Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Meet the constraints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

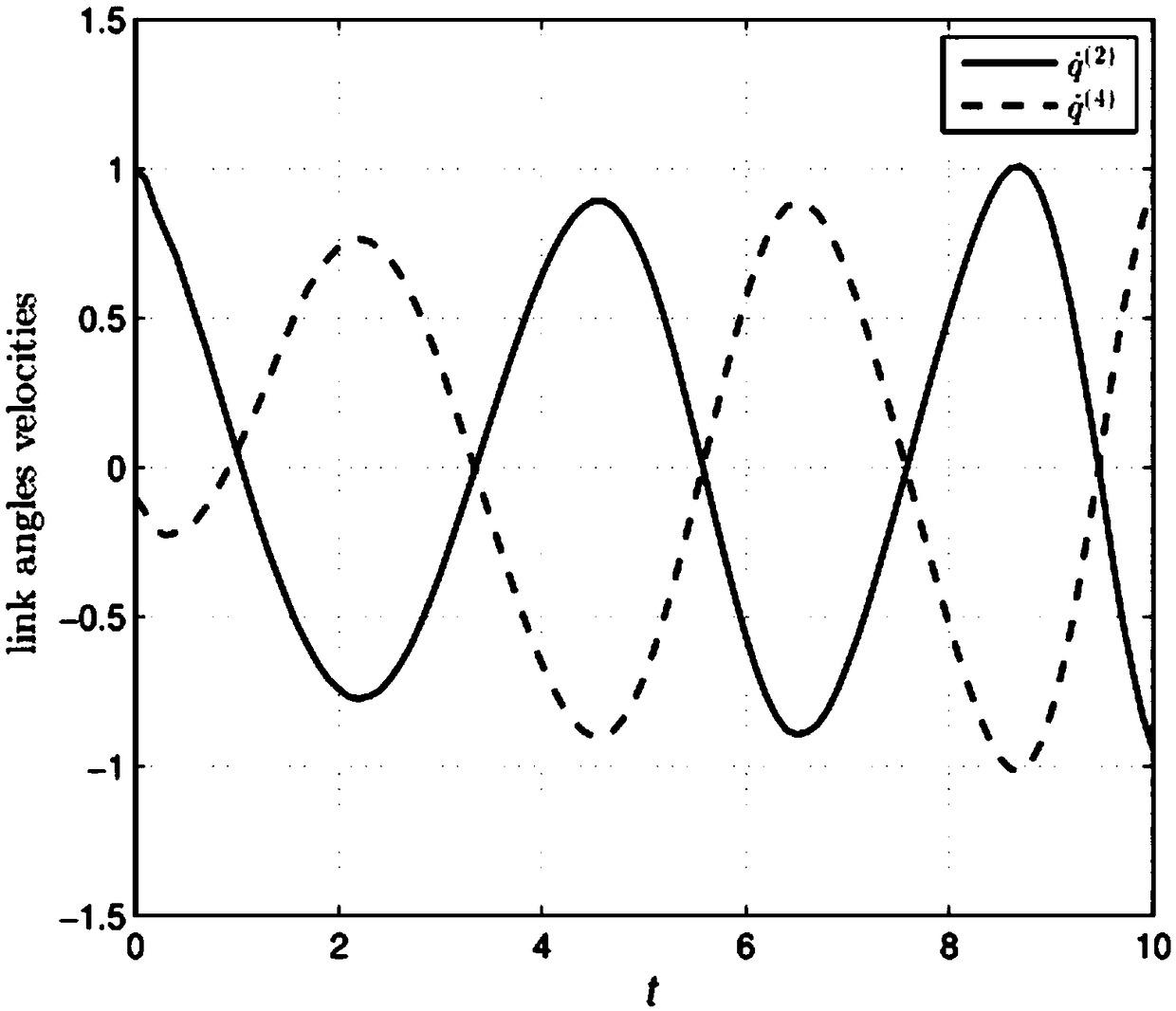

Track planning method for robot joint space conveyor belt following movement

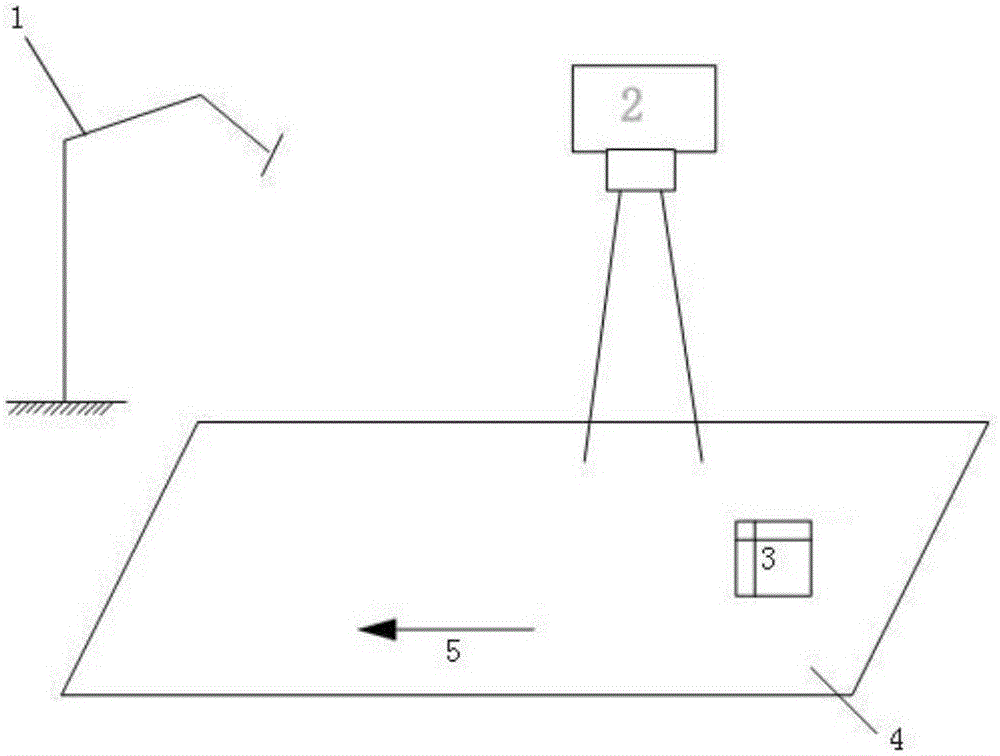

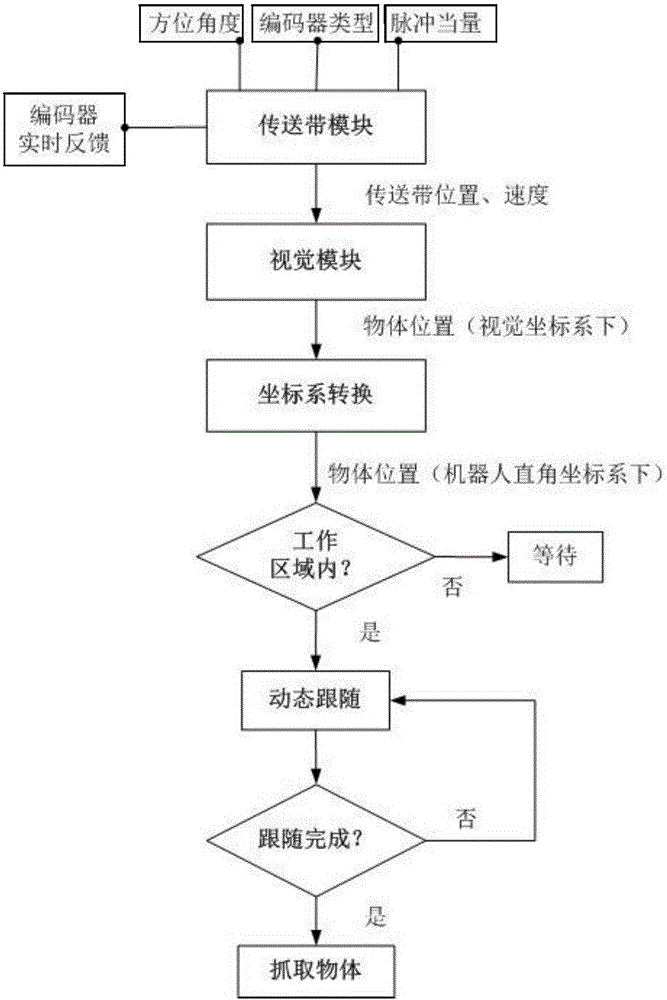

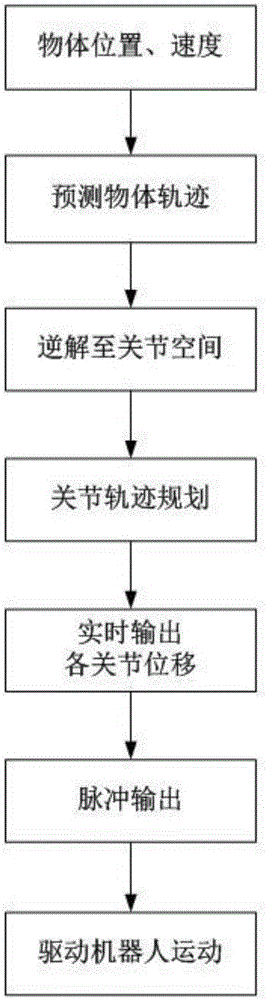

ActiveCN105700530ASimple visual algorithmSmooth joint speed curvePosition/course control in two dimensionsPlanning approachSacroiliac joint

The invention discloses a track planning method for robot joint space conveyor belt following movement. The method enables a robot to track a target object on a conveyor belt quickly and to move synchronously with the target object, so that dynamic following is realized and therefore related application functions such as grasping and the like can be implemented. According to the invention, the initial position and speed of the target object are determined through a visual system and the position of the target object is predicated in real time. Then conversion into the joint space is realized through inverse kinematics and track planning on different joints of the robot in the joint space is made. Therefore, dynamic following is realized. According to the invention, only joint restriction conditions need to be considered and the restriction conditions are simple. Besides, the method is the dynamic track planning method with optimal time and can ensure that the robot can track the target object in the shortest time. The method is simple and is high in following efficiency.

Owner:NANJING ESTUN AUTOMATION CO LTD

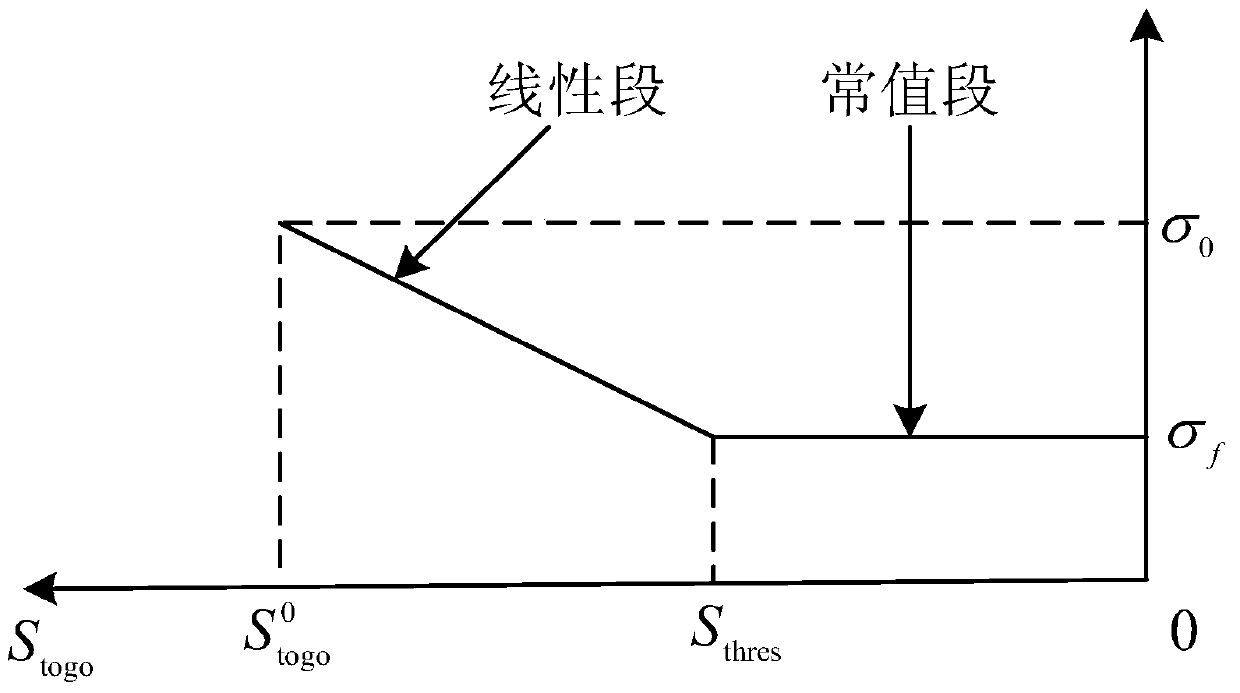

Prediction correcting guidance method of deep space exploration returning process

ActiveCN103863579ANo added complexityIncrease flight rangeSystems for re-entry to earthCosmonautic landing devicesCurrent pointDeep space exploration

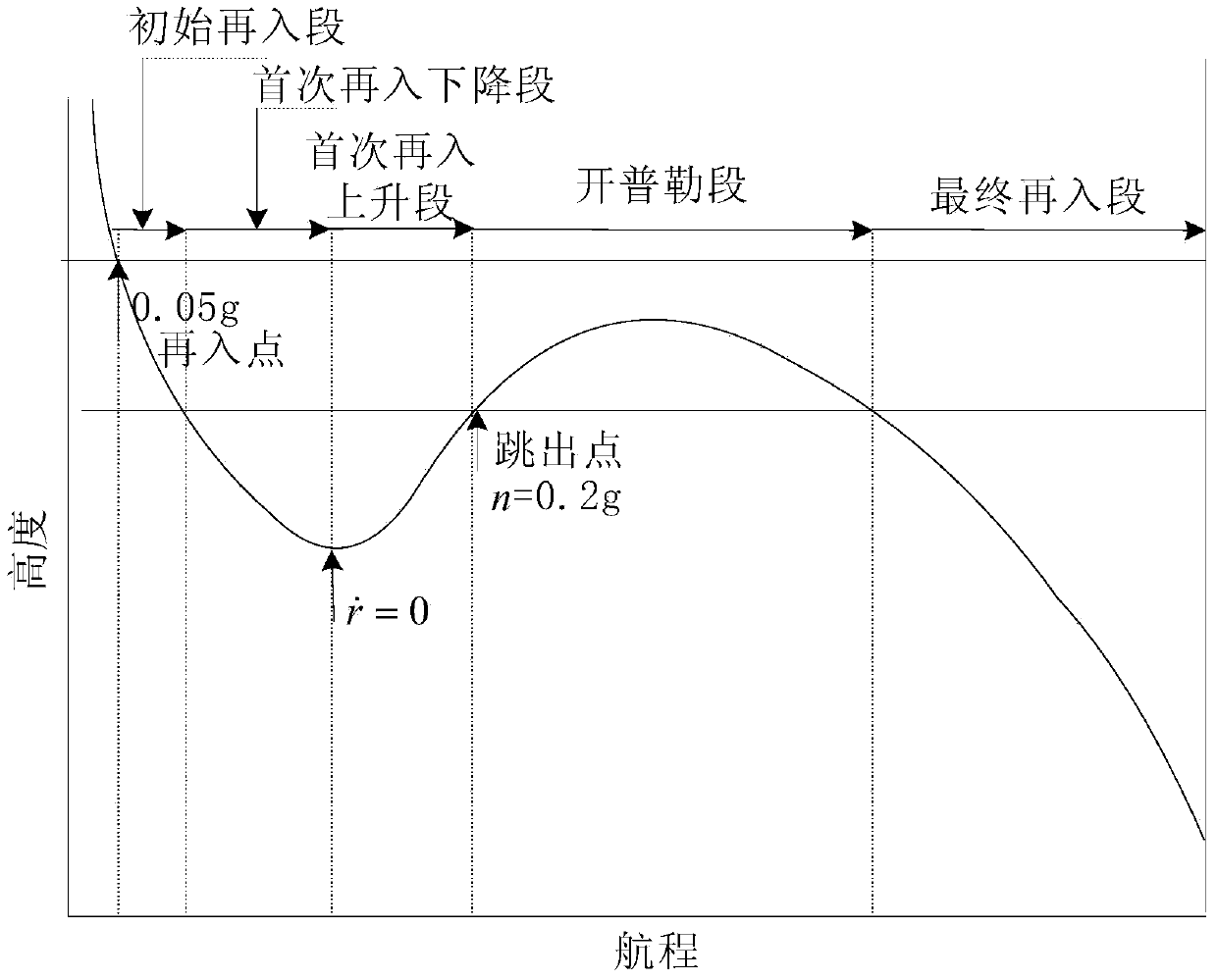

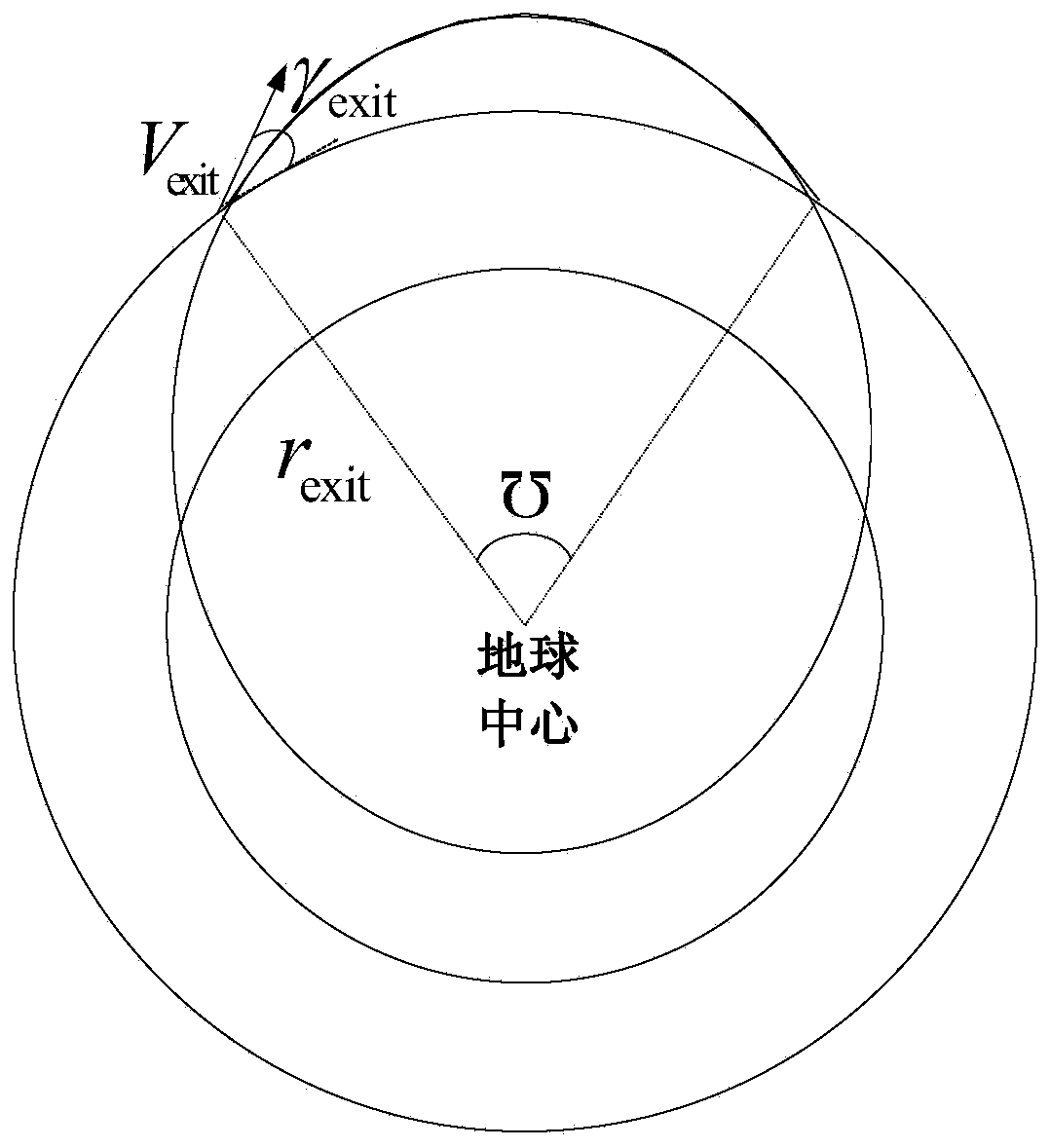

A prediction correcting guidance method of a deep space exploration returning process comprises the steps that (1) a heeling angle section used for deep space exploration returning process track prediction is determined; (2) the amplitude value | sigma 0 | of the heeling angle of a current point is computed in an iterative mode; (3) a salutatory reentry flight track of a returning device is divided into an initial reentry stage, a primary reentry descending stage, a primary reentry ascending stage, a Kepler stage and a final reentry stage, a final guidance rule of the returning device is determined, and the final guidance rule is that when the returning device is in the initial reentry stage or the primary reentry descending stage or the primary reentry ascending stage or the final reentry stage, the amplitude value | sigma 0 | determined in the step (2) of the heeling angle sigma 0 of the current point is used for guidance; and when the returning device is in the Kepler stage, | sigma 0 | = 180 degrees is used for guidance, and accordingly prediction correcting guidance of the deep space exploration returning process is completed. The guidance rule is designed at the Kepler stage of the track for achieving overload restrain on the deep space exploration returning process, and safe and accurate landing of the returning device is guaranteed.

Owner:BEIJING INST OF CONTROL ENG

Vehicle spare part sales volume forecasting method and system based on unified dynamic integration model and meta-heuristic algorithm

InactiveCN107705157ASolve the problem of accurately forecasting demand for various spare partsGood optimization accuracyMarket predictionsArtificial lifePredictive systemsPredictive methods

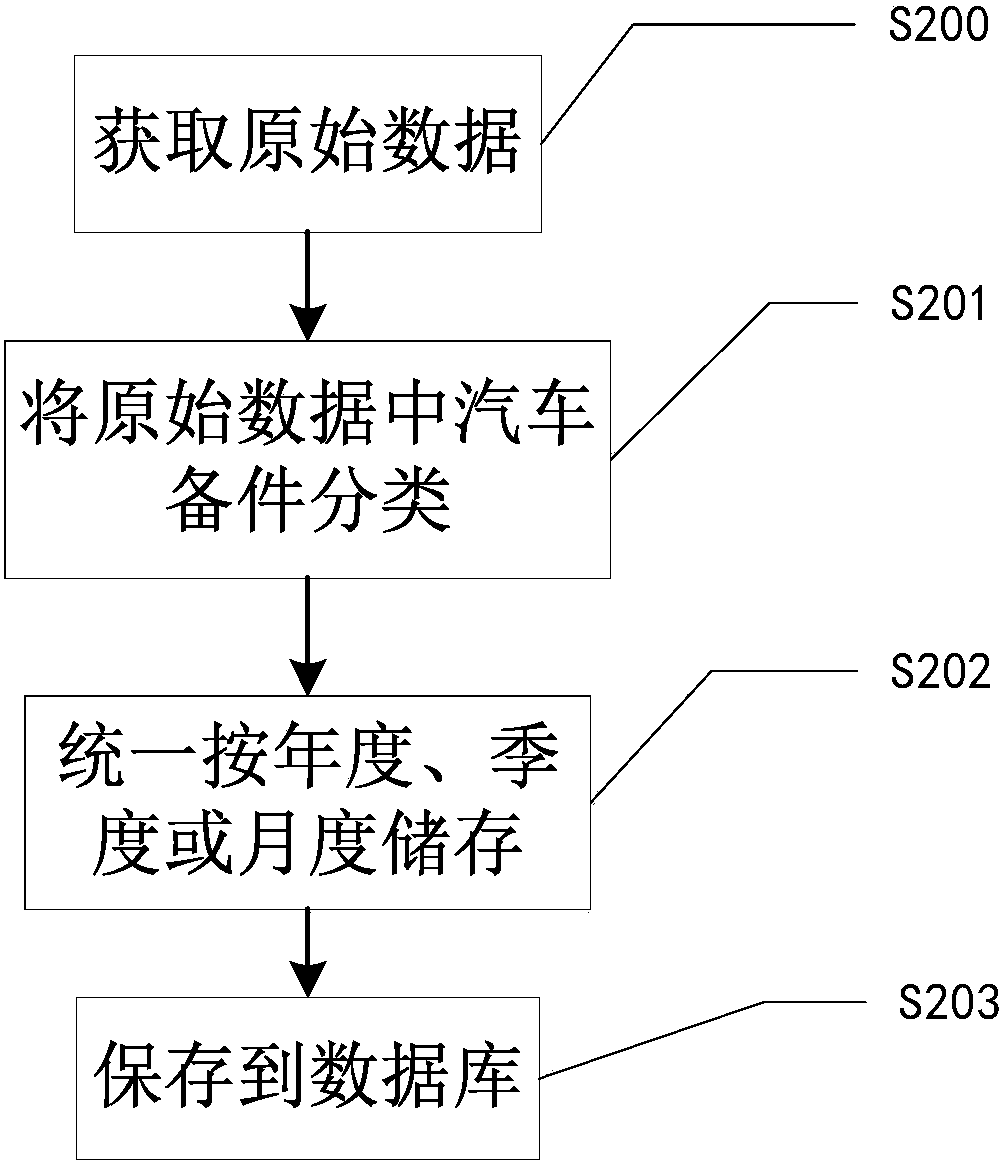

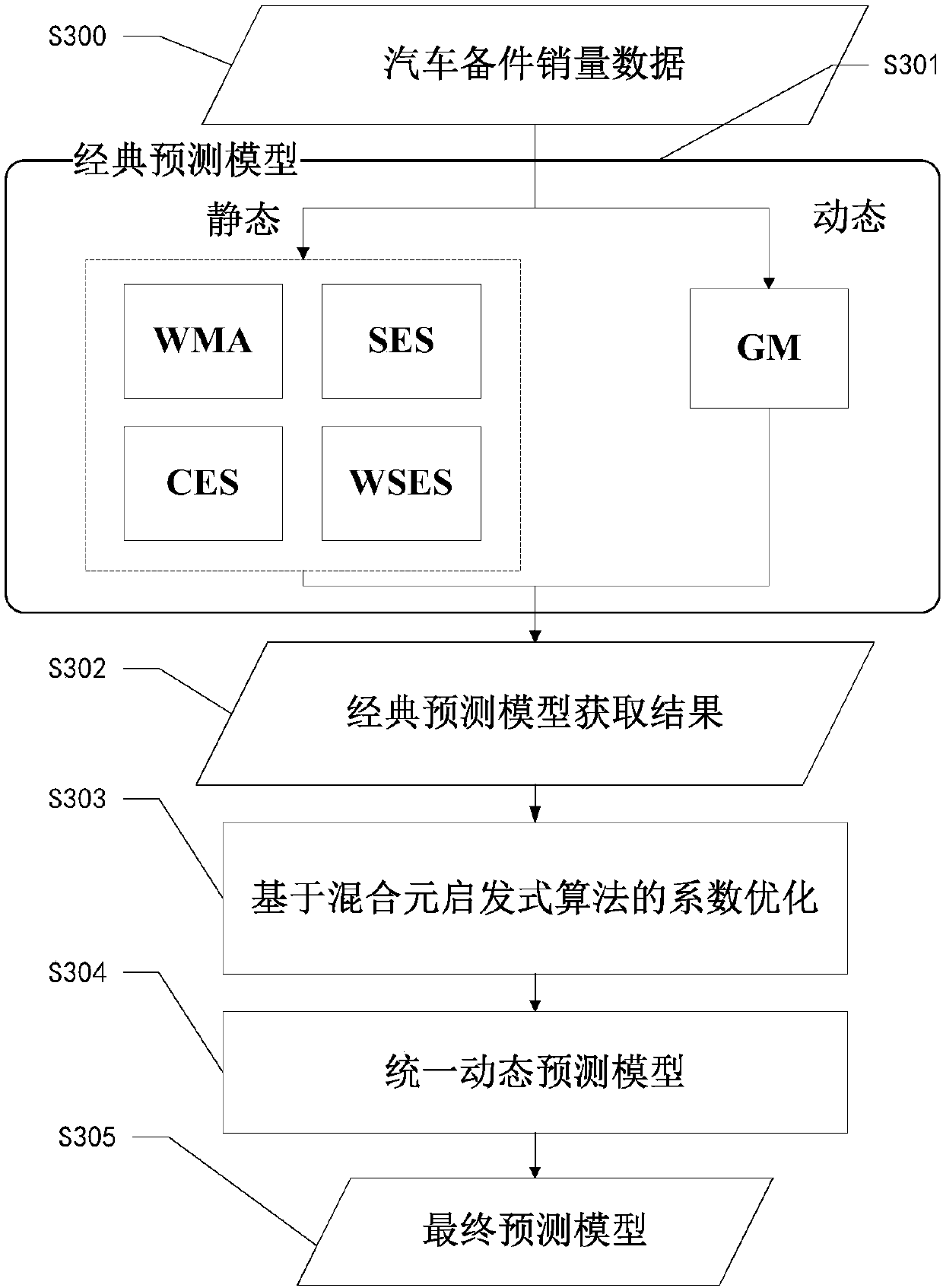

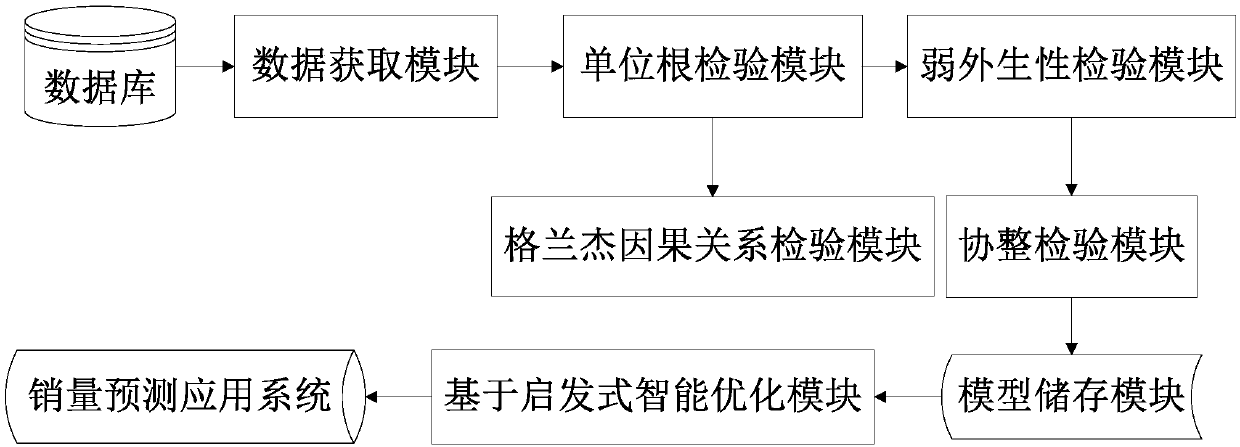

The invention provides a vehicle spare part sales volume forecasting method and system based on a unified dynamic integration model and a meta-heuristic algorithm. The method comprises the steps thata database is established to store data needed for forecasting the vehicle spare part sales volume, and the sales volume of various vehicle spare parts is comprised and is called as a forecasting variable; a data acquisition module is connected with the database and the vehicle spare part sales volume forecasting system to acquire the needed forecasting variable, and a number of parallel typical forecasting methods are used for forecasting to acquire forecasting results corresponding to various forecasting methods; furthermore, various forecasting results are stored, and a unified dynamic integrated model is established; the meta-heuristic algorithm is used to optimize the forecasting model coefficients; the acquired forecasting model is stored in a vehicle spare part sales volume forecasting application system; and a spare part sales volume forecasting result is generated after the corresponding vehicle spare part sales volume data are input. According to the invention, the model which is suitable for forecasting various vehicle spare parts is found; the characteristics of high optimization precision and the like of the meta-heuristic algorithm are used; and the vehicle spare partsales volume forecasting precision is effectively improved.

Owner:DALIAN UNIV OF TECH

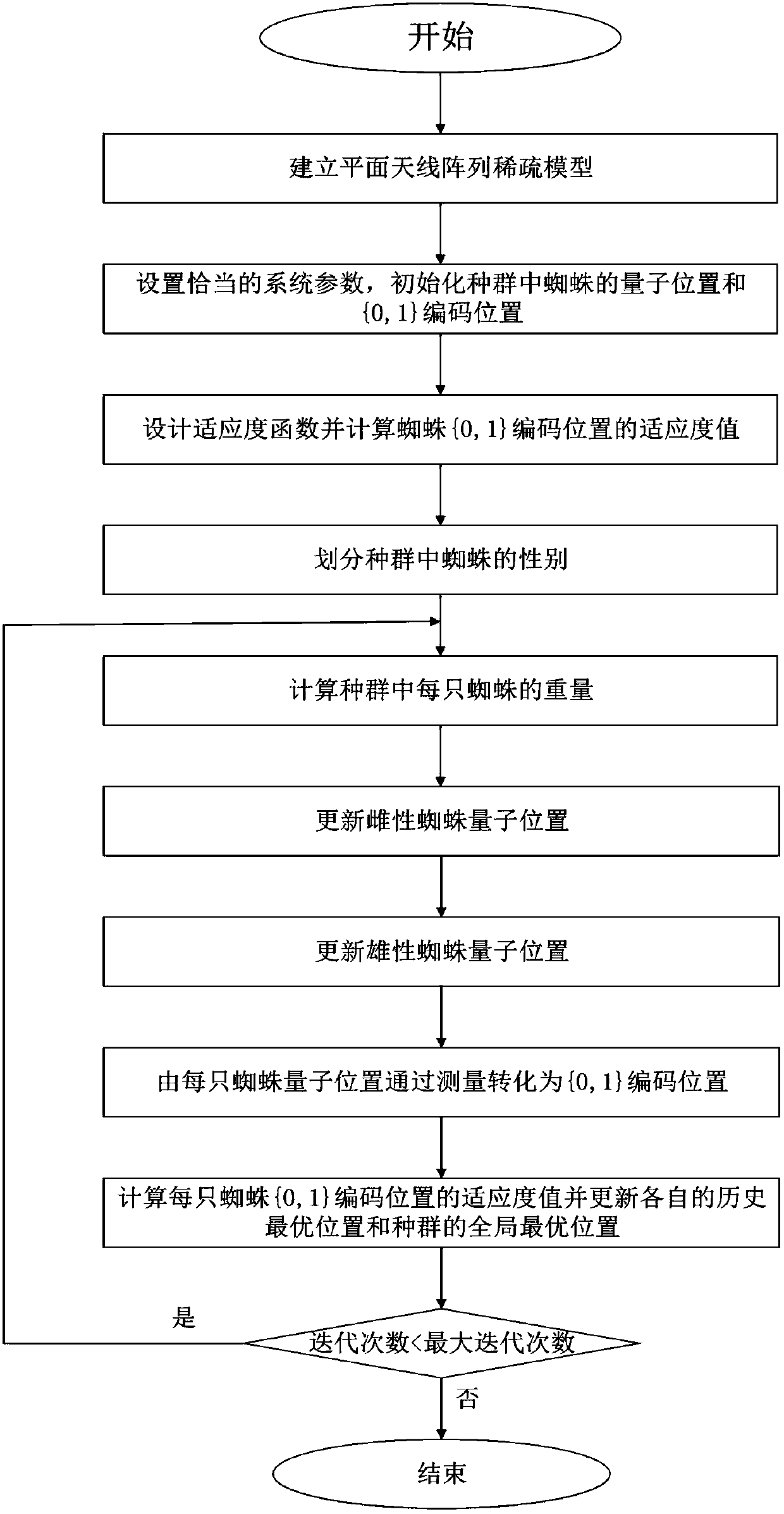

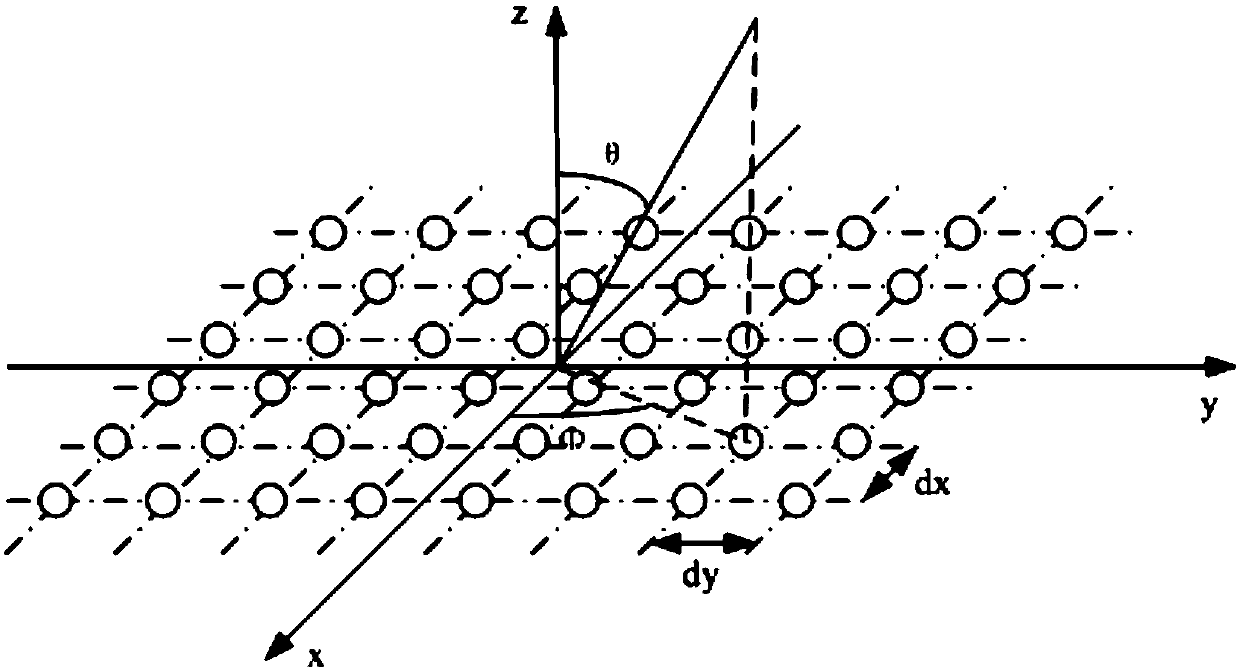

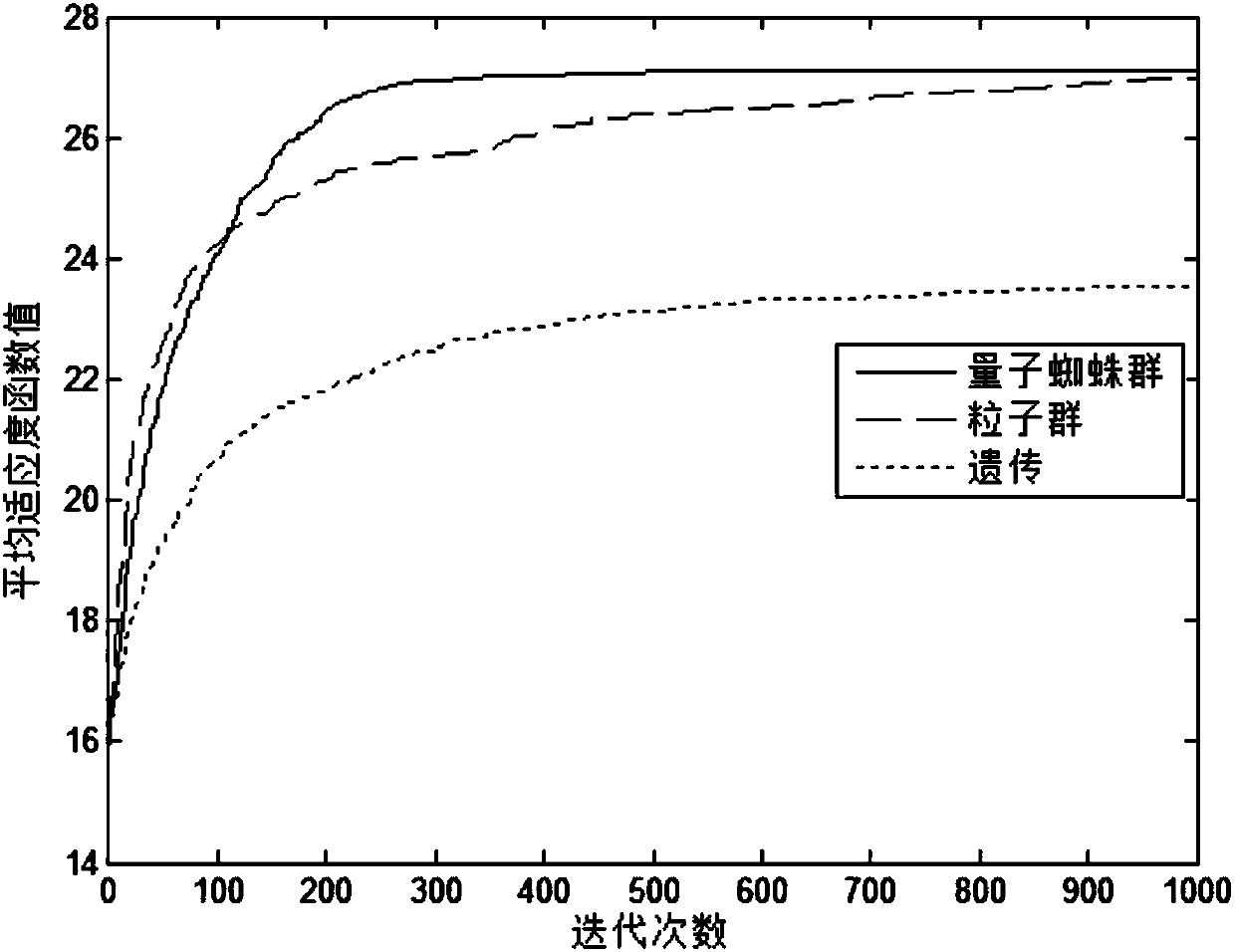

Planar antenna array sparse method based on quantum spider population evolution mechanism

ActiveCN107302140ASolving sparse problems with discrete variablesImprove the theory of evolution mechanismAntenna arraysArtificial lifeSparse methodsPlanar antenna array

The invention provides a planar antenna array sparse method based on a quantum spider population evolution mechanism. The planar antenna array sparse method comprises the steps of 1, establishing a planar antenna array sparse model; 2, setting system parameters; 3, performing evaluation on advantages and disadvantages of each spider coding position in a population by a fitness function, and taking the optimal position of the fitness function as the global optimal position of the whole population; 4, dividing genders of spiders in the population; 5, calculating weight of each spider; 6, updating quantum positions of female spiders by adopting an analog quantum vector rotation door rotation based on the updated quantum vector rotary angle; 7, updating quantum positions of male spiders by adopting an analog quantum vector rotation door rotation based on the updated quantum vector rotary angle; 8, updating the respective historical optimal positions; and 9, judging whether the maximum number of iterations is reached or not. By adoption of the planar antenna array sparse method, the difficulty existing in multi-constraint planar array antenna sparsity is solved, and various requirements on the planar sparse array are satisfied.

Owner:HARBIN ENG UNIV

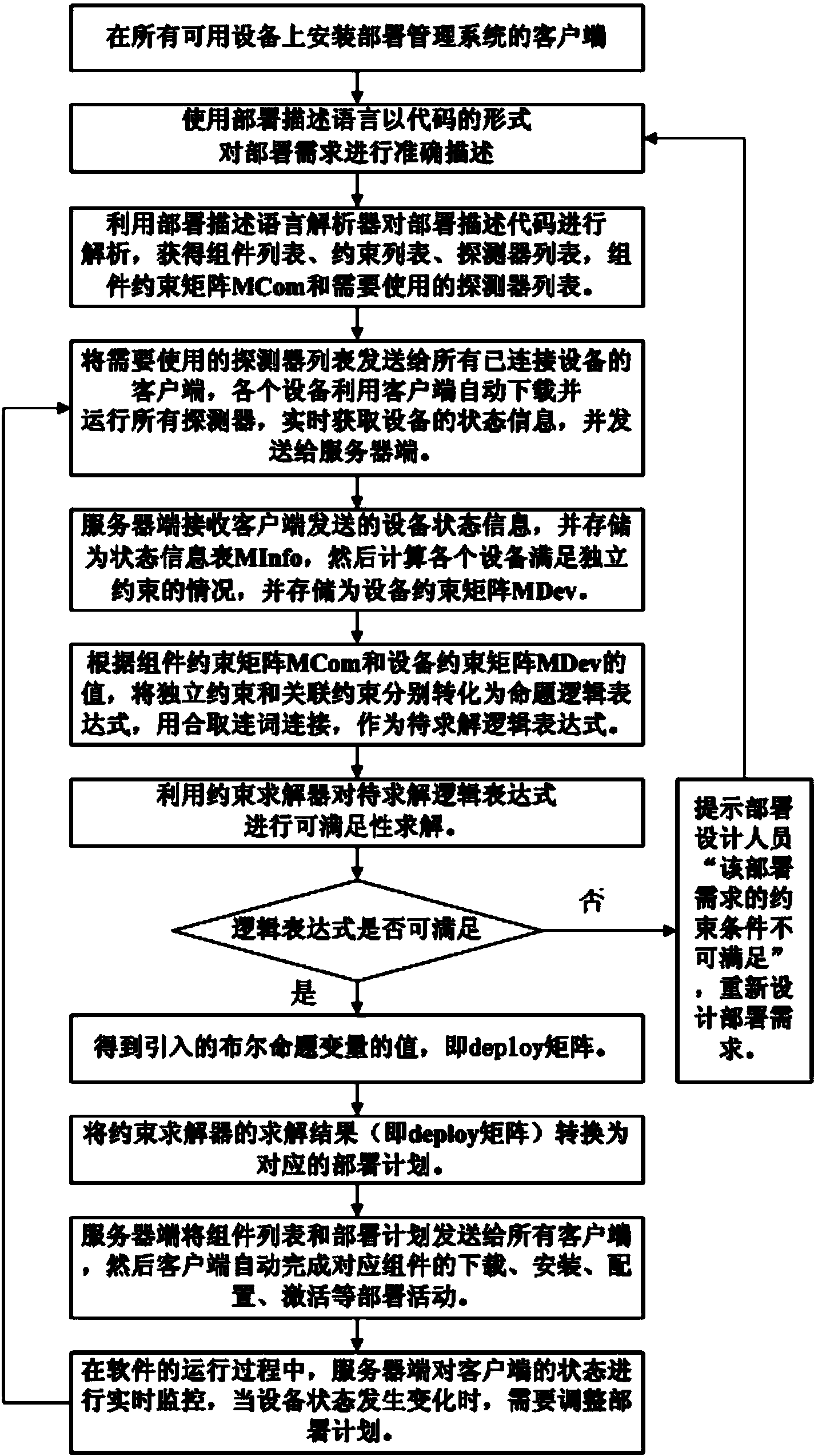

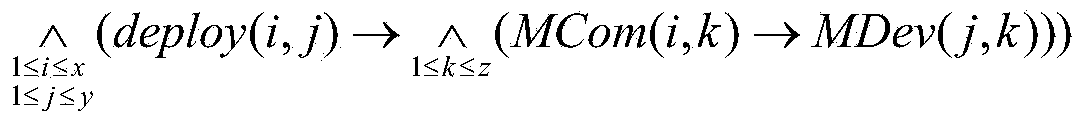

Automation and self-adaptation method for deploying multi-component software under complex constraint conditions and deployment management system thereof

InactiveCN104298525AFully automatedStrong deployment automationProgram loading/initiatingSoftware deploymentComputer software

The invention discloses an automation and self-adaptation method for deploying multi-component software under complex constraint conditions and a deployment management system thereof, and belongs to the technical field of deployment and maintenance of computer software. Firstly, the deployment demand and deployment constraint conditions of the multi-component software are described in a deployment description language; then, according to the deployment demand and equipment status information detected in real time, the deployment management system can automatically and dynamically generate a deployment plan meeting the constraint conditions and automatically perform the deployment activity by using an equipment status information detector, a constraint solver and an automatic deployment device and calling the constraint solver. Thus, the automation and self-adaptation of deploying the multi-component software under the complex constraint conditions are achieved. Meanwhile, the software deployment efficiency is high, the software deployment cost is low, and the software deployment quality is good.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

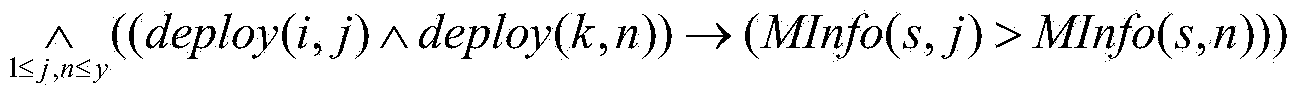

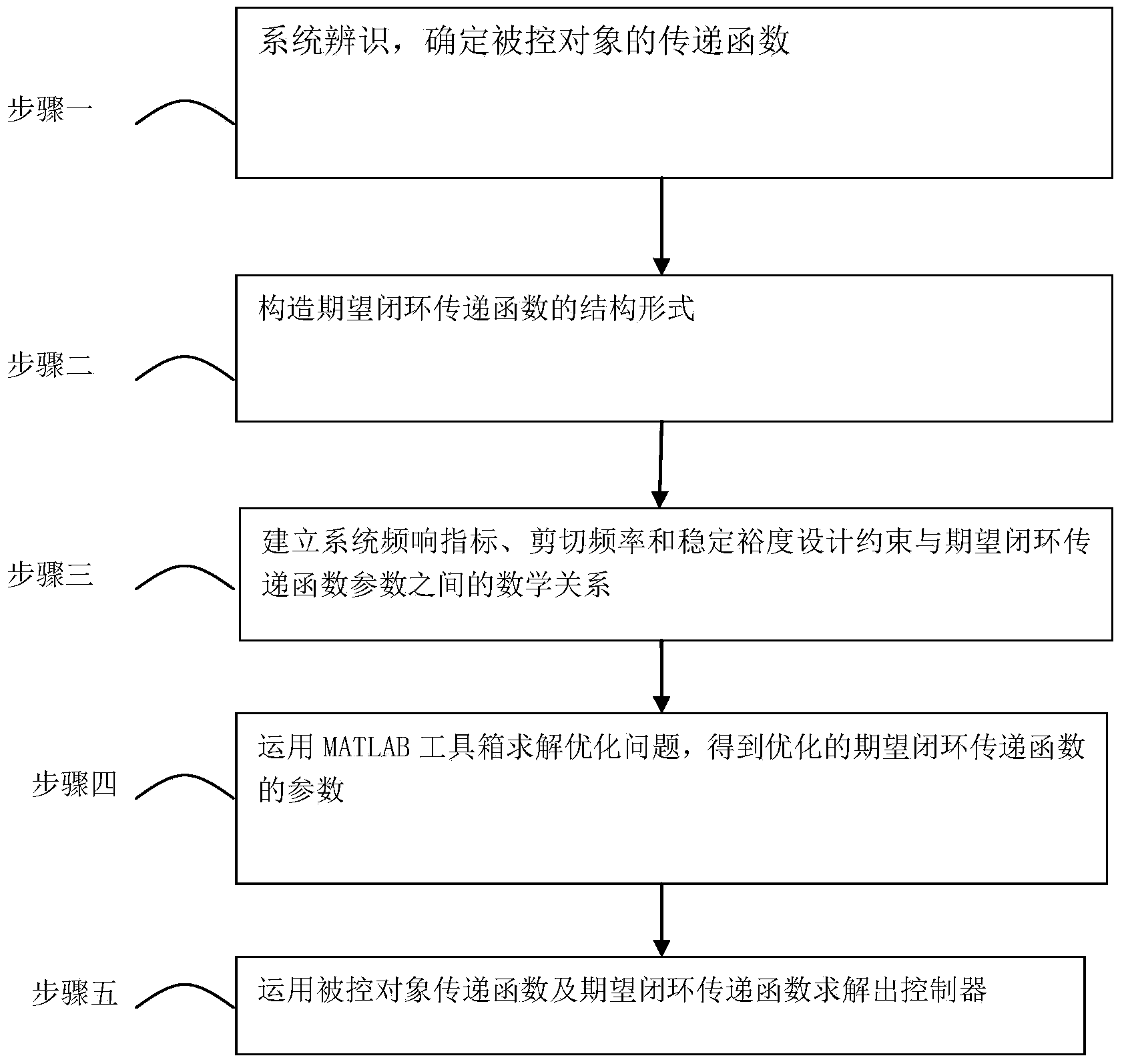

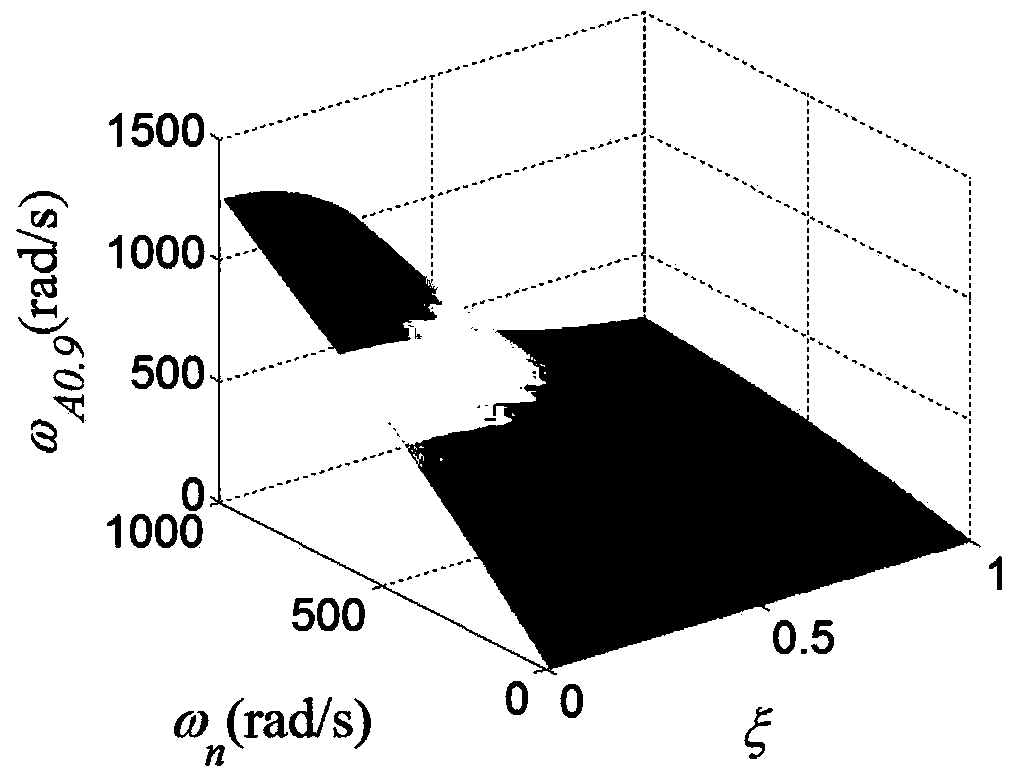

Servo system controller optimization method based on expected closed-loop transfer function

InactiveCN104181905ASimple design methodMaximize diggingTotal factory controlProgramme total factory controlSignal transfer functionClosed loop

The invention belongs to the technical field of controller optimization, and relates to a servo system controller optimization method based on an expected closed-loop transfer function. The method aims to solve the problems that because the quantitative relation between the frequency response index and the controller parameters of a present controller is not established and whether the design result is satisfactory or not is determined by experience of designers to a great extent, it can not be guaranteed that the performance of a closed-loop system is the optimal and 'double-ten' controller optimization methods are rarely reported. The method comprises the steps of firstly, determining the transfer function of a controlled object; secondly, constructing the structural form of the expected closed-loop transfer function; thirdly, establishing the mathematic relations between the expected closed-loop transfer function and the system frequency response index, the shear frequency and the stability margin constraint condition respectively; fourthly, obtaining the optimized parameters of the expected closed-loop transfer function; fifthly, working out the controller.

Owner:HARBIN INST OF TECH

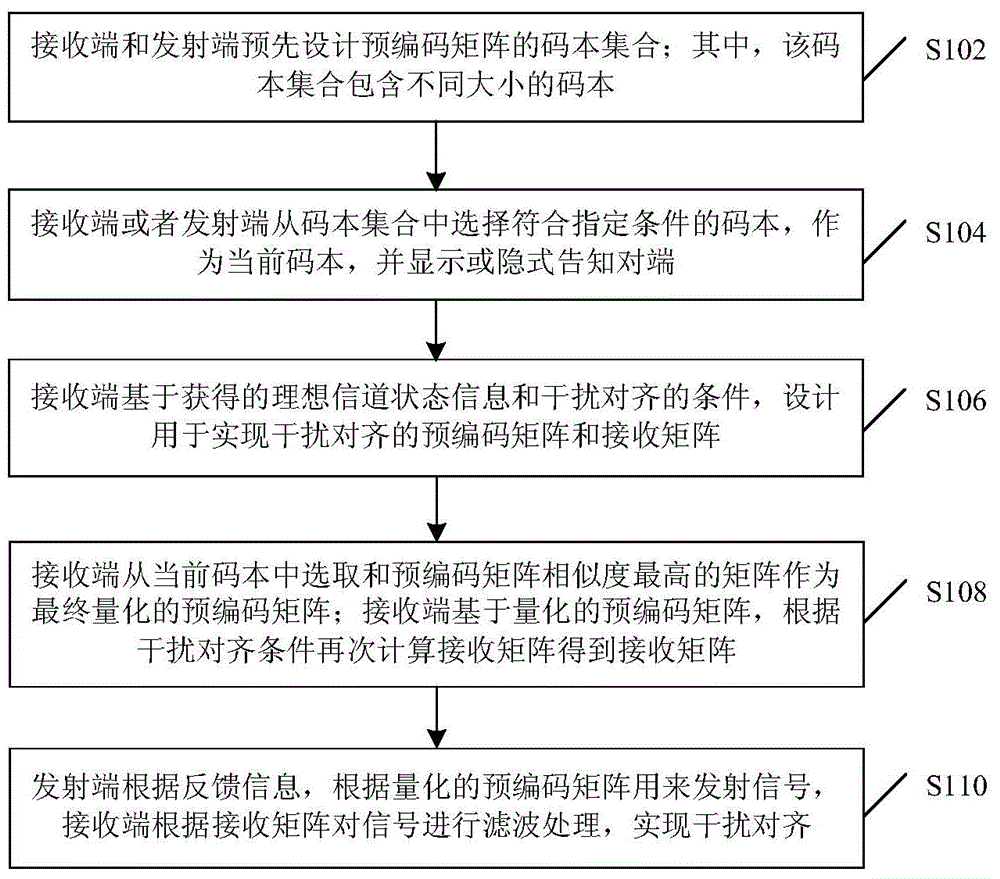

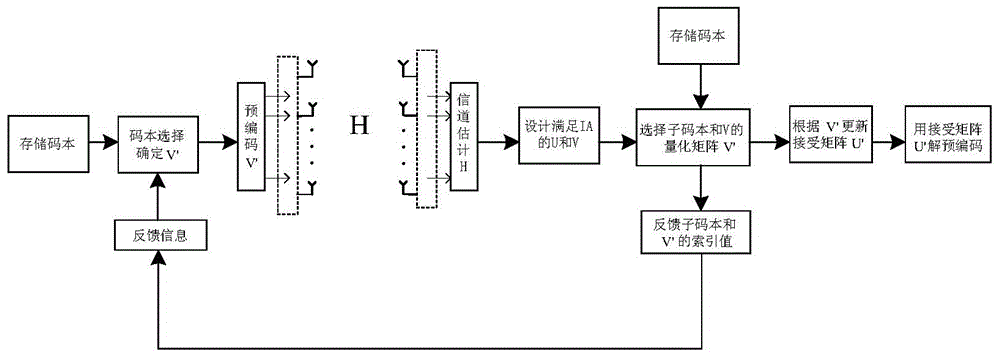

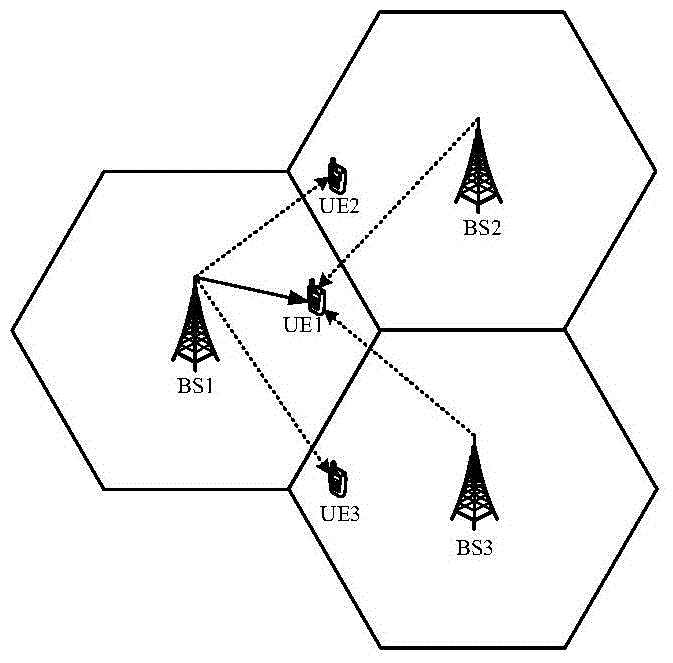

Method and device for realizing interference alignment based on design and selection of codebooks

ActiveCN105306174AMeet the constraintsSolve the problem that the ideal channel state information cannot be obtainedSpatial transmit diversityTransmitter/receiver shaping networksChannel state informationComputer science

The invention discloses a method and device for realizing interference alignment based on design and selection of codebooks, wherein the method comprises the following steps that: a receiving end and a transmitting end pre-design a codebook set of a pre-coding matrix, wherein the codebook set contains codebooks of different sizes; the receiving end or the sending end selects a codebook conforming to a specified condition from the codebook set, takes the codebook as the current codebook, and informs an opposite end in a display or implicit manner; the receiving end designs a pre-coding matrix V and a receiving matrix U for realizing interference alignment based on obtained ideal channel state information and an interference alignment condition; the receiving end selects a matrix V' having the highest similarity with the pre-coding matrix V from the current codebook, and takes the matrix V' as a finally quantified pre-coding matrix V'; the receiving end calculates the receiving matrix U again according to the interference alignment condition based on the quantified pre-coding matrix V' so as to obtain a receiving matrix U'; the transmitting end is used for transmitting a signal according to the quantified pre-coding matrix V' based on feedback information; the receiving end filters the signal according to the receiving matrix U'; and thus, interference alignment is realized.

Owner:ZTE CORP

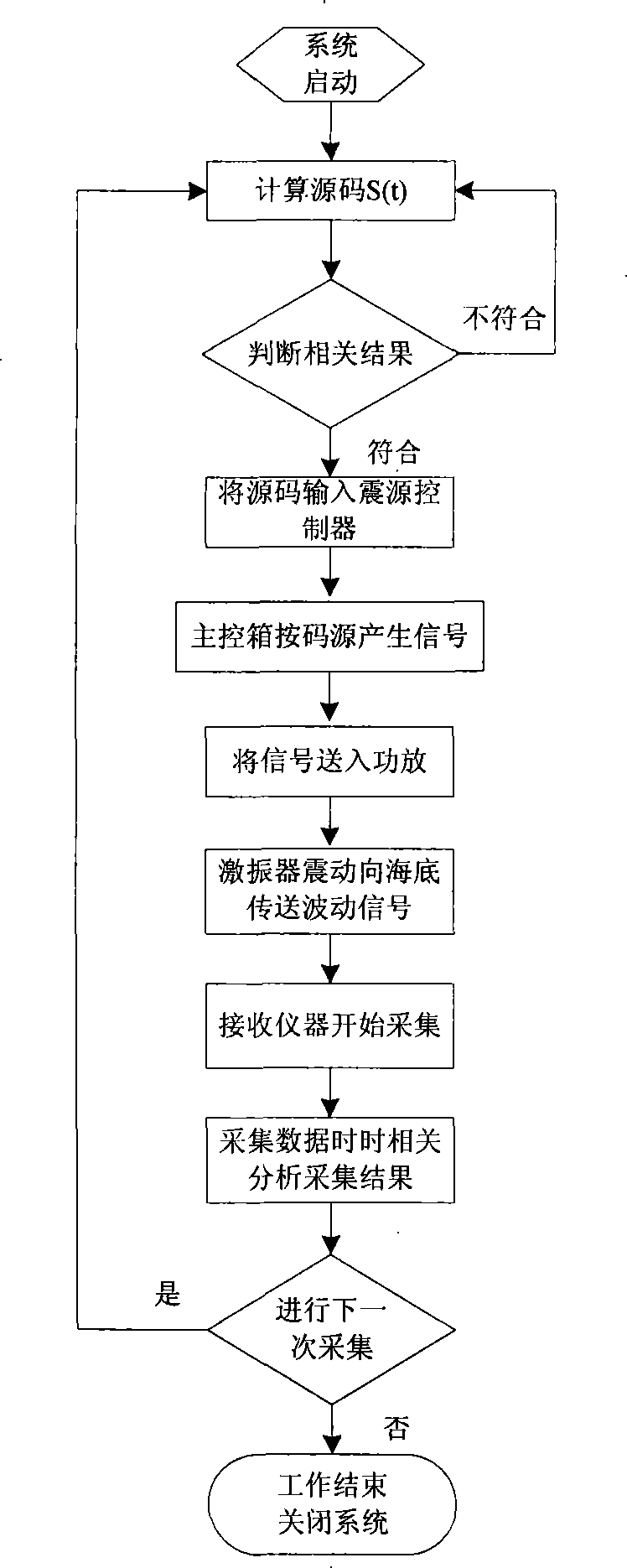

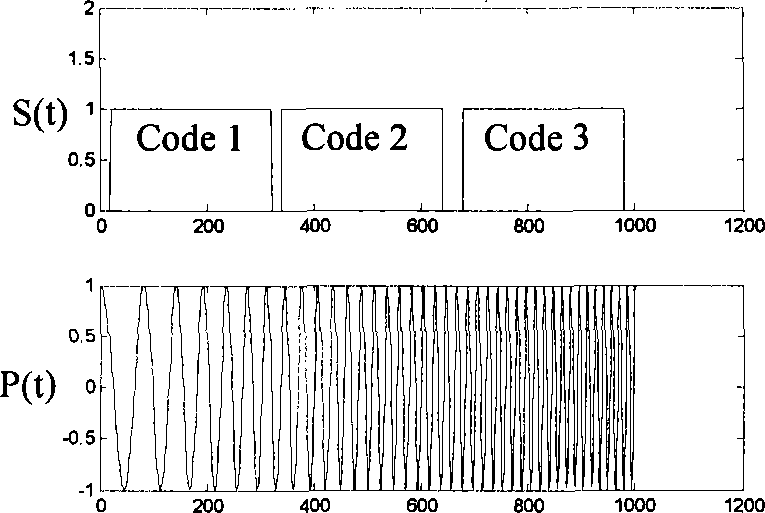

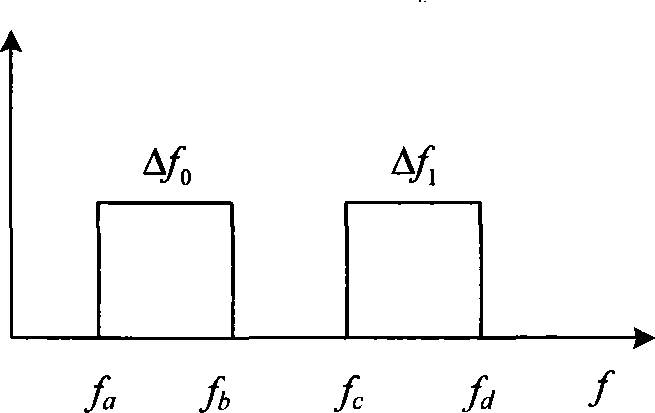

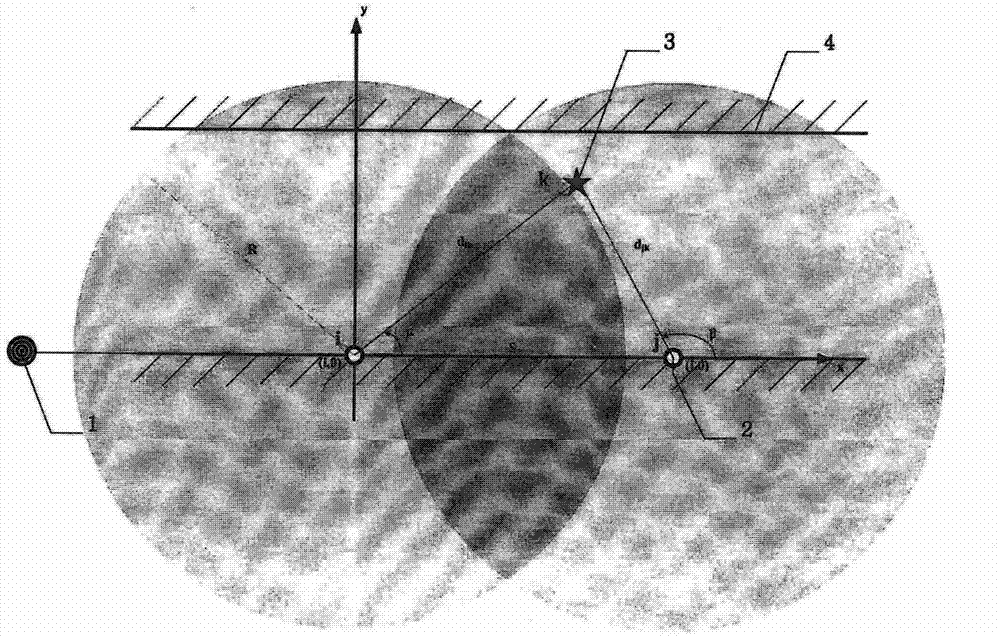

Sea combined controled vibrator short time subsection scanning method

InactiveCN101251602AImprove signal-to-noise ratioReduce adverse effectsSeismic signal receiversSeismology for water-covered areasSeawaterImage resolution

The invention relates to a method of scanning in short time and by sections with a combined sea controllable vibroseis, comprising the following steps of: placing a sealed controllable vibroseis array in the sea to enable vibration exciters of the controllable virboseis to be coupled with the sea water completely; computing source code (S(t)) according to a target zone, dividing a Chirp signal with a set frequency interval into N sections, controlling the frequency sections of scanning signals of the N controllable vibroseises to enable the N controllable vibroseises to complete the scanning of different long frequency sections in short time, performing related processing to reflected signals received by a collecting system and obtaining a seismic profile with a conventional seismic processing software. The method of scanning the sea in a short time and by sections with a combined controllable vibrosei solves the problem of low resolution in sea seismic exploration due to the effect of the seismic exploration carrier, improves the Signal to Noise Ratio so that the effect of the seismic exploration carrier to the seismic exploration is reduced to the most lowest point, realizes the seismic exploration of high resolution at shallow layer of the sea and also solves the problem that only fixed point scanning can be adopted on the prior sea controllable vibrosers and the movement of the seismic exploration carrier affects the resolution of the seismic exploration during the sea seismic exploration.

Owner:JILIN UNIV

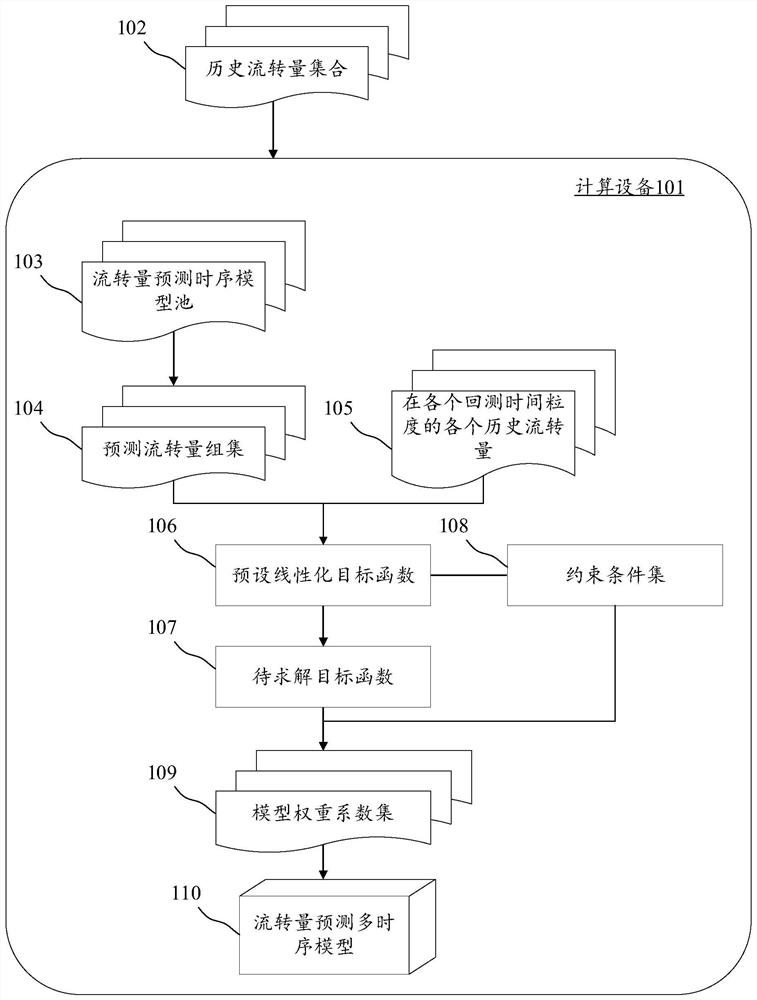

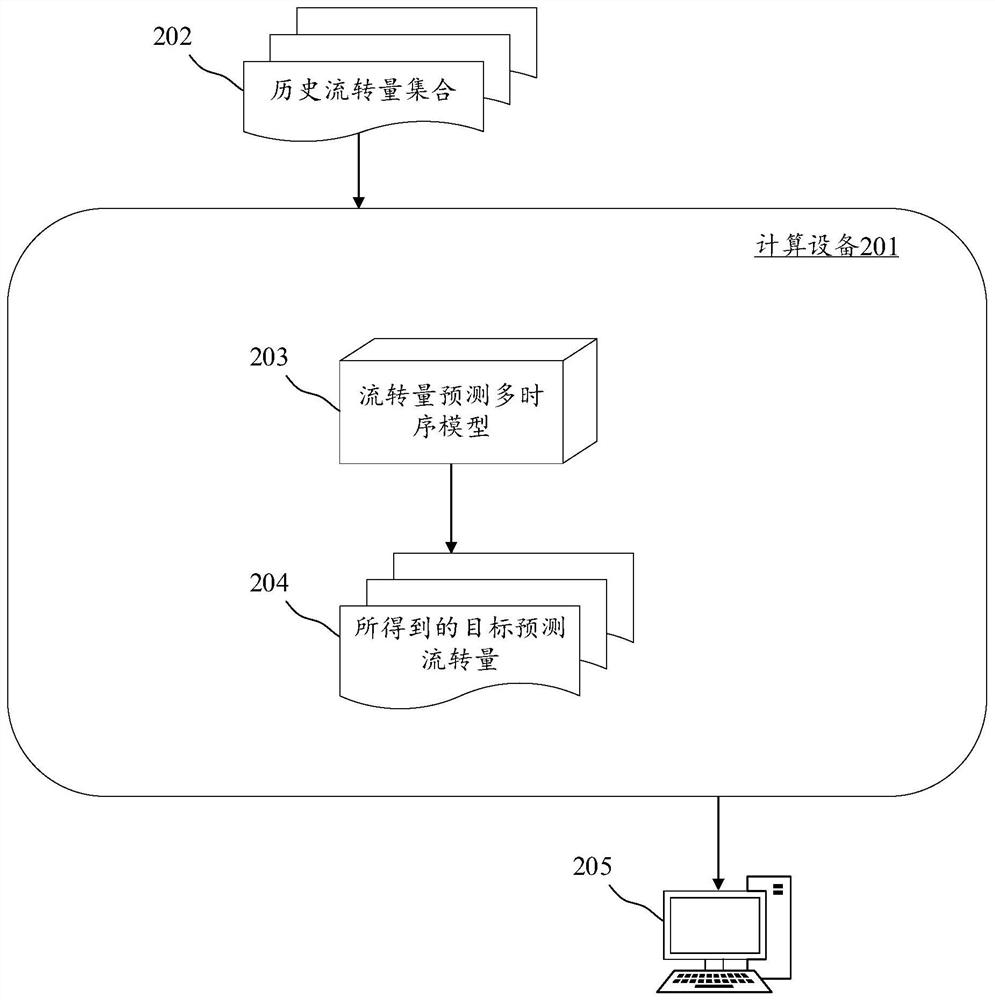

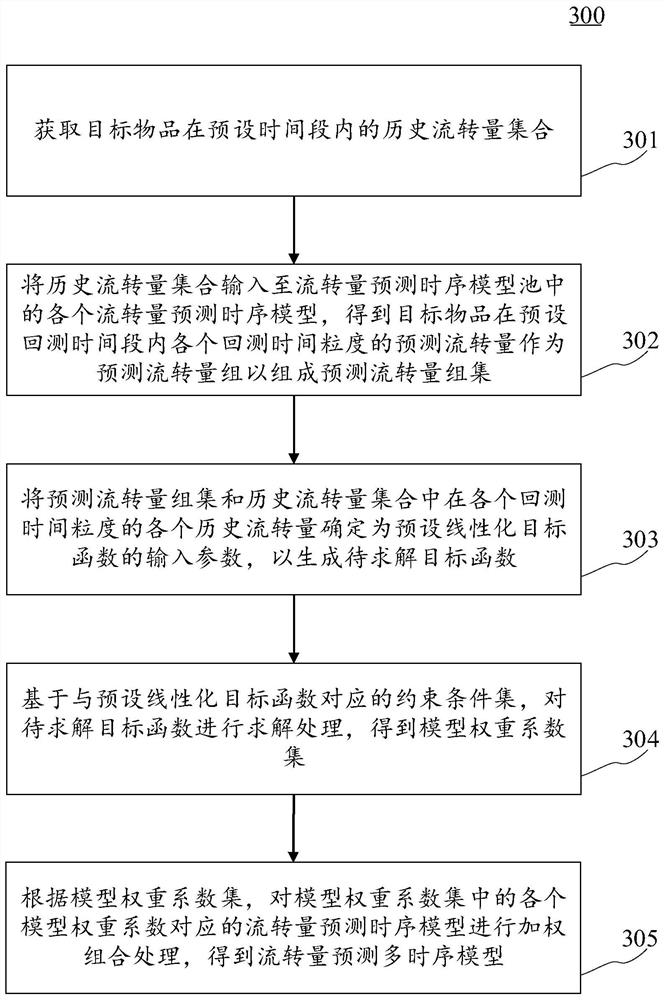

Flow quantity prediction multi-time-sequence model generation method, information sending method and device

PendingCN113408797ASimplify the determination processImprove forecast accuracyForecastingLogisticsAlgorithmSequence model

The embodiment of the invention discloses a flow quantity prediction multi-time-sequence model generation method, an information sending method and an information sending device. A specific embodiment of the method comprises: obtaining a historical flow volume set of a target article in a preset time period; inputting the historical flow quantity set into each flow quantity prediction time sequence model to obtain a predicted flow quantity set; determining each historical flow in the predicted flow set and the historical flow set in each back-test time granularity as an input parameter of a preset linearization objective function to generate a to-be-solved objective function; based on the constraint condition set, solving the to-be-solved target function to obtain a model weight coefficient set; and according to the model weight coefficient set, performing weighted combination processing on the flow prediction time sequence model corresponding to each model weight coefficient in the model weight coefficient set to obtain a flow prediction multi-time sequence model. According to the embodiment, the accuracy, robustness and stability of flow prediction are improved, and the model determination process is simplified.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

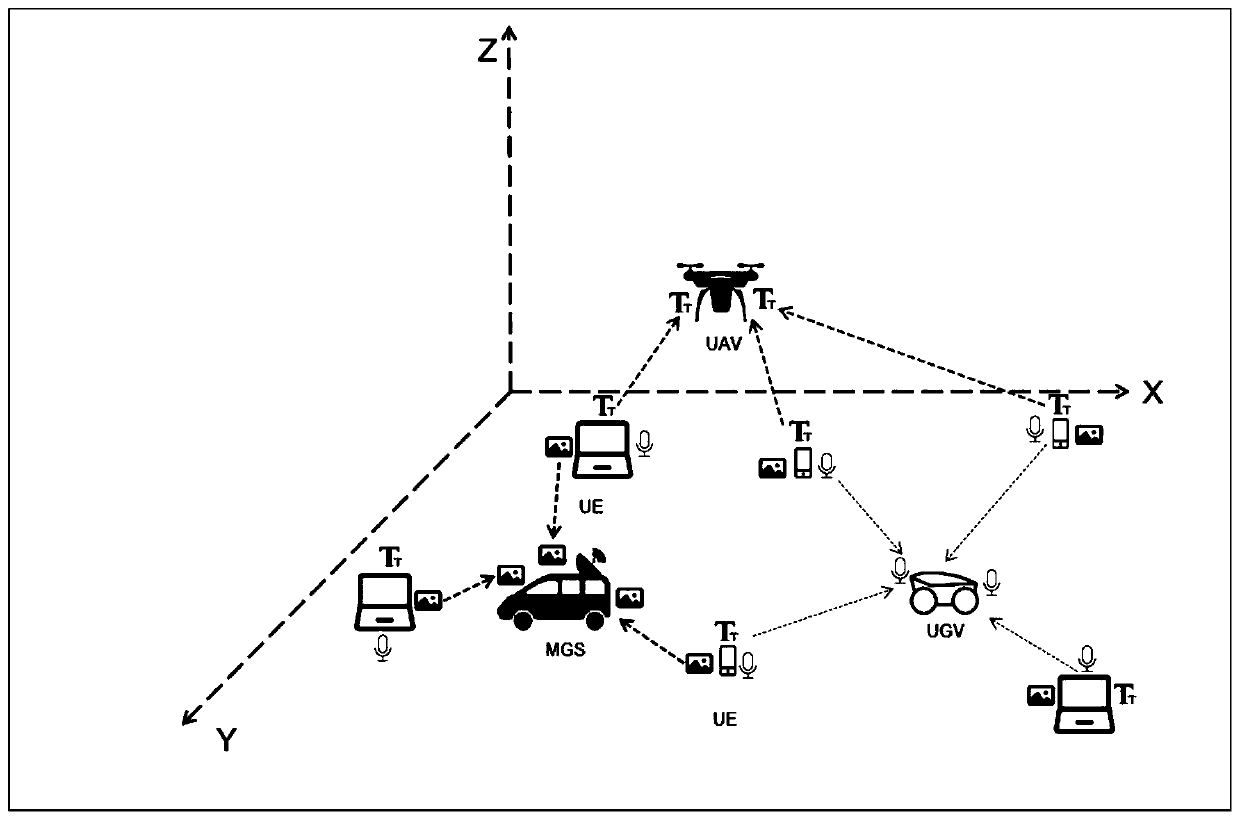

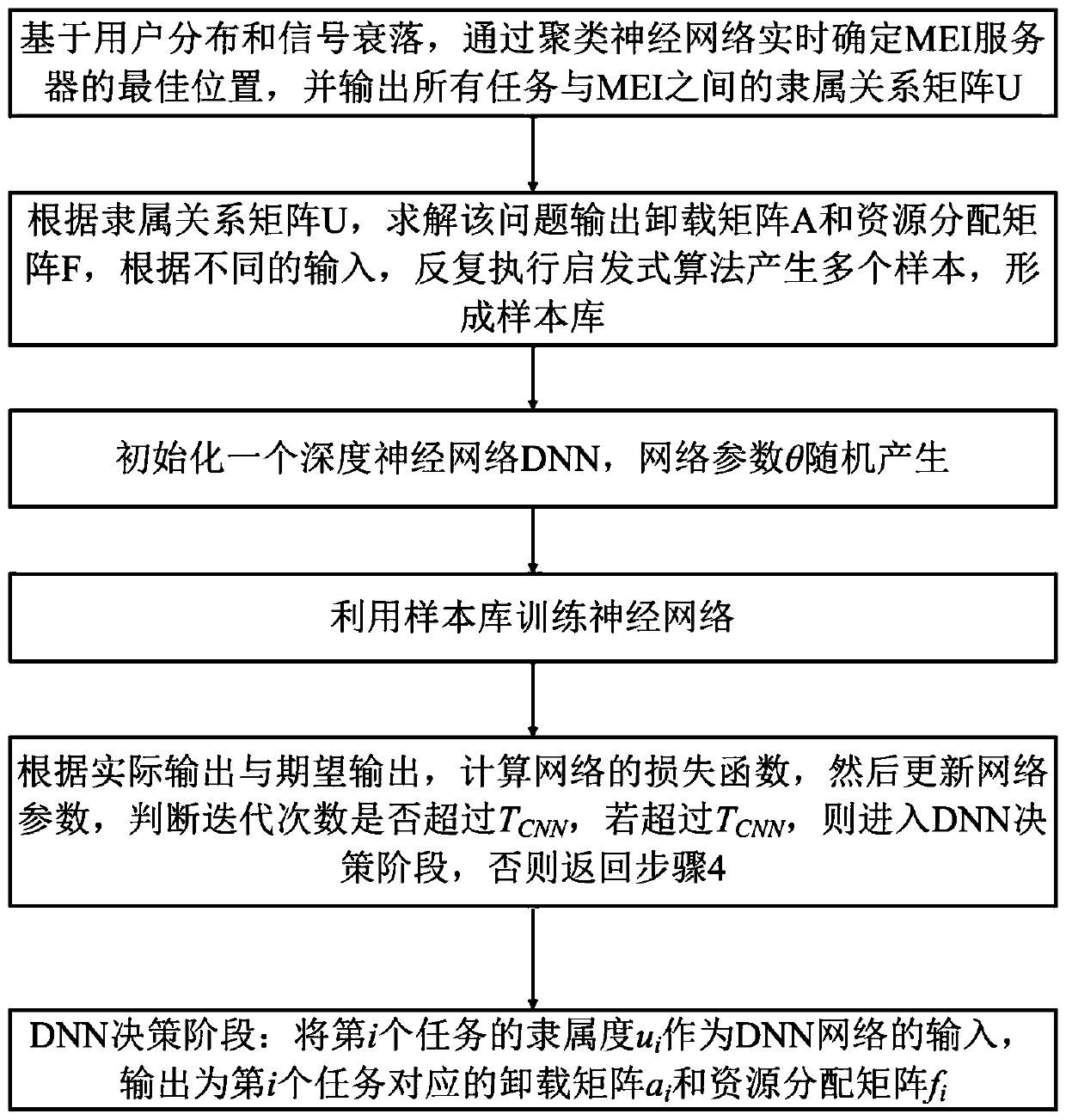

Real-time multi-modal language analysis system and method based on mobile edge intelligence

InactiveCN110958625AMeet various needs of analysisSave computing resourcesResource allocationCharacter and pattern recognitionInterference (communication)Algorithm

The invention discloses a real-time multi-modal language analysis system and method based on mobile edge intelligence, and the system comprises three types of mobile edge intelligent servers: a mobilebase station (MGS), an unmanned vehicle (UGV) and an unmanned aerial vehicle (UAV), and the computing resources of the three types of mobile edge intelligent servers are sequentially reduced, and themoving flexibility is sequentially improved. According to the real-time multi-modal language analysis system, language data of a user is divided into three modalities, namely characters, voice and images, and a calculation task is allocated to a proper MEI server to be executed according to the calculation and analysis difficulty and the size of required calculation resources. According to the method, a real-time multi-modal language analysis and calculation problem in a dynamic environment is constructed, then a task unloading matrix and a resource allocation matrix are generated through a deep learning online optimization method, and meanwhile, movement path planning of an MEI server is automatically implemented according to channel conditions and interference during communication. Thetrained DNN can be suitable for a dynamic scene in which the number of multi-modal computing tasks changes, and has very high practicability.

Owner:HUNAN NORMAL UNIVERSITY

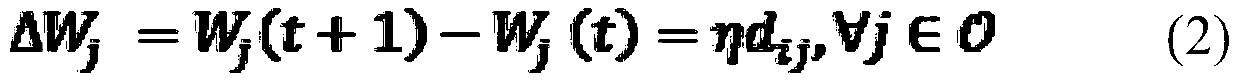

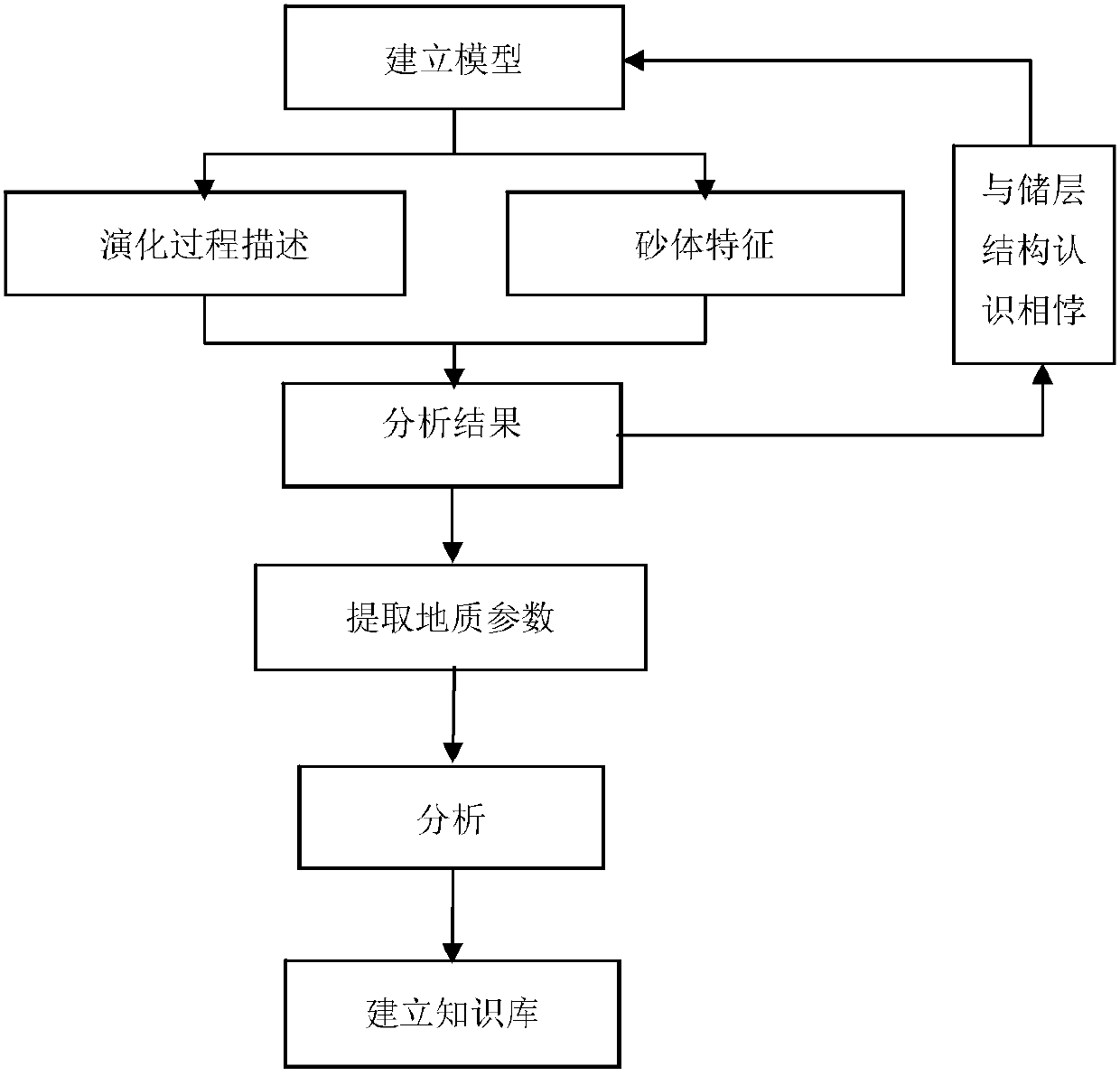

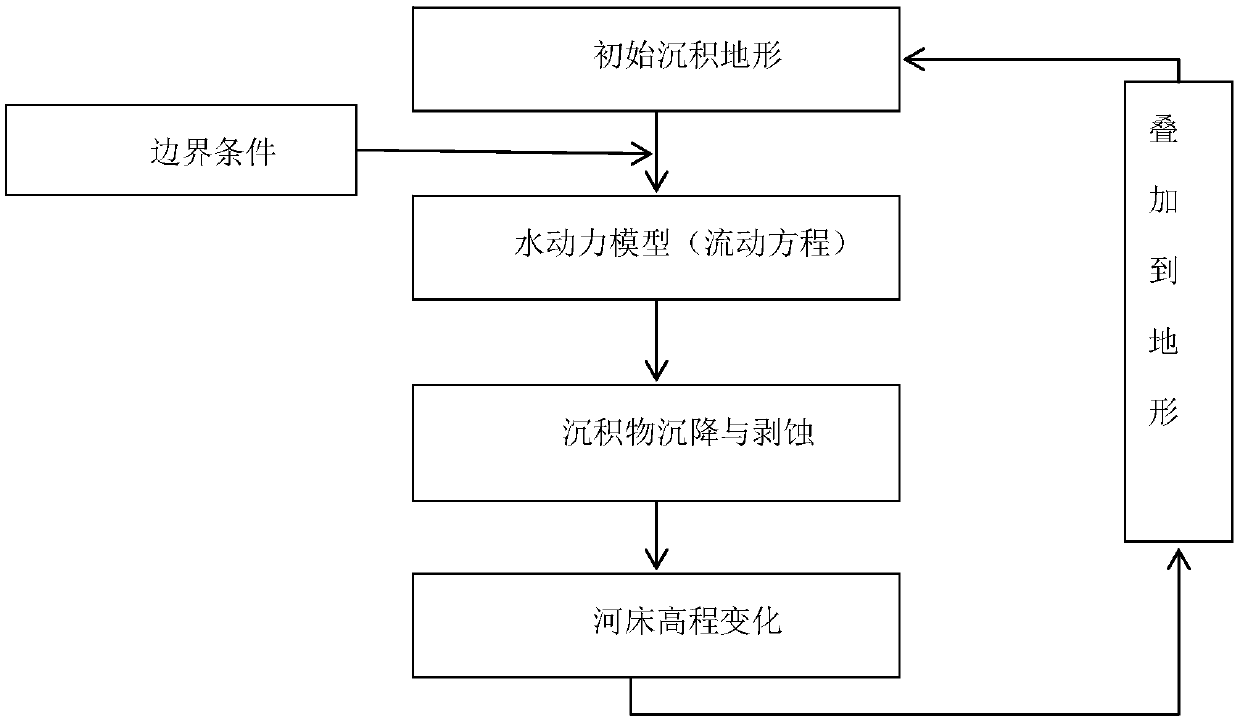

Geological knowledge base establishing method based on numerical simulation

ActiveCN110019594AHigh precisionThe principle of the experiment is simpleData processing applicationsDesign optimisation/simulationTransfer procedureGeological scientist

The invention relates to a geological knowledge base establishing method based on numerical simulation. The method includes: according to a mathematical equation and a boundary condition of hydrodynamics, superposing the deposition amount and the denudation amount which are obtained by simulating the hydrodynamic process and the sediment transmission process; obtaining a new sedimentary model, comparing and analyzing a simulation result and geological parameters of a target layer, performing geological dissection on the simulation result when the comparison and analysis results are consistent,extracting the geological parameters, and summarizing a geological phenomenon and a distribution rule of geological data, thereby establishing a corresponding geological knowledge base. Therefore, the material cost is saved, the constraint condition required by geologists to construct the geological model can be met, and the problem that the cost is high when a sedimentary physics simulation experiment is carried out through modern sedimentary investigation is effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP +2

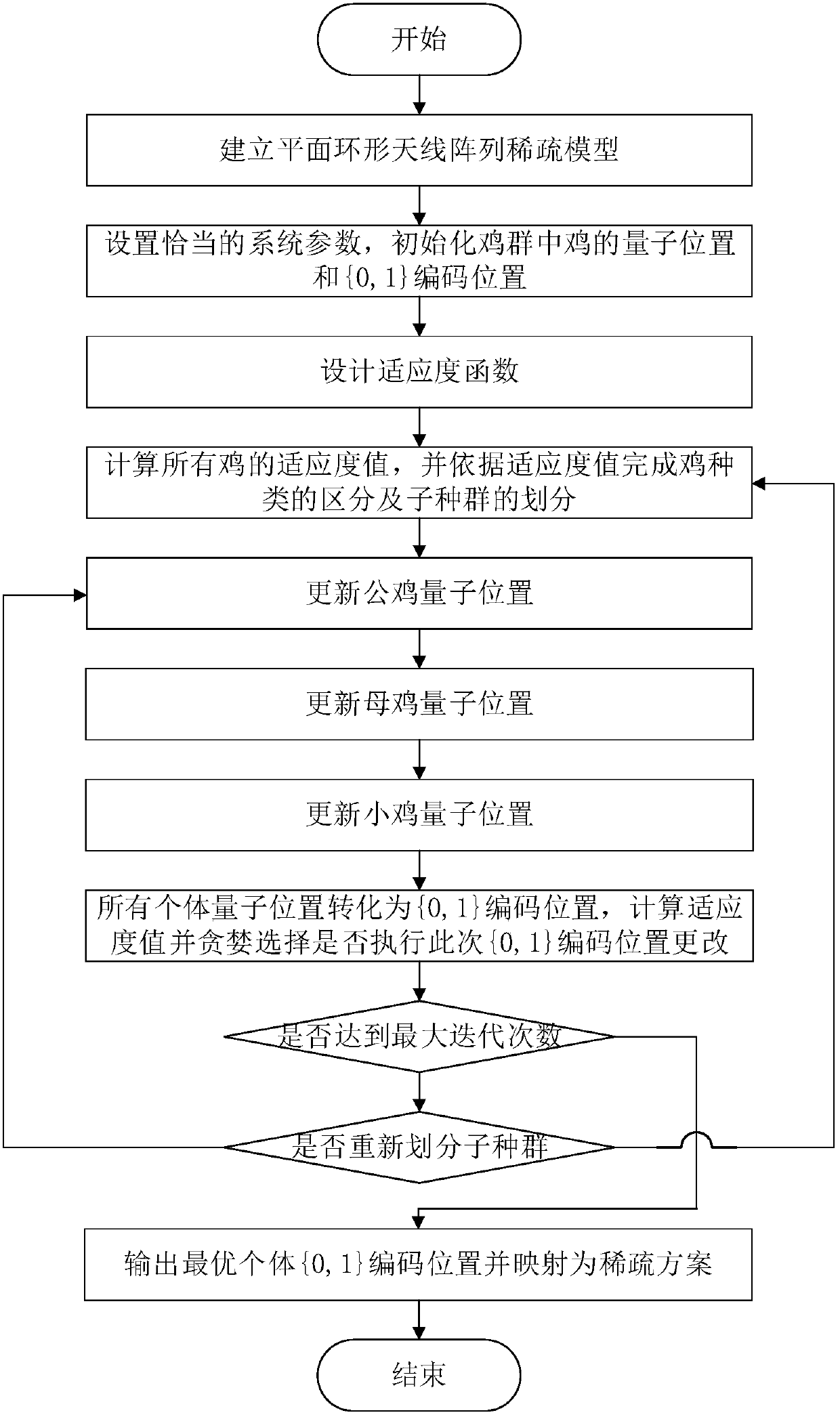

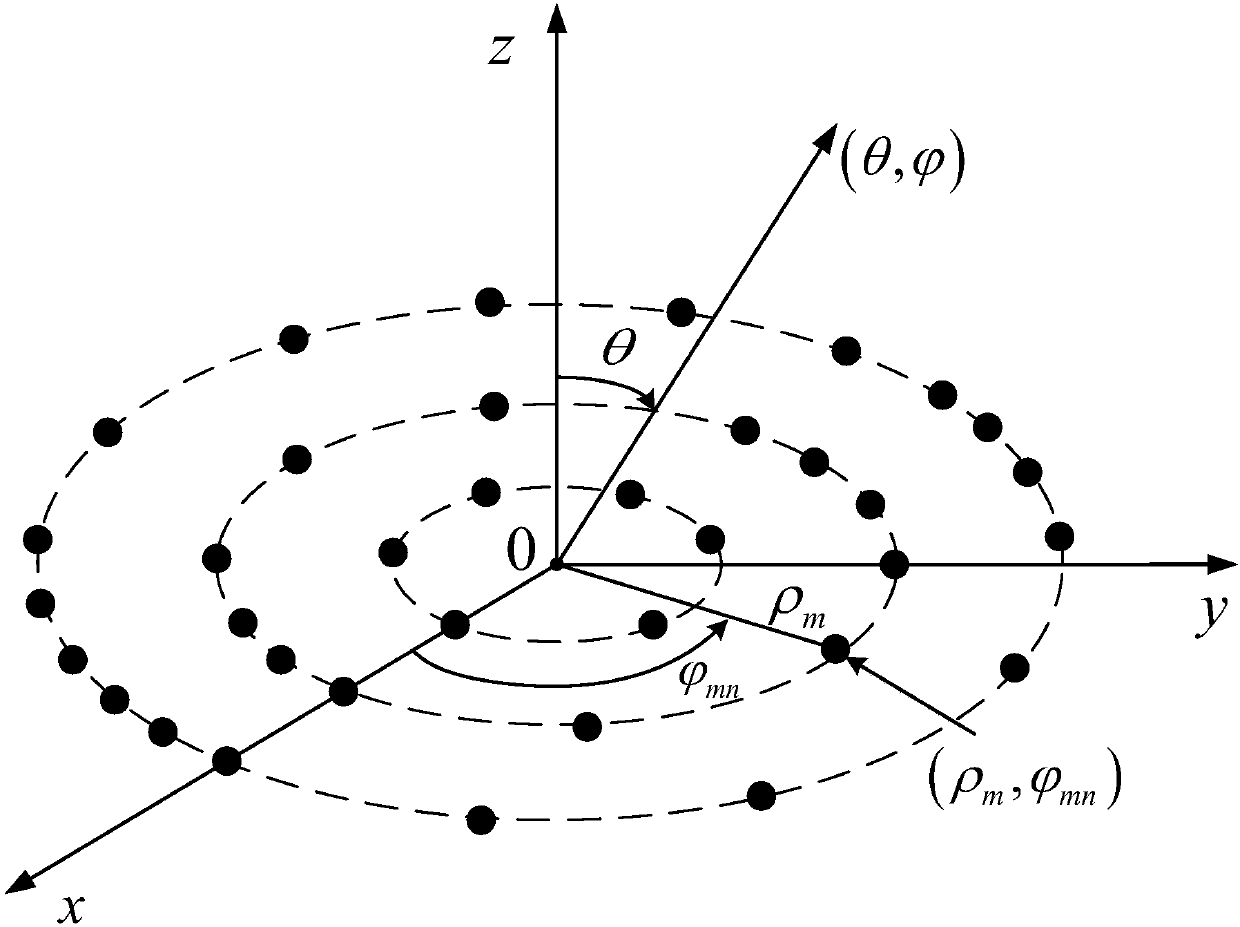

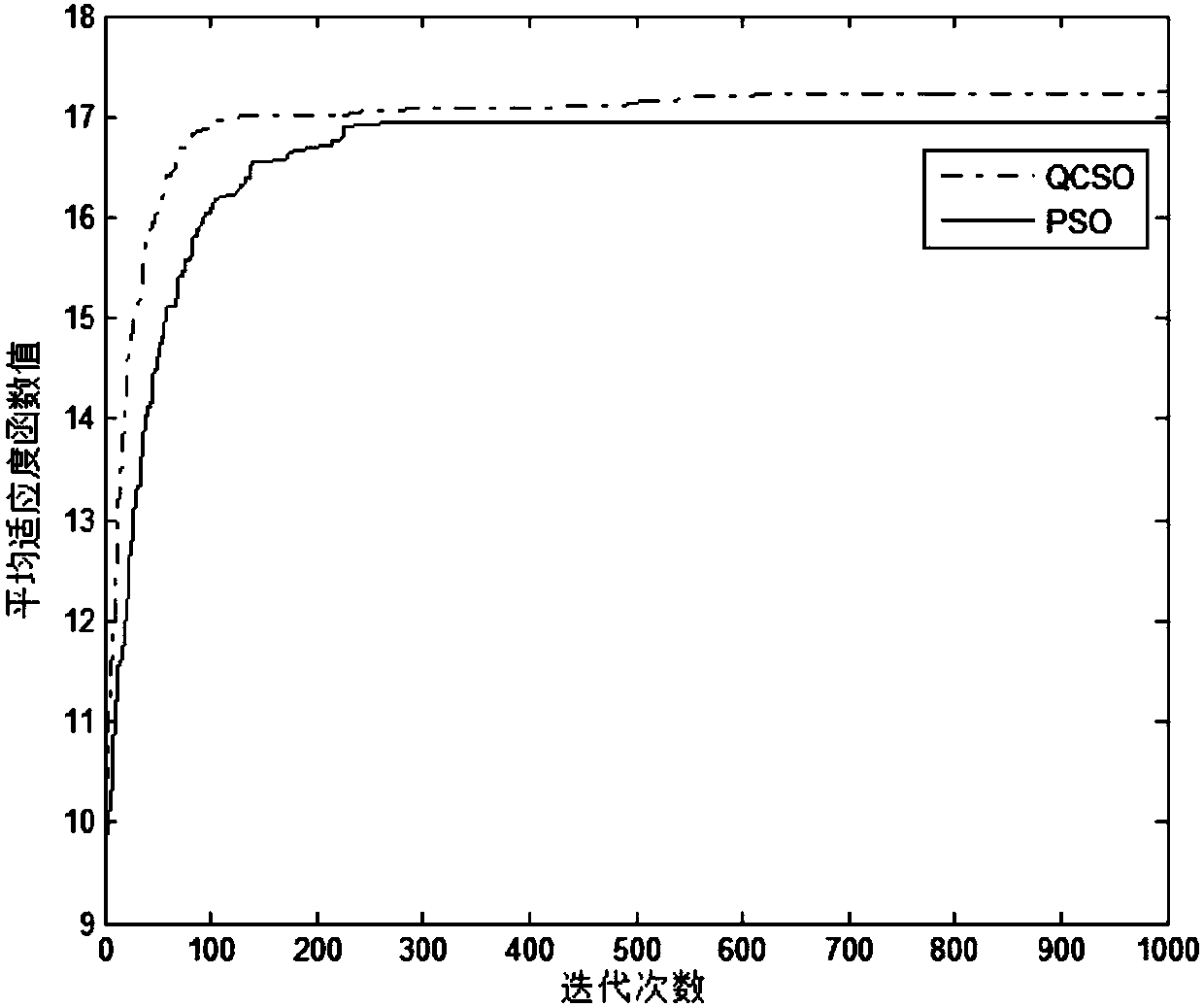

Annular antenna array sparse method based on quantum chicken evolution mechanism

ActiveCN107657098ASolve high-dimensional puzzlesFast convergenceGeometric CADArtificial lifeSparse modelSparse methods

The invention provides an annular antenna array sparse method based on a quantum chicken evolution mechanism. The method comprises the following steps that: 1: establishing an annular antenna array sparse model; 2: setting an initial parameter; 3: designing a fitness function; 4: calculating the fitness value of each chick in a population, distinguishing the category of the chicken, and dividing sub-populations; 5, 6, and 7: independently constructing the quantum vector rotation angle update formula of roosters, hens and chicken, updating the quantum vector rotation angle, and updating a quantum position; 8: through a measurement way, converting into a [0,1] coding position, calculating the fitness value of the [0,1] coding position, and updating the individual historical optimal solutionand the global optimal solution of each chick; and 9: judging whether a maximum iteration is achieved or not. The method is higher in rate of convergence and higher in accuracy of convergence, and hasa good spare effect on solving the problem of annular antenna array sparse construction, the complexity and the cost of antenna array system are greatly lowered, and an expectant requirement is achieved.

Owner:HARBIN ENG UNIV

Electrical power system multi-target overhaul optimization method under market environment

ActiveCN104217255ATroubleshoot maintenance schedule issuesMeet the constraintsGenetic modelsForecastingReal arithmeticElectric power system

The invention discloses an electrical power system multi-target overhaul optimization method under market environment. The electrical power system multi-target overhaul optimization method comprises the following steps: obtaining the data of each electricity generator; establishing a power grid multi-target overhaul optimization model under the market environment; carrying out real number encoding to a unit output variable and a unit overhaul variable of the model, carrying out 0-1 binary encoding to a unit on-line state variable and a unit starting state variable in the model, and converting the unit on-line state variable and the unit starting state variable into dependent variables represented by the unit output variable and the unit overhaul variable from independent variables; initializing the unit output variable and the unit overhaul variable; taking obtained variable initialization values as the population initialization input of a quick non-dominated sorting method for solving to obtain an optimal solution set; and determining a final unit overhaul and output scheme from the obtained optimal solution set by adopting a multi-target decision method. The electrical power system multi-target overhaul optimization method is simple to execute, is high in expandability and can be used for solving multi-target overhaul optimizations of different target functions and constraint conditions.

Owner:ZHEJIANG UNIV

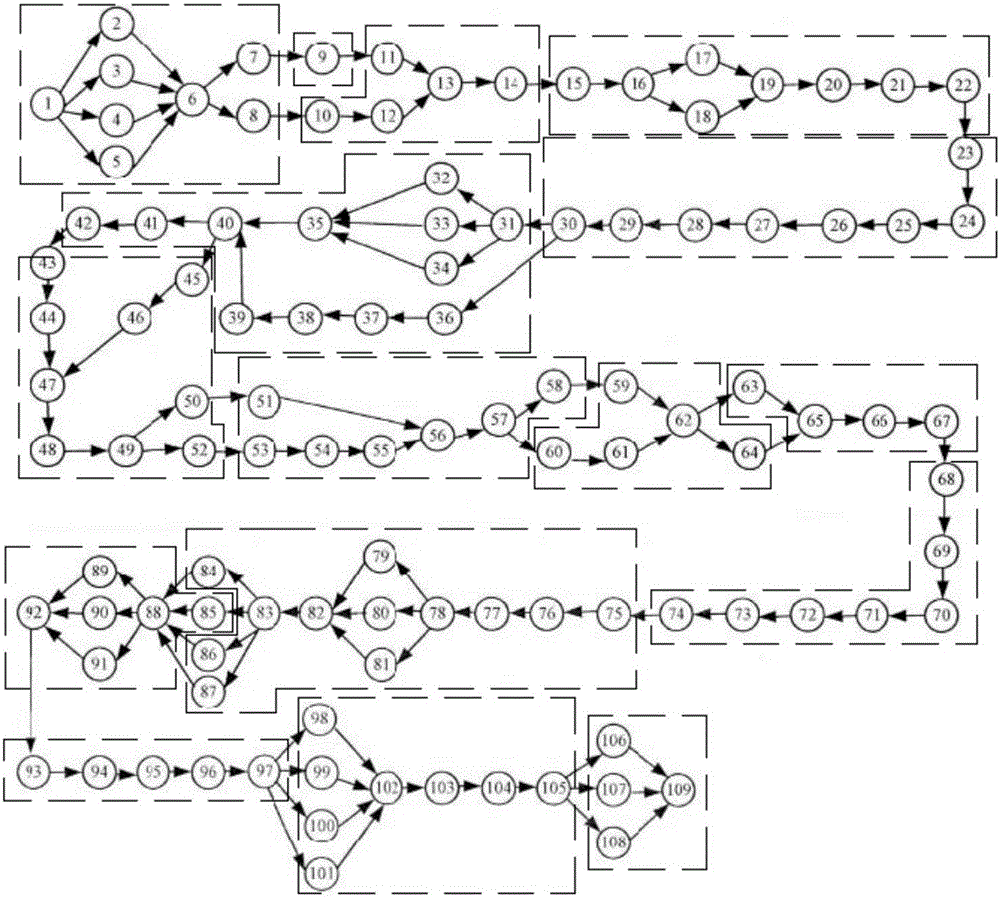

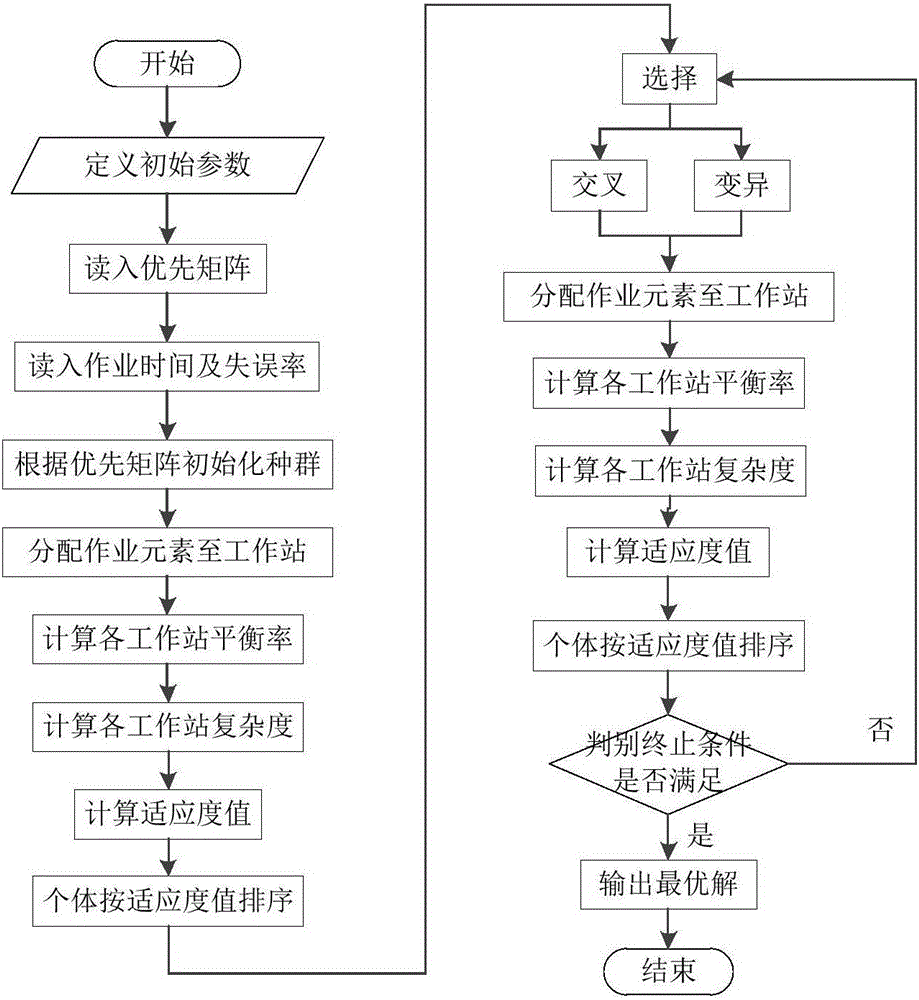

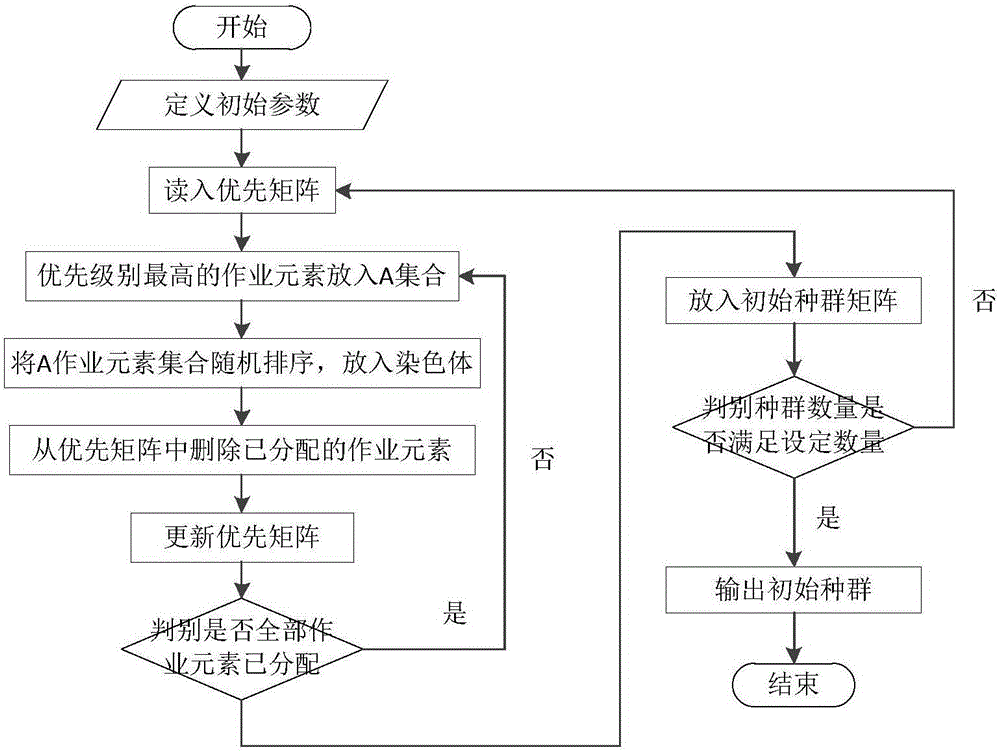

Assembly line balance method drawing complexity into consideration

InactiveCN105760621AComplexity balanceReduce production takt disorderDesign optimisation/simulationConstraint-based CADGenetic algorithmUncertainty factor

The invention relates to an assembly line balance method drawing complexity into consideration, in order to obtain a distribution solution of each working element of an assembly line in each working station. The method comprises the following steps: (1) defining working element complexity and working station complexity; (2) acquiring a constraint condition of a multi-target optimization model, and establishing the multi-target optimization model by targeting at the maximum balance ratio and the minimum working station complexity balance index according to the working element complexity and the working station complexity; (3) solving the multi-target optimization model by adopting a genetic algorithm to obtain an optimal distribution solution. Compared with the prior art, the assembly line balance method has the advantages of balancing the working time of each working station, balancing the complexity of each working station, avoiding balance failures of the assembly line, caused by accumulation of uncertainty factors, improving the robustness of the balance solution of the assembly line and the like.

Owner:TONGJI UNIV

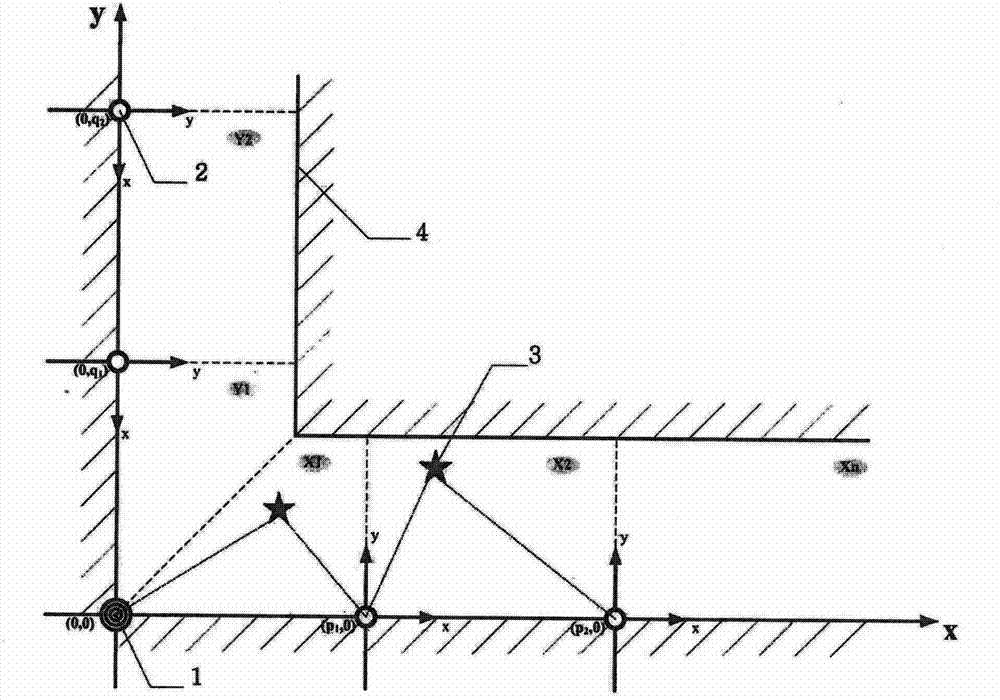

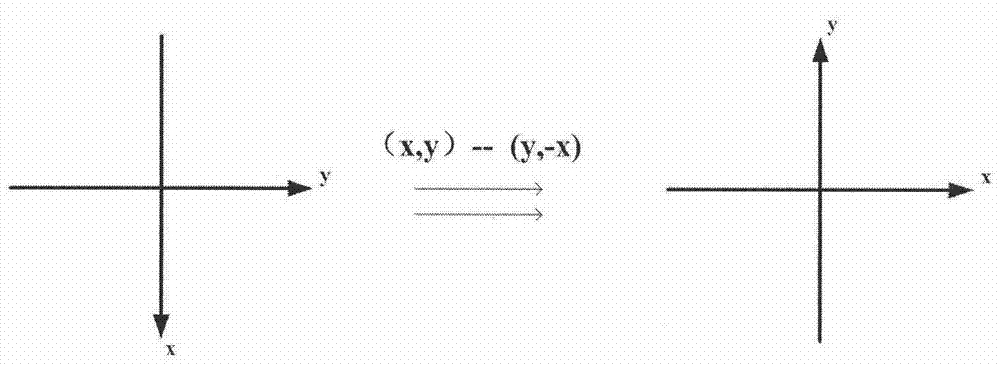

Positioning method based on coal mine underground wireless sensor network

InactiveCN102781092AHigh precisionImprove convenienceNetwork topologiesGlobal Positioning SystemComputer science

The invention discloses a positioning method based on a coal mine underground wireless sensor network. The positioning method is characterized by arranging anchor nodes on the unilateral wall of a laneway at equal distances, dividing blocks by utilizing the intervals of the anchor nodes, firstly performing block local vector positioning on a target node, and further combining with ID (identity) conversion of the anchor nodes to form global coordinates of the laneway. According to the positioning method disclosed by the invention, the coal mine underground non-GPS (global positioning system) positioning limiting conditions can be met, positioning precision and convenience can be improved, the principle is simple and easy to implement, and equipment cost required for positioning is greatly reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

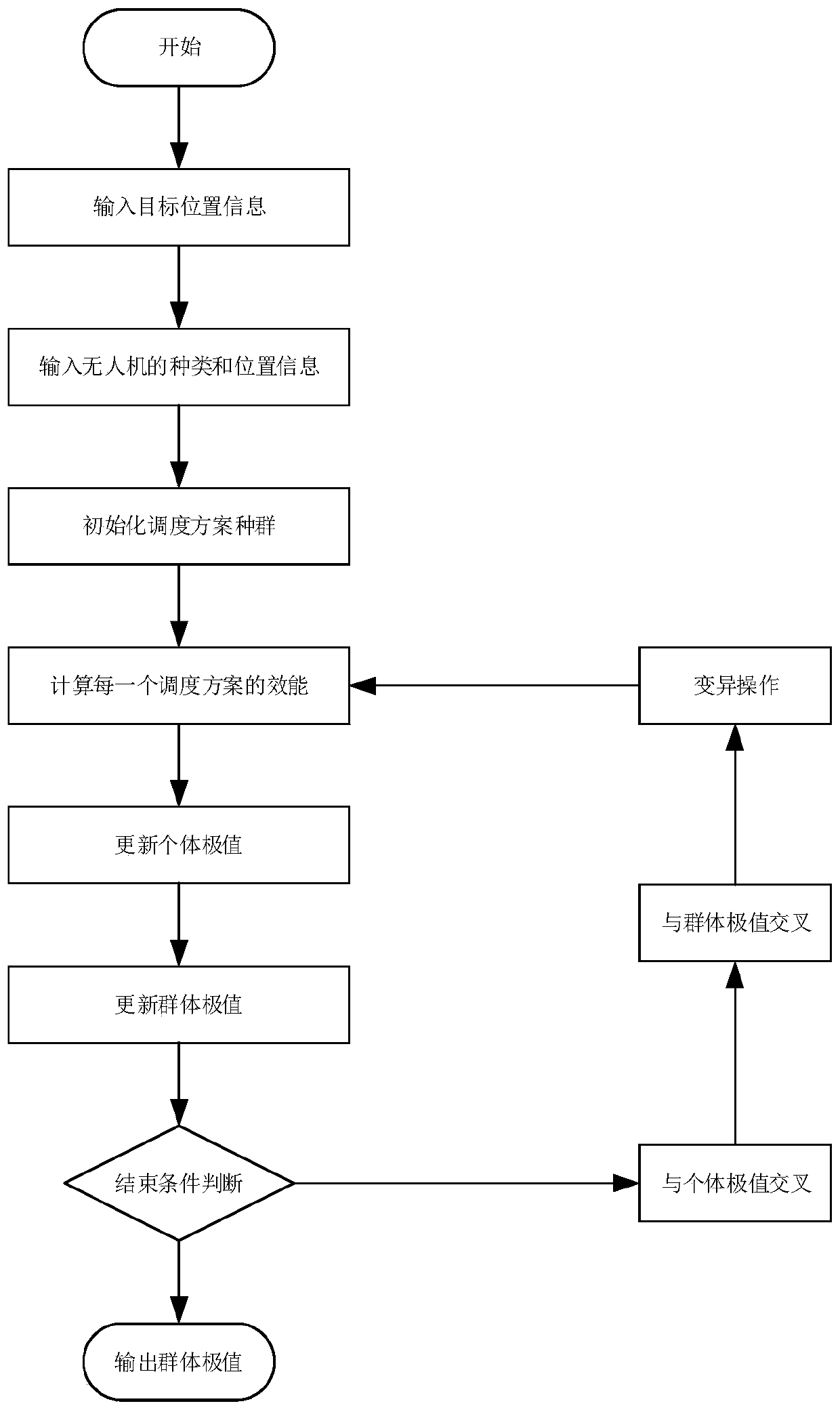

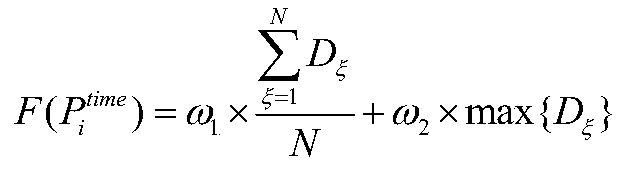

Multi-unmanned aerial vehicle cooperative task scheduling method based on improved discrete particle swarm algorithm

ActiveCN110232492AAvoid getting stuck in local extremaMeet the constraintsArtificial lifeResourcesUncrewed vehicleDiscrete particle

The invention discloses a multi-unmanned aerial vehicle cooperative task scheduling method based on an improved discrete particle swarm optimization algorithm, and solves the problem of unmanned aerial vehicle cooperative multi-target attack task scheduling according to the position of an enemy target and basic information of an unmanned aerial vehicle. According to the method, the constraint condition of task scheduling is fused into particle updating, the particle iteration mode is improved by using cross mutation, and the algorithm is prevented from falling into a local extreme value by using mutation operation. According to the invention, an improved discrete particle swarm optimization algorithm is used to carry out comparative study on a scheduling scheme according to the voyage costof finishing tasks by the unmanned aerial vehicle and the maximum exposure time of the unmanned aerial vehicle, and an optimal task scheduling scheme is obtained through multiple iterations.

Owner:NANJING UNIV OF POSTS & TELECOMM

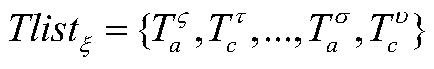

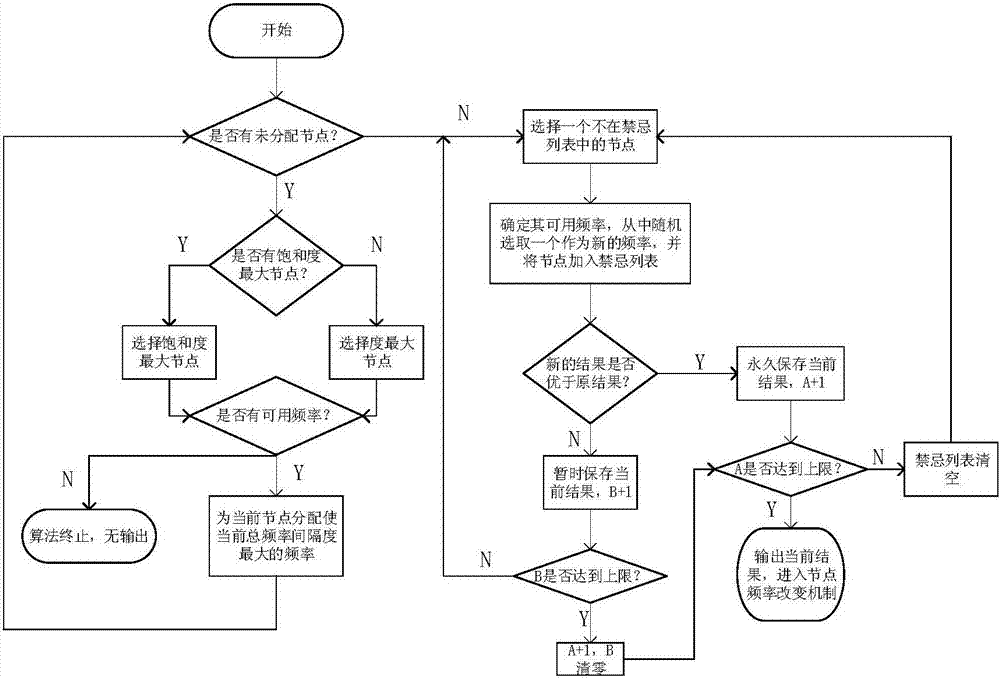

Node frequency distribution method in Ad Hoc network

InactiveCN104703283AReduce distractionsGuaranteed communication qualityNetwork topologiesTaboo listCommunication quality

A frequency distribution method for an Ad Hoc network includes step 1, setting minimum frequency space limitation, total frequency band bandwidth limitation, a maximum value of a first counter and a maximum value of a second counter, and initializing a taboo list, the first counter and the second counter to be zero respectively; step 2, selecting a node of a to-be-distributed frequency; step 3, determining a usable frequency of the node selected currently according to the minimum frequency space limitation and the total frequency band bandwidth limitation; step 4, performing optimization on the basis of a current frequency distribution result. By the Ad Hoc network frequency distribution method meeting the minimum frequency space limitation and the total frequency band bandwidth limitation, interference among nodes is reduced to the greatest extent, communication quality is guaranteed, frequencies used by the nodes can be changed according to environmental conditions dynamically on the basis of completed distribution, and limitation conditions are met.

Owner:SHANGHAI JIAO TONG UNIV

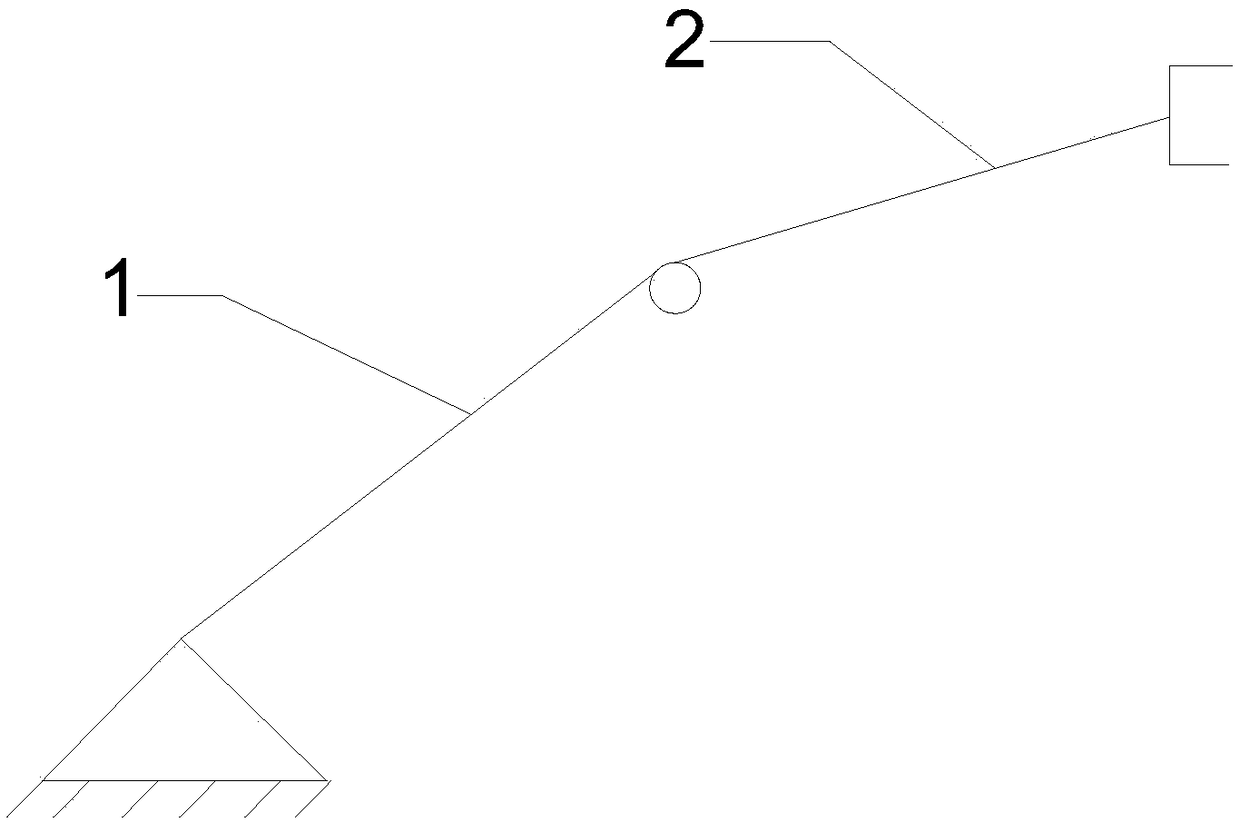

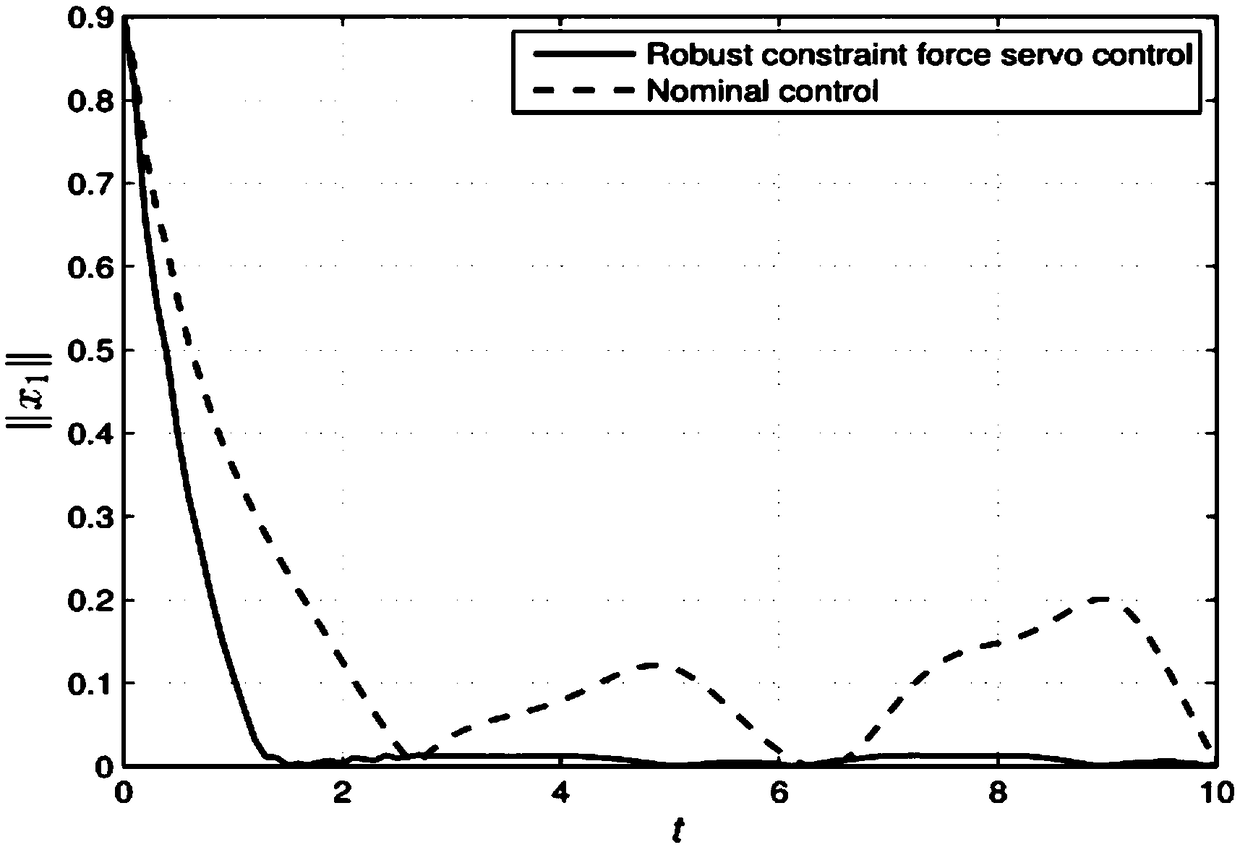

Constraining force robust servo control method and device for under-actuated flexible mechanical arm system

The invention discloses a constraining force robust servo control method and device for an under-actuated flexible mechanical arm system. Under the basic framework of Udwadia and Kalaba, the constraining force robust servo control method obtains a constraining force closed-loop form which can be applied to the design of the control device, which is feasible for servo constraint; in addition, a virtual control is nested to divide the whole system into two subsystems, then through an analogous Udwadia-Kalaba control part control method and a robust control part control method, so that the angleof a connecting rod approximately follows a given constraint, meanwhile, the consistent boundary performance of the control device and the consistent final boundary performance of the whole control device are ensured.

Owner:HEFEI UNIV OF TECH

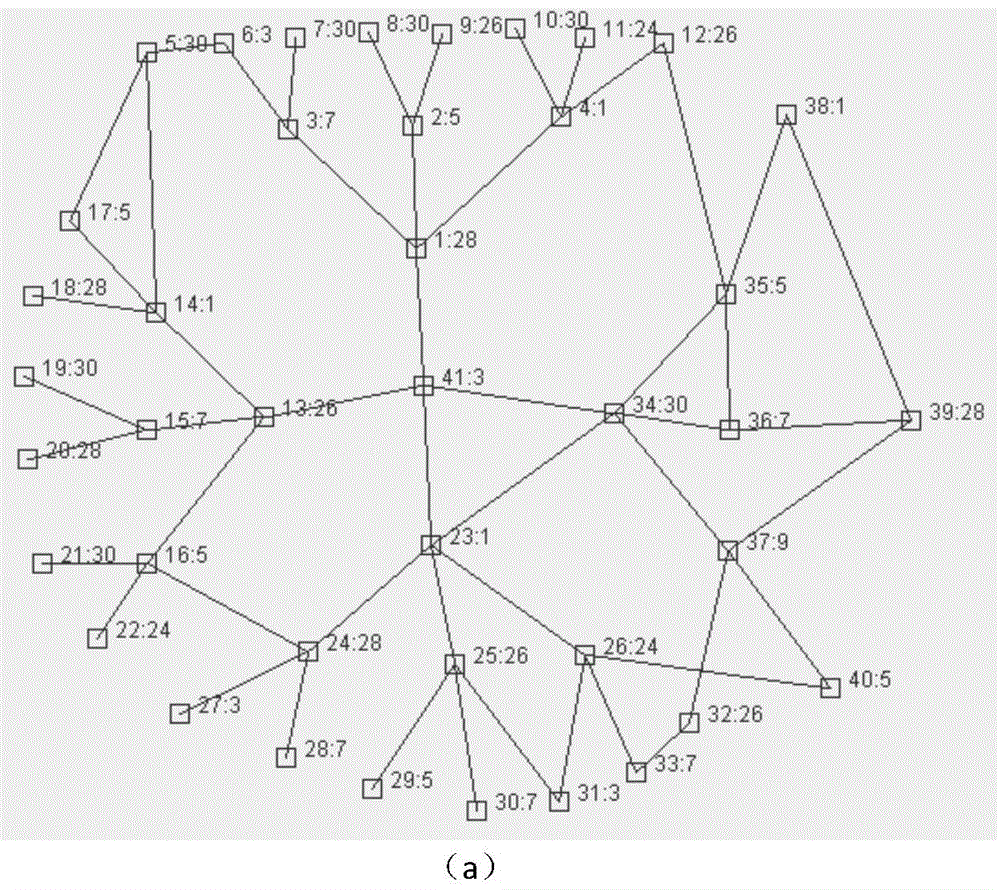

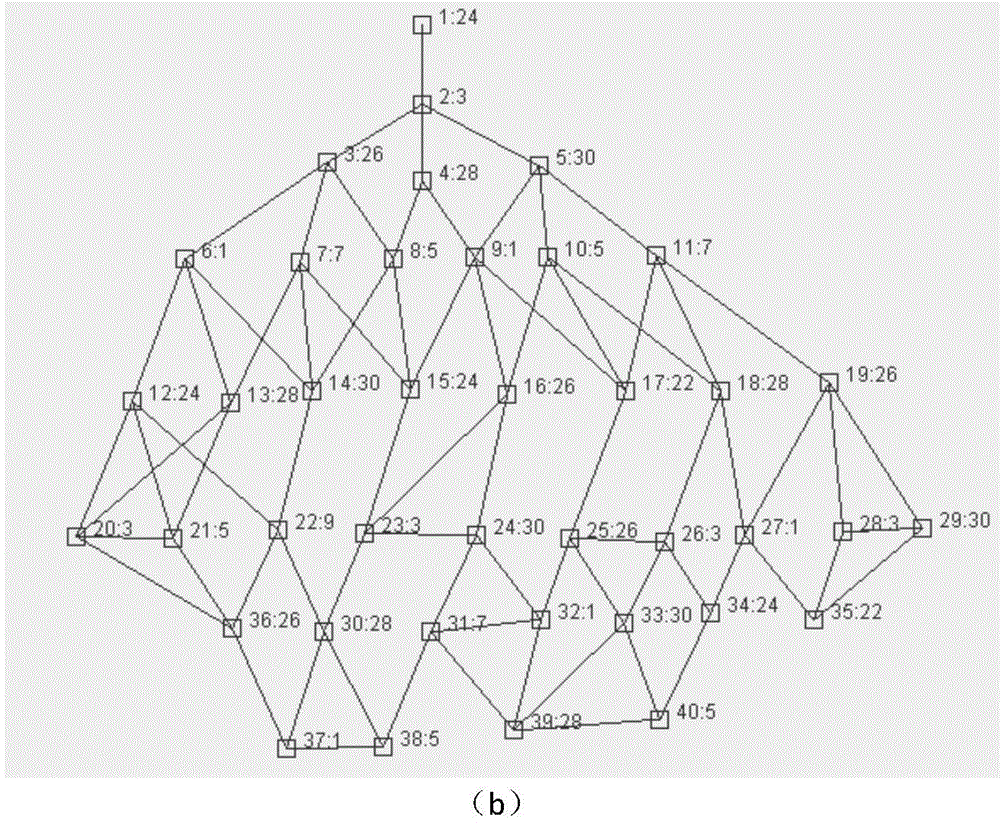

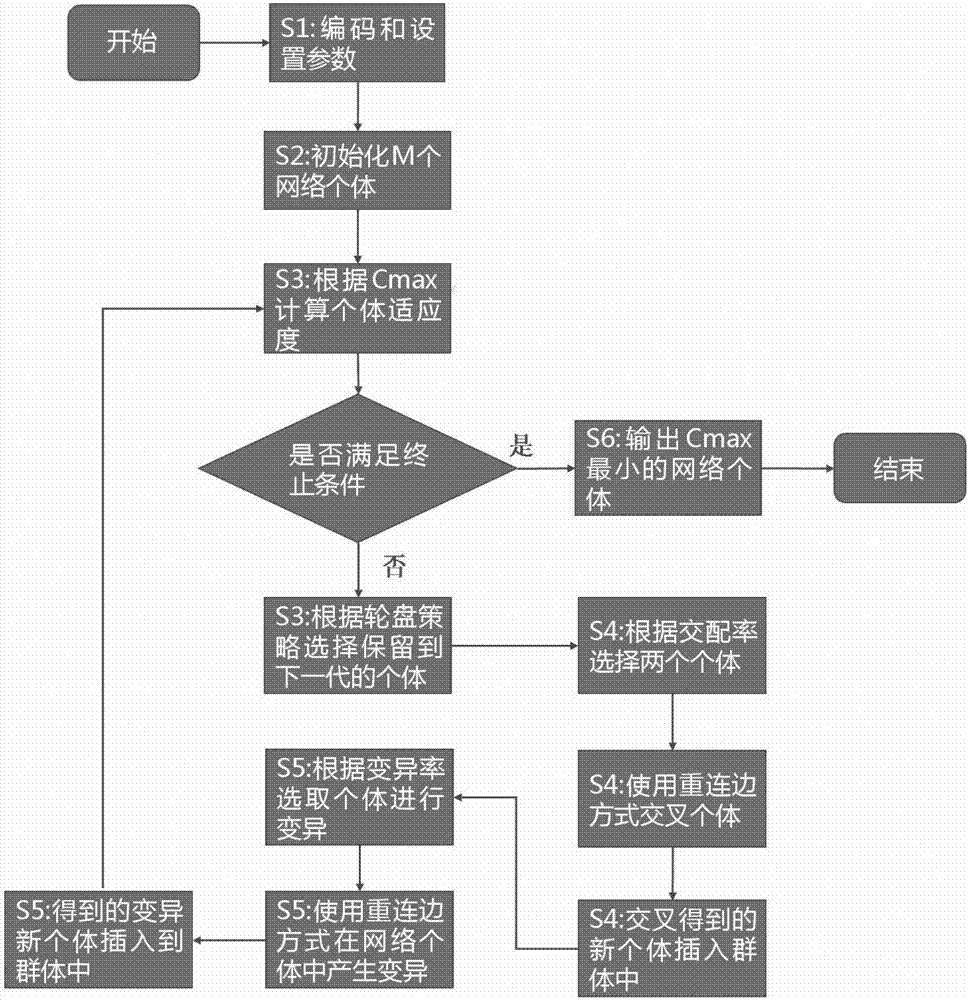

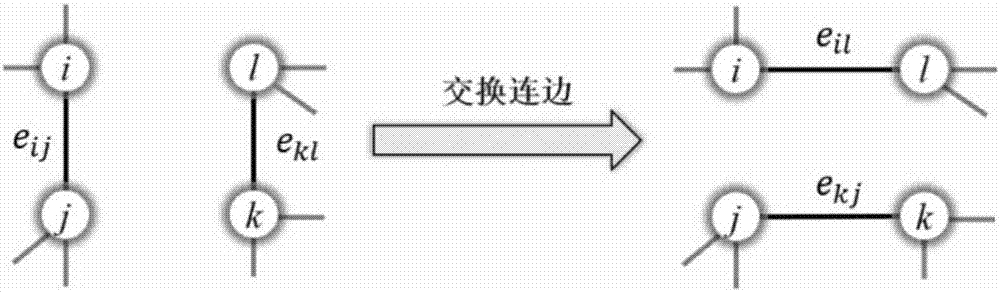

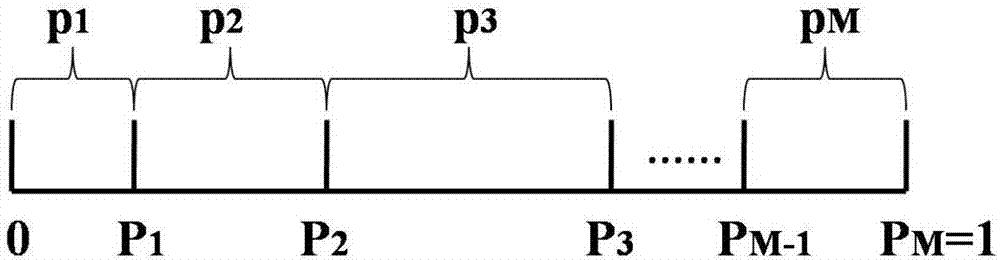

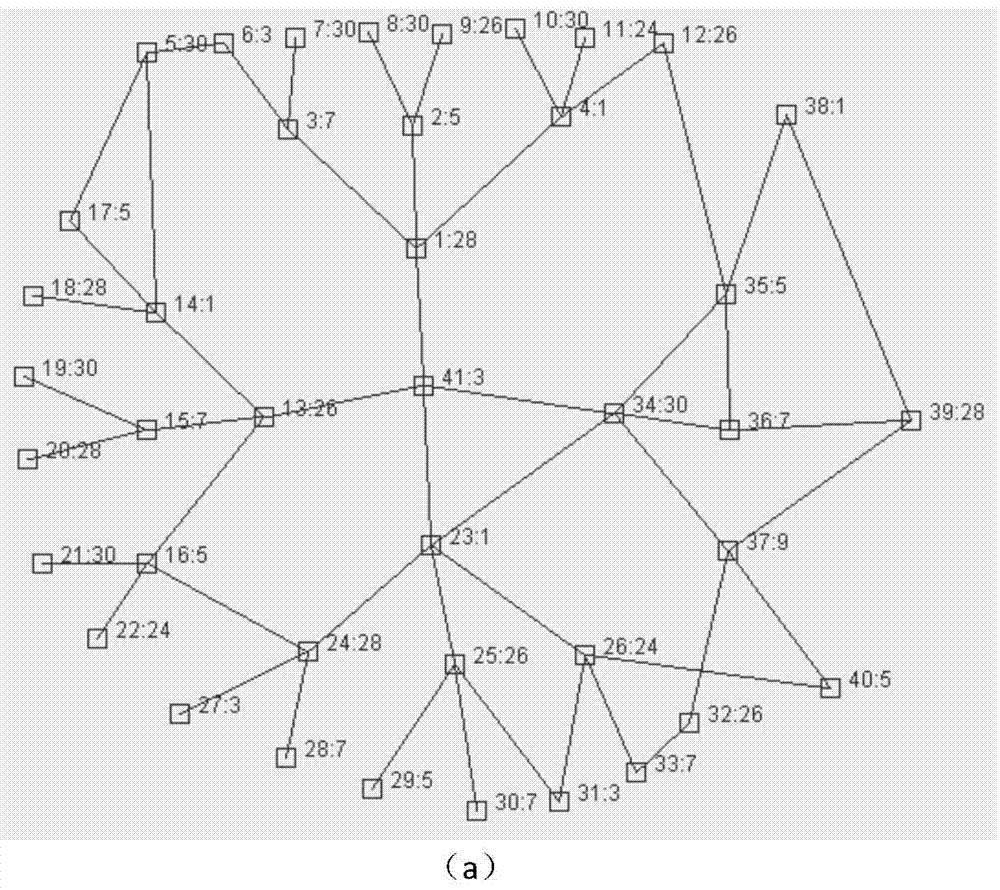

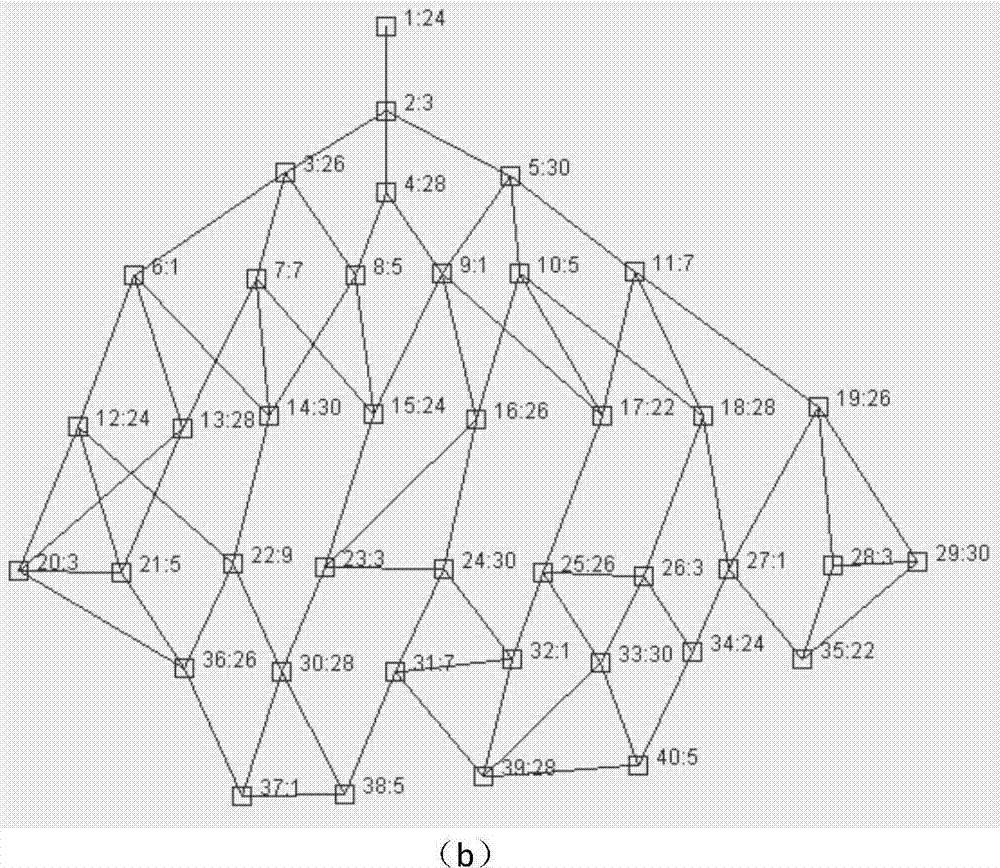

Communication network structure optimization method based on node use probability

ActiveCN107395426AImprove communication transmission capabilityExcellent topologyData switching networksNODALNetwork structure

The invention relates to a communication network structure optimization method based on node use probability. Communication network index Cmax is reduced through a genetic reconnection optimization method, and an approximate global optimal solution is obtained. The genetic reconnection optimization process comprises the following steps: S1) coding and setting initial parameters of the genetic optimization process; S2) initializing network individuals; S3) selecting the individual reserved to the next generation; S4) carrying out mating to obtain a new individual; S5) carrying out variation to obtain a variant new individual; and S6) calculating fitness indexes of M network individuals, iterating the steps S3)-S5) until meeting end conditions, and outputting the network individual, the Cmax of which is smallest, optimization being finished. The method can improve network communication transmission performance to the maximum degree under the condition of ensuring communication transmission efficiency without additionally increasing communication transmission mediums or ports.

Owner:SUN YAT SEN UNIV

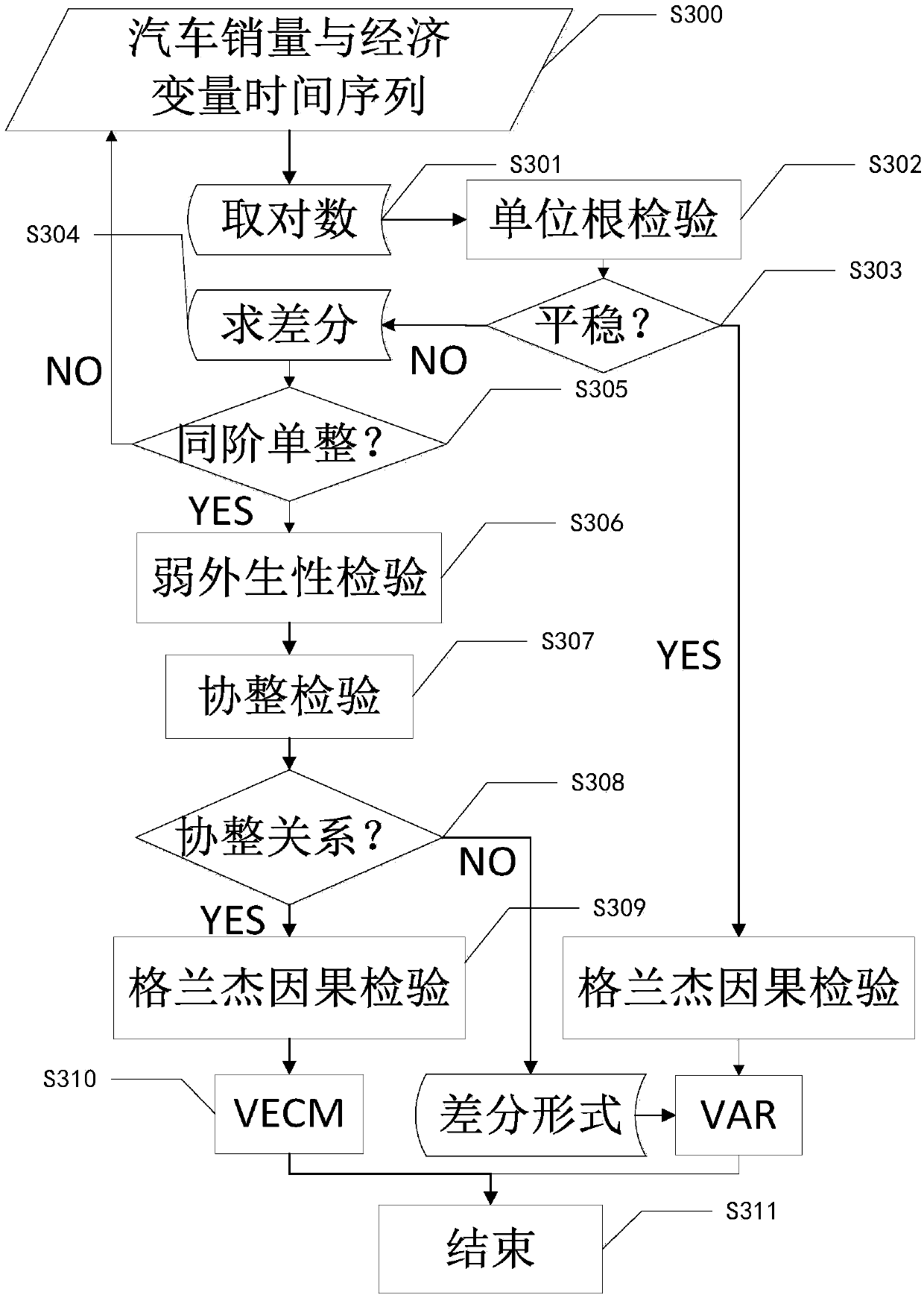

Econometrics and heuristic intelligence combined automobile sales prediction method and system

InactiveCN107705160AReduce distractionsCharacterize the dynamic evolution lawInternal combustion piston enginesMarketingPredictive methodsStructure relation

The invention provides an econometrics and heuristic intelligence combined automobile sales prediction method and system. The method comprises the following steps of: storing data required by automobile sales prediction through establishing a database, wherein data comprises economic indexes, brand automobile sales and automobile sales, which are called as prediction variables; connecting the database and the automobile sales prediction system through the data so as to obtain required prediction variables, and verifying structural relationships between the variables so as to obtain endogenousvariables with a long-term equilibrium and causal relationship; establishing a vector error correction model for the endogenous variables; optimizing coefficient of a prediction model by utilizing a heuristic intelligence algorithm; and finally storing the obtained prediction model into a sales prediction application system, and generating a sales prediction result after inputting corresponding economic variables, brand automobile sales data and former-year automobile sales data. According to the method and system, a model suitable for long-term prediction is found, and the characteristic of high precision of the heuristic intelligence can be utilized at the same time, so that the automobile sales prediction precision is effectively improved.

Owner:DALIAN UNIV OF TECH

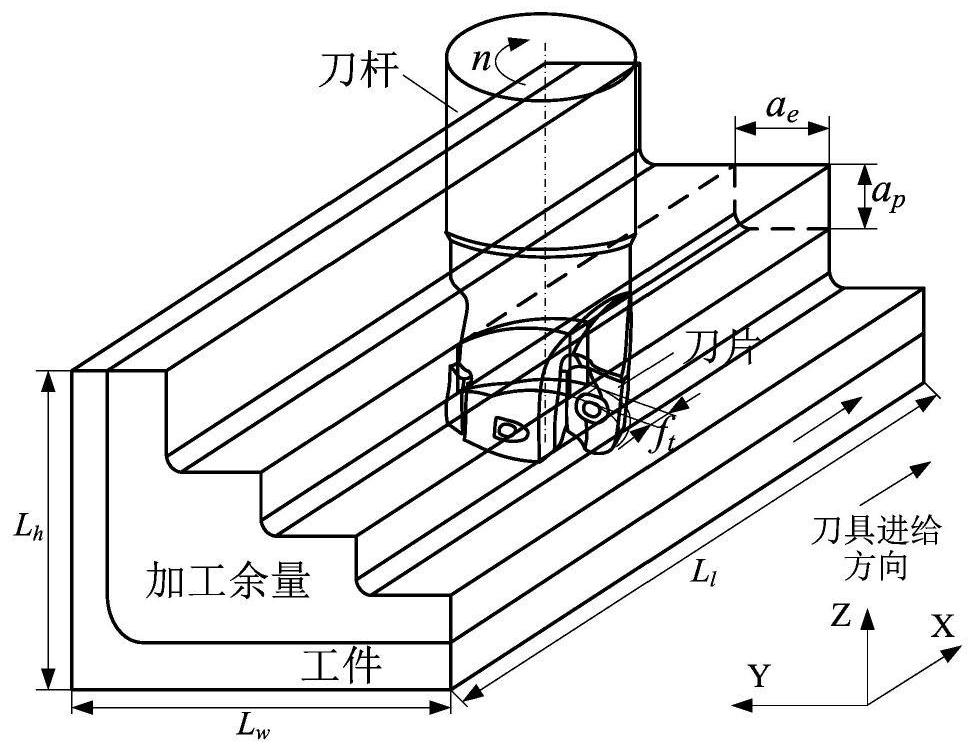

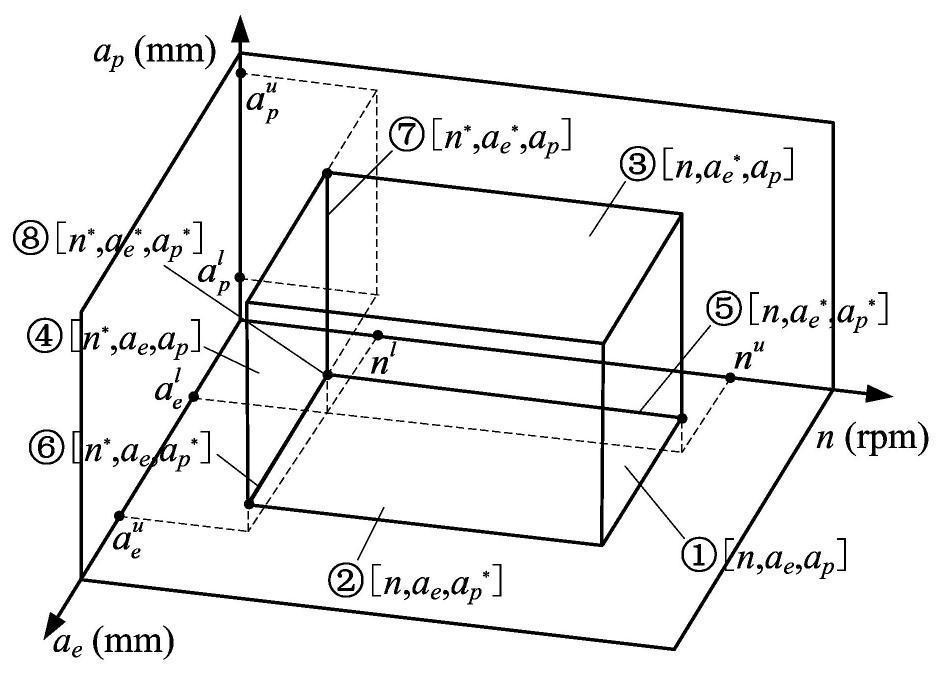

Efficient milling parameter optimization method for rough machining of difficult-to-machine material fused with tool wear monitoring

PendingCN114004042AImprove processing efficiencyHigh removal rateGeometric CADConstraint-based CADProcess engineeringOptimization problem

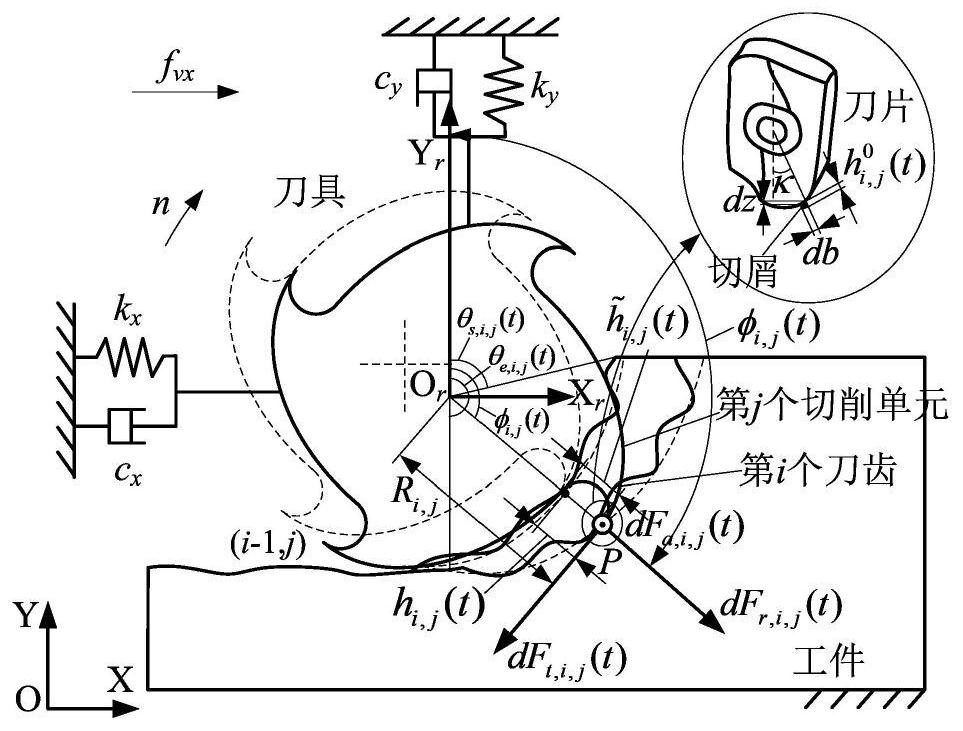

The invention discloses an efficient milling parameter optimization method for rough machining of a difficult-to-machine material fused with tool wear monitoring. The method comprises the steps that firstly, an optimization problem characterization model with the machining efficiency as a target and the spindle rotating speed, the radial cutting width and the axial cutting depth as optimization variables is established, and multiple constraint conditions such as a basic parameter feasible region, stability, spindle torque and power are considered; secondly, the problem of tool abrasion caused by the difficult-to-machine material is considered, the quantitative relation between the three-phase current of the main shaft and the milling force is established, and real-time estimation of the tangential specific shear force coefficient is achieved; furthermore, a numerical solution method based on random vector search is provided, an optimization process integrating offline optimization and real-time monitoring is given, and optimal processing parameters are obtained. According to the parameter optimization method provided by the invention, the rough machining efficiency of the difficult-to-machine material can be greatly improved, and efficient flutter-free milling machining is realized.

Owner:XI AN JIAOTONG UNIV

Quadrotor unmanned aerial vehicle trajectory planning method based on space-time joint optimization

ActiveCN112068586AAchieving joint space-time optimizationIncrease calculation ratePosition/course control in three dimensionsRotocraftFlight vehicleSimulation

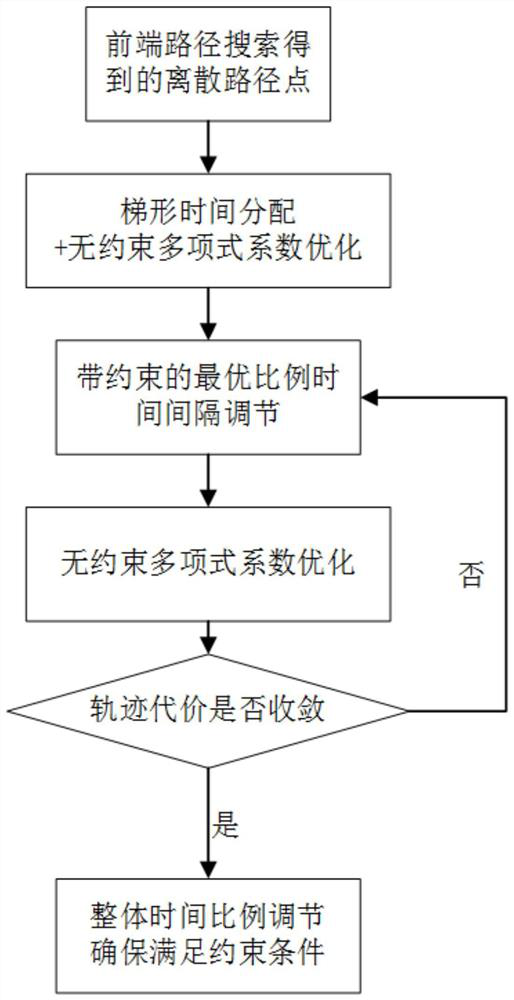

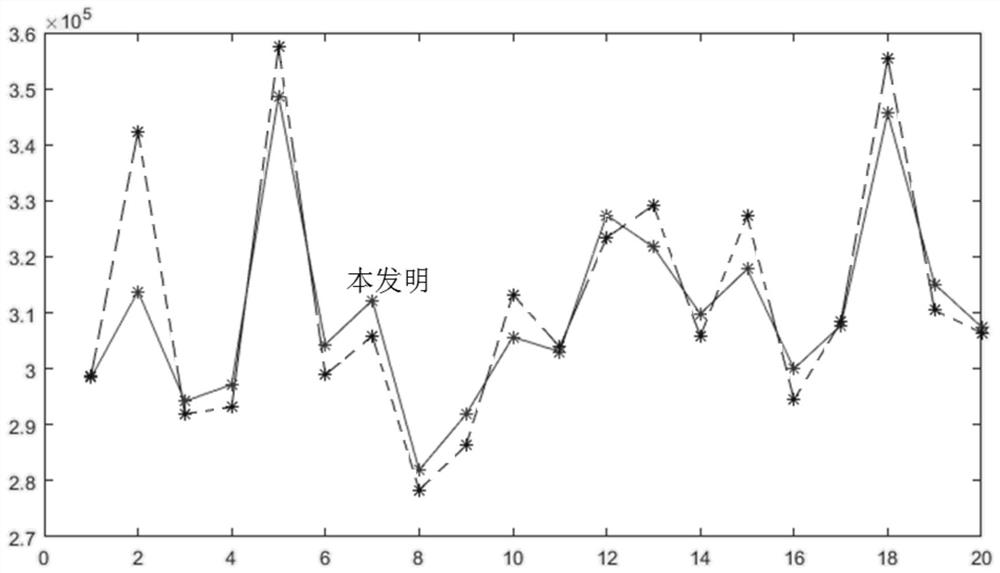

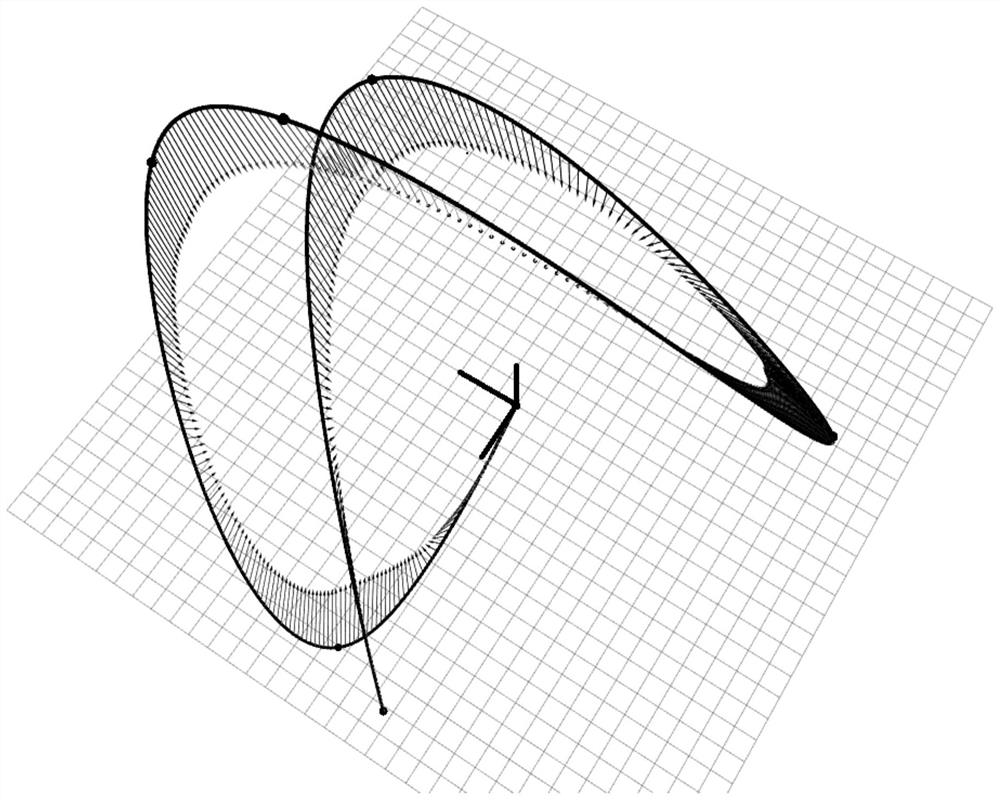

The invention discloses a quadrotor unmanned aerial vehicle trajectory planning method based on space-time joint optimization. The method comprises the following steps: searching a front-end path to obtain discrete path points, allocating a time interval to each section of path by adopting a trapezoidal time allocation method, and optimizing through an unconstrained polynomial coefficient to obtain an initial trajectory path; based on duration cost and energy consumption cost of the initial trajectory, carrying out proportional adjustment on the time interval under the condition that constraints are considered, solving an optimal adjustment proportion, and updating the time intervals of all trajectory segments; then, alternately carrying out two links of unconstrained polynomial coefficient optimization and proportional adjustment of a time interval, and when trajectory cost tends to converge, ending a circulation step; carrying out overall proportion adjustment on the whole trajectorypath, ensuring that the whole trajectory meets constraint conditions, and acquiring a final optimized trajectory; and enabling the unmanned aerial vehicle to follow the trajectory by using the path points obtained by time discretization of the polynomial trajectory. According to the invention, the space-time joint optimization of the trajectory is realized, and meanwhile, a calculation rate is greatly improved.

Owner:XI AN JIAOTONG UNIV

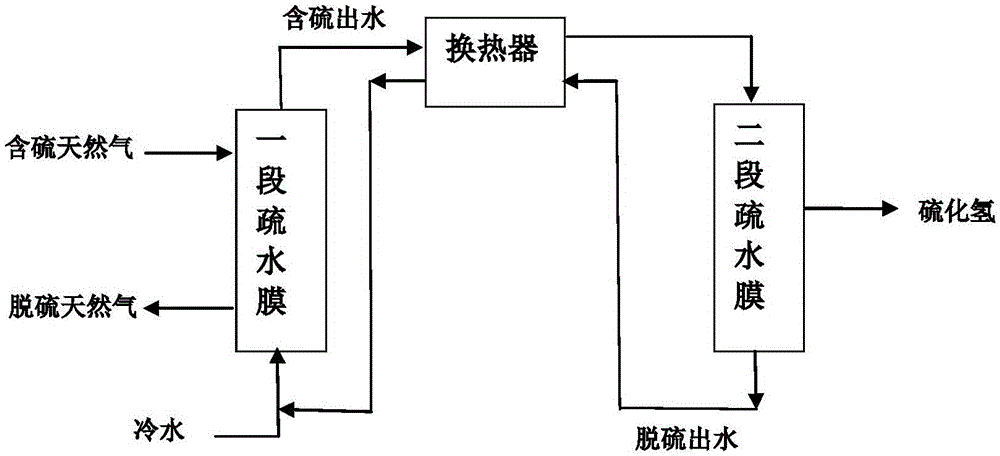

Method for removing hydrogen sulfide in natural gas

InactiveCN106552476ASettle the lossSolve the problem of foamingDispersed particle separationGaseous fuelsPhysical chemistryPermeation

The invention relates to a method for removing hydrogen sulfide in natural gas. The method comprises the following steps: 1) using difference of different gases in water, taking water as absorption liquid, employing a first segment of a hydrophobic membrane for absorbing hydrogen sulfide in the sulfur-containing natural gas to water at the other side of the membrane, forming a sulfur-containing effluent; 2) employing a second segment of the hydrophobic membrane, pumping the negative pressure at membrane permeation side of the second segment of the hydrophobic membrane, extracting the hydrogen sulfide in the sulfur-containing effluent through the second segment of the hydrophobic membrane to the membrane permeation side, and collecting the material to remove the hydrogen sulfide in the natural gas. The method employs water as the absorption liquid, which is environmentally friendly, the problems of equipment corrosion due to solvent loss, foaming and degradation as well as solvent degradation by alkylol amine absorption in a natural gas chemical absorption process desulphurization technology can be solved, land occupation area of equipment is reduced, land occupation is saved, skid-mounted and modularization processing can be realized for the place-limited region.

Owner:CHINA PETROLEUM & CHEM CORP +1

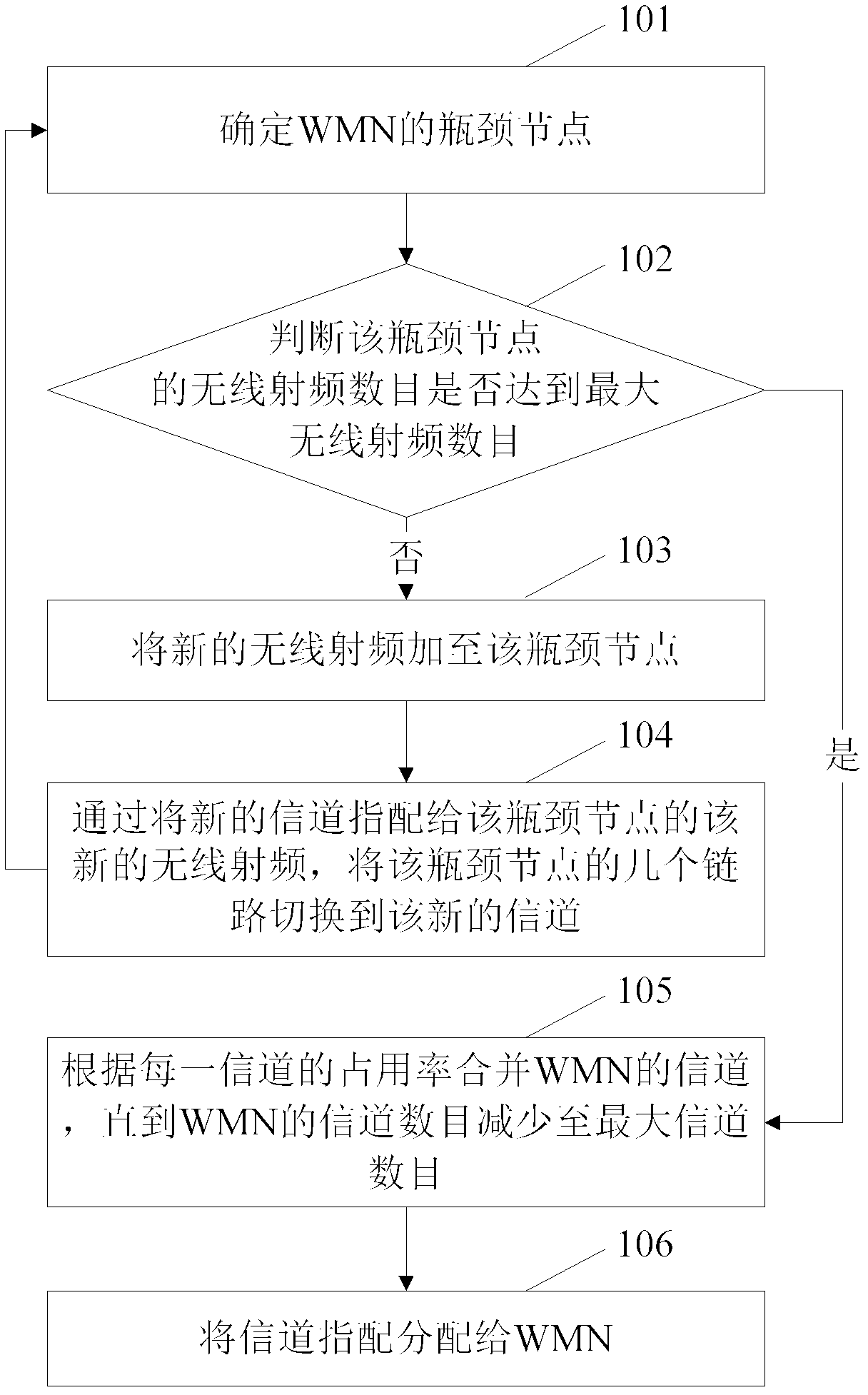

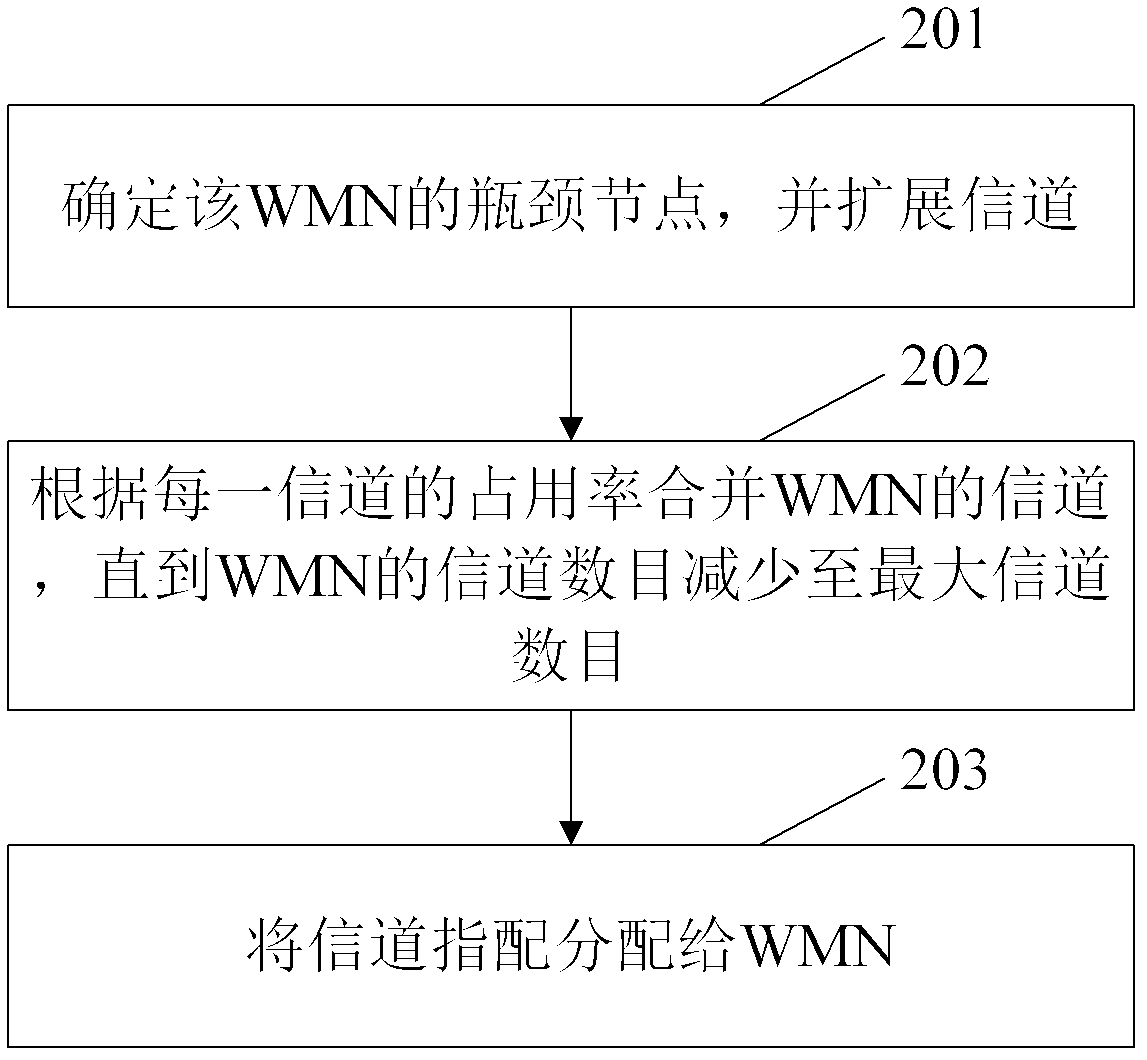

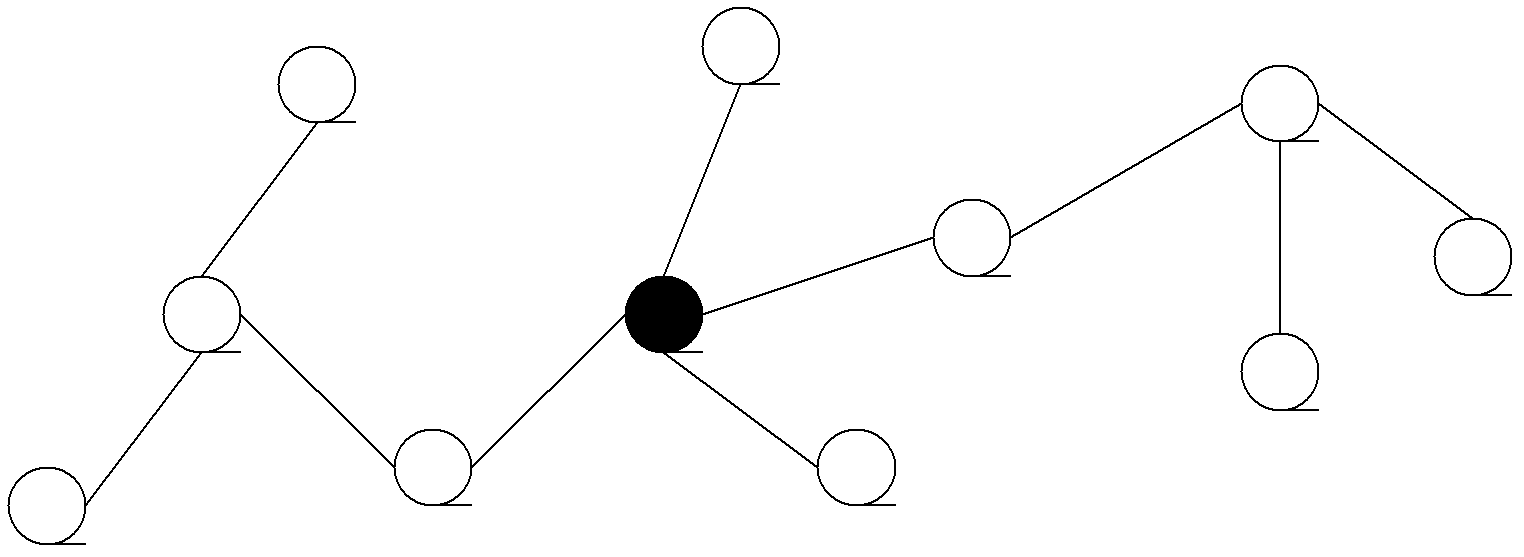

Method, apparatus and system for assigning channels in a wireless mesh network

ActiveCN102293023AMeet the constraintsNetwork traffic/resource managementAssess restrictionComputer networkWireless mesh network

A method for assigning channels in a wireless mesh network includes: creating channel assignment from initial topology of the network by iteratively determining a bottleneck node and expanding a channel; mer ging the channels of the chan nel assignment according to the occupancy of each channel until channel number of the channel assignment is equal to the maximum number of channels; distributing the merged channel assignment to the network. The present invention further discloses a device and a sy stem for assigning channels in a wireless mesh network. The requirement for planning of the frequency / radio assignment is given a tech nical solution.

Owner:HONOR DEVICE CO LTD

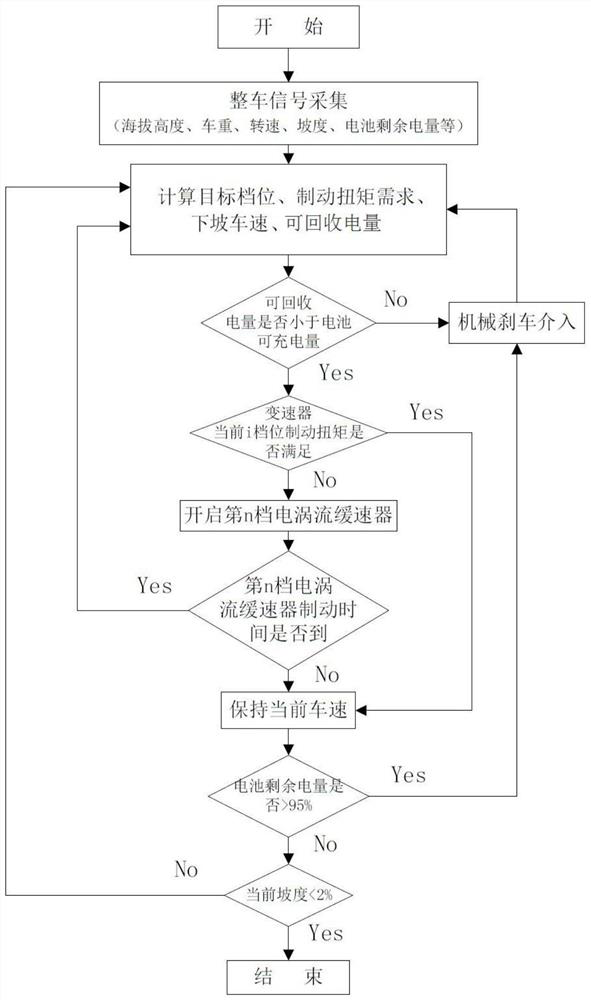

Downhill energy recovery control method and system for pure electric mining truck

ActiveCN112549977ARealize reasonable recyclingAutomatic adjustment of braking torqueElectrodynamic brake systemsControl devicesBrake torqueElectrical battery

The invention relates to an energy recovery method of an electric vehicle, in particular to a downhill energy recovery control method and system for a pure electric mining truck, and aims to solve thetechnical problem that an existing energy recovery method for the pure electric mining truck cannot meet the energy recovery requirement under the condition that the gradient is 15%-50%. The method comprises the steps of collecting whole vehicle information in real time; calculating the vehicle speed, the transmission target gear, the motor braking torque and the recyclable electric quantity under the current slope; judging whether the recyclable electric quantity is smaller than the rechargeable electric quantity of the battery; judging whether the motor braking torque meets the current gearbraking torque requirement of the transmission; determining to start an n-th-gear retarder; judging whether the residual electric quantity of the battery reaches the charging upper limit of the battery; judging whether the current gradient is smaller than a gradient set value; the invention further provides an energy recovery system for realizing the method. The energy recovery system comprises atransmission, a retarder, a whole vehicle mechanical brake, a motor, a motor controller, a battery and a whole vehicle controller.

Owner:SHAANXI FAST GEAR CO

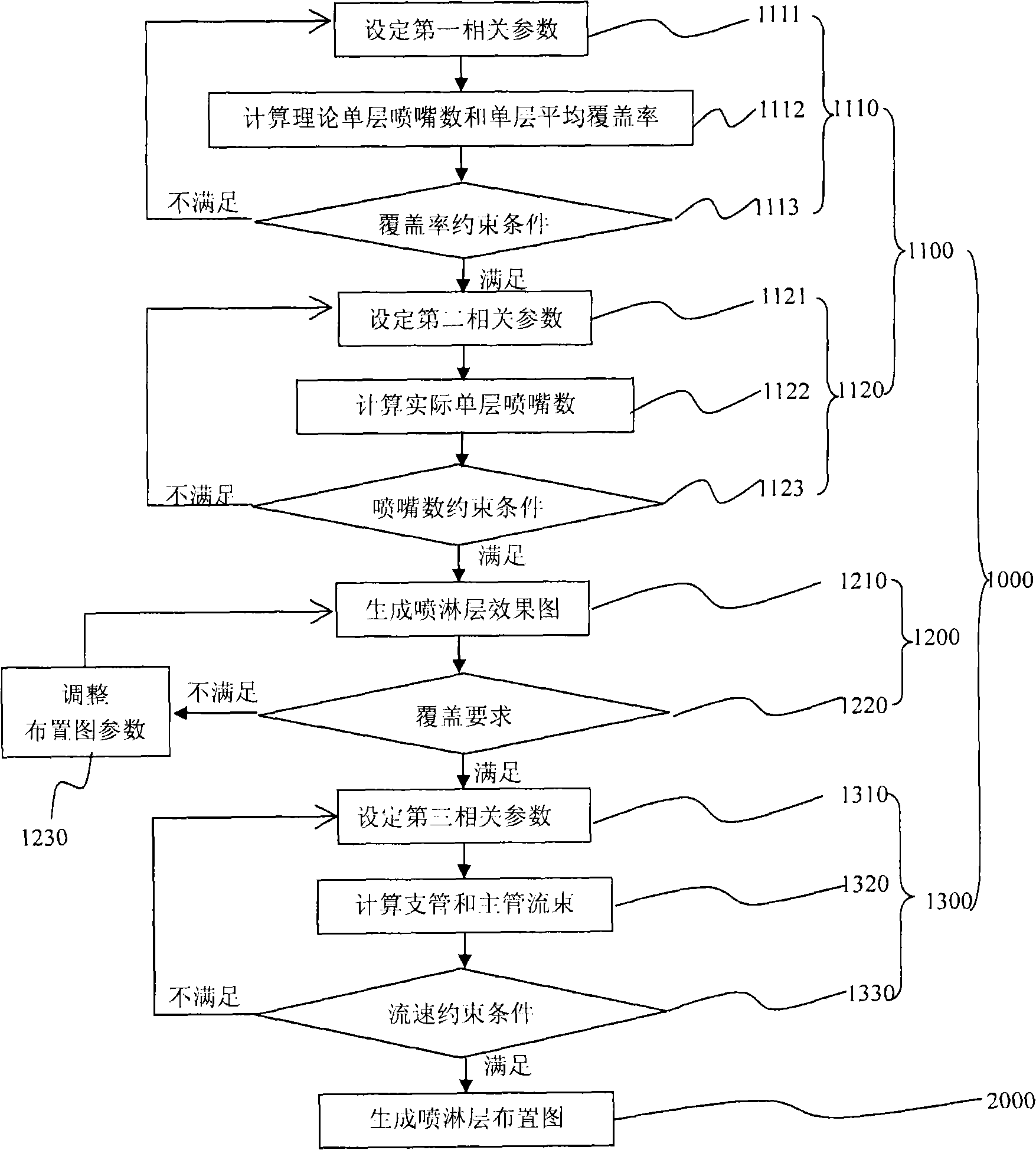

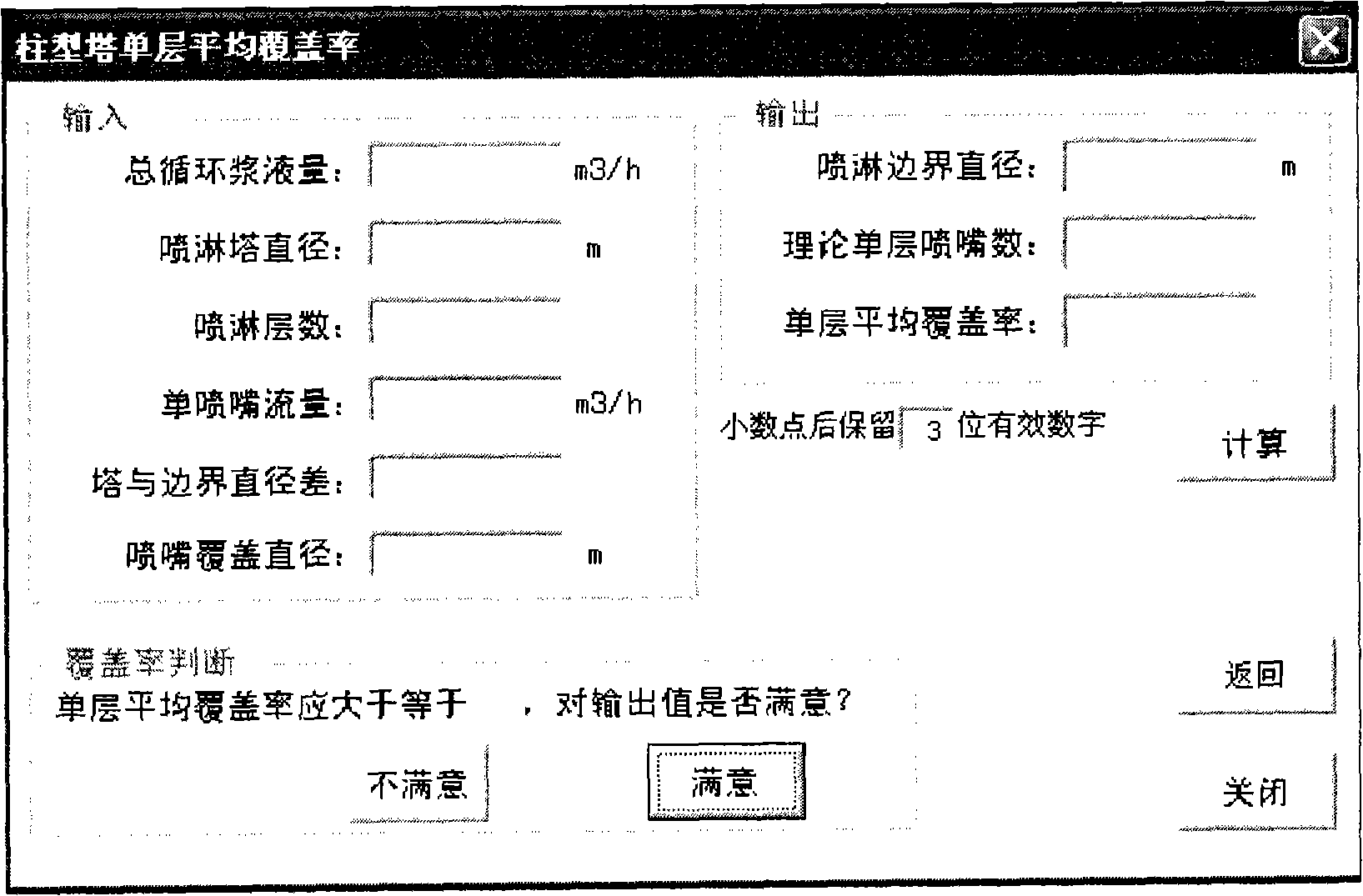

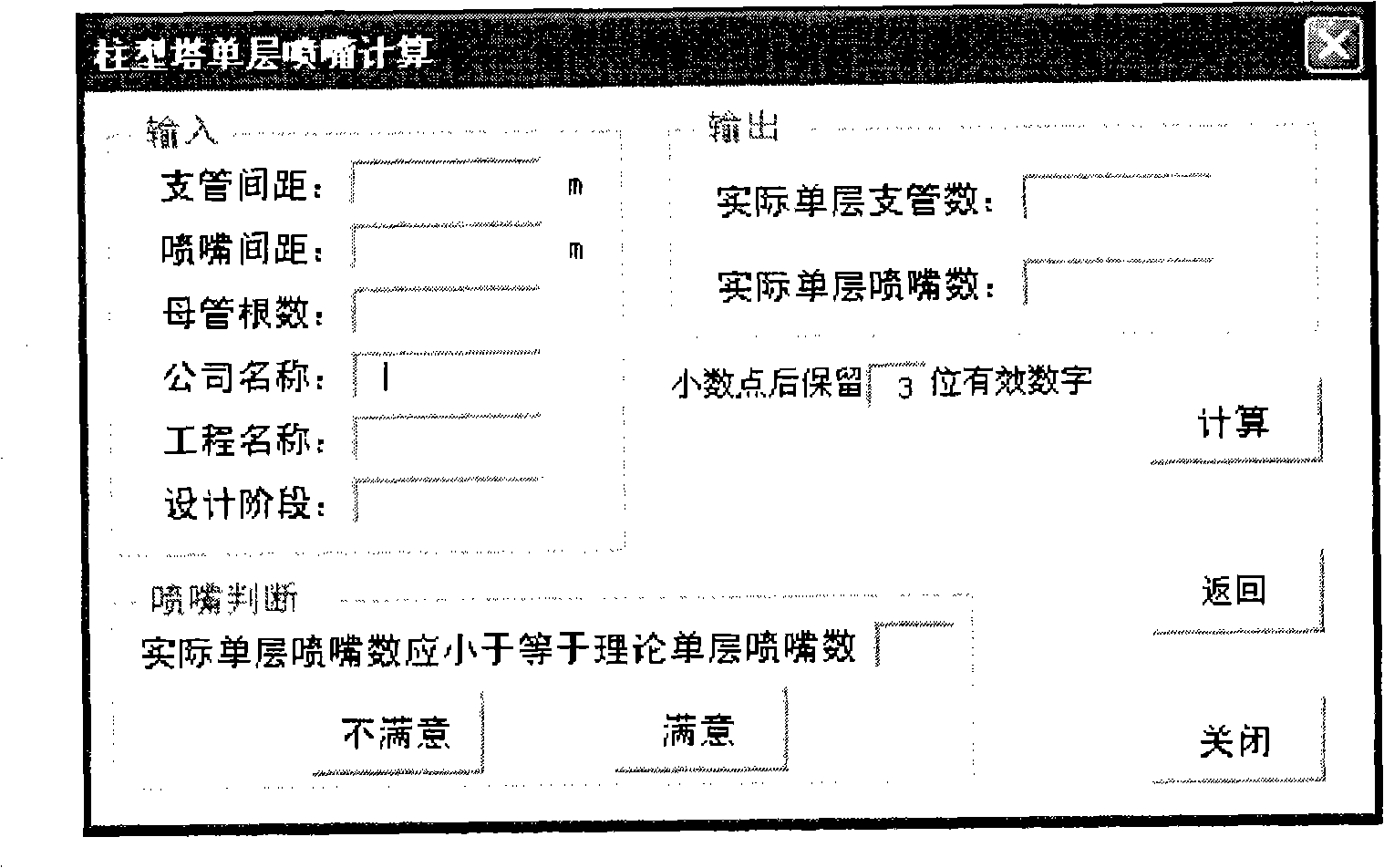

Method for automatically generating spraying layer arrangement plan of spray tower and device therefor

ActiveCN101785963AMeet the constraintsEasy and intuitive operationDispersed particle separationSpray towerSlurry

The invention discloses a method for automatically generating a spraying layer arrangement plan of a spray tower and a device therefor. The spraying layer arrangement plan is automatically generated according to arrangement plan parameters by utilizing a specific program in a computer. In one embodiment of the invention, the arrangement plan parameters in a first part and a second part are determined based on a nozzle quantity constraint condition of constraining the single-layer nozzle quantity and a flow rate constraint condition of constraining the flow rate of circulating grout in a pipeline, and the arrangement plan parameters relevant to the nozzle arrangement are adjusted and / or determined according to the coverage requirements of the nozzle coverage state of the spraying layer. The method and the device improve the working efficiency of designers, and free the designers from the complicated work; meanwhile, the design accuracy is improved, and fault of the designers in the checking process is reduced.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

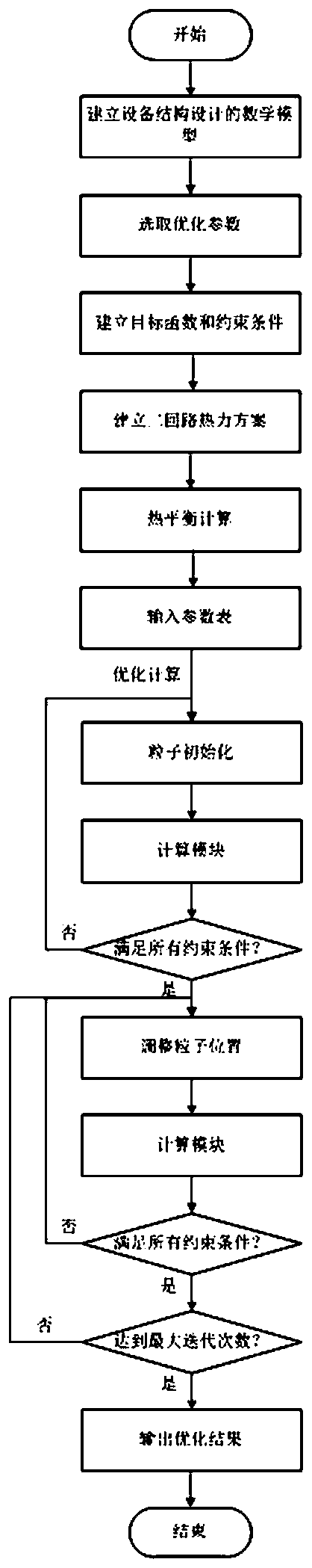

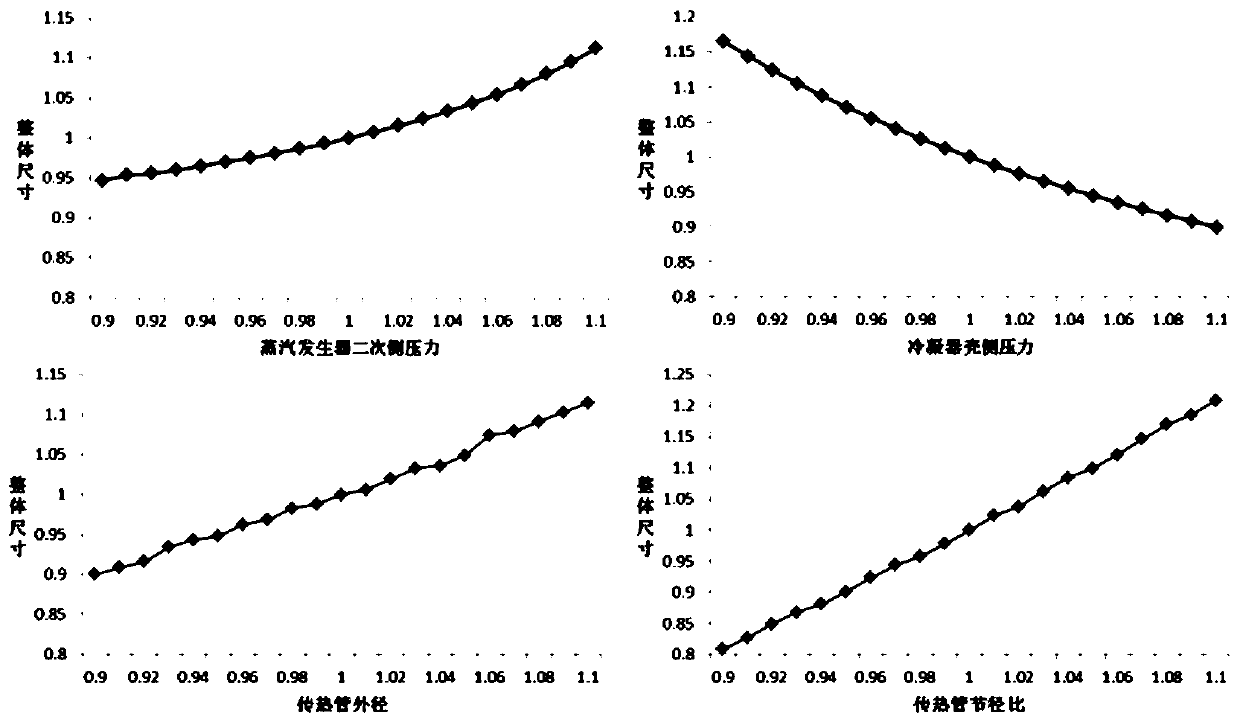

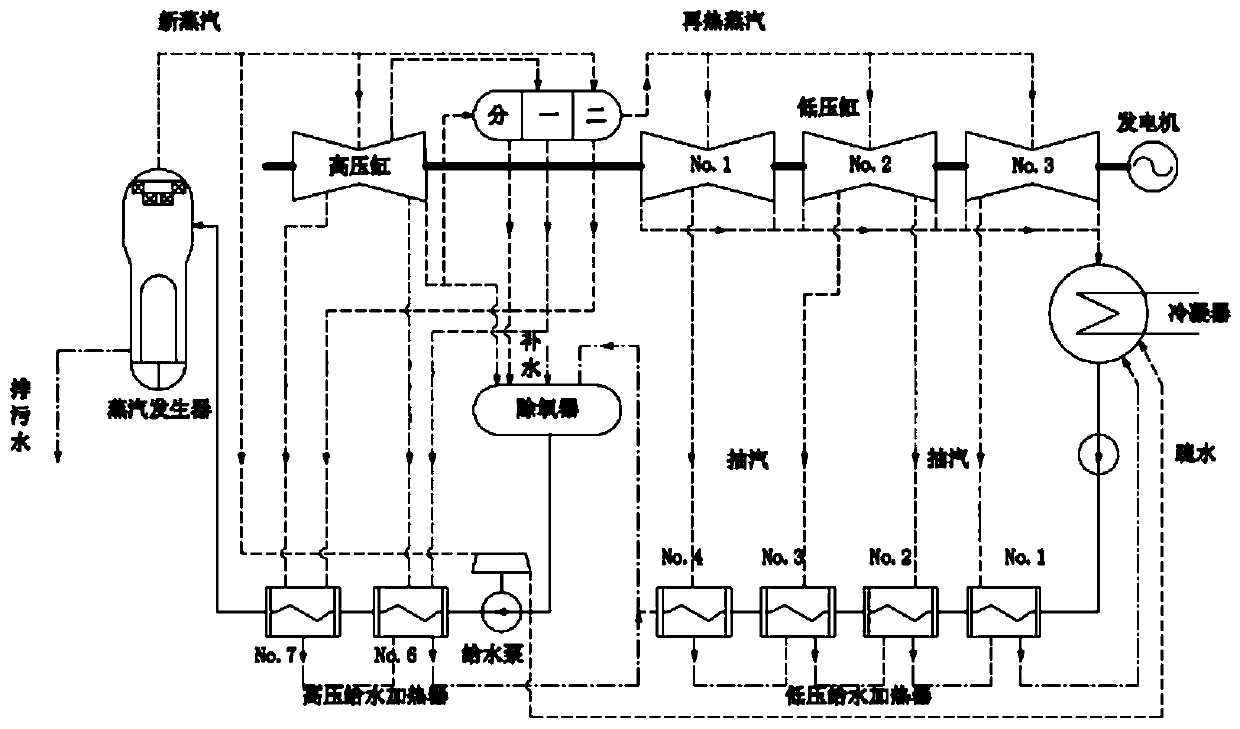

Method for optimizing volume of main equipment o secondary circuit of floating nuclear power station

ActiveCN110795857AEliminate self-velocity termAvoid the choice of weighting factorsNuclear energy generationDesign optimisation/simulationProcess engineeringNuclear power plant

The invention discloses a method for optimizing the volume of main equipment of a secondary circuit of a floating nuclear power station. The method comprises the following steps: (1) establishing a mathematical model for structural design of the main equipment of the secondary circuit; (2) selecting optimization parameters; (3) establishing a target function; (4) establishing constraint conditions; (5) establishing a secondary circuit thermodynamic scheme; (6) carrying out heat balance calculation; (7) calculating the total volume of the equipment to obtain a target function value; (8) optimizing parameters, namely optimizing the optimized parameters through an improved particle swarm algorithm, calculating the particle speed, obtaining the position of the next generation of particles, andupdating individual optimal particles and global optimal particles; and (9) repeating the steps (6)-(8) until the preset number of iterations is completed, and taking a group of optimization parameters enabling the target function value to be minimum as an optimal solution. The method provided by the invention ensures that the devices can be matched with each other when the structures of the devices are designed; and the adopted improved particle swarm algorithm can achieve global optimization.

Owner:HARBIN ENG UNIV

A method for allocating node frequency in ad Hoc network

InactiveCN104703283BReduce distractionsGuaranteed communication qualityNetwork topologiesTaboo listCommunication quality

A frequency allocation method for Ad Hoc networks, including the first step of setting the minimum frequency interval limit, the total frequency band bandwidth limit, the maximum value of the first counter, the maximum value of the second counter, initializing the taboo list to zero, and initializing The first counter is zero, and the second counter is initialized to zero; the second step is to select the next node to be allocated frequency; the third step is to determine the currently selected node according to the set minimum frequency interval limit and total frequency band bandwidth limit Its available frequency; the fourth step is to optimize based on the current frequency allocation results. The invention meets the frequency allocation of the Ad Hoc network that meets the minimum frequency interval limit and the total frequency band bandwidth limit, minimizes interference between nodes, and ensures communication quality. On the basis of completion of the allocation, the node locations can be dynamically changed according to environmental conditions. frequency of use while meeting the constraints.

Owner:SHANGHAI JIAOTONG UNIV

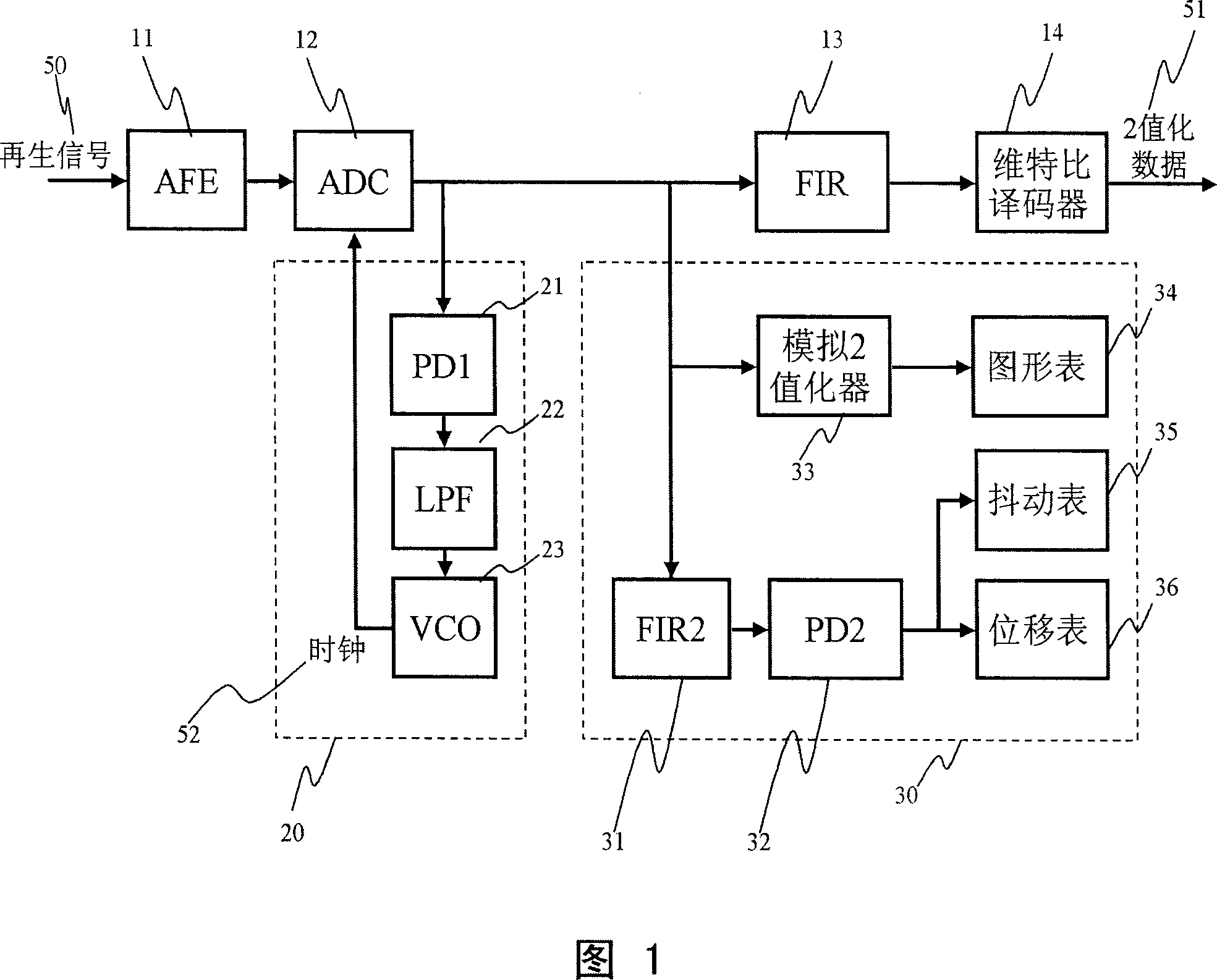

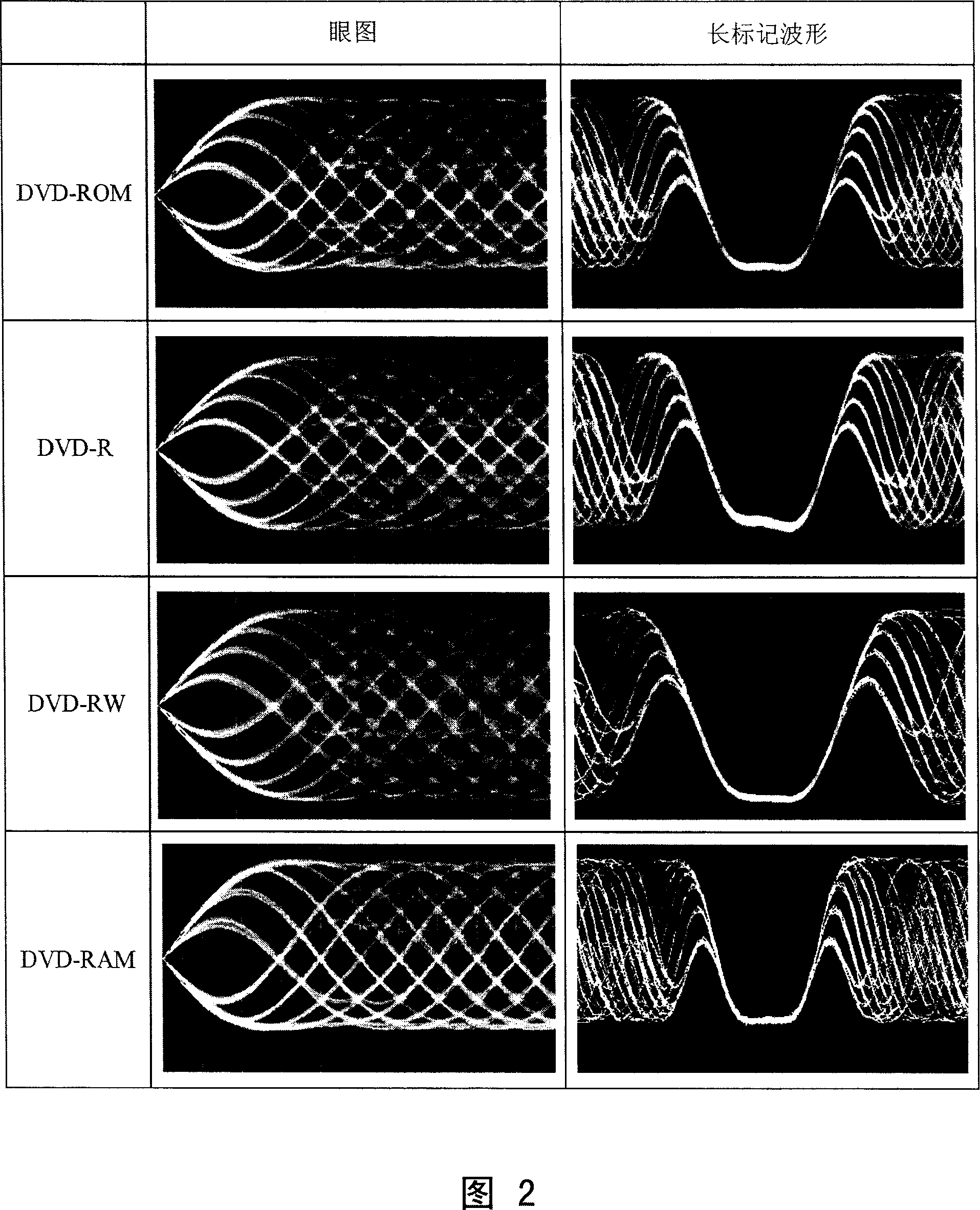

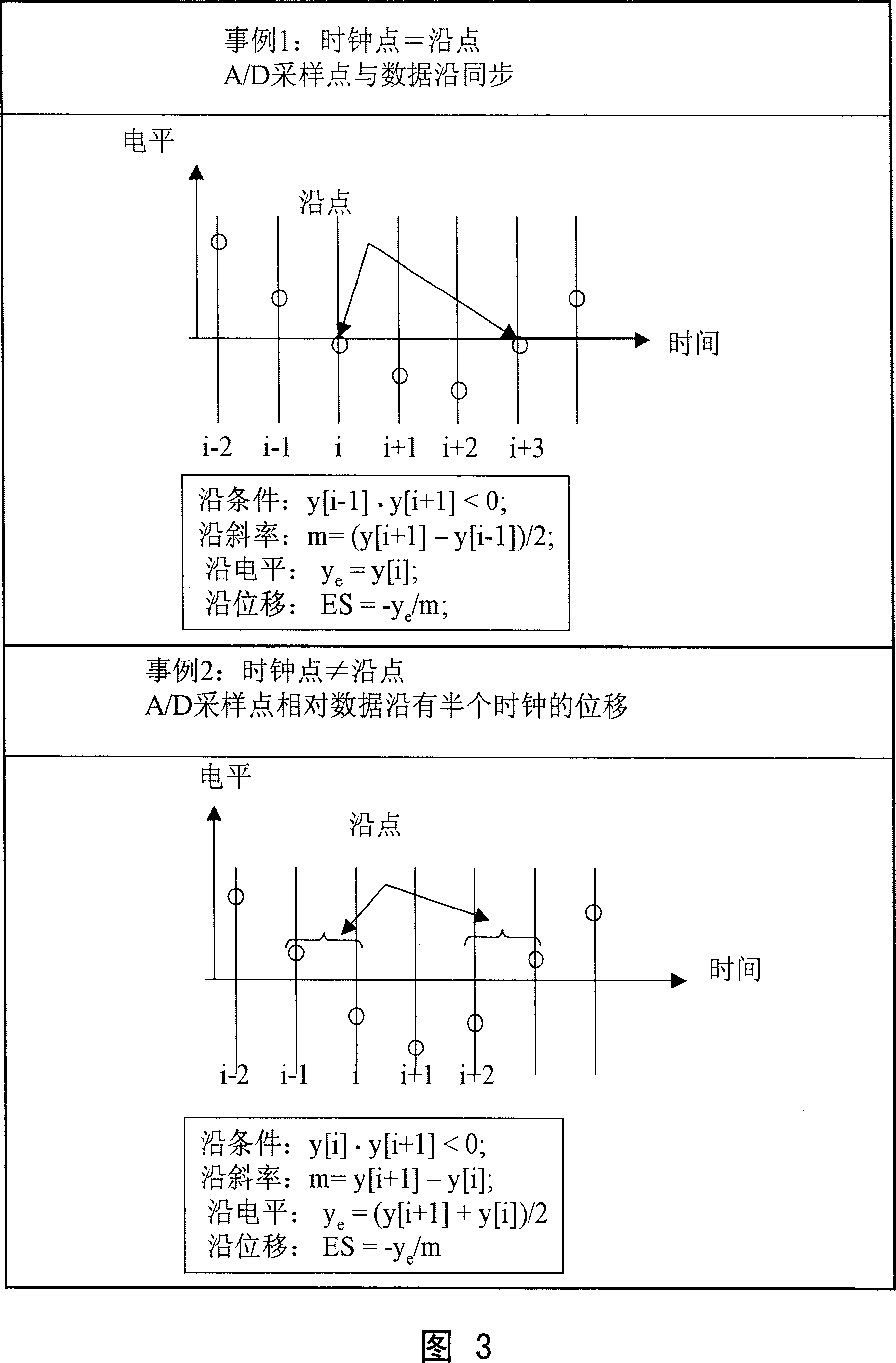

Optical disk device

InactiveCN1971735AReduce processing timeGuaranteed regeneration interchangeRecording strategiesModification of read/write signalsRadio signalJitter

A write type optical disk device with the PRML mode allows accuracy in the trial writing to be improved accompanied with the high speed processing while assuring the readout compatibility. A readout signal that has been A / D converted at timing that interposes the edge has its phase compensated with the even numbered FIR filter. The level at the edge point and the absolute values thereof are accumulated respectively so as to provide a circuit for detecting the edge shift and jitter. Coping with the high speed processing, the edge shift of the readout signal is detected at the position where the edge shift is around zero, thus improving the accuracy in learning of trial writing.

Owner:HITACHI CONSUMER ELECTRONICS CORP +1

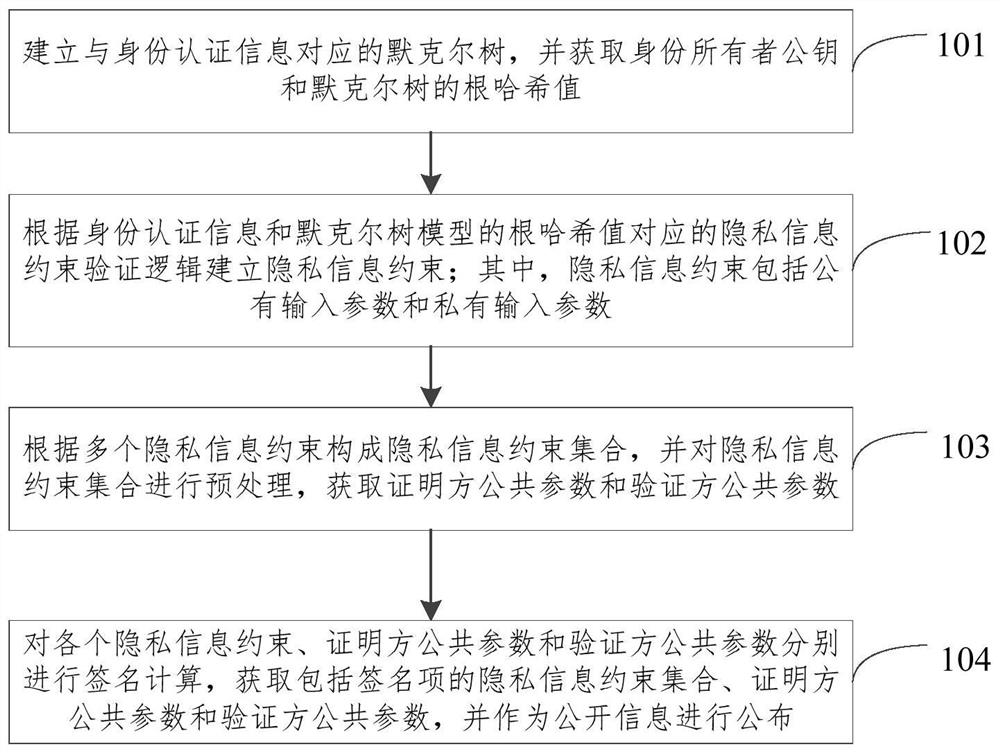

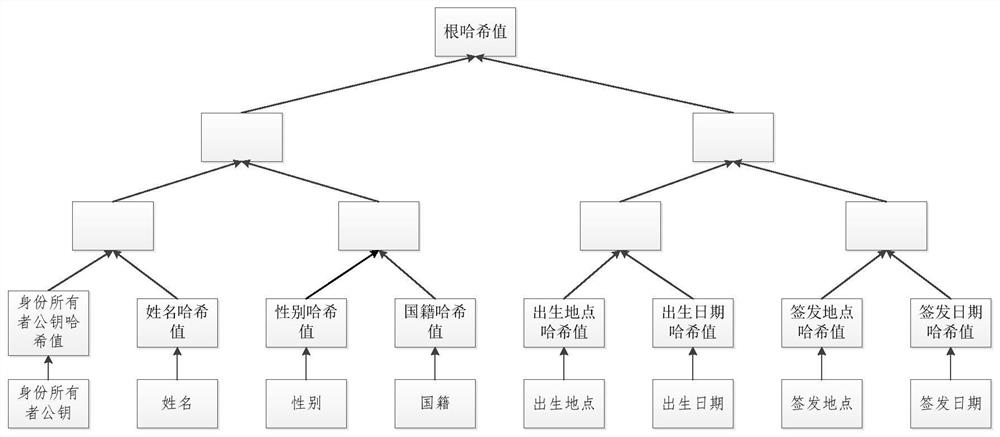

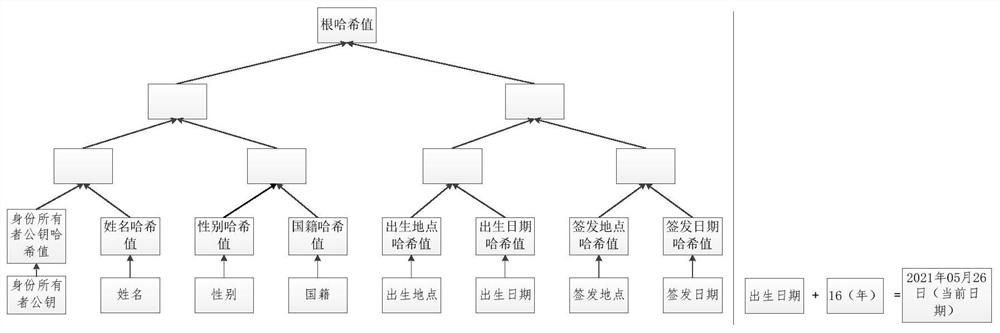

Identity authentication data modeling method, device and system based on privacy protection

ActiveCN113507373AMeet the constraintsMeet minimum identity verification requirementsUser identity/authority verificationHigh level techniquesData modelingTheoretical computer science

The invention relates to an identity authentication data modeling method, device and system based on privacy protection, and the method applied to an authority end comprises the steps: building a Merkel tree model of identity authentication information, obtaining all end public keys of an identity and a root Hash value of the Merkel tree model, and obtaining the public keys of all ends of the identity and the root Hash value of the Merkel tree model; establishing a privacy information constraint according to the privacy information constraint verification logic, the identity authentication information, all identity end public keys and the privacy information constraint verification logic corresponding to the root hash value of the Merkel tree model; processing the plurality of privacy information constraints to obtain a public parameter of a proving party and a public parameter of a verifying party; and respectively performing signature calculation on each privacy information constraint, the proving party public parameter and the verifying party public parameter to generate a privacy information constraint set comprising signature items, and publishing the proving party public parameter and the verifying party public parameter as public information. Therefore, the identity authentication information has the endorsement capability of an authority, and corresponding constraint verification is carried out on different privacy data according to the requirements of application scenes.

Owner:北京优品三悦科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com