Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Meet the needs of large capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

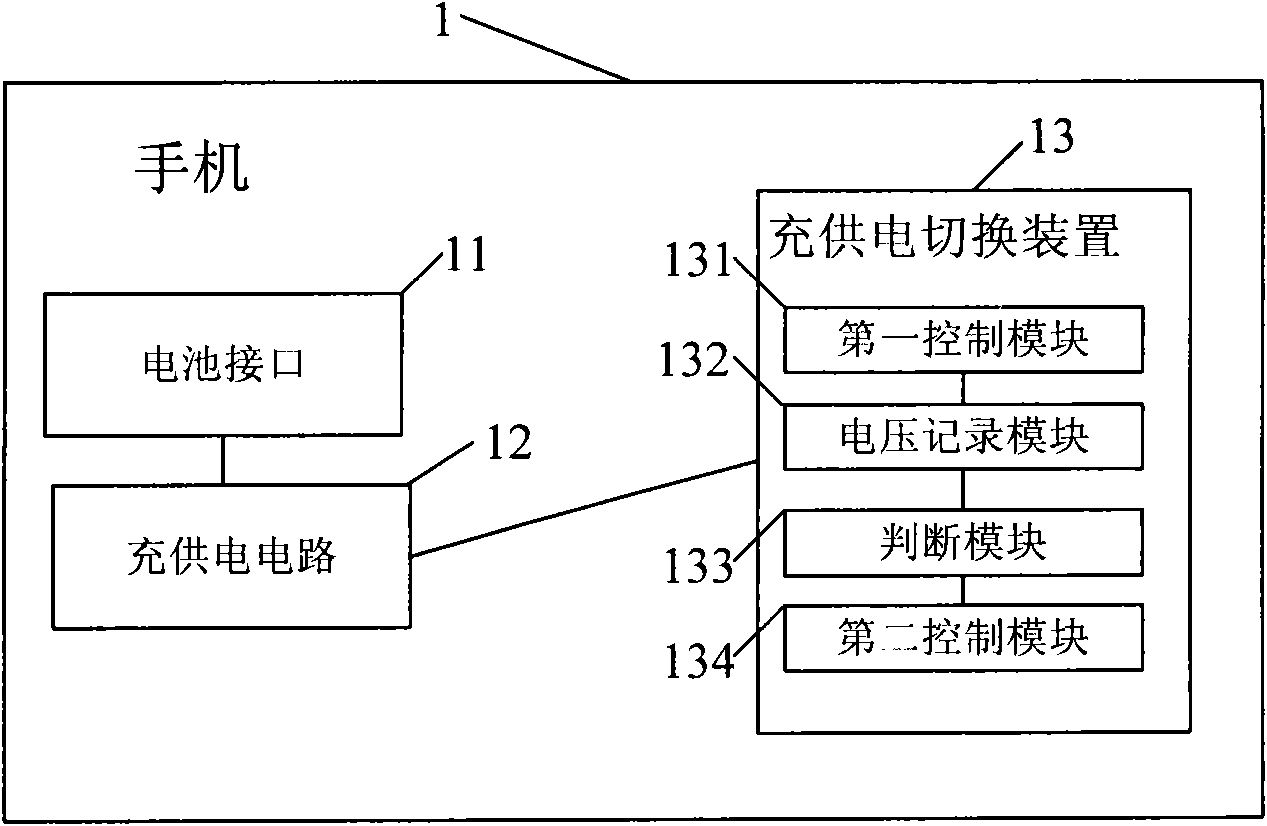

Mobile communication terminal and double-battery charge and power supply switching method thereof

InactiveCN101610304AMeet large capacityMeet the needs of large capacitySubstation equipmentEnd cell switching arrangementsElectrical batteryElectricity

The invention discloses a mobile communication terminal and a double-battery charge and power supply switching method thereof. The main board of the terminal is provided with two battery interfaces and a charge and power supply circuit connected with the two battery interfaces. After the start-up of the terminal, the switching method comprises the following steps that: S1, a battery A supplies power, a battery B is idle and the voltages of the two batteries are recorded; S2, when the voltage of the battery A fails to meet power supply conditions, whether a charger is plugged in is judged; S3,when the charger is plugged in, the battery A supplies power while being charged, and the battery B is still keep idle; S4, when the battery A is fully charged and the battery B is undercharged, the battery A supplies power and the battery B is charged; and S5, when both the batteries are fully charged, the step S1 is returned to. The mobile communication terminal uses double batteries for charge and power supply, thereby meeting requirements on large capacity of mobile phone batteries. In addition, immediate switching is performed to allow another battery to supply power to ensure the continuity of the power supply of a mobile phone in case of accidents, for example, a battery is removed and software receives interruption sent by the system.

Owner:SHANGHAI SIMCOM LTD

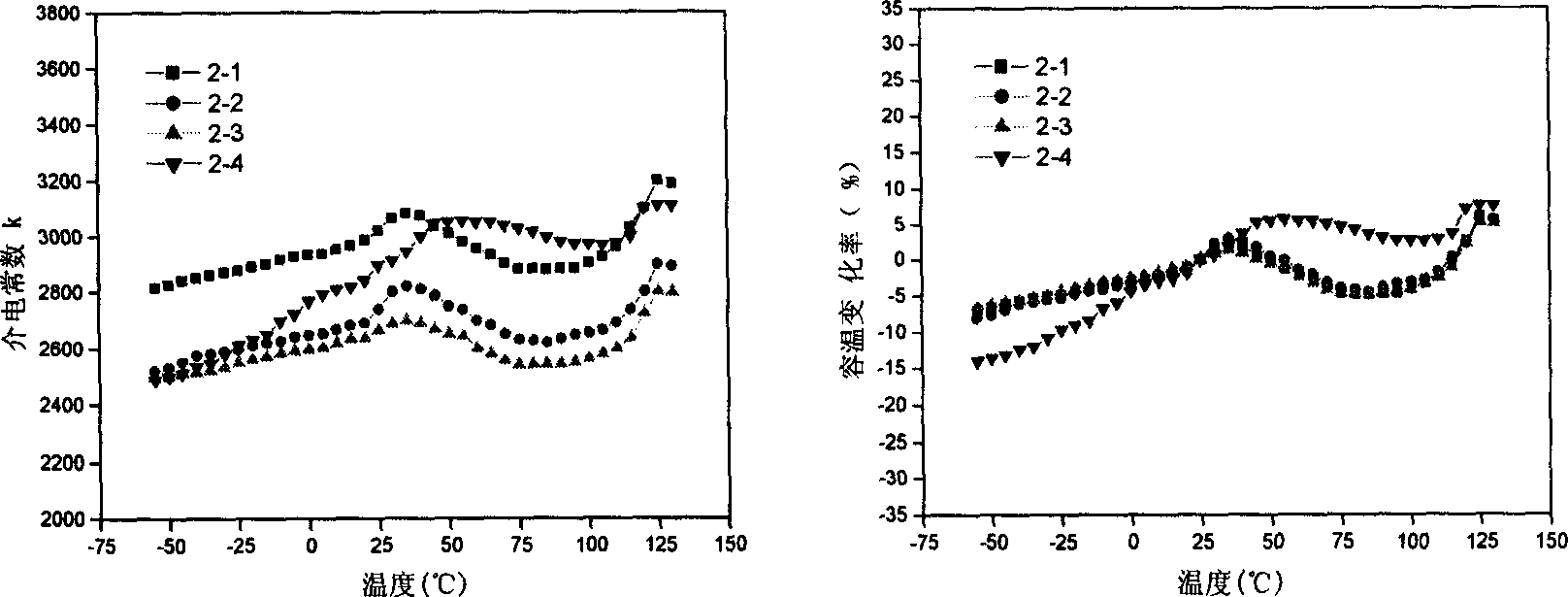

Nanometer ceramic-material doping agent, ceramic capacitor media material and production thereof

InactiveCN1854105APromote lowerMeet miniaturizationFixed capacitor dielectricPiezoelectric/electrostrictive/magnetostrictive devicesDopantCeramic capacitor

A nanometer ceramic material dopant, medium material of ceramic capacitor and their production are disclosed. The formula of the dopant consists of aA.bB.cC.dR2 O3.eSiO2; A contains Na2O; B contains one or multiple of MgO and CaO; C contains one or multiple of MnO2 and Co3O4; R contains one of multiple of Y, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, among them a, b, c, d and e are coefficient, by computing mol%, 0<=a<=10%, 0<=b<=25%, 0<=c<=15%, 20%<=d<=60%, 10%<=e<=50% and b and c can't be zero at same time. Its advantages include large capacity, adjustable material formula, low sintering temperature, less medium loss, high dielectric constant and better reliability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

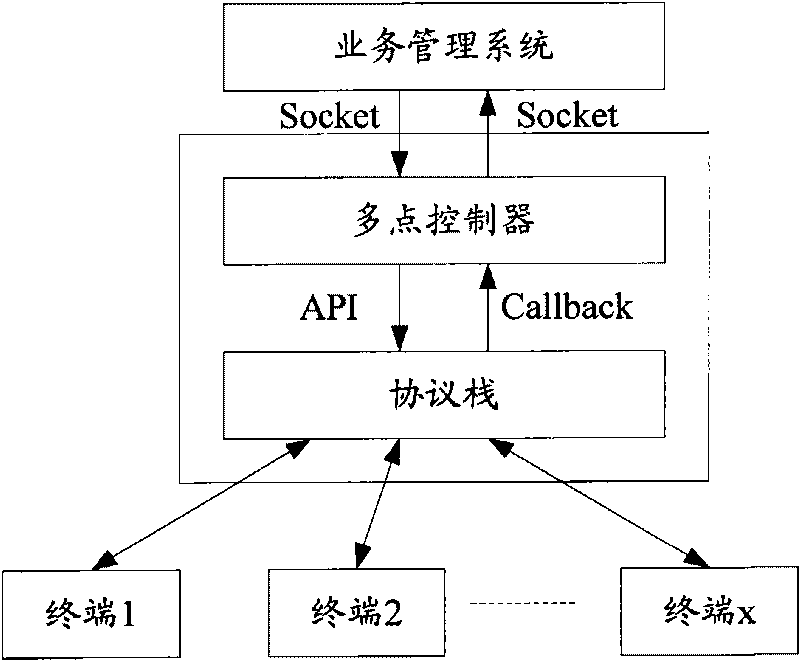

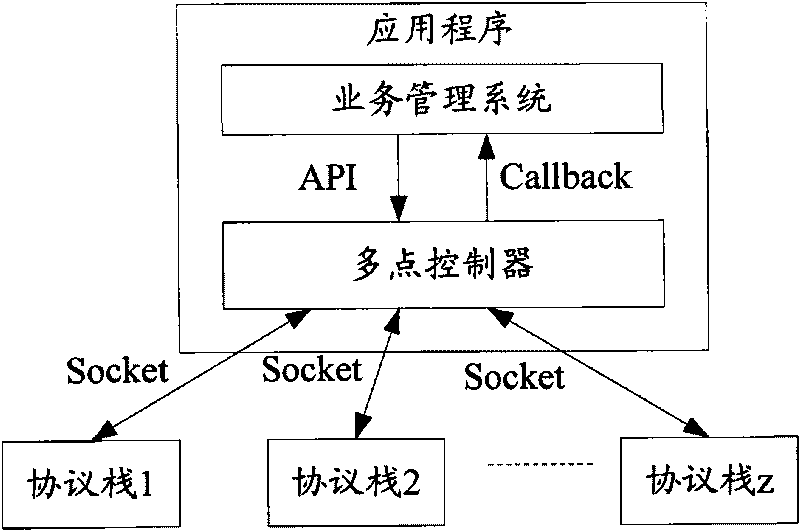

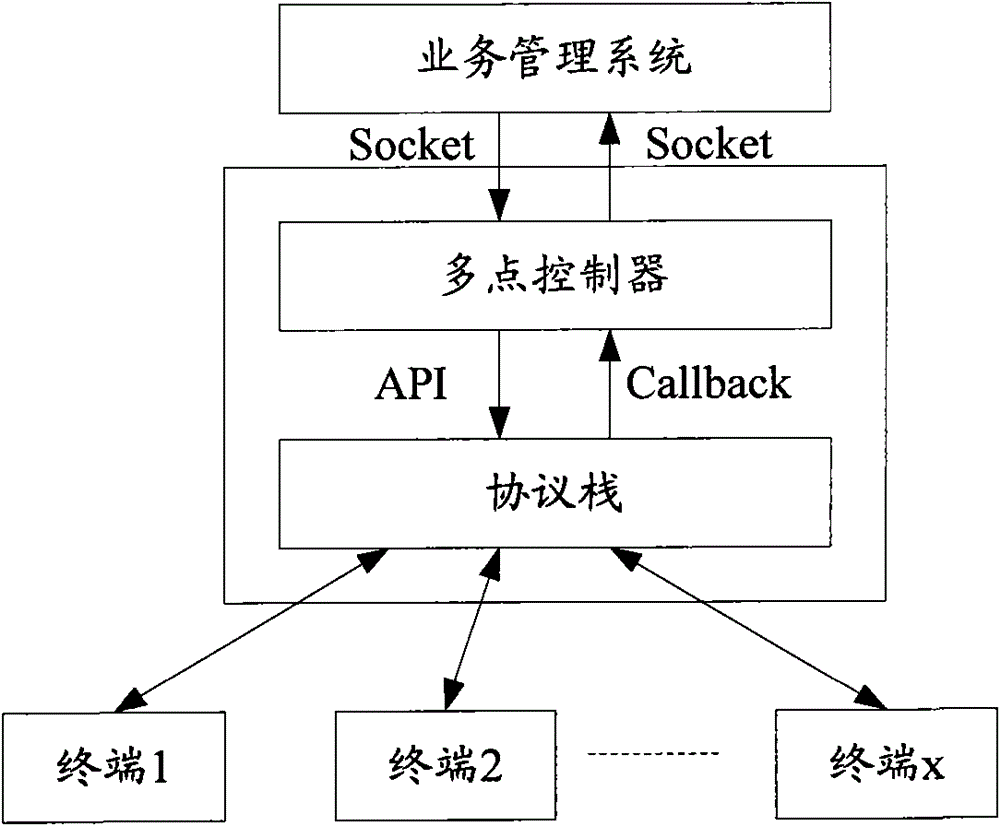

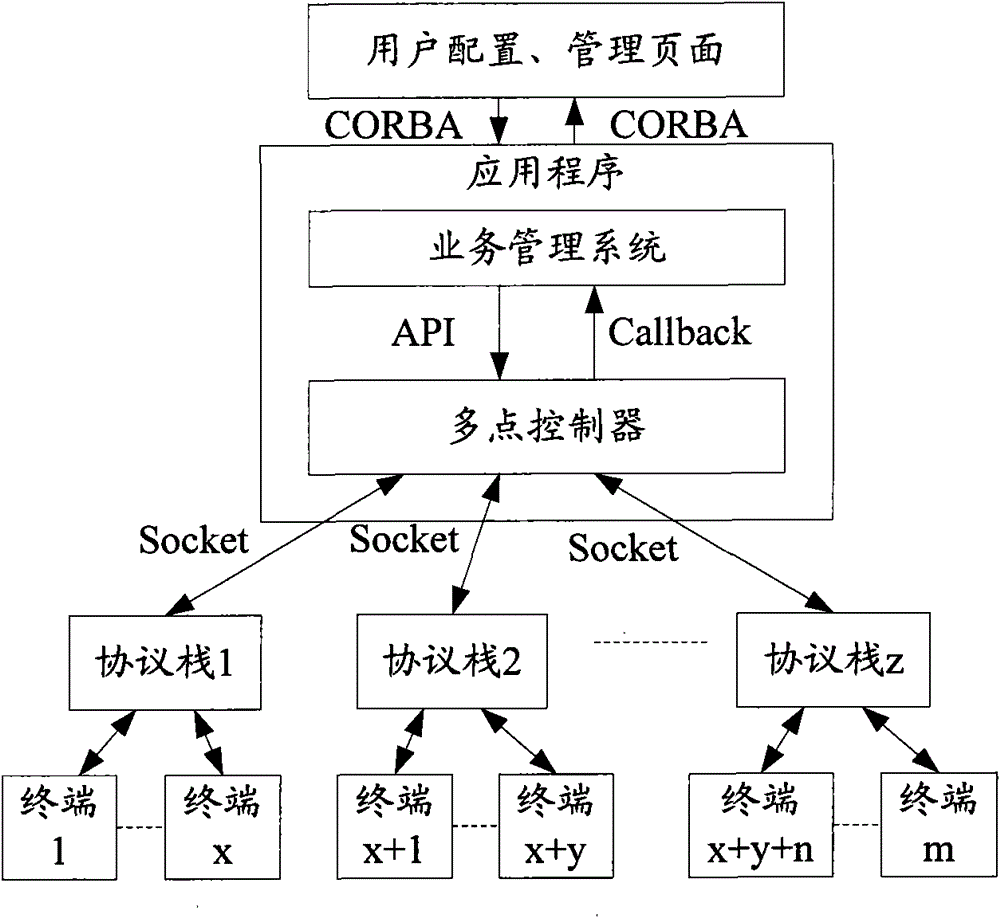

Video conference service dispatching method and video conferphone system

InactiveCN101707687AFix performance issuesMeet the needs of large capacityTelevision conference systemsTwo-way working systemsTelevision systemProtocol stack

The invention discloses a video conference service dispatching method which comprises the process that during the video conference, an application program distributes call requests of a terminal to a plurality of protocol stacks according to the occupied situation of the protocol stack resources. The invention also discloses a video conferphone system. In the invention, by the application programs and according to the occupied situation of the protocol stack resources, the call requests of the terminal are respectively distributed in the plurality of protocol stacks, thus effectively solving the performance problem that the call requests are concentrated in the same protocol stack.

Owner:ZTE CORP

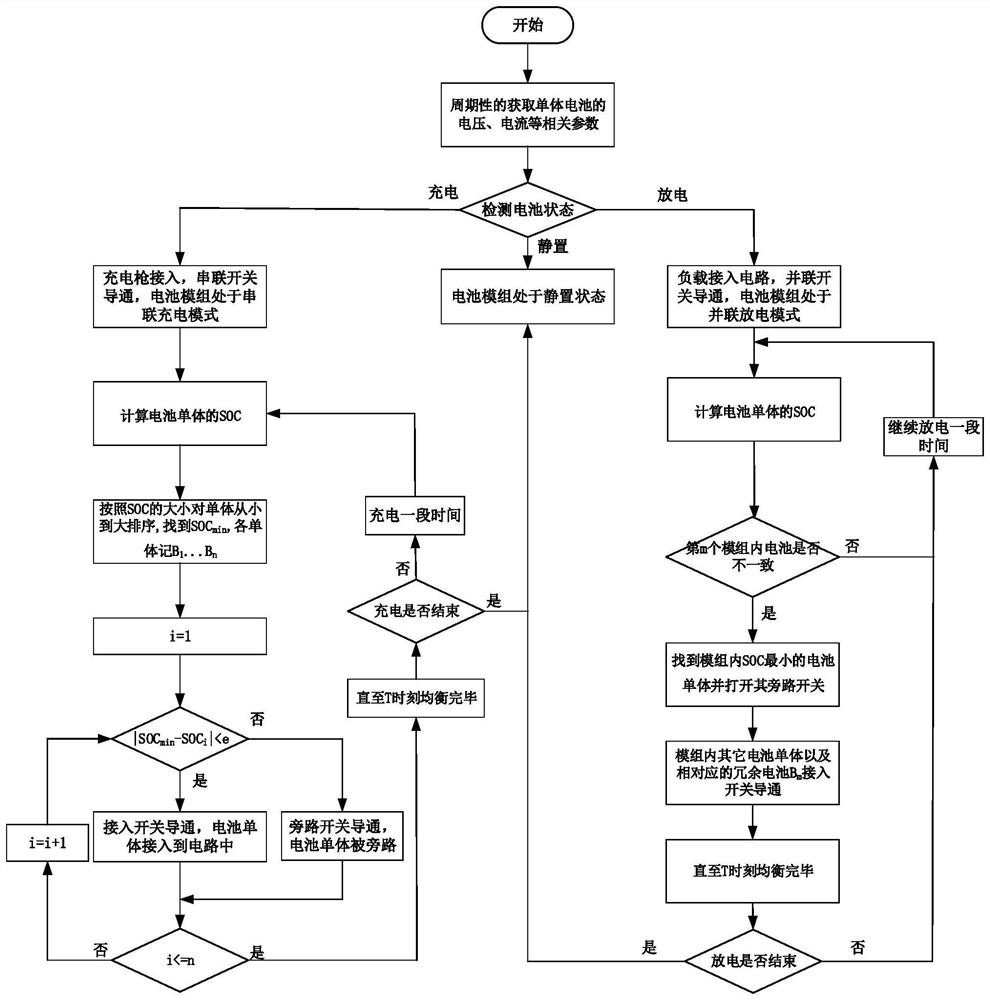

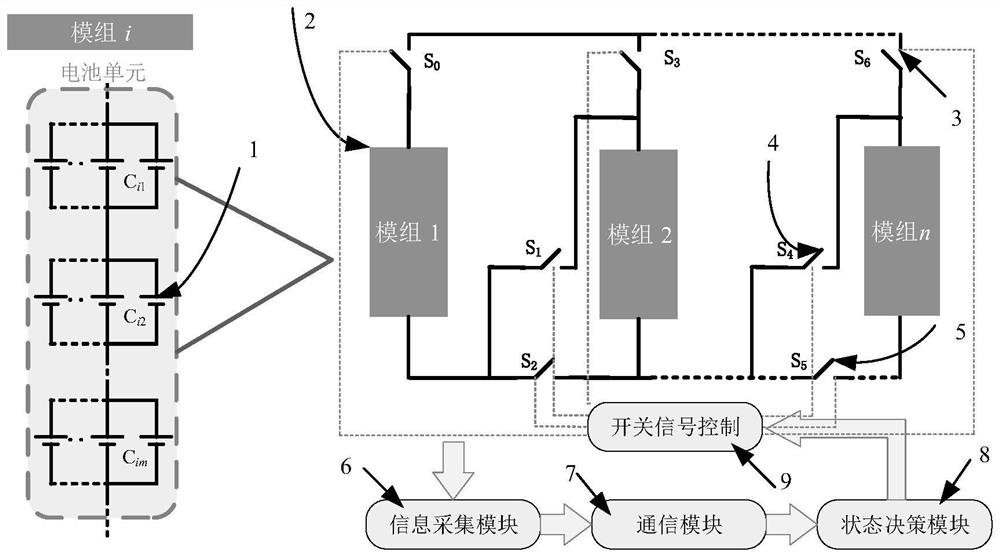

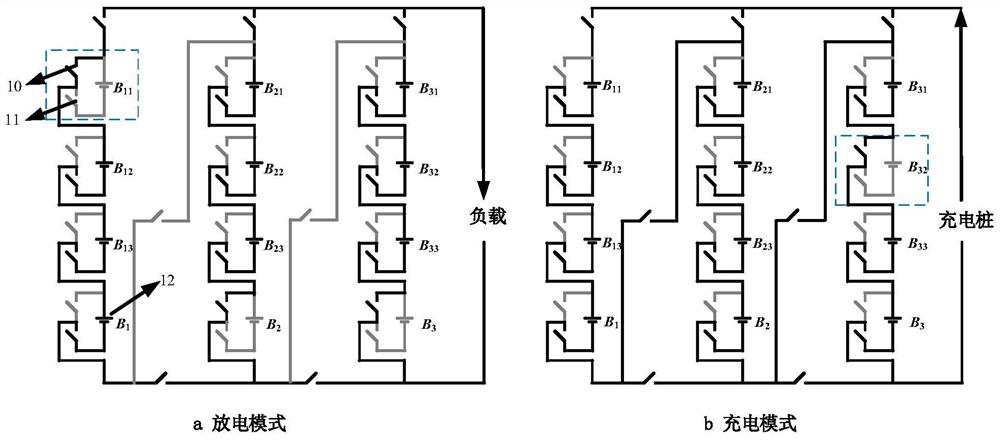

Battery charging and discharging system based on reconstruction and charging and discharging control method

PendingCN114709896AThe overall structure is simpleFlexible in groupsCircuit monitoring/indicationCharge equalisation circuitElectrical batteryCharge and discharge

The invention discloses a reconfiguration-based battery charging and discharging system and a charging and discharging control method, and belongs to the field of battery energy storage. Comprising an energy storage system circuit and a battery management subsystem, the energy storage system circuit comprises a plurality of battery modules and a plurality of controllable switch groups corresponding to the battery modules, and each battery module comprises a plurality of battery monomers connected in series and a redundant power supply for equalization; a bypass switch and a series switch are arranged around each battery monomer and are used for connecting or bypassing the battery monomer; the end-to-end joints of every two adjacent battery modules are connected through a switch; and the switch is connected with the battery management system and is used for controlling the on-off of the switch. And each battery module adopts a modular design, and the structures of the modules are the same, so that the overall structure is greatly simplified, the grouping of the batteries is more flexible, and large-scale processing production and whole vehicle application are facilitated.

Owner:XI AN JIAOTONG UNIV

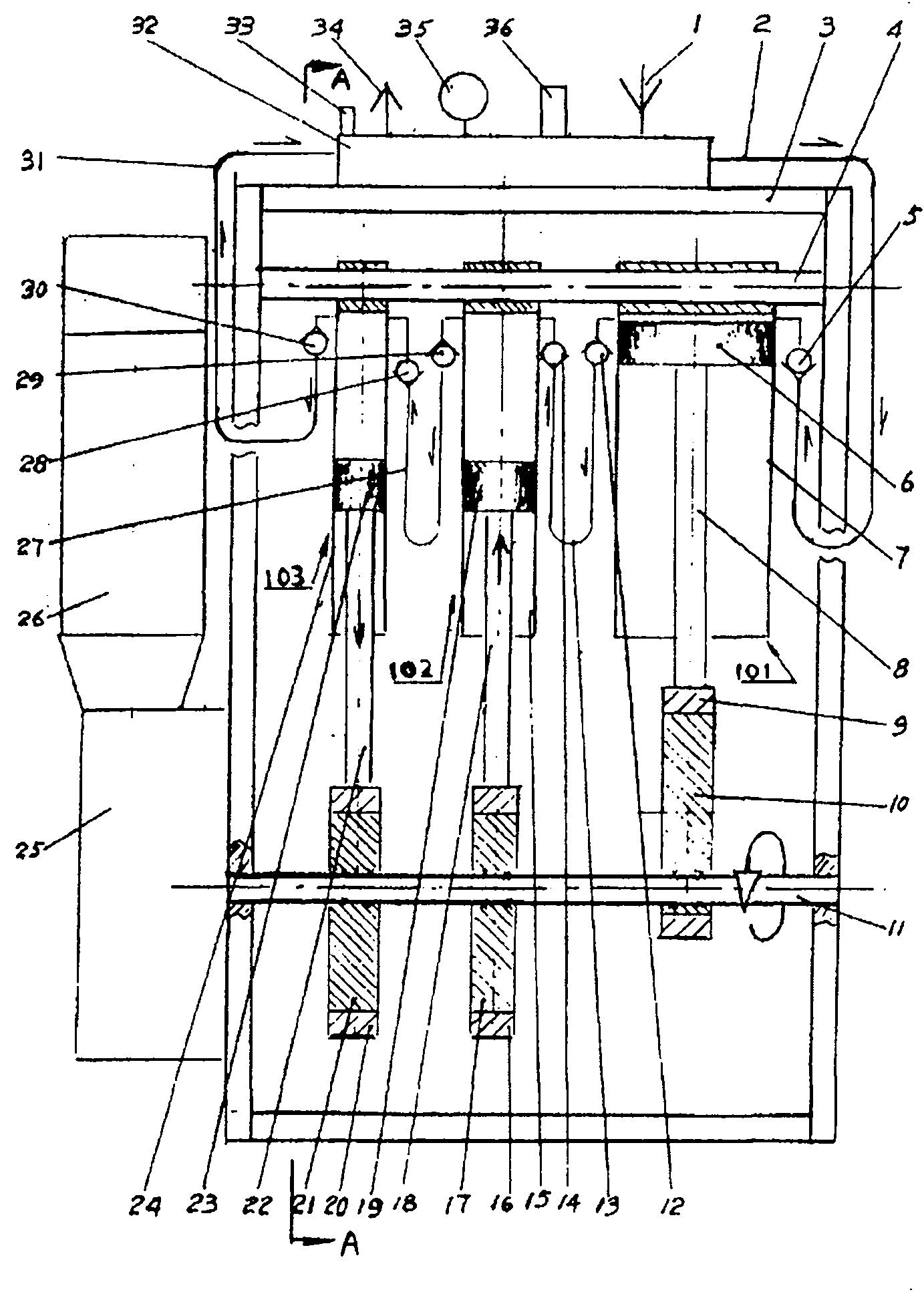

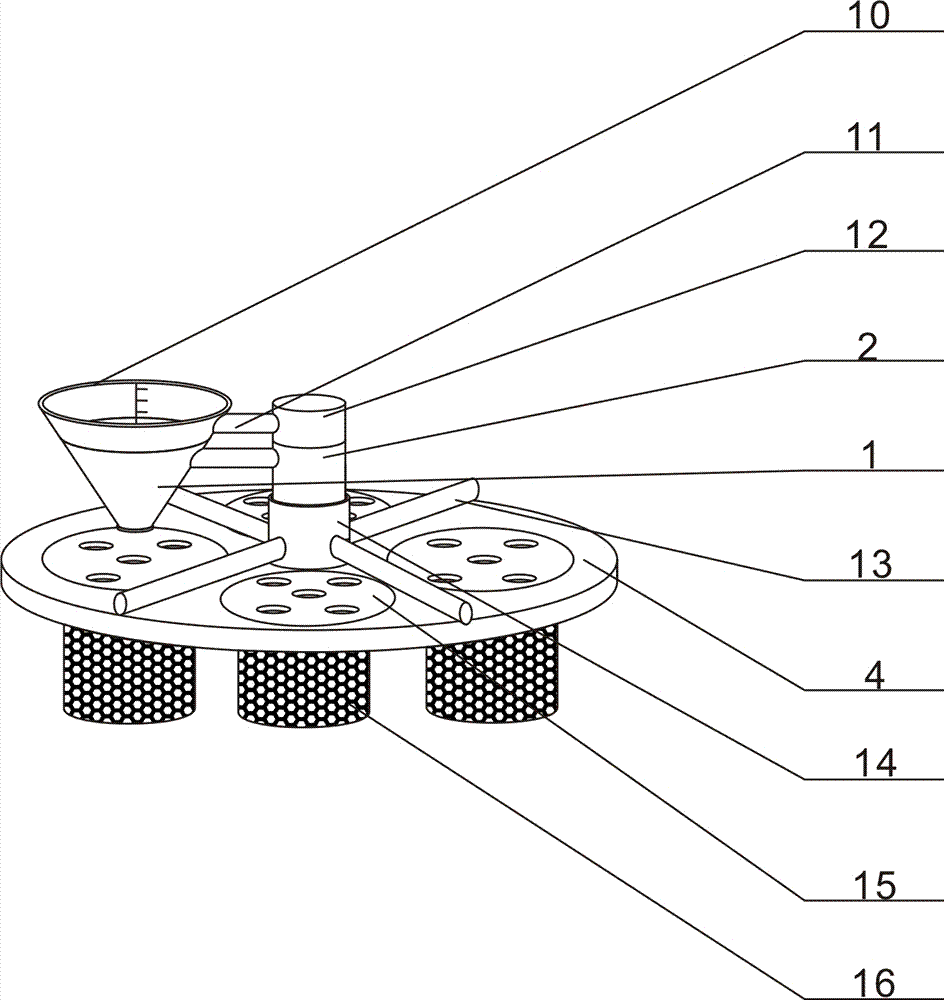

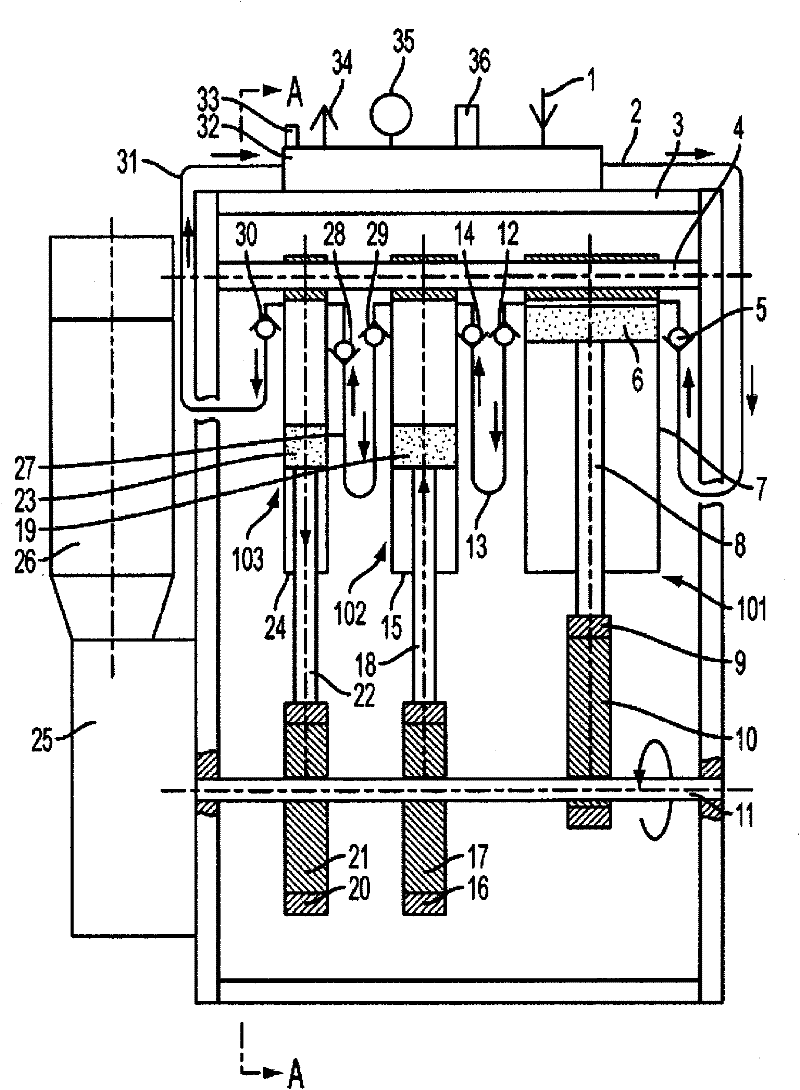

High compressed air cylinder filling machine

ActiveCN101839392AMeet the needs of large capacityEasy to storePiston pumpsMulti-stage pumpsDrive wheelGas cylinder

The invention relates to a high compressed air cylinder filling machine comprising an electric driving machine, a reduction gearbox and a drive shaft. An eccentric driving mechanism comprising at least two eccentric driving wheels is mounted on the drive shaft; at least two swing type compression cylinders are connected in series with a plurality of one-way valves and hose pipes to form a high compression mechanism, and are connected with a piston, a piston rod and a slide ring to be as a whole and then sleeved on the eccentric driving wheels through the slide ring; the other end of the piston rod is connected with a cylinder barrel which is sleeved on a supporting shaft which is mounted in a frame-shaped stand; a confluence plate is mounted on the frame-shaped stand and is provided with a pressure switch, a pressure gauge and a safety valve; the outer circumference of the compression cylinder is provided with concave-convex lines for heat dispersion; the frame-shaped stand is internally provided with a cooling fan, and the frame-shaped stander is provided with a transparent outer cover; the electric driving machine drives the reduction gearbox to transmit rotating motion to the drive shaft so as to enable the eccentric driving wheels to rotate and subsequently to drive the slide ring, the piston rod and the piston entirely to make straight reciprocating motion relative to the cylinder barrel for compressing gas, and the gas compressed by multistage is output to fill in a high pressure storage cylinder.

Owner:昌祺国际有限公司

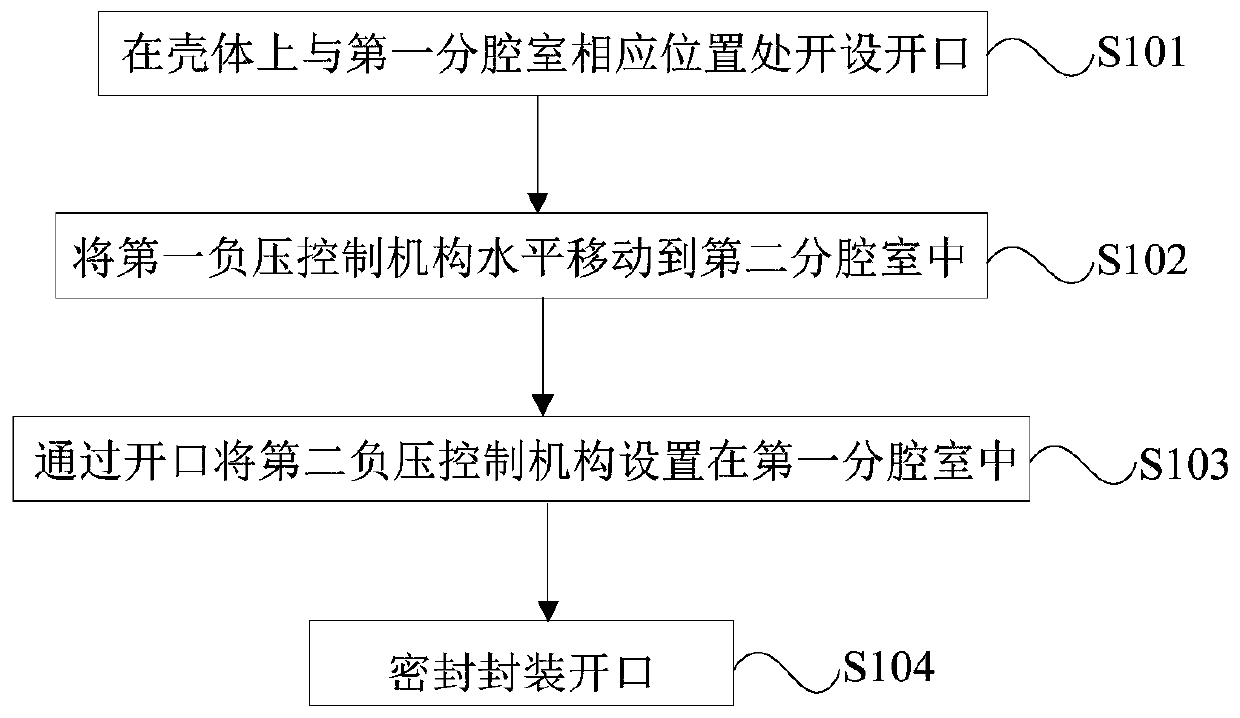

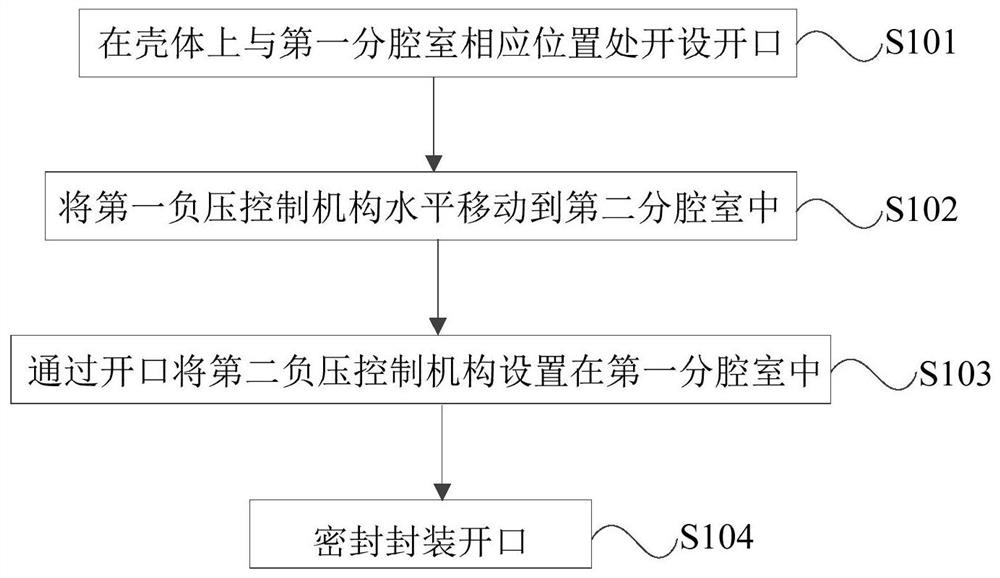

Ink box recycling method and recycled ink box

ActiveCN111376609AIncrease ink capacityIncrease capacityPrintingProcess engineeringMechanical engineering

The invention provides an ink box recycling method and a recycled ink box. The ink box comprises a shell and an ink storage chamber located in the shell, wherein the ink storage chamber comprises a first sub-chamber and a second sub-chamber; a first negative pressure control mechanism is arranged in the first sub-chamber; and an ink outlet is formed in the position, corresponding to the first sub-chamber, of the shell and communicates with the first sub-chamber. The ink box recycling method comprises the steps that an opening is formed in the position, corresponding to the first sub-chamber, of the shell; the first negative pressure control mechanism is moved into the second sub-chamber; a second negative pressure control mechanism is arranged in the first sub-chamber through the opening;and the opening is sealed and packaged. The first negative pressure control mechanism and the second negative pressure control mechanism are jointly used for storing ink, and the capacity of the ink box is improved; and meanwhile, the new second negative pressure control mechanism in the first sub-chamber corresponding to the ink outlet has high adsorption force and control force, the ink can still be maintained in the ink storage chamber after the ink capacity is increased, the ink leakage phenomenon is avoided, and the use performance of the ink box is improved.

Owner:ZHUHAI NINESTAR MANAGEMENT CO LTD

Bromfenac sodium eye drops and preparation technology thereof

PendingCN107375207AStir wellAvoid accumulationOrganic active ingredientsSenses disorderFiberSodium bisulfate

The invention provides bromfenac sodium eye drops and preparation technology thereof, and relates to eye drops and preparation technology thereof. The eye drops comprise the following components in percentages by weight: 0.001-0.15% of a bacteriostat potassium sorbate, 0.10-3.25% of an anti-oxidant sodium bisulfite, 0.04-2.52% of a lubricant magnesium lauryl sulfate, 0.15-0.55% of bromfenac sodium, a pH conditioning agent and injection water. A series of mixing and stirring steps are used in order to prepare the bromfenac sodium eye drops. A stirring mechanism on a base plate as well as stirring fans on a vertical plate and stirring fiber bars arranged on the stirring fans are used for realizing partial stirring in one cubic centimeter, partial stirring can be used for substantially reducing suspended solids, stirring time is shortened, uniform dissolving is realized, content of each component in bromfenac sodium eye drop bulk pharmaceutical chemicals is uniform, stirring efficiency of bulk pharmaceutical chemicals is substantially improved, and current speed during stirring is substantially improved.

Owner:LIAONING MEILIN PHARMA

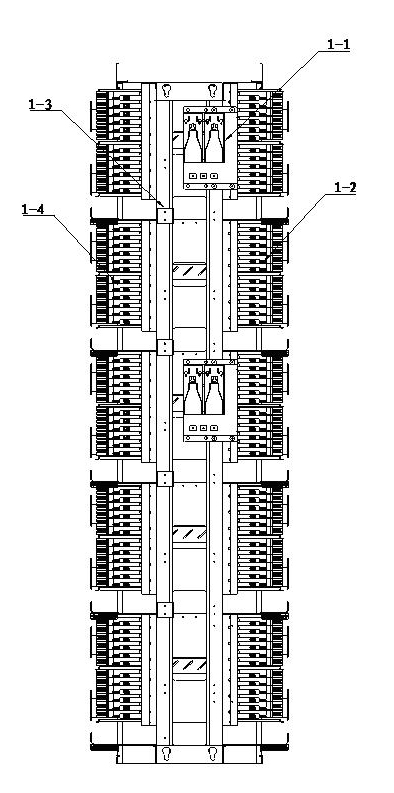

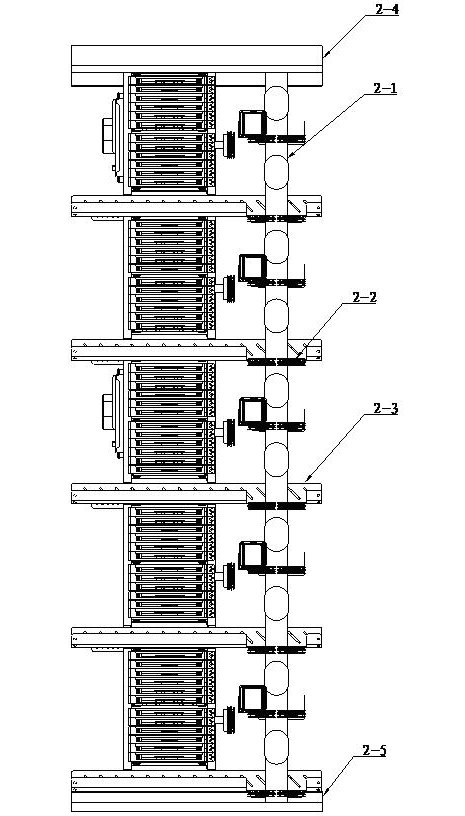

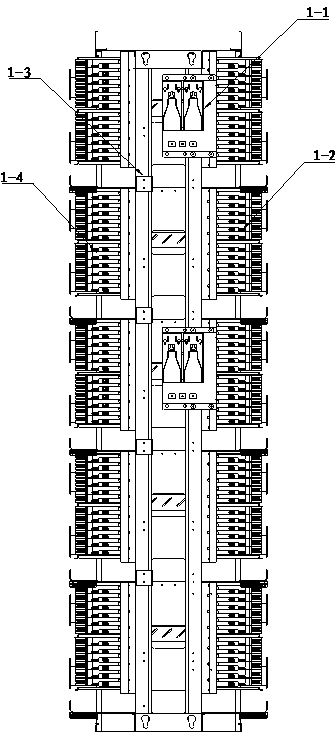

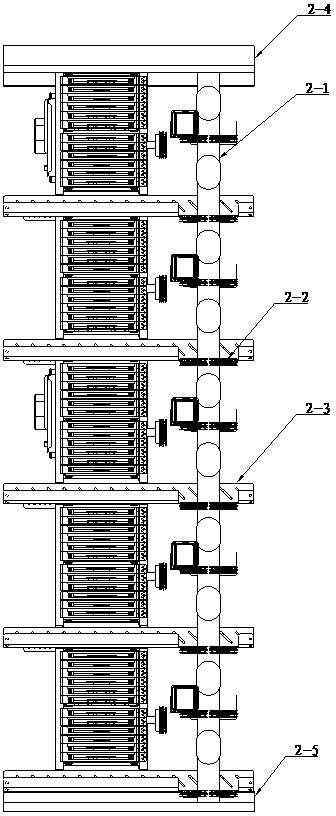

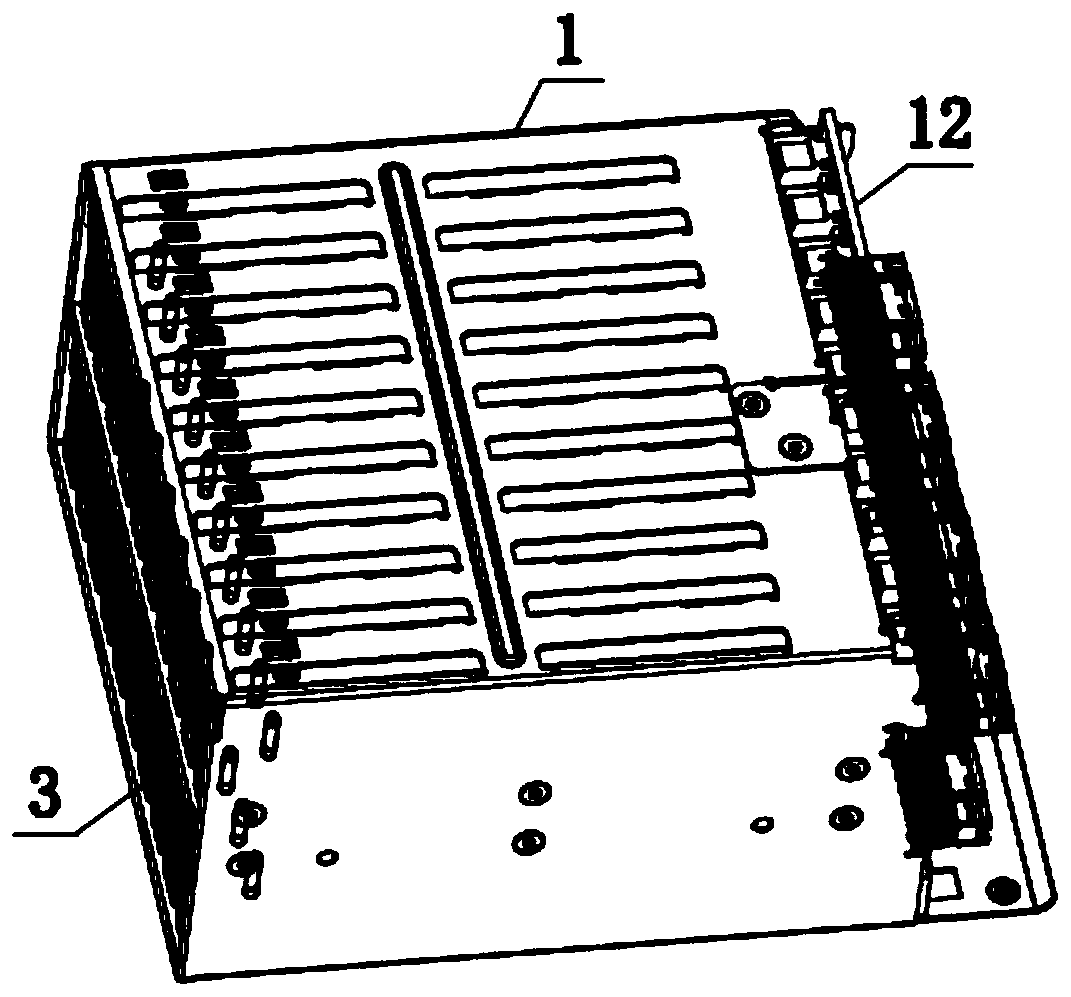

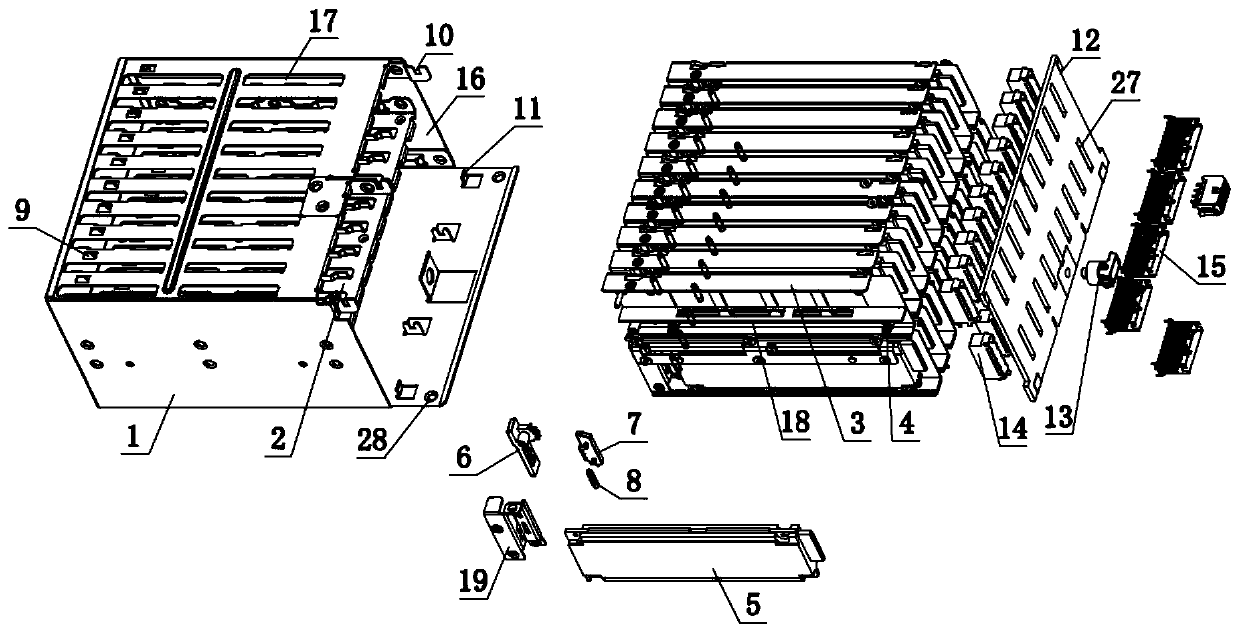

Optical fiber main distributing frame of MAN (Metropolitan Area Network)

The invention relates to an optical fiber main distributing frame of an MAN (Metropolitan Area Network). The optical fiber main distributing frame is characterized by comprising a stand as well as an optical cable fixing and stripping device, a line side module, an equipment side module and fiber jump passages which are arranged on the stand, wherein the optical cable fixing and stripping device is arranged at the left side of the stand, the line side module is arranged to the front of the stand, the equipment side module is arranged at the back of the stand, and the fiber jump passages are respectively arranged in corresponding positions on the stand according to respective actions; the front and the back of the stand are both provided with same side fiber jump passages and spacing-frame fiber jump passages; a fore-and-after fiber jump passage is arranged at the right side of the stand; the line side and the equipment side are independently connected through the fore-and-after fiber jump passage; the interior of the line side or the equipment side is independently connected through the same side fiber jump passages; and adjacent stands are independently connected through the spacing-frame fiber jump passages. The invention has the advantages that the independent fiber jump passages are extremely convenient for fiber jumping and can meet the needs of an access network and an MAN for accessing optical fibers and cables.

Owner:CHINA INFOMRAITON CONSULTING & DESIGNING INST CO LTD +1

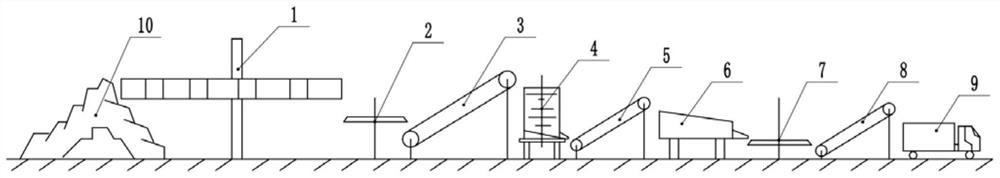

Tailings processing system

ActiveCN110626814AMeet the needs of large capacityAvoid the problem of not being fully taken over by the conveyor beltThrowing machinesSolid waste disposalMining engineeringCrusher

The invention discloses a tailings processing system. The tailings processing system includes a material feeding device, a first material splitting machine, a first conveyor, a crusher, a second conveyor, a material selecting device, a second material splitting machine, and a third conveyor, the tailings in a tailings storage are processed and conveyed, and finally different grades and different types of materials are output at the material selection device and conveyed onto a transport vehicle respectively for different types of further processing and application; through the systematic configuration of from the tailings storage to the entire processes of loading, crushing, sorting, and transportation, the to-be-processed tailings are processed from the tailings storage to the output of various types of available materials, and the current vacancy of the lack of a preliminary treatment system of the tailings is filled.

Owner:青岛博政信息技术有限公司 +1

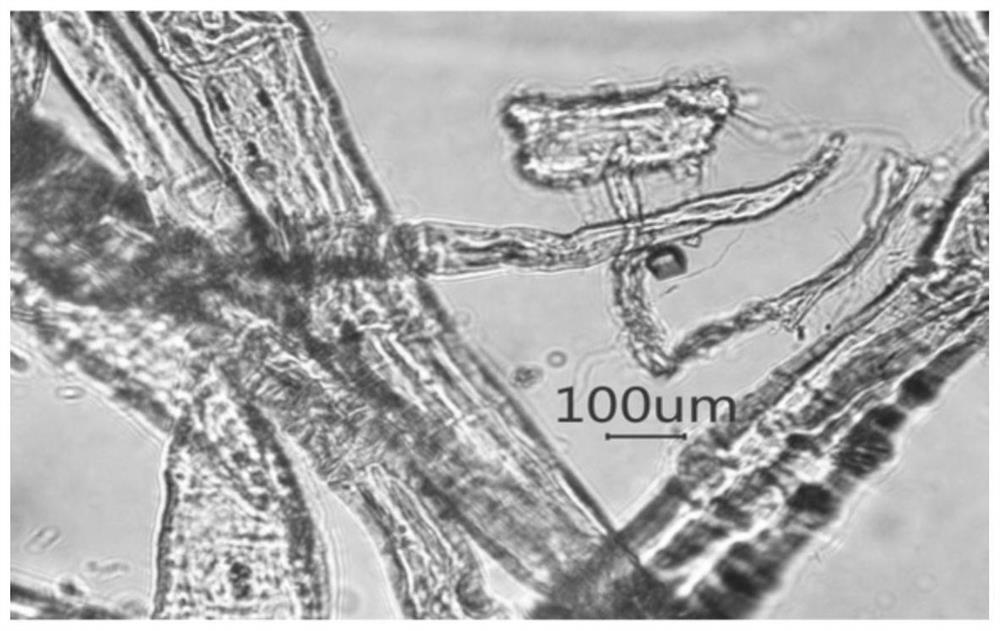

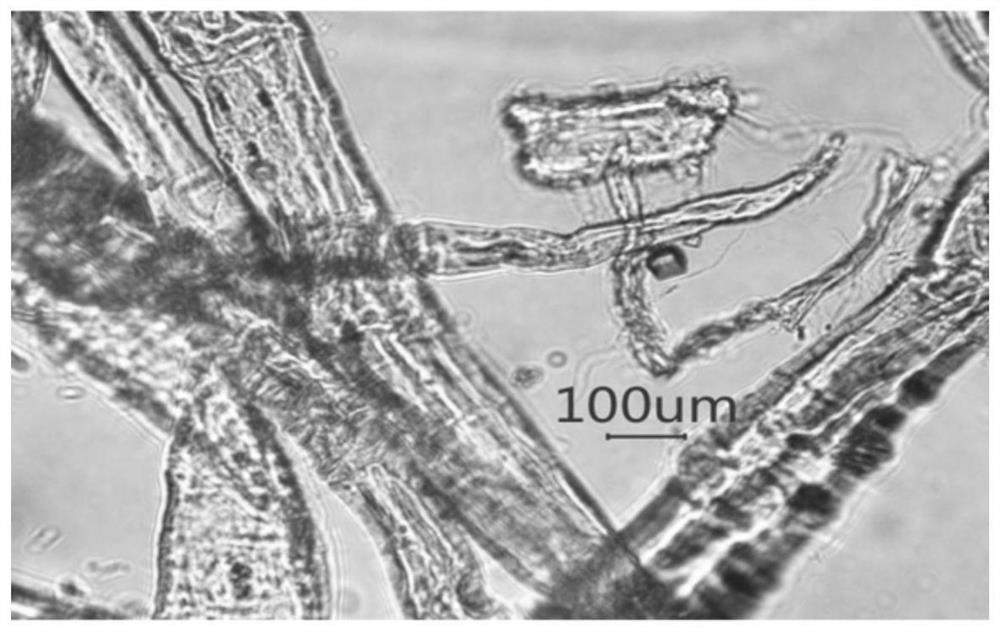

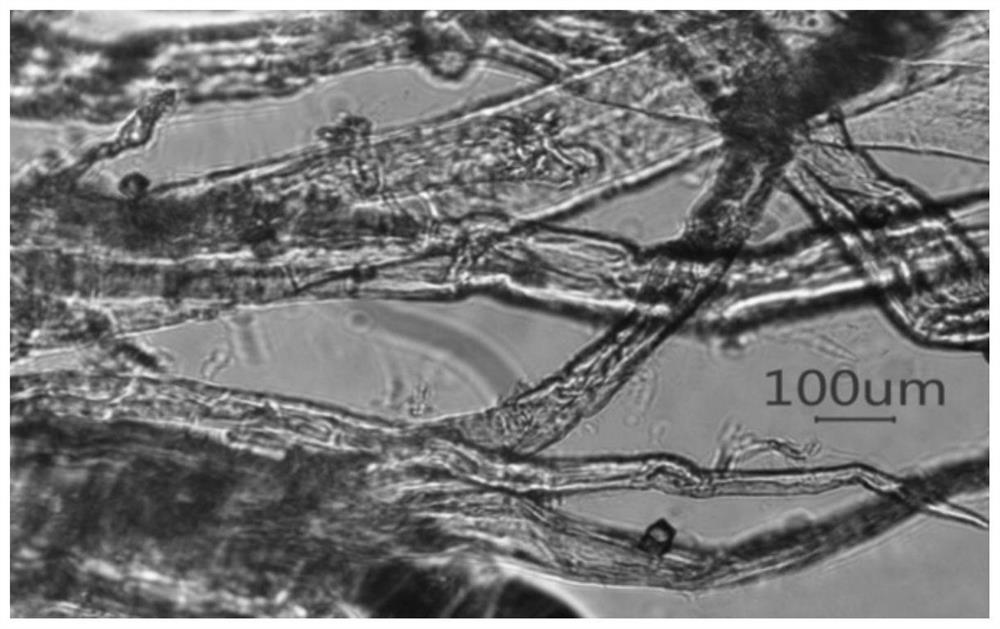

High-capacity Lyocell cellulose stock solution and continuous preparation process thereof

ActiveCN113388897AImprove qualityMeet the needs of large capacitySpinning head liquid feederMonocomponent cellulose artificial filamentCelluloseSolubility

The invention discloses a high-capacity Lyocell cellulose stock solution and a continuous preparation process thereof. The continuous preparation process comprises the following steps of carrying out repulping treatment on a pulp plate to obtain a pulp suspension; activating the pulp suspension to obtain an activated pulp suspension; squeezing and crushing the activated pulp suspension to obtain wet pulp; performing homogenization treatment on the wet pulp to obtain tempered pulp, wherein homogenization treatment comprises airflow treatment; and mixing the tempered pulp with a solvent, performing evaporating, and performing full dissolving to obtain the Lyocell cellulose stock solution. The wet pulp obtained by squeezing is homogenized and tempered, so that the accessibility of the fiber surface is increased, a solvent can better enter the internal structure of cellulose, the humidity is uniform, and the stock solution formed after the pulp is mixed with the solvent is higher in solubility and higher in quality. In addition, on the premise of the same reactor area, the production capacity is obviously increased, so that the production is continuously and stably carried out.

Owner:BEIJING SANLIAN HOPE TEXTILE & CHEM TECH

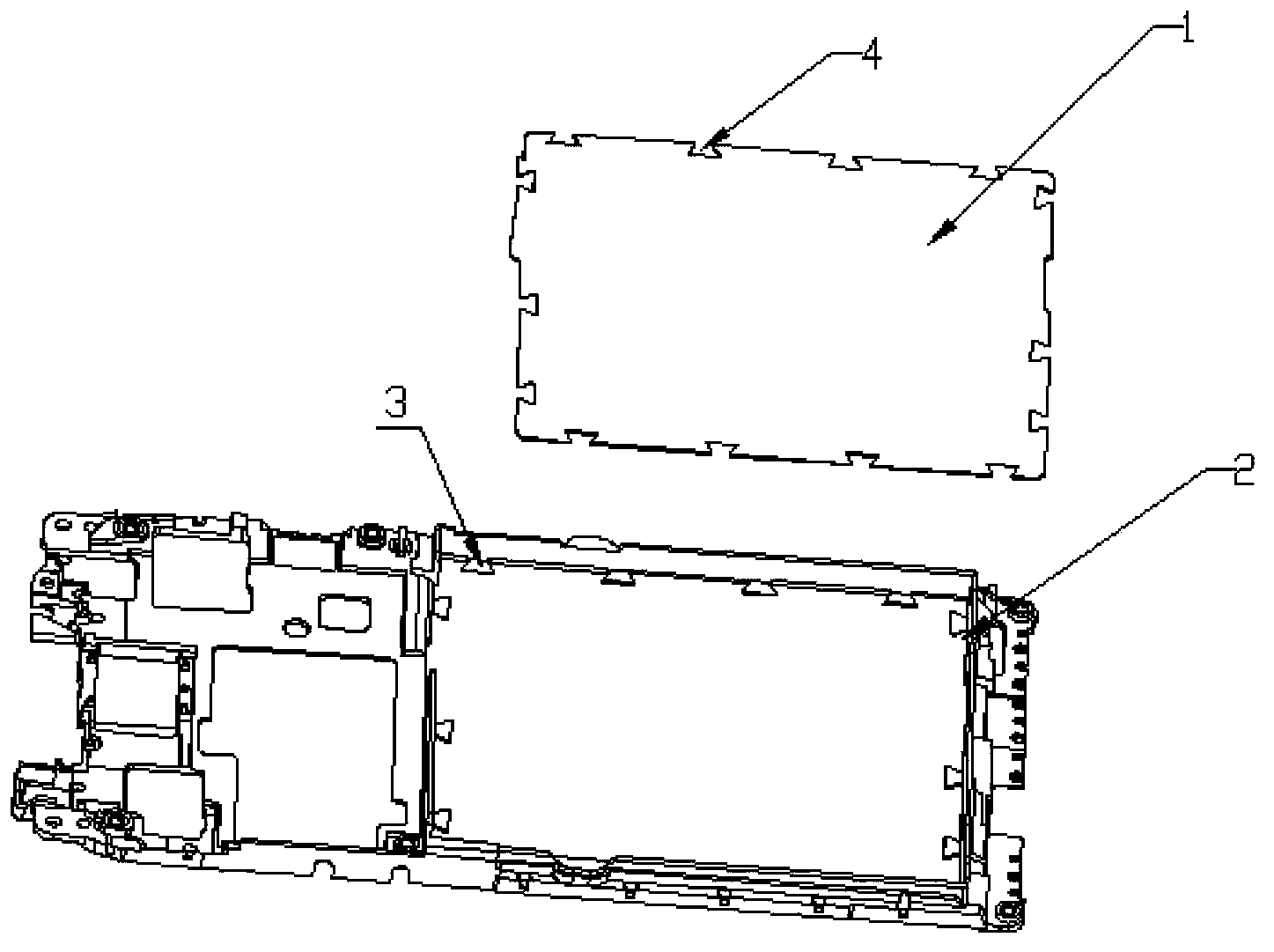

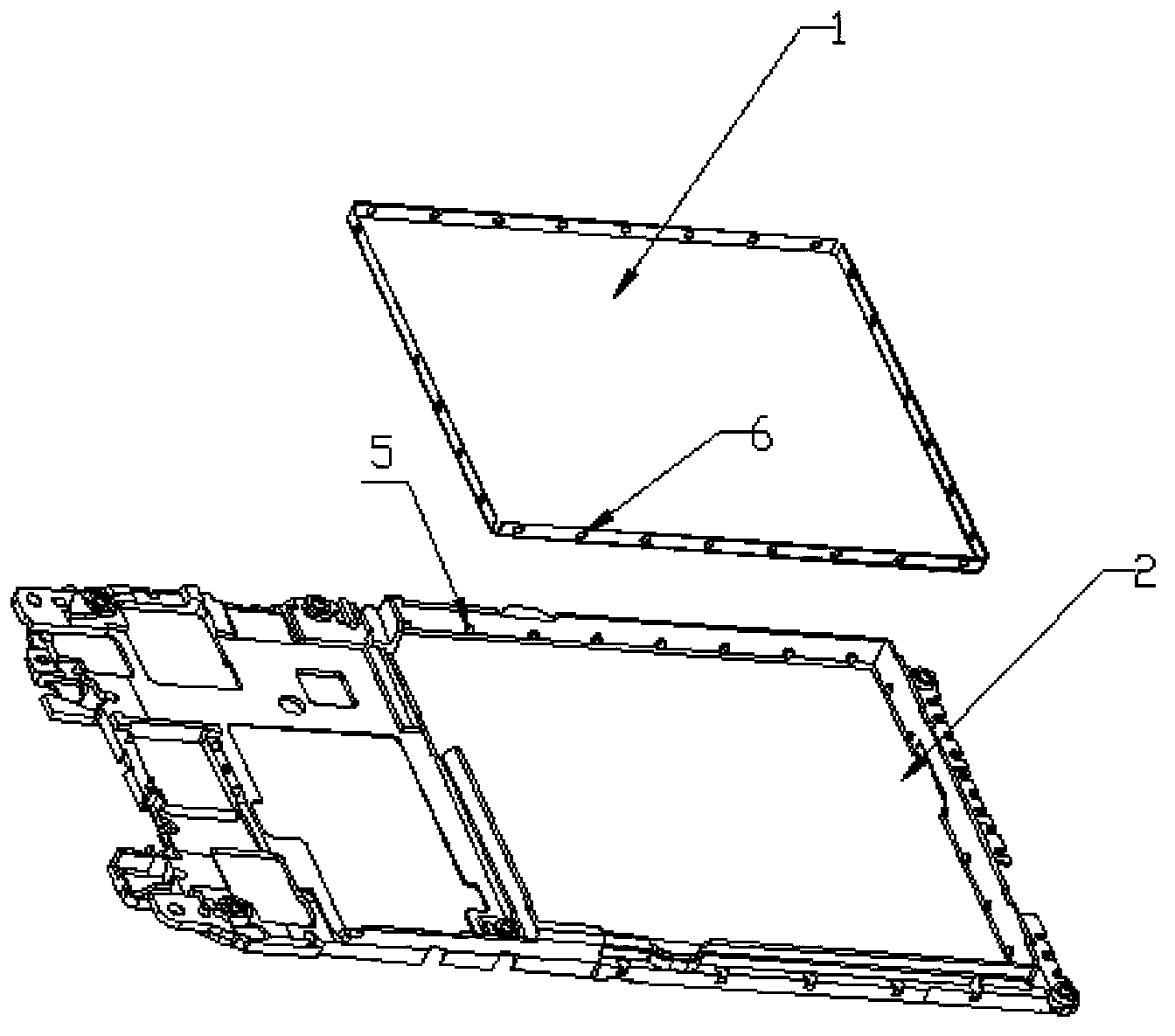

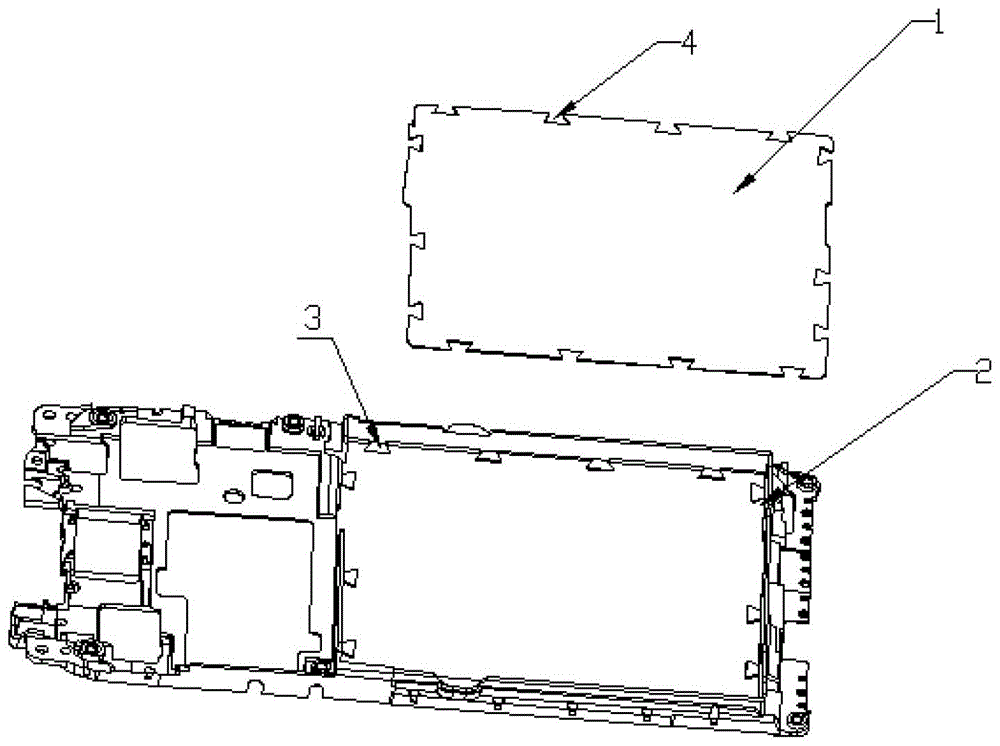

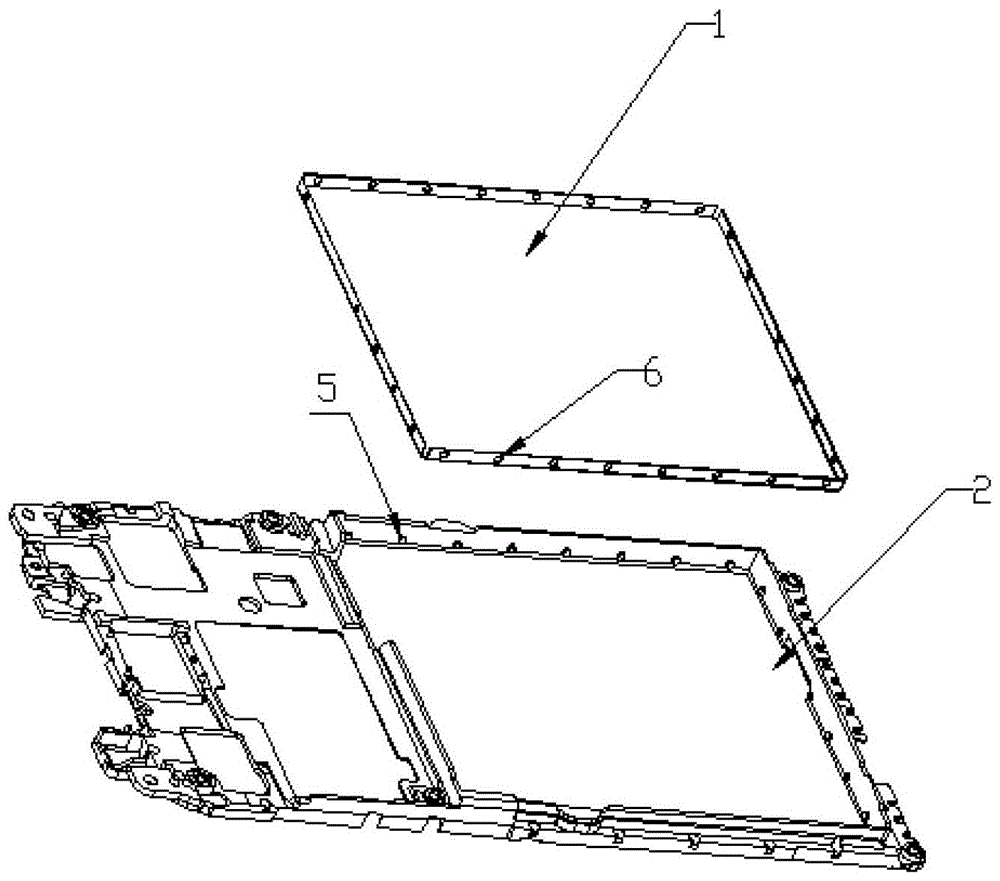

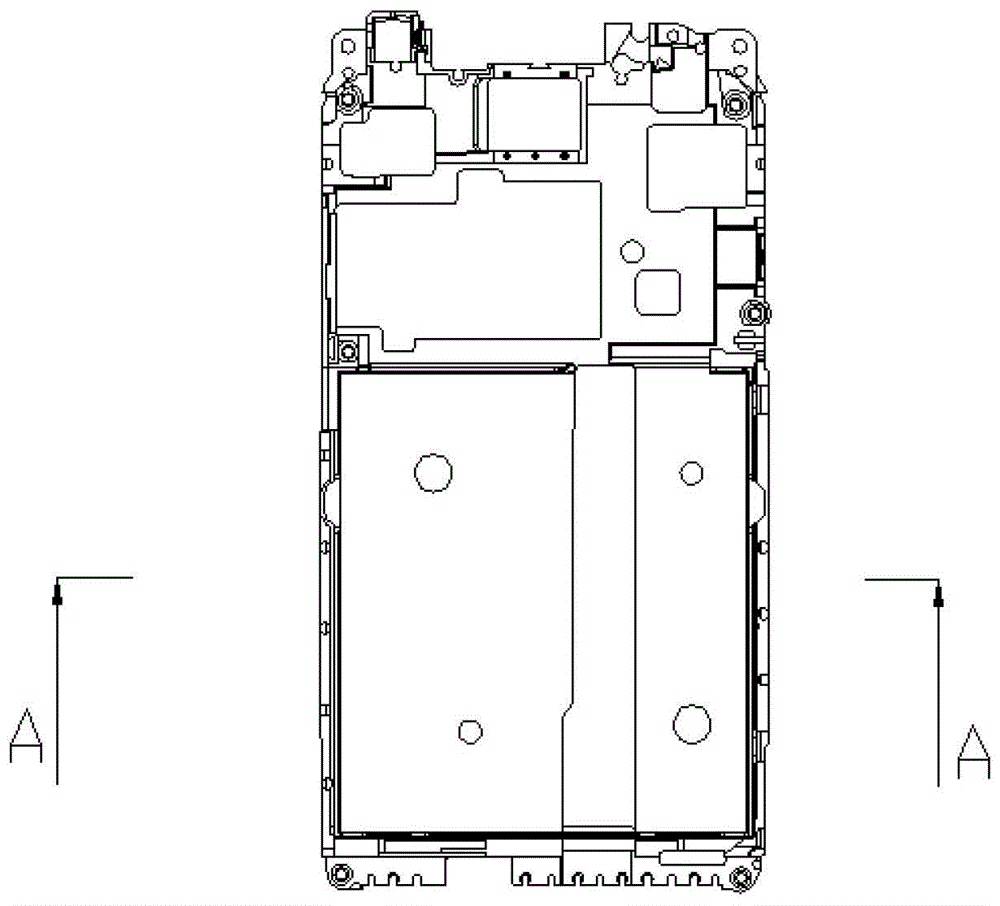

Mobile phone battery supporting board of improved structure

InactiveCN103581370AReduce thicknessIncrease storage spaceTelephone set constructionsLarge capacityElectrical and Electronics engineering

The invention discloses a mobile phone battery supporting board of an improved structure. The mobile phone battery supporting board comprises an outer frame and a base support, the base support is fixedly embedded in the inner side of the outer frame, and a battery containing space is formed by the base support and the inner side wall of the outer frame. The split structure with the outer frame and the supporting board combined together is adopted, the supporting board is manufactured in a punching mode, the thickness of the supporting board is lowered, the battery containing space is enlarged, the requirement of people for a thin mobile phone is met, and the requirement for a large-capacity battery is met.

Owner:KUSN GUANGHE ELECTRONICS TECH

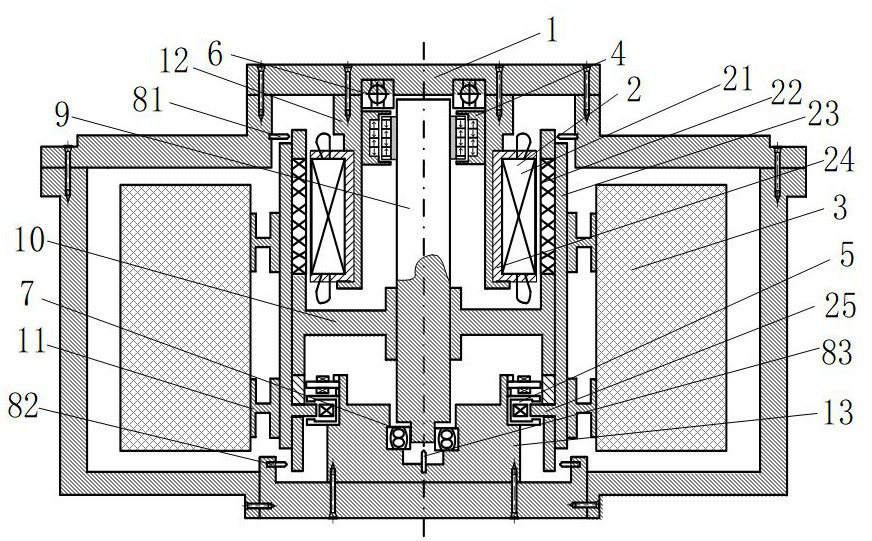

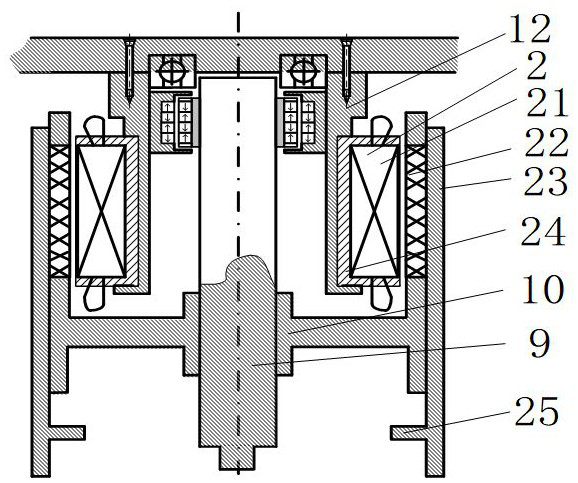

Flywheel energy storage device based on outer rotor bearingless permanent magnet synchronous motor

ActiveCN113037001AIncrease the moment of inertiaMeet the needs of large capacityEnergy storageStructural associationMagnetic bearingBall bearing

The invention discloses a flywheel energy storage device based on an outer rotor bearingless permanent magnet synchronous motor. A rotating shaft is arranged at the center of the interior of a vacuum closed casing; the upper end of the rotating shaft is connected with an upper cylindrical table through an axial passive magnetic bearing; the upper cylindrical table is fixedly sleeved with a stator bearingless permanent magnet synchronous motor; a motor inner stator coaxially and fixedly sleeves the upper cylindrical table; the inner wall of the middle section of a motor outer rotor is fixedly connected to the rotating shaft through an inner hub; the outer wall of the motor outer rotor is fixedly connected to the inner wall of a the flywheel rotor through an outer hub; the lower end of the rotating shaft is connected to the center of the lower cylindrical table through a self-aligning ball bearing; a three-degree-of-freedom radial-axial hybrid magnetic bearing is arranged between the upper end of the cylindrical table and the motor outer rotor; the lower end of the motor outer rotor extends downwards in the axial direction; a circular truncated cone horizontally extends inwards in the radial direction on the inner wall of the lower section of the motor outer rotor; and the circular truncated cone serves as a magnetic bearing outer rotor of the three-degree-of-freedom radial-axial hybrid magnetic bearing. According to the flywheel energy storage device based on the outer rotor bearingless permanent magnet synchronous motor of the invention, higher energy can be obtained, and a large-capacity requirement is realized.

Owner:JIANGSU UNIV

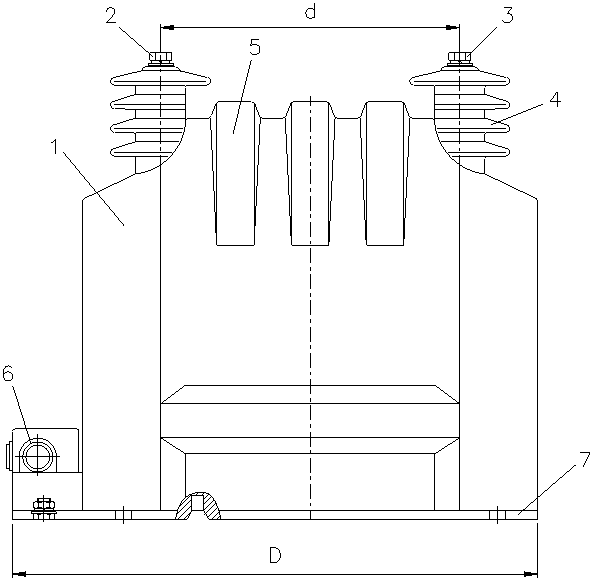

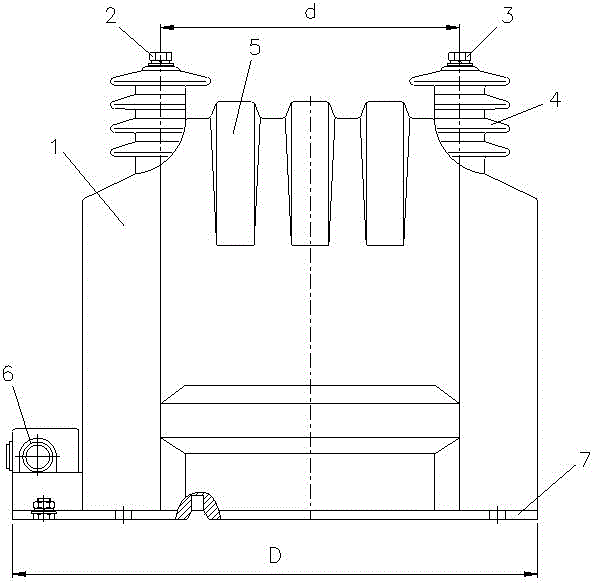

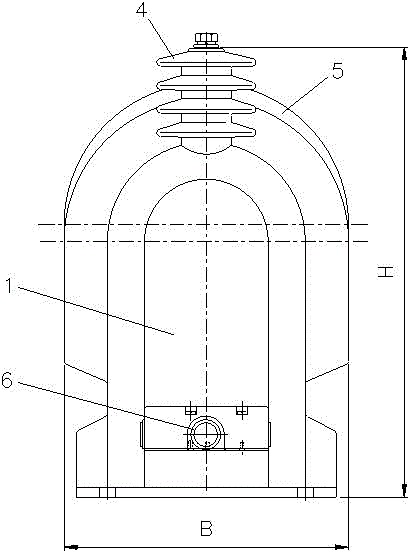

High-altitude high-capacity indoor all-insulation voltage transformer

ActiveCN103325558AIncreased safe creepage distanceIncrease the effective cross-sectional areaTransformersTransformers/inductances casingsTransformerEngineering

The invention relates to a high-altitude high-capacity indoor all-insulation voltage transformer. The all-insulation voltage transformer comprises a primary coil, a secondary coil, an iron core and an insulation outer shell, wherein a first terminal and a second terminal of the primary coil are symmetrically arranged on the two sides of the top of the insulation outer shell, and strings are arranged on the periphery of the first terminal and the periphery of the second terminal. A plurality of bosses are arranged at the top of the insulation outer shell and between the first terminal and the second terminal, and one sides, close to the bosses, of all the strings except for the uppermost string are removed. Specially-made iron core sheet layers are stacked to form the iron core, and the cross section of the iron core is oval. According to the high-altitude high-capacity indoor all-insulation voltage transformer, the design of the opposite and secondarily opposite special strings is adopted, the bosses are arranged at intervals, and therefore the safe creepage distance of the whole transformer over the ground is increased. The effective section area is increased by means of the iron core with the special section shape, double requirements for high altitude and high capacity are met, and the applicable range is wide.

Owner:STATE GRID CORP OF CHINA +1

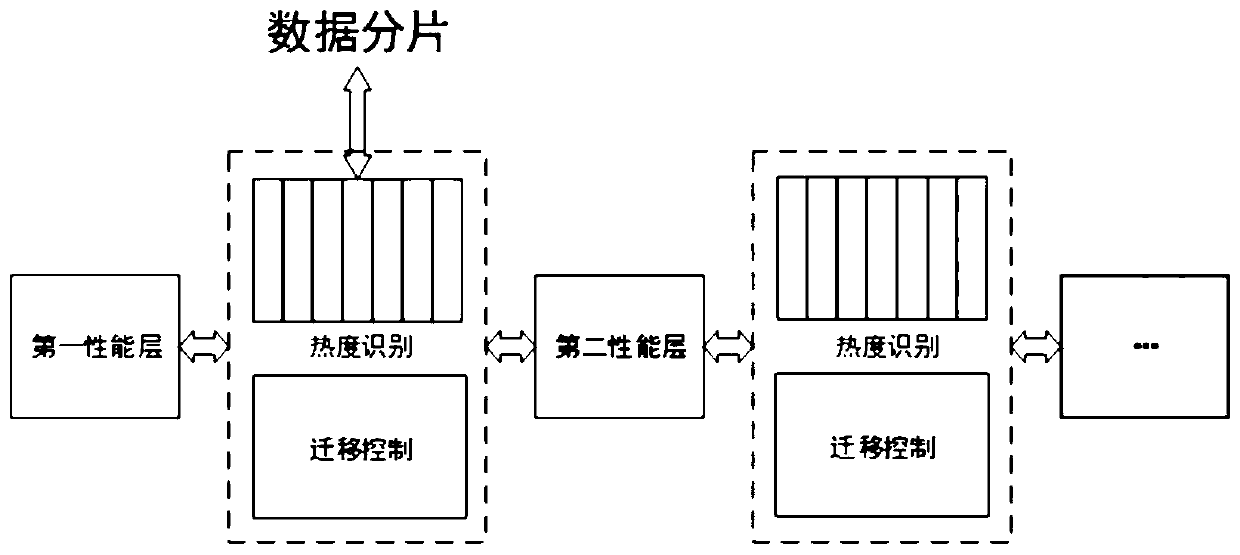

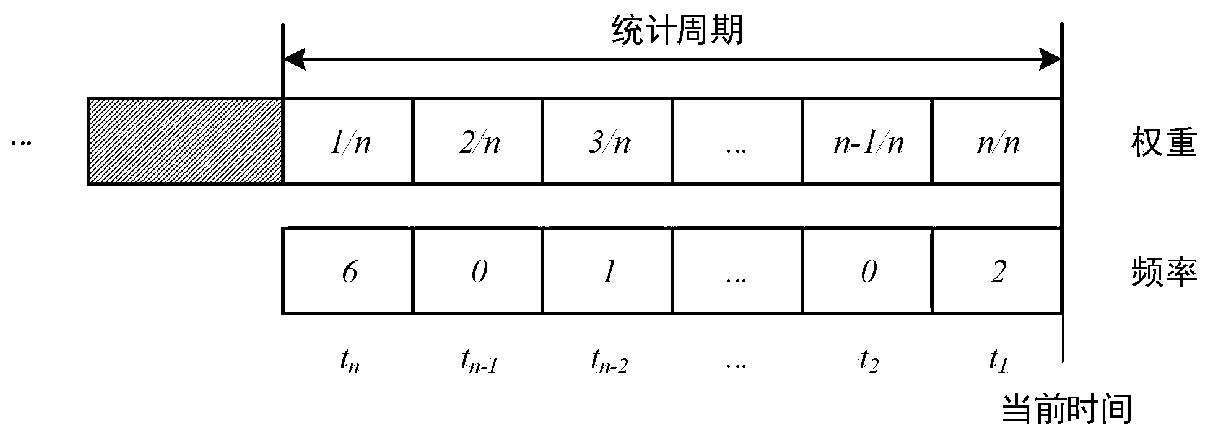

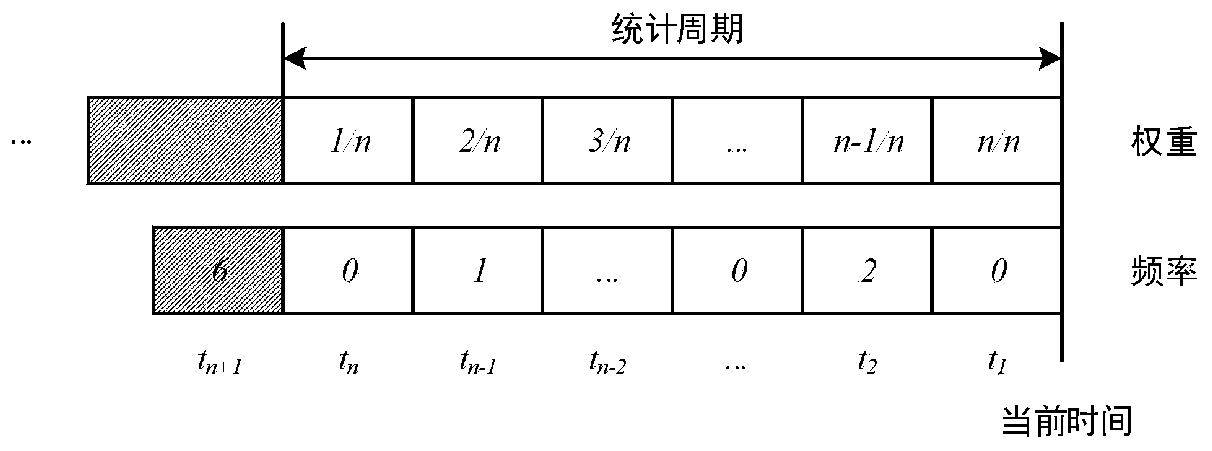

Attenuation type hierarchical storage system and method based on distributed storage system

InactiveCN110162273AMeet the needs of large capacityQuick interactionInput/output to record carriersUltrasound attenuationLow speed

The invention relates to an attenuation type hierarchical storage system and method based on a distributed storage system, and relates to the technical field of distributed storage. According to the invention, the timeliness of data in the information system is utilized to identify data flowing into the system with different heat degrees, a large number of cold data which are not accessed any moreare migrated out of precious high-speed storage media, and then low-speed storage media which are low in price and large in capacity are used for storage, so that rapid interaction between the hot data which are frequently accessed and a user is achieved through the high-speed storage media. With data migration, a large amount of cold data of the high-speed performance layer moves to the low-speed capacity layer; and a small amount of hot data in the low-speed capacity layer moves to the high-speed performance layer, so that the high-performance requirement on the access rate in a large-scalestorage system is met, the high-capacity requirement of mass data on a storage medium is also met, and meanwhile, the total ownership cost of the system is effectively reduced.

Owner:BEIJING INST OF COMP TECH & APPL

A high-altitude and large-capacity indoor fully insulated voltage transformer

ActiveCN103325558BIncreased safe creepage distanceIncrease the effective cross-sectional areaTransformersTransformers/inductances casingsTransformerEngineering

Owner:STATE GRID CORP OF CHINA +1

Optical fiber main distributing frame of MAN (Metropolitan Area Network)

The invention relates to an optical fiber main distributing frame of an MAN (Metropolitan Area Network). The optical fiber main distributing frame is characterized by comprising a stand as well as an optical cable fixing and stripping device, a line side module, an equipment side module and fiber jump passages which are arranged on the stand, wherein the optical cable fixing and stripping device is arranged at the left side of the stand, the line side module is arranged to the front of the stand, the equipment side module is arranged at the back of the stand, and the fiber jump passages are respectively arranged in corresponding positions on the stand according to respective actions; the front and the back of the stand are both provided with same side fiber jump passages and spacing-framefiber jump passages; a fore-and-after fiber jump passage is arranged at the right side of the stand; the line side and the equipment side are independently connected through the fore-and-after fiber jump passage; the interior of the line side or the equipment side is independently connected through the same side fiber jump passages; and adjacent stands are independently connected through the spacing-frame fiber jump passages. The invention has the advantages that the independent fiber jump passages are extremely convenient for fiber jumping and can meet the needs of an access network and an MAN for accessing optical fibers and cables.

Owner:CHINA INFOMRAITON CONSULTING & DESIGNING INST CO LTD +1

High compressed air cylinder filling machine

ActiveCN101839392BMeet the needs of large capacityEasy to storePiston pumpsMulti-stage pumpsDrive wheelGas cylinder

The invention relates to a high compressed air cylinder filling machine comprising an electric driving machine, a reduction gearbox and a drive shaft. An eccentric driving mechanism comprising at least two eccentric driving wheels is mounted on the drive shaft; at least two swing type compression cylinders are connected in series with a plurality of one-way valves and hose pipes to form a high compression mechanism, and are connected with a piston, a piston rod and a slide ring to be as a whole and then sleeved on the eccentric driving wheels through the slide ring; the other end of the piston rod is connected with a cylinder barrel which is sleeved on a supporting shaft which is mounted in a frame-shaped stand; a confluence plate is mounted on the frame-shaped stand and is provided with a pressure switch, a pressure gauge and a safety valve; the outer circumference of the compression cylinder is provided with concave-convex lines for heat dispersion; the frame-shaped stand is internally provided with a cooling fan, and the frame-shaped stander is provided with a transparent outer cover; the electric driving machine drives the reduction gearbox to transmit rotating motion to the drive shaft so as to enable the eccentric driving wheels to rotate and subsequently to drive the slide ring, the piston rod and the piston entirely to make straight reciprocating motion relative to thecylinder barrel for compressing gas, and the gas compressed by multistage is output to fill in a high pressure storage cylinder.

Owner:CHANGQI INT CO LTD

Mobile communication terminal and double-battery charge and power supply switching method thereof

InactiveCN101610304BMeet the needs of large capacityGuaranteed uninterrupted powerSubstation equipmentEnd cell switching arrangementsElectricityBattery charge

The invention discloses a mobile communication terminal and a double-battery charge and power supply switching method thereof. The main board of the terminal is provided with two battery interfaces and a charge and power supply circuit connected with the two battery interfaces. After the start-up of the terminal, the switching method comprises the following steps that: S1, a battery A supplies power, a battery B is idle and the voltages of the two batteries are recorded; S2, when the voltage of the battery A fails to meet power supply conditions, whether a charger is plugged in is judged; S3,when the charger is plugged in, the battery A supplies power while being charged, and the battery B is still keep idle; S4, when the battery A is fully charged and the battery B is undercharged, the battery A supplies power and the battery B is charged; and S5, when both the batteries are fully charged, the step S1 is returned to. The mobile communication terminal uses double batteries for charge and power supply, thereby meeting requirements on large capacity of mobile phone batteries. In addition, immediate switching is performed to allow another battery to supply power to ensure the continuity of the power supply of a mobile phone in case of accidents, for example, a battery is removed and software receives interruption sent by the system.

Owner:SHANGHAI SIMCOM LTD

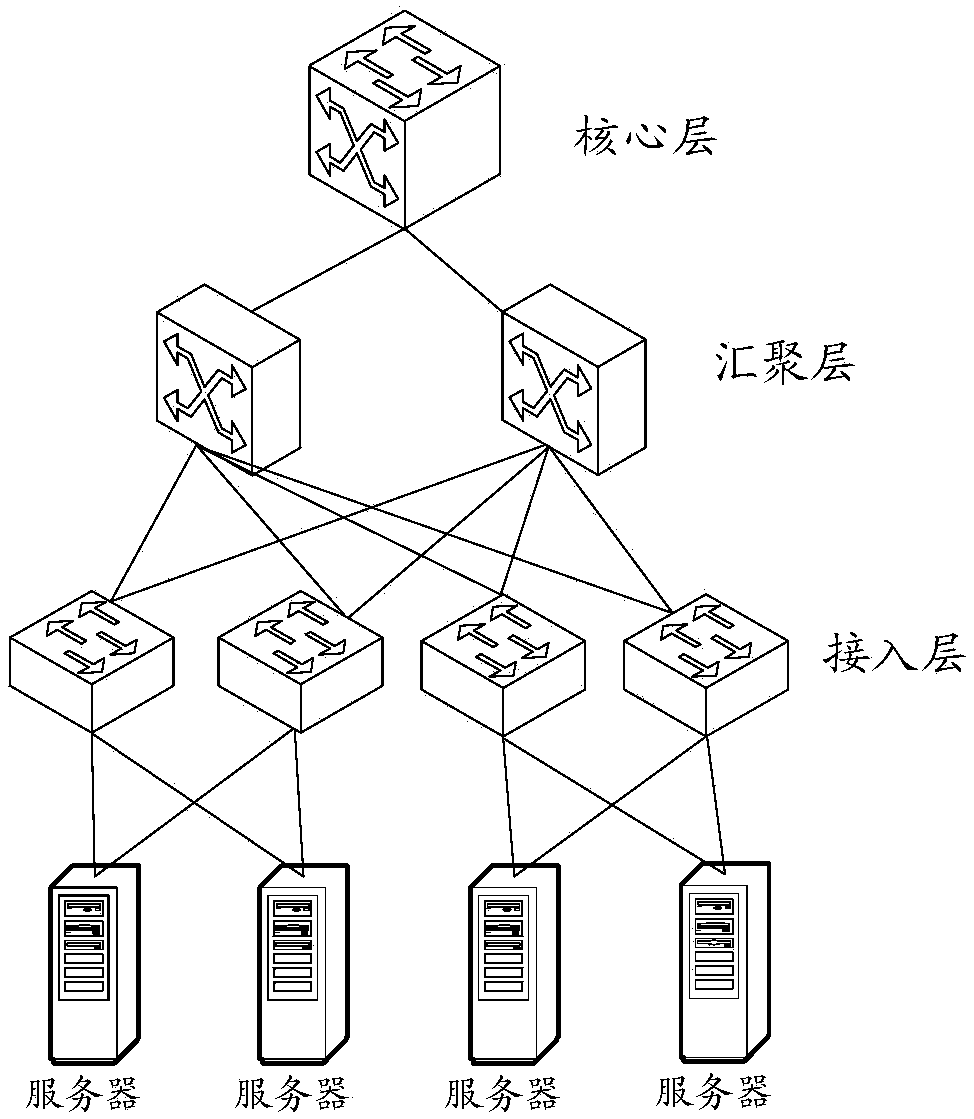

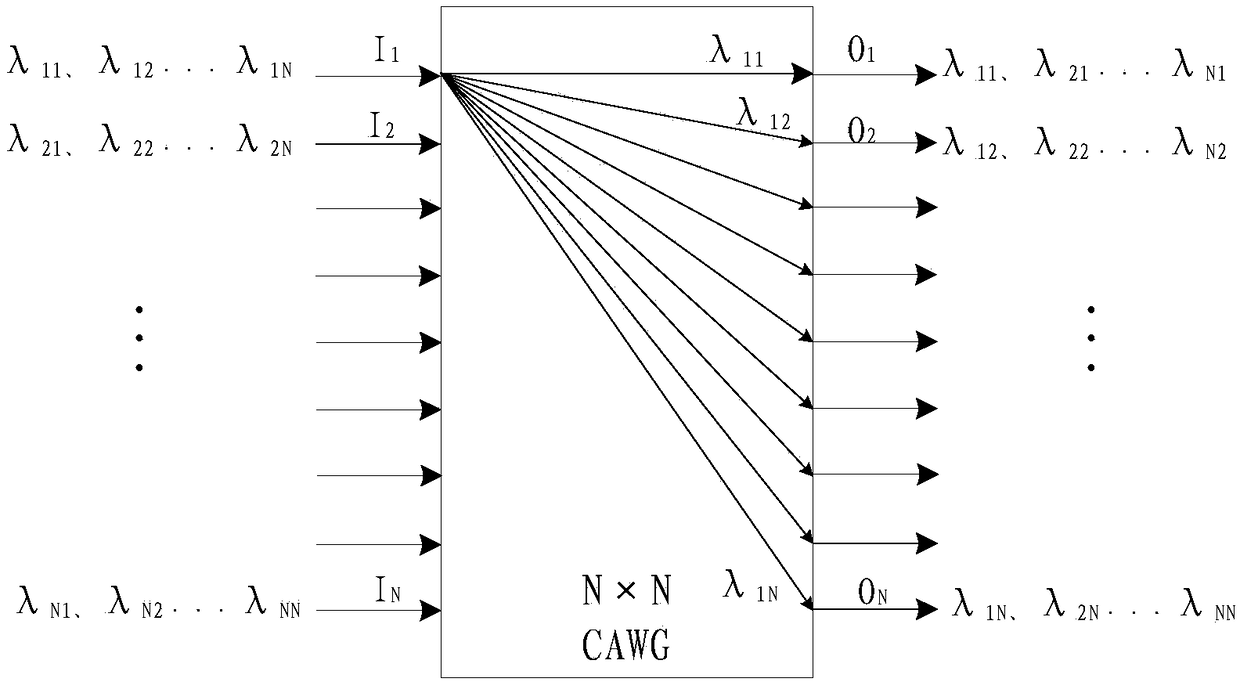

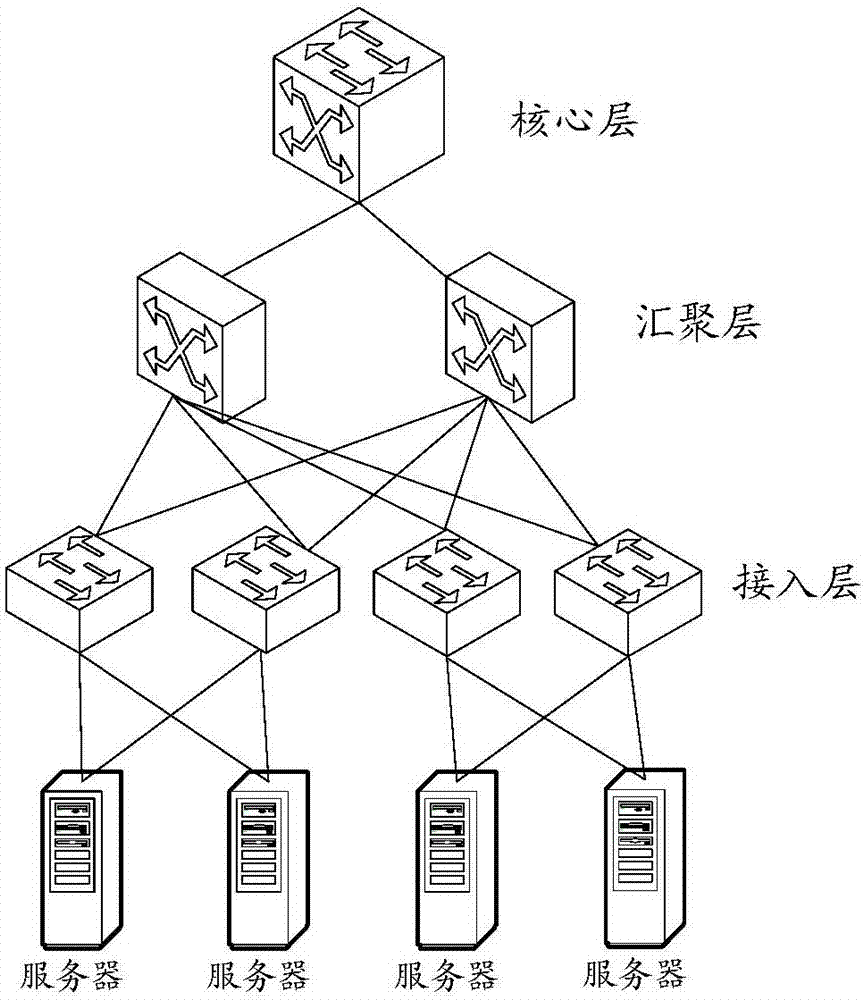

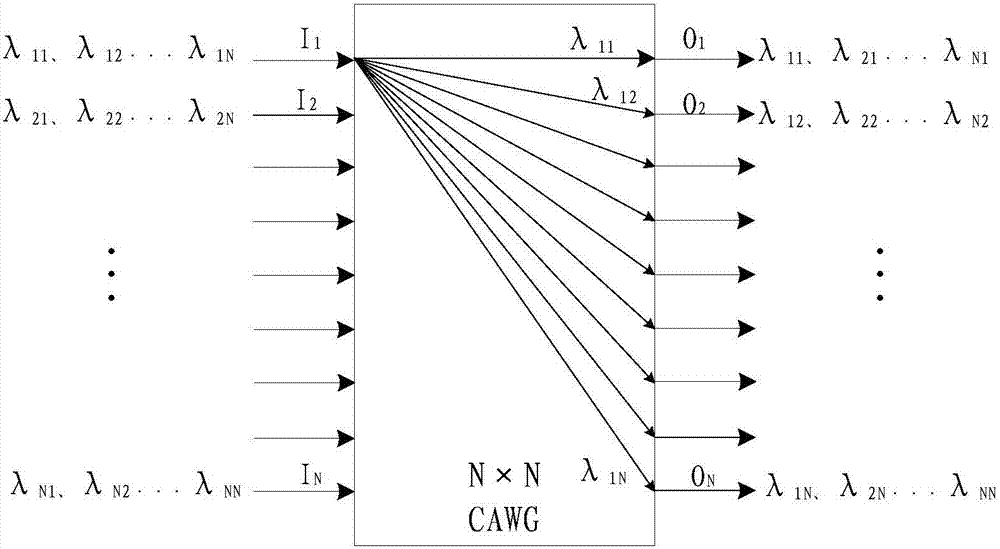

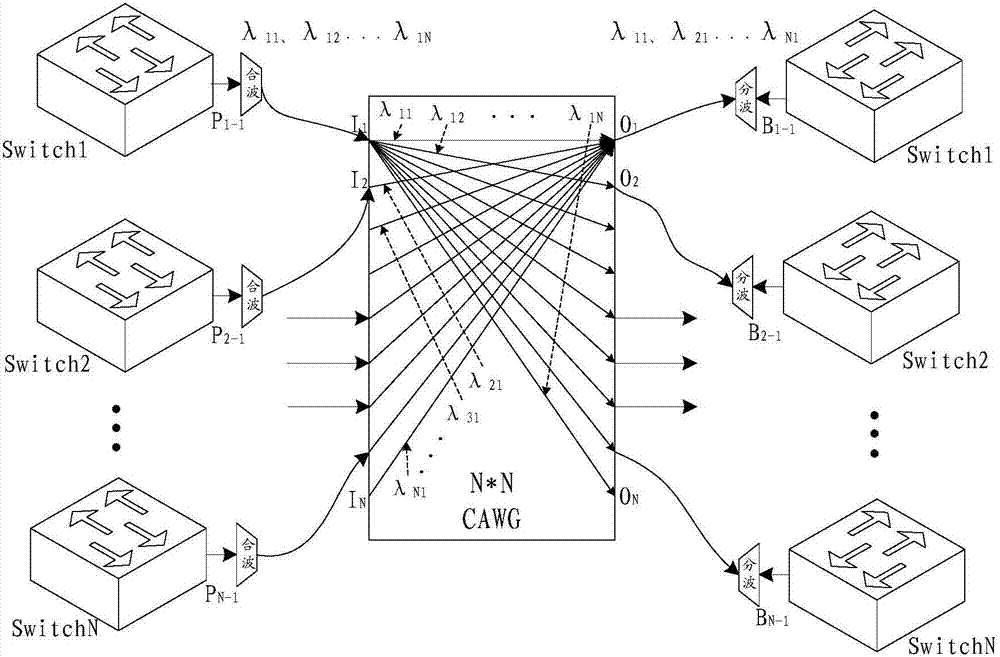

A data center mesh network and connection method

ActiveCN107231210BMeet the needs of large capacityReduce usageWavelength-division multiplex systemsData switching networksPhysical spaceData center

Owner:HUAWEI TECH CO LTD

Ink cartridge recycling method and recycling ink cartridge

ActiveCN111376609BIncrease ink capacityIncrease capacityPrintingProcess engineeringMechanical engineering

Owner:ZHUHAI NINESTAR MANAGEMENT CO LTD

A tailings treatment system

ActiveCN110626814BMeet the needs of large capacityAvoid the problem of not being fully taken over by the conveyor beltThrowing machinesSolid waste disposalProcess engineeringCrusher

The invention discloses a tailings processing system. The tailings processing system includes a material feeding device, a first material splitting machine, a first conveyor, a crusher, a second conveyor, a material selecting device, a second material splitting machine, and a third conveyor, the tailings in a tailings storage are processed and conveyed, and finally different grades and different types of materials are output at the material selection device and conveyed onto a transport vehicle respectively for different types of further processing and application; through the systematic configuration of from the tailings storage to the entire processes of loading, crushing, sorting, and transportation, the to-be-processed tailings are processed from the tailings storage to the output of various types of available materials, and the current vacancy of the lack of a preliminary treatment system of the tailings is filled.

Owner:青岛博政信息技术有限公司 +1

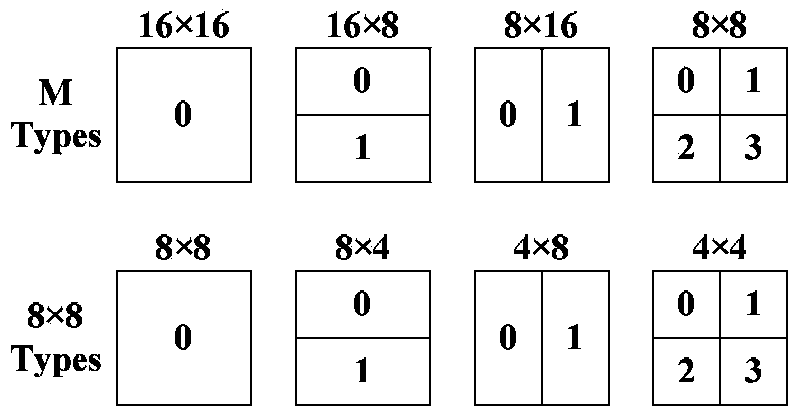

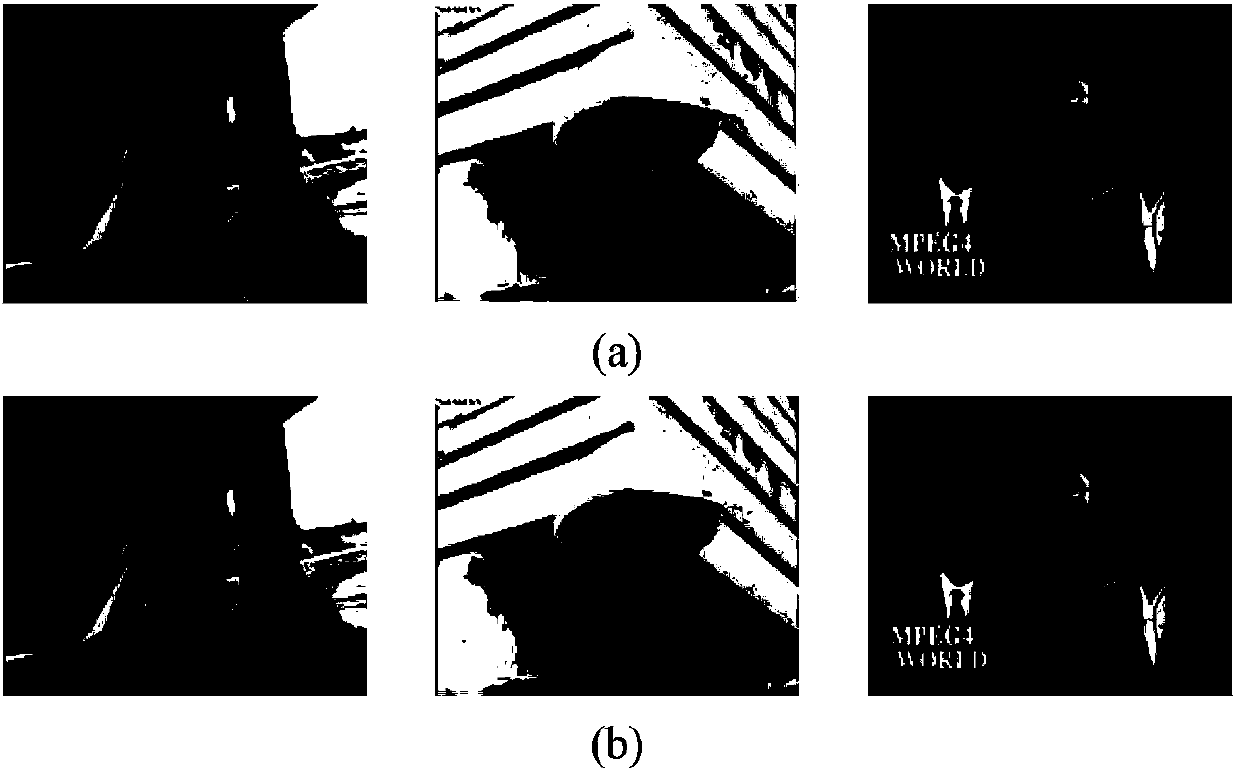

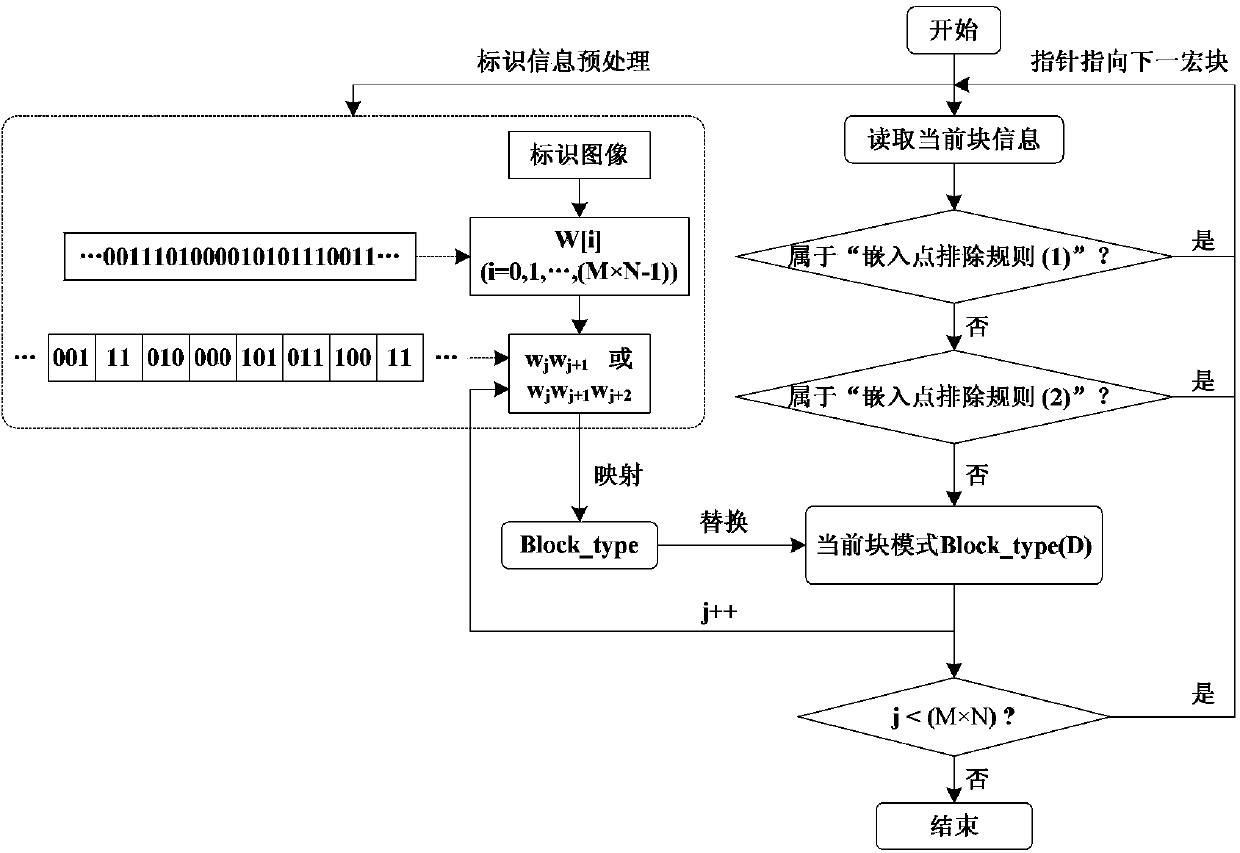

H.264 large-capacity information hiding method based on information variable-length packet structure

InactiveCN102685500BAccurate decodingMeet the needs of large capacityDigital video signal modificationTheoretical computer scienceInformation hiding

The invention discloses an H.264 large-capacity information hiding method based on an information variable-length packet structure. The method is specifically characterized in that an information variable-length packet concept is introduced at an H.264 inter-frame prediction link, the identifier information is classified into seven groups of unrepeatable full-information groups with the length of 2 to 3bits by utilizing the improved Exp-Golomb code word structure concept, and seven varieties of mapping rules between the inter-frame prediction mode and the information groups to be hidden. On the basis of the mapping rule, the inter-frame prediction mode of the existing macro block is modulated to realize the hiding of the video information. The position of a host macro block is determined by a prescribed embedded point exclusive rule, each host macro block corresponds to two or 3 bites of identifier information, so that the large-capacity requirement of the video information hiding algorithm can be satisfied. The extraction process of the identifier information is free from utilizing an original video and can be completed only by decoding inter-frame prediction mode part in the code stream, so that the video real-time processing requirement can be met.

Owner:HEFEI UNIV OF TECH

Memory card module structure

InactiveCN110058658AIncrease the number ofImplement modular configurationDigital processing power distributionEngineeringMemory cards

The invention discloses a memory card module structure including a magnetic disk frame. A guide rail is arranged in the magnetic disk frame. The inner side wall of a bracket is connected with a fixingstud in a riveting mode. The inner side wall of the bracket is connected with a memory card body through the fixing stud and screws in a threaded mode. A handle is hinged to the inner wall of the left side of the bracket, and the side, away from the left side of the bracket, of the handle is connected with a lock catch piece in an engaged mode. Through a magnetic disk frame, the advantage of modular configuration is realized. The memory card body can be subjected to hot plug operation from the outside of the case through the magnetic disk frame for maintenance. Therefore, rapid operation is achieved without the need to open an upper cover of a case because a memory card body does not need to install in the interior of the case and fix on the mainboard. Meanwhile, the number of memory cardbodies is greatly increased, and the requirement of high capacity is met.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Data center MESH network and connection method

ActiveCN107231210ARealize interconnectionSolve the problem of high usageWavelength-division multiplex systemsData switching networksPhysical spaceData center

The invention relates to a data center MESH network and a connection method. The data center MESH network provided by the embodiment of the invention comprises K<2> CAWGs (Coaxial Adapter Waveguides) and K switch groups, wherein each switch group comprises N switches, and is interconnected in intra-group connection and inter-group connection ways; each switch comprises KxN connection ports and K pairs of receiving-transmitting ports; each pair of receiving-transmitting ports comprises a transmitting port and a receiving port; in intra-group connection, N switches in each switch group are connected with N switches in the same group through one CAWG; in inter-group connection, each of the N switches in each switch group is connected with N switches in any other switch group in the K switch groups through another CAWG respectively. Through adoption of the data center MESH network and the connection method provided by the embodiment of the invention, the defects in the prior art can be overcome. Connection of a large-capacity data center MESH network is realized by the CAWGs; the large capacity demand of a future data center network is met; the quantity of used optical fibers is reduced; and the physical space of a machine room is saved.

Owner:HUAWEI TECH CO LTD

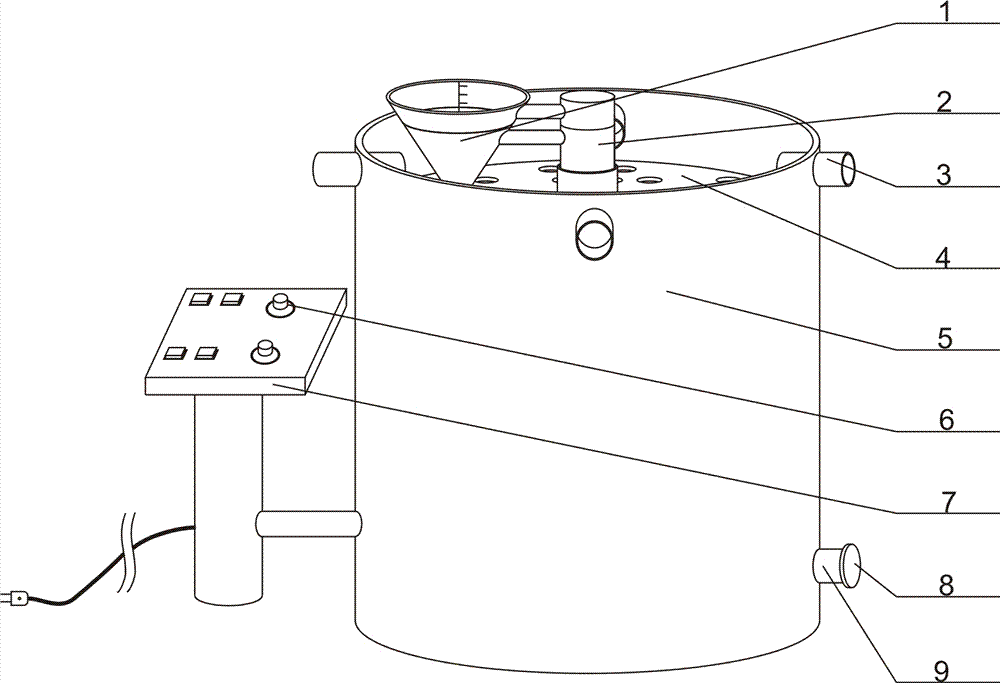

Soymilk machine with wide capacity

InactiveCN101849773AReduce the overall diameterReduce capacityBeverage vesselsMilk substitutesEngineeringKnife blades

The invention discloses a soymilk machine with wide capacity, comprising a machine head, a cup body, a heating device and a crashing device. The invention is characterized in that the upper part of the effective cup body of the soymilk machine is large and lower part thereof is small; the capacity of the cup body at a 30 mm position apart from the lowest part of the effective cup body is 10-60% of the capacity of the cup body at a 30 mm position apart from the uppermost part of the effective cup body; the diameter of the cup body at a 30 mm position apart from the lower part of the effective cup body is 30-75% of the diameter at the biggest position of the upper part of the effective cup body; the capacity of the cup body at 30 mm position apart from the lowest part of the effective cup body is 50-350 ml, and the diameter of the cup body at a 30 mm position apart from the lower part of the effective cup body is 40-100 mm; and a vertical position of blades in the crashing device is positioned between 1-30mm heights of the effective cup body of the soymilk machine. By using the soymilk machine of the invention, making soymilk in small capacity and soymilk in large capacity can be achieved; the requirements of obvious different capacities of soymilk amounts at ordinary time and when entertaining relatives and friends for a single or a small family with two persons can be satisfied; the requirement of making small-capacity soymilk, brown rice cereal and fruit and vegetable juice which have special nutrition or replaced breast milk for infants and the only school children.

Owner:白先放

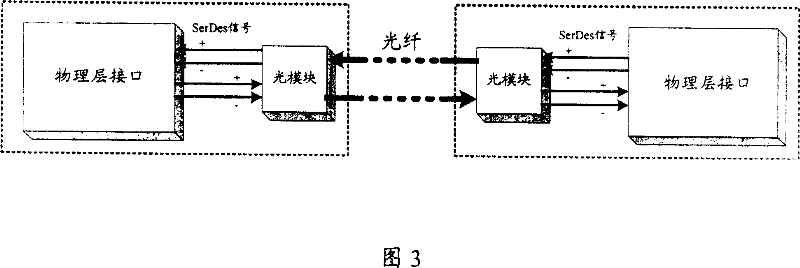

Management information interactive system and special interface card and master control card in network equipment

ActiveCN100355239CLarge capacityNo increase in quantityData switching detailsPhysical layerInterconnection

An interactive system of managed data in network device comprises main control card and interface card. It is featured as setting CUP and physical layer interface chip on two said cards, connecting two said cards to rear panel through Ethernet GE interface of 1000 mega for achieving data interacting between main control card and physical interface chip on interface card physical layer by utilizing rear panel wiring, setting GE interface as optical interface mode for realizing interconnection of main control card to interface card by using SerDes signal wire on rear panel.

Owner:XINHUASAN INFORMATION TECH CO LTD

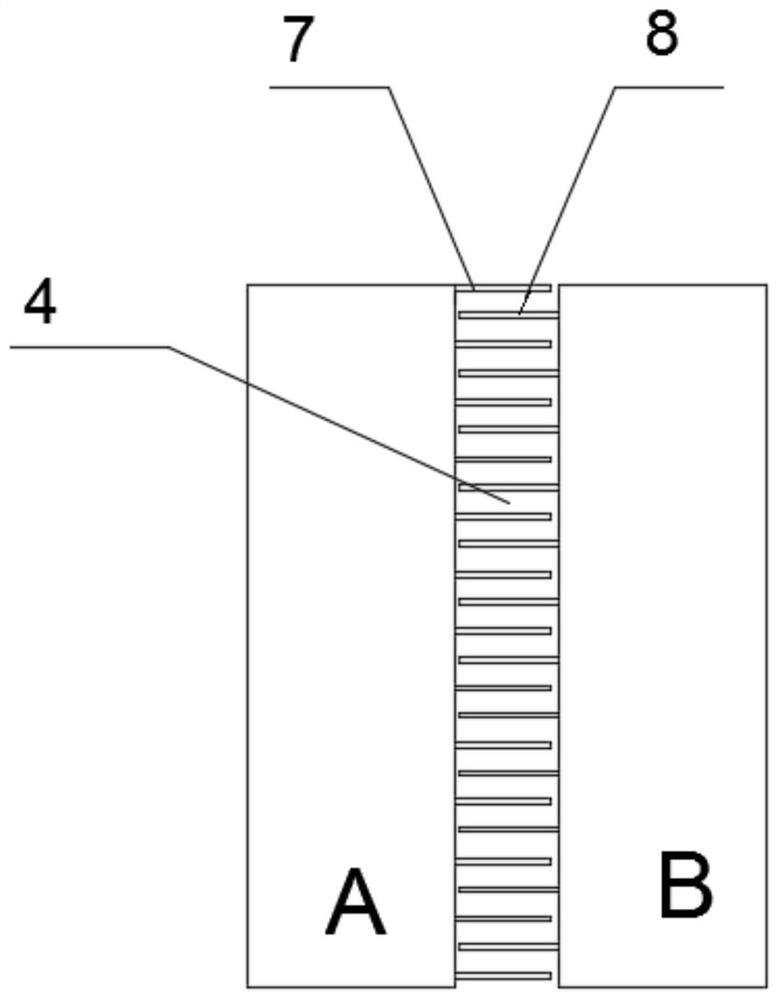

Tubular filter with quasi-basis total parameters

InactiveCN112952320AMeet the needs of large capacitySeries capacitors avoidWaveguide type devicesCapacitanceHemt circuits

The invention discloses a tubular filter with quasi-basis total parameters. The tubular filter comprises a microstrip line substrate, a feed-in line, a feed-out line and interdigital coupling line sections; a plurality of low-impedance microstrip lines and a plurality of high-impedance microstrip lines are arranged on the microstrip line substrate; the plurality of low-impedance microstrip lines and the plurality of high-impedance microstrip lines are distributed at intervals in a crossed manner and are connected in sequence; the series capacitor is realized by using the interdigital coupling line sections, and the interdigital coupling line sections can realize the series capacitor with a relatively large capacitance value, so that the requirement on the relatively large capacitance value when a broadband filter is designed by using a tubular filter circuit prototype is met; meanwhile, the interdigital coupling line sections are used for realizing series connection of the capacitors, and the capacitors between suspended microstrip line double-layer circuit boards are prevented from being used for realizing series connection of the capacitors, so that the design of the tubular filter with quasi-base total parameters can be realized by using a microstrip line single-sided pattern, and due to the adoption of the microstrip circuit, interconnection with a microwave active circuit can be realized very conveniently.

Owner:重庆两江卫星移动通信有限公司

Video conference service dispatching method and video conference system

InactiveCN101707687BFix performance issuesMeet the needs of large capacityTelevision conference systemsTwo-way working systemsTelevision systemTelecommunications

A method for scheduling a conference television service and a conference television system are provided. The method comprises the following steps: multipoint controllers and protocol stacks are set in different processes; and the multipoint controllers arrange calls from terminals to the multiple protocol stacks according to the occupation cases of the process resources of the protocol stacks. The method and the system solve the capability problem derived from that the call requests from the conference television terminals are centralized in an identical protocol stack to be processed, satisfies the high capacity requirement for operating the conference television service, and improves the capability of the multipoint controller unit.

Owner:ZTE CORP

Mobile phone battery support plate with improved structure

InactiveCN103581370BReduce thicknessIncrease storage spaceTelephone set constructionsPunchingEngineering

Owner:KUSN GUANGHE ELECTRONICS TECH

A large -capacity Lyocell cellulose raw solution and its continuous preparation process

ActiveCN113388897BImprove qualityMeet the needs of large capacitySpinning head liquid feederMonocomponent cellulose artificial filamentCellulosePulp and paper industry

Owner:BEIJING SANLIAN HOPE TEXTILE & CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com