Method for automatically generating spraying layer arrangement plan of spray tower and device therefor

A technology for automatic generation and spraying of layers, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc. The effect of easy operation and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]There are usually multiple spray layers in the spray tower of the flue gas desulfurization system, and each spray layer has multiple nozzles arranged in one plane. Moreover, each spray layer has a pipeline for conveying circulating slurry, and these nozzles are arranged at intervals on the pipeline. When working, the pipeline transports the circulating slurry to each nozzle, and the nozzle sprays the slurry into the spray tower, so that the slurry contacts the flue gas in the spray tower, thereby washing the flue gas, so that the Pollutants (such as sulfur dioxide, etc.) in the flue gas are removed.

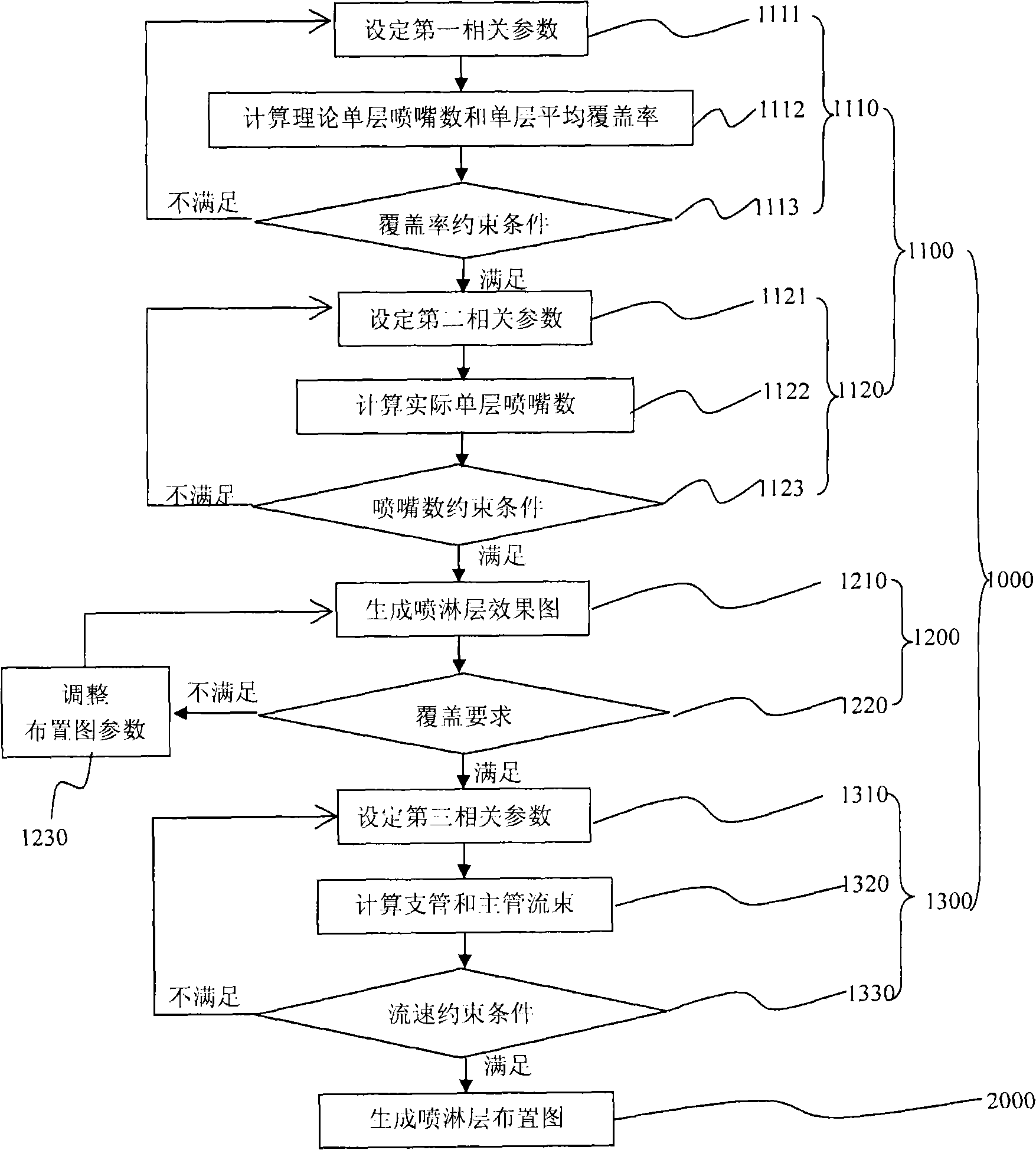

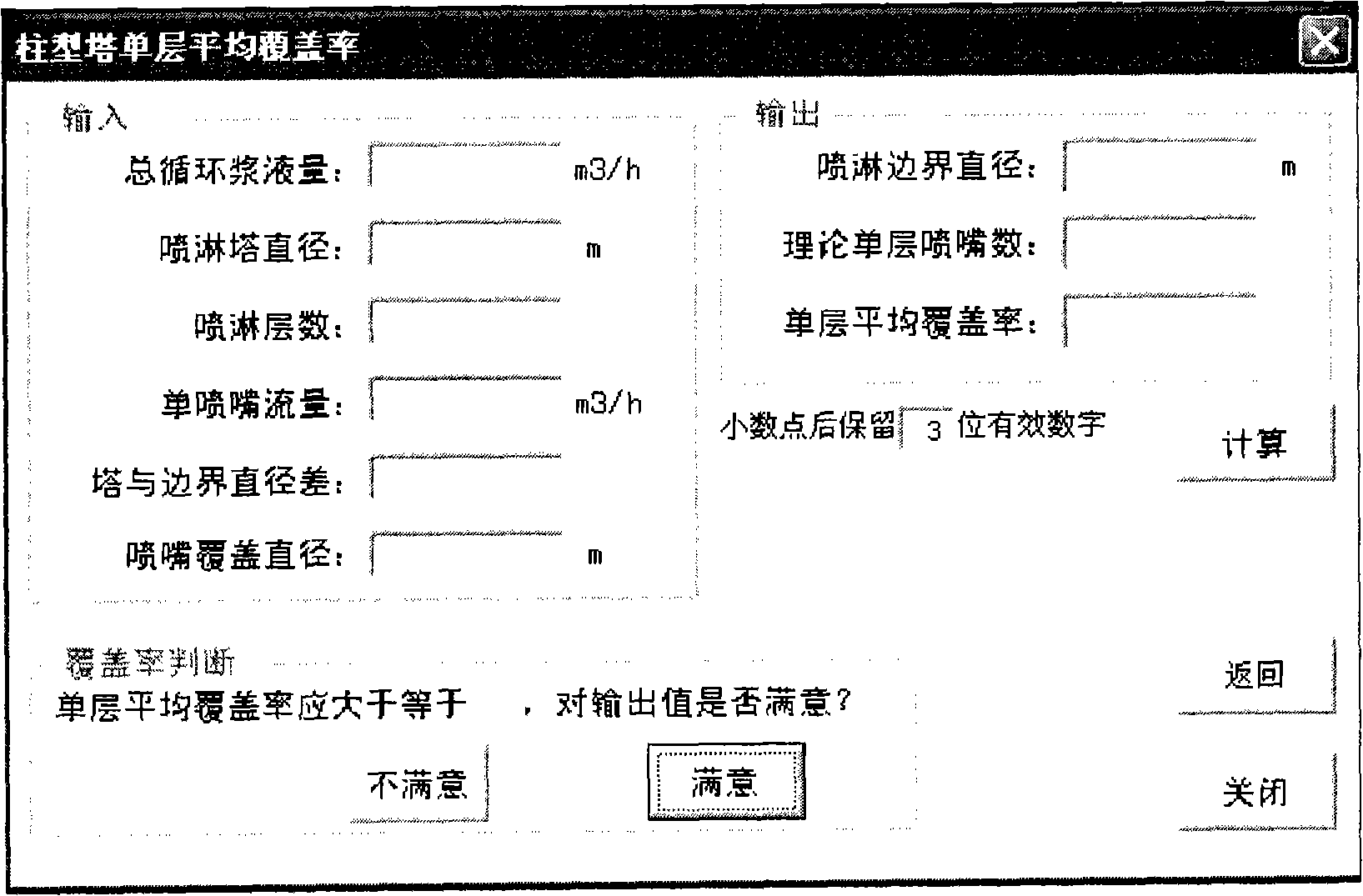

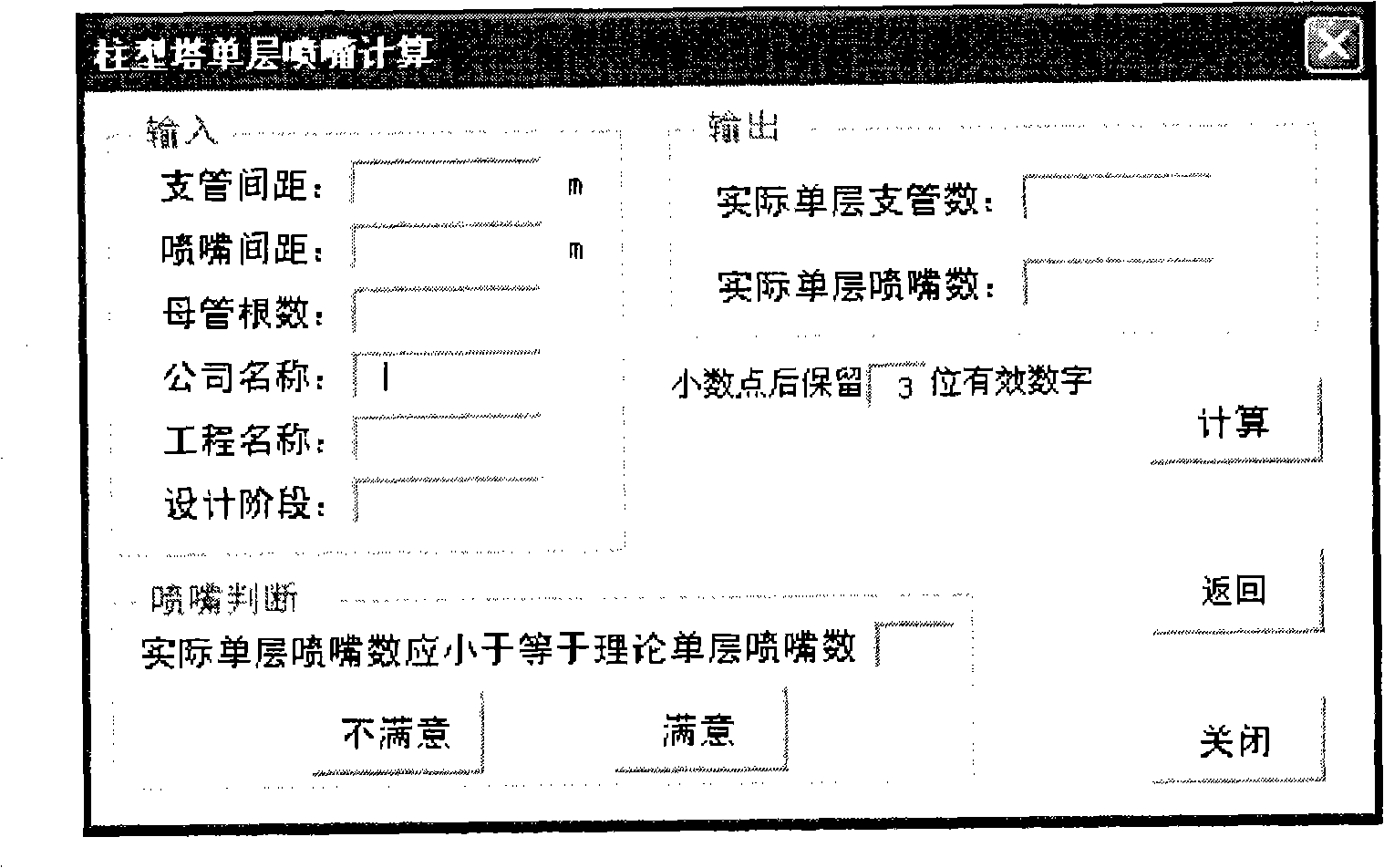

[0050] When designing the spray layer in the spray tower, it is usually necessary to design a spray layer layout diagram for each spray layer, such as Figure 8 The shown spray layer layout diagram generated according to an embodiment of the present invention is shown. Spray level layouts typically show the piping and nozzle layout, and optionally indicate various other l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com