Current transformer

A technology for current transformers and conductive tubes, applied in the field of transformers, can solve the problems of failing to meet the temperature rise requirements, insulation damage, insulation aging and shortening the service life of equipment, reducing volume, increasing effective cross-sectional area, and solving Effects of installation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

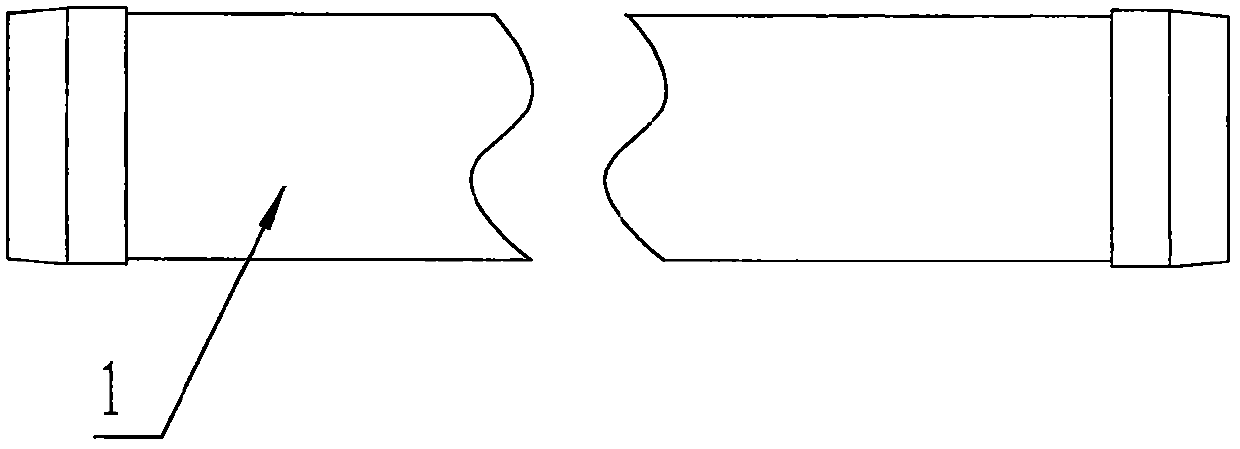

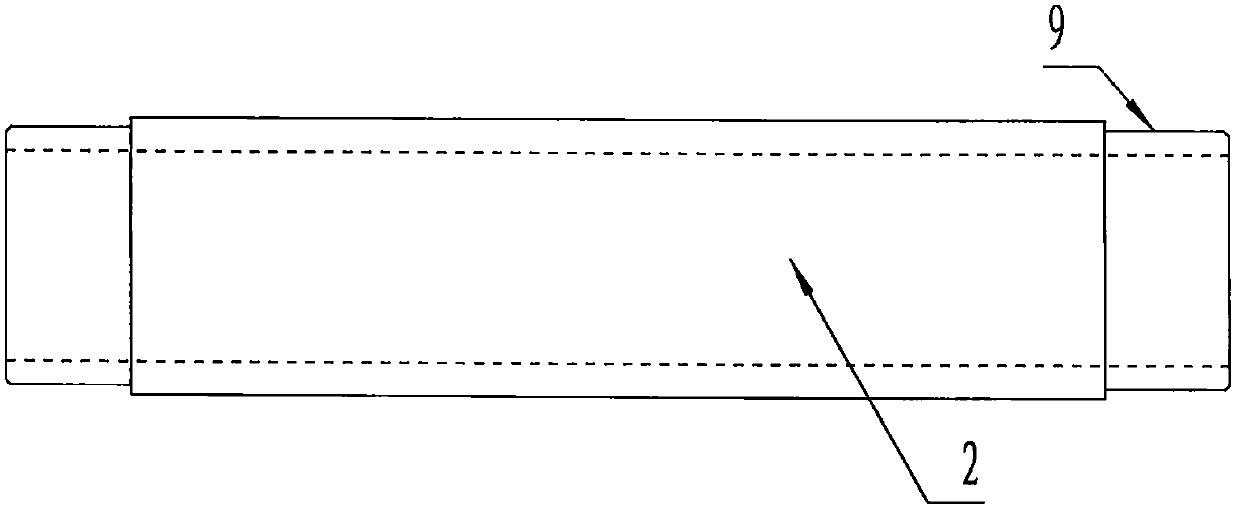

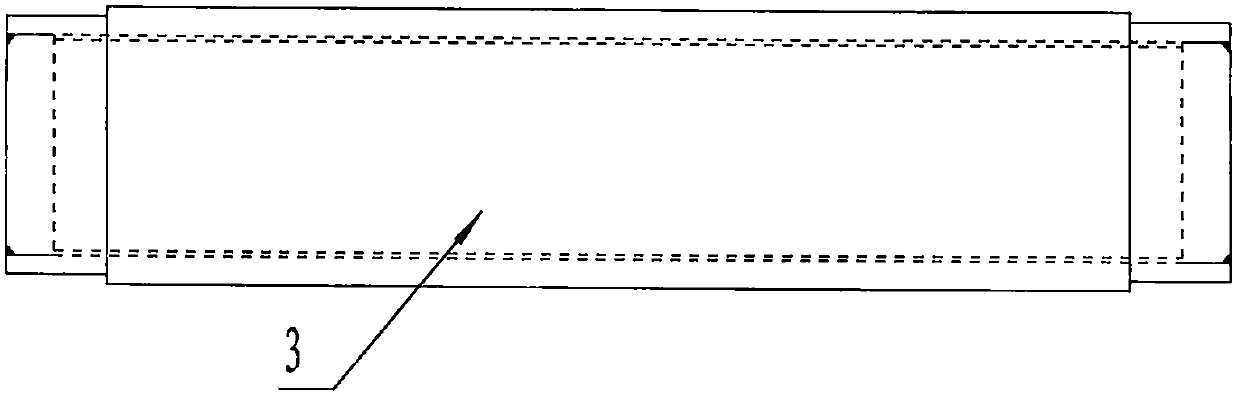

[0009] Such as figure 1 , figure 2 , image 3 As shown, the primary coil 3 is a split structure, which is assembled by a cylindrical conductive rod 1 and a tubular conductive tube 2 and then welded by silver welding. This split structure allows current to flow through both the conductive rod 1 and the conductive tube 2 , can overcome the influence of the skin effect; such as Figure 4 , Figure 5 As shown, the primary terminal block 4 is in the shape of an "L" and consists of a connecting arm 5 and a flat terminal block 6. The flat terminal block 6 has threaded holes 8. The upper end of the connecting arm 5 is provided with a connecting hole 7, and the two ends of the conductive pipe 2 are provided with steps. 9 is installed in the connection hole 8 and welded with silver solder, so that the primary coil 3 and the wiring board 4 are connected together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com