High-altitude high-capacity indoor all-insulation voltage transformer

A voltage transformer and large-capacity technology, which is applied in the direction of inductors, transformer/inductor shells, transformer/inductor cores, etc., can solve the safety hazards of anti-resonance ability of semi-insulated products and the large demand for secondary capacity of voltage transformers , unable to meet market demand and other issues, to achieve the effect of large internal structure space, increase effective cross-sectional area, and increase safe creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

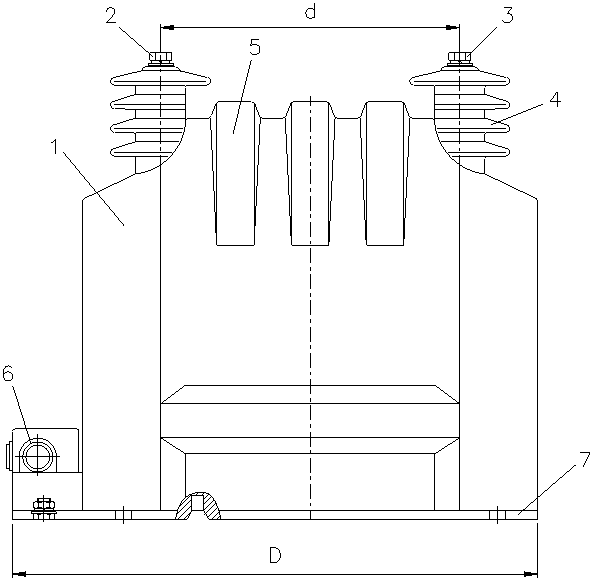

[0017] Such as Figure 1~2 As shown, a high-altitude and large-capacity indoor fully insulated voltage transformer includes a primary coil, a secondary coil, an iron core and an insulating shell 1, and the primary insulation thickness of the primary coil to the secondary coil and to the iron core is not less than 11mm The two sides of the top of the insulating shell 1 are symmetrically provided with the first terminal 2 and the second terminal 3 of the primary coil, the first terminal 2 can be used to connect the A terminal of the high-voltage electric wire, and the second terminal The terminal 3 can be an N terminal used to connect the neutral point, the outer circumference of the first connecting terminal 2 and the second connecting terminal 3 is provided with an umbrella group 4, and the top of the insulating shell 1 is connected between the first connecting terminal 2 and the second connecting terminal. A plurality of bosses 5 are arranged between the connecting terminals ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com