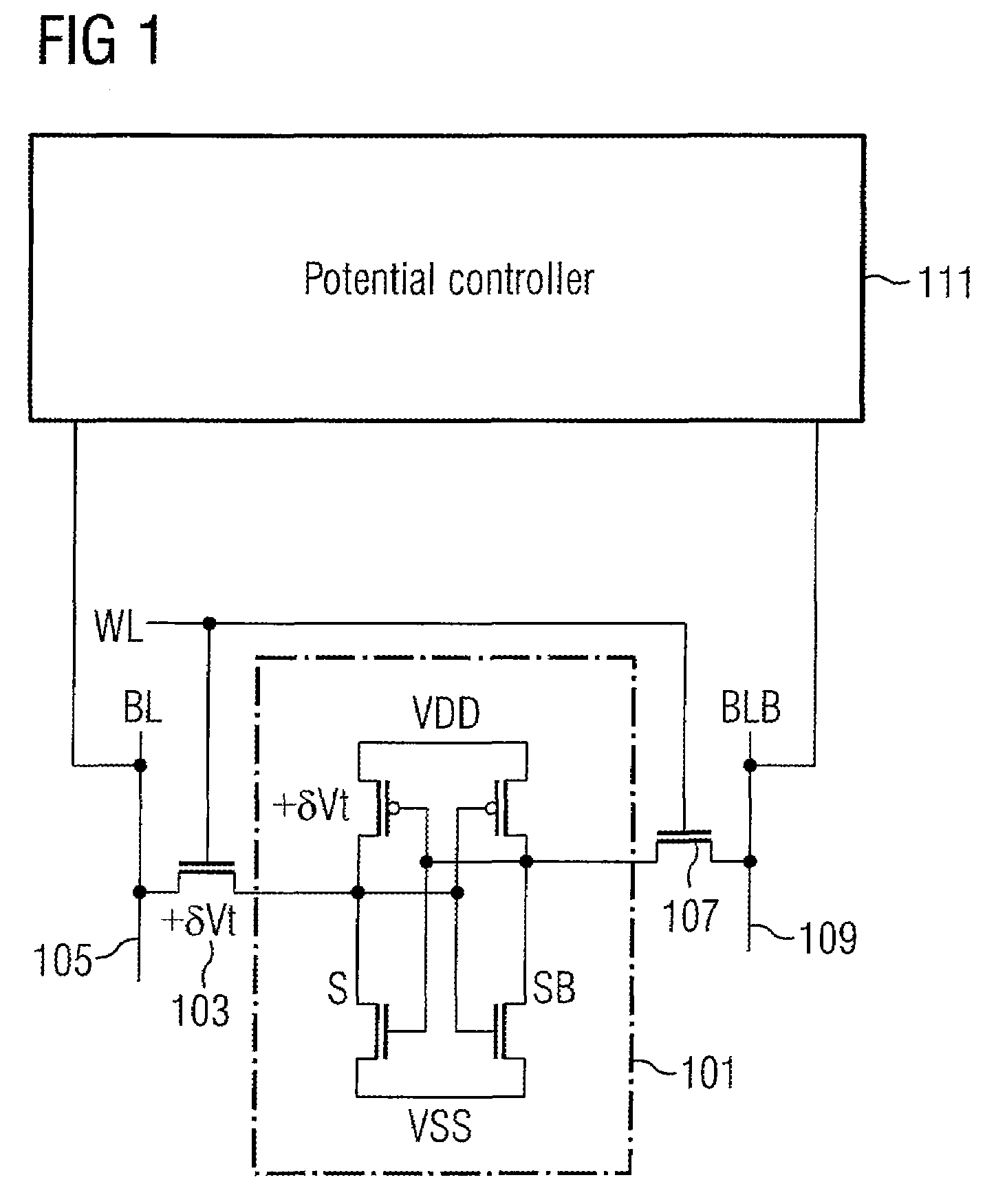

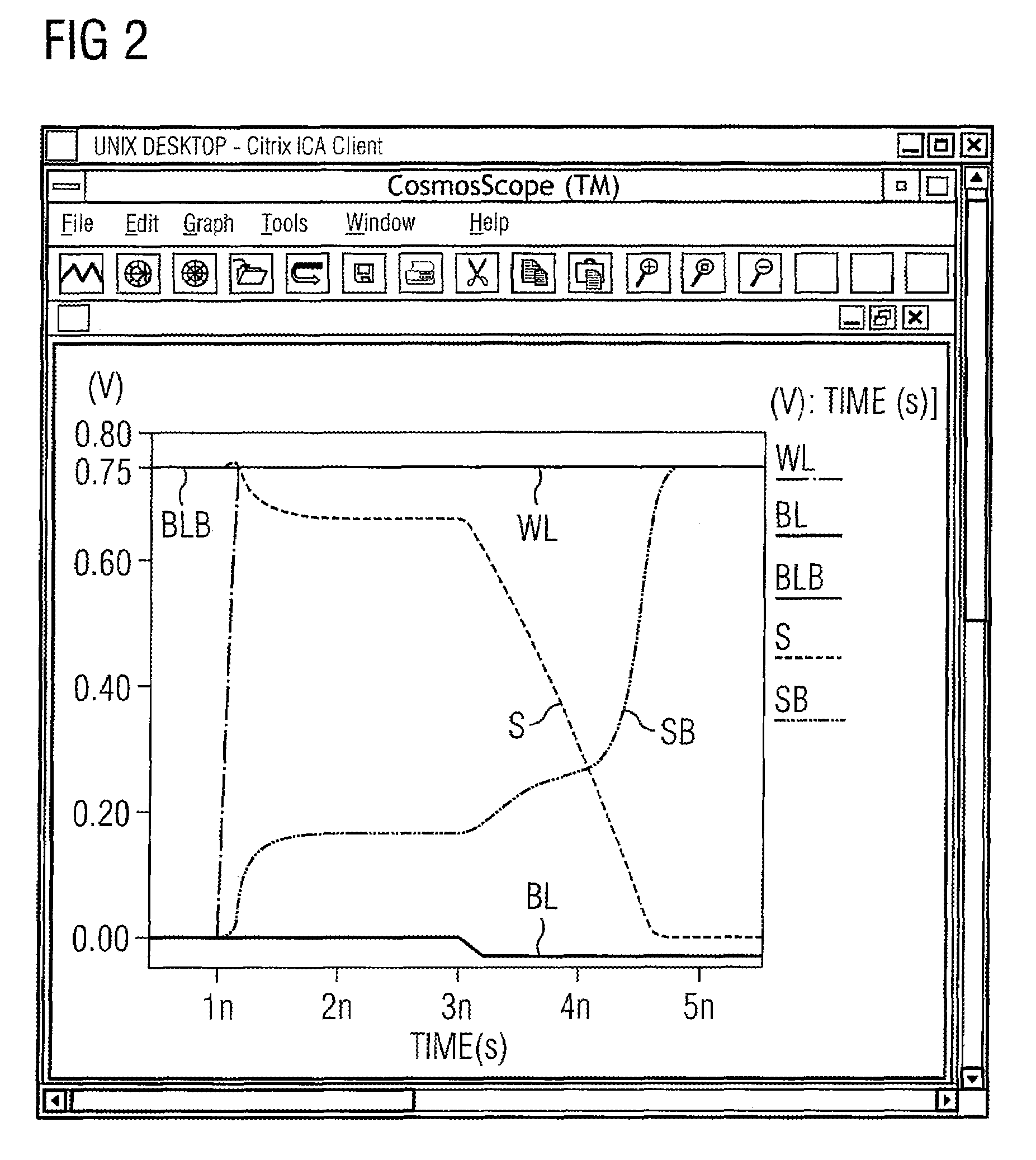

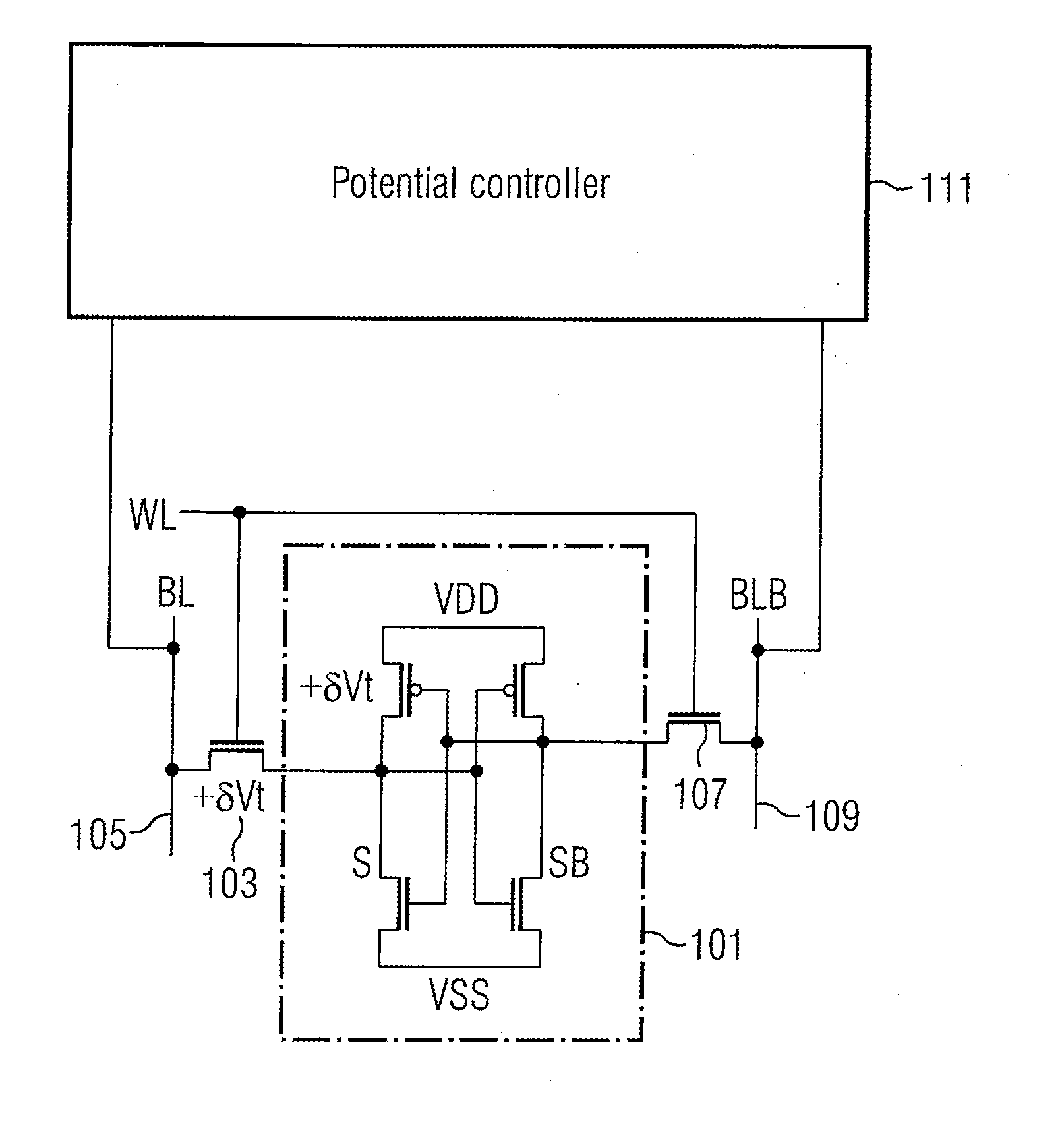

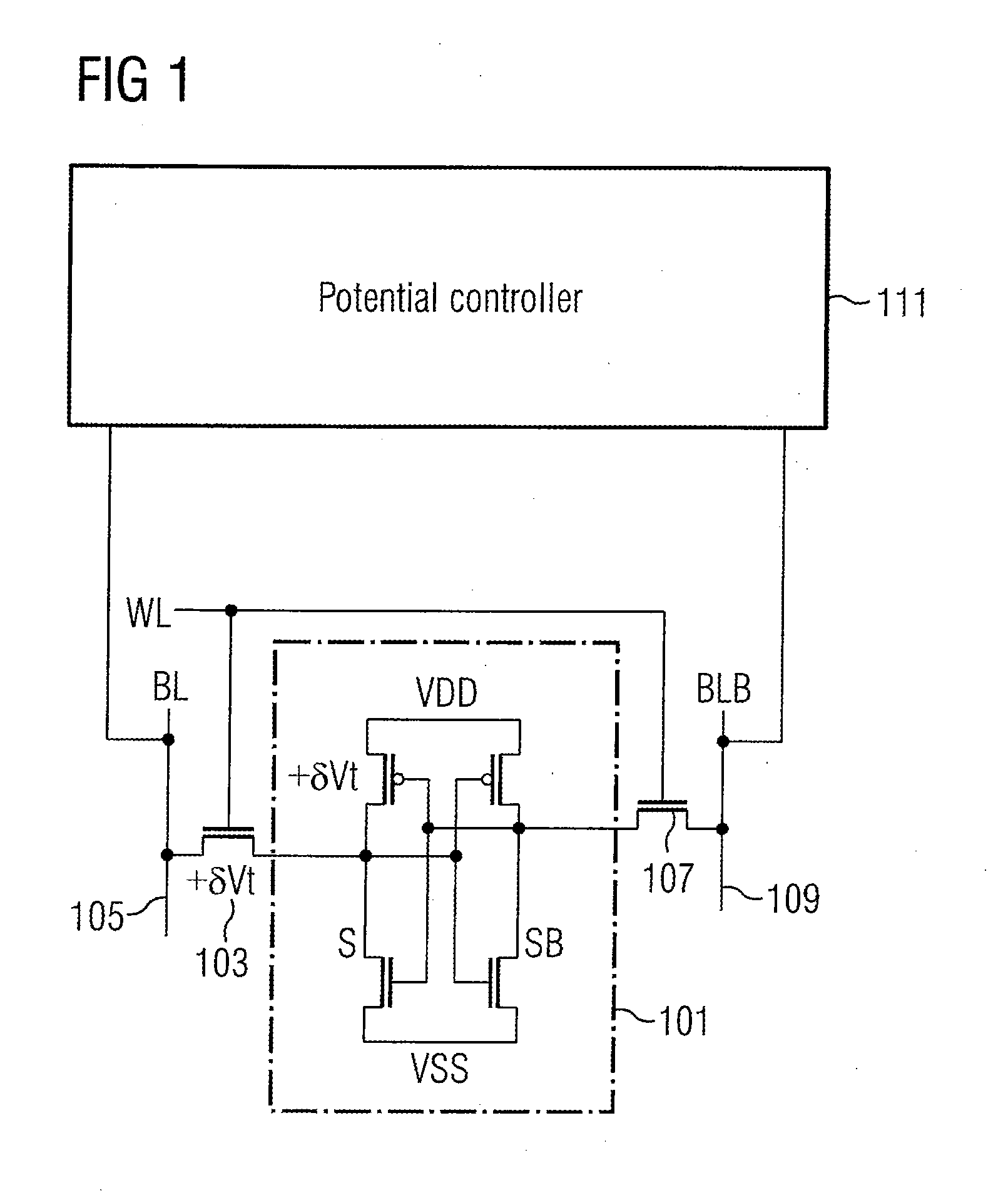

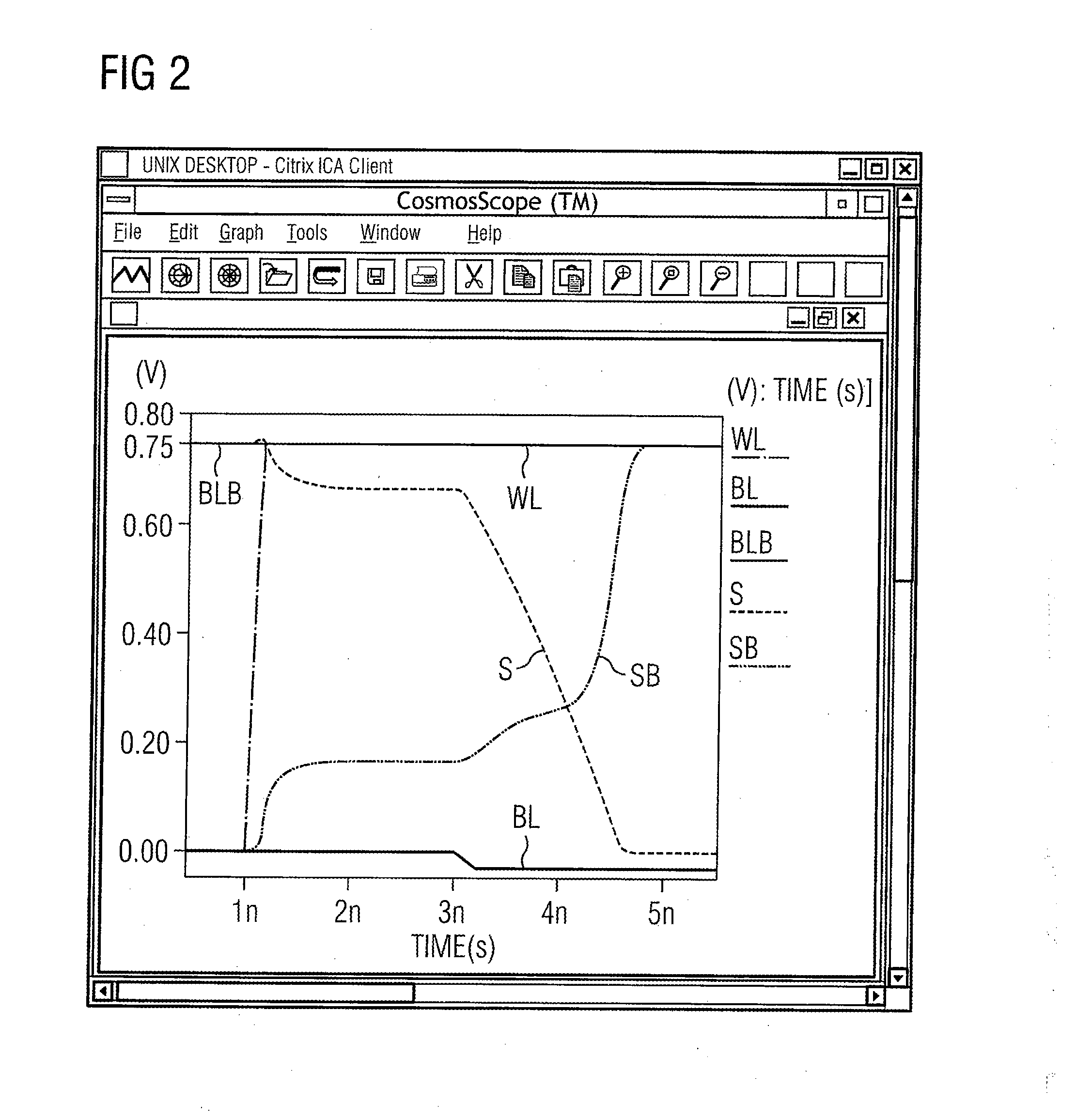

Memory device with improved writing capabilities

ActiveUS7486540B2Improve write reliabilityImprove reliabilityDigital storageBit lineComputer architecture

Method and memory device for reliably writing an information value to a memory element of the memory device. A first information value is represented by a first potential and a second information value is represented by a second potential. A bit line is provided for writing either the first information value or the second information value to the memory element. A potential controller is coupled to the bit line, where the potential controller is configured to apply a third potential to the bit line, which is less than the first potential when writing the first information value to the memory element.

Owner:INFINEON TECH AG

Memory device with improved writing capabilities

Method and memory device for reliably writing an information value to a memory element of the memory device. A first information value is represented by a first potential and a second information value is represented by a second potential. A bit line is provided for writing either the first information value or the second information value to the memory element. A potential controller is coupled to the bit line, where the potential controller is configured to apply a third potential to the bit line, which is less than the first potential when writing the first information value to the memory element.

Owner:INFINEON TECH AG

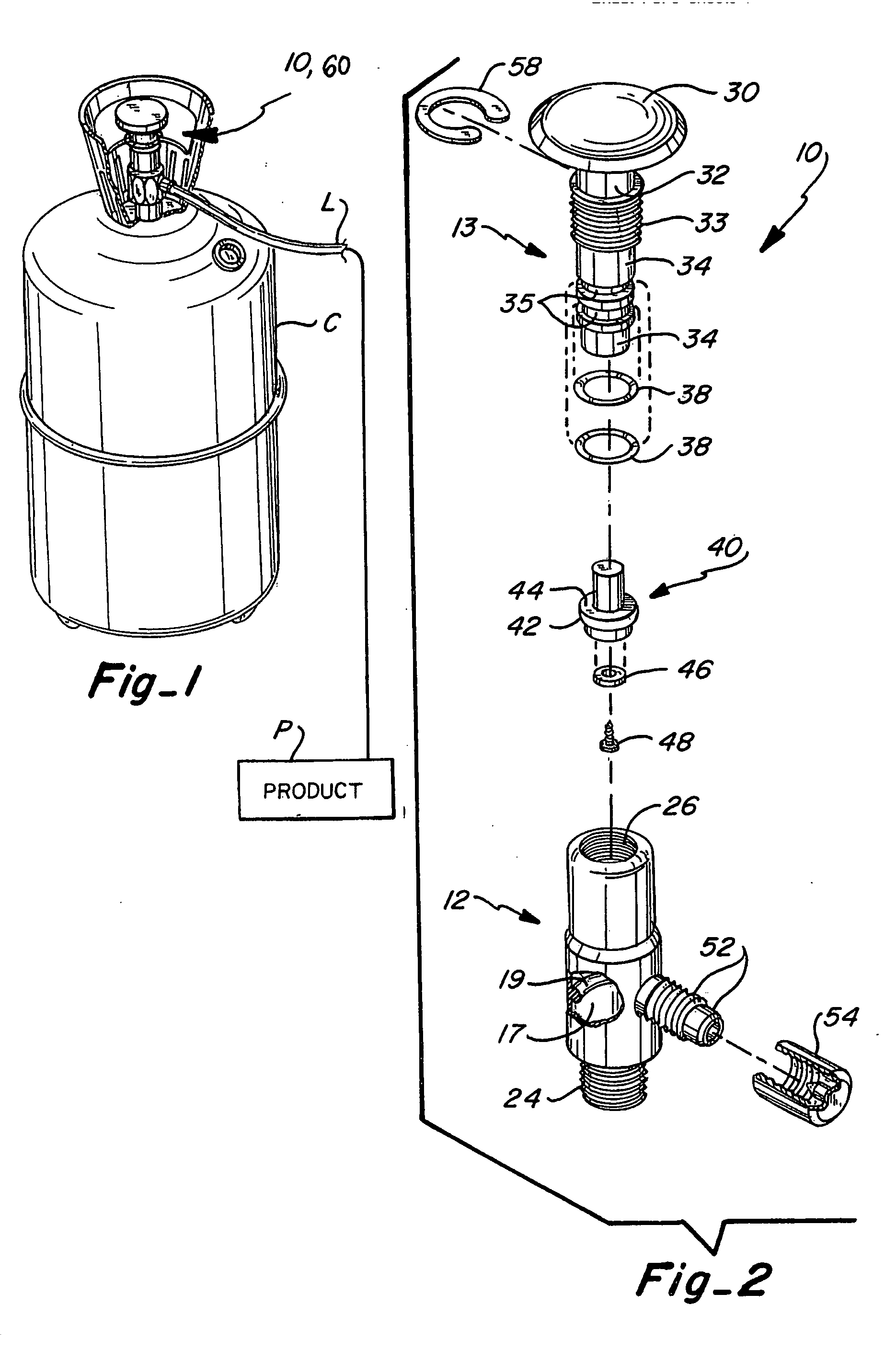

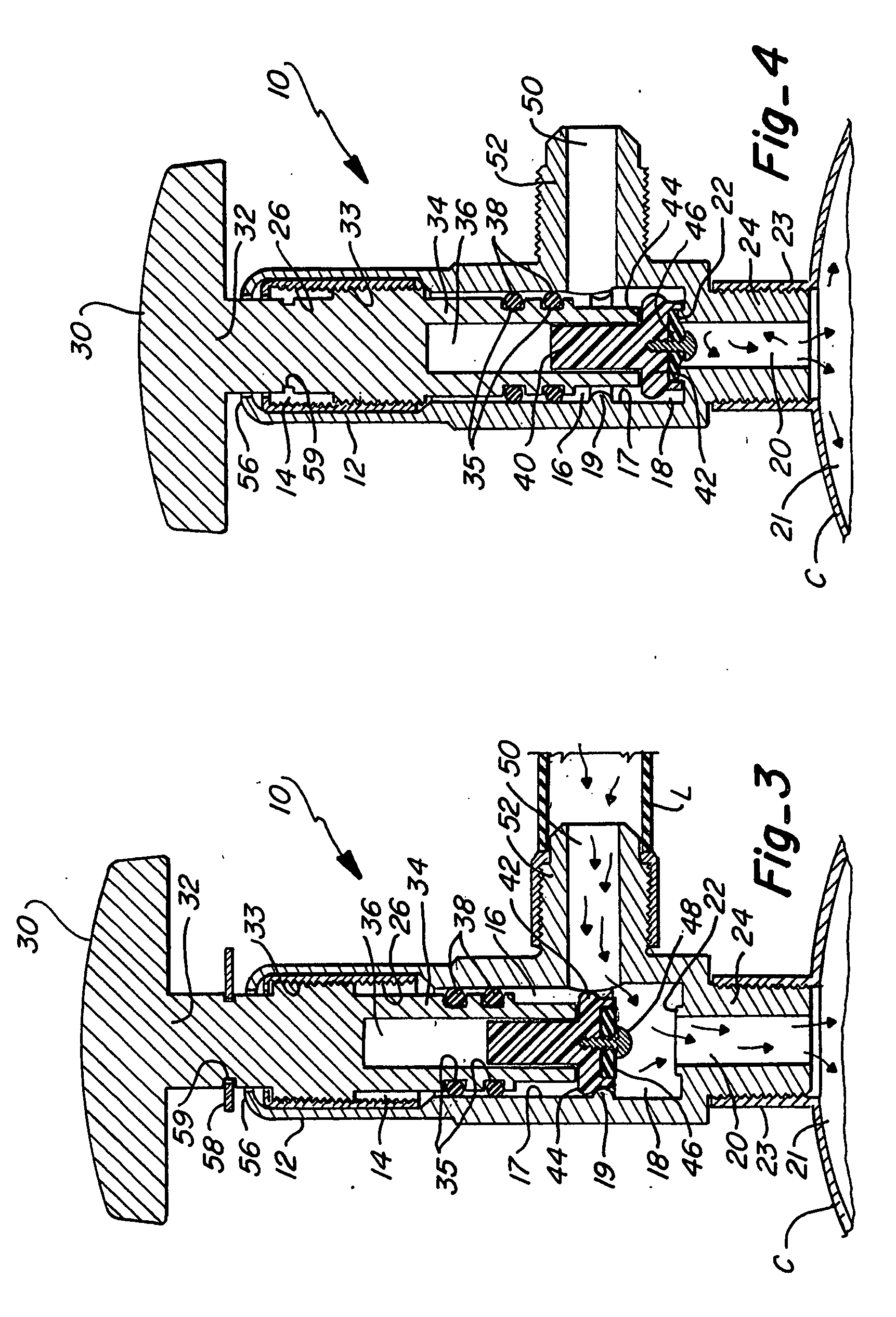

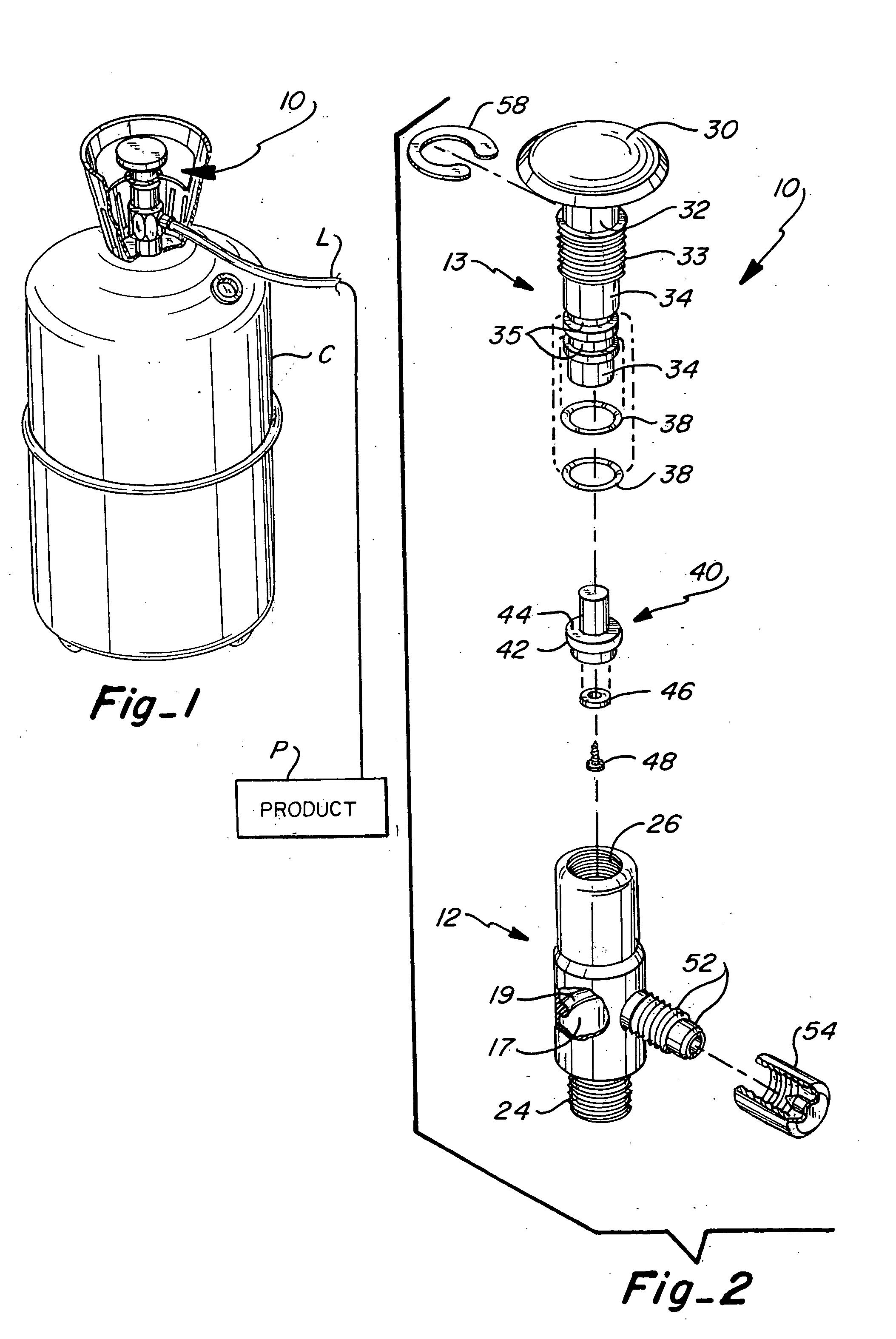

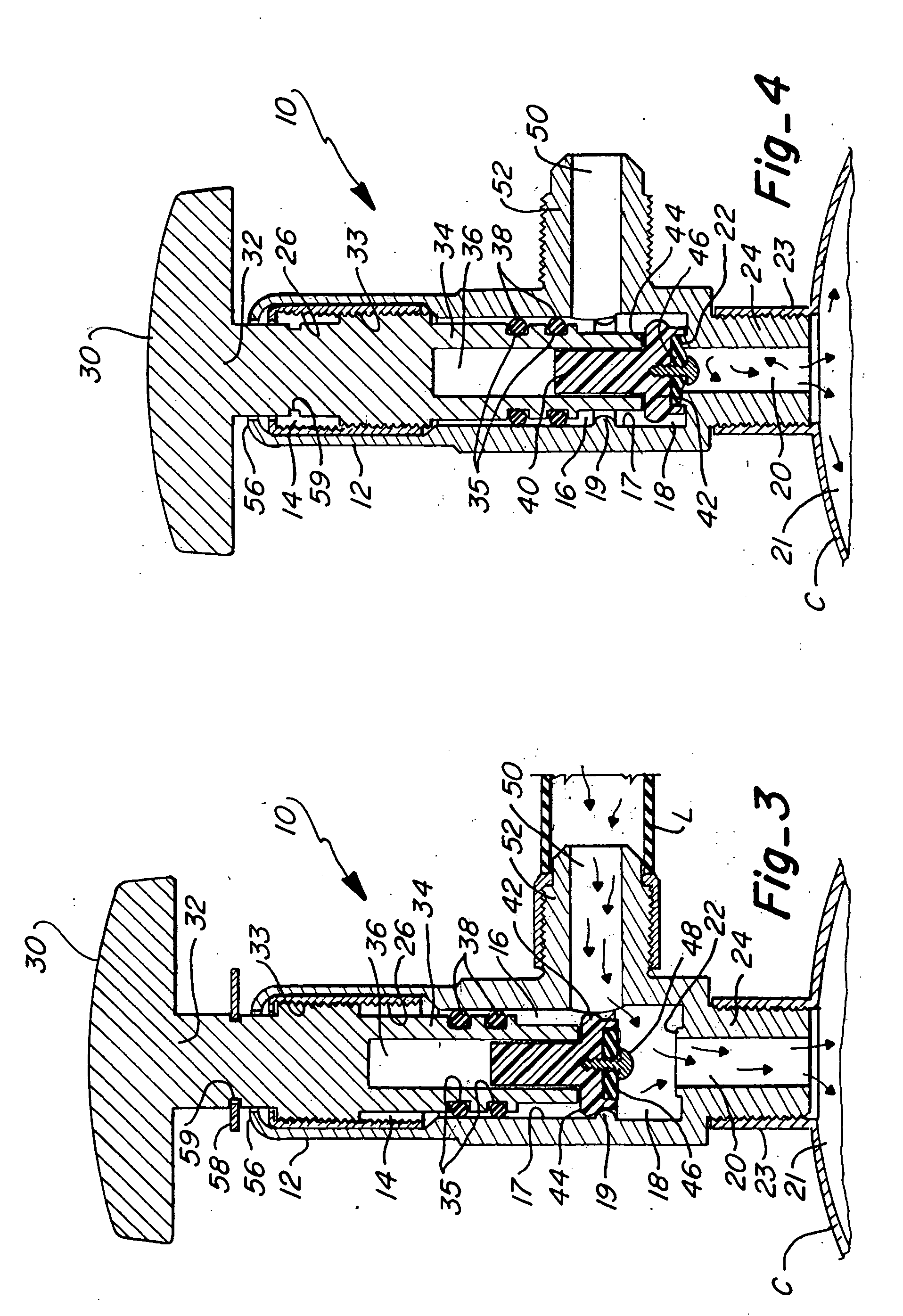

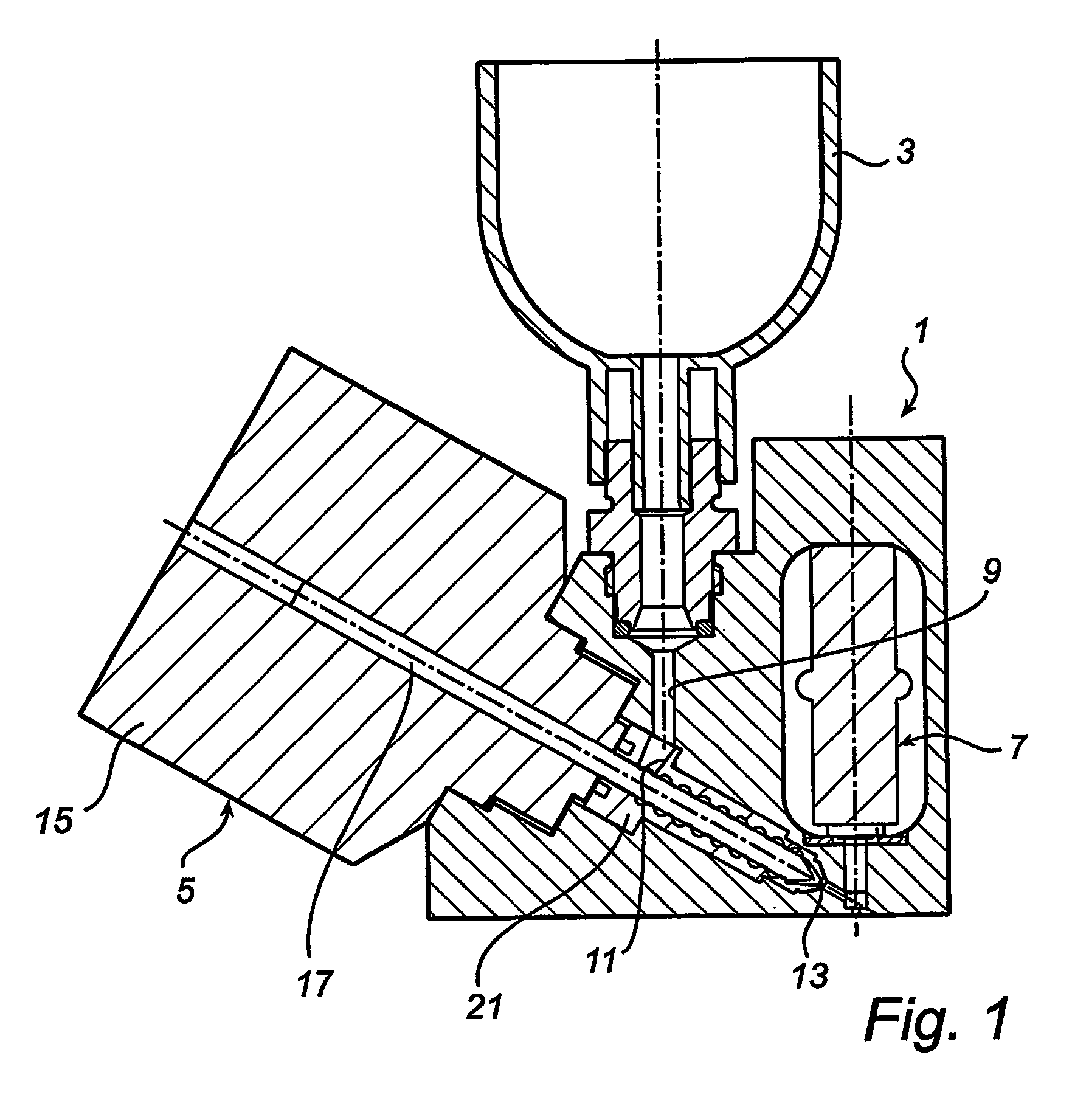

Non-refillable valve

InactiveUS20060081804A1The overall structure is simple and reliableEasy dischargePlug valvesOperating means/releasing devices for valvesVALVE PORTValve seat

A non-refillable valve is provided that allows for an initial filling of a container, but prevents subsequent refilling of the container. In one embodiment, the valve includes a valve core having a retaining means for maintaining the valve core in an open or non-sealing position to allow flow through the valve and filling of the container. The valve core may then be advanced to seal the container, and subsequently selectively operated to discharge the container as desired. Further refilling of the container is prevented by the force of fluid reentering the valve which forces the valve core to its seated engagement with the valve seat.

Owner:DISCOUNT REFRIGERANTS

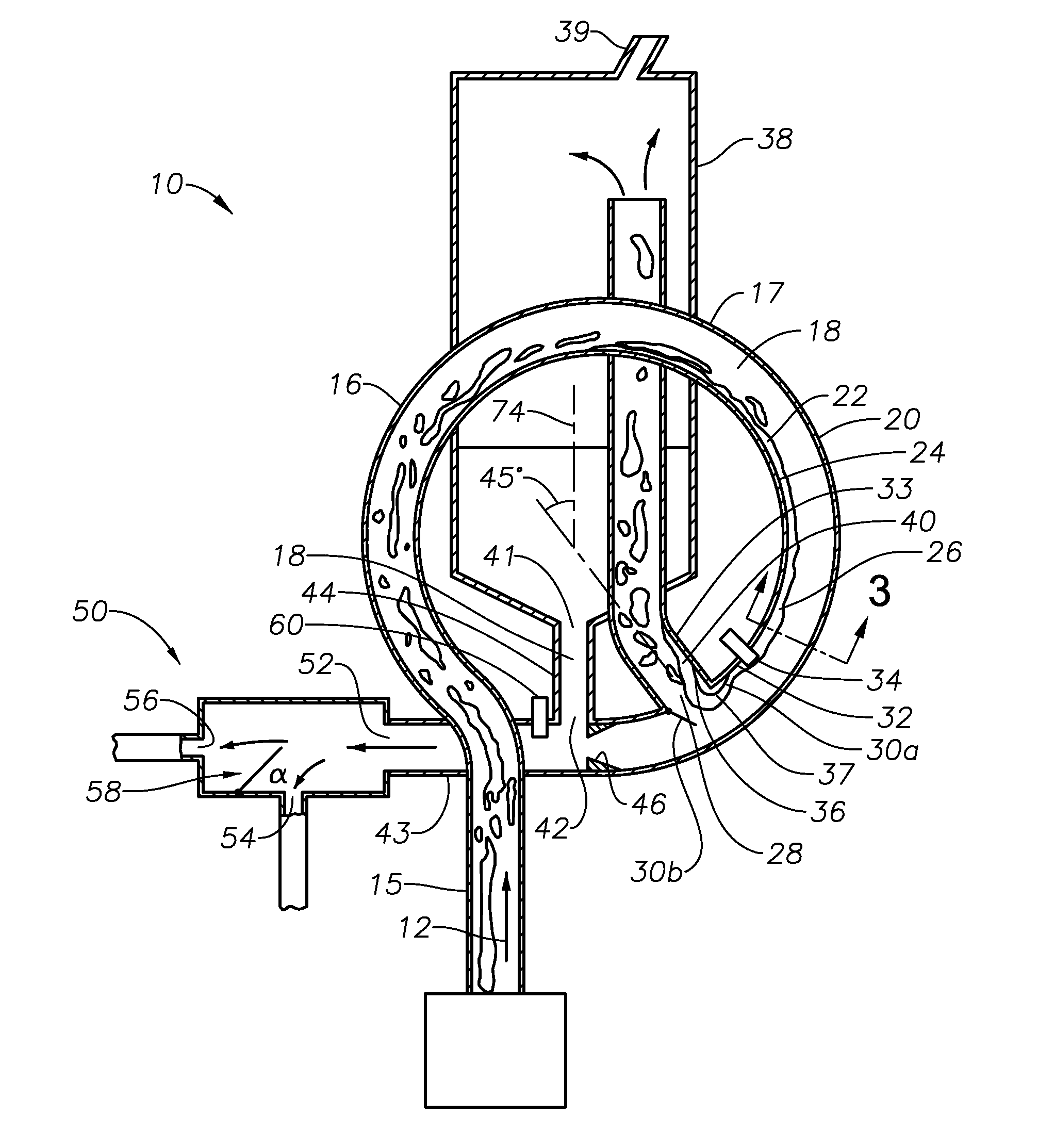

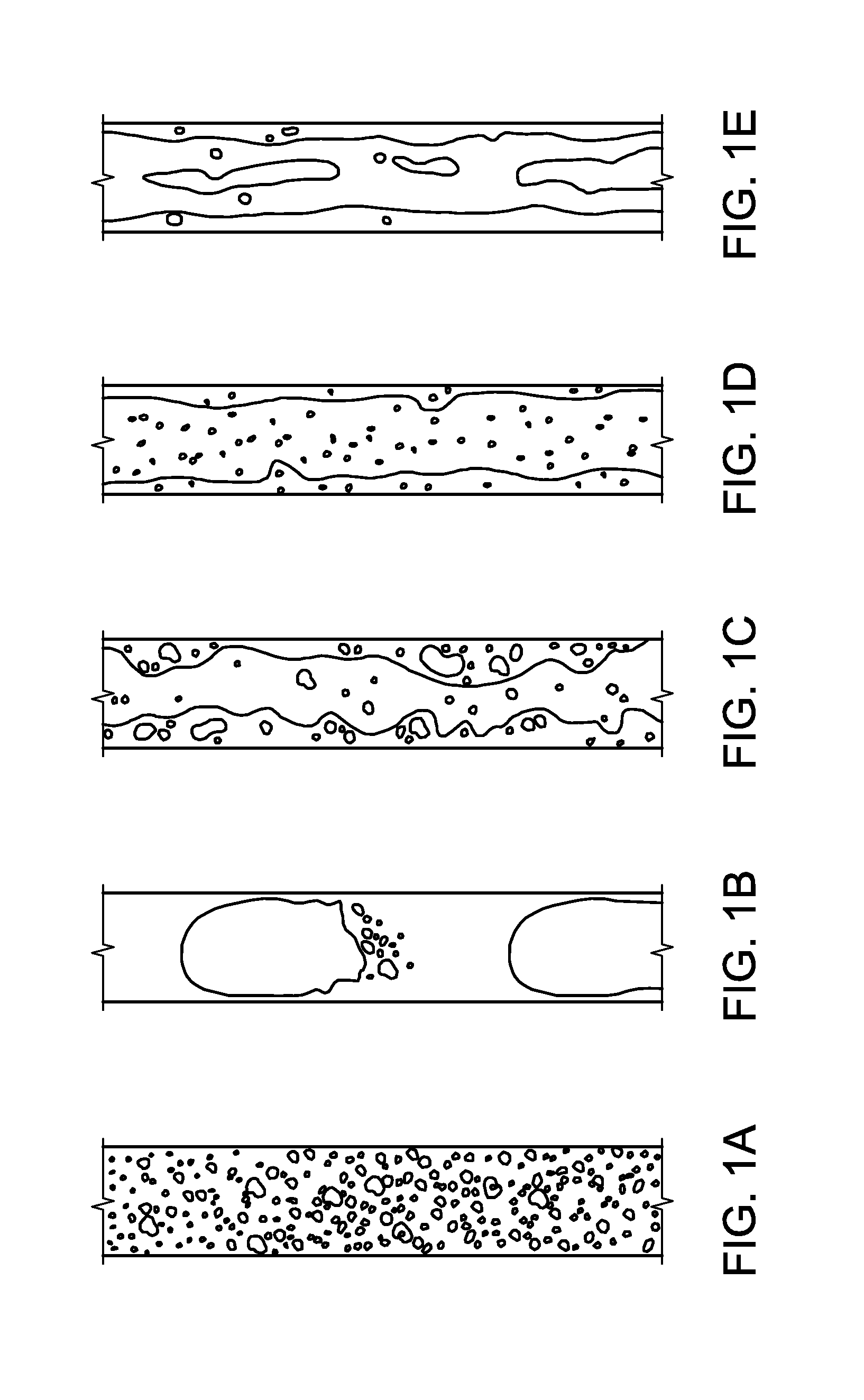

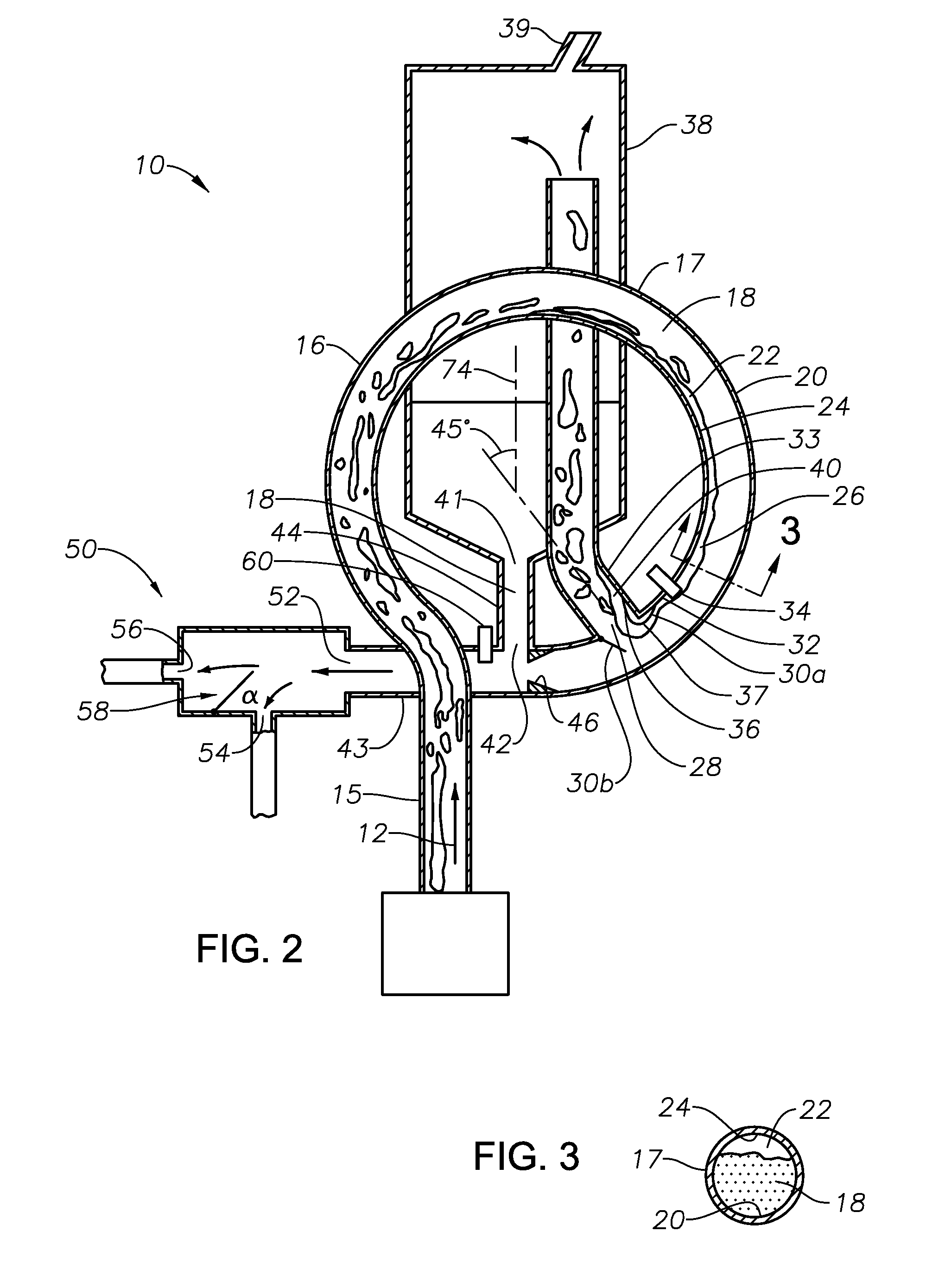

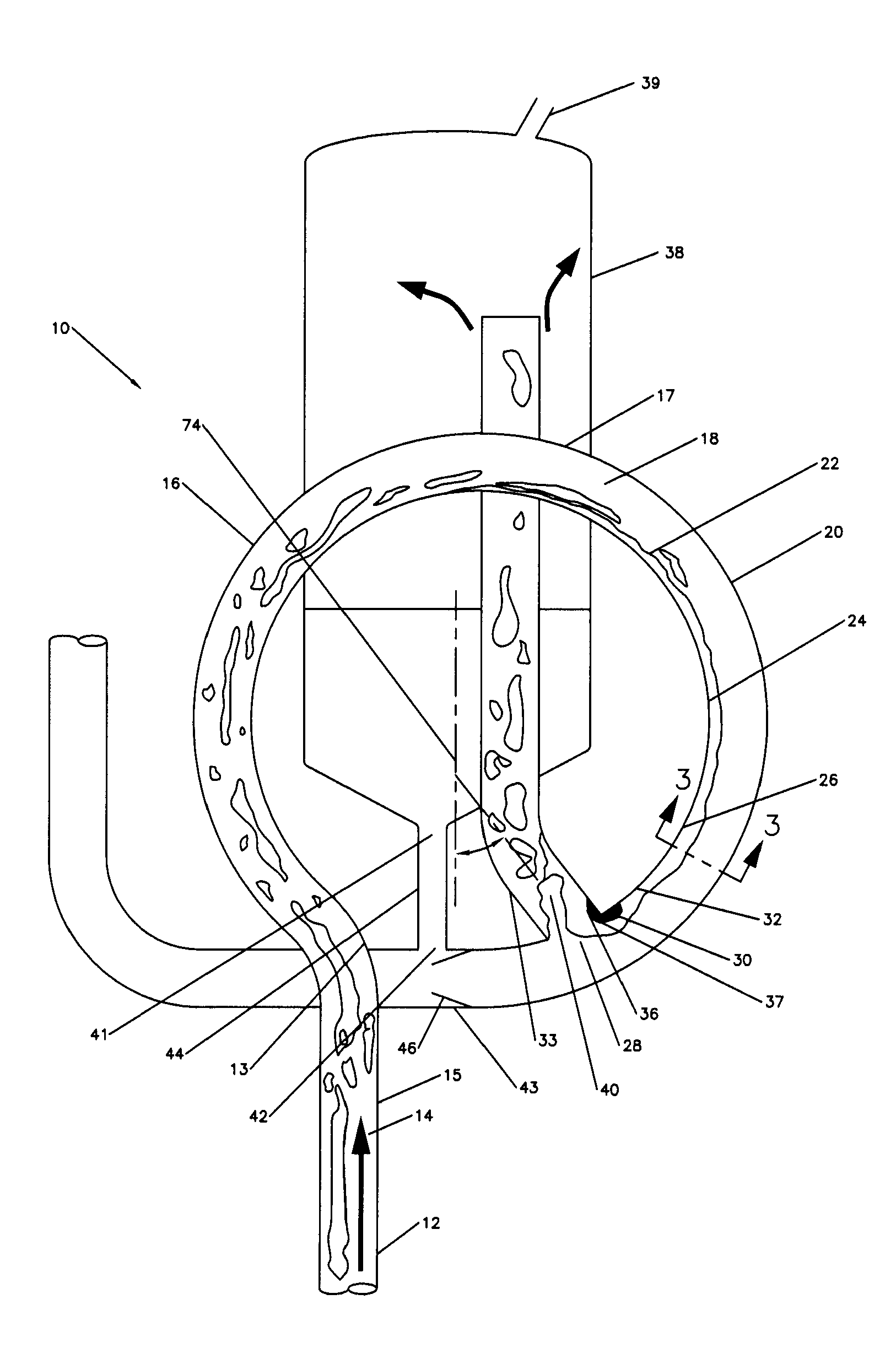

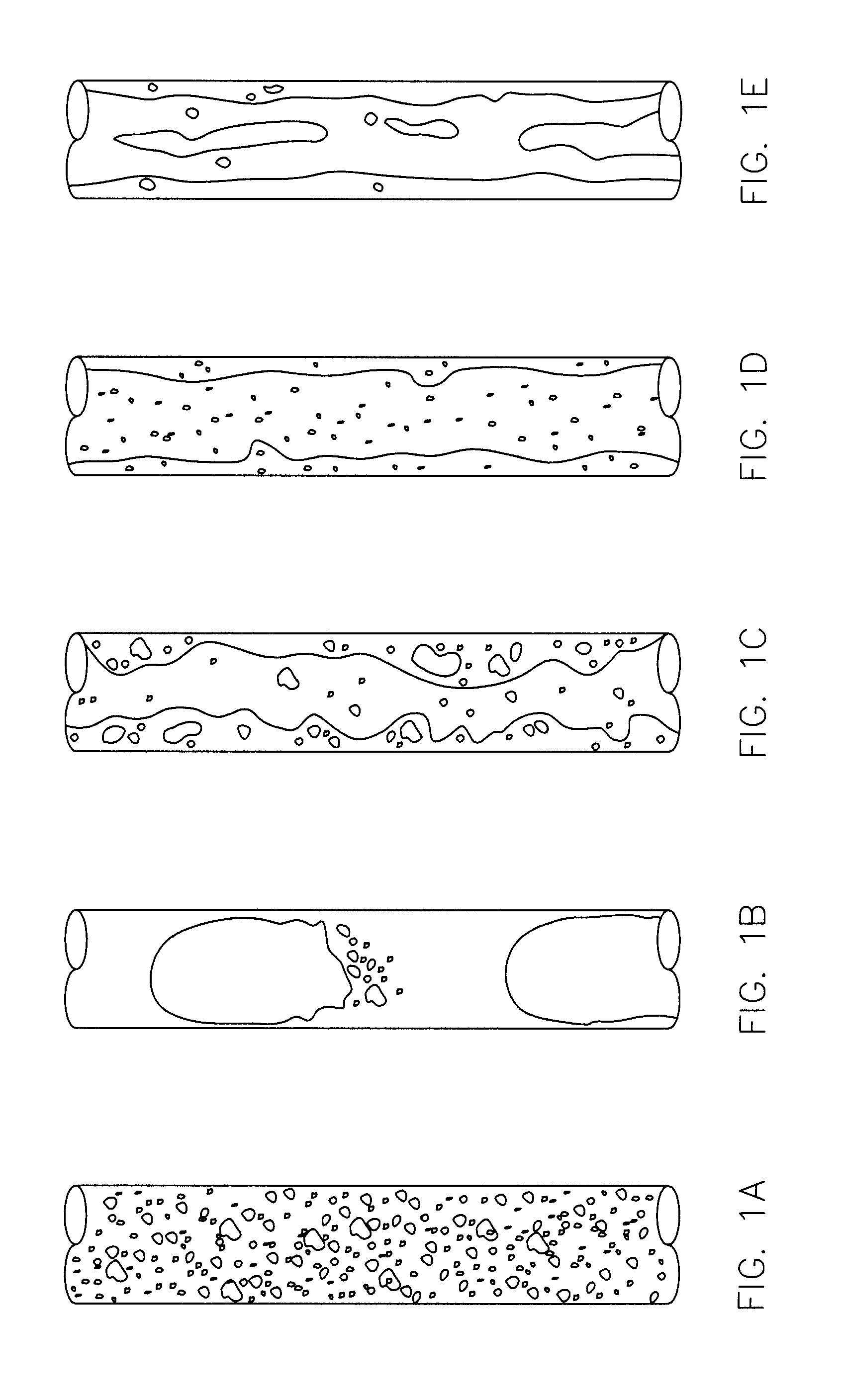

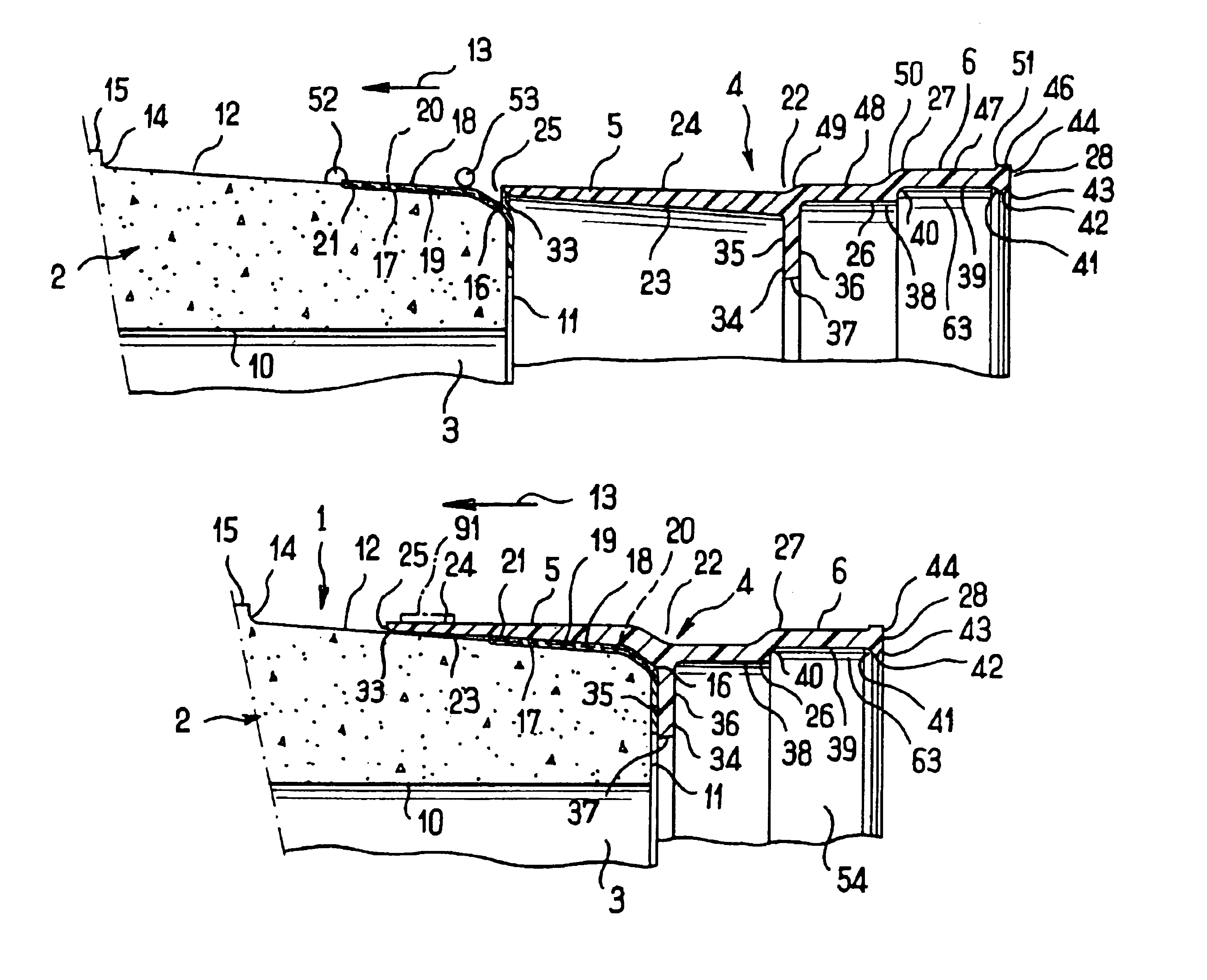

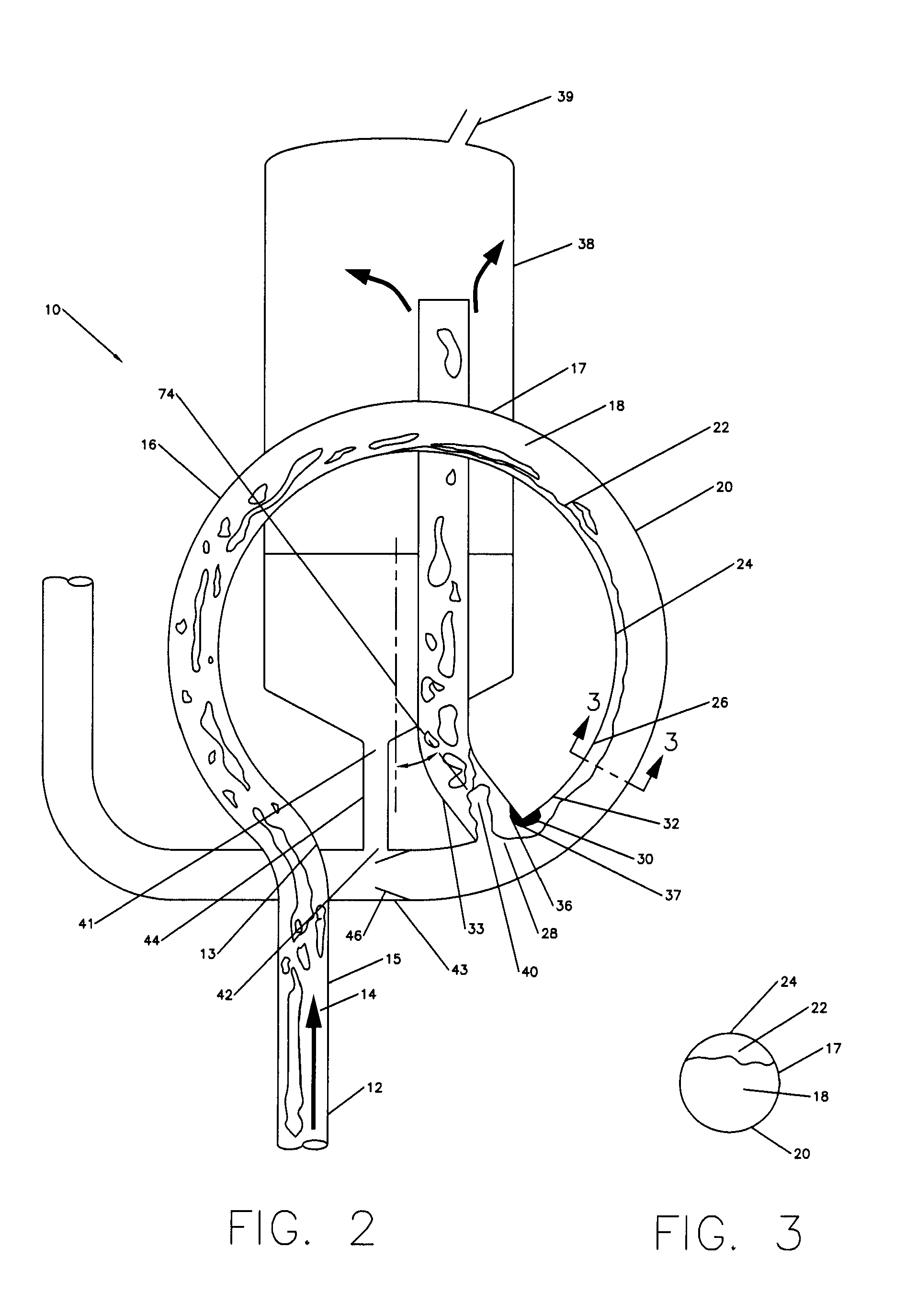

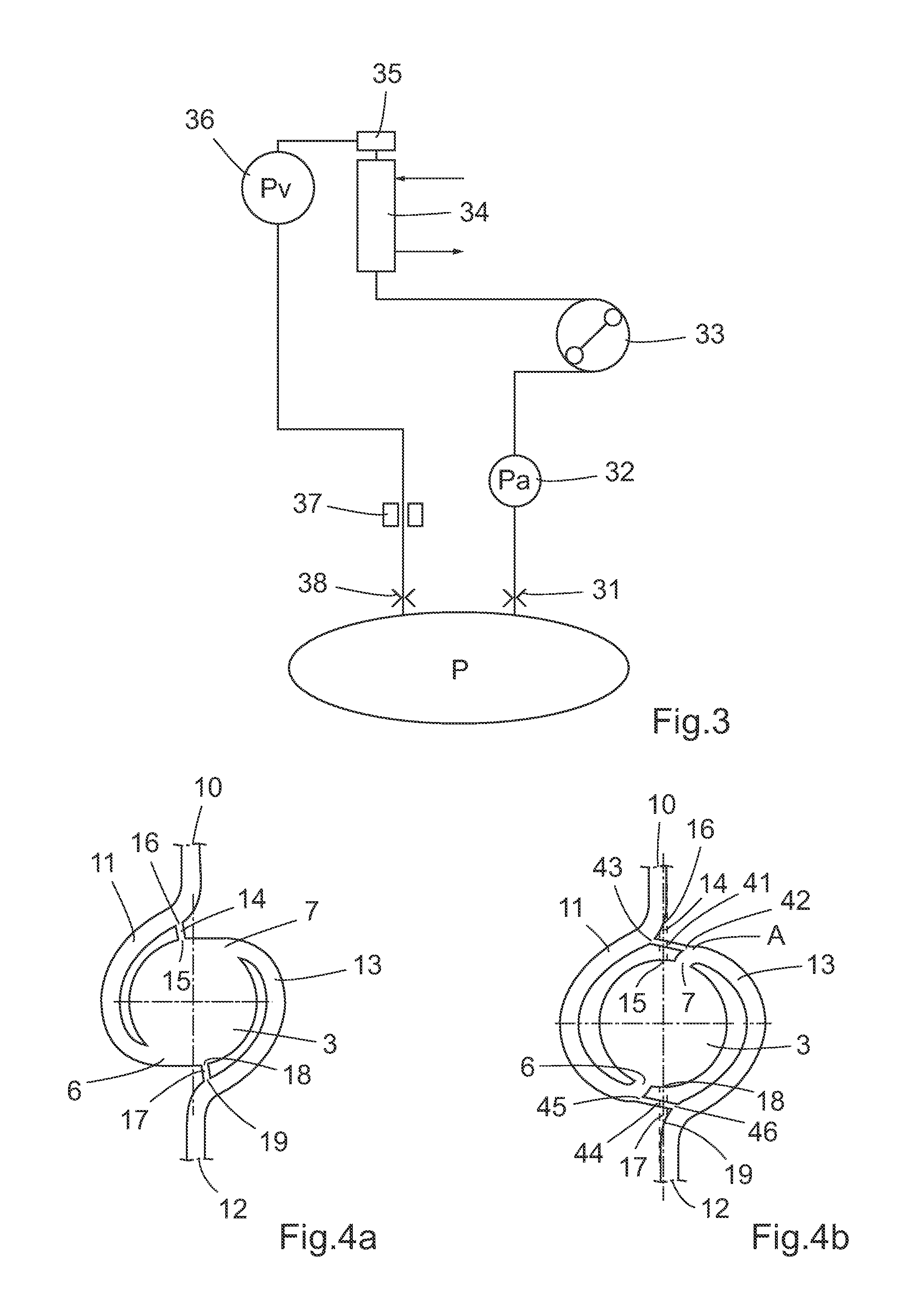

Apparatus and method for gas-liquid separation

ActiveUS20140260993A1Raise the ratioEfficient separationCombination devicesAuxillary pretreatmentVapor–liquid separatorPhase splitter

A multi-phase separation apparatus shapes fluid flow in a flow shaping line preferably shaped to have a plurality of loops with consecutively decreasing diameters. Shaping the two-phase flow drives the heavier, denser fluids to the outside wall of the flow shaping line and allows the lighter, less dense fluids such as gas to occupy the inner wall of the flow shaping line. With the gas positioned on the inner wall, an exit port on the inner wall permits a majority, if not all, of the gas, along with a minimal amount of liquid, to be diverted to a conventional gas-liquid separator at a flow rate much lower than the total flow rate within the flow shaping line. The remaining liquid flow in the flow shaping line is subsequently introduced into an adjustable phase splitter to separate different liquid components from one another.

Owner:HAVEN TECH SOLUTIONS LLC

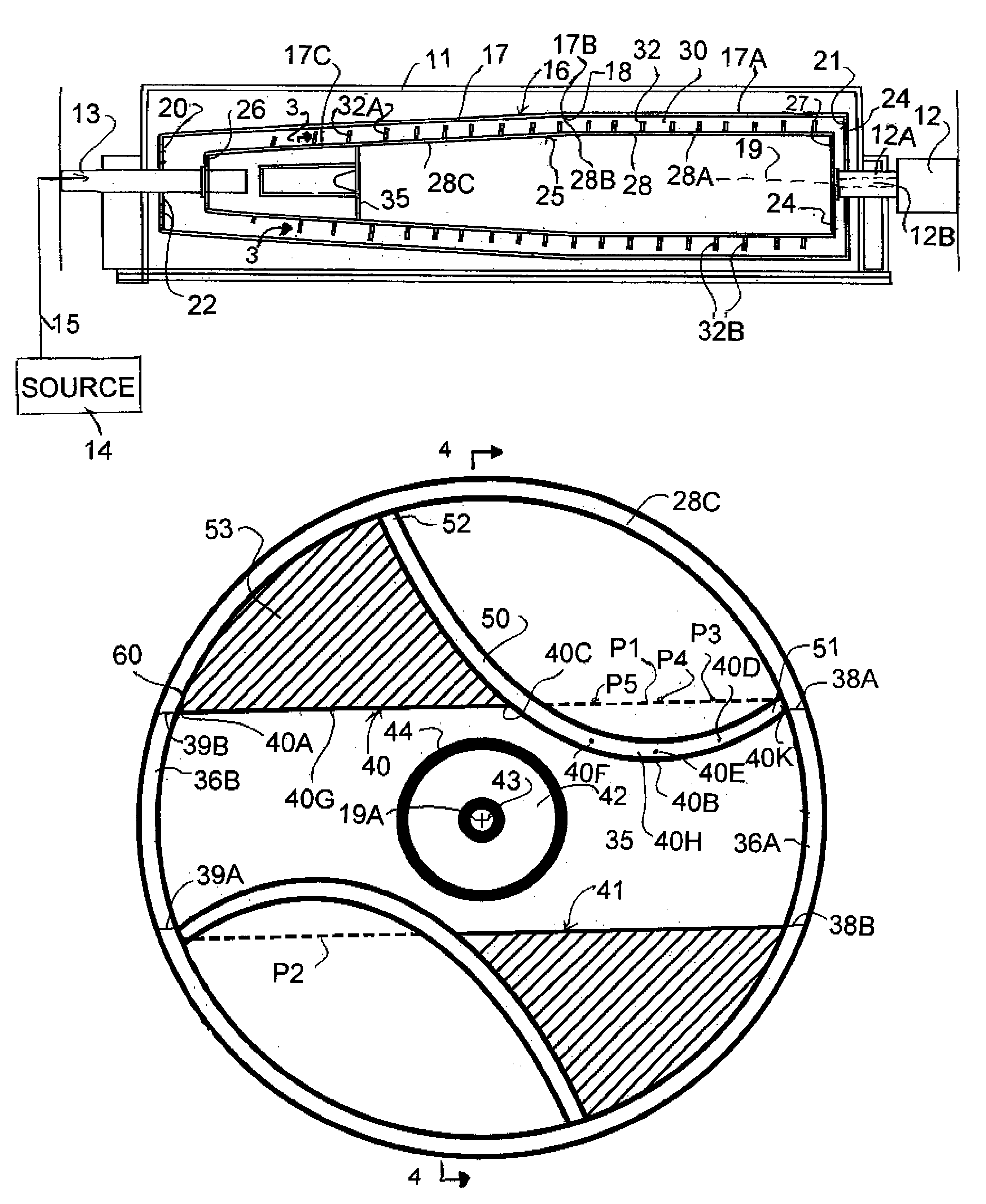

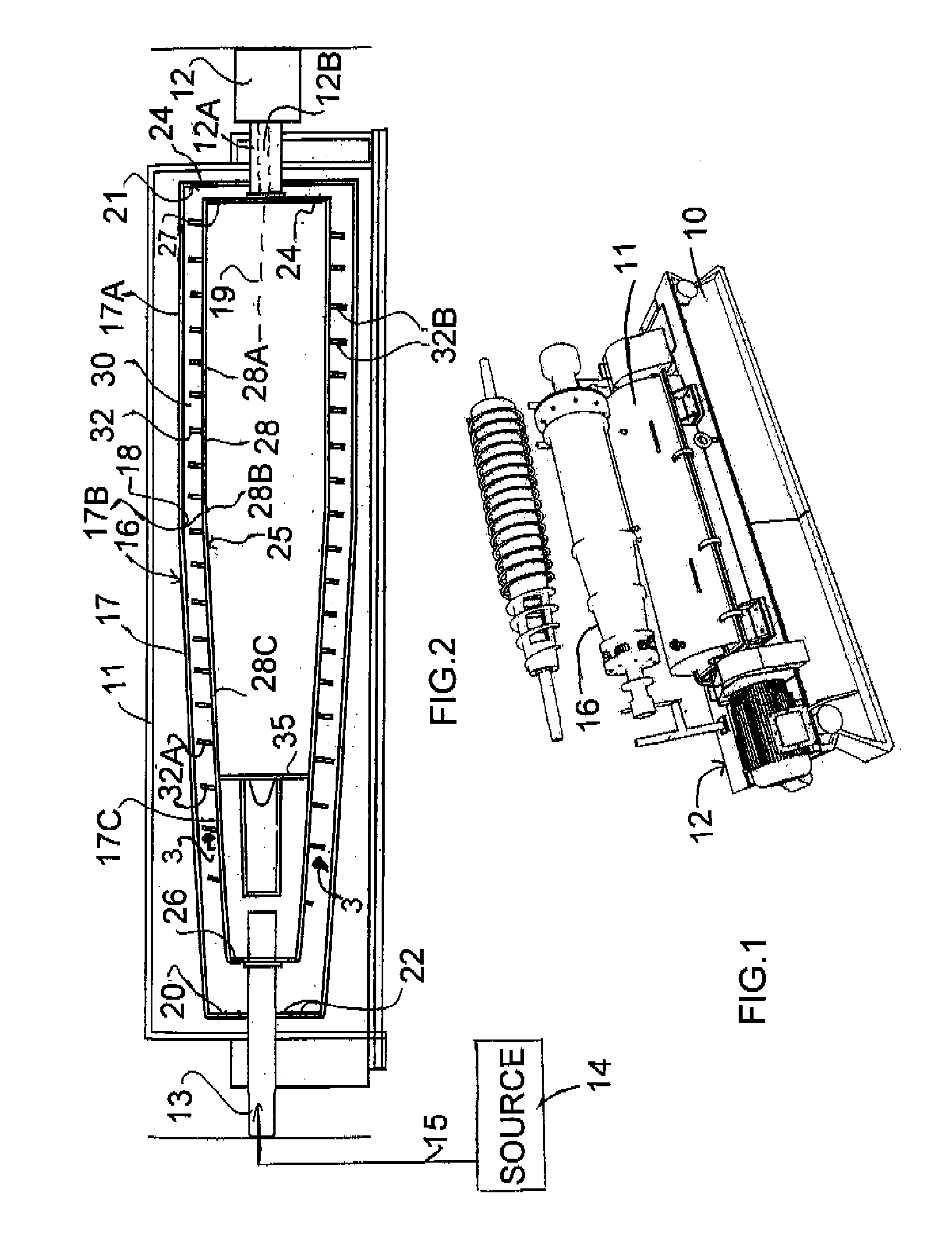

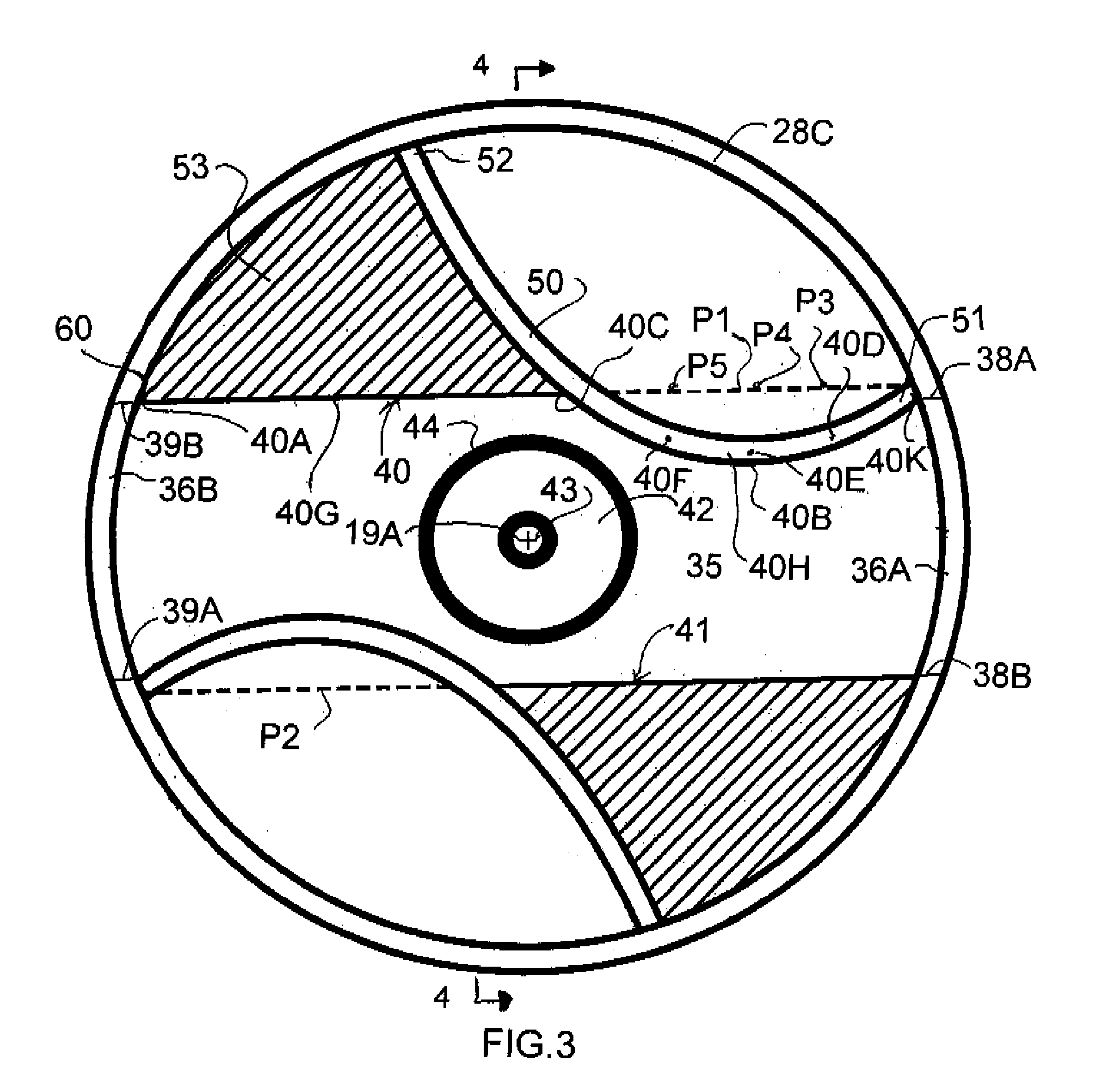

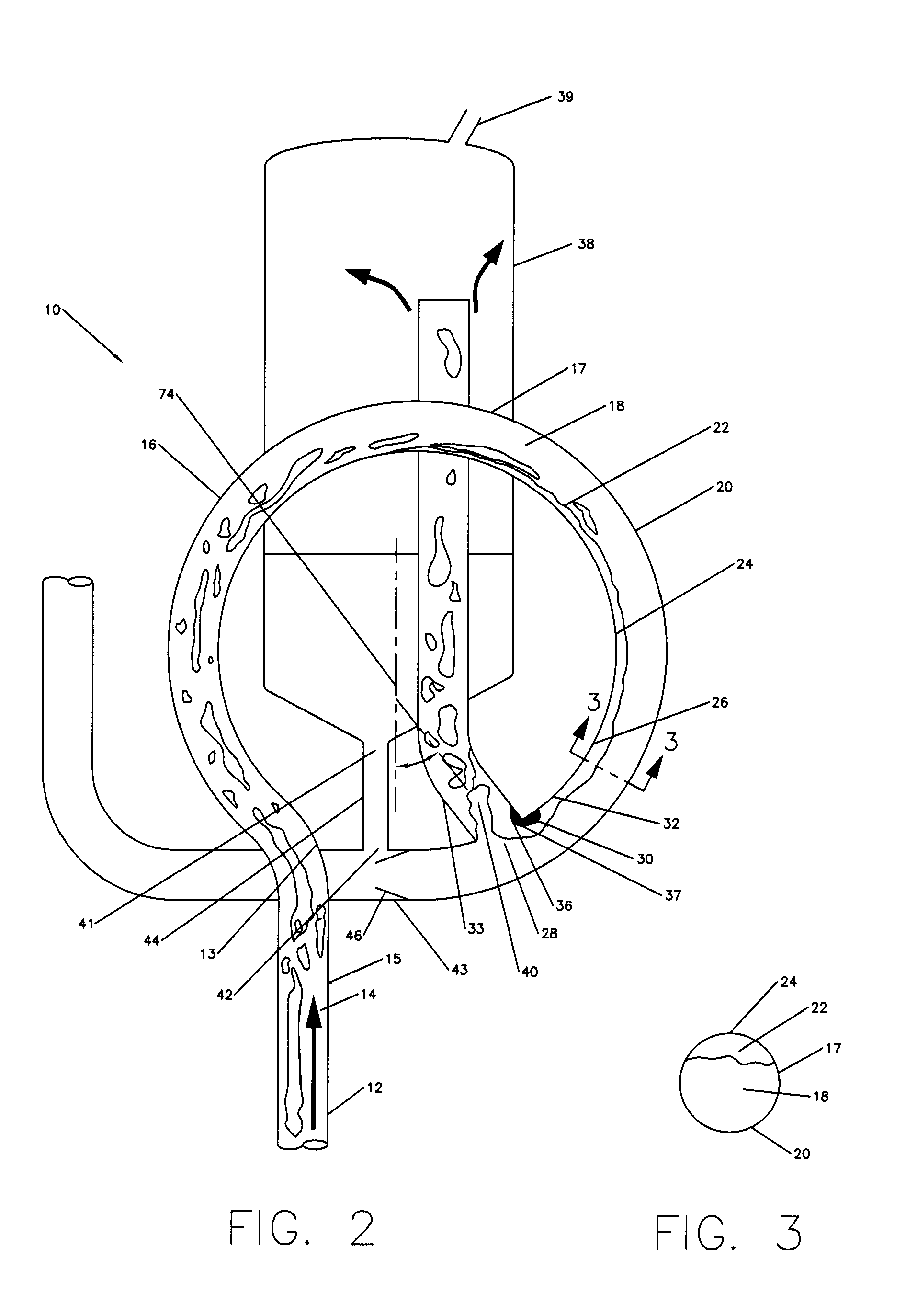

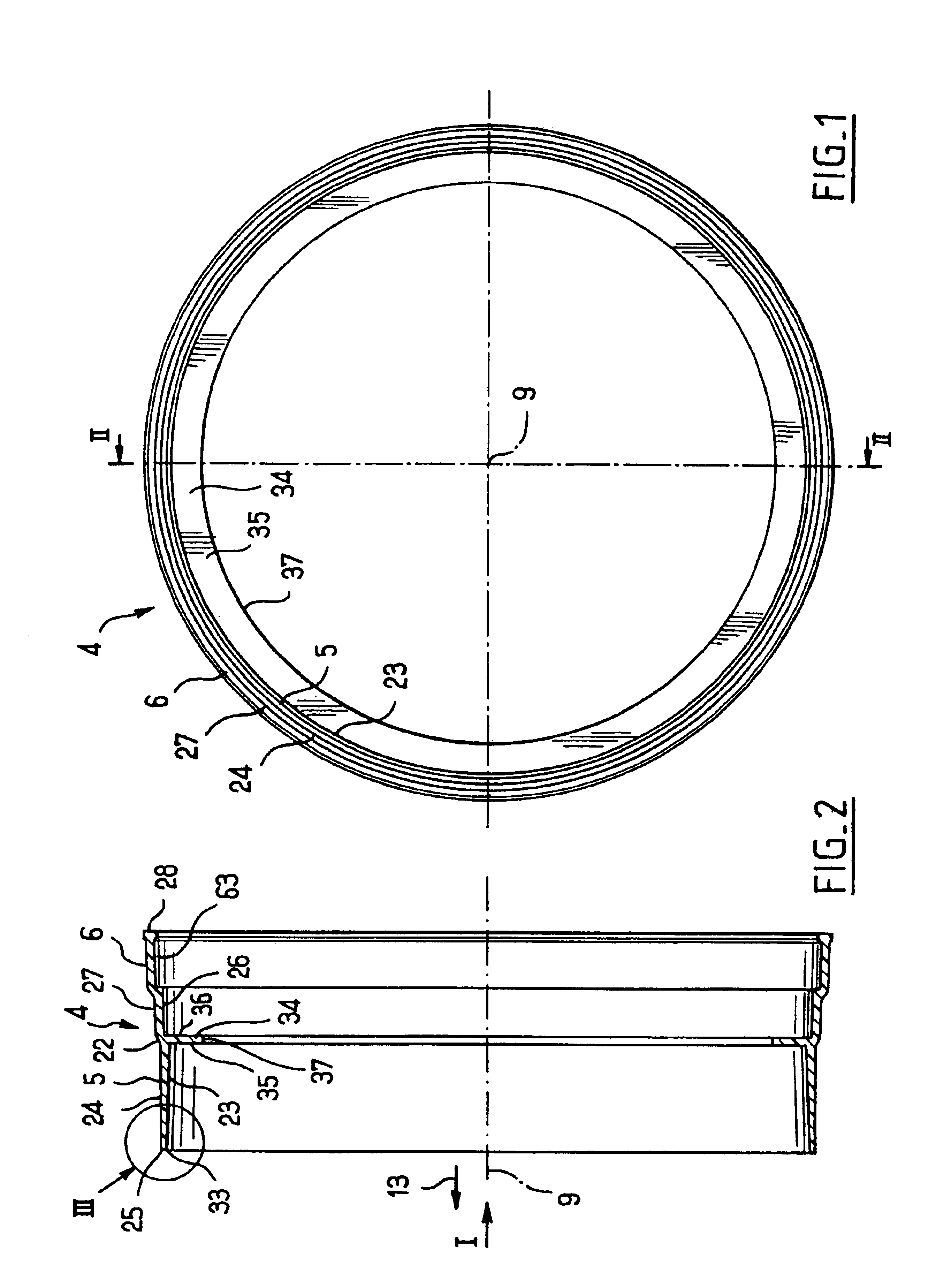

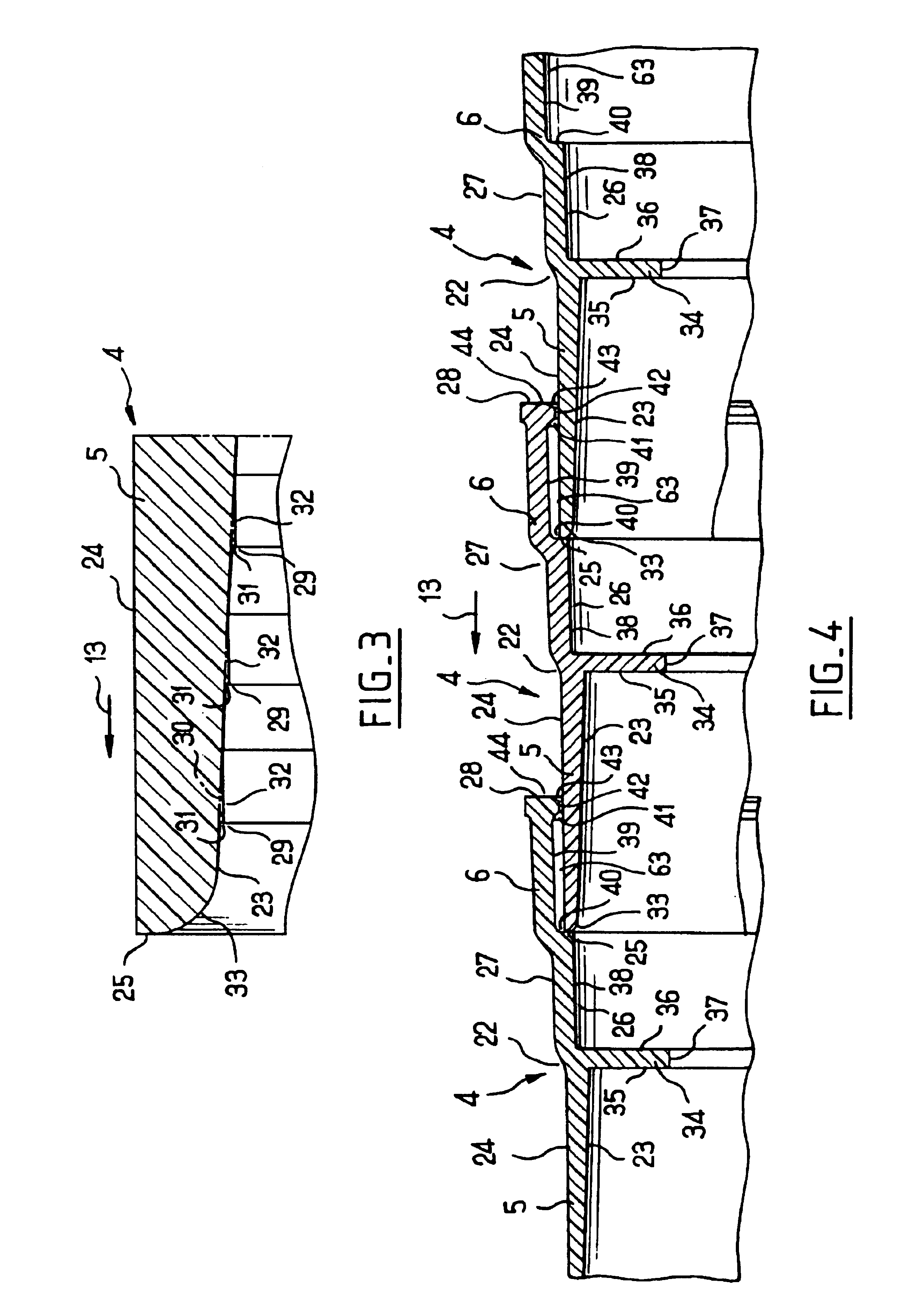

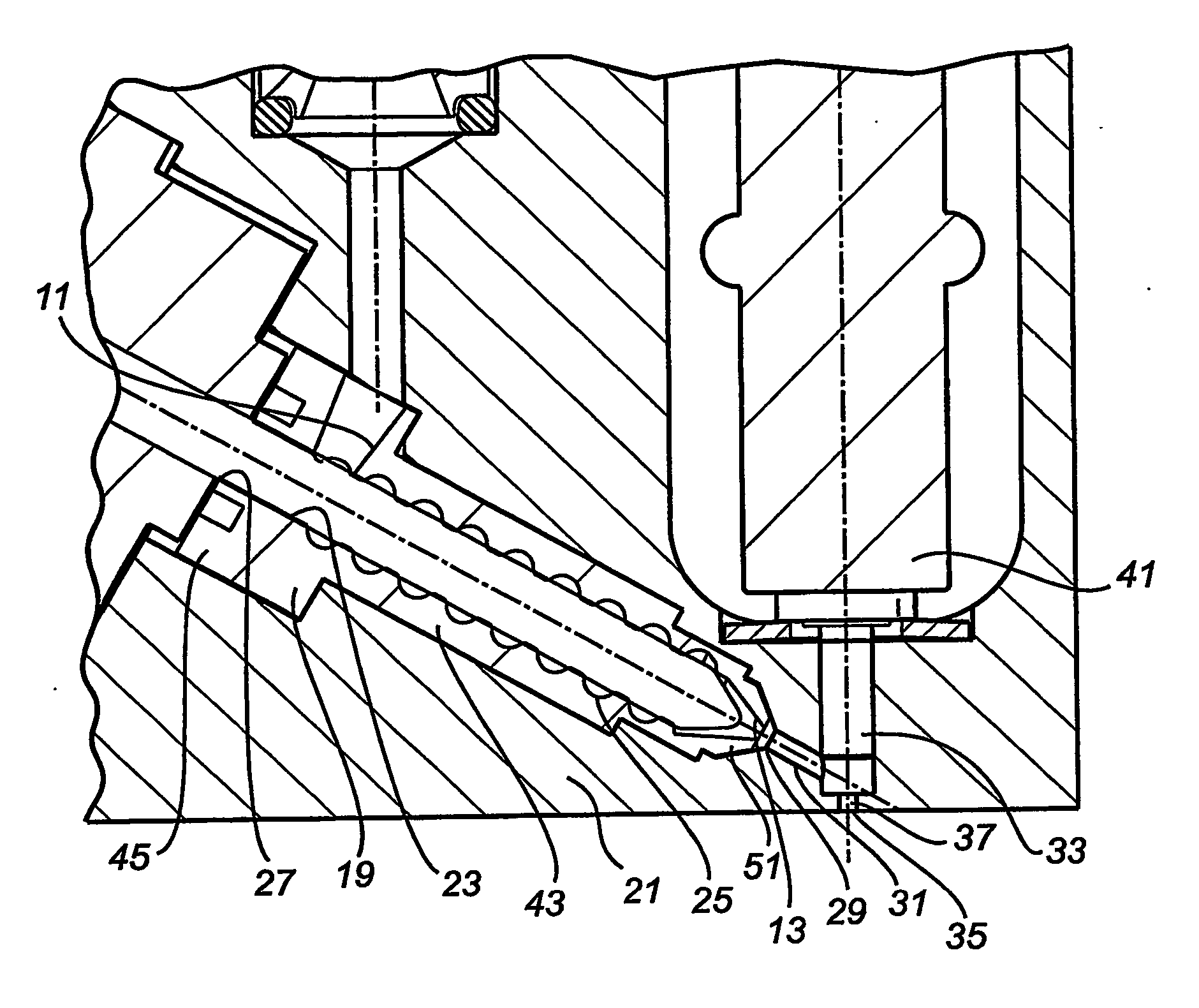

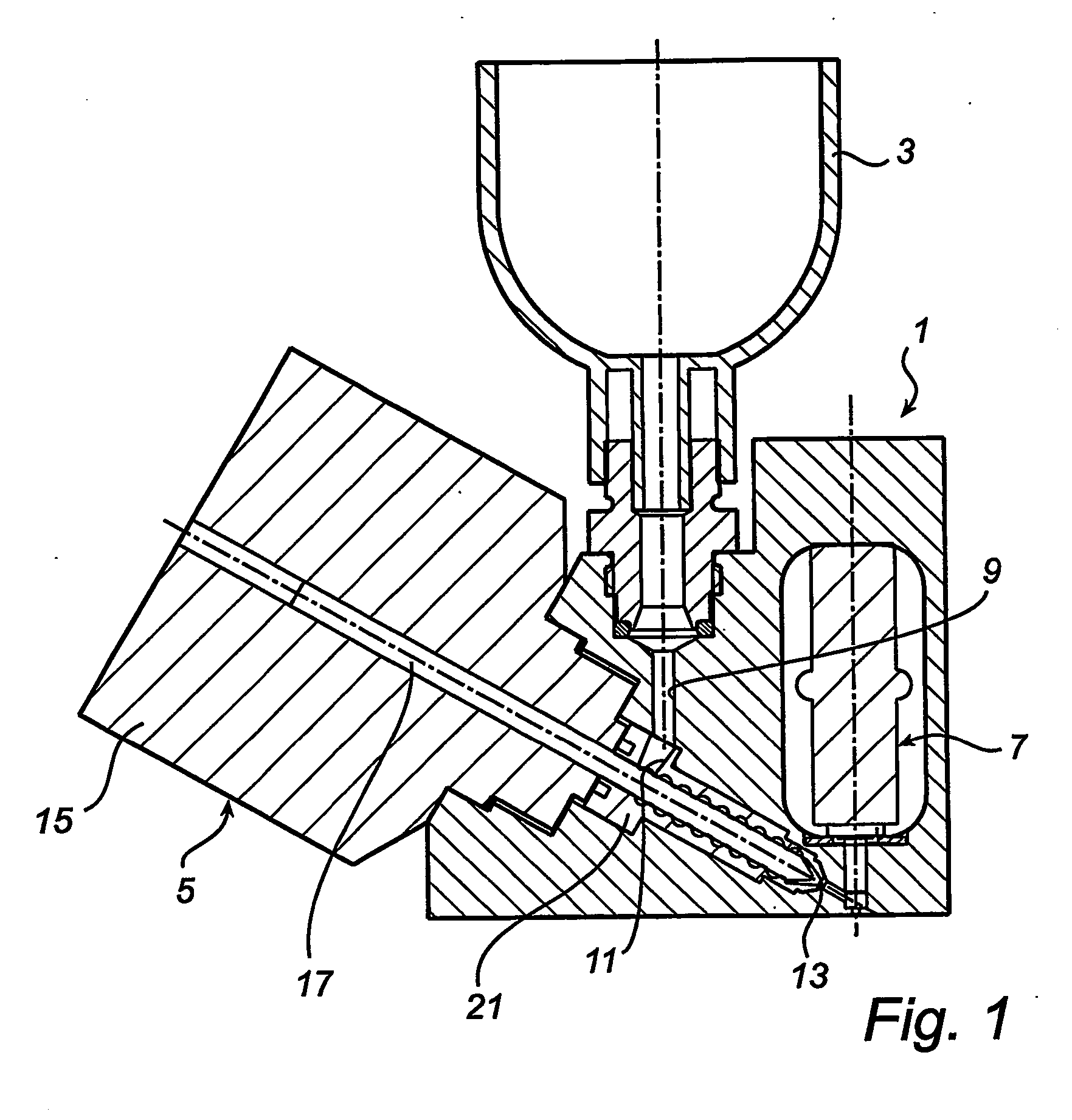

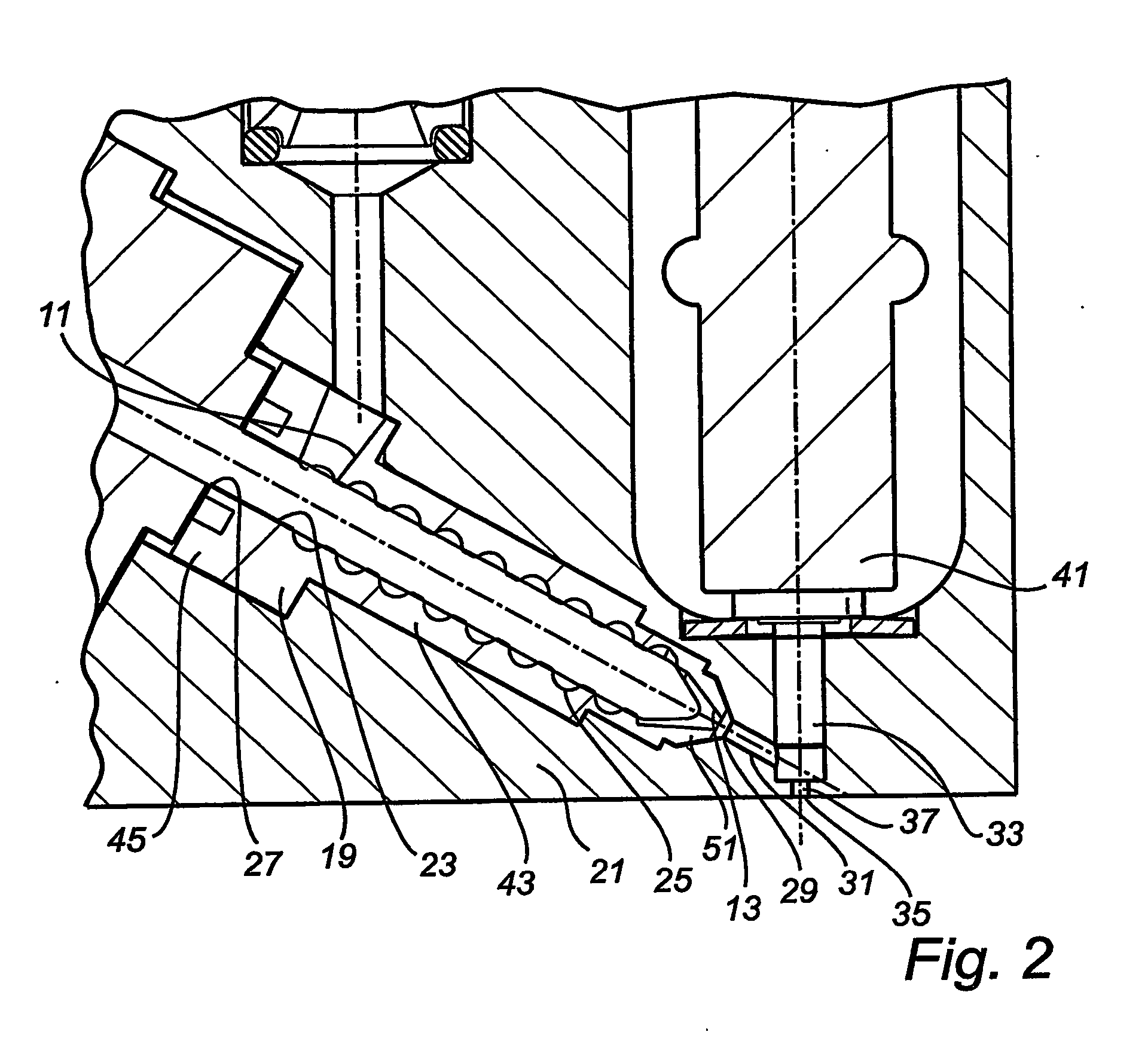

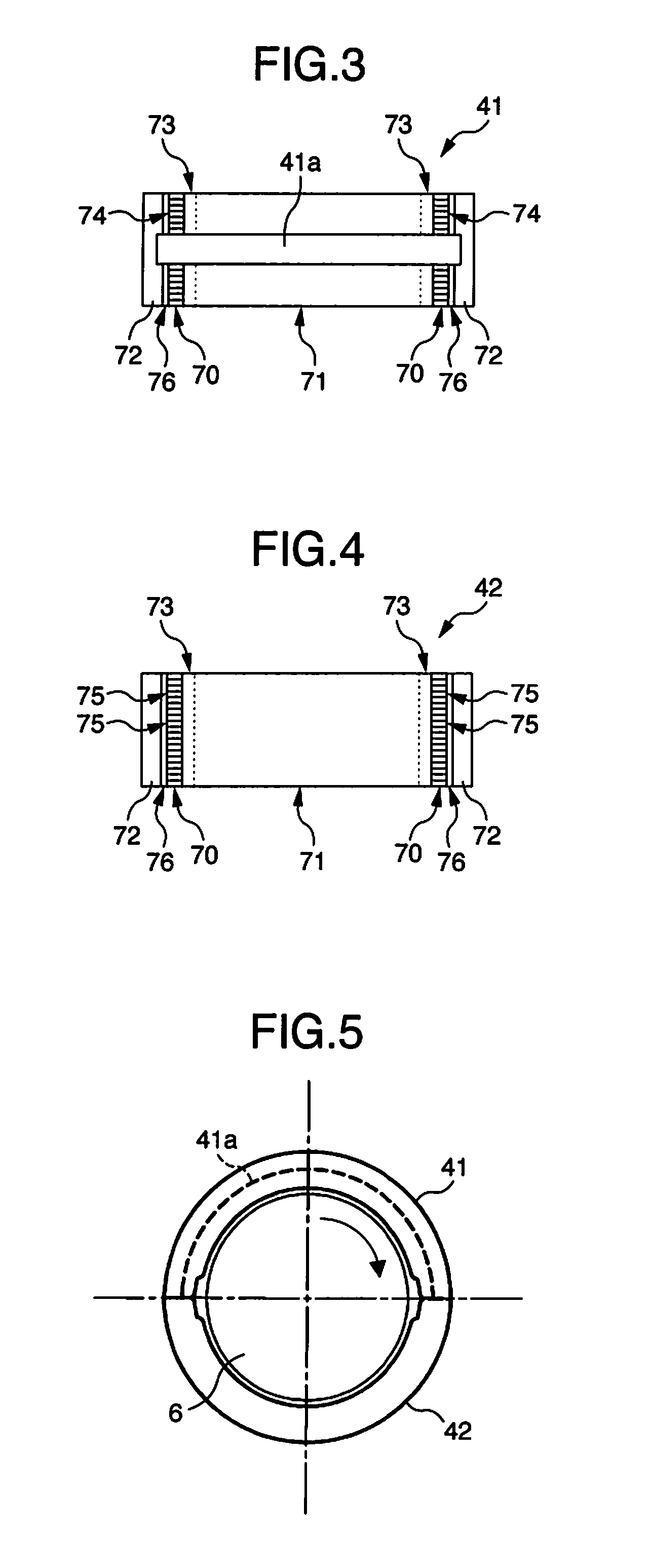

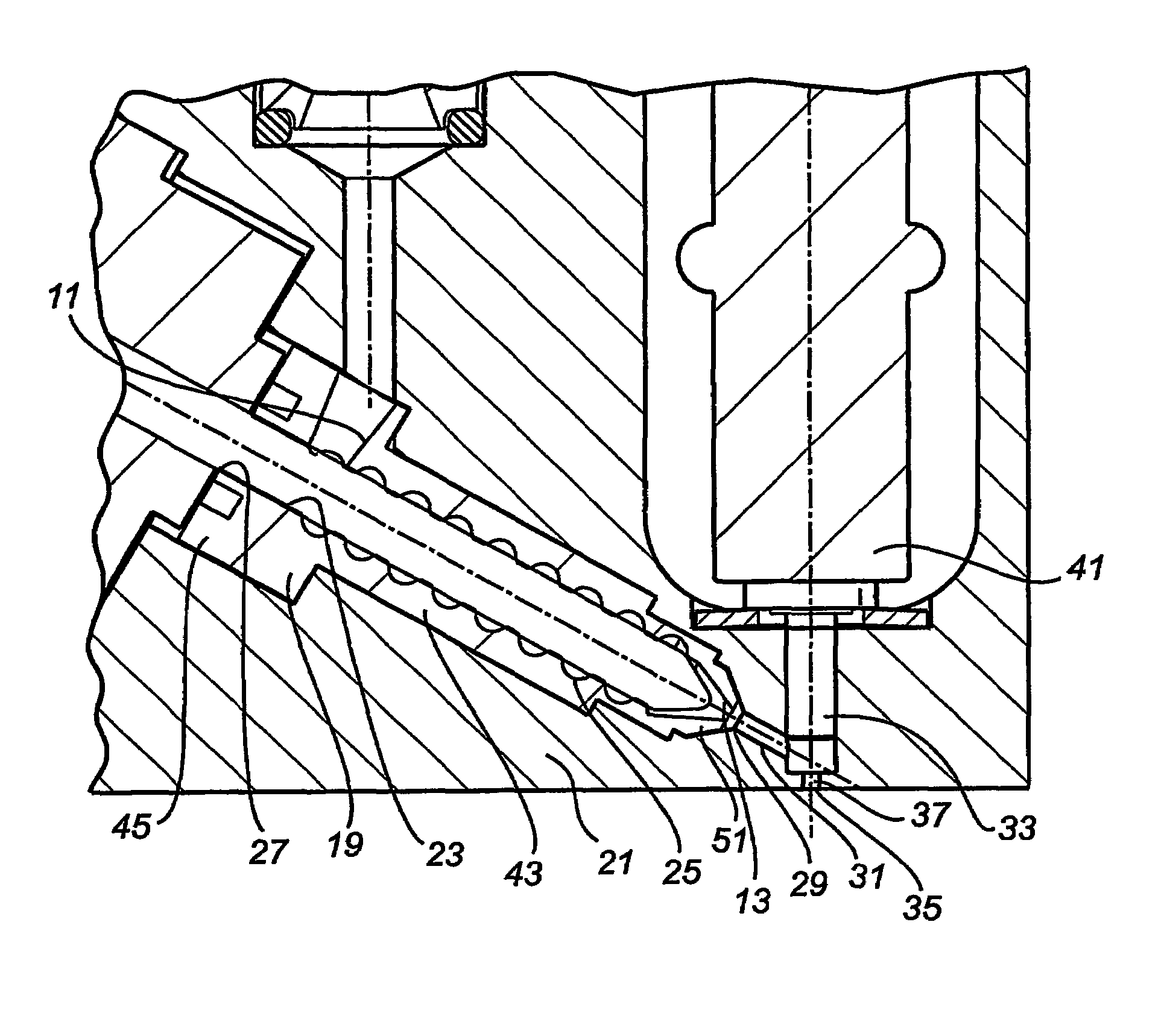

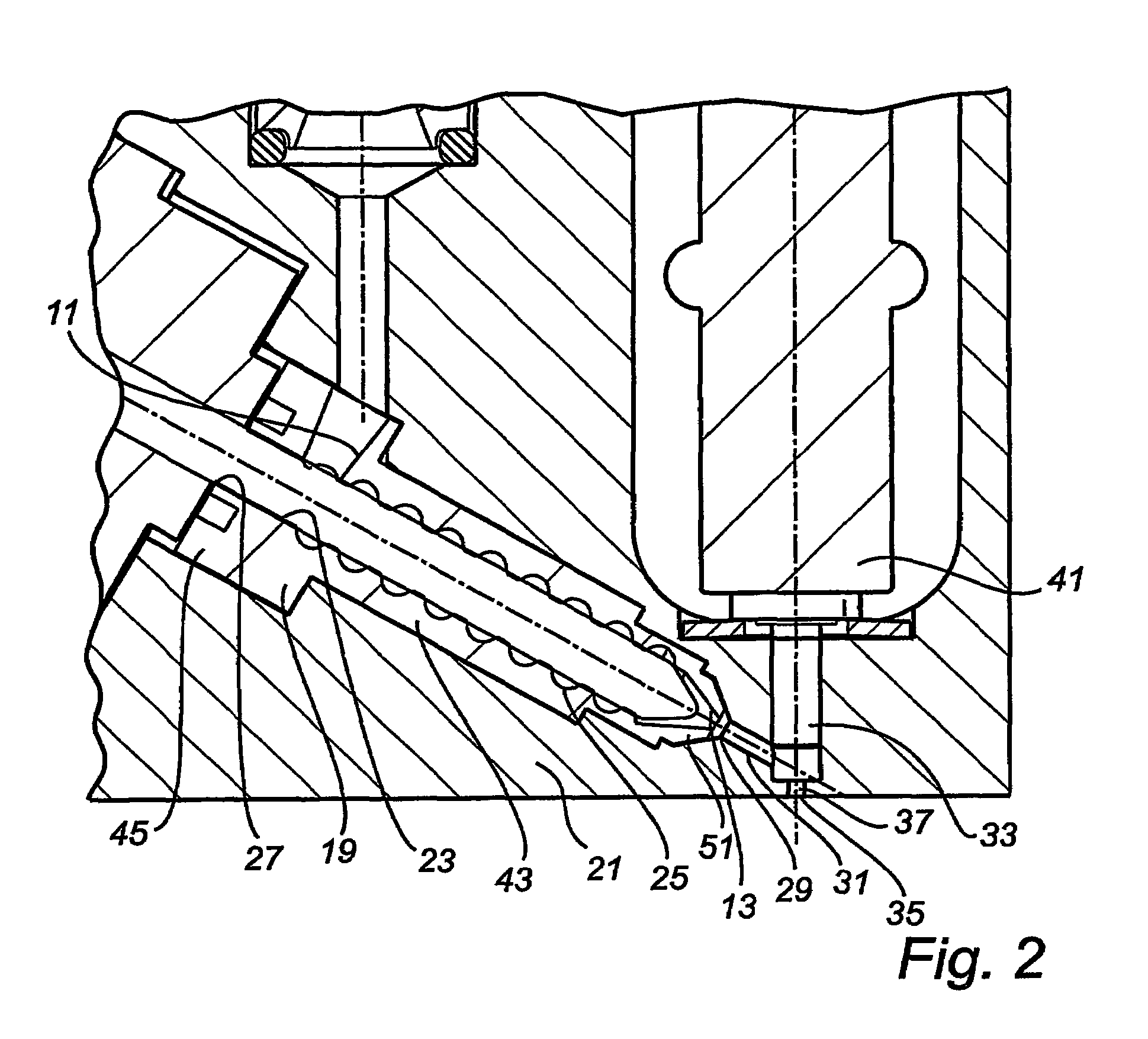

Centrifuge with shaping of feed chamber to reduce wear

ActiveUS7282019B2Better engagementEnhanced effect is goodRotary centrifugesEngineeringMechanical engineering

A centrifuge of the type having an outer bowl and an inner rotor both of which are generally cylindrical and rotate in the same direction but at slightly different rates separates slurry fed into the interior of the rotor into solids and liquid. An auger flight on the outside surface of the rotor carries the solids along the annular channel between the outside of the rotor and the inside of the bowl. The slurry is fed into a chamber at one end of the rotor and through outlet holes in the sides of the rotor into the channel. An end plate of the chamber has a forwardly projecting domed central nose which extends into the flowing slurry. Transverse guide plates of the rotor act to engage the slurry and accelerate it into rotation with the rotor before escaping through the holes. The guide plates are shaped with curved angularly projecting ribs on the downstream side in front of the hole over which the slurry flows in a smooth path before exiting the hole.

Owner:LANTZ EDWARD CARL

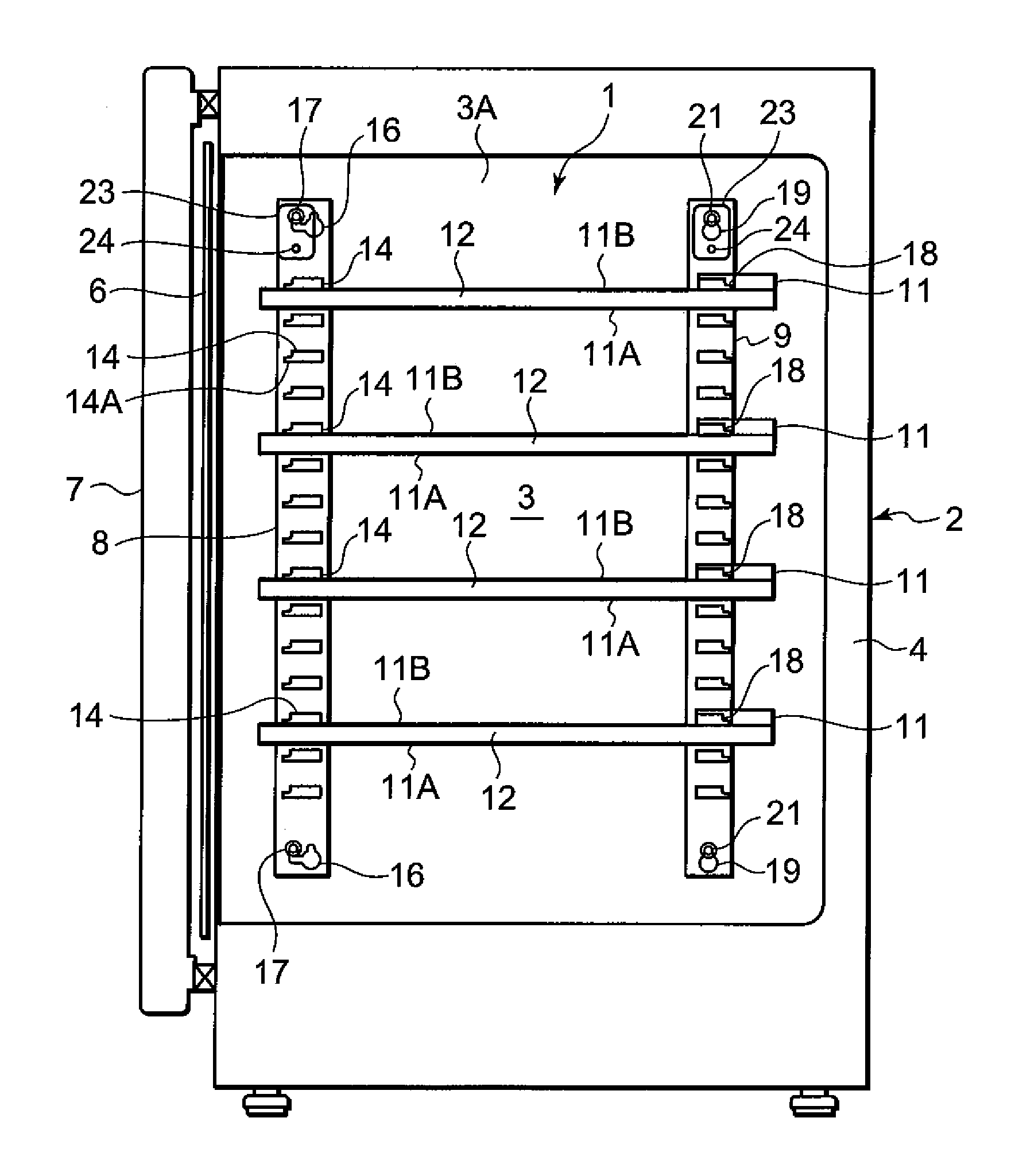

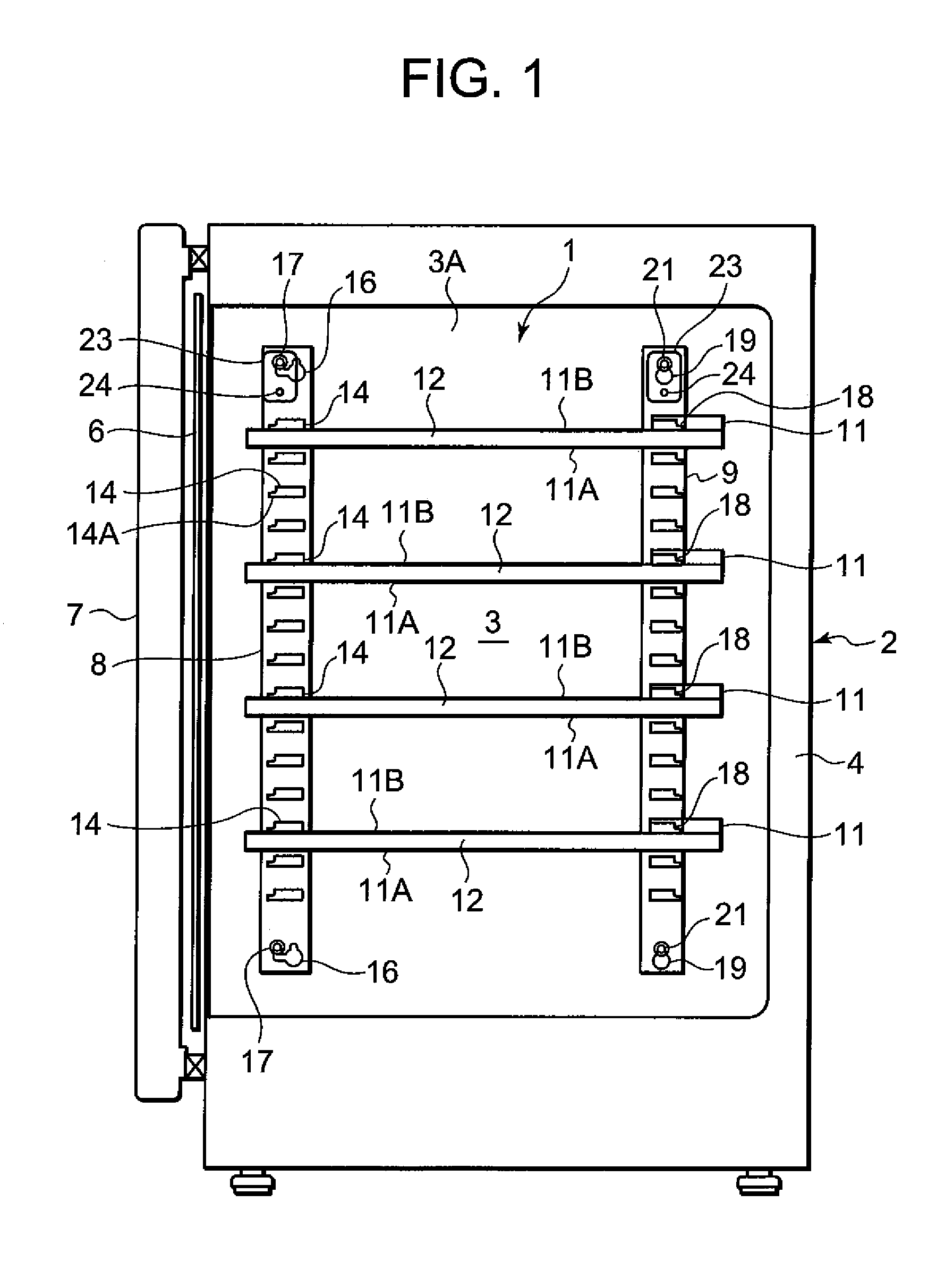

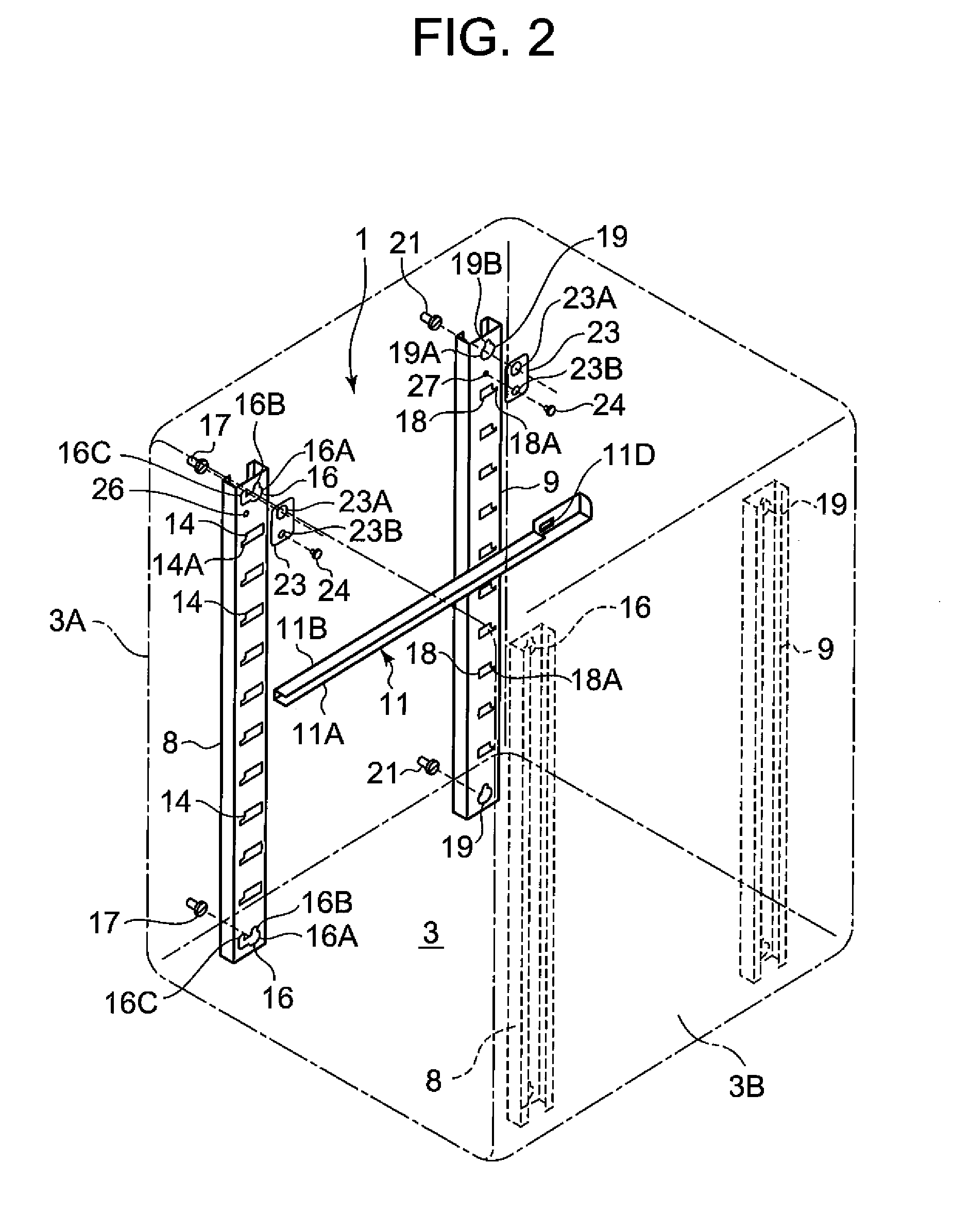

Rack device and incubator having the same

InactiveUS20090195129A1Change heightRestrict movementHeating or cooling apparatusDiagnosticsTelecommunications

A rack device is provided in which a receiver can be prevented from being separated off from a rack post and an incubator having the rack device is also provided. A rack device 1 in which a receiver 11 is mounted between a pair of rack posts 8 and 9 to hold a rack on the receiver 11 includes a pair of engaging hooks 11C and 11D which are formed in the receiver and a plurality of engaging holes 14 and 18 which are formed in both the rack posts and in which both of the engaging hooks of the receiver disengageably engage, respectively. The rack posts are configured to be able to change an interval therebetween and select a first state in which the engaging hooks can be disengaged from the engaging holes and a second state in which the movement of the receiver is restricted while the engaging hooks be kept to engage in the engaging holes by changing the interval between the rack posts.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

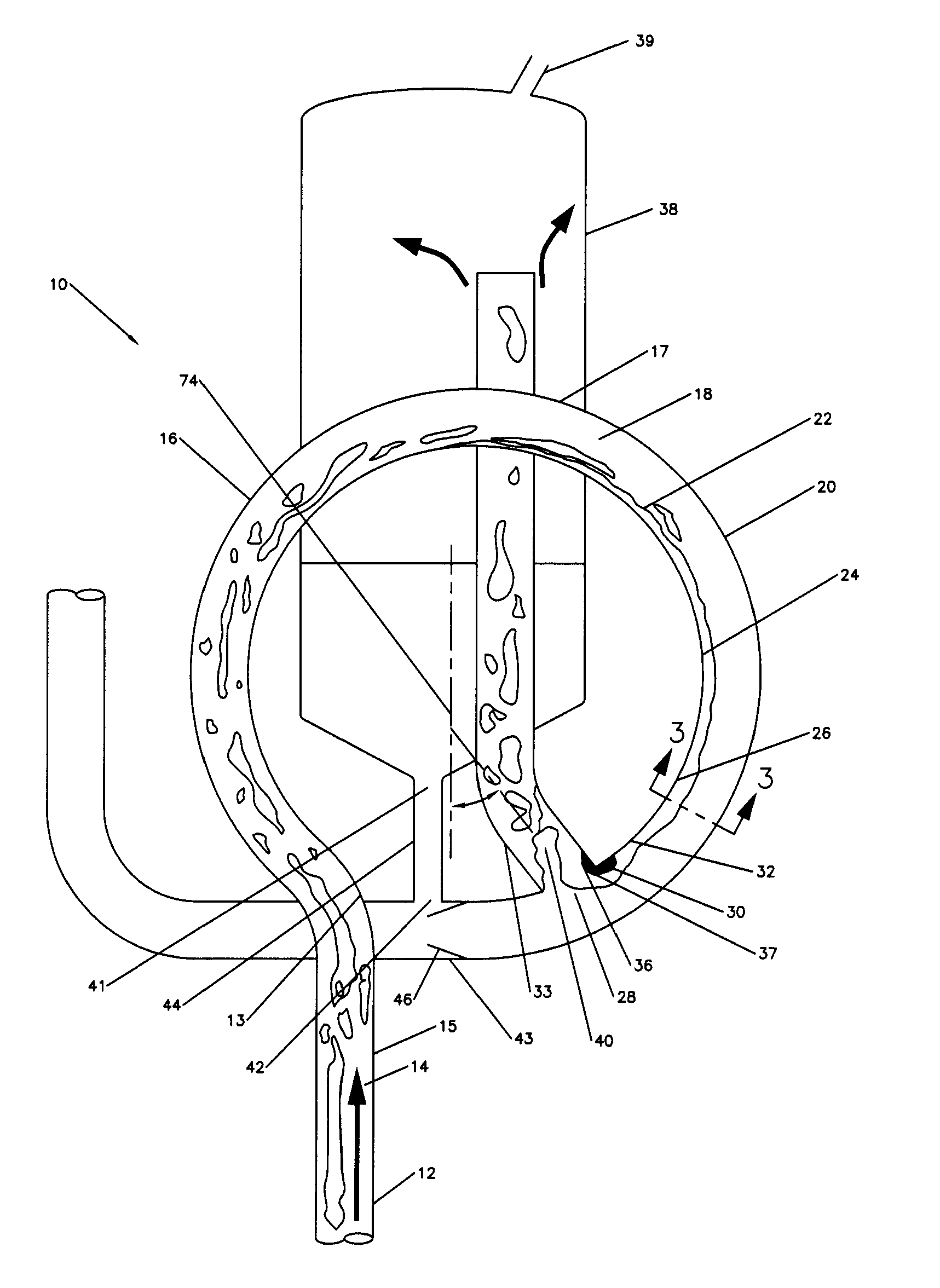

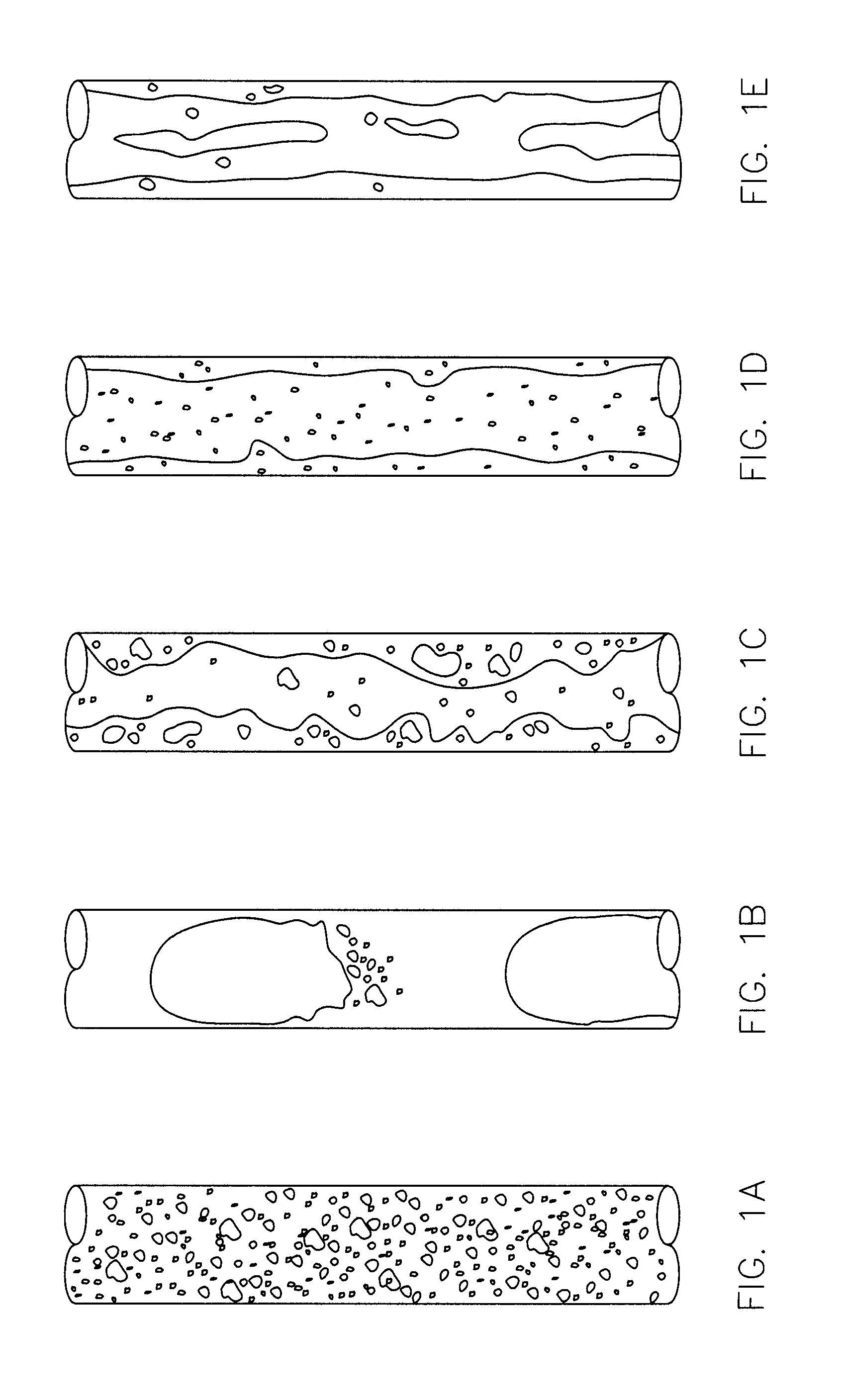

Apparatus and method for gas-liquid separation

ActiveUS20120199000A1Easy to operateEfficient separationLiquid degasificationFluid removalEngineeringCentrifugal force

A two phase gas-liquid separation apparatus is provided that shapes the flow in a flow shaping line. Shaping the two-phase flow allows centrifugal force to send the heavier, denser liquid to the outside wall of the flow shaping line and allows the lighter, less dense vapor or gas to occupy the inner wall of the flow shaping line. With the gas positioned on the inner wall of the flow shaping line, an exit port on the inner wall will allow for the majority, if not all, of the gas, along with a low amount of liquid, to be sent to a conventional separator. A high ratio of vapor / liquid at a flow rate much lower than the total flow rate within the flow shaping line is sent to the conventional separator. This allows for efficient separation of the vapor from the liquid with the use of a smaller conventional separator.

Owner:HAVEN TECH SOLUTIONS LLC

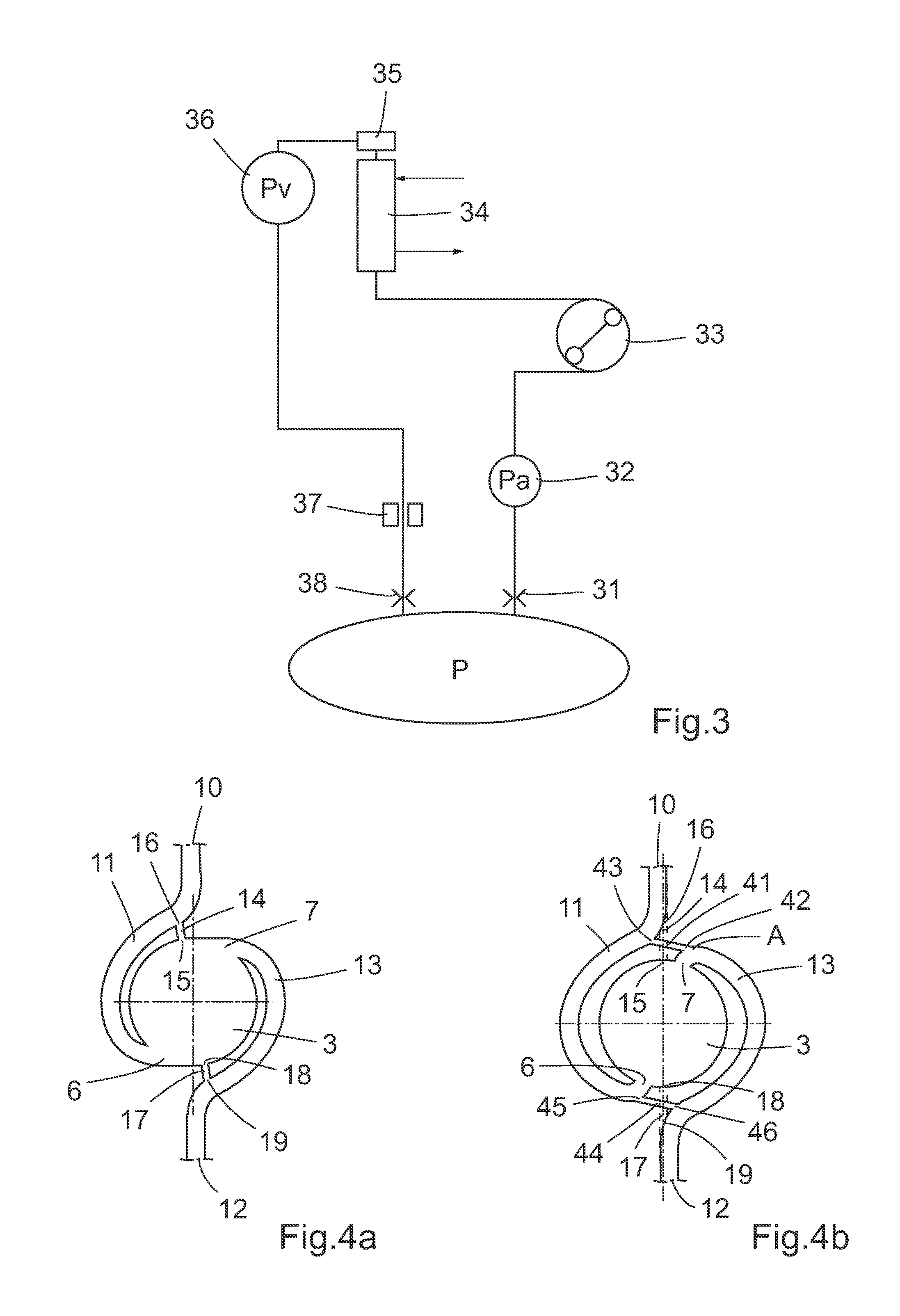

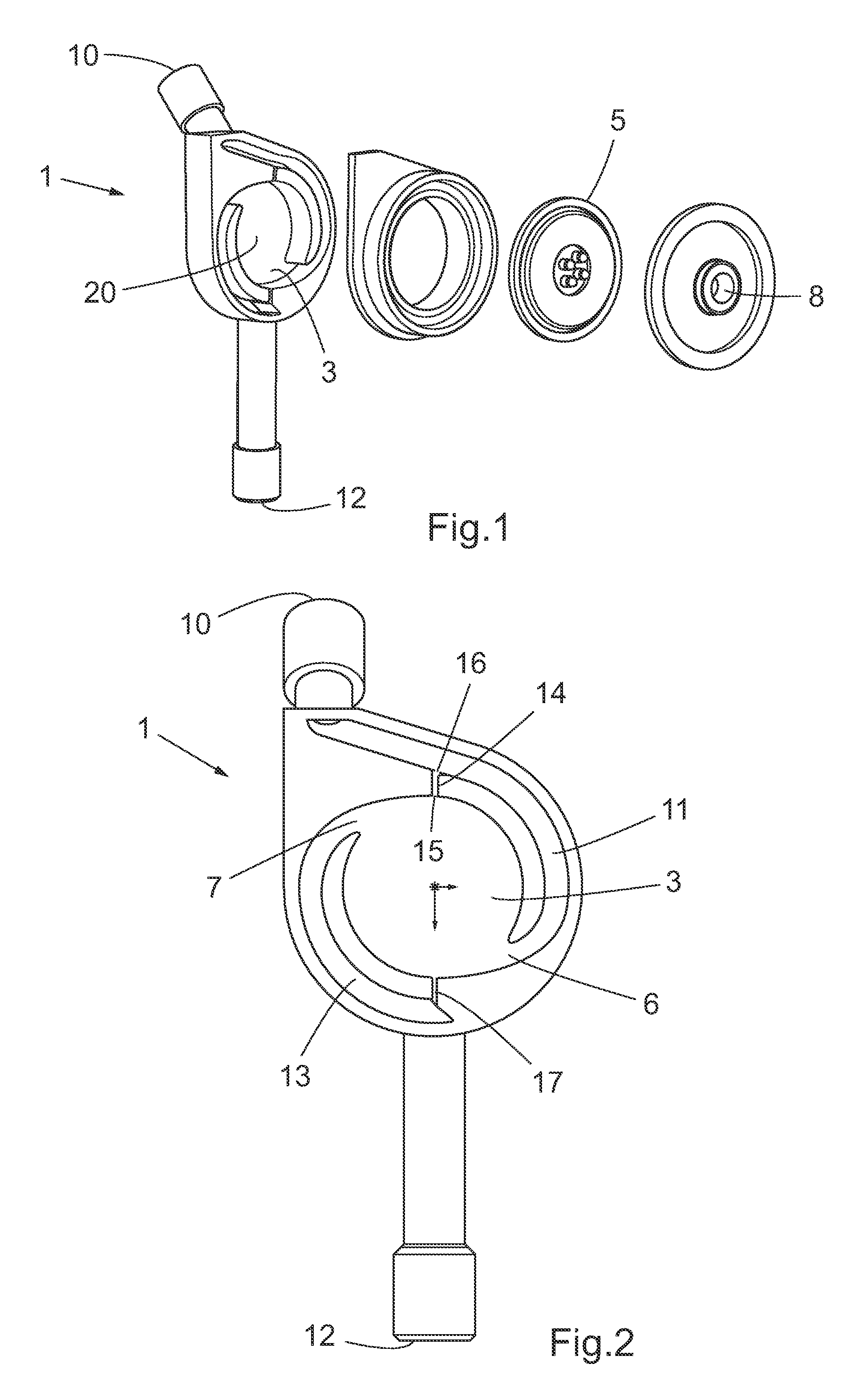

Pressure sensing device and use of the same in a connecting structure

ActiveUS20100186518A1Readily forcedFluid pressure measurement using elastically-deformable gaugesSuction devicesTransducerPressure sense

A pressure sensing device adapted for having a liquid flowing there through and for sensing the pressure of said liquid. The device has a casing being fluid-tightly divided into a first and a second chamber by a flexible, impermeable wall. The first chamber has a first opening for the liquid, said opening being placed at the lower part of the chamber, and a second opening for the liquid, said opening being placed at the top of the first chamber. The second chamber has a measuring port, which is connectable to a pressure transducer for bringing the second chamber into gas-tight communication with the pressure transducer. The device has a first orifice to permit the liquid to flow into and out of the device, the orifice being placed at the upper part of the device at a higher level than the second opening. A first channel is connecting the first orifice with the first opening. A second orifice permits the liquid to flow out of and into the device and is placed at the lower part of the device at a lower level than the first opening. A second channel connects the second opening with the second orifice.

Owner:GAMBRO LUNDIA AB

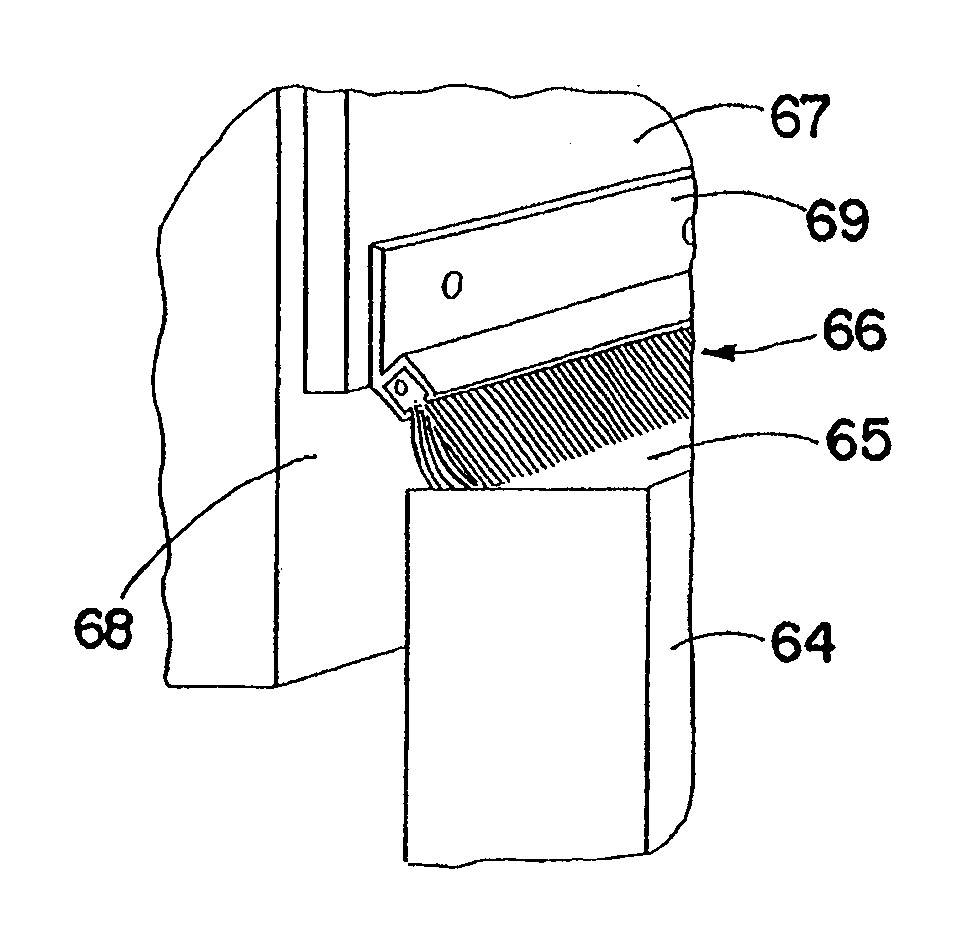

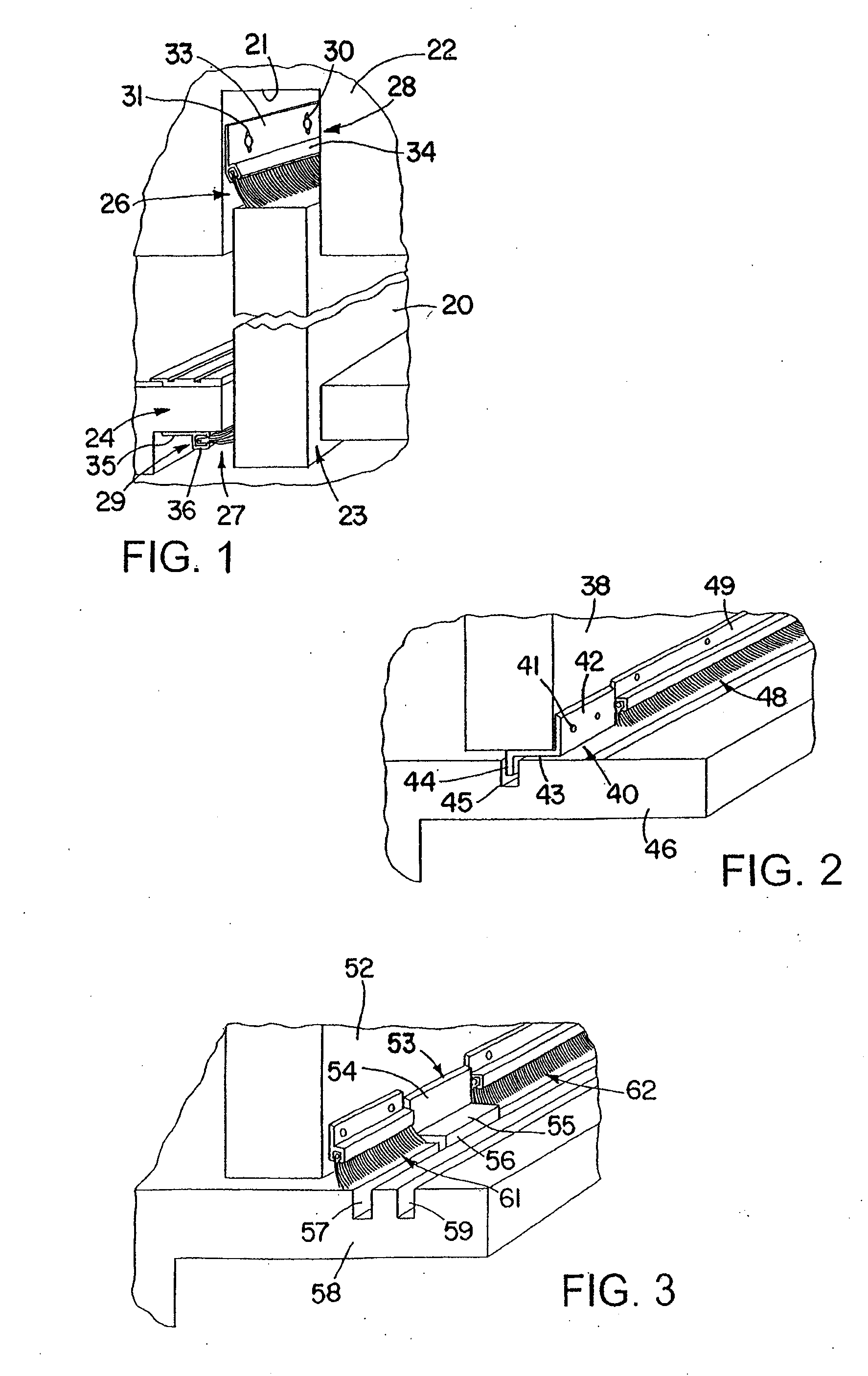

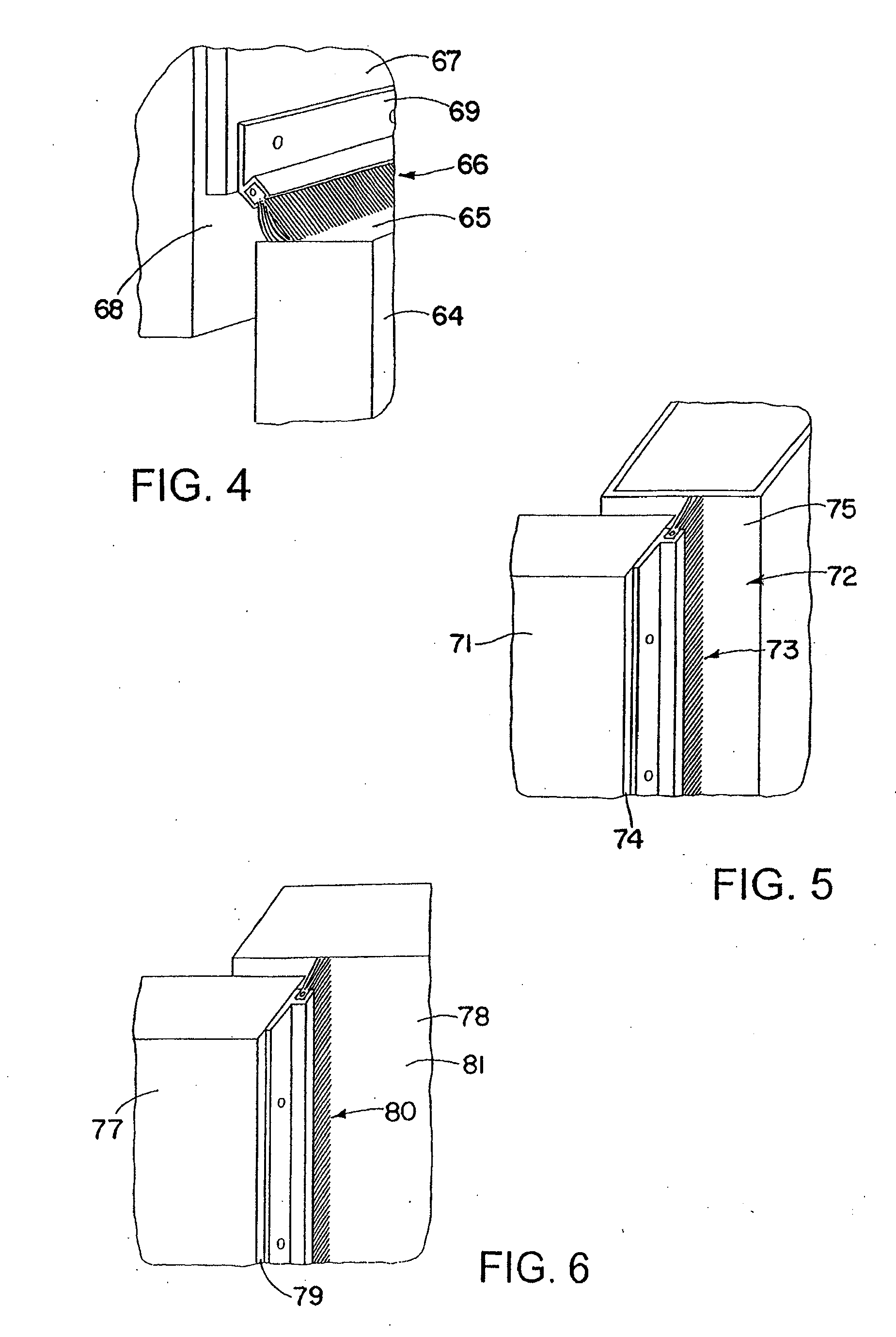

Environmental brush seal

InactiveUS20100083581A1Improve sealingHigh pressureEngine sealsElectrical apparatusEngineeringBand pattern

A passive brush seal effectively to limit conditioned air such as humidity, temperature or filtered air, or contaminated air such as smoke or fumes from an area of greater pressure to one of lower pressure. The passive brush seal is in the form of a strip brush with triangular filaments that provide an improved block to the flow of gases. The shape of the filaments is such that they inter-fit or interlock and separate less readily. Important applications are as elevator seals or clean room or computer room seals.

Owner:MATTICE DOUGLAS A

Steam generator

InactiveUS20100034526A1Readily forcedSteam generation heating methodsElectrode boilersHome applianceHeating element

The invention refers to a steam generator for household appliances. The steam generator comprises a container having an inlet for water and an outlet for steam, and an electrical heating element fixed to the container. The container comprises a first part and a second part which are connected along a joint such that a critical pressure inside the container causes a slit to appear in a predefined section of the joint, said slit providing a security vent for releasing pressure.

Owner:EICHENAUER HEIZELEMENTE

Pipe or the like, a female end ring, and a method of manufacturing such a pipe or the like

InactiveUS6854770B2Improve sealingReadily forcedSleeve/socket jointsFluid pressure sealed jointsAdhesiveEngineering

A pipe formed from a concrete cylinder has an end ring with a ferrule which can be snuggly mounted on one end of the pipe and a skirt axially adjacent to the ferrule for receiving a mail endpiece of another pipe. The ferrule is expanded as it is mounted on the cylinder and exerts a compressive force against the outer peripheral face of the cylinder for forming a secure seal. A rib may be disposed on an inner annular surface of the ferrule and an adhesive may be applied for enhancing the seal between the cylinder and the ferrule.

Owner:SABLA BONNA

Apparatus and method for gas-liquid separation

ActiveUS8419833B2Easy to operateEfficient separationLiquid degasificationFluid removalEngineeringCentrifugal force

A two phase gas-liquid separation apparatus is provided that shapes the flow in a flow shaping line. Shaping the two-phase flow allows centrifugal force to send the heavier, denser liquid to the outside wall of the flow shaping line and allows the lighter, less dense vapor or gas to occupy the inner wall of the flow shaping line. With the gas positioned on the inner wall of the flow shaping line, an exit port on the inner wall will allow for the majority, if not all, of the gas, along with a low amount of liquid, to be sent to a conventional separator. A high ratio of vapor / liquid at a flow rate much lower than the total flow rate within the flow shaping line is sent to the conventional separator. This allows for efficient separation of the vapor from the liquid with the use of a smaller conventional separator.

Owner:HAVEN TECH SOLUTIONS LLC

Rod-shaped force transducer with improved deformation behavior

ActiveUS9791332B2Accurate measurementCostlyWeighing apparatus using elastically-deformable membersForce measurementTransverse axisFour quadrants

A force transducer for measuring compression and / or tension forces includes a rod-shaped deformation body and at least four strain transducers applied on the deformation body and configured for measuring longitudinal and transverse strains thereof. Front and rear elongate recesses are provided on the front and rear sides of the deformation body in the area of an intersection between a central longitudinal axis and a central transverse axis of the deformation body. Left and right upper indentations and left and right lower indentations are provided on the deformation body respectively at the four quadrants bounded by the axes. A ratio of a cross-section on a center plane extending orthogonally to the central longitudinal axis and including the central transverse axis, to a sum of first and second partial regions of the cross-section, is from 1.56 to 2.15.

Owner:HOTTINGER BRUEL & KJAER GMBH

Viscous medium feeder

ActiveUS20050092774A1Improve sealingSufficient flexibilityLiquid surface applicatorsVolume meteringEngineeringDrive motor

This invention relates to a viscous medium feeder, which has an inlet, an outlet, a tubular portion, a routable cylindrical shaft arranged in and extending coaxial with said tubular portion, and a drive motor connected to the shaft. The tubular portion has an internal thread, which is connected, at one end thereof, to the inlet, and, at the other end thereof, to the outlet. Further, the tubular portion is elastic, and the shaft abuts inner wall portions of the tubular portion. The invention also relates to a feeder tube, and a jetting device.

Owner:MYDATA AUTOMATION

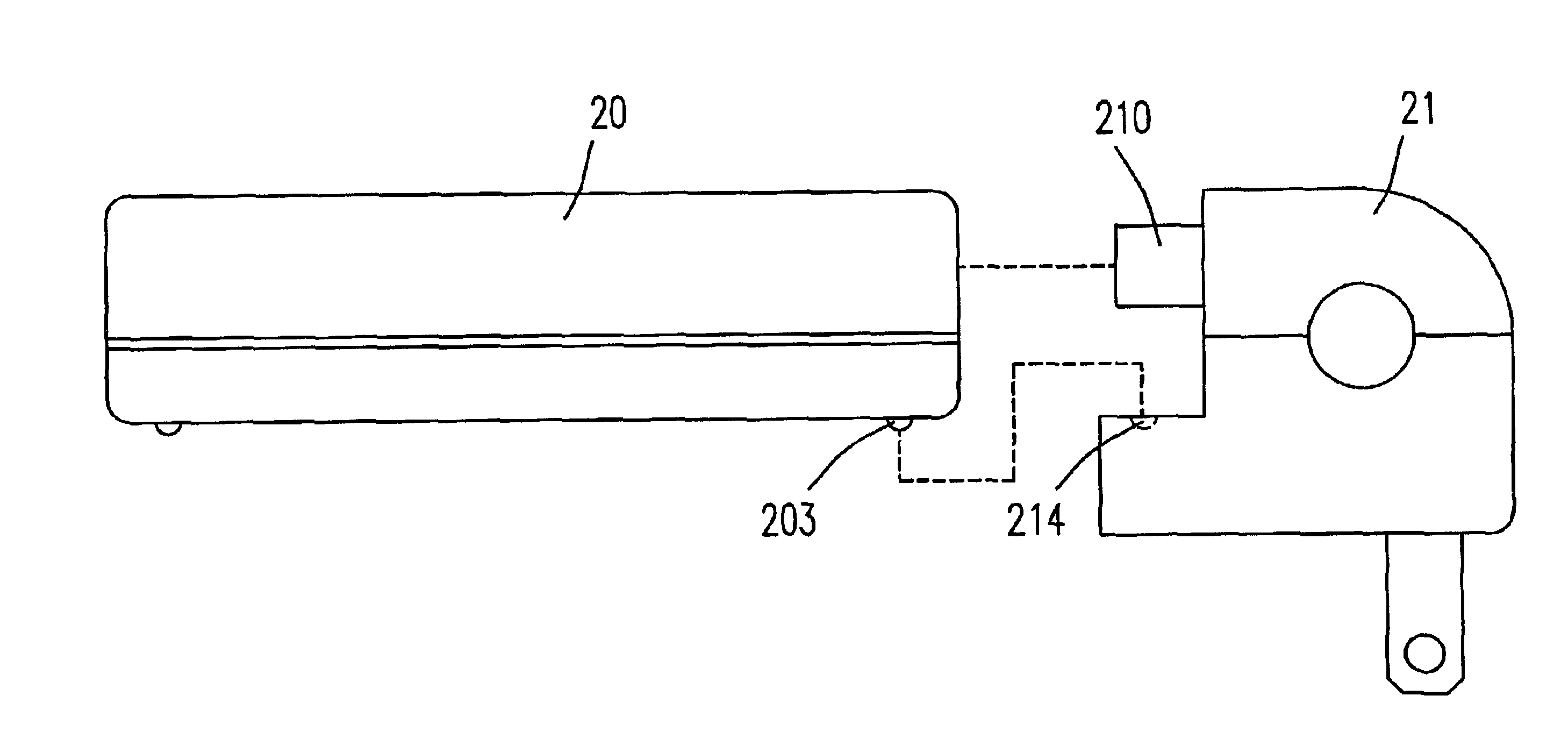

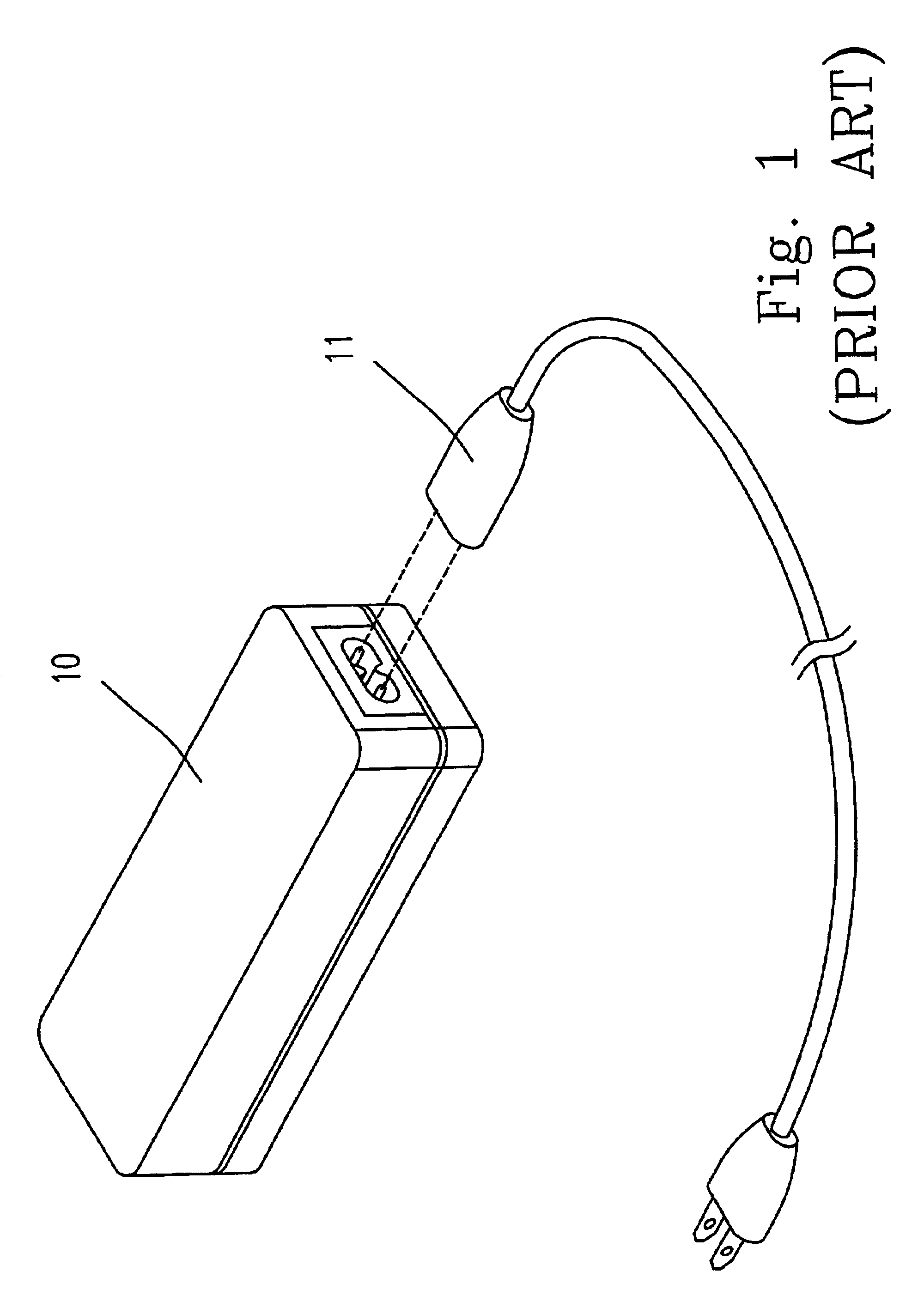

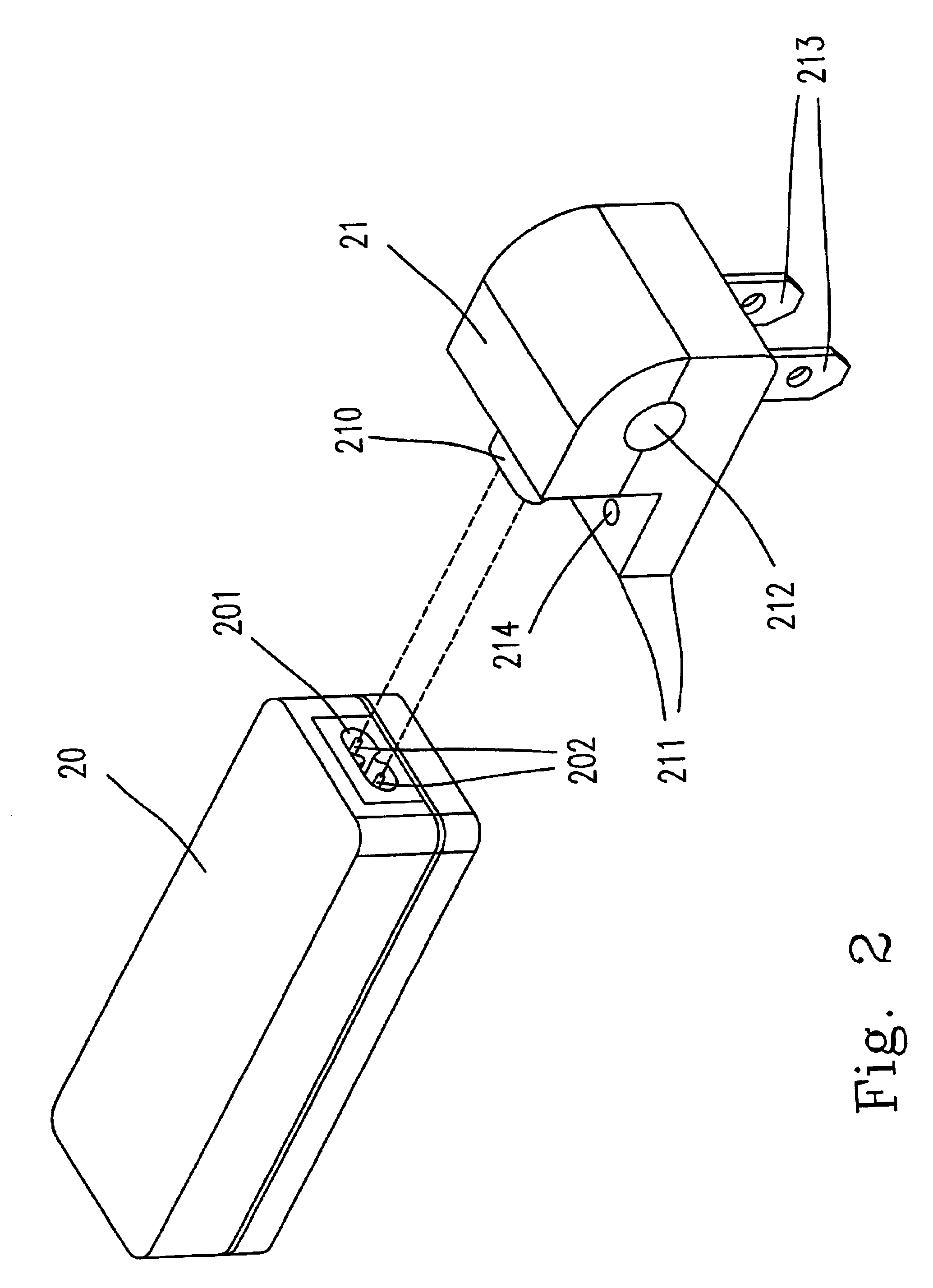

Power adapter

InactiveUS6851961B2Easy to useEasy to carryCoupling device connectionsElectric discharge tubesElectricityElectrical devices

The present invention discloses a power adapter for connecting an electric appliance to an AC main power. The power adapter includes an electrical device having at least two metal prongs in the power input / output end thereof, and a connector having at least two recesses for sleeving the metal prongs respectively and electrically connecting the connector to the electrical device. In addition, there is a height difference between the bottoms of the connector and the electrical device. Moreover, each of the two sides of the connector includes a hollow region respectively for the convenience of assembling and disassembling the connector and the electrical device. Furthermore, there are pit-knob matching structures in the connector and the electrical device for fixing the position and preventing unfastening of the connector and the electrical device in the assembling state.

Owner:DELTA ELECTRONICS INC

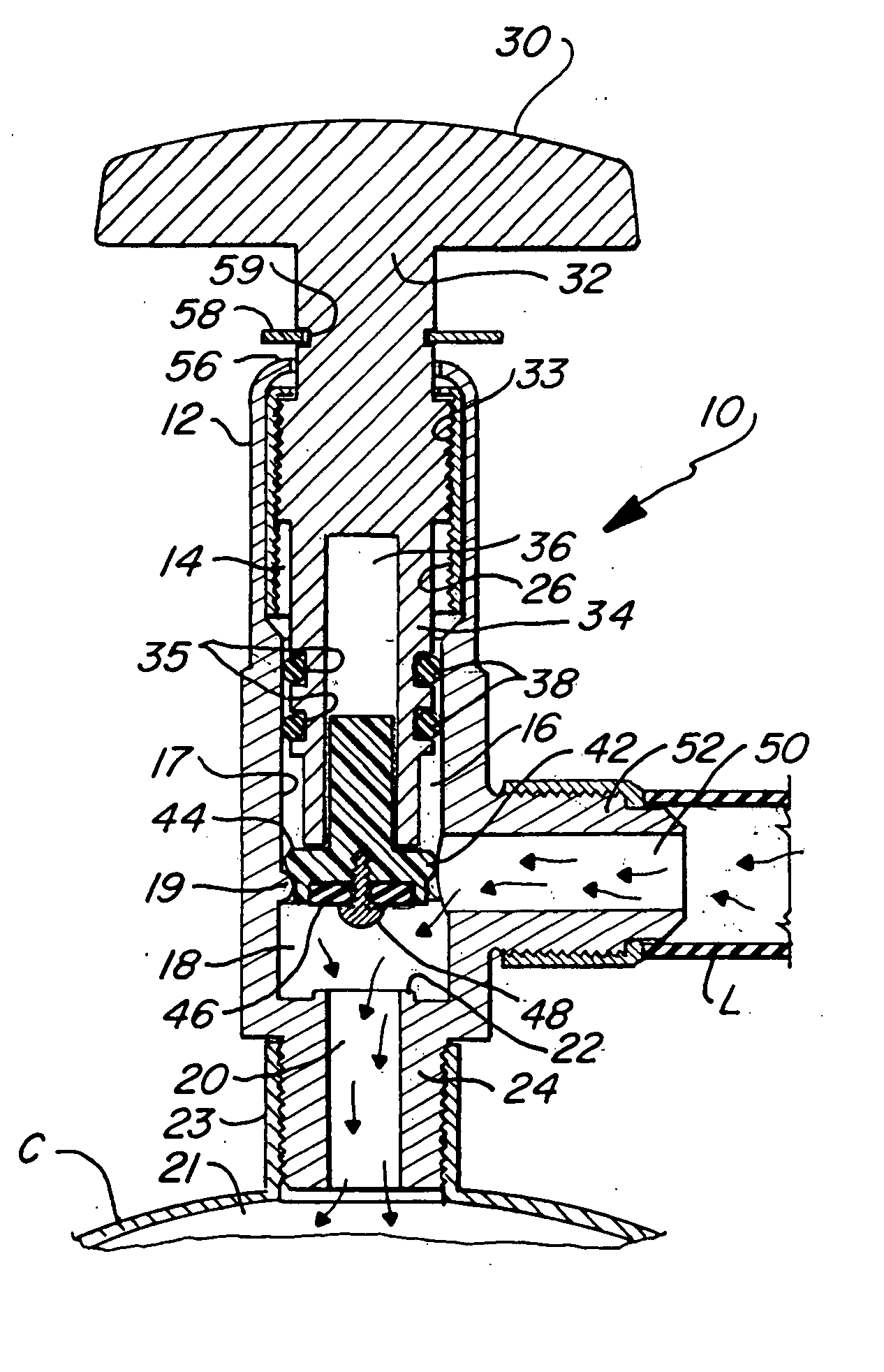

Non-refillable valve

InactiveUS20050082501A1Simple and reliable constructionThe overall structure is simple and reliableOperating means/releasing devices for valvesLift valveValve stemEngineering

A nonrefillable valve is provided that allows for an initial filling of a container, but prevents subsequent refilling of the container. The valve operating assembly includes a valve stem and a valve core which is slidably received in the distal end of the valve stem. In a first position, the valve core resides above a rim or protrusion within the chamber. After filling of the container, a second position is defined when the valve stem is operated to force the valve core beyond the protrusion and in seating engagement with a valve seat, thus sealing the container. The valve is then selectively operated in a third or open position to discharge the container as desired. Subsequent refilling of the container is prevented by the force of fluid reentering the valve which forces the valve core to its seated engagement with the valve seat.

Owner:DISCOUNT REFRIGERANTS

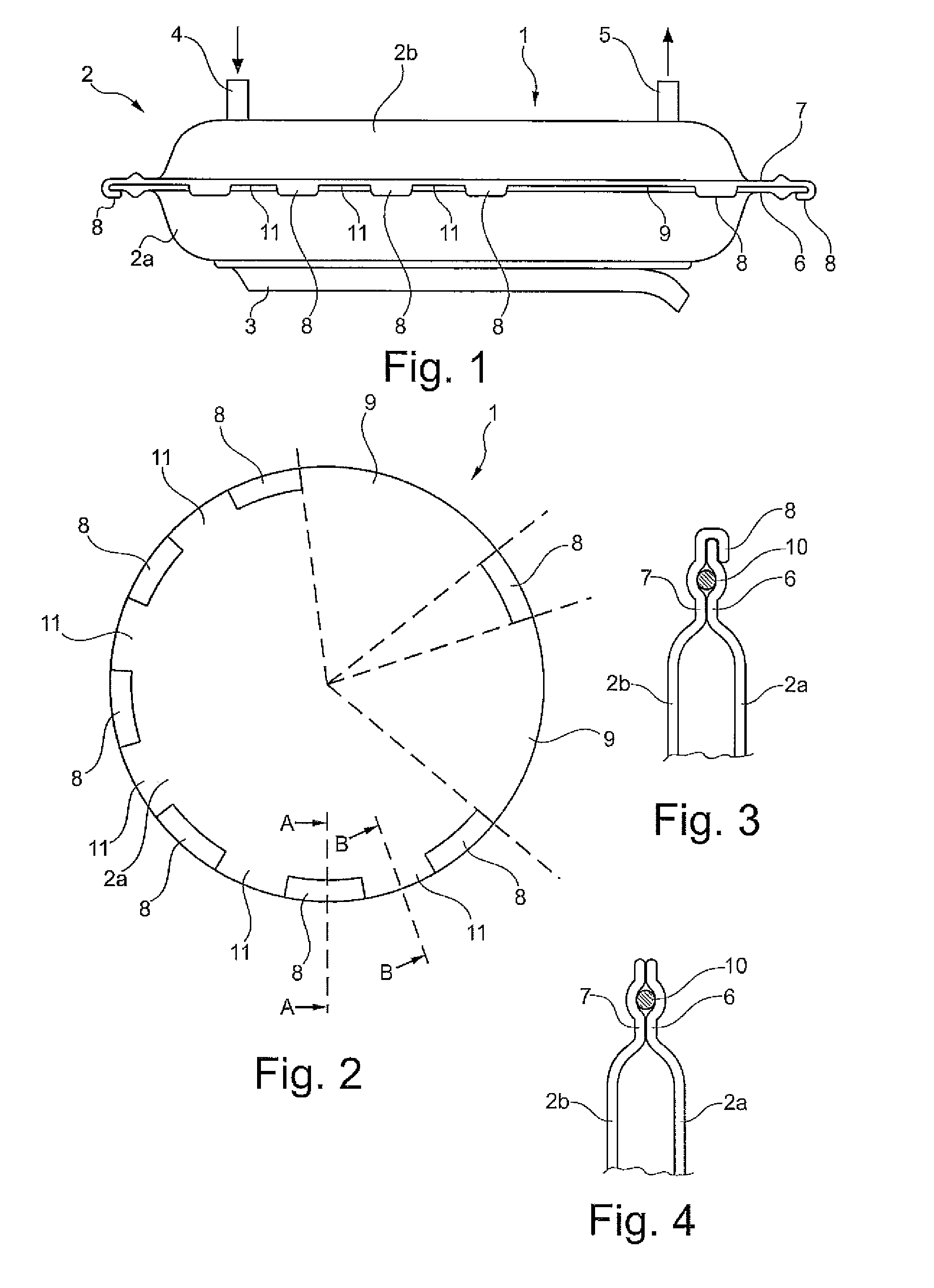

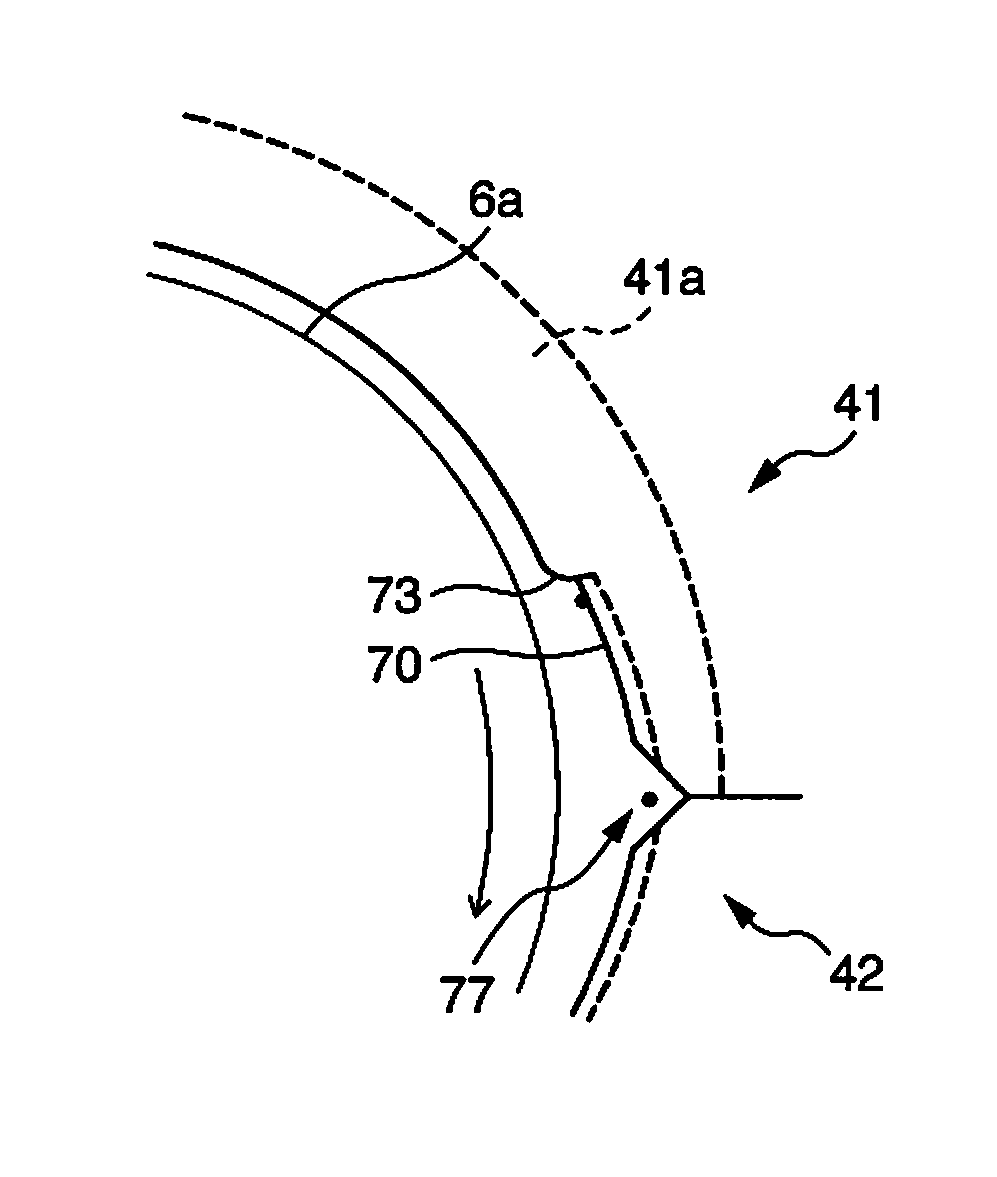

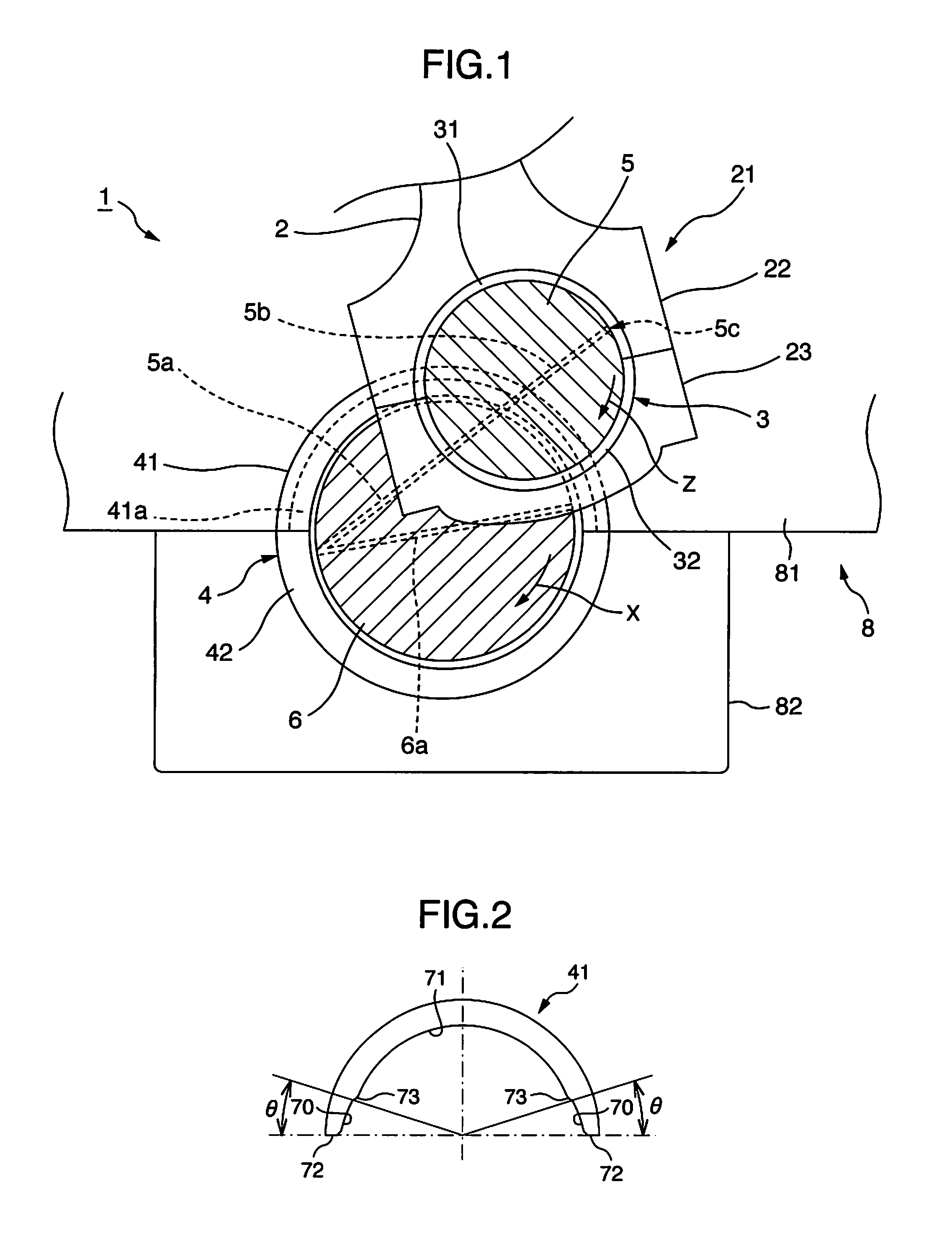

Main bearing for crankshaft of internal combustion engine

ActiveUS8979379B1Readily forcedExcellent in foreign matter discharging efficiencyCrankshaft bearingsShaftsExternal combustion engineEngineering

A main bearing for a crankshaft of an internal combustion engine has first and second half bearings forming an axial groove on an inner circumferential side of a butting portion. Each half bearing has a main cylinder portion including a central portion in a circumferential direction, and crush relief portions each extending toward the central portion from an end surface of the half bearing in the circumferential direction with a center angle of 3° to 15°. A plurality of crush relief grooves are formed in each crush relief portion to extend in the circumferential direction and communicate with the axial groove. The first half bearing has an oil groove extending in the circumferential direction and a transition region having an inward protruding curved surface with a wall thickness becoming thinner toward the crush relief portion from the main cylinder portion.

Owner:DAIDO METAL CO LTD

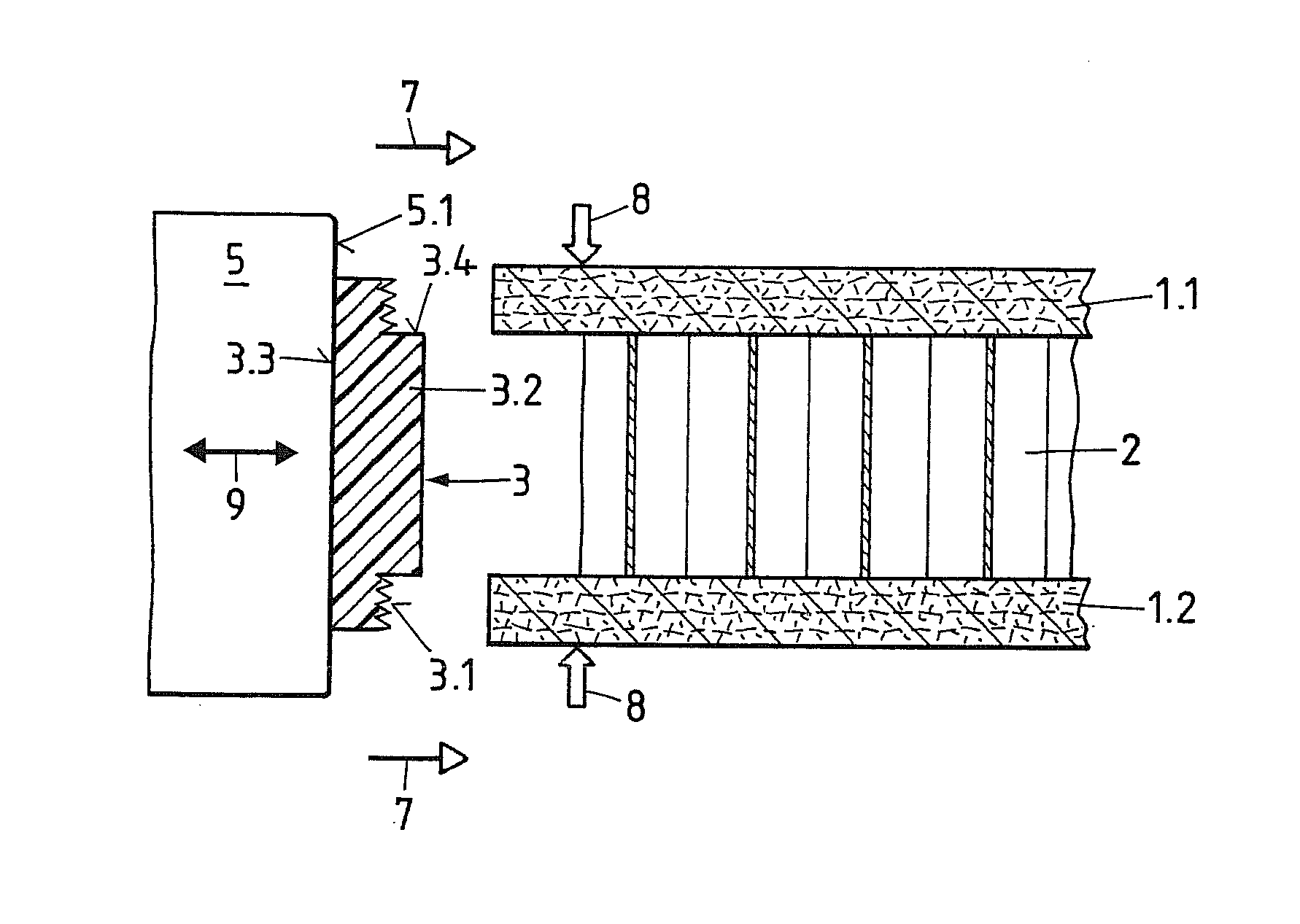

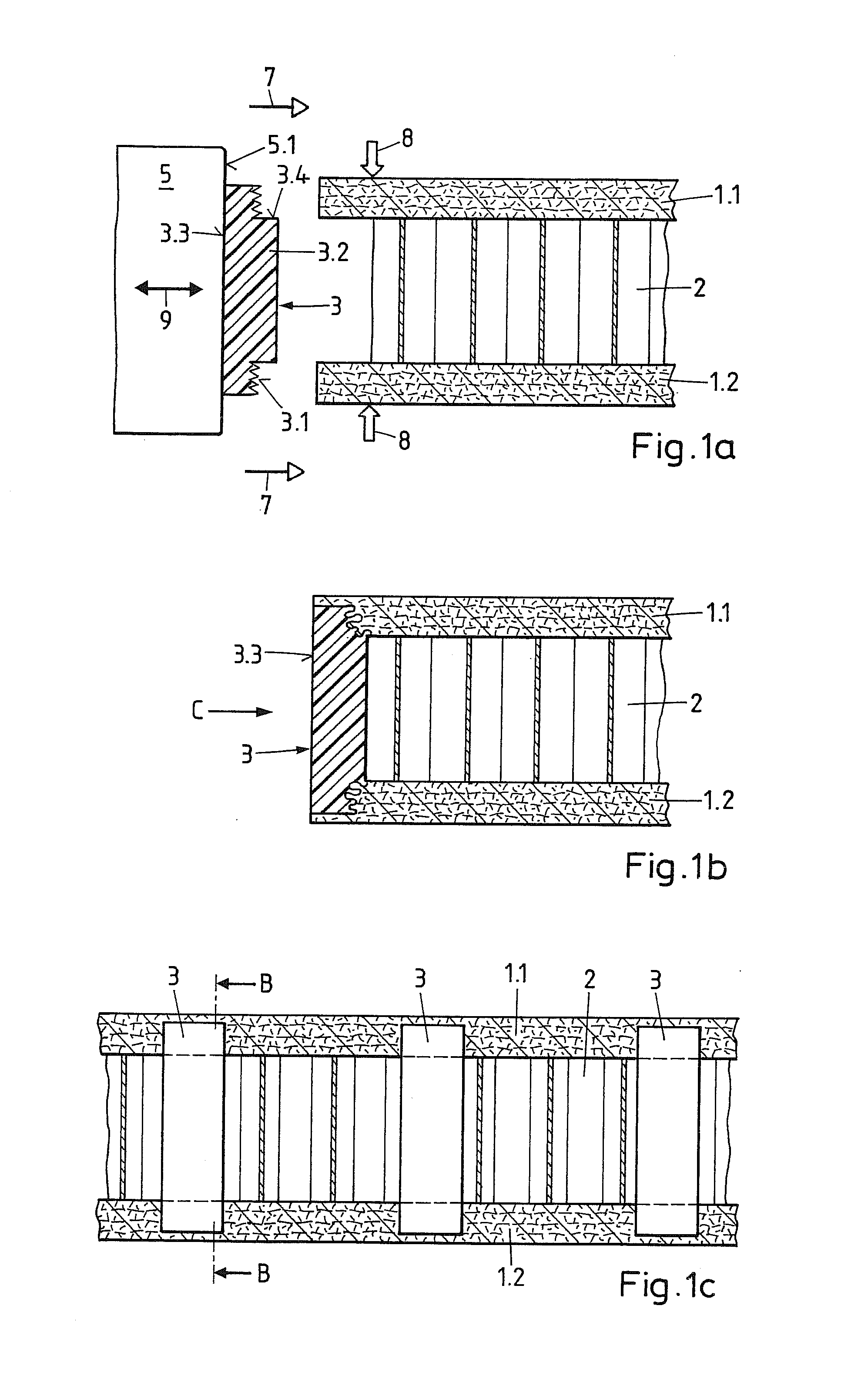

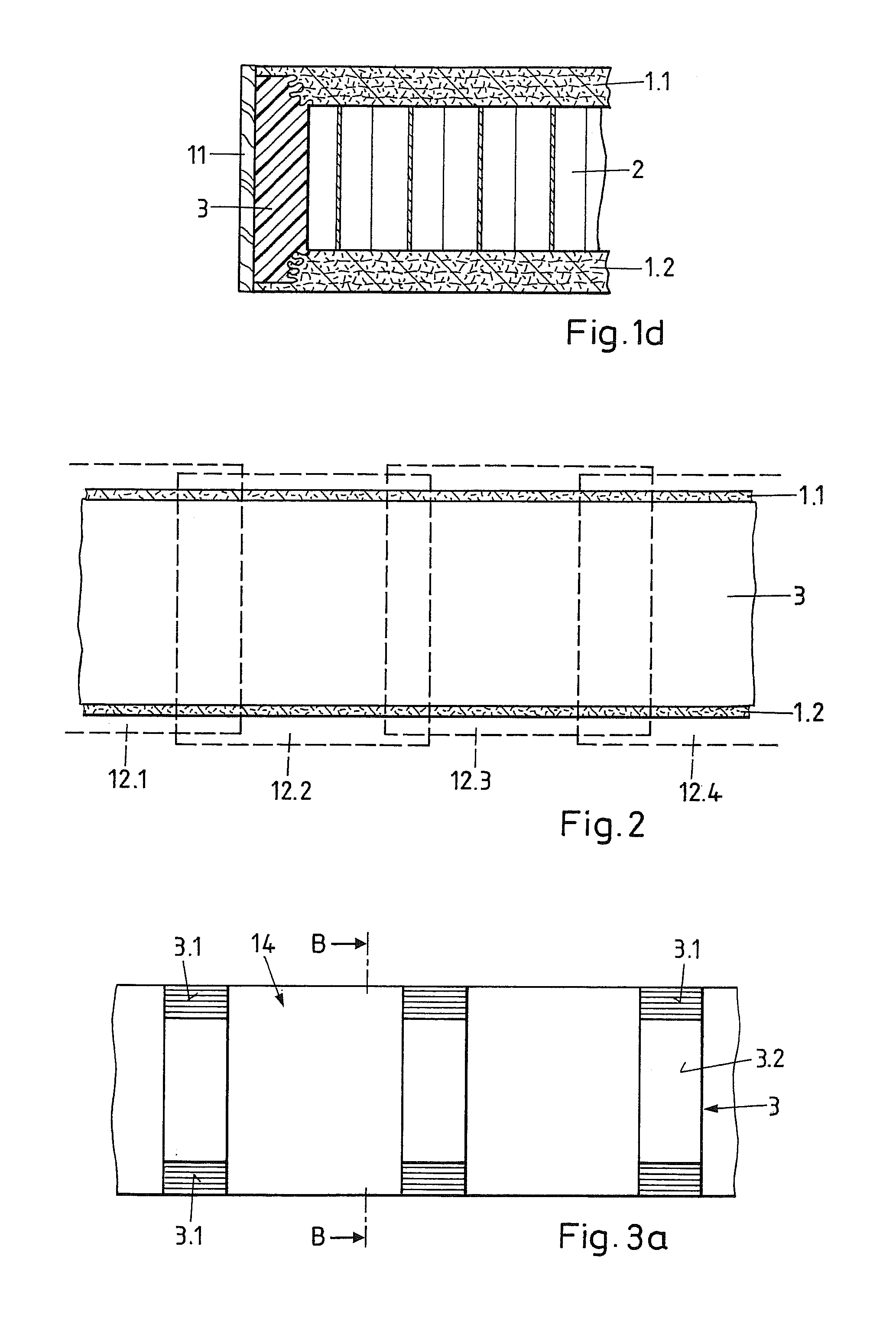

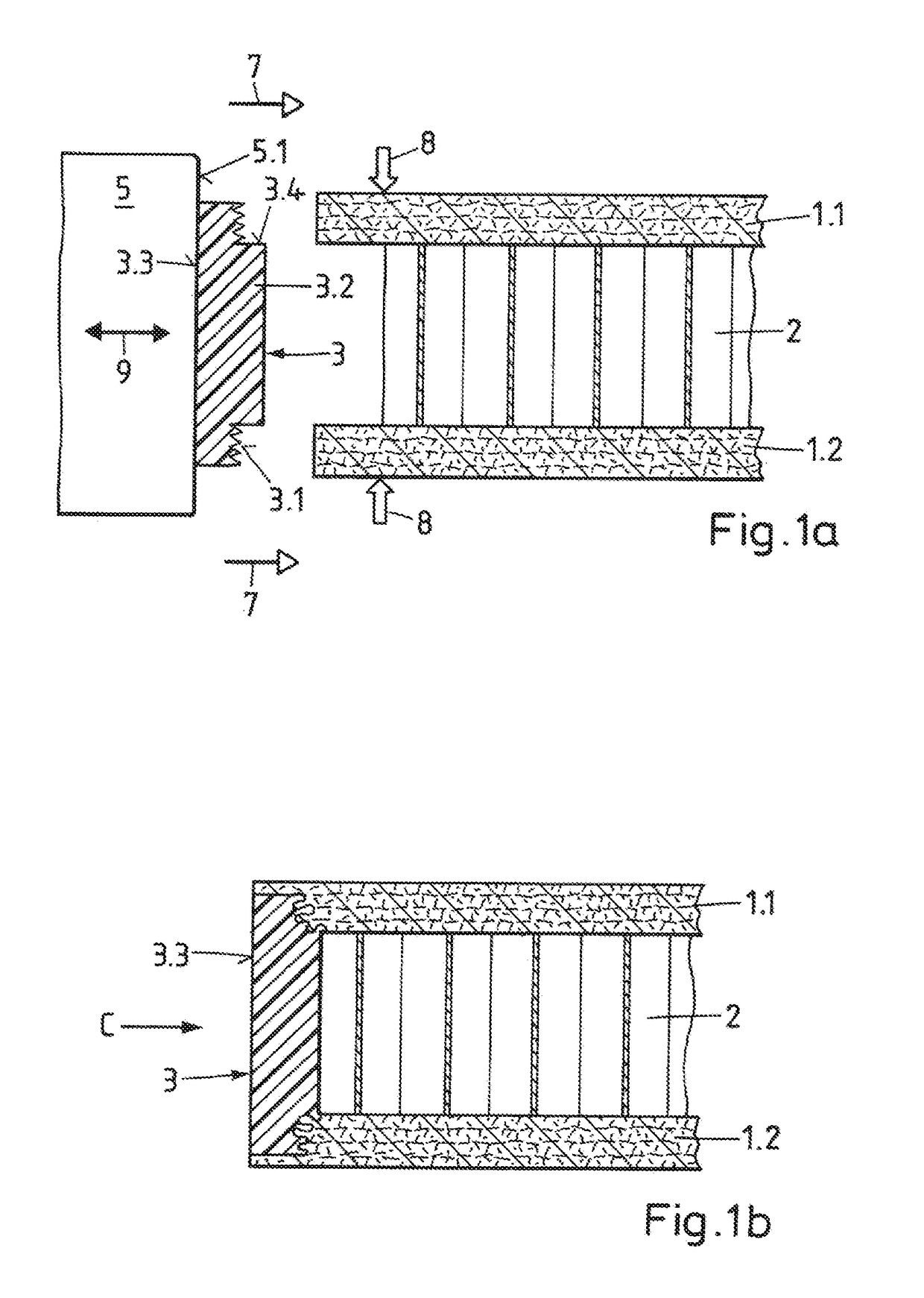

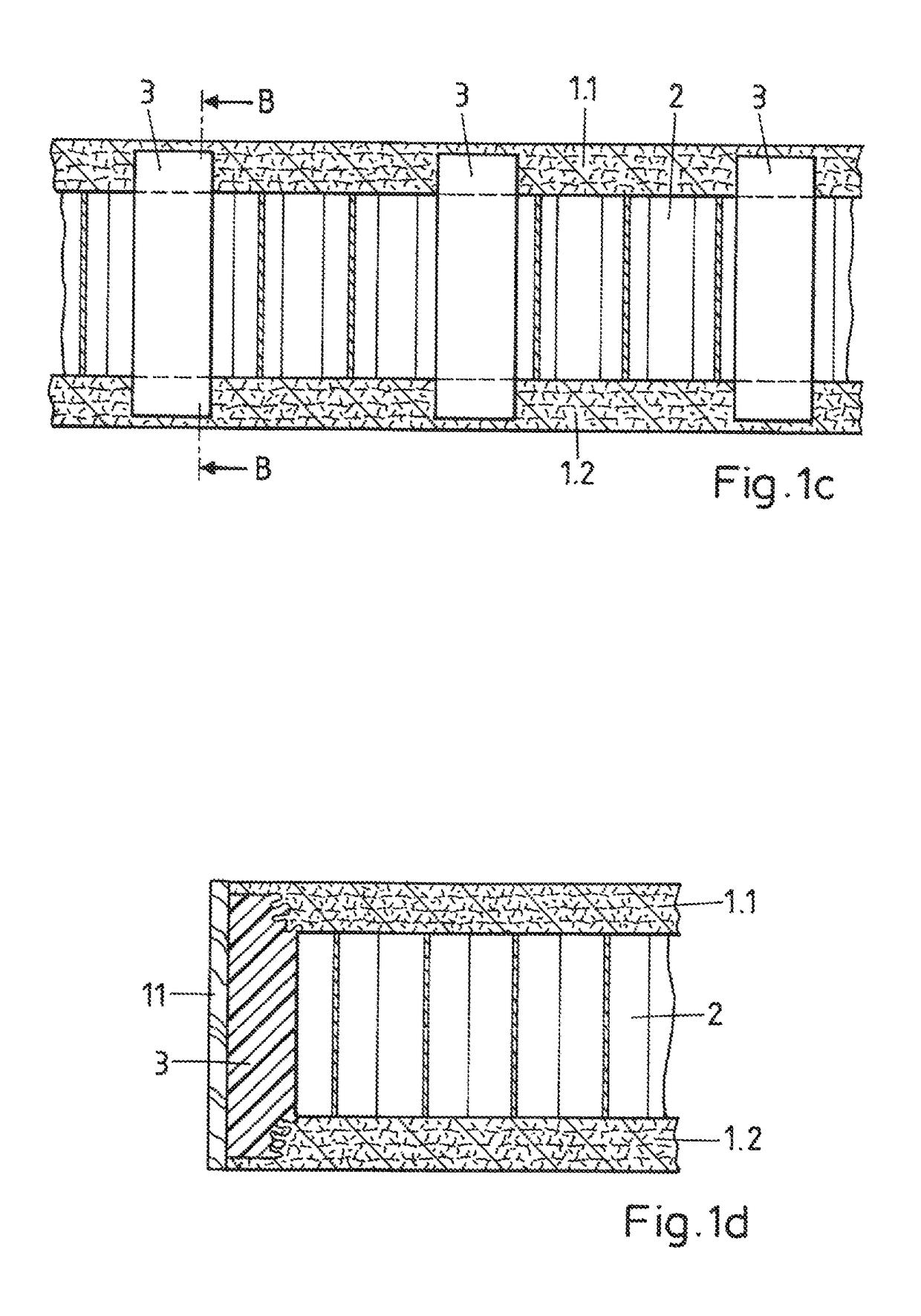

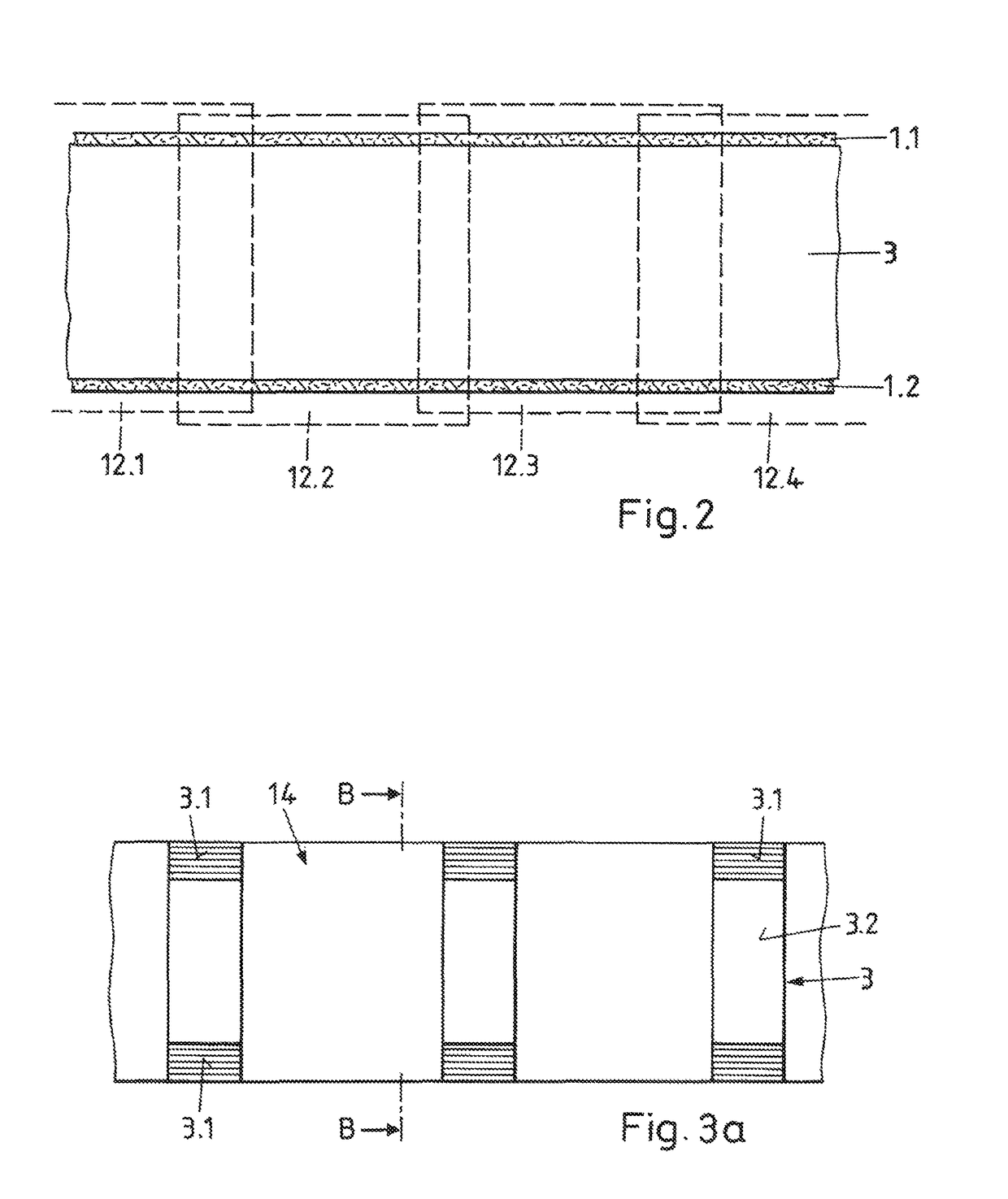

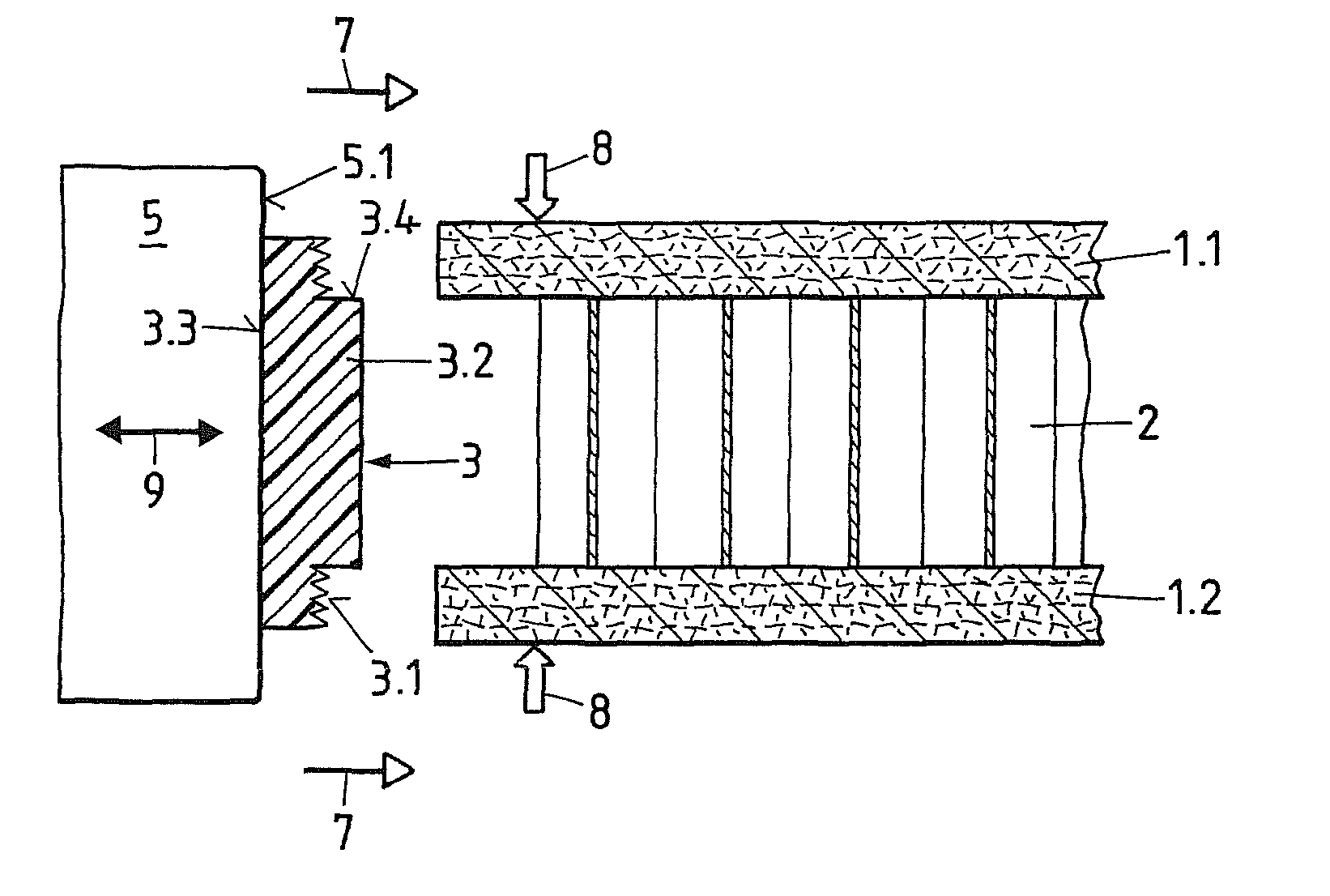

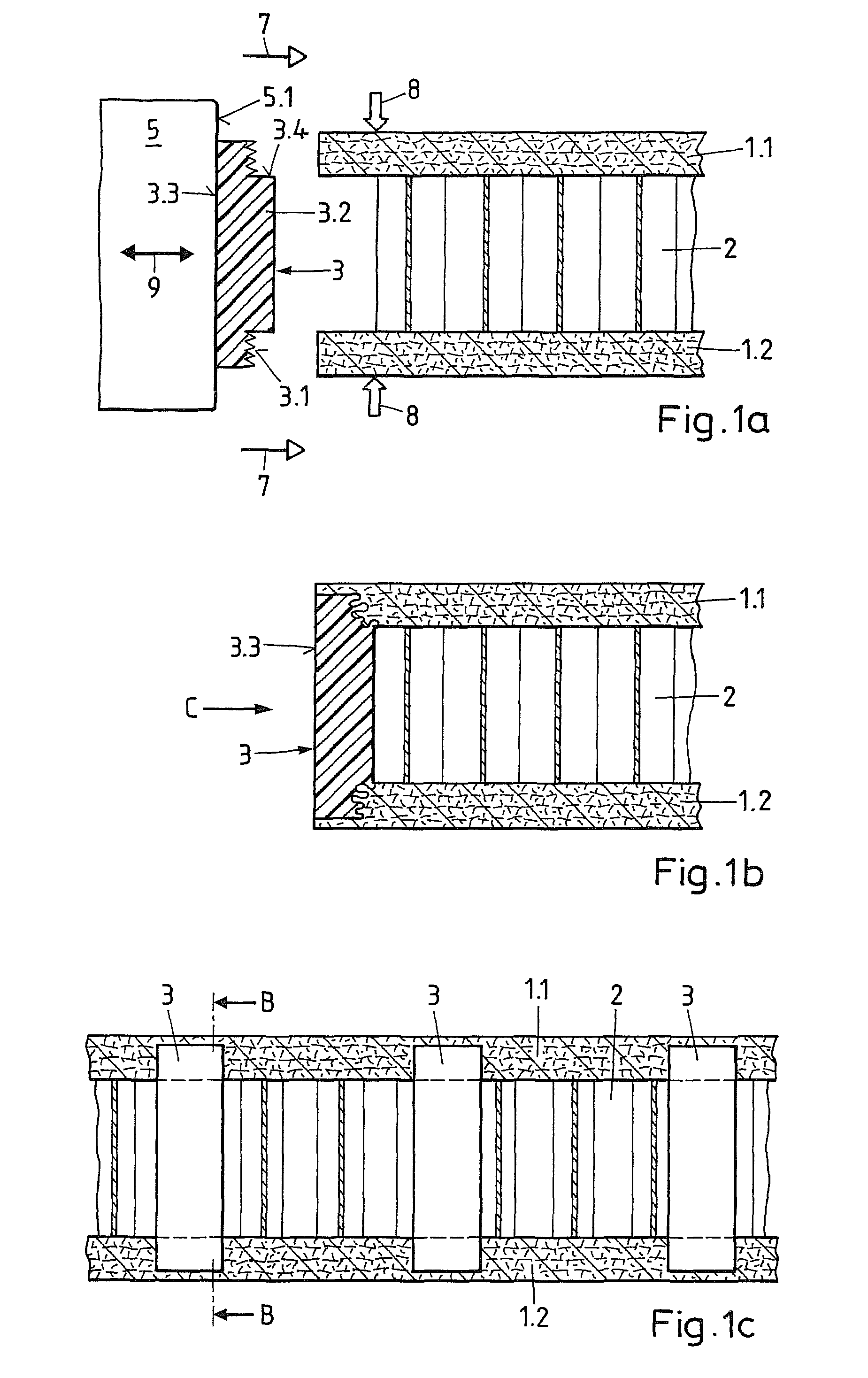

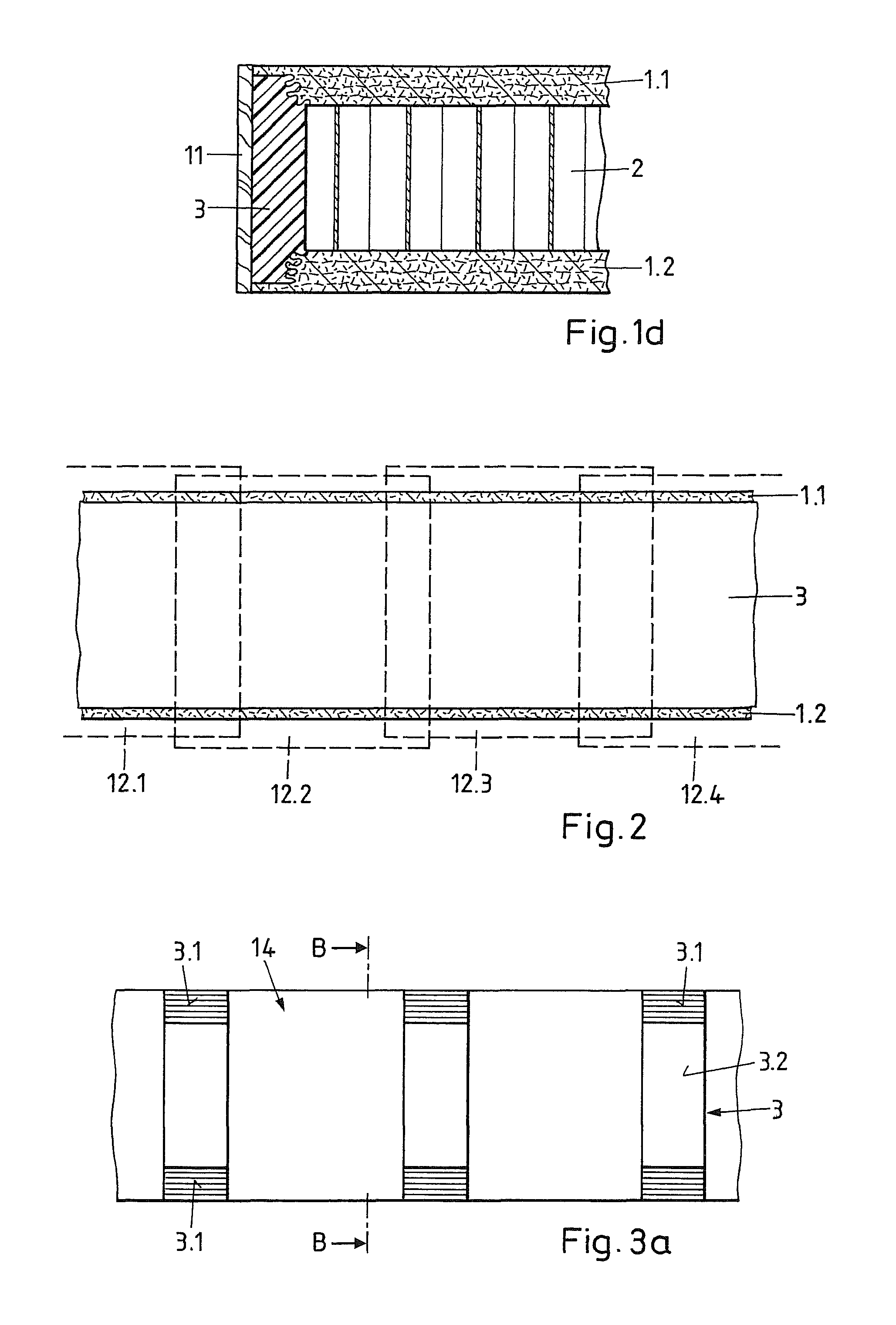

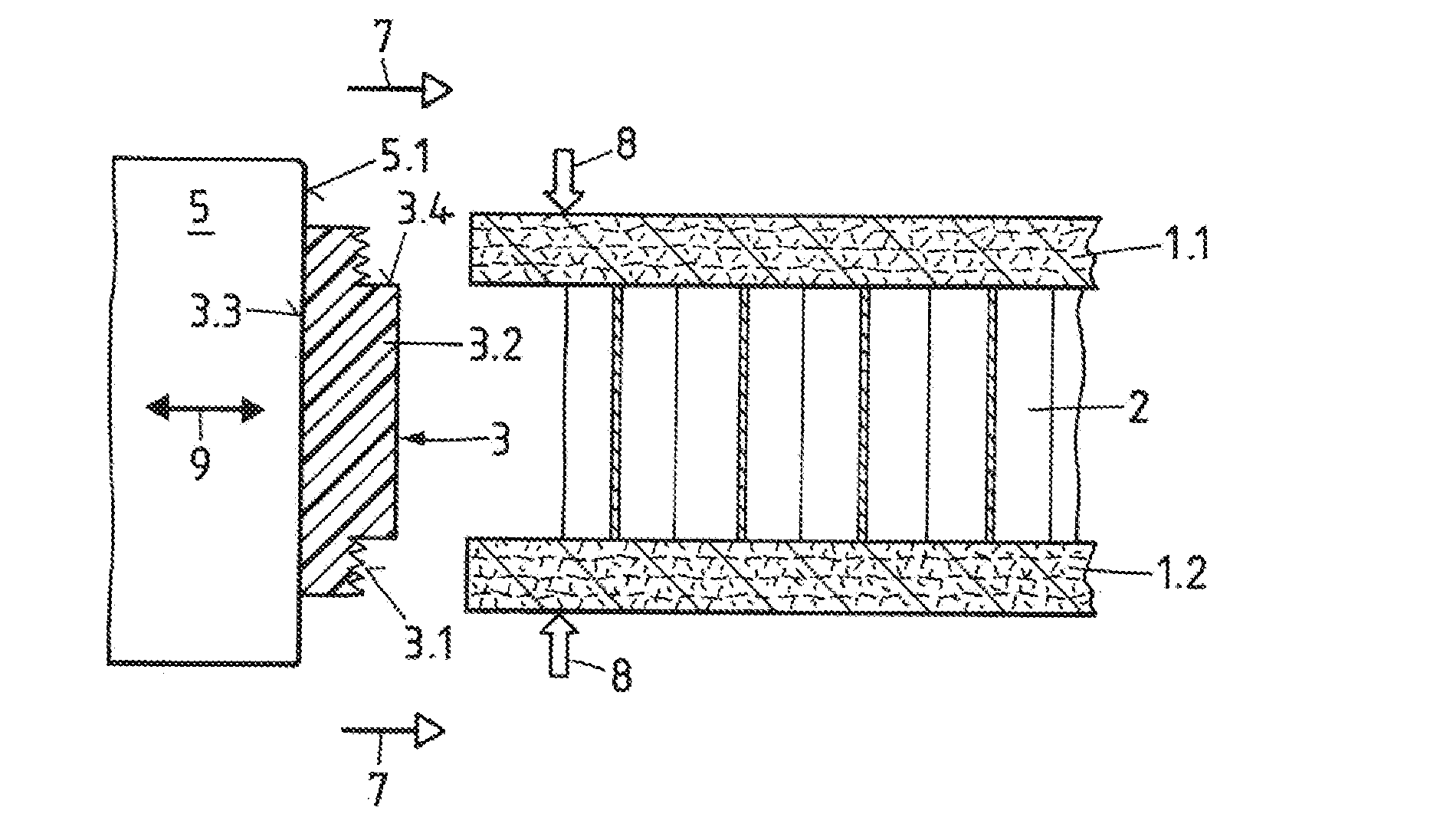

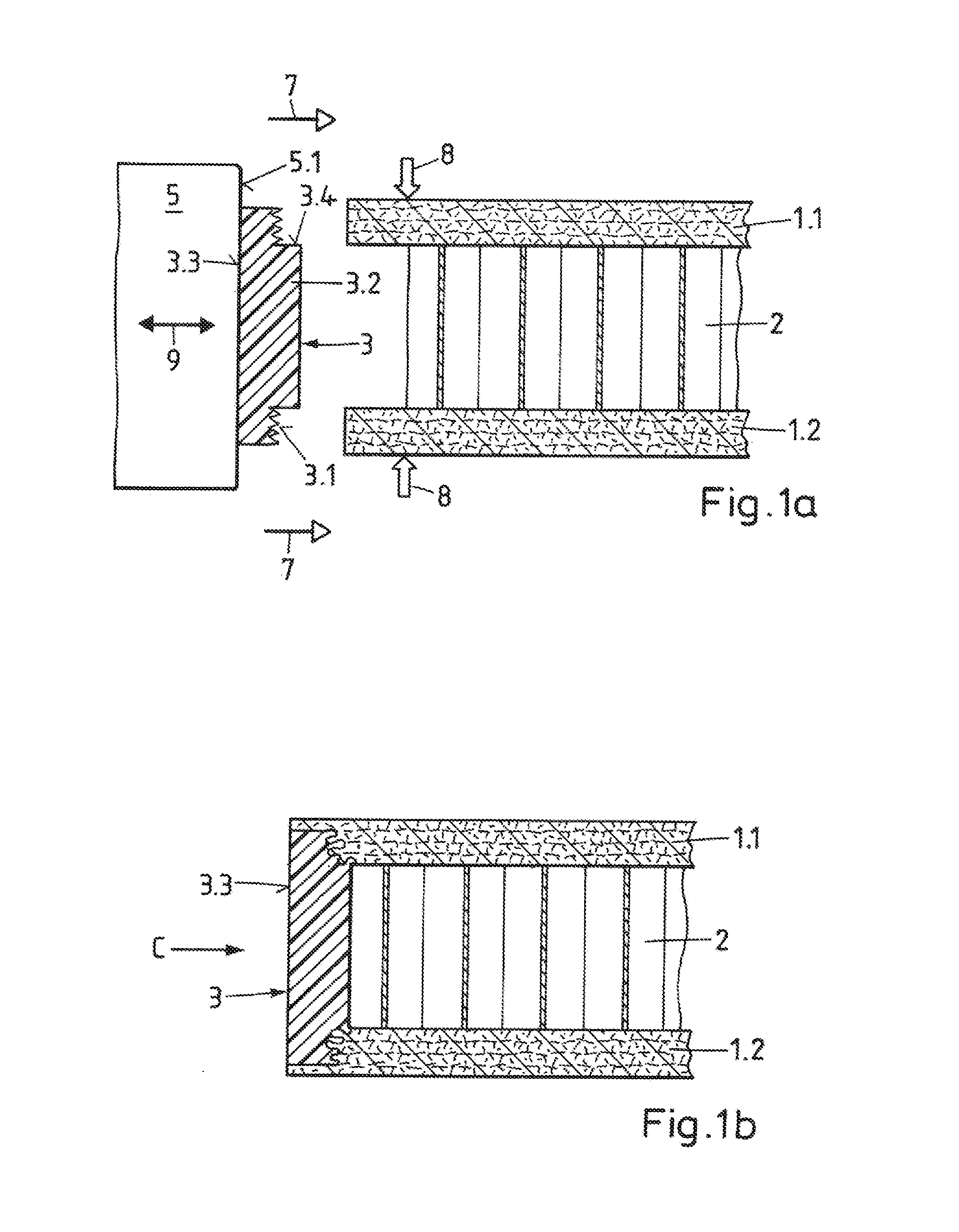

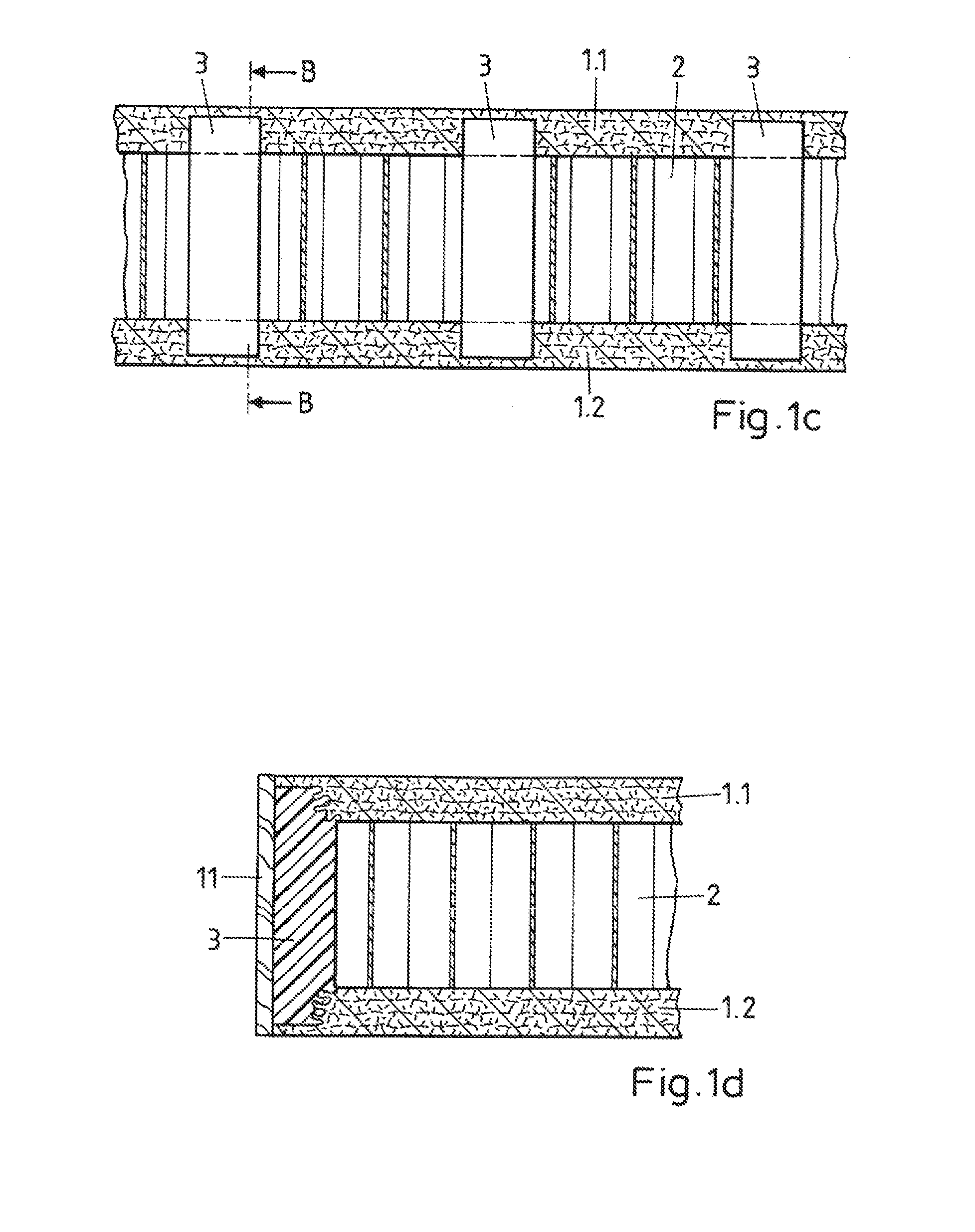

Method for producing a lightweight component, and support element

ActiveUS20110272078A1Low costSimple meansOther plywood/veneer working apparatusLaminationWaddingEngineering

The lightweight component is equipped with two cover layers, which are made of a wood material, for example, and a filling disposed in between said layers after cutting everything to size, having an edge support comprising thermoplastic material. This is done in that the edge support is anchored both in the first cover layer and in the second cover layer starting from the narrow side, wherein the anchoring is achieved in that the edge support is brought into contact with the respective cover layer and mechanical vibrations are coupled into the edge support by a sonotrode engaging from the narrow side, wherein the edge support at the same time is pressed against the cover layer such that in the region of a transition between the thermoplastic material and the wood material of the cover layer part of the thermoplastic material is liquefied and pushed into the cover layer material, thereby producing a positively engaged anchoring after hardening.

Owner:WOODWELDING

Viscous medium feeder

InactiveUS7648052B2Eliminate the problemReadily forcedLiquid surface applicatorsEngine of intermeshing engagement typeEngineeringDrive motor

Owner:MYDATA AUTOMATION

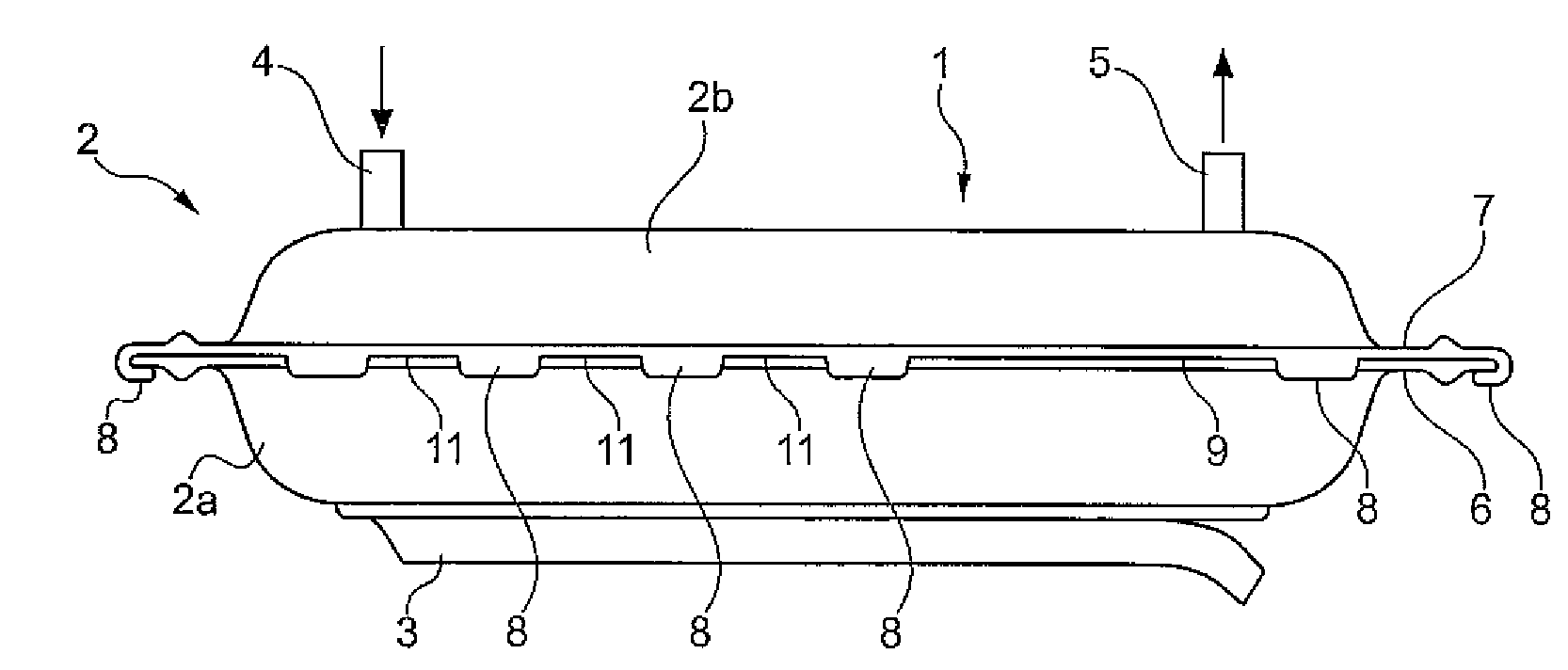

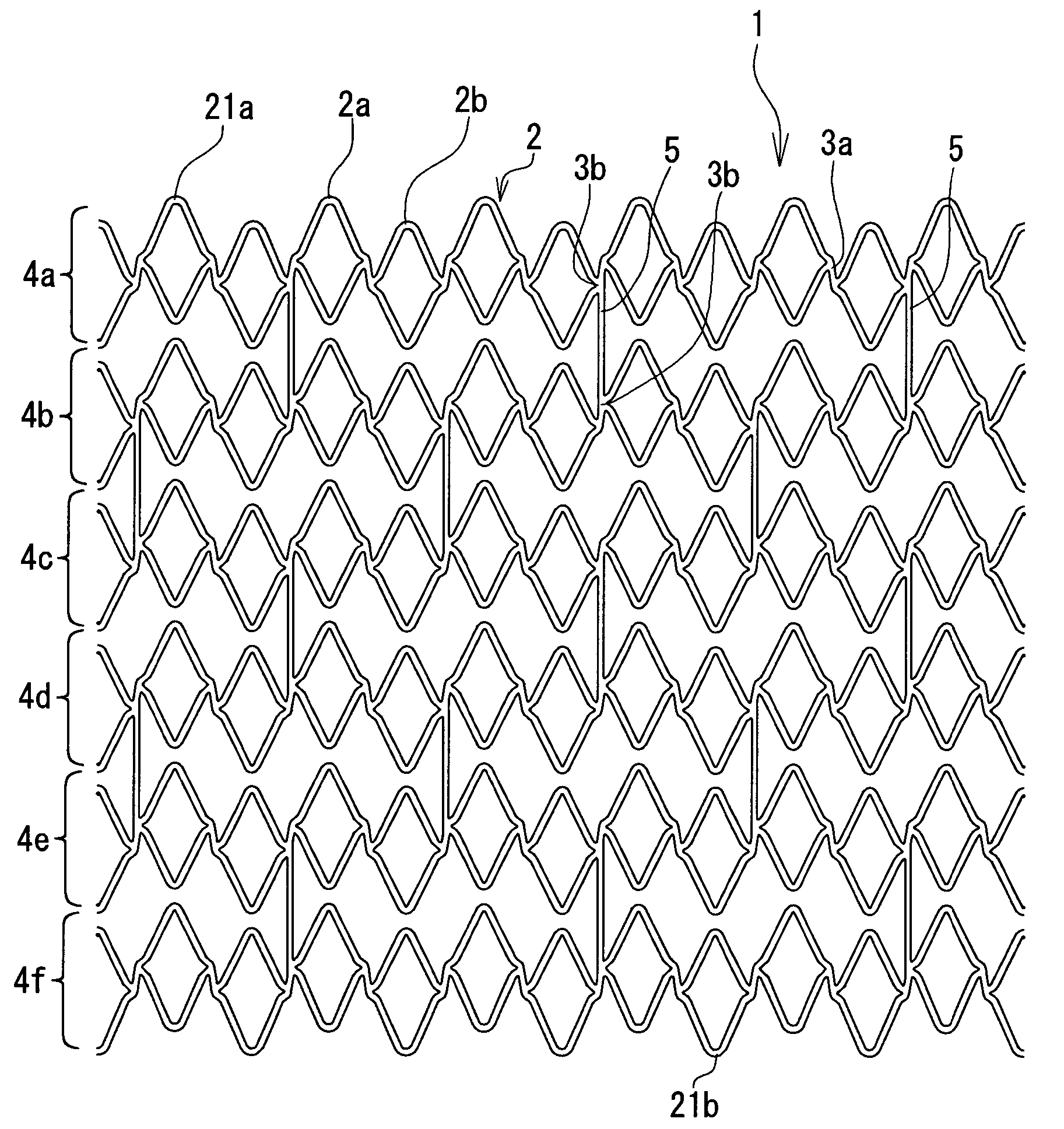

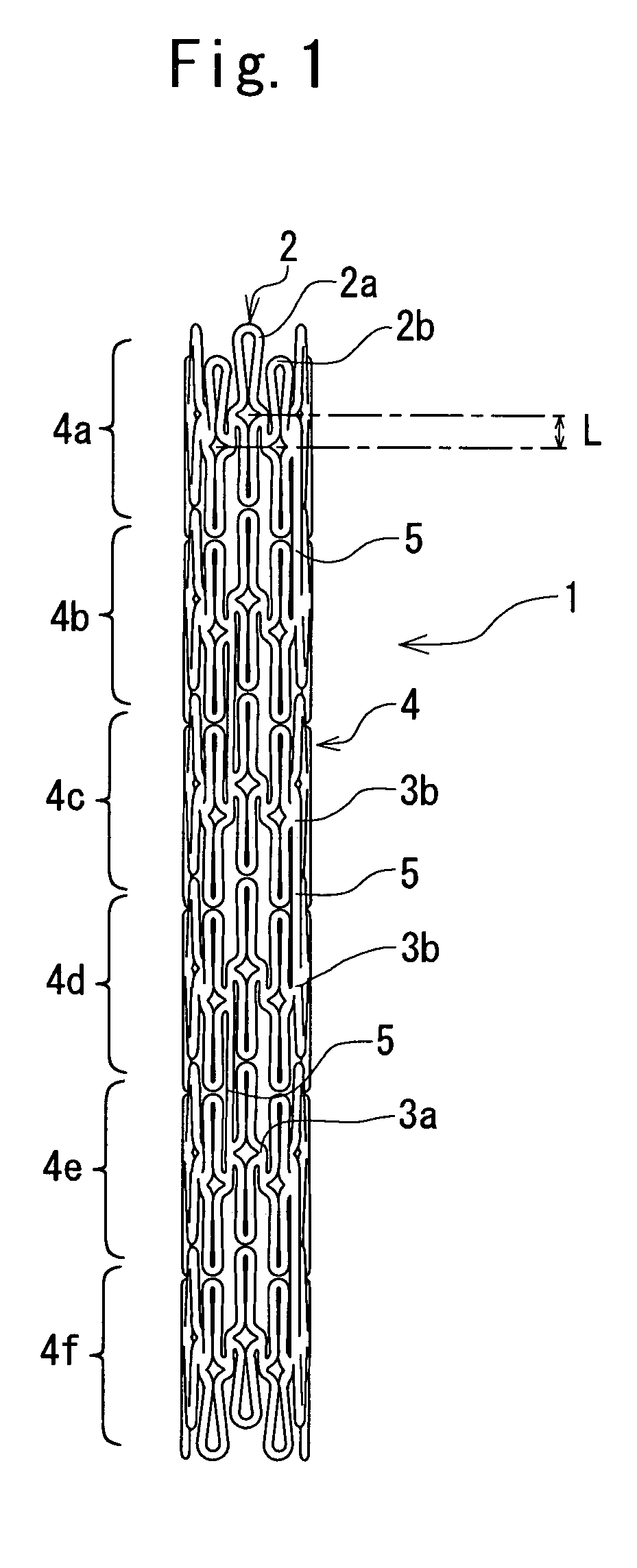

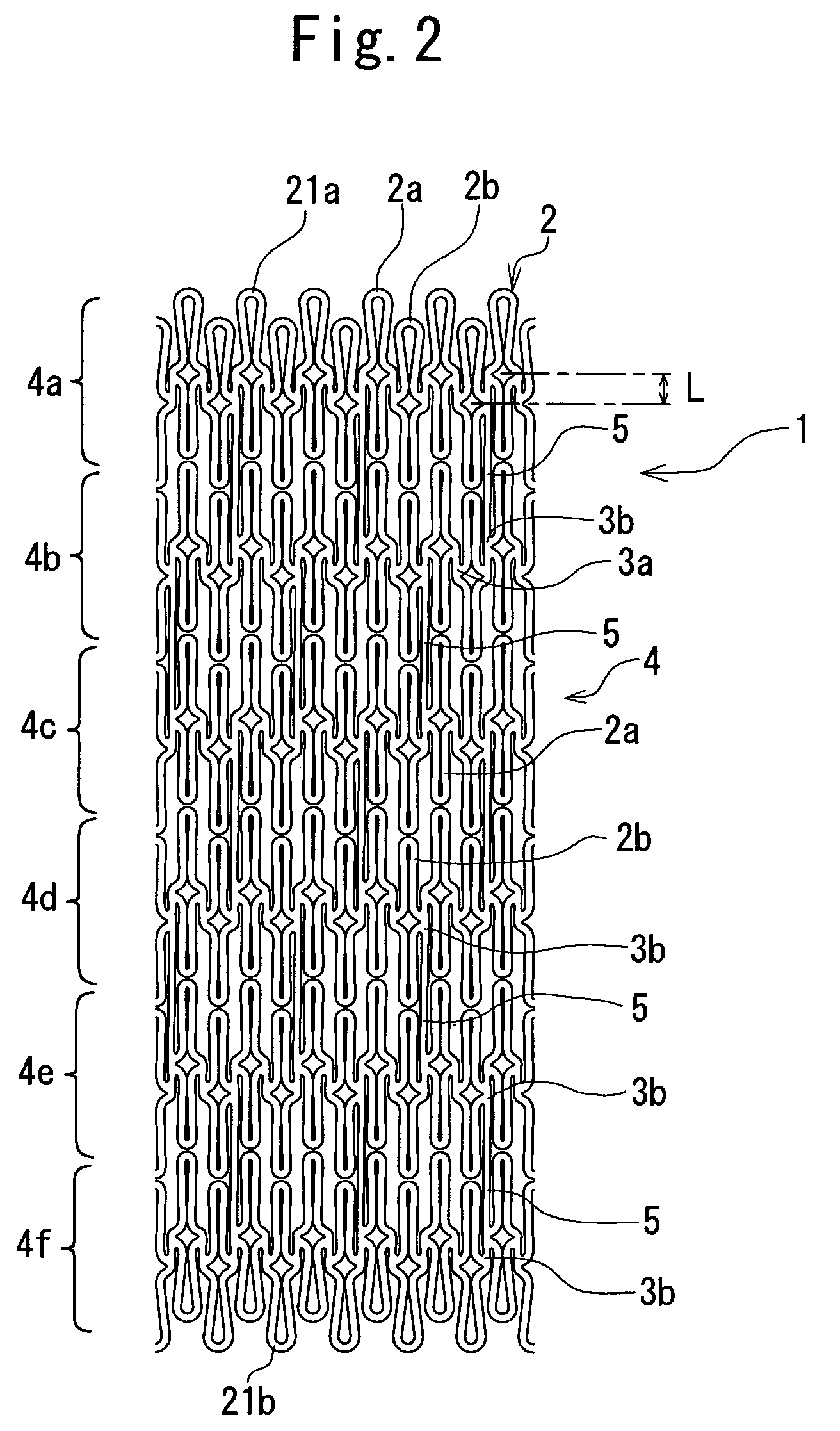

Indwelling stent and living organ dilator

ActiveUS7407508B2Good shape retentionLittle changed in overall lengthStentsSurgeryInsertion stentDilator

A stent includes annular units arranged in the axial direction of the stent, wherein each of the annular units includes a plurality of annular elements so arranged as to surround the stent axis, the adjacent annular elements being joined to each other through a joint, and the adjacent annular units are interconnected at their joints by at least one link. The annular elements in each annular unit are so arranged that one of the adjacent pair of annular elements is located on the proximal end side in the axial direction of the stent relative to the other of the adjacent pair of annular elements, end portions of each annular unit are projected zigzag, and the zigzag projected end portion of one annular unit is in the state of penetrating into the adjacent annular unit. The joints in each annular unit are substantially parallel to the stent axis.

Owner:TERUMO KK

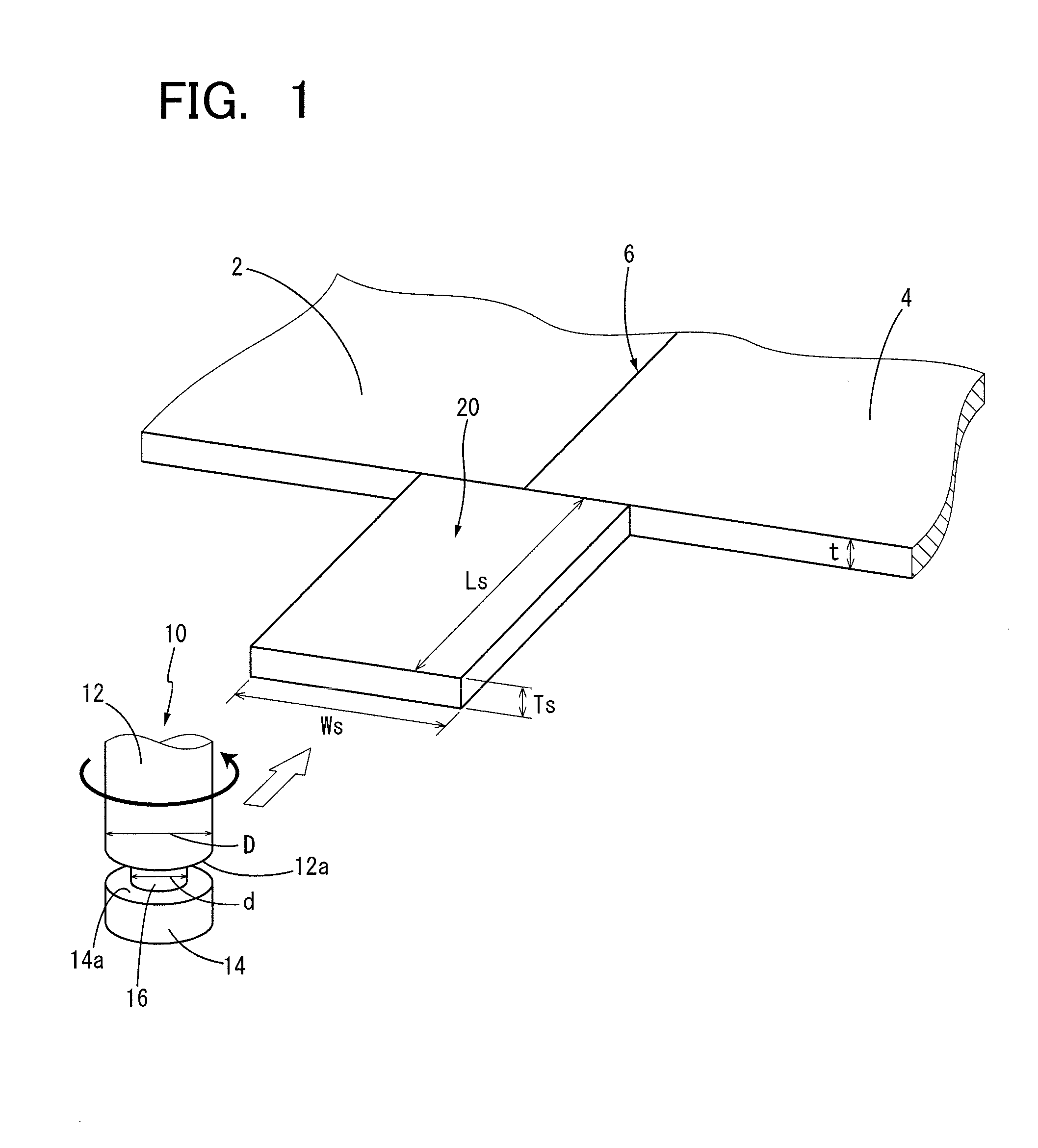

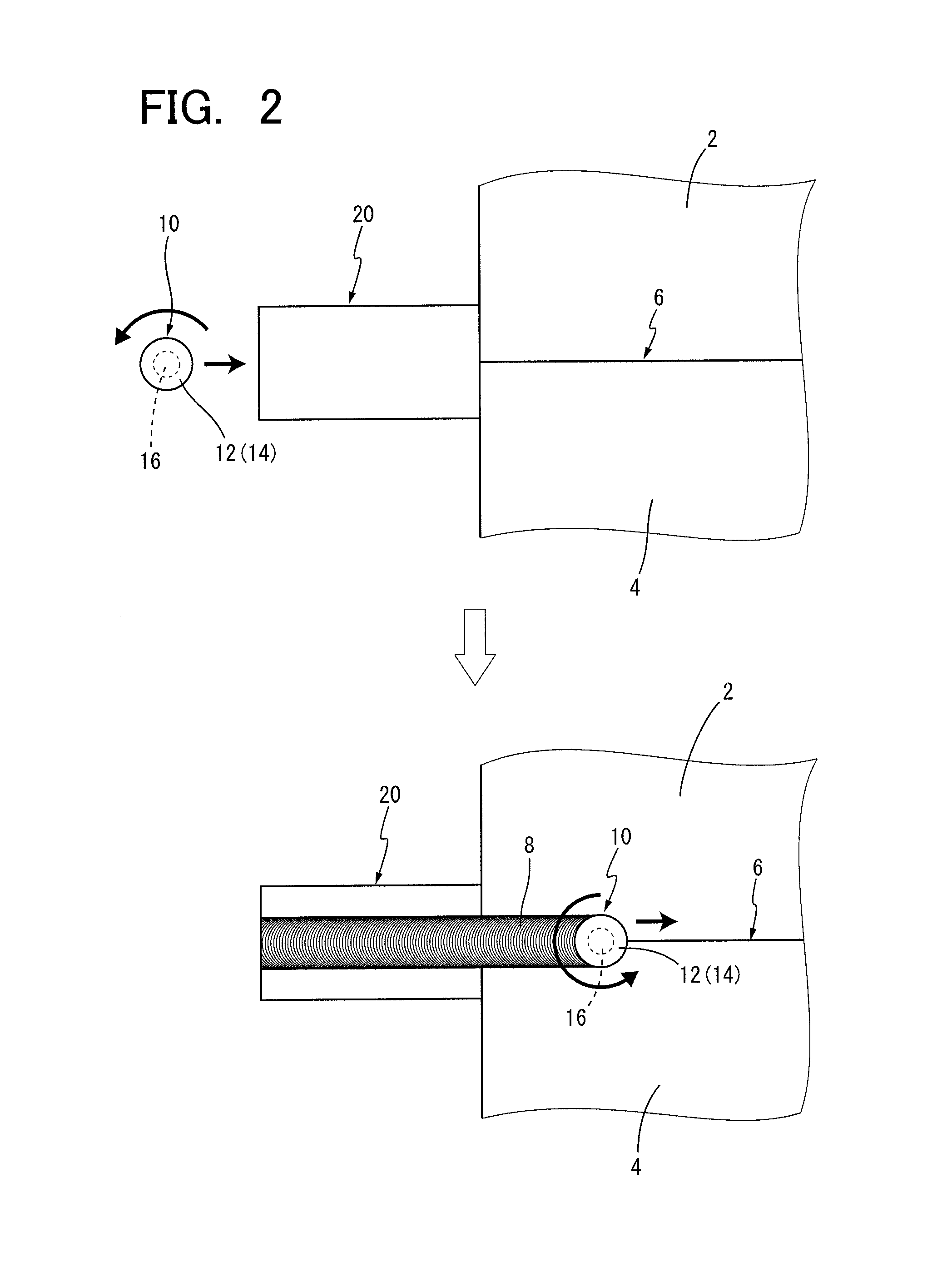

Friction stir welding method

ActiveUS20160151855A1Simple mixing processReadily forcedWelding/soldering/cutting articlesMetal working apparatusMaterials scienceFriction stir welding

A friction stir welding method which permits advantageous production of a product which has a sound welded area without joint defects, by joining together two members formed of the same material or respective different materials selected from a cast aluminum alloy and 2000 series, 4000 series, 5000 series and 7000 series aluminum alloys which are considered difficult to be joined together by the friction stir welding method. An initiation tab member formed of a 1000 series, 3000 series, 6000 series or 8000 series aluminum alloy is disposed in abutting contact with end faces of joining portions of first and second members (in an abutting part), on the side of initiation of the welding operation, and the friction stir welding operation is performed by moving a probe of a rotary tool through the initiation tab member into the joining portions of the two members.

Owner:FURUKAWA SKY ALUMINUM CORP

Pressure sensing device and use of the same in a connecting structure

ActiveUS8113060B2Readily forcedFluid pressure measurement using elastically-deformable gaugesSuction devicesTransducerPressure sense

A pressure sensing device adapted for having a liquid flowing there through and for sensing the pressure of said liquid. The device has a casing being fluid-tightly divided into a first and a second chamber by a flexible, impermeable wall. The first chamber has a first opening for the liquid, said opening being placed at the lower part of the chamber, and a second opening for the liquid, said opening being placed at the top of the first chamber. The second chamber has a measuring port, which is connectable to a pressure transducer for bringing the second chamber into gas-tight communication with the pressure transducer. The device has a first orifice to permit the liquid to flow into and out of the device, the orifice being placed at the upper part of the device at a higher level than the second opening. A first channel is connecting the first orifice with the first opening. A second orifice permits the liquid to flow out of and into the device and is placed at the lower part of the device at a lower level than the first opening. A second channel connects the second opening with the second orifice.

Owner:GAMBRO LUNDIA AB

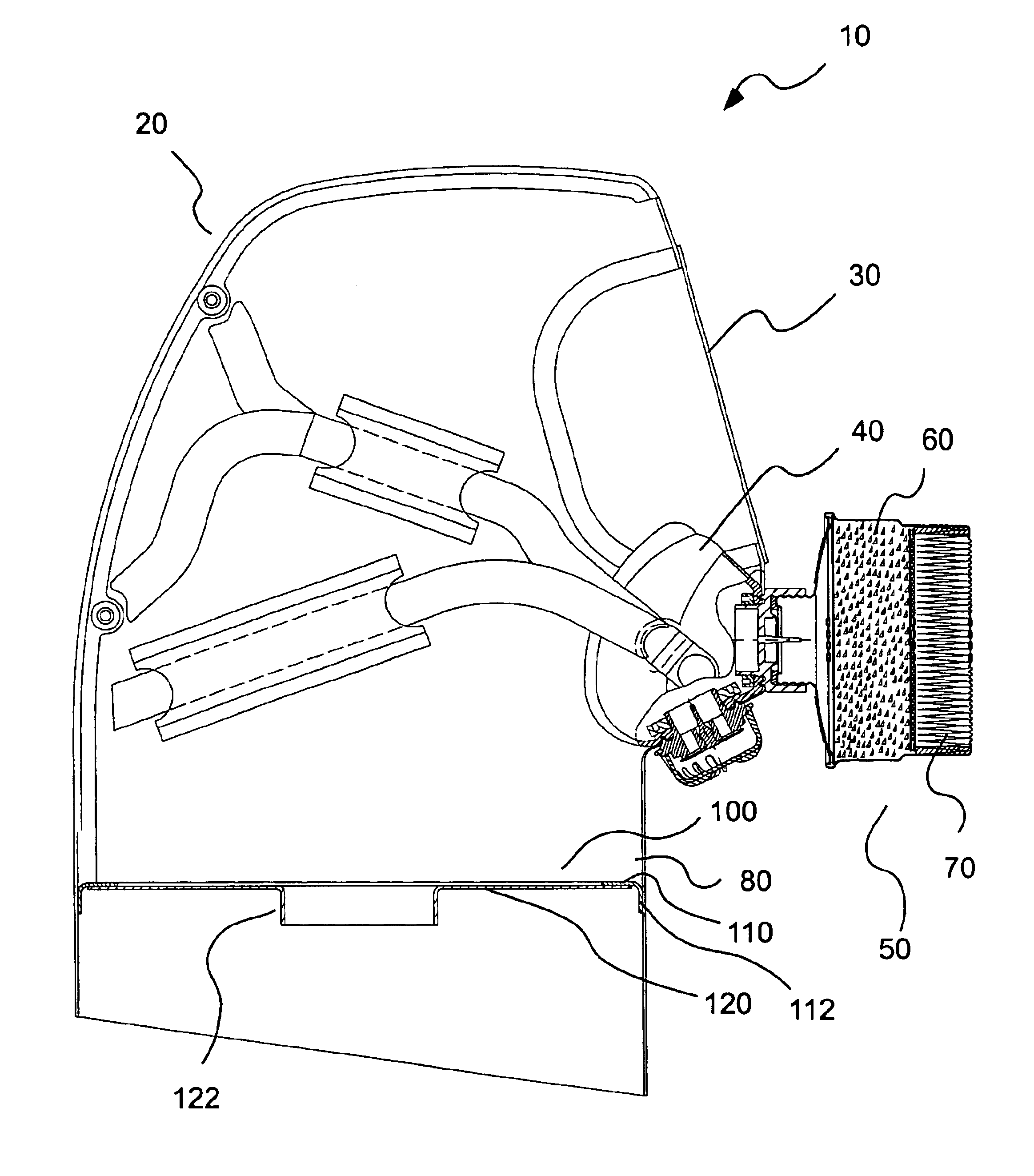

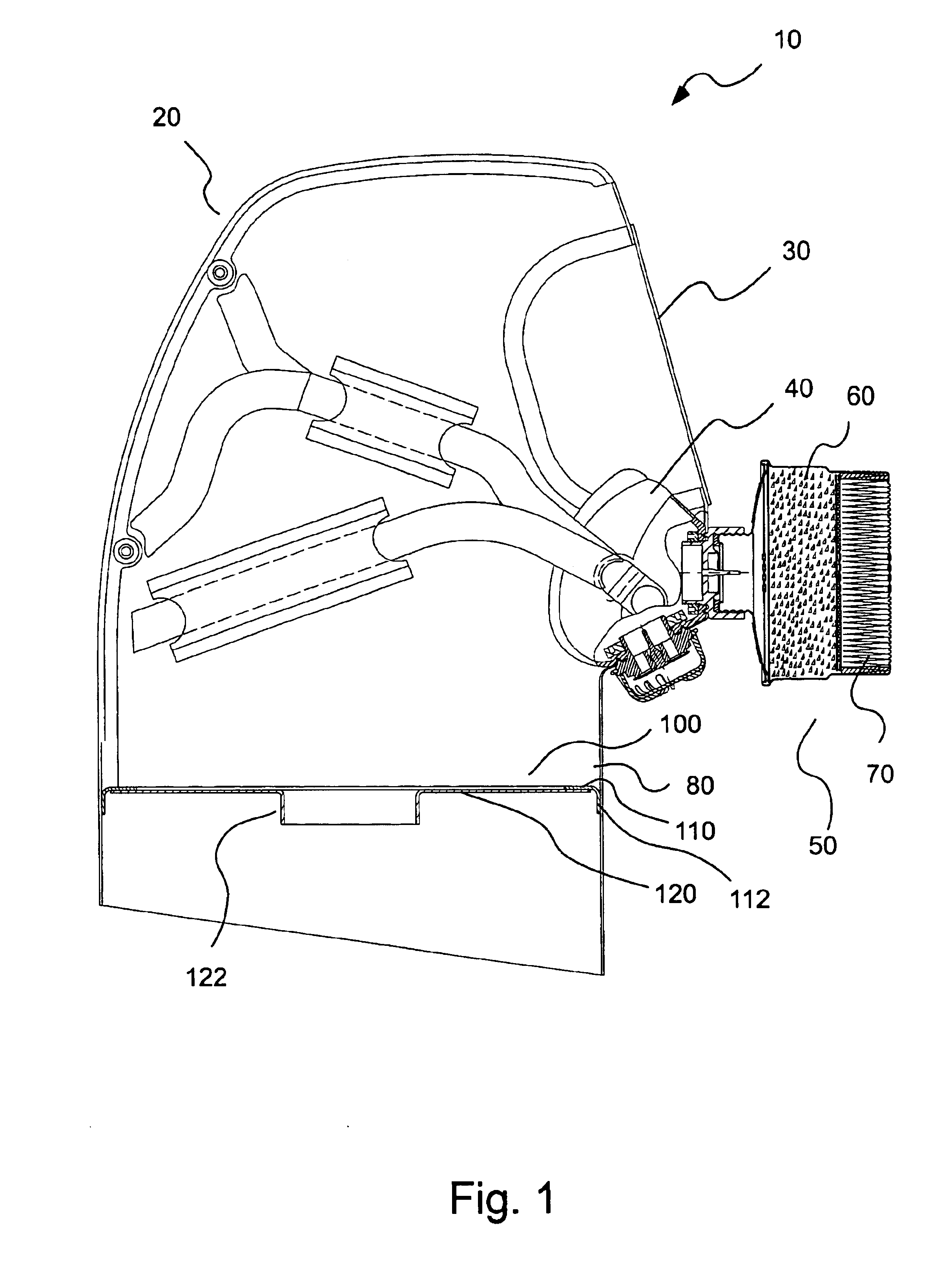

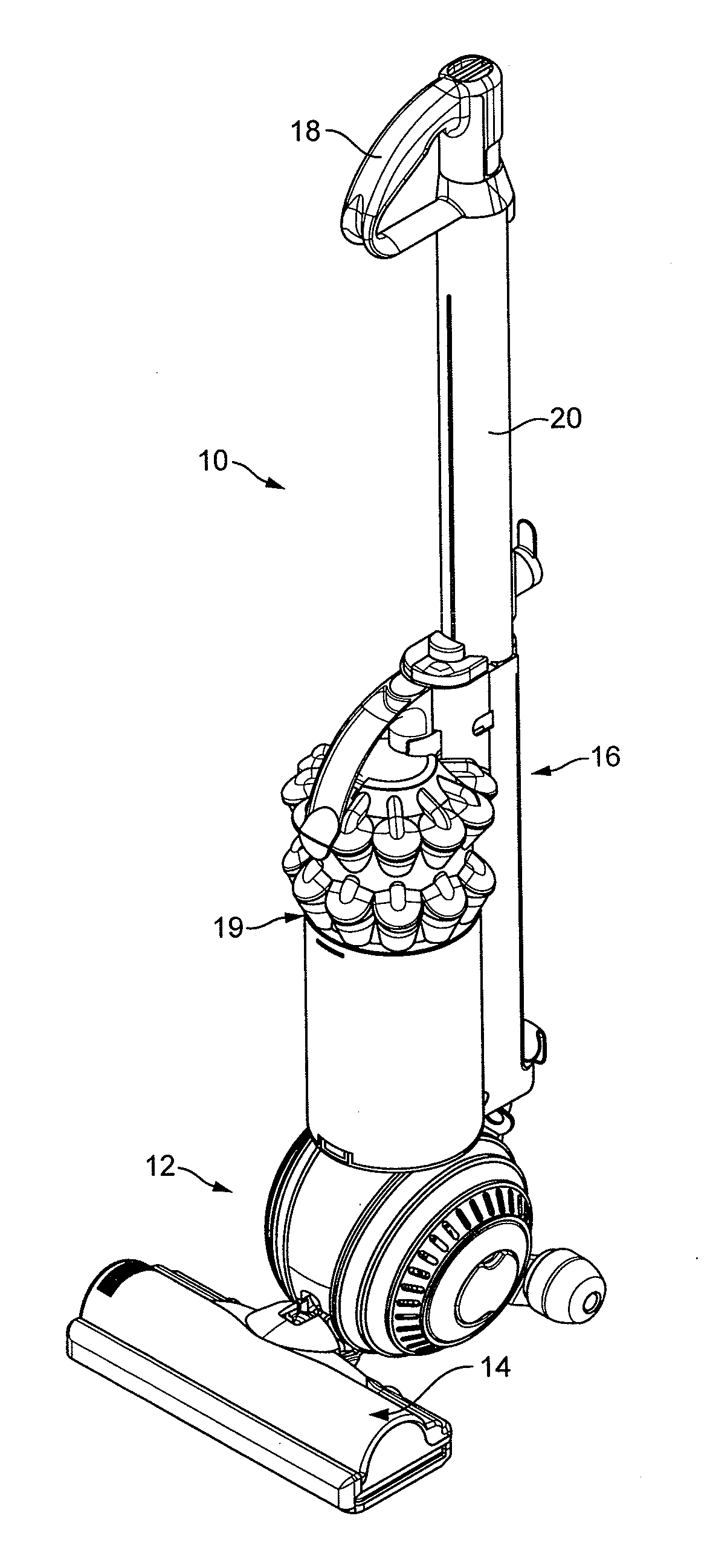

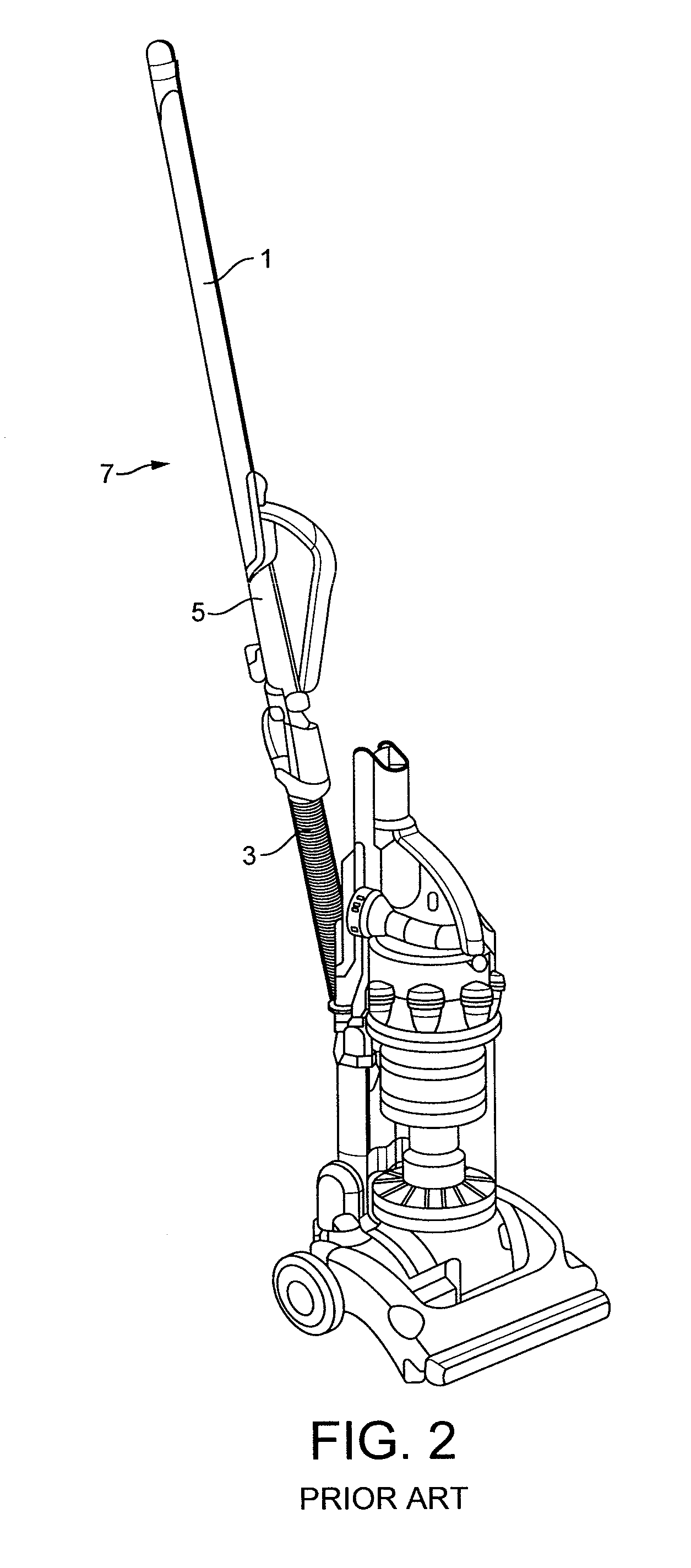

Upright vacuum cleaner

InactiveUS20130081226A1Compact storageConvenient ArrangementSuction hosesSuction nozzlesEngineeringVacuum cleaner

An upright vacuum cleaner comprising a telescopic suction wand fluidly connected to a separating apparatus on the cleaner via a hose and which is used, as required, to clean above the level of the floor. The wand comprises a lower wand section, an upper wand section telescopically mounted to the lower wand section and a moveable locking member which, when the wand is released for use, is biased towards a locking position for locking out the wand sections in telescopic extension. The locking member is releasable from this locking position via a reaction member provided on the cleaner, against which reaction member a user may readily force the biased locking member out of the locking position using the locked-out wand.

Owner:DYSON TECH LTD

Method of fastening an edge structure to a construction element

ActiveUS10059076B2Improve stabilityMinimize impactOther plywood/veneer working apparatusLaminationCouplingEnergy coupling

Owner:WOODWELDING

Method for producing a lightweight component, and support element

ActiveUS8597446B2Readily forcedSmall depthOther plywood/veneer working apparatusLaminationWaddingEngineering

The lightweight component is equipped with two cover layers, which are made of a wood material, for example, and a filling disposed in between said layers after cutting everything to size, having an edge support comprising thermoplastic material. This is done in that the edge support is anchored both in the first cover layer and in the second cover layer starting from the narrow side, wherein the anchoring is achieved in that the edge support is brought into contact with the respective cover layer and mechanical vibrations are coupled into the edge support by a sonotrode engaging from the narrow side, wherein the edge support at the same time is pressed against the cover layer such that in the region of a transition between the thermoplastic material and the wood material of the cover layer part of the thermoplastic material is liquefied and pushed into the cover layer material, thereby producing a positively engaged anchoring after hardening.

Owner:WOODWELDING

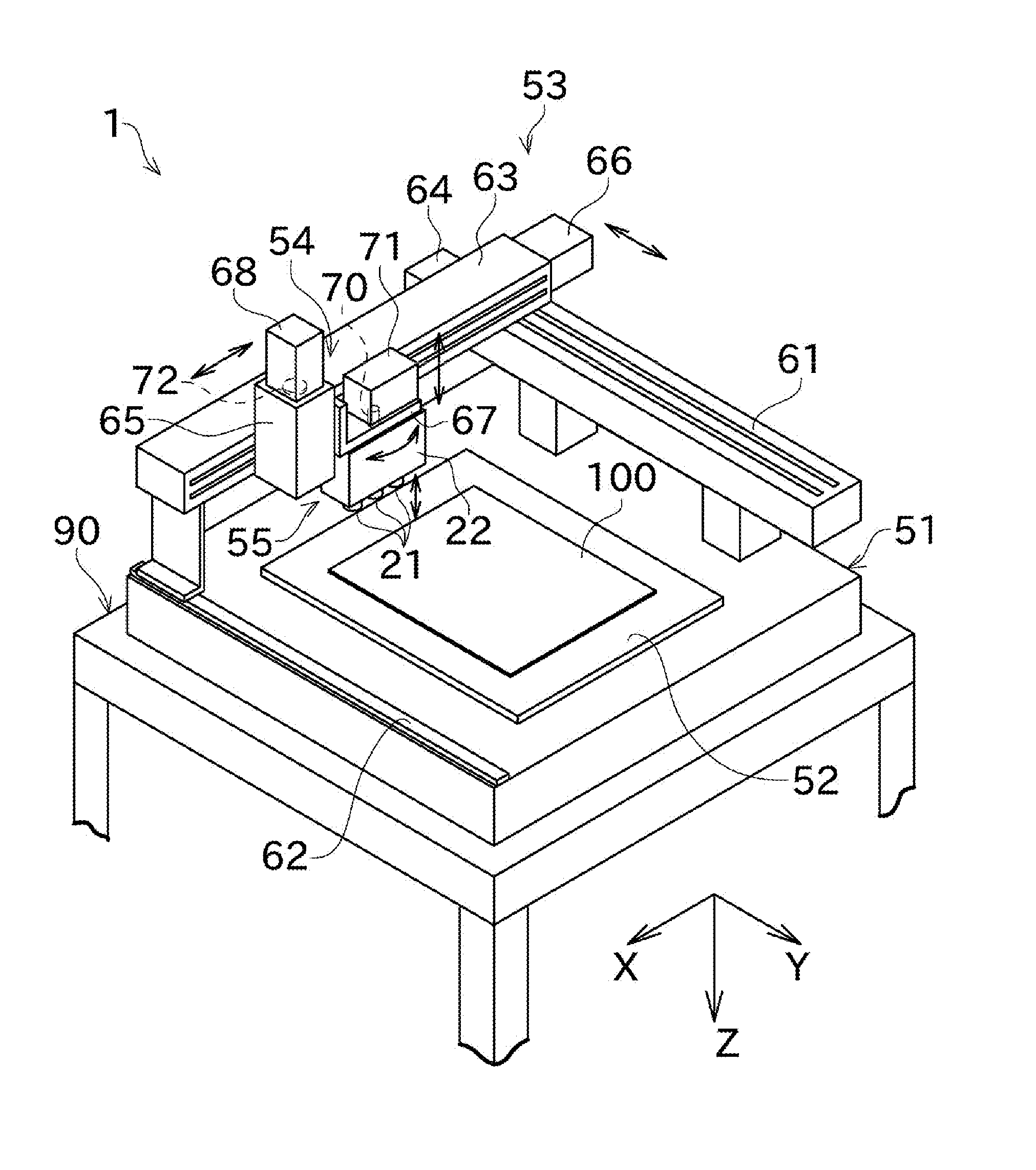

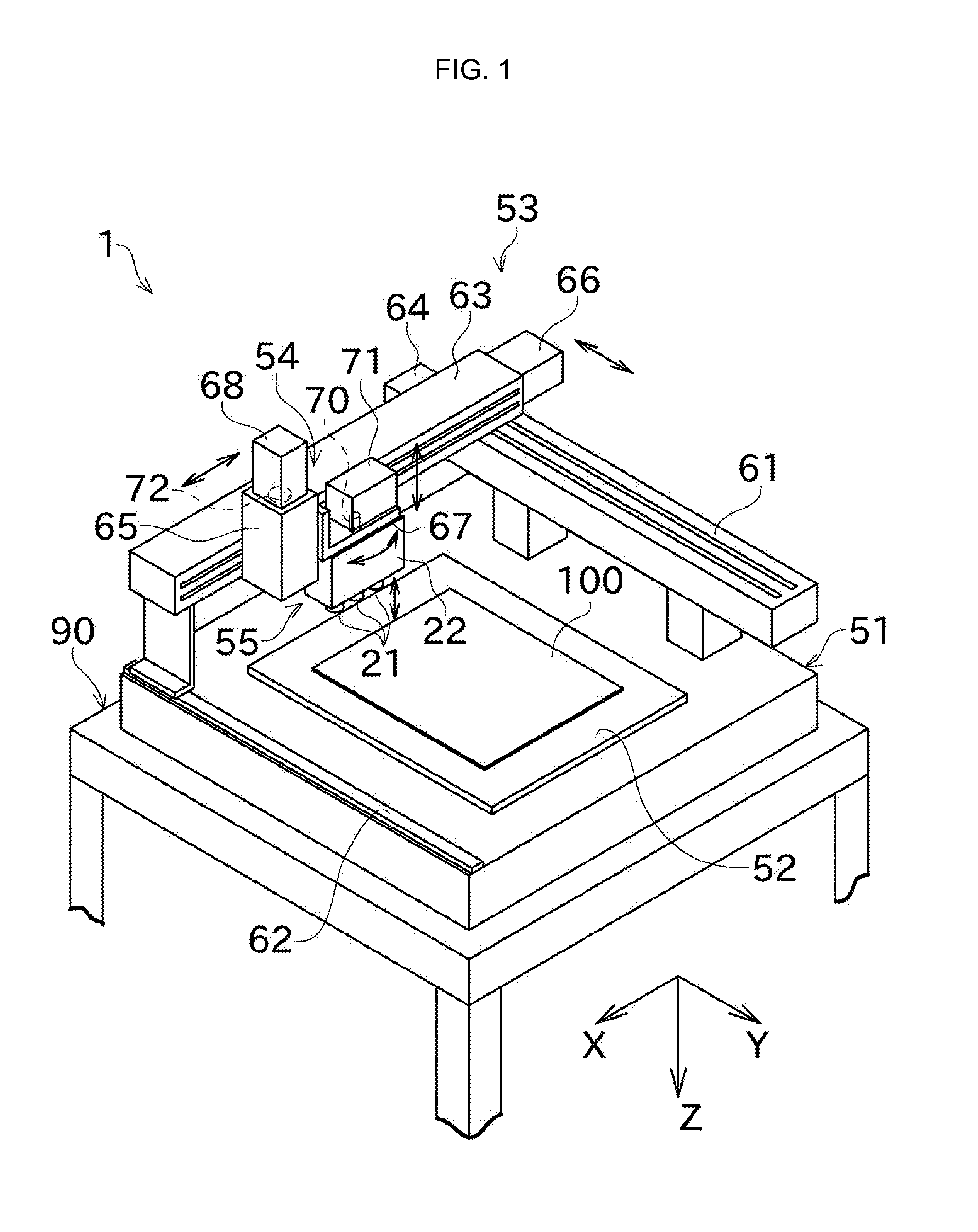

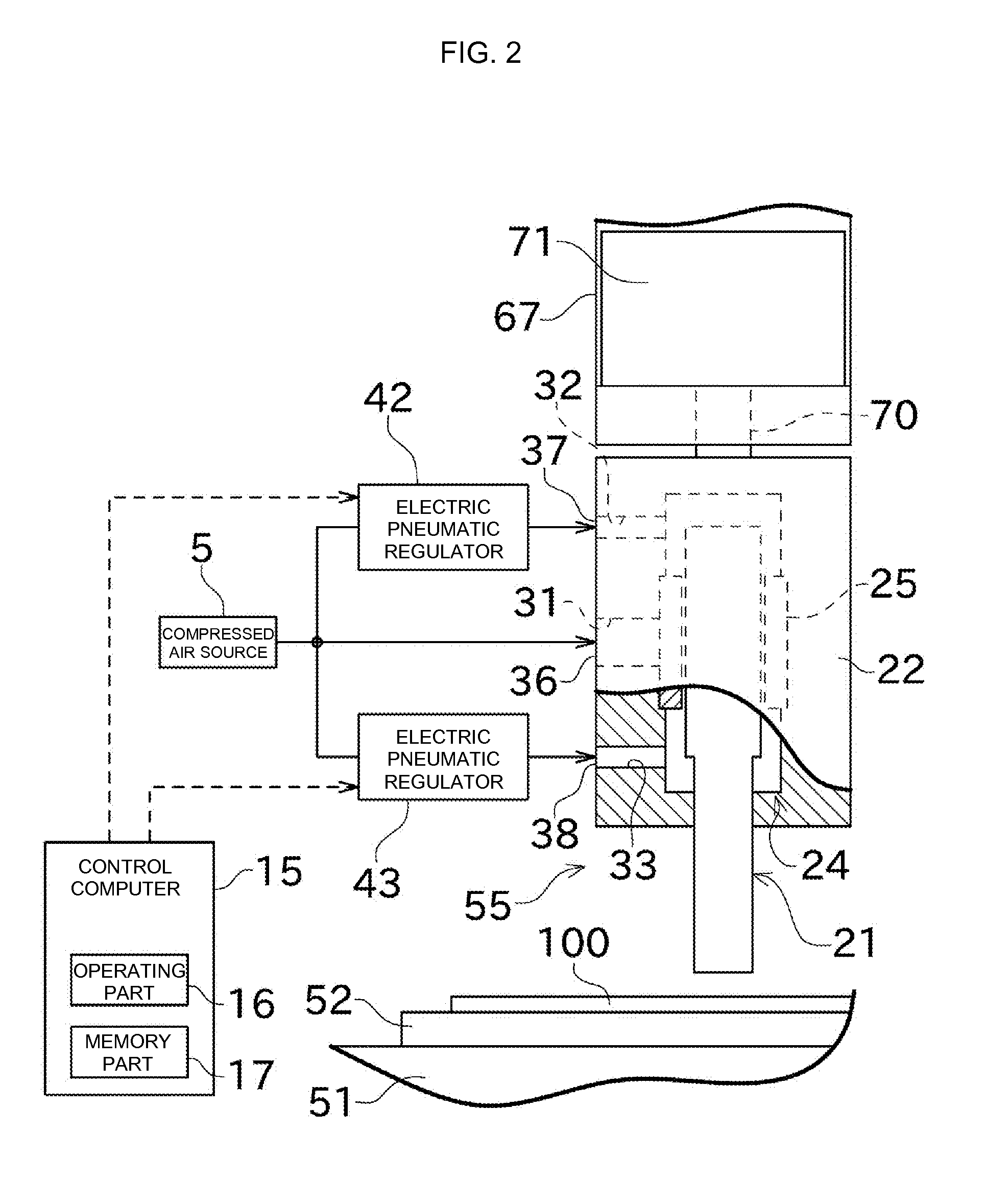

Touch panel inspecting apparatus

InactiveUS20150212625A1Flexible and easy to changeImprove inspection efficiencyError detection/correctionInput/output processes for data processingEngineeringTouchscreen

A touch panel inspecting apparatus includes a workpiece holder, a pseudo finger, an X-Y movement mechanism, a memory part, an electric pneumatic regulator, and a panel signal acquiring part. The workpiece holder allows a touch panel, which is an inspection target, to be set thereon. The pseudo finger is contactable with the touch panel set on the workpiece holder. The X-Y movement mechanism moves the pseudo finger relative to the touch panel. The memory part stores therein a set value of pressing force of the pseudo finger, in a changeable manner. The electric pneumatic regulator regulates the pressing force to bring the pseudo finger into contact with the touch panel, based on the set value stored in the memory part. The panel signal acquiring part acquires an electric signal output from the touch panel.

Owner:NIDEC-READ CORPORATION

Method of fastening an edge structure to a construction element

ActiveUS20160114550A1Improve stabilityMinimize impactOther plywood/veneer working apparatusLamination ancillary operationsCouplingEdge structure

A method of fastening an edge structure to a construction element includes providing the construction element, being a planar structure with with two cover regions and a middle region between the cover regions; providing the edge structure being continuously extended, the edge structure having contact surfaces with a thermoplastic material shaped to lie against the cover regions in an outer surface of the construction element, and, opposite the contact surfaces, a coupling-in surface for coupling energy into the edge structure; coupling energy into the edge structure and pressing the contact surfaces against the cover regions until at least a portion of the thermoplastic material is liquefied and pressed into the cover regions; and repeating or continuing the steps of coupling and pressing until the edge structure is attached to the building element at a plurality of discrete locations or over an extended region along an edge of the construction element.

Owner:WOODWELDING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com