Aluminum alloy anode material for air cell, preparation method and aluminum air cell

An aluminum-air battery and air battery technology, which is applied to battery electrodes, fuel cell-type half-cells, primary battery-type half-cells, circuits, etc. The commercial application of air batteries, the reduction of anode utilization, etc., achieve the effect of excellent anti-alkali corrosion resistance, excellent electrochemical performance, and low self-corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

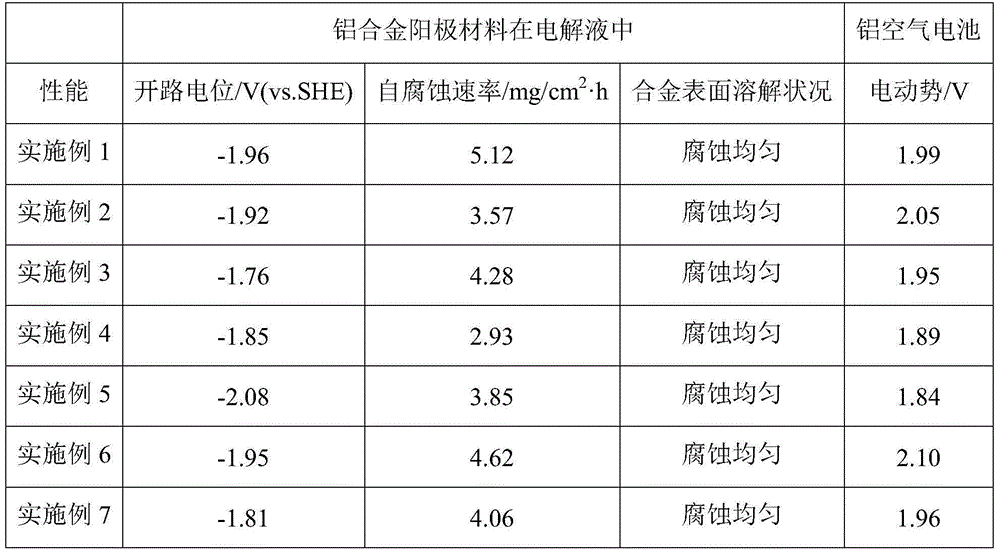

Examples

Embodiment 1

[0033] The aluminum alloy anode material for an air battery in this embodiment is composed of the following components in weight percent: Zn4%, Ga0.08%, In0.06%, and the balance is Al.

[0034] The preparation method of the aluminum alloy anode material for the air battery of the present embodiment comprises the following steps:

[0035] 1) Under the protection of argon, place the aluminum ingot in the crucible of a ZGJL0.01-40-4 induction melting furnace, heat it to 690°C to melt the aluminum ingot, add zinc ingots, gallium grains and indium grains, and heat it while heating Rotate the container to melt and mix the metal evenly, continue heating to 750°C and keep it warm for 5 minutes, then pour into block ingots;

[0036] 2) The block ingot obtained in step 1) is rolled at 180° C. into a sheet material with a thickness of 3 mm to obtain the aluminum alloy anode material for the air battery.

[0037] The aluminum-air battery of this embodiment includes an aluminum alloy anod...

Embodiment 2

[0042] The aluminum alloy anode material for an air battery in this embodiment is composed of the following components in weight percent: Zn6%, Ga1%, In1.5%, and the balance is Al.

[0043] The preparation method of the aluminum alloy anode material for the air battery of the present embodiment comprises the following steps:

[0044] 1) Under the protection of argon, place the aluminum ingot in the crucible of a ZGJL0.01-40-4 induction melting furnace, heat it to 700°C to melt the aluminum ingot, add zinc ingots, gallium grains and indium grains, and heat it while heating Rotate the container to melt and mix the metal evenly, continue heating to 730°C and keep it warm for 5 minutes, then pour into block ingots;

[0045] 2) The block ingot obtained in step 1) is rolled at 160° C. into a sheet material with a thickness of 1 mm to obtain the aluminum alloy anode material for an air battery.

[0046] The aluminum-air battery of this embodiment includes an aluminum alloy anode, an...

Embodiment 3

[0051] The aluminum alloy anode material for an air battery in this embodiment is composed of the following components in weight percent: Zn3%, Ga3%, In0.01%, and the balance is Al.

[0052] The preparation method of the aluminum alloy anode material for the air battery of the present embodiment comprises the following steps:

[0053] 1) Under the protection of argon, place the aluminum ingot in the crucible of a ZGJL0.01-40-4 induction melting furnace, heat it to 710°C to melt the aluminum ingot, add zinc ingots, gallium grains and indium grains, and heat it while heating Rotate the container to melt and mix the metal evenly, continue heating to 760°C and keep it warm for 6 minutes, then pour into block ingots;

[0054] 2) Rolling the block ingot obtained in step 1) into a sheet material with a thickness of 3 mm at 200° C. to obtain the aluminum alloy anode material for the air battery.

[0055] The aluminum-air battery of this embodiment includes an aluminum alloy anode, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com