Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Low self-corrosion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

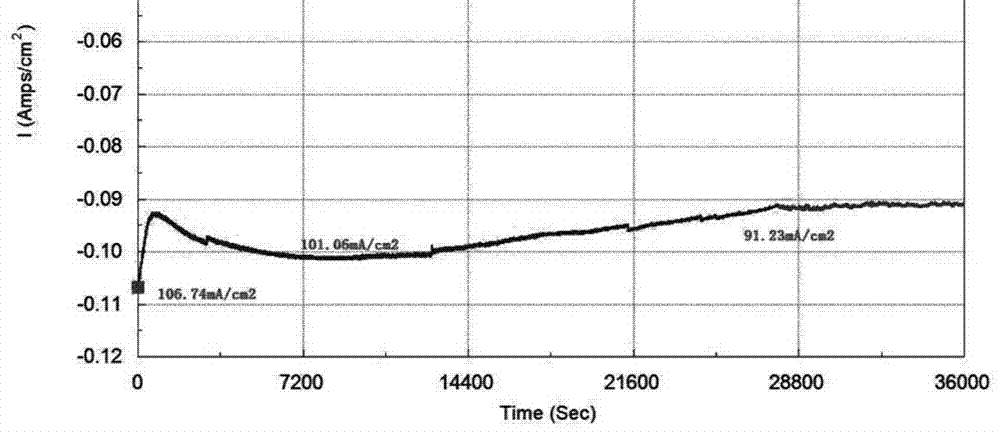

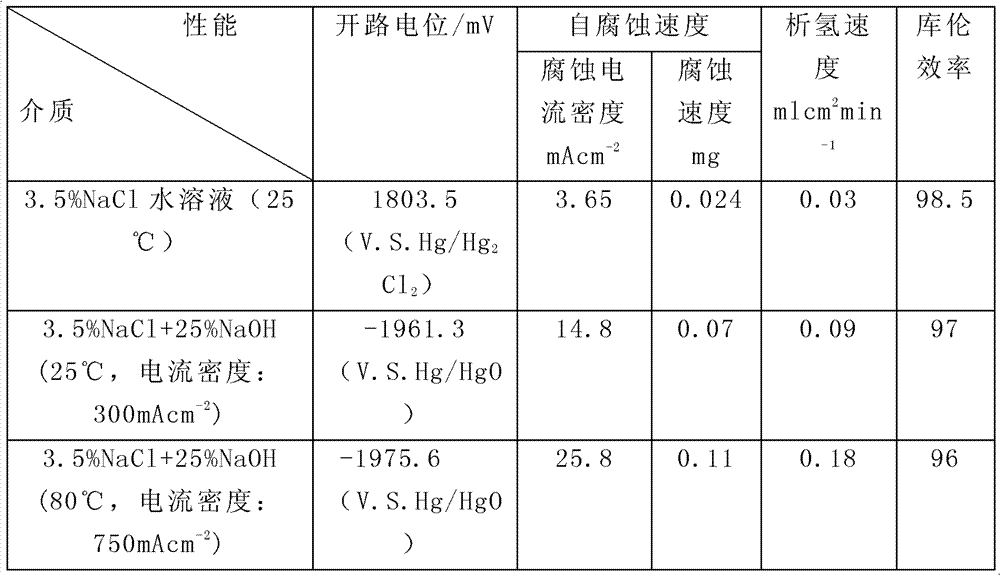

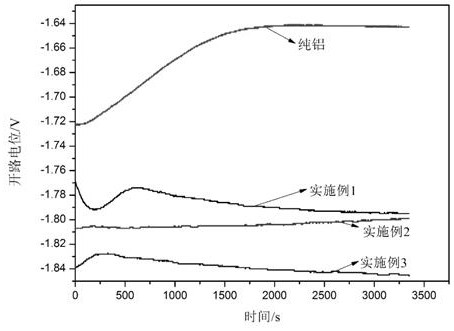

Electrolyte corrosion inhibitor for aluminum-air cell, electrolyte and preparation method

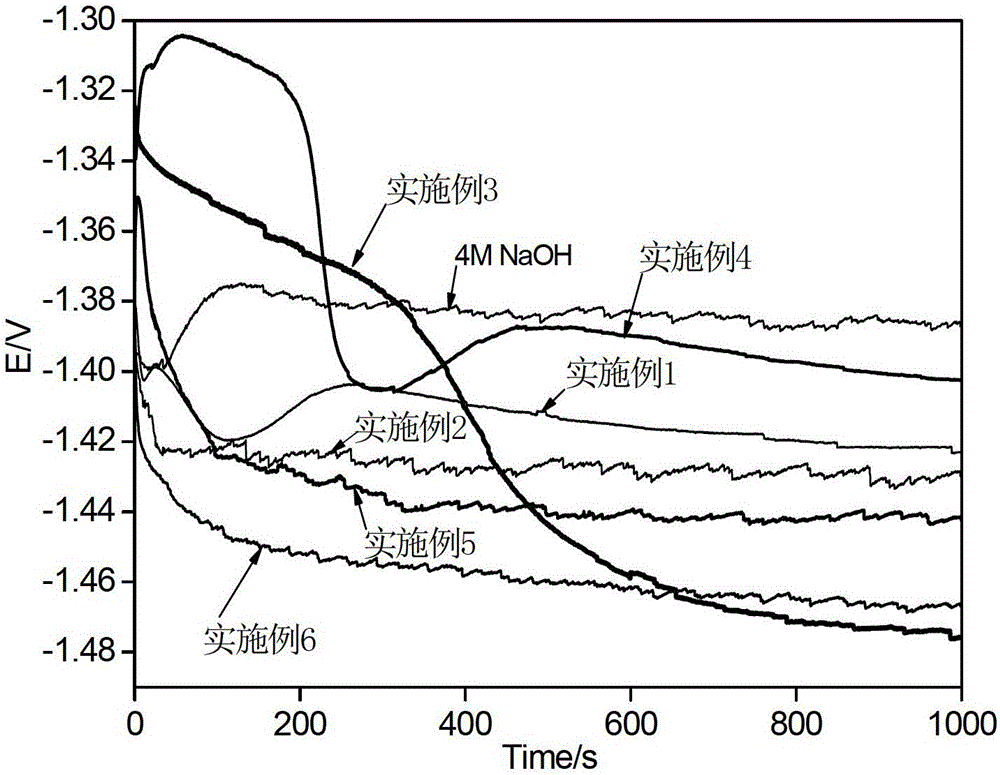

InactiveCN103633396AReduce hydrogen evolution self-corrosion rateProne to anodic polarizationFuel and primary cellsAluminum anodePhysical chemistry

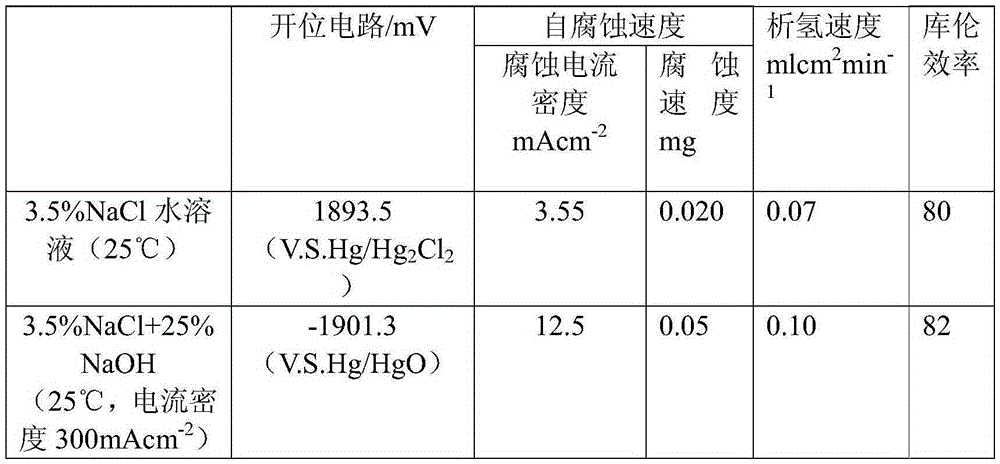

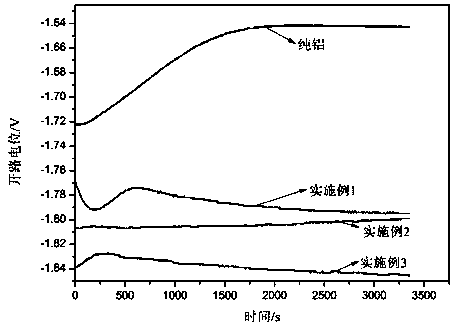

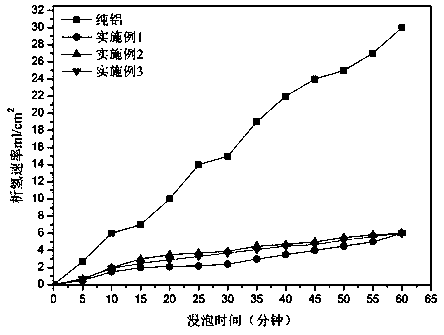

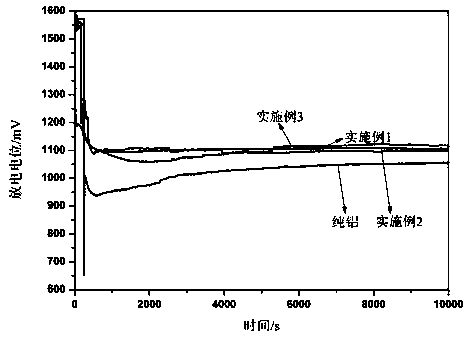

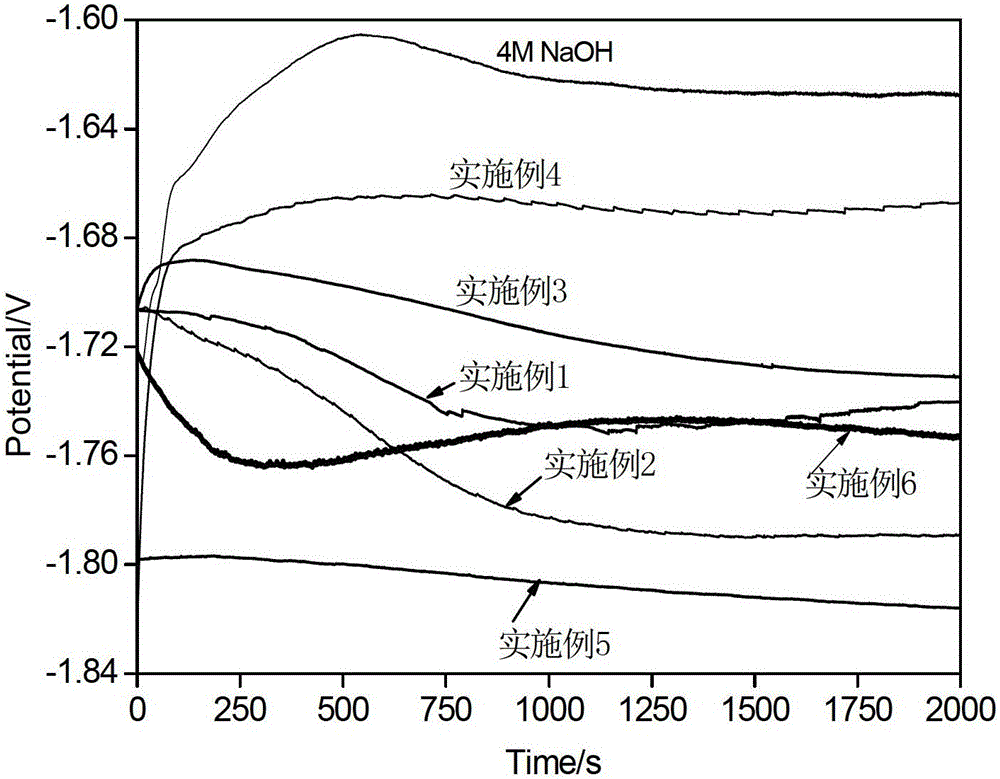

The invention discloses an electrolyte corrosion inhibitor for an aluminum-air cell, an electrolyte and a preparation method, belonging to the technical field of chemical batteries. The electrolyte corrosion inhibitor mainly comprises sodium hyposulfite which has a concentration of 0.005 to 0.2 mol / L in the electrolyte and may further comprise the auxiliary additive sodium stannate which has a concentration of 0.01 to 0.03 mol / L in the electrolyte. The aluminum-air cell provided by the invention has the advantages of simple composition, low cost, safety and accordance with environmental protection requirements, can substantially reduce the hydrogen evolution self-corrosion rate of an aluminum anode, enables the open circuit potential of the aluminum anode and working potential under the condition of impressed current to undergo substantial negative transfer, allows an aluminum anode alloy to have good corrosion resistance and high electrochemical activity and meets the requirement of an alkaline aluminum-air cell for large current density discharging.

Owner:HENAN UNIV OF SCI & TECH

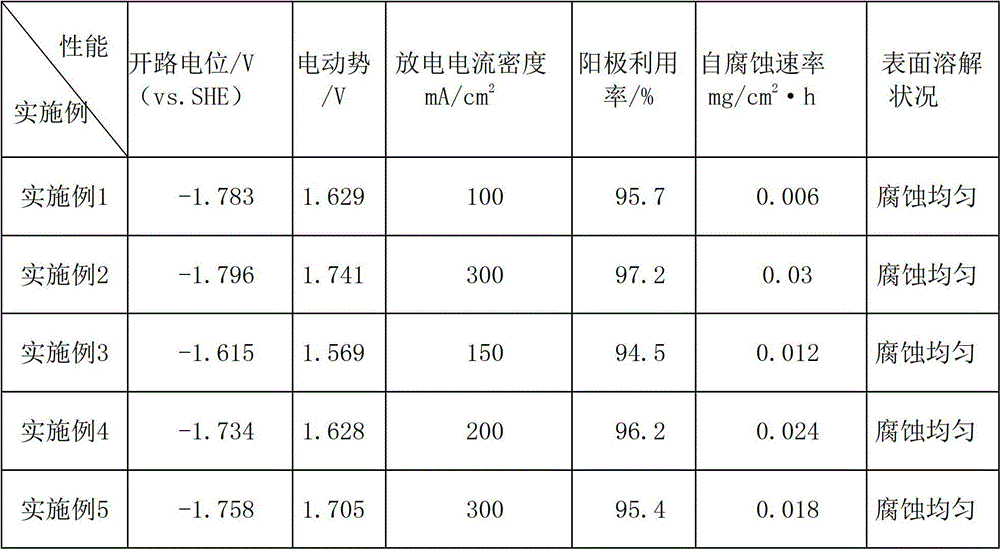

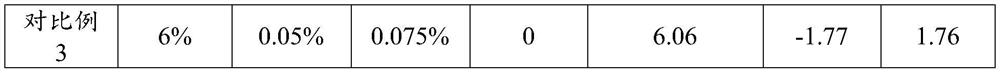

Manganese-aluminum containing anode material and preparation method thereof, as well as air cell prepared by using anode material

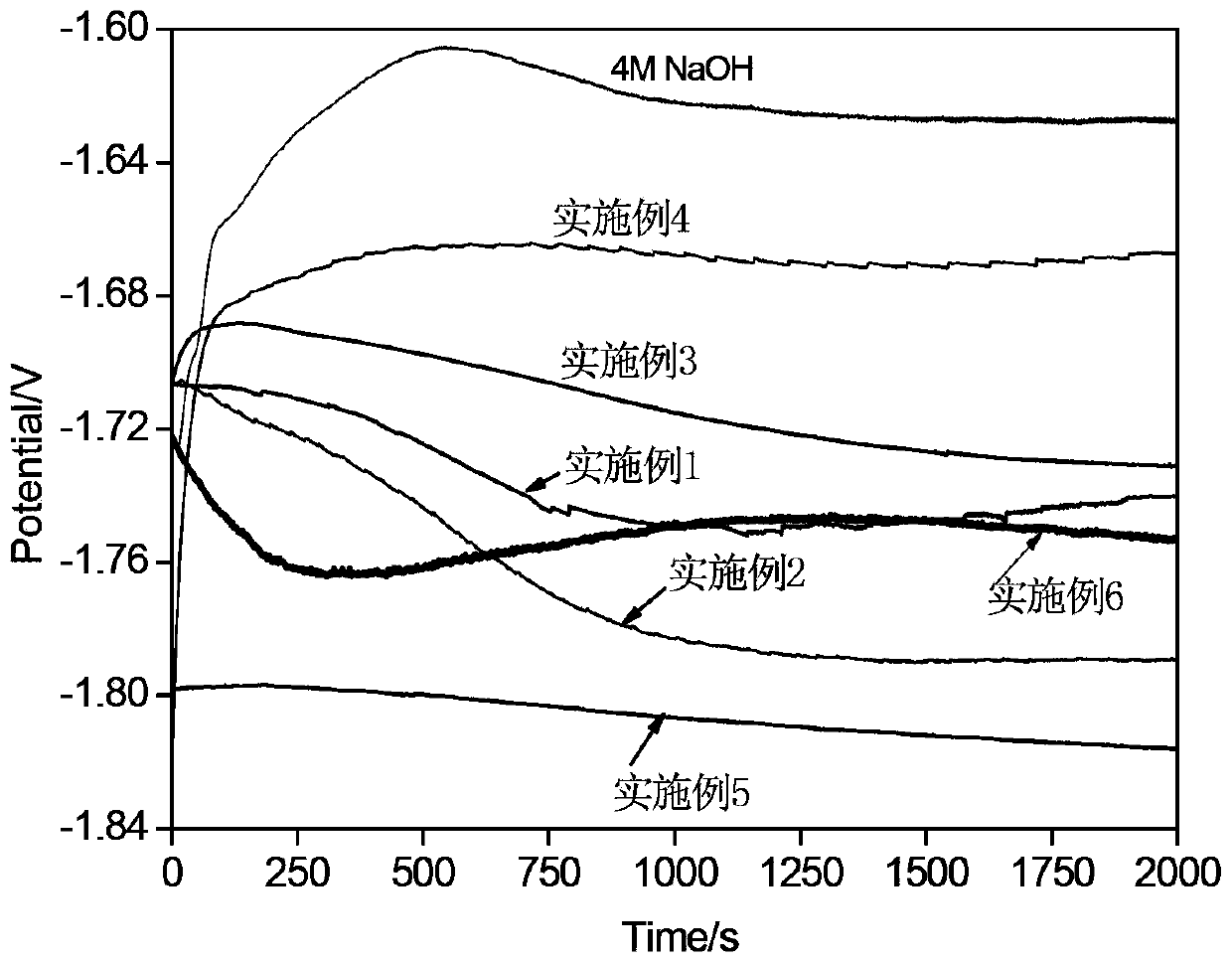

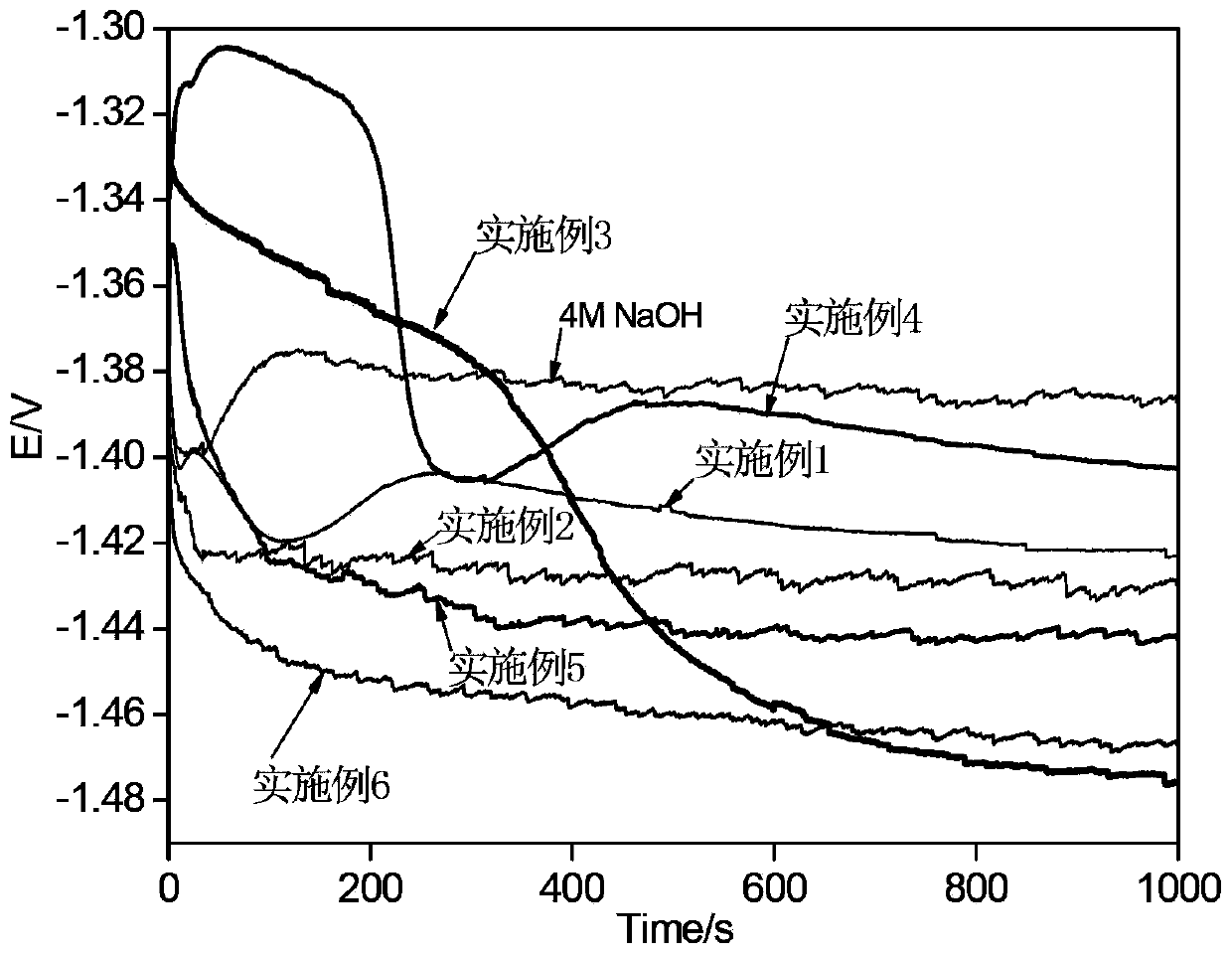

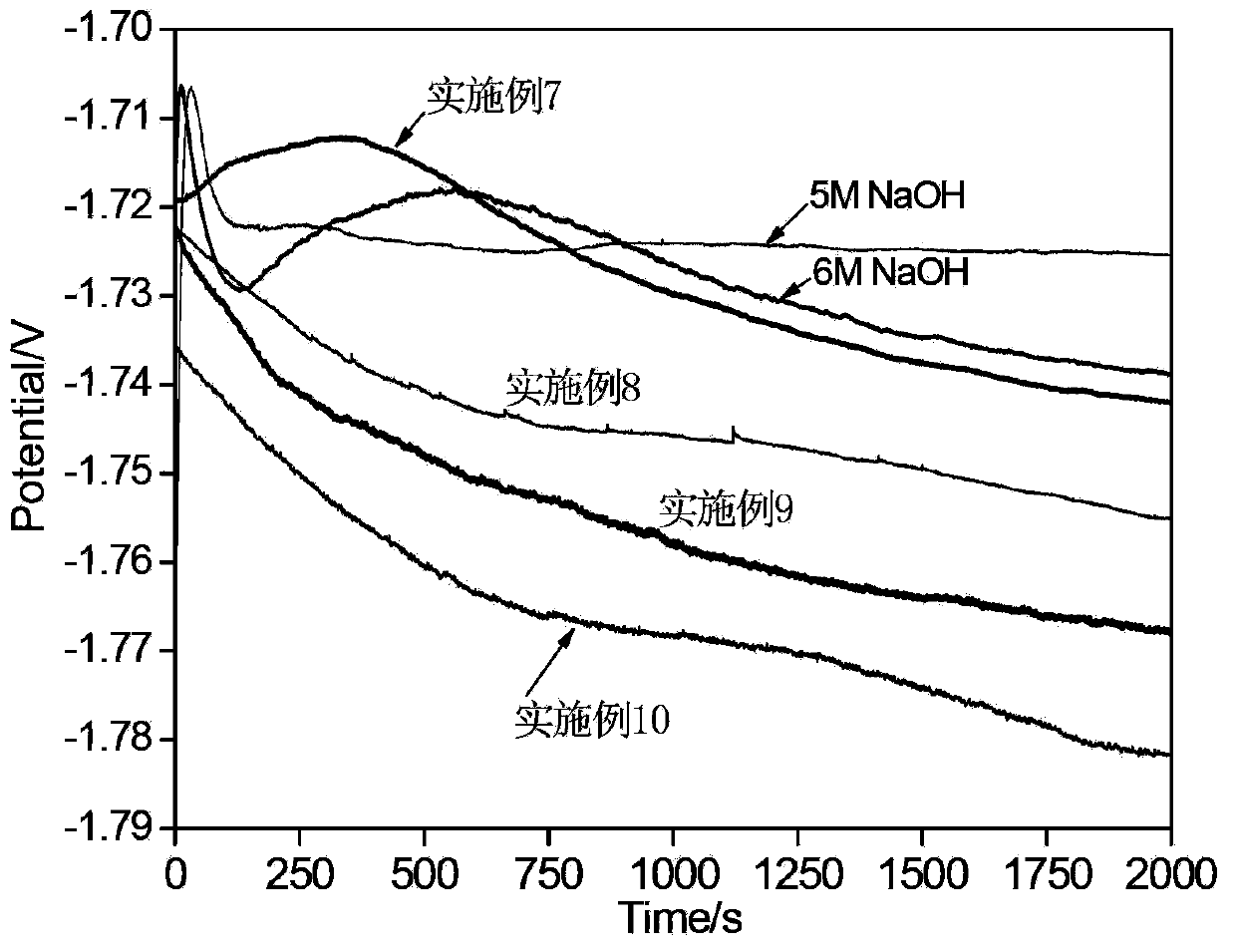

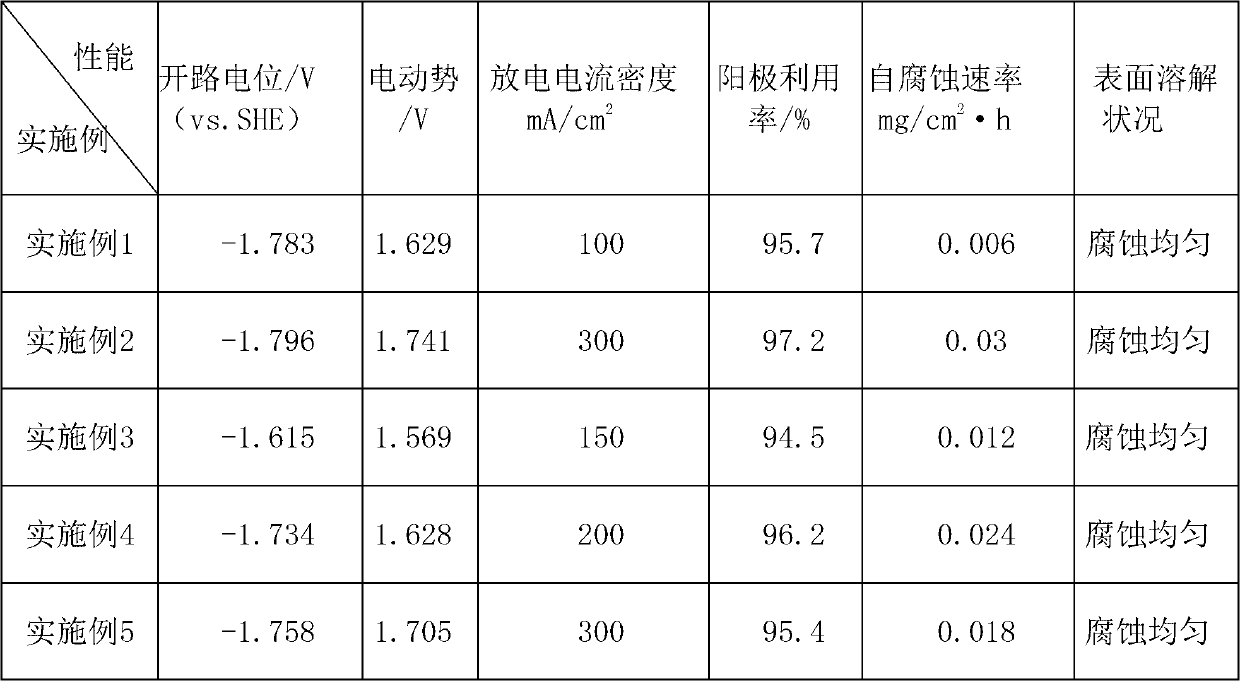

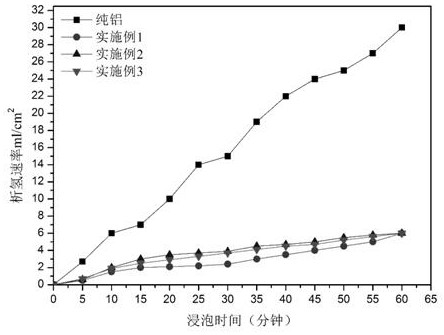

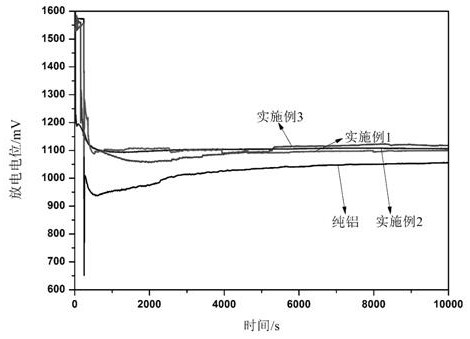

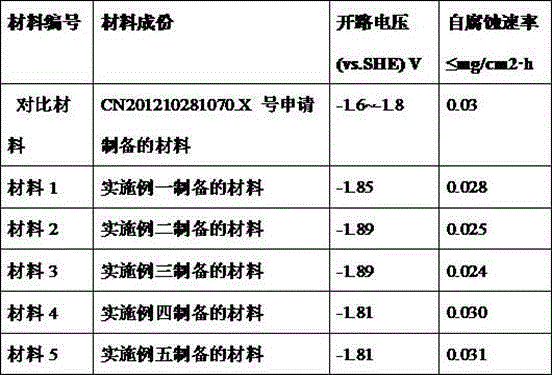

InactiveCN102820472AImprove performanceUniform surface corrosionFuel and primary cellsCell electrodesElectrolytic agentAir cell

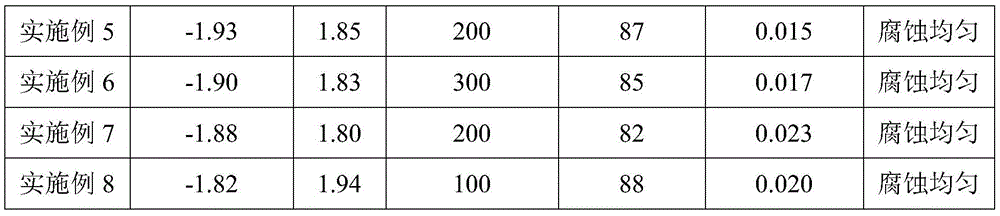

The invention discloses a manganese-aluminum containing anode material for an air cell, and a preparation method and an application of the manganese-aluminum containing anode material. The air cell comprises a manganese-aluminum containing anode, an air cathode and neutral electrolyte. The anode material comprises the following elements in percentage by weight: 0.05 to 2.5 percent of Mg, 0.05 to 1.5 percent of Sn, 0.05 to 2.5 percent of Ga, 0.1 to 1 percent of Mn and the balance of Al, and is prepared through an inert gases protection induction smelting method. With the adoption of the manganese-aluminum containing anode material, the open-circuit voltage is negative (minus 1.6 to minus 1.8V (vs.SHE)), the anode utilization is high (larger than or equal to 94%), the self-corrosion speed is low (smaller than or equal to 0.03mg / cm<2>*h), the surface corrosion is uniform, and the manganese-aluminum containing anode material belongs to high-performance anode material for the air cell operated in a neutral solution.

Owner:HENAN UNIV OF SCI & TECH

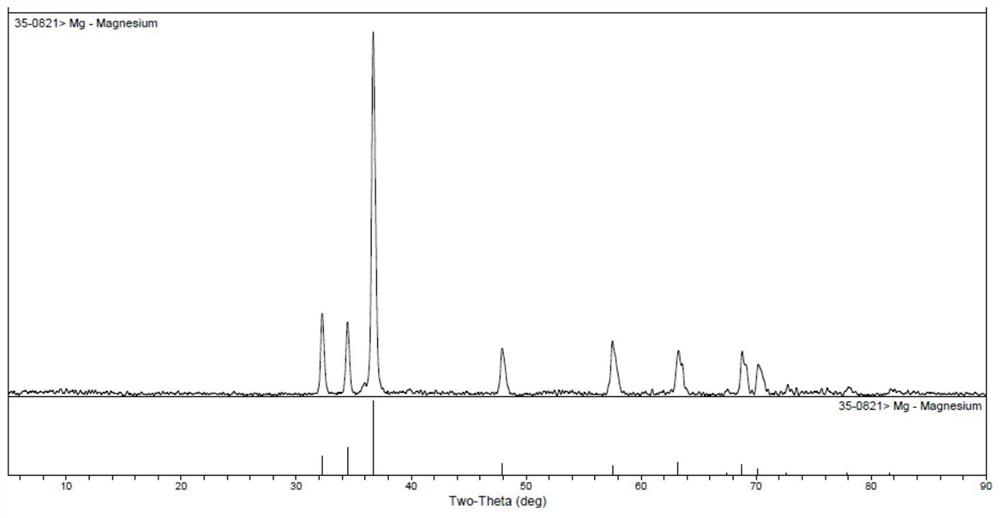

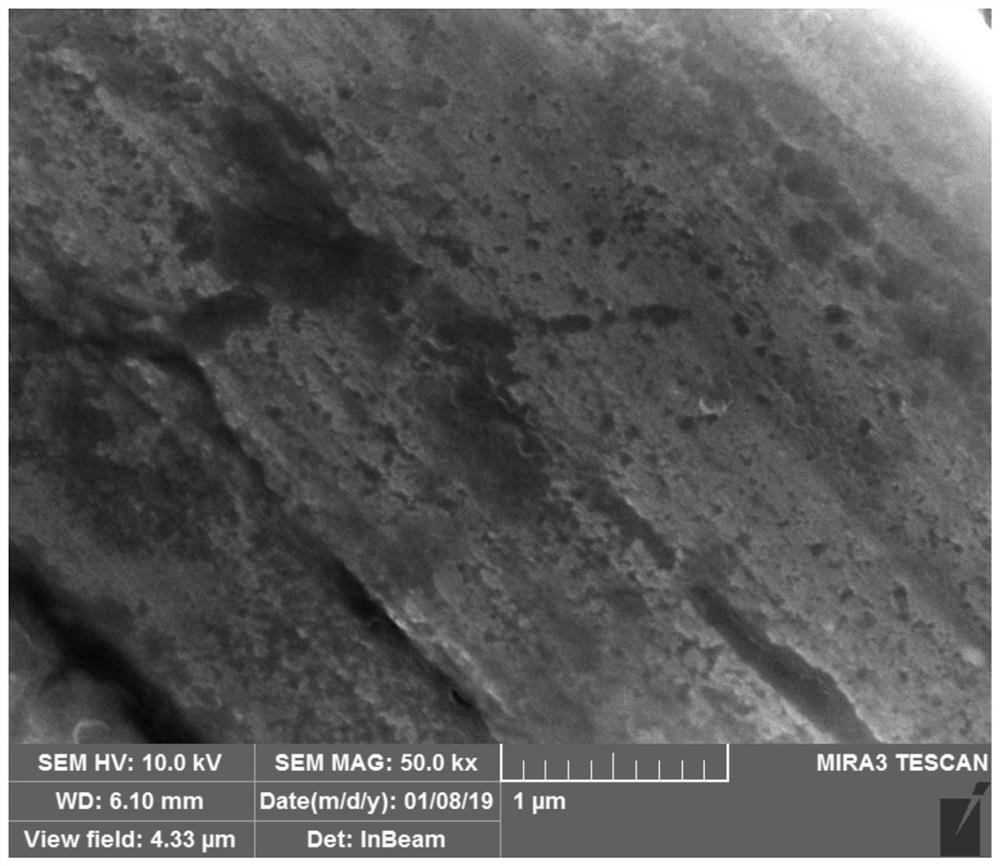

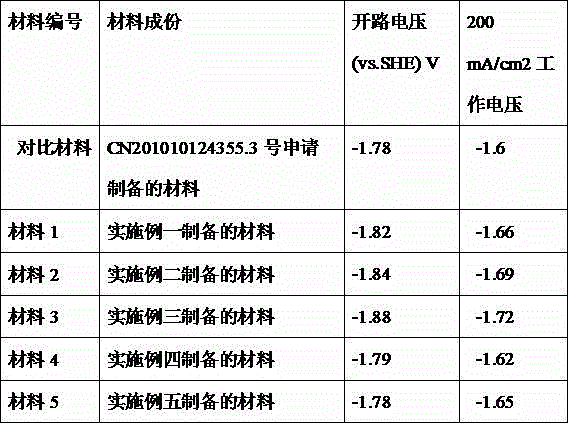

Rare earth-containing amorphous/nanocrystal aluminum anode composite material, preparation method and aluminum air battery

InactiveCN104372206AImprove electrochemical performanceAbundant resourcesFuel and primary cellsCell electrodesRare-earth elementDissolution

The present invention discloses a rare earth-containing amorphous / nanocrystal aluminum anode composite material, a preparation method and an aluminum air battery, and belongs to the techncial field of air batteries. The aluminum anode composite material comprises, by weight, 0.5-5% of Mg, 0.02-2% of Sn, 0.02-2% of Ga, 0.1-5% of La or Ce, and the balance of Al. According to the present invention, aluminum with the purity of more than or equal to 99.8% is adopted as the base, the trae amounts of Mg, Sn, Ga and the rare earth element La or Ce are added so as to reduce the self-corrosion rate and improve the electrochemical property and the surface dissolution uniformity of the alloy, especially the trae amount of the rare earth element is added to the aluminum alloy, and the addition of the rare earth element to the aluminum has effects of oxygen removing, hydrogen removing, desulfuration, melting rate accelerating, metal burning loss reducing, change of species distribution and refinement modification of iron and other harmful impurities, and the like so as to slow down the self-corrosion of the aluminum alloy, such that the anode utilization rate is improved.

Owner:HENAN UNIV OF SCI & TECH

Method for preparing rare-earth aluminum alloy electrode material

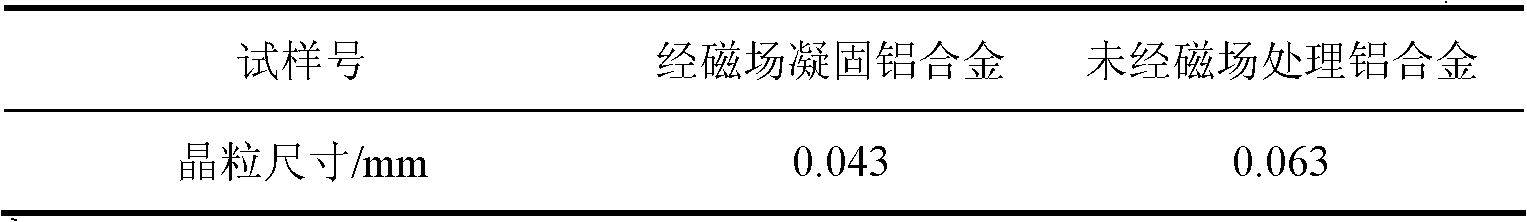

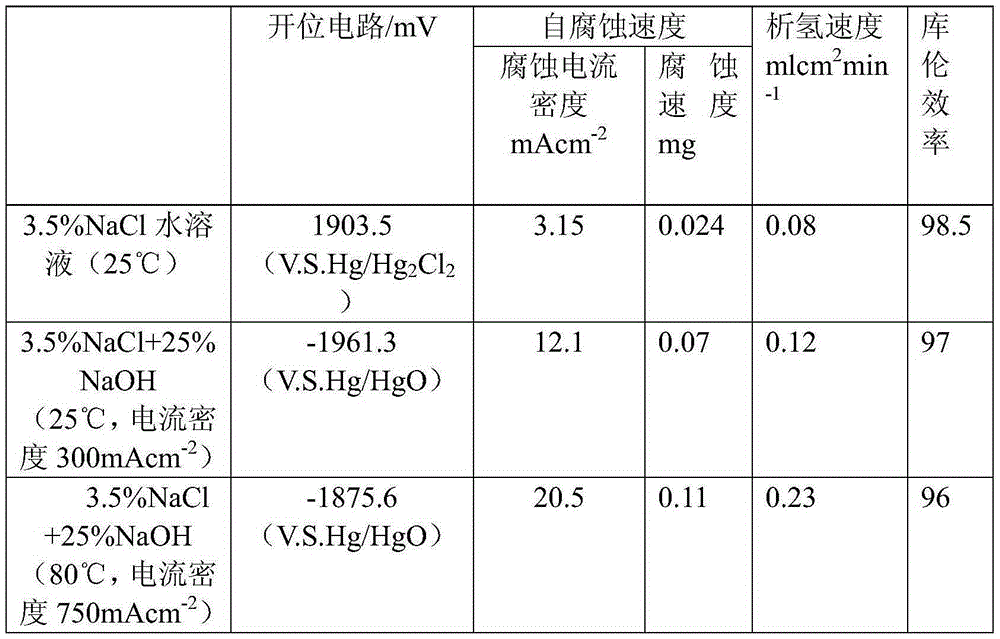

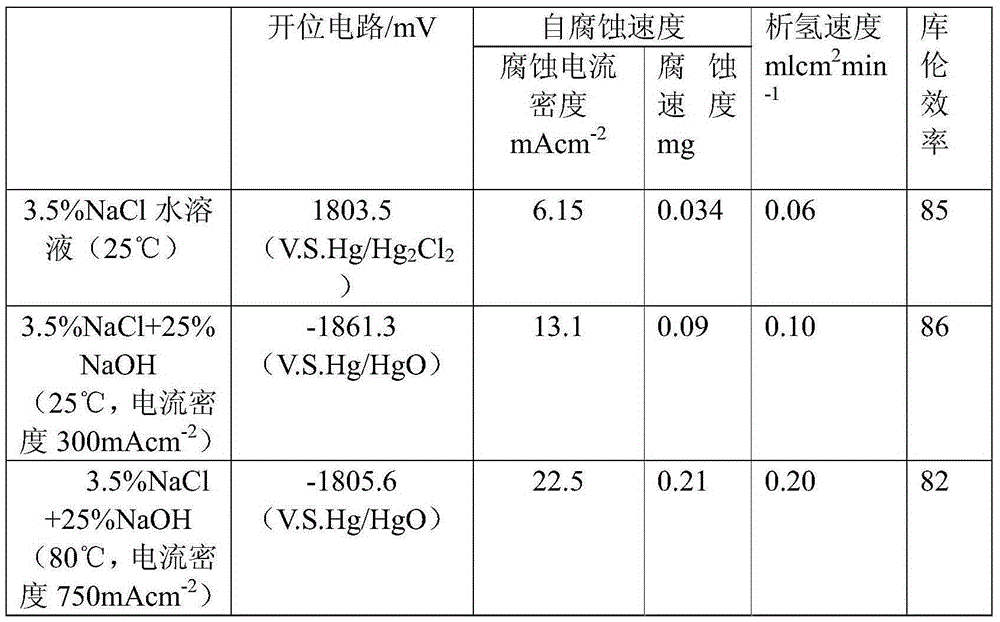

The invention provides a method for preparing a rare-earth aluminum alloy electrode material. Aluminum (CP level) with purity of more than or equal to 99.9 percent, serving as a raw material, is added with the following elements in percentage by mass: 0.05 to 49 percent of Zn, 0.05 to 0.15 percent of Ga, 0.05 to 0.20 percent of In, 0.01 to 0.10 percent of Pb, 0.05 to 0.30 percent of Mn, 0.05 to 0.30 percent of Sn and 0.20 to 0.50 percent of Re; and the mass content of impurities is less than or equal to 0.01 percent. According to the method, the rare-earth aluminum alloy electrode material is prepared by adopting doping of rare-earth elements, and the rare-earth aluminum alloy electrode material with excellent performance is obtained by solidification treatment of an external magnetic field so as to provide material support for practical application of an aluminum fuel cell. By the solidification treatment of the external magnetic field for the rare-earth aluminum alloy electrode material, the polarization performance of aluminum alloy electrodes can be improved, hydrogen evolution corrosion can be inhibited, the utilization rate of an anode is improved, and the working potential is increased.

Owner:CENT SOUTH UNIV

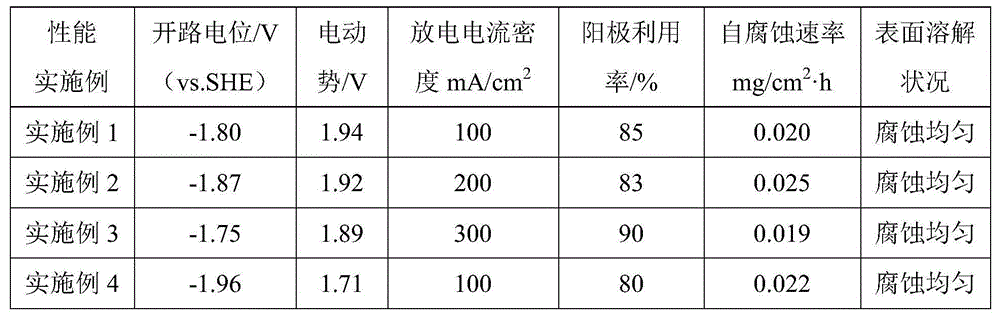

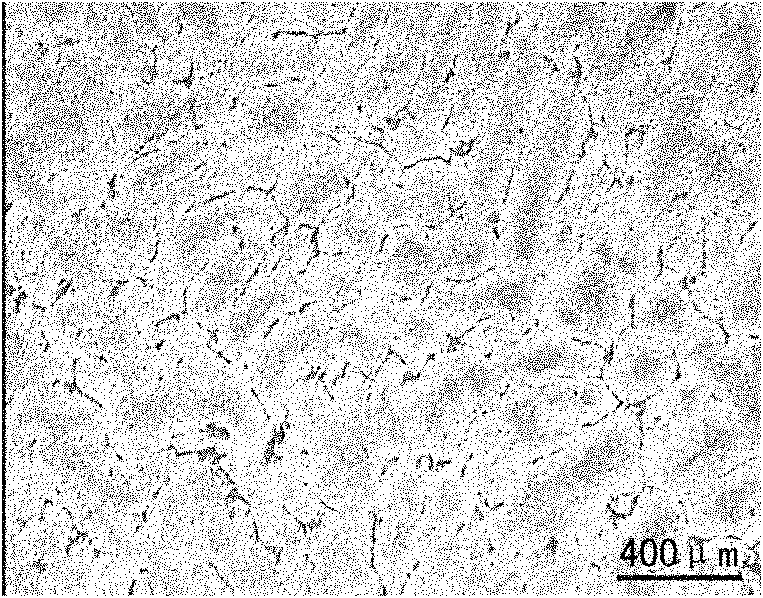

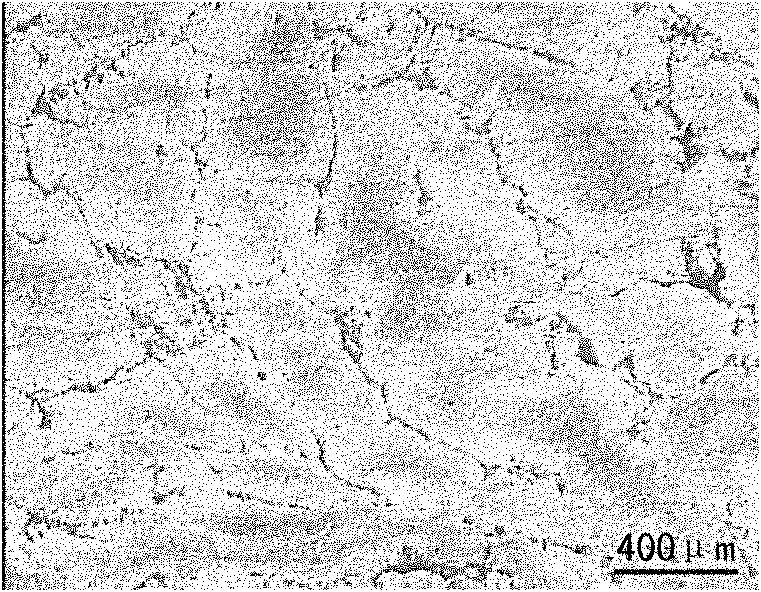

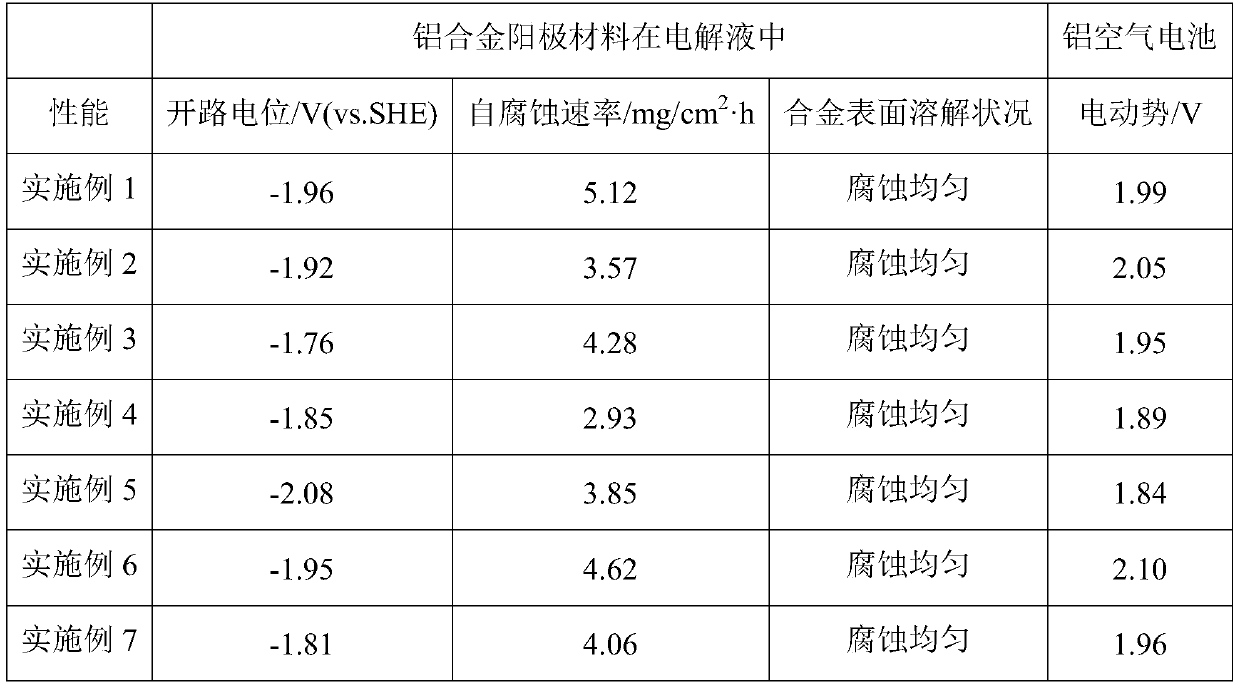

Aluminum alloy anode material for air cell, preparation method and aluminum air cell

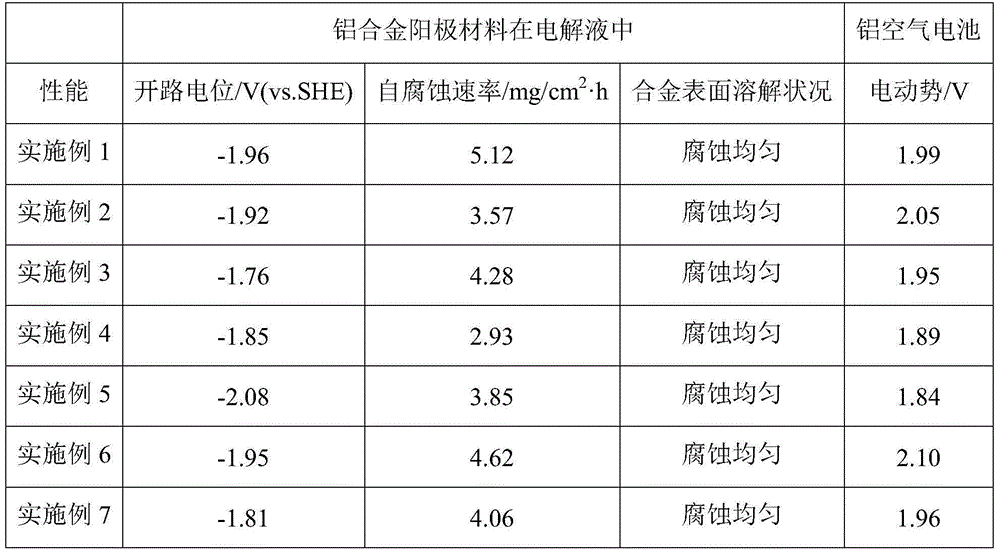

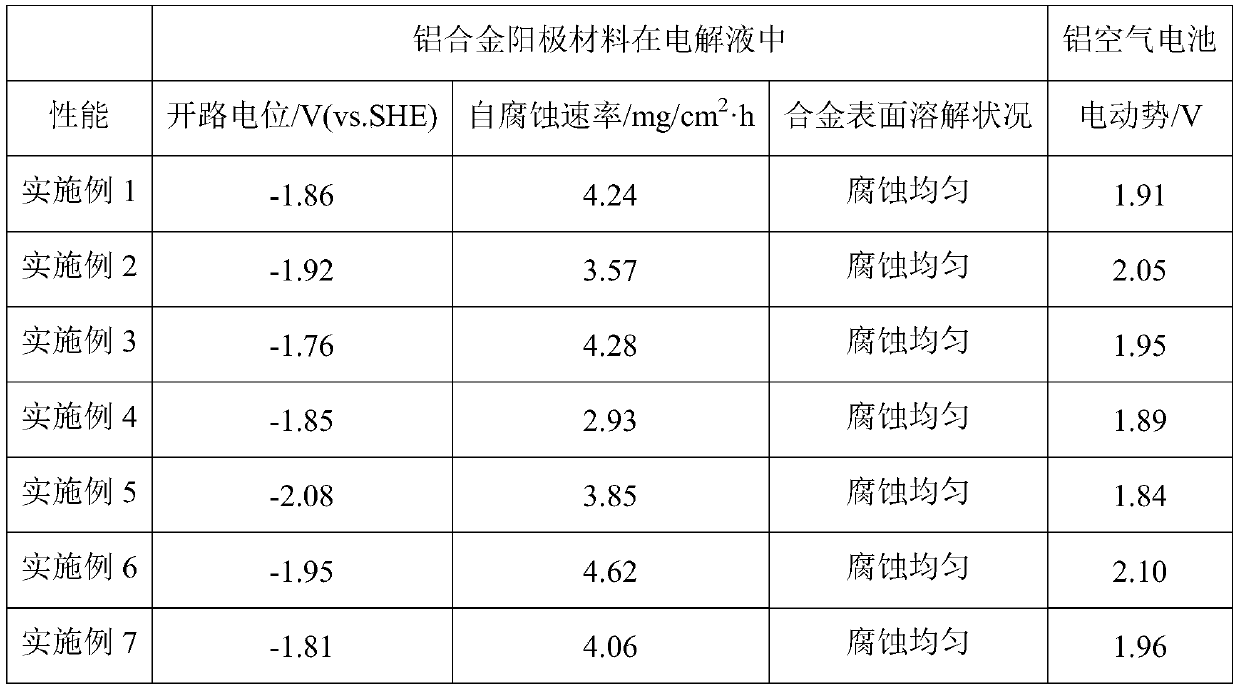

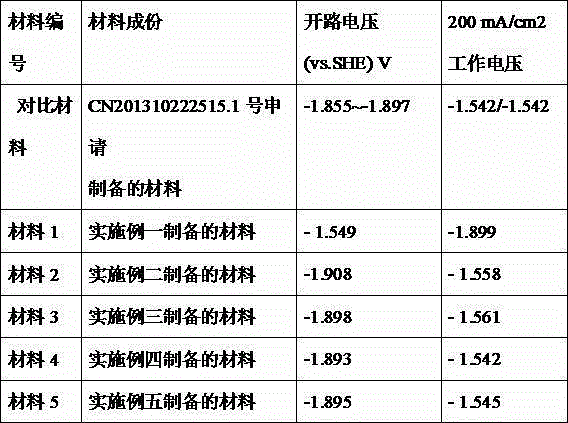

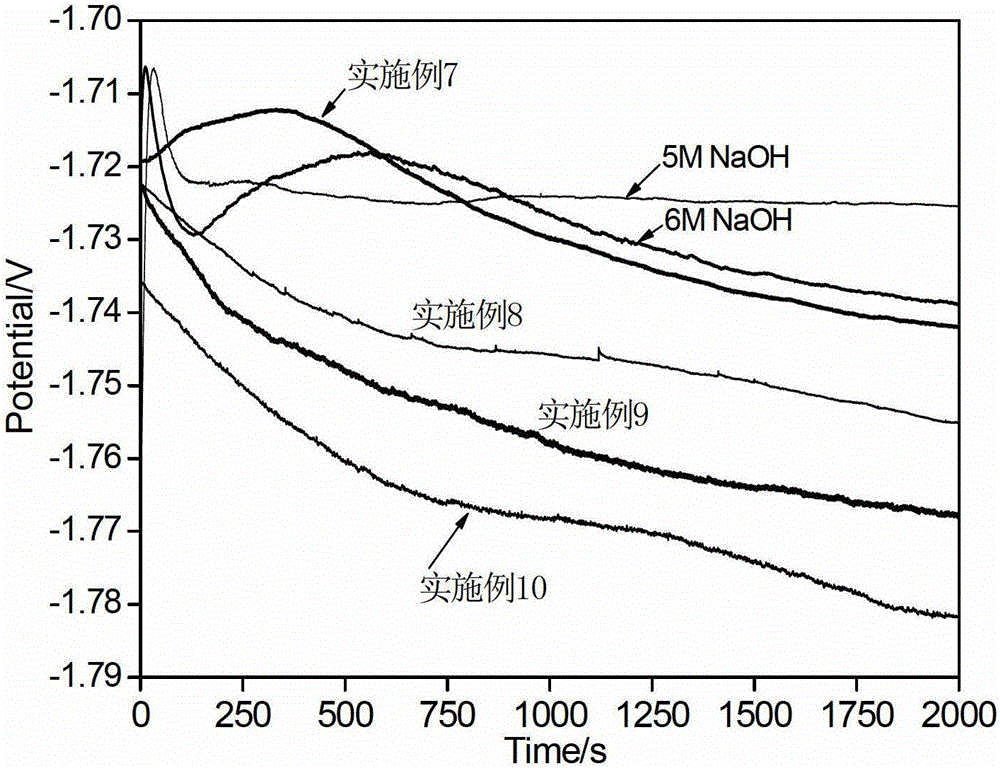

InactiveCN105140596AImprove performanceImprove electrochemical activityFuel and primary cellsCell electrodesIndiumElectromotive force

The invention discloses an aluminum alloy anode material for an air cell, a preparation method and an aluminum air cell. The aluminum alloy anode material is composed of the following ingredients, by weight, 0.05%-6% of Zn, 0.05%-4% of Ga and 0.01%-2% of In, the balance being Al. Zn, Ga and In elements are added in the aluminum alloy anode material, the electrochemical activity is good, the self-corrosion rate is low, the open circuit potential is less than and equal to -1.76V (vs.SHE) in an alkaline electrolyte, and an electromotive force of a monomer cell is more than 1.84V. Through alloying, the electrochemical performance of the anode is raised obviously, the self-corrosion rate is lowered, the self-corrosion rate is less than 5.12mg / (cm<2>*h), and surface corrosion is uniform. The aluminum alloy anode material has excellent performances, and is a novel aluminum alloy anode material suitable for usage in an alkaline electrolyte.

Owner:HENAN UNIV OF SCI & TECH

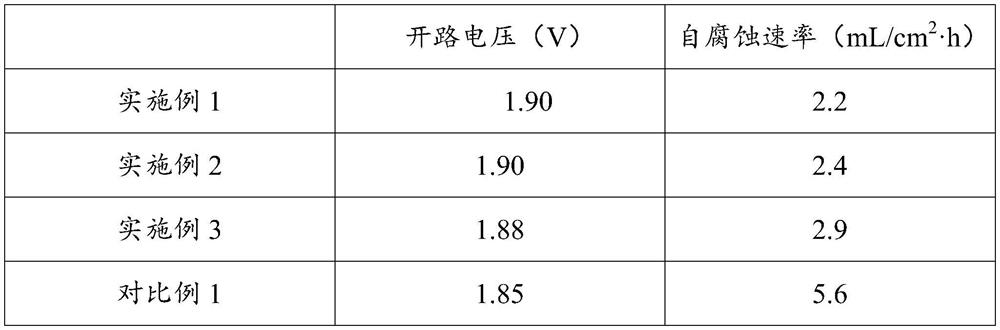

Aluminum-alloy anode material for battery and preparation method of aluminum-alloy anode material

InactiveCN105244489ACompatibility is reasonableImprove electrochemical performanceCell electrodesElectrochemistryCorrosion

The invention provides an aluminum-alloy anode material for a battery and a preparation method of the aluminum-alloy anode material, belonging to the technical field of an alloy material and solving the problem of non-ideal electrochemical performance of the traditional aluminum-alloy anode material for the battery. The aluminum-alloy anode material comprises the following constitutes based on mass: 0.5-1.0% of Mg, 0.1-1.0% of Ga, 0.5-1.0% of Bi, 0.05-0.8% of Ce, 0.005-1.0% of Pb, 0.005-0.05% of Ca and the balance of Al. The aluminum-alloy anode material for the battery has the advantages of high open circuit potential, low self-corrosion rate, high utilization rate of a positive electrode and the like.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Aluminum air battery anode material and preparing method thereof

ActiveCN109321766AExcellent electrochemical performanceLow self-corrosion rateFuel and primary cellsCell electrodesAluminiumMachining process

The invention discloses an aluminum air battery anode material and a preparing method thereof. The aluminum air battery anode material comprises, by mass percent, 0.10%-0.15% of bismuth, 0.10%-0.15% of lead, 0.015%-0.035% of gallium and the balance aluminum. The anode material is prepared through the machining processes of mixing, smelting, rolling and heat treatment. The anode material componentdesign is reasonable, the cost is low, the product performance is good, the preparing process is simple, and the aluminum air battery anode material and the preparing method of the aluminum air battery anode material are suitable for large-scale industrial production.

Owner:KUNMING UNIV OF SCI & TECH

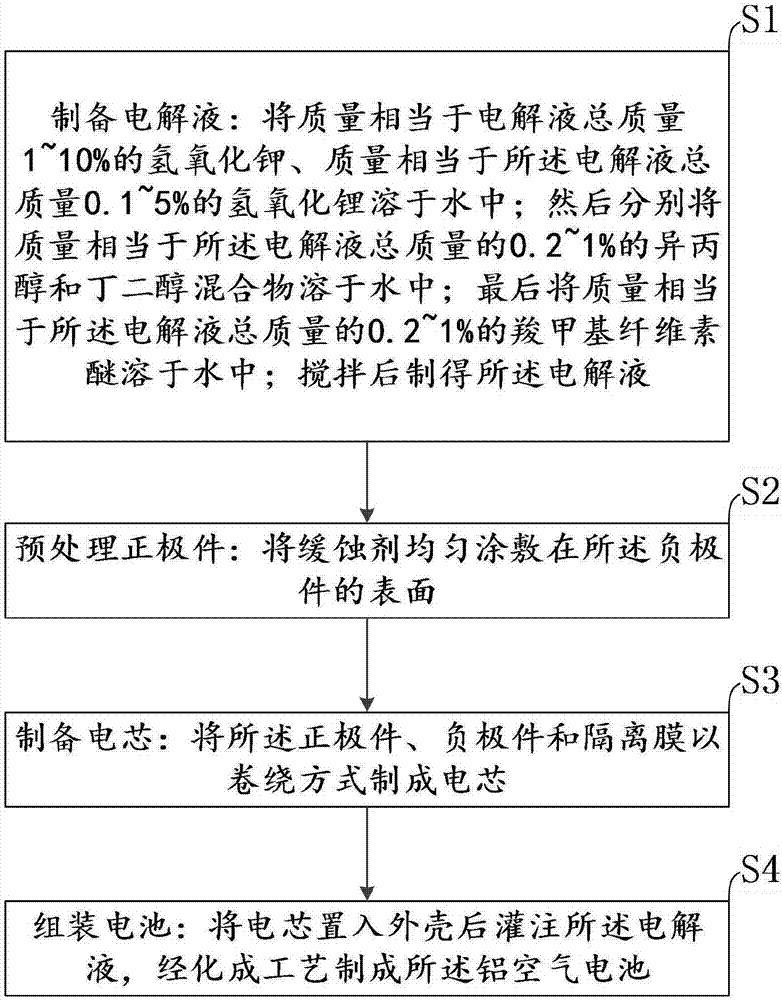

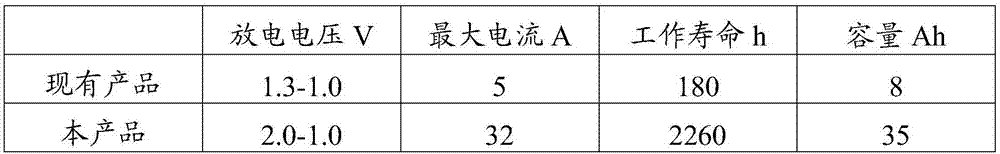

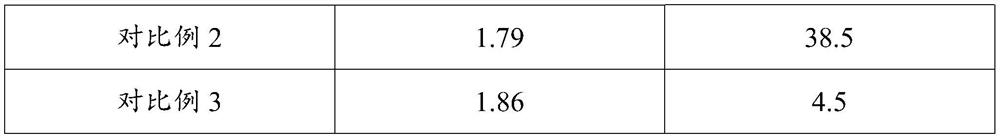

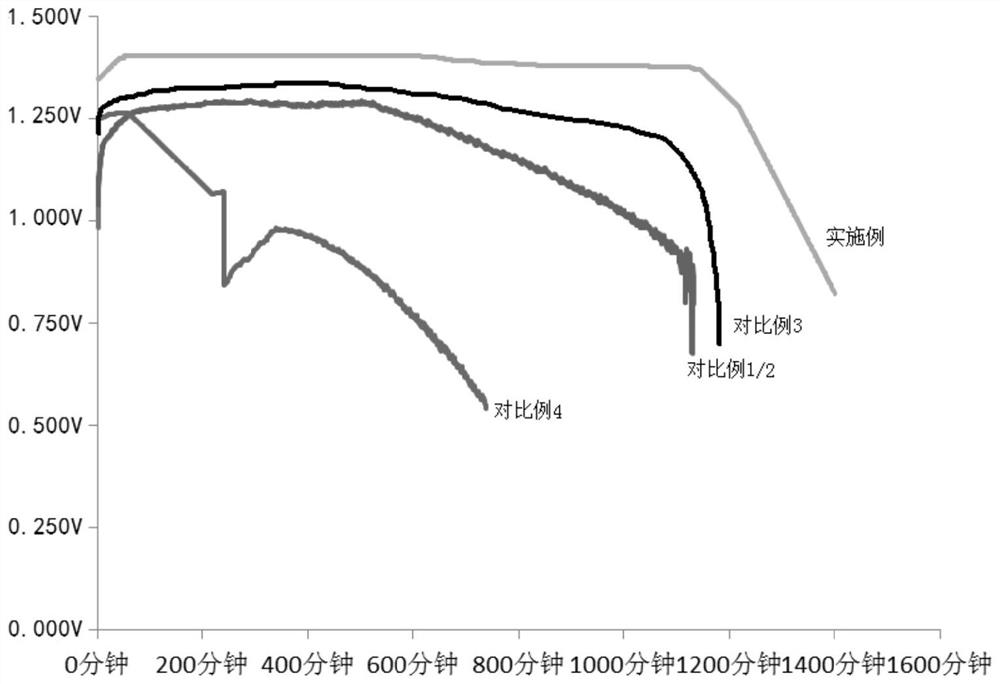

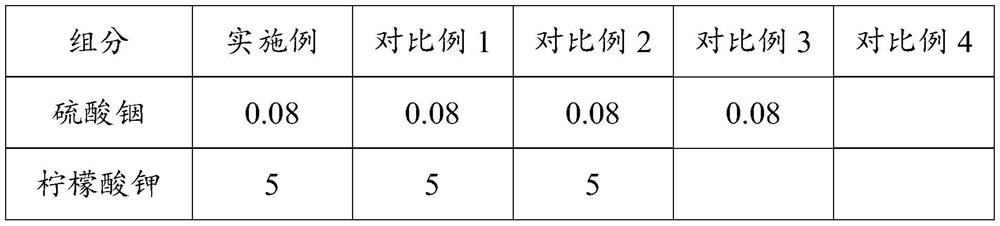

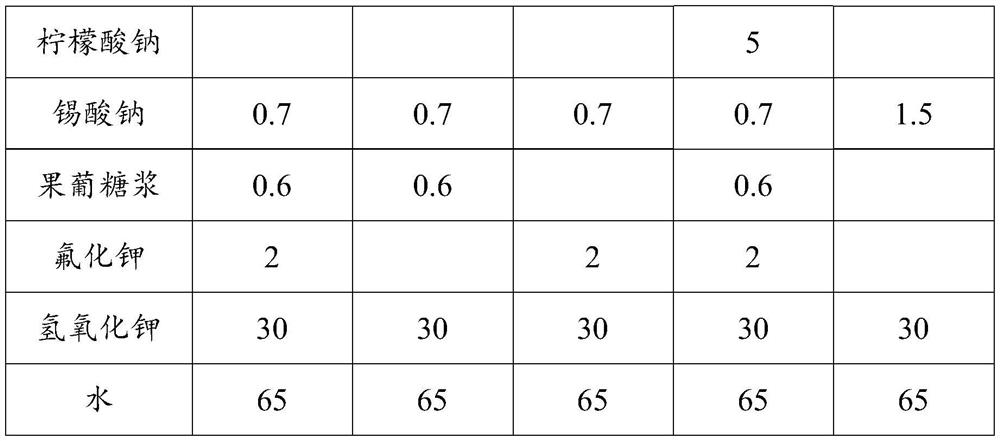

Aluminum-air battery electrolyte, aluminum-air battery and manufacturing method thereof

InactiveCN107275720AReduce alkalinityLow self-corrosion rateFuel and primary cellsCell electrodesLithium hydroxidePotassium hydroxide

The invention discloses aluminum-air battery electrolyte, an aluminum-air battery and a manufacturing method thereof. The electrolyte contains potassium hydroxide, inorganic solvents, lithium hydrate, a corrosion inhibitor, a stabilizing agent and a thickening agent, wherein the mass of the potassium hydroxide accounts for 1 to 10 percent of the total weight of the hydroxide; the mass of the lithium hydrate accounts for 0.1 to 5 percent of the total mass of the hydroxide. The aluminum-air battery electrolyte, the aluminum-air battery and the manufacturing method have the advantages that the alkalinity of the electrolyte is reduced through the use of a mixed solution of the lithium hydrate and the potassium hydroxide; the self-corrosion speed of the metal aluminum electrode is reduced; the stability of the electric conductivity is ensured; the mixed liquid of stannate and glucose is used as a corrosion inhibitor, and the use of the inorganic corrosion inhibitor is reduced, so that the production cost is reduced.

Owner:深圳市航盛新材料技术有限公司

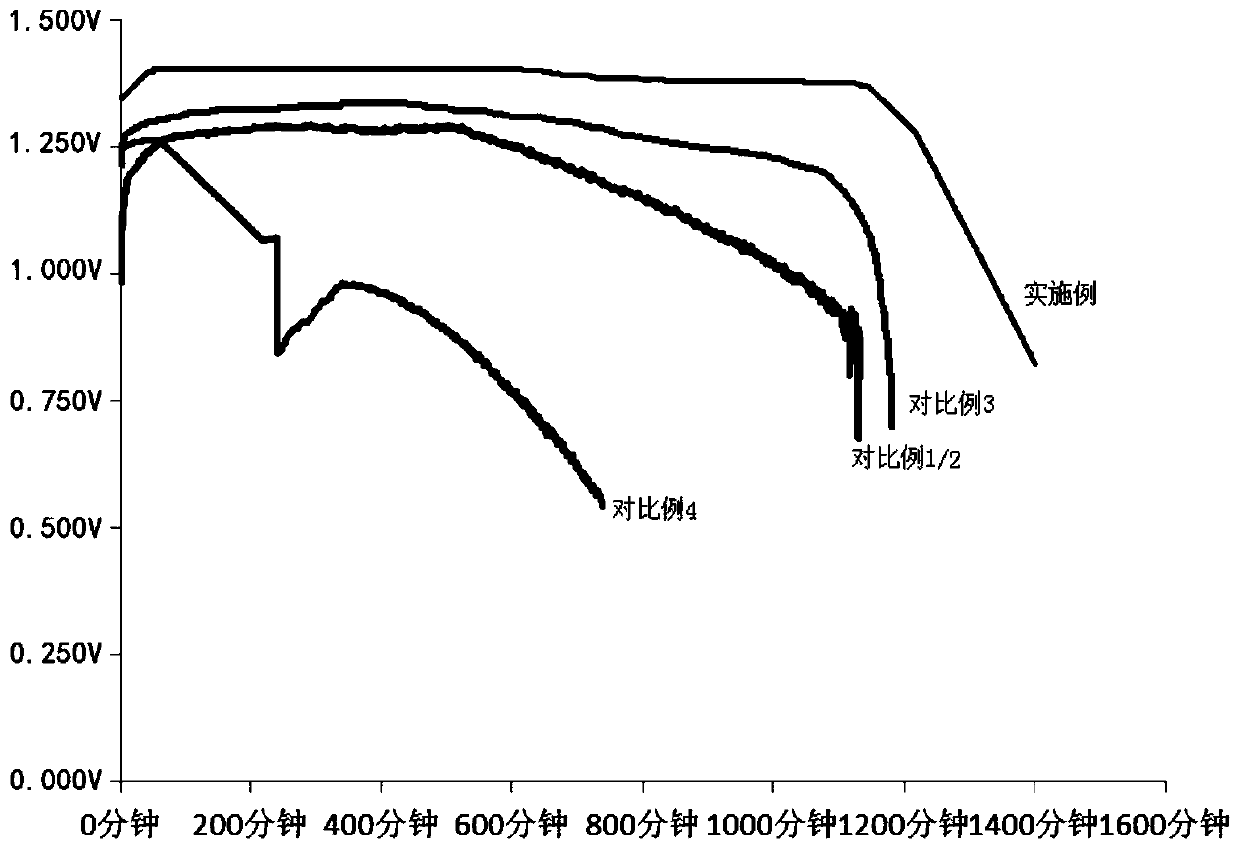

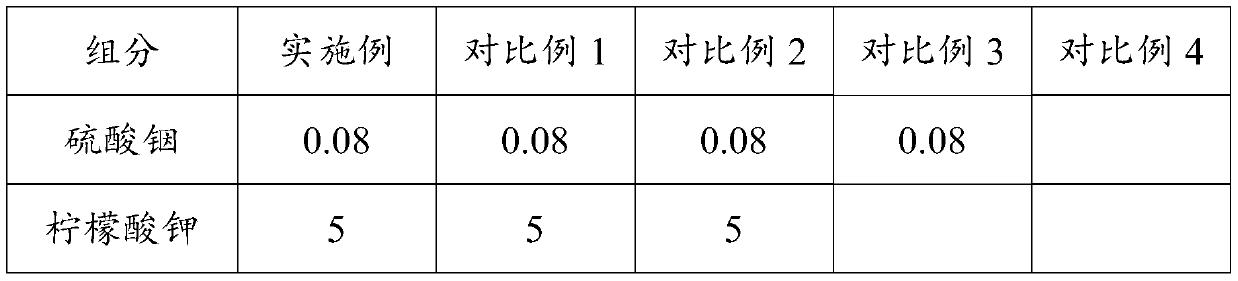

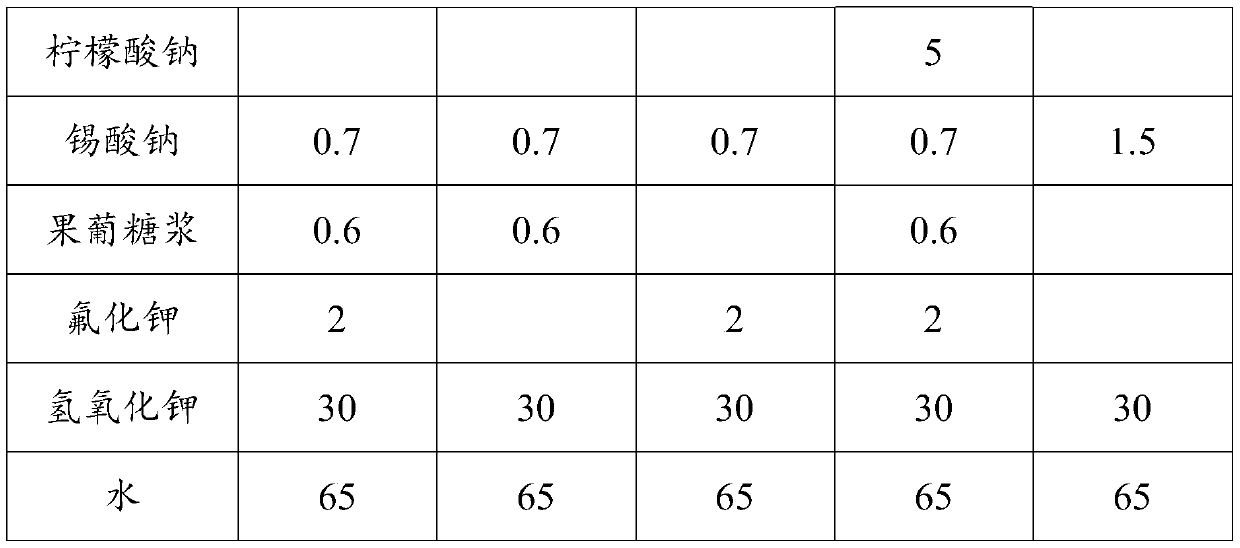

Alkaline electrolyte for aluminum-air battery and aluminum-air battery

ActiveCN110165340ALow self-corrosion rateImprove discharge performanceFuel and primary cellsAqueous electrolyte cellsAluminum anodeHigh-fructose corn syrup

The invention discloses an alkaline electrolyte for an aluminum-air battery and the aluminum-air battery. The alkaline electrolyte comprises a corrosion inhibitor and an alkaline electrolyte solution.The corrosion inhibitor is prepared by compounding sodium stannate, potassium citrate, high fructose corn syrup and potassium fluoride. The corrosion inhibitor can effectively reduce the self-corrosion rate and aluminum anode polarization of an aluminum plate and improve the discharge performance of the aluminum-air battery.

Owner:CHANGZHOU YOUTEKE NEW ENERGY TECH

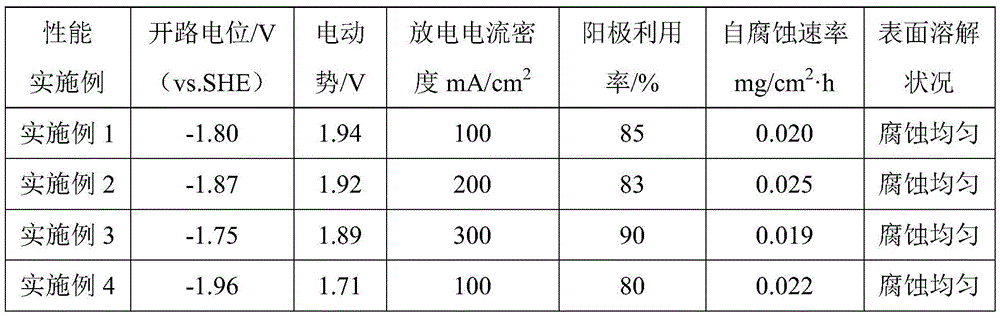

A kind of aluminum alloy anode material for air battery, preparation method and aluminum air battery

InactiveCN105140596BImprove performanceImprove electrochemical activityFuel and primary cellsCell electrodesIndiumElectromotive force

The invention discloses an aluminum alloy anode material for an air cell, a preparation method and an aluminum air cell. The aluminum alloy anode material is composed of the following ingredients, by weight, 0.05%-6% of Zn, 0.05%-4% of Ga and 0.01%-2% of In, the balance being Al. Zn, Ga and In elements are added in the aluminum alloy anode material, the electrochemical activity is good, the self-corrosion rate is low, the open circuit potential is less than and equal to -1.76V (vs.SHE) in an alkaline electrolyte, and an electromotive force of a monomer cell is more than 1.84V. Through alloying, the electrochemical performance of the anode is raised obviously, the self-corrosion rate is lowered, the self-corrosion rate is less than 5.12mg / (cm<2>*h), and surface corrosion is uniform. The aluminum alloy anode material has excellent performances, and is a novel aluminum alloy anode material suitable for usage in an alkaline electrolyte.

Owner:HENAN UNIV OF SCI & TECH

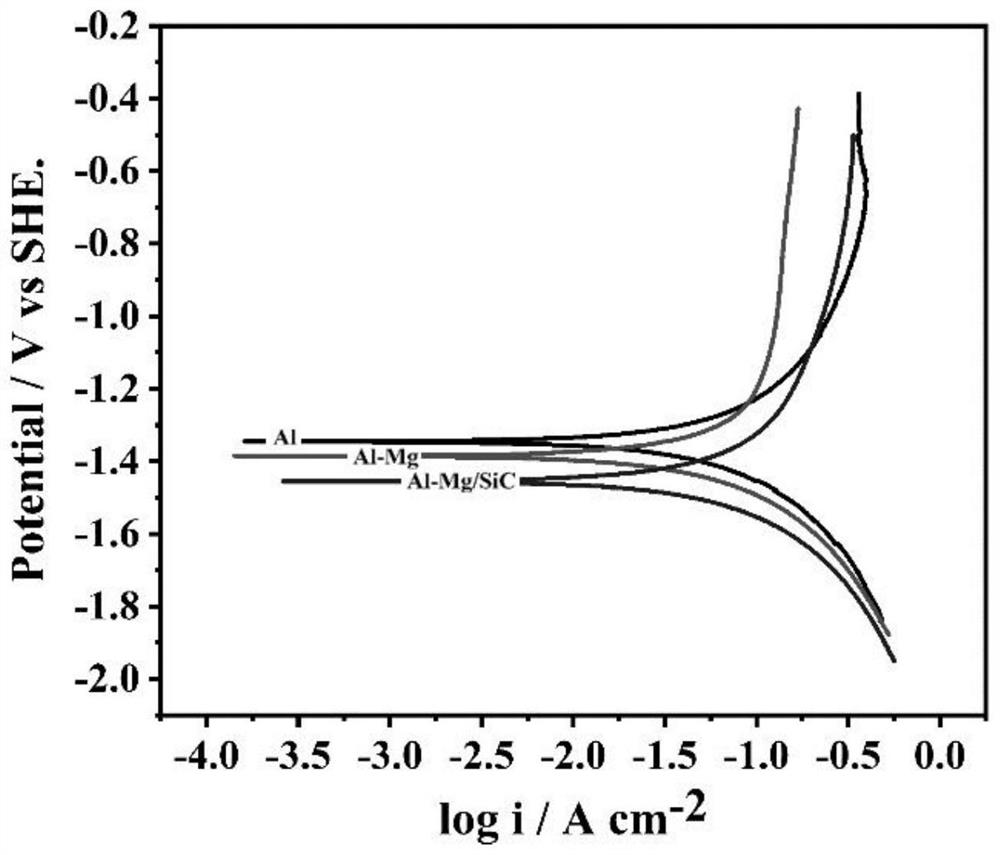

Manganese-aluminum containing anode material and preparation method thereof, as well as air cell prepared by using anode material

InactiveCN102820472BImprove performanceUniform surface corrosionFuel and primary cellsCell electrodesElectrolytic agentAir cell

The invention discloses a manganese-aluminum containing anode material for an air cell, and a preparation method and an application of the manganese-aluminum containing anode material. The air cell comprises a manganese-aluminum containing anode, an air cathode and neutral electrolyte. The anode material comprises the following elements in percentage by weight: 0.05 to 2.5 percent of Mg, 0.05 to 1.5 percent of Sn, 0.05 to 2.5 percent of Ga, 0.1 to 1 percent of Mn and the balance of Al, and is prepared through an inert gases protection induction smelting method. With the adoption of the manganese-aluminum containing anode material, the open-circuit voltage is negative (minus 1.6 to minus 1.8V (vs.SHE)), the anode utilization is high (larger than or equal to 94%), the self-corrosion speed is low (smaller than or equal to 0.03mg / cm<2>*h), the surface corrosion is uniform, and the manganese-aluminum containing anode material belongs to high-performance anode material for the air cell operated in a neutral solution.

Owner:HENAN UNIV OF SCI & TECH

Air battery anode aluminum alloy preparation method and air battery

ActiveCN111560544AReduce hydrogen evolution corrosionLow self-corrosion rateFuel and primary cellsCell electrodesCrystalliteLanthanum

The invention discloses an air battery anode aluminum alloy preparation method and an air battery. The method comprises the following steps that industrial pure aluminum, high-purity lanthanum, KBF4 and K2TiF6 are weighed, and the weight percentage of the elements is controlled to be as follows: 5%-10% of Ti, 0.1%-0.5% of B, 0.5%-1% of La, and the balance Al; the industrial pure aluminum is completely melted, a temperature is controlled to be 800 DEG C or above, KBF4 and K2TiF6 powder which is uniformly stirred in advance is pressed into aluminum melt by using a graphite bell jar for uniformlystirring, the temperature is kept constant for 15-30 minutes, then the high-purity lanthanum is added, uniform stirring is conducted, the temperature is kept for 20-40 minutes, and a covering agent is added in a stirring process; the melt is cast into a cast ingot to obtain a grain refiner; the following components are weighed in percentage by weight: 0.05%-0.2% of Zn, 0.2%-0.4% of Ga, 0.01%-0.05% of Sn, 0.05%-0.1% of In, 0.1%-0.2% of Bi, 0.5%-1% of Mg, 0.1%-0.3% of Ce, 0.3%-0.5% of the grain refiner and the balance aluminum; and the aluminum is melted, the Zn, the Ga, the Sn, the In, the Bi,the Mg and the Ce are added for smelting, then the grain refiner is added for refining, casting into a casting blank is conducted, annealing is conducted, rolling into an aluminum plate is conducted,annealing is conducted again, and the annealing time is 30-40 min / mm. The prepared material is used as an anode of an aluminum air battery, so that an open circuit potential can be improved, and theself-corrosion rate can be reduced.

Owner:HUNAN SEIRIOS NEW MATERIAL TECH CO LTD

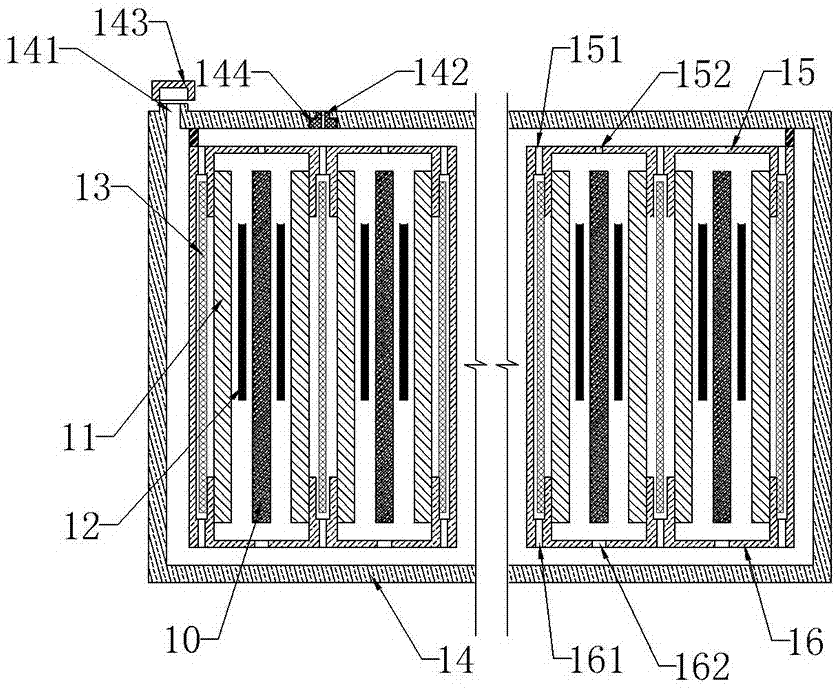

Portable high-efficiency aluminum-oxygen power battery and preparation method thereof

ActiveCN107017411AImprove electrochemical performanceHigh activityFuel and primary cellsCell electrodesElectrical batteryCyclodextrin

The invention discloses a portable high-efficiency aluminum-oxygen power battery and a preparation method thereof. The method comprises the following steps of mixing a perovskite manganese oxide, MnO2, a conductive agent and polytetrafluoroethylene emulsion, dispersing and making the mixture to paste with water, coating the paste on two surfaces of a nickel net for drying, and preparing an oxygen catalytic electrode by repeated rolling; preparing an aluminum positive electrode plate by employing an aluminum-alloy metal sheet; mixing potassium hydroxide and cyclodextrin to prepare a colloid electrolyte, and rolling the colloid electrolyte to form a sheet shape; mixing ABS and PC to prepare a shell of the power battery; fixing the oxygen catalytic electrode and the aluminum positive electrode in an electrode reaction cavity of the shell, and arranging the sheet-shaped colloid electrolyte between the oxygen catalytic electrode and the aluminum positive electrode; and forming a battery path among the oxygen catalytic electrode, the aluminum positive electrode and the colloid electrolyte in the electrode reaction cavity after water is injected into the shell, wherein oxygen is slowly released from a solid-state oxygen sheet at an outer side of the oxygen catalytic electrode and is provided for oxidization-reduction reaction of the battery so as to complete the power generation process of the aluminum-oxygen battery.

Owner:深圳市锐劲宝能源电子有限公司

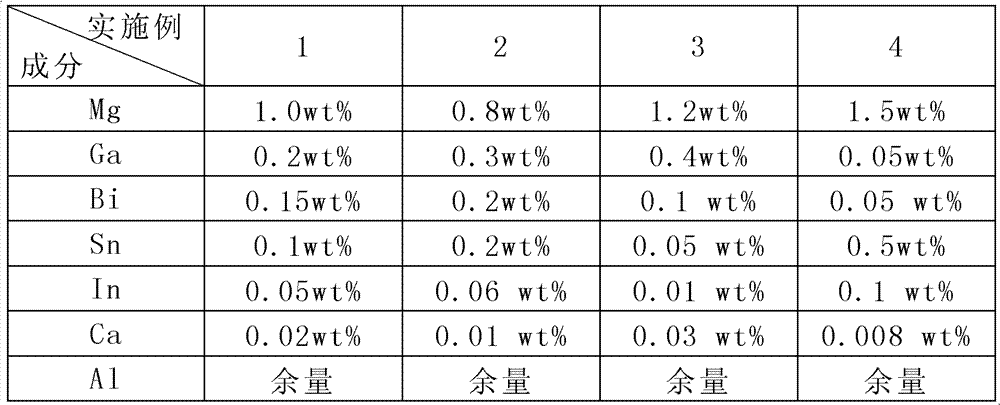

Aluminum alloy anode material for battery and manufacturing method thereof

ActiveCN101901893BImprove electrochemical performanceCompatibility is reasonablePrimary cell electrodesMetallurgyElectrical battery

The invention provides an aluminum alloy anode material for a battery and a manufacturing method thereof, belonging to the technical field of alloy materials and solving the problem that the electrochemical property of the traditional aluminum alloy anode material for batteries is not ideal. The aluminum alloy anode material for the battery comprises the following ingredients in percentage by mass: 0.5 to 2.0 percent of Mg, 0.005 to 0.5 percent of Ga, 0.005-1.0 percent of Bi, 0.005 to 1.0 percent of Sn, 0.005 to 0.2 percent of In, 0.005 to 0.05 percent of Ca, and the balance of Al. The aluminum alloy anode material for the battery has the advantages of high electrochemical property and low self-corrosion rate.

Owner:ZHEJIANG GKO IND CO LTD

Aluminum-air battery electrolyte as well as preparation method and application thereof

InactiveCN111641009ADelay hydrogen evolution corrosionHigh open circuit potentialFuel and primary cellsAlkaline electrolytesElectrolytic agentPotassium hydroxide

The invention discloses an aluminum-air battery electrolyte as well as a preparation method and application thereof. The aluminum-air battery electrolyte comprises the following components: 2-6mol / L of potassium hydroxide, 0.1-0.5 g / L of lauryl glucoside, 0.1-0.3 g / L of sodium stannate, 0.1-0.3 g / L of potassium oleate and 0.05-0.1 g / L of zinc oxide. All the components are matched, hydrogen evolution corrosion of the aluminum plate can be greatly delayed, and high open-circuit potential is guaranteed.

Owner:HUNAN SEIRIOS NEW MATERIAL TECH CO LTD

Alkaline electrolyte for aluminum-air battery and aluminum-air battery

ActiveCN110165340BLow self-corrosion rateImprove discharge performanceFuel and primary cellsAqueous electrolyte cellsAluminum anodeElectrolytic agent

Owner:CHANGZHOU YOUTEKE NEW ENERGY TECH

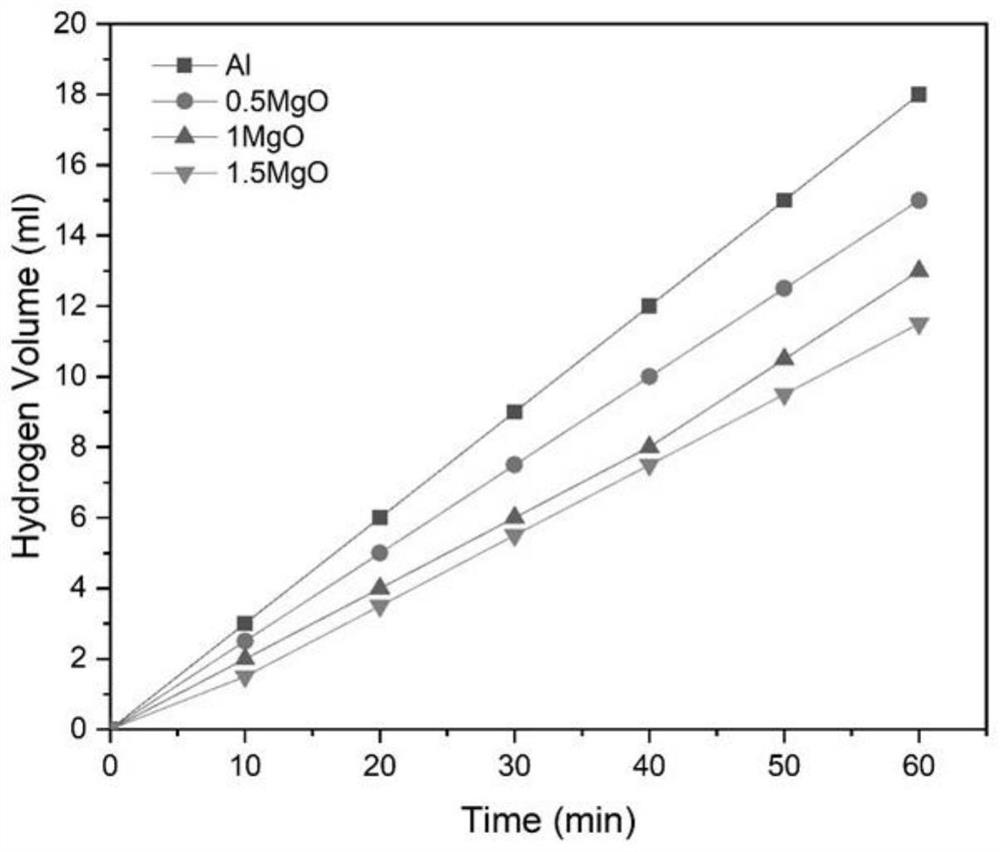

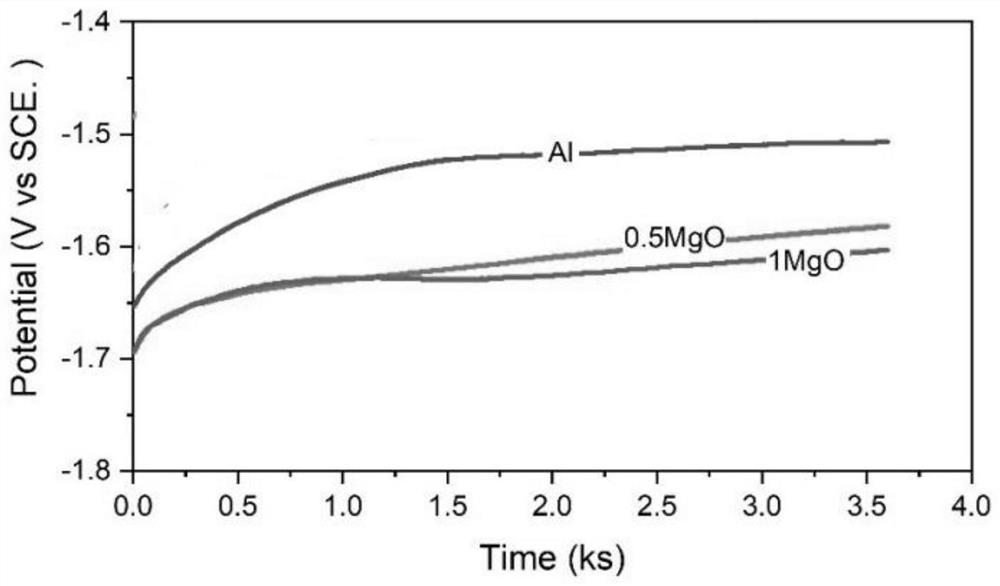

A kind of aluminum-air battery ceramic particle composite anode material and preparation method thereof

ActiveCN112921201BHigh anode utilizationIncrease profitFuel and primary cellsCell electrodesElectrolytic agentMetallic materials

The invention relates to an aluminum-air battery ceramic particle composite anode material and a preparation method thereof, belonging to the field of metal materials. The preparation method provided by the invention includes: preheating the ceramic particles first, and mixing them with heated and melted pure aluminum or aluminum alloy, and then adopting ordinary aluminum melting furnace + mechanical stirring or vacuum semi-solid stirring technology to obtain evenly dispersed particles Composite anode material, the granular composite material obtained by casting is directly cut, or further press processed to make composite anode for aluminum-air battery. Because the preparation method provided by the invention is simple, the cost is low, the obtained composite anode material has good electrochemical activity in alkaline electrolyte, low self-corrosion rate, and high battery anode utilization, so the preparation method provided by the invention is suitable for large-scale Chemical production and processing.

Owner:TONGJI UNIV

A kind of aluminum-air battery anode material and preparation method thereof

ActiveCN109321766BImprove electrochemical performanceLow self-corrosion rateFuel and primary cellsCell electrodesMetallurgyMachining process

The invention discloses an aluminum air battery anode material and a preparing method thereof. The aluminum air battery anode material comprises, by mass percent, 0.10%-0.15% of bismuth, 0.10%-0.15% of lead, 0.015%-0.035% of gallium and the balance aluminum. The anode material is prepared through the machining processes of mixing, smelting, rolling and heat treatment. The anode material componentdesign is reasonable, the cost is low, the product performance is good, the preparing process is simple, and the aluminum air battery anode material and the preparing method of the aluminum air battery anode material are suitable for large-scale industrial production.

Owner:KUNMING UNIV OF SCI & TECH

Anode material for air battery and preparation method thereof

ActiveCN103774018BGood electrochemical compatibilityReduce oxidationCell electrodesMetallic materialsBattery cell

The invention belongs to the field of metal materials and particularly relates to an anode material for an air battery and a preparation method of the anode material. The alloy material is negative in open-circuit voltage and low in self-corrosion rate. The invention also provides the preparation method of the anode material for the air battery. The preparation method is simple in process and low in production cost, and is suitable for industrial production. The anode material comprises the following components in percent by weight: 0.5-0.8% of Zr, 0.01-0.04% of Sm, 0.5-0.7% of Cd, 0.5-0.7% of Be, 0.05-0.07% of Fe, 0.04-0.06% of Os, 6-9% of Zn and the balance of Mg.

Owner:常熟紫金知识产权服务有限公司

A kind of electrolyte corrosion inhibitor, electrolyte solution for aluminum-air battery and aluminum-air battery

InactiveCN105140595BImprove corrosion resistanceImprove electrochemical activityFuel and primary cellsElectrolytic agentElectrical battery

The invention discloses an electrolyte corrosion inhibitor, an electrolyte for aluminum air cell and an aluminum air cell. The electrolyte corrosion inhibitor is an ethanol solution of lavender essential oil, and the volume percentage content of lavender essential oil is 10%-60%. The main components of lavender essential oil comprise linalool, linalyl acetate, eucalyptol, beta-ocimene, 4-terpineol and camphor. Group molecules contain lone pair electrons, oxygen atoms in the groups are absorbed on a metal surface through the lone pair electrons, an insoluble complex layer is formed, thus the metal surface is separated from an aqueous solution, and a corrosion inhibition function is achieved. The electrolyte corrosion inhibitor prepared from lavender essential oil extracted from plants and ethanol is a novel green environmental protection corrosion inhibitor, and has advantages of low cost, low toxicity or no toxicity, no environmental pollution and the like. The electrolyte corrosion inhibitor is added in an electrolyte, a self corrosion rate of an aluminum anode can be lowered remarkably, the electrochemical performance can be raised, and the electrolyte corrosion inhibitor has good economic benefits and environmental benefits.

Owner:HENAN UNIV OF SCI & TECH

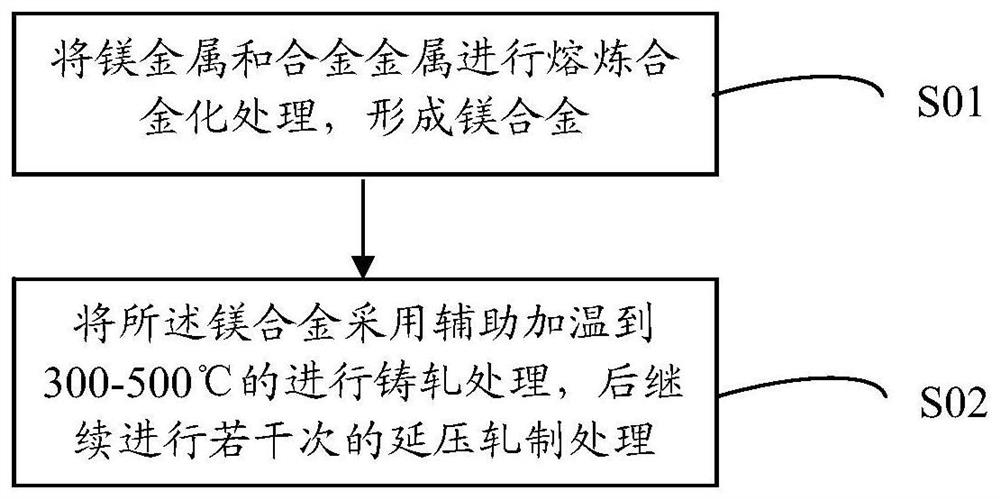

Process for manufacturing magnesium air fuel cell anode material

Owner:维恩克(鹤壁)镁基材料有限公司

Metal-air battery metal electrode material and its preparation method and application

ActiveCN110048129BGrain refinementReduce passivationFuel and secondary cellsCell electrodesIndiumManganese

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Electrolyte and aluminum air battery

PendingCN113851665AImprove discharge efficiencyPromote commercial applicationFuel and primary cellsAqueous electrolytesDischarge efficiencyElectrolytic agent

The invention discloses an electrolyte and an aluminum air battery. The electrolyte comprises the following preparation raw materials: sodium chloride and a corrosion inhibitor. The corrosion inhibitor is prepared from the following raw materials: natural amino acid, carbohydrate and plant essential oil. According to the aluminum air battery disclosed by the invention, the electrolyte containing the tea tree essential oil, the amino acid and the carbohydrate is adopted, so that not only can the self-corrosion of the alkaline aluminum air battery be controlled to be too fast, but also the high electrochemical activity of the aluminum anode alloy can be ensured, and the aluminum air battery has important significance on improving the discharge efficiency of the battery and prolonging the discharge life; and commercial application of the aluminum air battery is facilitated.

Owner:HUNAN SEIRIOS NEW MATERIAL TECH CO LTD

A kind of rare earth magnesium electrode material and preparation method thereof

Owner:NANJING UNIV OF INFORMATION SCI & TECH

A kind of rare earth-containing amorphous/nanocrystalline aluminum anode composite material, preparation method and aluminum-air battery

InactiveCN104372206BImprove electrochemical performanceAbundant resourcesFuel and primary cellsCell electrodesRare-earth elementDissolution

Owner:HENAN UNIV OF SCI & TECH

A casting electrode material and preparation method thereof

ActiveCN103774011BImprove electrochemical performanceUniform tissueCell electrodesFoundry mouldsMetallic materialsAlloy

The invention belongs to the field of metal materials, and in particular relates to a casting electrode material and a preparation method. The invention provides a cast electrode material, the alloy material has a relatively high negative value of working potential; the invention also provides a preparation method of the cast electrode material, the preparation method has simple process, low production cost and is suitable for industrial production. In the casting electrode material of the present invention, the weight percentage of each component is: Sc0.1-0.3%, Th0.03-0.05%, As0.04-0.08%, Fe? 0.3-0.5%, Os0.02-0.04%, Se1-2%, the rest is Mg.

Owner:江苏迪丞光电材料有限公司

Preparation method of corrosion-resistant magnesium alloy sacrificial anode

PendingCN112064037AOvercoming the high rate of self-corrosionLow self-corrosion rateElectrolytic inorganic material coatingElectrically conductiveCorrosion

The invention discloses a preparation method of a corrosion-resistant magnesium alloy sacrificial anode. The preparation method is characterized by comprising the following steps: 1, carrying out corrosion-resistant treatment on a magnesium alloy sacrificial anode material to form a corrosion-resistant layer on the surface; and 2, performing conductive post-treatment on the surface of the corrosion-resistant layer to finally form a corrosion-resistant conductive magnesium alloy sacrificial anode material. The technical problems that in the prior art, because the self-corrosion rate of a magnesium alloy anode material is too high, the service cycle cannot be met generally, and a large amount of magnesium alloy is consumed in a self-corrosion mode while protection is conducted are solved.

Owner:GUIZHOU POWER GRID CO LTD

Electrolyte corrosion inhibitor for aluminum-air battery, electrolyte and preparation method

InactiveCN103633396BReduce hydrogen evolution self-corrosion rateProne to anodic polarizationFuel and primary cellsAluminum anodePhysical chemistry

The invention discloses an electrolyte corrosion inhibitor for an aluminum-air cell, an electrolyte and a preparation method, belonging to the technical field of chemical batteries. The electrolyte corrosion inhibitor mainly comprises sodium hyposulfite which has a concentration of 0.005 to 0.2 mol / L in the electrolyte and may further comprise the auxiliary additive sodium stannate which has a concentration of 0.01 to 0.03 mol / L in the electrolyte. The aluminum-air cell provided by the invention has the advantages of simple composition, low cost, safety and accordance with environmental protection requirements, can substantially reduce the hydrogen evolution self-corrosion rate of an aluminum anode, enables the open circuit potential of the aluminum anode and working potential under the condition of impressed current to undergo substantial negative transfer, allows an aluminum anode alloy to have good corrosion resistance and high electrochemical activity and meets the requirement of an alkaline aluminum-air cell for large current density discharging.

Owner:HENAN UNIV OF SCI & TECH

A kind of organic composite corrosion inhibitor for pulp layer paper and its slurry

InactiveCN103789773BImprove conductivityImprove adhesionNon-fibrous pulp additionCoatingsElectrical batteryActive agent

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

A kind of preparation method of anode aluminum alloy for air battery and air battery

ActiveCN111560544BIncrease profitReduce hydrogen evolution corrosionFuel and primary cellsCell electrodesElectrical batteryIngot

The present application discloses a method for preparing an anode aluminum alloy for an air battery and the air battery. The method includes: weighing industrially pure aluminum, high-purity lanthanum, KBF 4 、K 2 TiF 6 , the weight percentage of the control elements is: Ti5~10%, B0.1~0.5%, La0.5~1%, and the balance is Al; completely melt the industrial pure aluminum, control the temperature above 800℃, and use graphite bell jar Pre-mixed KBF 4 、K 2 TiF 6 Press the powder into the aluminum melt and stir evenly, keep the temperature for 15-30 minutes, then add high-purity lanthanum and stir evenly, keep the temperature for 20-40 minutes, and fill the covering agent during the stirring process; cast the melt into ingots to obtain the grain refiner; Weigh Zn0.05~0.2%, Ga0.2~0.4%, Sn0.01~0.05%, In0.05~0.1%, Bi0.1~0.2%, Mg0.5~1%, Ce0.1 by weight percentage ~0.3%, the grain refiner is 0.3~0.5%, and the balance is aluminum; melt aluminum, add Zn, Ga, Sn, In, Bi, Mg, Ce to melt, add grain refiner to refine, and cast Cast billets, annealed, rolled into aluminum plates, and then annealed. The annealing time is 30-40min / mm. The prepared material is used as an anode of an aluminum-air battery, which can increase the open circuit potential and reduce the self-corrosion rate.

Owner:HUNAN SEIRIOS NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com