Mobile phone battery support plate with improved structure

A mobile phone battery and structure improvement technology, applied in the direction of the structure of the phone, can solve the problems of casting process limitation and difficult molding, and achieve the effects of satisfying the battery capacity, reducing the thickness and increasing the accommodating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

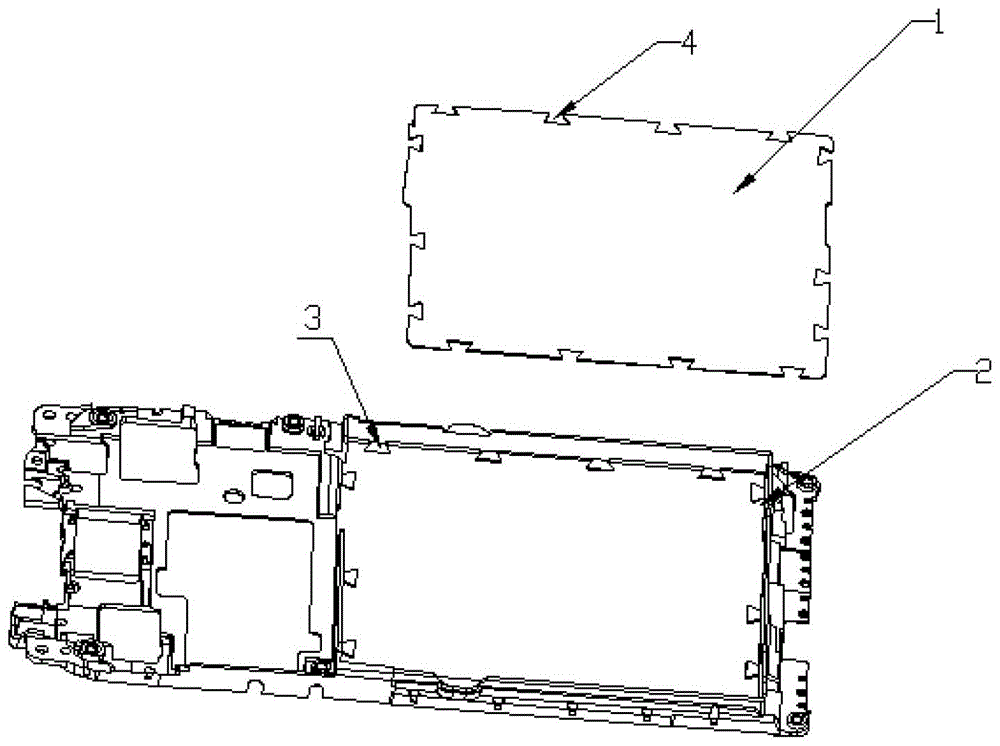

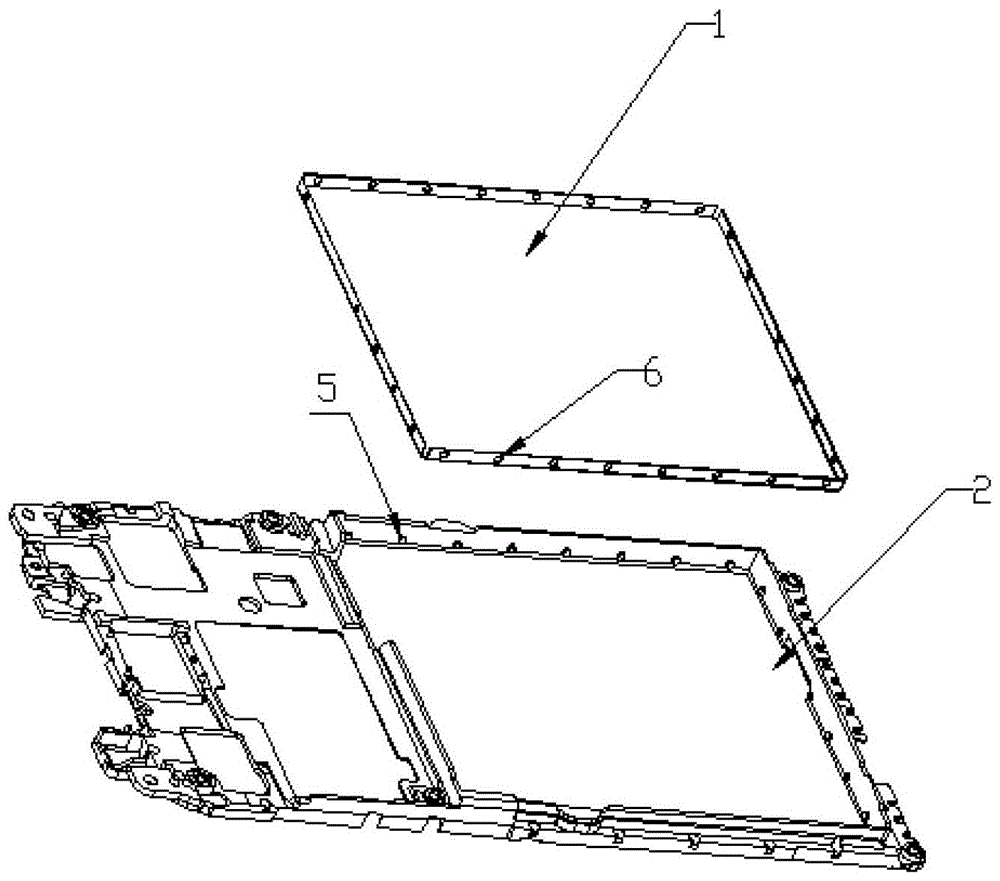

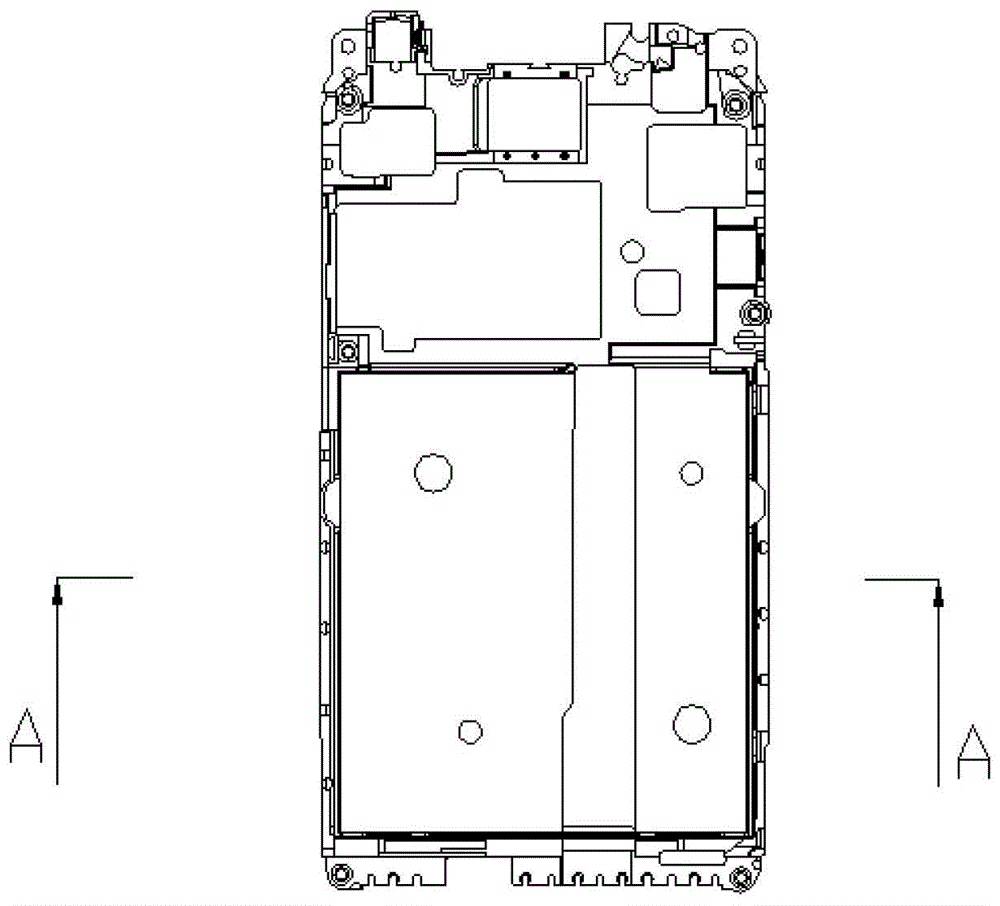

[0014] Embodiment: A mobile phone battery support plate with improved structure, including an outer frame 2 and a bottom bracket 1, the bottom bracket 1 is fixedly embedded in the inner side of the outer frame 2, and the bottom bracket 1 and the inner side wall of the outer frame 2 form a battery accommodating space, the mobile phone battery support plate is a combination of the outer frame 2 and the bottom bracket 1, the bottom bracket 1 can be formed separately, and its thickness can be reduced without affecting the molding of the outer frame 2, so that enough space can be left for the battery Expanding the capacity does not need to increase the thickness and size of the mobile phone to realize the expansion of the battery capacity, which meets the demand for a thin mobile phone but a large battery capacity.

[0015] The structure in which the bottom bracket 1 is fixedly embedded in the inner side of the outer frame 2 is as follows: the inner side wall of the outer frame 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com