Aluminum air battery anode material and preparing method thereof

An aluminum-air battery and anode material technology, which is applied to battery electrodes, fuel cell-type half-cells and primary-cell-type half-cells, circuits, etc., can solve the problem that the efficiency has not been effectively improved, the composition structure is complex, and the electrochemical performance is poor. and other problems, to achieve the effect of low cost, simple preparation process and low self-corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

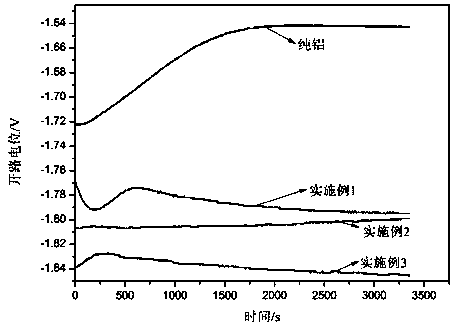

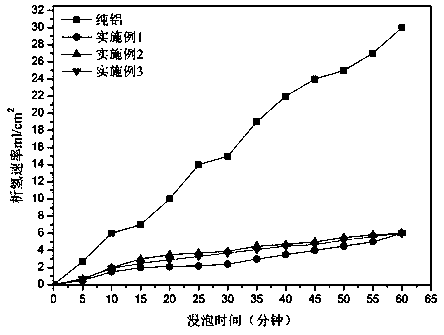

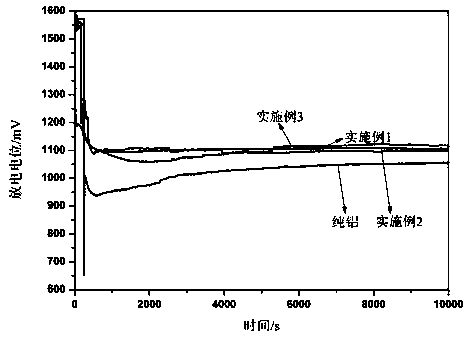

[0021] An aluminum-air battery anode material, the composition and mass percentage of which are: bismuth (Bi) 0.10wt%, lead (Pb) 0.15wt%, gallium (Ga) 0.02wt%, and the balance is Al.

[0022] The preparation method of the aluminum-air battery anode material of the present embodiment comprises the following steps:

[0023] (1) Ingredients: Weigh Bi, Pb, Ga, and Al according to the material components. The weighing operation is completed in a vacuum glove box at 5°C. The weighed materials are wrapped with aluminum foil with a purity of 99.99% and stored in a vacuum In the drying oven, the vacuum degree of the vacuum drying oven is 60Pa, the temperature is -5°C, the purity of Bi, Pb, Ga, and Al raw materials are all 99.99%, and the weight of aluminum foil is included in the total weight of aluminum;

[0024] (2) Melting: In a nitrogen atmosphere, preheat the graphite crucible to 200°C, add aluminum ingots, continue heating to 740°C and heat for 45 minutes after the aluminum is me...

Embodiment 2

[0028] An aluminum-air battery anode material, the composition and mass percentage of which are: bismuth (Bi) 0.15wt%, lead (Pb) 0.10wt%, gallium (Ga) 0.035wt%, and the balance is Al.

[0029] The preparation method of the aluminum-air battery anode material of the present embodiment comprises the following steps:

[0030] (1) Ingredients: Weigh Bi, Pb, Ga, and Al according to the material components. The weighing operation is completed in a vacuum glove box at 6°C. The weighed materials are wrapped with aluminum foil with a purity of 99.99% and stored in a vacuum In the drying oven, the vacuum degree of the vacuum drying oven is 70Pa, the temperature is 0°C, the purity of Bi, Pb, Ga, and Al raw materials are all 99.99%, and the weight of aluminum foil is included in the total weight of aluminum;

[0031] (2) Melting: In a nitrogen atmosphere, preheat the graphite crucible to 180°C, add aluminum ingots, continue to heat to 720°C and heat it for 50 minutes after the aluminum is...

Embodiment 3

[0035] An aluminum-air battery anode material, the composition and mass percentage of which are: bismuth (Bi) 0.12wt%, lead (Pb) 0.12wt%, gallium (Ga) 0.015wt%, and the balance is Al.

[0036] The preparation method of the aluminum-air battery anode material of this embodiment comprises the following steps:

[0037] (1) Ingredients: Weigh Bi, Pb, Ga, and Al according to the material components, and the weighing operation is completed in a vacuum glove box at 8°C. The weighed materials are wrapped with aluminum foil with a purity of 99.99% and stored in a vacuum In the drying oven, the vacuum degree of the vacuum drying oven is 55Pa, the temperature is -2°C, the purity of Bi, Pb, Ga, and Al raw materials are all 99.99%, and the weight of aluminum foil is included in the total weight of aluminum;

[0038] (2) Melting: In an argon atmosphere, preheat the graphite crucible to 230°C, add aluminum ingots, continue heating to 760°C and heat for 60 minutes after the aluminum melts, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com